International PetFoodVolume 6Issue 1January 2024 www.internationalpetfood.com www.perendale.com Mealworm protein - Alternative Protein Solutions - Nurturing Wellbeing - Revolutionising Pet Nutrition Inside the Innovative Approach of a Petiva January 2024 Up-coming International PETFOOD conferencesfind out more on page 37 Download your online version:

YOUR RELIABLE PARTNER

A reliable team for a reliable project

Projects in 150 countries

55 million m3 built

New pendular and rotative sensors

ATEX 20 certified, the zone with the highest risk

· SY-DP1 Pendular . Robust and simple. It does not require power and maintenance.

· SY-DR1 Rotative . Sensitive. It has 2 operating modes depending on the density of storage material.

Top Project worldwide

Flexibility and adaptability

symaga.com • +34 91 726 43 04 • symaga@symaga.com

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 01242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons

Tel: +44 (0)1242 267706 shannonp@perendale.co.uk

Niamh Cassidy

Tel: +44 (0)1242 267704 niamhc@perendale.co.uk

Community Manager

David Harvey

Tel: + 44(0)1242 267700 davidh@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 (0)1242303792 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta clarissag@perendale.com

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 364 64 57 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor

Tel: +44 (0)1242303791 jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 (0)1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 (0)1242 303790 tutit@perendale.co.uk

Development Manager

Antoine Tanguy

Tel: +33 6 78 57 76 45 antoinet@perendale.co.uk

January

10 Industry News

COLUMNS

6 Roger Gilbert

7 Joseph P Kearns

8 Professor Simon Davies

Perendale

Publishers Ltd

International Petfood - Volume 6 - Issue 1 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 28 Training 29 Troubleshooting 30 Production focus 9 The PetFood Journal REGULAR ITEMS 27 Industry Profiles 33 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces

FEATURES

14 Mealworm protein

18 Alternative Protein Solutions

20 Nurturing Wellbeing

24 Revolutionising Pet Nutrition Inside the Innovative Approach of a Petiva

Look who’s doing the talking…

You may be thinking that it’s all happening on social media where everyone has an opinion and is expressing it, often without any significant knowledge about their subject matter.

In fact, there are lots of well-balanced and thought through comment that addresses an issue by informing us of the facts before drawing conclusions.

Roger Gilbert Publisher –

Roger Gilbert Publisher –

However, you have to wade through volumes of content and waste hours of time being distracted and misguided by sharp headlines and images that deliver nothing of importance in the content that follows.

That’s not happening in our industry where your favourite magazine - International Petfood along with its sister publications

- put before you individuals of significant expertise to address subjects in the depth and detail you require in your businesses day-to-day.

I’m talking about the conferences and seminars that we provide the industry with through the exposition and events we attend worldwide.

You can see the list of those coming up this year highlighted on the cover of this edition.

The accompanying photograph on this page is testament to the knowledge experts from across the production chain are prepared to deliver that will change the way you do things and add to your bottom line.

International Petfood magazine is proud to be associated with these companies and the individuals who take the time to inform you the manufacturer about new and useful developments in the production of rations.

I was particularly pleased to host with our editor Joe Kearns the Pet-Aqua Conference during Victam LatAm held in Saõ Paulo, Brazil towards the end of 2023. Offered over two half-days, and to standing room only, Pet-Aqua attracted representatives from these two industries from across Latin America.

It shows that not everything is available via AI or Google Search and that human interaction and verbal explanation with written back up texts, remains vital to the successful transmutation and retention of knowledge.

If you’re looking for the best insights the industry has to offer in terms of technical development and equipment operation in 2024, look no further than one of our conferences.

Alternatively, if you can’t attend in person look to our Online Milling School (run by Perendale and Progressus) to see many of these presenters in the two courses we will be holding this year for Petfood Production. Happy New Year to you all. I look forward to meeting or seeing you in 2024.

Our last edition

Did you miss our December 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from the Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

Biotechnology in Petfood in Enhancing Quality and Sustainability by Robson Barducci, Anderson Dias & Leticia Pacheco, R&D Specialists, Biorigin, Brazil

Biotechnology is a multidisciplinary field that utilises living organisms, biological systems, and processes to develop products and technologies that benefit

society. The application of biotechnology in this context has the potential to improve the quality, nutrition, and sustainability of pet foods, contributing to the health and well-being of the animal.

To read more, go to: https://issuu.com/international_ aquafeed/docs/ipf2312_web/18

Petfood Conveyor Launch: Starting Up on Time and With Confidence by Del Williams, Technical Writer on behalf of Cablevey Conveyers, USA

To move delicate petfood products or powders, most processors do extensive homework before purchasing a tubular drag cable conveyor to ensure that it meets their needs in terms of function and price. After the purchase, the conveyor must be expertly assembled and tested to ensure smooth production startup and continued performance.

To read more, go to: https://issuu.com/international_ aquafeed/docs/ipf2312_web/20

THE PUBLISHER

International Petfood

Live from Pet-Aqua 2023, São Paulo - From left (front row) Roger Gilbert, Publisher and moderator IPF; Dr Fabiano Cesar R&D Manager at ADIMAX, and Michel Pereira Michel Bauer Pereira Global Application Manager for Aqua & Pet at Andritz, and Keith Erdley, Process Technologist at Wenger.

From left (back row) Marco Prati, CEO of PLP Systems, Ed de Souza, Extrusion systems process Director at Wenger, Joe Kearns, editor at International Petfood magazine, Thomas Runde, CEO and Sales Director of Tietjen, João Fernando Alber Koch, Global Technical and Product manager

Happy New Year to everyone for 2024. It will be interesting to see what develops as this year unfolds. 2023 was full of travel and events where the industry showed it is well on its way back from the last few years of interrupted activities.

Looking forward to the 2024 events on petfood and feed production in general. These industries do have common ground and thus it is most interesting to keep up with new developments and devices that will serve the industry. What drives these developments and how do they get realized and put into use?

THE EDITOR

Joseph P Kearns Editor,

Joseph P Kearns Editor,

I thought a different tangent would be interesting to start the year. Why is the petfood production industry so dynamic? My guess is that it is based on the pet owners, millions of them who love their pets and care for their welfare, as their pets are fun and pleasant to be around. Many of these pet owners are in the business and advancing their love for pets through their activities in business.

Admittedly, having had five outstanding four-legged friends, my case is not so different. All were pals who loved to get in the truck in the up-front looking out the window position.

All were bird dogs and they loved finding quail and pheasants out in the wild. They knew what we were doing, and obviously loved their part in this. For me the greatest part of the trips was watching and interacting with the dogs. I had always though how great it would have been to be able to talk with them for a day. We communicated and our feelings about each other were mutual, and from the heart.

Where is this heading? Well, as with all pet owners, we attend to everything the pets need. When you have a hunting dog you see how his energy and activity level, and everything is going and no doubt all of this enters your thoughts on how you can do better for them if needed. It is the same for all pet owners, you are going to take care of your best friend.

There were not many choices back when this industry really started, and no doubt Universities and Veterinarians had big impacts in changing this. Courses on pet nutrition, studies on feeds and every aspect were mainly at institutions of higher learning. Some of the biggest petfood companies were started by Veterinarians who obviously had visions of what a petfood should be. When feeds went from scraps either from the table or factory byproducts towards processed feeds trials were unending on nutritional studies for pets.

Mostly standard ingredients initially used in petfoods were basically from feed mills. Nutritional studies were no different than studying chickens and seeing what worked best for their growth or egg production. The difference was however nutritional studies for the pet’s well-being and proper growth. These events did not happen overnight and are actually still ongoing.

An example of development the movement from what was referred to as the ‘brown and round’ petfood to more advanced formulas as seen today. Petfood production back in the day was simple, the machines were simple and some not so effective. In any case, typically a formula used for dogs which was as you can see feedmill style would have been: 18 percent meat and bone meat, 18 percent wheat mids, 18 percent soybean meal and 46 percent ground corn. Once extruded about eight percent of number two tallow would be added. Vitamins and minerals were also added, and this yielded a nutritional complete diet for adult dogs.

Continuing as mentioned was all the research and feeding trials in the industry as it was growing and evolving. New ingredients, novel ingredients and all kinds of testing was also required on production equipment in testing settings to confirm the ingredients were extrudable and in what amounts. Grinding studies to optimise the raw material, water and steam flow, pumps for liquid raw materials conveying equipment, drying, cooling, coating, and all other activities, needed to be developed and proved to be generally accepted in the industry. Of course, many of these developments were modified over the years for improvements and to fit the situations as they developed. How about an example or two?

Cutting the product at the knife

Initial designs had the extruder shaft extend through the die with a perpendicular attachment which knocked the product into uneven pieces post die. Testing with a junk yard old drive shaft with U-Joints and variable speed drive motor resulted in what is typically used today. Back then a variable speed motor had sheaves that moved with a belt to modulate the speed. Today direct hook up to advanced motor technology allows for exact control of the rotational speed of knives.

Advancements in the metals used resulted in much longer wear life of parts, not only knife blades but many of the other parts that wear due to frictional developments, like the barrel parts. Machining tolerances greatly improved over time and the improvement in extruder screws, sleeves, dies, shafts and other high wear or critical parts is easily seen. All the design changes, metallurgy and machining improvement typically resulted in improved wear life.

In petfood it would not be unusual to see parts change only once a year. This is possible if attention to all the details is made; grind of ingredient, running conditions, and formulation, for example. A good fine grind is easier to cook and accepts the water faster thus the heat transfer from steam is easier and quicker. Adding the optimum amount of water and possibly a bit of fat allows for a good cook while not excessively wearing the screws.

The year ahead

So, what do we expect to see in 2024 - more of the same as the industry moves forward. New ingredients or modified ingredients, additives, flavors, fresh vegetables, fruits, yeasts, cultured products, and insect products are all out there and waiting to be used in petfood. We will see new and novel production equipment move into the mainstream, quality control by computers for optimal process settings, packaging designs, plant designs and many more.

When have we not seen amazing new and novel products from every angle of our industry show up each and every year? Okay, I admit for years my view of new products centered around my area of extrusion and related production equipment. Today, in this capacity, the future of this industry is in seeing the developments and knowing the products we are seeing. This includes testing products for bacteria on product contact areas, plant sanitation gear, processing equipment improvements, new technologies, and many more.

See you out there and let us know if you have something new the industry should hear about - or we might just come find you ourselves. joek@perendale.com

International Petfood - January 2024 | 7

International Petfood Magazine

Riboflavin

The energy yielding vitamin for dogs and cats

Riboflavin, also known as vitamin B2, plays a crucial role in the diet and nutrition of dogs and cats, contributing to various physiological functions essential for their overall health. This water-soluble vitamin is part of the B-vitamin complex and is involved in a range of metabolic processes. In the context of canine and feline nutrition, riboflavin is vital for energy metabolism, growth, and maintenance of various bodily functions. It is a key component of enzymes involved in energy metabolism, specifically in the form of coenzymes like flavin mononucleotide (FMN) and flavin adenine dinucleotide (FAD). These coenzymes participate in the oxidation-reduction reactions of the electron transport chain in every mitochondrion, facilitating the production of adenosine triphosphate (ATP), the primary energy currency of cells. This is particularly important in highly active dogs and cats or those engaged in strenuous activities. Riboflavin is crucial during periods of growth and development, such as puppyhood and kittens. It plays a role in the biosynthesis of new cells and tissues, contributing to the overall growth and maturation of the dog and cat. Adequate riboflavin intake is especially important in pregnant and lactating females to support the growth of the developing foetuses and the nutritional needs of nursing puppies.

Many enzymes involved in various metabolic pathways require riboflavin as a cofactor. These enzymes participate in processes such as the metabolism of amino acids, fatty acids, and carbohydrates. This makes riboflavin indispensable for the proper functioning of enzymatic reactions in dogs and cats, influencing their overall metabolic health. As such, is a key component of the antioxidant enzyme glutathione reductase, which helps protect cells from oxidative damage. Antioxidants play a crucial role in neutralizing free radicals that can contribute to cellular damage and aging. Therefore, riboflavin indirectly contributes to the overall antioxidant defence system in dogs and cats, supporting their overall

health and longevity.

The vitamin is associated with the maintenance of healthy skin and coat in dogs and cats. It is involved in the regulation of skin cell growth and repair, and a deficiency may lead to dermatological issues such as dry or flaky skin. In addition, riboflavin contributes to the formation of the mucous membranes, including those in the eyes, which are vital for overall ocular health. Riboflavin is involved in the production of red blood cells, which are essential for oxygen transport throughout the body. Adequate riboflavin intake contributes to the prevention of anaemia and ensures proper oxygenation of tissues, supporting overall canine and feline health and welfare.

Liver, kidney, fish, and eggs are excellent natural sources of riboflavin and of course offal (sources of animal organs and viscera) and other such rendered animal by-products is often used in the petfood industry obtained from abattoirs. High standards ensure hygiene and quality to maintain freshness of the rendering supply chain. However, dry vitamin premixes are carefully designed by specialist companion animal nutritionists to guarantee that all pet foods are consistent in their vitamin levels including riboflavin.

The increasing trend towards freshly frozen raw meat diets for dogs and cats as well as use of higher vegetable based ingredients needs some careful consideration of riboflavin concentrations in the finished balanced diet.

In conclusion, riboflavin is a vital nutrient for dogs and cats, influencing their energy metabolism, growth and development, maintenance of skin and coat health, antioxidant defence, red blood cell formation, and enzyme function. Ensuring an adequate supply of riboflavin through a balanced and nutritionally complete diet is essential for promoting the overall health and well-being of dogs and cats throughout their life stages.

8 | January 2024 - International Petfood

Professor Simon Davies Nutrition Editor, International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion.

The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief.

These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2024

International Petfood - January 2024 | 9

Cult Food Science launches Bmeaty

Cult Food Science, a pioneer in the investment, development and commercialisation of cellular agriculture technologies and products, is pleased to announce details and commercialisation plans for its third proprietary ingredient, a blend of yeasts called Bmeaty.

Palatability is a major concern for meat-free pet brands as well as companies developing cell-cultivated meats for cats and dogs. Bmeaty is made through a process of primary fermentation and fractionation. After yeast is made in fermentation vats, scientists fractionate the yeast cell wall using a hydrolysis process. The extract, hydrolysed yeast and a carrier yeast make up the new ingredient.

Bmeaty joins a suite of proprietary and patented ingredients developed by CULT. Bmuune is a nutritional yeast mixed with fermented proteins that offer pets a spectrum of health benefits, including improved digestion, immune system support and overall cognitive and heart health.

The ingredients are currently being sold to Petfood brands and will be an ingredient in several plant-based products released in 2024. The company is also in advanced partnership discussions with Petfood brands in North America and Europe.

Dave’s

Pet Food rolls out new branding during national pet wellness month

Dave’s Pet Food, LLC, a family-owned, affordably priced premium petfood company, recently launched its first major rebrand in the company’s 22-year history.

The company’s comprehensive efforts in October were timed to align with national pet wellness month, when the industry is focused on promoting the health and wellness of all pets. The rebrand includes everything from the new logo and label designs to a new website and exciting product innovations, including treats.

“From the start, my vision for Dave’s Pet Food was to make the best, most delicious and nutritious petfood possible and offer it at a price that wouldn’t break the monthly budget. I firmly believe you can, and should, have both available to you as an owner. They shouldn’t be mutually exclusive,” said Dave Rayner, CEO and founder of Dave’s Pet Food.

Customers got their first glimpse of the new Dave’s Pet Food logo when the completely redesigned and, for the first time – soon-to-be shoppable – website launched late in October. The logo will begin to roll out a variety of SKUs including dry, canned and a variety of new semi-moist and freeze-dried therapeutic treats. Consumers can expect to see new label designs for 95 percent meat, limited ingredient formulas, naturally

“We are excited to unveil our latest ingredient Bmeaty, which solves a key problem facing many Petfood manufacturers. This expands our ingredient portfolio and helps set us up for success as we scale out this new line of business,” said Mitchell Scott, CEO of CULT.

“Feeding our cats and dogs healthy, environmentally positive diets can sometimes feel impossible,” said Joshua Errett, VP of product development of CULT. “Bmeaty can help solve that challenge of meat-free, sustainable diets.”

healthy formulas, and stewlicious on shelf and online throughout 2024. The website was designed with a flexible ‘special features’ section, which will help guide and educate buyers on the label changes.

10 | January 2024 - International Petfood N

Spanish petfood manufacturer obtain the IFS food certification

Nugape Petfood has obtained the prestigious International Featured Standards(IFS) food certification, which consolidates the manufacturer as one of the most important companies in Spain in its sector, guaranteeing that its quality and safety protocols are as demanding as those applied to products for human consumption.

From its factory in Villanova de Arousa (northwest of Spain), Nugape exports its products to more than 40 countries. With more than 50 people on staff and a commitment to local, quality raw materials, its brands include Cebican, Sandegal, Danna and Dousti with a strong presence in Europe, Middle East, Africa and Asia.

Nugape already has some of the main safety certifications, such as the IFS Global Market, or continuous quality analysis technologies such as the NIR, but the IFS Food represents a very relevant milestone in its history, placing it among the chosen global group of petfood producing companies that

demonstrate safety, quality and traceability protocols equivalent to those of human food.

To obtain the certificate, AENOR’s the prestigious Spanish certification firm – independent auditors have supervised for months the company’s governance and commitment processes, quality and safety, resource management, operational processes and measurements and analysis of all its products.

Obtaining the IFS Food certification also comes at a time of strong expansion for the company, with the launch of a new packaging line that will allow Nugape to achieve a production of up to 1200 bags/hour, and which, together with other improvements will allow in the near future to reach an annual production of 120,000 tonnes. Nugape is also working on various projects to improve the company’s environmental sustainability, such as the installation of heat pumps to reduce gas use and CO2 emissions, or the installation of 5000m2 of photovoltaic panels.

THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED:

� CHIEF COMMERCIAL OFFICER

� GENERAL MANAGERS

� MANAGING DIRECTORS

� CHIEF MILLERS

� FEED & POULTRY MANAGERS

� MAINTENANCE MANAGERS

� R&D NEWPRODUCT DEVELOPMENT

� SALES & MARKETING

� PLANT MANAGERS

� CFO’S

BOURNE AES R C H & RECRUITMENT SELE C T I NO

���� bournerecruitment.co.uk ���� +44 7764 465 897

RECRUITING GLOBALLY International Petfood - January 2024 | 11 N

Entobel sets industry record with new plant

Entobel, a global leader in the production of functional insect protein for animal and plant nutrition, celebrates the opening of its new black soldier fly (BSF) production plant, the largest of its kind in Asia.

“Today marks a major milestone in our journey to transform the insect protein landscape and supply sustainable feed ingredients to the rapidly growing aquaculture and pet food industries,” said Alexandre de Caters and Gaëtan Crielaard, co-founders and co-CEOs of Entobel.

Entobel’s state-of-the-art facility was constructed in an industry record time of 12 months and is currently the world’s most CAPEX-efficient BSF production facility. The facility features 50 levels of vertical rearing, incorporating automation via robotics, cutting-edge sensors and data analytics that enhance productivity.

Leveraging a US$33 million Series B funding round raised in 2022 and backed by Mekong Capital, Dragon Capital and The International Finance Corporation (IFC), the Vung Tau facility marks Entobel’s second

industrial-scale production facility in Vietnam and will have an annual production capacity of 10,000MT of insect protein. The facility will serve as an economic and community anchor, creating 150 jobs in manufacturing and operations.

Entable has a clear line-of-sight for regional expansion including continued expansion in Vietnam and is preparing to build new facilities in markets, such as Indonesia and Malaysia. Entobel is targeting the launch of its Series C funding round in H1 2024 to support its growth plans.

Myos Corp announces new patent for increasing mobility and activity in dogs

Myos Corp, a medical nutrition company, announced that it has been awarded a US Patent for its signature proprietary product, Fortetropin – further cementing its sciencebacked claims to enhance mobility and activity in aging canines.

Fortetropin is the key ingredient in Myos Canine Muscle Formula, an all-natural dietary supplement that has been shown by eight published peerreviews clinical studies to have tremendous muscle health efficacy in mammals. The new patent, Myos Corp’s eighth to date, specifically addresses the use of Fortetropin in treating canine muscle loss in conditions such as rheumatoid arthritis, osteoarthritis and hip dysplasia, while also improving mobility and activity levels and reducing lean body mass wasting.

The global pet supplement market is experiencing rapid growth, reflecting a broader trend in pet care toward health and longevity. This expansion is particularly pronounced in the realm of senior dog care, where a growing number of products are being developed and marketed specially for aging canines. This segment’s growth is fuelled by pet owners’ increasing willingness to invest in their pets’ health, akin to how they care for human family members.

N 12 | January 2024 - International Petfood

Join us and a panel of top industry speakers on March 11 th 2024 at Room MR 224, BITEC, Bangkok, Thailand for the Aquatic Asia Conference - the premier event for the aquaculture industry.

Conference theme:

Future World Feed Through Aquaculture

For more information and to register scan the QR code or visit:

13 March 2024 10:00am - 12:00pm

Bangkok, Thailand part of

For more information and to register visit: https://millingandgrain.com/bmfm24

20 24 MAXIMISED FLOUR MILLING 14 MARCH INFO & REGISTER @ BANGKOK, THAILAND Organised by A CONFERENCE FOR FLOUR MILLERS FlourMax_flyer.indd 4 12/01/2024 16:07

11 March 2024 http://myaqua.info/gBbL For more information and to register, visit: For further enquires please contact: Tuti Tan - tutit@perendale.co.uk Dr Mian Riaz - mnriaz@tamu.edu Extrusion Conference Part of Health and Nutrition Asia BITEC, Bangkok, Thailand Organised by Petfood & Aquafeed 12/01/2024 16:09

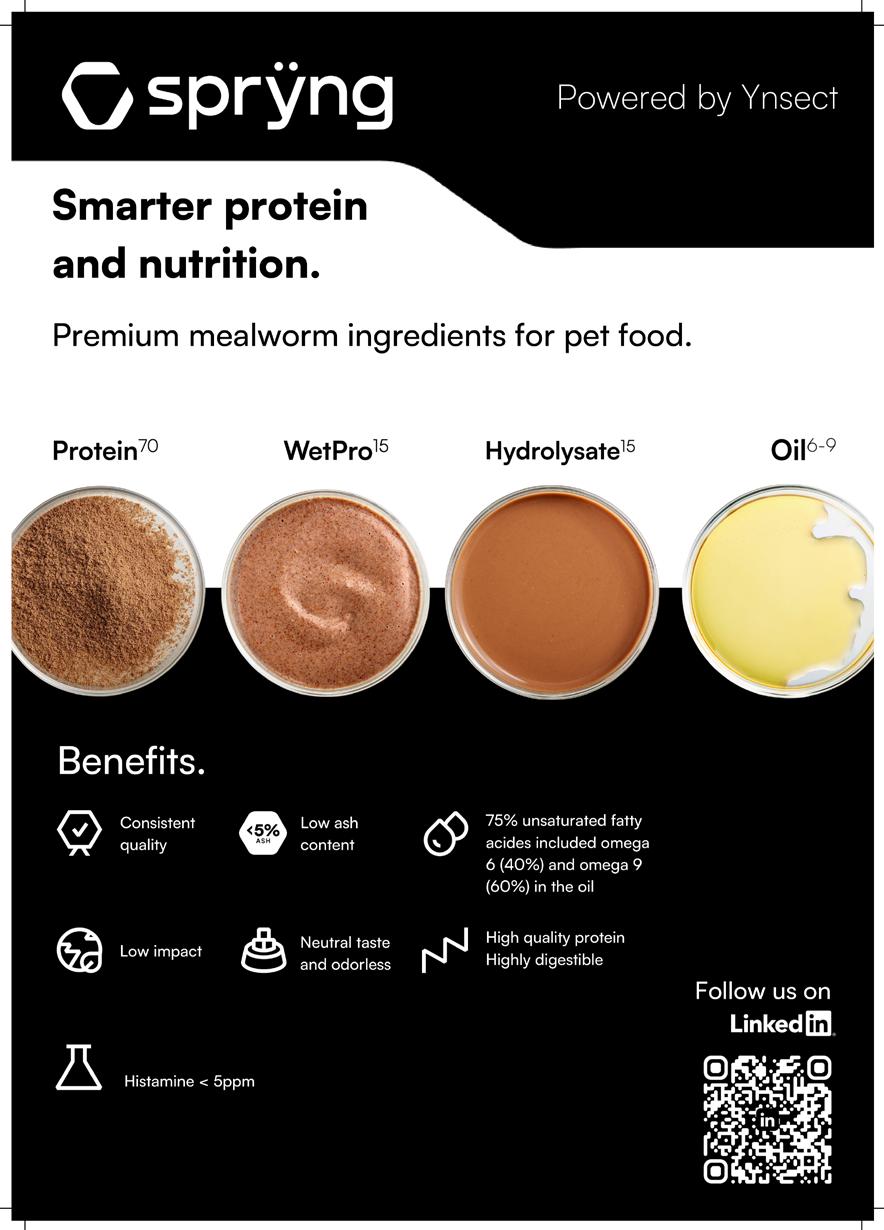

Mealworm protein Benefits in combating pet obesity

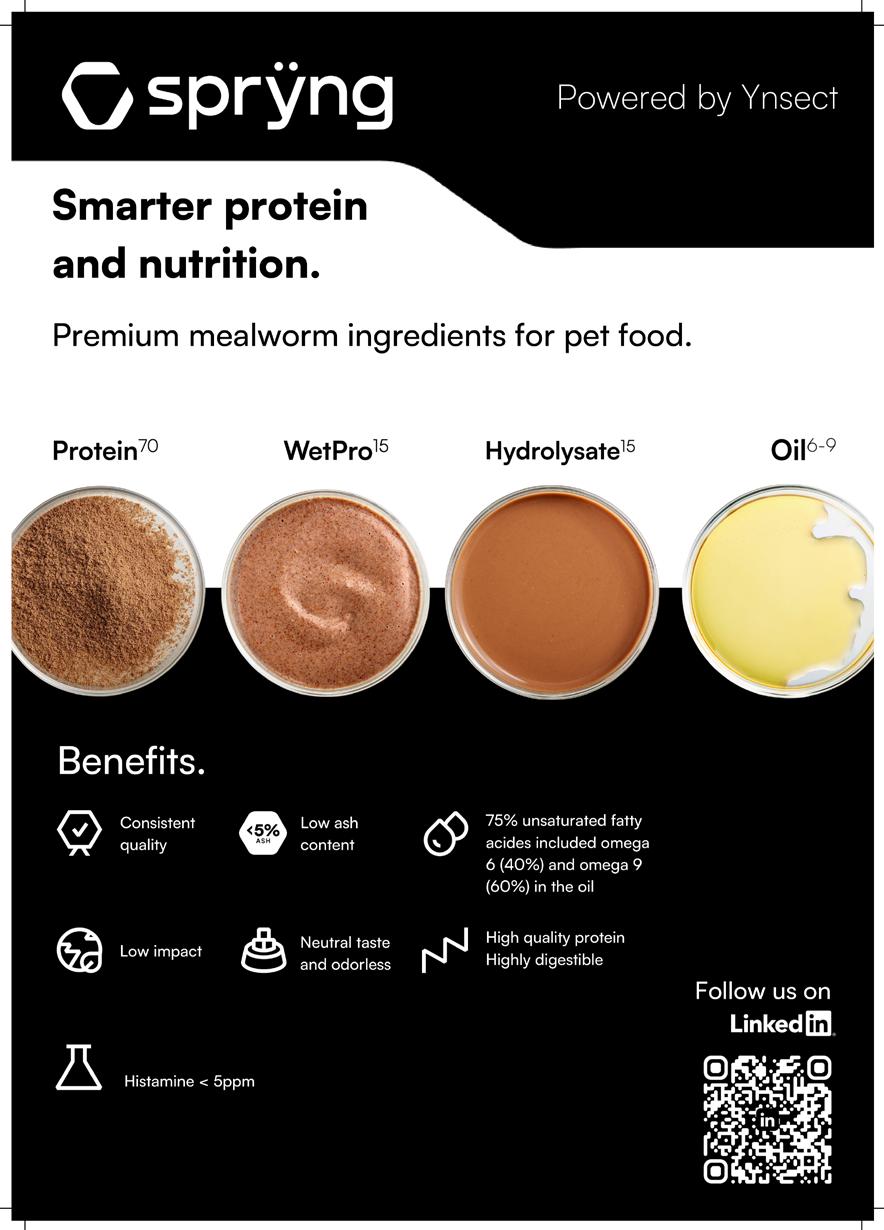

by Dr Lorena Sanchez, Scientific Project Manager, Sprÿng Powered by Ynsect, France

The global obesity crisis, a health concern of epidemic proportions for humans, is sadly affecting our companion animals too. According to the Association for Pet Obesity Prevention, 59 percent of dogs and 61 percent of cats worldwide are currently obese — a figure that has risen over the past decade by 169 percent for cats and 158 percent for dogs. Although factors such as breed and neuter status can predispose certain animals to obesity, the broad extent of the trend suggests that owner-related factors, such as diet choice and feeding practices, are largely responsible. Compared to healthy animals, obese pets have lower vitality, as well as increased pain and emotional disturbance. Life expectancy is reduced by approximately 1.5 years for both cats and dogs, and there are numerous associated health risks including cancer, inflammation, diabetes (particularly for cats), high blood pressure, kidney disease and respiratory disease. Such serious health concerns carry a financial consequence for the pet owner in increased medical expenses, and pet obesity is estimated to account for 20 percent of pet insurance claims.

Strategies for combatting pet obesity

Fortunately, there is evidence that much of this is reversible. Studies have shown that obese pets that follow a supervised weight loss program can regain their vitality, and that restricting food intake can both increase life expectancy and delay the onset of chronic disease. To achieve such success, owners must increase their pet’s physical activity, and modify their own (often long-standing) feeding practices. This will typically involve both a moderation of the quantity of food (for example, reducing the

number of treats offered), and understanding what constitutes a quality diet: a low-calorie, high-fiber, high in protein of good quality, and low-fat diet is a safe and effective way to lose or maintain weight in pets.

Recent studies on obese rats and mice suggest that a particularly good source of dietary protein for combatting obesity may be mealworm protein.

The global market for dietary insect protein is quite young but growing rapidly—it is expected to reach US$1.74 billion by 2028, and pet food applications account for 75 percent of this. Originally, the primary incentive for exploring insect protein as an alternative to animal protein was environmental: insect farming requires significantly less water and is less landdependent than conventional livestock; its GHG production is lower; and insects have a low feed conversion ratio, which means they convert low-protein ingredients to high-protein ingredients very efficiently. Now there is increasing evidence to suggest that consuming mealworm protein may not only be beneficial for the environment, but also for health.

Mealworm protein reduces fat accumulation and total lipid content

A growing body of research on rodent models of obesity has demonstrated that including mealworm protein the diet has a marked anti-obesity effect. In a recent study from Kelly Swanson’s group, mice were fed a high fat diet, with casein as the protein source. Once the mice had become clinically obese, some of the obese mice continued on the same diet, while others were fed similar diets in which the protein source was replaced by Sprÿng’s mealworm protein. After eight weeks, the mice whose diet included the mealworm protein slowed their weight gain.

14 | January 2024 - International Petfood F

––4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25 International Petfood - January 2024 | 15 N

Elsewhere, numerous studies on genetically obese rats and mice have demonstrated that animals fed a diet with mealworm meal as the protein source produce visibly less fat tissue than animals fed their standard casein diet. What’s more, within the fat tissue, the fat cells themselves (adipocytes) are smaller. This effect can be reproduced in the laboratory by growing adipocytes in vitro, and adding an extract of mealworm: the treated adipocytes are not only smaller, but—significantly— their production of triglycerides is reduced by 70 percent.

Triglycerides are a type of lipid molecule, formed in the liver from fatty acids: the more fat tissue in the body, the more fatty acids are carried to the liver in the blood, and the more triglycerides are produced. Furthermore, high triglyceride levels are often associated with high levels of other lipids, including cholesterol. This total lipid content is an important indicator of obesity-related ill health: in dogs, hyperlipidemia has been linked to gastrointestinal dysfunction such as vomiting and diarrhea, seizures, and cloudy eyes; in cats, skin lesions and peripheral neuropathies are common; and pancreatitis can also result. In the studies on obese rats, the total lipid content in the liver was reduced by 60 percent in rats fed mealworm protein; and the total lipid content in blood plasma was reduced by almost two-thirds.

insect cuticle was added, and indeed, this diet produced many of the same lipid-reducing effects as the diet in which casein was completely replaced by mealworm meal. Specifically, there was a decrease in the production of several proinflammatory lipids associated with fatty liver disease (ceramides, glycosylceramides, and sphingomyelin). Additionally, several changes to gut microbiota were observed, including significant increases in Actinobacteria—known to have anti-inflammatory effects and to counteract fatty liver disease—as well as Lactobacillaceae and Bifidobacteria, both known to alleviate accumulation of lipids in the liver. These observed microbiota changes may lead to a reduction in proinflammatory lipid production in the liver.

Part of the beneficial effect of chitin may reflect its function as a dietary fiber, it is already well understood that increasing dietary fiber is part of a strategy for combatting pet obesity. Numerous weight control products already available on the market, for both cats and dogs, include a greater number and variety of fiber sources than maintenance kibbles products. When using insect meal as a protein source in pet food, such as Sprÿng’s Protein70 and WetPro15, the highquality protein comes with supplementary dietary fiber in the form of chitin.

Whatever the precise mechanism, there is no question that including mealworm protein in the diet is beneficial in counteracting obesity, at least in rodents. While future research on cats and dogs is necessary, these findings are already very promising for a future in which it seems likely that the use of insect protein in pet food will continue to rise, although the initial motivation may have been environmental, it seems our beloved companions may end up healthier, and be around for longer, as a consequence.

Beneficial health effects of mealworm cuticle

What is it about the insect meal that causes this reduction of lipid production? The answer might be chitin, a polysaccharide found in mealworm cuticle (comprising the exoskeleton). To test the hypothesis that mealworm cuticle reduces lipid production in rats, obese rats were fed a normal casein diet to which ground

F 16 | January 2024 - International Petfood

Bulk Sampling?

You could buy a sampler or, Invest in a Samplex…

The Choice is simple... The Solution is

Alternative Protein Solutions

For furry family members

by Jennifer Adolphe, Pet Technical Sales Manager, ADM, USA

Pet parents are seeking out pet food and treats that mirror their own diets, looking for sustainable sources of protein and ingredients with clean label cues, such as all-natural, plant-based, non-GMO, or organic for their furry family members. These clean label claims, in everything from individual ingredients to colours and flavours, signal to consumers that the pet food and treats they have chosen are high quality.

While traditional protein sources found in pet food are typically derived from fresh meat and rendered meat meals, protein supply is increasingly becoming a global issue. As the world’s population continues to increase, responsible protein production is of critical importance for food security and environmental impact. Pet parents recognise this too, with many looking to pet food and treats that can assist in minimising negative environmental effects. In fact, 42 percent of global pet owners say they want to purchase pet food with sustainably sourced ingredients. To help meet this demand, alternative protein sources have risen as an essential factor in the global food system for both humans and their pets. Plant- and yeast-based proteins are options that can be used in pet food and treats to supplement or replace animal protein ingredients. Even insect protein, like black soldier fly meal, is being used in some pet foods today.

It’s essential to recognise that for pets, achieving the right nutritional balance matters more than the inclusion of particular ingredients. Before a novel source of protein makes its way into pet food or treats, it must be validated through research to ensure it is acceptable for pets and will nutritionally support a balanced

diet. For example, ADM has partnered with researchers at the University of Illinois to determine the biological availability of essential amino acids from various plant- and yeast-based ingredients for use in dog and cat foods. The research found that dogs and cats were able to digest and absorb plant-based protein sources, such as soy, just as well as those of traditional animal protein. Research projects have also been conducted at the ADM pet nutrition center in Brazil and have confirmed that plant-based formulations are well accepted by dogs and can support digestive health by enhancing microbiota diversity.

Yet some pet owners are hesitant to feed their pets plant-based proteins made of ingredients like soy or corn, and “no soy” pet food has been persistent in the industry for decades. However, ADM research indicates that 80 percent of today’s pet parents are seeking or are open-minded to soy in their pet’s food. And many are citing veterinary recommendations as a top motivator for selecting foods and treats made with soy, with ADM research indicating that 28 percent of pet parents who were exposed to veterinary research about the improbability of soy allergies in dogs or cats would change their opinion and feed soy to their pets in the future.

Flexibility of formulation

With pet owners’ changing demands for ingredients and food formats, manufacturers require flexibility in formulation to continually meet these needs. ADM helps advance pet food and treat development to deliver sensory appeal to pets and their owners as well as balanced nutrition for overall pet wellness. For example, a single high-quality ingredient may assist in providing several nutrients, such as wholesome ancient grains that can deliver protein, starch and dietary fiber. Legacy grains, such as

18 | January 2024 - International Petfood

corn and wheat, are as nutritionally sound and appropriate as other popular sources of carbohydrates in today’s pet foods. The ADM pantry also includes soy, peas, chickpeas, lentils, beans and other pulses; complex proteins like Versity® dried yeast and Hilucia™ black soldier fly larvae (BSFL) products; and a variety of fruit and vegetable extracts.

Additionally, ADM Ventures, the corporate venture capital division of ADM, has made two important investments to support the development of expanded protein sources and responsible production practices for pet foods.

One venture is with Bond Pet Foods, a startup at the frontier of the alternative protein landscape. Bond Pet Foods will employ precision fermentation technology to make nature-identical chicken, beef, fish and other meat proteins for innovative pet food applications. The fermentation process also requires no animal proteins.

A second venture is with Innovafeed, a producer of black soldier fly larvae and global leader in the growing space of insect proteins. Recently, the Association of American Feed Control Officials (AAFCO) has approved BSFL to be used in adult dog food and treats in the U.S. Insect ingredients are becoming more desirable due to growing awareness of their unique nutritional benefits, with consumers warming up to the idea of insect protein being used in pet foods. In addition, insects like the black soldier fly are used to upcycle low-quality feedstock into premium ingredients to support a circular economy and corporate sustainability initiatives.

With more pets in the home than ever, the need to provide pet food products that match their owner’s lifestyles has increased drastically. Pet parents are looking to brands to provide pet food and treats that are both good for their furry family members and for the planet. ADM’s vast ingredient portfolio and support of disruptor brands like Innovafeed and Bond Pet Foods is bolstering innovations in pet nutrition while unlocking the potential for wider distribution of alternative proteins worldwide.

PETFOOD INTERNATIONAL

International Petfood comes to you either in print or digitally.

Whichever way you want to receive, please sign up on our MagStand for your personal copy which will give you access, from your desktop, to our back-issue library. https://store.magstand.com/petfood

The App can be downloaded from your favourite app store.

We invite you to use the code below for a free edition of our March magazine either mailed to you or via our App

Use coupon code:

Download your online version

The most advanced software solutions for pet food production from intake

finished product. Scan the QR-code and learn more! International Petfood - January 2024 | 19 F

to

ATLANTA24

Nurturing Wellbeing

Deeper look into inflammation & its effects

by Dr Cinzia Boggino Scavone, Business Development Manager & Dr Allison Millican, Global Technical Services, Zinpro Corporation,USA

Supporting our pet’s happiness, health, and wellbeing is of the utmost importance, as they are more than just our pets, they are family. Thus, when our dog or cat appears sick, unthrifty and/or unhappy, we work to understand the driving factors. One driver is likely inflammation.

Inflammation in cats and dogs is a common factor when the aforementioned symptoms are recognised. Although our first thoughts about inflammation are typically unfavourable, inflammation is imperative to regain health. An appropriate and robust inflammatory response is necessary to repair damaged tissues and battle the bacteria and pathogens making us or our pet’s sick. However, if inflammation persists once the issue is resolved, this can drive a cascade of negative and damaging effects.

Demystifying the Inflammatory Response

When the body recognizes foreign intruders, signals are sent recruiting non-specific immune cells to the area of detection to defend against the invader and enable increased blood flow to the impacted area, surmounting an inflammatory response. Inflammation can be caused by pathogens (germs), viruses, fungi, external injuries, etc. Inflammation can be localized or systemic (throughout the body), manifesting as fever, redness, pain, swelling, and heat. As a principal mechanism of the innate immune system, inflammation aids to eliminate harmful

pathogens from the body, yet, when the response is overzealous or sustained beyond what is necessary it perpetuates damage versus repair. The two types of inflammation are categorised as acute and chronic.

• Acute inflammation is the first line of defence to a pathogen or injury. A short-term process where the immune system sends white blood cells to the site of the injury or invasion of the pathogen to initiate the healing process. This response should be rapid and robust, appearing within minutes or hours following activation of an immune response.

• Chronic inflammation occurs when the immune response fails to eliminate the cause of the immune response or acute inflammation. Chronic inflammation can last for weeks, months or longer.

While a robust and appropriate inflammatory response is necessary, excessive, or prolonged inflammation, if not controlled, will become detrimental, damaging healthy tissues, cells, and DNA. Furthermore, immunocompetence is dependent on having appropriate energy and nutrients; therefore, nutrients normally employed for growth, maintenance of tissues, reproduction, or activity are redirected to fuel the inflammatory response. For example, animals with chronic inflammation will likely have poor skin and coat due to the nutrients needed to nourish and maintain skin integrity, shiny coat and paw pad integrity which are diverted to sustain the ongoing inflammatory response. Compounding the issue, illness in our pets often diminishes appetite and food intake.

20 | January 2024 - International Petfood F

Linking Poor Gut Integrity to Chronic Inflammation in Cats and Dogs

When dogs or cats experience itchiness or skin irritation, many pet owners seek solutions to alleviate the discomfort and redness. However, some may not realize that the underlying cause of the visible signs of inflammation could be linked to compromised gut health.

n

n Involved

Mn

The epithelial tissues lining the gastrointestinal (GI) tract form a barrier, preventing bacteria, pathogens, and naturally occurring toxins in the gut from passing through the intestinal lining and entering the bloodstream. A breakdown in barrier, results in a condition known as leaky gut.

Digestive disturbances or mild-to-moderate food allergies can contribute to leaky gut, leading to loose or runny stools. Indicating damage or irritation within the GI tract, prompting the immune system to focus on this area. Consequently, immune cells are diverted from their usual role of maintaining skin health, exacerbating the skin-related issues in pets and creating inflammation in the GI tract.

Role of Trace Minerals in the Immune System

n

n

n Protects against

Fe

Se

n

n

In addition to dietary factors, compromised gut health can result from psychological stressors, such as irregular feeding schedules for your dog or cat or disruptions to their usual routine. Stressful events, whether physical, environmental (such as heat stress), or psychological, can trigger an increase in cortisol, a stress hormone. Elevated cortisol levels signal a reduction in blood flow to the gut, impacting motility, immune protection, and nutrient absorption, thereby increasing risk of epithelial barrier disruption causing leaky gut.

Revolutionizing batching with unmatched precision Easy maintenance Track & trace Reporting Continuity Employee shortage Health safety and environment Accuracy Short batch times Micro dosing and weighing equipment for: Offering a solution to your challenges such as: VISIT US DURING IPPE: BOOTH A1353 ALFRA - Part of KSE Group www.ksegroup.com Advertenties AllPetfood – Print – ½ page.indd 1 10/01/2024 10:37 F International Petfood - January 2024 | 21

Manganese

Iron

Selenium

Known to contribute to more than 300 enzymes systems

Maintain the health and integrity of skin due to its role in cell replication and repair

and gut integrity and defense

n

n Skin

in wound healing

against oxidative damage as it activates Superoxide Dismutase (SOD)

Improve immune function through enhanced macrophage (white blood cell) killing ability n Protects against oxidative damage as it activates Superoxide Dismutase (SOD)

n Protects

n

in the immune response

Involved

for oxygen transportation n Response against stress as

Essential

the immune system as

active

neutrophil production

affects phagocyte

blood cell) killing

Strong effects on

it is

in

and

(white

ability

Required for antibody development and lymphocyte (white blood cell) replication

oxidative

Superoxide

Protects against oxidative damage as it activates enzyme Glutathione Peroxidase (GPX) Cu Copper Zn Zinc activates enzyme catalase

damage as it activates

Dismutase (SOD) n

Barriers and mucus membranes are also part of the innate immune system and remarkably, 60 to 80 percent of the immune system is dedicated to safeguarding the gut against leaks and the resulting damage. Prolonged inflammation progresses the issues, enabling further barrier breakdown. As a result, we may observe disruptions in the skin’s epithelial tissue, leading to hotspots, dry or scaly skin, increased shedding, a coarse or lacklustre coat, the onset of unpleasant odours, irritability, and persistent, bothersome itchiness.

Beyond issues related to the integrity of the digestive tract and the condition of the skin and coat, persistent inflammation can contribute to various health challenges in pets, including diabetes, obesity, fatigue, insomnia, depression, anxiety, and an elevated susceptibility to infections. Therefore, effectively addressing and managing inflammation in your family companion is crucial for ensuring their long-term health and wellbeing.

The Vital Significance of Trace Minerals in Immune Health

Although trace minerals, including zinc, iron, manganese, copper, and selenium, are required in modest quantities, their biological impact is immense, serving as structural and catalytic cofactors for proteins and enzyme systems that

support whole body health and wellbeing.

Given the strict necessity of metals in numerous cellular processes, trace minerals emerge as essential contributors to proper immune function. Delving deeper into their significance, trace minerals prove instrumental in managing chronic inflammation in cats and dogs by fostering a resilient and balanced immune response. They contribute to the formation of robust first-responder cells and maintain equilibrium between pro-inflammatory proteins (cytokines – chemical messengers) and their anti-inflammatory counterparts. Combined, zinc, manganese, copper, iron and selenium join forces through the antioxidant process, as they aid in removing free radicals (inflammatory waste products) from the body, preventing damage. Furthermore, they aid in maintaining epithelial barriers (cellular integrity and tight junctions) that provide the first layer of protection.

Source Matters: Choosing the Right Dietary Trace Minerals

When contemplating trace minerals for dietary inclusion, it’s crucial to understand differences between available sources for supplementation. The primary categories being, traditional inorganic sources, such as oxides and sulfate forms, and organic or chelated alternatives. However, not all organic or chelated trace minerals exhibit equal efficacy.

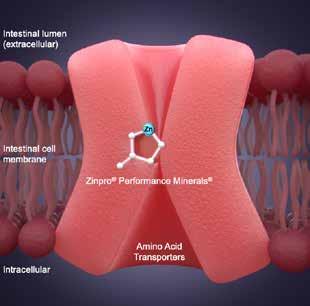

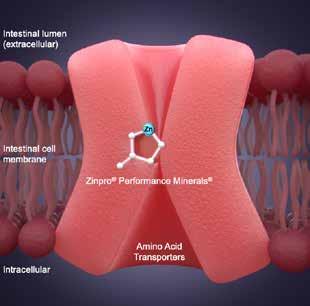

Zinpro® Performance Minerals® are proven to be the most readily available form of trace mineral source on the market. The unique 1:1 bond with an amino acid allows these trace minerals to be absorbed differently, via the amino acid transporters and utilized by the animal more efficiently.

Leveraging a distinctive absorption pathway, Zinpro Performance Minerals play a pivotal role in reinforcing the immune system and enhancing epithelial tissues, thereby fostering a resilient and balanced immune response.

The stable molecular structure of Zinpro Performance Minerals offers additional benefits by safeguarding essential vitamins against oxidation within vitamin-mineral premixes and maintains complexation throughout processing conditions like extrusion. Diets enriched with Zinpro Performance Minerals provide confidence that the trace minerals provided in the diet are absorbed and utilized to support and maintain a healthy gut and immune system, enabling protection for our pets from pathogens and leaky gut, ensuring their wellbeing and happiness of our fourlegged family members.

22 | January 2024 - International Petfood F

Absorption Pathway of Zinpro Performance Minerals

World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55 F International Petfood - January 2024 | 23

Revolutionising Pet Nutrition Inside the Innovative Approach of a Petiva

by Mehmet Uğur Gürkaynak, International Petfood Magazine, Türkiye

by Mehmet Uğur Gürkaynak, International Petfood Magazine, Türkiye

International Petfood was fortunate to visit Petiva, a leading brand dedicated to delivering highestquality products aimed at enhancing the health and well-being of pets, in December and understand its unique approach to petfood production.

Under the stewardship of company owner Halil Özkan, Petiva has secured a notable position within the petfood sector. Our visit and discussion with Halil Özkan shed light on Petiva’s prominent standing in the industry.

Spanning a closed area of 6,000 square meters on a 12,500-square-meter plot, the factory’s strategic proximity to Karasu Port offers logistical advantages, facilitating swift and efficient operations throughout production and distribution phases.

Employing modern manufacturing technologies such as high vacuum technology and automatic density control, Petiva ensures the production of top-quality pet food. This enables pet owners to readily select the most suitable nourishment for their cats and dogs. At the forefront of Petiva’s ambitions is the aspiration to establish itself as Turkey’s premier global brand and elevate national brands to international markets, thereby reducing reliance on foreign markets.

The detailed insights into the company’s endeavours underscore its steadfast commitment to the health and happiness of our pets. As stated by company owner Halil Özkan, Petiva remains dedicated to offering the pinnacle of care for our pets by harmonizing technology and expertise with a compassionate approach grounded in respect for nature and humanity.

Where quality and innovation meet for pet health

The well-being of our pets is an integral aspect that significantly impacts their lives. Keeping this in mind, the company remains steadfast in its efforts to ensure the highest quality nutrition for our beloved pets, conducting all processes within the ambit of the Quality and Food Management System.

Özkan articulated the significance of Quality Control and R&D endeavors, stating, “Our Quality and Food Management System encompasses all stages, from sourcing raw materials to delivering the final product to customers. We meticulously work to uphold superior product quality through our stringent quality control protocols and dedicated laboratories, encompassing pet food production, packaging, storage, and shipment.”

24 | January 2024 - International Petfood

Petiva’s products are crafted with natural formulas devoid of artificial colorings and sweeteners. Noteworthy for their superior quality and nutritious properties, these offerings are tailored with specific formulations catering to diverse age groups. Enriched with a wealth of vitamins and minerals, these products not only contribute to overall pet health but also guarantee a quality, healthy life by amalgamating scientifically proven methods with expert knowledge.

Primary measures for pet health

The company shapes its quality policy with a customercentric approach, intending to evolve from product design and development to final delivery, aligning with customer requirements. Özkan emphasized the active involvement of employees through comprehensive in-house training and ongoing improvement initiatives, fortifying the effectiveness and efficiency of their quality management system.

Beyond a quality-centric approach, Petiva places considerable emphasis on its environmental responsibilities. It aims to judiciously utilise natural resources, curtail waste generation, and remain compliant with environmental regulations. Özkan highlighted, “To uphold food safety, precision forms the cornerstone of all our business activities. We meticulously oversee every facet of the food chain within the formula production process.”

The company bolsters its quality control and management through established systems, particularly in food production, while prioritizing food safety and sustainable pet health. Özkan emphasized, “To bolster the well-being of our customers’ pets, we offer products of exceptional quality and reliability, a testament to our stringent food safety and quality standards.”

Petiva continues to distinguish itself in the sector through its unwavering focus on quality control and management processes, aimed at supporting pets to lead healthy, highquality lives. The commitment to elevating quality standards and embracing a culture of continuous improvement underscores their dedication to enhancing the health of our pet companions.

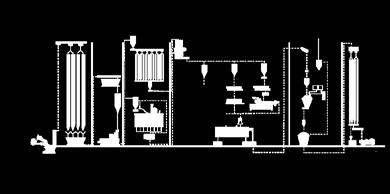

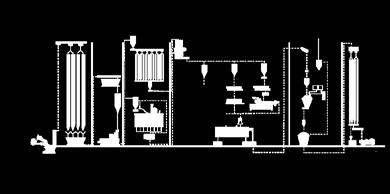

Halil Özkan is proud about his high quality products and the machineries he uses for production. He gave the same attention at choosing the machineries and equipments. One of the suppliers are Wenger, a leading provider of cutting-edge processing Solutions. Wenger has unveiled a game-changing advancement in pet food production. Collaborating closely with Petiva, Wenger has delivered high-quality machinery, including a Single Screw Extruder equipped with a High Shear Conditioner (HSC), Back Pressure Valve (BPV), and top-notch Process Controls. Notably, the extruder, manufactured at Wenger’s operations in Brazil and branded as “Maverick,” showcases the pinnacle of Wenger’s design prowess.

This collaboration between Wenger and Petiva has transcended conventional industry standards. Their joint efforts have not only conquered challenges but also established a seamless production process.

Renowned for continuous innovation and global influence, Wenger’s ingenuity in plant-based proteins, pet foods, and aquatic feeds sets an unparalleled standard. Their solutions are recognized worldwide, solidifying Wenger’s position as one of the industry trailblazer, elevating pet food production to new heights of quality and innovation.

Another machinery supplier was Yemmak. The decision to opt for Yemmak’s machinery stemmed from their proven track record in processing and engineering solutions, aligning with Petiva’s quest for top-tier quality in pet food production.

Yemmak’s comprehensive involvement in Petiva’s project extended across machinery and equipment procurement, process design, project management, as well as installation and commissioning processes. Their turnkey solutions were tailored to facilitate the production of premium pet food, ensuring a streamlined and efficient operational setup for Petiva.

The array of process solutions offered by Yemmak encompassed stages such as raw material receiving, grinding, mixing, cooling, oil coating, cleaning, and extrusion lines. With a legacy spanning back to 1965, their global footprint extends to over 300 turnkey projects worldwide, solidifying their expertise in meeting diverse industry needs.

Quality control process

Özkan, the company’s owner and visionary, elaborates on the steps involved in the quality control process, stating, “The selection of raw materials holds paramount importance in producing top-tier pet food. We meticulously source certified raw materials meeting national and international standards from carefully vetted suppliers. Our laboratories conduct analyses in strict accordance with raw material specifications. The outcomes of these tests undergo rigorous scrutiny and approval, adhering strictly to our production and quality benchmarks. Only raw materials meeting these stringent standards are integrated into the production process.”

International Petfood - January 2024 | 25

Apart from the careful selection of raw materials, Petiva implements stringent quality control measures throughout the production stages. Notably, analyses encompassing physical, chemical, and microbiological assessments play a pivotal role in evaluating product suitability for pet health. Özkan underscores this process, stating, “We execute an extensive array of controls throughout the production phase, spanning from chemical analyses to palatability, ease of digestibility, and microbiological properties. In addition to physical appraisals and microbiological criteria, crucial factors such as toxicological and mycotoxin evaluations are also considered.”

Petiva’s quality control process emphasizes precision and reliability in analyses. In particular, analyses utilising NIR (Near-Infrared Spectroscopy) devices serve as critical tools in confirming the accuracy of obtained results.

Innovation in quality and scientific pet health approach

By amalgamating high-quality protein sources with natural vegetables, the company formulates recipes ensuring a guarantee of a healthy life for pets. Halil Özkan stressed the company’s dedication to pet health, stating, “A complete and balanced diet directly impacts the health of pets. Therefore, we tailor special nutritional programs, considering animal type, breed, age, and physiological conditions.”

“The texture and shape of the kibbles support feline dental health, while precise quantities of calcium, magnesium, and phosphorus are formulated to foster growth and development in kittens or expectant pets,” explained Özkan.

Petiva’s products are enriched with specialized ingredients fostering overall pet health. Omega-3 and Omega-6 fatty acids, along with taurine and immune system-supporting components, contribute to pets leading a robust life. Özkan elaborated, “Our products contain fish oil, fruits, and specific vitamins infused with essential taurine, crucial for heart health support while fortifying pets’ immune systems.”

Petiva’s R&D vision hinges on perpetual innovation and creativity. “In developing our brands, our aim is to maintain transparent and reliable communication. Through fostering emotional connections with our employees, business partners, and pet owners, we diligently work toward the health of our beloved pets.”

The company’s facilities has a production capacity of five tonnes and are equipped with cutting-edge technological machinery from leading industry brands. “Designed for maximum automation through advanced process technology, our facility aims to mitigate health concerns by minimising human errors,” stated Halil Özkan.

The production process commences with the acquisition of carefully selected raw materials, sieved, filtered, and cleaned before being transferred to product silos. Computer-controlled systems determine pet food rations taken from these silos, preparing one-tonne batches in specialized mixers.

Özkan elucidated that during production, vital additives such as vitamins, minerals, and taurine are precisely incorporated using automatic pre-mixing systems. The homogenization and cooking stages are meticulously designed to cater to pets’ specific needs.

Shaped by special extrusion machines during the cooking stage and subjected to final checks, the products progress to the packaging stage. Given batch numbers to ensure traceability, the products are then prepared for shipment.

Petiva’s investments in technology and precision in its processes underscore its commitment to pet health and its pursuit of providing top-quality products. Guided by Halil Özkan, Petiva remains steadfast in elevating industry benchmarks and crafting products fostering a healthy life for pets.

| January 2024

BioCraft Pet Nutrition

BioCraft Pet Nutrition, founded in 2016, is the first and only biotech company developing cultured meat for the growing pet food market. Founder and CEO Shannon Falconer, MSc, PhD, left her post-doctoral research fellowship at Stanford University and turned down a prestigious academic scholarship to apply her scientific prowess to create meat-based, nutrient-dense pet food that doesn’t come at the expense of harming the environment or other animals.

In 2021, BioCraft introduced the first cultured meat product for the pet trade—cat treats made from mouse cells—a milestone for the company and the entire industry. BioCraft (formerly Because Animals) was the first to create a proprietary growth medium as an alternative to fetal bovine serum (FBS), helping reduce production costs by well over an order of magnitude and representing a key step towards commercial scale. BioCraft has developed the only truly environmentally sustainable and humane meat ingredient for pet food. It’s not a meat alternative; its meat produced in an alternative way that does not rely on conventional animal agriculture practices.

Today, the BioCraft team has grown to include a roster of PhD scientists, a veterinarian, and serial entrepreneurs, all focused on taking animals out of the supply chain by producing the healthiest, most environmentally sustainable and supply-chain stable meat for dogs and cats.

BioCraft is now focused on building partnerships with pet food manufacturers looking to incorporate cultured meat — which offers sustainability, animal welfare, quality and safety benefits — into their portfolios.

According to BioCraft, cultured meat provides for a more uniform raw protein material that is less likely to be contaminated by common pathogens seen among traditional, animal-based proteins.

The company uses proprietary cell lines to grow meat — without the use of fetal bovine serum — in a controlled and pathogen-free environment. Cells are grown in a liquid medium of vitamins and minerals, according to the company. The finished product is similar to a traditional “meat slurry” in consistency,

which is familiar to pet food processors and can be used in a one-to-one replacement for animal-based meat in a variety of formulas, including dry kibble, wet food, treats and even fresh pet food formulas.

According to BioCraft, the company’s cultured meat products are not genetically modified and are free from GMOs, chemical and bacterial contaminants, antibiotics, pentobarbital, steroids or other hormones. The nutritional profile of BioCraft’s cultured meat ingredients stack up against animal-based meat, meeting all protein, key vitamin, fat and amino acid requirements, including taurine.

Location

BioCraft is located in both North America and Europe, with R&D performed via its subsidiary company, BioCraft Pet Nutrition GmbH in Austria. BioCraft investors include Draper Associates, SOSV, KEEN Growth Capital, Orkla Food Ingredients, Sentient Investment, Hack Capital and angel investors. BioCraft Pet Nutrition GmbH is a recipient of grant funding from the Austrian Research Promotion Agency (FFG).

Investors of BioCraft include Draper Associates, SOSV, KEEN Growth Capital, Orkla Food Ingredients, Sentient Investments, Hack Capital and angel investors. BioCraft Pet Nutrition GmbH is a recipient of grant funding from the Austrian Research Promotion Agency (FFG).

International Petfood - January 2024 | 27 Industry PROFILE

Industry Training

Bühler Pet Food and Aqua Feed Workshop

Bühler’s Pet food and aquafeed workshop is returning on 26-29 February, 2024. The workshop will take place at Bühler’s Headquarters extrusion application centre, Uzwil, Switzerland.

The Pet/aqua feed workshop will provide attendees with an introduction to the basics of extrusion technology, focusing on preconditioning, energy, moisture, and mass flow balance. A four-day hands-on workshop at the Bühler extrusion pilot plant will utilize twin-screw extrusion technology and covering a variety of subjects.

Using hands-on workshop-style teaching, attendees will learn - introduction to the basics of extrusion technology, focusing on preconditioning, energy, moisture, and mass flow balance, discussion of single v/s twin screw extrusion technology, screw configuration, die and knife technology, SME control and product density control and its significance in vacuum coating, micro-feed for Aqua, fresh meat addition and filled pillow treats for pet food.

Practical demonstrations will help participants to apply everything they learn in Bühler’s modern pilot plant. The aim of the demonstrations is not to produce perfect

copies of anyone’s products but to demonstrate the endless opportunities of extrusion technology. The applications target modifications of cereals and pulses, bypass proteins etc., fish feeds (floating, sinking) including vacuum coating, shrimp feeds and/or feeds for other aquatic species, influence of alternative protein and starch sources etc., dry, semi moist and/or bicoloured pet foods, treats, addition of slurries, etc, and texturisation of proteins.

This workshop is intended for operation supervisors, engineering, or R&D personnel, etc. i.e. people, which are actively involved in technological aspects and feasibility considerations of extrusion.

The workshop offers hands-on training with experiences extrusion experts, training documentation, with lunch and transport provided and a certificate of participation upon completion.

For more details visit:

https://www.buhlergroup.com

/global/en/training/Buhler-pet-aqua-feed-workshop.html

Your industry training platform

TRAINING

The Online Milling School provides a comprehensive 12-week remote learning experience covering all aspects of feed milling, from raw material handling through to final packaging and dispatch. www.onlinemillingschool.com FISH FARMING TECHNOLOGY

28 | January 2024 - International Petfood

Troubleshooting

It is the time of year where most plants would have shut down in the Holiday Season. It is typical to have any time-consuming work accomplished during this period such as scheduled overhauls of any major equipment. Years ago, petfood processors determined once the equipment became durable enough to last a year the obvious point to prepare for the next year was during this break.

Wear on some machines is such that they need attention more than others. Hammermill screens, for example, need to be replaced as needed and thus quick changing screen machine designs help minimise down time. Machine design is usually constructed to have access for timely repairs.

What would be the top or most frequently changed parts in a modern petfood extrusion production facility? Knife blades are normally number one as product appearance is critical and seen right off and thus corrections are made. Today product quality is number one and this is an important fact in selecting the parts that should be on hand in the plant for replacement purposes. Let’s make lists by area. To start, the supplier of the gear should be the best source on the lifetime of their equipment and their parts: Raw material area, bearings, seals, lubricants, gears, motors, electrical components, and sensing gear. Yes, you can have too much but the idea is to develop a list that works for you based on down time related to when parts can be delivered. Standardisation in some cases can reduce spare parts held due to multiple use areas.

The processing area, mainly the extrusion equipment is where to place the most attention. Big heavy parts need planning to replace and availability. If there is one, the gear box on your extruder should have a lifetime rating, extruded screws and sleeves have expected wear lives. Dies do wear and the associated electrical, plumbing and control systems also have lists of parts to have on hand.

In many cases all of the above should be predictable by the equipment supplier, including predicted spare parts that should be on the shelf. With computer control systems the sensors and controls should be well covered. The computer control packaged worked with over the years have all had the ability to run if a sensor is out in most cases or a clued in sparky can temporarily jumper a bypass until the part is available.

The extruder barrel parts can be considered the hardest to get quickly due to many factors, such as availability, distance shipped, overseas paperwork etc. The amount of wear in this area is directly related to the running conditions, formulation, and its preparation. Everything seems to go hand in hand with production balanced for product quality, wear, operational costs etc. Then all becomes more predictable.

Studies years ago showed that feed performance, wear, utility, use as well as capacity and product quality were at its highest with lowest cost when running at about 22 to 30 percent moisture in the extruder. Lower moisture increased friction and increased vitamin losses, higher moisture reduced cook due to slippage in the barrel and thus both lowered feed performance. Typically, single screw extruders wear and when the initial gap between the screws and sleeves is 2 to 2.5 times the original then some of the screws need replaced. More on this next month..

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The extruder barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the extruder barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating