2 minute read

HIGH CORROSION PROTECTION, EXCELLENT EDGE

COVERAGE: FREILACKE DEVELOPS A NEW POLYESTER SYSTEM BASED ON PRIMID

by Oliver Zanner

Emil Frei GmbH & Co. KG - Bräunlingen-Döggingen, Germany o.zanner@freilacke.de

Many ingredients such as TMA or BPA (bisphenol-A) have been criticised in recent years because classified as hazardous.

FreiLacke developed new, non-declarable polyester coating systems with the FREIOTHERM powder coating PS3005 and PP3005 series, particularly suitable for industrial applications and for construction and agricultural machinery.

‘Primid’ is the trade name of a hardener that belongs to the chemical class of β-hydroxyalkylamides and shows its strengths especially in the cross-linking of powder coatings. In addition to very good corrosion protection, the material offers high weather resistance and excellent colour stability. The use of Primid hardener and its toxicologically favourable profile means FreiLacke’s new polyester system does not require labelling: It is completely free of problematic components. Compared to epoxy resins, the production of polyester coatings requires significantly less energy.

Environmental protection is therefore already considered in the formulation of this system. Aside from that, epoxy resins are mainly produced outside Europe whereas the new polyester system makes costly transport by sea unnecessary. Finally, coaters thereby circumvent the well-known price volatility of epoxy resins, which continues to fluctuate strongly. One minor drawback: so far, the new coating system can only be used under standard baking conditions (10 minutes at 180 °C object temperature). A variant for low-temperature applications (10 minutes at 160 °C) for high-quality pre-treatments is already in progress. The newly developed polyester-based powder coating was designed with the focus on excellent corrosion protection properties.

FREIOTHERM powder coatings based on PS3005 and PP3005 can be used as single-layer or two-layer coatings. “The new twolayer coating system provides corrosion protection that almost reaches the level of a classic epoxy primer,” explains Alexander Schelling, who is responsible for powder coating development at FreiLacke.

“The advantage for the coater is that there is no need for a separate primer and the topcoat is simply applied twice.” When using a topcoat with high pigmentation costs, however, it is still advisable to use a separate primer.

The FREIOTHERM powder coatings PS3005 and PP3005 are available on request in all surface finishes – smooth, fine and coarse structured – as well as in gloss levels from high gloss to silk gloss.

Forward-looking development

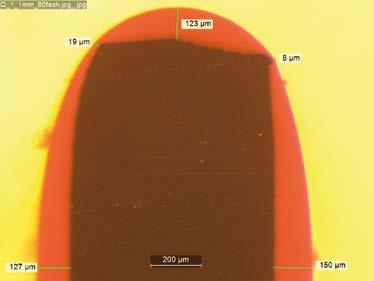

In addition to excellent corrosion protection, the new system also offers very good edge coverage, which virtually eliminates rust damage. “If edges and laser cuts are sufficiently rounded, the polyester coating can also be used in a single layer and, compared to classic industrial/facade powder coatings, brings a clearly noticeable added value in terms of corrosion resistance,” emphasises Jakob Zihsler from FreiLacke’s powder coating development department.

The PS3005 was developed in response to a specific customer request from the agricultural and construction machinery sector. FreiLacke took this as an opportunity to revise the existing corrosion-optimised systems as a whole. “The development took about two years. We started the development proactively because we knew this was coming,” explains Zihsler. The above systems can also be modified according to customer-specific requirements. In the meantime, more than ten reference customers are already using the new systems in a wide variety of modifications. ‹