The Power of Precision

From tools that make clean cuts to sharp strategies that increase efficiency and mitigate risk, discover ways you can strengthen your business.

From tools that make clean cuts to sharp strategies that increase efficiency and mitigate risk, discover ways you can strengthen your business.

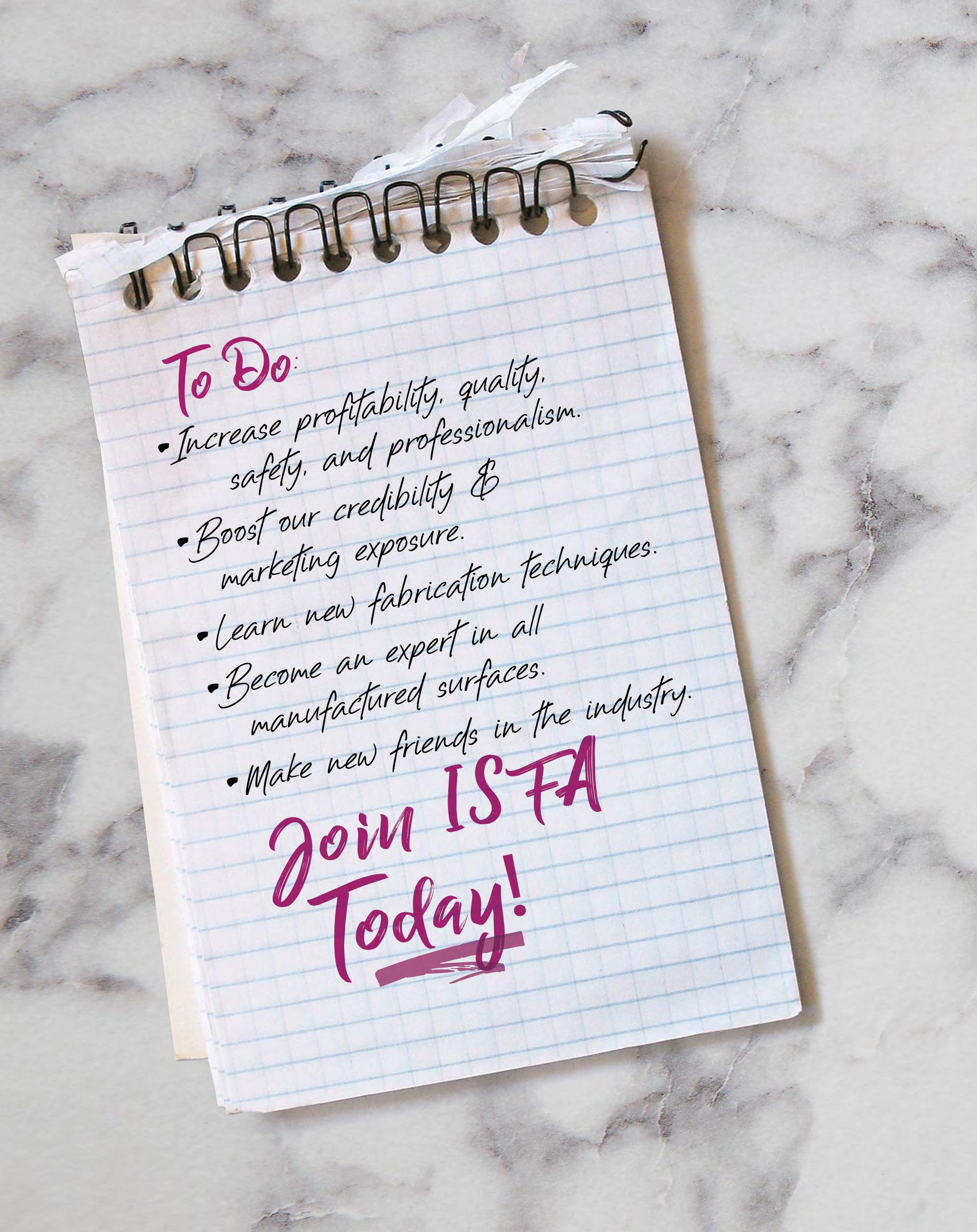

FOUNDED FOR FABRICATORS BY FABRICATORS TO LEARN MORE ABOUT THE BENEFITS OF MEMBERSHIP, VISIT WWW.ISFANOW.ORG.

Editor: Sarah Peiper

Contributors:

Stephen Alberts

Nancy Busch

Paul “Max” Le Pera

Austin Maxwell

Jessica McNaughton

Tim Saddoris

Louise Scott

Travis Sterrett

Ed Young

Proofreader: Marsha Jo Scott

Design:

V2 Marketing & Management

Printing and Distribution: LSC Communications

Countertops & Architectural Surfaces (ISSN 2372-983X) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2023. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures.

Photography/graphics provided by:

Adobe Walls Stoneworks

BACA Systems

BB Industries

Betterley Industries

Breton USA

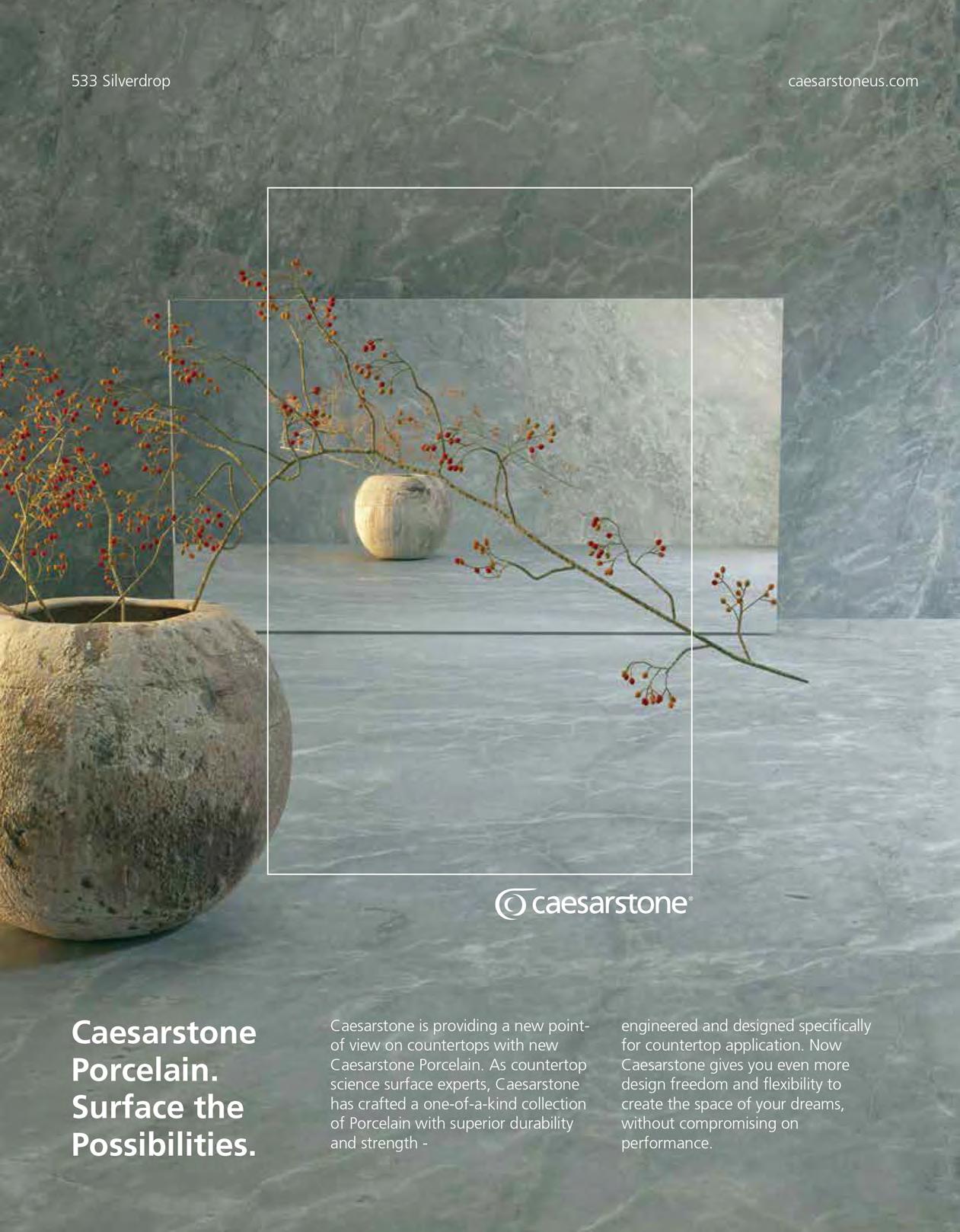

Caesarstone

Colonial Saw

Coverings

Coverlam

Diabu

Diamond Products

Durasein

Ed Young

GEM Industries

Hyundai L&C

Integra Adhesives

Laminam

Lapitec

Levantina

Museum Surfaces

No Lift Install System

Park industries

Prodim Systems

Rep Methods

Sonesta Ocean Point Resort

Vicostone

ZENESIS

ZOLLER

POSTMASTER: Send address changes to:

LSC Communications

c/o Countertops & Architectural Surfaces magazine

3401 Heartland Drive

Liberty, MO 64068

THE OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

Cover Photo

Integra Adhesives manufactures an innovative range of color-matched seaming and assembly methyl methacrylate adhesives, as well as a range of color-matched Sealants for the surfacing industry. Integra Adhesives products are specifically formulated for the fabrication and installation of every countertop including solid surface, quartz, stone, porcelain, laminate and compact laminate. The Integra range of seaming adhesives will save you time and money, will offer you stronger joints which are great on the new thinner sheets and will keep you healthier as they contain no styrene or isocyanates.

To learn more visit www.integra-adhesives.com.

14 Do You Schedule Your Maintenance Time or Does Your Machinery Do It for You?

Get the most out of your machinery with a Total Productive Maintenance approach.

When there’s uncertainty, cutting costs and maximizing productivity are crucial. Follow these steps and you’ll be breaking shop records.

With the right tools, you can optimize processes, reduce waste, and improve efficiency in your shop. Consider these saws and accessories that can keep your shop on the cutting edge.

With steadfast commitments to a quality product, its customers and employees, this Texas fabricator achieves excellence at every step of the process.

I’ve been gardening since I was a kid — pulling weeds, harvesting veggies and deadheading flowers for as long as I can remember. Back then, it was a chore, but as an adult, it is therapy. Coming from a long line of gardeners and farmers didn’t set me up for instant success; my green thumb was hard-earned. I experienced countless losses, but a few wins kept me at it until I finally found my stride. I think killing a lot of plants is a gardener’s rite of passage.

Living in the Midwest, I had a good four months to make the best out of the season and grow enough to preserve for the winter, so I was all about large beds with rows and rows of tomatoes, peppers, beans, squash, onions, herbs, not to mention flowers. Now I live in a climate with a continuous growing season, so my approach is a bit different. Less is more in a lot of ways.

Flower beds and fruit trees aside, I’m down to a 12 ft. by 4 ft. bed for vegetables. I adopted the square foot gardening method — a highly efficient and space-saving technique that allows gardeners to maximize their productivity in limited spaces. Developed by Mel Bartholomew in the 1980s, it involves dividing the gardening area into small square foot plots, each containing a specific number of plants depending on their size. Adopting this approach has enabled me to increase productivity and decrease my margin for error. I can plant densely and make the most of the space. I can do succession plantings: As soon as one crop finishes, I can replant for a continuous supply. Even though I am growing 12 months out of the year, it’s a huge time-saver. Less weeding, huzzah! It takes careful planning and consideration, but this square foot garden is a game-changer.

That said, even in the simplest of circumstances, things can go awry. For example, the downside to living in this climate is that you have no cold season to freeze out all the pests. So I read a lot of gardening blogs and books to troubleshoot what’s eating the cabbage or why my

cucumber vines are wilting. There’s still so much to learn, and even the best gardeners can only prepare so much when most of the battle is reacting to a problem. Maybe some of you can relate, gardener or not. Whatever your business or hobby, progress is about learning and growing.

Sometimes you have to react to unforeseen circumstances or make a plan to overcome challenges you know are heading your way. So you make an effort to learn about new ways of doing things or seek new products that can help you solve a problem. Within the building and remodeling industry, many of you are wading in the shallows of the skilled labor pool or making plans for an economic downturn. In this issue of Countertops & Architectural Surfaces, we’re with you every step of the way. From making the most out of your processes for the sake of efficiency (page 24) to a machinery maintenance plan that keeps things running smoothly (page 14) to a roundup of the latest saws and accessories that can help you streamline your processes and improve accuracy (page 28), this issue is full of solutions to all kinds of shop problems.

It’s crucial to be forward-thinking and innovative — discover new ways of doing things, like filling vacancies on your staff (page 20) or partnering with those across the industry to further sustainability (page 34). In this issue’s fabricator profile, read about Adobe Walls Stoneworks, a first-class fabrication company out of Amarillo, Texas, that upped its showroom game and saw big returns (page 40).

Success comes to those who plan for it, those who nurture it, and those who evolve with changing circumstances. Make plans A, B, C and D — however many it takes. You reap what you sow.

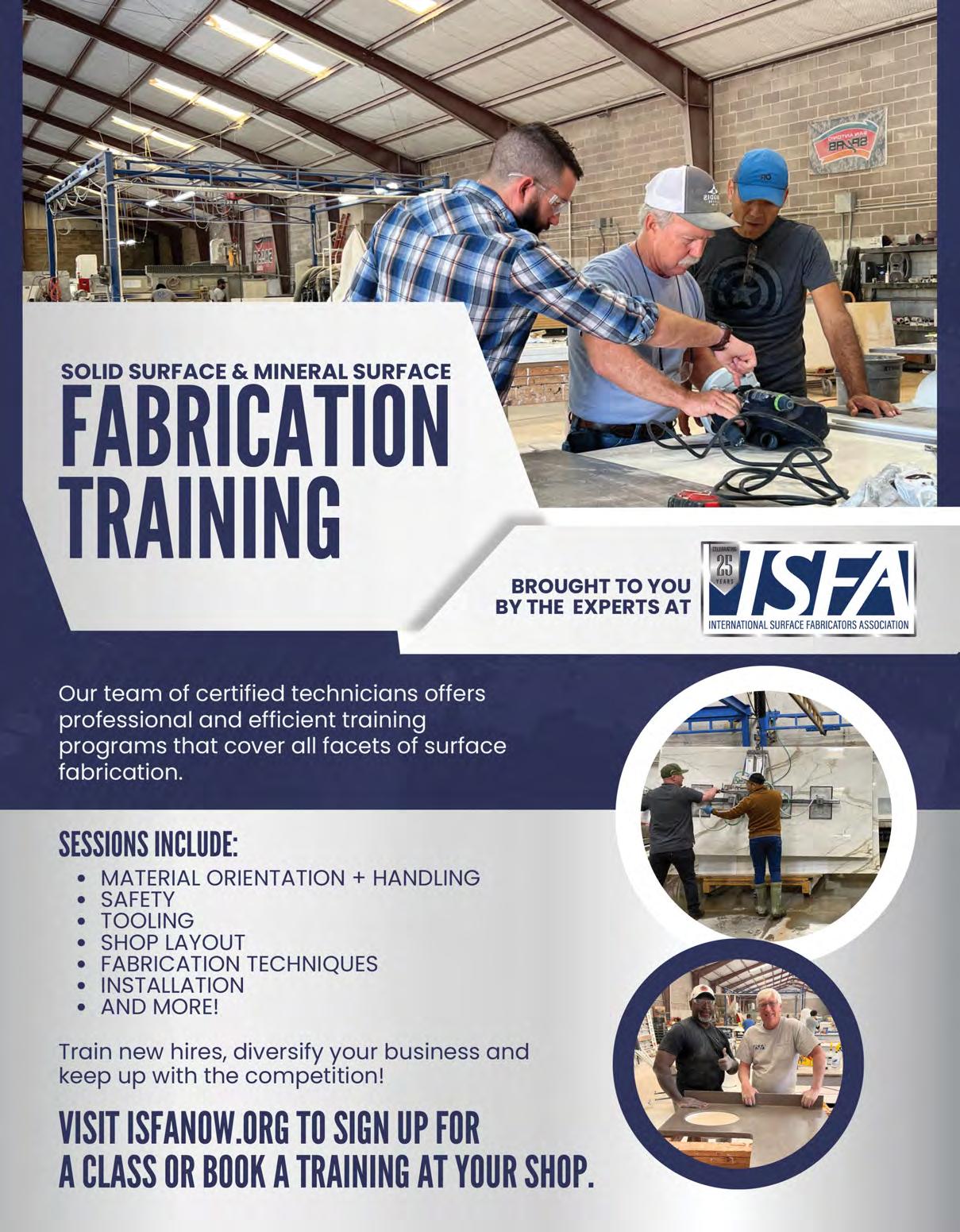

ISFA Solid Surface Fabrication Training

June 6-7

Lakewood, Wash. www.ISFAnow.org

ISFA Webinar: 3 Tips for Presenting Price & Sending Quotes

June 7

www.ISFAnow.org

AIA Conference on Architecture

June 7-10 San Francisco www.conferenceonarchitecture.com

Behind the Surface Podcast: Silica Safety and Industry Standards with NIOSH

June 12

www.ISFAnow.org

BACA Systems Installing Profitability Seminar

June 15

Addison, Ill. www.bacasystems.com

Oregon Stone Summit: Know Your Business

June 15

Beaverton, Ore. www.naturalstoneinstitute.com

Digital Stoneworking Expo

Presented by Park Industries

June 22

Cincinnati

www.parkindustries.com/stone/event/ digital-stoneworking-expo/

Behind the Surface Podcast: On the Cutting Edge with Park Industries

June 26 www.ISFAnow.org

Behind the Surface Podcast: Savvy Software for Surface Fabricators

July 10 www.ISFAnow.org

ISFA New Member Workshop

July 12 www.ISFAnow.org

ISFA Fabricator Crawl

July 19-20

Chicago www.ISFAnow.org

Pennsylvania Stone Summit: Take Your Organization to the Next Level

July 20

Bridgeville, Penn. www.naturalstoneinstitute.com

Behind the Surface Podcast: Tracking Sales

July 24

www.ISFAnow.org

BACA Systems Installing Profitability Seminar

July 27

Orlando, Fla. www.bacasystems.com

ISFA Webinar: Improve These 3 Things To Transform Your Sales

August 2 www.ISFAnow.org

Behind the Surface Podcast: Integrating Software in Your Business

August 7

www.ISFAnow.org

ISFA Solid Surface Fabrication Training

August 8-9

San Antonio, Texas

www.ISFAnow.org

ISFA MemberConnect Meeting

August 17

Virtual www.ISFAnow.org

Behind the Surface Podcast: Digital Tools for Templating

August 21

www.ISFAnow.org

BACA Systems Installing Profitability Seminar

August 24 Meridian, Ohio www.bacasystems.com

Behind the Surface Podcast: Marketing Tools that Lead to Growth September 4 www.ISFAnow.org

ISFA Webinar: The Right Way To Do Discovery in Your Sales Process September 6 www.ISFAnow.org

ISFA Mineral Surfaces Training

September 13-14 Massillon, Ohio www.ISFAnow.org

Behind the Surface Podcast: B2B Lead Generation

September 18 www.ISFAnow.org

BACA Systems Installing Profitability Seminar

September 21 Location TBD www.bacasystems.com

Missouri Stone Summit: Know Your Business

September 21 St. Louis www.naturalstoneinstitute.com

Cersaie

September 25-29

Bologna, Italy www.cersaie.it

Marmomac

September 26-29

Verona, Italy www.marmomac.com

Coverings, the premier international tile and stone exhibition and conference in North America, honored 15 exceptional individuals across the stone and tile industry at its annual trade show in April. The Coverings Rock Stars program has a long history of honoring up-and-coming trailblazers in the tile and stone industry who continually revolutionize and inspire as pioneers of success.

The coveted annual awards reinforce Coverings’ mission to support the advancement and achievements of the industry by distinguishing exemplary young leaders and fostering networking and educational opportunities. Award winners represent the industry’s brightest and most inventive young professionals raising the bar on performance and excellence.

Builder/Remodeler: Christopher Rachel, owner Superior Home Solutions Ashland, Neb.

Contractors/Installers: Nathan Cooper, owner Infinity Bath Aberdeen Proving Ground, Md.

Cody Cox, operations manager Cox Tile Inc. San Antonio, Texas

Randall Johnson, tile contractor The Tile Geek, LLC Meridian, Idaho

Maria Meyer, tile artisan apprentice Dragonfly Tile & Stone Works, Inc. Shorewood, Wis.

Elly Warner, apprentice installer Hawthorne Tile Portland, Ore.

Schannon Yodice, owner/tile contractor That Tile Chick League City, Texas

“The Coverings Rock Stars program celebrates many incredible tile and stone industry experts of which the 15 most outstanding nominees are being honored across various categories this year,” said Jennifer Hoff, CEO of Taffy Event Strategies, LLC, the event management company for Coverings. “The winners are an extremely talented group of individuals who provide inspiration for their peers and colleagues from the creativity, innovation and commitment they consistently showcase.”

A committee of longstanding tile and stone industry leaders thoughtfully evaluated nominations to select this year’s inductees for Coverings Rock Star status. The 2023 Rock Stars represent numerous industry segments and include the following winners:

Distributor: Melanie Lawton, showroom manager Best Tile Company North Scituate, R.I.

Interior Designer: Kenya Jones-Lowell, interior designer hospitality MG2 Corporation Puyallup, Wash.

Manufacturer: Heather Ruhl, national technical manager TEC/H.B. Fuller Construction Products, Inc.

Retailer: Jack Rautiola, head merchant, renovation Wayfair Boston

Stone Fabricator: Austin Maxwell, president Maxwell Counters, Inc. Farmer City, Ill.

Others: Casandra Guthrie, manager, IS & sales Choices Wholesale Flooring Solutions Albuquerque, N.M.

Manasa Rao, sustainability manager WAP Sustainability Consulting Chandler, Ariz.

Vincenzo Spina, stone consultant STONEX Consulting Dubai, UAE

Coverings 2024 will be held April 22-25, 2024, in Atlanta. The conference continues its aim to provide distributors, retailers, fabricators, contractors, specifiers, architectural and design professionals, builders, and real estate developers opportunities to network with industry professionals, gain cutting-edge knowledge, source the trendiest and most innovative products on the market, and so much more. For more information about attending, sponsoring or exhibiting at Coverings 2024, visit www.coverings.com.

Crossville Inc. announced aggressive carbon reduction goals affecting its tiles’ global warming potential with a goal of achieving a 30% reduction in manufacturing embodied carbon by 2030. The company’s short-term goal is equally aggressive as it seeks to achieve an additional 10% reduction by 2024 as compared to its 2019 measurements.

The company is the first U.S. tile Manufacturer to set specific short-term carbon reduction objectives.

From its founding, Crossville has recognized that a product that comes from the earth should have minimal impact on the earth. In 2014, Crossville completed its first energy usage assessment, which led

the company to develop its Environmental Product Declarations. Five years later, Crossville achieved a 10% reduction in the tiles’ embodied carbon, beginning the path of carbon reduction in its facilities and operations. Based on that reduction, Crossville has developed new aggressive goals that embody changes the company will make to its processes to affect the tiles’ global warming potential. The company announced short-term goals of achieving an additional 10% reduction in the tiles’ global warming potential by 2024 and a 30% reduction from its 2014 baseline by 2030.

“We are exploring all the ways internally that we can drive energy reduction strategies with changes to product and process,

including investigating all new evolving technologies that improve energy efficiency while maintaining a commitment not to compromise quality,” said Lindsey Waldrep, Crossville’s vice president of marketing.

The company’s ongoing commitment is to alter and reduce manufacturing’s carbon impact through changes to product and manufacturing processes. However, Crossville products are still influenced by the energy needed to produce them. For this reason, the company can further reduce its tiles’ carbon footprint by purchasing verified emissions reductions, or carbon offsets, whereby embodied carbon is offset by contributions to projects which help make the world better, greener and more sustainable.

The stone industry has come a long way in the use of technology since I worked with my first fabrication shop client over 20 years ago. Almost every shop I visit today has some or all of the following:

• CNC saws.

• Water jet cutting.

• Digital templating.

• Robotic sawjets.

Unfortunately, the most common form of maintenance I see for this expensive equipment is a break-fix approach — we fix it after it breaks. This creates a heavy reliance on the machine manufacturer to supply parts quickly. It also creates unnecessary and costly schedule interruptions for the fabricator.

A few shops do a decent job of preventive maintenance. This includes:

• Greasing a fitting.

• Changing lubricant.

• Changing filters.

Some fabricators even knock the dust and dirt off their machines from time to time. To run a fab shop effectively, a more robust approach to maintaining machinery is needed.

To get the most out of a machine you have invested hundreds of thousands of dollars in, you need to consider a Total Productive Maintenance (TPM) approach.

TPM is a process that maximizes the productivity of equipment for its entire life cycle and will extend the life of the equipment. Through the

o 1. Check coolant level through clear Plexiglas

o 2. Check heat exchanger fans (strings should be moving)

o 3. Check servo drive fans (string should be moving)

o 4. Check heat exchanger air filter (change when dark)

o 5. Check servo drive air filter (change when dark)

o 6. Check way lube reservoir (add when low)

o 7. Check main motor air filter (change when dark)

o 8. Check main motor cooling fan (string should move)

o 9. Check mist collector motor and air filter (change when dark)

o 10. Check bar feeder hydraulic motor air filter

o 11. Check bar feeder hydraulic oil level (add when low)

participation of all employees, TPM creates an environment that encourages improvement efforts in safety, quality, cost, delivery and creativity.

If you don’t schedule time to maintain your equipment, your

equipment will do it for you. If you don’t want surprise maintenance stoppages that always occur during a critical job, then you need to plan your maintenance.

TPM is the combination of the three types of planned maintenance:

1. Preventive maintenance

Preventive maintenance is intervalbased maintenance. It consists of periodically inspecting, servicing and cleaning equipment, and replacing parts to prevent sudden failure and process problems. This includes changing the oil every 500 hours of run time, applying grease to a fitting every week, and replacing the bearings every 3000 hours. This is the most common type of planned maintenance.

2. Predictive maintenance

Predictive maintenance includes inspecting and diagnosing equipment components to determine the service life of those components. The intent is to maximize the life of the components and to replace them before that life is exceeded.

Predictive maintenance includes activities like regular:

• Chemical analysis of lubricating fluids to determine if critical components are wearing appropriately.

• Vibration analysis of shafts and bearings to assess condition.

• Infrared temperature evaluation of mechanical and electrical components.

• Nondestructive testing of stressed components.

3. Corrective maintenance

Corrective maintenance includes improving various aspects of equipment and components so that maintenance and repairs can be carried out quickly and reliably. This frequently includes modifying access to components to improve visual evaluation, labeling wear items so the correct replacement part is used and marking the proper operating range on gauges.

TPM also integrates the operator in Autonomous Maintenance (AM). In AM, the machine operator performs daily activities to aid in detecting and correcting abnormalities to prevent reduced machine performance. This includes visual inspection, routine cleaning, lubrication and data collection. The most effective AM programs have detailed documentation allowing any operator to complete the daily activities. (See examples in Figure 1.)

To gauge the effectiveness of the above activities, TPM uses a metric called Overall Equipment Effectiveness (OEE). OEE assesses the availability of the equipment, the performance efficiency of the equipment and the rate of quality output. (See Figure 2.)

There are several key steps to effectively implementing TPM.

1. Initial cleanup. Clean the machine until it looks like it did the day it arrived from the manufacturer. Cleaning helps you see any obvious areas of lubricant leaks, and since you have to physically touch every area of the machine, you will quickly identify any issues with loose electrical connections, compressed air leaks, broken latches, etc.

2. Assess the condition of the machine. Address the obvious items identified above. Also, assess whether the machine can perform to the original manufacturer speeds and process rates. Repair or replace any component that is needed to meet those original specs. This gives you a solid baseline from which to operate.

3. Standardize your maintenance procedures. Establish how you will label part numbers for consumables like filters and belts. Determine what corrective maintenance methods you will use. Document these items and train everyone on them.

4. Implement AM. Develop the daily routines required of machine operators and make these activities easy to perform correctly. Implement documentation for recording these activities and any anomalies found. Audit frequently.

As a shop owner, you have invested

hundreds of thousands of dollars in the critical equipment needed to run your business. To ensure your business can consistently produce the quality products your customers expect and to meet your schedule commitments, you need to manage the condition of your equipment. If you don’t plan your downtime, your machines will do it for you. Your machinery needs to be kept in like-new condition so that it will operate at the speeds it was designed for. You need the consistent quality your equipment is designed to deliver. TPM is the best approach to ensuring your equipment supports your business goals. C C C C

A A A A

B B B B

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www. fabricatorscoach.com or reach Ed directly at Ed@fabricatorscoach.com.

When you’re trying to reach your customers through digital marketing tactics, there are a lot of great tools on the market that can help you achieve your goals. Using the correct software for your fabrication shop can save your staff time and money, but you need a good balance. While there is such a thing as software overload in the countertop industry, I often see companies not using enough digital tools. Let’s review some tools I recommend for any countertop company’s marketing efforts.

A Facebook business page can help your shop reach a broader audience, establish its brand and spread awareness on the social network. By showcasing different materials you carry, posting photos and videos of completed projects, and engaging with customers through comments and messages, your shop can build a following — an audience. While most shops have Facebook pages, many don’t consistently post content. Try to post a few project photos a week on your page. And don’t forget about Instagram! This photo-driven platform is perfect for project photos and material or trend content.

A Google Business profile will give homeowners accurate and up-to-date information, such as business hours and location. This information is displayed on Google Maps, making it easier for customers to find your shop’s location with turn-by-turn directions. Your profile will house your reviews, helping build trust and credibility with homeowners. We see a good amount of traffic, phone calls and customer inquiries from a shop’s Google Maps listing. Make sure everything is accurate on your profile, and create a communication strategy with your customers that encourages them to leave positive reviews.

Google Analytics and call tracking tools like WhatConverts and CallRail can be highly beneficial for a countertop shop. The best part about Google Analytics is that it’s free! You can analyze website traffic, identify high-performing pages and track user behavior. This information can then improve website design and enhance the user experience. Call tracking tools enable a shop to better understand their overall numbers in terms of leads coming in. Set up goals inside of Google Analytics and track phone calls and quote form leads from your website.

A CRM system like Pipedrive, Hubspot, STONE ENGAGE, or Salesforce can help a countertop shop manage its sales leads more effectively. This is probably the number one issue we see with shops. They want to increase revenue and get more leads, but they do not use anything to manage the leads. Using a CRM enables a shop to track customer interactions, monitor leads and forecast sales. CRMs can automate lead tracking, send alerts for follow-up, and provide valuable insights into lead behavior. Having your team manage a simple sales pipeline will bring you more business and close more jobs. The beauty of the CRMs mentioned is that the follow-up messages can be automated — a terrific time-saver.

Advertising on Facebook can help your countertop shop get more project leads by targeting homeowners based on location, demographics, interests and behavior. Your shop can promote project pictures and packages that you are offering. I suggest starting with a smaller budget of around $20-$30 per day to

test the waters. After you gain data to see what’s working, you can focus your campaigns on ways you know will bring results.

Google Ads can help your countertop shop get more project leads by targeting users searching for granite countertops, quartz countertops and tons of other keywords. Your shop can create compelling ad content, directing users to a landing page or quote form to request more information. By monitoring ad performance and optimizing campaigns, your shop can increase its visibility, generate more leads and ultimately grow its business. As with Facebook, I suggest starting with a $20-$30 per day budget here to see what works.

Are you emailing all of your leads and contacts a monthly newsletter? If you aren’t, you could be losing out on business. Newsletter software like Mailchimp, STONE ENGAGE and Constant Contact can help your countertop shop get more project leads by sending regular emails to subscribers, showcasing new products, promotions and completed projects. Stay top of mind with your customers by reminding them each month about what you offer and showcasing your projects. The added benefit of a newsletter is that it can travel beyond your contact list when someone forwards it to a friend or relative who might be looking for a new countertop.

Canva is a fantastic tool for designing creative elements for social media, websites, printed materials, business cards — you name it. You can create the content using design templates, editing tools and a media library. You can upload your project photos and feature them in one of the thousands of design templates in Canva’s arsenal.

This is truly a great solution that can make anyone a graphic designer.

Scheduling your social media posts in advance is a great way to put out content consistently. Tools like Buffer, Hootsuite and STONE ENGAGE make this easy to do. Have someone on your team create at least 15 posts per month and then schedule three per week using one of these tools. Using a social media tool will also help you look at each platform’s analytics. You can see which posts get the most likes and shares and determine the time of day you get the most engagement, which could help you optimize your content.

You have probably heard of AI tools these days, and right now, ChatGPT is all the rage. You can ask this tool to write something on just about any topic under the sun, and it will create content with the click of a button. This is a great way to get content ideas or refresh existing copy for advertising, blog posts, social media and more. Below is an example of a social media post it wrote:

Stephen Alberts is the owner of the Countertop Marketing Co. and STONE ENGAGE. They specialize in helping countertop companies grow the retail side of their business outside of word-of-mouth and referrals. They also offer software to help you engage more with customers and close more countertop projects. To learn more, visit www.countertop marketingco.com or www.stonengage.com You can also email Stephen at steve@countertop marketingco.com

To get this social media post, I entered: Write a two sentence Facebook post that mentions a granite countertop sale we have and use emojis in the post.

There is no shortage of software solutions that can help you achieve your marketing goals. Keep in mind: You don’t have to do everything all at once. I recommend clients start with the first four tools on this list and expand from there. If used properly, these digital marketing tools can help your shop operate more efficiently and grow the business.

Everyone knows that the strength of our organizations is only as good as the people we employ. Having the right people on your team is essential. Getting the right people in place might be one of the most challenging aspects of running a business. In our current market, filling openings and finding the right talent for your organization can be difficult. With an unprecedented labor shortage, you may need to think outside your usual hiring process.

Hiring good people requires more time, effort and money than most realize. Worse, it costs your operation time and money when key positions go unfilled. People are working on tasks that anyone could do (you included) rather than spending their time on things that only they can do. Having the right people in place can be profoundly intangible in its effects (sometimes hidden). Still, we would assert that nothing makes a smoother operation, a stronger team, happier customers and lower stress levels.

Great candidates are out there looking for the right next step in their careers, and they might not realize that the stone industry could be an excellent fit for their talents. Or maybe a great candidate with stone experience is available, but your job description isn’t compelling enough. Or those qualified candidates who have tried applying can’t get ahold of busy hiring managers. Hiring great people is a competitive process. It can be done well but must be prioritized as much as the other strategies within your business.

When looking for your next great hire, is anyone on your team ready to be promoted? Before you post that next job opening, look for candidates internally. Who on your team is prepared to level up? Promotions are essential because employees want a viable career path. Changing someone’s scope can reenergize their work ethic instead of incentivizing them to work hard due to a pay increase. Doing this opens up other roles within your organization that may be easier to fill.

When looking outside your organization, remember that candidates have a digital footprint. Everyone in our world does these days. There are tools out there that can help you quickly identify candidates with the right experience. Consider a few of these:

• LinkedIn Recruiter Lite Subscription: Not quite as expensive as a full-on LinkedIn recruiter membership but offers increased resume searching capabilities on the platform.

• Indeed Recruiter Subscription: This is similar to the LinkedIn recruiter subscription, although a bit pricier. It does offer an increased ability to search Indeed’s extensive candidate database to find the right candidate.

• Ashby: This recruiting software requires some financial investment and focus of energy on your side but will work on your behalf to find, contact and seamlessly communicate with candidates.

When considering a candidate, focus on the three C’s: culture, character and competency.

• Culture: Do you know what your company culture is? Do you know yourself and your leadership team enough to understand who will be a good fit? Ensuring a candidate will thrive in your environment is as important as the technical skills they bring to the table.

• Character: Are candidates telling the truth? Do you have time to call three references to find out? Just because someone was let go in the past doesn’t necessarily mean they were at fault. Ask some leading questions in the interview to learn about their ethical compass.

• Competency: What are the pillars of each job description? Ensure you’re clear about your needs and that your candidate responds well to the tasks you’ll be asking them to do. Measuring competency is all about hardcore, concrete data. What previous data can the salesperson you’re interviewing present to you as measurable proof of success? How many square feet per day was the template technician candidate previously able to accomplish? Did you test that person to determine if they can accurately read a tape measure? Did you test them to find out if they can run the laser?

How do you get great candidates across the finish line? Onboarding is usually about efficiency and clear communication. Candidates will not convert if the onboarding process takes more than a few days. They must hear from

you if you want to keep them interested in your position. Get an offer letter with competitive pay and benefits, and get them started as soon as possible.

When communicating with your potential new hire, we recommend having a liaison between you and them — an advocate who can keep communications consistent and effective. Enroll someone in human resources, administration or operations to help with this, or consider hiring a recruiter to be part of your team. Finding great people, putting them through the appropriate evaluation processes, and getting them across the finish line should be someone’s full-time job. If no one on your team has time and you aren’t able to hire someone internally, partner with an external recruiting firm.

A recruiting company will pursue candidates who aren’t even job shopping and quickly catch those who are. They have the time and resources to search that you and your leadership teams do not have. They can fill any position and work alongside your existing recruiting efforts to help you fill jobs faster — and with better talent — so your company can thrive.

Travis Sterrett is the director of sales for Bronwick, a national full-service recruiting firm that helps companies in the stone industry find and acquire the talent they need to run and grow their businesses. Bronwick is interested in long-term partnerships with companies ready to take their hiring to the next level through focused attention on getting the appropriate people in “the right seats on the bus” (—Jim Collins, Good to Great). Learn more at www.bronwick.com.

The labor market is challenging, but using these tools can fill openings and inspire good work among new hires and existing employees. If you cannot focus on recruiting full time in-house, allowing a recruiting firm to come alongside your team could be a helpful next step. The money you invest will pay dividends when your new hires quickly bring value to your company. Perhaps you’ll even find your next leader — someone who could take the reins when you retire. C A B 2

I was mentored by some of the best plant managers in the country and I noticed one consistent behavior among the best leaders. They all started by working with operators to understand the problems and inefficiencies.

Uncertainty right now is a real thing. We’re still recovering from COVID and we’ve just had the second- and third-largest bank failures in history. We have no idea what the fallout is or how the economy will perform moving forward. Regardless of what happens, you still need to run a strong shop and get the most from your machines and your people. So, if … it … does hit the fan, you’re prepared.

When there’s uncertainty, cutting costs and maximizing productivity are crucial. But isn’t it really important at any time? In some cases, you’ve invested between $250,000 and $500,000 in these machines. You should be pushing them to the limits to get maximum production. Follow these steps and when you’re done, you’ll be breaking shop records, producing more slabs than you thought possible on your machines, and have a process that ANYONE can run if the dreaded turnover visits your door.

In my past life, I worked for the second-largest food-producing company in the world, ConAgra Foods. I was on a special technology team and I got to travel around the country to see how things were made, like Chef Boyardee, Egg Beaters, Swiss Miss, and more. I’ll eat all of it except for Chef Boyardee’s Ravioli. Not only do I not buy it, but I close my eyes when I walk by it in the grocery

store. Trust me, you don’t want to know what’s in this stuff.

Outside of learning how these products are made, I was mentored by some of the best plant managers in the country and I noticed one consistent behavior among the best leaders. They all started by working with operators to understand the problems and inefficiencies. It makes sense if you think about it, but is often overlooked by managers.

Your employees have chosen to run your CNC or wet saw. They know they’re good at it, and, believe it or not, many of them enjoy it.

I liken it to a NASCAR race. I’ll never forget the first race I went to — the speed, the power, the noise, the r-u-m-b-l-e. It’s exhilarating! You can literally feel it in your bones. But then, it was the circles. And more circles. Then, even more circles. How could anyone enjoy that for hours on end? Around and around and around.

Well, they do. And these people know how to run their machines better than anyone else, and they achieve things that are impossible for most. If you or I were in the driving seat, we could never do what these skilled and trained professionals could do. So, what is the one thing that would completely destroy the race in a matter of minutes — and it’s not a pileup?

STOP KEEPING SCORE.

If they stopped counting how many times they

went around the track or what position they were in, why would they bother pushing their machines to the limit? Why can’t we tap into the same competitive environment to achieve on the shop floor?

Before you invest in that new machine, make sure you’re running your current machinery the best you can with the operators you have. Here’s how to do that.

Step 1: Track your downtime and create visibility.

Leaning into the NASCAR theme, I own another company called ThriveMES that tracks and improves machine downtime all over the world. One of my favorite stories was about what we did for Amsoil, the premium oil company. In all types of manufacturing, there are changeovers. This is the time it takes to convert a machine from running one product to another. Amsoil does about three to four each day per manufacturing line. Their schedule was planned for 20 to 25 minutes per changeover. Once they started tracking it, they found it was actually closer to 45 minutes. Imagine how that adds up across dozens of lines!

After measuring it, they were able to manage it. They went from 45 minutes to under 20 minutes per changeover. This enabled them to run their busiest time of year without any overtime and make preventive maintenance a priority to keep the machines in tip-top shape without messing with the production schedule.

Staying with the NASCAR theme, another customer, AIRLIFT (they invented the air suspension that helps cars hug corners), found out that some machines just far outperformed others. They actually ended up shifting all their production to a handful of operators and machines, and significantly increased output. Do you know which machines and operators in your shop work most efficiently? You are likely shorthanded, so you may be able to consolidate your production into fewer machines to work more efficiently or maybe even with fewer operators. But, you don’t know if you don’t measure it.

Step 2: Create a competition.

Once you measure it, you have the facts you need to see what’s causing you the most downtime. So, how do you manage it? I had a client who said his bottleneck was the wet saw. He was considering kicking out a wall and buying a new wet saw.

Tim Saddoris is the president of Grand Onyx, a firm dedicated to building world-class surface fabricators. Grand Onyx helps companies define operational processes and create road maps to achievements that enable more predictable revenue, stronger margins and foster legacy businesses that stand the test of time. To learn how Grand Onyx can help with hiring or automating your business, visit www.GrandOnyx.Pro.

Tim’s always willing to connect … AFTER the NASCAR race is over.

You can uncover the roadblocks that are preventing you from operating at peak efficiency, so you can take proactive steps to improve productivity. Instead of running in circles, you can start running circles around your competition — just like the NASCAR drivers do on their victory lap.

So, we started tracking his machine usage — the percentage of time the machine is running during a scheduled shift. You get that by subtracting the downtime from the amount of time it should be running.

His average machine usage was 65%. That meant for more than a third of the day, his wet saw wasn’t running. In an eight-hour shift, that’s about three hours of total downtime. That’s a lot of wasted time that machine isn’t producing. When we showed the operator we were tracking production, he started to pay attention. Within a few weeks, machine usage jumped to 85%. That’s an extra 1.5 hours of production — just because we were keeping score.

Now, I can’t say he didn’t do anything differently, because obviously he did. But what?

Step 3: Document the process.

Once you’ve improved the process, you need to document what changed to capture that knowledge for the future. As your operator has pushed the limits, ask what they’re doing differently. Can it be documented?

With this client, we discovered that the time between jobs had been reduced from eight minutes to five minutes. Over the course of a day, that’s a big deal. The operator had changed the job-to-job process. By documenting what he was doing differently, we made it part of the standard operating procedure for any operator. This is especially important in dealing with the inevitable turnover that’s likely to occur in the future. Better processes become part of the training for replacements.

If you don’t have the time or capacity to document, here’s a suggestion. Talk to your local mechanical or industrial engineering college. Ask to participate in a school project or offer an internship or school project to document your process. I’ve seen it done. These kids are so excited to document your process and get some real-world experience — and it’s free!

Another idea is to consider discreetly setting up a camera. While you don’t want to spy on your employees, recording the workflow can help you find places you can streamline operations. You can pick up a Wyze Camera and SD card. They’re cheap but work just fine and can store weeks and weeks of footage. Reviewing the video can help uncover patterns that create inefficiencies. And maybe you’re not going to do this yourself, but you could enlist that college student to do it. You get the info and they get the experience. Win-win.

A A A

B B B 2 2

2

When it comes to cutting stone, porcelain, solid surface or quartz, having the right tools can make a world of difference in terms of accuracy and productivity. Faster cutting speeds, reduced downtime for blade changes or adjustments, and improved accuracy can contribute to shorter completion times and increased output. With the right tools and accessories, you can optimize your cutting processes, reduce material waste, and improve overall efficiency in your shop. Consider these saws and accessories that can keep your shop on the cutting edge.

BACA Systems is adding to its cutting lineup the Robo SawJet M-Series, an allinclusive mitering sawjet packaged on the industry-proven, reliable and maintenancefree Kuka Robot. With 650+ systems in production and countless success stories, the Robo SawJet M-Series is the right choice for all cutting processes. The M-Series introduces the all-important mitering process to the Robo SawJet product line. It features 0-50 degree dynamic miter angle control for both the saw and waterjet process. Also included is a new revolutionary technology to maintain accurate parts. All of BACA’s robot systems allow for the customization of the machine layout. This allows for traditional front load, side load, or pass-through cell configurations. BACA provides the only system that can be converted from a single tank to a dual tank with minimal expense. Learn more at www.bacasystems.com.

Made in Germany by Diabu, this cleancutting, fast blade for quartzite, granite and quartz cuts with 20 mm high water pocket segments that reduce chipping, speed up cutting and allow less friction. Cut Taj Mahal in a single pass! Available in 14-, 16- and 18-inch sizes. Various arbor sizes are available. The recommended rpm per size for quartzite are 1500 rpm for the 14-inch blade, 1350 rpm for the 16-inch blade, and 1200 rpm for the 18-inch blade. Depending on the materials, you’ll get cutting speeds between 35 and 130 inches per minute. More information is available at www.diabu.net.

The ADW iKon blade is made specifically for Dekton, Neolith, Laminam and other ultra-compact surfaces. This blade is certified and ready to cut fast and provides life with a 10 mm segment and a silent core for your projects. A leader in the UCS market, ADW is available from BBI. It is available in 14-, 16- and 18-inch sizes and is designed for wet use only. The 16-inch blade runs at 2000 rpm with a speed of 3 to 5 feet per minute. The 18-inch blade runs at 1800 rpm and cuts 2 to 4 feet per minute. For miters, operators should reduce rpm speeds by 30% for optimal performance. Learn more about this and other blades from BBI at www.bbindustriesllc.com.

With power, flexibility and accuracy in one compact machine, the VOYAGER XP

CNC Saw is the cutting solution you need. Powered with a 27 horsepower motor and automated

Adding to STRIEBIG’s arsenal of features designed to make panel processing safe and easy, the Edition 60 features a strong integrated panel lifting device allowing for ergonomic, smooth cutting of panels by one operator. The comprehensive standard equipment and legendary STRIEBIG accuracy guarantee short processing times and safe operation. The Edition 60 panel saw is a full-size, fullyloaded Standard S machine plus two-panel lifters that can be used for materials up to 10 feet by 7 feet and up to 350 pounds (175 pounds each), allowing for easy one-person panel processing. Users can add a third lifter to process panels up to 16 feet by 7 feet and weigh up to 525 pounds.

Other features include the wood support wall with integrated small parts support, panel lowering device with two panel lowering units, pneumatic clamping of the motor carriage and auto-locking support rollers, digital measuring system DMS-Y with fine adjustment, and laser line to show placement of horizontal cuts. V-grooving and coving are available on all models. Whether you need a primary cutting solution or an offline saw for remakes, all models give you seam-ready cuts. New machines can be ordered with a fine adjustment thumbwheel and digital counter built into the saw head for fast and precise depth adjustments on the grooving head. Find more information at www.csaw.com.

ultracompact programming, it cuts difficult materials such as porcelain and quartzite with ease. Its 5-axis design brings versatile capabilities like incremental routing, arc cutting, mitering, leathering, engraving and more. The TightCut feature nests parts closer together, increasing material yield by nearly 10% while reducing the time spent milling. This helps with cutting sinks, “L” pieces and seams efficiently. With simple programming and the ability to cut in manual mode, its operator-friendly controls make it the perfect saw for your first CNC cutting machine.

One customer shared, “Park made my first CNC experience so great, I can’t help but recommend the VOYAGER XP. I am loving the saw and the service I’ve received. Everything has been quality through and through.” Learn how you can grow with the VOYAGER XP at www.parkindustries.com/voyager.

Driven by its pioneering spirit, Lapitec continues to invest in research and innovation to offer fabricators cutting-edge technologies and meet the needs of demanding fabrication shops. Lapitec Academy developed the Veloce Blade to increase the processing performance of Lapitec sintered stone and other materials.

Extensive testing has been conducted on traditional and nontraditional cuts, making it a reliable tool for a variety of cutting scenarios. Available in two sizes (14 inches and 16 inches) with a 50/60 arbor and two pin holes, it’s suitable for both straight and miter cuts.

This technology’s thick and durable core construction combined with a segment height and width of 10 mm by 3 mm offers unparalleled cutting performance. Professionals in the industry will find this blade invaluable for their cutting needs, and it is sure to set a new standard for sintered stone cutting performance. For more information, visit www.lapitec.com.

The newly upgraded Combi by Breton is an advanced combination waterjet and bridge saw. The Combi is fully equipped with automated features to maximize production and efficiency, such as vacuum cups to reduce overcuts. Miterwave is the software and hardware package designed to execute perfect miters, especially on porcelain, sintered and ceramic material. Built to last, this new version of the classic combination machine comes in a compact and rigid monoblock structure without requiring invasive foundation work to increase stability and perform higher-quality work with greater accuracy. All Breton machinery comes with a guarantee of local, American-based service, including a 24-hour hotline. For more information, visit www.bretonusa.com.

For more than 25 years, Terminator has continued to innovate to provide efficient products for its customers. With its continuous rim construction, Terminator’s “oldie, but goodie” Continuous Rim blade is another perfect pair for your porcelain and granite projects. Laser cut “J” slots facilitate cutting performance. Four-inch and 5-inch diameters can be used wet or dry. Seven-inch and up blades are for wet use only.

The Nanocut.Q3 blade has been designed, tested and retested to yield fast, reliable results on quartzite materials. On 3cm Taj Mahal quartzite, it achieves pass-cutting parameters of 120 IPM for standard 90-degree cuts and 45 IPM for 45-degree miter cuts. The ability of the Q3 to cut freely on a hard material makes it a great cross-over blade to cut other materials such as granite and engineered stone. Savings can be realized by not purchasing multiple blades and reducing blade change-out times. For more information, visit www.terminatordia.com.

The Betterley V-Grooving Router is the only hand-held router designed to miter fold half-inch-thick solid surface material. Miter folding solid surface material saves time by creating built-up edges, dropped aprons, backsplashes and more in a single-pass operation. The tool cuts a precise “V” groove (or miter) in the material, an adhesive is applied in the groove, and the material is then folded. The resulting joint is virtually invisible with no adhesive squeeze-out on the exposed surface, providing a finished square edge as is or ready for profiling without the additional edge routing and sanding typically required for built-up edges. With the ability to quickly adjust the fence from 1 to 6 inches from the edge of the sheet, the tool easily accommodates almost any application for drop edges, aprons and backsplashes. To learn more about this and other tools, visit www.betterleytools.com.

Distributed exclusively in the United States by GranQuartz, the ZOLLER »smile 420« presetting and measuring machine allows stone fabrication shops to quickly and precisely preset tools outside of a CNC machine. The presetter calibrates offline to reduce setup times, increase machine productivity, extend tool life and save money. The machine’s SK 50 high-precision spindle means almost any tool-receiving system can be inserted without conversion measures. The »smile 420« gains enhanced

data gathering capabilities when used with the ZOLLER »flash« Tool Management System. This software tracks tool usage and location and notifies users when it’s time to dress or EDM tools. As more data is collected, users can forecast future tool consumption, estimate when new tools are needed, determine tool consumption by user and machine and more. This hardware and software combo saves users an average of $25,000 annually per machine. To learn more about the »smile 420« and schedule a demo, visit www.granquartz.com.

Meet the newest ZENESIS silent core bridge saw blade, OBSIDIAN, designed to cut fast and clean on engineered stone, porcelain, marble and even the hardest quartzite. This is made possible using their latest and most innovative diamond patterning technology. This new technology increases the number of cutting/contact points by up to three times and significantly improves performance. The unique metal bond matrix is engineered to work with virtually all natural and engineered stone. It’s available in sizes ranging from 12 to 20 inches with segments of 25 mm and an arbor size of 60/50 mm. Learn more at us.zenesistechnology.com. C

A

By Louise Scott

By Louise Scott

Time, Time, Time.

Let’s look at a day in the life of a stone fabricator. The fabricator’s first job of the day is to glue up some mitered edges for an upcoming installation. The process begins with the fabricator opening a can of adhesive. They take out a large scoop onto their mixing board, making sure there is more than enough to complete the job with one mix. After inspecting the color of the countertop to be assembled, they slowly add pigments, mix it all together and inspect the match. They realize more pigment is required, add more and mix again, repeating until the color is finally close enough. They add their activator and give one final mix. Next, taking their palette knife they begin applying adhesive to the edge, trying to keep the adhesive application even, while moving quickly to transfer all the adhesive needed from their board to the countertop edge. It’s a race against time to get all the adhesive applied and then position the slabs into place and clamped before the adhesive sets; the adhesive is curing whether they’re ready or not. After assembly, our fabricator is left with their mixing board of excess adhesive, adhesive dripping on the floor, and adhesive squeeze-out to clean off the surface before it sets.

Now imagine that first fabricator is a new employee. The time to train and get good at mixing pigments and learning the technique for mixing and applying adhesive is significantly longer than training a new employee on a cartridge.

If that same fabricator used a tube of premixed adhesive, their first job would be to pull up the color match app and find the correct adhesive to use. Then they head over to the shelf and grab the cartridge and a new mixing tip, pop it on, give it a purge, and begin laying a bead. Laying down the perfect amount of adhesive in seconds, they’re able to stop and assemble as they work as the adhesive that’s still in the cartridge won’t cure until they need it. And because they were able to use exactly what they needed, there is little waste material on the floor, and only a tiny bit left in the mixing tip to be thrown away. The cap is

replaced on the cartridge, ready to be used again for the next job. Using cartridges instead of bulk means shorter onboarding of new staff and the ability to use subcontracted labor if required.

Cartridge-based adhesives create standardization in the fabrication process. They ensure the perfect mix of adhesive and hardener, and perfect color matches. Mixing tips eliminate air pockets that are often introduced with hand mixing. With more time to fix and assemble, removing color matching from the equation, and no air pockets, every fabricator can produce the

same quality of work quickly and easily. Industry surfacing trends have moved to clean whites, grays, neutrals and blacks. Gone are the days of surfaces with various colors and large pieces of quartz to help hide seams. Unfortunately seams are harder to hide, and customers have higher expectations. An adhesive with the correct color and transparency is a must.

Cartridge-based adhesives use the latest Methyl Methacrylate (MMA) technology, and they come with the GREENGUARD Gold certification which means they are free from styrene, isocyanates and other harsh chemicals. They are safer for employees and safer for customers in the environment where the countertops are installed. Because the fabricators aren’t mixing chemicals right under their nose and there is less chance of spills, cartridges reduce unsafe exposure.

In addition, cartridge-based adhesives have minimal waste. As the adhesive is dispensed, the pistons in the cartridge

clean the inner walls of the tube, meaning every bit of product is removed from the cartridge and usable for installation. When the cartridge is empty, it is ready for disposal.

Some fabricators believe that MMA adhesives are good for solid surface, but not strong enough for quartz or stone. This is not the case. Today’s cartridgebased MMAs can tackle the toughest tasks, they are strong and durable, and they have been stringently tested.

Interior trends are seeing countertop materials being applied vertically to walls and fireplaces and large waterfall edges. The results are dramatic and exquisite. New challenges require MMA adhesives to offer advanced properties of greater shear strength and reduced sag on application.

Demand for outdoor installations has also forced adhesives to adapt to weathering conditions and ultraviolet exposure. Integra Adhesives is one such manufacturer offering adhesives like Surface Bonder Zero and Rapid designed

specifically not to drip, making it perfect for vertical or angled applications. Surface Bonder Ultra, developed for higher strength bonding on ceramics, is weatherproof for outdoor kitchen applications.

Every aspect of assembly has been tested, and in every case, the MMA cartridge-based adhesives provide a more consistent result, easier application, less waste and faster throughput.

Looking purely at volume, one might compare the cost per milliliter of a can of knife grade adhesive versus a cartridge of premixed adhesive and come to the incorrect conclusion that cartridge costs more. Instead, considering the savings from mixing, curing time, quality, training, waste, and most importantly, safety, the postive impact of cartridge-based adhesives becomes more evident. C

As we delve even deeper into holistic sustainability and how ISFA can help drive beneficial lasting change to the industry, we need to focus on alignment and continuity in the enterprise chain. This chain refers to stakeholders in the transactional field — primarily manufacturers, distributors and fabricators — for this discussion.

To this end, ISFA is looking at many ways to create a superhighway that aligns manufacturing with fabrication so that the sustainability story that begins with environmentally friendly, responsible factories and products do not end at the time of material dispatch from warehouses. Linking eco-vested fabricators to like-minded products and manufacturers will encourage the continuity of the sustainable story while driving a more significant and ultimately more responsible impact on the industry and the environment.

We see a growing number of data points for sustainable initiatives today, indicative of momentum. These include products, manufacturing environments and more. Companies can operate and report on their commitment to the environment, align with the growing demand for sustainable projects, and differentiate with a humanitarian flair. All good reasons, and yet their story and greater sustainable value proposition are not necessarily transferred from enterprise to installation. While it is not their responsibility to ensure such, manufacturers can play a vital role in helping to create alignment. Consistent with their stated missions, they should also want an aligned hand-off of their green efforts to a fabricator that will further support environmental and holistic stewardship.

So how can ISFA help design and encourage such an integrated alignment model? Well, a precedent has been set that we can follow. Much as architects and project owners seek to optimize their Leadership in Environmental and Energy Design (LEED) points, fabricators can and should do their part to support, complement and continue this leadership paradigm through a proposed ISFA designation: Leadership in Environmental & Energy Fabrication (LEEF) certification. Essentially LEEF certification will have ways for fabricators to earn LEEF points. The

more points earned, the higher the designation on the LEEF tiered certification scale.

The 35,000-foot view here creates a formal way to acknowledge and incentivize investments in sustainable operations by a fabricator while facilitating the all-important continuum we are seeking. Whereas to date, sustainable investment in a fabrication business tends to stem solely from the personal beliefs and values of the company’s leadership, now we are looking to establish some potential financial incentives for fabricators to pursue eco-stewardship.

Theoretically, a LEEF fabricator could be a primary goto for a manufacturer with eco-friendly products and where environmental stewardship is a core value. This alignment helps to deliver an integrated solution to the architect or project owner while optimizing the care and concern component on environmental impact from cradle to bed (from manufacturing to installation).

To begin the evaluation process, we contacted a handful of companies more reasonably known for their penchant for sustainability. We asked their thoughts on their commitment to sustainability and how they might value and support a LEEF initiative.

Countertops & Architectural Surfaces polled DuPont (Corian Design), Lapitec and Cosentino for their thoughts.

CTAS: Tell us your sustainability story. What efforts in processes and products is your company making toward sustainable materials and manufacturing?

Corian Design: We take a three-pronged approach in our commitment to sustainability:

• Enabling a circular economy.

• Promoting transparency.

• Minimizing our environmental impact.

life cycle environmental impact of each, and Health Product Declarations (HPDs) that give information on human and environmental health.

• In a drive toward zero sample waste, we’ve updated our sample program to help keep materials out of landfills by facilitating the return of unused samples for recycling.

• We’ve also introduced the Corian Design Visualizer App, a digital approach to viewing the stunning array of Corian aesthetics in potential end-use applications and, again, reducing sample waste.

Select Corian Solid Surface colors contain at least 6% and as much as 13% recycled material and are certified by Scientific Certification Systems (SCS) for stated recycled content.

Promoting Transparency

Corian Design materials are NSF 51 certified, UL certified as mold resistant, and do not contain bisphenol A (BPA) — all certifications that align with the American Institute of Architects (AIA) Materials Pledge. Corian Design materials have also received important independent certifications for environmental performance, including GREENGUARD Gold, National Green Building Standard (NGBS) Green Certified, and Living Building Challenge (LBC) Red List Free.

Corian Design is committed to using innovation expertise to reduce the environmental impact of its products and operations. Here are some of the ways we do this:

• Suppliers and raw materials are chosen responsibly, using pigments free of heavy metals and toxins.

• Pre-consumer waste in manufacturing has been reduced and recycled into new products, eliminating it from landfills since 2011.

• The process water used at our Corian Quartz facility is recycled.

• 100% of the electricity used to make our products in our North American facilities comes from renewable energy sources.

• Corian Design products have Product-Specific Type III Environmental Product Declarations (EPDs), providing the most credible, independently verified information about the

• Corian surfaces can be easily repaired, increasing the potential in-use lifetime of the products and reducing the need for frequent replacement.

We continue to examine ways to increase manufacturing efficiency and reduce waste in our production processes, as well as determine ways to recycle materials at the end of their life cycle. We are focused on providing sustainable solutions for our customers and the environment.

Cosentino: Cosentino has integrated sustainability into every facet of its business and has made incredible progress toward its goals.

All Silestone products are made with our pioneering HybriQ+ technology, a sustainable manufacturing process that uses 99% reused water, 100% renewable electric energy, zero water waste, and a minimum of 20% recycled raw materials within its composition. Also, this new manufacturing process significantly reduces the presence of crystalline silica to a maximum of 10% (HybriQ) or 50% (HybriQ+) — compared to 80%-100% for others in the industry — to aid in making the fabrication process safer than ever.

approximately 20% of Cosentino’s annual electrical consumption. At our factory, we reuse 99% of the water that we consume. This year, our Wastewater Reclamation Plant will become active, putting the wastewater discharged by our neighboring communities to new use, marking another milestone in our sustainability efforts.

Finally, Cosentino has its own Waste Management and Recovery Plant, which enables the company to manage tons of solid waste, some of which can be recovered and used as recycled raw materials in our products.

Within our ultra-compact Dekton offerings, all products have been certified carbon neutral since 2020, representing the only cradle-to-grave carbon-neutral offering of its kind, while the Dekton plant recently received zero waste certification.

Outside of product manufacturing, our headquarters in Almeria, Spain, has the largest ground-mounted self-consumption photovoltaic plant in the country with nearly 37,000 solar panels, and we are working on placing more solar panels on the roofs of each of our factories to further lower energy consumption. This plant generates enough megawatts per year to cover

Lapitec: Lapitec does not include any resin or oil derivatives, nor does it have any digital prints on its surface, which other materials use to imitate the effect of natural stone. Lapitec is created using exclusive technology: The process involves vacuum vibrocompression, joining feldspar mineral grains together without using binding resins, and then sintered at high temperatures. This results in a Lapitec slab that contains no crystalline silica. Lapitec is also manufactured with 15% pre-consumer recycled content, and all the water used during the production process is fully recycled and reused.

CTAS: It’s clear you’ve been investing in sustainable products, processes and concepts, demonstrating your commitment to sustainability as a manufacturer. What are the driving forces behind your initiatives? For example, is sustainability viewed as a department with a function, such as marketing or logistics, or is sustainability a core value woven into all aspects of your organization where environment and products are just some of the yields for the focus?

Corian Design: Our long corporate commitment to sustainability drives us. Our sustainability strategy is grounded in our purpose to empower the world with the essential innovations to thrive, and inspired by the United Nations Sustainable Development Goals (U.N. SDGs). We’ve designed our nine 2030 Sustainability Goals to be challenging—to provoke technical breakthroughs and new ideas for addressing society’s biggest challenges while also addressing the material sustainability topics most relevant to our stakeholders.

Cosentino: Sustainability is woven into every aspect of our business, and we believe every employee at Cosentino plays a huge part in our sustainability progress. For us, it is more than just a trending topic. We base our development on respect for the environment and sustainability, and our ongoing corporate commitment to society and the local communities where we operate. We’ve been working hard to lessen our environmental impact for many years and plan to continue.

Lapitec: We’re currently working with our parent company, Breton, to document our efforts within a third-party verified sustainability report. All divisions are involved in this process, and a specific team has been created to commit to this goal. The core of the material itself is rooted in the very concept of using only sustainable minerals.

CTAS: How do you connect your sustainability story with fabricators and specifiers? What is the perceived value for fabricators to partner with you BECAUSE of your sustainability?

Corian Design: Our partnerships enable fabricators to leverage our knowledge of product stewardship and best practices for product recycling, reuse or renewal. These practices are not only cost-effective but also look at a long-term view of inherent customer benefits by reducing landfill waste where possible.

Cosentino: Our industry partners are very aware of our environmental initiatives and the competitive advantage it brings. In fact, each year, we bring together our partners in manufacturing and processing to discuss the latest innovations and how we can better the future of the industry together at our annual C.Next Fabricators Summit. We also provide educational workshops and training.

Sustainability is the future and something we as an industry must consider throughout the entire process, from manufacturing to fabrication. Our innovative technologies, like HybriQ and Quick Cut, allow us to deliver high-performance, sustainable products with beautiful designs. And as mentioned above, these sustainable innovations also allow for more safety in the industry. Silestone made with HybriQ Technology drastically reduces the percentage of crystalline silica in the product’s composition, creating a new product category. Cosentino is the only manufacturer that has invested in and worked for years toward this achievement, which transforms the composition of Silestone.

As more customers seek out and value sustainably made products, our partners know they don’t have to compromise with Cosentino.

Lapitec: Our sustainability story is deeply rooted in our products since Lapitec is completely inert and does not release any substance into the environment where it is fabricated and installed. Specifically, the fact that Lapitec is silica-free is an actual value for our fabricators since it’s a step toward improving their safety in the workplace, given the problems created by other materials that do contain this harmful mineral.

CTAS: If a group of fabricators who invested in and prioritized sustainable fabrication existed, how do you envision your company’s alignment with this group? Would it be valuable to you to connect with such a group to further your sustainability story and encourage alignment and optimization via the enterprise chain through to the installation of your products and values?

Corian Design: We have a long history of association with industry-leading organizations with an environmental focus. Corian Solid Surfaces would assess any new certification opportunities or organizational startups to determine whether the goals and values align with the Corian business and the larger

SUSTAINABILITY MATTERS

DuPont corporate environmental and sustainability goals to determine if involvement makes sense.

Cosentino: Just as we value the sustainability certifications for our products, we would value this type of certification in our partners. It is important to partner and collaborate with other industry leaders whose sustainability goals are aligned with ours. However, we do want to distinguish that while these specific designations are important, our goal is to ensure that the fabricators, manufacturers and specifiers aim to lower their carbon footprint across all business areas. That’s why Cosentino is helping to push the architecture and design industry to become more aware of their sustainability practices as a whole.

Lapitec: The product life cycle is reversible, meaning that the material may potentially be destroyed and turned back into powder — back into a raw material — and be able to be reused again in the production process. Having forward-thinking fabricators understand and convey this message while educating their clientele and partners on this could help influence the industry so that we are all moving in the same direction.

The last 25 years have seen several cycles of sustainability knocking at the industry’s door, only to have the momentum somewhat fade away until the next renaissance. What we see now, in 2023, is a movement that is not fading away; in fact, we have a zenith of impact, and this includes everything from eco-friendly products to manufacturers supporting zerowaste initiatives to manufacturers not only incorporating but proudly touting the use of renewable energies, and whose manufacturing environments are built and operating on firm sustainable pillars. This spinning wheel of holistic sustainability seems to be getting strong traction.

A A

Jessica McNaughton serves as president at CaraGreen, a provider of sustainable building materials, including many alternative surfacing materials. She has 20 years’ experience in sales, marketing, business development and strategy. Previously the director of sales and marketing at CaraGreen, Jessica has maintained her status as a LEED Accredited Professional since 2009 and she hosts a podcast, Build Green Live Green. She can be reached at jessica@caragreen.com.

B B B B International Surface Fabricators Association • Vol. 16 / Issue 2 • 39

2 2 2 D V

Owner Justin Howe got his start in residential construction, where he quickly identified a niche in countertops. Unsatisfied with the quality of countertops coming from his local market, he opened Adobe Walls Stoneworks (AWS) in 2003. Located in Amarillo, Texas, AWS is now the largest full-service countertop fabricator in the Texas Panhandle. With steadfast commitments to a quality product, its customers and employees, AWS strives for success with excellence at every step of the process.

Today, with the help of Sales Manager Torie Garrard, Operations Manager Micah Neely and Production Manager Mario Robles, General Manager Chris Sturdevant stands at the helm while Justin pursues other businesses in his portfolio. With 30 years of experience in management and sales, including 10 years in residential and commercial

Some members of the Adobe Walls Stoneworks team accept the 2022 Remodeler of the Year award from the Texas Panhandle Builders Association. From left to right: Greg Howard, commercial estimator; Jeebs Holguin, template manager; Jenny Lemley, sales and design specialist; Torie Garrard, sales manager; Sarah Young, outside sales and event coordinator; Mario Robles, production manager; and Chris Sturdevant, general manager.

building, Chris has the background needed to run a successful operation. “We have weekly meetings to keep Justin informed on what’s going on here,” clarified Chris. “But for the most part, Justin trusts us because we’ve got a proven track record of growing the business year over year.”

Designated Remodeler of the Year in 2022 by the Texas Panhandle Builders Association, AWS covers a radius of 120 miles around Amarillo. They have two locations, including a fabrication center and the only indoor stone gallery in the area. AWS spares no expense by employing fully automated, computerized fabrication equipment and the latest laser technology for templating. They also carry the region’s largest selection of natural and engineered stone. On average, they fabricate about 1000 square feet of material per week.

AWS has 24 employees, most of whom have been on staff for five years or more. They use incentive programs to reward their employees for going the extra mile. The sales team operates on a base salary plus commission, and the fabricators also have a bonus program. On top of their base wage, they get a bonus per square foot cut. There are dry-erase boards throughout the shop that keep track of the number of days without a mistake. “They get to 30 days, and we have a