8 minute read

UCT research sheds light on PICP stormwater purification

Permeable interlocking concrete paving (PICP) provides two functions: controlling the rate, as well as the quality of stormwater drainage from roads and parking areas in urban environments. The flow rate is managed by temporary storage within the PICP structure.

The quality is improved through a variety of different mechanisms, depending on the pollutants, which include heavy metals, hydrocarbons, pathogens and nutrients. Sedimentation plays an important role in the removal of some of these pollutants, through deposition in the openings between the pavers. However, nutrients are generally soluble and thus tend to pass through the openings into the underlying aggregates from where they are released back into the environment.

In South Africa, PICP’s nutrient removal (ie the removal of orthophosphates and nitrates) has generally been treated as secondary to its drainage capacity: more as a nice-to-have than an essential function. However, nutrient removal plays a vital role in preserving urban stream- and river-based ecosystems and the more it is researched, studied and understood, the more effectively it can be achieved.

Pollution control

Engineers who design for pollution as well as drainage control must contend with factors such as the quality of the local stormwater, the type of pavers, the possible use and location of different geotextiles, the difference in performance between washed and unwashed aggregates, the impact of piped outlets and the timing of rainfall events.

Studies on pollutant removal from PICP stormwater have been conducted worldwide, but no common agreement has yet been reached on the most effective designs. For example, there is is a lack of consensus on the inclusion of a geotextile to enhance water purification because its presence has been observed to accelerate the clogging of PICP systems. Furthermore, conditions vary from location to location, A final layer of “pea-sized” gravel let alone country to country, so without (2-4mm quartzite/gritstone) was placed local knowledge on the type and nature between the pavers to provide a flow of pollutants and how best to deal with path for the surface water. Some cells them, design engineers are left shooting in included a layer of geotextile between the the dark; a situation which base and bedding layers, has prevailed in SA since while others did not. In the inception of permeable certain cells the aggregate paving in 2007 – until now. was carefully brushed clean,

Kimberley Liu BSc (Eng), while in others, the stone a civil engineering Master’s was left in conditions more student at the University typical of installations in of Cape Town (UCT) and the field. In one case, there her supervisor, Prof Neil was a raised outlet to create Armitage, published a paper a permanent wet sump at in 2020 which sheds light the bottom of the cell. Three on local pollutant removal. types of pavers were used in Entitled The Link Between (Above): Kimberley Liu. the research: Aquaflow® Permeable Interlocking Concrete and Permealock® (both Paving and Nutrient Removal, it covers research specifically designed for PICP designs) into the nutrient removal performance of 10 and a standard exposed aggregate paver PICP test cells constructed at UCT’s civil laid with gaps for water infiltration. Three engineering laboratory. types of geotextile were trialled: Fibertex® (non-woven), Kaytech® bidim (non-woven) Test cells and Inbitex (non-woven). Each test cell comprised a HDPE container In addition, field testing was carried out ensuring 1 200mm x 1 100mm x 400mm on the new engineering building parking lot (depth). They were fitted with perforated located on UCT’s upper campus in a bid drains with a valve-controlled outlet. Each to verify the laboratory investigations in a cell was filled with a 250mm sub-base layer more realistic setting. Monitoring chambers of 50-63mm aggregate, covered with a were installed at the underdrain outlets to 100mm base layer of 19-25mm aggregate allow for water quality testing. and topped with a 50mm layer of 2-6mm Infiltration tests were carried out to bedding gravel. determine the infiltration rate of each

PICP test cell with the use of a single-ring infiltrometer, following the test procedure given by the ASTM C1781: Standard Test Method for surface infiltration rate of permeable unit pavement systems.

Each test cell was pre-flushed with 10 litres of clean potable tap water, applied with a watering can (to simulate rainfall). The outflow from each cell was then tested to determine the “baseline” water quality, prior to the addition of any external pollutants. The pH, temperature and electrical conductivity (EC) of the discharged water from the bottom of each PICP cell were measured in situ using hand-held probes. Grab samples were analysed for total suspended sediment, orthophosphatephosphorus, ammonia-nitrogen, nitritenitrogen and nitrate-nitrogen.

Each cell was then subjected to multiple “seasons” of accelerated rainfall events, using pre-prepared synthetic stormwater containing suitable soluble pollutants to test their treatment efficacy. The synthetic stormwater testing was carried out in two distinct phases. In the first phase, three rainfall seasons were simulated in October 2017, September 2018 and April 2019 respectively, using water containing the commercial fertiliser “Growing Orchid” at an appropriate concentration as the pollutant. Each season comprised nine distinct “storm” events that were applied one per day, using a 10-litre watering can.

Close control

The pH, temperature and EC of the outflow were determined for each cell and for each rainfall event. Samples were analysed in the water laboratory on the first, fifth and ninth days for the concentrations of ammonianitrogen, nitrite-nitrogen, nitrate-nitrogen and orthophosphate-phosphorus.

The second phase of the research took place during August–September 2019. The use of “Growing Orchid” as the source of stormwater contamination was abandoned because of problems with inconsistent nitrogen-to-phosphorus ratios, which gave rise to inconsistent influent quality – and thus, potentially, outflow quality.

Synthetic stormwater was thus produced in the laboratory by adding NH4Cl, K2H2PO4 and KNO3 to tap water in carefully measured quantities in

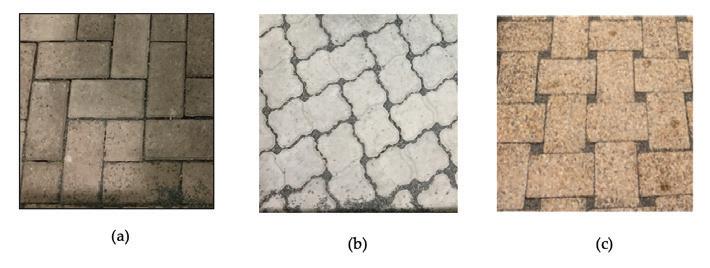

(Above): Permeable interlocking concrete pavement (PICP) test cells (Cell A and Cell F laid with Aquaflow® pavers, Cell B, C, D, E, G, H laid with Permealock® pavers, and Cell I and Cell J laid with ‘traditional’ exposed pavers).

a 500-litre tank. A new rainfall regime was purposed with intermittent dry and wet periods to represent the four months of the “typical” Cape Town rainy season, but in an accelerated 1,5-month period (see Table 3). The pH, temperature and EC of the outflows from each cell were measured daily, while samples were analysed in the water quality laboratory for ammonianitrogen, nitrite-nitrogen, nitrate-nitrogen and orthophosphate-phosphorus on a weekly basis.

The flow over and through the NEB parking area was tested during four significant storm events (ie >7mm) between 2018 and 2019. The pH, temperature and EC were tested in situ using hand-held probes. Grab samples were then taken to the water quality laboratory for measurement of the ammonia-nitrogen, nitrate-nitrogen, nitrite-nitrogen and orthophosphatephosphorus concentrations.

The paper outlines the lab testing procedures and their results in extensive

detail, which was too long to be covered in this article. However, as mentioned above, influent pollutant concentrations were not always consistent during Phase 1 and the use of two different fertiliser concentrations made it difficult to compare influent and effluent concentrations from the samples collected during this phase. They were therefore only regarded as indicative and were discarded in favour of the results obtained from Phase 2 testing.

After the lab test results had been analysed, some of the results were as follows: • The cells using washed aggregates had higher ammonia-nitrogen removal efficiencies than those with unwashed aggregates, while the cell with the raised outlet (creating a “sump” in the underlying stone aggregate) had the highest ammonia-nitrogen removal efficiency of all. • All the experimental cells appeared to add significant quantities of nitratenitrogen in quantities which ranged from 160-2 580%. This was probably due to the nitrification process of ammonia to nitrate. • The cells with exposed aggregate pavers produced less nitrite-nitrogen and nitrate-nitrogen than the other two types of pavers. • The cell with the raised outlet produced the most nitrate-nitrogen. • The presence of geotextile had a negative impact on the nitrate-nitrogen removal efficiencies. • When the pH levels were within the optimum range of 7,6-8,8 for the growth of nitrifying bacteria, the nitrification process resulted in a reduction of the ammonia-nitrogen concentration and an increase in nitrate-nitrogen concentration. Lower pH levels resulted in higher nitrate-nitrogen concentrations. • The removal efficiencies of orthophosphate-phosphorus ranged from

37-11%, compared with the mean of 47,7% removal rate of orthophosphatephosphorus in other studies. • The presence of a geotextile resulted in a higher orthophosphate-phosphorus removal efficiency than those without. • The cells with washed aggregates had higher orthophosphate-phosphorus removal efficiencies than those with unwashed aggregates. • The cell with the raised outlet had the lowest orthophosphate-phosphorus removal efficiency of all, which might have been caused by the fine particles being slowly washed through the permeable paving and desorption due to the lack of useful adsorption sites.

The paper concluded with the observation that while PICP is effective in removing ammonia-nitrogen, it does so at the expense of an increase in nitritenitrogen and nitrate-nitrogen. The authors recommend further research to establish whether the creation of an anoxic zone, coupled with introduction of a suitable electron donor to the PICP, could address this shortcoming. • A full copy of the paper can be downloaded at: http://dx.doi.org/10.3390/ w12061714.

(Above): A typical cross-section of the PICP test cells.

(Below): Paver types: (a) Aquaflow®, (b) Permealock® and (c) standard exposed aggregate.