FACTORY TOWN PRE-FABRICATED WAREHOUSE FACILITIES

What is Factory Town ?

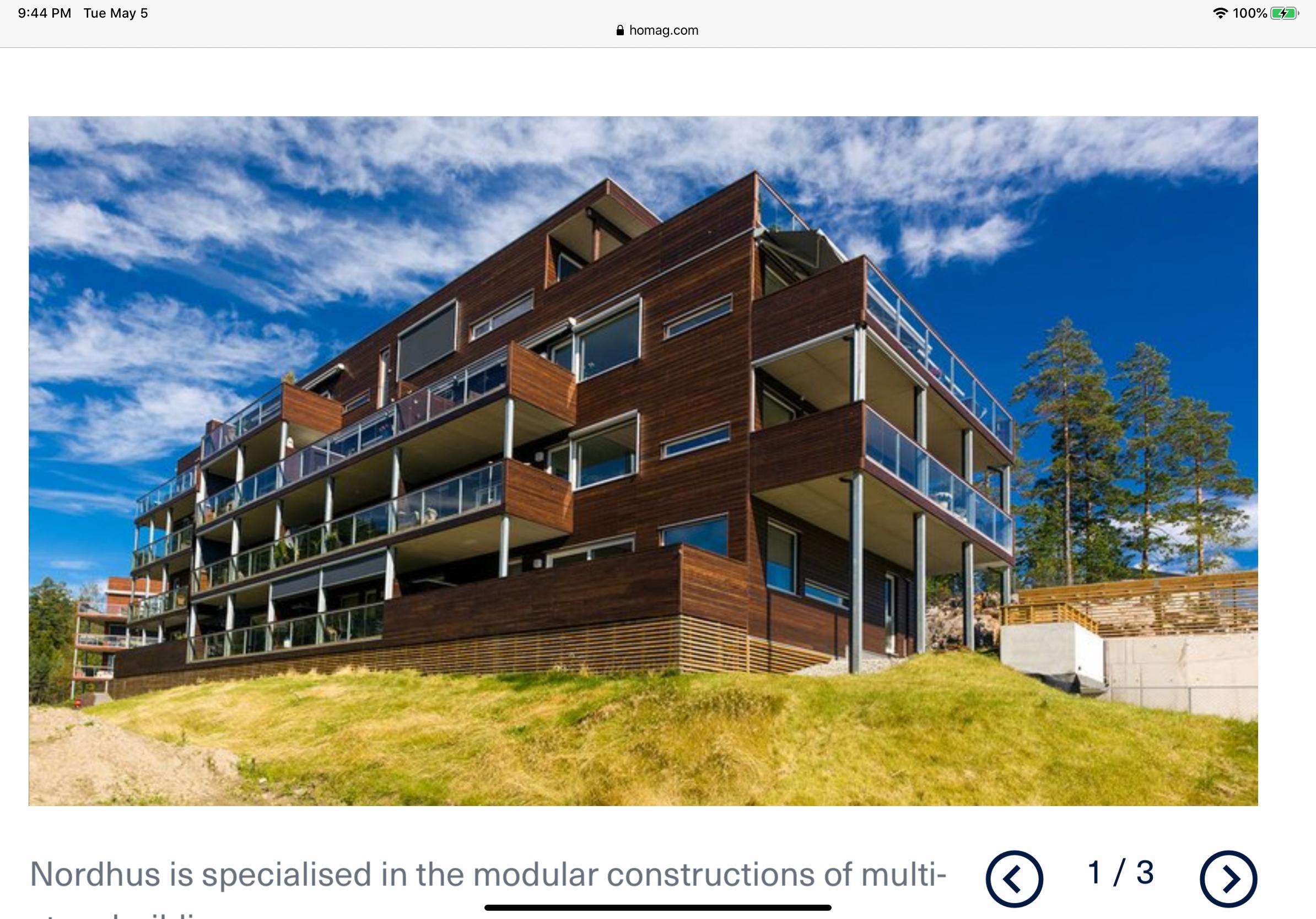

Factory Town is a modern manufacturing complex that builds economic and energy efficient modular housing, doors, and windows in two-flat and single-family formats. Factory Town designs and builds units utilizing state of the art automated assembly lines, trained staff and dedicated professionals.

Factory Town is an economic engine for community development, a direct solution to the rising demands of efficient affordable housing and a way to increase affordable homeownership and build underserved communities by bringing equitable investment.

Why Factory Town ?

The Chicago metropolitan area needs more than 229,000 affordable housing units and modular home manufacturing is a quicker build and installation process. In addition to reducing waist and site disturbance, the Modular Home designs are sustainable, modern and pricing is cost controlled. Manufacturing jobs produce higher compensation than any other job sector per capita.

SOUTH SUBURBAN FACTORY TOWN PREFABRICATED WAREHOUSES

Prefabricated windows and doors plant

Prefabricated Building and Assembly Plant

SOUTH SUBURBAN FACTORY TOWN

FACTORY TOWN SOUTH SUBURBAN

Modular Home and Window Assembly Plant 200,500 sf Facility

PLANT VIEW FROM GROUND LEVEL

Prefabricated Home Plant 200,500 sf Facility

SOUTH SUBURBAN FACTORY TOWN PREFABRICATED HOME PLANT

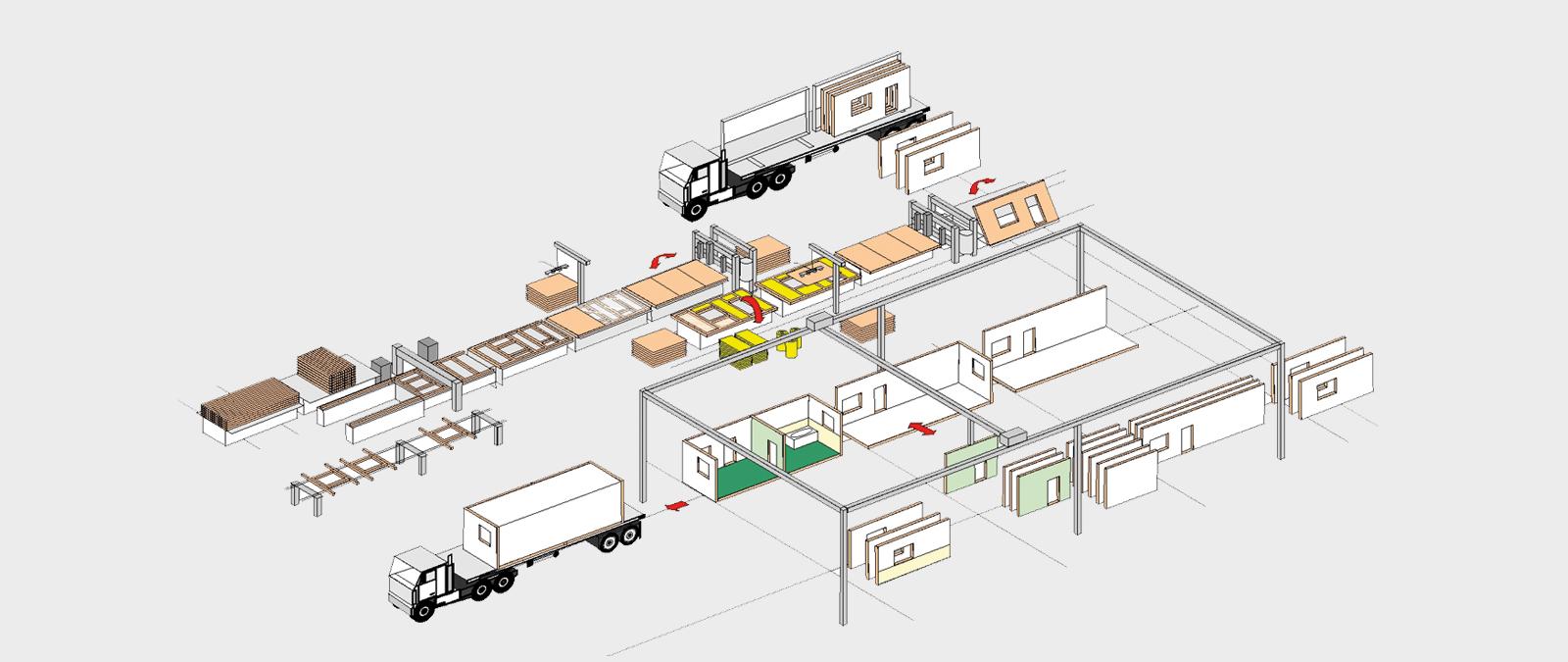

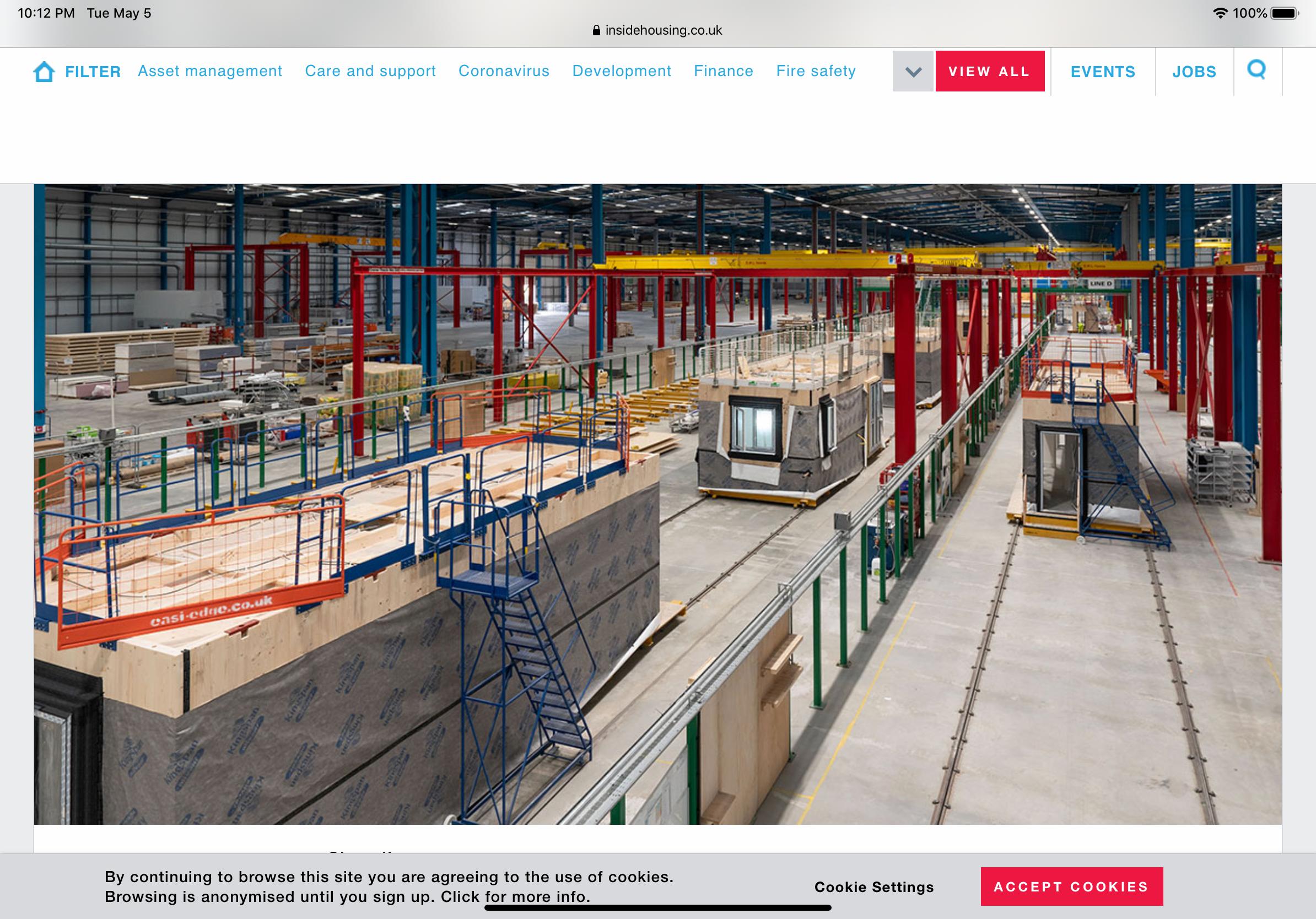

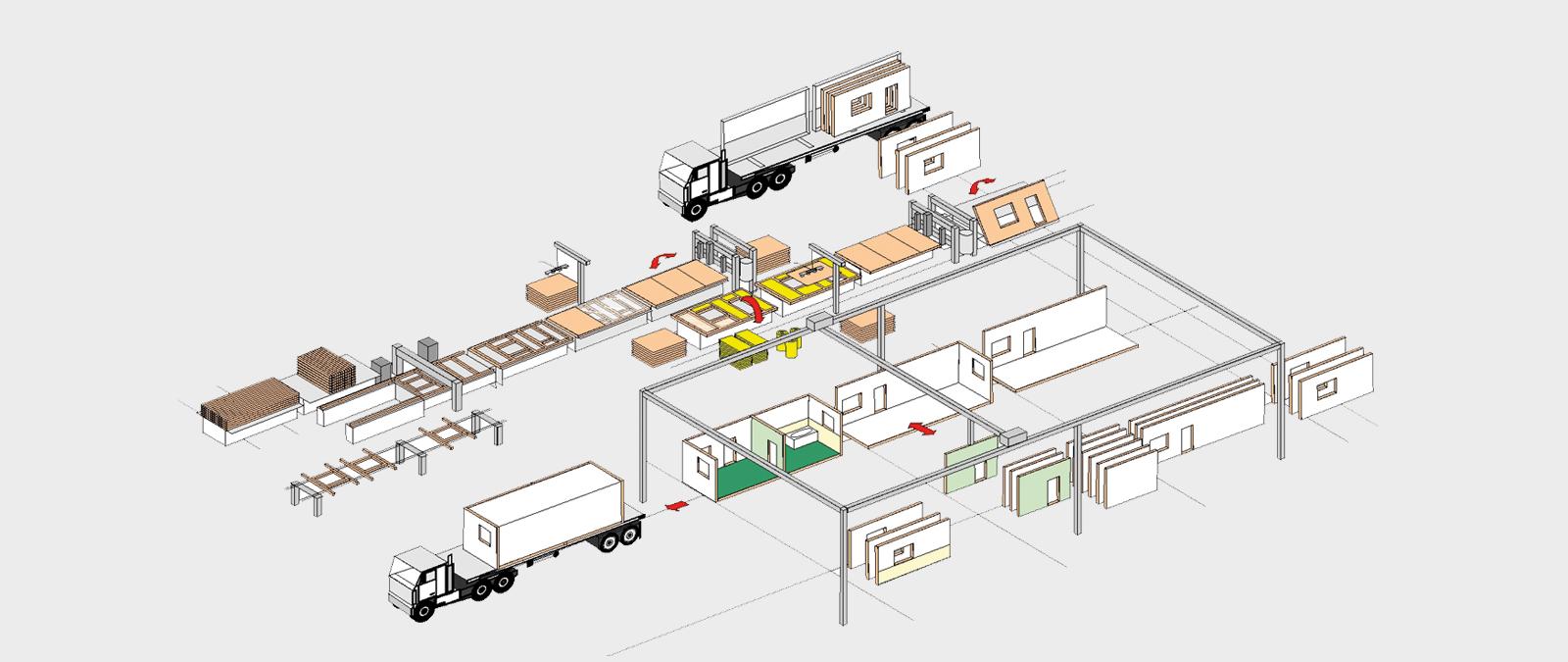

The prefabrication home plant is a state of the art technological wonder. It is designed as an automated home design and building facility to erect all raw wood materials into prefabricated components such as, exterior and interior walls, floors, roofing and ceiling systems. This plant will be built on the west end of the proposed site.

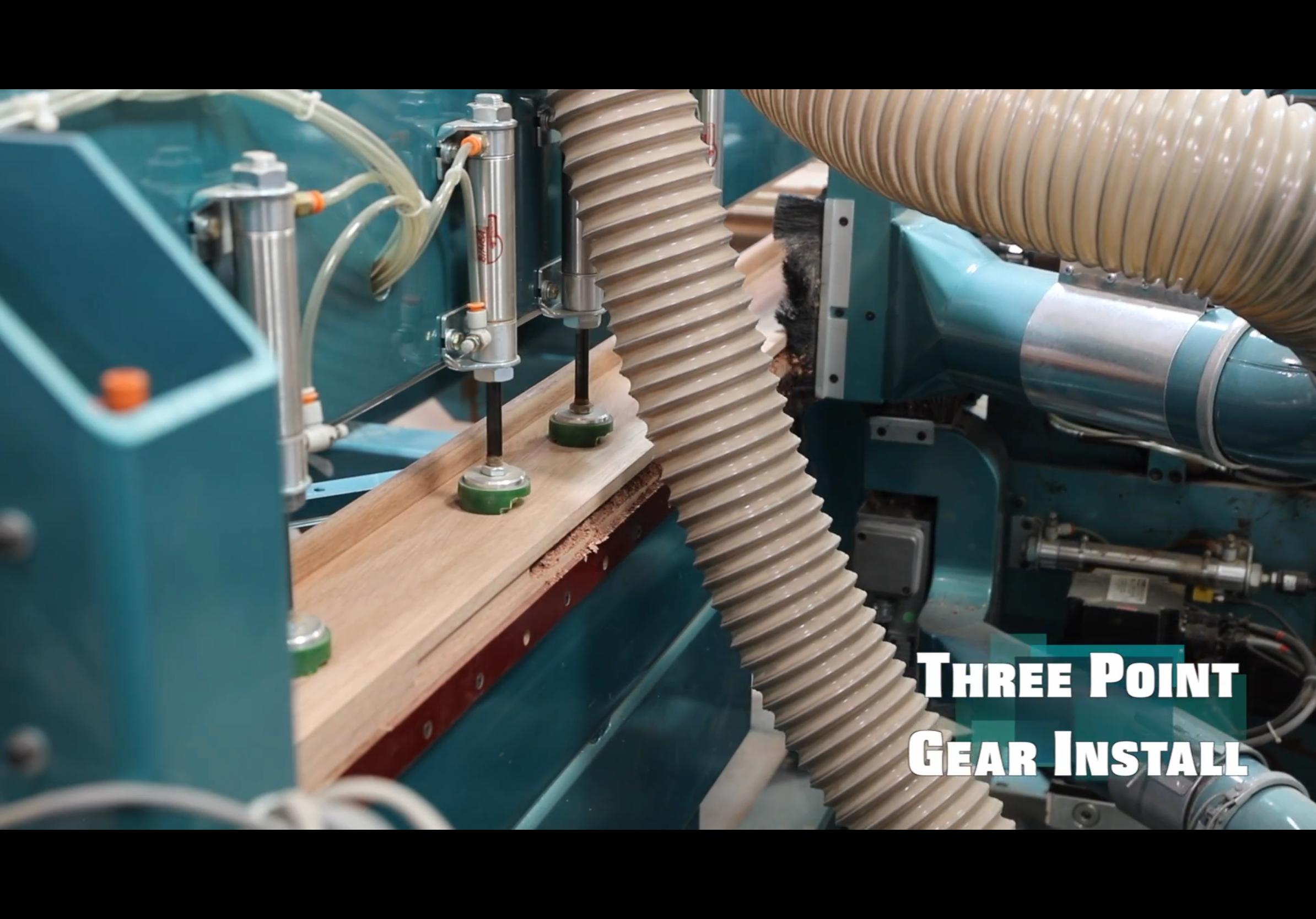

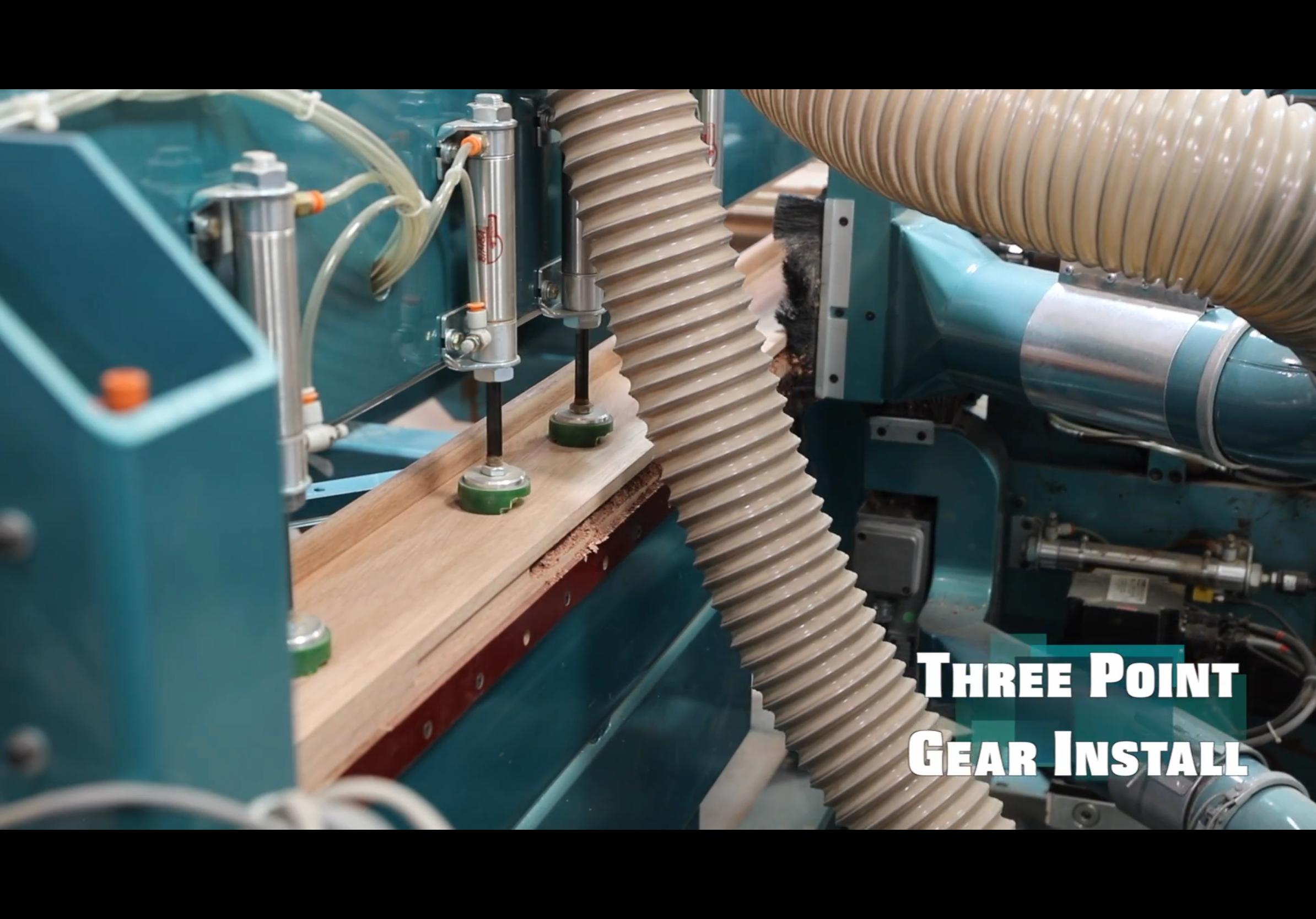

PREFABRICATED PLANT INTERIOR TECHNOLOGY

Construction Factory Town Innovation Center

I. About the Equipment Manufacturer

II. Solutions for Raw Frame Construction

III. Automation Technologies

[CFTIC ]

I. About the Equipment Manufacturer

Carpentry Machines:

From fast cutting to complex beam processing the carpentry machines are equipped to tackle a wide range of processing tasks - from making a quick cut to completing a complex beam processing operation. Use the carpentry machines in carpentry applications, timber frame construction, half-timbered construction and prefabricated house construction.

Carpentry Machine BEAMTEQ B-660:

All six sides of a component in a single run benefitting from an underfloor unit, the BEAMTEQ B660 enables fully automated processing of all six sides of a component. Quickly and easily manufacture traditional block house joints, blocking grooves on rafters and dovetail connections on both sides of ridge beams.

BENEFITS

•Excellent beam processing performance: Depending on the product range, a processing speed of up to 30% faster than the industry standard can be achieved

•Easy to use since tilting is not necessary

•Rapid installation on-site: The uniformly precise design of all machine components facilitates the assembly process

•Space-saving setup thanks to the compact design

Carpentry Machine BEAMTEQ B-660

Assembly Tables:

Assembly tables enable you to easily manufacture timber frame construction elements with a high degree of dimensional accuracy. They are suitable for a wide range of applications including wall, roof, floor and gable elements.

Self Assembly Table BUILDTEQ A-300:

We Provide the Technology, You Build the Table

Assembly table as a flat-pack solution: We provide you with assembly instructions that you can use to easily build the table yourself. The BUILDTEQ A-300 from WEINMANN provides you with a universal tool for producing timber frame walls and roof and floor elements.

Carpentry Table BUILDTEQ A-500:

The universal tool for carpenters

It is in small and medium-sized carpentry businesses in particular that the WEINMANN carpentry table really achieves its full potential. The BUILDTEQ A-500 offers a flexible all-round solution for anyone manufacturing wall, gable, roof and floor elements, frame walls and roof dormers in timber frame construction.

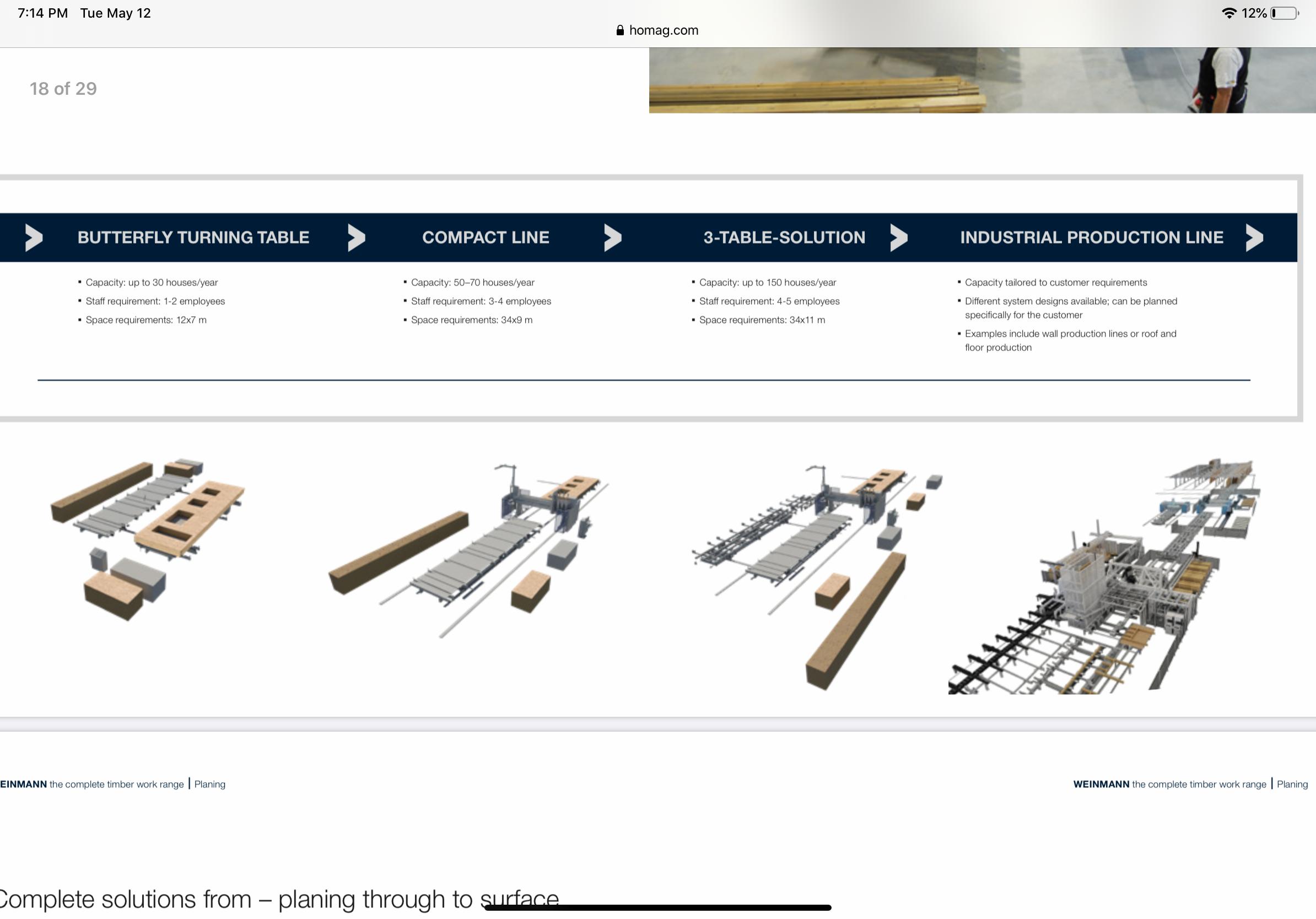

Butterfly Turning Table:

Turning elements in a single movement

The butterfly turning table offers the ideal solution for turning your elements, allowing you to process both sides. Once the first side has been processed, the element is transferred to the second assembly table where it is completed.

Element Table MOVETEQ:

Multifunctional solution for production lines

The MOVETEQ element tables are truly versatile components in the production line and take over tasks such as turning elements, aligning elements at the correct angle to ensure safe sheathing and processing, transporting elements, and tilting elements for storage.

Roof and Floor Fable BUILDTEQ F-500:

The specialist tool for roof and floor production

Produce your roof or floor elements quickly and easily with the BUILDTEQ F-500 . The table uses CAD data to specify the position of the beams fully automatically and clamps them securely. If the table is integrated into a production line, the elements can also be transported, installed and turned. The fully automated setup process is performed only during non-productive time, meaning that there is no waiting time from one item to the next. The table produces accurate rectangles and correctly mounted elements in next to no time.

Self Assembly Table BUILDTEQ A-300

Carpentry Table BUILDTEQ A-500

Butterfly Turning Table

Element Table MOVETEQ

Roof and Floor Table BUILDTEQ F-500

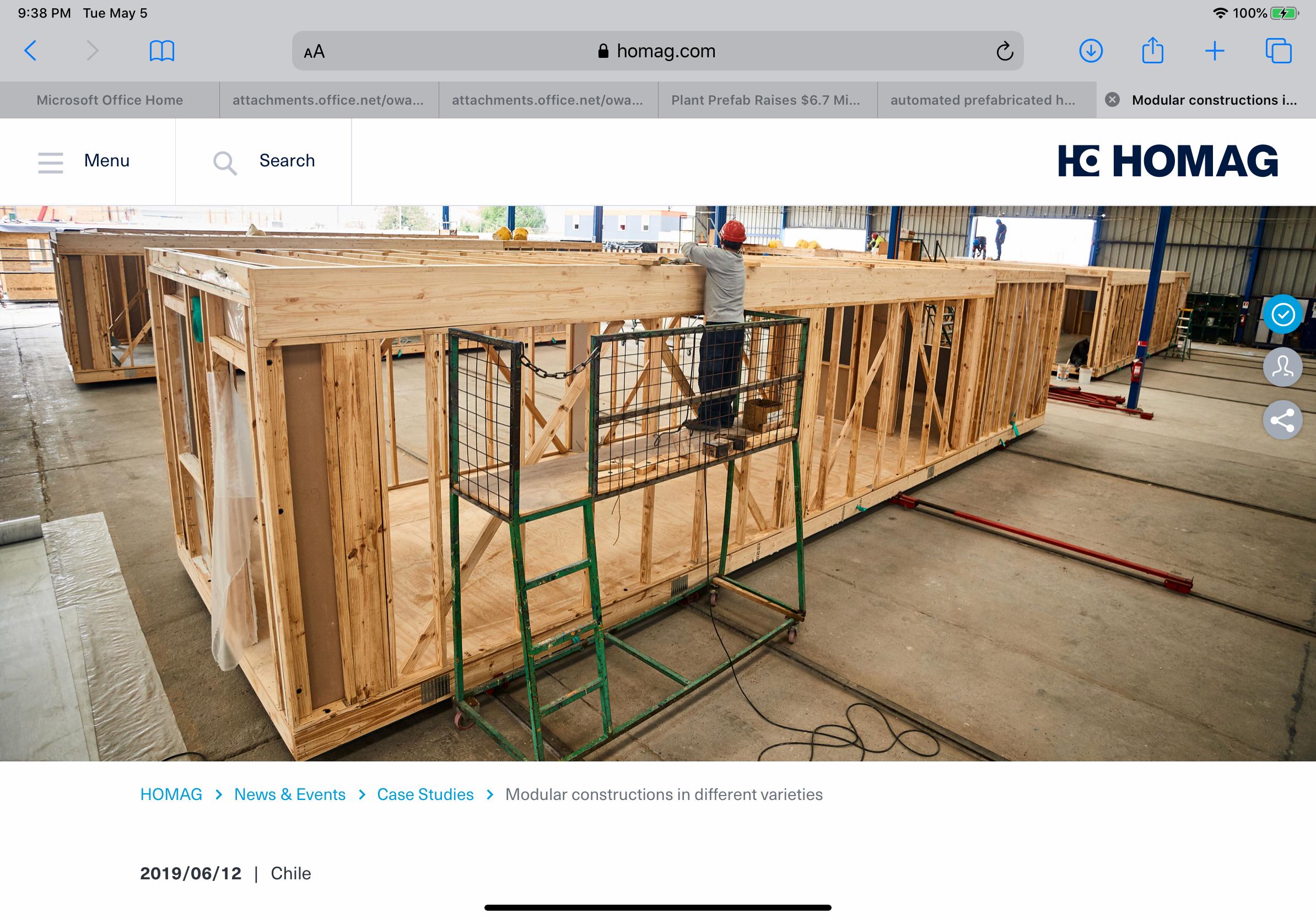

II. SOLUTION FOR RAW FRAMING CONSTRUCTION

Framing Station & Combi Wall Systems:

You are looking for a system for the production of your frame works? Whether you produce simple frame works or complex constructions offers you two options. The framing stations can be also integrated in a production line. The space in your production hall is limited? Therefore the combi wall systems offer a comfortable solution. The framework assembly and element sheeting takes place at one workstation. Frameworks with sheeting one side can be produced with little space requirement.

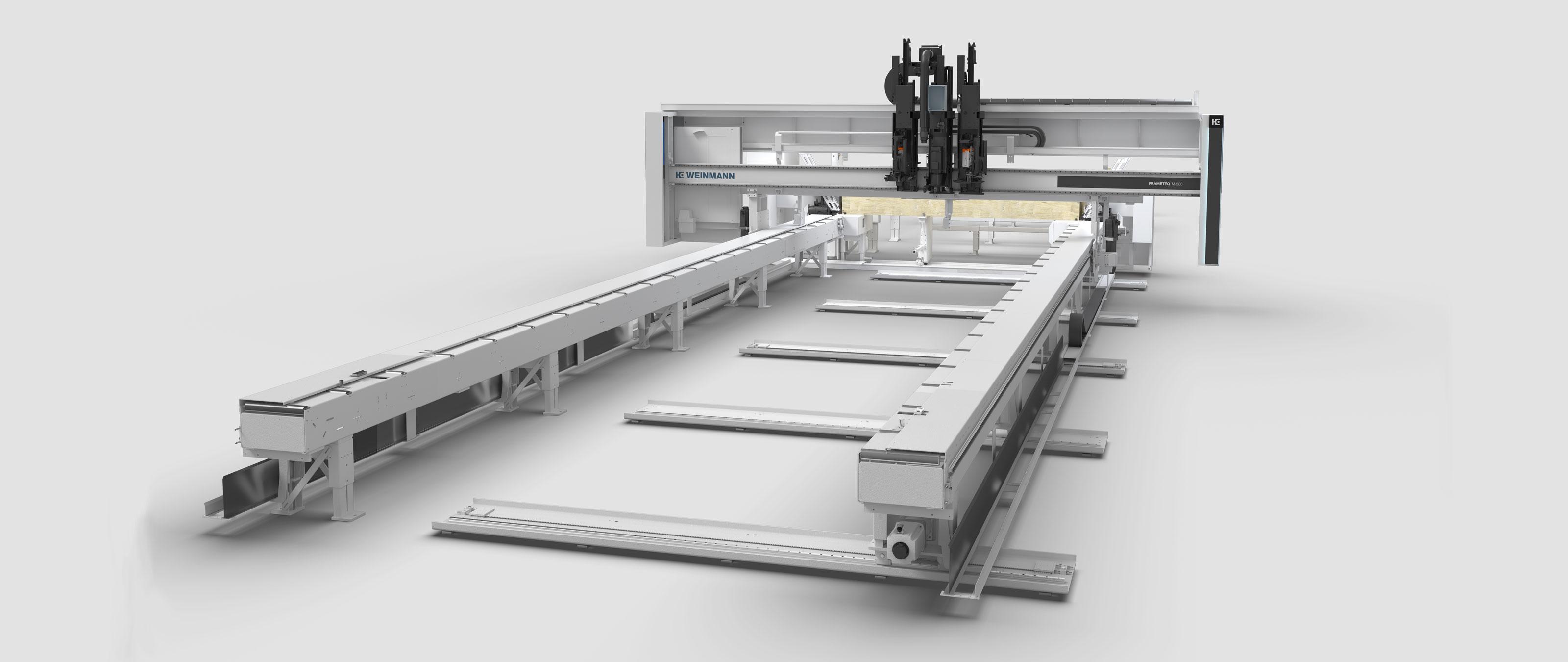

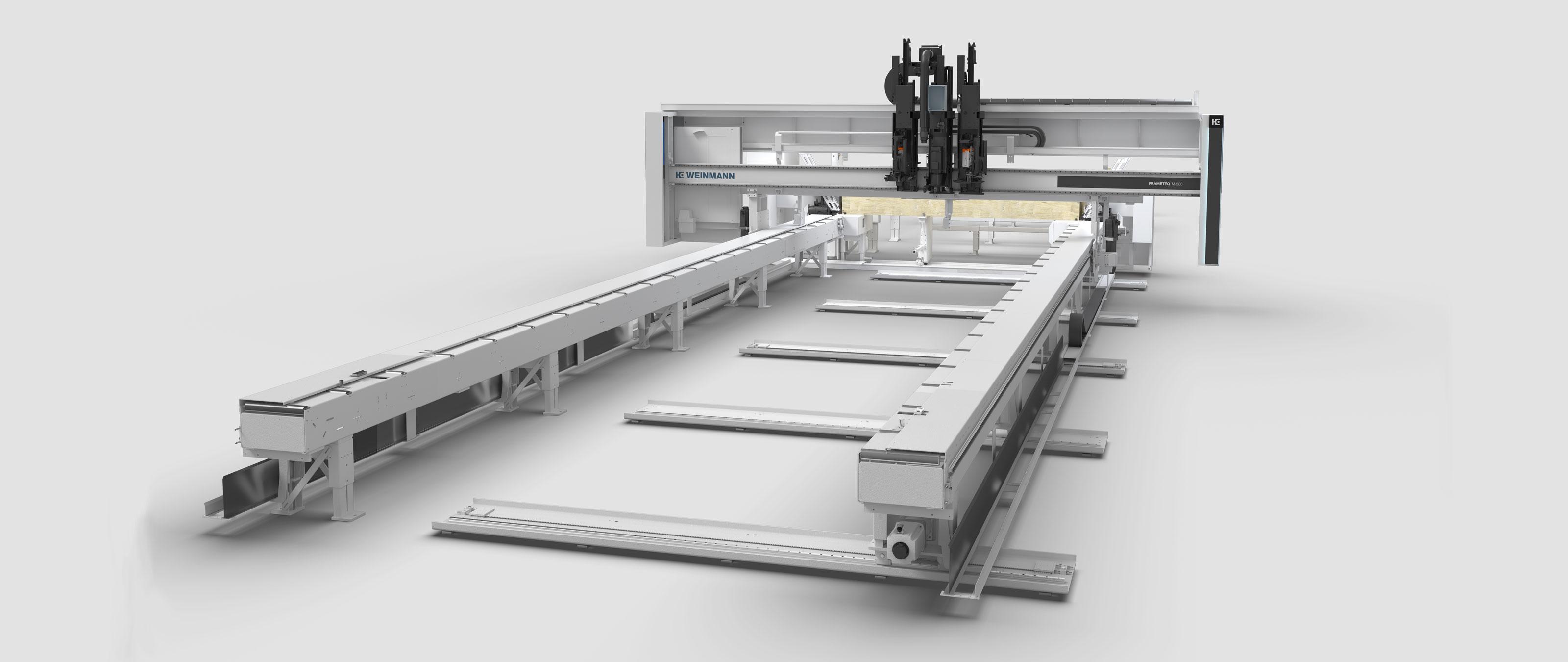

Framework Station FRAMETEQ F-500:

Complex frame works produced with ease

Complex and challenging frame works can be manufactured quickly and easily with the FRAMETEQ F-500 framework station. Top and bottom plates are fed in manually, positioned at the stops and automatically tensioned. The studs are also automatically positioned, tensioned and secured. The higher level of automation offered in comparison to the FRAMETEQ F-300 significantly increases the performance of the machine.

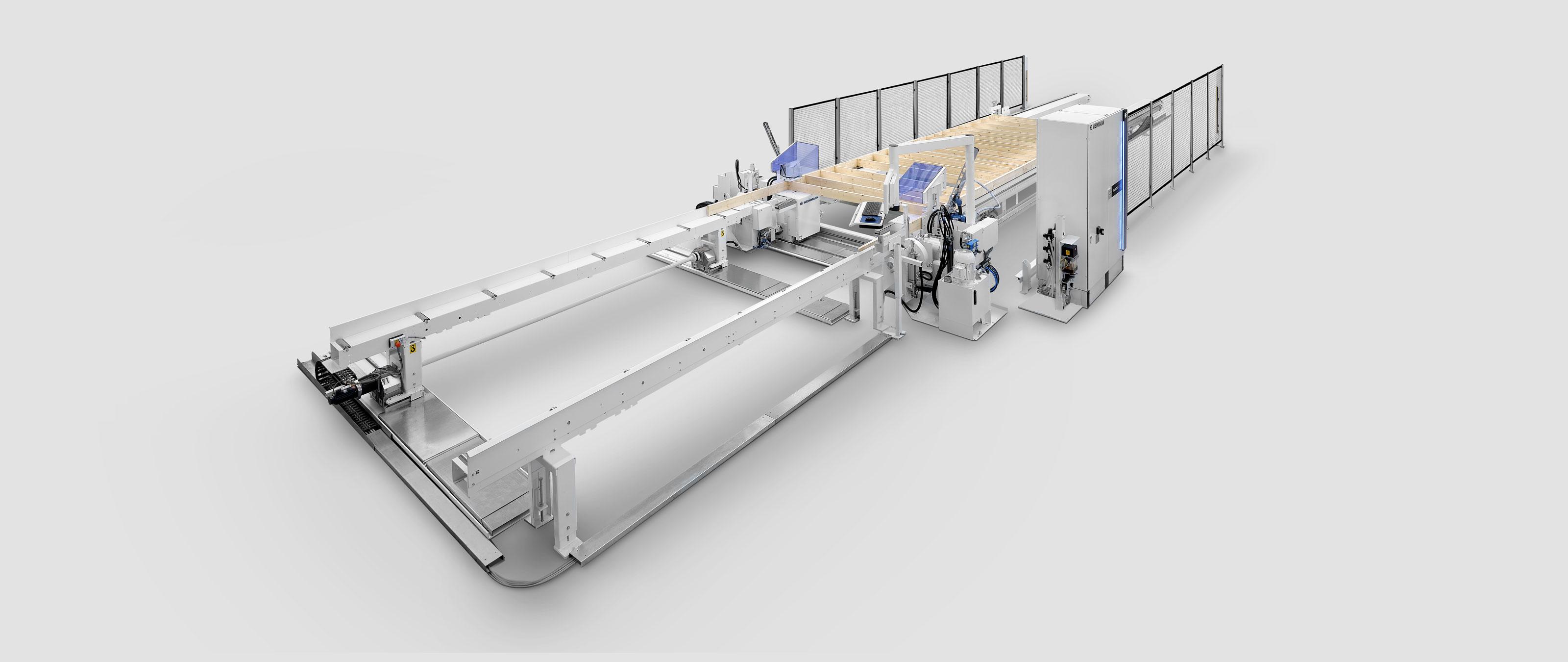

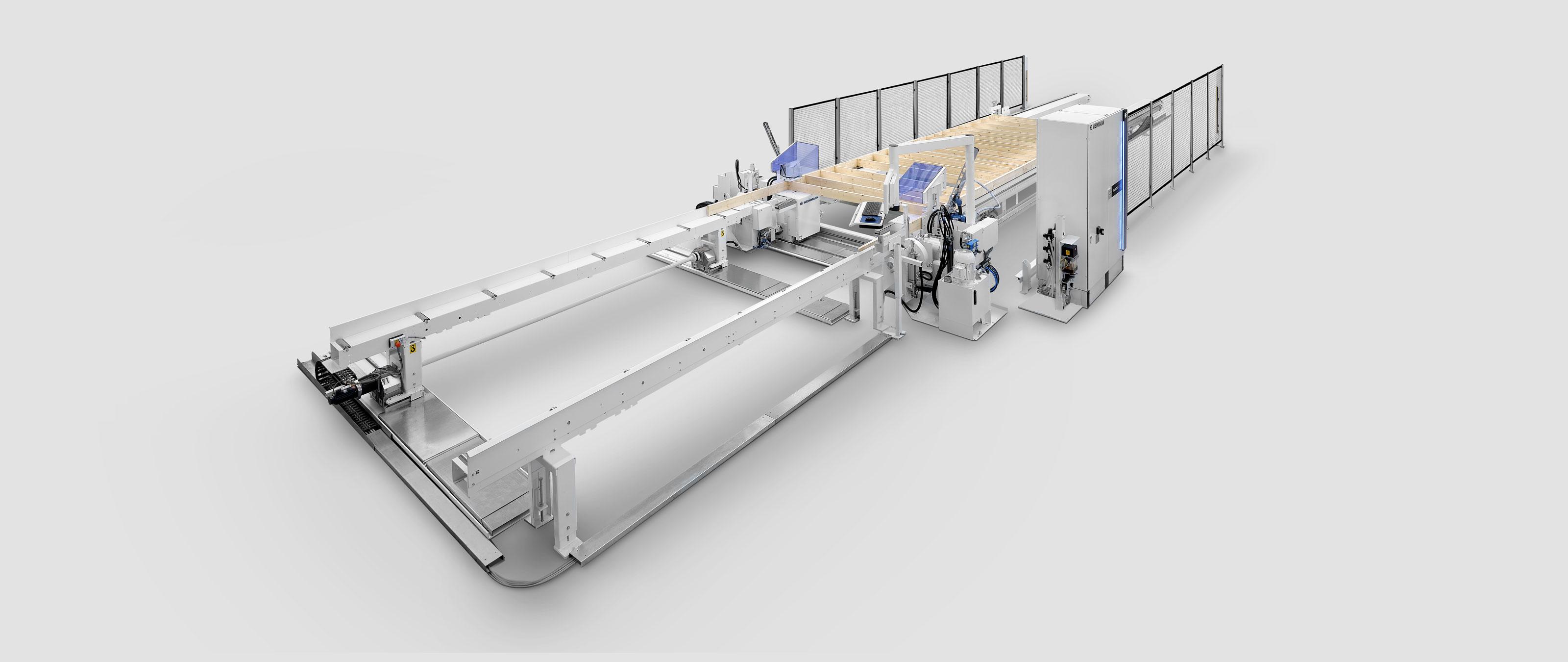

Combi Wall System FRAMETEQ M-500: A

high-performance combination

The FRAMETEQ M-500 combi wall system can be used to manufacture framework with sheathing on one side with just one operator – while still ensuring high quality and performance. The framework is automatically aligned, tensioned and secured. Attachment and processing of the sheathing is also performed as part of an automated process on the same workstation.

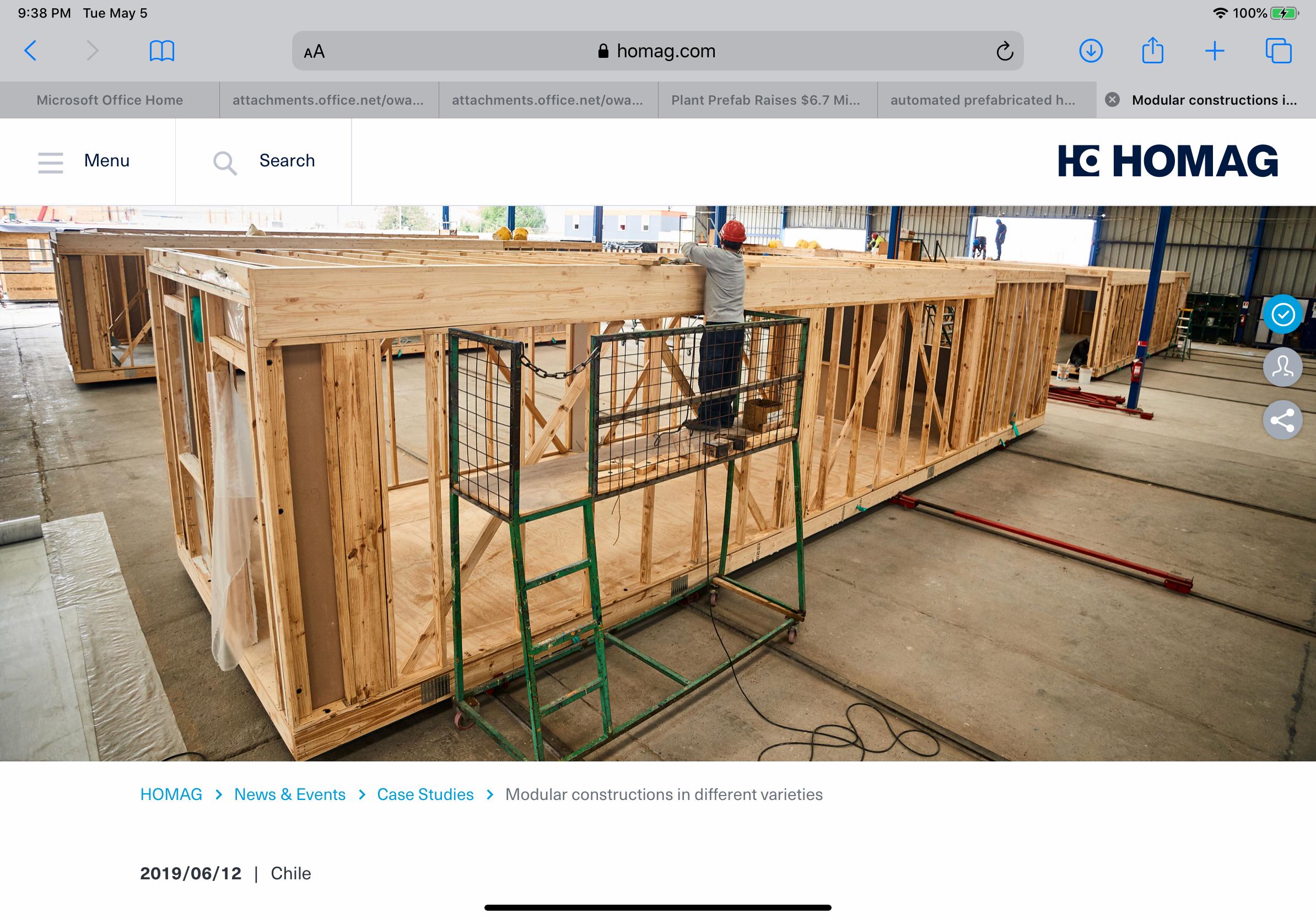

Robots in Timber Framing:

Robot management in framework production

Availability of approximately 100%, high repeat accuracy and high-precision material handling: robots are reliable partners and increase the cost-effectiveness of woodwork production automatically. In combination with the framework station, the robot allows studs and plates for wall elements with windows and doors or special elements such as gables to be inserted fully automatically. Regardless of whether it's standard and special studs or the top and bottom plate, the robot inserts a wide variety of studs into the framework automatically and with high precision. In this process, the six-axis robot transports stud weights of up to 75 kg without any problems.

Framework Station

FRAMETEQ F-500

Combi Wall System

FRAMETEQ M-500

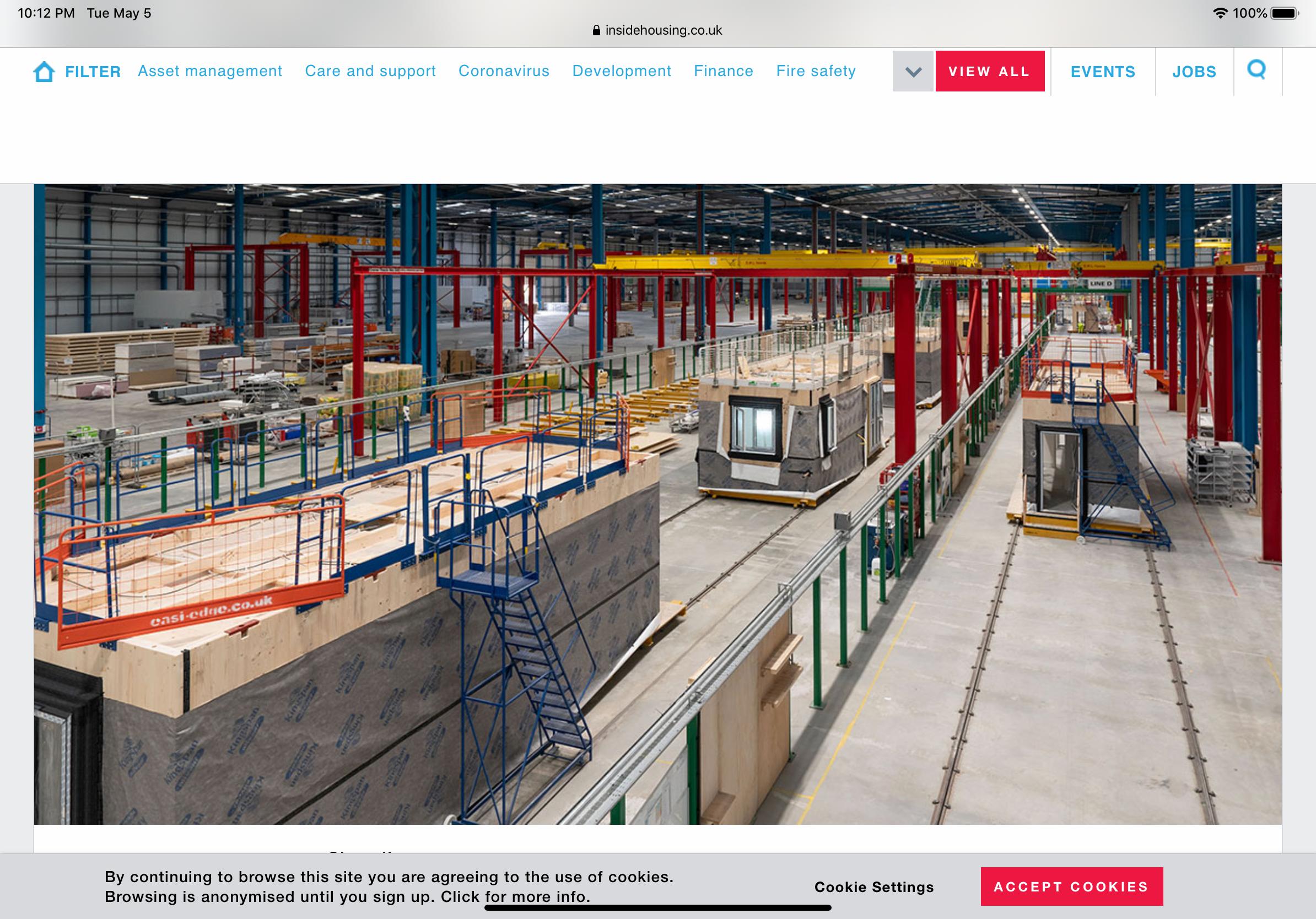

Modular Home Assembly Line

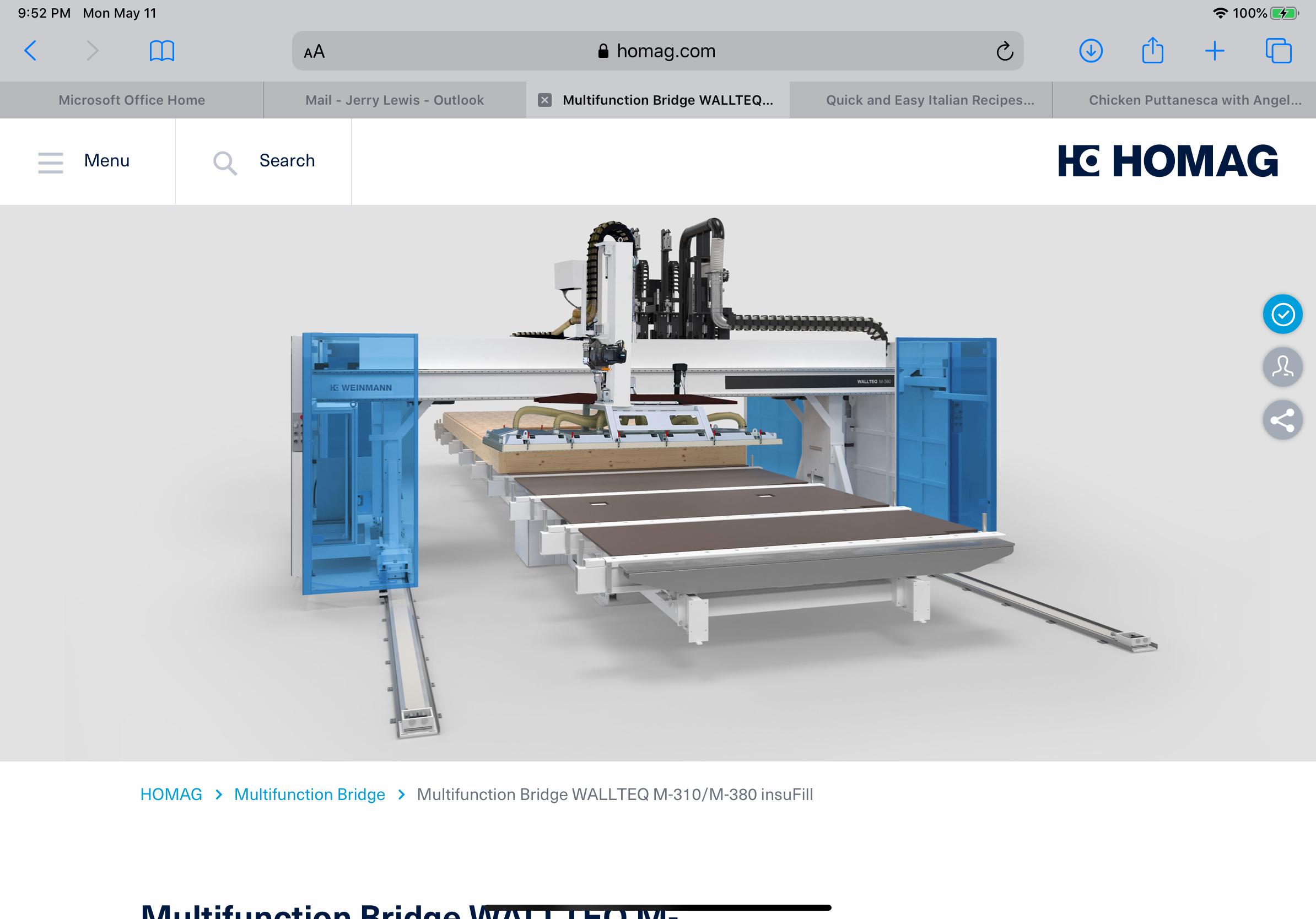

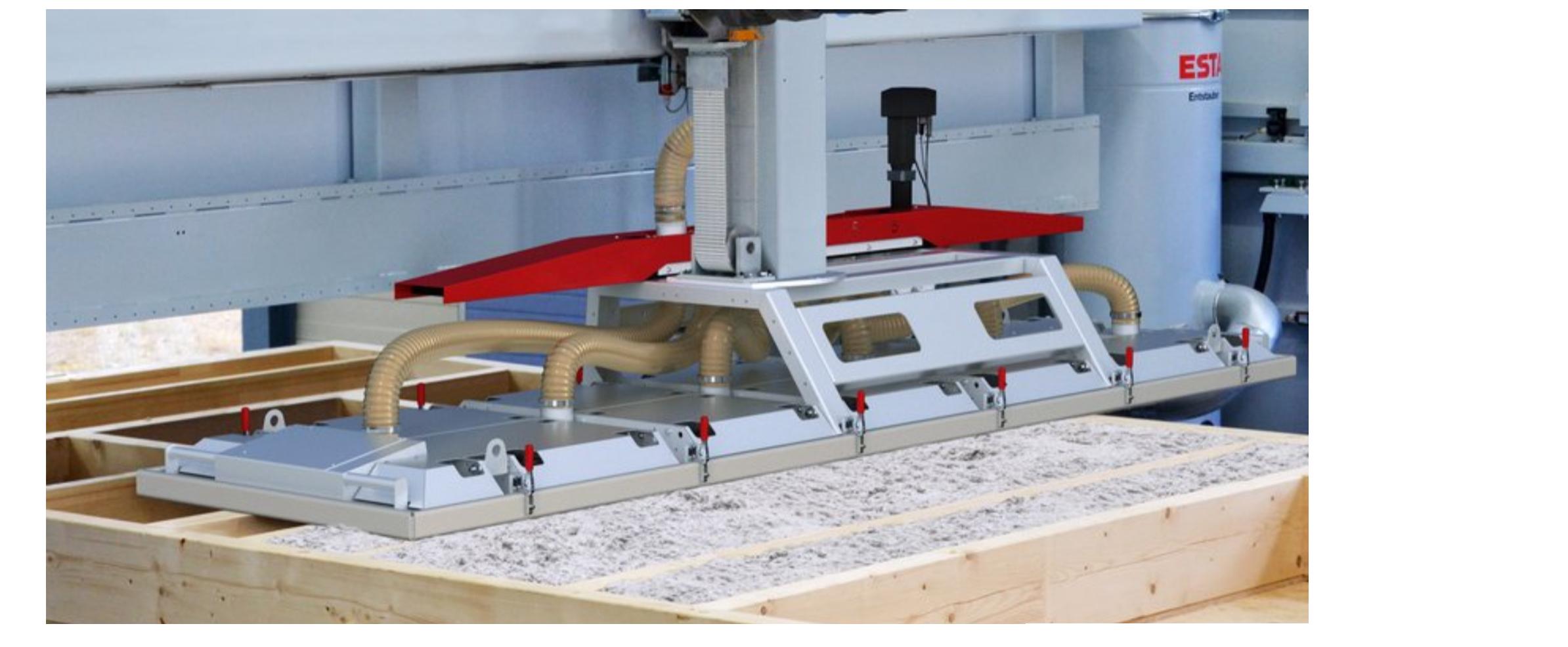

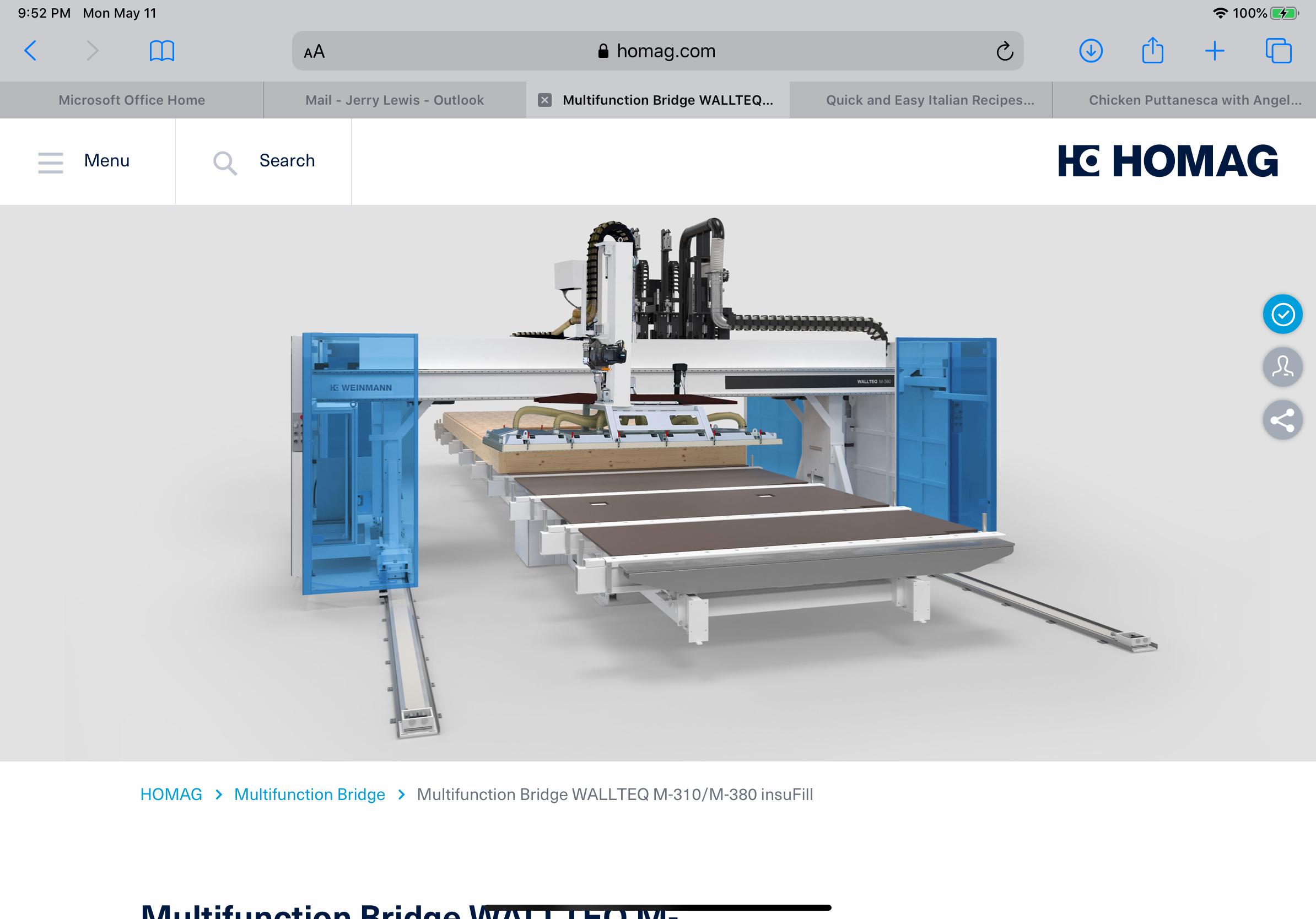

Multifunction Bridge WALLTEQ M-310/M-380

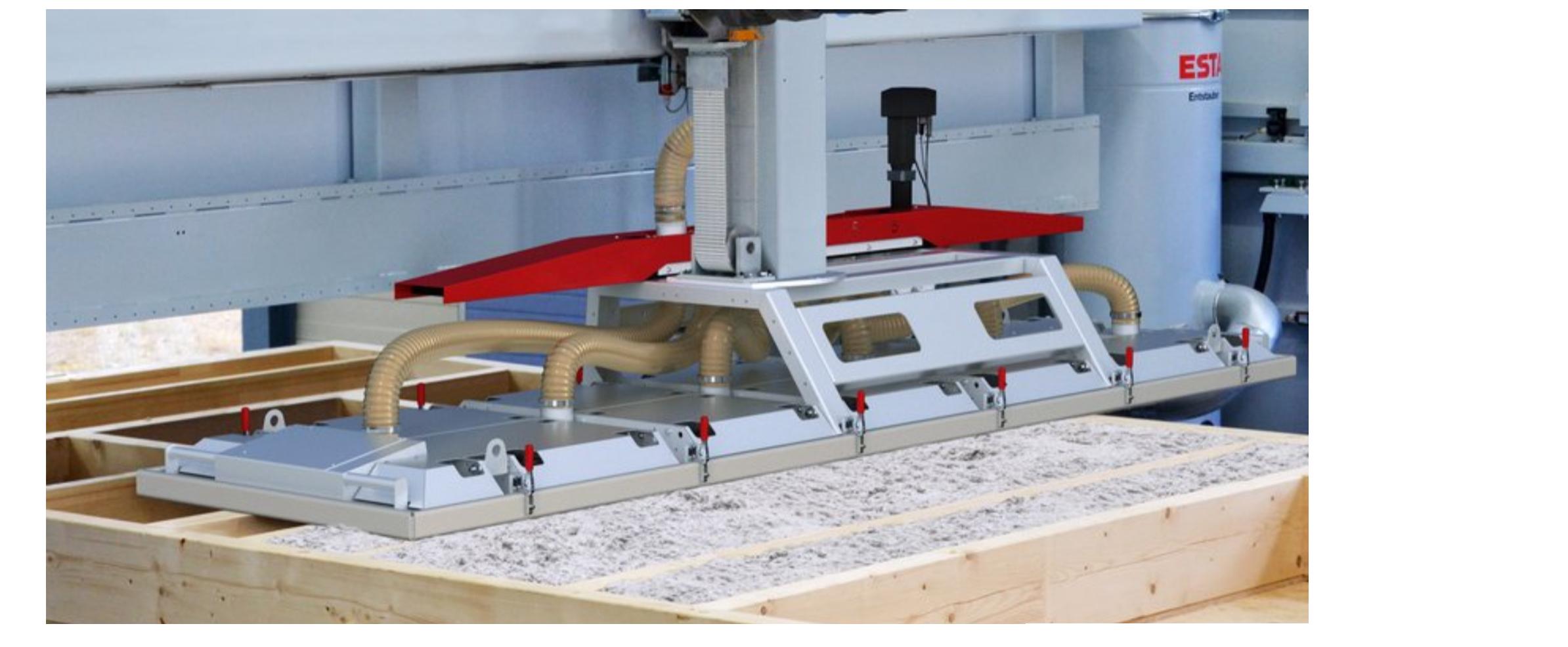

insuFill Your Solution for automated insulation

Insulation Procedures

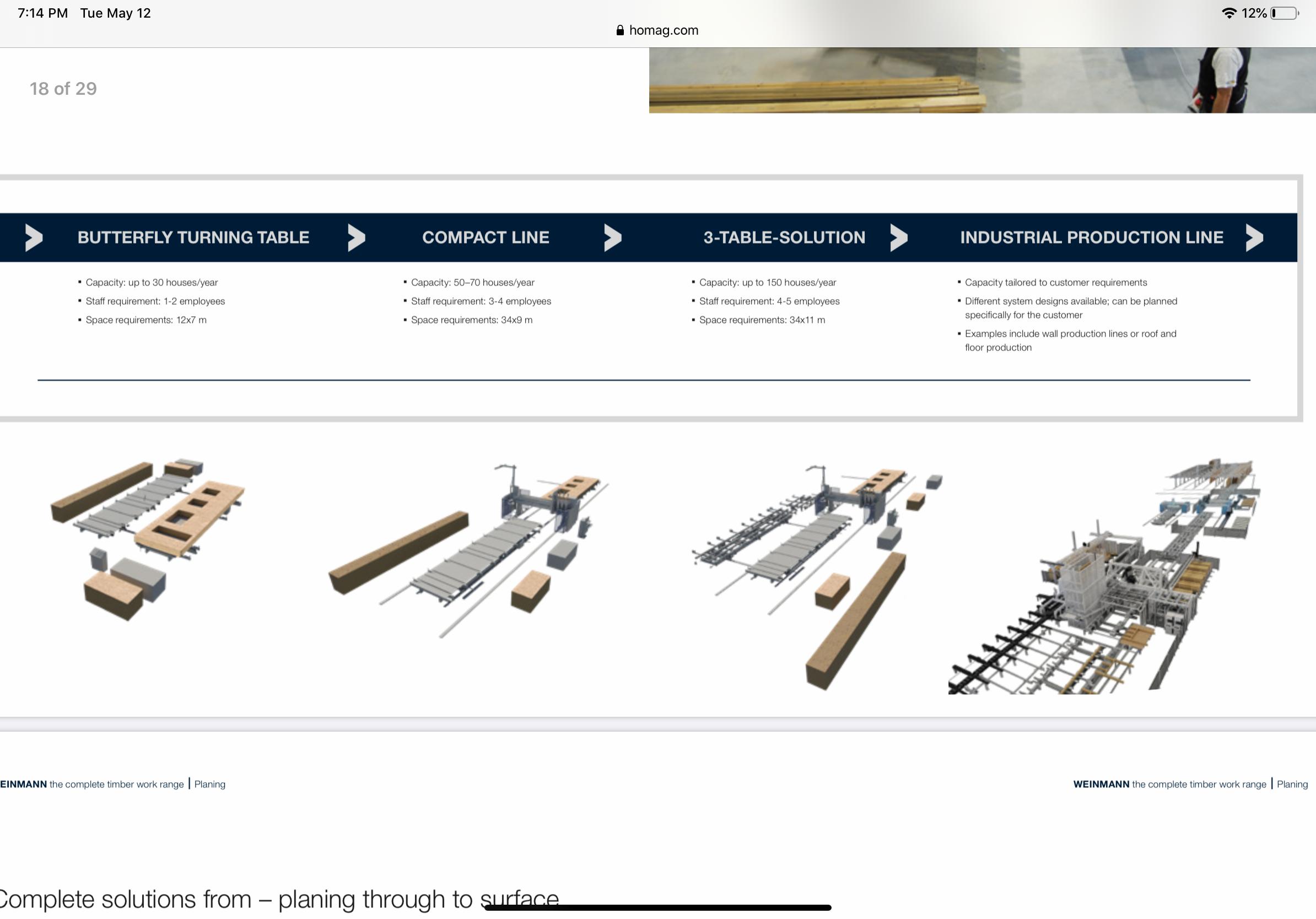

Planned Production Line Choices

III. AUTOMATION TECHNOLOGIES

Robots in Timber Framing:

Robot management in framework production

Availability of approximately 100%, high repeat accuracy and high-precision material handling: robots are reliable partners and increase the cost-effectiveness of woodwork production automatically. In combination with the framework station, the robot allows studs and plates for wall elements with windows and doors or special elements such as gables to be inserted fully automatically. Regardless of whether it's standard and special studs or the top and bottom plate, the robot inserts a wide variety of studs into the framework automatically and with high precision. In this process, the six-axis robot transports stud weights of up to 75 kg without any problems.

FACTORY TOWN EAST

MODULAR HOME AND WINDOW ASSEMBLY PLANT

The modular home and window assembly plant is a state of the art technological wonder. It is designed as an automated modular home, window and door assembly facility to erect prefabricated components and combined them with all the necessary electrical, plumbing, HVAC and FFE material to complete a fully assembled modular unit ready to be installed in the field. This plant will be built on the east end of the proposed site.

MODULAR AND WINDOW ASSEMBLY PLANT SYSTEMS

Construction Factory Town Assembly Centre [CFTIC]

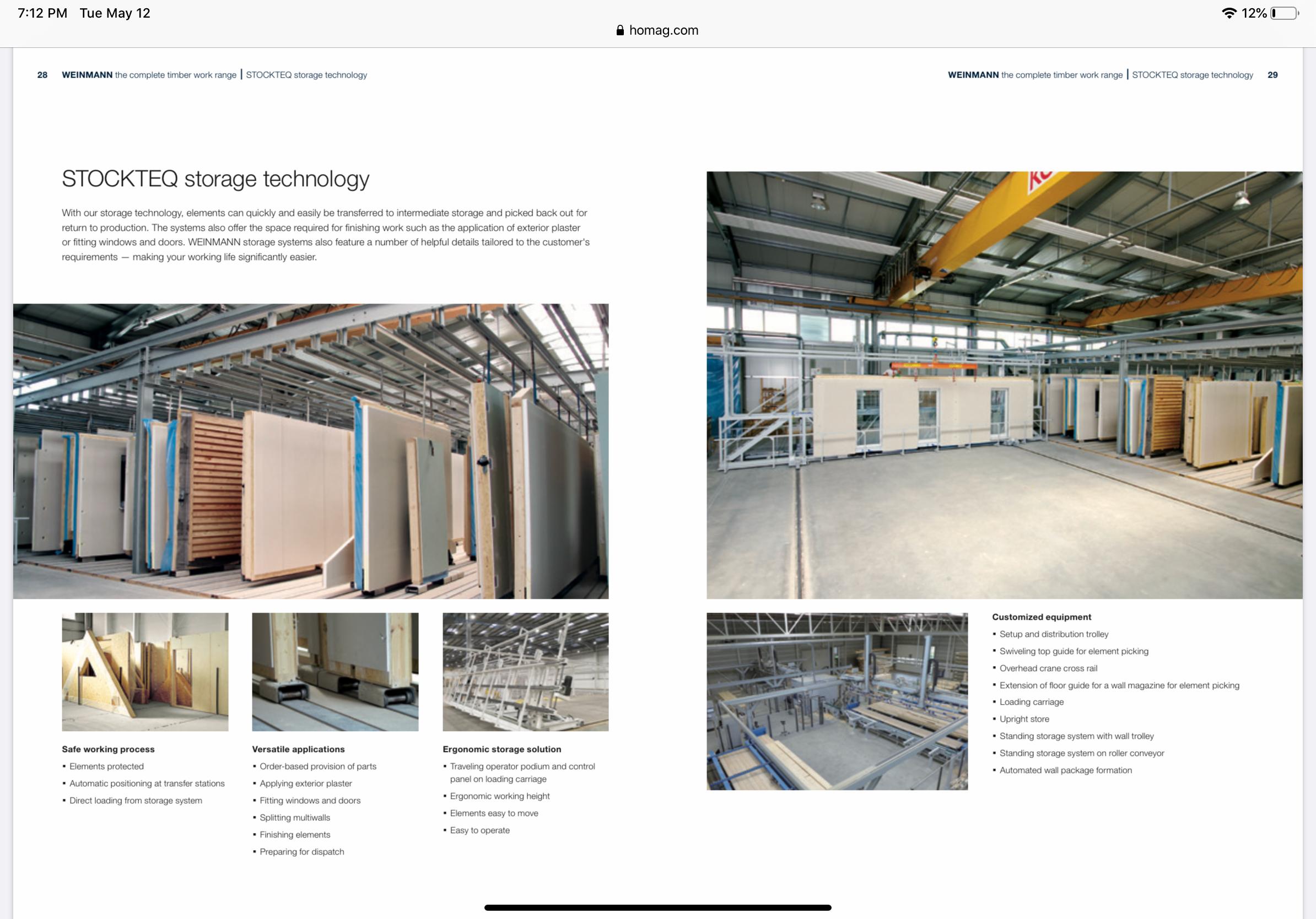

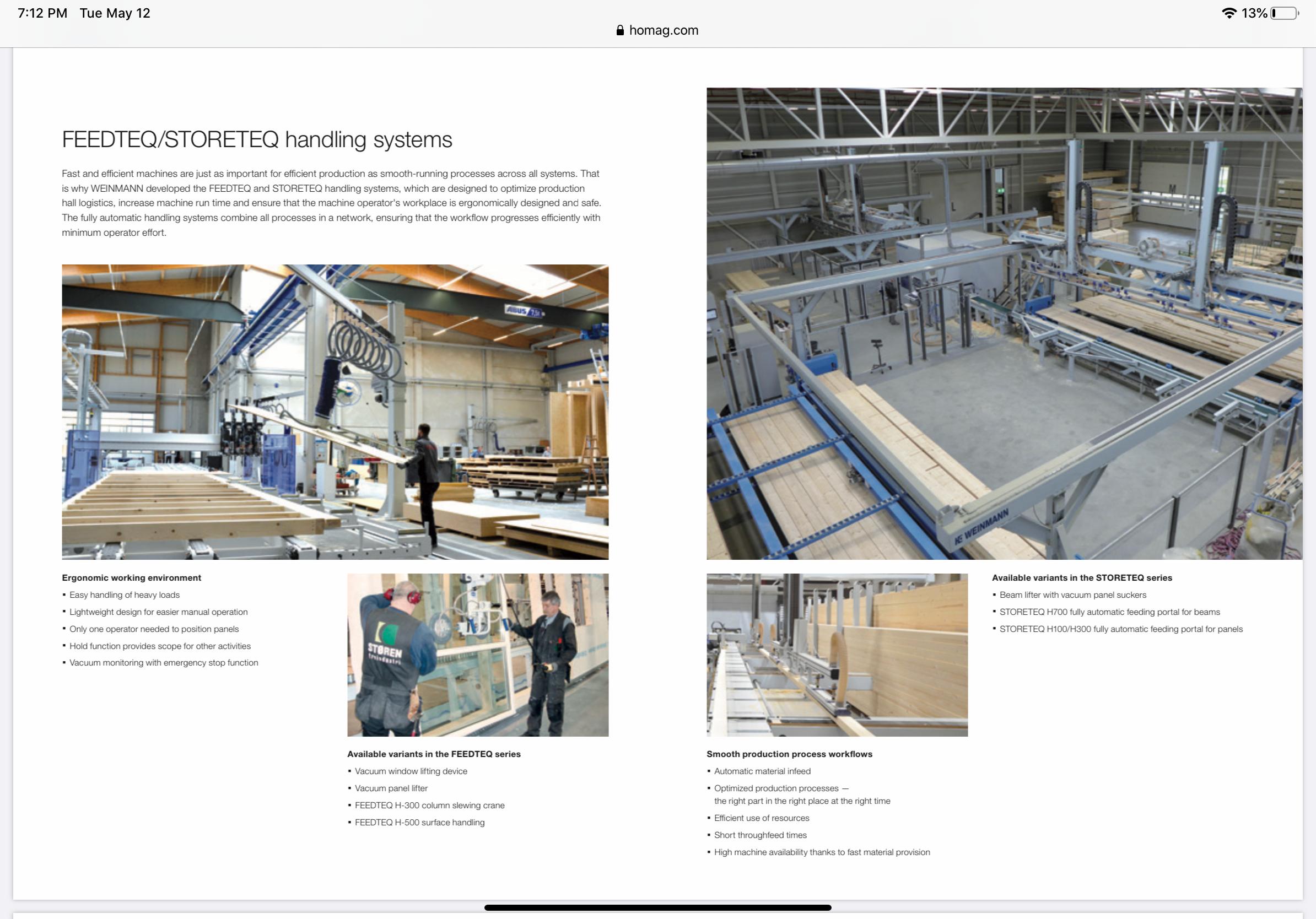

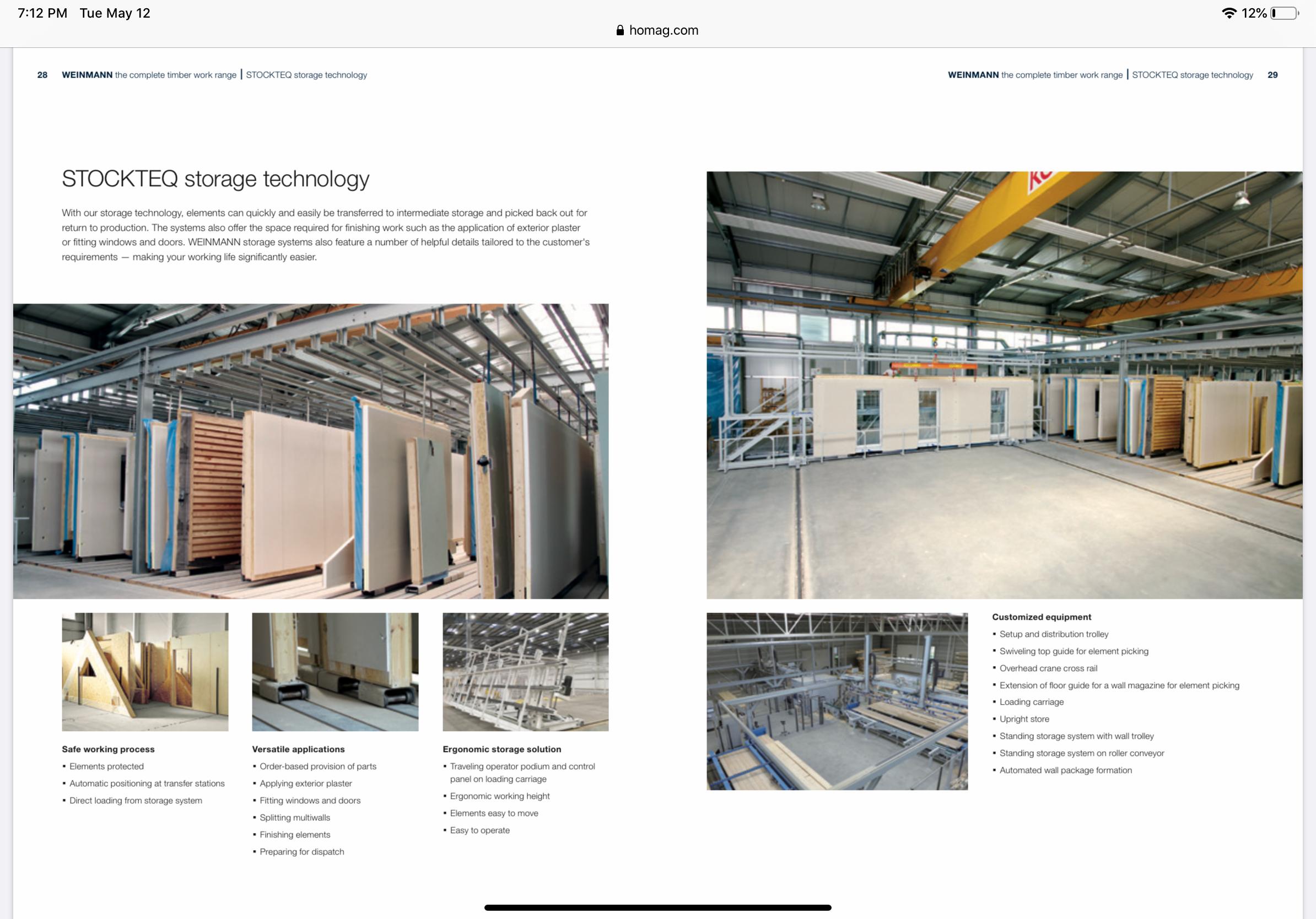

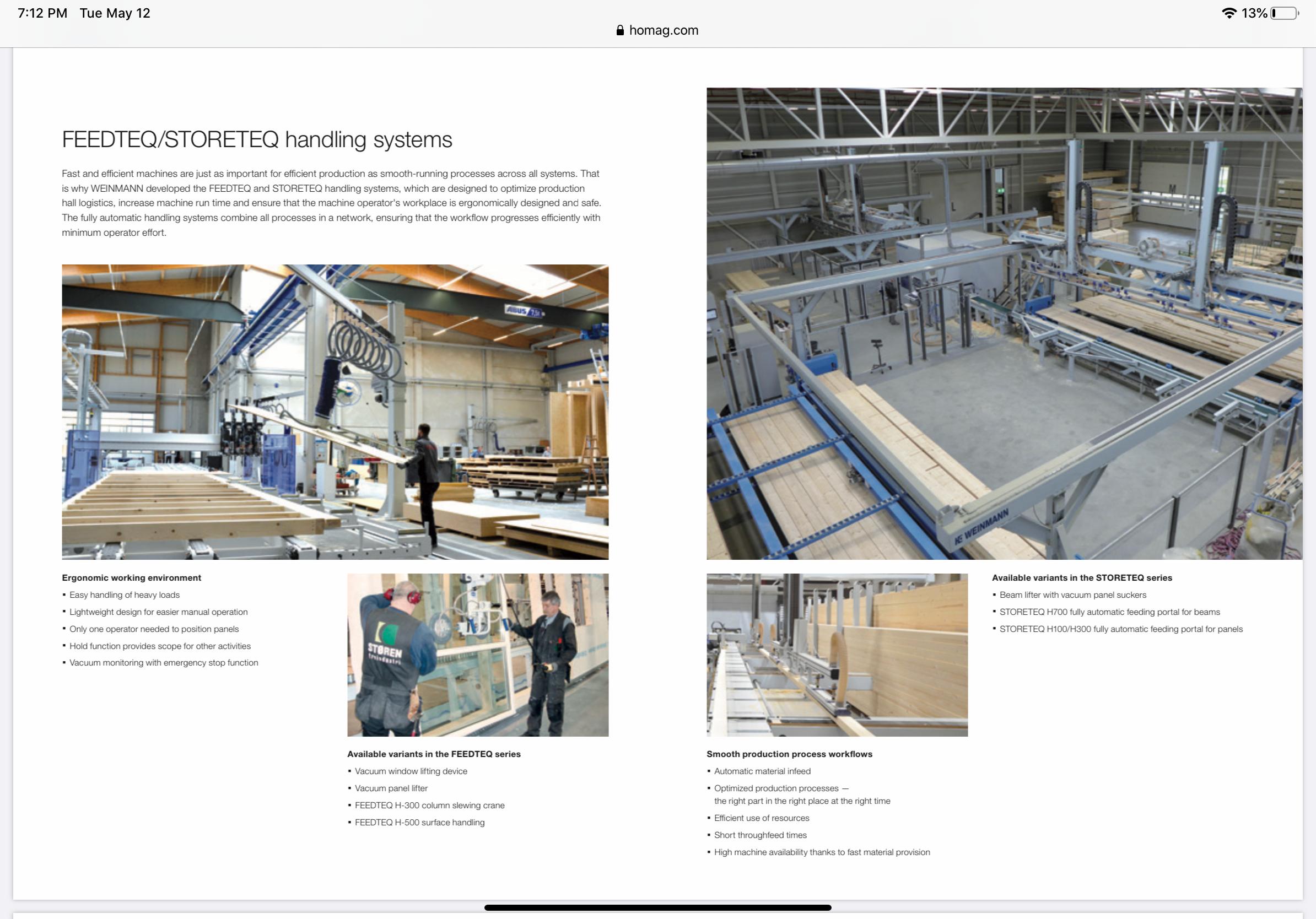

1. About Assembly and Storage

2. MEP Rough-In

3. Window Installation

Modular Assembly

Rough Framed Assembly

Enclosed Unit Ready for Exterior Finishes

MEP INSTALLATION PHASE

Stocking and Storage Assembly

Automated Lifting and Handling System

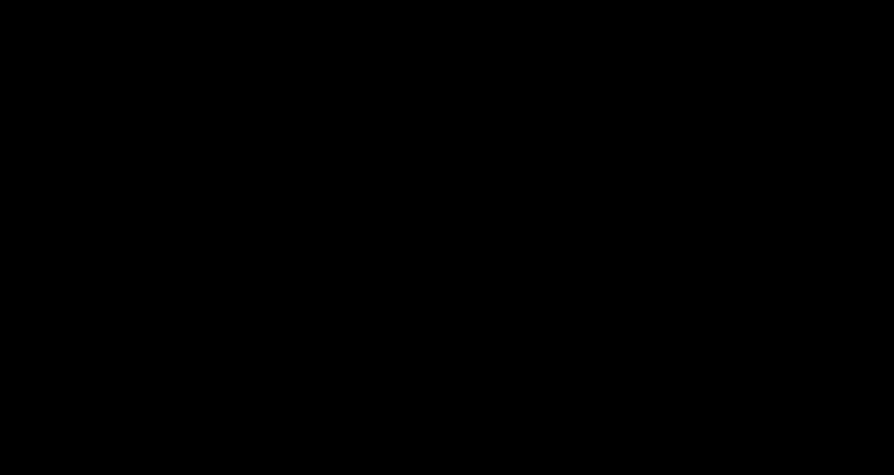

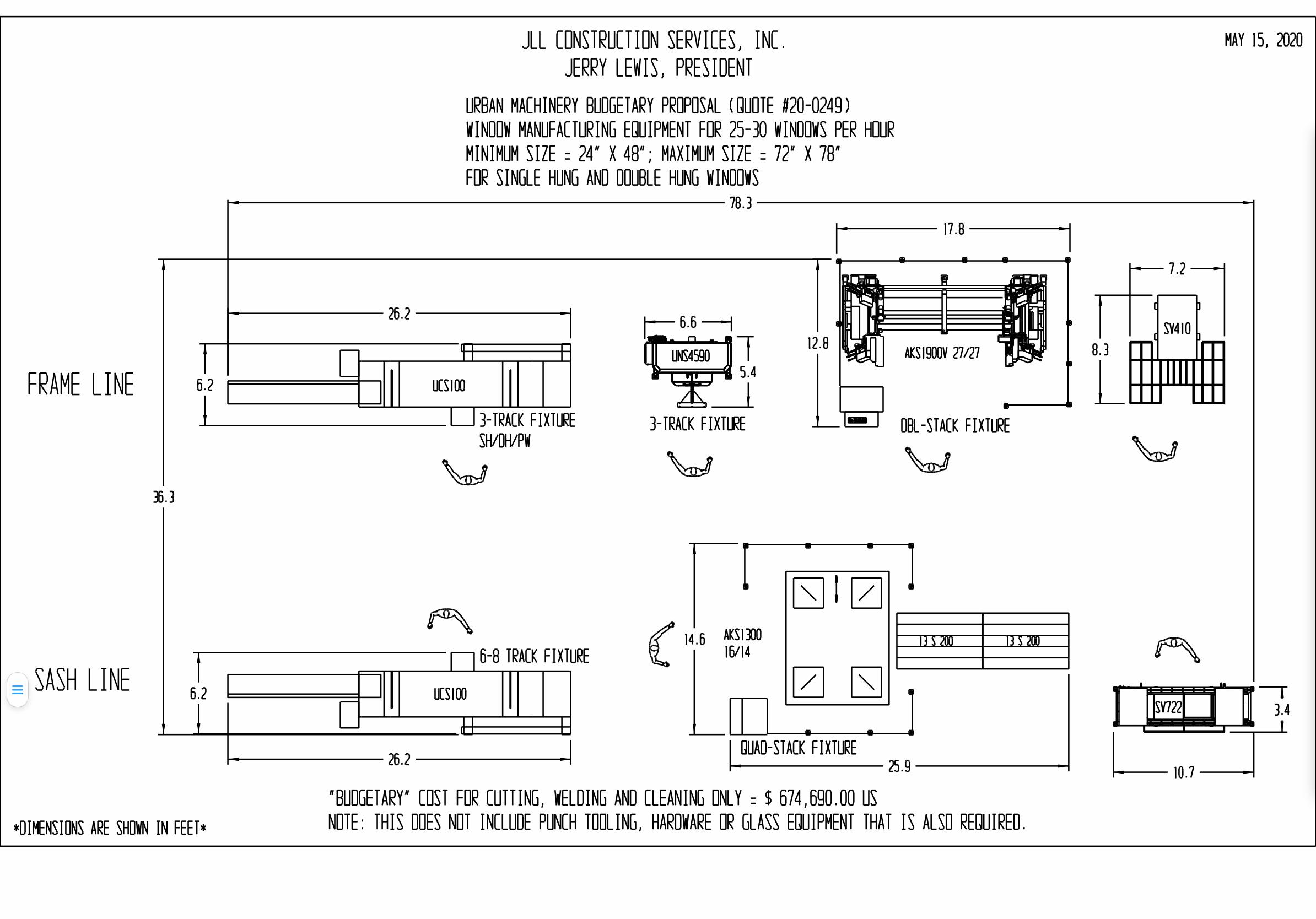

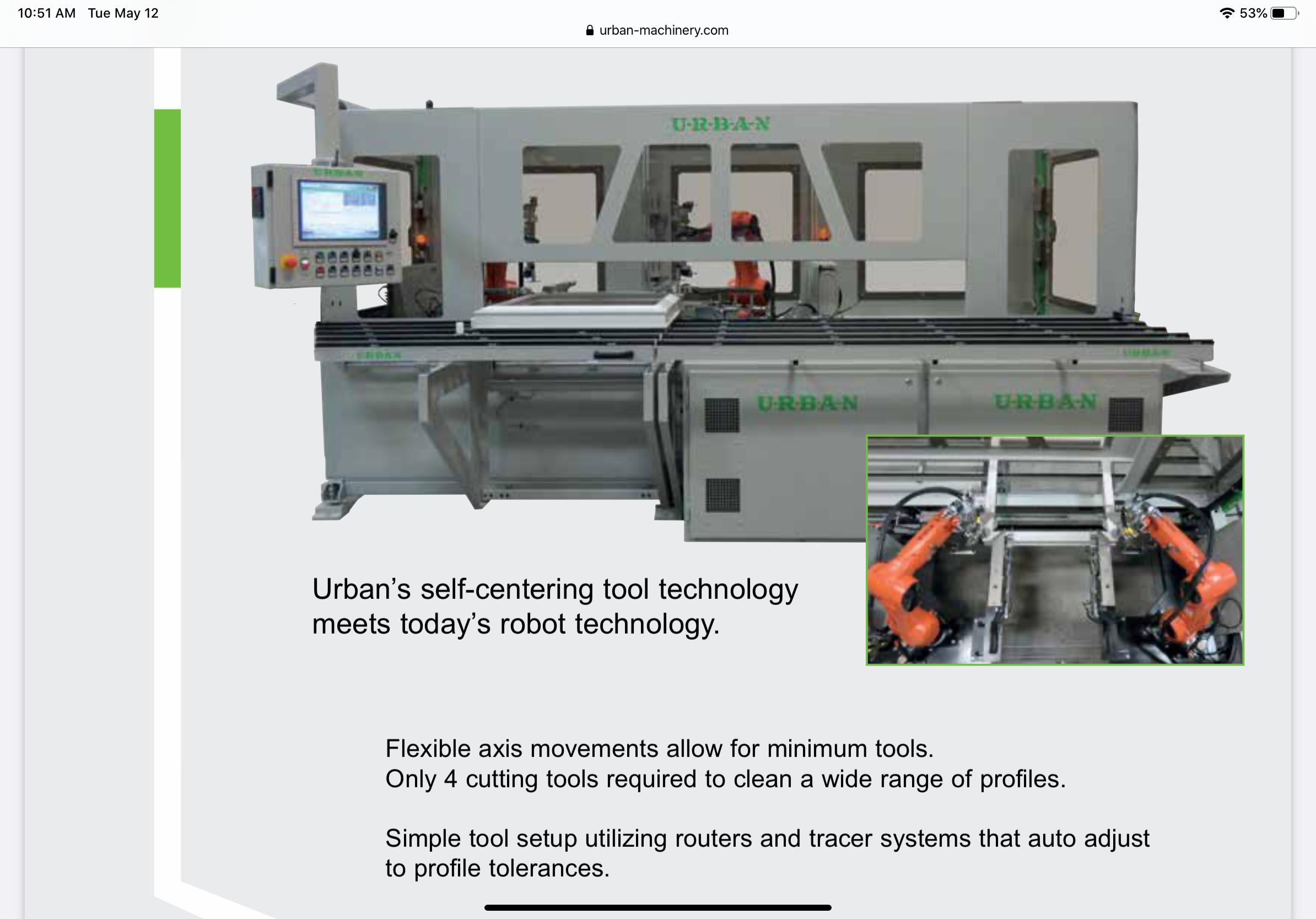

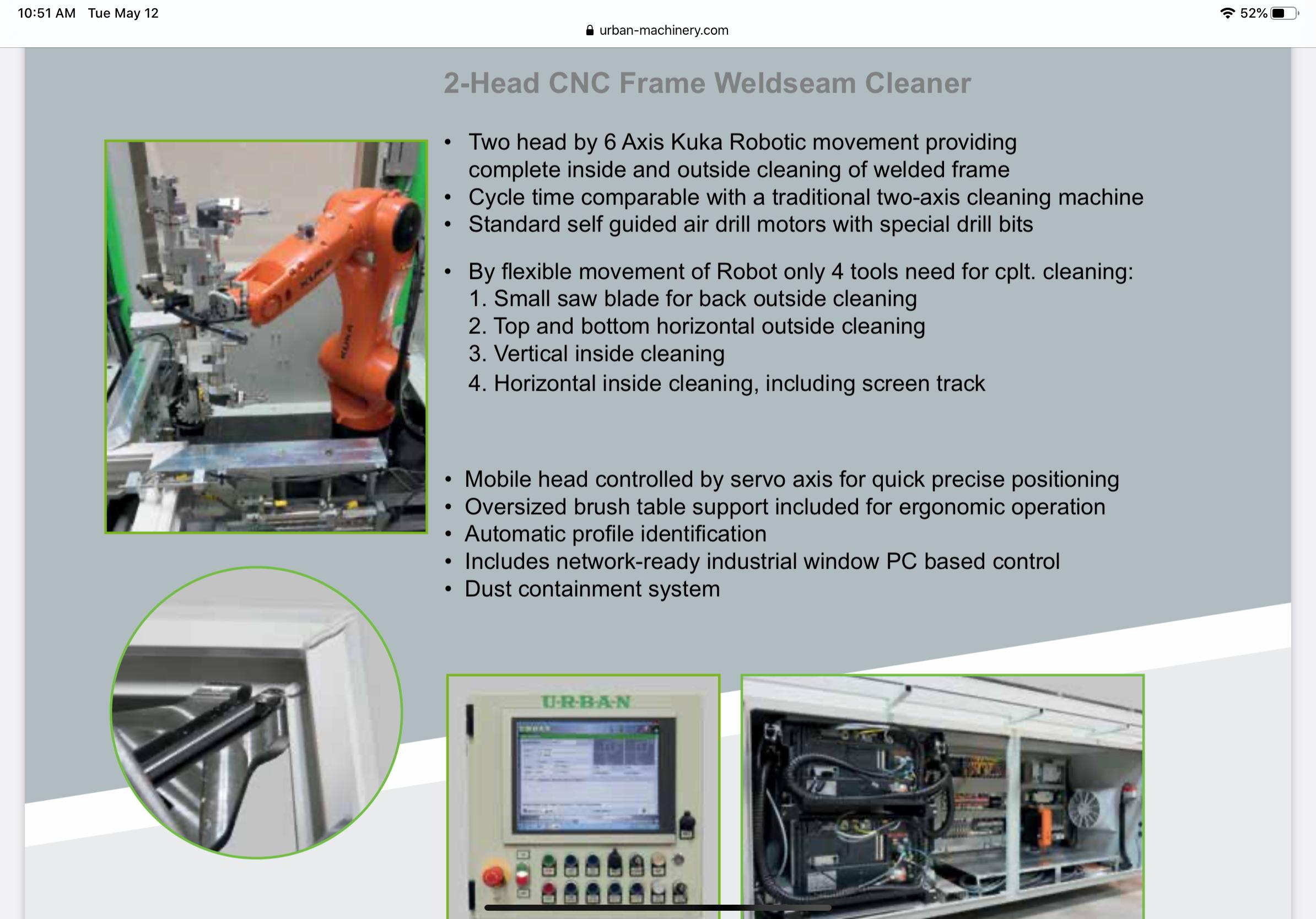

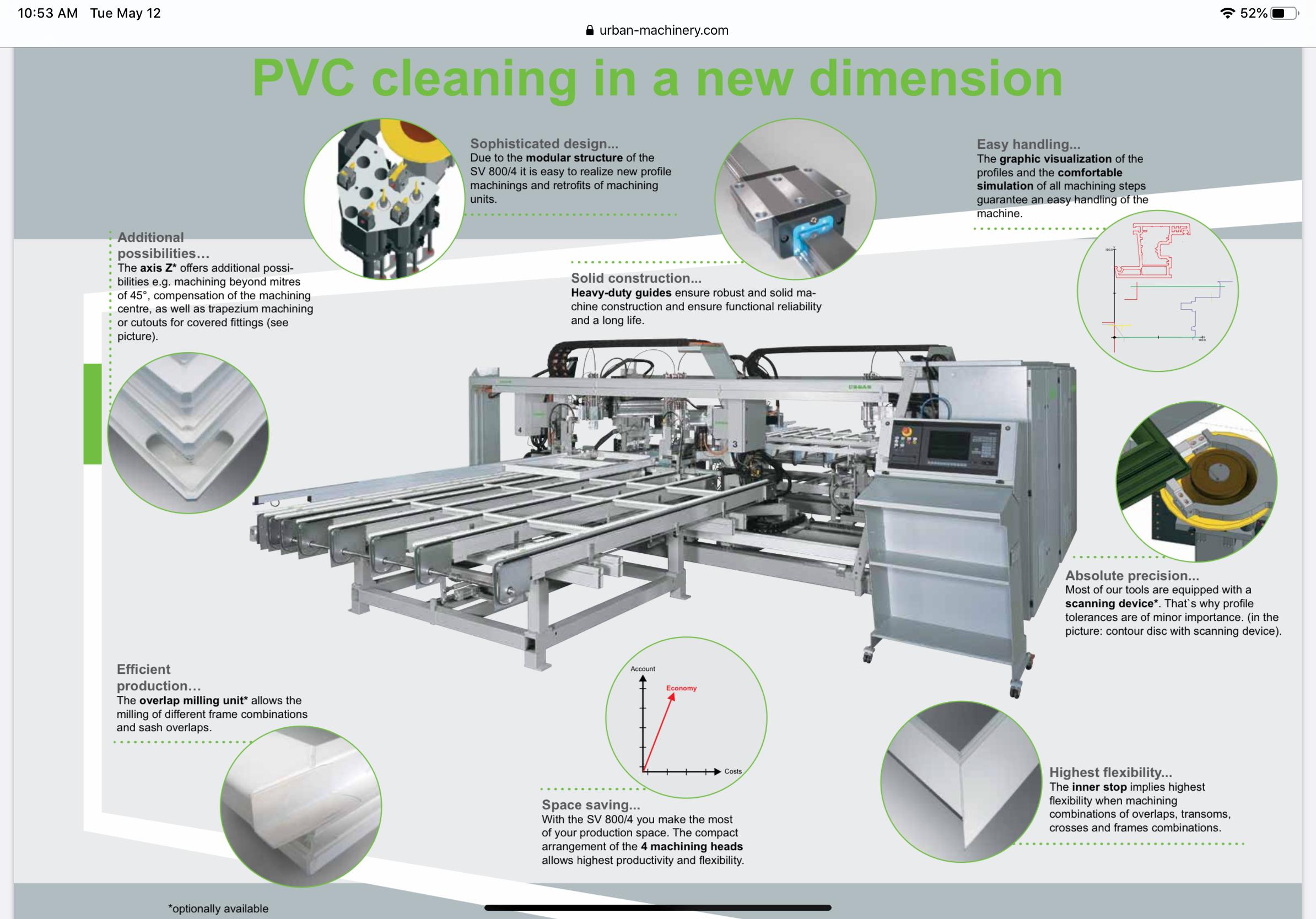

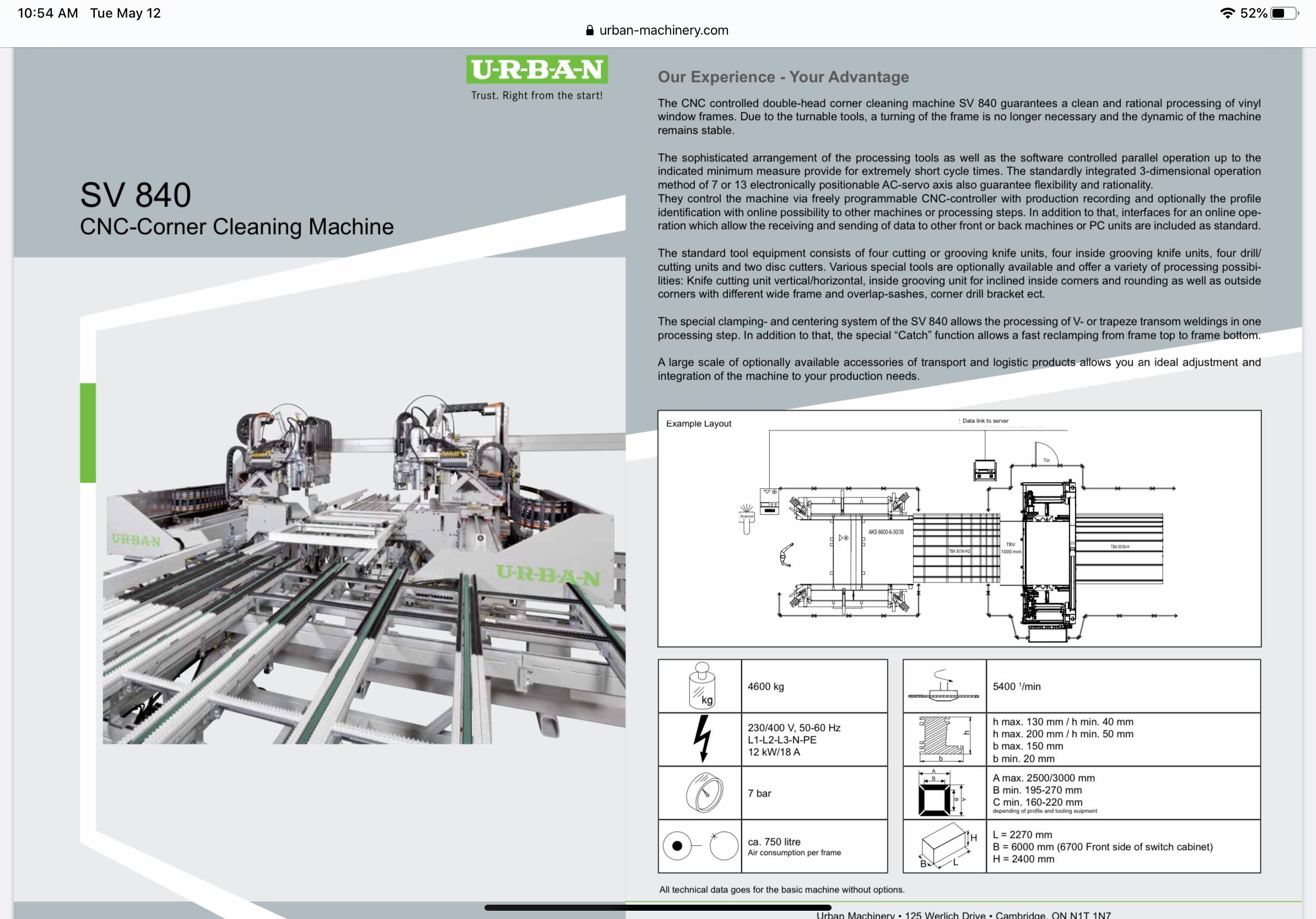

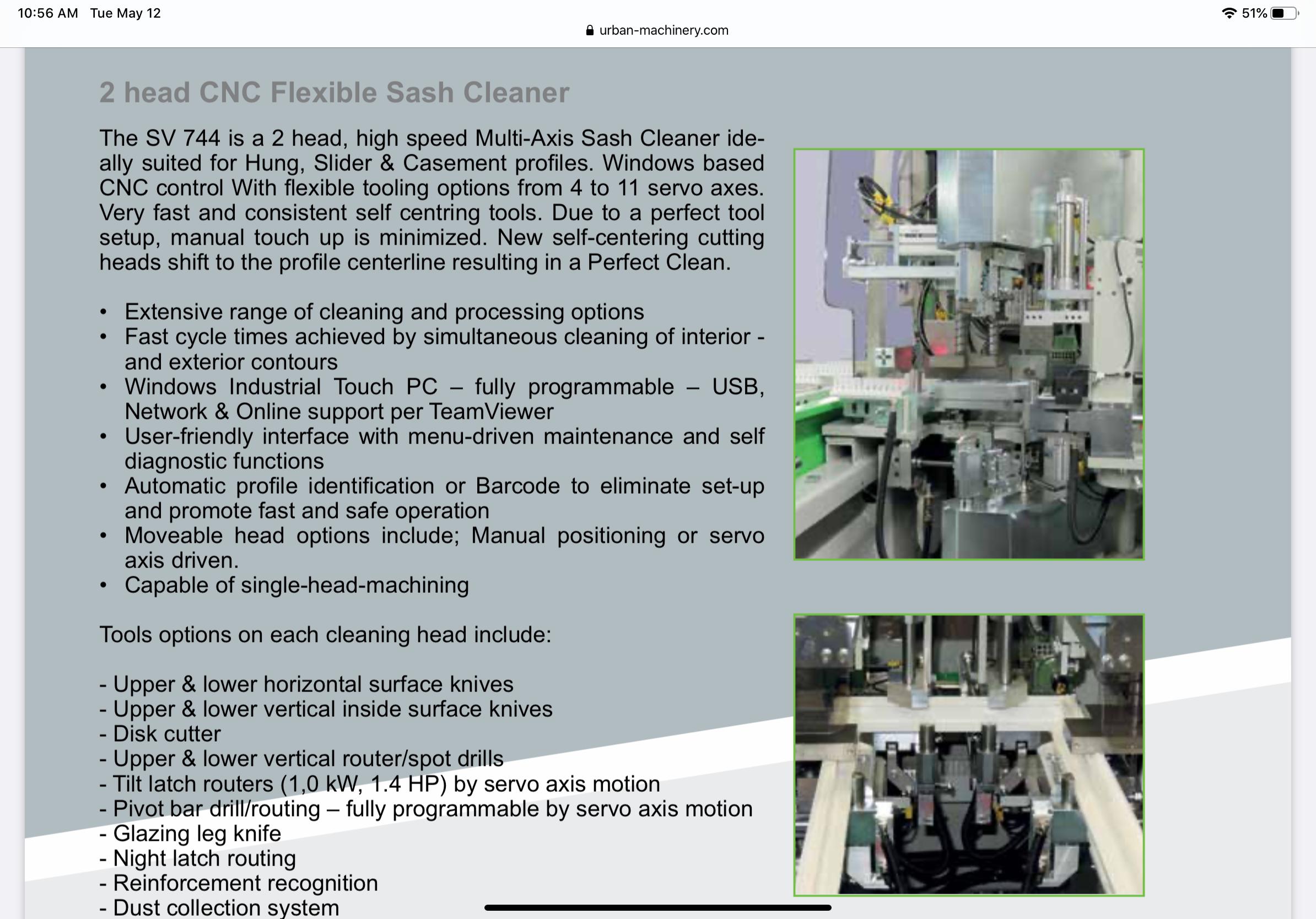

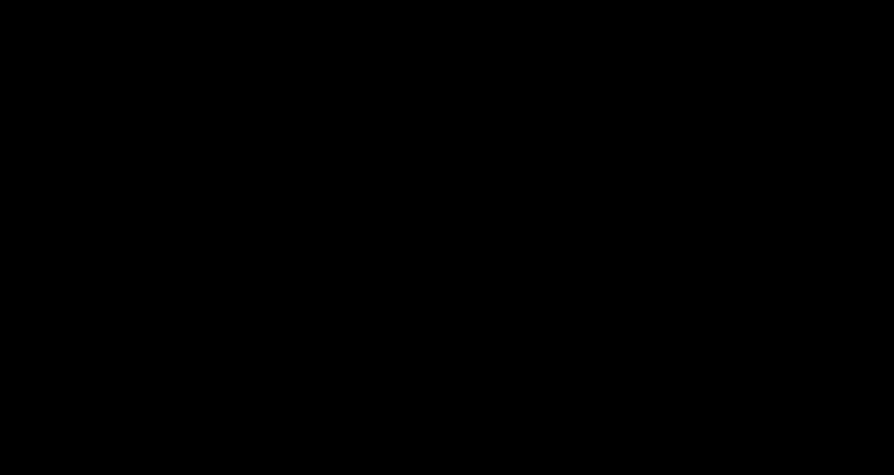

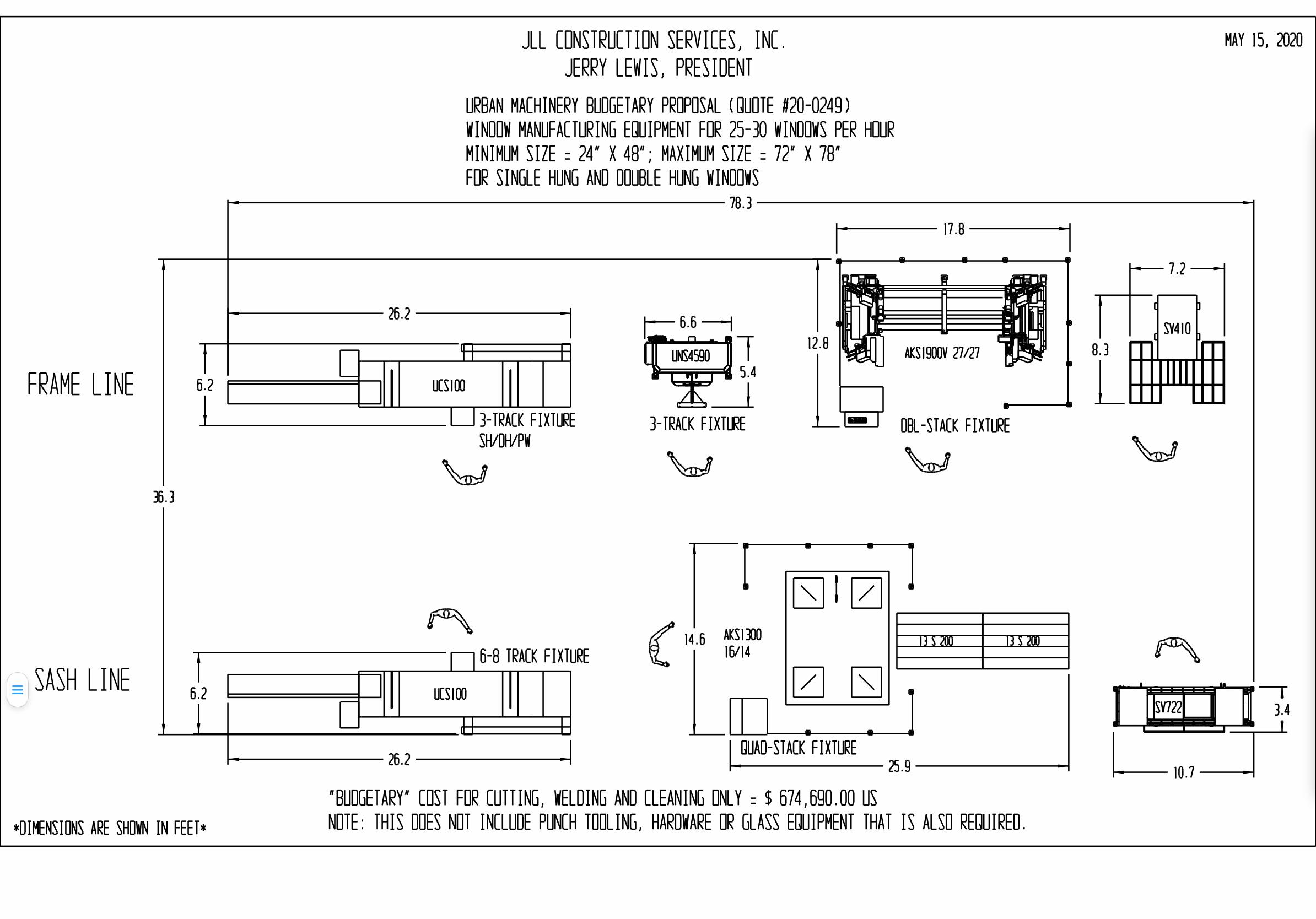

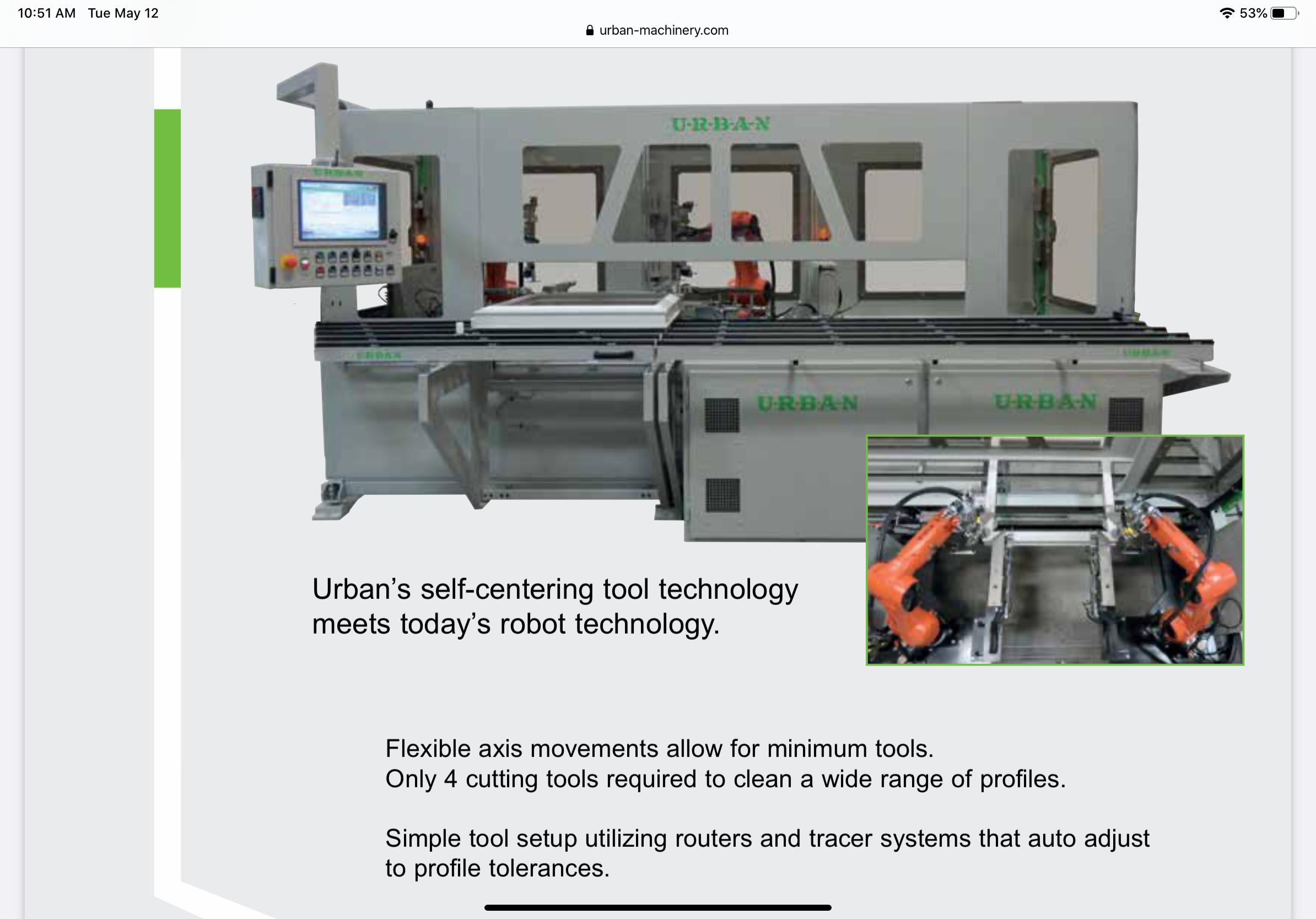

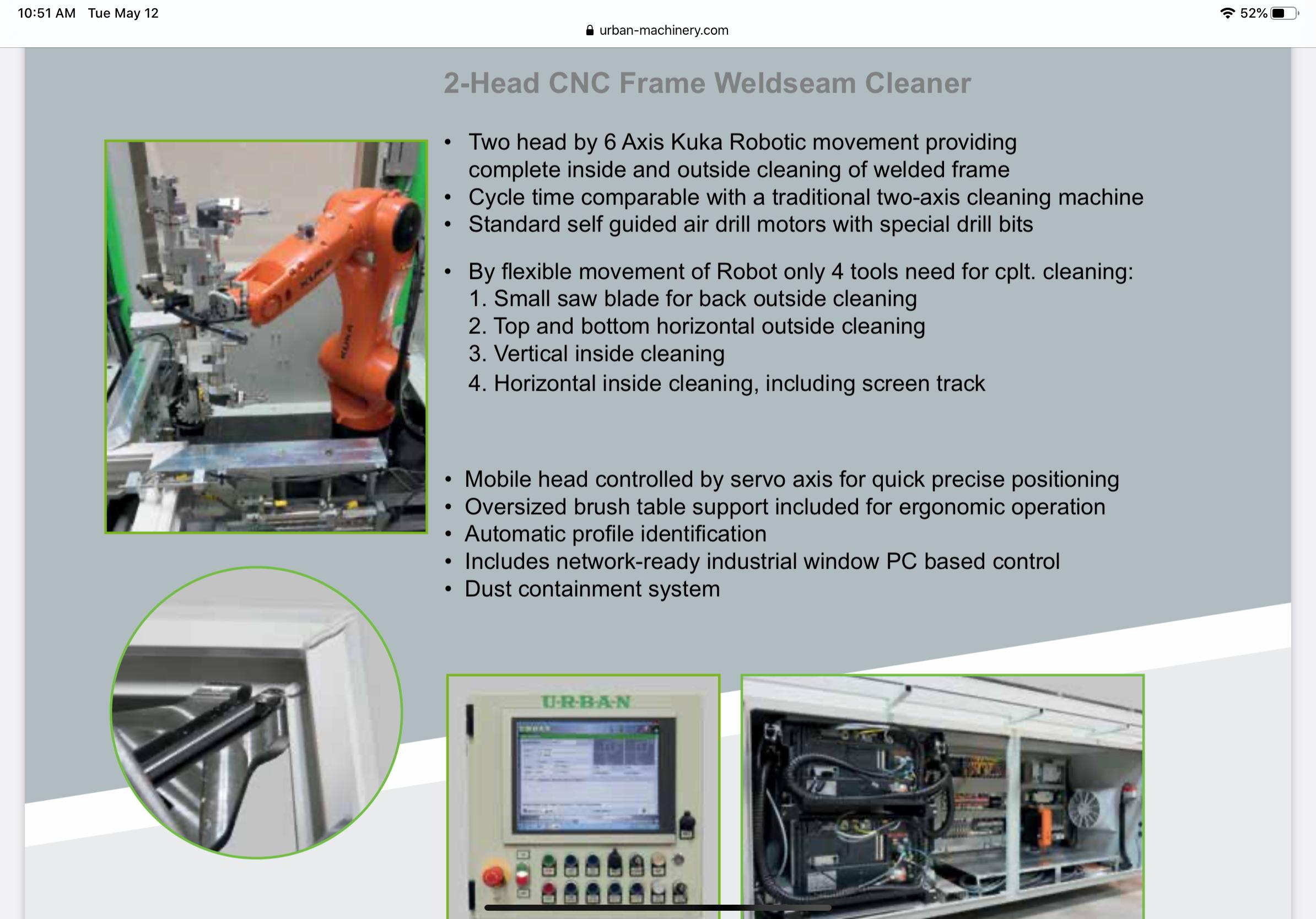

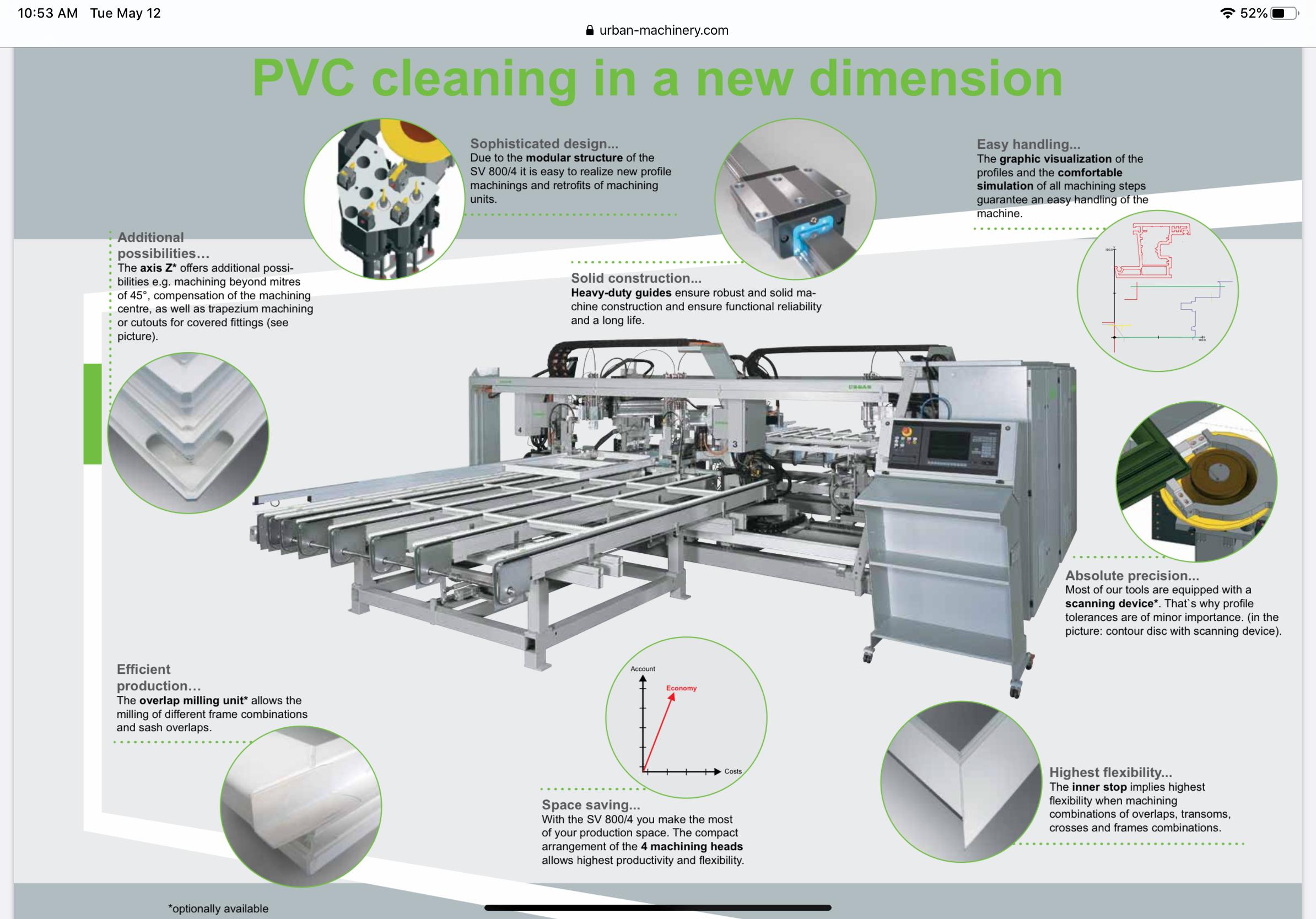

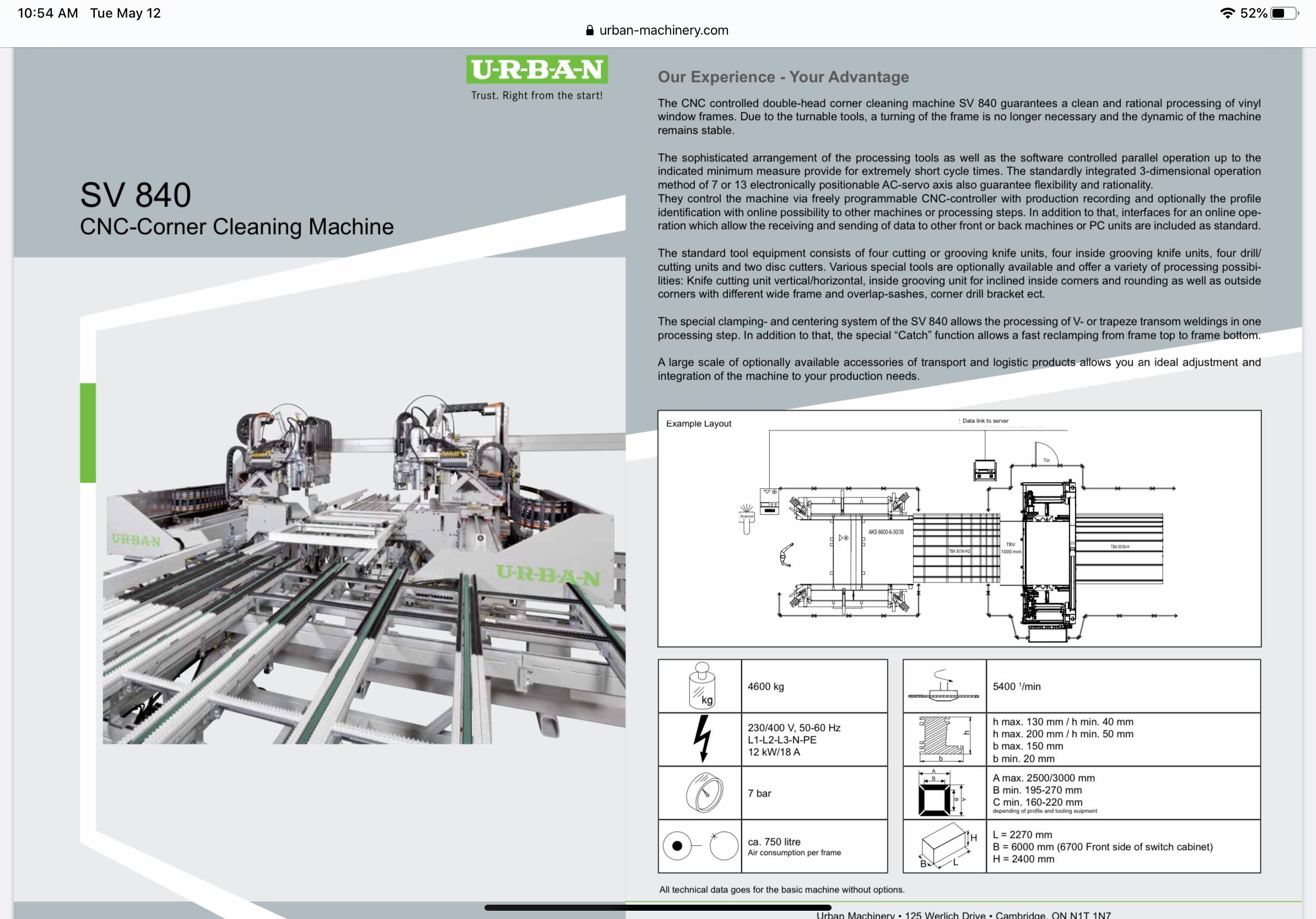

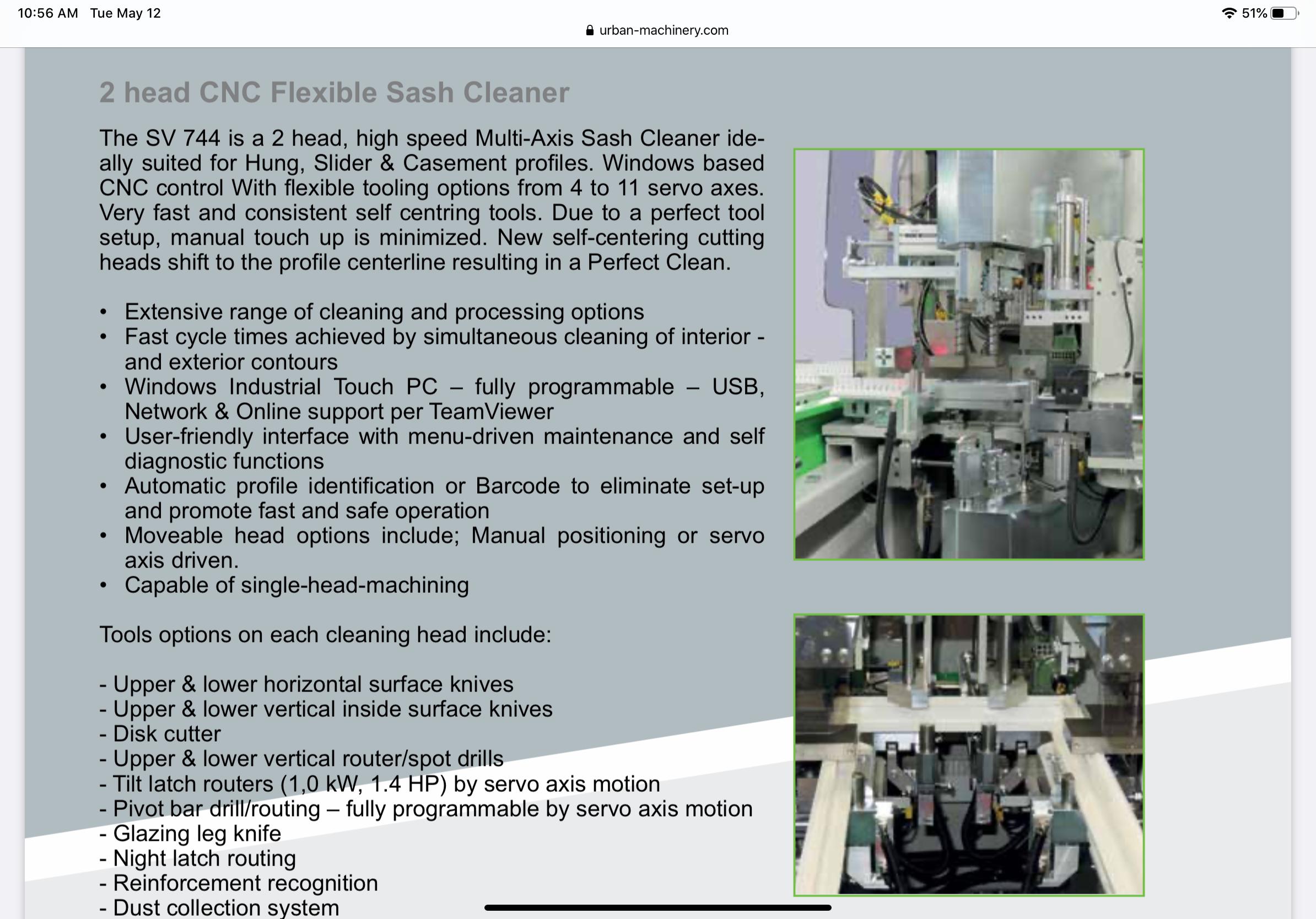

Window Assembly and Installation Operations

Window Assembly and Installation Operations

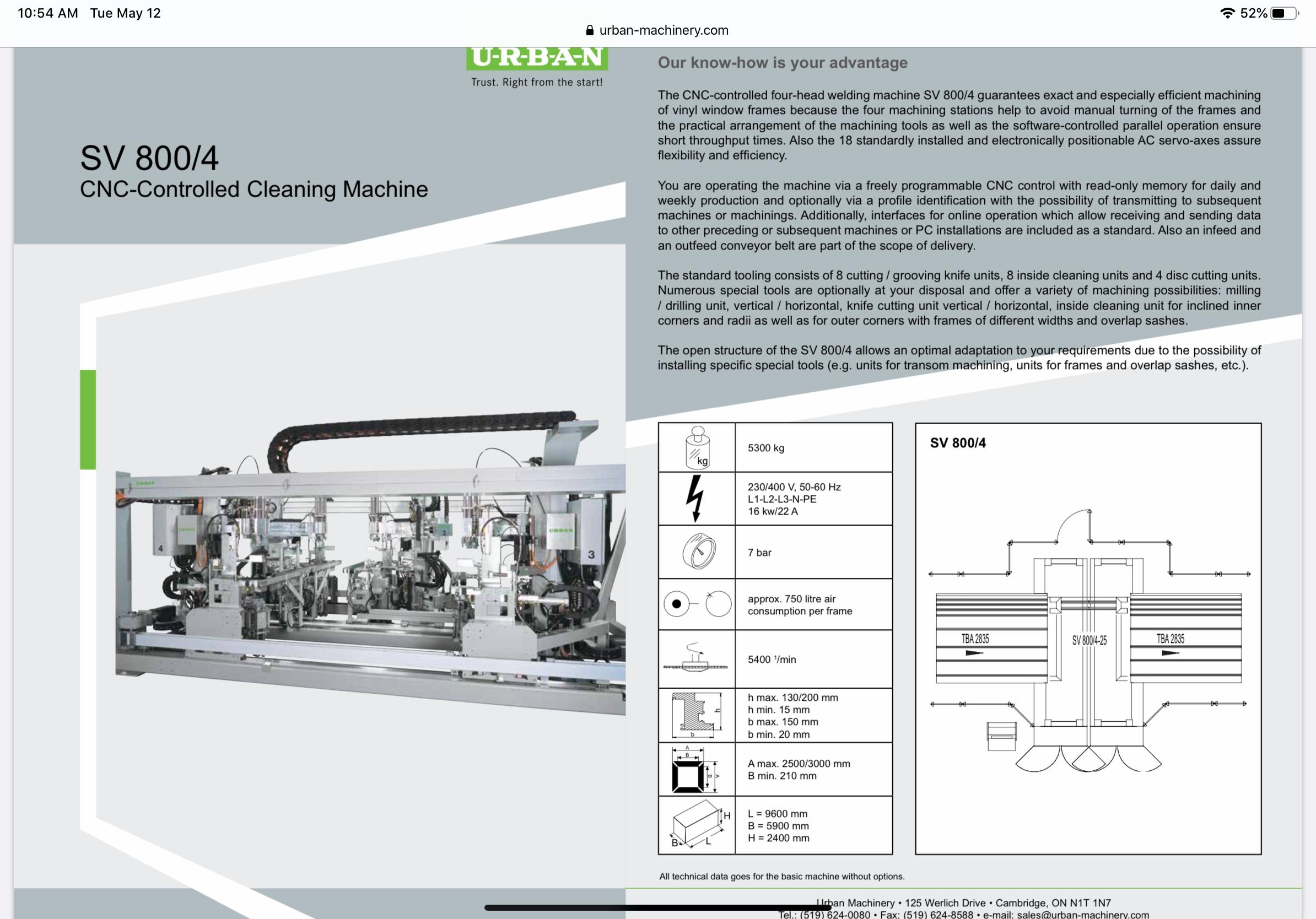

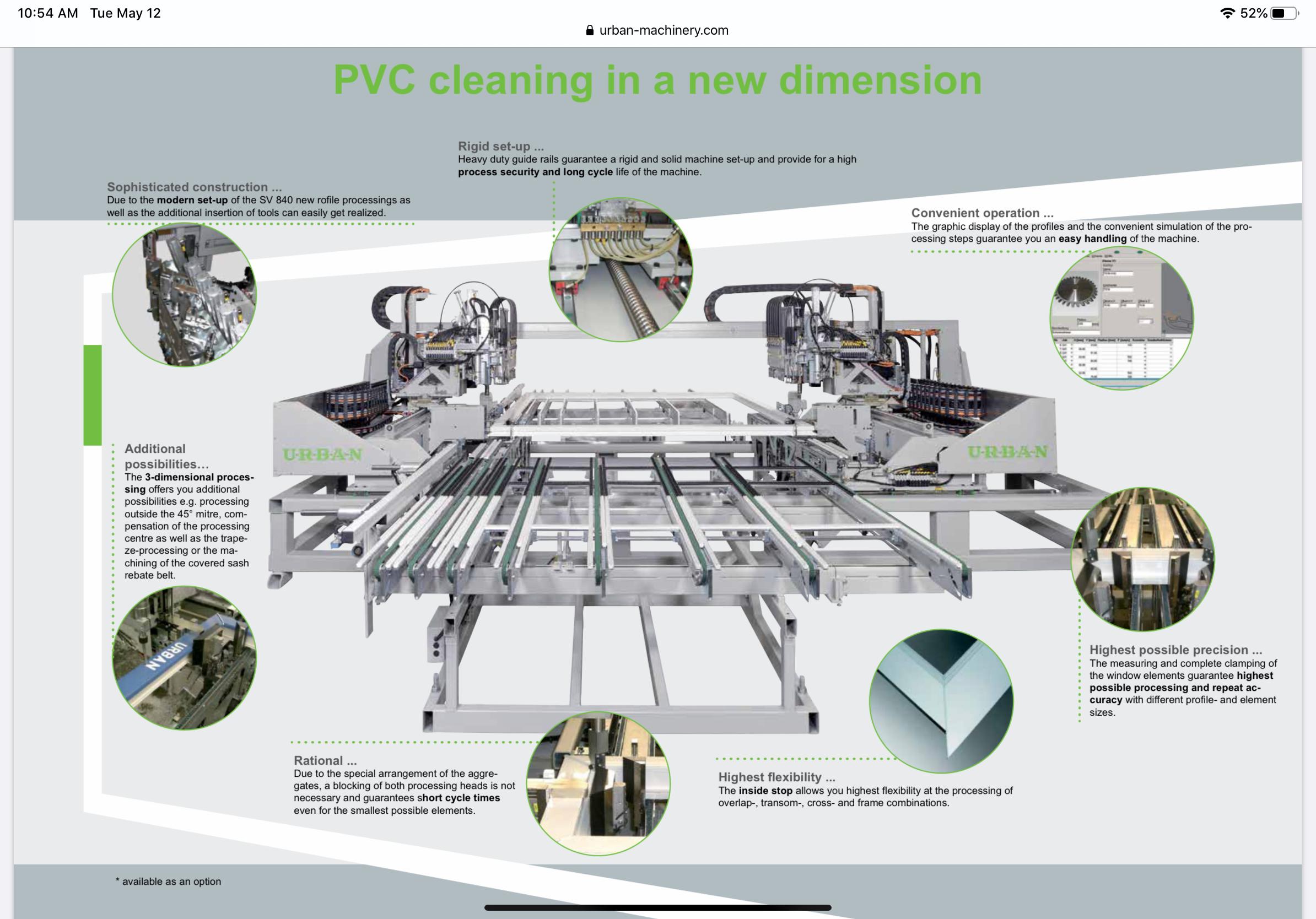

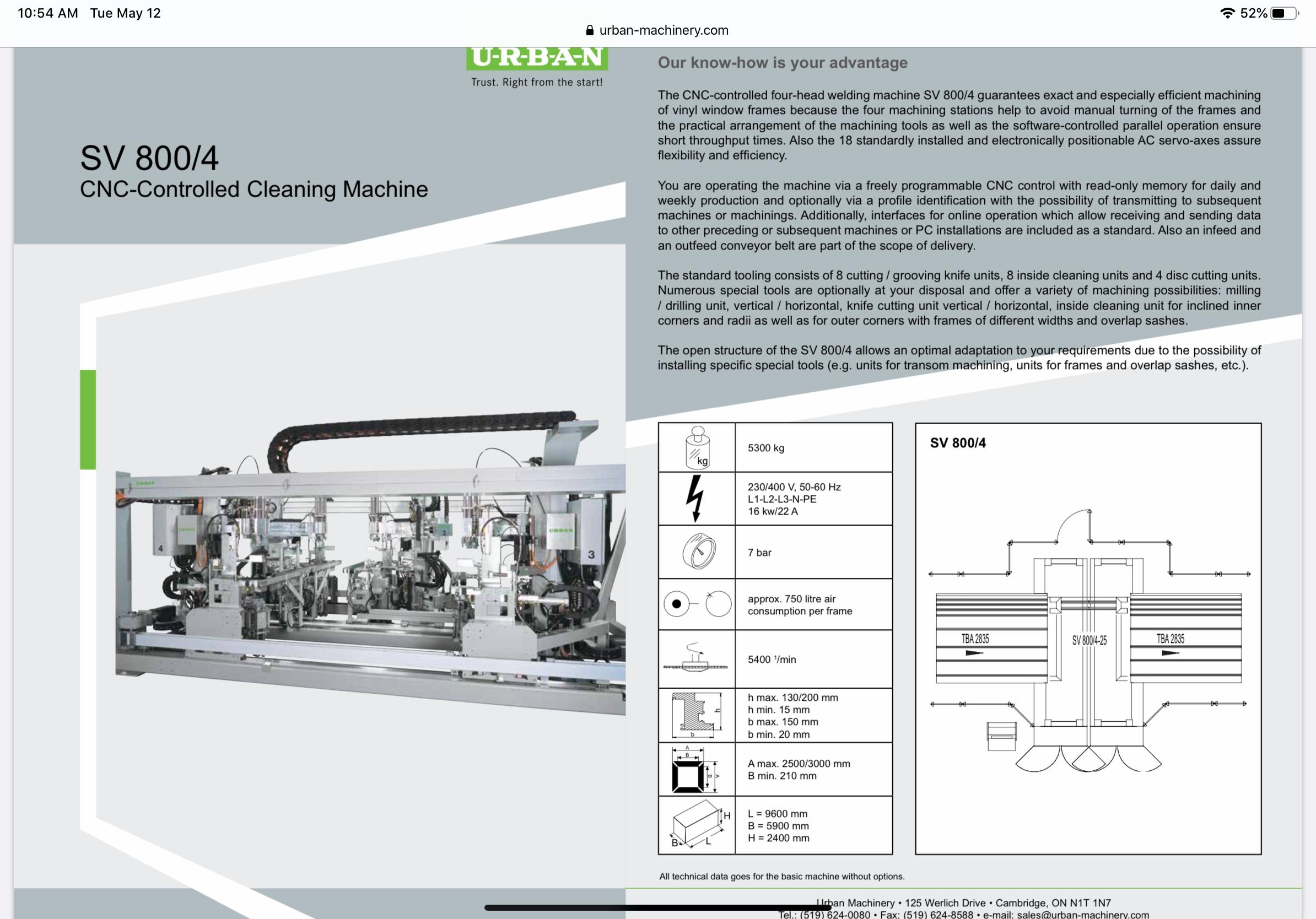

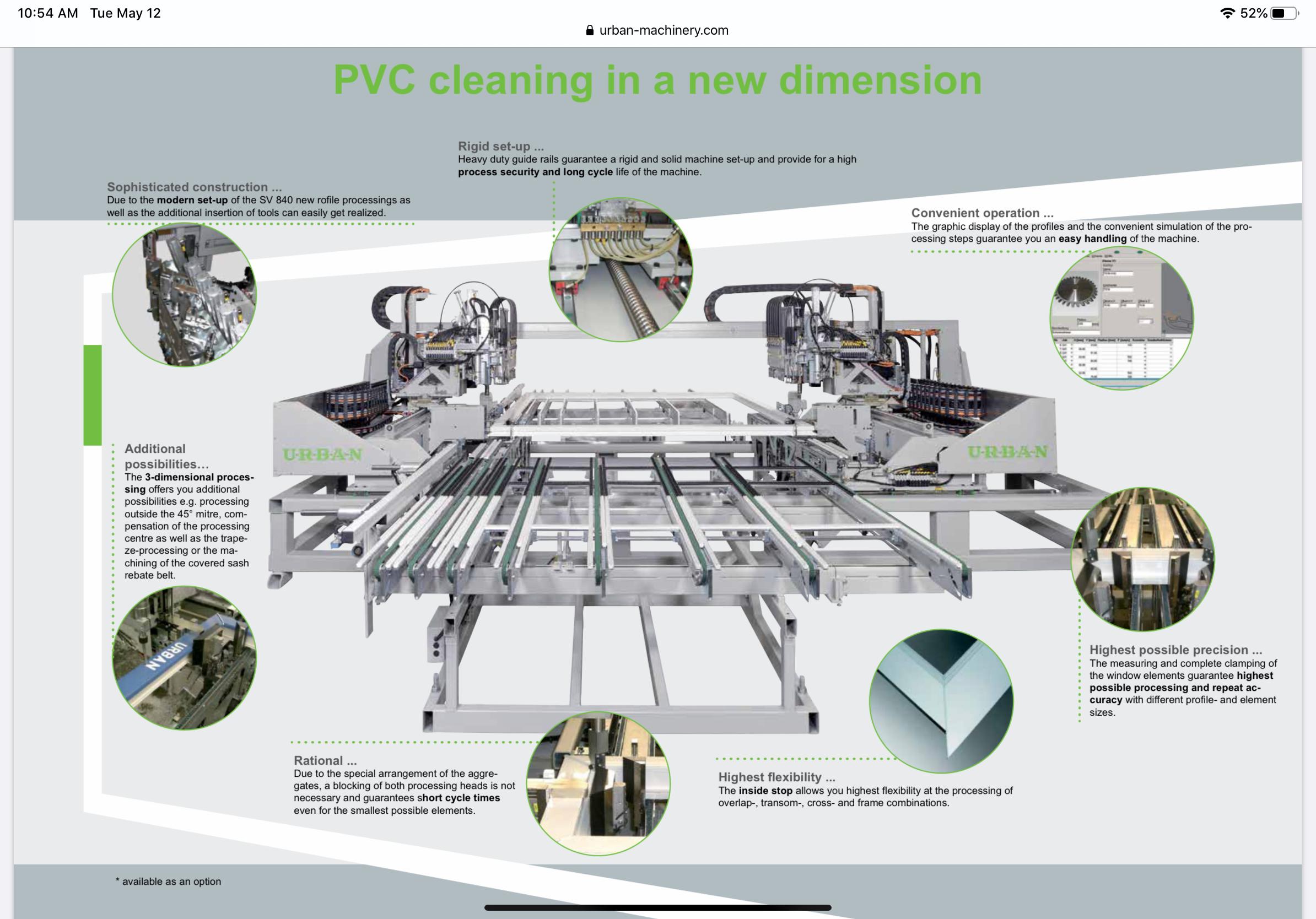

PVC CLEANING IN A NEW DIMENSION

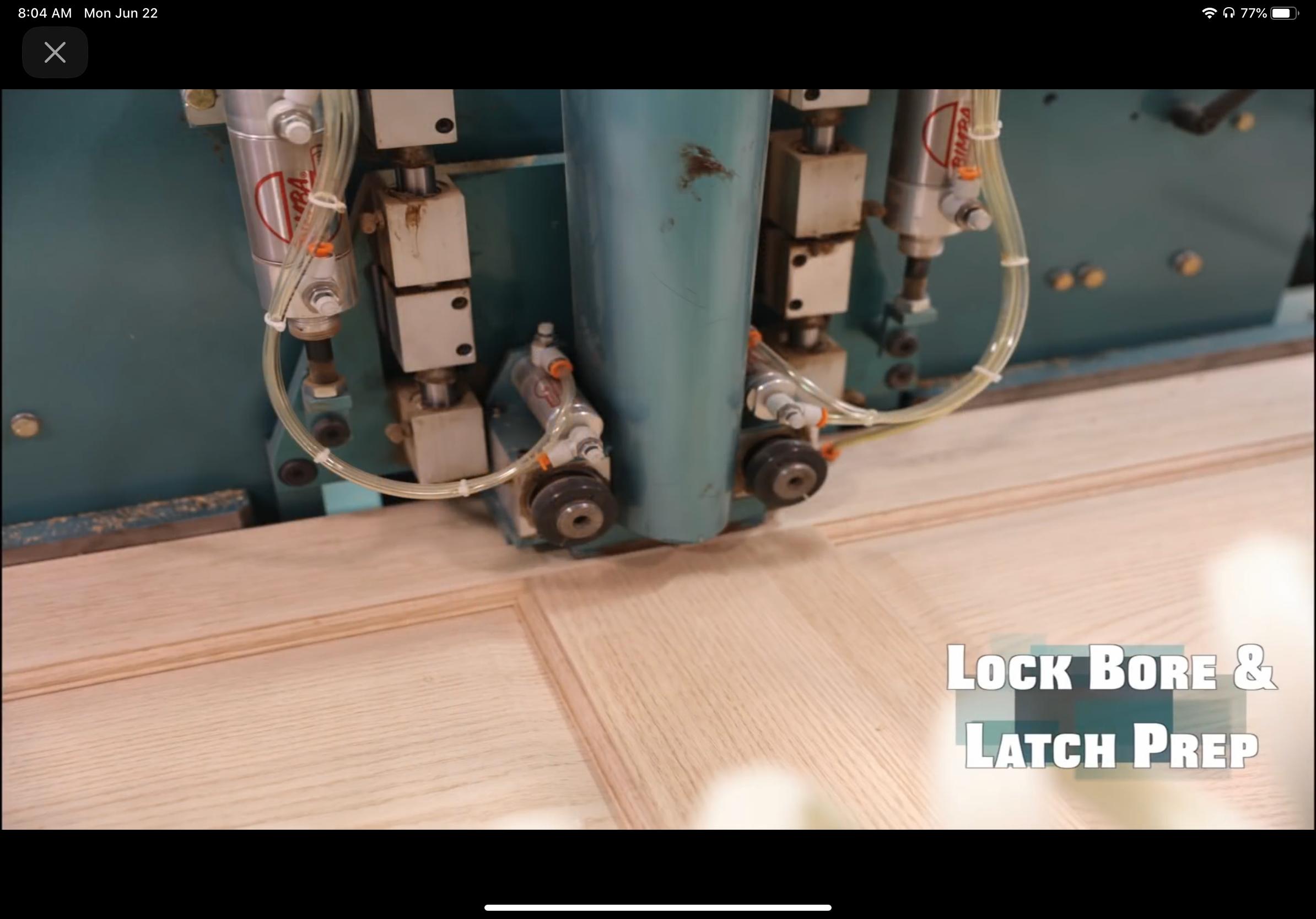

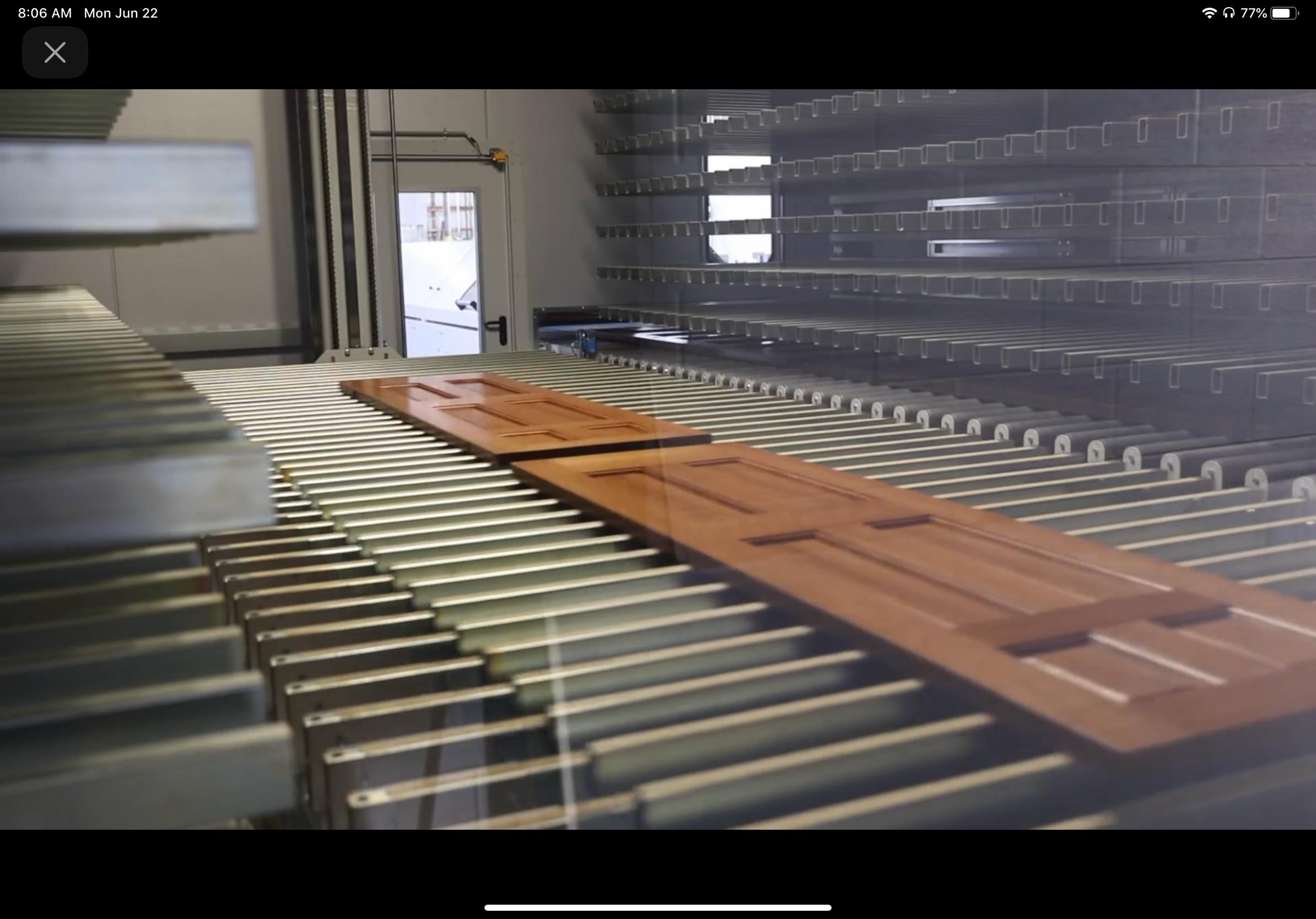

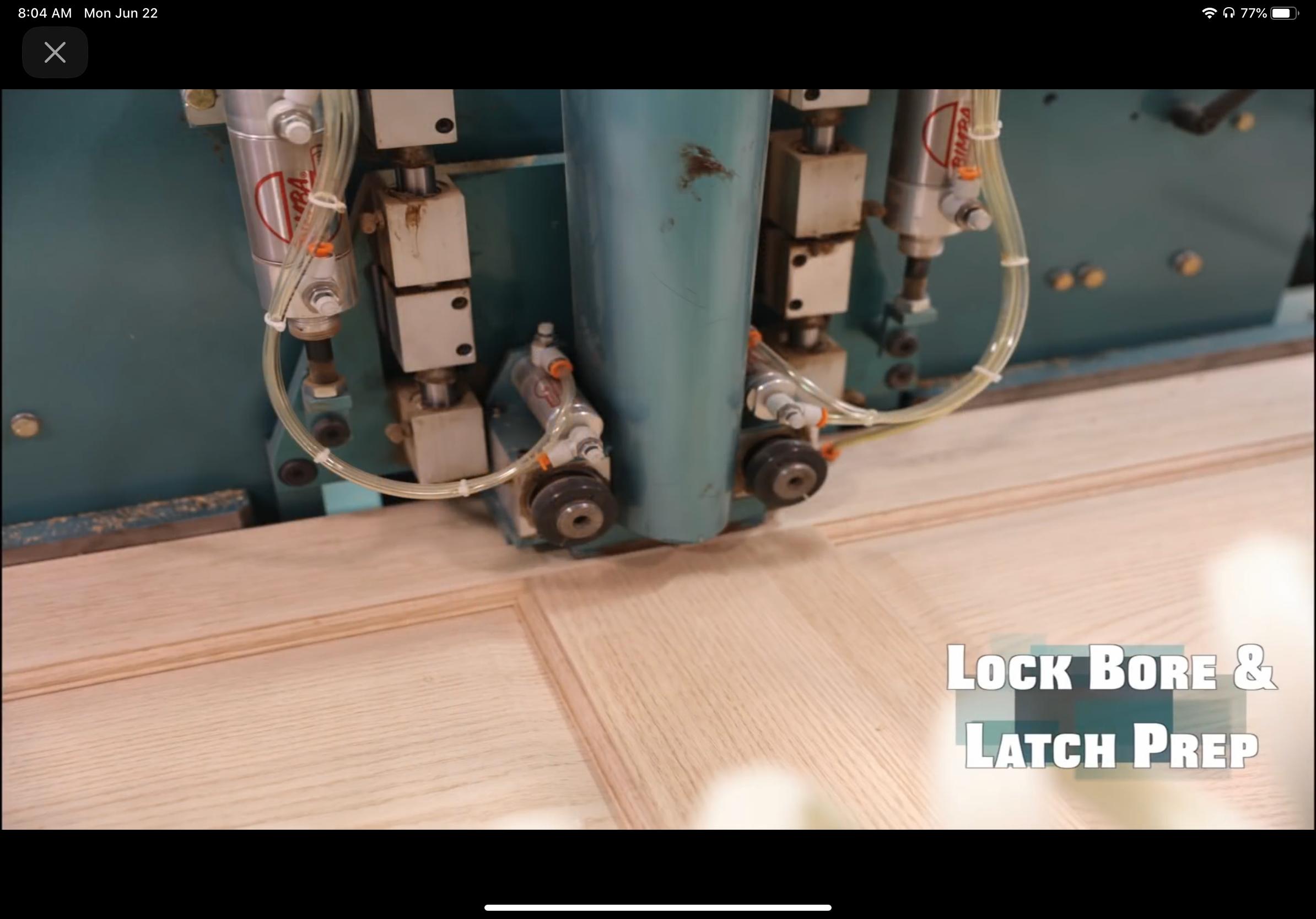

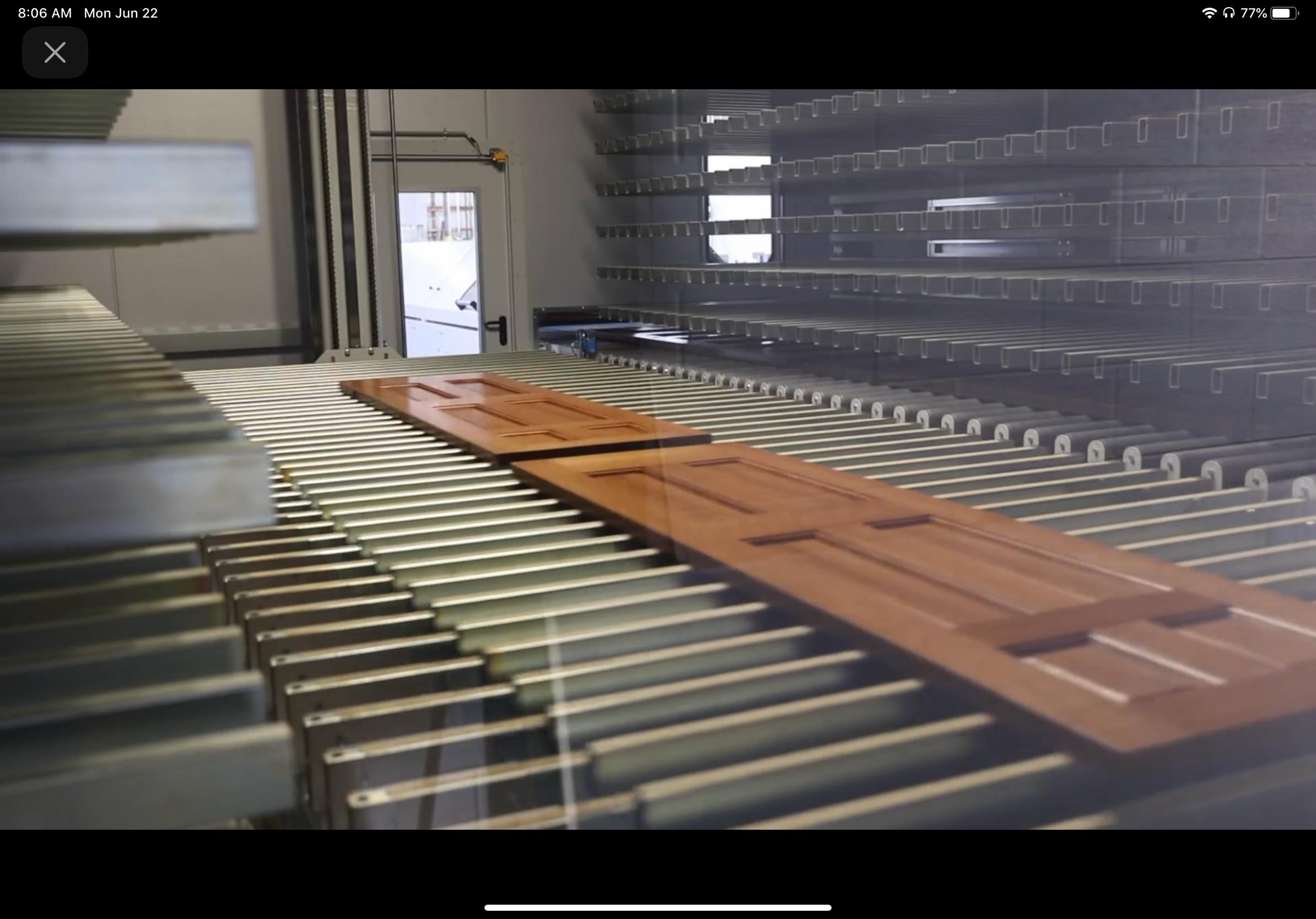

DOOR MANUFACTURING

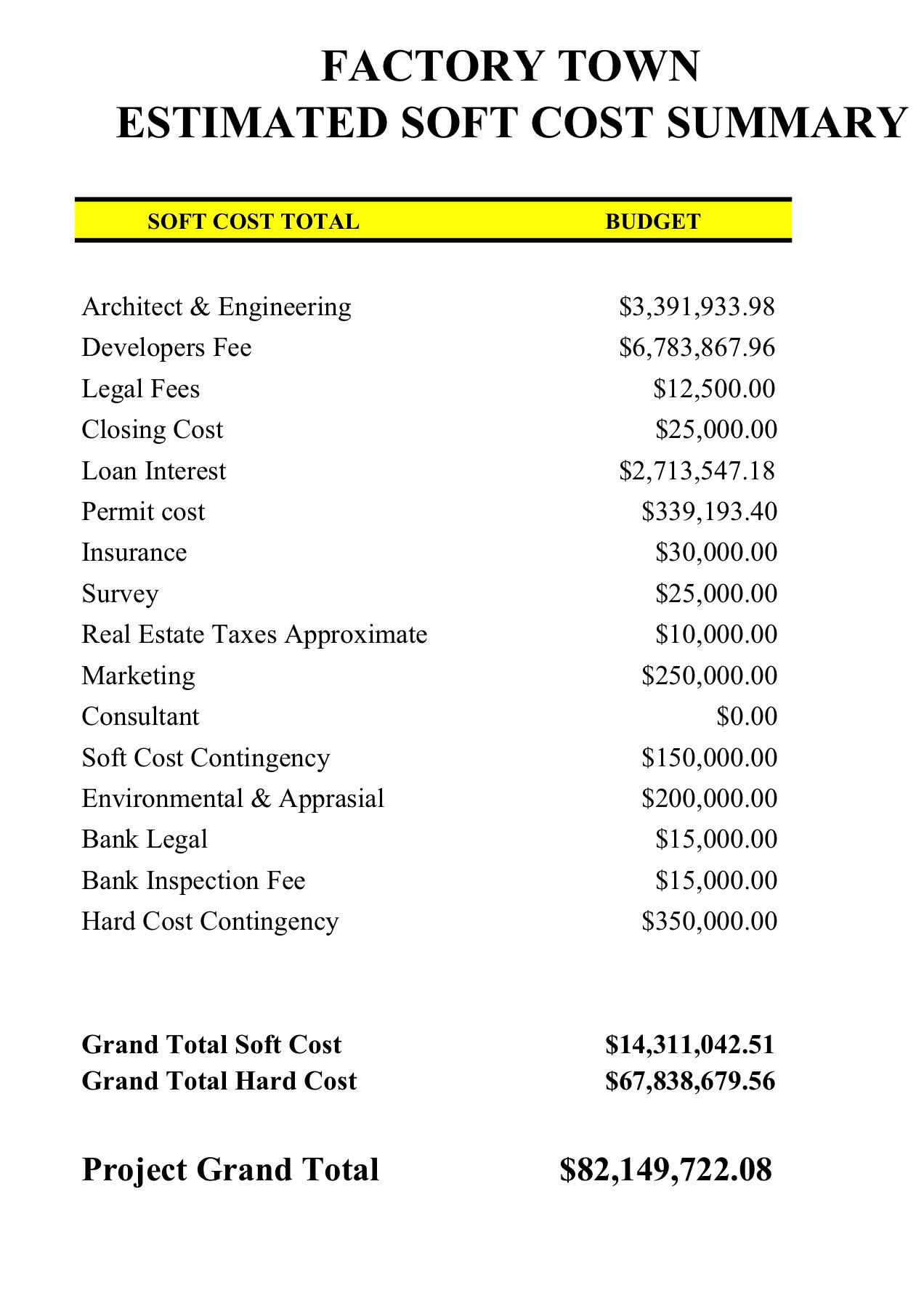

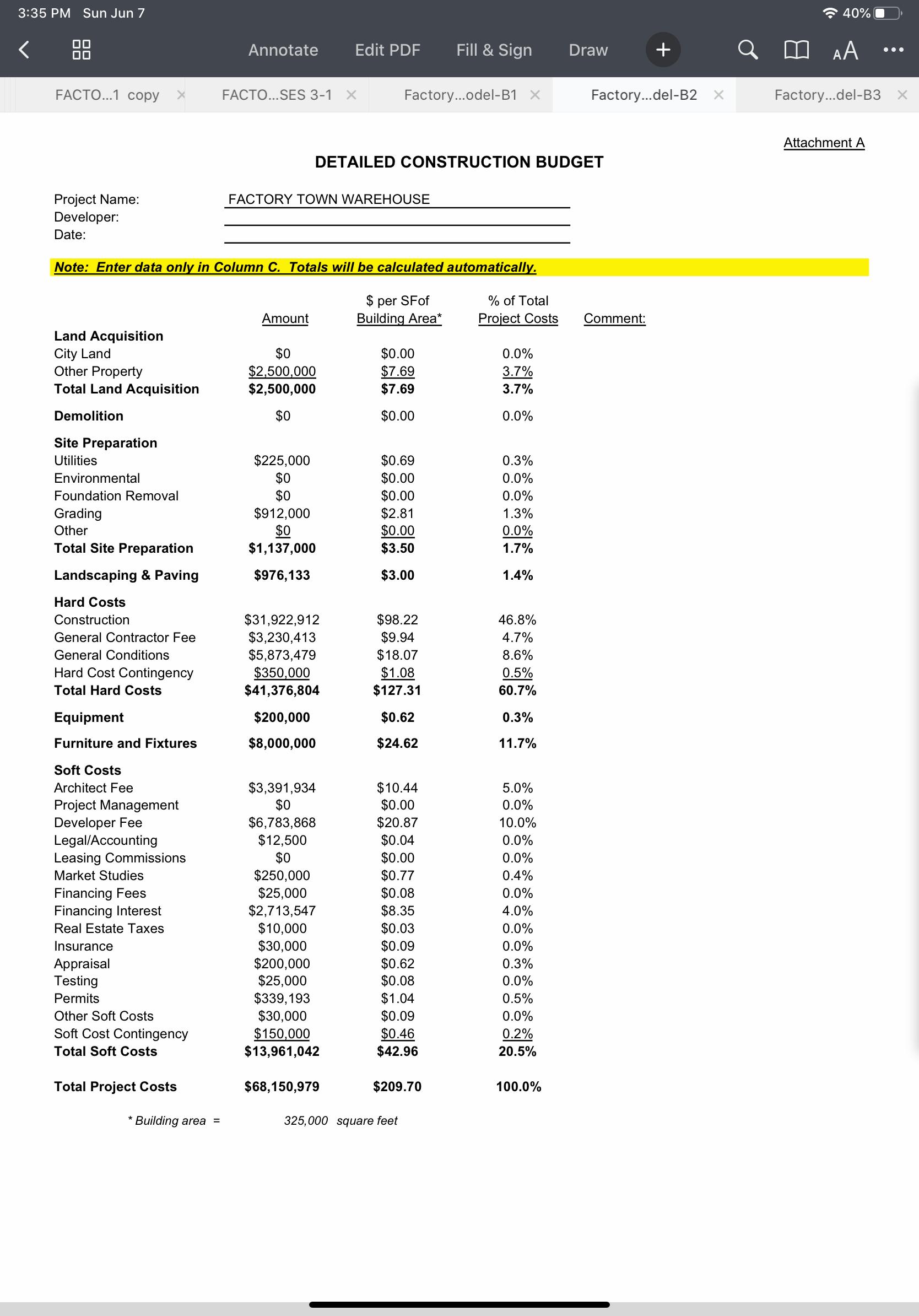

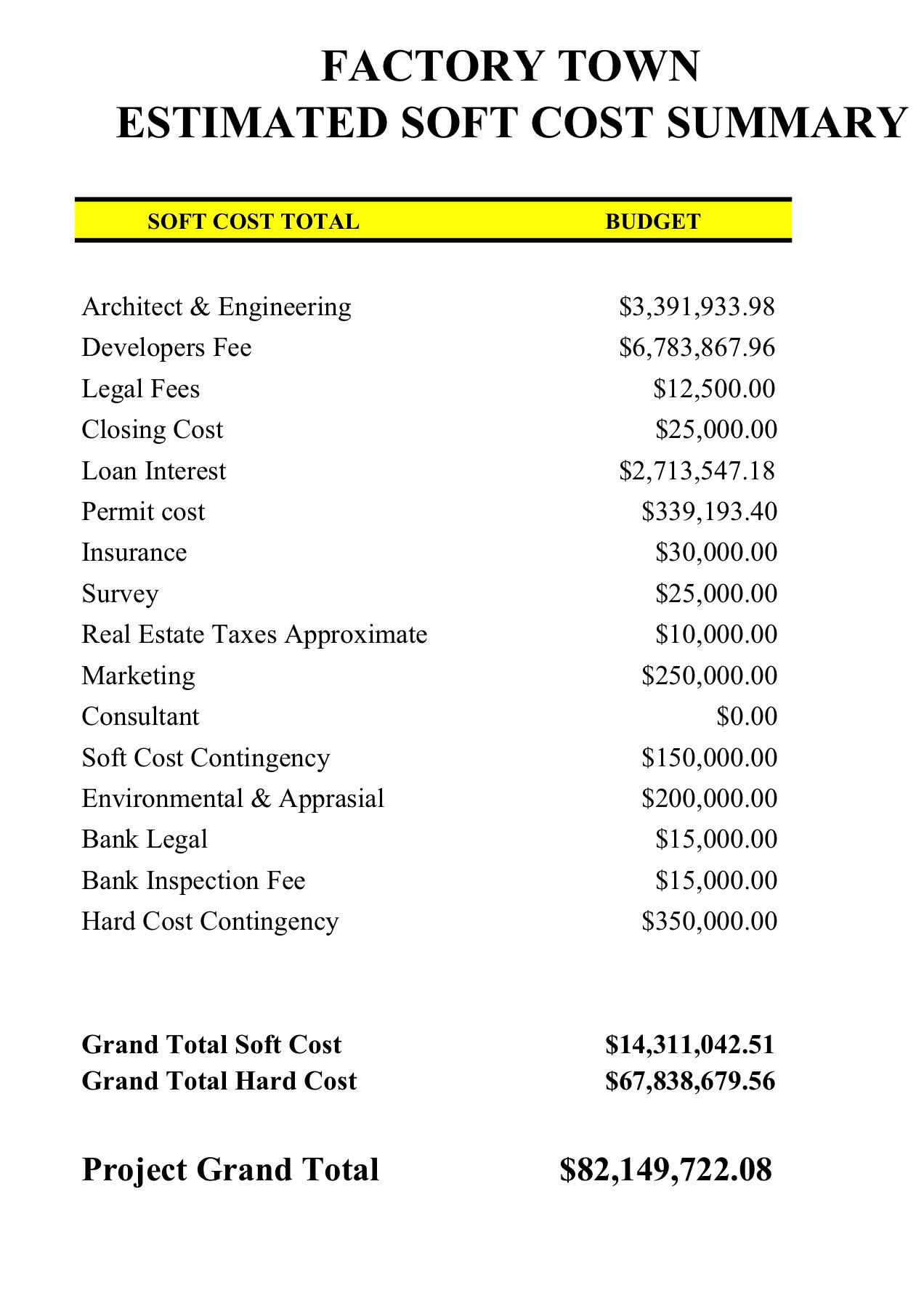

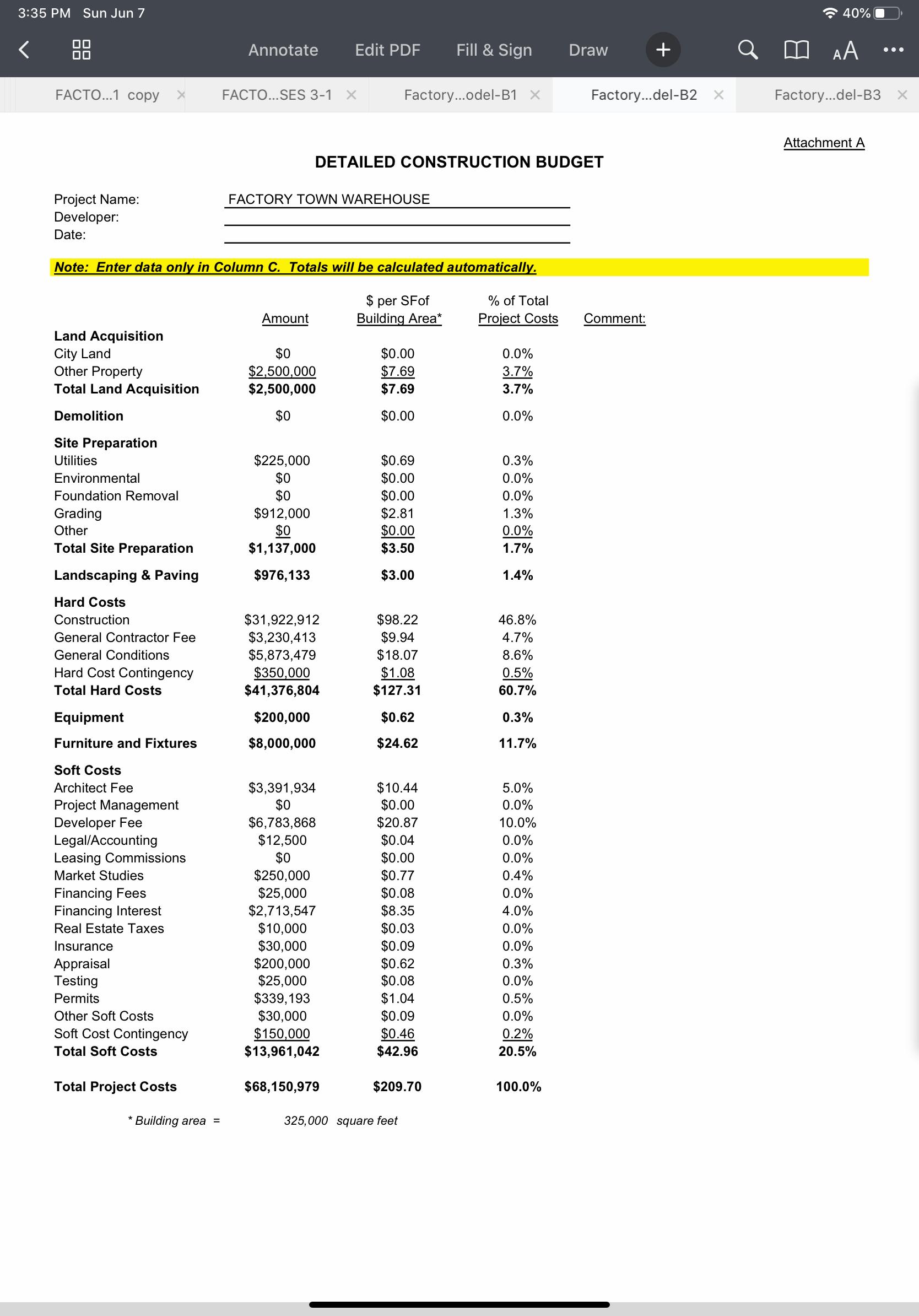

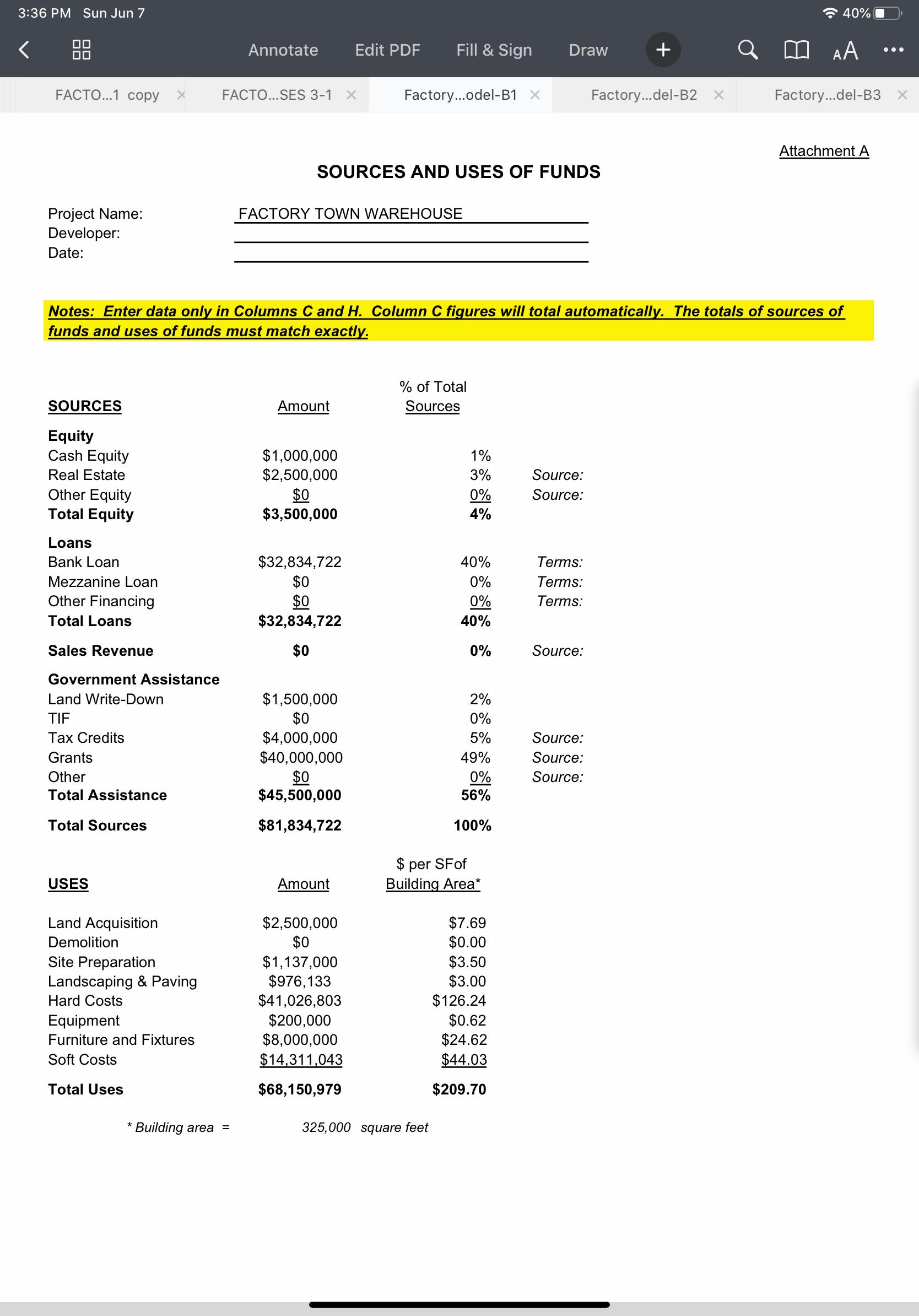

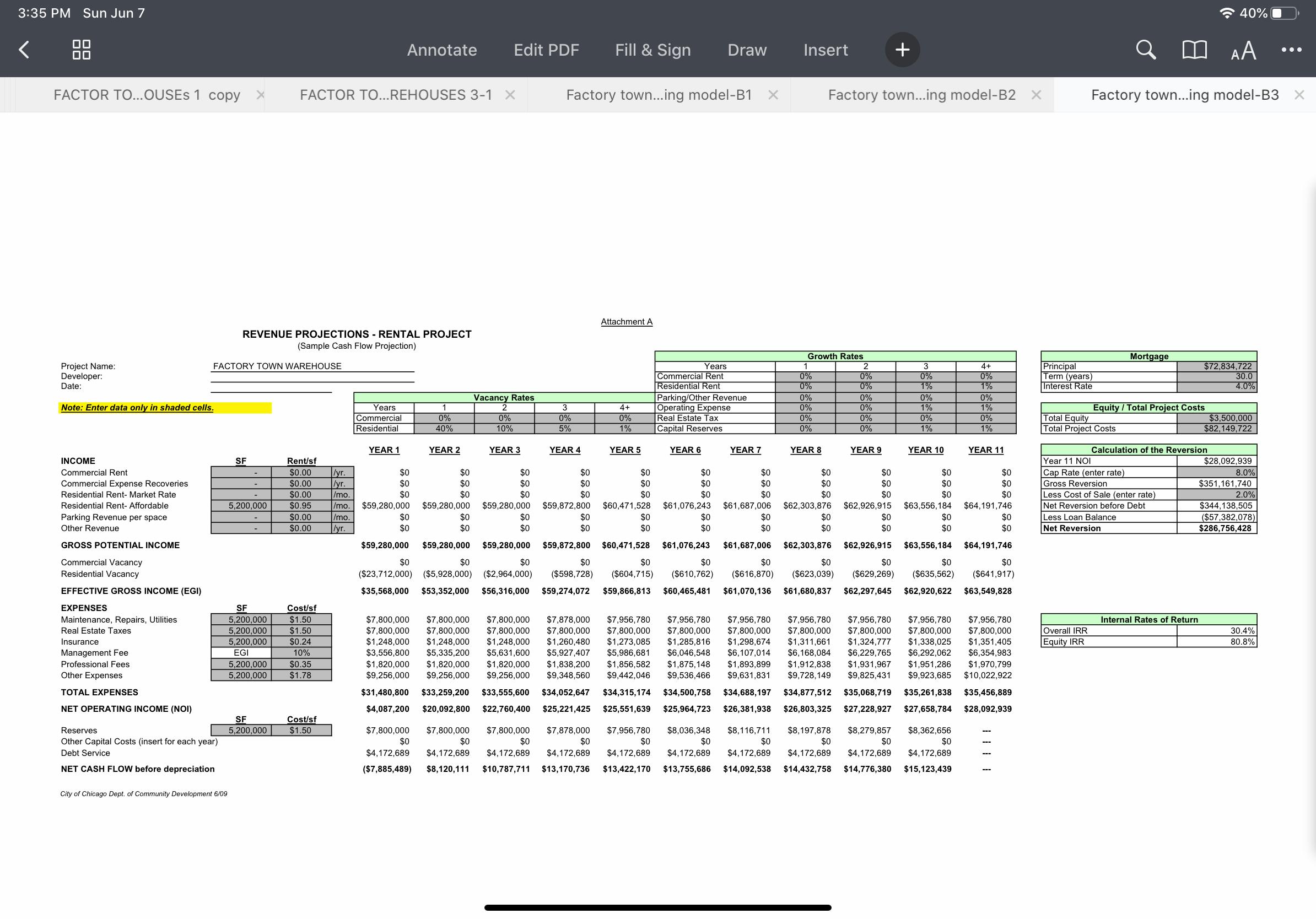

FACTORY TOWN WAREHOUSE CONSTRUCTION COST STRUCTURE

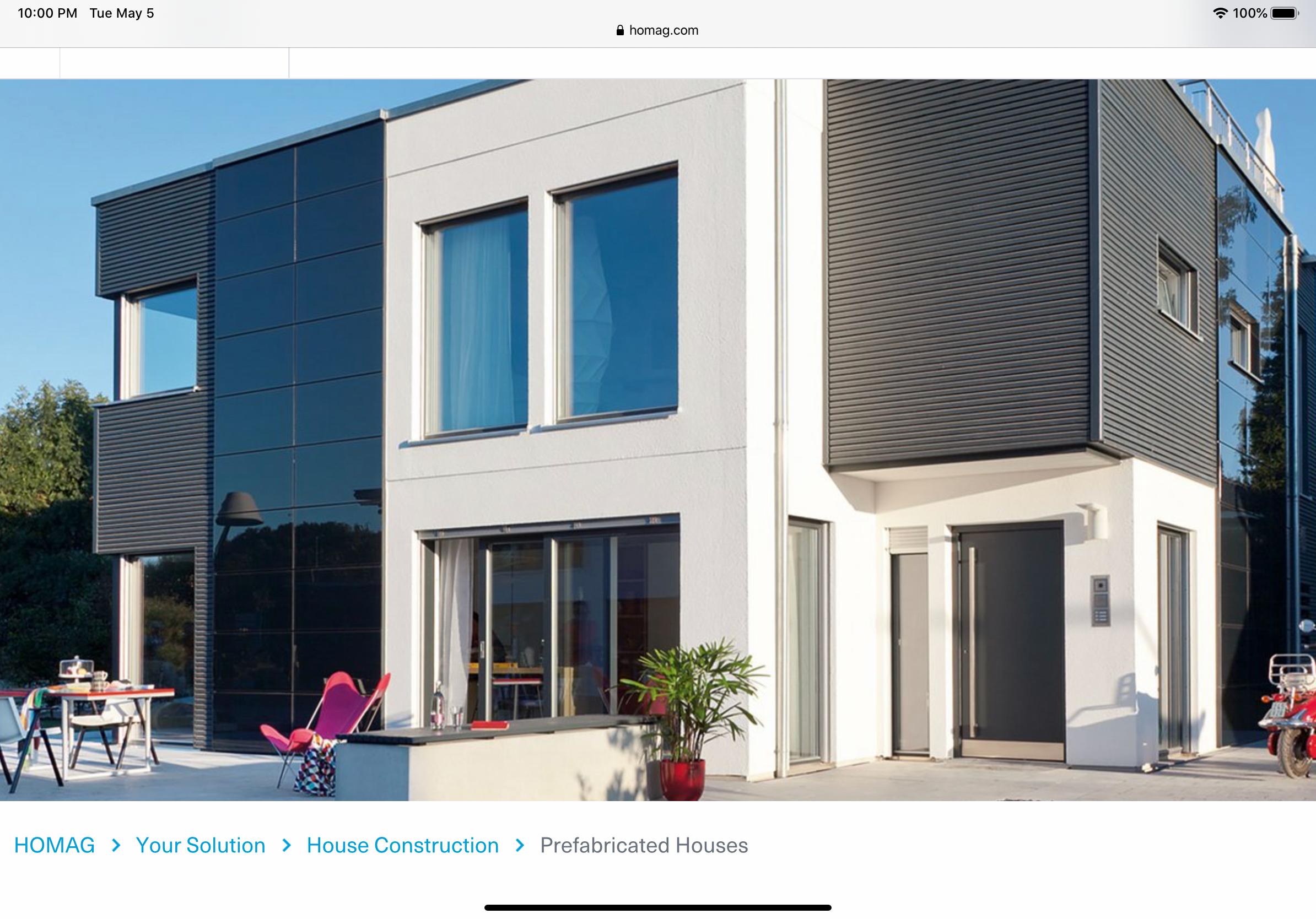

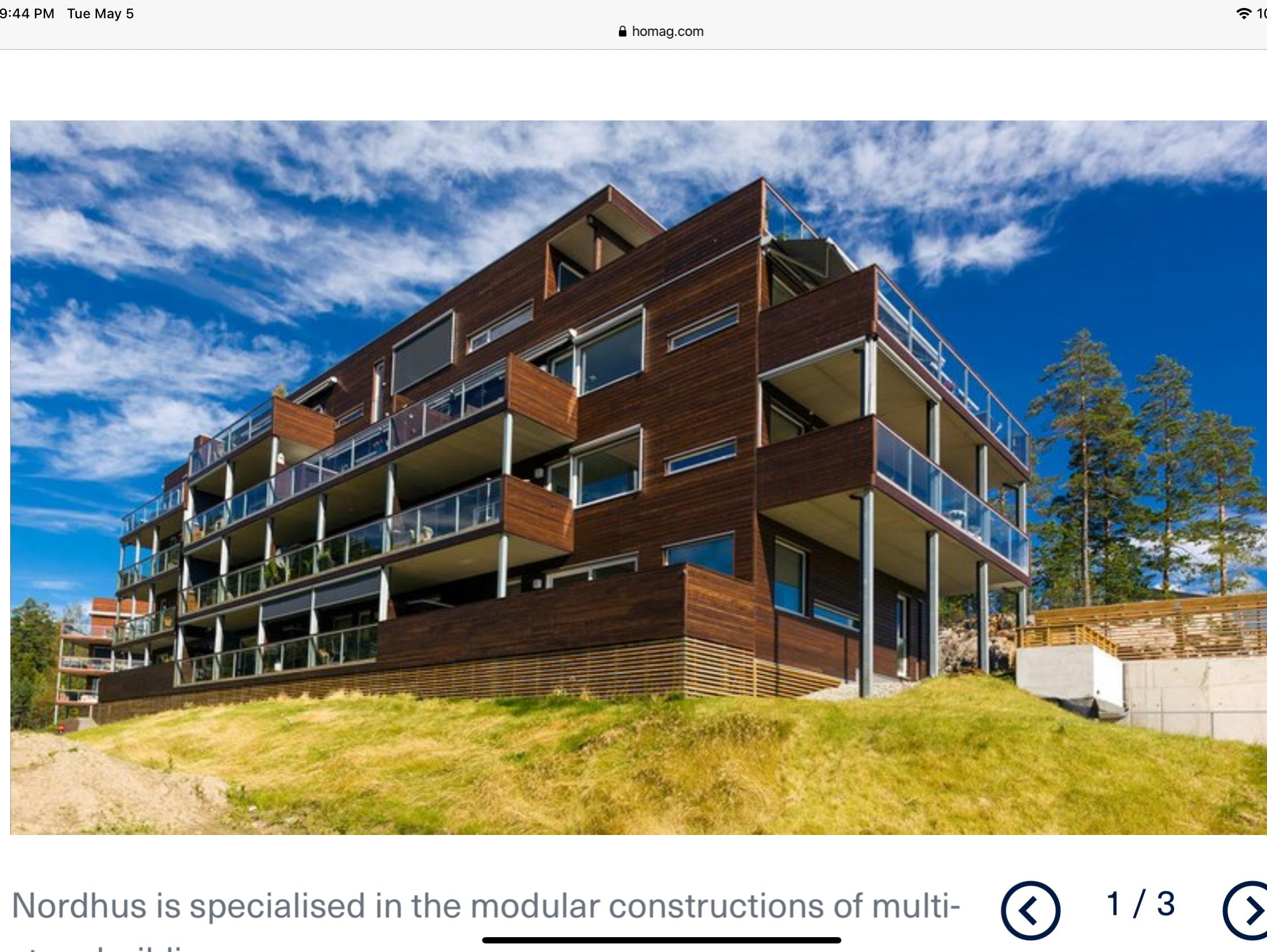

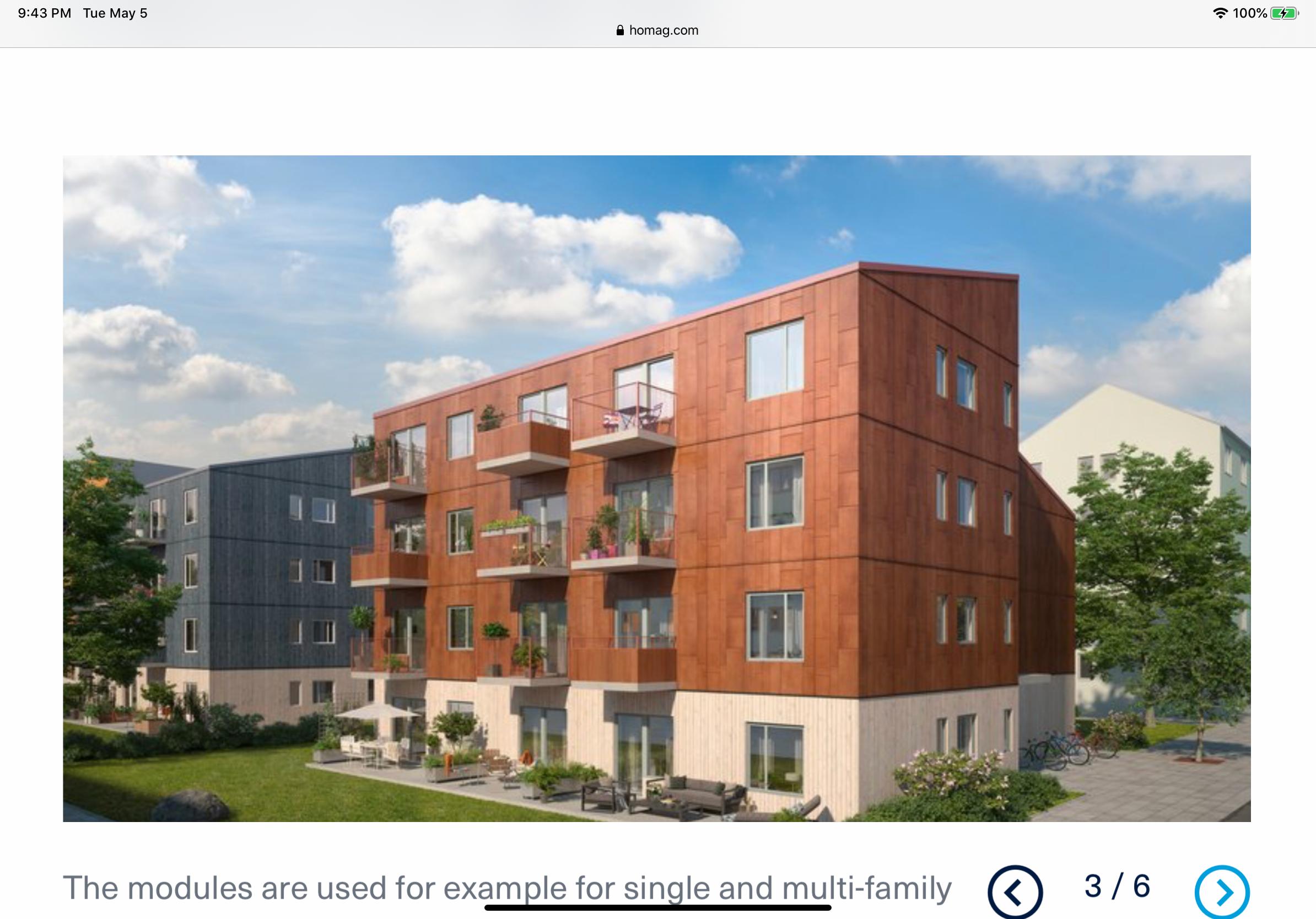

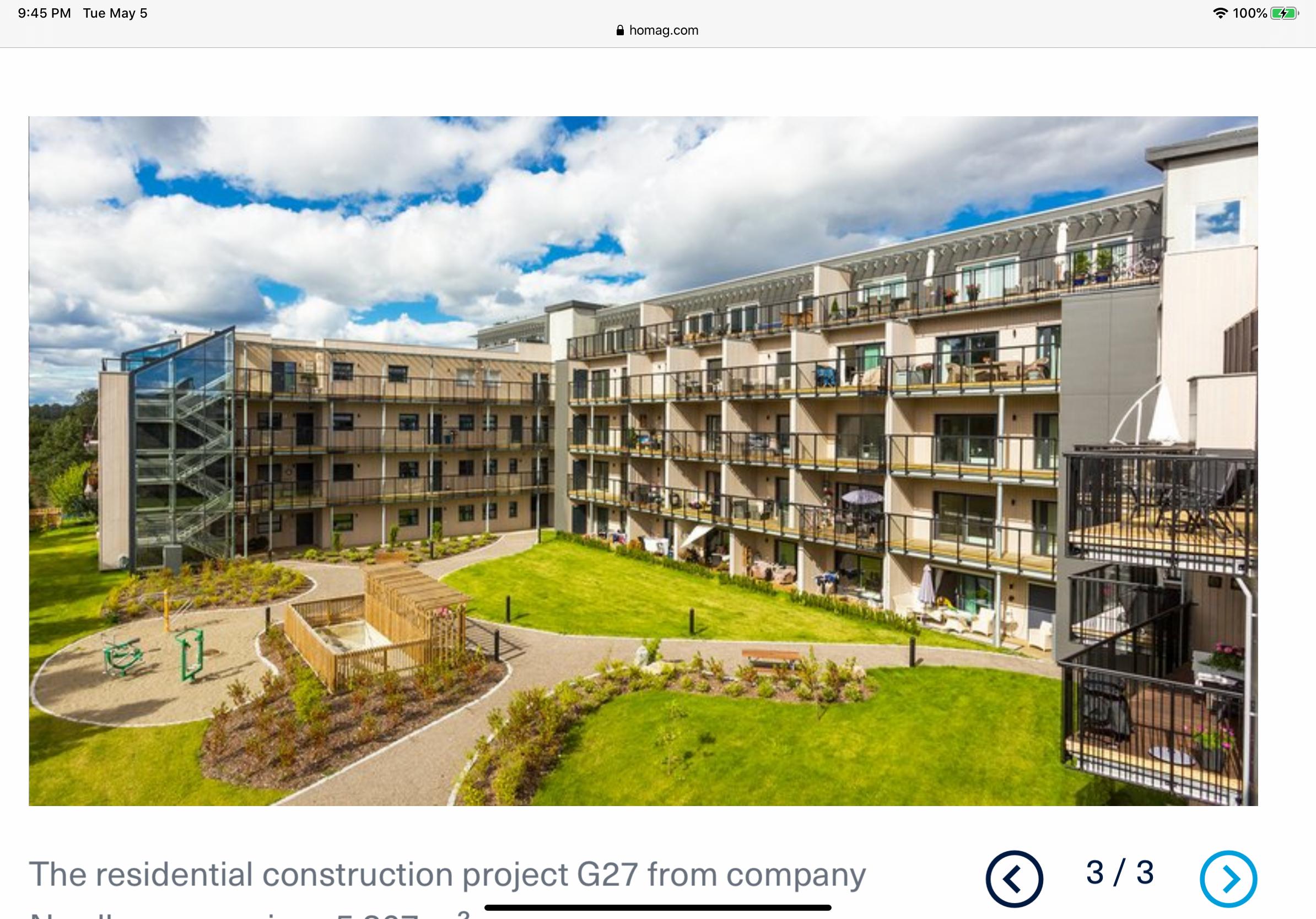

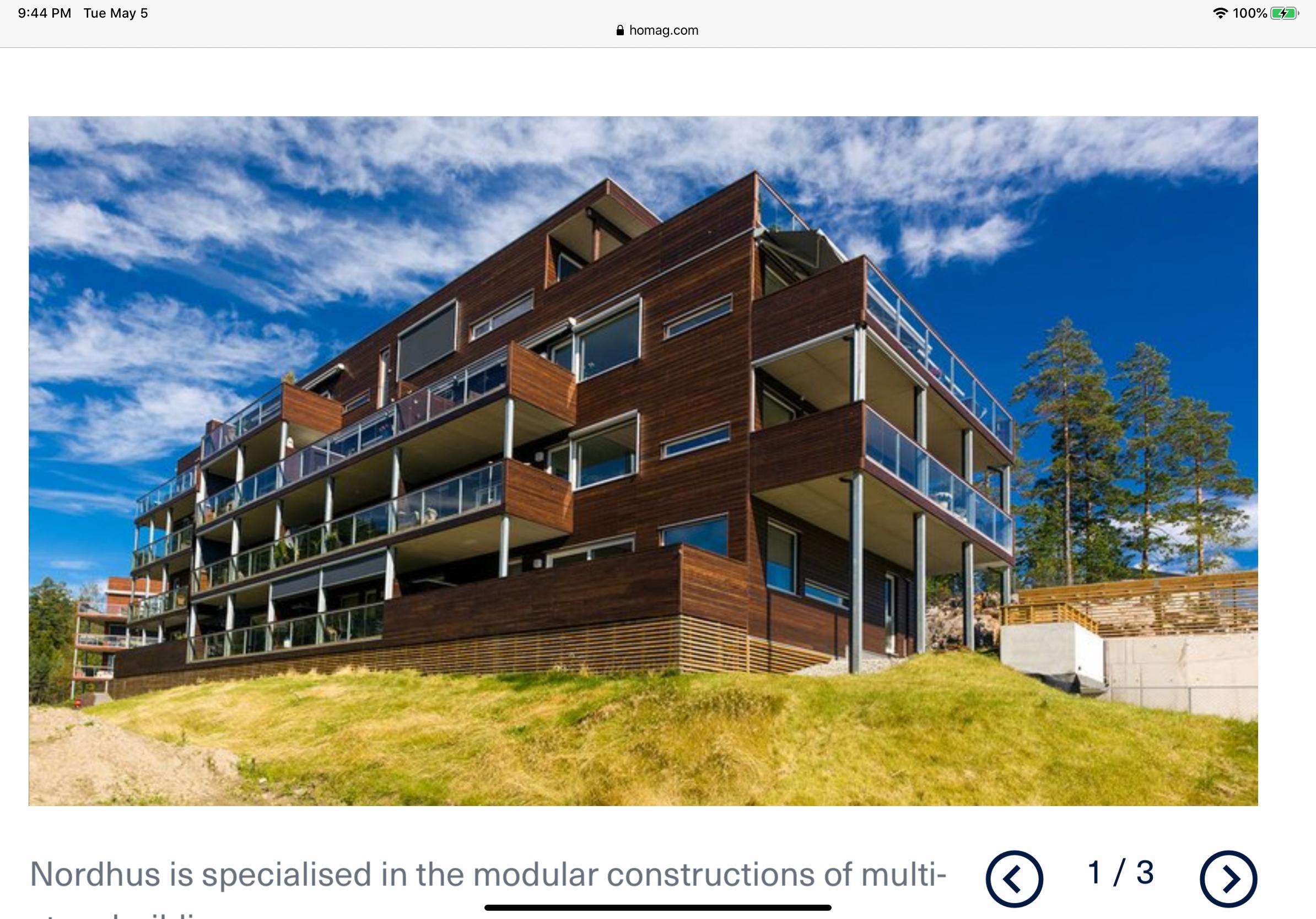

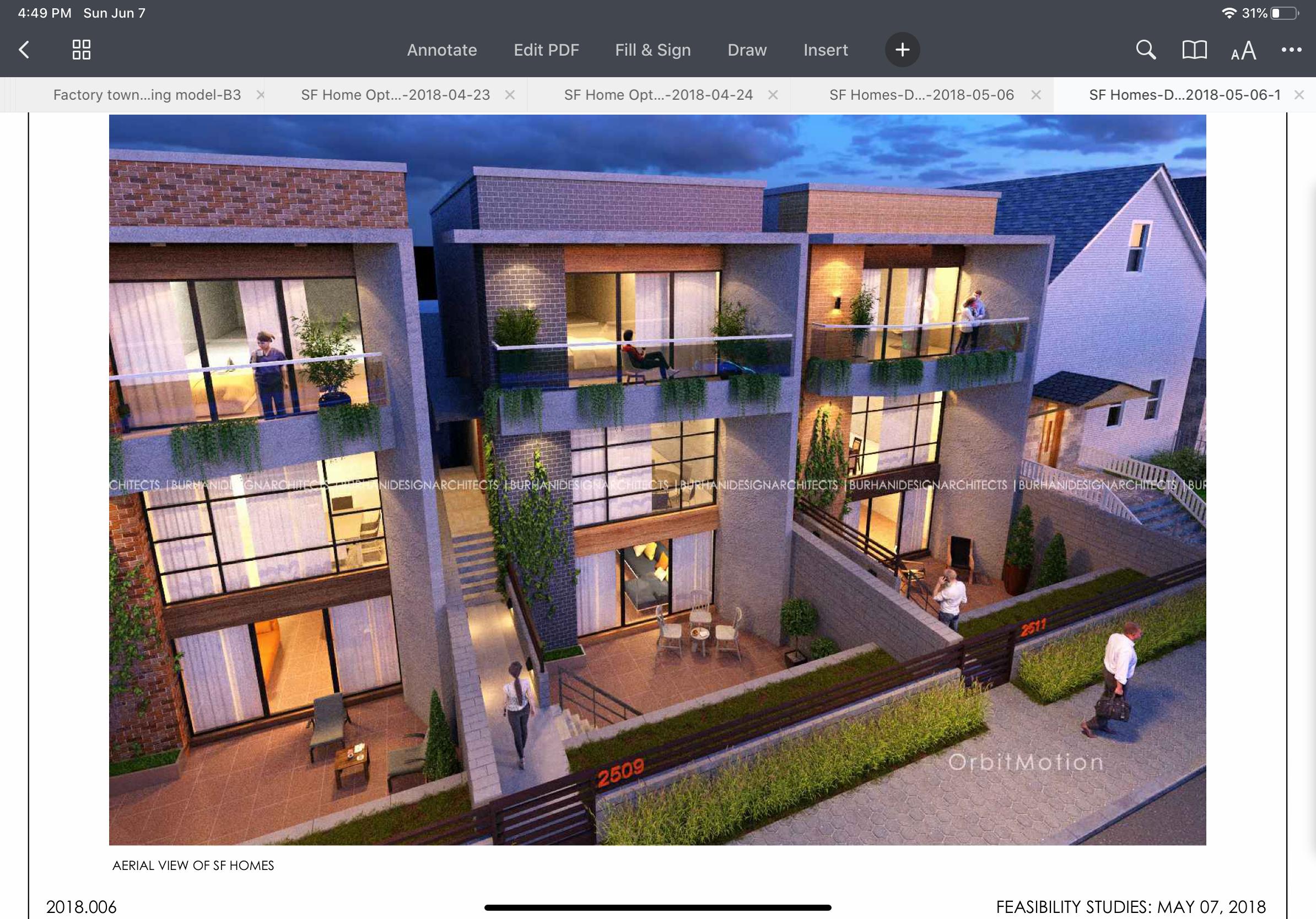

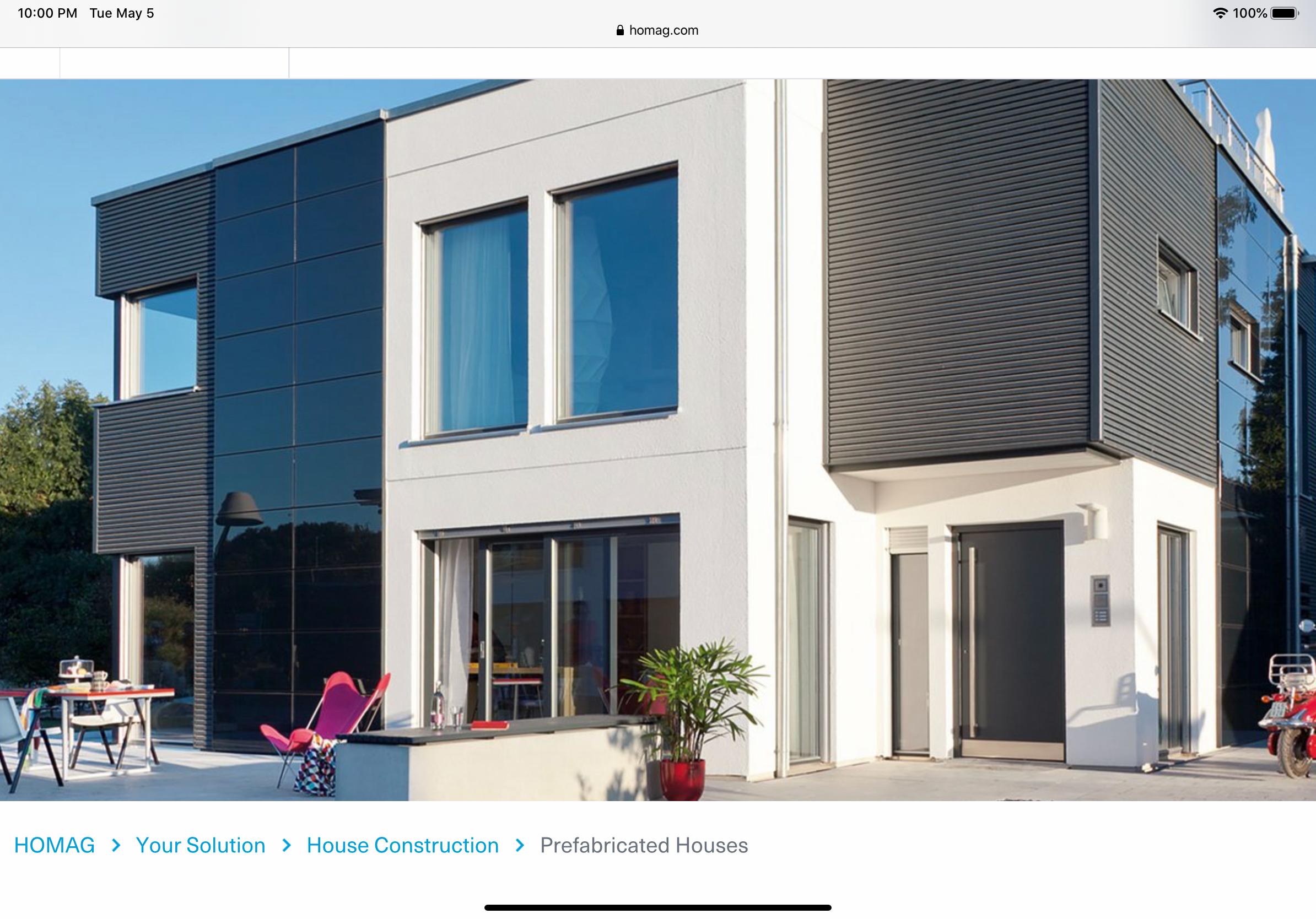

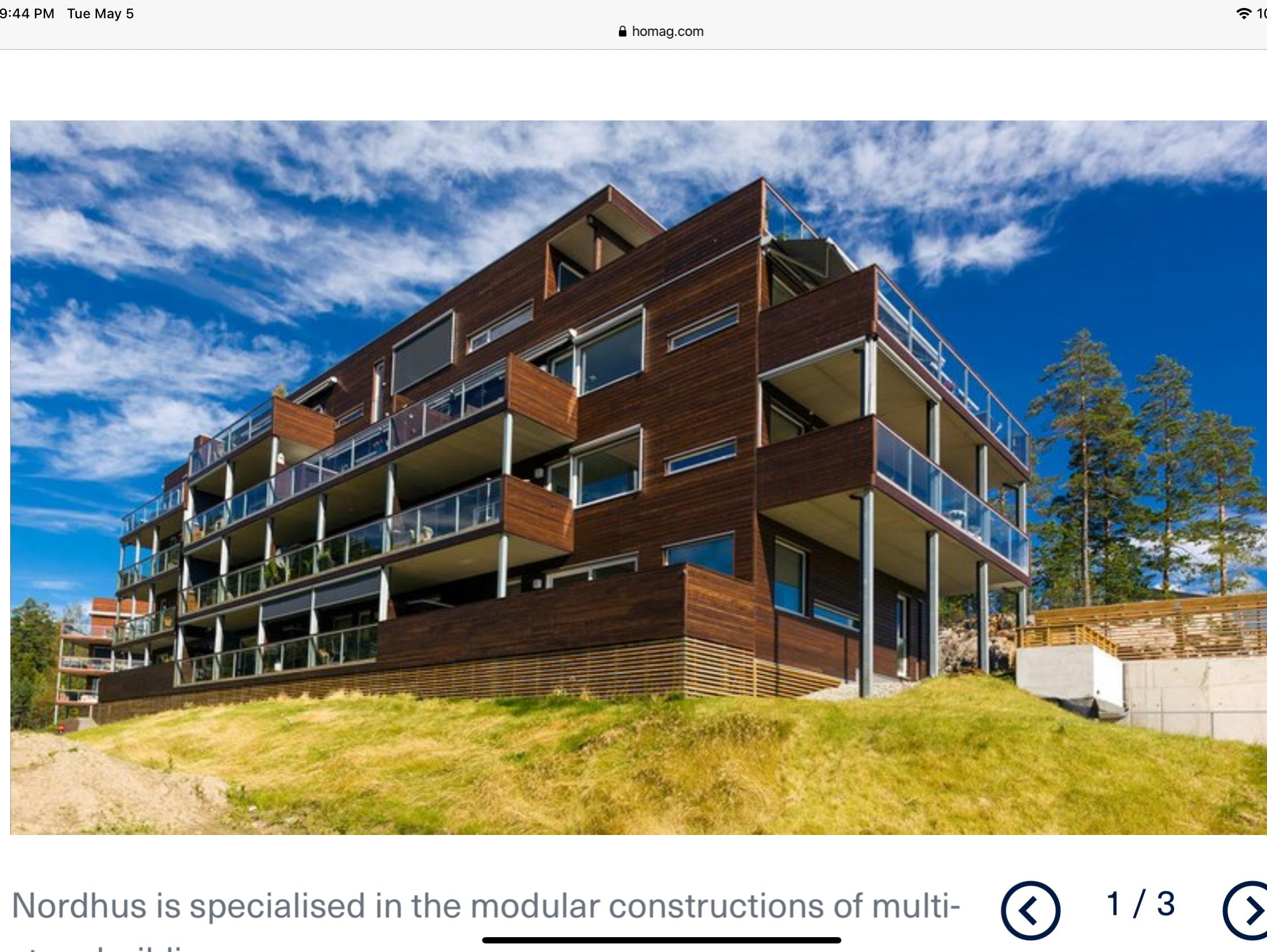

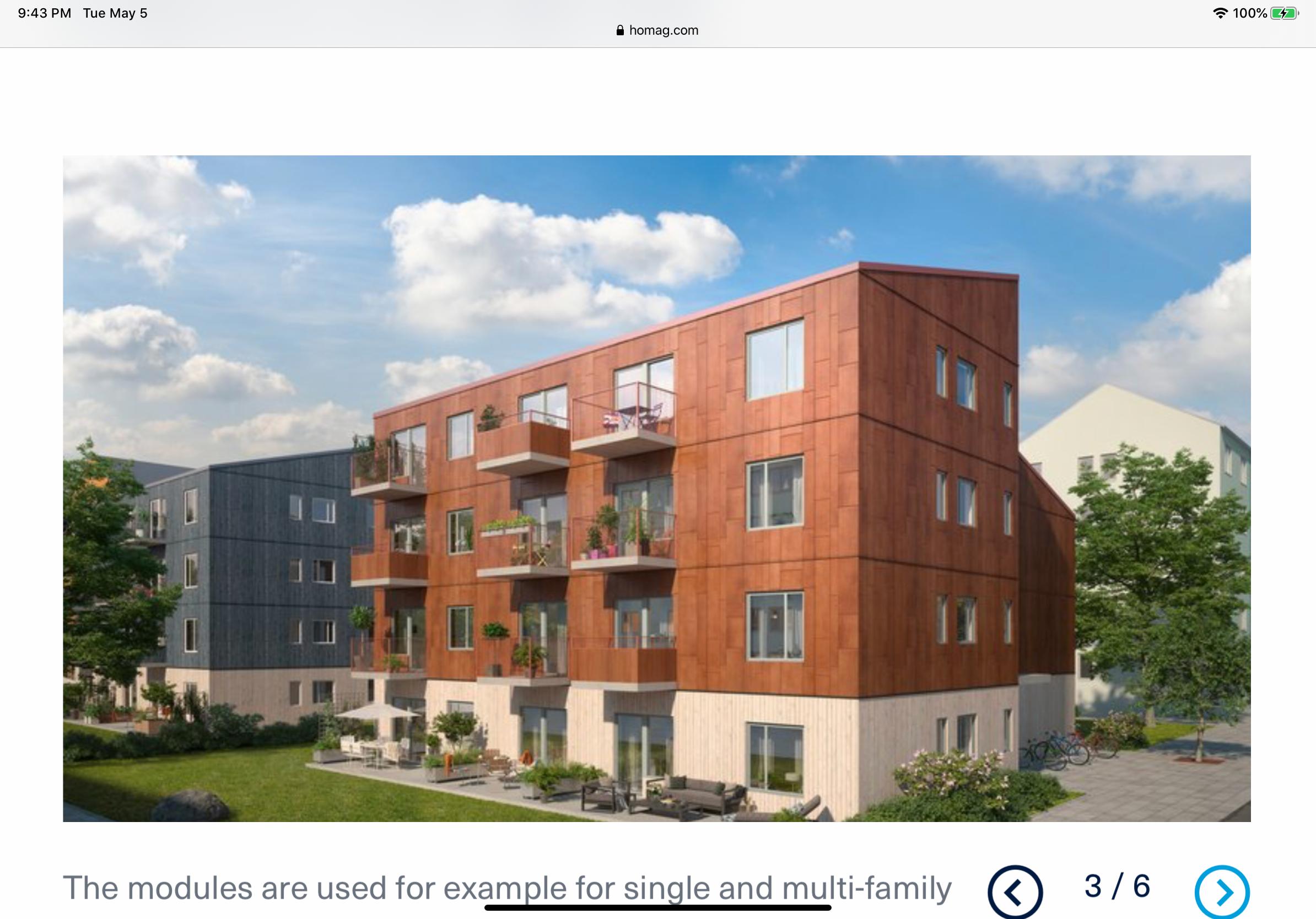

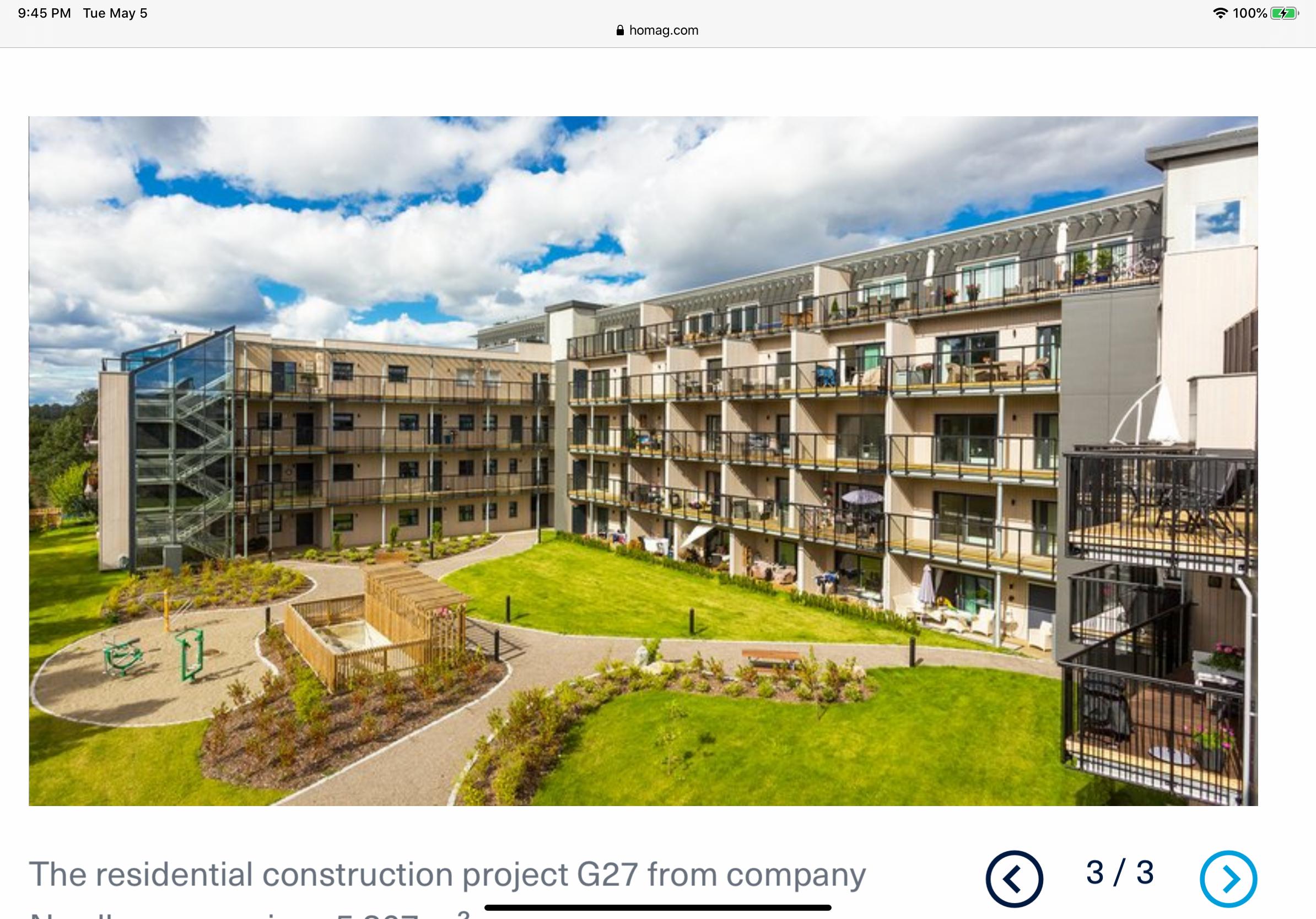

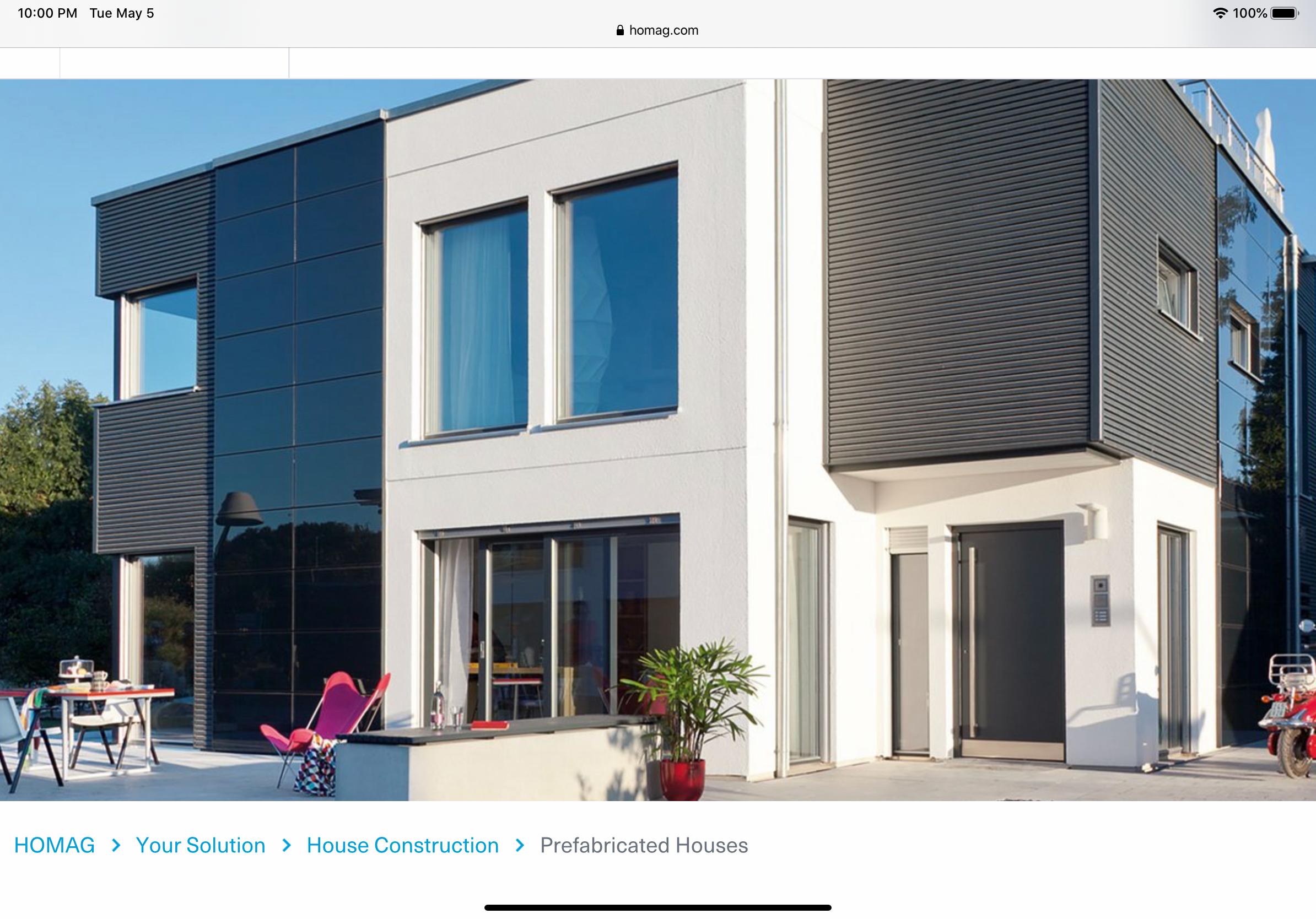

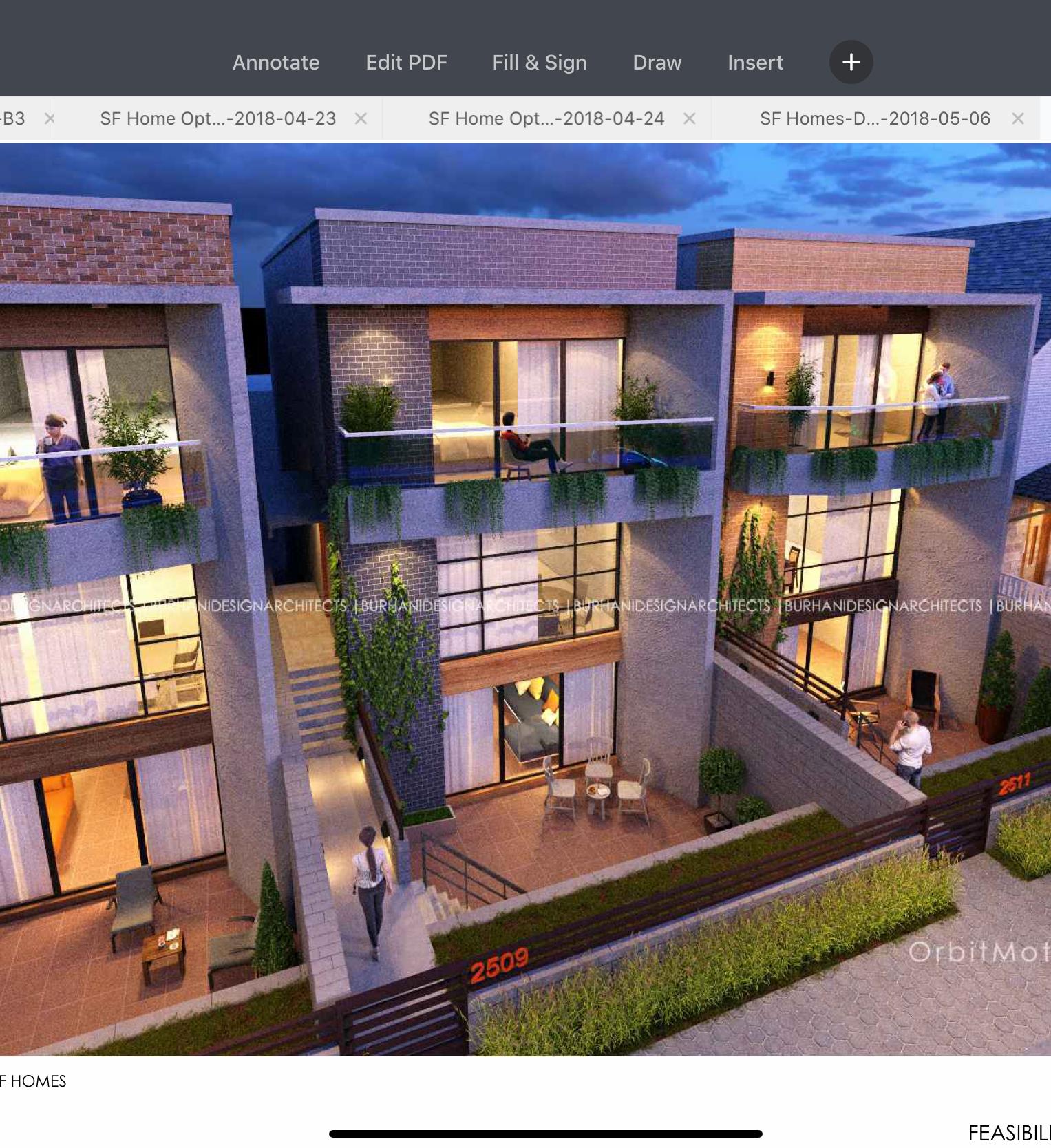

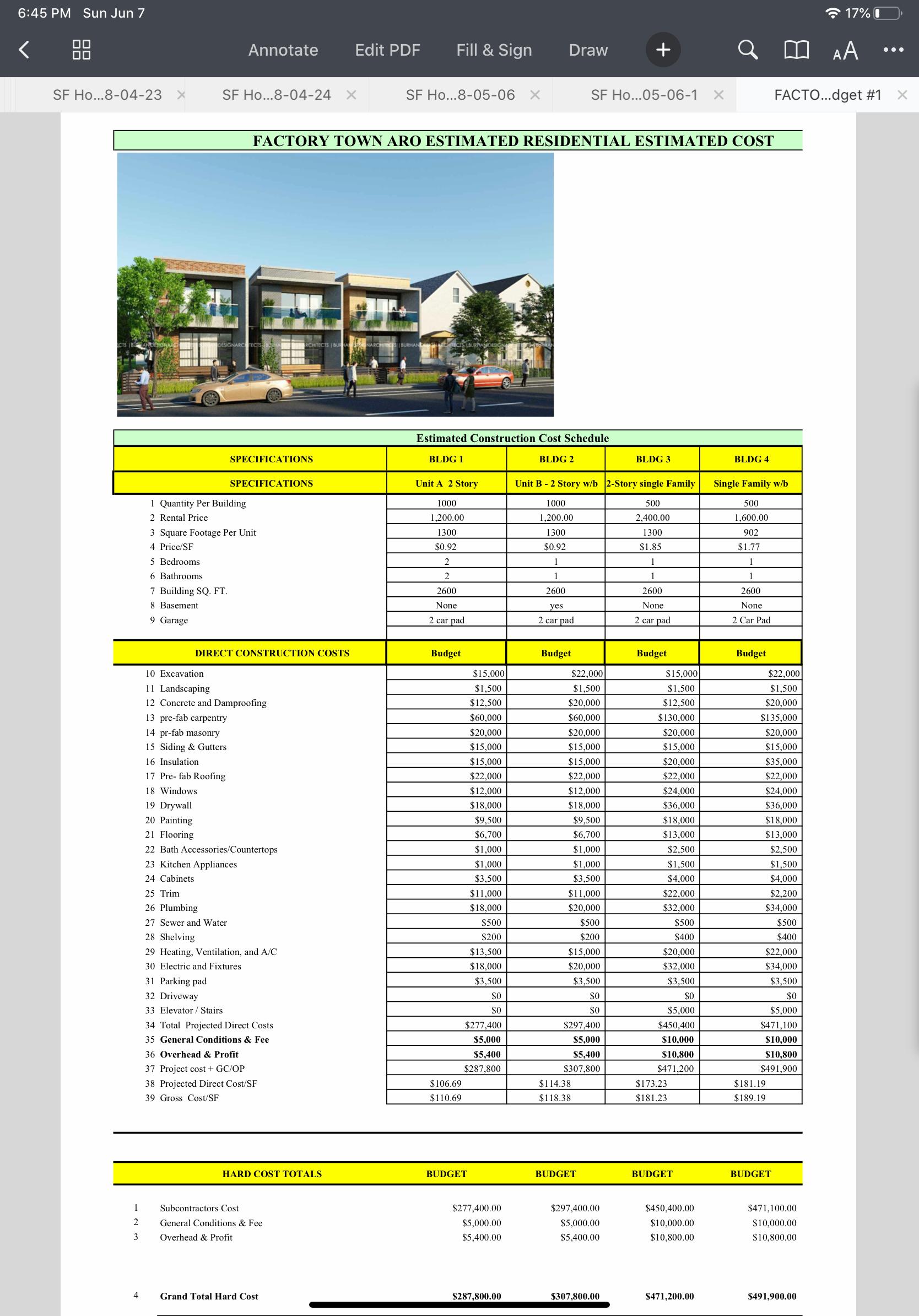

Finished Product Types On Sites

Multi- Unit Building 2-Story Single Family

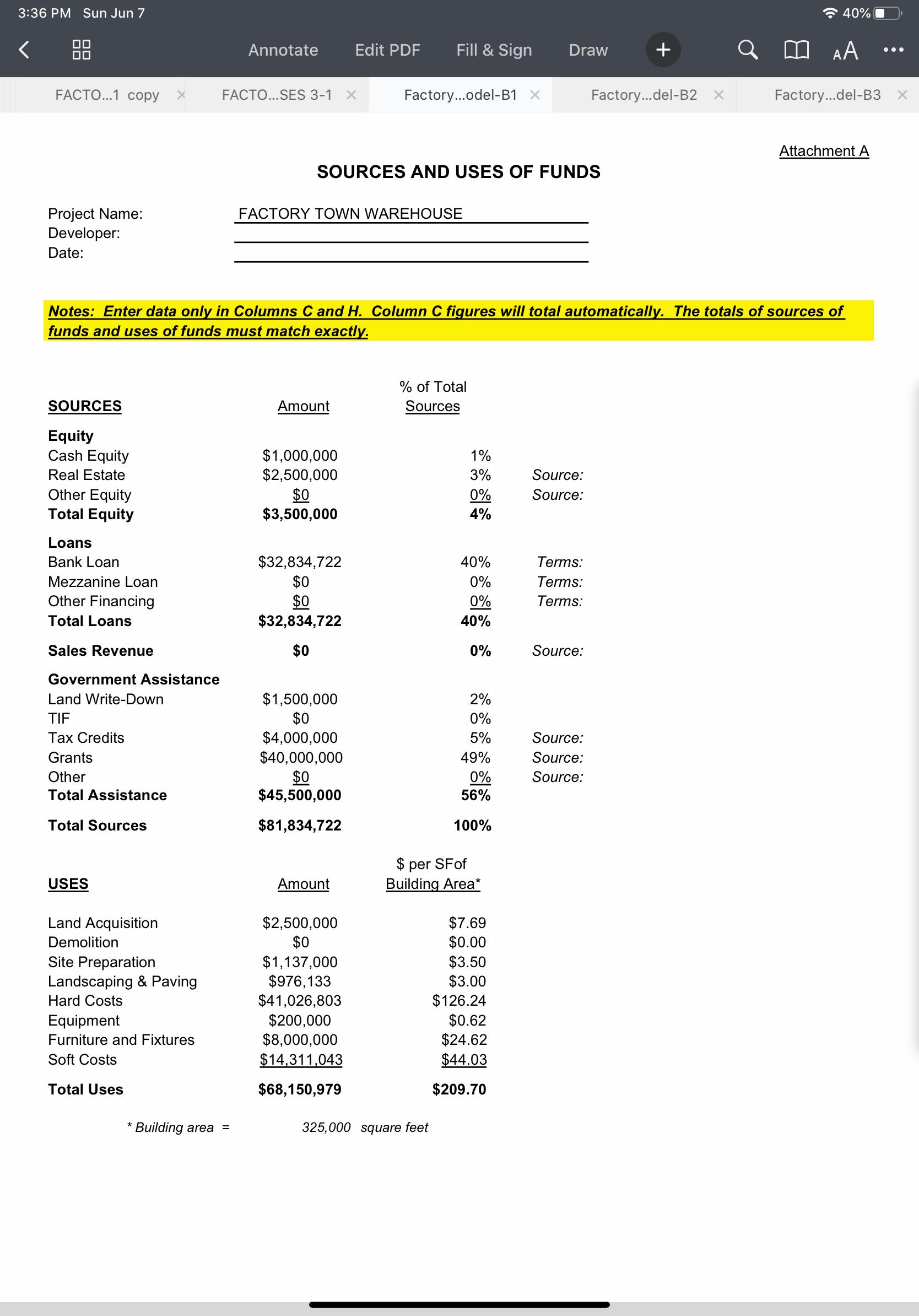

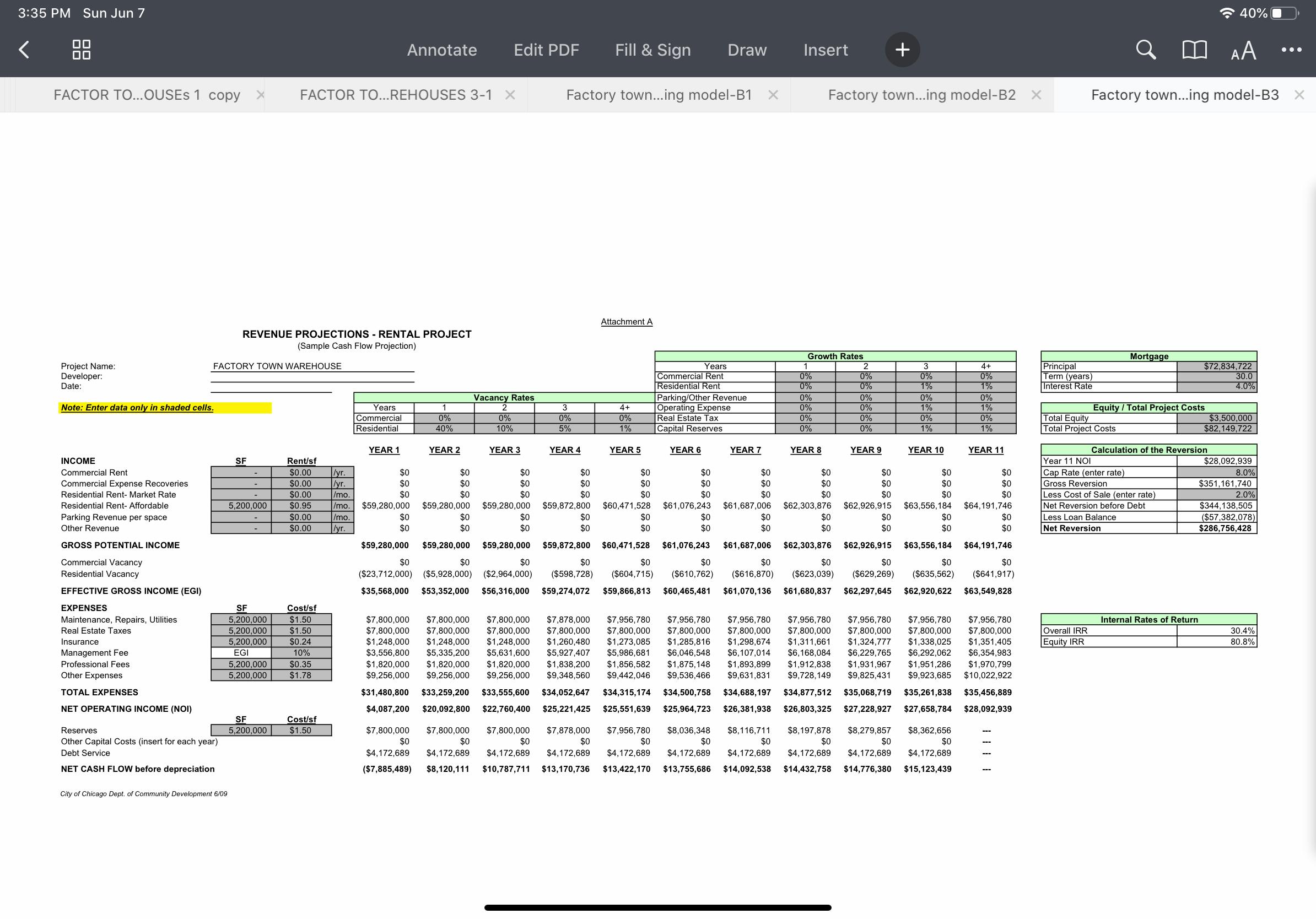

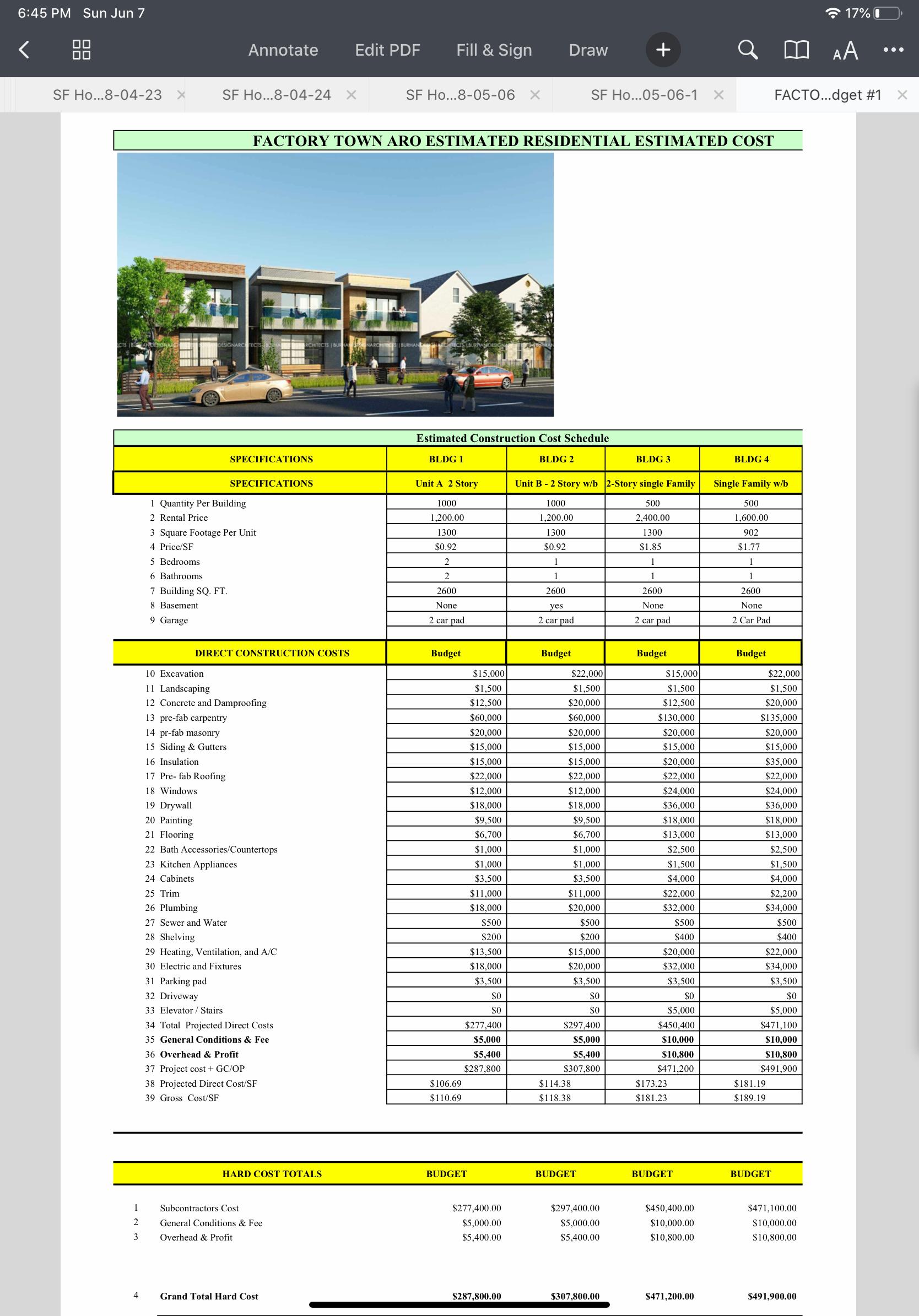

PRE-FABRICATED HOME COST STRUCTURE & SOURCES AND USAGE STATEMENT

PRE-FABRICATED TWO-STORY AND SINGLE-FAMILY HOUSING UNITS

Duplex With Basement

Duplex Without Basement

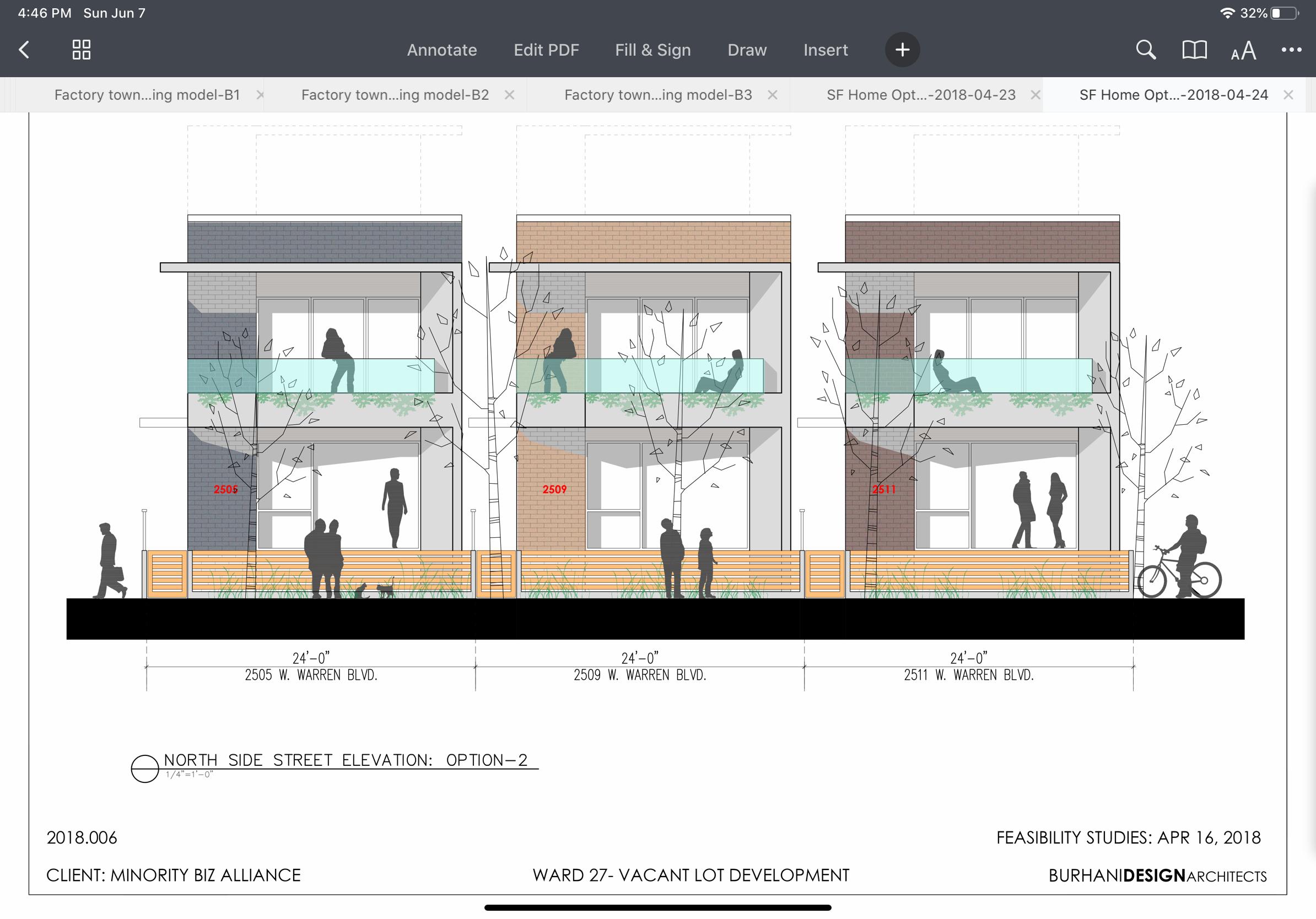

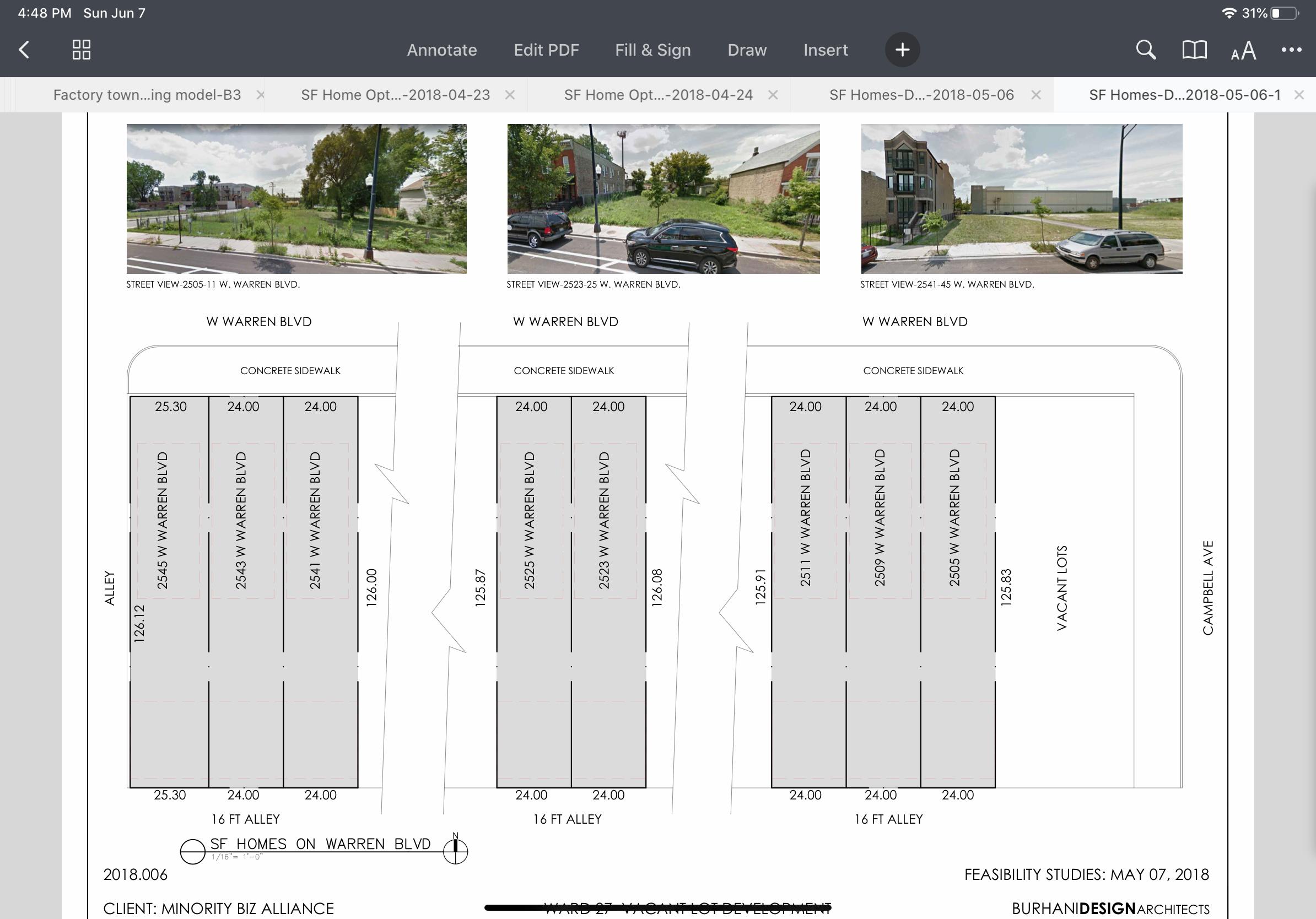

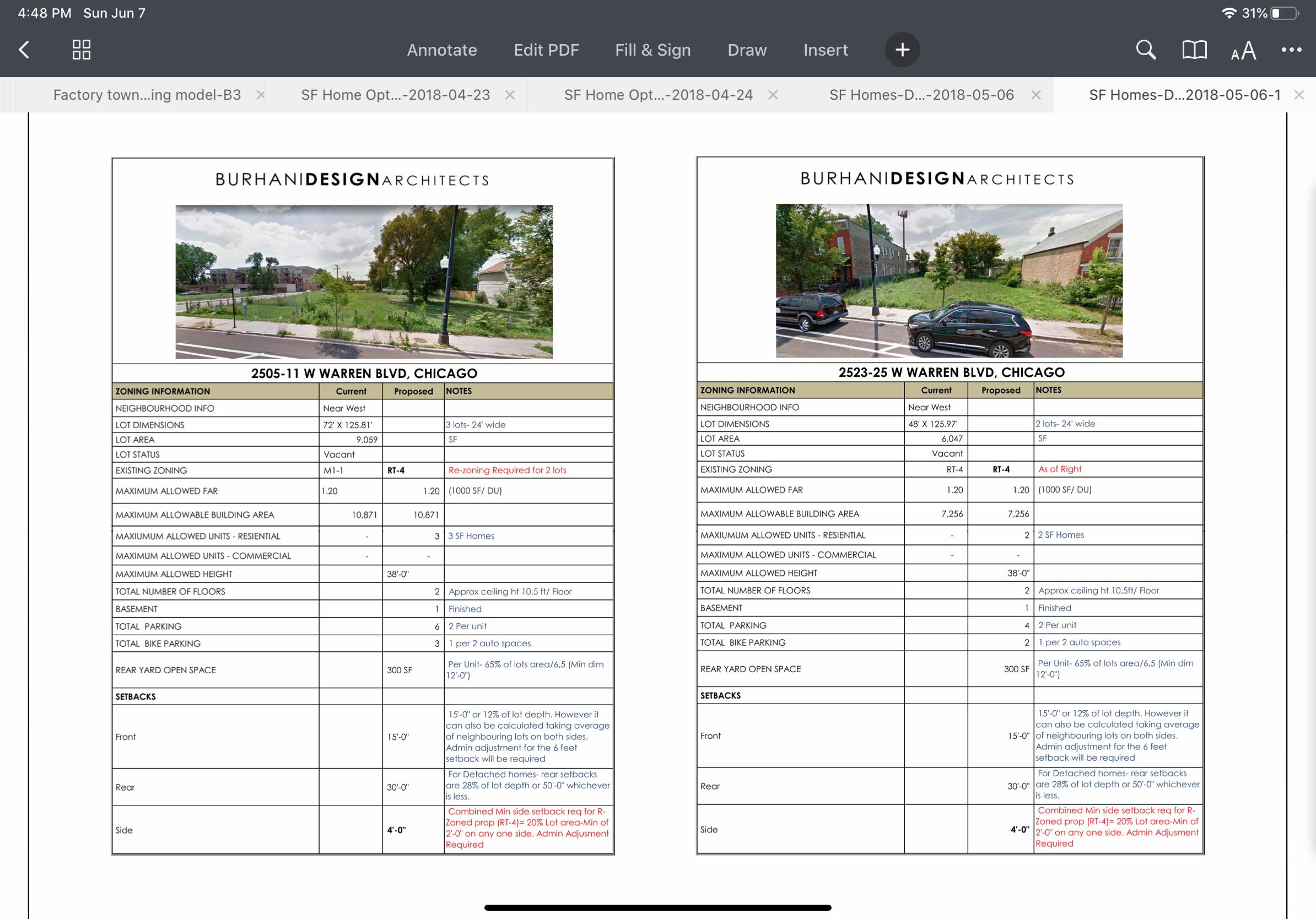

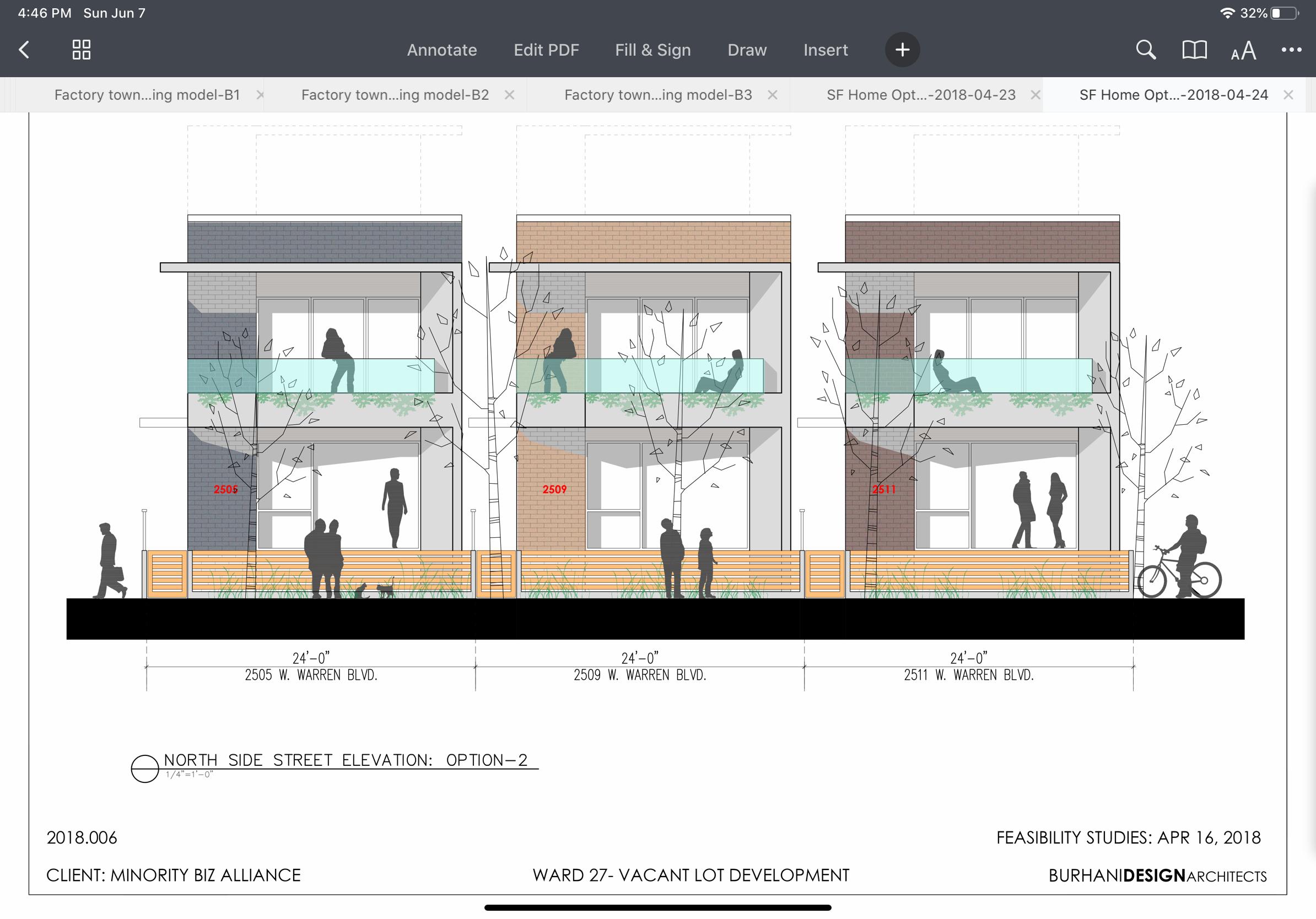

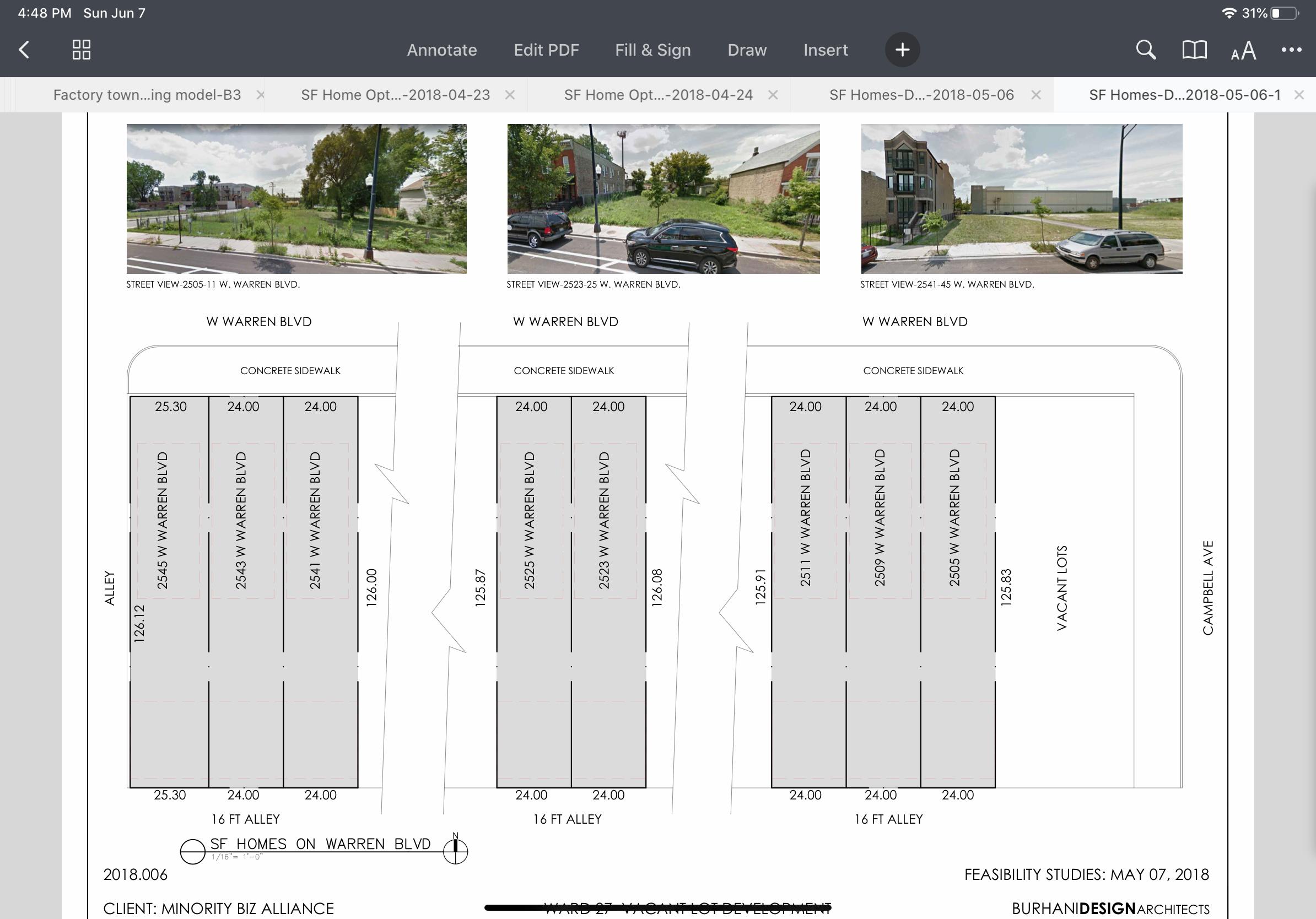

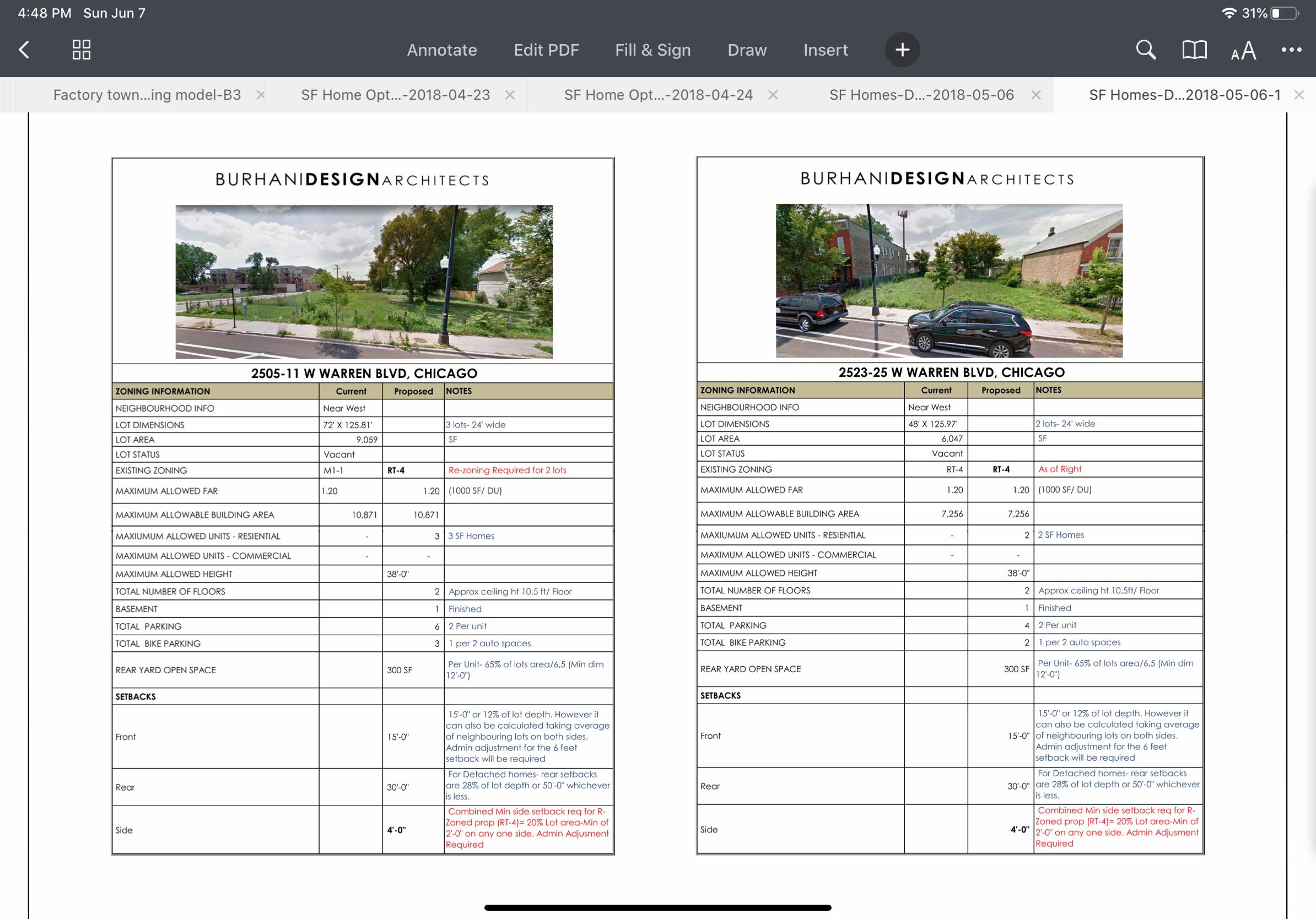

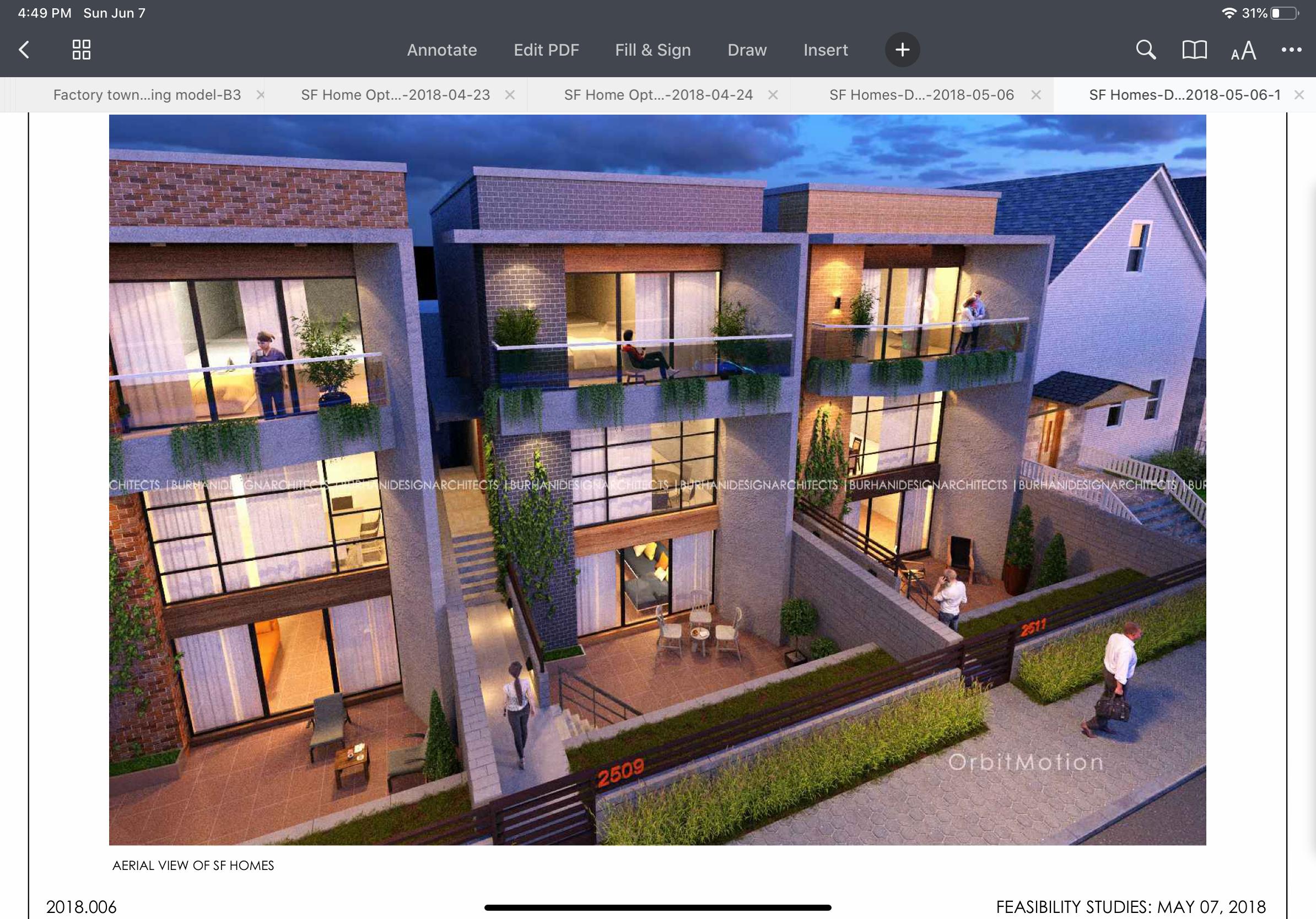

Proposed Single – Family Lot Builds on Warren Blvd.

CITY OF CHICAGO LOCATION MAPS AND EXAMPLES

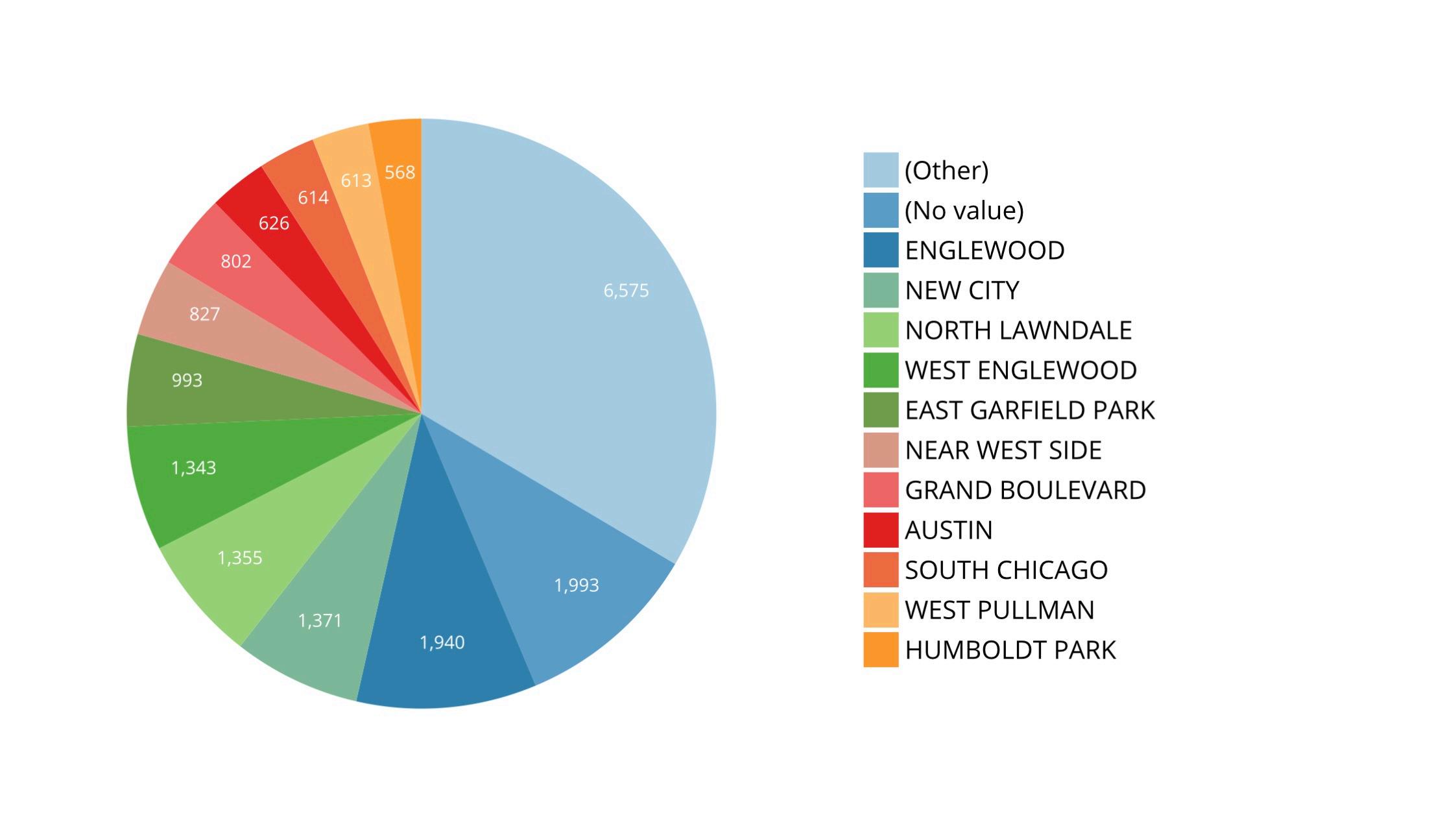

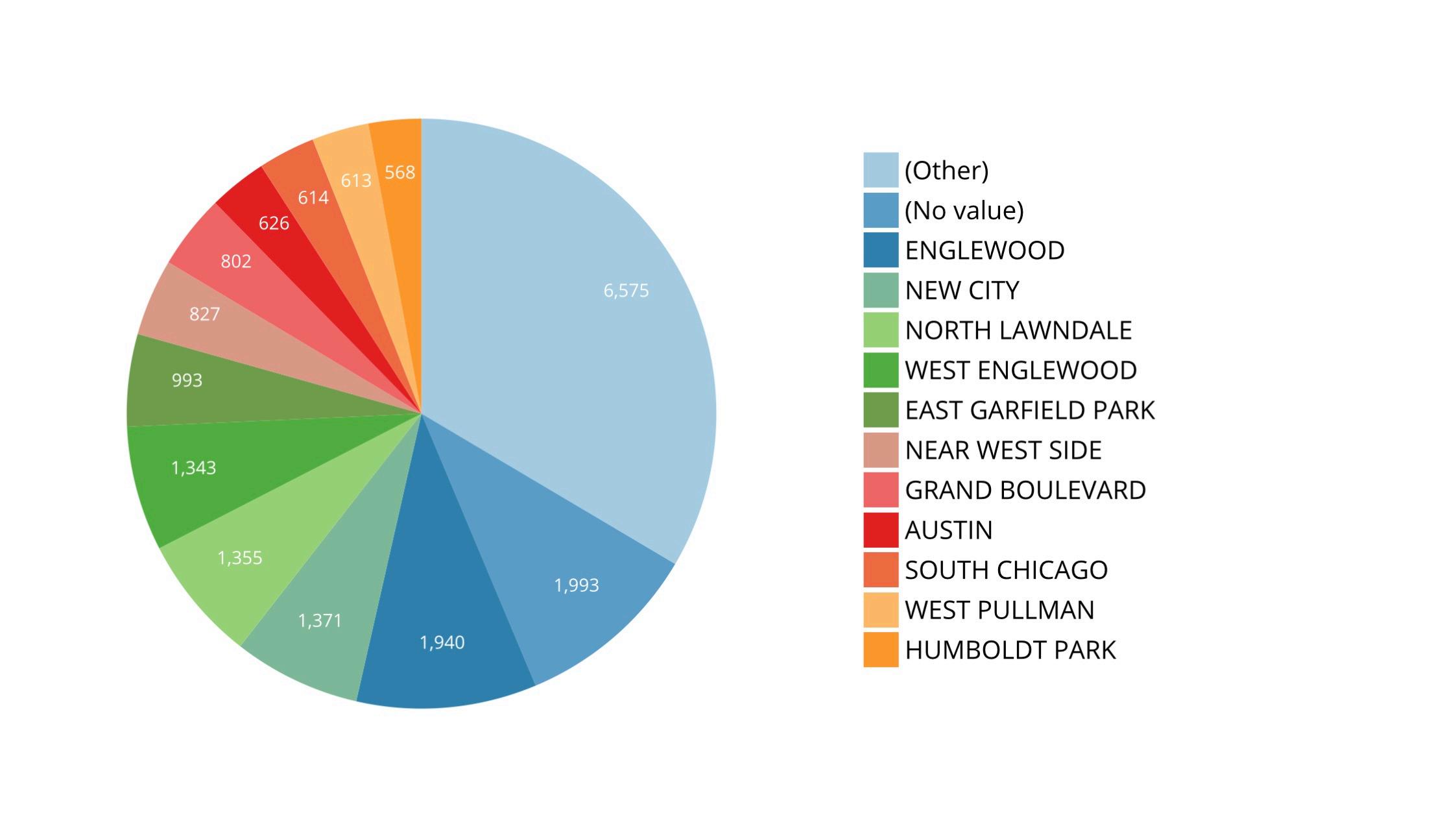

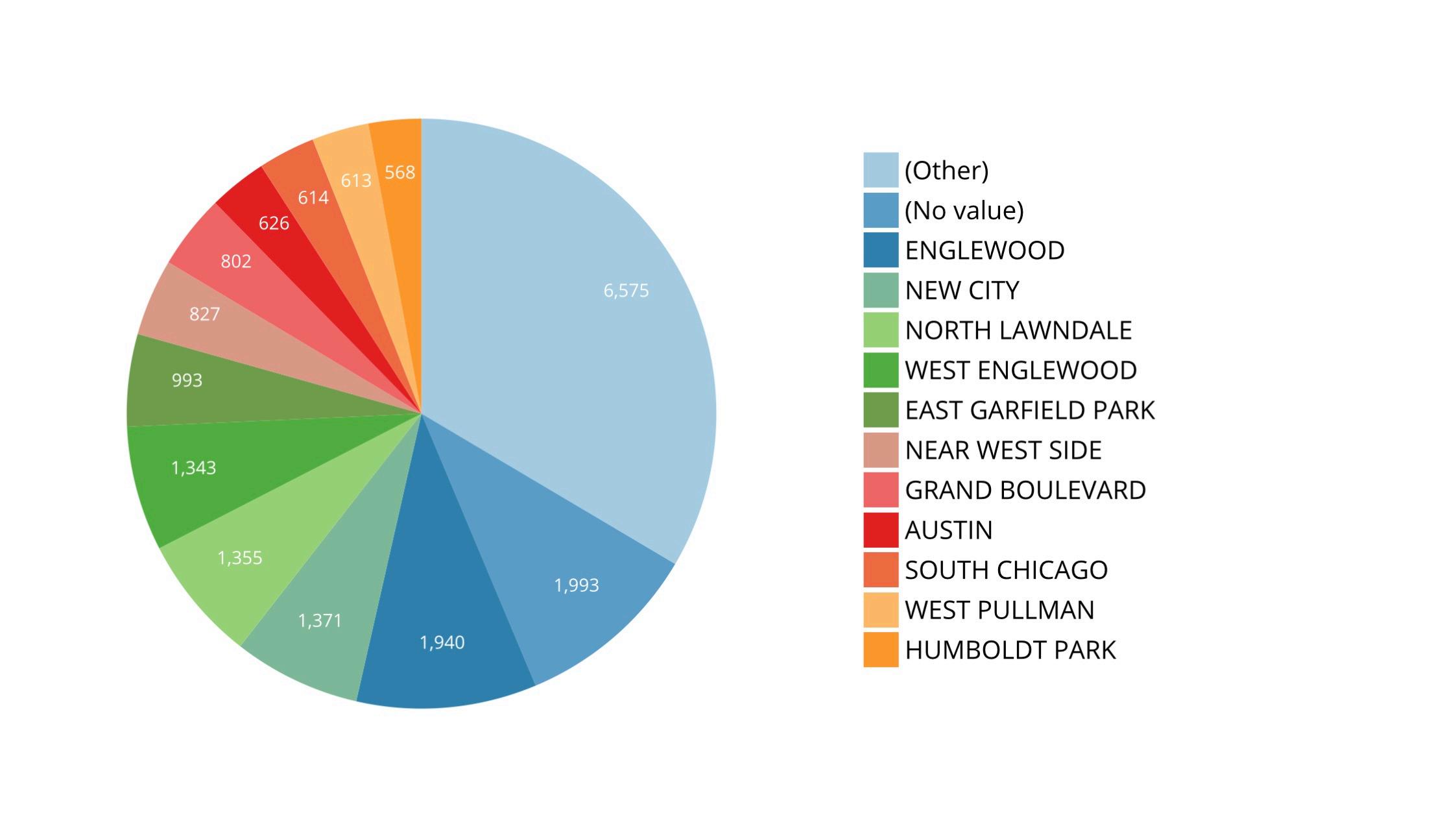

VACANT LAND PER LOT COUNT CURRENTLY OWNED BY THE CITY OF CHICAGO BY COMMUNITY

VACANT LAND BY AREA

- TWO ARO UNITS, ONE TWO FLAT BLDG OR ONE SNGL FAMILY HOME

27Th WARD ARO DEVELOPMENT INFILL ILLUSTRATION

46 LOTS 92 UNITS 50 LOTS 100 UNITS

59 LOTS 118 UNITS

25 LOTS 50 UNITS

The illustration above represents the infill of an additional 180 lots and 360 units. Based on the new ARO Pilot program this can be accomplished with only 2 prime 400 unit developments and 1 secondary of 10% offsite and create over another 12 professional service jobs, 4,500 sf of affordable commercial rental space, the employment of more than 18 minority subcontractors and contribute to the continuing employment and education of over 300 - 400 warehouse employees.

The production of the 252 units and the additional 360 units is only 20% of the prefabricated warehouse production capabilities. Based on the illustration there will be a minor need for a zoning change to meet the goals as shown above.

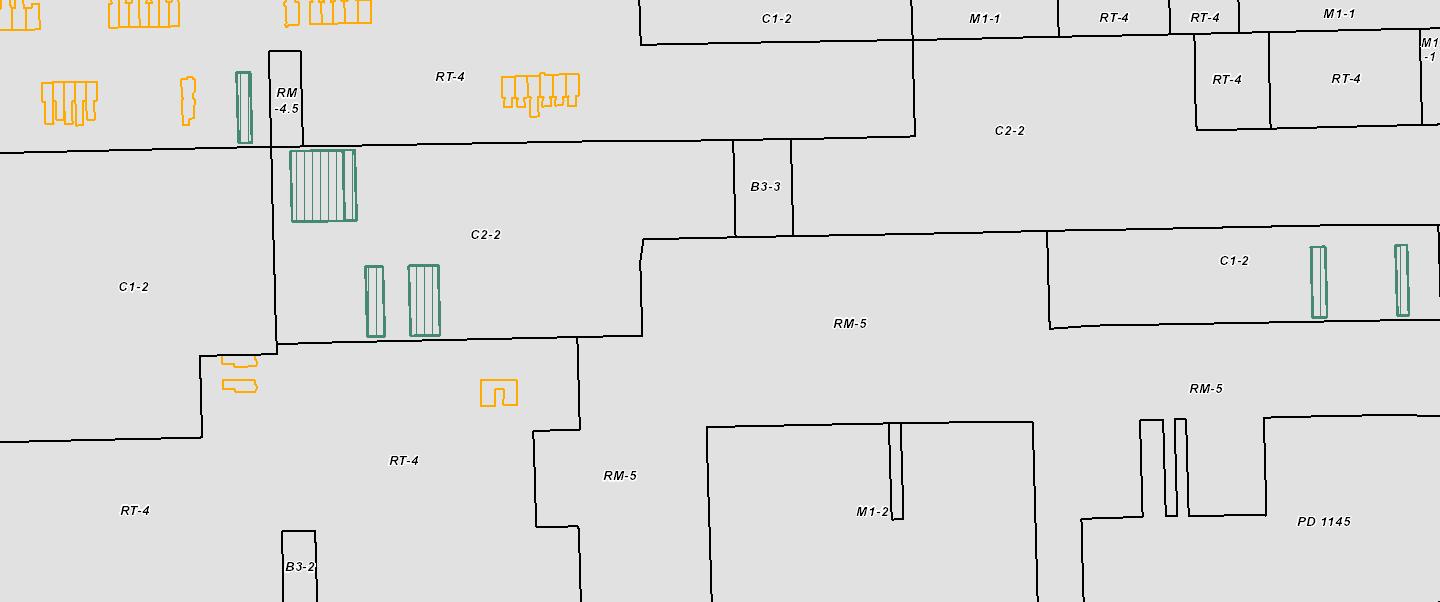

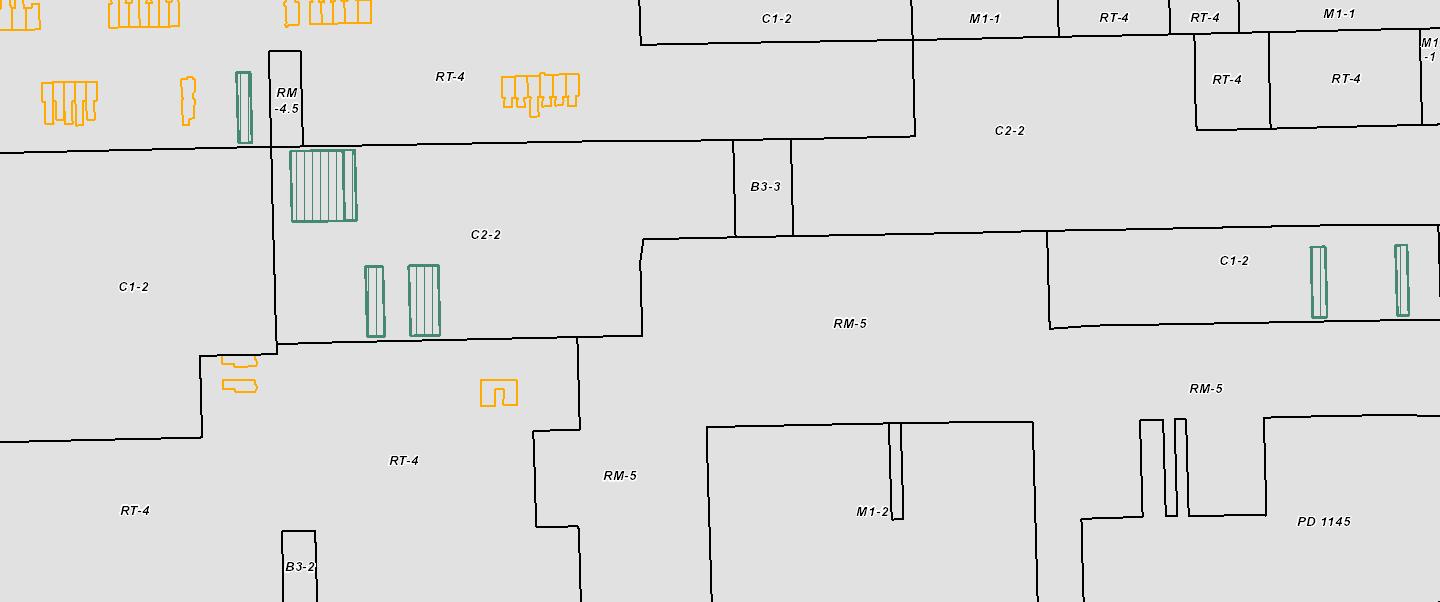

7/5/20, 6 : 56 PM City of Chicago::Zoning Website Page 1 of 1 https://gisapps.chicago.gov/ZoningMapWeb/?liab=1&config=zoning Zoning and Land Use Map Department of Planning and Development

Pg 3

- TWO ARO UNITS, ONE TWO FLAT BLDG OR ONE SNGL FAMILY HOME

27Th WARD ARO

DEVELOPMENT INFILL ILLUSTRATION

51 LOTS 102 ARO UNITS

The illustration above represents the infill of an additional 51 lots and 102 units. Based on the new ARO Pilot program this can be accomplished with only 2 prime 400 unit developments and 1 secondary of 10% offsite and create over another 8 professional service jobs, 2,000 sf of affordable commercial rental space, the employment of more than 10 minority subcontractors and contribute to the continuing employment and education of over 300 - 400 warehouse employees.

The production of the 150 units and the additional 102 units is only 8% of the prefabricated warehouse production capabilities. Based on the illustration there will be a minor need for a zoning change to meet the goals as shown above.

7/5/20, 6 : 54 PM City of Chicago::Zoning Website Page 1 of 1 https://gisapps.chicago.gov/ZoningMapWeb/?liab=1&config=zoning Zoning and Land Use Map Department of Planning and Development

- EXISTING NEW MARKET RATE SINGLE FAMILY HOME Pg 2

- TWO ARO UNITS, ONE TWO FLAT BLDG OR ONE SNGL FAMILY HOME

27Th & 28Th WARD ARO DEVELOPMENT INFILL ILLUSTRATION

50 ARO UNITS 66 ARO UNITS

34 ARO UNITS

The prefabricated warehouse facility has the ability to produce 3000 units a year. There are approximately 19,500 empty lots in the city of Chicago of which 14,560 are owned by the City of Chicago and 4,500 owned by others. The illustration above represents the infill of approximately 75 lots and 150 units. Based on the new ARO Pilot program this can be accomplished with only 4 prime 400 unit developments of 10% offsite and create over 10 professional service jobs, 3,000 sf of affordable commercial rental space, the employment of more than 16 minority subcontractors and contribute to the continuing employment of over 300 - 400 warehouse employees.

The production of 150 units is only 5% of the prefabricated warehouse production capabilities. Based on the illustration there is no need for zoning change to meet the goals as shown above.

7/5/20, 7

Zoning and Land Use Map Department of Planning and Development

https://gisapps.chicago.gov/ZoningMapWeb/?liab=1&config=zoning

Pg 1

Window Assembly and Installation Operations

Window Assembly and Installation Operations