m a g a z i n e

e d g e d e t a i l i n g edge detailing decorative panel what’s here & what’s coming machines & tapes

fasteners & fixers unseen & installation friendly

m a g a z i n e

e d g e d e t a i l i n g edge detailing decorative panel what’s here & what’s coming machines & tapes

fasteners & fixers unseen & installation friendly

Clever storage from European manufacturer Kesseböhmer has been a trade-favourite product for many years thanks to its reliability, space-saving and user-friendly qualities. The pull-out storage fittings add invaluable additional storage to one of the busiest rooms of the home helping to sort, organise and keep frequently-used items within easy access at all times ... and now a complete range of these Kesseböhmer pull-out fittings are available in an all new style!

Introducing: ARENA Pure. The name says it all, as the sleek new style features a minimalistic and understated design. The height of the tray remains the same as the current ARENA Style range and therefore is the ideal height to contain items, without the risk of falling, while also remaining easy to access. Pure features a high quality powder-coated aluminium finish in dark anthracite and clean, minimalist edges for a sleek modern look. Coming July 2024.

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Invisible joins, glue free tape and an edged product that needs little clean up. Kiwis have been quick to embrace new edge banding technology for its efficiency and quality of finish. We look at developments in machinery and processes.

Master Joiners 4

Nathan Busch asks what does our product say about our practices and suggests that by staying aligned with materials, techniques and best practices we pave the way for long term success.

Laminex Update 14

Rachel Silcock introduces herself as the new Laminex GM and is encouraged by the investment and adoption of new technologies which she sees across the industry.

NKBA news 76

The NKBA introduce Simon Wilkins and describe his journey and training from fabrication apprentice, to CNC operator, to job detailer and onto his current role as kitchen designer.

Steering a Course 78

Ian Featherstone ponders on the worlds of artificial and emotional intelligence and suggests there is a lot to be said for face to face connection with the people we are actually doing business with.

News & Info 4 - 18

State of the Industry 80

NZJMF membership 82

Classifieds 88

Advertiser index 88

EuroCucina 2024 showcased an array of trends and innovations that redefine modern living spaces. From rich colour palettes to exciting textures and materials, Blum provides some highlights from the show.

Always concerned about sustainabilty and safety in the materials it uses to manufacture furniture, Lundia has recently moved to a water based coating system from Resene to provide the finish for its products.

Our major panel manufacturers and importers continue to provide a changing kaleidoscope of materials, surfaces, designs and colours to tempt designers and users, we look at some recent additions to the market.

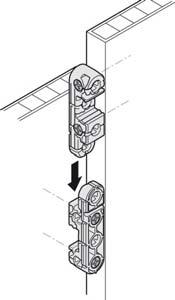

A lot of innovation in hardware and panel fixings has been around simplicity of installation, multi functional use and providing hidden connections. We highlight three different systems which are relatively new to the NZ market.

from the president 16.05.2024

The joinery sector is experiencing changes in scheduled work. We are receiving a steady stream of quote requests, giving us some insights into what lies ahead. This is happening against a backdrop of shifting interest rates, less consents, and the costs of materials and fuel. We must recognize the collective impact of these changes and challenges on our resilience.

This period of adjustment is an opportunity for the joinery industry to take stock. While the pace may have slowed down, all of joinery should remain vigilant, particularly concerning wood dust levels. Creating a practical controlled environment for dust management is crucial, and it's a responsibility we must all take on. As production fluctuates it's critical to review standards. It's not just about how we operate, it's about ensuring that the finished product aligns with our commitment to excellence.

It's not just about how we operate, it's about ensuring that the finished product aligns with our commitment to excellence

From the moment it leaves our factories to its final installation, the quality of our work speaks volumes. I encourage joiners to ask yourselves, what does your product say about your practice? It can be challenging but it's a good professional tactic to self-assess and recalibrate as needed.

In the world of joinery, we're constantly striving for innovation and excellence in materials and techniques. But amidst the hustle, it's crucial to align our focus

on industry standards. This is something that at Master Joiners, we want all joiners to pay attention to. We know that in Joinery, the details make the difference, something that is little understood outside of joinery. We face daily challenges like managing wood dust, ensuring safety gear, and coping with staff shortages. These challenges emphasise the importance of mindset alongside procedures. While each joinery business operates at its own pace, it's essential to avoid falling into routine. Taking time with colleagues at meetings, conferences, or casual chats can spark growth and support moments for reflection and learning. During tough times, it's tempting to stick to what's familiar.

Alignment goes beyond checkboxes, it's about guiding every decision. By staying aligned with materials, techniques, and best practices, we pave the way for long-term success.

Many have heard me reference the term of professionalism and how its not what we do but rather how we do it. I say this because I believe it. Setting standards and championing quality and compliance sits at the heart of that. I encourage all Joiners to consider adjusting, aligning and taking care of some of these details. We will be talking more about these variables and more over the coming months. I invite all joiners to join the discussion, connect and align.

Nathan Busch National President Registered Master

Nathan Busch National President Registered Master

Joiners

Edgebanding has always been an important part of the joinery/ cabinetmaking/kitchen scene. It forms part of the nest based manufacturing process so popular here in New Zealand and is an ever evolving process. In this issue we have a look at not only the machinery but also the all important accessories including the various tapes and glues used these days that make for better efficiency and quality of finish. Another interesting range of product are the various types of fasteners and panel fixing systems used to make installation simple and provide hidden connections. This flows in turn to our third main feature looking at the latest in decorative panel. This has been marked by an ever changing range of materials, surfaces, designs and colours for the commercial and residential scene.

I note our regular column from Ian Featherstone this time, some great ideas to help your business. Being in front of your clients in person and not just an on line presence makes for real contact and meaning. Worth a gander. Some of the editorial content in the Edgebanding feature is of note as well particularly the article from Homag on the role of edgebanding in the woodworking industry. Although focused on Homag machinery it has some interesting insights about edgebanding at large. We also have lots of new product to see such as the universal connectors from Hafele and the REVEGO pocket systems from Blum. There is a lot going on out there creatively from a lot of companies we all know. Have a look at this issue and you will find out about some of them. I would also draw your attention to an editorial from new General Manager for Laminex NZ, Rachel Silcock. Her answers to some questions I put to her are solid and interesting.

With there being no AWISA Exhibition this year former exhibitors are looking around at what they can do locally. Machinery manufacturer Biesse recently held an event at their Wiri location with demo’s and factory visits called Biesse Auckland Inside with architectural hardware supplier Blum NZ who also ran a function at their showroom and Head Office in Avondale. Perhaps a way forward in the future? It certainly attracted a lot of attention. Following on from this event will be another in mid August run by W & R Jack Ltd called JacksTech 2024 at their premises in East Tamaki in Auckland. There’s an advert in this issue with all the details

We are now heading into the winter of ’24, a time to buckle up, keep warm and focus on the job at hand, whatever that may be for you. We wish you all well through what looks to be both an interesting and challenging time for all. Catch you next time Bob Nordgren

Editor Michael Goddard michael@joiners.net.nz

Publisher Bob Nordgren bob@joiners.net.nz

1173-6836 42 Aldersgate Rd, PO Box 27 - 513, Mt. Roskill, Auckland, 1440, New Zealand. Ph: 64-9-624 4680

The recent Grand Opening of SCM Australia's new 3000 sq/m showroom and technology center was attended by visitors from across Australia and New Zealand.

The 45 machines in operation covered SCM Group key technologies including machining centres, cutting solutions, drilling solutions, edgebanding, surface finishing, packaging, solid wood processing, joinery machines and digital services. A truly outstanding event.

The new Sydney technology centre is open to all New Zealand customers for demonstrations and expert advice. Contact Machines R Us for more information or to book a visit.

T 09 820 9486

E sale@machinesrus.co.nz machinesrus.co.nz

FIT are delighted to announce the appointment of Darryl Robinson into the newly-created senior management role of Chief Revenue Officer.

With more than twenty years building a stellar career in home appliances - across first Robert Bosch New Zealand then its successor BSH Home Appliances - Darryl brings a wealth of experience, strategic knowledge and business acumen to head FIT’s sales and marketing teams.

Darryl joined the FIT family in March and has already been out and about meeting many of FIT’s trade partners. The team are already accustomed to hearing the hearty Robinson laugh.

“I am really looking forward to supporting Lyndon and Marty’s aspirations for the growth of FIT and helping grow the business to the next level as part of the overall FIT journey,” says Darryl.

After several years of organic growth, FIT’s directors, Lyndon Boakes and Marty Boakes, are pleased to be making this critically important investment into the future of what remains a Kiwi family-owned business with a deep commitment to Kiwi kitchen makers, kitchen designers, cabinet makers and joiners.

Welcome aboard, Darryl; the FIT team are so very pleased to have you on our team as we look to the future.

HOMAG Australia is pleased to announce they have added to their team profile in NZ employing two well know, respected and experienced woodworking machinery guys.

On the sales side Wynand Louw joins HOMAG counting the move as a significant milestone in his career. Wynand hails from South Africa immigrating with his family in 2017 and brings with him 11-years of woodworking machinery experience. Wynand is already well known in the northern North Island community and no doubt you’ll be meeting him as he makes his way around the country.

On the service side Butch Bolante has joined HOMAG. Many of you know him already. He is well credentialed having worked for 11-years servicing HOMAG equipment in Dubai and subsequently since 2018 in NZ. Brings a great smile into the room along with a ton of knowledge and knowhow.

Said Ross Campbell managing director of HOMAG Australia ‘we are very pleased to have Wynand and Butch join HOMAG. They add to our existing highly experienced team of industry specialists that we can grow our business with innovative solutions delivering top notch service in New Zealand’.

Join with Master Joiners and connect with industry leaders and experts, exchange ideas, and drive our profession for a stronger

Meet Bruce Poling, the Joinery Coach. Bruce and his team will share their experience, deliver practical demonstrations, and provide actionable insights.

Program discussions include

• Construction contracts,

• Regulatory updates,

• Low-e glass,

• Timber joinery detailing qualification.

• Proactive solvency and essential touchpoints

• Timber joinery outlook

• Standards Visit www.masterjoiners.co.nz to get registered today.

All

Stainlesssteel fabricator

Steelfort Engineering are set to host the Central Branch of the Master Joiners monthly meeting at their Palmerston North factory on the 11th of June and Commercial Products Manager John Jenkins and his team are putting together an interactive visit for members.

“It is our objective for the late afternoon event to not only ‘talk’ the members through the multiple stages of creating a Stainless Steel bench but also to make the visit an ‘interactive’ event,” says John. “Our intention is to allow members the chance to physically try welding Stainless Steel, then to sand-up their weld and finally to polish the weld.”

Central JMA branch President Kristine Holmes is excited about the event and encourages members

to attend. “Where else would you get this sort of opportunity. What a fantastic offer from Steelfort.”

The meeting is set from 3pm5pm at the Steelfort factory at 500 Rangitikei St, Palmerston North.

“Treat yourself to an early finish, have a go at a new skill and join us at a local bar afterwards for a bit of post tour networking,” says Kristine.

Central Master Joiners June meeting to be held at Steelfort Engineering June 11, 3-5pm, contact Central President Kristine Holmes 06 355 4646 for more details.

For 77 years, Steelfort Engineering Company has been a trusted name in stainless steel design, fabrication, and manufacturing.

Transform your space with the elegance and durability of Steelfort Stainless Steel. Our high-quality benchtops are perfect for any skilled fabricators, our custom benchtops come in straight, “L,” and

Steelfort’s stainless-steel benchtops are rust, corrosion, and stain-resistant, making them ideal for homes, commercial kitchens, and hospitals.

steel benchtops.

Phone or email for a no obligation quote.

Aperfect blue autumn day greeted those attending Biesse Inside at Biesse’s showroom in Wiri over two days in early May, which no doubt helped in delivering a constant stream of the regions kitchen and cabinet makers to do a little networking and view the Biesse machinery in action.

Biesse were showing off a wide range of machinery from their showroom covering nesting, edging and CNC processing across multiple materials. New to the showroom was the Biesse Master One capable of being set to cut both glass and stone and offering the latest initiatives in both safe handling of material and production efficiency.

A lot of interest was shown in the Hyfuse edging system developed here in NZ by HP Tech. Hyfuse can be easily retrofitted to Biesse’s latest edgebanding models and provides cost efficient access to the zero glue line concept for clients of a certain size or particular requirement.

Support partner Blum provided a large presence primarily showing off their new Revego pocket door system which gained a lot of attention with its clean lines and easy installment process. While Robertson & Sinclair with their tooling options and Joinery IT covering software, provided visitors with a complete manufacturing overview.

Once again Biesse used the event as a fund raising opportunity for the Child Cancer Foundation with nearby kitchen manufacturer Kitchenmania. Biesse Inside attendees were charged a nominal fee to tour the Kitchenmania factory fitted with Biesse machinery and 100% of the fees were donated to the Child Cancer Foundation. With Biesse and Blum matching this total a substantial sum of over $5,500 was raised for this worthy charity.

And when it was lunch, for those with a taste for slow cooked meat in wood fired ovens the wings and ribs were delicious, along with the authentic woodfire pizza which was served daily.

Partnering with CARTERS makes it simple to get the pieces of the puzzle sorted for that perfect finish, every time.

You can count on us to stock the market’s bestknown brands. By servicing the joinery market for decades, we understand that a joiner’s requirements are unique and have speciality joinery branches across the country to support your business.

Let’s partner together.

when you spend $750 (excl GST) or more on Bestwood Veneer in June & July 2024*

I’m pleased to be able to contribute to my first column in Joiners Magazine as the General Manager of Laminex New Zealand. No stranger to the industry, having worked at Laminex over 9 years ago, it is an industry I’m excited to reconnect with. Upon my return this April, I’ve had a chance to visit a number of our customers and I’ve been encouraged by the investment and adoption of new technologies. It’s equally pleasing to see the genuine and assiduous nature of our joiners remains strong.

We know that market dynamics are changing weekly and speculation is clearly divided with respect to interest rate relief. When we unplug from the media and connect on the ground, there is some optimism on the horizon. As is often the case when the new build market retracts, there are some indicators that our additions and alterations pipeline has still got some legs. When house prices take a hit, it perhaps becomes more compelling to sit tight, invest for the recovery or simply stay put and enhance the heart of one’s home. Downturns present different challenges for each of us, but this is not unchartered territory and we can learn from each other. It’s a real opportunity to lean into our supply partners, leverage our strong associations and examine where we can drive operating efficiencies.

It goes without saying, we must always focus on continuous improvement, especially as it relates to our core business. We need to act with genuine intent and care to improve our service to our customers, everyday. I’m a big believer in being insights led and as part of responding to the voice of our customer, we deployed a NPS survey in May; thank you to everyone that provided feedback. I’m excited to see the results to understand what we are doing well, and where we can improve.

During the quieter period, ways to reach out to new audiences is important. On our website, we have the ‘See and Buy’ web page that connects consumers with a business to help them with their project. If you’re interested in featuring on the listing, reach out to your Laminex sales business partner to go through what details we need.

I think you’ll also be pleased to hear that the team have been busy preparing a number of range updates. I’m excited to see one of our most popular brands undergo a refresh - my personal and enduring favourite, Melteca. Watch this space come July!

Over the coming months, I look forward to learning more about each of you. I will also be attending the Master Joiners conference in September, so I can meet as many of you as possible to understand your business and how we can succeed together.

Rachel Silcock General Manager Laminex New Zealand

Rachel Silcock General Manager Laminex New Zealand

Sometimes, you have to take away to get more. With AVENTOS HKi, it’s about taking away 750 cubic cm of hardware from the inside of your cabinet. And what you get? Space for creativity.

AVENTOS HKi offers innovative design, cutting-edge features, and unparalleled functionality to lift your projects to new heights. With familiar installation processes and the benefits of the existing lift system range, AVENTOS HKi is a hassle-free addition with all the convenience you expect from Blum.

From the planning to the installation, Blum’s product development team have put passion into the creation of AVENTOS HKi, ensuring that the benefits are felt in every stage of the product’s life. From easy planning on Product Configurator to simple installation with the EASY ASSEMBLY app, and finally, smooth and effortless opening and closing in the cabinet.

Envisioning the perfect space for AVENTOS HKi in an upcoming job? Contact your Blum Account manager for more information, or email info.nz@blum.com

Wednesday 14th - Friday 16th August 19 Allens Rd, East Tamaki, AUCKLAND

Win tickets to All Backs v Argentina at Eden Park

Panel

• Edgebanding with genuine laser technology

• Two new affordable CNC nesting lines

• Discover the benefits of 6-sided CNC production innovation

• See PCS Safe Saw Technology in action

• Pre-Hung Door manufacturing made easy with 5-axis CNC

• Automated CNC Peanut & Dowel drilling and insertion

Timber

• Rip safely with the Hokubema power feeder

• Efficient, safe and affordable optimisation with EasyStop from Weinig

• Get a new face: finishing with the Structura brushing machine

Win tickets to All Blacks v Argentina at Eden Park!

In May this year, Blum teamed up with our friends at Biesse, Kitchen Mania, and more to create an insightful and successful two-day event at the Biesse Showroom. The event saw hundreds of industry professionals from all corners of New Zealand come together to learn and discover new products and machinery in the industry.

Blum brought two REVEGO displays: one offering personal hands-on training on assembling and installing REVEGO, and the other an interactive design-based display showing how REVEGO can look in situ. Blum also brought a BOXFIX plus assembly device for quick and efficient assembly of Blum box systems and showed demonstrations for different products.

Biesse hosted a fantastic event showcasing their best machinery options and have received positive feedback from the industry. Over the two days, buses also shuttled attendees to and from the Kitchen Mania showroom. All proceeds from ticket sales went to the Child Cancer Foundation, which Blum and Biesse matched, resulting in $5890 raised for this beautiful cause.

After the event’s second day, Blum concluded the experience with an evening at the Avondale showroom, showcasing new interactive and innovative product displays and the warehouse extension.

Missed out? Don’t worry. Contact your Blum Account Manager to make an appointment at your local Blum Showroom, and we’ll be happy to show you everything on display from Blum!

To coincide with New Zealand Sign Language Week (May 6-12), BCITO launched a new website aimed at demonstrating the opportunities for deaf New Zealanders in the construction industry.

The Building Abilities site features stories of Kiwis who have succeeded in BCITO apprenticeships and gone on to careers in the building trades, alongside resources from BCITO and Deaf Aotearoa to help learners and employers.

There are more than 4,500 deaf users of New Zealand Sign Language (NZSL), and around 23,000 New Zealanders across the country use it regularly. However, lack of awareness about deaf people’s abilities remains a significant barrier to work.

“Sometimes employers have no experience or knowledge of deaf people and/or NZSL, so they are hesitant. Yet more often than not, deaf people begin a job, and the employer realises that the deaf individual is more than capable of doing the same work as their hearing workmates,” says Lachlan Keating, Chief Executive of Deaf Aotearoa.

“Providing all learners with the right resources to have meaningful careers in construction is our reason for being, and we’ve focused on developing strong partnerships with organisations such as Deaf Aotearoa to break down those misperceptions and barriers. At a time when the industry is still facing a shortage of skilled workers, we need to do everything we can to inspire and empower more people to consider a trades career or gain a trade’s qualification,” says Greg Durkin, Director of BCITO.

Barry (Baz) Kay is one of the former BCITO apprentices whose story appears on the Building Abilities site. Profoundly deaf since birth, he spent more than 20 years filleting fish because a lack of support during schooling had left him with literacy issues and a perception that he’d only be able to do low-skilled work. Through a family friend who happened to be a builder, he found a position as an

apprentice at Invercargill’s Trent Builders and received support from BCITO to complete his qualifications in 2019.

“My Training Advisor, Andrew Green (BCITO Principal Advisor - Learners with Disabilities), supported me through the process. He visited me every two weeks to go through the things that were challenging me. This included using imagery to define building terminology and explaining certain words that I wasn’t able to understand. My wife would help out by translating into sign,” Baz explains.

Since then, he’s become a highly skilled carpenter and valued employee, and he’s keen to help dispel the misconceptions employers can have about how much deaf people can do.

“Deaf people have very good eyes –they’re very visually orientated and are very good with their hands. A lot of deaf people do have barriers in employment, so it’s worth giving people an opportunity and treating deaf people the same as hearing employees as well, because the only difference is that we can’t hear,” Baz says.

To access the Building Abilities website and find out more about opportunities for deaf people in the trades, visit buildingabilities.co.nz.

WORK SMARTER

TRAIN AN APPRENTICE

ALREADY HAVE THE EXPERIENCE?

GROW YOUR BUSINESS THROUGH TRAINING

Have your team work smarter, learn up-to-date skills.

Help them learn the skills and become qualified.

Get skills recognised with a formal qualification.

Training an apprentice is an investment in your business and the industry.

Rachel Silcock is the new General Manager for Laminex NZ. Bob Nordgren from JOINERS Magazine took the opportunity to put some questions to her regarding her background and role at Laminex NZ over the next few years; the following are her response.

Can you give us a little of your background and why you came to Laminex NZ?

When I reflect back on me as a youth, my understanding of what was possible career wise, was limited to the traditional academic fields of law, medicine or teaching. Maybe a communications degree or a crack at IT would’ve also been a consideration – particularly given the emerging trends in those industries. Those more hands-on in orientation might have considered a trade apprenticeship, engineering school or horticulture. At no point was there an exploration of the construction sector and the diverse range of careers possible in this arena. It most certainly wasn’t a pitch at Career Day at an all-girls school. Interesting how things have changed, these days when I’m rubbing shoulders with the youth and mention that I work in the construction sector, the enthusiasm is palpable.

The Construction sector employees nearly 11% of New Zealanders and on a global scale, is forecast to represent around $18,819 billion by 2027. Who wouldn’t want to explore their career prospects in our industry - both locally and internationally. It becomes even more compelling when you think about the enduring nature of our industry. There will always exist a need to build and refresh the spaces we occupy. In order for the industry to grow and evolve, we need to capture the attention of young, bright minds and I’ll be making it part of my mission to do so!

In terms of my own journey, well I embarked on my university studies determined to land a career in medical sciences. How I ended up in Construction and at Laminex, is more a tale of timing and curiosity. I took a temp role at PlaceMakers in 2008 to pay off my overseas excursion and buy myself some time to

reset and reflect on my career options ... the rest is history. I’m no stranger to the business, having worked across various functions from 2010-2015. Most recently, I was the NZ Business Director for James Hardie. Quite the departure in terms of product offer but a business that until recently, aligned with the areas I was passionate about, specifically, NZ manufacturing. After 8.5 years at James Hardie NZ, I decided to come back to Laminex. It was compelling because the opportunities are real, we are investing in our local manufacturing footprint and we have phenomenal people.

If you had to choose a mission statement for the role what would it be?

Gone are the days of a stale mission statement that collects dust on the shelf. To me, a mission statement is a declaration of intent, at a point in time. As a business, we need to be agile and when we go about planning our mission, we need to consider a couple of key factors - business maturity and market. Both of those things have been impacted over the last few years. Operating with a constrained supply of materials and labour, with unconstrained demand caused a real shift in our culture, sales maturity and operating models. Entering into a new cycle, requires some reflection – what are our fundamentals, do we have the capability and the offer that sets us, and our customers apart from the competition.

A couple of things are going to be instrumental for us as we move through this market cycle. At the moment, my focus is ensuring everyone’s clear on why each of us show up everyday. That genuine personal connection to our strategy sounds simple, but is absolutely mission critical to be effective and efficient. It also underpins job satisfaction and a

growth mindset. Secondly, we must be exceptional at our core business. A few months ago, I brought a new car and joined the local car club. At my first meeting, the guest speaker was John Rutherford, the current CEO for Ford Motor Group. A company that is constantly focused on evolving their core brands. I’d been trying to articulate a need to focus on our core business and he summed it up nicely, he said; Try harder at being better at what we’re good at, vs being all things, to all people.

I’ve got a couple of other reflections on purpose and mission, particularly when they get typed up on a poster and forgotten about. Think about a start-up business, in the beginning

the goals and the why, they are crystal clear. While there requires a high degree of agility and resilience, everyone is in lockstep with a north-star. With so many trends to chase and with the passage of time, businesses that span multiple segments and have long tenure can become overly complex. Your initial intention and purpose can get lost in the noise of being everything, to everyone. In that moment, it becomes harder for your people and customers to understand your Why.

If we are to succeed through this next cycle, we must understand our core business, what we do well, what it takes to become Trusted Advisors vs transactional service operators. When people can articulate how they, as

individuals unlock success, we know we are on the right track. When our customers echo this, we know we have a winning recipe.

Laminex NZ has long been to the forefront in a very competitive market. What do you see it has to do to remain to the forefront?

To be at the forefront of any industry, we must be insights led. When you’ve been trading in a particular category and market for some time, it’s natural that knowledge and lived experience leads us to make certain assumptions. When the cadence of change is high and market dynamics are shifting, we must press pause and be open to new perspectives. Look at the data, ask questions, invest in research – our end user, what has changed for them? When was the last time we asked them what matters, what drives them. Just because we’ve driven a particular road a 1000 times, we must always be looking out the front window with an inquiring mind.

The other area where I see real opportunity, is improving how we lead through change. It’s ironic that change is constant. It’s happening all around us, all the time and no change is possible without engaging your people. Time and time again, I see business of all sizes, poorly executing change. Large businesses will get consultants in to “lead the change”. If we want to be a market leading business, we need to evolve, and that means getting alongside our people and supporting them through change.

There is a real science to understanding how we do this well – starting with understanding human behaviours, underpinned with emotionally intelligent leadership. Dig deeper and understand what causes the

resistance, be clear when they ask, what’s in in it for me? How does it align to your strategy, with your ‘Why’. We must create the space to slow down, connect and re-learn if we are to successfully lead change.

The business is part of an international operation. What do you see as your role and that of Laminex NZ in this bigger picture?

Without a doubt, international markets will provide us with an array of possibilities to explore but offshore trends can also be a distraction if we are not acutely aware of how they align to the needs of our local market. The first pass hurdle for me will always be, are we excelling at the core of what we do well and then, does the opportunity further enable us to be better everyday for our customers.

On the near-term horizon, I’m very curious as to how we can unlock new technology to enhance our operating model. But more importantly, in the current climate we need to keep a keen eye on regulatory standards and how international markets and geopolitical events effect our sector. Overnight, a wholesale change led by governing bodies can completely change the way we go to market, and we need to be constantly abreast of the sentiment and indicators that could influence this. Think Climate Change, Silica, fire standards after Grenfell and the recent tragedy at Loafers Lodge in Wellington.Without a doubt we have a duty of care to ensure we respond to these events and learnings.

2024 is set to fill the void left by the AWISA show's absence, promising to be the most significant woodworking event New Zealand has seen in years. Simon Hornby, Head of Sales at Jacks gives us an exclusive preview of what visitors to JacksTech can expect.

"JacksTech 2024 will be more focused on New Zealand's woodworking industry than AWISA ever was," Simon explains. "For instance, edgebanding in New Zealand is far more advanced than in Australia. Our market is incredibly quality-driven, with the highest per capita uptake of laser tape in the world."

“Through our partnership with KDT, Kiwis now have the opportunity to access affordable edgebanders featuring authentic laser technology. Combined with a team of highly experienced edgebander technicians, this collaboration ensures a win-win situation for Kiwi manufacturers.”

"Our independence allows us to scour the globe for the latest innovations in efficiency, versatility, and safety," Simon says. "We consider what best suits New Zealand conditions and bring those innovations to our industry. At JacksTech 2024 we’re introducing 10 new machinery solutions for Kiwi manufacturers to explore. Visitors can assess if these technologies are right for them, and if so, how these new machines will enhance their productivity and quality."

“In addition to showcasing cutting-edge machinery, JacksTech 2024 will include industry partners specialising in tooling, materials and software. These partners will share the latest innovations in their respective fields, providing visitors with a comprehensive look at the future of woodworking in New Zealand.”

“Don't miss out on this premier event designed to drive the Kiwi woodworking industry forward. Join us at JacksTech 2024 and discover the latest advancements tailored for New Zealand manufacturers.”

JacksTech Wed 15th - Fri 16th August www.jacks.co.nz

Invisible joins, glue free tape and an edged product that needs little clean up. Kiwis have been quick to embrace new edge banding technology for its efficiency and quality of finish. We look at developments in machinery, processes and materials with particular reference to New Zealand preferences and usage.

Automatic edge bander designed to process panels for different applications with excellent productivity and quality performance. Ideal for medium-sized companies, it is a highly versatile solution thanks to the possibility of using different types of gluing: EVA, PUR glues and hot air technology.

VERSATILITY

A perfect glue line for high quality panels is possible thanks to the SGP glue pot that allows the use of the EVA and PUR glue with simple and quick changeovers. Processing of narrow panels up to 60 mm wide and gluing of solid wood edges up to 12 mm thick.

QUALITY

Machining of 2 true radii, with all finishing units - including the 2-motor rounding unit - with simple and quick settings. NC axes for fast and error-free machining changes for the HP version.

USER-FRIENDLY

Quick and easy management of machine functions thanks to the large touch control panel and Maestro active edge HMI software, with 3D preview of the machined panel.

PRODUCTIVITY

Great efficiency with the panel return device fastback 21 and 25 allowing the complete edgebanding process managed by a single operator

The EDGETEQ S-300 series is tailored for high-demand environments, where automation and throughput are paramount.

In the world of woodworking and joinery, the precision and finish of edge treatments are not merely details - they are essential elements that define the quality and durability of the final products. Edge banding machines, which apply tapes of material to the raw edges of wood panels to create a clean and continuous appearance, are vital to this process. HOMAG Australia, offers a range of edge banding machines that cater to various levels of production needs and is a preferred partner for woodworking professionals in New Zealand.

Understanding edge banding machines

Edge banding machines are crucial in the furniture manufacturing and woodworking industries for applying a wide array of edge banding materials - such as PVC, ABS, acrylic, melamine, and wood veneers - to board or panel edges. This process not only enhances the aesthetic appeal of the products but also protects the edges from wear and damage.

The typical workflow in an edge banding machine starts with the application of glue to the edge of the panel, followed by the application of the edge banding material. Following this, the excess material is trimmed to ensure a flush finish with the panel surface. Higher-end machines incorporate pre-milling units that prepare the edge for bonding, and post-processing units like scrapers and buffers that polish the edge band to achieve a high-quality finish.

Comprehensive range why HOMAG stands out in NZ HOMAG offers a wide spectrum of edge banding machines, from simple, manual devices to highly complex, automated systems. This variety ensures that whether a joinery is focused on bespoke, low-volume productions or highvolume industrial outputs, there is a suitable HOMAG machine to meet those needs. The availability of different models, such as the EDGETEQ S-200, S-240, and S-300, provides options for businesses of all sizes and capabilities.

Foundations of Precision

The EDGETEQ S-200 series represents HOMAG's entry into the edgebanding arena, designed with a focus on precision and flexibility. This machine caters to a variety of edgebanding materials like PVC, ABS, and veneer, showcasing its versatility. Key to its operation is the Quickmelt glue application system which

A wide spectrum of edge banding machines for a wide spectrum of edge tapes

rapidly melts adhesive, ensuring a consistent glue line and immediate adhesion to the workpiece edge.

A pneumatic pressure zone follows the glue application, adjusting to the material thickness to ensure uniform bonding, an essential factor in achieving a seamless finish. Despite its designation as an entry-level machine, the S-200 integrates features such as a two-motor end trimming unit and a scraping feature for PVC materials, spotlighting its capability to deliver refined finishes.

Elevating Versatility

As we ascend the technical ladder, the EDGETEQ S-240 introduces enhanced features aimed at flexibility and superior finish. The inclusion of a pre-milling unit sets the stage for exact edge preparation, compensating for any surface irregularities and ensuring a flawless glue joint. This model’s defining feature is the optional LaserTec technology, applying a zero-joint edge with unparalleled precision, thus significantly improving the aesthetic appeal and durability of the final product.

Beyond aesthetics, the S-240 offers the flexibility of working with a broader spectrum of adhesives, including EVA and PUR, catering to specific material properties and durability requirements. The machine's modular design allows for the integration of additional processing units, including multifunctional corner rounding, highlighting its adaptability to complex edge banding tasks.

The high-performance midrange solution

The EDGETEQ S-300 series is tailored for high-demand environments, where automation and throughput are paramount. This model is distinguished by its robust automated capabilities, facilitating an end-to-end edge banding solution with minimal human intervention. The S-300 series boasts features such as automatic adjustment to panel thickness and edge banding material changes, significantly reducing setup times and increasing production efficiency.

Incorporating HOMAG's advancement in laser technology, similar to the S-240, the S-300 also offers the LaserTec option for a zero-joint finish. However, the S-300 goes beyond by integrating comprehensive monitoring and control systems, allowing operators to manage the machine's multitude of functions seamlessly. This level of automation extends to the post-processing units, where individual modules for trimming, scraping, and buffing operate in a synchronized manner to deliver a product that requires little to no manual post-processing.

In the domain of woodworking, the minutiae of finishing technologies often dictate the line between the ordinary and the exceptional. HOMAG’s series of edge banding machines - the EDGETEQ S-200, S-240, and S-300 - serve as a testament to the intricate interplay of engineering and craftsmanship.

Paul Walkinton, co-owner and managing director at DBJ Furniture Limited, elaborates on the necessity of HOMAG edge banding solutions in crafting

their premier cabinetry. "For our high-end and custom cabinetry, particularly in the luxury segment, discerning eyes appreciate the subtleties that set our products apart. The accessibility of HOMAG's edge banding machines to work with a variety of materials using AirTec, PVC glue, and PUR glue is indispensable for our melamine's, acrylics, and wood veneers. The nimbleness in changing between materials without compromise to quality is a true game-changer. Moreover, we're not just investing in machinery—we're investing in the reliability and support HOMAG provides, which is essential for us."

Advanced technology

HOMAG’s edge banding machines are equipped with advanced technology that promotes efficiency and precision. Technologies such as the LaserTec system deliver invisible joint quality by using a laser to melt the edge banding material directly onto the panel. This results in a seamless bond that is not only aesthetically superior but also durable. Such advanced features are particularly important in markets like New Zealand, where the demand for high-quality craftsmanship is significant.

Eduardo Fernandes, director of Evolution Building Solution, is particularly impressed with the flawless finish resulting from the laser technology: "The precision of the laser finish on our EDGETEQ model is something to behold - no visible line, no post-processing, just a perfect product ready for assembly. It's a significant step forward, cutting out manual labor and allowing us to channel our focus into other areas of our craftsmanship and design."

Durability and reliability

Woodworking machinery represents a significant investment, and the robust construction and engineering of HOMAG edge banding machines ensure that this investment is long-lasting. HOMAG’s reputation for durability means that businesses can depend on their machines for continuous operation without frequent downtimes, thereby maximizing productivity and profitability.

William Haverland of Cutting Edge Cabinetry speaks to the substantial time savings afforded by the HOMAG's technology: "In a workshop that constantly shifts between edge tapes - even multiple colors within a single job - the capacity to swap quickly is invaluable. With HOMAG's edge banding solutions, we're saving considerable time, which translates to increased production capacity and efficiency. This is pivotal for delivering the quality and speed our clients expect of us."

In the world of woodworking, the quality of support services is just as crucial as the capabilities of the machinery itself. HOMAG’s presence in Australia and New Zealand, with dedicated service teams and spare parts availability, offers a layer of security and reassurance to New Zealand's joiners and woodworkers.

Prompt customer service and access to technical support mean that businesses can maintain high operational efficiency. For professionals in this industry, downtime means lost productivity and, potentially, compromised client relationships. HOMAG Australia, understands this dynamic well. The company's introduction

of a toll-free service number, 0800 466 241, in New Zealand exemplifies its commitment to providing seamless support and service to its clients. This service is more than just a help line; it is an integral part of HOMAG Australia's promise to deliver not only exceptional machinery but also exceptional service.

Commitment to the woodworking community

HOMAG Australia has demonstrated a long-standing commitment to the woodworking industry and joiners, not just as a machinery supplier, but as a partner to businesses. This commitment is evident in their efforts to understand market-specific needs and provide solutions that are not just technologically advanced but also aligned with the practical requirements of woodworkers and joiners in New Zealand. The choice of edge banding machine can significantly impact the quality and efficiency of woodworking operations. In New Zealand, where quality and craftsmanship hold significant value, HOMAG’s edge banding solutions stand out as a beneficial partnership for woodworking professionals.

The customers are looking for reliability, they're looking for performance, they're looking for edge banders that can deliver a high-quality finish consistently and the HOMAG edge banders fit that bill perfectly.

is perhaps

Every so often, a development comes along that is bound to transforman entire industry. A recent innovation out of New Zealand offers cabinet makers the opportunity to significantly improve the edge quality of cabinet parts, eliminate manual cleaning and reduce edge bander maintenance, all at a surprisingly competitive price.

HyFuse for the Perfect Edge Quality cabinetry is largely determined by the quality of the bond of the edge tape to the panel. Since the early 1960’s, when the first edge banding machines were presented to the market, suppliers have strived to develop a more perfect joint. The invention of LASER activated edge tape allowed for joints without visible gluelines. Zero joints not only provide the highest level of quality to the panel, but they are also more resistant to heat, humidity and bacteria than EVA glue. The original laser technology is expensive, later developed technologies are a lot more affordable but tend to require precise adjustments to get a perfect result.

And now, with Biesse, a new era of edge banding has begun with the introduction of a technology using a Hydrogen flame to activate the functional layer of ‘laser’ edge tape to produce a finish of the highest quality. The technology was developed by HyFuse® and could be New Zealand’s best-kept secret, with thirty machines in that country already using the new development. Biesse, a leading supplier of technological solutions to the cabinet industry has now partnered with HyFuse to bring this innovation to the industry.

Henk van Oeveren who is one of the inventors of the Hyfuse technology explains: Hydrogen technology uses heat generated from the combustion of hydrogen and oxygen to activate the functional layer of the zero joint edge banding tape. The flame of the hydrogen-oxygen mixture is directed towards the edge band through a nozzle with a row of tiny holes to melt the functional layer. The Hydrogen is supplied from bottles sourced from standard gas supply companies. One D sized bottle will apply approximately 4km of tape.The

required oxygen comes from an oxygen concentrator that is part of the HyFuse system. The concentrator uses on average 50 litres of compressed air per minute and is supplied through a 6 mm air hose.

What are the Benefits?

The HyFuse edge banding technology comes with a virtual shopping list of benefits. First and foremost, Hyfuse makes an edge bander extremely easy to run. There are only 3 heat settings and these directly relate to the panel thickness. Heat transfer is not affected by tape colour. There are normally no different heat settings required for tape brands either.

Hyfuse technology can be retrofitted to existing edge banders

If your current Biesse edge banding machine has premilling, an essential prerequisite for achieving a Zero joint between panel and edge, HyFuse technology can be retrofitted to your machine. When the time comes to upgrade to a new Biesse edge bander, the Hyfuse unit can simply be transferred to your new machine.

Switching between glue and laser is quick.

If you need to change back to glue for timber or veneer edges, the change-over is as quick as flicking a switch.

Hyfuse technology is very safe

Because the flame can quickly be turned on and off as required, the Hyfuse technology is not only energy efficient, but also safe. The Hyfuse system continuously monitors gas pressures, the moving of the tape and the temperature of the nozzle which must stay below sixty degrees Celsius. Any detected anomaly will cause the shut off of the flame in less than half a second.

The system does not increase the temperature in the machine Henk explains, “Hydrogen burns differently from other gases. The hydrogen flame radiates very little heat, all transfer is through convection. This means only the functional layer gets warm but the burner stays cool even at full production. The HyFuse system starts 10mm before the panel and stops 10mm afterwards, there is no energy used or heat generated between panels”.

Low running costs makes Hyfuse economically the best choice

Electrical power and air consumption are negligible and there is no need for a big compressor. The cost of heat activated tape is generally a little more expensive and there is a cost for the Hydrogen gas of about 4 cents per metre but this is easily offset by the savings. There is no cost for glue or cleaning agents. But the biggest saving comes from increased productivity, no more cleaning glue from panels and no more cleaning glue from parts of the machine.

The Specifications?

HyFuse will process boards of up to 30mm thick at 20metres per minute; the maximum panel thickness is 36mm. For faster applications Biesse has developed the Hydrogen Force System (HFS) technology. With Biesse HFS the hydrogen gas is made through the electrolysis of water, so no bottled gas is needed. With HyFuse and HFS, Biesse has a solution for all users.

Even More Great News

Giuseppe Serpentino is Biesse Oceania’s edge banding Technical Application Manager. He says, “Talk to Biesse to see if this new technology can be fitted to your existing Biesse edge bander and transferred to a new Biesse edge bander at any time in the future so there is only one purchase of this ground-breaking innovation.”

There is no doubt that zero edge technology has now become an affordable and high-value option for all cabinet makers. The environmental implications of using Hydrogen are significant; in fact, HyFuse uses only 10% of the energy needed for other zero edge technologies, It is the greenest edge banding solution. It truly is a ground breaking solution for the perfect edge.

In the competitive world of cabinet manufacturing, the choice of materials and technology is crucial for ensuring the quality and durability of the final products. Laser edging technology stands out as a significant advancement over traditional methods, offering unmatched benefits.

For cabinet makers, investing in laser edging means delivering a superior product with enhanced durability and a premium finish. The seamless appearance and performance provided by laser edging are nearly impossible to achieve with traditional methods, making it a key differentiator in a crowded market.

A major advantage of laser edging is the elimination of glue from the production process. This results in reduced start-up times, no glue pot changes, and less postproduction cleaning—efficiencies that lead to higher productivity and profitability. The higher cost

of laser edging is quickly offset by production efficiencies and the ability to command higher prices for superior quality cabinets.

Kantek recognised the importance of supporting customers choosing laser edging. This is evident in their expanded stock range, which now includes over 75 decors matching local panels, ensuring customers have a wide variety of options available. They also offer distinct options to suit individual needs with different materials, price points, delivery terms, and custom matches, coupled with expert technical support.

More recently, they have added Riepe’s LP120/12 release agent to their range, which is specifically formulated for use in

high-heat zones created by laser technologies. This fine spray prevents contamination of edge bander pressure rollers, marking and friction on edging, and the protective film peeling off highend edges.

Embracing laser edging is a commitment to excellence in craftsmanship. It is an investment in quality that enhances customer satisfaction and strengthens brand reputation. With increasing availability of affordable new “laser” technologies and the support offered by Kantek, the long-term benefits make laser edging a wise choice for any cabinet maker looking to stay ahead in the industry.

Biesse Jade 240 Edgebander + HyFuse

There have been a few changes since JOINERS Magazine first featured HBH Joinery in an article back in December 2021. Back then owner Richard Hart had just bought a CNC router from Proform CNC Ltd. Now he has purchased a Fravol Master 200-23 edgebander from them as part of the ongoing growth of the business. The machine was installed in October 2023. Bob Nordgren had a chance recently to catch up with Richard to update progress at HBH Joinery and find out why he bought the FravolMaster 200-23 edgebander.

“Proform is a great company to deal with” comments Richard “with good machinery and excellent service to back it up. That’s why we deal with them.”

Since 2021, HBH Joinery has grown considerably. “We focus on high-end, one-off architecturally designed homes in the Wanaka/ Central Otago region coming largely from architects” explains Richard. “A natural outcome of this has been the need to take our operations to the next level of quality and production.”

The company now has seven staff including two apprentices, up from just three staff back in 2021, and has doubled their factory space from 220 to 420 square metres. “I saw the need to upgrade some of our machinery, and in particular, our edgebanding capability. I spoke with other joinery business owners and received good feedback about the Fravol edgebander range, which led me back to Rob (Hutchings) at Proform.”

The size of their factory meant they needed an edgebander with a smaller footprint. Proform, now part of the Australian machinery supplier Farnese, held the agency for the Italian-made Fravol range of edgebanders. “The Fravol M200-23 fits our needs in terms of features, while also having a small footprint and being an affordable price. Plus, it was a logical choice to go back to Rob and his team, since we already knew their install and service quality.” Richard said. So what was he looking for feature wise?

“I wanted an edgebander that would be simple, easy to run and integrate into our operation smoothly.” The machine operates with PO glue, has a quick warmup time (10-15 minutes), provides a zero-edge glue line, boasts a waterproof edge and a simple clean-up process at the end of a longday.

The 200-23 also has a Synchro Plus corner unit, which offers a quarter rounding process for various kitchen doors as well. A colour touch screen and an easyto-learn operation has meant it can be used by all staff

“Our productivity in kitchen manufacturing has increased in the last six months and the quality of finish with this edgebander has been excellent” notes Richard.

“With the high end-work we do, the quality of finish is crucial. Well-made kitchen cabinetry is the foundation of a top-quality kitchen. It complements a customer’s choice of benchtops, which can be anything from granite, marble, porcelain, and stainless steel.” says Richard. The future is about ensuring quality outputs that match production demands.

“We couldn’t do it without our incredible team along with the use of integrated software, like Mozaik and Vectorworks,which seamlessly connect to our upgraded machinery.”

For more information contact Richard Hart at HBH Joinery in Tarras, Central Otago on 027 347 4740, email richard@hbhjoinery. co.nz or visit www.hbhjoinery.co.nz

In the evolving landscape of woodworking and furniture manufacturing, the pursuit of aesthetic perfection and durability in products has led to significant technological advancements. Among these is HOMAG's airTec technology. Breaking away from traditional edge banding methodologies, airTec introduces an innovative approach towards achieving a flawless finish in panel furniture manufacturing.

In New Zealand, the popularity of airTec technology is on a remarkable ascent, with its integration into woodworking processes becoming increasingly prevalent. Currently, about 80 percent of the new HOMAG edge banders being introduced to the market are equipped with the airTec system. This trend reflects a clear demand among woodworking industry and joiners for machinery that not only promises reliability and superior performance but also consistently delivers exceptional quality finishes. Furthermore, the ease and speed with which HOMAG airTec edge banders can be configured to accommodate a diverse range of materials stand out as a significant advantage, perfectly aligning with the expectations and requirements of the customers.

airTec:

The Foundational Concept airTec technology revolves around the principle of using a highly concentrated stream of hot air to melt a functional layer on the edge band material, thereby creating a seamless bond between the edge band and the workpiece. This method contrasts starkly with conventional glue pot techniques, moving towards a cleaner, more integrated finish that obliterates the seam between the panel and its edge - colloquially known as a "zero-joint" finish. This is achieved by melting and molding the edge banding material in a way that it becomes indistinguishable from the panel it binds to. The result is not just aesthetically superior but also creates a more durable edge, resistant to factors like moisture or wear over time.

The Rationale Behind airTec

The principles guiding the development of airTec were two fold: aesthetic excellence and

the elimination of vulnerabilities associated with traditional edge banding methods, primarily moisture intrusion and delamination. HOMAG initiated this technological development with an acute awareness of these issues. The goal was to address genuine market needs and crafting requirement.

The Tangible Advantages of airTec

The advantages of employing airTec are manifold but can be distilled into two primary benefits: enhanced product longevity and a visually appealing, seamless finish. The absence of glue lines ensures that the finished product appears as a unified whole, significantly contributing to its aesthetic value. More practically, the elimination of glue lines also removes a common entry point for moisture, which can undermine the structural integrity of the panel over time.

The Technical Benchmarks of airTec

Delving into the specifics, airTec distinguished itself through several key technical benchmarks:

1. Precision Temperature Control: The system is engineered to adjust the air temperature dynamically, based on the material being used. This ensures the activation of the adhesive layer without compromising the integrity of the edge band or the substrate.

2. Targeted Airflow: airTec employs a focused airflow mechanism that directs heat precisely where it is needed. This targeted approach minimizes the risk of thermal damage to the surrounding areas of the panel.

3. Material Versatility: The technology supports a variety of edge banding materials, including Laser

Above: HOMAG edge panels zero-joint and left edgeband with pigmented edge profile - can be realized with EDGETEQ models.

tape, ABS, PVC, and several veneers, offering flexibility to manufacturers in choosing materials that align with the design and durability requirements of their projects.

4. Integration and Automation: Importantly, airTec has been developed to seamlessly integrate into HOMAG’s edge banding machines. This integration allows for the process to be automated and synchronized with the other stages of edge finishing, enhancing production efficiency.

Application Spectrum: Where is airTec Used? airTec is versatile in its application, finding usage across a broad spectrum of HOMAG machinery. Its deployment isn't confined to a singular class of edge banding machines but spans from the smaller, more flexible units aimed

In the world of joinery, the New Zealand Building Code is not just a recommendation - it's a legal obligation. As a joiner, you bear the responsibility for ensuring that all your supplied joinery meets these stringent requirements. JMF can help you navigate the complexities with confidence.

Understanding the Building Code Requirements

Specific clauses in the Code directly relate to doors and windows, including:

at bespoke manufacturers to the larger, automated lines designed for industrial-scale production. This wide-ranging applicability underscores airTec’s adaptability to varying production scales and requirements.

Machines Featuring airTec:

• High-Performance Edge banders: Targeted towards larger manufacturers, these machines are equipped with airTec to ensure highspeed production without compromising the finish quality.

• Compact Edge banding Machines: Even in smaller scale operations, airTec is available to ensure that quality isn't dictated by the size of the operation.

The efficacy of airTec is intrinsically linked to the type of edge band material used. This technology necessitates the use of edge bands that have been specifically prepared with a thermally reactive layer and commonly referred to as laser tape. These materials - spanning the gamut from ABS, PVC, to certain high-grade veneersundergo a special treatment to

ensure they respond optimally to the hot air application. It is this specificity in material design that underpins the effectiveness of airTec, ensuring the seamless joint that is its hallmark.

In Conclusion

airTec, developed by HOMAG, does not merely represent a step forward in edge banding technology but signifies a shift towards a more refined, aesthetically driven, and durable approach to panel finishing. By dissecting its conceptual framework, appreciating its benefits, acknowledging its origins, and understanding its scope of application and material compatibility, one gains a comprehensive perspective of airTec’s role in modern woodworking. This is not merely technology for technology's sake but a thoughtful response to the nuanced demands of furniture production.

As the woodworking industry continues to evolve, the development of compatible materials also progresses, ensuring that airTec remains at the forefront of edge banding technology.

• B1 Structure

• G4 Ventilation

• B2 Durability

• G7 Natural Light

• E2 External Moisture

• H1 Energy Efficiency

• F2 Hazardous Building Material

Regardless of project scope - whether it's a new build, a renovation, or simple repairs - your work must meet these standards, independent of architectural specifications or council checks.

Demonstrating Compliance: The JMF Advantage

To aid joiners in proving compliance, JMF offers a comprehensive solution. Their full suite of joinery has been rigorously tested to meet NZS 4211 standards, covering all relevant B1 and E2 clauses. Here’s how JMF can support your compliance journey:

Comprehensive Manuals: JMF provides detailed manuals outlining the manufacturing process of their joinery suite.

Compliance Tags: Affiliated manufacturers can purchase tags from JMF to attach to their joinery products. These tags serve as a "green ticket" with the council, evidencing that the joinery complies with the Building Code.

Industry Ownership and Collaboration

Now is the perfect time to join forces with JMF and secure your place in an industry committed to excellence and compliance.

Get in touch with Sarah from JMF today by emailing sarah@jmfnz.co.nz or calling 021 566 092

As the joinery industry navigates through economic challenges, Hutchco stands out by prioritizing customer success and affordability. Through strategic partnerships, Hutchco is making high-quality PP laser edging more accessible to joiners across New Zealand. This commitment to customer satisfaction is exemplified by the success stories of two notable clients: Mastercraft Kitchens Wellington and Sharp & Page.

Sharp & Page, a leading kitchen and cabinetry manufacturer since 1936, has always prioritized highquality manufacturing and cuttingedge technology. “We switched to laser edging seven years ago as part of our commitment to continuous improvement and

manufacturing efficiency,” says Adam Sharp, Managing Director of Sharp & Page. “The invisible edge line and added moisture resistance of the Prolaser Fusion are game-changers for us.”

With the rise in popularity of prefinished boards in New Zealand, Sharp & Page’s customers are increasingly opting for these durable alternatives over traditional painted surfaces. The Prolaser Fusion-Edge, with its zero joint technology, has been pivotal in meeting this demand. “The improved supply line of prefinished boards means our customers have more durable and aesthetically pleasing options,” adds Sharp.

Mastercraft Kitchens Wellington, a prominent name in the cabinetry industry, serves a diverse clientele ranging from builders and developers to retail clients. Paul Lunn, Company Manager,

emphasizes their comprehensive service range: “We provide cabinetry for new builds and renovations, often producing everything from kitchens to entertainment units.”

Three years ago, Mastercraft Kitchens Wellington invested in new machinery, making the adoption of laser edge capabilities an obvious choice. “Many of our prospective clients were asking about laser edging,” Lunn notes. “Taking glue out of the recipe means we have less downtime in our manufacturing process. You cannot fault the finish when using Prolaser edging.”

“Our research for edge supply was assisted by our machinery supplier,” Lunn continues. “They advised that not all laser edging is created equal. Our choice of edge supplier came about through seeking advice from our machinery supplier and our outstanding supplier contacts.”

The collaboration between Hutchco and Surteco Germany has been pivotal to extensive expansion of Prolaser FusionEdge range. This strategic initiative also empowers Hutchco to be more competitive with rates. Mark Leith, Managing Director of Hutchco, expresses the significance of this: “We're now positioned to offer competitively priced bulk rates for White Prolaser PP Laser edging, especially timely as joiners navigate through some difficult economic conditions”.

The introduction of popular woodgrain décor matches in a complimenting hybrid finish of the hugely admired organic and timberland pressings, reflects Hutchco’s dedication to meeting diverse customer needs. Marketing Specialist Tux Hika highlights the need for versatility: “Our customers expect simplicity without compromising the visual aesthetics. With the vast array of finishes now available, it's critical that we offer embossings which are broadly applicable.”

Prolaser Fusion-Edge offers five surface finishes—Satin/Velvet/ Naturale, Pearl, Matte, Gloss, and Organic/Timberland—available in 22mm and 45mm with 29mm & 35mm readily achievable.

Through customer-centric practices, and a commitment to sustainability, Hutchco continues to support businesses like Sharp & Page and Mastercraft Kitchens Wellington, enabling them to thrive in a competitive market. As the industry evolves, Hutchco’s dedication to excellence and affordability ensures they will remain a trusted partner for joiners across the region.

For more information on Hutchco’s products and services, visit www. hutchco.co.nz

Sharp & Page – Omaha, Photo Mark Scowen.

Sharp & Page – Omaha, Photo Mark Scowen.

Everett Collection/Shutterstock.com

Everett Collection/Shutterstock.com

Some of us still remember them, others have heard about them. Cars from the last century that virtually required owners to be a mechanic. Weekly oil checks, grease jobs, valve adjustments, carburettor tunes, and of course the choke for cold starts. It all seems a long time ago now, because new technologies have since firmly put all these hassles in the past, at least for cars ...

Fortunately, similar improvements are now finally happening for the edge banding process. The now widely available "Laser" tape applied with the in New Zealand developed "Hyfuse" system are leading the charge. No more glue pots warming up, no glue changes, no cleaning or solvents. No gluepot maintenance. Just turn on the machine, run jobs,

New Zealand's early adoption of laser technology underscores the global momentum toward sustainable manufacturing practices.

In recent years, the European furniture industry has witnessed a remarkable surge in demand for laser edging solutions, with notable year-on-year spikes observed in Germany's office furniture sector and Western Europe's kitchen industry. According to Sherif Salem, Area Sales for Proadec Portugal. Salem emphasizes the critical role of such advancements in enhancing the aesthetic appeal and operational efficiency of furniture manufacturing processes.

Adam Sharp, from Sharp & Page, a leading kitchen and cabinetry manufacturer since 1936, stated, "We switched to

laser edging 7 years ago as part of our commitment to continuous improvement and manufacturing efficiency. We were drawn to the invisible edge line, and also the added moisture resistance that the Prolaser Fusion provided."

"The zero-joint effect achieved with FUSION-EDGES ensures unparalleled stability in production," notes Salem.

"Manufacturers no longer contend with multiple glue types, streamlining operations and optimizing machine utilization."

By incorporating a functional layer on the reverse side of edge banding, joiners eliminate the need for adhesives, thus reducing glue waste to zero. This aligns seamlessly with SURTECO’s ambitious "zero waste" production goal, championing the recycling of plastic and ink waste in-house.

"Innovation is at the heart of our operations," states Salem. "Through close collaboration with machine manufacturers and raw material suppliers, our R&D is a continuous development, guaranteeing high quality and stable production procedures.”

With the market rapidly evolving, forward-thinking New Zealand joiners are poised to lead the

turn off. Simple; as it should be. For the more traditional amongst us, don't worry, you can still use your gluepot after fitting Hyfuse to your machine!

Hyfuse is extremely energy efficient, does not require a big compressor, storage tanks or large power cables. So, to move your edge banding into the twenty first century, contact Henk or Neil from HP Tech or your local Biesse representative.

North Island

Neil Pollington +64 21 781 742

South Island

Henk van Oeveren +64 3 547 6699

charge, championing quality, sustainability, and innovation. Mark Leith, Managing Director of Hutchco Enterprises, expresses confidence in the industry's growth trajectory, stating, "We're confident that the growth in laser usage is only increasing, which is evident in the rising demand for laser machines over the past year alone."

As these professionals integrate advanced technologies and ecofriendly practices, they're not only meeting current demands but also setting new benchmarks for the future of furniture manufacturing.

Hutchco Enterprises www.hutchco.co.nz

30 Years Years

When sizing panel material, tools used can generally be loud and heavy due to their structural design, resulting in stress on machines and excess noise for the user. Over ten years ago, Leitz developed the pioneering tool solution for this problem that still sets the standard in terms of sustainability, efficiency and quality in edgebanding: the lightweight and quiet DiamasterWhisperCut jointing cutterhead.

Since then, Leitz has developed this cutter into a complete system family. With the available product variants, including one with an integrated HSK 32 R adaptor, users can optimize existing jointing concepts and improve their production costs.

Leitz for the best in Edgebander tooling with the Diamaster WhisperCut & WhisperCut Plus: The light and low noise jointing cutterhead with the PLUS of efficiency.

Noisy and heavy tools result in stress for man and machines. The light and low noise Diamaster WhisperCut jointing cutterhead is specially designed to reduce noise and increase efficiency.

SUSTAINABILITY

Light, low noise and reusable

Considerable noise reduction of up to 5 dB(A) through optimised tool body shape and weight halving

Reduced load of spindle and machine through light tool body

Reusable tool body saves resources

Perfect results

Clean workpiece finish through troublefree chip ejection and excellent chip collection with DFC-technology Perfect quality even with demanding panel materials QUALITY

EFFICIENCY

Cost reduction and increased productivity

Reduced costs per running metre through sharpenable cutting edges and reusable body

Shorter set up times through constant diameter

Optimum knife usage by exchanging unused cutting edges within the tool

Light, quiet and efficient are just three advantages of the WhisperCut programme. The technical design of the tools enables them to produce perfect edges and cut surfaces and also makes the jointing cutterhead significantly quieter. The closed shape of the light metal tool body allows for noise reduction of up to 5 dB(A) as well as higher balance accuracy - reducing stress on machine bearings. The high level of machining quality is also underpinned with proven DFC® technology, which enables up to 95 percent of chips to be collected, creating longer running times and better finishes. In addition, the lightweight aluminium tool body is fully recyclable.

To this day, the Leitz WhisperCut system still sets the standard within the industry for jointing cutterheads, especially regarding costs and maintenance. The specially developed diamond cutting edges allow for multiple resharpening servicing and additionally, the replaceable cutting edges can be switched out by the user. This allows the diameter of the tool to remain constant, reducing set up and adjustment times compared to conventional systems, maximising efficiency. There are several versions of the cutter available; the basic version allows cutting edges to be resharpened up to three times, with the WhisperCut

PLUS version featuring an enlarged resharpening area on the cutting edges allowing up to ten resharpens. Both versions are available with a bore or shank.

For users of laser edging systems, Leitz also has the WhisperCut EdgeExpert variant in its product range. Resharpenable up to three times, its special cutting edge arrangement provides even better machining quality.

With the development of the WhisperCut system family, Leitz has reinforced its position as the world leader in the customeroriented development of tool systems for the furniture industry. With more than 120 Leitz Service Centres around the globe, users can easily have their tools serviced and resharpened perfectly to manufacturer quality conveniently. These solutions in new dimensions show why Leitz simply offers more in quality, efficiency and productivity –resulting in more success for users of Leitz products.

Leitz Tooling 0800 578 665 sales@leitz.co.nz

The DiamasterWhisperCut product range is available in numerous design variants and can be used on almost all common machine types. (Photo: Leitz)