Hard work areas

tops & sinks that look good and last

Drawer fronts to make or to buy

m a g a z i n e September 2023

Cabinetmaking & Kitchen Manufacturing Industries O n s h o w i n E u r o p e On

Joinery,

show in Europe

Ligna & interzum

www.hafele.co.nz

Innovative strength, courage and optimism: these qualities have accompanied Häfele from the very beginning, and also characterised the founders back in 1923. The original 2-man business, which was a specialist hardware store, has developed into a global company, Häfele SE & Co KG, with subsidiaries in 38 countries and more than 8,000 employees. Time and again during Häfele’s eventful company history, courage, innovative spirit, flexibility and perseverance have manifested themselves and taken the company forward. The world’s leading expert in intelligent hardware technology, lighting and electronic access control systems is currently celebrating “The First 100 Years” and very much looking forward to what the next 100 years looks like.

JOINERS Magazine September 2023 page 1 Maximising the value of space. Together. www.hafele.co.nz | www.hafelehome.co.nz A powerful blend of design, function and quality. This is the Häfele philosophy. Creating individual, inspiring, functional spaces that have a positive impact on the way you live. Together with our Partners, we have the knowledge and expertise to make your home smart, well organised, flexible and future proof. Simply a better place to be.

for a perfect finish start with GoldenEdge HMR0

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Eco Friendly helpingtheenvironment

JOINERS Magazine September 2023 page 2 www.nelsonpine.co.nz

HMR0 MS 21526 J FURNITURENo.FITTINGS& 3208038

Nelson Pine Industries Ltd, Nelson, New Zealand

COLUMNS

Master Joiners 4

Incoming president Nathan Busch introduces himself and talks about the need for professionalism in all we do.

Laminex Update 12

Mike Arthur comments on his travel around the country and shares the latest additions to the company’s products and services.

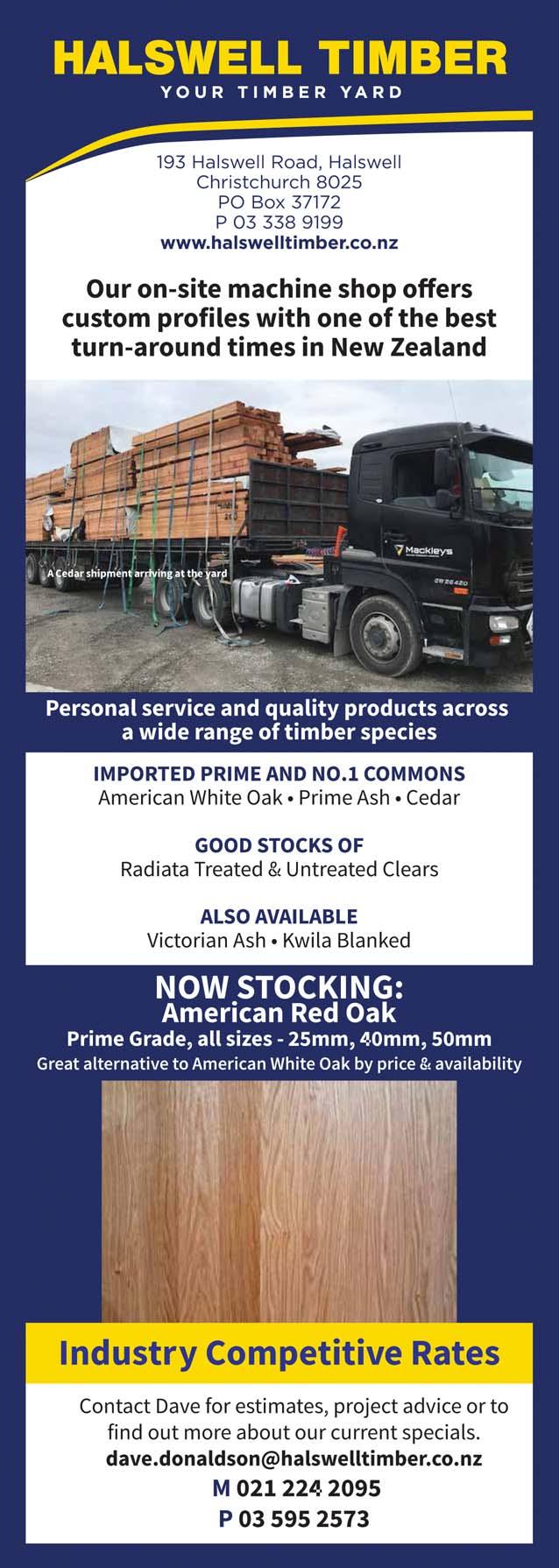

NKBA news 93

The NKBA profile a new member and promote their new 2023 Awards publication as a guide to contemporary kitchen & bathroom design in NZ.

Steering a Course 94

Ian Featherstone suggests sticking to the knitting wont get us where we want to go anymore and we need to embrace new ideas and diversity.

REGULAR

News & Info 4 - 16

State of the Industry 96

NZJMF membership 98

Classifieds 104

Advertiser index 104

Conference winner 18

Bob Nordgren reports on the annual Master Joiners Conference held in Wellington in late May and gives us a behind the scenes look at the Supreme Award winner from Wellington firm Craftbuilt Industries.

History & innovation 22

For almost 100 years Tunnicliffe Timber have been supplying timber to the country’s construction and trade industries. Ongoing innovation means that today it stands at the forefront of timber technology.

Ligna & interzum 24

Held a couple of weeks apart in Germany these are two not to be missed shows for all in the kitchen, furniture and wood processing industries. We speak to several who attended both to view and to display the latest in design, product & machinery.

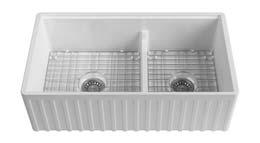

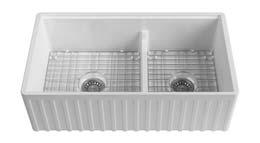

Work surfaces 56

Solid surface, stainless steel, porcelain, ceramic, laminates - hard wearing, functional and aesthetic. We look at a range or work tops and sinks in a variety of materials, all worthy of their place in the centre of the kitchen.

Up front 68

With manufacturers offering a wide range of materials and designs to fit most specifications an increasing number of kitchen makers are finding it easier to buy in their door and drawer fronts when fitting out a kitchen or residence.

JOINERS Magazine September 2023 page 3

m a g a z i n e

COVER

Supreme Award winner p.20

Laser tape retro-fitting - p.47

Photo courtesy Craftbuilt Industries

from the president

13.08.2023

Professional conduct

Ihavelaced up the boots of the National President and I welcomed those boots, a few months in and I feel these boots were made for jogging), Andrew Reilly has the slippers of the Past President, he is not sure it will give him an edge on the golf course!

As this is my first editorial as the National President, I would like to share a little bit about myself. I live in a rural town Hinds, south of Ashburton. We have a 160-ha farm where my joinery workshop is also based. I am kept busy between both farming and joinery business. I have one employee in the workshop, and we have a very busy schedule. Rebecca my wife is a Medical Laboratory Scientist and I have a 22-year-old daughter and an 11-year-old son. Family time is a high priority and I love watching my kids play sports. I enjoy all sports but especially rugby, rugby league and basketball.

I did my joinery apprenticeship in Invercargill at Lloyds Joinery before moving home to Christchurch to further my joinery career. I started my own joinery business Busch Joinery in 2005.

professionalism is not the job you do, it’s how you do the job

I was elected National President in June and feel more comfortable in the role as time passes. Allison has made the transition very enjoyable and is so helpful and accommodating. There is lots of work to be done and getting head office staffed is on high priority.

I confess to having a personal disposition for professionalism in my personal relationships or professional endeavours. I believe that maintaining a sense of professionalism involves being reliable, setting your own high standards, and showing that you care about every aspect of your job. It’s about being industrious and organized and holding yourself accountable for your thoughts, words and actions. Ultimately, I believe it is an important part of who I am as a person and how I contribute to my profession as a joiner.

As the saying goes “professionalism is not the job you do, it’s how you do the job”. How you do your job begins with those key interactions with the customer this can reflect on productivity and overall success of the relationship.

Check that your messages are clear and effective by following the dos and don'ts of professional email communication and phone calls. Personal branding should never be overlooked. When heading out to client meetings, and you have been on the tools all day because you are filling in for staff absences sometimes it's easy to forget your personal presentation.

I am looking forward to hearing your views on what impacts success during the highs and lows of the market, where does professionalism fit into that. Chat about it next time you're having Friday drinks, it is interesting to hear how others see and experience it.

My final words is to acknowledge the professionalism of those who have filled these Presidents boots over the many years Master Joiners has been advancing the

objects of its members, we all bring a little something that makes up a whole and I am confident that in this era of the organisation and our profession, we will continue to advance harmony in action.

Nathan Busch National President Registered Master Joiners

JOINERS Magazine September 2023 page 4

JOINERS Magazine September 2023 page 5 0800 781 200 sales@egmontair.co.nz www.egmontair.co.nz 0800 781 200 Fax 06 278 1225 EgmontAir Dust & Fume Extraction Your dust extraction specialists EgmontAir Dust & Fume Extraction A BREATH OF FRESH AIR FOR YOUR WORKPLACE » • Create a cleaner and more productive workshop • Protect your employee’s health with the latest in dust extraction • Phone for technical advice or information • Wood Dust Extraction • Spray Booths • Centralised Extraction Systems • Suction Benches • Exhaust Fumes Extractors • Grinding Dust Extractors • Welding Fume Extraction • Extraction Fans

Editor Michael Goddard michael@joiners.net.nz

Publisher Bob Nordgren bob@joiners.net.nz

A full house

Wehave a full house for this issue that completes twenty eight years we have been publishing the magazine. Of interest to many of you will have been the international trade shows Ligna and Interzum held in May in Germany. We have a fair bit of commentary from various suppliers who participated in these events which will give those who stayed home a taste of what was on offer.

Of course in late May was the Master Joiners Conference held this year in Wellington. A real talking point was the impressive venue: the almost completed Takina Events Centre right in downtown Wellington. I’m picking a great future for this site. The big event was of course the Awards night. The Supreme Award was taken out by Wellington firm Craftbuilt Industries with their marvellous staircase. We have a good spread reviewing the Conference and looking at how the Supreme Award winner was made in this issue.

When it comes to kitchen doors and drawer fronts there is quite a range to choose from. It really is quite surprising as to the range and variety at hand as you will see in our feature on these products. I guess you can’t go past anniversaries either. We with our humble 28 year history and Hafele with their 100 year anniversary. Along with their international record they also have a strong foot print here in New Zealand which we allude to in this issue as well. Last but not least is our feature looking at sinks and benchtops, always an interesting look as they are always changing and moving forward. This feature is no different. Another company of interest is Tunnicliffe Timber about which we have a spread in this issue. Worth a read. Thank heavens we are now moving into Spring and then Summer!

Enjoy this issue as it is a full one.

Bob Nordgren

Advertising statements or

opinion are not necessarily those of the publisher, its staff, the New Zealand Joinery Manufacturers Federation Inc., or their executives, unless expressly stated. All articles printed in JOINERS Magazine are subject to copyright and cannot be reproduced without the express consent of the Publisher or the authors therein. Advertisements and articles are accepted without liability as to the accuracy or otherwise of the factual matters represented.

JOINERS Magazine September 2023 page 6

The magazine for the joinery, cabinetmaking & kitchen manufacturing industries

Publication of the New Zealand Joinery Manufacturers Federation magazine

1173-6836 42 Aldersgate Rd, PO Box 27 - 513, Mt. Roskill, Auckland, 1440, New Zealand. Ph: 64-9-624 4680 JOINERS Magazine is the official publication of the New Zealand Joinery Manufacturers Federation. It is distributed to members of the joinery, cabinetmaking and

industries and is published quarterly in March, June,

Joiners Magazine Online www.joiners.co.nz

PRINTERS DISTRIBUTORS from the Publisher

Official

ISSN

kitchen manufacturing

September and December.

editorial

M

Show reports from Europe p.24

JOINERS Magazine September 2023 page 7 P-System The time-saving joining system with form-locking anchoring Lamello products are exclusively available in New Zealand by: Penrose Branch – Head Office 727 Great South Road Penrose Auckland, 1061 Phone: +64 9 571 0045 Email: sales@rands.co.nz North Harbour Branch 26 Hillside Road Glenfield Auckland, 0627 Phone: +64 9 444 6389 Email: nh@rands.co.nz Hamilton Branch 9 Keddell Street Frankton Hamilton, 3204 Phone: +64 7 847 8928 Email: ham@rands.co.nz Christchurch Branch 200 Montreal St Christchurch Central Christchurch, 8011 Phone: +64 3 662 9502 Email: christchurch@rands.co.nz Free Demo? Contact your closest Branch! Tenso P-14 Divario P-18 Tenso P-10 Clamex P-14/10 Medius Clamex P-10 Clamex P-14 Clamex P-14 Flexus

NZ Timber Design Awards 2023

finalists announced

Wehave had a record number of fantastic entries this year – which is definitely a good problem to have! There has been some tough decisions being made behind the scenes from our judging panel, and we are happy to now confirm, and announce, the 2023 finalists!

Keeping in mind that winners will be announced at the official gala dinner, you can relish in the beautiful finalists entries on the Timber Design Centre’s website now (soon to be renamed), and start to celebrate the pure timber-talent that we have had the privilege of hosting this year.

The judges for this year’s programme included New Zealand Institute of Architects president Judith Taylor, New Zealand Timber Design Society past president David Carradine, sustainable architect at Scion Andrea Stocchero, and Structural Engineer Jan Stanway, from WSP.

As with previous years, the task for the judges is no easy feat; with all entries showing innovation, aesthetic appeal, creativity and practicality made possible through the use of timber; ranging in projects from furniture, to multi-storey buildings. The entries made it obvious that the architecture, manufacturing and engineering sectors in New Zealand are ready to embrace the challenges of creating low carbon timber solutions by incorporating state-of-the-art technology with innovative applications of timber and a variety of engineered wood products.

As noted by the judges, “It was really impressive to see different parts of the building industry coming together and working collaboratively to develop such innovative solutions using timber. The combinations of materials, forms and technological advances will pave the way for the future of sustainable and resilient buildings in Aotearoa New Zealand. Structural systems, interior finishes and exterior applications have all been considered as opportunities for showcasing the unique and beneficial applications of timber.”

With some final commentary from Timber Design Centre Director, Robert Finch; “The breadth of innovative thinking and really clever use of timber, combined with other materials demonstrated in the 2023 Awards entries is just extraordinary! I congratulate all the entrants and finalists on the wonderful showcase of what is possible with timber in our built environment”

We would like to thank our Sponsors, as without their support these awards would not be possible.

For full list of finalists go to www.timberdesigncentre.co.nz/award

JOINERS Magazine September 2023 page 8

St Kentigerns Preschool - finalist Commerical & Public Design Award, Phil Smith, Smith Architects. (photographer Caroline Ducobu)

Opuke Thermal Pools - finalist Hybrid Design Award, Sheppard and Rout Architects Ltd with structural engineers Ruamoko Solutions.

Kohinga - St. Albans Community Centre – finalist Sustainable Design Award, Emma O’Neill, PTL Structural & Fire. (photographer Crispin Schurr)

JOINERS Magazine September 2023 page 9 Resene AquaLAQ TM Waterborne low VOC coating system for cabinetry, joinery, shop fittings, kitchens and doors Call 0800 108 008 or email help@reseneauto.co.nz to become a trained and registered applicator | reseneauto.co.nz/aqualaq • Economical • Hard and Durable • Waterborne 1K System • Authentic Resene colours Water Based Paint Licence No 1296003 AquaLAQ is waterbased, low VOC, low odour and Environmental Choice approved. Better for your business and better for your customers.

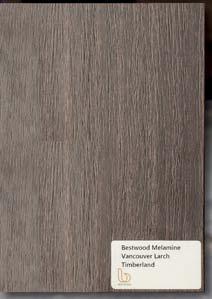

Vancouver & Alberta Larch

Bestwood is releasing two new melamine decors to the market later this month (September) with a cool mid-century vibe. CARTERS Joinery Supplies team are excited about the impending launch and look forward to being able to provide these new options to their joinery partners soon.

Vancouver Larch and Alberta Larch both have a finely-grained quarter-cut timber appearance that was very popular with furniture and cabinetry-makers through the 1940s, 50s and 60s and is now enjoying a renaissance.

The dark chocolate of Vancouver Larch pairs beautifully with softer pastels such as pistachio and duckegg blue and makes a striking complement to white and offwhites too.

The soft warm tones of Alberta Larch make it a hugely versatile option that will pair well with warm veined benchtops along with dark navy and green.

Both melamine designs are identical but presented with different colouring. They exhibit a softly striated colour across the panel that creates more interest than might be found in a traditional quarter cut veneer.

While wood such as teak (now expensive and difficult to sustainably source) was the favoured material used in midcentury cabinetry, the lines of furniture and cabinetry were clean and simple, moving away from the previously busier styles of art deco and focusing much more on functionality than form.

With these two woodgrains sampled in the strongly textural

Timberland finish, they provide a very useful alternative to consider when clients’ budgets might not stretch to veneer. And offer the perfect answer to those embracing mid-century modern design styles.

JOINERS Magazine September 2023 page 10

Bestwoods two new decors have a finely-grained quarter-cut timber appearance reminiscent of mid 20th century design.

New Bestwood Decors

JOINING IT ALL TOGETHER

Partnering with CARTERS makes it simple to get the pieces of the puzzle sorted for that perfect finish, every time.

You can count on us to stock the market’s bestknown brands. By servicing the joinery market for decades, we understand that a joiner’s requirements are unique and have specialty joinery branches across the country to support your business.

Let’s partner together.

COMING SOON

Two new melamine decors are about to be released providing the perfect answer to those embracing mid-century modern vibes.

JOINERS Magazine September 2023 page 11

150 YEARS 50 BRANCHES 1 ACCOUNT 0800 CARTERS | www.carters.co.nz

update

Greetings!

It’sofficially Spring and we’re looking forward to some calmer, warmer weather. I’ve been travelling around the country throughout August to visit our Laminex team and share our refreshed Vision and our plan for the next three years; we had strong engagement and positive feedback. You can expect continued focus on great service from our team and improvements to ensure we are easy to do business with.

As part of continuous improvement, we’ve upgraded our telephony system. The new system will enable call recording for coaching, resulting in data and info capture, so you shouldn’t need to repeat the same details to multiple people. Another great feature is requesting a call back based on your position in the queue.

I enjoyed meeting with a number of customers during my travels, many of whom are tracking well but anticipate the market to soften for the next 12 months with higher interest rates and a pending election dampening growth.

We welcomed new Laminex team members to our Dunedin Branch in August – Deborah Jones and Millie Elliot, who are both experienced and have a strong customer focus. We’re excited to have them join the Laminex team - and you can read more on page 14.

At Laminex NZ the health and safety of our team, customers and our community are our highest priority. As a founding member of New Zealand Engineered Stone Advisory Group we assess safety practices of every new Laminex fabricator. We are working with all our fabricators to ensure they gain RCS Accreditation and can meet the standard required to process Caesarstone. You can find a list of fabricators with Engineered Stone Fabricator RCS Accreditations on the Impac.co.nz website.We have begun phasing in our low silica (less than 40%) Caesarstone range from this month.

Our showroom at the Home Ideas Centre in Auckland suffered damage during the floods earlier this year. We are proud to share that our updated showroom is now complete with over 200 products on display making it the space to refer your customers if they want to view a range of Laminex products in larger format. Also look out for our new 12mm Laminam porcelain decors that we’re launching soon – watch this space!

Mike Arthur General Manager Laminex New Zealand

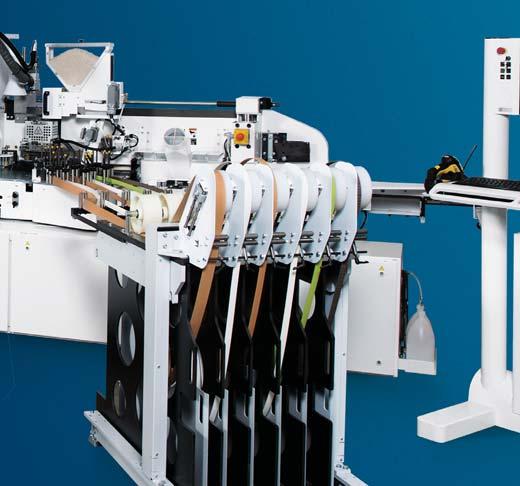

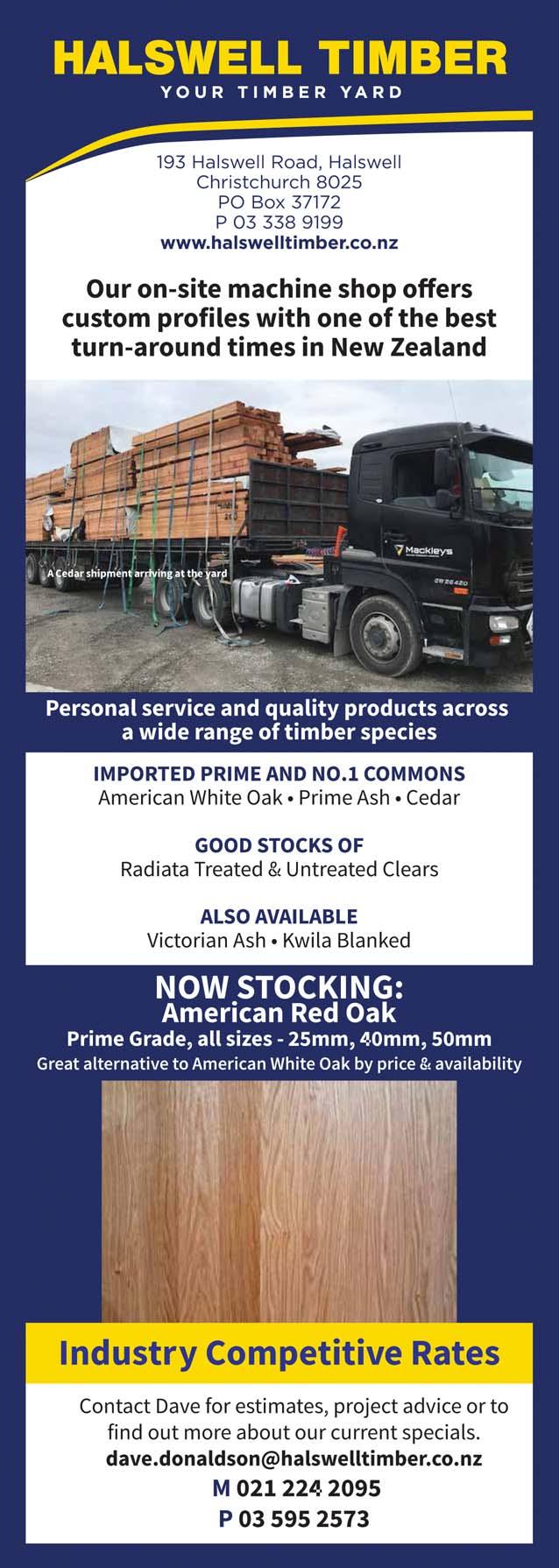

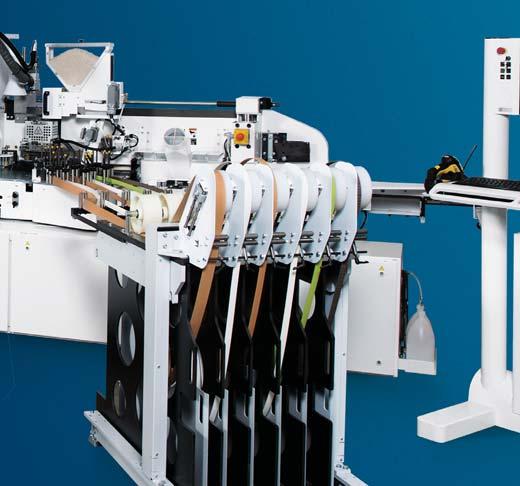

Proform announce new partnerships with Fravol, Masterwood & Fimal

Fravol are a manufacturer of high quality edgebanders in Italy. Fravol do not compromise on quality and have a wide range of machines to suit all applications and budgets from curvedpanel edging machines all the way to servo-controlled Fusion Zero-Edge finishing edgers. In collaboration with Jowat, Fravol have developed a unique glue spreading system, like no other. Using Polyolefin glue, it has excellent technical features: heat resistance, high yield, zero bondline and stability. Fravol are the only edgebander manufacturer using this amazing glue as standard.

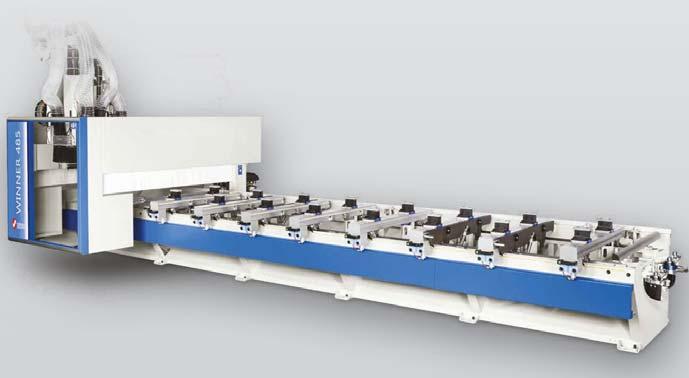

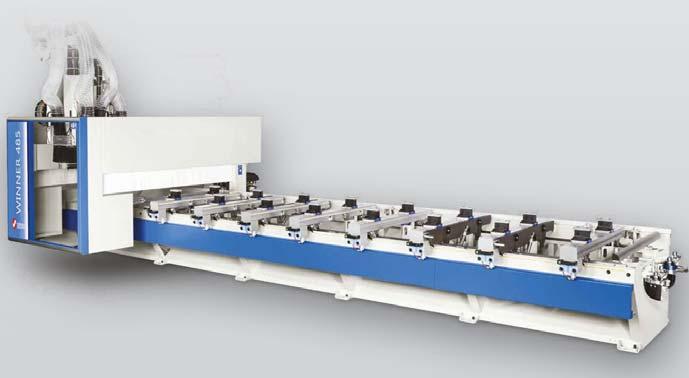

Masterwood, based in Rimini, Italy, has a wide range of quality CNC routers from the flat bed CNC to the traditional pod and rail 5 axis Winner 485 machine. Masterwood has been producing woodworking machinery for more than fifty years, helping the furniture and joinery industry with their passion and professionalism.

Fimal are a well-established leading manufacturer of panel saws based in Vigonza, Italy. A trusted Italian brand for over 60 years. While they have a wide range of woodworking machinery, they are especially advanced in their field of panel saws.

Rob Hutchings, General Manager of Proform CNC Ltd comments “We are incredibly proud to partner with these great Italian brands. This allows Proform to supply a very wide range of machinery to its customers and not compromise on quality.”

For further information contact Rob Hutchings at Proform CNC Ltd on 021 711 248, email rob@farnese.co.nzx or visit www.proformnz.co.nz

JOINERS Magazine September 2023 page 12

Laminex New Zealand™

M200-23

The modern, compact design of the Italian FRAVOL M200-23 EDGEBANDER saves space without compromising on performance or edge quality. A mix of solutions, applications and technologies in just 3 metres.

WINNER 485 5 AXIS CNC

The Winner series from Masterwood has been designed to meet the needs of most companies, offering the best technical solutions on the market. Winner machining centres offer flexibility of usage, reliability and high productivity.

FIMAL TABLE SAW

A classic among machines for processing wood and wood products.

F.I.MA.L. circular saws are the perfect woodworking solution for people who must perform frequent cuts with different angles.

JOINERS Magazine September 2023 page 13 DESIGN FEATURES

PH 04-5268589 www.farnese.co.nz info@farnese.co.nz 68 Montgomery Crescent, PO Box 40-809, Upper Hutt, New Zealand

ACFA awards finalists

The finalists for the 2023 ACFA Industry Awards Night have been announced. The finalists of this year's awards can be found across ACFA's social media and website and are ready for everyone to peruse this year's projects. Each year the quality of entries continues to raise the bar, demonstrating the calibre of craftsmanship and professionalism of our industry. The 2023 awards capture the projects created between 1st July 2021 and 30th June 2023

The judging process is by a panel of independent experts which consists of industry representatives who have a strong knowledge of the industry, operations, manufacturing, and trends. Bias towards any person or company is controlled through the ‘blind’ judging process – any reference to a company or person is removed from the material the judge reviews. This ensures every entry is evaluated on equal grounds.

The high calibre of entries made the judges work hard, with another record-breaking number of entries across 25 awards. Judges

assess each entry on three main criteria - design, functionality, and innovation. When asked to provide a summary of the entries in 2023, the judges used the words ‘Diverse’ and ‘Inspiring’. The judges commented on the careful consideration on the way functionality had been incorporated into the entries and the level of detail our industry puts into the build of a project.

The calibre of finalists showcases the importance to recognise the quality of projects our industry produces. Dean Brakel, CEO of ACFA shares, “The ACFA Industry Awards exist to recognise outstanding achievements within the furniture, joinery, and cabinetmaking industry. The awards showcase our industry’s hard work, dedication, and craftsmanship. Every single person who entered this year’s awards should be proud of what they are achieving.”

The industry is set to come together on Friday 15th of September as the winners are announced at a dinner, celebrating industry excellence at Dockside in Darling Harbour Sydney.

Debbie Jones

Debbie joined the Laminex team in August and is Southern Sales Business Partner. Debbie was introduced to the building products industry after deciding to follow her passion to be part of the journey with clients and see their ideas turn into reality. Having worked with two of the largest stone fabricators, Debbie comes with a wealth of knowledge already.

Debbie is based in Cromwell and will service customers in the lower South Island. Outside of work, you may find Debbie out on the boat on Lake Dunstan, or cycling one of the scenic trails and enjoying some award-winning wine refreshments at the end. She is excited to be part of the Laminex team and will be travelling around to meet her customers over the next several months.

Brittany Smith joined the team at Blum Christchurch in February 2022 as a Specification Consultant for Joiners in Mid-Canterbury and the West Coast and Architects south of Christchurch. Brittany says, "New Zealand produces amazing joinery". In her role, she loves seeing talented designers and cabinetmakers coming up with incredible solutions.

Brittany worked as a Cabinetry Designer for nine years before joining Blum, gaining extensive experience on residential and commercial projects. Working as an inhouse designer, she was able to get a greater understanding of design as well as cabinetry.

Millie joined the Laminex team mid-August and is Regional Sales Support for Dunedin branch, taking over from Michael Clark. She has been working within the industry for nearly five years, having most recently worked for a major furniture manufacturer.

A designer by trade, she’s interested in interior design and the industry through the diverse range of products and people, and seeing designs come to life. Millie is excited to be part of the Laminex team and get to know the Southern customers; feel free to stop into the branch to say ‘Hi’.

Brittany has been busy this year customising a campervan for travelling, making all the cabinetry herself. She has welcomed the opportunity to develop her skills in this area. "I'd never really made anything in my life, so it was fun to make some joinery. It also gave me a better understanding of how things went together. I love learning new skills!"

In the past, Brittany has done an OE in Europe and lived in London, but now enjoys all the South has to offer - snowboarding, camping, hiking, skating, surfing and biking, as an outdoor adventure enthusiast.

JOINERS Magazine September 2023 page 14

Have you met our Account Manager and Specification Consultant, Brittany Smith?

Australian Cabinet & Furniture Association

Millie Elliot

At Laminex

JOINERS Magazine September 2023 page 15 2024 MODELS FOR 2023 PRICING Register today to experience some of our showroom machines running live onsite demonstrations. Talk to our industry experts onsite and get yourself up to speed with the latest industry news and trends. • Live demonstrations onsite • Demonstrations streaming live from the Sydney Showroom • Trade Partners and industry solutions onsite • Learning and training programs • Italian hospitality 20 - 21 September 2023 9:00AM - 5:30PM OPEN HOUSE Register today! Visit www.biesse.com/au/wood/events or contact 0800 BIESSE (243 773)

Häfele ce celebr ate 100 year s lebrate 100 years

Innovative strength, courage and optimism: these are the qualities which have accompanied Häfele from the very beginning and have always distinguished the founders, merchants Adolf Häfele and Hermann Funk, who established Häfele in 1923 as a specialist hardware shop near Nagold.

This valued contact point for the carpentry trade has now become a global company. Häfele SE & Co KG, with subsidiaries in 38 countries and more than 8000 employees. In the 2022 financial year, the Häfele Group achieved sales of 1.87 billion Euros with an export share of 81%.

Nagold is still the headquarters of the international Häfele Group, which has developed into the leading expert for hardware and fitting systems, electronic access control systems and LED lighting over the decades.

The furniture industry and also architects, joiners, cabinetmakers and dealers from more than 150 countries rely on the expertise of the innovative family business, which has been under the management of Gregor Riekena since January 2023. The anniversary year is being characterised by the company’s origins and also the view into the future: Häfele is celebrating their first 100 years in a fitting manner in Nagold and selected locations worldwide.

JOINERS Magazine September 2023 page 16

Gregor Riekena (right) became the new head of Häfele in January 2023 taking over from Sybylle Thierer who had led the company since 2003.

Häfele CEO’s

Hääfele NZ reflect global growth

With Häfele worldwide celebrating their first 100 years, what about Häfele here in New Zealand? Bob Nordgren from JOINERS Magazine took the opportunity to ask Häfele New Zealand’s Managing Director Michael Farrugia about the company’s history here in New Zealand.

How and when did Häfele start operations here in NZ and what were the original aims and resultant strategy for Häfele?

The business was incorporated in NZ July of 1989. Prior to this date Häfele Australia serviced the NZ market from Australia. We could see back then that the NZ market was crying out for innovation and local availability of hardware fittings, so we decided to set up a fully fledged Häfele subsidiary for the NZ market. Initially Häfele NZ Ltd consisted of Peter Farrugia and his wife Karina, working from their home in Halfmoon Bay Auckland. Late 1989 Häfele NZ Ltd found its first permanent home with a warehouse facility in Sir William Avenue East Tamaki, allowing us to achieve our goal of local availability and service for a large range of innovative hardware fittings.

What did moving to a purpose built headquarters in 1998 in Auckland mean for Häfele NZ?

By 1998 Häfele NZ Ltd had grown considerably and needed additional space to support the growth. As part of our long term commitment to the NZ market, it was decided to build a purpose built building for our operation in Accent drive East Tamaki. At the time we built over a 2000sqm warehouse thinking that it would last us many years, however with the continuing growth in the early 2000’s it became apparent that we would need to extend our warehouse and office capacity to support the growth. In 2005 we built our first High Rise warehouse being 15mtrs in height, giving us double the storage space as well as much needed office space to house the growing number of staff needed to support the growth.

In 2019 we completed an additional high rise storage facility giving us a further 3000sqm of high bay warehousing, which should keep us in good stead for the coming years.

You took over after Uwe Adam as Managing Director in 2009. Häfele in New Zealand has grown to be the largest supplier in it’s field by turnover, it has major centres both in Auckland, Christchurch and Wellington, what have been the highlights for you to date and what of the future for the company here in New Zealand?

I joined the company from Australia in 1990, I would say there have been many highlights over the 30 odd years but I am most proud of the fact that we currently employ over 120 people in our business “The Häfele Family”,

a number of our staff have been with us a long time, watching them grow and treat the business as if its their own is probably what I am most proud off

As most of our industry knows, the Häfele group were victims of a cyber attack in February this year, this was an enormous challenge for the group and we wouldn’t have been able to navigate our way through this enormous challenge if it wasn’t for the dedication and passion of our staff to #BuildBackStronger.

JOINERS Magazine September 2023 page 17

Auckland head office.

Top: Peter Farrugia and his brother Michael have managed Häfele NZ for most of the last 3 decades; Häfele’s Auckland premises in 1989. Bottom: Christchurch sites in 1996 and today.

celebrating 65 years

It has been some 65 years since the NZ Joinery Manufacturers Federation was incorporated into the business it is today and what better way to celebrate this year than at the brand new Takina Events Centre in Wellington.

With the ‘inspired to grow’ theme to the fore this year’s annual Master Joiners Conference was a well attended event and will no doubt be remembered as a highlight of the Master Joiners 2023 calender. The first take out was the choice of venue: the Takina Events Centre, an impressive convention centre that undoubtedly will serve Wellington well in the coming years.

The Conference got underway with a Joinery Factory trip to Ferndale Furniture and Joinery productions in Lower Hutt on the Thursday afternoon for those interested while later in the day there was a Master Joiners Assembly open forum to discuss such topics as Master Joiner standards, future membership, research projects on sustainability, apprentice training and joinery professional development. This was followed by the traditional happy hour in the trade exhibition hall at the Events Centre leading to The Gathering: a well attended networking evening and a walk’n’fork dinner.

After breakfast in the exhibition hall and the opening address from the Master Joiners

President Andrew Reilly we heard from the Keynote speaker Dr Ganesh Nana, Chair of the Productivity Commission Te Komihama Whai Hua o Aotearoa who delivered a very interesting address on the role of economics and the effects on our communities. This was followed by Dr Dougal Sutherland who spoke about practical steps in boosting wellbeing in the workplace and then a session from Mike Clark with a practical session looking at things from the customer’s perspective. Of particular interest on the Friday afternoon were the concurrent break out sessions. For many the session on Compliant Timber Joinery attracted a lot of attention. Other sessions looked at the Design and Detail Practitioners group, the art

JOINERS Magazine September 2023 page 18

25 - 27 June 2023

Master Joiners Conference, Takina Events Centre Wellington,

and need for back costing, a look at joinery business in the next 12 months from Matthew Duder, MD for Eboss and a look at the need to market your business. A great end to the formal day came from Keynote speaker Lisa O’Neil later in the day: an energising and inspiring chat about how to look at life differently. The Friday night Master Joiner Quiz held at the Takina Events centre went off really well with nibbles and drinks and lots of crazy questions! Congrats to the winning team.

The Saturday programme kicked off with a look at how to get more young people involved in the joinery industry. Getting young people’s perspective is vital to getting

young ones involved in this industry. The rest of Saturday was taken up with various activities ranging from the Boomrock session of various competitions, white water rafting, fishing and clay bird shooting, sailing and the Weta Workshop. I chose the latter as I had been there back in 2015 or 16 when we had the last Conference here in Wellington. A bit of hands on making a gunshot wound was a bit long winded but interesting all the same (picked up a Weta T shirt too!). Then we came to the Master Joiner Awards for 2023 held at the Event Centre. At what was a well attended event congratulations must go to all the winners be they in the Apprentice Awards, the main awards or the various special Master

Joiner Awards. Note must be made of the Supreme award that this year went to Levin firm Craftbuilt Industries and their amazing staircase. All in all, a very good conference. Thanks must go to Chief Executive Allison Delaney and her tireless team for a very smoothly run event. Thanks also to the staff of the Takina Events Centre, they did a great job making this conference a memorable one.

Bob Nordgren

Bob Nordgren

JOINERS Magazine September 2023 page 19

Photos courtesy Master Joiners Association

Master Joiners Supreme Award 2023

Craftbuilt Industries

About the winner

Craftbuilt have built a reputation for artisan wood working and furniture making of which this Award winning staircase is just one expression. As their website says they ‘design and curate high quality fitments and bespoke wooden masterpieces. Our craft is ever evolving, catering for the most innovative designs for residential, commercial and corporate fitouts.’

Craftbuilt originated in Levin in 1992, current owner Simon Raikes has worked there since 1996 when he was 16 years old and purchased the business off his former boss in 2018. They currently have five staff and are about to launch into building a brand new 1080m 2 factory and showroom which they are really looking forward to.

For more information contact Simon Raikes, Craftbuilt Industries Ltd at their factory at 2 Bruce Rd, Levin 0800 488 777 or Simon on 021 608 324, email sales@ craftbuilt.co.nz or visit www. craftbuilt.co.nz

A work of art

This year’s Supreme Award at the 2023 Master Joiner Awards held in Wellington went to Levin based firm Craftbuilt Industries with their outstanding 7.3 metre tall Oaktree staircase.

The staircase is made up of an elliptical trunk clad in American White oak veneer pressed to 6mm bendy ply and with 66 shaped branches reaching up through two floors to the tree top canopy where it meets screen printed tree graphics on a plywood ceiling.

“We have a real passion for curved and geometrical staircases at Craftbuilt so this challenging project caught our eye and imagination from the start” comments Craftbuilt Industries owner Simon Raikes.

Built for the new Wellington Children’s Hospital and known as Te Wao Nui a Tane or ‘great forest’, it took some 12 months and 1000’s of hours spread over several delays, including Covid 19 lockdowns, between March 2021 and March 2022. The project had several very challenging aspects to it Simon recalls. “Logistical issues ran alongside the very real construction challenges this staircase presented. Getting skilled staff during the Covid period as well as travelling from Levin where we are based to Wellington every day (on the old road I might add) were constant factors.”

The construction and installation of the staircase involved close cooperation between Craftbuilt, the Architects Studio Design+Architecture and the main contractors McKee Fehl and Ducare NZ Ltd who manufactured the structural steel frame for the staircase.

The materials used were 20mm birch ply for treads and risers, 4x2 and 6x2 timber for framing dwangs and studs, 12mm pine Bendy ply, 6mm oak crown cut Bendy ply, Oak crown cut veener

on 4mm ply laminated to create a 25mm duralite poly panel (to reduce weight), and solid white Oak timber for handrails and bends

“This was a project that involved many site visits for things such as templating and marking out prior to actually making the various components” comments Simon.

The core of the staircase was the structural steel 150mm x 150mm x 10mm box section steel tower rising from seven 7.3 metre uprights made by structural steel engineers Ducare NZ Ltd. “The install of the steel work involved three spider cranes from Banks cranes in Paraparaumu and was a exciting part of the project as once erected the tree started to grow fast.” Simon notes. Once installed Craftbuilt went to work framing out all the studs and dwangs, laminated Bendy ply around the trunk up to the height of 7.3 metres and then laminated and fabricated the two sets of curved stairs 1.5 metres wide and fitted in place.

Once the steel work was completed then came the install of the screen printed ply ceiling panels which were cantilevered off

large LVL beams and the creation and install of the 66 ‘branches’ made from Oak duralite panels. “These panels were all different shaped curves and lengths. They were all edge banded in our factory using our portable Festool edge banding machine for what was an extremely complex design that consisted of basic to very complex design and build skills. The workmanship required and attention to detail using an array of hand and power tools, CNC routing, years of know how and experience, hours of planning and sweat and muscle. It’s a job we took great satisfaction from” recalls Simon.

Any really outstanding aspects for Craftbuilt in this project? “Well apart from the overall complexity, I think the trickiest part for us was the base of the ‘tree’ the architects designed a lovely kiddies cubbie for parking the scooters in at the base of the trunk, the archway was curved 2 ways plus the jambs were different widths due to one jamb being parallel and the other jamb being cranked on a 45 angle!! This archway really had me thinking hard, good work from the team!”

Judges’ comments

JOINERS Magazine September 2023 page 21

“What a work of art, this masterpiece is visually stunning. This stair is complex, the photos don’t do it justice.”

The core of the staircase was in structural steel.

Tunnicliffe Timber merging history with innovation

Since 1929, nestled in the verdant heart of New Zealand's Eastern Bay of Plenty, Tunnicliffe Timber's story

Today, standing at the forefront of advanced timber technology, Tunnicliffe continues to craft the future of

Legacy Carved from Timber

The Tunnicliffe narrative traces back to humble beginnings as a native sawmilling operation, an endeavour as enduring as the timber it transformed. As the decades unfurled, Tunnicliffe weathered a pivotal merger, a name change, and the Kawerau pulp mill surge of the mid-20th century. The latter, in particular, propelled Tunnicliffe into a vortex of growth and innovation.

1997 marked a shift, as the original Tunnicliffe family name was reinstated. This nostalgic reversion offered an opportunity for introspection, a chance to honour a rich heritage whilst charting a trail into new territories.

A Vision Rooted in Innovation

The dawn of a new era arrived in 2018, under the stewardship of Mark and Elizabeth Andrew. Their innovative vision, geared towards sustainable timber treatment, earned support from the Provincial Growth Fund (PGF) via the Kānoa – Regional Economic Development & Investment Unit, enabling Tunnicliffe to embrace cutting-edge thermal modification technology.

Mastery Over Time:

The Birth of TMT+H3.2

Tunnicliffe's long-standing relationship with thermally modified timber can be traced back to 2003/2004. Back then, the company became the proud owner of New Zealand's first-ever thermal modification kiln, an open system.

This early adoption armed the company with unrivalled local expertise in the realm of thermally modified timber. Their mastery over this open system granted Tunnicliffe deep insights into its strengths and shortcomings. Recognising a need for progression, the company charted a course towards a more resource-efficient closed system. This move not only amplified efficiency but accelerated processes, encompassing every imaginable feature, save for a cup holder.

The Process:

The Making of Tunnicliffe TMT+H3.2

The creation of Tunnicliffe TMT+H3.2 involves a two-step process, each contributing uniquely to the final product's characteristics. The journey begins with the application of

Thermal Modification Technology (TMT) in a carefully controlled closed system. This pivotal step enhances the dimensional stability of the timber, improves its thermal insulation properties, and ramps up its resistance to decay, rot, and wood-boring insects.

Contrary to the open system variant, the closed TMT system retains a fraction of the timber's moisture content. This residual moisture is integral to the next stage of the process, catalysing an exothermic reaction and establishing the ideal conditions for interaction with the MCA treatment.

Subsequently, the timber undergoes a Light Organic Solvent Preservative (LOSP) application of Micronised Copper Azole (MCA), a cutting-edge preservative employing copper and an organic co-biocide, azole. This pressure-impregnated solution adds an additional layer of durability and resilience to the thermally modified timber, providing robust resistance against fungal decay and insect attack.

JOINERS Magazine September 2023 page 22

Tunnicliffe truck and yard in the early days. The Open System Kiln arrived in 2004 - NZ’s first thermal modification kiln.

has unfurled, borne of resilience, innovation, and a deep respect for the land. sustainable construction, its roots reaching back almost a century.

The Result: Performance & Aesthetic Excellence

Tunnicliffe TMT+H3.2 represents a composite greater than the sum of its parts. It combines the stability and thermal insulation of TMT with the resilience and decay resistance of MCA, arming a readily available softwood with the superior attributes of high-end hardwoods. Moreover, Tunnicliffe TMT+H3.2 is a visual delight, exhibiting a captivating colour palette of Gold, Orange, and Caramel tones. This aesthetic transformation offers architects, homeowners, and tradespeople a high-performing, environmentally friendly, and aesthetically pleasing alternative to imported hardwoods for exterior design applications.

The Key: The Closed System TMT

The closed TMT system plays an essential role in the success of Tunnicliffe TMT+H3.2. It ensures a uniform distribution and enhanced penetration of the MCA preservative, significantly contributing to the timber's overall performance and unique visual appeal.

In essence, TMT+H3.2 presents the industry with a sustainable alternative to imported hardwoods and exotic timbers. It elevates local, renewable Radiata Pine to unmatched levels, making it a preferred choice for eco-conscious builders, architects, and specifiers.

A Century's Legacy in Every Plank

Tunnicliffe Timber's journey mirrors the evolution of the timber industry itself. From a modest sawmill to creating the revolutionary TMT+H3.2, the company's commitment to innovation and sustainability, bolstered by its proud family legacy, positions Tunnicliffe Timber at the forefront of sustainable building materials. The wisdom of the past propels the technology of the future, shaping a sustainable world.

JOINERS Magazine September 2023 page 23

TMT+H3.2 shows tones of gold, orange and caramel.

TMT+H3.2 presents the industry with a sustainable alternative to imported hardwoods and exotic timbers.

www.tunnicliffes.co.nz

The Closed System Kiln’s installation in 2022 provides a more controlled environment.

Ligna & interzum

With 80,000 plus visitors at Ligna and 60,000 plus at interzum these two shows are among the biggest internationally and cover all aspects of the kitchen, furniture and wood processing industries. Over the next few pages we speak to several who attended, both to view and to display the latest in design, product and machinery.

September 2023 page 24

Cologne 9-12 May 2023

Hanover 26-30 May 2023

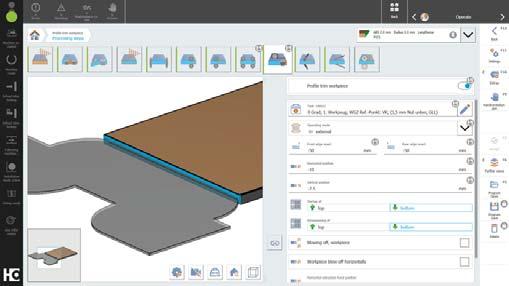

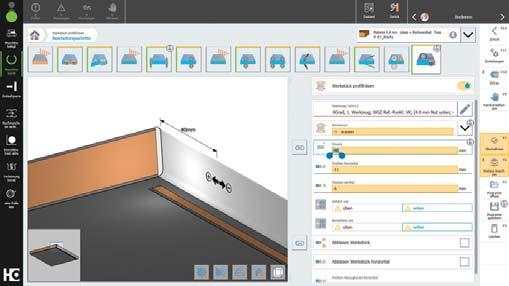

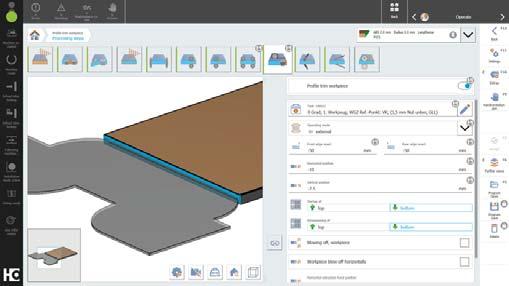

Various applications, one system. HOMAG iX

HOMAG iX - 3D design and production for furniture and interior fitting.

With HOMAG iX software, you have the flexibility to deliver to your customers their designs profitably. A software solution should support your entire process: planning and resentation, design and manufacturing. It must be able to adapt to changing customer requirements during the process. Based on proven CAD/CAM technology, you can save up to 70% of the time to get work from the customer idea to the production process with HOMAG iX.

www.homag.com | sales-australia@homag.com | Toll free 1800 355 635

YOUR SOLUTION

Jacks Ligna 2023 Review

Exploring innovations in challenging times

Themuch-anticipated Ligna 2023 did not disappoint, although some show attendees expected to see more innovation, considering the four-year gap since the last show. It is evident that manufacturers have encountered challenging times, navigating the obstacles posed by Covid-19 related lockdowns, including lockdowns, supply chain disruptions and significant cost increases. As a result, resources that would typically have been allocated to research and development had to be redirected to other departments to ensure smooth operations. The consequence: not a lot of new technology on show.

Nevertheless, there were promising developments in various areas, particularly in edgebanding, material handling, safer saw technologies, and versatile CNC drilling solutions. One highlight was Homag's introduction of a new entrylevel edgebander, the Ambition

1120FC, which is now available with an airTec system capable of processing laser tape. This move makes laser tape processing more affordable than ever before, opening up new possibilities for smaller manufacturers.

Another exciting trend at the show was the increasing prevalence of robots designed to handle stacking, loading, and de-stacking tasks. While currently more suitable for larger manufacturers due to the costs involved, the escalating labor expenses and the growing ease of integrating robots suggest that this technology will likely see further development and adoption in the industry.

Safety was a paramount concern, with several manufacturers showcasing their panel saw safety systems. Felder's Preventative Contact System (PCS), unveiled at Ligna 2019, has proved to be a significant success, with thousands of saws now equipped with this safety feature, preventing

the growing ease of integrating robots suggest that this technology will likely see further development and adoption in the industry.

potential accidents involving the sawblade. As safety continues to be a top priority, it is conceivable that such systems may eventually become mandatory for all new commercial saws.

Visitors to LIGNA were able to view several new versatile drilling and edge processing machines - CNC machining solutions to accommodate the abundance of new cabinet construction hardware available on the market. Connectors like OVVO, Lockdowels, Lamello Clamex, and Peanut speed up cabinet assembly, reduce labor costs, and save time and materials. Most of the major CNC suppliers

presented at least one example of a CNC drilling and routing center that could efficiently machine up to six faces in a single process, further streamlining production processes.

Overall, despite the challenges faced by manufacturers in recent times, LIGNA 2023 demonstrated that the industry is still pushing forward with innovative solutions that enhance productivity, safety, and efficiency in the woodworking sector. Hannover’s hotels were as full and overpriced as ever, and there was no shortage of wheat beer or pork knuckles for visitors to the world’s largest woodworking show. As technology continues to evolve and adapt, the future of our industry looks promising, fueled by a drive to meet the demands of an ever-changing market.

Simon Hornby Head of Sales W & R Jack

JOINERS Magazine September 2023 page 26

Format-4 kappa 450 x-motion panel saw which is now available with Felders Preventative Contact System (PCS).

Back on the big stage in Hanover!

Atotal of 80,000 visitors from 160 countries came to Hanover to see the latest innovations and megatrends for woodworking – many interested visitors also traveled from Asia and America. "An impressive 60 percent of visitors came from abroad. This means that LIGNA has further expanded its position as the world's leading global trade show," said Dr. Jochen Köckler, Chairman and CEO of Deutsche Messe AG, on the official LIGNA homepage.

This rush and a great enthusiasm of the visitors were also clearly noticeable at the Leitz booth. The focus of the world market leader in its trade show presentation this year was on the topics of knowledge and efficiency. Whether acquiring new customers, intensive networking or simply meeting again face-to-face for snacks and drinks – Leitz was even able to exceed the goals it had set for itself at LIGNA.

Certainly the quality of exciting and interesting discussions with customers and guests increased compared to previous fairs. In the middle of the week Leitz invited journalists to the traditional press conference where they learned more about this year's innovations and key topics of the world market leader. The attendance was excellent and the hall was filled on every seat.

The Leitz Relay Tour also got the big stage at the beginning of the world's leading trade fair. Many highly motivated employees rode the LIGNA baton across Germany from Oberkochen to Hanover over a period of several weeks - on a CO2 neutral basis - by bicycle. A great sign of sustainability, team spirit and an extraordinary achievement by all participants. As a grand finale

after 1,200 kilometers, Miriam Staudte, Minister of Forestry for Lower Saxony, welcomed Leitz Managing Director Jürgen Köppel at the grand LIGNA opening ceremony to hand over the baton.

After five days at LIGNA, expectations were not only met but exceeded. Jürgen Köppel was delighted to note on the last day of the trade show: "It was a great experience to finally be back in Hanover after a four-year break. We all absolutely missed the special trade fair atmosphere with the face-to-face contacts."

LIGNA 2023 was characterized by intensive conversations and smiling people. That's why Leitz employees are already looking forward to the year after next, when the motto will once again be: "Finally, LIGNA again."

Easy to use Design & Manufacturing software

JOINERS Magazine September 2023 page 27 3D DesignPhoto Realism & PanoramaCut ListsImport 3d ModelsShape Editor - Custom Cabinet DesignCreate Your Own CatalogKray Rendering – PRO100 PRO100 PRO100 CNCPRO100 Download - IT’S FREE! Here’s why you need PRO100 for Cabinet Making

It is also important for us to do our own research at shows like Ligna and see what direction our competition is heading in, so a very worthwhile show for anyone involved in the woodworking industry in New Zealand.

Automated & connected

SCM's new entries attracted considerable interest at Ligna 2023, paticularily the Group's new automated and connected solutions providing software and services for integrated digital processes, along with world previews of innovations in timber construction and laser sanding.

SCM presented innovations in all the application fields for secondary wood processing, both physically at the trade fair as well as digitally and interactively.

Some of the new entries that elicited the greatest interest included automated and connected solutions developed for highly bespoke, versatile and sustainable production.

The Smart&Human Factory system for the furniture industry presented new flexible cells with robot and integrated with unmanned AMR shuttles: Gabbiani GT2 for beam saw, Stefani Cell E for edgebanding and Morbidelli CX220 for drilling.

Also being presented for the first time at Hanover was a Smart&Human Factory model

MRUs on the SCM stand

Machines R Us Managing Director John Fleet & Technical Sales Manager Daniel Kees on the SCM stand at Ligna.

for joineries, an integrated cell for flexible and bespoke production from raw material to the finished piece of furniture, enhanced by its integration with an MES software. These include the new functions on the Maestro CNC nest cutting optimiser, the Maestro Optiwise optimiser for single-blade and angular panel saws, Maestro power TMS, optimiser to manage the tools inside the tool storages on the CNC machining centres and Maestro 3drill for drilling.

Also attracting attention was the platform for Maestro connect digital services integrated into the “Woodworking made Izy” and the new Service Bundles, SCM service packages created to offer an integrated solution that helps the customer with any requirements.

sophisticated, fashionable finishing effects, as well as the Superfici new entries on display in Hall 16. They include the new compact XL sprayer, the UV LED polymerisation system and the Excimatt Excimer technology for super matt finishing effects.

The CNC machining centres for panels and solid wood presented include Morbidelli M100 with new FlexDrive worktable; Morbidelli X200 with new in-cab labeller for nesting machining; Accord 500 to manufacture doors, windows, stairs and solid wood elements.

The new Olimpic 500 was presented for edgebanding to be used by artisan businesses looking for all the advantages of an edgebander in a compact space.

Ligna was a very good show for us with substantial orders placed and enquiries from New Zealand customers who made the trip. It is clear SCM Group is a technology leader when you walk around Ligna, it is there for all to see.

Aside from being able to see so many manufacturers and new technologies in one place, the

respect shown to the SCM brand that we represent, was the many trades people that have been through their apprenticeships and training using SCM products some going back to the 1970's. So a very long and successful history in New Zealand.

It is also important for us to do our own research at shows like Ligna and see what direction our competition is heading in, so a very worthwhile show for anyone involved in the woodworking industry in New Zealand.

John Fleet

Also on show were SCM Surface Technologies products for integrated surface treatment, starting with the new DMC system TC automatic sandingcalibrating machine with laser unit and never ending power sources, developed to create threedimensional marking on parquet, wood elements, MDF panels to be ennobled, fibre cement panels and solid surfaces. Solutions capable of satisfying any processing demand for exclusive,

Some of the new entries presented digitally include the Stefani SBX squaring-edgebanding machine for accurate squaring and top-quality machining, and Windorflex, new automatic cell to produce complete windows and doors.

Lastly, an extensive offer for artisan joinery where the new "Blade Off" safety system and the new Starteck CN K 3-axis compact are highlighted.

JOINERS Magazine September 2023 page 28

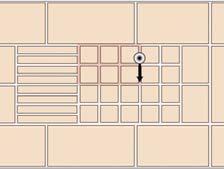

CNC Nesting Machining Centres for drilling and routing

x200 / x400

The new generation of Nesting CNC machining centres meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity.

FLEXIBLE

Capable of any machining process without removing the spoilboard and even in 3D thanks to the X-PODs and the JQX (Just Quality eXtreme) 5-axis electrospindle.

FASTER

Nesting processing at 50 m/min, saves 60% of time on drilling cycles thanks to the new drilling heads (also with double saw blade) and less than 15” for the tool change thanks to the FAST tool changer directly installed on the mobile unit.

MORE VACUUM

Thanks to the X-Vacuum System, the vacuum is condensed into the area of the worktable where the workpiece is being processed. Perfect to process small workpieces or highly breathable materials.

MODULAR

The ultimate solution to simplify work: cell version, available to configure the machine no matter the material flow required.

JOINERS Magazine September 2023 page 29 606D Rosebank Rd, Avondale, Auckland, New Zealand www.machinesrus.co.nz l 09 820 9486

morbidelli

Resource efficiency & value creation

The leading technology provider for solid wood and panel processing presented itself in Hanover with the brands Weinig and Holz-Her on an exhibition area of 5,000 sqm. Under the motto WEINIG OFFERS MORE, visitors experienced many of the almost 50 machines and systems live in action at the Weinig Group in Hall 27.

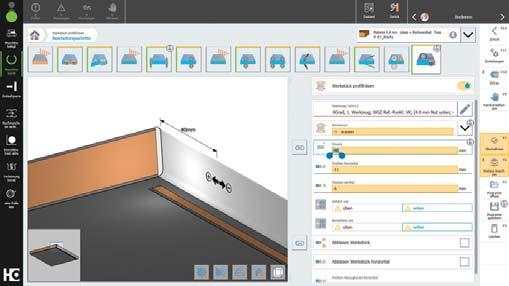

A clear edge into the future

At Ligna, Holz-Her had on display the new Auriga 1308XL multi and the Streamer 1057XL power in the entry-level range. Both machines are axis-controlled and make the setup work much easier for the operator.

The Auriga 1308XL multi is a versatile machine capable of processing a wide range of materials, including delicate surfaces. With 11 NC servo axes and the flexibility of the Glu Jet adhesive application system, the requirements for processing different materials can be met quickly and easily. In addition, the axis control system enables precise positioning and high repeatability. Predefined processing profiles can be selected via the control system and guarantee uncompromising processing of 1 mm or 2 mm edges.

The multi-aggregates are also equipped with the proven IntelliSet system. This allows the operator to adjust the tool in the 1/100 mm range via an interactive graphic display, for example to compensate for the thickness of a protective film.

The Streamer 1057XL power, on the other hand, is the ideal machine for small and mediumsized operations. With its axiscontrolled technology, it can be changed over in a very short time, which speeds up and optimizes the production process.

In addition, the simple operation ensures that even inexperienced operators quickly become familiar with the machine.

Another highlight in the field of edge banding machines was the software-controlled and optimized automatic rinsing process with the patented Glu Jet adhesive application system. The automatic rinsing process makes changing glue child's play. The software automates the rinsing of the adhesive and ensures that the process is fast and clean. The operator can switch between different adhesive types such as PUR or EVA at the touch of a button, and the machine automatically sets the correct parameters for temperature and adhesive quantity.

The software automatically calculates the used edges. The machine control system shows the customer the remaining quantity of the edge roll live, thus facilitating the handling of countless edges as well as remaining strips. This reduces the risk of production downtime due to missing material, for example.

In addition, the software has an adhesive type library that allows the operator to switch back and forth between different adhesive types at the push of a button. All necessary setting parameters, such as the correct temperature or amount of adhesive, are set automatically, allowing the operator to switch adhesive types quickly and easily without having to make time-consuming manual adjustments. This new software version enables customers to optimize their production processes and increase their efficiency.

"The Auriga 1308XL multi and the Streamer 1057XL power are real highlights in our product range and offer our customers new possibilities to work flexibly and efficiently. We are thrilled to be able to offer our customers these innovative machines," says Angelo Amico, Product Manager at Holz-Her.

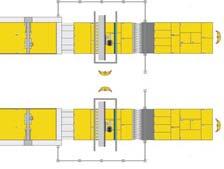

Automation is also becoming increasingly important in smaller workshops to remain competitive and work profitably. It is precisely for this purpose that Holz-Her

demonstrated the new ReturnMaster 5940 Return System and the 5990 Intelligent Stacking Unit, which were presented in combination with a Lumina 1596 edge banding machine.

Fully integrated into the edgebander's control system, the return unit enables intelligent one-man operation for increased productivity and maximum flexibility. The return unit automatically detects workpiece lengths or widths and automatically rotates parts as needed. This shortens production time and significantly increases line yield.

There are various processing modes from pure part return to nested stacking on pallets. To assist the machine operator, each mode was displayed in real time via a central graphic. In addition, the dynamic machine infeed lock of the edge bander controls the optimal parts sequence.

(continued over page)

JOINERS Magazine September 2023 page 30

Holz-her offer a wide performance spectrum from individual solutions for small business to upscale series production.

What do you need What do you need in an edgebander? in an

Accuracy, easy operation, finish, reliability, training & support.

Holzher edge-banders have full CNC motorization on all axis with accuracy to 1/100th of a mm which means fast and accurate adjustments for a perfect finish.

The Holzher operating system is clear and easy to use, the radius adjustments are done through a visual interface where you can see the knife moving as you adjust it. All pneumatic adjustments are done via automated regulators on the panel (glue thickness, guillotine pressure, etc).

Our complete range uses the patented Glue Jet system GJ301 with motorization.This unit is driven to the height of the board independently, it is calibrated exactly to the board presented to it, so no glue is left on the top or bottom edge (no glue transfer into the machining area or messy clean-up), the

internal discharge port means that any glue purged from the system goes into a stainless container. Because the glue system is sealed PUR is no problem to use (without freezing or vacuum).

Holzher reliability is well known these machines are constructed in Germany/Austria to exacting standards and thoroughly tested before delivery using the best components money can buy.

We train to the highest standard as this is one of the most important parts of sale. The time required often varies we have found, so we use the time required rather than having a fixed time format.

Holzher machines are supported and serviced by us at TMS. We have been involved with Holzher for over 25 years and are fast, accurate and knowledgeable.

We know our product intimately.

mikef@techms.co.nz Rajan Pillay, 021 504 929, raj@techms.co.nz

JOINERS Magazine September 2023 page 31

Edgebanders • CNC’s • Upright CNC’s • Wallsaws • Beamsaws www.techms.co.nz

Mike French, 021 353 632,

patented glue jet easy operation

Lumina 1958

Resource efficiency & value creation (cont.)

The right solution for every type of CNC machining.

Holz-Her's Dynestic series of nesting machining centers includes three series with different sizes and various levels of automation. These machines offer the advantage of precise formatting and CNC machining in a single setup. And they do so with extremely low handling requirements for the machine operator. In addition to unique workpiece identification with, for example, picking, machining and edge information, nesting technology is ideally suited to the use of state-of-the-art joining techniques such as the Clamex P-System or Cabineo connectors. Traditional dowel connections can also be produced by finishing with horizontal drilling and driving of the dowels on Holz-Her machines.

With the new Power-Pin 7605, Holz-Her has introduced a compact drilling and dowel inserting machine that makes just that possible. In the future, operators will be able to drive in wooden dowels fully automatically, thus ideally complementing nesting. Manual driving in of the dowels after CNC machining is completely eliminated, which not only saves time but also increases process reliability.

Users can choose between a "classic" or "dynamic" version. Both machines feature innovative technology, intuitive operation and a compact design. While the pressure beam of the PowerPin classic has to be manually adjusted to the material thickness, this is done fully automatically and program-controlled in the dynamic version. In addition, in the "dynamic" version, the drilling depth and the Z-height of the holes are approached by servo motors. Options such as the practical VISE LED position display and additional horizontal drills are also available for the dynamic variant.

With the Power-Pin 7605, users can drive in both pre-coated dowels and standard wooden dowels with D1 glue (viscosity 150 - 350 mPa.s.). With the optional second step feeder,

the changeover from 6-mm to 8-mm dowels is also completed in a matter of minutes. The dowel lengths that can be processed are 30 mm, 35 mm and 40 mm. The large-area support table enables multi-field loading so that several workpieces can be processed efficiently next to each other, and the intuitive clamping concept ensures safe and fast loading and unloading. We offer several automation levels to choose from.

Compact in every respect. All units and storage tanks are fully integrated in the machine. With a footprint of only 4 m³ and an extremely low overall height of 1755 mm, the Power-Pin fits into any workshop. In addition, the machine lid provides a practical storage place for workpieces to be produced - at a back-friendly height of 1215 mm. Depending on the material flow, the Power-Pin can stand freely in the room or be placed against the wall.

Into the future with the Evolution production cell The increasing automation pressure from the furniture industry is not only coming from companies with an industrial level; small craft businesses are also following the signs of the future. Be it to counteract the shortage of skilled workers or to make their own business futureproof through digitalization and individualization.

It was precisely for this group of visitors that Holz-Her displayed the Evolution production cell at Ligna, a compact single-machine solution for the precise and fast production of furniture parts. The production cell consists of a vertical Evolution CNC and a Kuka robot, which in combination enables almost unmanned production of furniture parts in a very small space. For workpiece manipulation in the production cell, the Kuka robot is equipped

with a sophisticated vacuum cup concept to handle components from the drawer front to the cabinet side. The software controls the individual suction segments fully automatically for this purpose, and each suction cup can be controlled individually. Workpieces from 200 x 70 mm to large parts of 3000 x 1200 mm can be manipulated in this way. An integrated camera on the robot arm automatically reads the DataMatrix code and independently loads the machining program for the CNC machine. It also recognizes reference points applied to the label so that the Kuka robot can correct the position of the component if necessary.

Holz-Her uses EtherCAT communication technology to connect the Kuka robot used, which guarantees a fully integrated solution and optimal integration into the plant. Furthermore, it enables faster and safer communication between machine and robot. Further connection modules for communication with nesting or console CNC's are already implemented. The Scene Reverse function allows finished parts to be transported back to the insertion point or starting point.

This means that the machine does not have to be fully integrated in the safety area. A complex return system is therefore not required, which saves space and still allows the operator to perform manual machining on the right side of the machine. For use on multiple machines, the Kuka robot can be expanded to include a linear seventh axis. Long distances between the machines are thus bridged and several jobs can be processed fully automatically at the same time.

JOINERS Magazine September 2023 page 32

Over an exhibition area of 5,000 sqm Weinig showed almost 50 machines and systems in live operation.

JOINERS Magazine September 2023 page 33

HOMAG edgebanders

From entry-level models to industrial production, HOMAG showed future-oriented solutions for carpenters and joiners in all performance classes of edge banding machines at Ligna. Digitalization played a central role.

EDGETEQ S-240 Maximum edge quality at the entry-level with a feed speed of 11 m/min With the EDGETEQ S-240, model 1230 HF edge banding machine, HOMAG offers an entry-level solution for woodworking shops with comprehensive unit equipment, entry-level automation, and a high level of flexibility in post-processing.

It is equipped with a magazine for rolls of material and solid wood strips up to an edge thickness of 6 mm, with a joint trimming unit, gluing unit for processing EVA/ PUR, snipping unit with automatic chamfer/straight adjustment and automatic adjustment of flush/ overhang trimming. For automatic adjustment of the snipping motors to two positions. Trimming unit with pneumatic three-point adjustment and the profile trimming unit with automatic adjustment between thin and thick edges. The finishing area has three units: a profile scraper with quickchange heads, a glue joint scraper with pneumatic adjustment and a buffing unit.

EDGETEQ S-300, 1440 E, with continuous multi-radius technology on the single-motor profile trimming unit and ergonomic air cushion table. The equipment of the EDGETEQ S-300, model 1440 E, offers

competitive advantages for both woodworking shops and smalland medium-sized businesses — especially in the case of frequently changing edge thicknesses.

The two-profile technology— here with the profiles R1 and R2—on the single-motor FF6210 profile trimming unit brings more flexibility to processing thanks to the fast, precise change by touch via the control system. Setup times and the machine length are shortened, thereby increasing cost efficiency.

The EDGETEQ S-300 is equipped with a new ergonomic air cushion table at the machine infeed and outfeed. The ergonomic machine infeed and outfeed ensure safe and convenient workpiece feed and removal. The variable feed speed is 8–14 m/min. The machine is equipped with a joint trimming unit, the QA65N universal application unit for the optional

processing of EVA or PUR hotmelt glue and the edge magazine for strips and rolls of material. Post-processing takes place using the snipping unit, the multi-level trimming unit and the singlemotor profile trimming unit. The multi-level profile scraper, the glue scraper and the buffing unit ensure the perfect finish.

EDGETEQ S-380 and the LOOPTEQ O-300 return conveyor — as a cell. The combination with the return and the new automatic two-part edge magazine increases the productivity of the edge banding machine. The LOOPTEQ O-300 workpiece return is ideal for a wide range of parts, from small and light workpieces to large and heavy ones. The units are controlled intuitively, and the parameters are entered using powerTouch on the 24-inch multitouch monitor. A new air cushion table concept including sliding

carriages will also be presented (also for the EDGETEQ S-500). The ergonomic machine infeed ensures a safe and right-angled workpiece feed. For processing edge overhangs and copying corners, the MF60 multifunction trimming unit features a stepping motor for automatically adjusting to different edge thicknesses.

For perfect glue joints, the EDGETEQ S-380 model 1672 E is equipped with the universal QA65N application unit and the universal melting unit (2.5–4 kg/h), which can be used for production with PUR or EVA.

The change of glue type in the universal melting unit can be performed quickly and easily with two special interchangeable

(continued over page)

JOINERS Magazine September 2023 page 34

EDGETEQ S-240 edge banding machine

Ergonomic air cushion table at the machine infeed.

Automatic glue quantity metering on the universal application unit.

Universal melting unit with melting capacity of 2.5 kg/h.

EDGETEQ S-500 | airTec

airTec is both an industrial and craft-oriented solution.

The big advantage of airTec is aesthetically. The edge banding with no glue lines looks a lot better because the seamless join between board material and tape material. No glue, no mess, better for the environment. In the manufacturing process there is less cleanup after the work pieces have been through the edge bander. And there is less maintenance required on the edge bander and saves quite a lot of time.

YOUR SOLUTION www.homag.com | sales-australia@homag.com | Toll free 1800 355 635

HOMAG edge banding machines (cont.)

tanks for PUR cartridges or EVA granulate. The universal application unit is equipped with automatic glue quantity metering. Via the powerTouch user interface, the glue application quantities are set simply, precisely and quickly. This leads to optimum glue joint quality, higher availability and performance, as well as greater cost efficiency.

Before gluing, the joint trimming unit creates the basis for a precise workpiece edge. Post-processing is carried out with the HL70 two-motor snipping unit, the MS40 multi-level trimming unit, the MF60 multifunction profile trimming unit, the MZ40 multilevel profile scraper unit and the finishing units of the glue joint scraper, cleaning agent sprayer and buffing unit.

The multifunction profile trimming unit with two motors and the flexTrim multi-radius tool offers precise adjustment options for perfect corner processing. The structural shelf function also allows profile trimming of edges on raw panel corners.

Sharp and blunt-angled parts, workpieces with longitudinal grooves or with hinge holes, workpiece thicknesses from 8–60 mm, sensitive surfaces and much more can all be processed optimally using the EDGETEQ S-380 at a feed speed of 8–20 m/min.

EDGETEQ S-500 profiLine with Edge Data plug-in performance

The EDGETEQ S-500 edge banding machine, with a feed speed of 16–25 m/min, is extremely flexible, highly automated and equipped with state-of-the-art software via woodCommander 5.