p a n e l e d g e panel edge

in search of the perfect finish

swings and slides

opening and closing cabinets

timber in design

NZ Wood-Resene award winners

in search of the perfect finish

opening and closing cabinets

NZ Wood-Resene award winners

Häfele pride ourselves on the incredible range of products we have available. We are constantly sourcing the latest innovations from suppliers around the globe and that’s what sets us (and you - our customers) apart with over 12,000 SKU’s available. The Complete Häfele has been our signature catalogue from day one, and still a much loved reference to this day - featuring the full range of products available from around the globe across over 1500 pages.

Featuring the kiwi trades favourite product.

Providing the full range available from around the world.

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Master Joiners 4

Paul Ingram reports on what his organisation has been doing during the lockdown and offers some suggestions for the days ahead.

Steering a Course 58

Ian Featherstone likens our situation to a storm and those whose boats are the most shipshape will get through better.

Due Process 60

Geoff Hardy advises us that their are more building reforms on the way but hang in there because we will be stronger for them in the long run.

NKBA report 61

Suzie Rees emphasises that keeping in touch with their membership has been a priority during the Covid-19 crisis and some of the initiatives are likely to be retained as we return to normal.

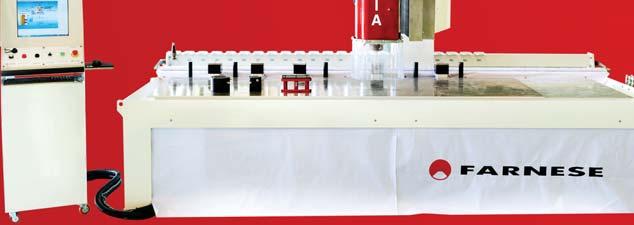

Subject to significant wear and tear and constant performance upgrades and capabilities, the edgebander is one machine in the shop that benefits from regular reviews as to whether it is still the best machine for the job.

A look at the concept of the ‘networked digital workshop’ from Homag and the digital apps they have developed to support and track the production process through the factory.

The best of them go unnoticed - support structure for the quiet and smooth functioning of our doors and drawers. Of essence they need to be strong, durable, and functional. They also need to be easy to install and adjust - we go to three leading suppliers who always have the trade, as well as the end-user in mind.

ITM Joinery in Nelson recently moved premises, prompting an upgrade in key machinery for their joinery shop. We talk to their Joinery Manager Paul Rusbatch about what they bought and why.

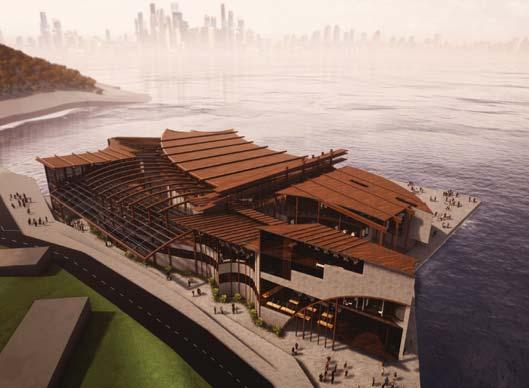

The NZ Wood - Resene Timber Design Awards always deliver an impressive range of entries pushing the boundaries of thinking in timber construction and design, this year is no different. We have all the winners in pictures.

History is being made in 2020. The stories of a virus that locked down the world will sit alongside those told of wars, revolution, and the building of and knocking down of walls.

The Master Joiners Leadership team made some phone calls over the lockdown and caught up with members to check in and gain some insight to the state of play in their business. The resounding themes from this are resilience, determination and positivity. Joiners are a tough bunch and are up for any challenges ahead.

Conflicting with this determined positivity is the doomsday commentary we hear, read, and watch. There is a danger that if that is the loudest noise, it will become self-fulfilling. I’m not suggesting that we should ignore the numbers but there are a wide range of opinions from the economists and at the moment it’s all guess work, after all we’ve never been here before.

So how best to deal with these conflicting mindsets? My thinking is to run some scenarios – blue skies, most likely, and worst case for my business. Think about what expenses are luxuries, what fat can be shed, how can I reduce required working capital, I’ve sold a vehicle to help fill the hole in the cashflow. Build some strategies and make a plan ... and then put them on the shelf for now.

Reality is that right now I suspect we are all busy. Almost everyone we spoke to when we called had work lined up to come back to, many for a few months ahead. There has been a flurry of enquiry too created by Kiwis being locked up at home and planning renovations, money has never

been cheaper. There is a chance that demand will ease later in the year but for now we should make the most of the bounce-back and row the boat hard.

The world will be a different place post Covid and that’s not all bad. We had 5 weeks away from our normal routines and for those with office based roles it’s been even longer. There are things we’ve all had to do differently and some of those changes we’ll keep – maybe a work from home day each week or using teleconference for a meeting rather than travelling out of town.

If the gloomy economists are right and the economy goes to the wall then our industry will be in for a tough time. The government is spending unprecedented amounts of money in an attempt to prop up the economy and businesses have access to loans to fund losses which can only be a short term tactic surely. We’re not at the front line yet, the tourism and hospitality industries have taken the initial impact. If household incomes are affected by wage reductions and job losses there will be less to go around and that new kitchen will need to go on hold. There will always be opportunities though, we may need to adapt to a new market, shift our thinking and our offerings. History shows that there have been success stories from depression and recession. Wrigley’s, IBM, Zippo, Rocket Lab and Xero are brands that rose from the ashes or were formed during tough times.

If the time comes, reshaping a business is not something to be taken lightly. Many people will be worried about the security of their jobs and I think its important to face up the realities and share the “what if’s” with our teams. There is some comfort in knowing the truth and what tactics the plans

on the shelf include. This is the time to look after people. Play to your strengths and provide them with everything they need to do the same. There may be a case for reducing hours, sharing the load, reducing salaries and wages. Many of us have adjusted to 80% of usual income and found there is still food on the table. As an industry we will need to try and sustain our training if things get rough so we are well placed in the future. If you are faced with needing to lay off a trainee then the Master Joiners network and our industry training providers may be able to help find another opportunity for that person. I watched two contrasting new stories recently which made me think. They highlighted different approaches to managing human resources. One was the story of a group of restaurants who have made 150 staff redundant and are in the news for all the wrong reasons which won’t have done their reputation or brand any favours. The other piece was about the Paul Kelly Motor Company in Christchurch. This is an organisation that took all its 40 staff to Las Vegas a couple of years ago. When lockdown hit their sales went from 150 cars per month to none. The staff unanimously agreed on a plan which saw the top 26 salaries cut to support the wages of the rest of the team. This plan will see them get through the first 60 days and has been great publicity for them.

Master Joiners have a toolbox that can support resilience and determined positivity. Without the same opportunities to get together at conference, regional events, or to provide professional development workshops for the time being, there have been a series of webinars recently with more planned. The topics have represented some of the suggestions offered when we

called and are aimed at dealing with the challenges in front of us during and post lockdown. If you missed the webinars, the resources from these are available in the members section of the MJ website. Also on the website is the members forum which was a great channel to share information around employee subsidies and Covid-19 protocols. This is one way of accessing the Master Joiners network which is the real strength of a membership organisation.

Among our membership there are decades of experience not just in manufacturing cabinets and joinery but running a business in good times and bad. People that lead sustainable and resilient companies – Global Financial Crisis survivors. If you are a GFC survivor and would be prepared to help a fellow member then I encourage you to check in with your regional president or with Allison at MJ HQ and extend that offer. If you could benefit from some help, someone to bounce some ideas off, to help build some scenarios to put on the shelf, then get in touch also. Ask for help, be a post Covid success story, a survivor, don’t go it alone!

My parting thought is for everyone to take care, catch your breath, and reset. All this thinking and planning is hard work and mentally taxing. Now there is some business as usual to be done.

EDITOR

Michael Goddard michael@joiners.net.nz

PUBLISHER

Bob Nordgren bob@joiners.net.nz

Whata roller coaster year it has been! Being back to Level 2 feels more like normal but not quite. We have a way to go yet. We are pleased to publish this our June issue. With no Conference and no AWISA we have had to change our course a bit but we still have some interesting stories worth a gander. Edgebanders and edgebanding accessories are always something those in the trades especially cabbies and kitchen makers need to keep up with so we have a bit on these products along with commentary on the continued creep of digitalisation in the manufacturing process.

Hinges and runners are another oft touted range of products we see a lot of. It is no surprise then to see new models every now and then as we have in this issue. It has been good to hear that the trades we deal with appear pretty busy as we went into Level 2. You have to remember that things were going quite well before the lockdown process began some two months ago so its not that unusual. Here’s hoping the pattern continues as the economy begins the long process of winding up again.

Of note has been the continued out pour of new products such as that from NZ Panels Group. Am expecting more later in the year from a range of our clients. A plug for a long time client of ours, One Finance Ltd. The need for financing will be something on the minds of a lot of businesses here in New Zealand. Graham and Shaun have been involved with the trades we deal with for over twenty years now so look them up if you need some help with financing that new machine or finding out about various finance options.

A special note here that our next issue out in September will be number 100. We are planning a few things accordingly and if you want to be in what will be a well read issue then be in touch! In the meantime enjoy this issue and stay safe. A hearty thanks to all our contributors and advertisers: we couldn’t do this without you

Bob Nordgren

Joinery solutions are a defined, specialised area within the CARTERS business that focus on the needs of the Joinery sector. CARTERS don’t believe in a one size fits all approach for their customers, they believe in supporting their partners with the right product, expertise and information to deliver a superior project.

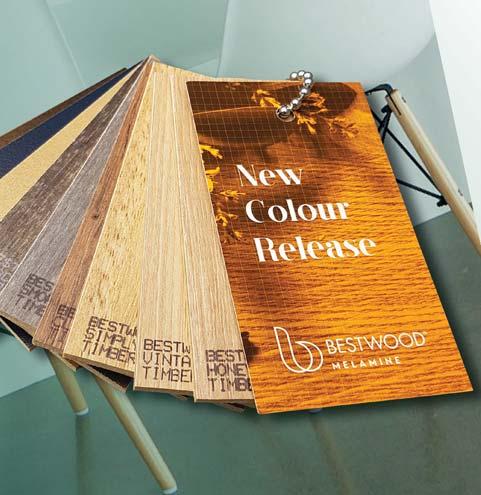

In February, CARTERS Joinery Account Managers were invited to preview the new Bestwood Melamine colour range as part of ongoing product training. The nine new designs were inspired by European design trends and had input from some of New Zealand’s top designers. Early feedback to the range from designers has been enthusiastic, suggesting that specifications will follow on in short order. The CARTERS team felt the six woodgrain designs complemented the Timberland plate finish also available and were excited to be able to offer it to their clients from May.

CARTERS see their Joinery Account Managers as the link between your business and theirs - they handle everything from providing an estimate on your next project to discussing changes on your order, through to meeting with you to review services and forecast your next projects.They are supported by the extended CARTERS dedicated team and can provide a variety of solutions and materials to keep your business working.

Now more than ever, online ordering is becoming the norm and CARTERS new Trade Portal for account holders is providing the ability to do just that. Their recently launched Trade Portal allows customers to shop online 24/7, as well as access all their estimates and account information, search invoices, download data for accounting software plus create favourites lists for frequently ordered items and more. CARTERS General Manager Sales, Josh George says

“CARTERS Account Managers are assisting credit account holders to get set up with logins now. We know that having online access means that customers can tackle their ordering or administration when they have the time to do it”.

Delivery to site has also been a big focus since Alert level 3 took effect, and CARTERS delivery service has been key to ensuring building can continue. They have ensured processes have been put in place for all

deliveries to be contactless for the foreseeable future and will support the industry by adhering to best practice guidelines.

“The CARTERS team across our nationwide network of 50 branches are ready to support you and your business as we move forward through these challenging times,” says Josh George.

CARTERS dedicated Joinery Supplies team are here to support your business, by providing a variety of solutions and materials for your job, in one stop.

We partner with the best-known brands in the market and understand the products needed by joiners for the perfect finish.

• Alchemy

• Vintage Ash

• Honey Ash

• Simply Eucalyptus

• Smoked Ash

• Blackened Teak

• Classic Walnut

• Patina

• Indian Ink

In a modern world collaboration is not a commonly used noun when consumers think about planning their home renovation or new building projects. The art of collaboration and manufacturing quality joinery is second nature to Registered Master Joiners. That collaboration is a bringing to life of design specifications which often reflect the heart, hopes and dreams of the consumer. The connectivity between consumers, designers, builders, and Joiners grows confidence and provides reassurance where it matters most to consumers, who are investing hard earned money. Therefore, the planning and preparation phase of projects should include a Registered Master Joiner.

Registered Master Joiners have been around for a long time and with good reason. It is the commitment to ethics and standards, quality workmanship and access to superior materials which underpin highly sought-after timber manufactured products. Many Registered Master Joiners have their own inhouse design team who use state of the art technology software and machinery adding another dimension to the collaboration effort on behalf of the consumer.

For Joiners who wish to be considered for Master Joiner membership, email info@ masterjoiners.co.nz to be connected with your nearest Master Joiners regional leadership team.

Innovation, capability, and trendsetting does not just happen, it evolves with years of experience in a professional network of creative and committed journeyman craftsmen. Throw in the Registered Master Joiner network of associates; frankly, you have something of a powerhouse. Access to good pricing structures, quality hardware, specialist surfaces and more; contribute to the Master Joiner’s pursuit of excellence for the consumer.

Registered Master Joiners are providing a diverse range of timber joinery products within a full suite of professional services.

But wait there’s more! Sounds cliché but heck its true as many Registered Master Joiners are JMF affiliated meaning they can manufacture NZS:4211 compliant exterior timber doors and windows and will tag their work validating its compliance.

Life is a celebration, but home renovation projects are a collaboration, don’t you agree?

To begin your project collaboration visit www.masterjoiners.nz to find a Registered Master Joiner in your region.

does it mean to

to work with, co-operate, partner with, combine, share ideas, joint effort ...

Blum New Zealand are here to support local Kiwi businesses in the design, construction, manufacture and cabinetmaking industry. We’re more than a product, more than the colour orange. We are a service, we are supportive, and we are a team.

Blum have many free services available to everybody on E-SERVICES, which can help you plan, design, specify and configure – all at the click of a mouse. It’s easy to sign up to gain instant access to a sea of information, whether you have an account with Blum or not!

Do you have a “favourite job” that features Blum products? Send through some images to info.nz@ blum.com and you could be featured on Instagram or Pinterest @ blumnewzealand

Our fantastic team of Blum Account Managers are here to work with you to help you and guide you as you require. If you have a product, service or technical support query, flick through an email or give us a call!

Whatever you need, Blum New Zealand is here to help! Contact your Blum Account Manager or email info.nz@blum.com to get in touch.

E-SERVICES is Blum’s ingenious solution designed to help our trusted partners in everyday use. The free services are available to everyone. Sign up at blum.com and instantly gain access to our basic E-SERVICES package, including Product Configurator – the perfect tool to configure your hardware requirements. Or Product Database – find a sea of descriptions, technical data, drawings and CAD data on Blum products quickly and easily! No matter the demand, there’s an E-SERVICE to help you and your business.

Become an expert at using Blum E-SERVICES! Visit e-services.blum. com

HOMAG and imos strengthen co-operation

The 3D design software marketed under the name woodCAD|CAM is a development by imos AG. The HOMAG Group AG now strengthens its cooperation with the imos AG as a software supplier in order to ensure that you are provided with excellent software for your production. HOMAG iX is the result of this cooperation and an advancement of woodCAD|CAM.

A step forward for a better product!

Our renowned and globally used CAD/CAM system is being relaunched. As of 1st April, 2020 woodCAD|CAM became HOMAG iX. Why? See below the main benefits available to you with HOMAG iX.

Benefits

• Availability of the latest software version

• Access to the iX Support Center incl. Online Academy, training videos and much more

• New: Softlock License Management

• Improved support and service quality

• With integrated digital products from HOMAG

Availability HOMAG iX 2019

• New customers who have bought HOMAG iX 2019 since 1st April, 2020.

• Users of woodCAD|CAM who have signed a maintenance contract just need to carry out an update as of 1st April, 2020.

• Users of woodCAD|CAM without maintenance contract can buy an update or sign a maintenance contract at very favorable conditions until 30th September 2020.

Of course, you can continue to use woodCAD|CAM, however, the program will not be developed further and not be maintained in the long term.

Your next step: Update now and get the benefits! Make use not only of the many benefits of HOMAG iX 2019 but also of the most favorable conditions for an early transition. Take the next step towards an even better software and contact your local HOMAG sales partner.

Greetings everyone, it’s been a challenging time for our industry including master joiners, suppliers and customers. At Laminex we’re optimistic about the future and the resilience of our people and our industry.

While our industry conferences have been cancelled or deferred, it’s great to see online forums, webinars and zoom meetings being used to connect us all with our peers, suppliers and customers. Laminex New Zealand launched HI-MACS Solid Surface via a webinar during level 4 “ lockdown” and had high levels of interest and strong engagement - following the Q&A run by our Technical Services Manager, Murray Christiansen. Key elements of the presentation focussed on the revolutionary new products in the HI-MACS range, the strong investment in research and development and the new décors.

For those of you who live in Auckland, we’re really excited about the opening of our new showroom at the Home Ideas Centre this month It’ll be a great place to send your customers who will be able to view most of our brands in the one location. For those of you outside of Auckland, the plan is to create these showrooms throughout the country over time.

Laminex has also invested heavily in our online shop so that you can order online 24/7. Our customers, who are already buying online, enjoy the ability to order from anywhere at anytime – contact us on 0800 303 606 to take advantage of this new option, or visit our website www.laminex.co.nz. In addition to our online shop, we’ve added new functionality so that it’s really easy to order samples online – this was primarily to replace and update our aging QuickChip website. We’d love you to give it a go and order a sample or two!

Lockdown aside, sales growth has continued with our joinery customers - assisted by residential building consents +9% to 37,600 for the 12 months to March 2020. Commercial consent value for the same period was flat at $7.1b following strong growth last year. During the month of March consents did soften and we anticipate the market will take time to recover after the April lockdown.

Finally, thank you to everyone who responded to our customer satisfaction survey recently. Your feedback is fantastic and will help us to continue to improve our product and service offering. Understanding our customers is our highest priority.

We also appreciate your feedback telling us you value our technical support. We’ll continue to invest in the capability of our people to ensure you get the best support for you and your customers. Thanks again for your constructive feedback, we value your business and look forward to continuing to develop our partnership.

Please feel free to contact me directly with any insights or comments. My email address is mike.arthur@laminex.co.nz or give me a call on 021 220 3744

Mike Arthur General Manager Laminex New Zealand

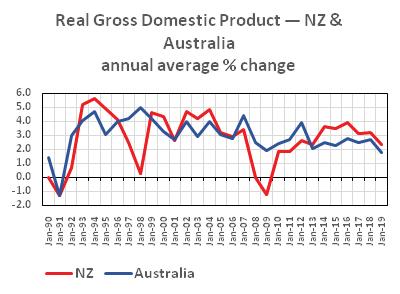

New Zealand’s had it pretty good for the last 10 years with uninterrupted Real GDP growth averaging 2.8%pa. It’s too early yet to see how the Covid-19 story will end, but it’s clear we are all in for a tough time. Back in 2009 Real GDP fell to about -1.3% in the wake of the GFC, but many commentators think we will do well to stay above -10% in the next 12 months. Hopefully this proves overly pessimistic but in any case the next year or two will be very challenging, especially for anyone who has not had to manage through a recession. As a survivor of Black Friday, SARS, Dotcom and the GFC, what advice would I offer to a manager needing to chart a course through rough water for the first time?

First, get your mindset right. Covid-19 won’t have us pinned down for ever. Every recession is followed by a recovery. If you want to be there for the upturn, you’ll need to be genuinely committed to doing the hard yards.

Second, remember two old sayings: within change lies opportunity, and necessity is the mother of invention. The world has changed and I fear for anyone who hopes to wait passively for a return to normal.

On the contrary, I predict an almighty tussle for market share. With fewer jobs to price and more companies chasing the work it will be very difficult for you to sell a product (say a kitchen) of comparable quality at a higher price than your competitors. At the same time, your costs for materials, labour and overheads will be very similar to your competitors.

Squeezed between costs and prices, neither of which you can control, it will be tempting to conclude that the only way to survive is to win jobs by cutting prices. In times of recession this strategy is likely to prove disastrous for the simple reason that there will always be someone who will be willing to do the job cheaper. Those who engage in a race to the bottom may never surface again. You should not be in business to work without profit, and if you fall into this trap

Robin Jack,I fear you will not survive past the short term. The challenge is to win profitable jobs, where you find the “edge” that makes this possible?

How does the quality of your product or service compare with your competitors? (Be honesthow do you know?) What specific steps could be taken to improve your quality so you can command a higher price? List them. Remember that value is in the eye of the customer. Could you create a perception of superior quality by taking the customer beyond the showroom and into your factory where she can see the magic of sophisticated manufacturing technology turning dreams into reality?

Change your business model

Change is about the only certainty in today’s world, and the acceleration of change is relentless. We can’t all be disruptors on the scale of Steve Jobs, but we can be alert for any opportunities that arise from changes in the way we live. Tens of thousands of people have just experienced working from the kitchen table – how many of these might buy a home office “pod” custom-designed to fit their particular spaces (as we now design custom kitchens, for example)? Could you sell a home learning pod through the local school? There are thousands of elderly folk shifting into Retirement Villages – many of them have money and could use custom-designed compact furniture to store and display their precious things. Anti-bacterial surfaces would add to the appeal of such products.The “same old, same old” will not cut the mustard – so what will you do that sets you apart from your competitors?

Improve your manufacturing efficiency

Making a profit would be so easy if you could get your materials more cheaply than your competitors, pay your people less than market rates and get special discounts for your rent, power and insurance. Or if you could just raise your prices. Clearly, that’s a dream – in reality the market will determine both the cost of your inputs and the price of your outputs.

What the market does not control is your productivity – how efficiently you convert your inputs into outputs. In essence, an efficient plant produces more output from less input, and the difference goes straight to the bottom line. Put bluntly, as recession bites, inefficient companies will not be profitable and some will not even survive.

For 50 years I have been working with customers to improve their manufacturing efficiency. Usually this has been around investment in new technology, but it’s surprising how often better productivity can be obtained from existing machines by re-training operators, attending to maintenance, eliminating wastage or changing factory layouts to improve workflow. In times of recession every stone must be turned over in search of improved productivity. Unless you are working on your manufacturing efficiency your competitive position is eroding - because your competitors are not asleep!

Beware the status quo!

Let me finish with a story to illustrate the danger of the status quo. Several years ago my company submitted a proposal for plant with a capital cost of about $150,000

which showed a rate of return over 60%, a payback period of 1.6 years, and a very healthy net present value when we discounted the cashflow. This was based on single shift production. This project stalled for nearly three years. But eventually we completed the installation and within 3 months the machine was operating on 2 shifts. The cost of delaying this investment decision for three years did not appear anywhere in that company’s financial statements, and was not known to its shareholderswho would have been justifiably aggrieved at the profit they missed during those three years. This is what Henry Ford meant when he famously said: “If you need a machine and don’t buy it, then you will ultimately find that you have paid for it and don’t have it.”

It’s true that investing in new plant in recessionary times needs careful consideration, but as in the cartoon, it’s also true that a smart investment could be the salvation of your company –particularly while finance is so cheap. Each situation needs to be carefully assessed on its merits with a trustworthy supplier.

In the previous edition of this magazine the Australian Woodworking Industry Suppliers Association announced that the AWISA 2020 exhibition that was to take place in July 2020 was being postponed. This was for all the now very obvious reasons. At the time of making this decision AWISA was considering moving the dates to early 2021.

AWISA is one of the largest bookings at ICC Sydney, occupying all the exhibition halls, most of them for 15 days. It has proved difficult to find a vacant space of this size early in 2021 that did not clash with other

woodworking exhibitions around the world. Indeed, some of these events were also being postponed and it was clear that AWISA could have made a decision on dates to then find that a northern hemisphere show was promoting dates that clashed. Mid 2021 was also impossible with the two major German trade shows, Ligna and Interzum taking place in May 2021.

The AWISA board has therefore decided to delay the next AWISA exhibition until the dates that were already booked at ICC Sydney for AWISA 2022. “We are pleased to announce that

AWISA 2022 will take place at ICC Sydney from 6-9 July 2022,” said AWISA chairman, Brett Ambrose. “Obviously we are all disappointed not to be running an exhibition in 2020. Some people were a little surprised when we made our postponement decision as early as the beginning of March. However, it was the right decision at the time, and regrettably it has proved to have definitely been the correct one.”

“We now look forward to presenting another world class trade show in 2022. The four years between AWISA 2018 and AWISA 2022 will make the show an even more important event to visit with four years of technology change on display by machinery exhibitors, and four years of new products being on display by hardware, fittings and decorative product manufacturers. Also, it is sure to be time for the industry to get together and entertain clients in the style for which AWISA exhibitions are well known,” he said.

“We are delighted to present to our Leitz, New Zealand Branch located in Auckland, the prestigious Service Certification,” said Sam Czyczelis, Managing Director for Leitz Tooling Australia and New Zealand when presenting the Service Award Certification to Wolf Hoheisen, Country Manager New Zealand.

The audit was carried out on the 24th February 2020 to ISO and Leitz Tooling International standard requirements where the

From the onset of the Covid-19 spread, we at 3D Kitchen assumed there would be a significant slow down within the general cabinetmaking industry, and that this would have a negative effect on our own business. As it transpired this has been far less than anticipated. We have continued to have the same level of contact from our existing customers, providing remote support and on line training as before. In fact I would say that we have actually experienced an increase in this, probably due to many of you having a little extra time on your hands?

There has though been a difference between our New Zealand and Australian businesses, with the New Zealand level of sales staying steady so far. Whereas we have had a small drop in sales in the Australian market, but this is beginning to pick up again already now. The view of the future is definitely moving around to a more positive one. What do we see for the near future? ... it is sure that the Covid-19 threat has had a huge negative effect on the world economy and this will be felt for the next couple of years. But we are also sure that as the restrictions placed on business are gradually

Leitz Auckland Service Centre passed with shining Colours. Some of the conditions taken into account when assessing the service facility included processes/ organisations, workplace space, work place technology implemented, property and building condition, environmental plans and conditions, and not least occupational health and safety.

The effort and cooperation from all staff/employees, management and our counterparts in our overseas

branches has made this come to fulfilment which delivers a “World Standard Service Centre” in Auckland, that can service New Zealand in its entirety.

Leitz Tooling service centres assure service quality of “Tools like New” when returned to the customer.

Leitz Tooling NZ Ltd 0800 578 665 www.leitz.co.nz

removed, we will return to a more normal state and an increasing confidence leading to wallets being opened again. One negative impact we see for our business was the cancelling of this years AWISA trade show in Sydney. 3D Kitchen has exhibited there since 1998 and it has always proved to be a very good marketing opportunity for us. This year we were to showcase the latest release of our 3D design, production and CNC linking software, but that has now been pushed out to mid 2022. Plenty of extra time to prepare at least, and more space to develop further!

We would like to thank those of you who have continued to support 3D Kitchen despite the difficult time we are going through, and we are encouraged by the positive comments we have received. One way we at 3D Kitchen aim to help cabinetmakers in New Zealand, is to continue to offer our software as a give-away in every issue of this magazine. We know by the comments we get back that this has been a great boost to many of you and we are committed to keep this going.

Chris Adams 3D Kitchen

It is probably the piece of machinery replaced most in a typical cabinet making shop not only subject to the most wear and tear but also to a host of ongoing innovations designed to improve finish quality, increase throughput and expand design options. Whether its because your current machine is showing its age or the latest model has improvements that can’t be ignored the edgebander is a machine that needs constant review to ensure it’s the best machine for the job.

This entry level machine with switch control has the same Holzher Glue injection system as the larger machines with “all diamond tooling”, Premill, soft automatic tape feeder, radius scraper and “across the board” flat or finish scraper. “Laser like” finish at this price! And in stock now.

Mid range edgebander fully automated including automated air pressure adjustment with top of the line features. This machine is one of our largest sellers it is the first of the PLC control machines as we recommend that without Full automation a plc controller is pointless.

An industrial grade edgebander with Laser capability or secondary glue unit (PUR, PUR 2KG, EVA, or NIR Laser). It has a super accurate positioning system with CNC grade positioning motors and full automation. From this machine any function can be run at full speed 18 mtrs per min including corner rounding.

Heavy duty industrial edgebander. Affordable option with top of the line features including the automatic small piece support rail, full automation, NIR Laser (ready with a touch of a button noiseless and economic). All of the Lumina range can support multiple glue units. The industry range uses a bridge belts instead of rollers. It is electrically synchronised with the feed train for ultimate stability and hold at high speeds of up to 25m/min including cornering. Easy to use and easy to maintain.

The Lumina range can be configured with full range of extras including easy glide air tables, multiple Automatic or manual tape feeders, Veneer infeed guide, Automatic Multi tool units for different radius setting on all units and also Holzhers own range of panel handling and return tables. All Holzher machines are manufactured in their own factory, setting the industries highest standards of reliability and quality. We like to configure these machines to the customers needs and have proven that our installation back up and support is the best in the industry.

Frankco & Simon in East Tamaki, Auckland have been making furniture for offices and reception areas for more than twenty five years and state of the art edgebanding has always been important to their operation for both quality and design options. When they needed a knew edgebander to replace one of their ageing machines owner Frank Tong knew what he required in a machine; quality, versatility and ease of use. He approached trusted machinery supplier John Fleet from Machines R Us who hold the SCM dealership in New Zealand.

Frank Tong had purchased machinery previously through John Fleet and Machines R Us and liked their product and after sales service capabilities. “I purchased my previous edgebander off John, he is good to deal with, he responds well to your calls, provides good service and has a very good knowledge of all machinery.”

“We do a variety of work in different colours, sizes and shapes of panel so needed a machine that could provide for all those options now and future proof our business for the next few years. I was also looking for productivity gains and a machine with easy precise and quick adjustment. John suggested the SCM Stefani MD with integrated return system. After seeing it in action I agreed. ”

The specs of the Stefani MD are indeed impressive, all electronic, all user friendly and allowing for a variety of design settings and tape

options with a premium on quality finish. It has narrow strip loading to ensure edges are always square even for the slimmest and longest of pieces. It has pre-milling with super fine adjustment to deliver a superior edging surface and a contactless trim saw ensuring protection for high gloss surfaces or sensitive materials.

It provides two edging systems, one a standard EVA glue set up and a second system utilising the latest generation AirFusion

for a laser edge option which is virtually invisible. It has a 4 motor rounding unit with three radius options - 1mm, 1.5mm and 2mm accommodating a variety of edges and shapes - as well as top and bottom radius trimmers and scrappers in the same three options. Finally dual sets of surface scrappers and buffers and a complete spray system give a finish that needs no further action or clean up.

“The edging option were important and give us the versatility we need.” says Frank. “Airfusion allows me to quote for high-end work, comfortable in delivering the look and result required, while EVA continues to deliver an excellent finish for much of our office furniture range. The two systems serve us well. Easy to change in or change out they mean we can offer competitive pricing right across the range of of products we are asked to produce for our clients.”

The purchase has been a positive move for Frankco & Simon. “The advances in this machine are substantial, from quality of finish, to versatility in production, to a fully electronic user friendly set up which requires no manual adjustment at all. Everything is designed to make the machine easy and quick to set up and millimeter perfect in edge delivery. Coupled with this it is reassuring to know we have access to Machines R Us and their maintenance expertise to keep the machine in optimum working order”

“The SCM Stefani MD delivers us the versatility and performance we needed, a high speed machine, capable of delivering the range of options our market demands in terms of both design and costand it is very easy to use - a good recommendation from John,” says Frank.

We do a variety of work in different colours, sizes and shapes of panel so needed a machine that could provide for all those options now and future proof our business for the next few years

Perfect joint line and versatility of use with the new SGP (Smart Glue Pot) and the pre-melting unit PU BOX L Extraordinary level of finishing quality with AirFusion+ technology that allows edgebanding without glue. Simply the perfect edge bander for all companies who require continuous production of a large number of panels even though they are all different from one another.

Versatility and high machining quality. The use of "multi-edge" machining heads with electronic axes allows the machine to be set up automatically to machine panels with 2 different radiuses, solid wood and thin edges.

Ease-of-use with all inclusive equipment: pre milling, interchangeable glue pot, radius trimmers and radius scrapers along with corner rounding unit offers the “very best” performance in edge banders at this level. These features, coupled with its ease-of-use makes it the perfect edge bander for small woodworking, furniture and panel processing companies.

Edgebanding is the manufacturing process that has the greatest tangible impact on workshop productivity and product quality. It’s no wonder then that edgebanding is an area that has seen the most evolution in recent years.

Edgebanders from Jacks have been at the forefront of technology for many years now, helping businesses gain productivity and quality advantages. But equally as important as selecting the right edgebanding solution for your workshop is keeping your edgebander in the best condition. Jacks are only too aware of the importance of good backup and maintenance, and as such have invested in a team of 14 technicians – many specialising in edgbanders - as well as the largest supply of spare parts onsite in New Zealand.

Widely recognised as the leading manufacturer of industrial edgbanders, Homag out of Germany offer edgebanding solutions for small businesses right through to the largest panel-based furniture manufacturers such as Ikea. The Homag commitment to quality has never been compromised over the years and as such their edgebanders continue to be the standard bearer in our industry.

Homag offer the latest technology in processing EVA & PUR glue types as well as Laser tape with their airTec ‘zero’ join technology. Interestingly, New Zealand is one of the world leaders in ‘zero’ join technology, with a sophisticated market that really appreciates the quality of the edge join. The ‘zero’ glue-line appearance of laser edging achieves a new threshold of furniture and kitchen design aesthetic, providing a seamless transition between edging and panel. Kiwi joinery shops - and their customers – have embraced this quality more than anywhere else in the world.

Edgebanding with PUR glue provides an almost invisible join with the bonus of being completely waterproof, making PUR ideal for kitchen and bathroom furniture. PUR glue characteristics also include a high resistance to heat, cold, and chemicals.

A Homag is a long-term investment in efficient production and quality. A Homag equipped with airTec and/or PUR gives you the competitive advantage: edges that are less susceptible to wear and tear, and featuring a moisture, bacteria, and heat resistant finish that will increase the longevity of your components.

From the Felder range of edgebanders Jacks have selected the P200 pre-glue edgebander as an ideal solution for manufacturers looking to step into their first automated edgebander. The Felder P200 uses hot-air to activate tape that has had glue applied prior to processing on the edgebander. The advantage of this technology is the glue colour applied to the tape has been selected to best match the material colour which helps reduce the appearance of the glue line.

Other advantages include a quick heat-up time. The P200 is ready to go in just two minutes. Set-up between tape and material thicknesses is also fast and easy. The P200 also boasts two speed technology with the slower speed being ideal for a better quality finish on doors and/or on colder winter mornings whereby longer exposure of the tape to hot-air blower assist with a stronger bond between the edging and panel.

From German machinery specialists Mafell, the HIT-M is the first and only mobile edgebander for creating an optical “zero” joint. Straight, bevelled, curved and round components as well as moulded parts can be processed. Mitres edges of up to 55° can be easily processed, while heat up time is just a matter of seconds. Hand-held on site or using the optional processing table, Mafell’s HIT-M is your entry to production with laseredged tape.

Janssens

NZ’s own Janssens edgebander is so common in Kiwi cabinetry-shops that there’s little to say that the industry doesn’t already know. They’re still locally made and remain one of the most useful machines for panel-based furniture manufacturing.

Kantek Ltd are pleased to introduce their Business Development Manager, Eládio Gaspar. Last year Eladio moved his young family from South Africa with the support of Kantek and is enjoying the challenges of the New Zealand market.

Eladio holds a Bachelor of Commerce from The University of Johannesburg and has worked in the industry for over 10 years. He spent 6 years working with Rehau Polymer specialising in edgebanding, and a further 4 years as Sales Manager for the largest plastic profile extrusion business in South Africa.

Eládio aims to use his experience and knowledge to strengthen Kantek’s already compelling offer. “I started my career at the coal face of sales, working with edgeband operators and joinery owners when 3mm edging was still a thing”.

Virutex – from Spain – have an entry level AG98R manual edgebander ideal for repairs onsite, and versatile enough for all of those little jobs. Priced well under $1000 there isn’t a better edgebander for the money.

Virutex’s PEB250 has been developed from their popular hand-held glue-pot range of machines. Perfect for edgebanding large tops or onsite work, the PEB250 features a new variable speed adjustment. Controlled via a microprocessor on one of the hand grips it means you can slow the feed rate down around curves, and speed up on the straights! The PEB also has variable temperature control and adjustable glue application.

“Being a good partner in your customer’s business is all about trust” Eládio explains, “customers need to know that they can consistently rely on the performance of your products and the service your team offer. This is precisely why Kantek have again and again been singled out as exceptional suppliers, by customers who have dealt with us over 25 years of trading”.

Kantek pride themselves on partnering with world leading brands in their relevant fields, including Doellken edgetapes by Surteco, Jowat Adhesives, Riepe cleaning and release agents, MenageConfort storage solutions as well as Samet kitchen hardware. Coupled with their drive to consistently offer market leading service, Kantek aim to be integral to their customer’s successes.

“I’m excited to have joined our incredibly dedicated sales team and look forward to growing our presence in the market”.

www.jacks.co.nz

Eládio can be contacted on 021 872 991 should you want information, advice or to arrange a visit.

Last years winner of the Master Joiners Best Kitchen Award, Modern Age Kitchens & Joinery understand the importance of providing clients with a quality finish to their kitchens, they also know that reducing the manual labour involved in handling sheet materials is key to a successful operation. The machinery they use in their Christchurch factory reflects these points, a Biesse Skill CNC nesting machine and a Biesse Akron 1440 edgebander, both are core to their manufacturing success.

The Biesse Skill was purchased around five years ago and was a move by the company into automatic nesting, replacing as it did a single sheet router which required manual feeding and off loading. The productivity gains were immediate and substantial says Graham Woodham who runs the business with father Grant.

“You don’t make money by manually handling sheet material and the Biesse Skill has proved that to us. It has decreased our labour input and increased daily throughput in the factory while improving finish quality. Primary in this is its automation, it gives us the ability to lay 30 odd sheets in a stack, program it and leave it - it simply doesn’t stop cutting - little attention needed, no lifting required, no mistakes made, no injury potential. Likewise auto labelling has made a massive difference, a big timesaver, work automatically organised and again less potential for error.”

The Biesse Akron 1440 edgebander with return has similarly been a profitable capital outlay for

Modern Age Kitchens, improving edge finish capabilities while reducing handling. Purchased two years ago the Akron has the latest technology with AirForce and PUR capabilities providing the quality of finish and invisible glue line required for clients in their sector of the market.

“Our edging now requires less handling, it is much more economical and provides a lot better finish with several significant advantage over our previous machine, not least being its near invisible glue line,” says Graham. “Requests for invisible glue lines is a first option for many clients, especially those wanting white kitchens, no one wants to be able to see dark joins in their pristine white cabinetry. The AirForce capability on the Akron means this is an easy option for us and in fact we use laser type edging with it seamless joins as a big selling point with our clients.”

“The pre-milling on the machine is also excellent giving us the best possible edge to start the process. It also has many time

“having two machines from the same manufacturer working together side by side has benefits in terms of service and staff familiarity - in this case they look good as well.”

saving features, we have all our programs stored for easy job set up and change and all on-machine adjustment of cutters etc., can be easily and quickly done on the screen. It also has the ability to edge panel or doors with the hinge holes already in place and the return system means a lot less walking and double handling than was previously required.”

While machining capabilities were important in the selection of both machines so too was the back up and after sales service that Biesse provides.

“We have had Biesse machines for some years now and they have always performed well and the after sales support has been good. It helps that Biesse have a physical presence in Christchurch, parts are usually pretty quick to arrive and they have good technicians here as well as a very good online service.”

“Biesse training events are also helpful. It’s true that the best way to learn a new machine is to use it, but courses such as the recent Biesse Masterclass certainly speed that process up. We sent our operator along, he found it very good and came back with a few tips - one of which we are buying a new extra for the machine to take advantage of. These events also provide a good connection with Biesse and interaction with fellow users, we all have the same day to day issues and it’s good to see how others have solved them and also just to see what the machines are capable of outside of your own immediate use. Biesse appreciate that.”

A landmark in the Christchurch joinery scene, Bates Joinery has been in operation over 60 years. Owner Mark Allworthy joined in 1979 and has worked his way from apprenticeship to ownership in the subsequent 40 years.

In that time Mark has seen the importance of having quality machinery to produce a quality result, and it’s this quality result that keeps customer satisfaction high, and business flowing in. To make this a reality, Mark reviews every workshop machine at five or six years old to satisfy himself that it’s still the best machine for the job.

In 2018 it was the turn of their Brandt Ambition 1220C for review. While the machine had plenty of years left in it, Mark and the team saw the opportunity presented by high gloss acrylic. “It was clear the trend was towards a high quality, high gloss finish, and we decided to move early to capture some of that developing market”.

Mark looked at the options in the market for processing ‘zero’ glueline laser-edge tape, but in the end couldn’t go past the experience they’d had with their Brandt. “The Brandt was producing a quality finish, and we were very happy with both its reliability and the results we were getting, so choosing Homag again made sense.” (Brandt rebranded their machines Homag in 2017). “The level of service and support we were getting from Jacks was a big factor in our decision too –particularly the speed with which we could get a technician when we needed one.”

The Brandt was traded in and a Homag Ambition 1440AT was soon in its place, making Bates Joinery one of early adopters of ‘zero’ joint edgebanding in the South Island. Ideal for those looking for a productivity and quality advantage,

Homag’s 1440AT combines flexible processing of EVA, PUR glues and ‘laser-edged’ tape, along with automated setup for different materials and thicknesses. “We moved to PUR glue predominantly because of its water-resistance” explains Mark. “It just adds a quality to our range. We’ve got two gluetanks – clear and white – and we’re no longer using EVA at all.”

Bates have also implemented clear PUR processes to ensure they get the most from their glue, while keeping the machine and tanks in the best possible condition. As part of their machine they also invested in Homag’s XES200 – a clever storage solution to make working with PUR more efficient, with less waste and easier handling. see box

Soon after installation Bates added a Compakto return conveyor to the Homag – enabling single person operation. In fact, the primary operator, Kawal, operates both the CNC and the edgebander on a normal day – edging material straight from the CNC while the next sheet is being machined.

PUR glue hardens when exposed to air – making it hard to avoid wasting material (glue) and to keep the application units on an edgebander becoming hardened and unusable.

The XES200 unit, which can store two tanks at a time, creates a vacuum that enables a tank to be stored over a weekend and easily reheated for use on Monday. It also acts as a pre-heating station for regular colour changes, meaning quick changeover, and efficient production. What’s more the XES200 enables a tank to be cleaned away from the edgebander

Mark is very satisfied with their Homag. “It’s performing exactly as expected,” he says. “Adding high gloss acrylic to our range is complemented by our in-house design capability. Whether a customer wants a complete kitchen or just some feature highgloss panels, we now offer the full package.” With most of their work

coming from market builders and word-of-mouth then versatility and quality are key features of Bates’ brand, and the Homag has helped expand what they can provide to their Christchurchbased market.

What’s more, Mark’s not quite finished yet. “Part of the reason for investing in the 1440 and airTec capability was to future-proof our manufacturing” says Mark. “We have a few plans involving the Homag that we’re not quite ready to share yet – especially given we’re only just out of lockdown. But we know the Homag has more capacity, and we’re looking ahead.”

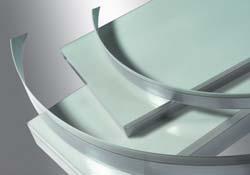

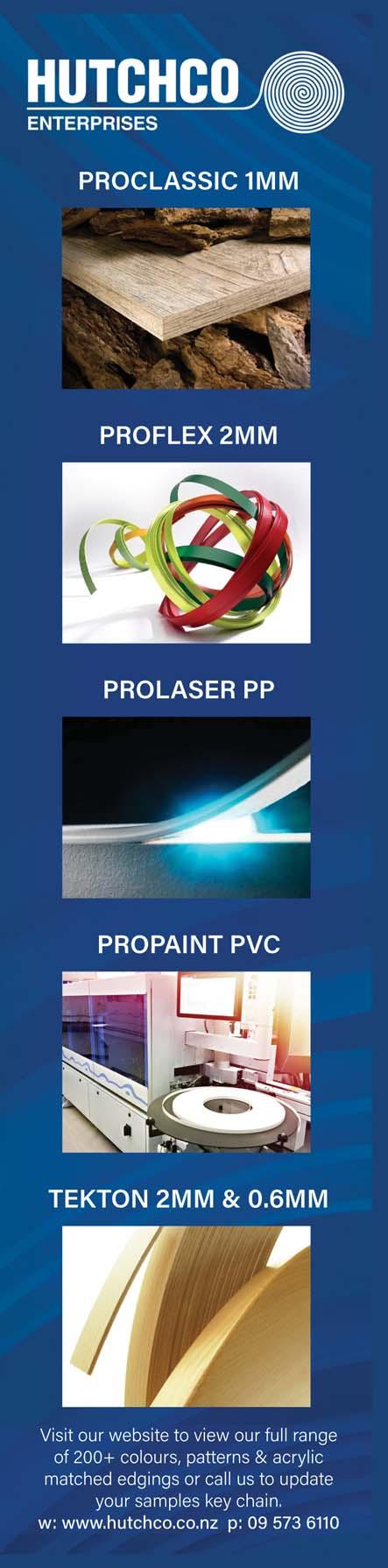

From the beginning, Nelson based kitchen manufacturer Living Design has opted to use real wood edging over colour-matched thermoplastic edgebanding for everything from carcasses and shelving to doors and drawer boxes. “As soon as you put a wood veneer edgebanding on standard melamine board you get a quality point of difference and if you get a dent in a wooden edge it is normally quite easily repaired.” say owners Annett and Klaus Todt.

Manufactured in Germany by Heitz and exclusive to Hutchco,Tekton’s multi-layer 2mm and 0.6mm veneer edging has been a staple for Living Design. “It wasn’t even a thought, it’s a sophisticated well-made product that we had used with our joinery business in Germany,” says Annett.

In late 2019 Hutchco introduced Multiplex Birch and White Oak pre-finished veneer edgings. The pre-applied UV resistant lacquer slows the effects of fading and UV damage while adding cost-saving benefits during the manufacturing phase. Living Design ran trials with the 0.6mm and new 1mm White Oak veneer edging which were highly successful in performance and eliminating multiple post production steps.

You start to get a sense of why Living Design are successful at what they do, every functional detail must also be aesthetically pleasing and designed without limitations. Klaus masterfully designs each piece by hand, combining years of experience a calculator and a conventional drawing board.

Now in their 10th year with anniversary celebrations put on hold due to the Covid-19 pandemic, Annett doesn’t give the impression their bespoke European designed kitchens, bathrooms and living spaces are going anywhere in a hurry.

Tekton 2mm and 0.6mm natural wood veneer edging is available by the coil in standard precut widths of 22mm, 29mm, 35mm & 45mm. White Oak 2mm offering a 65mm and 85mm wide exclusively through Hutchco.

Living Design Showroom & Workshop

71 Trafalgar Road, Mahana, Nelson 7173 Ph: 03 544 187

Andre Ismael, Lightstyle Photography Rustic Art Oak Veneer & Premium Oak Melamine drawer box, Primepanels. Tekton American Walnut (top left), Tekton American White Oak (above) and Tekton Multiplex Birch (left) now available in a prefinished wood veneer from HutchcoThere’s a lot going on right now around the world, and so much is changing - overnight it often seems! However, we choose to focus on the things that we are certain about right now: We’re here for you.

Here’s 6 things you can be certain about

Our Price: We charge you the same price as your mate at the joinery shop down the road, so you know you’re on an even playing field. It’s fair, it’s honest and it’s here to stay!

Fun Fact: over the last 7 years, our cut&clash door prices have only gone up a total of 1.2%. That’s like the price of a coffee for you and your wife on an average order, and also less than inflation!

Our Family: Sage Doors is 100% kiwi family business, and it’s going to stay that way.

Our Squareness & Size: We can confidently say - thanks to our fully automated, robotic edgebander – our doors are the squarest doors in NZ! Yes, that’s a bold claim, but our Edgebot has changed edgebanding for us.

Our Lead Time: It’s short & sweet. Mostly just short and getting shorter - and it’s here to stay!

Our standard selection* has a short & sweet lead time of 2-4 days (often closer to 2), so make sure to double check your order when you click submit as it could be packed by the time you call us the next day to make those changes! *mitred handles, built-up panels and non-stock colours aren’t standard and typically take a few days extra.

Our Stock: We’ve working closely with our awesome suppliers in Europe during lockdown to ensure that we don’t run out of any products when you need it most.

Our Mitred Handles: They are the real deal – with a seamless Invisedge® on that mitre (yep, no glue!). They look & feel the partwith no joins in the mitre, they are seamless and well loved.

What’s another thing that’s setin-stone? Lookcrete®! Here’s 5 reasons why it’s awesome, wellloved and here to stay:

It’s Melamine: This makes it both affordable & easy to work with. No need to worry about using different tools or hardware: if you’re a cabinetmaker, you know what to do with this stuff!

Look & Feel: Lookcrete® has a unique concrete texture, which looks and feels like a real concrete product.

Texture: It’s not just another white or grey – Lookcrete® has

got TEXTURE, both in the colour and the feel. It goes well with woodgrains, and concrete is a familiar industrial texture in today’s world. It gives an authentic and natural feel to your design.

It’s Durable: Yep. It’s melamine, so it won’t mark or erode over time like a real concrete surface. It’s also got our Invisedge® clashing to give it that seamless edge.

It’s Versatile: That means you can use it for kitchen cabinetry. Or a shop fitout. Or maybe a feature wall in your living room. A desk. Reception counters. Kitchen cabinetry. Bathroom vanities. Floating shelves. The sheets are a whopping 2800x1800, and we can edge panels up to 60mm thick, so the sky’s the limit!

www.sagedoors.co.nz

Leitz Tooling have been making tooling for the woodworking industry for over 140 years since the first drills were produced by Albert Leitz back in 1876 in Germany. The Leitz family has owned the business to this day.

Reliability and longevity are the keys to the success of Leitz Tooling. No more so than with the servicing of edgebanding machinery. The servicing of pre milling cutter heads for edgebander machines is done using the latest diamond sharpening machines and technologies in their Penrose Service Centre in Auckland. There is minimum machine downtime when you book their overnight service.

“Even the best quality tool can only provide optimum performance if it is regularly maintained by experts.” says Leitz Tooling’s New Zealand Manager Wolf Hoheisen “We use in our Auckland Service Centre the same machinery and programmes as in our tool production at Leitz in Germany. This gives our tools consistent top quality be they brand new or resharpened from our service centre. What’s more, we can use the same technology to sharpen tooling from all manufacturers.”

Leitz Tooling has some 140 service centres worldwide where great importance is placed on quality. This is underwritten with its quality management system certified to DIN ISO 9000 standards providing a uniform quality worldwide.

In the last issue we looked at the entry level concept of the digital workshop from Homag, here we turn our attention to the networked concept and the digital assistants that support the production process. In the “Networked digital workshop”, each machine is operated by one employee and is organized so that the work preparation, machinery and bench room areas are separate from one another. Some of the job data is available to machine users in digital form.

1. HOMAG iX Easy. Efficient. Impressive. HOMAG iX offers precisely the flexibility that is required to implement customer wishes quickly, individually, at a high quality and cost effectively. The 3D software developed for constructing furniture and interior fittings connects all important work steps—from sale, through design and up to production—into one integrated and efficient process.

The CAD functions for free and parameterized design support users in their daily work. Everything is achievable, from individual unique items to interior fittings in large quantities. The photorealistic representation means that impressive presentation and sales documents can be created easily and efficiently. In work preparation, HOMAG iX enables time savings of up to 70%, as production documents and CNC data are generated automatically and transferred to the machines. HOMAG iX is the optimal data supplier for the digital HOMAG products productionManager and intelliDivide.

2. All production data at a glance: productionManager (digital job folder)

Many businesses still use handwritten parts lists and drawings in paper form. The productionManager - the digital job folder - is used to ensure that the data is used consistently from the foreman's office, through production and up to the bench room. It summarizes all production-related data and replaces the individual paper documents. Users who have created their furniture in the cabinetCreator (furniture configurator) or with HOMAG iX can easily import all of the data into the digital job folder

with a click of the mouse and thus retrieve the data at any time via the tablet. Data from other CAD/CAM systems or industry solutions can also be imported. Carpenters/joiners now always have at their disposal a transparent status of all jobs and can easily add further parts.

3. Optimizing nesting patterns: intelliDivide Nesting

Optimization of cutting patterns is worthwhile for more than just panel dividing on saws. With the right optimization, significant cost savings are now also possible in the nesting process in particular. With the intelliDivide Nesting digital assistant for dividing panels in the nesting process, carpenters can get optimized nesting results for their CNC machine with just a few clicks. Above all, this saves time and personnel: optimization starts directly after the data is uploaded. For this purpose, the woodWOP programs are nested automatically on the unprocessed panels. At the end, operators can download the finished woodWOP program (the nest) for their machine. The material costs also fall: waste is reduced thanks to the optimal utilization of the panel material. Another benefit is that intelliDivide Nesting is flexible to use and can therefore be used for rectangular parts as well as free-formed workpieces.

4. All edges at a glance: The Edgeband Management Set How can I store my edgebands

in a way that is clear, clean and tidy? This is an issue that concerns a lot of woodworking shops, regardless of size. The solution is the Edgeband Management Set, which gives users a complete overview of all the information about their edge material.

o use the Edgeband Management Set optimally, carpenters need the materialAssist Edge app and a special edgeband rack. materialAssist Edge manages the stock of edgebands in the edgeband rack (including residual lengths), documents deposits and removals of edges and indicates the storage position. The corresponding labels for identifying the edgebands can also be printed directly from the app. The edgebands can therefore be identified and managed easily by scanning the barcodes. When operators want to edge a part, they simply select the correct edgeband in the app by touch. In that moment, the matching edge is quickly and easily identified in the edgeband rack by the LED display that lights up. The bottom

line for carpenters is that, in the workshop, the Edgeband Management Set ensures optimal organization in the preparation of edgebands and quicker set-up of the edge banding machine.

5. A slot for every part: production Assist Sorting productionAssist Sorting is the carpenter's digital assistant for sorting furniture and com-ponents at the work station in the workshop. The assistant has two decisive benefits: it ensures that all parts for the assembly in the bench room are complete and avoids time-consuming searching for components. The prerequisite for using this sorting assistant is a special sorting rack. Users scan the barcode on the workpiece and receive a suggestion of which rack compartment the first part of the furniture should be sorted into. In this way, the users pre-sort the parts for assembly in the bench room according to the individual items of furniture. The result is a simple, fast and secure process.

6. Support in assembly: The productionManager

The productionManager—the digital job folder—supports employees in the assembly of the furniture. In the first step, users can easily see which parts belong to the next cabinet they want to assemble. With the productionManager, they also have access to the required exploded-view drawings and part drawings and the 3D drawing of the furniture. In an additional overview, the assistant also shows the fixtures required. All information concerning any assembly job is therefore always at the users’ fingertips.

Like to know more about HOMAG software? Scan the QR code to connect ...

New Zealand Panels Group have cherry picked the best of the European design trends and combined those with input from some of New Zealand's leading designers to release nine new colours into the market.

The result is six gorgeous new woodgrain designs that look incredible when paired with our Timberland plate finish - a huge step up in both touch and texture. Three additional designs in oxidised gold, a dark metallic wash and deep blue have been chosen to complement both the woodgrains and each other.

In tandem with the new colour launch, we've also introduced a design competition which offers the chance to win a weekend getaway for two up to the value of $2500. (see below)

Visit our melamine colours page to view or download a full sheet swatch and order samples. Note our team will be out in the coming weeks visiting clients to update melamine folders and boards.

To make way for the new decors, the following colours are no longer available: Allure, Basalt, Etched Zinc, Irish Creme, Ash Pinstripe and Saltwash.

Terms and Conditions.

• Entries will only be accepted from New Zealand-based industry professionals: interior designers, kitchen designers, architects, joiners etc.

• Only one entry may be submitted per person.

• Designs must show a complete design concept such as a kitchen, bathroom, retail space etc. A mood board on its own will not be considered.

• Entries must state which Bestwood melamine colours are used and the finish preference.

• Entries must be submitted by the closing date of 30 June 2020.

We're not ones to tell you where to go, or what to do, so we're offering you the chance to win your own weekend escape for twoand we'll pick up the tab - to a maximum of $2500. (Clearly non-essential travel isn't on the cards right now, but our travel prize will be redeemable up until the end of Feb 2021). Simply send us an interior design concept featuring two of our stunning new Bestwood Melamine decors by 30 June 2020.

The winner will be selected by a panel of industry professionals based on creativity, clarity of design and best use of the new decors. Note the promotion is only open to New Zealand based professionals within the industry - designers, joiners, architects and kitchen manufacturers etc.

For inspiration and to enter go to www.bestwood.co.nz

• The $2500 prize is GST inclusive and will be arranged through a travel broker. You are free to arrange any travel you wish up to that amount.

• Travel must be taken by 28 February 2021.

• The winner will be announced before the end of July and the decision will be made by members of our invitation judging panel made up of industry professionals.

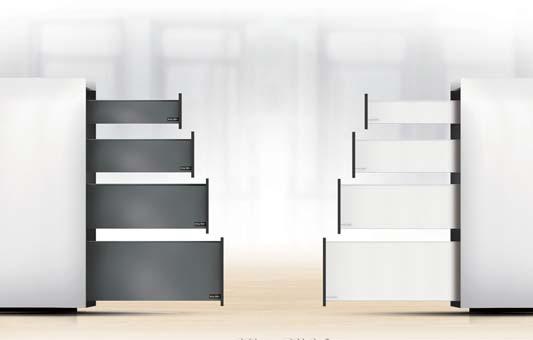

Hinges and runners come in a multitude of sizes and types developed to fit every niche and requirement. The best of them go unnoticed - support structure for the quiet and smooth functioning of our doors, drawers and more through out the house. Of essence they need to be strong and durable, quiet and smooth, easy to install and easy to adjust.

We asked local suppliers Hafele, Blum and Fit, who between them represent many of the worlds best brands, what they currently have on show.

Concelo continues to raise the bar in what you should expect from the most used appliance in your home - your bin.

The Concelo range is packed with features to suit the needs of the designer, the cabinetmaker and the homeowner, such as:

• Smooth, concealed runners equal to premium drawers

• Unique Clip'n'Clean components for ease of cleaning

• True 6-way cam door adjustment and locking bolt system to lock door in position

• Electronic Push-To-Open compatible

• Cinder and white bucket options in a range of sizes

An attractive solution at an attractive price - make Concelo the choice for your next project!

Contact Hideaway for more information. hideawaybins.co.nz/concelo

1. Smooth Liquid Dampening

Grass SCALA drawers feature highest quality European made runners with unique liquid dampening technology for a smooth opening experience and quality that will last a lifetime.

2. Fast Assembly Time

When it comes to drawer assembly, the ability to have drawer backs and bases all at the same width for every SCALA drawer provide great optimisation for a manufacturer. This means fewer parts to assemble compared to other drawer systems in the market.

3. Handle-Free Kitchens

The SCALA Tipmatic soft-close system is market leading technology and is the easiest to not only install but adjust the capacity needed.

4. Consistency in Design

Available in three striking colours of Ice, Silver and Stone, there is a shade to suit any design - with a range of inserts and organisers in an exact material and finish to match seamlessly!

5. Full Range

Nova Pro Scala drawer sides are available in 63, 90, 122, 186 mm and now introducing 250 mm high sides.

Most are already aware of the quality of Scala Drawer system – but it’s also extremely manufacturer friendly.

Smooth and effortless. Totally practical, the Alto Drawer System from Hafele offers an affordable solution coupled with silence, smooth running and ease of use. The synchronised opening action of the Alto Drawer is supremely comfortable - thanks to proven knowledge behind this soft-closing technology, leaving you in no doubt of its quality.

Features

• 35 kg load capacity.

• Full extension runners with integrated soft-close.

• Mounting: Front fix brackets snap into drawer sides with knock-in, screw-fix or expanding dowel mounting onto the drawer front.

As you’re no doubt aware, FIT are a family owned firm that, while most definitely 100% New Zealand owned and operated, goes to great lengths to source quality product from around the world. Several years ago, that sourcing effort brought King Slide into the FIT fold. Now, the team at FIT are delighted to bring to New Zealand a new, premium slimline drawer system called SIMLEAD, which comes from the quality King Slide range.

Premium slimline drawer system joins FIT’s range Simlead, the latest addition to FIT’s range is a new premium slimline drawer system created to exacting standards by King Slide. With metal walls just 13mm thick, Simlead is aesthetically pleasing and available in 4 panel heights: A (97mm), B (138mm), C (185mm) and D (249mm). With synchronised movements for minimal noise and smoothrunning motion, Simlead is available in several key runner lengths - 350mm, 450mm, 500mm, 550mm.

Its 8-way adjustment (including depth, side, height and tilt, for

precise gap alignment) and easy installation and removal via a unique locking device sets you up to achieve a perfect fit, painlessly and quickly. To see the installation process, check out the videos on the video library page of FIT’s website – www.fit-nz.co.nz

With two colour options – classic white and dark grey - and two load capacities - 40kg and 70kg - there’s a Simlead premium slimline drawer to suit your client’s particular requirements. Naturally the range features a smooth and consistent soft-close action.

Great news too is that there is no ‘bounce-back’ on Simlead’s push to open models.

Simlead’s Ever Active innovation means that the drawer can be pushopened from closed or partiallyopened position for completely hands-free operation; brilliant for low drawers – you can open with knee, toe or side of foot, even if already partially open – and for those many occasions where you approach the drawer with full, wet or dusty hands.

Switchable Push-Open Simlead’s push-open function can be enabled or disabled with a simple flip of a built-in switch. Select soft close only or push to open with soft close functionality based on your project requirements, without the need for additional components.

Great news too for joiners and cabinet makers using Cabinet Vision; Simlead drawers are already loaded and ready to go!

King Slide runners and the Simlead range are on FIT’s website now –www.fit-nz.co.nz

Contact your Fit rep, phone 0800 852 258 or email sales@ fit-nz.co.nz to discuss your drawer runner and system requirements.

Wind Lift – compact yet strong, elegant and unobtrusive, Wind maximises space in overhead cabinets and features smooth, controlled soft closing, even for wide spans. Push to open and Light options.

Eclipse Pocket Door – innovative mechanism that slides door into side of cabinet. Many applications –kitchens, laundries, wardrobes, work stations and more. Highly adjustable and removes easily if needed.

Pacta Falling Flap Door Stay –ideal for creating a fully aligned flat surface on desks, appliance work stations, table extensions and more. Pacta, for downward flap doors, is simple and stylish with a gradual controlled action and no bulky stays. Push to Open and Light options.

Bifold Gear – easy assembly, very quiet and just 80mm space lost when open.

Soft Close Hinges – a solution for any application including full and half overlays, inset and special angles, available

Talk to our knowledgeable team

Require something subtle but sleek for your dark cabinetry interiors?

Dark furniture is on-trend right now, and for a good reason. It creates a powerful visual impact while transmitting elegance throughout the exterior of the cabinetry. The onyx black hinge range from Blum is the ideal collection for all of your specification needs, complementing dark furniture discreetly and without compromising on form or function. Available in a variety of applications and with our award-winning integrated BLUMOTION - there's an onyx black Blum hinge for every piece of furniture, every kitchen, every cupboard and every idea.

Order for your next job? Available through online ordering!

MOVENTO is the ultimate drawer runner for wooden shelves and drawers. It may be a product that’s been in the market for a couple of years, but are you aware of everything this magical runner system can do?

Holding 40 to 60 kg of weight, they’re a perfect solution to many problems with high stability and excellent sag values. But MOVENTO is more than just a runner; it’s an innovation. Use MOVENTO runners in gorgeous