10 minute read

Engineering Developments are Mitigating Climate Change

PART ONE

Advertisement

By Norman Harris

Engineering in all sectors is a continuous process of development. Generally small and continuous improvements, but sometimes, a breakthrough.

When I first entered engineering, I took an interest in the generation of electrical power. My Mechanical World Yearbook of 1965 still had its bookmark in the pages recording the thermal efficiencies of coal Power Stations. Efficiencies were measured by division of the heat value of the coal put in and the heat value of the electricity produced. Efficiencies ranged from only 30% to 35%, with a league table of stations provided. All those station names have now disappeared into their local histories and most of the sites have moved on to other uses. Coal stations are now on restricted use and will cease to operate at all in the next 2 or 3 years. Leaving a hundred years of coal in the ground and some areas of the UK still depressed and desolate.

The first white knight for electrical power generation was nuclear. But the high costs of construction and an emotional fear of what happens if something went wrong hampered their adoption. Everyone has heard of the Three Mile Island (1979), Chernobyl (1986), and Fukushima (2011) disasters. Fukushima should never have been built on a geological fault line, but the ensuing tsunami was unavoidable. This disaster making Germany decide to abandon nuclear and move to dependence on Russian gas, potentially dangerous politically and much to the justifiable chagrin of the US Government.

As I said engineering in all fields is a continuous process of development and the challenge of Climate Change is no exception. I monitor the technical press and since Oct 2019 I have posted over 285 of such engineering developments reducing the impacts of climate change on the social media sites of LinkedIn and Twitter. In the second Part of this article, I will provide a review of where the greatest progress has been made.

In this the first part, I will start with developments in how we produce energy.

ELECTRICITY PRODUCTION

On any day, any member of the public can check on Gridwatch.co.uk, on how much electric energy we are using and how it is being produced. I did a spot check when developing the article and 48% of demand was served by gas generation, 14% by UK nuclear and a further 8% from France output which 90+% nuclear and solar 11% with wind at 2%. Overall, 19% 0f demand was served by renewable and a further 27% carbon neutral.

Add to this that the demand for electricity is forecast to go up fourfold as everything that moves goes to electric and if temperatures rise, more air conditioners will be installed.

Because it will take some time to develop and construct the new techniques of electrical energy production to safe operational standards. And also, because we need controllable, flexible sources and wind and solar despite their advantages are intermittent depending on the whims of Mother Nature. This should tell is that we will be using fossil-based fuels for a considerable time to come. If we are to meet out Climate Change commitments then we have to remove the carbon from the combustion oil fired generation produces. By “carbon” we always mean the gas “carbon dioxide” or CO2.

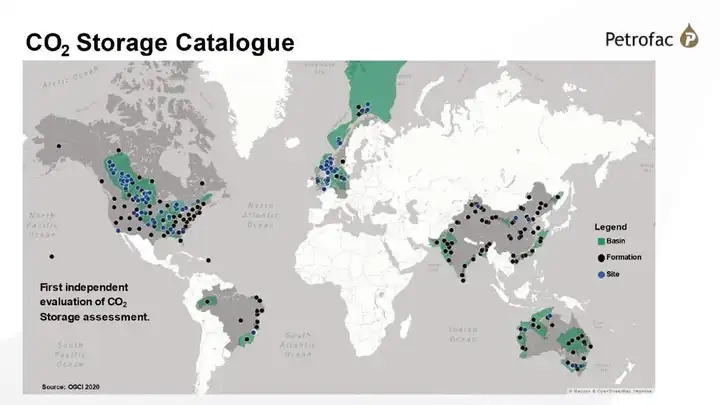

So, my first topic of engineering mitigating climate change is Carbon, Capture and Storage or CCS for short. There three principal processes vying for adoption based on safety and economics. About 10 years ago the UK was leading the world in this development with two pilot projects after around 6 years of development only for the Government to withdraw its support. But since we will need electricity in large quantities from fossil fuels for many years to come it has come to the fore again with some Government funding. The processes take the carbon and other harmful by-products out of the flue gases. Arguably the world now leads the UK, and it is proven technology as the slide below shows.

CO2 is not all bad There are lots of uses for it. So, the further acronym for CCUS of Carbon Capture, UTILISATION and Storage has been coined. These are too many uses to record here, but I mention refrigeration and the “smoke” gas of stage performances, along with water treatment, various plastics, mattresses, and of course carbonated drinks.

Over time it would be cost beneficial if factories using CO2 were to be built alongside the electricity generating facilities that produced the gas.

The storage of the gas from UK power generation would generally be in the depleted oil fields of the North Sea and the industrial estuary areas on the East Coast are already converting their pipework networks to deliver the gas to the North Sea oil wells. Fortunately, this also extends the life of the wells by pressurising out harder to get oil. The process is called Enhanced Oil Recovery (EOR), there is an acronym for everything!

Incidentally, we all need a little CO2 gas in the bottom of our lungs in order to breath well.

The power of the sun has driven everything since the earth began. And whilst it does heat the land and bodies of water we have not been able to harness it to use as we wish until very recently. Now after a period of Government subsidies which resulted in many homes with rooftop installations, the equipment has developed and is cost effective in its own right. A drive West from London on the M4 or a train ride North and one cannot miss huge fields of solar panels. Farmers now make more money from them than with crops or animals. And comparatively they need little care. Sheep grazing between and under the panels is optional. The fields do not look that great and an immense area is needed to produce a meaningful output on a national scale. And of course, they produce nothing in the dark or on dull days. WIND

Like the sun, wind has been with us since time began, but we have learned to harness it since Egyptian times. And Holland still preserves many picturesque windmills whose output was limited to a task such as raising water a metre or so or grinding cereals, always in the immediate vicinity of the windmill itself. But now engineering has progressed from these humble beginnings to huge arrays of many windmills with 100-metre-long aerofoil blades linked by cabling to the electricity supply network of the country. But there are downsides these installations are huge, and land based (onshore) installations are not popular. As the spot check of the power sources that I noted above on a still day they do not produce very much. Their siting offshore means if maintenance is needed it is costly. But development continues apace, and more and more sites are being constructed including totally floating ones in deeper water, which eliminates the cost of anchoring to the seabed. On days of gale force winds, they have to be shut down.

Lone modern windmills or solar panels have brought about the concept of Stranded Power. The sites may be too far from the current power distribution networks to be economically linked, so when there is excess power generated, rather than waste it can be stored (see Part 2) or turned into carbon neutral petrol. HYDRO

I turn now to waterpower as a source of clean, renewable energy. Man has known of its power since Archimedes. And Victorian engineers were masters of developing small water turbines. But the geography of the UK does not in the main lend itself to significant hydro generation. You need large quantities of water cascading down mountainsides or huge valleys that can be damned, flooded and turbines at the foot of the dam. The only dams built in the UK tended to be between the two World Wars as a means of storing water for drinking purposes. Environmentalists are right to resist dams wherever they are proposed in the world, as they destroy habitats, both of human and nature.

I mention tidal proposals which suffer the same environmental concerns. Even if approved they would only produce a modest output of 4 short periods of the day and the gaps would have to be covered by gas generation.

Much research has been done on the harnessing wave power which is of high potential as it is continuous, but so far engineers have not succeeded in building wave machines that are big enough and strong enough to produce meaningful power. Sub surface currents are less destructive, but I am not aware of a viable installation after considerable research.

The combustion of Waste to produce Energy is common in Scandinavian countries but less common here. It has the great advantage of avoiding landfill and could be used to reclaim existing landfill sites with their many disadvantages of large unsightly areas and poisoned ground water. Otherwise, plants can be placed in industrial areas to minimise the ground transportation of rubbish trucks. Clearly good scrubbing of the flue gases is needed to remove toxins and the CO2 by CCS. In addition to electricity such plants should provide district heating from the warm gas of combustion. I class this technology as akin to Bio plants intended to convert green waste into energy. Drax in Yorkshire, the largest power generation complex in the UK, has now converted entirely from coal to wood pellets. This has the seal of approval of climate change specialists, although I have reservations as there is the need to cut down forests and then replace the trees. I am sure that in general they are replaced, so provided it is part of the management of forest and woodland, it is OK. GEOTHERMAL

There are trends towards district heating and Heat Pumps and Geothermal have a part to play. The systems must be robust, and able to fall back on central power sources if there are issues. The UK is not seen as fertile territory for geothermal because unlike many countries there are no visible hot springs or gushers. But you do not have to go far into the ground to get a stable temperature which is warmer than the surface in winter. But at any time of the year the heat can be extracted by a process opposite to your refrigerator and warm your home or office. However, if you drill deeper the temperature rises enough to at least in theory provide heat for a small to medium power station, heating water to produce steam and hence electricity in the conventional manner, but without any flue gases. The process does involve drilling into the ground but unlike fracking only heat is extracted nothing solid that could cause any subsidence. To underline these comments an energy company has just announced a £4m project to extract the earth’s heat from under the City of London and to capture waste heat from buildings that would otherwise vent to atmosphere. NUCLEAR

I mentioned the role of nuclear at the beginning of this piece. The technology is green, renewable but subject to emotional resistance. But in power terms large stations are ideal for baseload and better for the environment than our continued dependence on oil or gas. A new development is coming along called SMRs, Small Modular Reactors. These are designed to supply power and heat to a single facility. They are factory produced and assembled on site. RollsRoyce is leading the way in this work. All the indications are that the power will be affordable, and the Office of Nuclear Regulation is likely to approve the designs this year or early next and with units built into new facilities to be constructed by the end of this decade.

This Part is not going to discuss Hydrogen which is a rapidly developing as a “multi-coloured” fuel, but not used for the production of electricity.

But in Part 2, I will discuss the changes in how energy is stored and used in which Hydrogen is a major factor...

Stay tuned for Part 2 in our November Issue!