LOCKED & LASERED: A PERFECT PAIR.

You get more space and more safe. We like to call it the best combo in baking. Together, the 909A/910A create the closing line of the future for bakeries, with tamper evidence, additional safety features and a space saving compact design. Partner our updated 910A high-throughput closure machine with our 10-inch “laser stitch” 909A to ensure your product stays tamper resistant, your team stays safer, and your

Learn more at kwiklok.com

The secret of change

Dear Readers, Opportunities don’t come along every day but occasionally they do and when the chance to take over at the helm of f2m presented itself, I just couldn’t turn it down despite the uncertainties of the world that we now find ourselves in. It’s an industry that I have been involved with for over 20 years and I’m relishing the thought of continuing my relationship with this wonderful publishing house. However, it would be remiss of me in the beginning of my first editorial not to mention our Founder and former Publisher, Hildegard M Keil.

For over 40 years she has not only dedicated her life to our magnificent industry but she has mentored many along the way. Myself included. She is and will remain one of the most driven individuals that I have had the privilege to meet and to work with. Writing this allows me the opportunity to raise my pen to an extremely dedicated and courageous woman and to say thank you. You have taught me how to be an optimist and an opportunist, so in this regard I am delighted, excited and proud to be taking over magazines that have been at the forefront of our industry for many, many years. The feeling that I have is one of utter gratification and fulfillment.

Some might say that this a bad time or the wrong time to be taking over, but I don’t see it as such; it’s a time to seize the opportunities presented and start building the new. These are indeed challenging and uncertain times, but as people we must move forwards.

I am a firm believer in the expression, “You are only as good as the team around you”, and in this regard I am very privileged that our team remains virtually the same. There is undoubtedly renewed vigor, energy and passion to excel and indeed develop and enhance with exciting new concepts on the horizon. We are not intending to tread water, but to battle the tides and the changing and challenging currents and move headlong into this Brave New World with optimism and with a widespread belief in technology as a futuristic remedy for the extraordinary and unprecedented problems caused by the pandemic. We will of course be reliant on your continued support to grasp the opportunities that arise. Here at f2m, we are not predicting the future, we would not wish to and we are not qualified to do so, but we will continue to be a leader in our field, to offer our readers the continued journalistic integrity that has made us what we are today and that you deserve. We see opportunity amongst the murky and cloudy waters with you alongside us.

When we least expect it, life sets us a challenge that tests our resolve and willingness to change. At such a juncture there is no point in pretending that nothing has happened or in saying we are not ready. The challenge itself waits for no one. It never discriminates. Life does not look back on itself. Together we must embrace change, embrace challenge and above all, be humbled by it.

“The secret of change is to focus all of your energy, not fighting the old but building the new.” – Socrates

Stay safe and well – Dirk Dixon

How much does your software know about bread?

Ours knows a good deal.

Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP and MES. And best-practice standards come as part of the package.

Would you like to know exactly why industry leaders count on CSB?

PUBLISHING HOUSE

Food2Multimedia GmbH i.g

Schoolkoppel 27

21449 Radbruch, Germany

+49 4178 244 9797

www.foodmultimedia.de

PUBLISHER

James Dirk Dixon dixon@foodmultimedia.de

EDITORIAL

Helga Baumfalk baumfalk@foodmultimedia.de

Annie Dixon annie.dixon@foodmultimedia.de

SUBSCRIPTIONS

Viktoria Usanova usanova@foodmultimedia.de

DISTRIBUTION vertrieb@foodmultimedia.de

ADVERTISING info@foodmultimedia.de

LAYOUT/GRAPHIC DESIGN

LANDMAGD Design aus der Heide

Linda Langhagen, design@landmagd.de

Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

IT

IT Consulting BRUNK

Felix Brunk, felix-brunk-net.de

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.–. Subscription rates are EUR 75.– per annum. Students (with valid certification of student status) EUR 40.– (All rates include postage and handling, but not VAT).

Cancellation of subscription must be presented three months prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department. Claims will not be accepted for any copies not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval. Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2020

Rademaker Academy

Quality in Knowledge

Knowledge is power. When detailed know-how about sheeting processes, production line operation and dough processing is lacking, problems affecting overall production costs and product quality might occur. In the Rademaker Academy, bakery knowledge is preserved and shared through education and training, enabling you to maximize the profitability of your bakery.

Flexibility is key

Olivier Sergent , President and CEO of the Mecatherm Group, discusses strategy with Baking and Biscuit International's Dirk Dixon.

Dixon: Since 2014 you have been at the helm of Mecatherm. 2020 has brought about unprecedented challenges for corporations on a global level due to COVID-19. Some would argue that we are in the middle of an existential crisis. How have you adapted, as an individual and as a leader in moving the company forward in this situation?

+ Sergent: The COVID-19 crisis has had an impact on both our staff and our customers, the two pillars on which our company is based. For our staff, it was a full-scale crash test, which impacted on each individual, their professional activities (home-office, management), the company's processes and the industrial activity with also some supply chain difficulties. Our governance bodies have enabled us to get through this stage while preserving the health of each individual and strengthening our managerial models.

As for our clients, they have been affected to varying degrees depending on their typology. Those who market their fresh packaged products to supermarkets were less affected than those selling their products to hotels and restaurants, for example. However, it is difficult to conclude on structural impacts.

Today, our major concerns are first and foremost to preserve the health of our employees, to ensure our customers' production capacity by maintaining our after-sales service, and

to continue to work as much as possible internally to be ready for the recovery.

As an individual, I have been able to measure the importance of a strong and supportive executive committee and shareholders.

+ Dixon: Prediction is often blinded by fact. Optimism is a mindset crucial for survival. How will the baking industry change? What will happen to the artisan bakers and what will happen to the industry?

+ Sergent: Many prospective studies have appeared, but today it is too early to pretend to draw structural conclusions. Nevertheless, consumers around the world are still driven by two main drivers: The first is to have good quality reference products or basic products available at the lowest prices. The second, depending on the situation, is to have products richer in "storytelling" (everyone putting what he wants under this concept: gluten free, organic, fancy, gourmet, local, ethical, etc.) This modern segmentation is permanent and will not be affected by the crisis.

One can imagine that in certain categories of the population in a situation of economic stress, the demand for the first increases. So that this demand is not frustrating for the consumer, the pressure will remain permanent to improve the quality of basic products.

Also that again, the trend existing in recent years, set up by industrialists, will continue with the coexistence of central units of massive production of basic products and a finer territorial network with units of average capacities and a great flexibility to serve storytelling products. Artisans and industrialists will, of course, continue to co-exist in this scenery to respond to local demands as closely as possible.

+ Dixon: We have seen Mecatherm move forward in a very positive manner since you have taken over. In the light of this, how important is the saying, “A company is only as good as the people it employs”?

+ Sergent: In the life of every company, there are periods of change in management models and the company must constantly reinvent itself by building on the successes of its history. The challenge has been to build a team that brings together in a balanced way the historic talents that have built the company over the past decades, and new talents from very different horizons and industries to bring a new perspective on the way the company is run.

It has also been an opportunity to welcome many representatives of the new generation to the company. It is a permanent job, never finished, but we are doing our utmost to make Mecatherm a company that attracts talents, retains them and makes them grow.

+ Dixon: What milestones has Mecatherm achieved over the last few years?

+ Sergent: Historically, Mecatherm’s success has been built around the baguette. In recent years, we have significantly expanded our geographical coverage of customers and the range of finished products that we address with innovative technical solutions, without forgetting, however, to constantly improve our historical product.

In addition, we have integrated two major constraints into Mecatherm's entire value chain: on the one hand, we offer equipment and production lines that continuously improve the quality of finished products whilst on the other hand we have a very important focus on industrial performance throughout the entire life cycle of the equipment (projects, start-ups, ramp-up support) and a very wide range of services that starts from the spare part and goes all the way to the application of digital techniques to help our equipment operate.

This approach has found its full expression in the products we recently launched for dividing, mechanization and baking of products from the Bakery-Viennoiserie-Pâtisserie sector.

+ Dixon: You recently held webinars on the topic of ‘Clean Label’. What did these discussions focus on and what has been the feedback from the bakers?

+ Sergent: Thank you for mentioning this. This approach is in line with Mecatherm's firmly stated desire to integrate the profession of industrial bakers into its activity: to not only meet their customers' expectations regarding the finished product, but also to understand the industrial subjects they live with every day.

The Clean Label is one of the elements of the "storytelling" products that we are all looking for as consumers. Its production has strong implications of course on the choice of ingredients, but also on the production process. This is why we brought

together ingredient manufacturers, mixer manufacturers, packaging manufacturers and scientists for this seminar.

+ Dixon: How difficult is it to adapt to the increasing demand for Clean Label products from a manufacturing standpoint?

+ Sergent: The real question is why do people insert different ingredients in the basic ingredients to improve the final product? It is because it makes it easier to process otherwise they wouldn’t put in these ingredients that are expensive and not really complying with the E free trend, so if they are adding ingredients it’s to make the production easier. What I mean by making the production easier is that it starts with mixing and it's very important in the makeup area where the rheological aspect of the dough can be improved by adding ingredients and if you have a good way of handling the dough you can make it without adding ingredients – as well during the proofing and conveying some ingredients strengthen the structure of the dough so it can support the shocks much better. If you have a good way of handling the product then you can do it without adding specific ingredients. During the baking process, if your oven has a lack of power on the bottom, the product will not rise in the oven and so if you add some ingredients it will help the development. If you have a good oven then you don’t need these ingredients to reach the same development. So, I would say stage by stage and at each step of the production of a product you can focus on how each step is done and you can remove ingredients step by step if you have the right technical solutions.

+ Dixon: What trends are you seeing at present with regards to consumer demand?

+ Sergent: As I said in my introduction, I do not see any fundamental changes in the trends already identified in previous years, but rather an acceleration. Nevertheless, beyond the product itself, additional constraints will emerge

Mecatherm has organized four webinars related to the “clean label” / “free from” topic.

WEBINAR 1

https://youtu.be/V0FaRW_y3i0

https://youtu.be/eSiUUk1nZIM

Why go to Clean Label in the baking industry?

WEBINAR 3

Baking Clean Label products

WEBINAR 2

https://youtu.be/doNtmWb5nZE

https://youtu.be/9JrwQsj_MiA

Division and moulding challenges of Clean Label products

WEBINAR 4

Production line solutions for Clean Label products

concerning packaging, reshaping at the point of sale and traceability requirements for development. Of course, the tremendous evolution of e-commerce will certainly ensure distribution evolves.

It seems to me that at the end of a phase as traumatic as the one we have just gone through with COVID-19, the transparency that was already requested will no longer be enough, but trust will become a differentiating factor. Trust that will have to be applied to all the stakeholders in the value chain: from the field to the plate.

+ Dixon: What challenges do your customers face now and in the future?

+ Sergent: When investing in a new production line that represents several millions of investment, it is necessary to have a clear vision on a large number of parameters: How will the consumer evolve? How will the distribution channels evolve (explosion of e-commerce)? What financial security can suppliers bring?

All these topics are under stress today, which makes investment decisions sometimes complicated for our clients. The answers that we can provide as a supplier are of course based on the flexibility and scalability of our equipment, as well as on the guarantees of our company's durability.

+ Dixon: What projects are you currently working on for 2020?

+ Sergent: This crisis has separated us physically from our customers, even if we have done everything to stay close to them. This has nevertheless highlighted the importance and the value that digital techniques can bring, not for management operations, with which manufacturers are already well equipped with, but for business tools for the people who operate, maintain, adjust and clean the lines. This field strategy, which aims to talk to people who live with our equipment during the day, night and weekends, seems essential to us and is perfectly in line with our values of putting people at the heart of our business and our mission to simplify their lives.

+ Dixon: During the last IBA you presented the M-TA oven. How has this system been received by your customers? Can you tell us about any particular installations?

+ Sergent: The success of this oven has been beyond our expectations. It has been awarded at IBA 2018 in Munich, then at IBIE Las Vegas and nominated at Gulfood Manufacturing Dubai in 2019.

This oven perfectly supports our strategy of flexible lines without any compromise on the quality of the most challenging products. The line flexibility is often synonymous with complex control and long changeover times. All the solutions we develop in software and hardware tend to positively address these challenges. The successes in North America, Europe, Russia and Africa confirm us in this direction.

The first M-TA oven installed after IBA 2018 was at the Ultrapharm plant in Poland (Finsbury Group) to produce tin bread and other gluten-free products. To date, the customer is fully satisfied with his equipment.

+ Dixon: The Baguette factory was a project that you launched in 2017. How important is this turnkey business for Mecatherm and how will it develop?

+ Sergent: While initial achievements have been successful, projects in preparation take a long time in countries where heavy investment decisions are subject to even more scrutiny than in more developed countries. Nevertheless, the strong social demand for basic products guaranteeing excellent food security and low prices is confirmed.

+ Dixon: Mecatherm has been synonymous with baguettes and their production. You have made a shift to bagels?

+ Sergent: This corresponds to our strategic approach. Depending on where you go in the world, people are expecting turnkey solutions for a single product. Our offer is spread into two ranges and we have dedicated production lines for specific products. We have the MecaBaguette line which is a historical product of Mecatherm, but we also have the MecaRusk line which is a standard line for rusks. We now have a standard line for bagels after having worked closely with a key player in the bagel make up line, ABI Ltd, and we have made a committed approach into how to create the best bagel on a very standard line economically whilst producing the best possible product. So, this is one approach and we have also developed the MecaFlex which is a very flexible baking system where you can connect a wide range of modules allowing customers the opportunity to enrich their lines as their business grows. You can feed this with a wide range of baking trays or tins. It is a very flexible line that is not dedicated to a specific product. As I have already mentioned, I believe that the industry will spread with two kinds of installations; one that has high output for a standard product, and for smaller entities and regions a smaller but more flexible line.

+ Dixon: What is the synergy like with ABI?

+ Sergent: Excellent. They are world leaders in the make-up lines and we work very much with them; not only for the makeup line but because they have a deep understanding and know-how when it comes to producing bagels. They explained to us what our ovens should look like, how the boiling and seeding aspects work and how to cool and to freeze; so many different things. So yes, our co-operation with them is excellent.

+ Dixon: Can we expect to see some exciting new innovations from Mecatherm for IBA 2021?

+ Sergent: Yes, you can, let’s meet at IBA 2021! All I can say is that it will be the continuity of the path traced for a few years, and always oriented on product quality and industrial performance.

+ Dixon: Thank you for the interview, Monsieur Sergent.

A system for industrial bread roll production

WP ROLL is the name of the system consisting of the EVOLUTION bread roll machine and the SOFT STAR CT high-performance dough divider from WP. Production is gentle on the dough, precise and hygienic.

WP BAKERYGROUP develops and installs production systems in the field of industrial bread roll production as turnkey solutions from the dough production to the finished product. This includes delivery, installation and commissioning as well as the necessary service. The heart of the industrial bread roll production is the EVOLUTION bread roll plant with the high-performance dough divider SOFT STAR CT. The high-performance dough dividing & rounding machine and the further developed EVOLUTION have been designed for multi-shift operation. The system is also suitable for the automatic processing of all commercially available bread roll and boiling doughs.

The maximum hourly output of the EVOLUTION industrial bread roll machine is 36,000 pieces. The total output has increased by 20 % compared to the previous model due to moving modules and new high-performance drives. The advantage: higher productivity, faster return on investment and less personnel and space requirements in relation to the hourly output. Due to the modular design, different products can be produced on just one system, allowing the company to respond to seasonal differences in the product range. The subsequent expandability leads to long-term variability in the product range.

Easy to operate

The designers attached particular importance to the ergonomic design for easy cleaning of the plant. The EVOLUTION has hinged doors and the SOFT STAR CT has a large access flap, which facilitates access for cleaning. In addition, all parts in contact with the dough can be swivelled or removed inside

the machine and the dough processing is separated from the drive area. The drive and dough processing areas are completely separated from each other. Due to the balcony construction, all functional components are freely accessible.

The system is easy to operate via the INUS user interface, which is used throughout all WP Kemper systems.

Similar to all dough dividing and rounding machines of the SOFT STAR series, the SOFT STAR CT also produces the dough pieces particularly gently and with 99% weight accuracy, the company announced and added that the EVOLUTION processes soft and demanding doughs very precisely. Due to upstream alignment stations, the transfers are very precise and ensure exact placement on, sheets and peel boards, thus ensuring high product quality in industrial bread roll production. +++

Continuous Mixing. Nonstop Perfection.

Bake your best buns every time with Exact Mixing.

Bread and bun production is challenging with variables like temperature, environment, recipe accuracy, flour quality, and operator training affecting the finished product. Exact Mixing’s advanced continuous mixing technology eliminates these variables and makes flawless buns at rates exceeding 15,000 pounds per hour.

Make perfect product all day, every day with Continuous Mixing.

• Just in time dough means less waste from line stoppages

• Less labor and energy usage vs. batch mixing

• Eliminates variables due to batch process

• Consistent bun size and color

• Excellent dough temperature control

• User-friendly, automated system operation and controls

‘Easy Clean’ Design

Whether sliced bread rolls, crispy rolls, yeast pastries or rye bread - the König plant manufacturer supplies the appropriate technical equipment for the production of a wide variety of rolls and breads.

"We see a big demand for cleaning reworked materials and the ‘Easy Clean’ design fits the bill as an easy to operate system. Offering a high degree of versatility for different types of bread rolls, the Combiline plus EC bakery machines are easier to clean, maintain and service.

We will therefore be continuing to extend the 'Easy Clean' series, which does what its name suggests to our commercial and industrial range," explains König Managing Director, Wolfgang Staufer.

König sees similar trends worldwide, such as the demand for more cost-efficient machines and processes through easier cleanability and maintainability to reduce non-productive time. A system should also offer flexibility and future security so that new products can be easily adjusted to when market requirements change. In addition, there is another trend: "In general, we see a development towards quality products. We are again limiting ourselves to the essentials: Baking with high-quality ingredients and giving bread the time, it needs, for example with long-time dough methods," Wolfgang Staufer explains.

Modular bread roll line

Easy cleaning, short changeover times and the prevention of contamination are becoming increasingly important for bakeries of all sizes. For this reason, König has completely redesigned the Combiline plus, already a benchmark for high product quality, to meet the demand and to minimize downtime. The ‘Easy Clean’ concept allows for reduced cleaning and downtime, while the innovative frame design ensures optimized hygiene and accessibility.

The system has a maximum output of 11,880 pieces per hour in 6-row operation. Bakeries can use this line to produce sliced rolls, ribbed rolls, Kaiser rolls, hamburgers, hot dogs, rose rolls etc.

The ‘Easy Clean’ design with a new type of frame construction ensures optimized hygiene and accessibility. According to the company, the slanted surfaces at a 45° angle prevent flour and dough residues being deposited. All conveyor belts can be relaxed without tools for easy cleaning. The plant offers generous floor clearance of at least 300mm and adjustable feet are not positioned directly next to each other. In the

plant design, screws were predominantly omitted, and welded constructions were mainly used to prevent dirt from depositing. The stamping station, forming station etc. are in open design for easy access; the forming tools are easy to remove and can be stored cleanly and are protected on their own storage trolley. The machine is also equipped with UVC tubes for sterilization of the hangers. This serves to disinfect the surfaces and inhibits the formation of mould.

Dough band machine in ‘Easy Clean’ design

The Artisan SFM EC will process both fine-pored doughs and coarse-pored doughs with high water content gently and accurately, and can process a wide range of bread roll varieties from corn snacks to crispy fresh to Mediterranean ciabatta. The Artisan SFM dough band machine in the ‘Easy Clean’ design is made as a modular system. It is easy to clean because the most important parts can be easily dismantled and nothing sticks to the surfaces due to the sloping surfaces and generous legroom. Since the system can be quickly adapted to different products, it is suitable for craft businesses.

The plant has a dough throughput of 400 to 1,200 kg per hour for rolls and 400 to 1,500 kg per hour for bread. For square rolls this corresponds to a capacity of 16,200 pieces/ hour with 6-row operation and 45 strokes/min.

Another special feature of the system is that the special shaping of the dough band without residual dough means that the dough quantity is 100% used, as opposed to other

systems which have losses of more than 15% due to residual dough, according to König. Forming tools such as inserts of the rounding station, cutting or punching tools can be easily changed without tools. Flour and sprinkling containers can also be changed easily by means of a slide-in unit. +++

Free forming

For the production of small pastries, the plant manufacturer Handtmann offers solutions for fully automatic production. The company promises dough dividing, forming and depositing in one step.

+For the production of rustic and glutenfree biscuits, Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/ Riss, Germany, offers an application solution that divides, shapes and deposits soft and precooked doughs in one process step. Under the term "free forming", a wide variety of product shapes such as round (e.g. Vinschgauer, gluten-free soft buns), oblong (e.g. rye rolls, gluten-free baguette rolls) and more can be produced, the company has announced. Here, soft, pre-cooked doughs (e.g. rye rolls with up to 100% rye content) can be placed directly into baguette trays or onto trays/peel boards after dividing and forming.

Moulding system

The Handtmann system solution, consisting of a VF 800 dough divider and the FS 520 forming system including servo-driven filling flow divider, enables fully automatic production of bread, rustic biscuits and baked goods such as gluten-free soft buns, according to the company. Production can be flexibly carried out on up to eight lanes/rows. The dough pieces can optionally be placed on trays, in baguette trays or directly on the conveyor belt. The "free" gentle shaping and the possibility of processing different types of dough offer scope for a wide range of product ideas, as well

as gluten-free biscuits. The visualization of the product shape and the calculation of the process parameters are done on the fly via the screen of the VF 800 control system. In a fully automatic production process, the dough is fed from the VF 800 to the filling flow divider in the FS 520 forming system. The filling flow divider with servo drive guarantees an exact volume flow, the company continues. This is the prerequisite for the gram-precise final weights of the individual dough pieces. The dough flows into the forming module in multiple lanes via the filling flow divider. The product is formed by a rotating perforated plate system. By exchanging a few format parts, a mould change can be carried out quickly and easily. Besides the main advantage of automated portioning, shaping and depositing of the dough pieces on baking product carriers in one step, another advantage of this system solution is the high weight accuracy. Due to the completely oil-free and flour-free dough piece and mould principle, further costs can be saved and process hygiene improved.

System solution

A product and process example for bread roll production is the production of small rye rolls with up to 100% rye content in baguette trays. The Handtmann system solution consists of a VF 800 dough divider with FS 520 forming system. The process solution can optionally be supplemented with a sifter to flour the portioned dough pieces. The production parameters here are as follows: Dough resting time 30 minutes, dough yield 186, dough insertion 150 g, cycle rate 45 cycles (corresponds to a capacity of 16,200 pcs/h) with deposit of 6 x 5 pcs/sheet and sheet size of 580 x 980 mm. The company also offers other suitable system solutions for the production of small baked goods. +++

++ Felix Egger is appointed new CEO of the RONDO Group

The Board of Directors of the RONDO Group has appointed Felix Egger as CEO as of May 1, 2020. Mr. Egger succeeds Bernhard Merki, who had accepted this position on an interim basis in 2019 in addition to his function as a member of the Board of Directors.

Felix Egger (M.Sc. El. Ing ETH/Executive MBA) has a broad experience in the export-oriented capital goods industry due to his many years of experience in international groups such as ABB or SMEs such as Gallus Ferd. Rüesch AG. From his last position as Managing Director of the well-known roof window manufacturer VELUX, Mr. Egger brings additional valuable knowledge from an end consumer business environment to RONDO. Felix Egger is a proven executive with broad experience from various functions.

"The Board of Directors is convinced that in Mr. Felix Egger it has found a competent and experienced personality who is an excellent fit for RONDO, both in terms of human and professional skills. Mr. Egger has an excellent track record in corporate management and brings with him profound knowledge in the areas of sales, innovation and digitisation,"

explained Bernhard Merki, who will remain associated with the RONDO Group as the new Chairman of the Board of Directors. +++

++ IREKS appoined Stephan Bergler as additional managing director

With effect from 1 July 2020, Stephan Bergler is appointed as a further managing director of IREKS GmbH. Thus the board now starts the second half of the year with six managing directors. Stephan Bergler (53), who holds a degree in brewing and business administration, joined IREKS in summer 2017 as project manager for special malts after many years as managing director and owner of a malt factory in Central Franconia. In autumn 2017, he was given the commercial management of the malt department. The granting of power of attorney for IREKS GmbH and the appointment as Managing Director of IRUSO GmbH took place on July 1, 2018. From July 1 this year, Stephan Bergler will be responsible as Managing Director for the entire malt business "from Farm to Brewery". In March 2020, the general meeting elected him to the presidium of the German Maltsters' Association, which had been headed by Stefan Soiné as president until then. +++

LABORSAVING AND HIGH-PERFORMANCE DEPOSITING LINE WITH DENESTER

++ PLMA names Peggy Davies as Acting President

The Board of Directors of the Private Label Manufacturers Association is pleased to announce that Peggy Davies has been named Acting President of the Association. Her appointment follows the death of Brian Sharoff, President, who passed away last month after a brief illness. Since 2016, Davies has served as PLMA Vice President, Association Relations. “For four decades, Brian was the face of PLMA,” said Lisa Manzoline, Director of Sales for Reynolds Consumer Products and Chairman of the Board of Directors of PLMA. “It is now our responsibility to focus on the future. As the Board of Directors, we understand this is a difficult and challenging time for many different reasons. We have full confidence that Peggy Davies will be a capable and dynamic leader of PLMA at this crucial juncture – one who is familiar with our member base and the unique challenges we face for the remainder of 2020 and into 2021. Peggy has the experience and qualifications needed, and is 100% ready to carry forward the important work of the association from day one, as the Executive Board conducts a search to determine a permanent successor.” +++

++ Lantmännen Unibake expands in Norway

Lantmännen Unibake has purchased the production facilities of a factory in Norway, which belongs to the French Bakery Company AS. The deal includes the takeover of the facilities and the employees working in the production facility in Lierstranda, near Drammen. According to just-food.com, the deal involves around 20 employees who will be retained. Werner Devinck, CEO of Lantmännen Unibake, on the takeover: "The French Bakery Company is a modern bakery with high bake-off expertise and high quality standards.

Geographically, the bakery is well positioned for our current activities in Norway and fits our strategy and ambitions. Based on our focus on sustainability from field to plate, locally produced bakery products and a short time to market, we believe there is great potential to further grow the business and continue to deliver excellent results". +++

++ USA: Bühler opens new Food Application Center

Bühler has opened its new Food Application Center (FAC) in Minneapolis (USA). The FAC was created to develop new methods of transforming pulses, peas, beans, oats, ancient grains, maize and many other crops into new food solutions such as flours, snacks, pasta, cereals and a myriad of extruded products, including plant-based meat analogues. As a new product and process development venue, the FAC features the latest in raw material processing and handling systems, capable of taking those raw materials through to finished product, ready for packaging, bringing a product from farm to fork, or from bean to burger. +++

Shick Esteve announces the opening of the Linxis North American Technology Center combining the equipment process capabilities and expertise of LINXIS Group company partners – DIOSNA, Unifiller and VMI. The technology center is utilized for the testing and demonstration of the

latest in industry-leading ingredient automation, mixing and pre-dough technologies, as well as leading-edge process control and IIoT technology.

The expansion of the existing 3,500 sq. ft. test lab into a temperature-controlled joint testing, training, and education center boasts many equipment and process updates. The facility measuring almost 15,000 sq. ft. also functions as Shick Esteve’s North American Research and Development Center. Coming in 2020 Shick Esteve will also be hosting ingredient automation and maintenance seminars.

“The Linxis North American Technology Center was designed and built to show our current and prospective customers how the latest in ingredient automation, dough technology and process controls can benefit their business. Customers can test specific aspects of automated ingredient systems, mixing and dough technology, all the way to a complete proof of concept from ingredient delivery through mixing and baking”, Jason Stricker, Director of Sales and Marketing. +++

Companies remain focus

Covid -19 and its continued impact.

How is the Covid-19 affecting your company?

We service multiple sectors of the baking industry from small craft bakeries and food service operations, to large industrial bakeries. The crisis affected those segments differently and, as such, our business with those sectors. In addition, we had to quickly respond to the Covid-19 outbreak to ensure the safety of our employees, while continuing our critical service to the European and global food supply chain. With operations in multiple countries it was important to make sure we addressed the needs and regulations of each location. We created a team with members from our locations in the UK, Spain and Romania to keep everyone up to date on current situations and safety protocols. This exercise has actually strengthened all of our cross-company communications.

What have the impacts been on supplies and installations?

We are fortunate to have well-established European supply chains and hold quite a bit of stock material to weather such challenges. This strategy has allowed us to keep all our facilities running continuously and servicing our customers throughout the crisis. We are also in the unique position of having multiple coating and manufacturing sites across Europe and around the world that can be utilized in the event one site is compromised.

How is Covid-19 affecting service?

We have worked tirelessly to ensure seamless support to our customers. If anything, our lead times have decreased due to the impact on the food service business. This has allowed us to flex capacity to support our other bread and roll customers who have been strained to keep up with demand.

We have also conducted numerous virtual calls, using platforms like Zoom, Microsoft Teams and High Five. This has provided us with the capability to stay connected to our customers and minimize the impact of travel restrictions.

How are you reassuring your clients?

We are trying to strike the right balance of communication with our customers so that they know we are still here to support them, but without over burdening them while they deal with their own operational challenges brought on by the crisis. Ultimately, our continued service is the best reassurance we can provide to our great customers.

Have you announced short term working?

We have been able to keep the vast majority of our teams fully engaged by tele-working where possible, and staggered shifts elsewhere to reduce the risk of spread to our teams. We have also reassigned team members to move forward process improvement plans and other investments so that we will be even more efficient and effective when this crisis passes.

What are your short-term plans after Covid-19?

We are looking forward to getting back out to see our customers and thank them for continuing to support our communities with critical food staples. We know that they have been overwhelmed by recent events and demands, and we will be en gaging with them to see how we can partner with them to emerge from this pandemic even stronger.

++ William Bundy – President, Global Manufacturing

ed and committed

How is the Covid -19 affecting your company?

We set up crisis management protocols right from the start, which enabled us to adapt our way of working in just a few days. Our information systems have proved to be particularly efficient, enabling the 100 people in the design office to work from home without loss of productivity. Our supply chain was only affected for 2 weeks and I would like to thank our sub-contractors from the bottom of my heart for having chosen Mecatherm to avoid any supply shortage.

Nevertheless, COVID-19 was a major "stress test" that called upon all our staff individually, professionally and managerially. We were able to test the company's very resilience on this occasion. I am very proud of the work and commitment of each and every one of our employees.

We entered the crisis with 3 objectives: to guarantee the safety of our staff; guarantee continuity of service to our customers; and guarantee Mecatherm's financial solidity at the end of the crisis. We are pleased to see that these objectives have been achieved.

How is Covid-19 affecting service?

The imposed geographic travel limitation were offset by: a hotline offered to all our customers during the crisis; the availability of programmers to connect to all our installations, and the mobilization when necessary of local supply chains with our customers to produce parts in an emergency (either in machining, sheet metal work or 3D-printing).

This is the most flexible and responsive service model we had in place before the crisis and has proven perfectly effective.

How are you reassuring your clients during?

We have implemented exceptional protocols internally and pro-active communications with all our customers in operations, one-to-one and regularly, in order to be as close as possible to their needs and to remain in privacy of their industrial activity.

We have received from them a lot of recognition for this pro-active approach.

During the crisis, we had the pleasure of continuing to take significant industrial orders, and of course of being able to reassure our customers about our financial solidity, including providing of substantial bank guarantees.

Have you announced short term working?

One of our aims was to maintain all our teams. This objective has been reached and we are not considering any measures to reduce the workforce.

What are you short term plans after Covid-19?

We expect investment activity to generally slow down overall in the coming year.

We remain at our customer’s disposal for more minor maintenance operations or upgrades of their existing lines and equipment for purposes of flexibility or industrial performance.

Our business model is such that we can easily cope with very significant activity increases or decreases. +++

++ Olivier Sergent, President and CEO of the Mecatherm Group

++ Olivier Sergent, President and CEO of the Mecatherm Group

Partnership for fine baked goods

The Micro Croissant ® from La Petite Bretonne is the star product in the Canadian bakery’s portfolio. The family-run company from Quebec, established 52 years ago, produces up to 1.2 million Micro Croissants ® every day.

An efficient production process calls for a high degree of automation. To expand its production, La Petite Bretonne relies on the proven expertise of the Schubert company from Germany. The Canadian company recently ordered a lightline Flowpacker for its main production site in Blainville, Quebec.

“La Petite Bretonne would need countless employees to be in the position to satisfy the high demand,” says Julian Conway, Sales Account Manager at Schubert North America and responsible project manager. Julian Conway and Serge Bohec, the owner of La Petite Bretonne, have enjoyed a close working relationship for more than a decade. To adapt the existing processes to the increasing production volume, the bakery was looking for a high-quality automation solution that is highly flexible, very compact and also cost-effective. The producer had already been operating several individual machines for end-of-line automation when he heard about Schubert’s new flow-wrapping unit, the Flowmodul.

The Flowmodul from Schubert is a flow-wrapping unit which is also integrated into the Flowpacker from Schubert’s lightline machine series. This range consists of three preconfigured, compact and highly efficient packaging systems. It boasts short planning and installation times as well as attractive procurement costs. The proven TLM standard modules and intelligent robot technology ensure reliable operation with high system availability.

At La Petite Bretonne, the new lightline Flowpacker would have to pack, among other things, filled Danish pastry (Danoise) and chocolate-filled croissants (Chocolatines) in different sizes on one line, while gently handling the fragile,

Performance:

+ 183 Danoises per minute

+ 220 Chocolatines per minute

+ 280 Mini Chocolatines per minute

heat-sensitive products. Schubert meets all these requirements in a complete system that comprises four pick & place robots, a 3D scanner and the Flowmodul. The 3D scanner checks the position, shape, volume, orientation and degree of browning of each product and allows only perfect baked goods to pass on to the next packaging step. The baked goods are then carefully placed into the Flowmodul’s feed chain by four pick & place robots and packed into flowpacks. First the longitudinal seam of the flowpack is sealed by an ultrasonic sealing unit. This is then followed with Schubert´s unique heat-sealing technology with the flying cross-sealing unit. It automatically adapts to the speed of the upstream pick & place robots and therefore enables constant sealing times with outstanding sealing quality. +++

++ Study: Contact with friends becomes more important as well as healthy food

Social distancing policies are reminding people of the importance of friends and family, according to a new Mintel study. In a study carried out in 6 European countries, consumers agree that contact with friends and family now has a higher priority than it did before the coronavirus pandemic broke out. The study further reveals that concerns about health risks and the impact on one's own lifestyle have been bought to the fore, with people focusing attention on health and well-being, particularly in relation to physical activity and healthy eating. From exercise at home to cycling and running, a third of Britons (34%), French (33%) and Italians (32%) said in the survey that they had become more active in sport during the pandemic. In contrast, "only" 27% of Spaniards, 24% of Polish people and 19% of Germans agreed with this statement. During the lockdown, the topic of healthy eating was given higher priority, especially by French consumers (37 %), followed by a third of Italians (34 %), 31 % of Britons, 29 % of Polish and Spaniards, and just 22 % of German consumers. +++

++ What motivated consumers to use delivery services

Many consumers in Europe called a delivery service for the first time during the COVID-19 crisis. According to the npd group, in the six largest European countries (UK, DE, FR, ES, IT, RU) 31% of all consumers said that they had used delivery services, but during the crisis the figure had risen to 42%. The question was, what motivated them? Surprisingly, they did not do it for convenience. They saw the delivered meal first and foremost as a pleasure for themselves or their family. In second place was the desire to get something special that they did not have to cook themselves, and thirdly to order food from their favourite restaurant. +++

++ COVID -19: Effects on European baked goods markets

C OVID -19 presents the food industry with challenges of unimaginable dimensions. Not all questions can be answered yet and the situation will continue to change. The French market research company GIRA wants to contribute to the clarification and is working on a new study to provide insights into the effects of the worldwide C OVID -19 crisis on the European baked goods markets. Consequences and problems are to be linked to the actual causes and a strategic evaluation of the consequences for future planning is to be worked out. In addition, the study will update figures and forecasts from the GIRA report "Bake-off Bakery Markets in Europe" published last December. You can find out more on the GIRA website at www.girafood.com or contact Anne Fremaux by e-mail at a.fremaux@girafood.com. +++

Continuous innovation in the Rademaker Industrial Bread Line

Rademaker’s Industrial Bread Line continues to be successful. So what is their secret?

+The line is recognised for its superb quality and hygienic design, its efficient operation, versatility, reliability and robustness. However, the real secret of Rademaker, a Dutch-based company that develops and provides solutions for the food processing industry all over the world, is that its technologists are continuously working on improving and optimizing the Rademaker Industrial Bread Line, so that its customers have state-ofthe-art equipment. Recent innovations include a further improvement in the DSS pre-sheeter to accommodate a larger variety of doughs and an improved dough recycling system. The mechanical basis of the Industrial Bread Line is solid and smart, although the true line and process optimization originates in the software that controls the line.

Rademaker introduced its first Crusto Bread Line in 2006, to meet customer demands and expand its portfolio of production lines for puff pastries, croissants, pizzas, pies and flatbread. In 2018, the new Rademaker Industrial Bread Line was introduced. Today’s market requires an ever-increasing variety of breads, with different dough types, different crumb structures and different sizes. Bakeries, wanting to accommodate the market requirements, in turn ask for modular bread lines that allow for fast changeovers, offering the highest accuracy, while meeting the most stringent hygienic requirements.

Four components

Rademaker’s Industrial Bread Line is based on sheeting technology. This is a conscious choice, as this gives bakeries the freedom to handle a wide variety of dough types, from ‘green’ to pre-fermented and strongly hydrated doughs. The line is capable of generating a wide range of high-quality products that can be produced at capacities from 500 kg up to 6,000 kg of dough per hour. It consists of four major components: pre-sheeting, sheeting, make-up & decorating and dough recycling.

Unique pre-sheeting system

Sheeting the dough is essential for the final product. The dough is kneaded by the mixer and processed in the presheeter. The pre-sheeter transforms dough batches into a continuous dough sheet. Rademaker’s Double-chunking Sheeting System (DSS) is proven and has been updated to meet the latest requirements. An innovative dynamic hopper transports the dough in a controlled manner, keeping the shape of the dough chunks linear and constant. Landscape sensors and separate belts carefully guide the chunks in the sheeter, ensuring size and weight accuracy. Chunk weight and length are exceptionally accurate, leading to a more stable and consistent dough sheet and the resulting highquality baked products.

Cost savings and better overall performance

Many types of dough, for example, Italian bread types such as ciabatta or focaccia, tend to have a very high water percentage, making the dough liquid and sticky. In the previous DSS version, oil was used to prevent the dough from sticking to the DSS hopper. This was effective but cleaning the line was time-consuming. Rademaker replaced the oil with wax, reducing the required amount by a factor four compared to oil. Cost-savings are considerable and return-on-investment for the wax distribution system is only 1 year. Cleanability is improved due to easily removable parts and because wax is used instead of oil. However, perhaps even more important, the wax-version of the DSS creates a more consistent chunk volume and a correspondingly more consistent dough sheet. This results in higher accuracy of the final product.

Superb dough homogeneity

Due to the minimal transportation height difference in the pre-sheeting system, dough homogeneity and structure are maintained. The wider belts with advanced flour strewing and optimized waste bins, in combination with a design that meets the most stringent hygienic standards, allow for

cleaner working. Compared to the previous version the new system is easy to operate and has better accessibility for cleaning.

Sheeting process

As part of the sheeting process, the continuous dough sheet created by the DSS is reduced to the required dough thickness. In some of the reduction stations, non-stick upper rollers reduce the dough thickness to the desired thickness, ensuring that dough characteristics remain intact. Depending on the specific customer demands, a further set of stress-free reduction stations and other sheeting options define the sheeting configuration.

Flexible cutting in make-up & decorating

The final processing steps take place in the make-up & decorating section of the Rademaker Industrial Bread line. The design upgrade has resulted in a length reduction, a 400 mm wide rework conveyor and an increased level of hygiene. The

weighing conveyor was also reduced in length and fixed to the floor for greater stability and higher accuracy. Amongst the various product cutting solutions is a Box Motion Cutter. It offers different cutting processes in one machine and a unique dough sealing solution, sealing the softer dough products and avoiding products from cracking open during baking. Due to its ergonomic design, tools can easily be changed from the side, making it easy for the operator.

Fast products changeovers

In the molding conveyor, the side guides are repositioned on the lower belt, yielding a better molding performance. A simple, single operator control that allows fast, fool-proof adjustment of the molding table in height and molding degree to ensure fast changeover and product flexibility. The molding conveyor’s unique design offers optimal access from both sides, allowing for fast product changeovers, cleaning and maintenance. As with other parts of the Rademaker Industrial Bread Line, the length has been reduced.

Unparalleled dough recycling

Traditionally, a part of the dough ends up as rework, especially when working with non-rectangular shapes such as omega baguettes. With Rademaker’s new, in-line dough recycling system, 10 to 40 % of the return dough may be re-used. Side trim and omega trim can be transported back to the start of the DSS as small cuts of rework are efficiently re-entered in

the process. Client-specific rework dough options can be catered for. Due to the controlled distribution of rework dough, the recycling process is highly stable and reliable.

Flexibility and line length

The Rademaker Industrial Bread Line is characterized by its flexibility. There are multiple configuration options and modules, which can be exchanged quickly and easily. The Rademaker philosophy calls for building functional production lines, as short as possible. With that in mind, the line length has been reduced by more than two meters compared to the first-generation Bread Line, saving floor space and resulting in a higher output per square meter.

Hygienic aspects

The Rademaker Industrial Bread Line is designed according to Rademaker Sigma guidelines, directly derived from various high-end requirements from GMA and EHEDG. Standoffs and machine surface are tilted at an angle to allow water to drain easily, to avoid contamination of the product zone and to reduce drying time after cleaning. Food-contact parts are constructed only with approved materials. All surfaces are smooth to help reduce microbiological contamination development. In addition, all parts of the line are designed for wet cleaning.

Work in progress

The Rademaker Industrial Bread Line is a work in progress, as Rademaker is continuously working on further improving the line, meeting and anticipating new customer demands, market developments and legal requirements. Rademaker thus aims to offer a solution for every industrial bakery, large or small. In addition to ‘engineered to order’ lines, Rademaker now increasingly focuses on ‘configured to order’ production lines, offering affordable standard solutions to most applications. The flexible, reliable and robust Rademaker Industrial Bread Line aims to give the highest uptime, a long lifetime, and minimal spare parts consumption. Fast maintenance, cleaning and changeovers ensure efficient production. This, together with the excellent dough handling characteristics, results in a proven decreased cost of ownership. +++

A hygiene design trio

G/BT GmbH Bakery Technology offers a triple team to gently make up wheat mixed, rye and gluten-free doughs.

+Making good things even better is the claim of G/BT GmbH Bakery Technology (GBT) in VillingenSchwenningen. The dream team of an Olympia 3000, a Bola 3000 H and an LR6 DW2 B1 has always been a good choice when gentle processing of wheat mixed, rye and gluten-free doughs is involved. First of all, the Olympia 3000 divides the dough. The hygienic design dough divider has undergone further technical optimization. According to the company, the plant processes all dough types gently and with accurate weights. It can even process doughs with a long dough resting time, and dough weights/dough pieces from 150 to 3,000 g are possible. The plant is operated via a touchscreen monitor. The integrated recipe management system allows 99 different recipes to be saved.

Next in line is the BOLA 3000 H belt-driven round molder, which processes doughs from wheat mixed to rye in the weight range from 300 to 2,000 g. Two separate drive motors allow the belt speeds to be controlled separately, which improves the results of molding. The height and angle of the molding channels can be adjusted individually according to the bakery’s requirements and needs. GBT’s BOLA 3000 H belt-driven round molder is designed for a high output capacity of up to 2,500 pieces/hour, depending on the weight, and with a 3,000 mm molding path.

The plant constructor relies on the LR6 DW2 B1 to enable the long-molding of wheat mixed and rye doughs. For this, the machine processes dough weight ranges from 200 to

3,000 g. The integrated pressure-flattening roller pair are adjustable independently of one another. The same holds true for all three plants: when further developing the hygiene design of the trio, the designers attached special value to hygiene and cleaning friendliness, as well as to easy operability and low energy consumption. +++

Flatbread lines: “The biggest single order” for GBT

GBT Bakery Technology and its sister company GBT Fördertechniksystems (Conveyor Technology Systems) will supply four fully-automatic flatbread production plants to a customer in the Middle East. Each line achieves a capacity of up to 14,000 breads/hour. The company did not state the order value, but Managing Director Wolfgang Fuhst said the conclusion of the contract was “the biggest single order in its 19-year history. According to information from the www.econo.de portal, GBT earned a balance sheet total of around EUR 7 million in 2017.

DEBAG invests in new production site

+DEBAG Deutsche Backofenbau GmbH has built a new production hall for shop ovens at its site in Königsbrück/ Germany. According to the company, the investment sum was in the six-digit range. The shop baking oven models MONSUN MINI, MONSUN CITY and the deck baking oven HELIOS can now be produced in considerably larger quantities at the new location than at the previous site. Furthermore, this will result in new capacities at the existing production line in Bautzen. This is now available for the serial production of the DILA and DECON shop ovens. "By expanding our capacities, we are now even more efficient in our manufacturing processes – both at the Bautzen site and at the Königsbrück site. We can now produce up to 40% more shop ovens – and thus meet the increased demand. At the same time, this also allows us to achieve significantly shorter delivery times for our customers," explains DEBAG Managing Director Oliver Theiß. With the expansion of the production capacities, 20 new jobs have been initially created. The DEBAG team now has a total of 270 employees, spread over its 3 locations in Germany. +++

Salty snacks in Germany: Balancing indulgence and the health market

+Indulgence is regarded as highly important to the average German consumer and in surveys these consumers generally respond more positively than other nationalities to the concept of treating themselves. A new Innova Market Insights report on the savory snacks market in Germany reveals that indulgence claims are the single most important influence on consumers’ snack purchase decisions, named by more than a quarter of respondents. This puts indulgence ahead of naturalness and health issues when it comes to choosing snacks.

New product development in Germany reflects a growing emphasis on balance, however, with indulgent choices now having to share more shelf space with an expanding range of healthier snacks. For example, popcorn has gained ground rapidly within NPD, with launch numbers up at a CAGR of 21% over 2015-2019 to reach a share of 7% of all snacks launches. Popcorn can deliver indulgence through diverse flavor choices, but it is also benefiting from a healthier profile compared with more traditional snacks, such as potato chips. The latter still account for around a fifth of

all snacks launches but have demonstrated an annual decline in introductions since 2015.

Stronger and more direct health claims remain relatively limited in the German snacks market, but there are some areas that are drawing attention. Claims related to protein contents have seen particularly rapid expansion, for example, reaching penetration of 6% of all snacks launches in 2019, with this share having risen at a CAGR of 51% since 2015. Plant-based snacks are also starting to attract more attention by German innovators, although there is still a long way to go to match the levels of NPD seen in the US and the UK.

Balance appears to be the key in German salty snacks development, with a market that is seemingly polarized between indulgence and healthier snacking. Future focus could, therefore, be centered on blending these two ideas and establishing products on a more “permissibly indulgent” platform, using indulgent tastes and flavors to add value to healthy formulations. +++

Designing cost and time saving solutions for an industrial bakery plant

American Pan UK is part of the Bundy Baking Solutions group and is a world leader in providing custom and stock baking tins and trays, proprietary coatings and refurbishment services. It is committed to innovation and to providing products to commercial bakeries for guaranteed long-term performance.

+One customer, two challenges, two perfect solutions. By investigating the cause of tray and tin failures and product waste, American Pan UK designed new products that saved one industrial bakery in the UK operating costs and time.

Challenge One

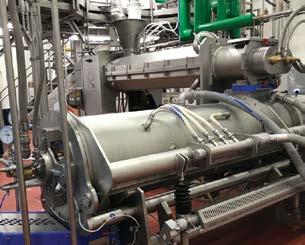

A large bakery plant in the UK was using a Mecatherm oven system with 2,000 x 800 mm sized trays accommodating 22 moulds per tray to produce baguettes and French sticks.

The company found that the coating on the tray it was using was not performing causing products to stick to the moulds resulting in a high percentage of waste (15%) and poor quality products. During the baking process, the baking the trays need to go from the oven to the spiral freezer within 5 minutes and therefore the coating has to be able to withstand heat, cold and condensation. The trays were

getting damaged during the process and warping causing line jams and stoppages. In order to repair the trays, the whole line had to be shutdown resulting in long periods of downtime and loss of productivity.

American Pan Solutions

A new tray design was used with a DuraShield, dark non-stick fluoropolymer coating.

+ Stainless steel frame for more strength and rigidity preventing damage to the frame

+ Corner gussets added to the frame to maintain rigidity and the square shape of the tray, ensuring the tray remains flat during its lifetime

+ Fully sealed frame with a watertight design

+ Tray insert constructed of high strength aluminum alloy that resists warping and retains pocket shape over the life of the tray

+ TabLock design used to replace rivets on the ends of the flutes and preventing product retention on the depanner and allowing for quick and easy screen replacement in the bakery

All these enhancements were added to prevent line jams and extend the life of the tray. A fully sealed frame ensures that condensation caused by the blast freezer is kept out of the frame. It is important to note that this design is also good for in-line washing of trays.

Results

The company saw improved efficiencies and reduced running times with waste decreased from 15% to 3% and operating hours be reduced by over 30%. The life of the tray was also doubled with an estimated 4,000 + releases before recoating/ replacing of inserts.

Challenge Two

The same large bakery in UK was using a high speed Lanham oven system with a 6 on bread strap set to produce 800 g white and wholemeal bread loaves.

The customer discovered that the bottom of the tins were wearing very quickly resulting in uneven baking and over baking of the bottom of the loaves. Due to wear and other factors, the tin sets were not maintaining their shape and would cause line jams and stoppages. Overall, the tin life was very short and costly.

American Pan Solutions

A new tin set was designed with an AmericoatPlus Glaze coating.

+ Bottom strap was positioned 2 mm below the bottom of the tine for protection of the bottoms through conveying

+ Slight tensioned bow at the bottom of the tins

+ Extra strapping just above the bottom strap to prevent warping of the set and ensure perfect alignment between top and bottom straps

+ 3+3 - 6 strap design to allow proper spacing for the bakery system center guides

The slightly tensioned bow in the bottom of the tins ensured that when heated the bottoms become flat and provide for a more consistent bake. With the AmericoatPlus Glaze coating the bakery was able to reduce the amount of release oil sprayed on the tins from 2.2 g per cavity to 1.2 g.

Results

With the introduction of the new pans, the issues with pan warping and wear were resolved and a reduced maintenance was required on the system because the pans were not jamming. The life of the pan was more than doubled. This was accompanied by improved product quality and consistency. AmericoatPlus Glaze provides more releases and recoating services can extend the coating life even more. There was a 45% decrease in the amount of oil needed as a release agent, eliminating the build up on conveyors and other equipment as well as improved overall hygiene and safety of plant. With reduced carbon build-up on tins there is reduced risk of product contamination. +++

Danish as part of the DNA

Dan Cake Portugal: How a Portuguese company became the world's second largest producer of Danish butter biscuits.

bbi: Danish Butter Cookies from Portugal, at first glance this seems to be an unusual symbiosis. How did it come about?

+ Dan Cake: At the time we founded the company, it was difficult to import products from other countries. Our strategy was therefore to build a diversified product portfolio with different technologies in Portugal. Since butter cookies are very popular, we decided to invest in the purchase of production lines to be able to produce them in our own country. Incidentally, today we are the only company outside Denmark that produces Danish Butter Cookies.

+ bbi: In Portugal you are the market leader in the category, "Bolos Familiares"...

+ Dan Cake: ...which is mainly because of our sponge rolls, the Swiss Rolls. In 1978 we started with industrially produced Swiss Rolls on the Portuguese market. Since then, we have held the number 1 position in the domestic market.

+ bbi: What do you produce at each of the two locations?

+ Dan Cake: Coimbra produces most of our cookies, biscuits, croissants, cupcakes, ladyfingers and popcorn. The Lisbon plant produces the Swiss Rolls, cakes, toasts, crackers, puff pastry and sandwich biscuits. At both locations we employ about 250 people in peak season. The plant in

Dan Cake Portugal

The history of Dan Cake Portugal SA began in 1978, when the company started manufacturing biscuit rolls (Swiss Rolls). The equipment and know-how was brought in from Denmark. This step was significant and shaped the company with "Danish" becoming part of the company's own DNA. Further technologies and competences from the Scandinavian country have been added. Today, the group is the world's second largest producer of butter cookies made to the original Danish recipe and one of the main producers of branded crisps.

Dan Cake Portugal exports to more than 70 countries. With 16 lines at two locations, the company has a production capacity of 55 tons per year. Two plants belong to it: one in central Portugal, in Coimbra, and a second in Portugal's capital Lisbon. In addition to butter cookies in various forms, the portfolio includes many other biscuits as well as crackers, toasts, rusks and cakes. Dan Cake Portugal produces half of its production volume as a private label, the other half is under its own brands

Coimbra has a production area of 18,000 m 2; Lisbon is larger with 24,000 m 2

+ bbi: What percentage is your export share?

+ Dan Cake: It is around 75 %. Our many (main) markets include the USA, Portugal, Spain, Italy, France, Austria, South Korea, Japan, China, Chile and Brazil.

+ bbi: Where do you see your greatest growth opportunities?

+ Dan Cake: Our main focus is on Spain, Germany and the USA. We believe that our position in these markets does not

Dan Cake, Danesita and Danor. Customers include international retail groups such as Walmart, Mercadona, Lidl, Carrefour, Continente, Pingo Doce, Park and Shop and Aldi. Website: https://danesita.com +++

Experience

Shick Esteve is proud to announce the opening of the LInxis North American Technology Center combining the process capabilities and expertise of LINXIS Group company partners – DIOSNA, Unifiller, and VMI. Experience first-hand how ingredient automation, dough technology and process management from the LINXIS Group can exceed your expectations.

Technology Center Features

• Dry and liquid ingredient automation

• Dry powder blending

• Pre dough and fermentation technology

• Grain soaking and delivery systems

• Continuous mixing technologies

• Vertical batch mixing

• Latest in integrated data and process control shickesteve.com

match their potential and that there are opportunities and synergies that will lead to additional volume.

+ bbi: What makes your company stand out?

+ Dan Cake: The extensive product portfolio that we manufacture using various technologies. It also includes our ability to customize and create products to meet the specific needs of consumers and customers. Of course we have all the necessary quality certifications.

+ bbi: What investments are you planning in the near future?

+ Dan Cake: Recently, we have invested in parts of the existing equipment to improve the efficiency of the production lines. We plan to invest in the packaging systems of some of our lines to adapt them to the changing needs of consumers and markets.

+ bbi: Do you see different trends in particular regions?

+ Dan Cake: In Asia, more attention is being paid to the perfection and complexity of packaging and smaller package sizes, whereas in Europe, there is more focus on the more

efficient use of packaging and ways to reduce packaging volume. But this is just one example amongst many.

+ bbi: Where do you see the biggest challenges on the biscuit market?

+ Dan Cake: As far as distance is concerned, we can say that we have a greater challenge in Asia and America. As far as product/quality/innovation is concerned, our challenge is to maintain our competitiveness and at the same time develop products with added value, such as our free-from range, but without compromising on enjoyment.

+ bbi: Dan Cake Portugal was an exhibitor at the ISM. What novelties did you show in Cologne in January 2020?

+ Dan Cake: Amongst other things, we presented 2 completely new product series. The new range "No Added Sugar", which includes three biscuit varieties, and our new organic range "Vita Organic" with five biscuit varieties. A real innovation is our clean-label product, a biscuit with only four ingredients.

+ bbi: Thank you very much for the interview. +++

Cake Concepts delivers Concepts around the world

Cake Concepts was established in 2012 and was built on lots of experience. CEO Simon Holl had been working in the industry for many years before starting up Cake Concepts.

+Today, Cake Concepts, with production facilities in the Amsterdam area of The Netherlands exports 95% of its Funcake and Pancake lines.

Our philosophy is based on, “Combining new technologies and customer demands to get the best and perfect Funcake and Pancake products", explains Mr Holl. “That's the driving force behind generating new ideas and innovation. As consumer demands change, new cake products must be healthy and tasty as well as also looking fabulous. And that combination is a challenge for most producers. In our constant drive to get the best for customers, as we love innovation, we do as much research as possible and listen carefully to market signals. We work closely with our customers to find out what they really want. It’s not just about developing and delivering the right machine, as we need to discuss the ingredients, the recipe, the batter and the filling. For example, when considering the recipe, the challenge is to obtain a soft texture and a long shelf life. By considering the product quality first and its shelf life as an optimizer for the supply-chain, we will have a game-changer”.

Cake Concepts produces industrial machines, which are unique due to the customization of the design according to the manufacturing requirements and the plant structure. As mentioned, recipes are really important and can affect the machine design. For example, an option is to add the cooling tunnel between the oven and the sandwich unit in the case of pancake production. This will allow for dairy application, even icecream or savory filings. The production capacity for pancakes depends on the product recipe; systems can reach up to 16,000 pcs/hr.

With Cake Concepts, Funcakes of any shape can be created using 3D design tools to produce unique products. At the center of each Funcake, there is a flavorsome and delicious filling – options are unlimited. The 3D design tools allow any form of product to be sculpted using the baking moulds.

The spectacular results are down to proven technology. The mould is closed during baking, allowing leavening agents in the recipe to generate gentle pressure during the process. The pressure pushes the batter outwards, meaning the contours of the mould are followed accurately. This results in a cake with a smooth surface and lots of detail. Every bite of a Funcake is spectacular. This is because the fillings are

applied before baking and follow the contours of the mould, allowing a high filling ratio.

“We produce with passion”, according to Mr. Holl “and we aim to deliver the best equipment to companies so that their products are unique to the market. Our equipment makes products that stand out from the ordinary.” +++

Hard

Slicing and packing breads

REGO HERLITZIUS offers a combination of the BS 45 belt slicing machine and the Vertec 30 for large bakeries to slice and pack breads.

+The REGO HERLITZIUS BS 45 is a powerfully performing, fully automatic belt slicing machine that can be used to slice a wide variety of bread types in continuous flow-through operation. The belts are arranged at an angle relative to the infeed, thus achieving optimum slicing results. Adjustable belt oiling assists the slice quality of the cutting process. Hardened belt knife guides that can be arranged in different slice thicknesses ensure stable, low-wear production.

A variety of cutting belts and tooth arrangements are available for different bread types, and the Teflon coating of the belts and belt guides give good cutting properties, because they reduce the coefficients of friction between the wearing parts.

Easy to clean

Doors that open sideways make the machine easy to clean and simple to maintain. Belts are changed by releasing the tension on the hardened belt drums; the belts can then be easily removed from the machine’s interior. Optional accessories such as driven belts at the infeed or an adjustable driven upper belt allow for good slicing of products with a very wide variety of consistencies.

An integrated bag blow-up table makes a combination with the REGO HERLITZIUS VERTEC 30 packing machine a

powerfully performing solution that is attractive for users requiring a capacity of 1,800 breads/hour. An operator fills the bread bags manually.

The VERTEC 30 uses a wire clip to seal the bread bags and a best before date can be printed directly onto the clips by a thermal printer unit. The VERTEC 30 can seal bags with widths in the range from 80 – 200 mm. Setting is via a touchscreen panel directly at the machine. Thus the BS 45 and the Vertec 30 form a compact solution. +++

Sustainability has high priority