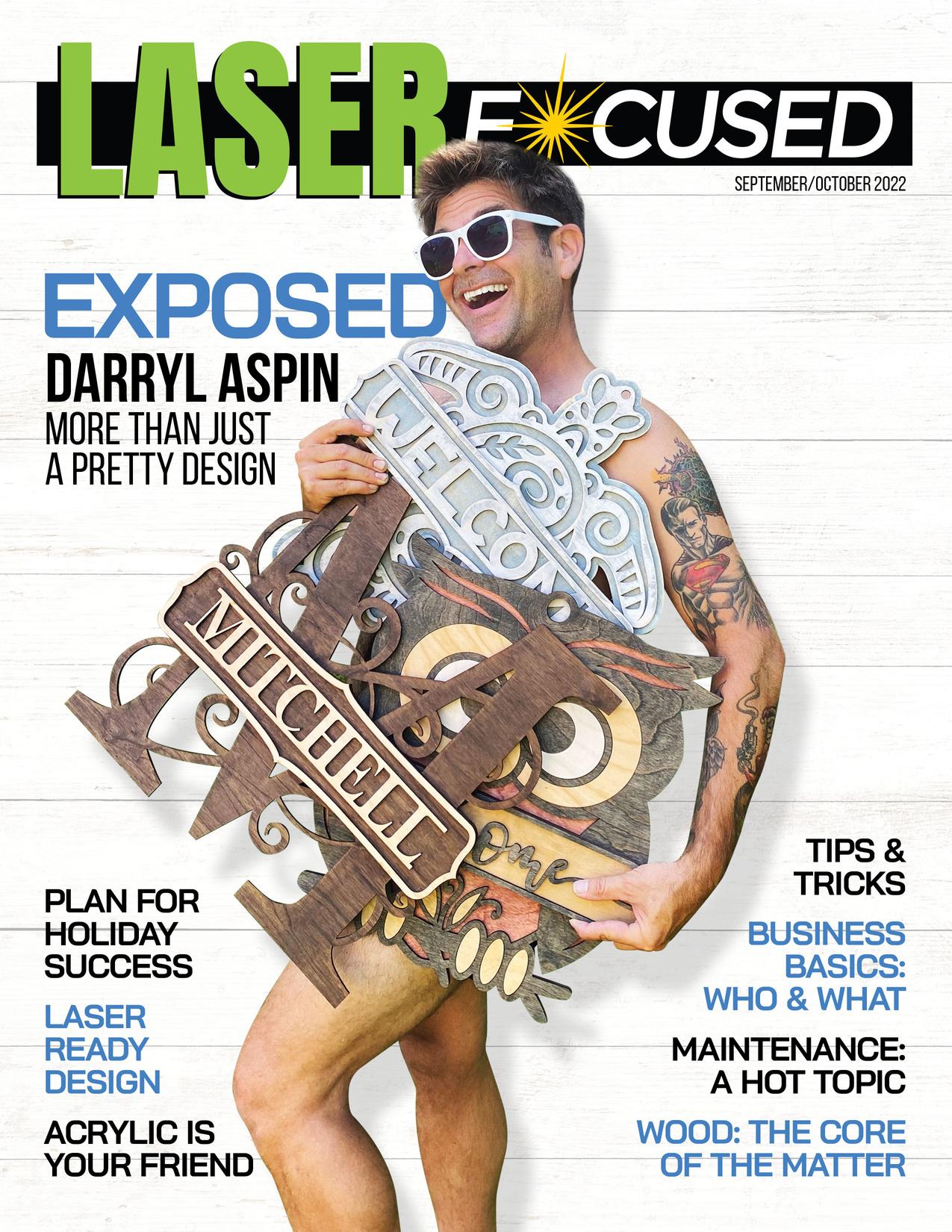

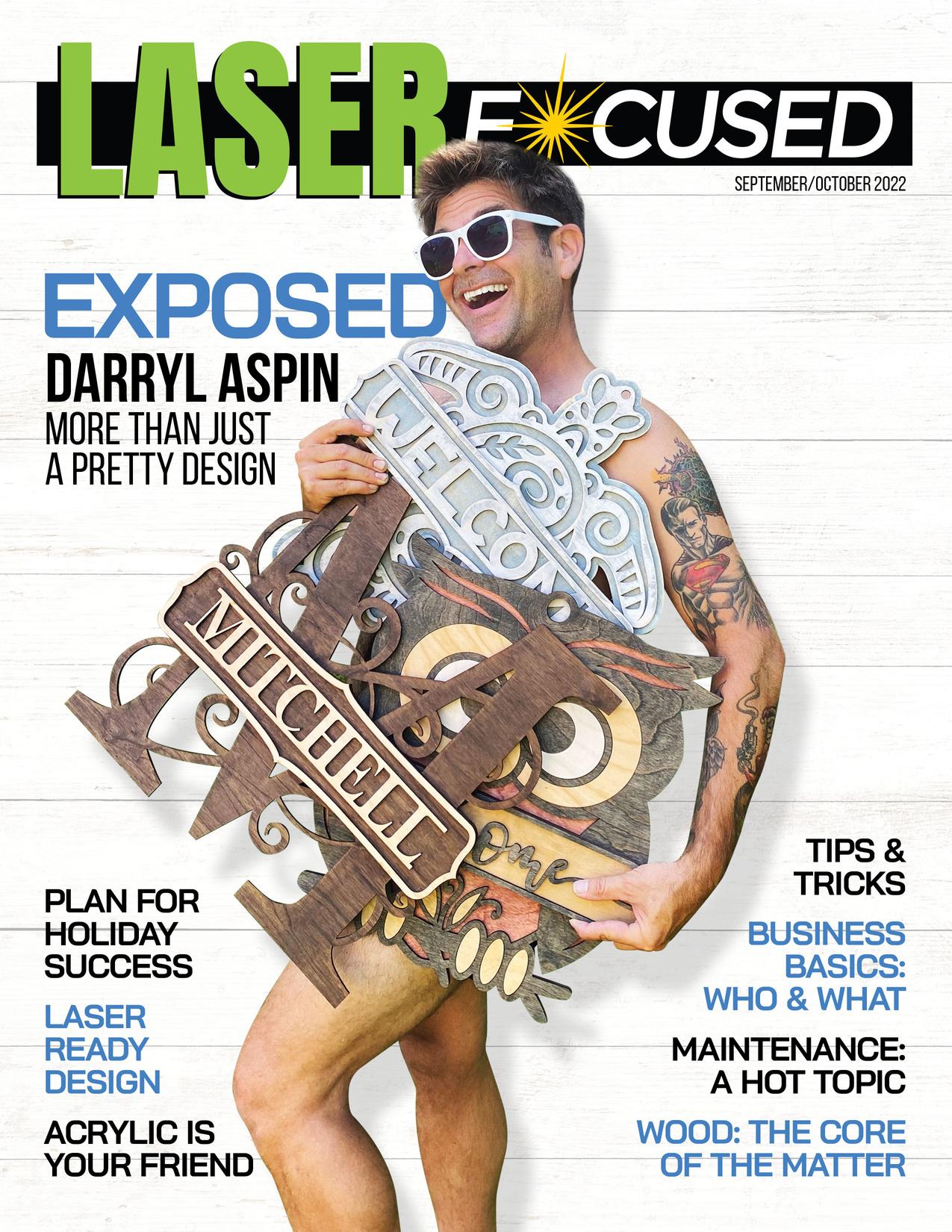

Recurring Columns Tips and Tricks On The Cover: EXPOSED Darryl Aspin

Business: Making Choices That Make Sense...

12345Robin Roberts, Robin's BirdBrain Designs & Laser Focused

Design: Preparing Your Files...

12345Michael Horton, Party of 4 Crafts

Maintenance: Things Your Laser Wishes You Knew...

12345Summer Shigley, The Spotless Forge

Materials - Acrylic: To Fear or Not to Fear...

12345Kris Mayberry, Craft Closet

Materials - Wood: The Core of the Matter...

12345Shayna & Mike Knight, The Crafty Knights

Suppliers: Holiday Prep - Taking Stock

Classifieds

12345Shishona Turner, Making Blank T A B L E O F

Robin Roberts, Editor & Publisher

Laser Focused Magazine, Spring, Texas

www.LaserFocusedMagazine.com. Info@LaserFocusedMagazine.com

C O N T E N T S

WELCOME!

I have questions – lots of questions. I had them last year when I bought my laser and have even more today! I'm not the only one, right?

Then I had a thought, “Hey! What if I created a publication that was a repository for all these questions and the best answers? I bet people would like that. Heck, I would like that!”

So the vision for what would become this magazine, LASER FOCUSED, was born. And now here it is “Hot off the (digital) press!”

When you subscribe – for free – you will automatically be notified when each edition is ready. It is my hope you will pour through them, learn new things, share tips and help find answers. I am certain that Laser Focused will become the place you turn to, looking for that helpful nugget you saw a couple of issues ago!

We will also add features as we grow such as:

a humor section because hey - we all have stories! So if you find funny

memes and stories, please submit them.

a Q & A column and we will need your questions! More tips! - we plan on two full pages in the future so please send in

your helpful hints!

How about prizes? Right from the start, with this issue, we have 2 drawings. On the first of September and October we will draw a name for a $250 gift certificate from and for Making Blank. Everyone subscribed as of midnight the night before will be eligible. This is donated by Making Blank, an advertiser, and we are grateful for this fun start! So, get subscribed if you aren't already (see below)! You get an extra entry into the drawings if you share Laser Focused with someone else and they subscribe citing you as the person who referred them so share away!

Please shop the advertisers. They have taken this leap of faith with me, are contributing to the knowledge base, and are here to help you be successful!

Thank you for your excitement and support in launching Laser Focused. I want to hear your feedback and keep growing something great together!

Enjoy the issue!

Never miss an issue

Click Here to Subscribe

E D I T O R ' S N O T E E D I T O R ' S N O T E

Robin Robin

Robin Roberts, Editor & Publisher

Robin

CONTRIBUTORS

Become

2 Drawings!

Subscribers as of August 31st & September 30th are eligible to win a $250 gift certificate to Making Blank! Subscribe now

a guest contributor

showcase your expertise with the Laser Focused readers. Contact us HERE

and

Shayna & Mike Knight, The Crafty

Knights

Michael Horton, Friendliest Glowforge Group on Facebook, Party of 4 Crafts

Kris Mayberry, Craft Closet

Summer Shigley, The Spotless Forge Time2Travel

Shishona Turner Making Blank

TIPS AND TRICKS

I get the magazine holders and separate smaller pieces and scraps that way I keep larger scraps in crates, sorted by material

If you’re doing markets or just doing packaging and using bags, boxes….use your Rollo (any thermal printer) to make labels for the bags.

Jasmine Michelle

Robin Roberts

Jasmine Michelle

Robin Roberts

People follow people not product. Build relationships, it’s not about the number of followers you have.

Dawn Basciano

Dawn Basciano

A great way to display your designs! We ended up making a mini blank version of all our different files and each one has a little piece of Velcro on the back and is sitting in the pocket for extra support We can now roll this up easily for transporting between vendor events. Easy replace old designs with new ones too!

Siobhan Graham

Do not use glass cleaners on your machines. They have amonia and pitt plastic Instead mix distilled water and vinegar in a 50/50 solution, put in a spray bottle and use it to clean your machine. It can be applied to surfaces but NEVER LENSES

Jonathan Gleich

favorite tiphere!!

Submit your

Tips from other laser professionals - if you have one, submit it HERE

Can'thearthistoooften ... **

**

**

**

** NOTE: Wherever you see ** you can click through and order the pictured item from Amazon. We're part of the Amazon Associates program and this supports Laser Focused Magazine.

DARRYL ASPIN EXPOSED

More Than Just a Pretty Design

It's a safe bet that you can find, in almost every community in North America, some iteration of a Spin Customs design. Maybe a monogram, perhaps a welcome sign, or simply a Christmas ornament – all in different sizes, colors, and finishes but the design itself is a creation from the mind of Darryl Aspin.

EXPOSED: DARRYL ASPIN

But that was never the intention when, on a blustery March day in 2020, Darryl ran across an ad for the Glowforge. Bored and hockeydeprived due to lockdowns, on a whim he hit the 'Buy Now' button and his Glowforge adventure began To him this was just a new art form to explore - there was no grand plan to conquer the world, just to have fun and play with a new toy. But the world thought differently and within a few weeks, while sharing posts of creations from his new tool (monogram, anyone?), people were ordering finished products and laser users were clamoring for the files. And just this past spring, needing more production capability, Darryl add a Thunder Nova 51 to his tools. "It's been a great addition. It's bigger and faster, a perfect upgrade for Glowforge users " [Video]

Design is not a new endeavor for Darryl Aspin who began his career as a paid artist when he i thi d d Ch i t f hi

He went on to college, majored in visual arts, and was immediately hired by a Toronto ad agency after graduation where he became the youngest Creative Director in the business. Within 5 years he stepped out on his own, launching Spin Commercial Creative.

Beyond business life, Darryl is married to his teenage sweetheart, Danielle. They live on the water, outside of Toronto, in a house full of love and laughter. They have two teenagers, Aeris, their daughter, and Caden, their son.

Aeris just graduated from high school and is headed toward a career in teaching, specifically working with kindergarteners. Her dad says, with no small amount of pride, that she has a magical way with little ones and was born to it. She is most like her dad with a wicked sense of mischief. You can sometimes catch Aeris on camera during live streams and she has been known to press the 'Go Live' button and not mention it!

Caden is the more reserved of the two kids, preferring to stay off camera. He is still in high school but has plans to be an electrician and is already working toward that. For now, as often as possible, he can be found playing video games.

Water is an important element for Darryl. It is the great equalizer and resetter of energy. It certainly played a central role in choosing their current home in Port Perry, Ontario

He spends as much time as he can on one of his boats or on a sea-doo, whichever calls to him at the moment. Even when Darryl travels he finds his way to the water – often hanging out on the west coast of Florida, close to family. And again – often out on a boat!

As we continued to chat I asked Darryl what surprised him the most about his laser journey, expecting an answer about the laser itself While he did talk a bit about how the capabilities and limitations altered his design process, that was not what affected him most “I was most surprised by how much people liked my art, the support of the community and so many people who just loved what I was doing. I found that refreshing and nice to see. [Video]

Up to that point in his career, Darryl explains, his whole focus as a commercial artist had been on servicing his clients through his agency –Spin Commercial Creative. As he puts ithelping big corporations get bigger and richer This laser community was a completely new thing to him It was an opportunity to help individuals, give back, spend time to help people to thrive “The Facebook groups are not just about business to me It's a community It's the way that it makes me feel It's a way to give back. It's a way for me to make people smile sometimes. It means a lot to me. So this is special to me still. 100% worth it, very rewarding.

What I want is everybody to succeed. I am not a jealous person. I love to cheer people on and surround myself with those who feel the same.” [Video]

Often you see people in this business who don't have an arts or graphics background say that they are not creative They feel people like Darryl are the imaginative ones and that they simply finish what he creates So I had to ask him what he would say to people who struggle with the idea that they aren't creative And his answer? “Hogwash! Everyone has a form of creativity Everyone has ideas, everyone can create. Even the simple act of choosing a color is creative. People, in general, are inherently creative. Some people are just more outwardly creative, like me. It only takes the ability to imagine which then inspires. If you're inspired, you'll create. Laser files are lines, that's all! I'm providing the instructions to the laser head on where to go. That's it. After that it is THEIR art now, they create the final art with colors and finishing Finishing takes massive amounts of creativity ” Watch the video to hear more on this [Video]

Knowing Darryl loves music I wanted him to share with us what that looked like in his life He is in a band as the lead singer and rhythm guitar player When performing the whole room is his stage and he says you will often find him out in the crowd, jumping on tables, trying to make people laugh and have a great time They play all around Ontario and perform across several genres including rock, country, and pop [Video]

As for what musician, living or dead, he would most like to do a set with he had two answers, the first being Gord Downie, since passed, of The Tragically Hip, an iconic Canadian band. His other choice is none other than Ed Sheeran. “He is ridiculously talented on his acoustic guitar. What he does on stage with his acoustic and loop peddles by himself, that would be absolutely amazing to do something with him onstage.” Agreed! (Hey – 6 degrees of separation – anybody know Ed and how we could get these two together?)[Video]

What you get when you talk to Darryl is his true self He is right there, engaged, enthusiastic and in the moment It made me w what words of wisdom had formed him in both life and business.

His motto in business is from his dad.

'Hustle, never be outworked.' You can see with Darryl that's true. He plays full out, hobby or a job, he gives it all he's g

His grandmother gave him words o wisdom to live life by, 'treat others as you would like to be treated Respect everyone and know we are all equal Nobody is above or beneath anybody Be kind '

His words to live by are essential to Darryl For you to get the sense of who he truly is, I quote him next word for word. I encourage you to watch the video to truly appreciate the passion of his sentiment.

“I know it's really simple, maybe people are expecting some grand thing from my head or something creative - it's not. I say it all the time. Be Kind. I really, truly cannot express to you enough how those two words, to me, mean

so much because there's a lot of crap in this world Be kind to other people You don't know what people are struggling with Every day people have anxiety and I suffered really bad through a five-year anxiety disorder I went public with that in my groups. I'm heartbroken sometimes by how cruel other people can be to each other. Be kind, be nice to each other because we're all we've got. We're all the same. Nobody's better than anybody. Be kind, please. That's what I live my life by. Every day I wake up and I ask myself, 'How can I make somebody else's life better? How can I make someone smile?' If they're having a bad day, even if I'm having a bad day, I will go out of my way to put on a happy face and do something stupid and silly and embarrass myself to make that person smile Because if that's the only smile they got that day then it's worth it.” His full answer was a bit longer and you can watch it here. [Video]

As we closed our chat, Darryl had some final words for all of you. “I love my communities. Thank you. I can not thank everybody enough for following me, supporting me I'm more than happy to give back with everything I've got and I love them all That's something I want everyone to know, how much I truly, truly appreciate them I don't take any of it for granted ” [Video]

Whoisournextcoverstory??? **Secret** Thepersonhasbeenmentioned inthisissue! Whodoyouthinkitis? GuessHere!

EXTRA ENTRIES FOR REFERRING SOMEONE!!*

2Drawings!

SubscribersasofAugust31st&September30th

areeligibletowina

$250giftcertificatetoMakingBlank!

Subscribenow

*have them put your name in when they subscribe!

EXTRA ENTRIES FOR REFERRING SOMEONE!!*

2Drawings!

SubscribersasofAugust31st&September30th

areeligibletowina

$250giftcertificatetoMakingBlank!

Subscribenow

*have them put your name in when they subscribe!

EXTRA ENTRIES FOR REFERRING SOMEONE!!*

2Drawings!

SubscribersasofAugust31st&September30th

areeligibletowina

$250giftcertificatetoMakingBlank!

Subscribenow

*have them put your name in when they subscribe!

Busin Making Choices T

When beginning your business, or considering rebranding, the best guideline is to consider, who is your customer. So many people do not start here. They just start and if asked will say, “Everyone is my customer.”

Stop right there. Before we go any further let's get this out of the way with a little tale...

Once upon a time, a hunter went out hunting for rabbits. As he made his way through the meadow he came upon three rabbits. “We will have a feast tonight and eat for days to come!” he thought excitedly. He began moving to capture the first rabbit, then the second one seemed slower so he veered toward it, at which time the third rabbit ran right past him – 6 inches away – and he dove to the ground for it, missing it by a fraction. As he righted himself he looked around. All three rabbits had disappeared into the tall grass. There would be no feast tonight.

The moral of the story is focus on one thing! If the hunter had pursued one rabbit, he would have most likely bagged it. When you splinter your attention quite often you end up with nothing or at best less than spectacular results.

And focus relates to both whom you serve and what you offer. We will start with the

who but you can start with the what. There is a debate about where to start but bottomline, when you do this process you should know that your item(s) is wanted and who wants it! How should you tackle this question of who? Think about your interests, your circle of friends and acquaintances, and any area of expertise you might have. For example, I knew many sales people through my business networking groups. They wanted something special to give as gifts to previous and/or potential clients. They had

budgets and were already committed to a purchase. They loved that the gifts could be customized and wanted to support someone they knew, liked, and trusted. Those salespeople were my first, easiest, and most profitable 'rabbits!' Ideally start by picking a market that you already have an entry into!

Further, develop your idea of the ideal customer. Ask yourself questions as you 'flesh them out ' What do they need and/or want? Where do they work? What is their income? What is their education level? Where would you find them? Who do you already know? What problem can you solve for them? Any other question you can ask to get a clear picture is also critical work you must do. Finally, what is their name? Brittany? Fred? Yep, name them! This is what is called your 'avatar” Write it all on a giant piece of paper and put it on your wall. When you start making choices,

CONTRIBUTOR: Robin Roberts, Robin's Bird

dBrain Designs & Laser Focused Magazine hat Make Sense

Importantly, once you know who you are 'talking' to and what you will offer it becomes easier to make decisions. Let's say you are going to do all things maternity, pregnancy, baby related. Nursery signs, name signs, milestone kits, wipe holders, etc, etc.. Along comes a great opportunity to purchase men's metal engravable wallets at an unheard-of price. You only have so much in your budget. Do you do it or not? Well, is that man your avatar? Not at this time! Decision made and you pass on the deal. Do you see how much easier it makes investing time and money wisely? And understand, it doesn't mean you can't create men's items eventually but for now, FOCUS!

Of course, if you have time, money, and space to have every last material, tool and gizmo, if getting a swift(er) return isn't the highest priority, then you can make a different decision. There's nothing that says you can't! (And I am in not-so-secret envy of that total freedom!) But if financial success and growth are your goals, focus is your friend! As you build this source of income for your family you now have a direction and a process for making decisions.

There is so much more to know about the business we are in. Make sure you check this column every issue where we will highlight best business practices and answer questions about the business of laser printing. Happy Hunting!

Robin Roberts is the owner of Robin's BirdBrain Designs, Editor and Publisher of Laser Focused.

ess 101

To Fear, or Not t

Masking*

There are 4 options to choose from with the masking

1 Remove all masking that comes on the acrylic and apply a thin layer of liquid dish soap on the acrylic.

Advantages: no weeding masking and it will keep the acrylic clean. After you are done engraving and cutting simply rinse the piece off with water and dry.

Disadvantages: removing the masking before using

2 Remove the masking on the side facing up in the laser bed but keep it on the bottom. Advantages: No laser residue on the back and the front will engrave without any interference. Weeding masking off only one side. Disadvantages: A remote possibility of laser burn marks on the front.

3 Leave all the masking on Advantages: Both sides of the acrylic stay clean Disadvantages: Masking may interfere with your engraving. It will all need to be weeded off in the end.

4. Remove all the masking and replace it with your own masking. Advantages: none, if the masking is laser safe.

Disadvantages: Waste time, masking, and money

MATERIALS

GUEST CONTRIBUTOR: K

EEngrave ngrave FFirst irst CutSecond CutSecond

*Acrylic can come with paper masking, clear masking or without masking. The acrylic we sell at Craft Close comes with either paper and clear masking Both these maskings are laser safe Check with the company you get your acrylic from to see if the masking is laser safe before cutting it on your laser.

ris Mayberry, Craft Closet Settings

oFear... Acrylic

Cut settings for acrylic depend on thickness, type-cast or extruded, denseness of designs, or clearness. For example, if you are cutting 1/16” mirror acrylic cut fast, like 200-speed full power (Glowforge). If you are cutting 1/8” dense glitter acrylic cut slow, like 140-speed full power. To find the perfect cut settings for each piece, cut small shapes at different speeds and write them down in your notes. Here is an example of a test cut file. (Cut Comparison Pdf)

Engraving and Scoring

Acrylic can be engraved and scored on either side. If it is translucent, clear, or mirror acrylic engraving from the back (turn the acrylic over, reverse the image on the dashboard, and engrave) will make it look more polished and cleaner.

Click

For the other kinds of acrylic, engrave and score from the front. If you leave the masking on during the engraving, it can be filled with paint before you take the masking off to keep the acrylic clean.

If you defocus the laser’s lens, some acrylic engraves will have a nicer look. This is done by manually setting the focus. For example, when I engrave ⅛” acrylic, I set the focus at .3” instead of .12”, for an even and smoother engrave.

So, what can you use laser-cut acrylic for? The possibilities are as wide as your imagination, so pick up a sheet and start creating your ideas!

Kris Mayberry is an owner of Craft Closet and loves helping with laser material questions You can reach her at info@craftcloset com, Etsy, Facebook, Instagram, Tiktok, Youtube or by following the links on her Linktree site

: ACRYLIC

to get your copy of this PDF

Do You Already Have an Online Presence? Or Just Starting to Need One?

Whether you have an established online presence or are just starting to map one out, it's time to meet Builderall, the world's largest digital marketing platform. You will have access to many tools, such as: Website Builders, Autoresponder, Email Marketing, Sales Funnel Builder, eCommerce, Members Area, eLearning, and much more. The whole digital marketing package is cheaper than taking the family out to dinner. We got your attention, right? Come to the digital marketing world and stay ahead of the competition with the best tools available!

Tell me more about Builderall

MAINTENANCE: Things You

GUEST CONTRIBUTOR: Summer I'm Sooooo

In the midst of one of the hottest summers on record, we are not the only ones suffering through the heat and trying to do our best to stay cool. While we can crank up the air conditioning, turn up the fans and let the cool breeze pass over us, our lasers depend on us to make sure they have the air flow that they need to stay cool. That may seem like it’s out of our control but I am here today to tell you how to get just a bit more breeze for your faithful crafting companion

Luckily, some of the laser companies have made the air intake on their lasers easily accessible Others, like the tabletop laser makers, not so much. We are going to address those tabletop lasers today and help alleviate some of the fear of the dreaded orange button of doom.

For the majority of tabletop lasers available today, the air intake is on the bottom right of the machine This leaves less than a half inch of clearance between the table surface and the intake to move the air needed to cool your laser cutter There are a few simple things that can help increase the air flow and keep your tabletop laser cool and working its best in the hot summer months.

First, lifting and leveling your laser make a huge difference. For this, I recommend two to three pieces of wood or metal that can be placed under your laser to give lift. I use three 1x3 pieces of wood placed evenly spaced under the laser, making sure to lea e at least 4 inches on each end of

cuts can be off and your frustration will be hotter than the mercury in the thermometer.

To level your laser, you will need a level with a bubble large enough to see and shims Shims can either be purchased at any home improvement store or, if you’re feeling creative, can be made out of your pile of scraps that you pretend not to notice growing in the corner. With the level

Laser Wishes You Knew

Shigley owner; The Spotless Forge

Once you have leveled your laser left to right, repeat the process front to back by turning your level 90 degrees and centering it on the closed lid again. This step should be pretty close already if the pieces of material you use for a lift are not warped

Finally, most manufacturers recommend calibrating your machine anytime you are Shims! Perfect use for scraps!

finished moving your tabletop laser. This will allow you to make minor adjustments as needed.

Following these simple steps will help you get the most airflow to your intake and keep your tabletop laser working to the best of its ability Remember, your laser has a recommended air temperature for it to run efficiently, so make sure that you have your crafting companion in a well-ventilated, temperature-controlled room if possible

The summer is almost over let’s keep cool together!

Summer Shigley is the co-owner of Your Content Creations LLC with her husband Les Your Content Creations LLC is the parent company of The Spotless Forge and Time2Travel Vacations Find out more about her by going to her Linktree site

ur

ooooo Hot!

DESIGN: Preparing You

GUEST CONTRIBUTOR: Micha

We’ve all been there, we bought or downloaded a “laser ready” file and had to spend inordinate amounts of time fixing it to make it ready for the laser. As a fileseller, it is very important to me that my files are ready for any laser. Since I have used a Glowforge, GweikeCloud, Atomstack Diode laser, K40, and a 100-Watt Chinese laser, I have had experience with a wide variety of lasers and I have a technique for preparing my files for any of them.

There are several things that you’ll have to keep in mind to prepare your files. The vast majority of lasers use either Lightburn, CorelDraw, K40 Whisperer, proprietary software, or online software to control the laser. The first thing you’ll have to consider is what file type to use. Diode lasers are mostly for engraving bitmaps, so we will not include them in this list of accepted vector filetypes.

Vector Filetypes

K40 Whisperer: SVG and DXF

Lightburn: AI, SVG, DXF

CorelDraw: Dozens including AI, SVG, DXF, PDF

Glowforge: SVG, PDF

GweikeCloud: SVG, PDF

What we can see from this list is that SVG is accepted by all lasers and should be your first priority when creating files. My experience says, however, that CorelDraw users have issues with SVG files that have had offsets in them, so I suggest providing a couple of other options as well like PDF and DXF.

Almost all or all lasers separate vector files by color Everything that you want cut is created in one color, everything scored is another, and everything engraved is another Here’s a summary

Color SchemesK40 Whisperer: Red is cut, blue is score, and black is engrave.

Lightburn: Separates by colors and then you decide what each color does.

Design for Any Laser

ael Horton, Party of 4 Crafts

CorelDraw:

Separates by colors and then you decide what each color does.

What you can learn from this is that although most laser programs give you the freedom to choose what each color does, K40Whisperer does not. Therefore, if you stick with the K40W palette of colors, it will work with every other software, too. So, I set all of my cuts to red, my scores to blue, and my engraves to black.

Separations

Glowforge:

Separates by colors and then you decide what each color does.

Many people purchase files because they do not want to learn to use design software on their own If you have a file that requires multiple materials and you include them all in the same SVG, the user will have to open them all and copy and paste the components into separate files for the different materials before they can use it That is NOT laser ready. Save each of your designs as separate files for each material (eg. One file for clear acrylic, one for red acrylic, and one for whiteboard).

These stadium files required two types of wood and acrylic, therefore each design included multiple files.

GweikeCloud Offline:

Separates by colors and then you decide what each color does

ProperSize

Ifyour design has pieces that fit together, it is important that the size of your design remains stable when you load it into the laser software. There are well-known issues continued, click here

r

Laser-related Facebook Groups

TOP 10 by Number of Members and Engagement

Laser Engraving And Cutting @ 60k members

New to Laser Engraving @ 56.7k members

Glowforge & Lasers for Crafters @ 49.2k members

Glowforge Users Group (GUG) @40.8k members

Glowforge Makers @ 40.6k members

Glowforge World @ 34.3 members

Will’s Laser Supply Sales Group @ 31.8k members

That Mom with a Laser @ 30.9k members

Free CNC & Laser Engraving files sharing ( SVG DXF AI EPS ) @21.2k members

Photo Laser Engraving @ 20.3k members

Laser-Related YouTube Channels

When I was both shopping and new to lasers these were four of the first YouTube channels I watched. Submit who you watch and the top 4 mentioned will be listed in the next issue!

That Mom With a Laser

Laser Engraving by Matt

85th and Pine

Custom Grains and Designs

Nevermissanissue ClickHeretoSubscribe

Design... continued from previous page

about Illustrator and Inkscape SVG files (and I assume others as well) resizing when imported into some of these programs There are plenty of YouTube videos to show you how to handle that. PDF files seem to preserve the dimensions of your file, so offering a PDF option for these files is always a good idea.

Summary

To make your files “laser ready” for the most lasers possible, use the color palette of red things cut, blue things score, and black things engrave To ensure that your files open properly in the most laser software programs, offer it in SVG, DXF, and PDF formats Do this and your files will truly be laser ready and your customers will love your shop for it

Michael Horton is the proprietor of Party of 4 Crafts

Find him on Etsy, the Friendliest Glowforge Group on Facebook, Youtube, the Partyof4Crafts website, and Instagram by going to his Linktree site

What is MDF?

MDF stands for Medium Density Fiberboard It is manufactured sheet of wood that is essential composed of sawdust (fine particles) and glu For Glowforge users, it is commonly known a draftboard Lighter-colored MDF tends to cu better, which means it usually cuts faster an leaves clean edges (meaning no soot or charrin on edges that need to be wiped). That is not t say that darker materials can’t cut, they ju normally cut slower and leave the charr on th edges.

What’s the Difference Between MDF and Plywood?

MATERIA At the Core o

GUEST CONTRIBUTORS: Shayna &

Light MDF vs Dark MDF

As described above, MDF is just sawdust and glue It has no woodgrain and hence no natural beauty of its own This also makes MDF smooth as it has no wood fibers Whereas plywood is normally constructed with outer veneers (a thin piece of wood on the outsides) and some kind of core material on the inside (the core can be made of more thin pieces of wood or MDF) Maple, Birch, Walnut, Oak, and Cherry are some of the different wood species that are used in the outer veneers Due to plywood having grain, it may need to be sanded Even on the smoothest plywood (because some woods are smoother than others) a light sanding would still be a best practice.

Plywood Core

MDF Core

Hardwood plywood and hardwoods (solid wood) include the same species of woods i e Birch, Maple, etc, but are NOT the same thing The difference is that hardwood plywood is made of thin layers of wood glued together as described above, while hardwood boards are literally boards are literally pieces of solid wood The width of a solid piece of hardwood is limited to the width of the tree it came from as opposed to plywood in which the veneers are peeled from a tree allowing for much larger widths for example 48” wide sheets.

AL: WOOD

& Mike Knight, The Crafty Knights

of the Matter

What’s the Big Deal with MDF Core Materials?

MDF Core Hardwood Plywoods are pieces of wood that have a veneer on the outside that is adhered to MDF on the inside MDF is less likely to warp due to the lack of woodgrain So when used as the core of Plywood, it helps keeps those pieces flatter. You then get the beauty of hardwood and the flatness and the consistent cutting (no voids or glue spots) of MDF. Veneer or Plywood Core sheets (which is your standard plywood) can have voids or glue spots.

Veneer on MDF Core

When Would I Use MDF as Opposed to Plywood?

MDF is primarily used for painted projects, DIY paint kits, for making templates, or testing new designs For these reasons, in most cases, MDF does not need to be masked This will help save time and money. Some people do apply stain to MDF, but with MDF not having any woodgrain, it doesn’t do anything but darken it. It’s not a popular practice, but can be done. Painting techniques depend on your MDF manufacturer. For painting tips on our MDF, check out the blog on our website.

Plywood has woodgrain and can be painted if needed, but it is best utilized when stained or clear coated. Some of your wood species like Cherry and Walnut, for example, are used for their natural beauty and usually only receive a clear coat. Birch and Maple are your go-to choice when looking to stain or get a Walnut look without a Walnut price. Also, when compared to MDF, plywood does better for outdoor projects

1/8" MDF

CUT: 190 speed/FULL power (Auto Focus)

SCORE: 300 speed/ 41 power

ENGRAVE: 1000 speed/ FULL power/ 195 LPI

1/4" MDF

CUT: 120 speed/FULL power (Auto Focus)

SCORE: 300 speed/ 61 power

ENGRAVE: 1000 speed/ FULL power/ 195 LPI

Mike and Shayna Knight are the owners of The Crafty Knights in Detroit, Michigan You can find them at www thecraftyknights com They are happy to answer any questions you have about what product is best for the project you have in mind!

SUPPLIERS: Sour Holiday Prep -

As the holidays approach, many of us are thinking, how are we going to be ready?

We’ve seen over the past few years what supply chain issues can look like What will be our big seller? What are we going to make for family and friends? Like the fflakes of 2020 or the gnomes of 2021, what will be the money-maker for holidays 2022?

The truth is, it can be a crapshoot. Trends are not predictable, until they are, and you are putting in crazy hours to keep up with no sleep and no family or me time. So, whether you are trying to prepare for your business or cover gifts for family and friends, here are ways you can be prepared as we head into the largest quarter of the retail and crafting industry

Get to know your supplier Alibaba and DHGate are mentioned several times a month in forums

However, these sites come with a lot of uncertainty for the buyer. A domestic supplier navigates and bears the responsibility for these uncertainties such as ability to return products that are not up to quality standards, large minimum order quantities (MOQ), long production or shipping timelines, long factory closures for holidays or COVID, customs and duty fees, fluctuating port fees and layover charges, insurance, etc Many large domestic corporations such as Hobby Lobby, Home

GUEST CONTRIBUTORS: Shi

Depot, TJ Maxx, Marshalls, and Aldi may have cool products or good sales, but if you want to establish a consistent product line, find a small business supplier you can build a relationship with or invest a year into establishing a product line with a factory

Melody Thornton with Custom Made Better shares, “As customers who make finished goods and products for the holidays, I think the best thing you can do to be prepared is to find a supplier you can trust to be a part of your team and a backbone to your business. A good supplier will go out of their way to make sure you have what you need when you need it In addition, communicate your needs with them- as a supplier I WANT to hear from my clients what they want and what their clients are telling them they want so I can make sure we're ordering and manufacturing these things ”

Plan ahead. On the supplier side, lead times can be anywhere from 4 weeks to 2 years. For suppliers that are importing from overseas, production schedules can span out more than 2 years. Kristi Wildman with KW Supplies shares their “lead times are 46 months” and Casey Cruise with Smokey Hills Designs said “for Holidays 2022, we are prepared with over 200,000 lbs of inventory and we’ve already submitted through to quarter 2 for 2023 orders For preparedness, our production calendar is forecasting into Holidays 2023 " Thornton is preparing for 2023 spring & Valentine’s Day and will start gearing up for Holidays 2023 immediately after December 25, 2022

ces for Success

shona Turner, Making Blank

Taking Stock

Know the process Holidays seem to come earlier and earlier every year Braden Todd with GS2 Awards is a seasoned pro at preparing for the holidays with over 14 years of experience in the laser industry “Heading into the holidays, we like to

tell everyone to assess what materials they plan to use and start watching sales now

When we get closer to rush season, there may be some lead times and the carriers can get bogged down

with all the packages We definitely recommend planning orders ahead of time whenever possible ”

Now - Make Lists – Now Pull up a notepad on your screen or a sheet of paper, or print this quick guide You’ll be making 3 quick brain dump lists – if you forget something, that’s ok because you’ll do this again. 1. What materials do I have on hand? 2. What do I enjoy making or what will make $$, 3. What do I need to order? (I recommend doing this method daily or weekly and keeping them for after the holiday craze is over where you’ll debrief - What went well? What went poorly? At that point, you can create a production calendar for 2023 and be even more prepared )

Next up - Plan Pick 4-5 items to focus on If you need some ideas, safe bets are ornaments, pets, firsts, memorials, kitchen items, and stocking stuffers (Firsts can be

marriage, first pet, first baby, first house, etc ) Match up what you think you have with what you think you need Now, take a look at your actual inventory of supplies –what do you need to order? Some supplies were running low as early as September for

the 2021 Holidays Plan differently for anything that requires Baltic birch plywood Some suppliers still have some in stock and some have been aggressively looking for alternatives

Order - ASAP Every supplier

will tell you, don’t wait until the last minute. Thornton shares, “Most of our clients have already started on Halloween and Christmas So that means any order coming in after August is truly a lastminute deal ” Cruise echoes this advice “The best advice I have is don’t wait till the last minute, and any projections and predictions shared early help us to prepare ”

A good supplier is navigating all the logistical processes to bring goods together for you. We love helping you Make! The more you plan, the more that helps us help you!

For a PDF for planning please click here!

Shishona Turner runs Making Blank Laser Supply Cooperative. Making Blank Business Page; Making Blank Group Page; To message her directly: m.me/100810301467948 or shishona@pauseibilities.life

-

CLASSFIEDS CLASSFIEDS

A marketplace to sell to fellow laser folks starting at $15 per column inch

Click for more information

Looking for high quality sublimation and laser blanks?

The Blanks Source would love to help! Join our Facebook group to be the first to see our new releases. The Blanks Source on Facebook

Files for sale

You can advertise here in the classifieds and build your design business!

Click here to get advertising rate information.

This spot is waiting for you!

COMING SOON! The Virtual Consignment Shop by The Spotless Forge

Want to sell laser but don’t want to do the marketing or negotiating? The new virtual consignment shop at TheSpotlessForge.com has got you covered! Snap a few photos, answer a few questions, then sit back and let us do the work for a reasonable fee.

*Save 10% on the consignment fee when you mention this ad*

Have something your fellow laser users would love?

You can advertise here in the classifieds and build your business! Click here to get advertising rate information.

Ready to dive in?

Click this ad for a discount when buying a GLOWFORGE. $125-$500 depending on model chosen.

Jasmine Michelle

Robin Roberts

Jasmine Michelle

Robin Roberts

Dawn Basciano

Dawn Basciano