ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

SEP/OCT 2024

Solving challenges - Reduced wear, increased efficiency

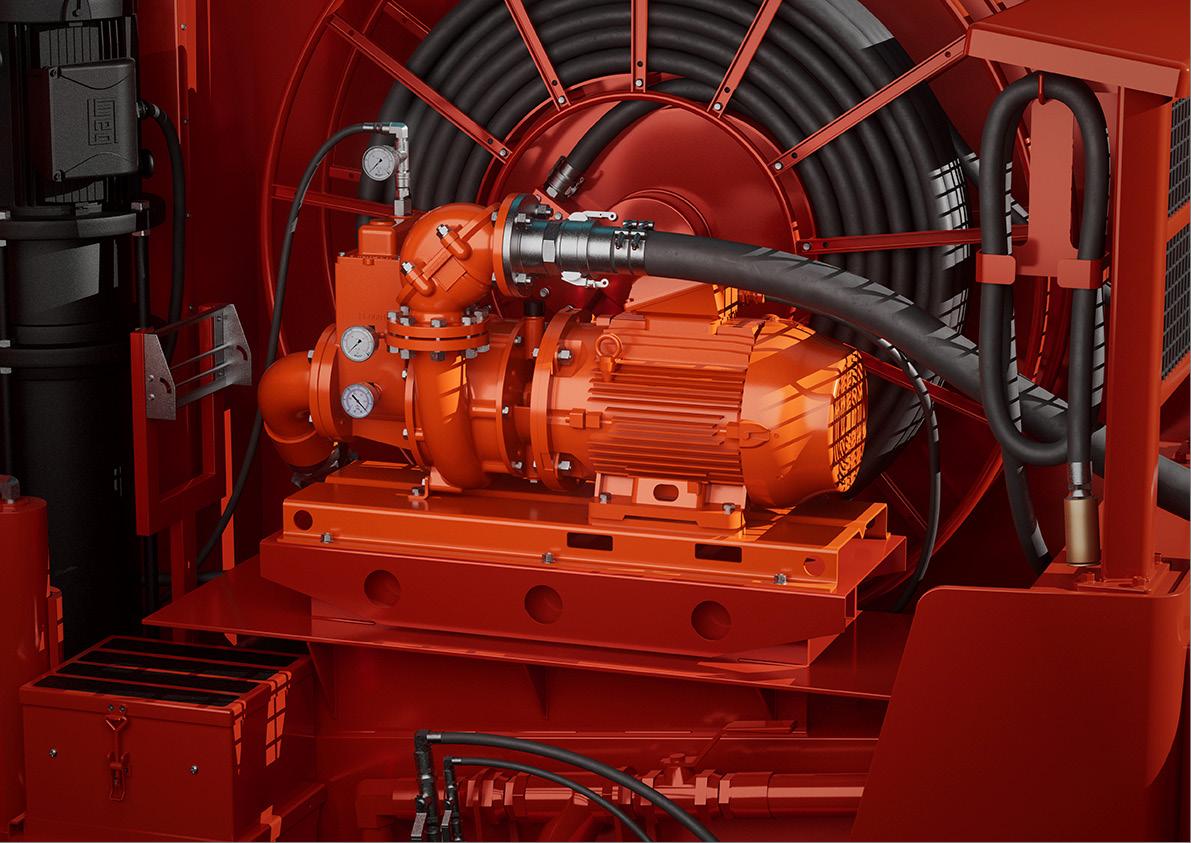

Xylem’s Godwin Rig Pump solves some of the toughest dewatering challenges in mining by seamlessly integrating with drilling rigs and using state-of-the art technology. The rig pump lasts up to five times longer than traditional submersible dewatering pumps.

When traditional electrical submersible pumps are used for dewatering mines, they can clog due to shotcrete and wear out due to solids in the water, the pumps can also be left snoring. In addition, mine operators must deal with trailing power cables connecting pumps and must manually move the submersible pumps.

Industries,

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Email: info@pumpsandvalves.co.za

Web: www.pumpsandvalves.co.za

Sales: James Thomas

Email: sales@pumpsandvalves.co.za

Production Manager: Xane Roestroff

Email: adverts@pumpsandvalves.co.za

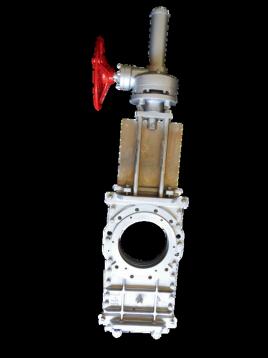

Since its founding in 1997, Ragon Industries has established itself as a key player, carving out a niche for its innovative valves that withstand the toughest operating conditions. Through continuous investment in research and development, the company has developed an extensive global footprint.

With a strong presence in markets across South America, Africa, China, Europe and Australia, Ragon is a trusted supplier for industries that demand reliable, highperformance valves, particularly in the mining sector.

End-users such as Samancor, Glencore, Sibanye Stillwater, Anglo, Harmony, De Beers, Goldfields, BHP, Sappi and various other project houses and suppliers are already standardised, using and selling Ragon products. The latest additions to the company’s range include the Dome, Angle Discharge Valves and Ceramic Coated Valves. Ragon also carry the complete product range for any automation and application types and processes.

“We specialise in the manufacturing of Butterfly, Knife gate and V-Port valves for slurry and other high abrasive substances,” says Nico Ras, MD. “Metal Hardening is done with cutting-edge technology such as a HVOF (HighVelocity Oxygen Fuel) spray/impregnating process, which is used to apply for wear and corrosion-resistant coatings to critical components. Combined with our proprietary PECU seal - a Urethane-based liner that works in harmony with the metal-hardened valve components – it makes our valves exceptionally durable and reliable for even the most demanding applications.”

According to Ras, in high-demand applications the valves offer a clear advantage. One of the key selling points of the RAGMAX valve is its lightweight design.

“Traditional slurry valves can weigh as much as 400kg, requiring multiple workers and heavy rigging equipment for maintenance or replacement. Our valve, in contrast, weighs just 40kg- about 10% of the weight of conventional valves - saving customers both time and money on labor and equipment costs.”

This lightweight design, combined with the valve’s extended lifespan compared to similar products, makes it a cost-effective choice for industries needing stable plant flow control with minimal disruption. Additional benefits include smaller actuators, low pipe stress, and the availability of cost-effective spares. Furthermore, the valves are easy to repair, reducing downtime and

maintenance requirements.

Growing footprint

backed by exceptional customer service

The company is actively pursuing a strategic global expansion, steadily increasing its footprint in key international markets. “Last year we invested in our own premises in Montana, Pretoria, where we now have a fully fitted factory with all the necessary equipment to deliver to our growing local and international clients.”

The company has also appointed an agent in South America and its market presence in China and Africa is steadily rising.

“There is increasing demand for high-performance valves that offer both durability and precision,” says Ras. “We continue to invest in our operations, equipment, and people as we work to distinguish ourselves from the competition. Our solution, which combines tungsten carbide hardening with the PECU urethane liner, is the first of its kind globally and a key breakthrough that truly sets us apart.”

He said the company prided itself on providing topquality products at competitive prices,

“Our recipe for success is simple - innovation, quality, and service. And that’s what we’ll continue to provide as we grow.”

Dewatering pumps play a crucial role in the mining industry, helping to regulate water levels and ensure safe and effective material extraction. These pumps have progressed significantly over the years in both technology and design, with a focus on durability and innovation to withstand the tough conditions of mining operations.

The mining industry encompasses a wide variety of activities, each with its unique dewatering challenges. Dewatering pumps are essential in managing highhead abrasive and corrosive materials in demanding environments. Their reliable and continuous operation is essential for preventing flooding and maintaining the stability of mining sites. Water accumulation at mining sites can result from groundwater intrusion or the mining process. Electric dewatering pumps are utilised in both underground and surface mining. For this reason, it is critical to consider the following key factors when selecting the right dewatering pump for mining:

Durability: Mining pumps must be exceptionally durable to withstand harsh conditions, including acidic and caustic solutions with abrasive solids.

Efficiency: Energy efficiency is critical in mining, particularly in remote locations with high energy costs. Advanced pump designs prioritise reduced energy consumption without compromising performance.

High-efficiency motors, including variable frequency drives (VFDs), enable pumps to operate at varying speeds, lowering energy usage during low-demand periods and extending equipment life.

Ease of Maintenance: Remote mining locations require easy maintenance and repair of pumps to minimise downtime. Modular designs and readily available spare parts streamline maintenance, reducing reliance on specialised repair teams and ensuring uninterrupted operations.

Corrosion-resistant materials like stainless steel and specialised coatings extend the pump’s lifespan in challenging mining conditions. Hardening techniques and ceramic coatings combat wear from abrasive particles, ensuring reliable operations over extended periods.

Integrating sensors with technology allows for the realtime monitoring of pump performance. These intelligent systems can predict and prevent unexpected failures and optimise operations based on specific application requirements.

This results in improved energy efficiency and operational reliability. Modular designs simplify maintenance and repairs, while compact pump designs excel in spaceconstrained underground mining, minimising pump installation and maintenance disruption.

As the mining industry expands and evolves, technological advancements in dewatering pumps are imperative. Companies like Tsurumi Pump are leading the way with innovative products that exceed the rigorous demands of modern mining.

Staying informed about the latest advancements in dewatering technology is indispensable for mining professionals. Understanding mining site requirements and innovative pump designs empowers mining operators to make informed decisions that enhance safety, efficiency and profitability.

Tsurumi Pumps SA, +27 (0) 82 404 4743, enquiries@tsurumipumpsafrica.com, www.tsurumipumpsafrica.com

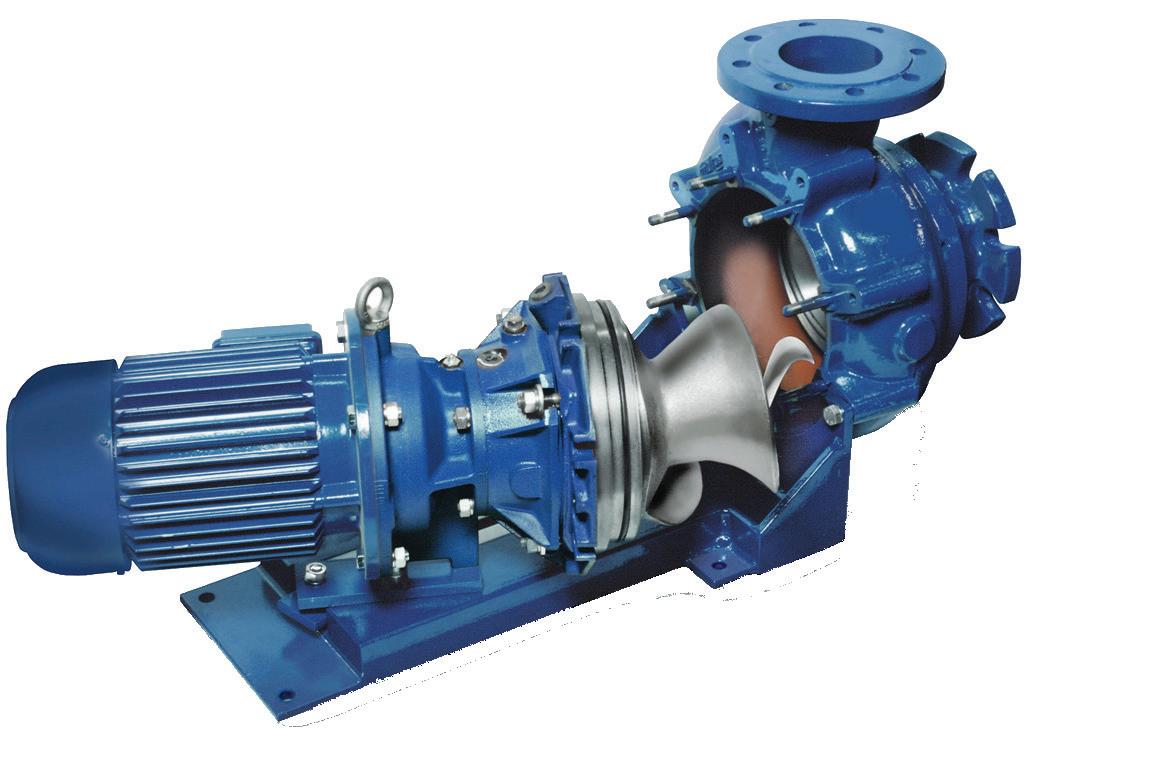

Did you know our CME supply and transfer pump comes with configuration options, a variety of materials and a high degree of customisation?

This reliable, modular and flexible multistage pump offers exceptionally easy installation, operation and service for supply and transfer in industrial processes.

Find out how this variable speed-controlled pump with pre-defined control modes keeps energy efficiency high and your processes in the factory effective.

CME is a reliable, quiet and compact horizontal end-suction pump with integrated frequency converter and intelligent features. The modular pump design makes it easy to make customised solutions.

Compact, reliable and flexible

A horizontal close-coupled multi-stage CME pump from Grundfos offers electronic control and energy savings. The

pump is designed to fit seamlessly with other components in small and large systems or as a stand-alone pump. CME pumps feature an integrated frequency converter, intelligent features that make installation and service easy, and an energy efficient E-drive that meets IE5 standards. Compact, modular, reliable and noiseless, the pumps are suitable for applications including washing and cleaning, temperature control, water treatment, and chemical and pharmaceutical industries.

Customisation is key

Several configuration options and a variety of materials ensure that the pump can operate in temperatures from -30 °C to 120 °C. You can also customise your CME pump with features such as oversize motors in case of higher viscosities and densities.

Versatile and safe

Available in cast iron or stainless steel, the pumps come in variants suitable for both water and non-corrosive liquids and aggressive liquids. They are also available with drinking water approvals.

A pump you can trust

Clamping of the pump impellers and washer makes the pump extremely robust and reliable.

Clever solution

Integrated frequency converter and intelligent features make installation, operation and service exceptionally easy.

Grundfos South Africa, +27 (0) 10 248 6000, lgradidge@grundfos.com, www.grundfos.com

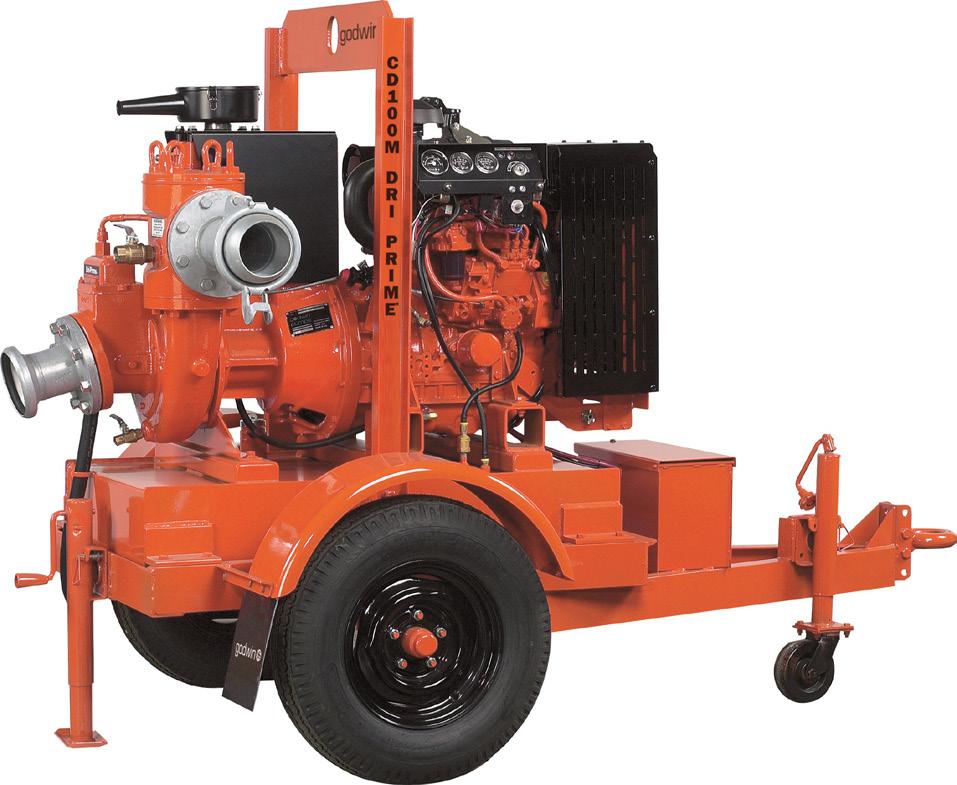

Availability of the right equipment – and the expertise to ensure ongoing performance – are proving to be important differentiators in the market for Integrated Pump Technology, as it forges further growth in Africa as a dewatering pump specialist for the mining sector.

Good stock levels are crucial in responding to customer’s urgent dewatering needs, says Jordan Marsh, Managing Director at Integrated Pump Technology – and this was once again confirmed at the latest Electra Mining Africa exhibition.

“With visitors to our exhibition stand coming from all over Africa, it was clear mining customers need a dewatering equipment partner who is responsive and has the right equipment in stock,” says Marsh. “They also need quick turnaround times on the larger diesel-powered pumps, which we can achieve with our Godwin units.”

The mining regions in which Integrated Pump Technology operates have some of the wettest mines in the world, where dewatering is essential for safe and efficient operations. With its range of Grindex submersible pumps and Godwin diesel driven pumps, the company has the depth of experience and local expertise to provide the

optimal dewatering solution.

“In one of our recent customer engagements in Zambia, we supplied suitable 90 kW pumps to a contractor who urgently needed to dewater a section of a mine,” he explains. “Due to our deliberate policy of holding extensive stock in-country, we could quickly get the units on site so that the customer could achieve their goal even quicker than they had planned.”

In addition to timeously receiving a quality solution, the customer also has the comfort of Integrated Pump Technology’s distributor’s high level of experience and knowledge of the product – which is further backed up by the company’s field staff who support its distributor network. Marsh highlights that the company’s localisation policy ensures local distributors are carefully chosen for their knowledge of customer needs, their regulatory compliance and their technical resources.

Holding good stock levels of relevant equipment is one aspect of being able to respond quickly to customers’ emergencies. Another important element is being able to put together pumps systems locally, he says.

“With our well-equipped technical facilities in South Africa, we apply our ‘local build’ approach to speed up the supply of the larger self-priming diesel pumps,” he says. “We know that mines can face lead times of 22 to 30 weeks when they order a fully-assembled pump from abroad. We can do the same job in just two to three weeks, all in accordance with original equipment manufacturer (OEM) specifications.”

The long lead times for overseas builds are often due to the

availability of diesel engines in the country of assembly, he points out. By leveraging its local partnerships with diesel engine OEMs, Integrated Pump Technology can rather source its engines in countries like South Africa. This allows the company to bring in only the wet end of the system, to conduct the assembly locally – and closer to the customer.

“With our strong technical capability, we provide the option of trailer or skid mounted diesel driven pumps,” he says. “The customer may also have a preference for a certain make of diesel engine, to suit their on-site skills set; we engage with a range of OEMs and can source various options for the customer.”

Marsh notes that similar priority is placed on the technical capabilities of its distributors, as Integrated Pump Technology regards their distributors’ in-country workshops as an extension of its own facilities. For this reason, these workshops are inspected and accredited, so servicing and repairs can be conducted to OEM standards. Skills development is also a key part of the process.

“When we appointed our distributor in Zambia, for instance, we brought the technical staff to Johannesburg for specialised training in working on our equipment,” he says. “This includes understanding the detailed procedures for stripping and repairing units, which they can practice hands-on in our facility.”

Integrated Pump Technology’s success in southern and central Africa is now opening doors for further expansion into west African countries, he adds. With the confidence of their OEM partners behind them, the company will soon be making its complete offering of Grindex and Godwin

solutions available to the mining and other sectors in this region.

Integrated Pump Technology, +27 (0) 11 894 2906, sales@pumptechnology.co.za, www.pump-technology.com

As the global water crisis intensifies and the cost of clean water escalates, efficient water usage has never been more crucial. Water, despite being one of the most vital resources, is often mismanaged, particularly in industrial applications.

However, a new wave of technological advancements is enabling industries to significantly cut their water consumption, offering the potential for near-zero water costs. By harnessing the power of cutting-edge wastewater recycling systems, businesses can now achieve sustainable water usage, even in applications typically reserved for clean water. This innovative approach integrates three key technologies, allowing industries to recycle wastewater for high-pressure applications. Here’s a breakdown of how this transformative system works in four simple steps:

Step 1: Efficient Water Collection

The process begins with the capture of used or wastewater from any underground or above-ground reservoir. A weir skimmer, connected to a Vesta air-operated double diaphragm solids-handling flap valve pump, transfers the water from the source. This robust pump is engineered to handle high-solid-content water, ensuring reliable operation even in the most demanding conditions. For challenging environments like solids separation in wastewater treatment, agriculture, food processing, and industrial applications, the Vaughan Heavy Duty Chopper Pump plays a pivotal role in pumping and conditioning liquids . Known for its CLOG-FREE GUARANTEE, this pump can shred and chop solids before pumping, preventing blockages and ensuring smooth operation, even when handling debris that would typically hinder standard pumps.

Once the water is collected, it moves to the Läckeby rotary drum screen, an advanced filtration device designed to separate solid particles from the liquid. With the capacity to handle up to 435 L/sec and perforations ranging from 0.6 to 10mm, this filtration step effectively removes all solids. The drum’s internal screw conveys these particles into a separate bin, leaving behind conditioned water that is now ready for further processing.

After filtration, the conditioned water is collected in a drum or container, making it immediately available for reuse. This crucial step closes the loop, allowing industries to dramatically reduce their reliance on fresh water by continuously recycling water that would otherwise be discarded.

The final step in the process involves the Hydra-Cell diaphragm pump, which uses the filtered water for both general and high-pressure applications, up to 310 bar and flows up to 595 l/min. This seal-less pump is designed to withstand corrosive and abrasive media, including particulates up to 0.8mm without suffering wear or damage and can even run dry indefinitely. Its durability and versatility make it ideal for a wide range of industries, including Water and Wastewater, Mining, Food & Beverage Processing, Wood, Pulp & Paper, Chemical & Petrochemical, and many more. In applications such as gland seal flush, dust suppression, pumping of hot fluids, chemicals, viscous liquids, salt water, ultrapure fluids and more.

By combining these advanced technologies, industries can now run high-pressure pumps at zero water cost, significantly reducing both water consumption and waste. As businesses strive for more sustainable practices, this compact and eco-friendly system provides a solution to one of the most pressing resource challenges of our time. This breakthrough not only benefits industries financially but also represent a major win for environmental sustainability. By reducing the need for fresh water, companies can lower their ecological footprint without sacrificing operational performance. The future of water use is here, and it’s more sustainable than ever.

Monitor Pumps & Systems, +27 11 618 3860, wim@monitorspumps.co.za, www.monitorpumps.co.za

In what is probably the most exciting development in the dewatering pump industry is the news that IPR (Integrated Pump Rental) has become part of Atlas Copco’s Specialty Rental Division within the Power Technique Business Area. Announced just ahead of Electra Mining Africa, this acquisition is expected to bring significant benefits to the mining sector.

Lee Vine, Managing Director of IPR, says the mining industry, known for its complex and demanding operations, relies heavily on effective water management solutions to ensure operational efficiency and safety.

“We have seen a shift where dewatering pumps, essential for managing water ingress and maintaining dry working conditions, are increasingly being rented with appropriate accessories,” he says. “This trend is driven by several factors that reflect the evolving needs and challenges of the mining sector and our recent acquisition by Atlas Copco will allow us to continue to grow both our geographic footprint in Africa while increasing our already comprehensive dewatering pump rental fleet.”

The company’s recent participation at Electra Mining Africa highlighted some of the pumps within its extensive range. This included Atlas Copco diesel self-priming pumps and submersible units as well as the range of Toyo heavy duty slurry pumps and IPR’s in-house designed SlurrySucker dredging unit.

“It is a fact that renting dewatering pumps offers mining companies a significant degree of flexibility,” Vine explains. “Instead of committing substantial capital to purchase equipment, companies can allocate resources more efficiently by renting dewatering pumps as needed. This approach allows for better financial planning and reduces the burden of maintenance and storage costs associated with owning dewatering equipment.”

Vine says the rental market for dewatering pumps is highly competitive, and IPR has stayed ahead of the curve by continuously updating its rental fleet to include the latest technological advancements. This, he says, means endusers benefit from access to state-of-the-art pumps that offer improved efficiency, reliability and environmental performance.

“Feedback from our customers underscores the major advantage that renting offers in terms of being able to leverage the newest technology without the need for frequent capital expenditures,” he says.

Another important advantage when renting dewatering and other pump solutions is that the mining operations can choose pumps that are tailored to the specific requirements of their projects. Whether the need is for high volume water removal, handling abrasive materials or operating in challenging conditions, IPR offers a diverse range of pump types and configurations which ensures that the most suitable equipment is selected for specific application needs.

IPR offers the market the advantage of comprehensive maintenance and support services, ensuring rented pumps and ancillary equipment remain in optimal working condition. “This reduces downtime and the risk of operational disruptions due to equipment failure,” Vine says. “Additionally, our experienced and skills team can provide valuable insights and assistance, further enhancing the efficiency of dewatering operations.”

“The ability to scale dewatering solutions up or down based on project demands is another significant advantage when renting pumps. This is important for both underground and surface mining operations, which

often face fluctuating water management needs, as they can quickly adjust their dewatering capacity by renting additional pumps or returning underutilised equipment,” he continues. This scalability ensures that mining companies can respond rapidly to changing conditions without the delays associated with procuring new equipment.

The IPR rental fleet comprises modern dewatering pumps designed to meet stringent environmental and regulatory standards. By renting newer models, mining companies can ensure compliance with environmental regulations, reducing the risk of penalties and contributing to sustainable mining practices. Advanced features such as energy-efficient motors and reduced emissions are increasingly called for, and the company can accommodate these requirements.

IPR, +27 (0) 87 759 8654, admin@pumprental.co.za, www.pumprental.co.za

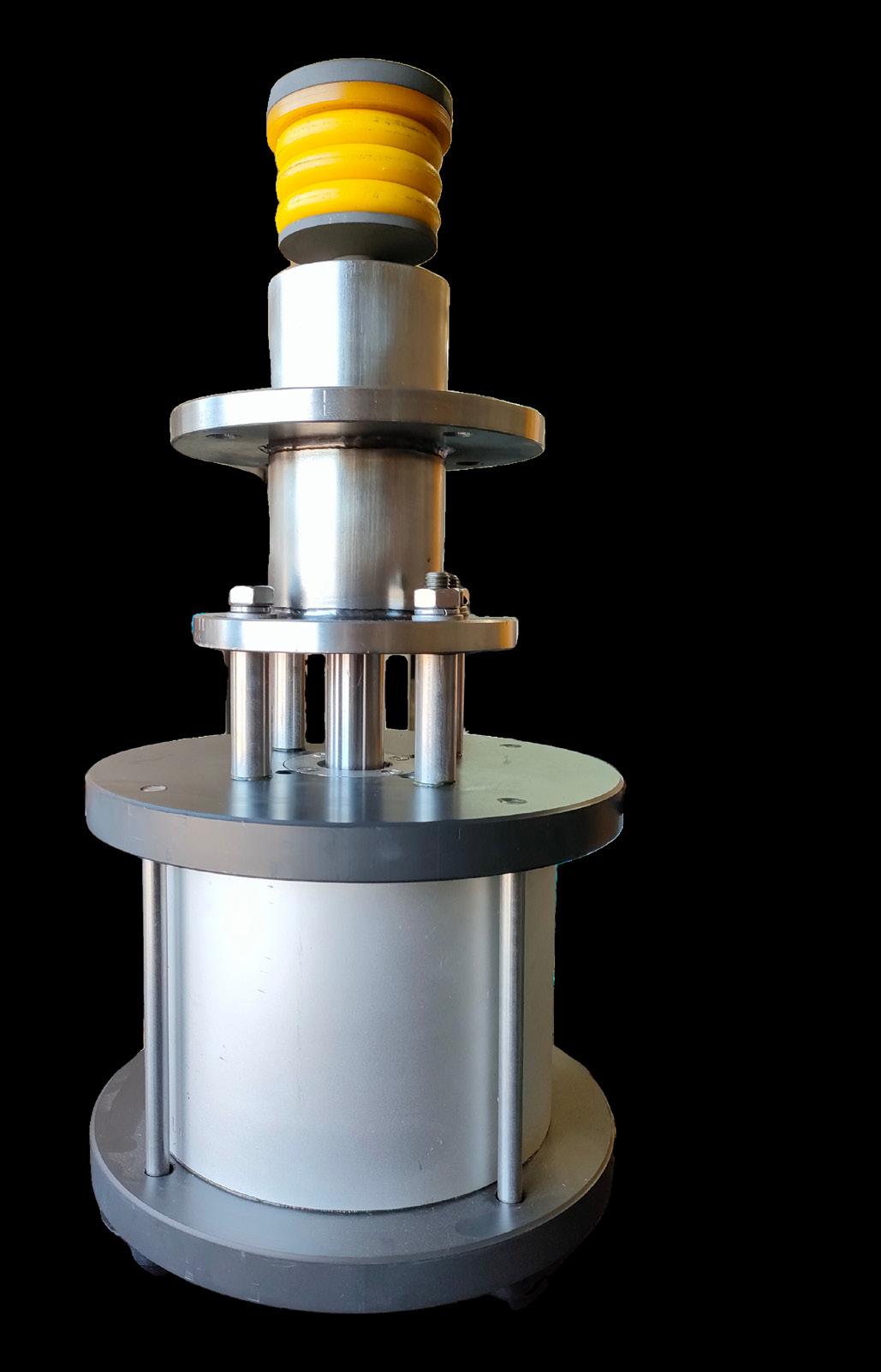

In demanding pump applications, air seals are increasingly offering a reliable solution. This innovative technology ensures reliable performance and reduced maintenance, making it ideal for applications involving abrasive slurries and coarse materials, according to Zach Nepa, Regional Manager at Sealing Equipment Products Co (SEPCO). Pipes, Pumps and Valves Africa finds out more.

“Some applications are significantly more challenging to seal than others,” says Nepa, advocating for the growing adoption of air seals, which are establishing new benchmarks in efficiency and durability—especially in equipment handling slurries and coarse materials.

“When these materials come into contact with traditional mechanical seals, they often lead to excessive wear and can even displace the seals, causing misalignment. Air seals, however, are a specialised form of mechanical seal designed to tolerate misalignment and provide effective sealing where conventional methods fall short. They work well in both dry and wet applications, from powders and bulk solids to hydro-pulpers and slurry pumps.”

Understanding the Mechanics

Nepa explains that the simplicity of air seals is one of their key advantages. “The design is quite straightforward. It’s a pneumatic seal that utilises air or gas to create an effective barrier, sealing the product efficiently.”

“From a side view, you can see how air is channelled into the seal, allowing it to build back pressure while feeding into an internal throttle,” Nepa continues, explaining the mechanics behind air seals. “The seal isn’t in contact with the shaft, which is critical. This back pressure prevents any product from escaping, effectively sealing it in.

“Air is fed into the throttle, which then distributes the air evenly around the shaft. This consistent airflow builds the

back pressure that holds back the material being sealed. Additionally, an anti-rotation pin is incorporated into the design. This allows the seal to pivot with the shaft, which is crucial in many mixing applications where shaft runout is common.”

This ability to move with the shaft is key, especially compared to traditional packing and mechanical seals. “When runout occurs with packing or mechanical seals, the shaft can press against the packing. Since packing has no memory to return to its original form, it leaves an open space that can lead to leaks. Over time, this uneven compression also creates friction points, accelerating wear and creating potential leak paths,” Nepa explains. “The flexible nature of air seals allows them to move with the shaft without causing damage, ensuring a longer-lasting, more reliable seal.”

“Air seals come in a variety of configurations, including solid, rotating, or split designs, with the split air seal being the most commonly used,” Nepa explains.

In simpler applications, solid air seals are mounted after the bearing is removed, and they work well in controlled environments. “But in real-world field conditions, installation isn’t always that straightforward,” he continues. “This is where split air seals come into play.”

The split air seal offers a clamshell design, which allows for much easier and quicker installation. “You can remove each part of the seal one by one, slide them together around the shaft, and pull everything into place. The entire process is incredibly simple and can be completed in under an hour, significantly reducing downtime,” Nepa notes. This ease of installation is a major advantage, especially for industries where equipment availability is critical.

Air seals are also highly customisable, designed to meet the needs of specific applications. “Take hydropulpers in paper mills, for instance,” Nepa continues. “These vertical applications face enormous pressure from paper stock, which can be highly abrasive and full of contaminants. In these cases, the air seal mounts to the bottom of the stuffing box, providing a bottom-entry solution. We can adapt the seal to prevent contaminants from entering the sealing area, ensuring the longevity and effectiveness of the seal even in such challenging environments.” This adaptability makes air seals a versatile and reliable solution across a wide range of industries where traditional sealing methods struggle to perform. One of the critical features of air seals is their ability to withstand extreme temperatures. While materials are typically adjusted to function within

a 500-degree range, innovative solutions have emerged to accommodate temperatures up to 850 degrees. This capacity allows for their use in high-temperature applications without sacrificing performance.

To ensure the proper installation and function of an air seal, there are several critical steps to follow, says Nepa. “Before beginning, make sure that all machine surfaces are free from contamination, dirt, and burrs. This ensures a smooth installation and prevents any damage or interference with the seal’s performance.” He also advises against overtightening bolts, saying this can lead to misalignment and damage the seal, while it is also crucial to keep the internal components of the system free of any sealant, grease, or lubricants.

According to Nepa, air seals are particularly valuable in the mining industry, where they are employed to seal slurries such as copper concentrates. These seals prevent leakage, thereby safeguarding downstream equipment from the cascading effects of seal failure. “With traditional contact seals, equipment often experiences wear and requires ongoing maintenance. In contrast, air seals offer a ‘set it and forget it’ solution, remaining operational throughout the life of the equipment.”

Nepa points out that even during washdowns and planned stoppages, air seals can continue to function effectively. This capability reduces the need for frequent maintenance and ensures ongoing protection of the equipment. “The design of air seals prioritises reliability and durability, allowing them to withstand the rigours of demanding applications,” he says.

The new Godwin Rig Pump tackles the hazards, damage, and costs of mining, tunnelling, and quarry dewatering applications. Dewatering is one of the most hazardous tasks when mining, quarrying, or tunnelling.

Personnel such as drill operators are exposed to risk as they enter drilling and blasting areas to prime or move dewatering pumps, avoid trailing electrical cables in wet and obscured conditions, and navigate other hazards.

Dewatering pumps also need frequent attention. They must move often to avoid damage from rock falls or blast zones, and they incur heavy wear from ingesting large objects and shotcrete residue. All these factors add to frequent maintenance, component replacement, and manual interventions—especially for priming and snoring.

Safe, reliable, and efficient dewatering

Xylem has developed the Godwin Rig Pump to tackle these specific dewatering challenges. This self-priming pump system solves the toughest dewatering challenges in mining by seamlessly integrating with drilling rigs and using state-of-the-art technology. The pump sits at the back of a drilling rig and can be controlled directly from the rig’s cabin. The suction section and front pipe sit near the drilling face, removing the need for a submersible pump. The electric cables remain with the rig and away from the active drilling area or trailing behind the rig.

The Godwin Rig Pump can operate in intermittent flows, avoiding the high wear caused by snoring. It has the unique ability to run dry indefinitely, thanks to its liquid oil bath mechanical seal, solid silicon carbide rotating and stationary elements, and high-abrasion resistant faces.

This pump is equipped with a hard-iron Flygt NC non-clog impeller, enabling it to handle troublesome shotcrete fibres, and the pipeline uses a pan strainer to manage large objects and other clogging hazards.

It incorporates a non-return valve to protect the pump’s prime and avoid problems such as water hammer pressure surges.

Built to last under the harshest conditions, the Godwin Rig Pump sets the benchmark for mine, quarry, and tunnel dewatering:

● Suction connection: 100mm (4in) flange

● Delivery connection: 80mm (3in) flange

● Max capacity: 160 m³/hr (44l/s) (705 USGPM)

● Max impeller diameter: 214mm

● Max operating temperature: 80ºC (176ºF)

● Max pressure: 7 Bar (101 psi)

● Max suction pressure: 2.8 Bar (40 psi)

● Max casing pressure: 10.5 Bar (152 psi)

● Max operating speed: 3560 rpm

The next generation of dewatering pumps, now in Africa Xylem’s Godwin Rig Pump has proven its strength in several major mining markets and is now available to African operators.

Mines, quarries, and anyone with extreme dewatering requirements can integrate these new, easy-to-move compact pump systems that improve performance and reduce site risks.

“Underground and quarry dewatering is very hazardous work, and it’s also very hard on dewatering pumps. Our designers and engineers looked closely at the specific issues that hamper traditional pumps, and worked with our extensive field experience to develop a next-generation dewatering pump that addresses those issues.

The Godwin Rig Pump is not simply a new dewatering solution. It’s superior in every way to previous options, improving safety, performance, efficiency, and lifetime value,” says Chetan Mistry, Strategy and Marketing Manager at Xylem Africa.

The Godwin Rig Pump provides faster and longer drilling without downtime while lowering costs, with anti-clogging features, dry-run protection, and a non-return valve to significantly reduce pump wear and damage. Compact and designed for rig operations, it reduces hazard risks from accessing the drill area or managing electrical trailing cables.

Xylem, makingwaves@xyleminc.com, www.xylem.com

In the world of pump technology, Seoca has positioned itself as a leader by offering a range of solutions that emphasize durability, reliability, and efficiency. Among its wide selection of products, vertical multistage pumps have become a standout choice for various applications, from residential water supply to industrial operations.

Alongside Seoca’s other pump options—including horizontal multistage pumps, submersible drainage pumps, submersible sewage pumps, plastic submersible pumps, and hot water circulator pumps—these vertical pumps are built on proven technology and constructed with superior materials, ensuring long-lasting performance and low cost of ownership.

Vertical multistage pumps: compact, reliable, and efficient

Vertical multistage pumps are designed to deliver highpressure water in a compact form, making them ideal for installations with limited space. Their vertical design minimizes the footprint while maximizing output, making them perfect for high-rise buildings, commercial facilities, and industrial operations that require high-pressure water handling. In these settings, their ability to operate efficiently and reliably under demanding conditions makes them a preferred choice.

Seoca’s vertical multistage pumps are built with premium materials, ensuring resistance to wear and tear, even when handling corrosive fluids or fluctuating temperatures. This robust construction extends the pump’s service life, reducing the need for frequent maintenance and minimizing long-term costs. Their multi-stage design allows water to pass through several impellers, boosting pressure at each stage and ensuring consistent performance across a wide range of applications.

Industry standard dimensions for easy replacement

One of the key benefits of Seoca’s vertical multistage pumps is their adherence to industry-standard dimensions. This design feature simplifies the replacement of pumps

from other manufacturers, making it easier for businesses and homeowners to upgrade or switch without extensive system modifications. Whether you’re replacing an outdated pump or upgrading to a more efficient model, Seoca’s pumps provide an easy-to-integrate solution, reducing downtime and installation costs.

While Seoca’s vertical multistage pumps stand out, the company’s full range of pumping solutions covers diverse needs.

• Horizontal multistage pumps are ideal for applications that require large volumes of water to be moved over longer distances, commonly used in irrigation, water transfer, and booster systems.

• Submersible drainage pumps and submersible sewage pumps are designed for tough environments where water and wastewater need to be effectively managed. Built to operate underwater, these pumps offer reliable performance in flood control, drainage systems, and sewage management.

• Hot water circulator pumps ensure efficient heat distribution in HVAC systems, contributing to both comfort and energy savings by maintaining the ideal water temperature in heating systems.

Beyond the pumps’ physical reliability, Seoca offers an advanced level of control and protection that enhances their usability and efficiency. With variable speed drive options and effortless pump control, Seoca allows users to easily adjust pump settings with the press of a button. This innovation means you can quickly and precisely tailor the pump’s performance to your specific pressure and system needs, whether for a small residential setup or a largescale commercial installation.

The ability to customize settings on demand ensures energy efficiency by reducing unnecessary pump strain, thus lowering operational costs. This feature is especially valuable in today’s eco-conscious market, where energy savings and operational sustainability are key considerations. By optimizing pump performance, users can enjoy a reliable and consistent water supply while minimizing energy consumption and costs.

Monitor Pumps & Systems, +27 (0) 11 618 3860, wim@monitorpumps.co.za, www.monitorpumps.co.za

IFAT Africa, sub-Saharan Africa’s ultimate showcase of technologies and solutions for water, sewage, refuse and recycling, will be back in South Africa from 8 - 10 July 2025. IFAT Africa is part of a worldwide series of events, including IFAT Germany, IFAT Eurasia, IFAT India, IE expo China and IFAT Brasil.

Organised by Messe Muenchen India and Messe München GmbH, IFAT Africa will be staged at Gallagher Convention Centre in Midrand, and co-located with analytica Lab Africa, the only trade show in South Africa for the laboratory technology, analysis, biotechnology and diagnostics sectors. This strategic co-location brings together hundreds of brands and up to 8,000 international stakeholders across a broad and synergistic value chain including water and waste, recycling, environmental technologies, laboratory technologies, analysis, biotechnology and diagnostics for three days of discovery and networking.

Featuring an exhibition of leading brands and solutions, as well as a strong supporting programme, IFAT Africa covers trends and technologies for water extraction and treatment; wells; process-water and rainwater harvesting; seawater desalination; irrigation and drainage; water and sewage treatment; treatment of sludge and residues; refuse disposal, treatment and recycling; road cleaning

and maintenance machines; treatment and disposal of hazardous waste, medical waste and electronic waste; environment management and services; and energy generation solutions including biogas and landfill gas technologies.

Bhupinder Singh, CEO of Messe Muenchen India, says the last edition of IFAT Africa, presented in 2023, drew interest from around the world, with international pavilions and a strong focus on sustainable development, a circular economy, waste management and localised R&D.

“In 2025, IFAT Africa will again highlight the top emerging trends and most pressing issues in the sector,” he says. Sponsorship and exhibitor packages are now available.

IFAT Africa, betty@blueberryconcepts.co.za, ifat-africa.com

A private sector collaboration among residents, companies, Nama Koi Municipality, and KSB Pumps and Valves (PTY) LTD to restore water supply to parts of the Nama Koi municipality brings desperate relief to the affected residents.

South Africa’s water infrastructure faces increasing pressure from ageing infrastructure climate challenges and budget constraints the Northern Cape municipality was experiencing challenges with regards to the pump repair. This is when local pump supplier, KSB Pumps and Valves, a major supplier of pumps and equipment for water infrastructure, played a pivotal role to alleviate the problem by donating an Etanorm pump to the Nama Khoi Municipality.

According to KSB Pumps and Valves’ Upington branch manager, Andre Jonker, the donation was part of a collaborative project to restore the Overberg potable water pump station after a pump failure and other issues caused the station to nearly grind to a halt. The remaining pump had been struggling to operate at full capacity, leading to water shortages across the community.

The pump donated, a KSB Etanorm pump, the flagship of the local pump manufacturer, is renowned for its efficiency, reliability and ability to handle a wide range of applications, including drinking water supply. The pumps designed for longevity and energy-saving due to their high efficiency and have proven to be a versatile solution for municipalities across the country.

“The donation of the pump not only restored water services but also ensured a more durable and energyefficient solution which will benefit the community for years to come. This joint effort highlights the power of collaboration between local businesses and municipal authorities. Several companies and experts joined forces with municipal experts to bring the pump station back online. It is an admirable achievement considering that all parties contributed their time, resources and expertise at no cost,” says Andre.

Following the successful restoration of water services, Mayor Rodney Kritzinger expressed his heartfelt gratitude

and acknowledged the joint efforts had saved the municipality a considerable amount.

“On behalf of the residents the Nama Khoi Mayor would like to express his sincere thanks to all the role players who helped save almost R1 million by applying their expertise and businesses to get the Overberg pumping station up and running again.”

The Mayor also extended special thanks to the following individuals and businesses:

• Abri van Niekerk and Tiaan van den Heever of Novatec for supplying and installing a new panel.

• Thinus van Schalkwyk and his team from Copper 360 for repairing the pump’s axles and supplying a new impeller.

• Kobus Zandberg for his organizational support.

• Nico Moore of Springbok Motor Rewinds for rebuilding critical components.

• Andre Jonker, Martin Fourie and the Management team from KSB Pumps and Valves for their donation of the KSB Etanorm pump, which was vital to the project.

Andre added that the restoration of the Nama Khoi pump station exemplifies how public-private partnerships can solve critical infrastructure challenges in South Africa. The stakeholders demonstrated leadership and commitment to the communities they serve. The initiative not only resolved an immediate crisis but also underscored the importance of long-term solutions to South Africa’s water infrastructure needs. “We are proud that KSB Pumps and Valves continues to play a vital role in safeguarding South Africa’s most precious resource—water.”

KSB Pumps and Valves, +27 (0) 11 876 5600, support.za@ksb.com, www.ksb.com

When was the last time you checked your hotel’s pump system? By upgrading to Grundfos intelligent and energy-efficient HVAC and water systems, you can save between 20% and 50%* in energy use.

Whether it’s a shower that takes too long to heat up, an unbalanced system that causes water hammering in the system, or an AC system that doesn’t work as expected, dealing with guest complaints is never high up on anyone’s to-do list. By switching to solutions and services designed to make your systems perform better for longer, you can save time handling grievances – so you can focus on other areas of operation.

Our intelligent, energy-efficient pumps, controllers, and converters have been designed to bring synergy to your systems so you can take more control over processes and spot and handle issues before they escalate.

And with access to our digital hub, we’ve made it even easier to store and analyse data so you can gain more insight into your applications and see where improvements need to be made. For a system that will make sure your guests receive the care they deserve. 24/7.

Intelligent, demand-driven pump solutions for highcomfort and low-carbon hospitality experiences. Unlocking water and energy efficient solutions in hospitality, without compromising comfort. Intelligent pump solutions for more sustainable hospitality buildings. Let’s energise tomorrow. The hospitality industry is changing drastically. It’s clear that energy use and carbon emissions need to be reduced before we run out of time in the fight against climate change.

Another key factor is consumer demand. 69%1 of travellers seek more sustainable travel options, and 71%2 are committed to eco-conscious choices. The challenge is that the current installed base in many hotels consists of inefficient solutions that operate manually without the possibility of optimising or improving control. To make sure all guests are provided complete comfort at all times, vast

amounts of CO2 are emitted and water is used excessively. The hospitality industry must accelerate its journey towards greater sustainability and energy efficiency to remain relevant and prepared for a changing world Fortunately, most of the technologies and solutions that can help us transform the hospitality industry already exist – and we at Grundfos are ready to make this a reality.

We are the strategic partner that can assist hotels and building owners achieve more intelligent and sustainable buildings that meet the increasing demands of today’s and tomorrow’s guests. And the demands of our planet.

Together, we want to create HVAC systems that use less energy to create better guest comfort – while reducing carbon emissions and energy use. And we’ll make sure you save OPEX and lifetime costs at the same time.

Grundfos South Africa, +27 (0) 10 248 6000, lgradidge@grundfos.com, www.grundfos.com

Did you know that a Hidrostal IPS SuperBetsy can drain a full bathtub in just one second? This mobile pump, equipped with the high-performance vacuum system BetsyPrime, stands out for its excellent performance, clog-free operation, and its ecofriendly, low-maintenance design.

The Independent Pumping System (IPS) SuperBetsy is a versatile solution, perfectly suited for semi-permanent or mobile applications such as dewatering, drainage, and flood control. Its clog-free design with a free passage of 75-120 mm, combined with an innovative hood and highly efficient, fuel-saving engines, makes it ideal for the toughest conditions. Outfitted with BetsyPrime and Intelligent Control, the SuperBetsy guarantees reliable operation. Available in sizes with flow rates ranging from 28-300 l/s, it also offers advanced monitoring, control, and GPS options.

• Renovation work on sewage pipes: SuperBetsy is used for drainage or sewerage work

• Bentonite at flow drilling: Removal of bentonite fluid for recycling purposes

• Wet well pumping: Versatile applications, including irrigation, flood defense, cooling water, surface and stormwater management, docks dewatering, and land drainage

• Dewatering to reservoirs or filter bags: Sludge or sediment filtering with filter bags or storage of temporary water supply for firefighting

Recently, the mobile SuperBetsy pump made a grand appearance during the Hidrostal roadshow in Austria, captivating representatives from municipalities, wastewater associations, environmental agencies, and fire departments alike.

During live demonstrations at RHV Salzburg and GAV

Krems, participants witnessed firsthand the versatility and powerful performance of the SuperBetsy. Whether used for tank bypasses during sewage plant renovations or emergency flood relief, the SuperBetsy showcased its robust capabilities in various real-life scenarios.

One of the key highlights of the roadshow was the SuperBetsy’s flexibility, power, energy savings and ease of transport, easily moved via trailer.

Matthias Hirsch, Head of SuperBetsy at Hidrostal, explained the pump’s key advantages:

“Equipped with a screw centrifugal impeller, SuperBetsy boasts a large free passage for solids. This, combined with the unique impeller design, ensures maximum resistance to clogging and exceptional efficiency. Whether handling viscous or challenging liquids like bentonite, raw sewage, fibrous materials, or liquids with a high solid content, the SuperBetsy performs effortlessly. Over the course of continuous operation, it delivers more than 60% savings in operational costs compared to other systems. That’s a significant financial saving over its entire service life.”

A mobile pump that convinces

Everyone agreed – the SuperBetsy is a mobile pumping system that truly delivers.

Hidrostal Pumpenbau GmbH, matthias.hirsch@hidrostal.com, www.hidrostal.com

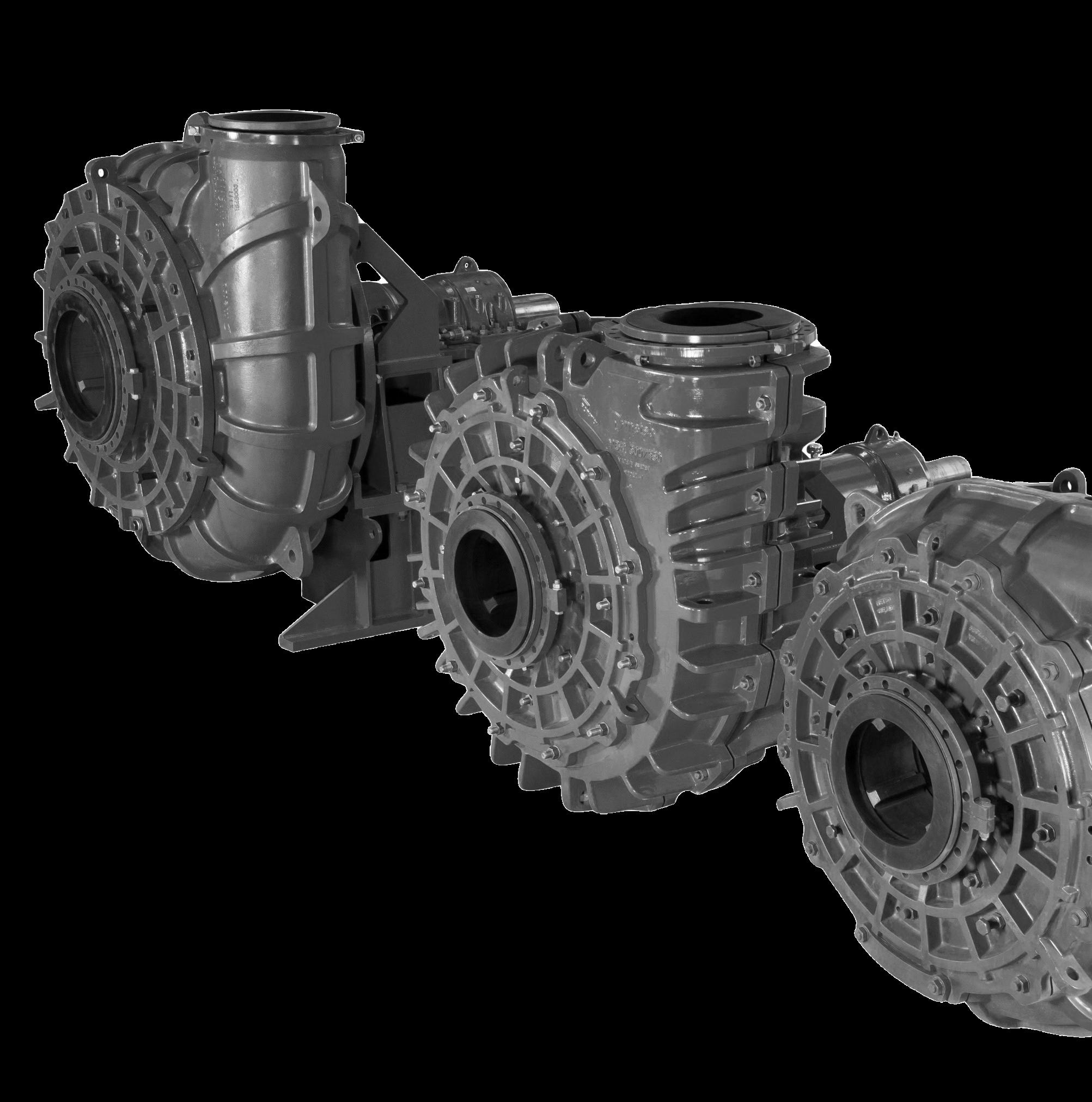

Zimbabwean mine with a monthly gold production of approximately 250 kg and proven reserves totaling 2.4 million tons faced significant challenges related to pump wear, maintenance, and overall plant availability.

Metso stepped in with a solution that not only addressed these issues but also revolutionized their gold production process.

The customer, whose mine is located in Zimbabwe, plays a pivotal role in the mining industry. Their existing mill

discharge pump suffered from high wear rates in its wetend components, and lacked technical support and spare parts availability, resulting in frequent stoppages.

These operational hurdles increased overhead costs, negatively impacted plant availability and limited overall production efficiency. Metso recognized this as an opportunity to enhance the customer’s gold production process.

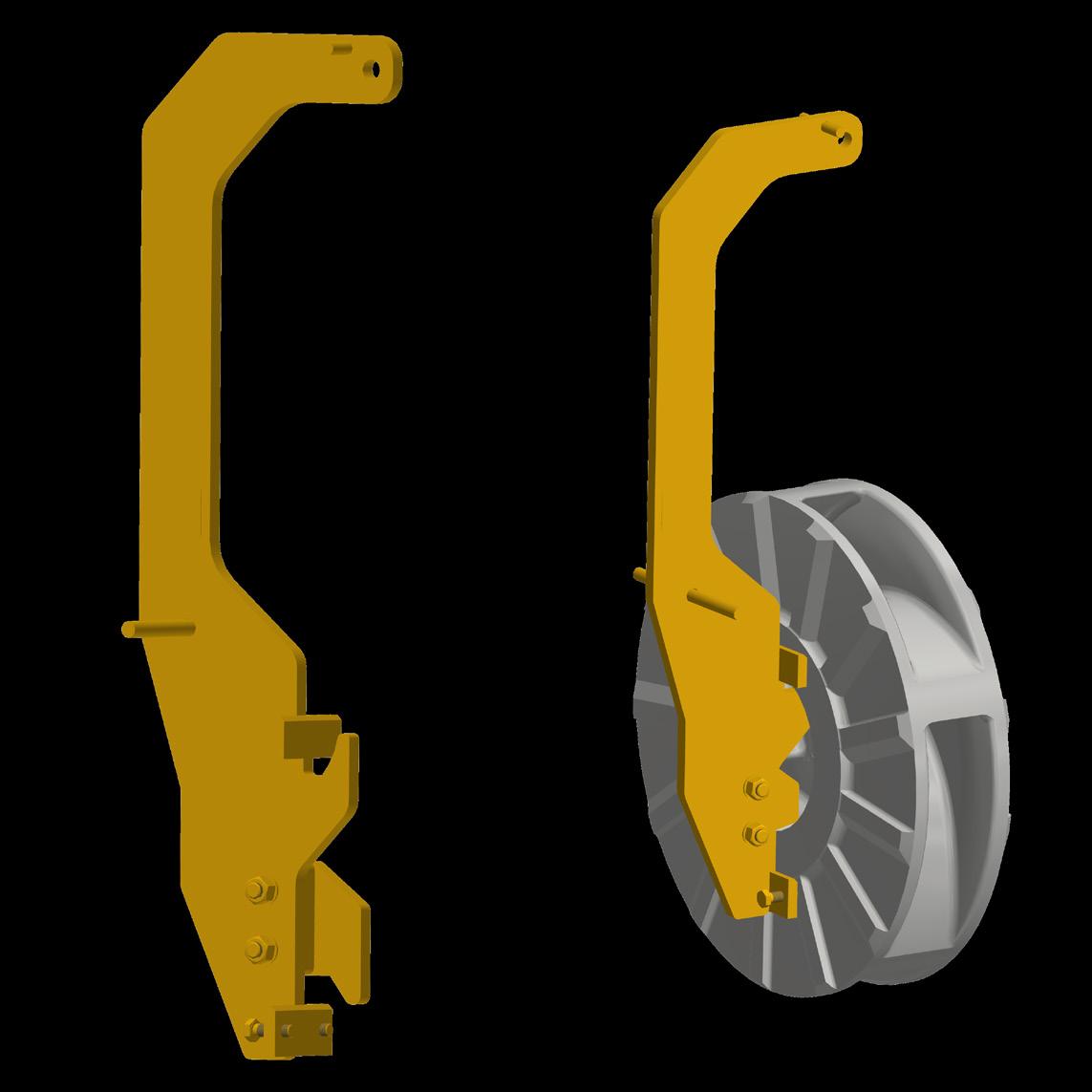

Metso’s experts proposed the customer a solution to introduce the new MDR250 pump, specifically designed for mill discharge applications.

The ongoing trial period for the pump spans for six months, with the end date set for October 2024.

The pump offers a remarkable 6-month lifespan for wet-end parts, significantly reducing the need for replacements.

Operating at a lower pump speed (595 rpm), it is

able to achieve the required cyclone pressure while minimizing energy consumption. Special tools, including an inlet door, an impeller lifter and a shaft handler, help facilitate safe and efficient maintenance.

Achieving a flowrate of 650 m³/h with a Total Dynamic Head of 33 m and cyclone feed pressure of 0.5 bar at a lower pump speed has showcased Metso’s industry expertise.

Improved mill circuit performance and reduced downtime

The customer embraced Metso’s solution that led to significant improvements in performance, such as reduced pump stoppages and maintenance resulting to reduced downtime, lower energy consumption, decreased wear parts inventory, as well as enhanced safety and sustainability. The implementation of the MDR250 pump

yielded stable cyclone efficiency operation pressure between 0.45-0.55, improving separation performance at a lower pump speed. Remarkably, there was no wear on the pump wet-end parts and slurry hose within the first three months of the trial period.

During this period, the mine produced 126,227 tons of ore and the pump operated for 1,449 hours.

Metso’s goal is to replace competitor pumps after the trial period concludes and future business opportunities with the customer include MD pumps, slurry hoses and cluster cyclones.

Metso continues to support growth and efficiency goals and be the partner of positive change.

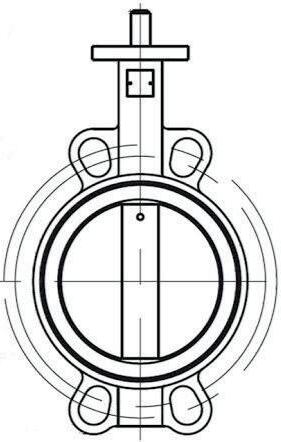

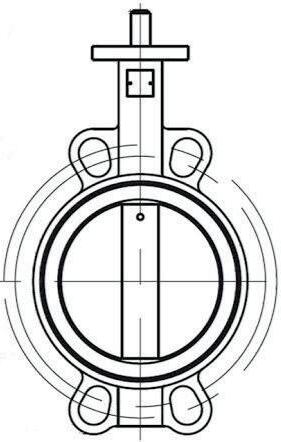

BMG delivers state-of-the-art valve solutions to diverse industries across Africa, in collaboration with InterApp – global leaders in the design and manufacture of highquality valves.

“Our shared commitment to quality, innovation and customer service ensures that we provide the best possible flow control products to our customers, helping them optimise their operations, enhance safety and minimise downtime,” states Susan Victor, Sales Manager, BMG’s Fluid Technology division. “BMG, which celebrates 50 years of business this year has established an extensive distribution network and this footprint, enhanced by in-depth market knowledge, makes us the ideal partner to bring InterApp’s valve solutions to the African market. In today’s industrial sector, the need for reliable, high-performance flow control solutions is more critical than ever.

“BMG’s skilled engineers and technical support teams work closely with customers to ensure selection of the appropriate flow control products for each specific application. Use of the correct valve ensures precise control, operational efficiency, reduced downtime, improved safety and extended service life.

“Through close teamwork, BMG and InterApp offer a comprehensive range of valve products for use in demanding conditions. These industries include the oil and gas sector, where high-pressure valves are critical to operational safety and in mining operations that require

corrosion-resistant valves to efficiently manage the flow of abrasive and chemical-laden fluids.

“Embracing advanced valve technology enhances seamless operations and reduces costly downtimes in all sectors, including food and beverage facilities, pharmaceutical production, water treatment and mining.”

“Looking ahead, InterApp and BMG specialists are committed to providing the African market with advanced solutions by driving continuous innovation in valve technology. We are committed to ensuring that the local market has access to the best-performing products available, supported by dependable technical expertise.”

Key products in BMG’s InterApp range are Desponia® and Bianca® butterfly valves, which are designed to handle corrosive fluids, extreme temperatures and fluctuating pressures.

These valves feature high-performance linings and coatings, ensuring longer lifespans and fewer maintenance cycles and are suitable for sectors including water and wastewater treatment, where durability and efficiency are critical.

Robust Bianca butterfly valves are designed for dependable shut-off and control of corrosive fluids, as well as highpurity applications.

Compact butterfly valves, with good flow characteristics and low maintenance requirements, are extremely versatile and ensure dependable operation, even in the toughest environments.

BMG’s InterApp Bianca centric butterfly valves, with durable PTFE liners, are built for long service-life and are suitable for aggressive and corrosive fluids and for applications where absolute purity is essential.

BMG’s multi-purpose InterApp Desponia and Desponia Plus centric butterfly valves, with a tough body and robust elastomer liners, are designed for safe and reliable regulation of liquids and gases in diverse sectors.

Desponia valves, which are available in sizes from DN 25 to DN 1600 and pressures up to 16 bar, are suitable for various industrial applications. This range can be supplied with a cast iron and ductile iron body.

The Desponia Plus range comes in sizes between DN 25 and DN600, with high-pressure applications up to 20 bar and is suitable for high-temperature or vacuum applications, as well as process automation.

This range is available with a body made of ductile iron,

cast iron or Stainless Steel. The liners and discs of this series play a crucial role in elastomer-lined butterfly valves, as they are the only two parts that are in contact with the fluid. Flucast® liners are suitable for abrasive applications and also meet FDA and EU regulations.

Notable features of this range include an external shaft sealing mechanism which protects the valve neck hole and a long neck design that allows pipe insulation. A retaining washer offers blow-out protection and O-rings that are built in the shaft passage, form part of the reliable shaft sealing system. Sealing lips on the flange face offer perfect tightness and the optimised liner shape ensures a precise grip to the body. The square driven disc offers effective and durable torque transmission and polished disc edges minimise friction.

The Desponia range ensures safe operation in water treatment processes, as well as in power generation and for demanding chemical processing applications. These valves can also withstand operation in the steel industry, where shut-off valves used to gas molten steel are exposed to harsh conditions. Valves with specially-coated discs offer high abrasion and corrosion-resistance, making them suitable for use in extraction processes in mining and slurries.

BMG’s Fluid Technology division supplies and supports an extensive range of components for fluid technology systems and general industrial applications.

These products include valves, hydraulic hoses and fittings, accumulators, cylinders, heat exchangers, hydraulic motors

and hydraulic plumbing, as well as pumps and reservoir accessories.

Fluid technology services also cover project engineering and consulting, cylinder design and manufacture, training, repair and testing, as well as on-site container services. BMG also offers total process and lubrication management solutions throughout Africa.

BMG, +27 11 620 1500, markb@bmgworld.net, www.bmgworld.net

Digital automation helps production run smoothly, precisely, reliably, and protects against unexpected system downtime. This also means that it significantly enhances the competitiveness of the user and helps conserve resources. Data is becoming the new currency of economy and ecology, especially in challenging times like these.

Sensors and measurement technologies collect data from valves and actuators, which is then evaluated to answer the question of whether an automated process is running efficiently.

For example, actuators automatically collect and store process data such as valve position, valve operations, ambient temperature and vibration. The digitally

recorded data allows the plant operator to identify where maintenance is required. Corrective measures can be initiated in good time, avoiding unexpected breakdowns.

Big things in store for the industry

However, digitally driven automation doesn’t only lead to optimised processes, reduced material usage and energy savings; it is also a promising strategy to combat the increasing shortage of skilled labour. From this point of view, the valve industry is providing valuable services, as it makes plant operators fit for the digital age.

But digitalisation is by no means the final chapter in the development of automation. In the future, artificial intelligence will have an increasing impact on processes. It will control systems, without human decision. Machines reacting to machines. There are exciting times ahead for plant operators and the valve industry!

VALVE WORLD EXPO, HartmannP@messe-duesseldorf.de, www.valveworldexpo.com

At AVK Valves Southern Africa, selecting the ideal solution for your application requirements is straightforward. The company emphasises that the correct quality valve ensures long-lasting durability and reliability.

Valve manufacturer AVK made a significant mark in the industry with the introduction of its first gate valve for water in 1969. Just eight years later, the company achieved prestigious European approvals, solidifying its reputation. With over 30 years of experience in the South African valve industry, AVK Valves Southern Africa has established itself as a leader in manufacturing custom-designed valves that meet the highest standards of quality, reliability, durability, safety, and value. “We offer a comprehensive range of gate valves, all backed by quality approvals from leading national and international testing authorities,” said a spokesman for the company. “Our unwavering commitment to high-quality production, continuous product development and improvement has earned us recognition and trust from customers worldwide.”

In line with its commitment to delivering enhanced value to customers, AVK Valves SA has established itself as a manufacturer of choice. The company has introduced a comprehensive range of resilient seated gate valves into the local market, primarily addressing the need to:

• Reduce the number of time-consuming and often awkward mechanical connections, improving installation efficiency.

• Minimise the number of mechanical joints, thereby

decreasing the risk of potential leak paths.

•Simplify assembly by reducing the number of subcomponents, which lowers the need stocking multiple stock items for maintenance purposes.

• Decrease the carbon footprint in our manufacturing processes to support CO2 reduction objectives.

According to the spokesman, the AVK RSV valve is a resilient seated gate valve engineered to meet the highest international standards for drinking water, treated wastewater and other neutral fluids. “This valve stands out as the most reliable and durable choice, featuring a 100% drop-tight resilient seal that can withstand temperatures up to 70⁰C. It incorporates a triple safety stem seal, effectively preventing leakage past the stem throughout the valve’s lifetime.” With rigorous quality assurance, the AVK RSV valve is fully tested to exceed national standards for durability, health, safety and product integrity. It is SANS 664 certified and features a fusion-bonded, pinholefree Non-toxic approved epoxy coating that ensures both durability and compliance with safe drinking water regulations.

“Customers can operate with confidence, thanks to our product designs in accordance with various international standards and engineering best practices. The wedges are

manufactured to exacting standards using rubber produced in AVK’s own Gummi rubber manufacturing facility,” said the spokesman.

Additionally, AVK products are type tested during the design phase to ensure they meet the standard criteria for strength, operation, and endurance. During assembly, the products are subject to dimensional and visual inspections, and a series of production tests in line with standards requirements.

Key advantages

The AVK RSV valve is meticulously designed to ensure zero leakage past the stem throughout its life expectancy, providing peace of mind for users. It offers versatile installation options, as it can be installed in both horizontal and vertical (up to including DN300) orientations, making it adaptable to various applications.

Additionally, the valve is available for buried service, featuring bonnet fasteners that are specially protected from fluids and the ingress of sand when installed underground. This design enhances the valve’s longevity and reliability.

With low maintenance requirements, the AVK RSV valve significantly reduces the cost of ownership, ensuring that customers benefit from a dependable solution that is both efficient and economical.

Unlike most manufacturers of resilient seated gate valves, AVK boasts its own in-house rubber factory, AVK Gummi, which produces all the rubber components needed for its valves. AVK Gummi specialises in developing and manufacturing high-performance, quality rubber components used in AVK RSV gate valves. These valves come in a variety of sizes, pressure ratings and end connections, making them easy to install and operate.

The AVK RSV gate valve is particularly well-suited for applications that demand longevity and reliability, where the wedge remains fully open or fully closed for extended periods.

AVK’s solutions provide peace of mind by significantly reducing the risk of unforeseen outages and breakages.

“If you’re unsure which type of valve is best suited for your needs, please reach out to consult with one of our professional AVK Product Specialists. They will guide you effortlessly through the selection process, ensuring you choose the optimal valve solution for your plant or installation requirements,” said the spokesman. “AVK really is the ultimate choice for longevity, durability, reliability, safety and reduced cost of ownership.”

AVK Valves Southern Africa, +27 11 908 3760, sales@avkvalves.co.za, www.avkvalves.co.za

Wastewater lift stations serve as the backbone of municipal sewage systems, quietly ensuring the seamless movement of wastewater from lower to higher elevations where gravity alone proves insufficient.

Despite their crucial role, these stations grapple with a persistent nemesis: grease buildup. This accumulation poses a significant threat, causing operational disruptions and environmental risks when left unattended.

Historically, lift station operators have turned to chemical treatments as the primary means of managing grease buildup. However, while effective to some extent, these methods carry inherent drawbacks. Environmental concerns, regulatory compliance issues, and the ongoing operational expenses associated with chemical treatments have spurred the quest for more sustainable alternatives.

However, a new technology offers hope for water managers in search of options. The HydraForce Lift Station Agitator, produced by Kasco, offers a transformative approach to grease management, harnessing the power of movement and agitation to combat buildup effectively. By eschewing chemical interventions, HydraForce mitigates environmental impact while alleviating regulatory burdens and reducing long-term operational costs.

Over the past year, HydraForce has been tested in four U.S. communities – and the results have been promising.

Farmers branch: a greasy situation transformed

In Farmers Branch, Texas, Director of Public Works James Ryan Sartor faced mounting grease issues amid rapid urban development. A sustainable remedy was needed.

“We had to upgrade to handle the increased flows,” said Sartor, “and as these new additions to the city were being occupied, we noticed the lift station was developing

a grease issue.” Sartor had recently learned about HydraForce from Axis Construction, a partner organization. Recognizing the need for change, Sartor decided to try the mixing system as an experimental solution.

“After examining its design and construction,” he said, “I talked with Axis about installing the device in a lift station wet well for grease remediation.”

The implementation of the HydraForce Lift Station Agitator yielded transformative outcomes. “By early May, we started to experience amazing results,” Sartor recalled. “The station was staying very clean, the water was clearer, and there was far less odor.” The agitator’s ability to mix and agitate the F.O.G. – fat, oil and grease –proved instrumental in preventing accumulation, ensuring uninterrupted lift station performance.

Moreover, Sartor highlighted the significant cost savings and operational efficiencies achieved by using HydraForce. “Our chemical treatments had been costing us thousands of dollars a year,” he remarked. “We now perform our standard weekly inspections of this site and have yet to experience a need for grease removal since installation.”

Rockwall: From “matting” to maintenance ease

Rockwall, Texas, also confronted enduring issues with grease buildup in its lift stations.

Shon Bellah, Production Technical Supervisor for the city, described the problem of “matting” – fat that congeals in a layer on the surface of wastewater in tanks. The fatty “mats,” which can be several feet thick, pose a severe

clogging risk for water treatment facilities. And they are extremely difficult to remove.

Bellah also opted to try HydraForce as a preventive force against grease development. He noticed an impact immediately.

“Before HydraForce,” he said, “we would treat our sewage with chemicals like Alkegen, and even then we had to vac the matting out every Friday. Not only did we have to pay for the chemicals, there were a lot of additional related time and human costs. It would take four or five people probably two to three hours of work to bring in the utility truck, vac the stuff out, dump it and wash it. But when we got the aeration device in, it helped out a lot.”

Bellah noted agitating the water to eliminate greasing reduced manual labor and enhanced operational efficiency. In fact, the implementation of HydraForce revolutionized Rockwall’s lift station maintenance practices. Bellah highlighted a significant reduction in the need for the weekly cleanings that had previously consumed those valuable resources. He explained, “We installed the HydraForce in September of 2022, and since then, we haven’t needed to vac the system at all. In fact, the first time was vacced it was just this past month – February of 2024. It’s been good, to say the least.”

HydraForce not only alleviated the burden of manual labor but also freed personnel to focus on other essential tasks, streamlining operations and optimizing resource allocation within Rockwall’s wastewater management framework.

“Everything’s running smooth like it’s supposed to. It just takes one big thing off your plate so you can focus more on your daily routine,” Bellah said. “And it frees up the truck in case there is an actual external problem or emergency.”

Keller: Peace of mind and environmental stewardship

Randy Worthen is the Water Operations Supervisor in Keller, Texas, a city of 46,000 that has no fewer than six lift stations – a high number for its size. Worthen had been using chemicals and bacterial treatments to combat greasing. Like his counterpart in Rockwall, Worthen found the frequent need to manually break up matting and remove it from his stations a drain on resources.

Worthen also hailed HydraForce as a game-changer in his city’s wastewater management approach. “I would say with no exaggeration, it’s a 99 percent improvement,” he said. “It’s a major, major improvement.”

HydraForce’s implementation ushered in a new era of efficiency and sustainability for Keller’s wastewater infrastructure. As it had in Rockwall, Worthen noted HydraForce had virtually eliminated the need for chemical treatments and manual cleanings, marking a significant departure from traditional maintenance practices. “We use no chemicals anymore,” he said. “None whatsoever.”

Beyond operational enhancements, Worthen said, HydraForce’s impact extended to environmental stewardship, mitigating the risks associated with lift station failures and overflows. He underscored HydraForce’s pivotal role in safeguarding Keller’s ecosystem and public health. After all, in Keller, more lift stations meant more opportunities for danger to the community or the

environment should any facility experience clogging that shut down operations.

“For me,” Worthen said, “it’s about more than just making our workload easier. It’s about peace of mind.”

Prescott: Dramatic reduction in cleaning frequency

In Prescott, Wisconsin, Matt Holman, a wastewater and water operator in the city’s Public Works/Utilities Department, emphasized the critical role of HydraForce in addressing the buildup of F.O.G., particularly in lift stations serving high-density restaurant areas.

Holman stressed the significance of HydraForce’s impact, stating, “Prescott’s been using the HydraForce diffusers in our main lift station for a couple of months now, and we have seen a drastic change in our use of cleaning services.”

HydraForce’s implementation in Prescott marked a transformative milestone in their wastewater management strategy. Holman underscored the tangible benefits of HydraForce, highlighting its instrumental role in reducing cleaning services and saving valuable time and resources. He noted, “You just pump the lift station down and it probably takes about ten minutes, versus 45 minutes to an hour before.”

The adoption of water agitation treatment not only streamlined operational processes but also ensured uninterrupted wastewater flow, mitigating the risk of potential disruptions.

The new tool is now playing a vital role in Prescott’s wastewater infrastructure, offering an effective solution to combat F.O.G. buildup and uphold operational efficiency in lift stations serving vital community sectors.

These narratives from Farmers Branch, Rockwall, Keller, and Prescott serve as compelling testimonials to the promise an innovative technology like HydraForce has for reshaping conventional wastewater management practices and philosophies.

Through its innovative mixing technology, HydraForce not only mitigates grease buildup but also redefines operational efficiency in lift stations, embodying a sustainable approach to wastewater treatment.

As James Ryan Sartor of Farmers Branch noted, “The HydraForce Lift Station Agitator not only eliminated the need for chemical treatments, it also resulted in significant cost savings and operational efficiencies.”

In an era defined by increasing environmental consciousness and the imperative for sustainable practices, the emergence of such technologies marks a pivotal moment in wastewater management.

As municipalities strive to navigate the complexities of modern infrastructure challenges, tools like HydraForce hold the promise of cleaner, more efficient wastewater systems, now and in the future.

HydraForce, support@kascomarine.com, www.kascomarine.com

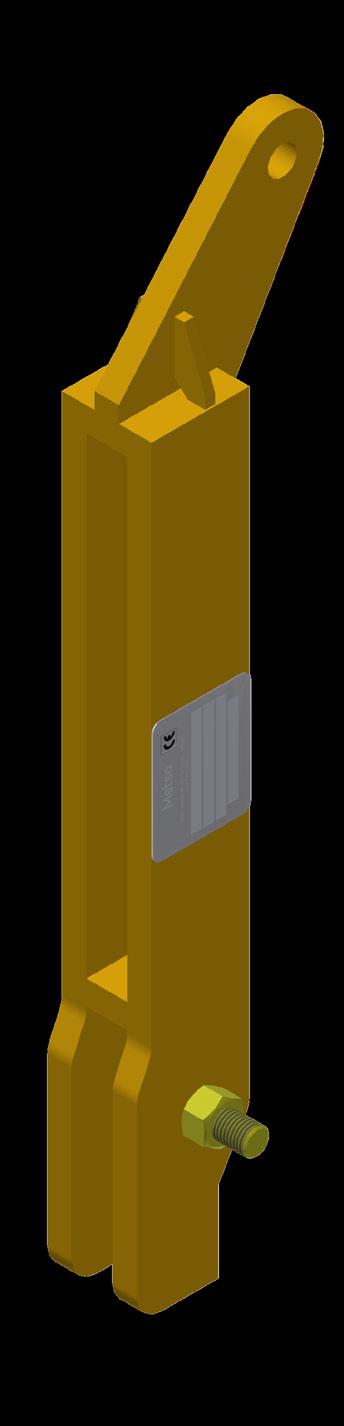

A hydraulic system is a closed system that converts pressurized fluid to mechanical energy. Hydraulic fluid is moved by pumps through control valves and on to mechanical actuators like hydraulic cylinders or motors, which then use the pressure to move implements such as tractor buckets, excavators, and lift cranes.

A hydraulic system comprises various components to keep the fluid under the desired pressure, clean, and moving in the right direction. Below is an overview of those components

Reservoir Tank

The hydraulic tank acts as a reservoir, holding fluid, and is connected directly to the pump. It allows air bubbles to dissipate and contamination particles to settle and the oil to cool while it is not circulating. A vented filter cap controls airflow, and a filter or strainer keeps contaminants from the hydraulic fluid.

Pump and Engine

The hydraulic pump moves liquid from the reservoir tank through the system driven by an engine. Pump designs are typically two-stage, PTO or manual hydraulic, while the engine can be gas, diesel or electric depending on access to power, the horsepower needed and mounting style.

Pressure Gauges and Relief Valve

Once liquid is circulating, gauges can be used virtually anywhere in the system to monitor pressure. In addition, a relief valve controls the fluid pressure that powers the hydraulic cylinder; excess fluid is returned to the reservoir tank. This prevents pressure build-up and potential damage to equipment.

Valve Assembly

The hydraulic valve assembly controls the direction, pressure and flow rate of fluid through a hydraulic circuit. It regulates the speed of motors and movement of cylinders. Directional control valves are most common, controlling fluid flow from the pump to the cylinders and other system components.

A hydraulic cylinder is an actuator that creates linear movement by converting hydraulic energy back to a mechanical movement – so it is the component that drives the work performed by mobile equipment. Cylinders can be used to lift, push, pull and press loads that require exceptional force.

Motor

Similar to cylinders, motors are actuators that converts hydraulic pressure and flow into movement, but it’s converted into torque and angular displacement (rotation) rather than linear motion.

The amount of pressure and displacement of a motor will determine how much torque is produced while the amount of flow will determine the speed.

The purpose of a flow control valve is to regulate the flow rate to motors and cylinders, thereby regulating the speed of those components.

This unit removes the excess heat generated from the hydraulic fluid and helps to keep the temperature within a limited range before returning to the reservoir.

Without proper cooling, the hydraulic system could overheat, causing component damage. Keeping the system properly cooled also extends hydraulic fluid life.

Bailey International, sales@baileyhydraulics.com, www.baileyhydraulics.com

At Fluid Power Pneumatics, we provide high-performance pneumatic solutions to meet the needs of various industries.

Our vane air motors are versatile, efficient, and reliable, making them the ideal choice for countless applications. Whether you need lubricated motors or oil-free options, we’ve got you covered.

Why choose vane air motors?

Our vane air motors offer exceptional adaptability, providing precise motor speeds and power output to handle even the toughest tasks. These motors are specifically built to withstand harsh environments, offering smooth operation and durability that keep your processes running efficiently.

• Lubricated Models: For heavy-duty applications, our seven lubricated models deliver up to 9.5hp (7kW) with variable motor speeds from 300 to 10,000rpm—offering the flexibility you need for a range of industrial uses.

Oil-less Models: Require zero lubrication? Our oil-free motors come in three models ranging from 0.18 to 2.5hp (0.13 – 1.86kW), with speeds up to 2000rpm. Ideal for environments that demand minimal maintenance and cleaner operations.

We understand that every operation has unique requirements. That’s why we offer a variety of mounting options, including hub, foot, face, and flange, along with single or bi-directional rotation. Whatever your mounting preference or directional need, we have a model that fits seamlessly into your operation.

4-vane & 8-vane options: Tailor your motor selection to your specific operational requirements with our 4-vane and 8-vane designs, ensuring you get the precise performance you need.

Maximize performance with fluid power pneumatics

With Fluid Power Pneumatics, you’re investing in more than just equipment; you’re ensuring consistent performance, reduced downtime, and improved operational efficiency. Our versatile solutions empower you to confidently tackle any task, whether big or small.

Fluid Power, +27 (0) 11 452 8795, enquiries@fluidpower.co.za, www.fluidpower.co.za

Achieving the best return on their plant investment is a primary goal for mines, and partnering with OEMs like Weir is a strategic way to enhance equipment performance while reducing the total cost of ownership.

The company is at the forefront of helping mines transition from reactive to prescriptive maintenance approaches, ensuring sustainable and safe operations through the optimisation of technology and equipment.

“We have an extensive footprint of equipment around Africa, and focus on adding further value to these assets through the correct maintenance strategy,” says Grant Potgieter, Strategic Services Manager at Weir. “This means a constant monitoring process, where we can track performance while looking for opportunities to raise our customers’ plant availability for greater productivity.”