SEP/OCT 2022 How to read a pump curve | Digitalisation as a game changer

ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

Solid Handling Specialists With more than 53 years in manufacture of dry bulk materials handling equipment, AMD-ROTOLOK is proud to continue the supply of quality equipment to our many long standing and valued both local and international clients Our partial product range includes: Rotary Valves Flap Valves Knife Gate Screw Conveyors Bucket Elevators, ect. Theo Sherman Managing Director Tel: +27 (0) 11 674 1166/7 | Cell: +27 (0) 82 411 8658 Fax: +27 (0) 11 674 4372 | theo.sherman@amd-rotolok.co.za www.amdrotolok.co.za

Locally produced pneumatic actuator meets international standards 4

PIPES

ABB extends microwave consistency sensor portfolio to offer new insertion design and larger flow-through options 6

Tosa Wrap™ – the return of a South African favourite 7 PUMPS

Weir Minerals’ display shows that pumps never stop evolving 8

Franklin Electric Subdrive QuickPAKS now deliver options for high efficiency 10

How AODD Pumps can satisfy all demands in mining operations 12

How to read a pump curve 18

IPR boosts fleet ahead of rainy season 19

Accredited local support underpins Grindex pumps in Zambia 20

VALVES

Digitalisation as a game changer 22

Setting a new benchmark in pneumatic actuators 26 Valve trends in the global water and wastewater industry 28

AR Controls well positioned to ride copper, cobalt and nickel wave in Africa and South America 30 Global leaders in the manufacture of durable thermoplastic valves and pipeline systems for corrosive media 32

WATER

Leveraging better wastewater treatment to save the environment and ourselves 34

New PLC improves Allmech Demineralisation offering 36 How mines can improve water usage 38

ADVERTORIAL

A business goes from smooth operations to an emptied bank account 16 New generation liquid ring vacuum pumps CS

INDUSTRY NEWS

Over 30,000 visitors at this year’s Electra Mining Africa 40 Lifting Africa & Pipes, Pumps And Valves Africa Golf day 2022 42 BUYERS GUIDE 43

On the cover

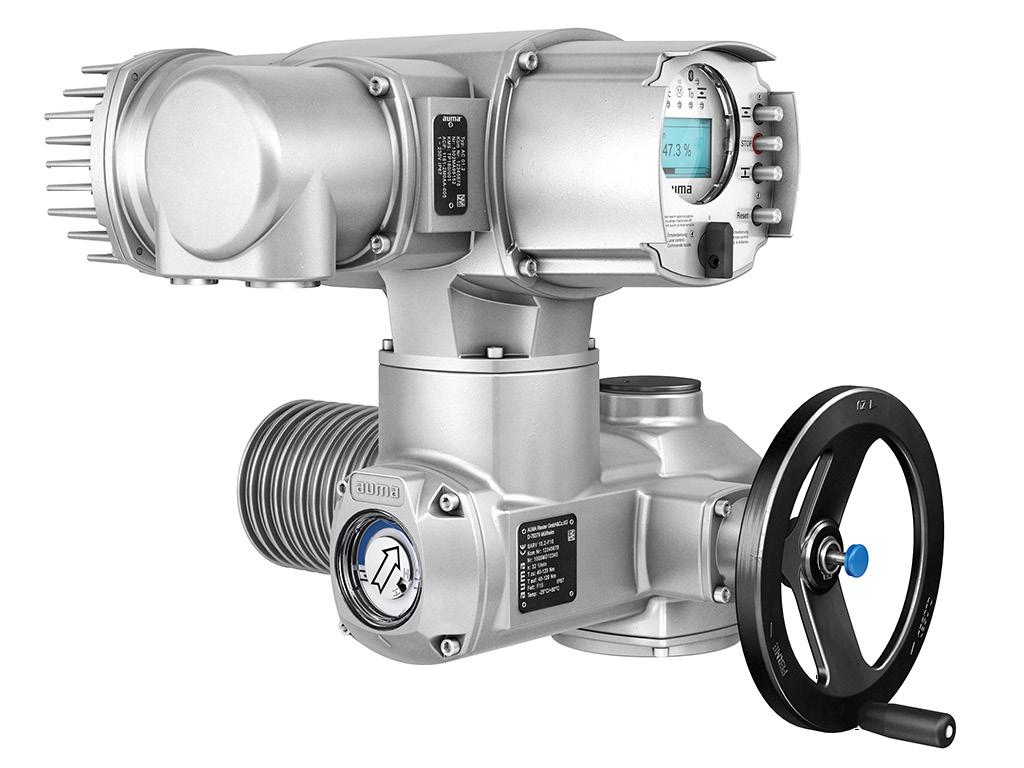

Aumanat, +27 (0) 31 700 6954, info@aumanat.co.za, www.aumanat.co.za

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Cell: +27 (0) 83 281-5761 Email: info@pumpsandvalves.co.za Web: www.pumpsandvalves.co.za Sales: Lusana Merckel Email: sales@pumpsandvalves.co.za Production Manager: Xane Roestroff Email: adverts@pumpsandvalves.co.za

CONTENT Pipes, Pumps and Valves Africa - Sep/Oct 2022 3 Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. Advertisers Air & Vacuum Technologies CS Allmech 31 AMD Rotolok IFC Asahi Africa 33 Aumanat OFC & OBC Bilfinger 15 Bray 7 C.R.I.

Pumps 39 ConExpo 21 Ernest Electro Engineering 27 Hitec Pumps 19 KSB 11 Pleix-Quip 41 Sam Engineering 29 Stewarts & Lloyds 37 Vac-Cent IBC Verder Pumps 35 Xylem 9

COVER STORY

COVER STORY

Locally produced pneumatic actuator meets international standards

Over the years

Member Peter

Meeting local content requirements

Historically pneumatic actuators have always been imported and with most local manufacturers struggling to compete with import prices the need to produce locally was never really pursued.

This changed when the Department of Trade and Industry and Competition (dtic) specified 70% local content for pneumatic actuators and put it on the designated products list.

“We were not able to comply with the requirements and so we started toying with the idea of manufacturing our product rather than walking away from jobs where we could not tender because we were not compliant,” says Meyer.

“We identified a gap in the market for a locally manufactured small compact rotary actuator and set about designing and making our own.”

It is a decision that has paid off. Not only does the company hold the patent right to its product which has been very welcomed in the local market but plans are in place to start exporting.

to deliver a product to the market that is lightweight and aesthetically pleasing but also of international standard and quality.”

Sep/Oct 2022

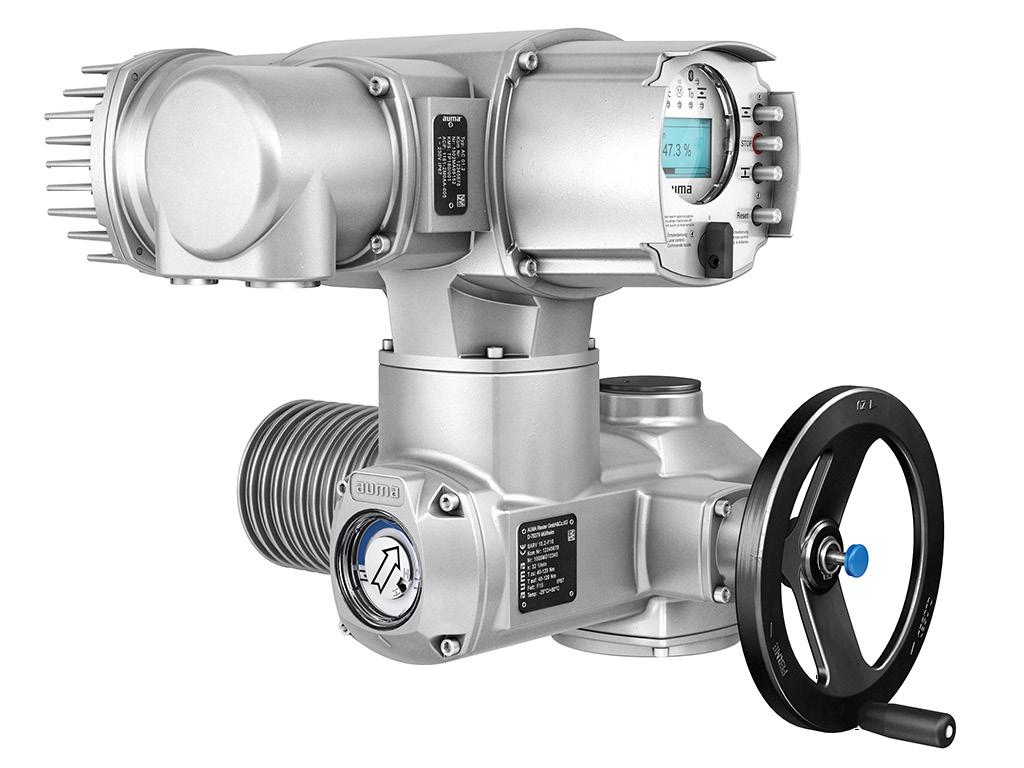

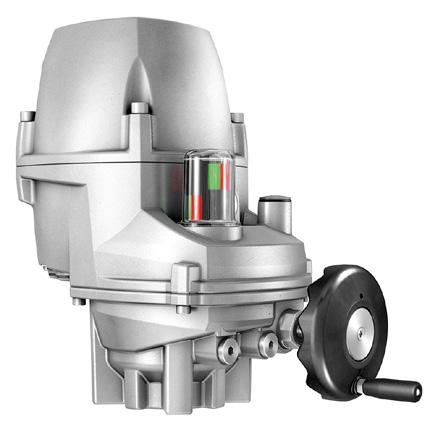

Aumanat has become synonymous with quality actuation products and complete valve automation solutions. More recently, the company is making headlines for another reason. It has designed and manufactured a Part-Turn pneumatic actuator, aptly named ‘Cam-Act’ (Cam actuator) due to its integral cam design, for the local and international markets. Pipes, Pumps and Valves spoke to Managing

“The benefits of the process, while difficult at times, have far outweighed the challenges. Our staff have become far more knowledgeable and skilled through this process while we have involved a range of local businesses in the process. From the raw materials to the casting at a small foundry, engineering, powder coating, the local seal and bearing suppliers are all local.”

More so, says Meyer, it has also resulted in the growth of the company. “AUMA is constantly launching new products based on industry demands. The new TIGRON Explosion proof actuator and the PROFOX Part-turn actuators are two of their most recent launches. We now include our own locally designed and manufactured Cam-Act Partturn pneumatic actuator to that list. We are currently implementing ISO 9001-2015 to further enhance the quality service we provide.”

Sep/Oct 2022 5

Pipes, Pumps and Valves Africa

Aumanat, +27 (0) 31 700 6954, info@aumanat.co.za, www.aumanat.co.za

PIPESPIPES

ABB extends microwave consistency sensor portfolio to offer new insertion design and larger flow-through options

ABB has updated its KPM KC7 Microwave Consistency Transmitter portfolio with a larger flow-through sensor to fit process pipes with a diameter of up to 16”, giving more customers the choice to measure the total consistency of mixed pulps with a flow-through sensor. The technology leader has also launched a redesigned insertion type with an improved dual-plate sensor.

Both of the device options will be used in the stock preparation area of mills, which feeds the wet end of the paper machine. The enlarged flow-through model, extending from a previous maximum of 12”, expands ABB’s market reach to those with wider diameter pipes that previously could only use insertion types, but that can now consider both. The larger size, capturing the whole pipe diameter, means the most representative measurement on the market and provides precise, reliable measurements of total consistency regardless of flow rate for superior process control.

For mills opting for the insertion style, the improved dual-plate design is the only one on the market with an optional temperature sensor that can be retracted for abrasive and unscreened processes, a feature also available with the flow-through model. The parallel antennas avoid microwave reflections in the pipe and generate a selfcleaning effect, removing the risk of obstructions and therefore increasing uptime and reducing maintenance costs compared to other devices.

Microwave measurement is becoming more popular due to its low calibration requirements, high accuracy, and ability to measure total consistency independent of process variables and fiber properties. Unlike optical and sheer force technologies, KPM KC7 is unaffected by both process changes, such as flow speed, pressure and turbulence, and variations in pulp species, fiber length and freeness.

“ABB individually verifies each sensor before implementation to ensure high accuracy, said Karin Hermansson, Product Line Manager at ABB. “With this update to fit larger pipes, reduce obstructions and ensure smooth temperature readings for even the most difficult processes, we can now meet the most diverse requirements in the complex world of papermaking.”

The expansion means that ABB’s KPM KC7 sensor portfolio is now equipped with an added pressure sensor – available as a spare part – to further improve diagnostics. With no moving parts or preventive maintenance requirements, the updated sensors - compatible with third-party couplings for simple upgrades and replacements - make for easy operation and maintenance to ensure a low total cost of ownership.

The application usage extends across paper, tissue, board and pulp producers, from recycled pulping to end of machine stock preparation, and can even be used for municipal and industrial wastewater. KPM KC7 is particularly good for users of recycled raw material and pulp and paper mill teams that prefer to measure and control total consistency with microwave technology.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries.

ABB’s Process Automation, +27 (0) 10 202 5105, ofentse.dijoe@za.abb.com, www.abb.com

6 Pipes, Pumps and Valves Africa Sep/Oct 2022

Tosa Wrap™ – the return of a South African favourite

Tosa Wrap™ is Macsteel’s patented external shrink wrap product. It’s uniquely self-healing to prevent corrosion and deterioration of a steel pipeline. Tosa wrap™ is a wrapped galvanised pipe, fitted with your connection of choice. It’s painted with bitumen, and then wrapped with a low-density polyethylene sleeve which gets heat-shrunk onto the pipe.

It offers three levels of corrosion protection; the galvanising, the bitumen and the LDP sleeve. It protects the steel because the sleeve ‘self-heals’ over time. The bitumen is under constant pressure from the shrink wrapping and if the wrapping is damaged, the bitumen seeps through and seals the puncture, so that nothing gets into direct contact with the base steel.

Tosa Wrap™ was first manufactured by Barloworld Robor in 1999 and has been known and sought after for its corrosion resistance for the last 20 years. Robor had immense success with the product up until about three years ago when the company halted operations. Part of Macsteel’s acquisition agreement with Robor, included the rights to Tosa Wrap™.

People in the industry know it and ask for it by name. This great product complements our Macsteel Fluid Control

business perfectly and offers Macsteel the opportunity to provide a bigger range of solutions to our customers. The product was absent from the market for three years, but after some upgrades and the retooling on the production line, Tosa Wrap™ is back and ready to take the market by storm. Tosa Wrap™ is about 30% cheaper than the equivalent product in the market. It was recently specified for project in the Eastern Cape, requiring about four kilometres of galvanised pipe. This paved the way for Macsteel to reintroduce Tosa Wrap™ into the market. If your project requires an affordable and sustainable anticorrosive solution, ask for it by name.

Pipes, Pumps and Valves Africa - Sep/Oct 2022 7 PIPES

PIPES

Macsteel, +27 (0) 11 871 0000, info@macsteel.co.za, www.macsteel.co.za HIGH PERFORMANCE FLOW CONTROL SOLUTIONS Bray offers a complete portfolio of flow control solutions to handle your most challenging applications. BRAY.COM Bray Controls Africa (Pty) Ltd Unit 11, ABC Business Park Mastiff Rd, Linbro Business Park Sandton 2090, South Africa Telephone: +27 10 007 3222

PUMPS

Weir Minerals’ display shows that pumps never stop evolving

While Weir Minerals Africa is known for its extensive range of pumps, Electra Mining Africa gave visitors more insight into how its pump innovations are shared – ensuring that all customers benefit from the company’s best ideas.

“Having a very broad spectrum of cutting-edge pump options at our disposal allows us to offer our customers exactly what they need,” says Marnus Koorts, general manager pump products at Weir Minerals Africa. “It also allows us to leverage technological advances from one brand to another.”

Among the innovations on display at the Weir Minerals Africa stand, for instance, was the Warman® pump’s WRT® technology, which improves wear life and energy efficiency with no additional capital cost requirement. This, he says, has also been applied to the company’s Envirotech® range, another strong slurry pump brand in Africa and the Middle East. The Warman® range includes slurry pumps, heavy duty mill circuit pumps, submersible pumps, dewatering pumps and process slurry pumps. Also in the range are GEHO® positive displacement pumps, known for long distance pumping of high-density tailings for distances of 200 to 300 km. “Electra Mining Africa gave us the chance to expose our customers to other aspects of our portfolio,” he says. “Most customers deal with the product lines relevant to their daily responsibilities – so it is exciting when they can see other aspects of our solutions that could add value.” Another eye-catcher at the exhibition stand was a 50 kW unit from the Warman® SSB submersible slurry pump range, utilising the wear technology present in the

industry-proven high chrome alloys used on slurry pumps, again leveraging technology from different brands. This unit boasted a high chrome impeller associated with its well-tested A05 material, with the motor encapsulated into the shell. “We have also finetuned the ergonomics related to handling these pumps, based on our extensive experience in the field,” says Koorts. “These units are moved around a lot, so lugs that are aligned sideways tend to break off if there is impact. We innovate even in small ways, by putting the lug facing upwards to avoid damage.”

In addition to continuous innovation, he highlights the critical importance of the company’s global infrastructure to support its wide range of pumping equipment. This gives customers confidence that service levels are consistent wherever the pumps are working.

“Whether our customer moves from Rustenburg to the Middle East, or from Canada to West Africa, they will find the same extensive range of our pumps supported to the same high standard,” he says. “This sense of consistency is important to our customers, especially given the amount of geographical movement of people in the mining sector.”

He notes the Warman commitment to the ethos of ‘Always Performing, Always Trusted, Always Innovating’ that rests on a depth of institutional knowledge across the company’s footprint, giving customers peace of mind across plant functions.

“Our level of know-how and accessibility to mining customers is what differentiates Weir Minerals Africa,” he concludes. “This is sometimes difficult to convey if you don’t appreciate our full extent of our offering; this is why our intensive face to face engagements at Electra Mining Africa remain so important.”

Weir Minerals Africa, +27 (0) 111 617 0700, africa.minerals@mail.weir, www.minerals.weir

8 Pipes, Pumps and Valves Africa - Sep/Oct 2022

CONDITION MONITORING

AND OPTIMISATION

Benefi optimyze™ CONDITION MONITORING TO OPTIMIZE YOUR BOTTOM LINE

The optimyze™ modular condition monitoring solution provides health guidance and predictive maintenance advice for rotating and fixed assets such as pumps, motors, heat exchangers and steam traps. It periodically monitors system vibration and temperature and allows everyday users to access simple-to-use monitoring tools from iOS or Android mobile devices.

• Predictive maintenance to monitor the health of mechanical and electrical assets •

management including asset location, size and manufacturing date • System transparency to optimize reliability • Optimized reporting that helps to simplify documentation, manage system maintenance and inform purchasing • The ability to automatically share data with multiple local users • Conveniently monitor system conditions on our simple-to-use mobile application

xylem.com

ts:

Asset

Industries: • Commercial

• Manufacturing • Agriculture • Water Utilities Applications:

Monitoring

• Monitoring

• Monitoring

• Monitoring

Using predictive analysis, optimyze identifies potential problems with your equipment before they occur, to help you manage system reliability and maintenance. Information is monitored, collected, stored and analyzed in the optimyze sensor. This allows you to understand the current health and historical trends of your assets, create maintenance reminders and generate detailed reports. As a result, you can perform preventative maintenance before issues become critical to uptime. • And more

Building Services

•

the vibration of pumps and motors

the temperature of pump bearings

the temperature of motors to prevent overheating and winding damage

the performance of heat exchangers

Franklin Electric Subdrive

QuickPAKS now deliver options for high efficiency

Franklin Electric has added new high efficiency SubDrive QuickPAK solutions to its lineup, giving professional installers an industry-leading, reliable constant water pressure solution that’s ideal for jobs up to five horsepower. They work across a variety of systems, including residential, irrigation or geothermal.

PUMPS

Powered by a 4-inch MagForce High Efficiency Motor, the new SubDrive QuickPAKs deliver unparalleled performance and increased efficiency combined with the trusted reliability and seamless operation of the legendary Franklin Electric 4-inch, three-phase submersible motor.

Upgrade to Groundbreaking Performance & Reliability:

• Unlock Up to 17% More Efficiency*: The 4-inch submersible motor that professionals have trusted for decades now leverages the latest technology to deliver the most power per volume in the industry. (*than the comparable three-phase induction motor)

• Get Peak Performance While Using the Least Amount of Energy: Powered by MagForce High Efficiency Motors,

these packages achieve the same horsepower rating while performing with the least amount of electricity at any given operational point.

• Easy Selection Meets Optimized Operation: Like all SubDrive QuickPAKs, the packages have been designed for ultimate operational compatibility. The predetermined motor, pump and drive combinations match flow and total dynamic head requirements, ranging from 7 to 90 GPM.

Unlock Benefits on the Job Site:

• Smaller, Lighter & More Powerful Design: Through increased power density, the total assembly is more compact, aiding professionals with ease of transport and installation. In fact, a 5-horsepower motor is 7” shorter and 18 lbs. lighter than a standard induction motor.

• Go the Distance with Longer Cable Length: While running on less current per horsepower rating, MagForce High Efficiency Motors allow on average 22% longer motor cable lengths per wire size, resulting in more cost-effective installations.

• Introducing the New FE Connect: The SubDrive platform uses an array of easy setup and assisted troubleshooting solutions to help save time during installation and reduce service hours. This includes the enhanced experience using FE Connect for smart devices.

Franklin Electric, +27 (0) 11 723-6500, info@franklin-electric.co.za, www.franklin-electric.co.za

10 Pipes, Pumps and Valves Africa - Sep/Oct 2022

A LONG DISTANCE RELATIONSHIP THAT WORKS.

MDX, LSA, LCC and LCV Heavy Duty Mining Pumps

Wear Resistant, High Performance –Global Quality Mining Pumps.

KSB South Africa is a globally recognized pump solutions provider that manufactures globally recognized products locally to the highest quality standards both internationally and locally.

We not only manufacture and service your slurry pumps, we offer total slurry solutions to your industry.

We not only manufacture and service your slurry pumps, we offer total slurry solutions to your industry.

With a modern Manufacturing, Sales and Service facility in Johannesburg, 9 branches in South Africa, as well as legal entities in Nigeria, Kenya, Zambia, Namibia and Angola –KSB is represented throughout the whole country.

With a modern Manufacturing, Sales and Service facility in Johannesburg, 9 branches in South Africa, as well as legal entities in Nigeria, Kenya, Zambia, Namibia and Angola –KSB is represented throughout the whole country.

One team - one goal.

One team - one goal.

KSB Pumps and Valves (Pty) Ltd • www.ksb.com/en-za • Your Level 1 B-BBEE Partner

KSB Pumps and Valves (Pty) Ltd • www.ksb.com/en-za • Your Level 1 B-BBEE Partner

PUMPS

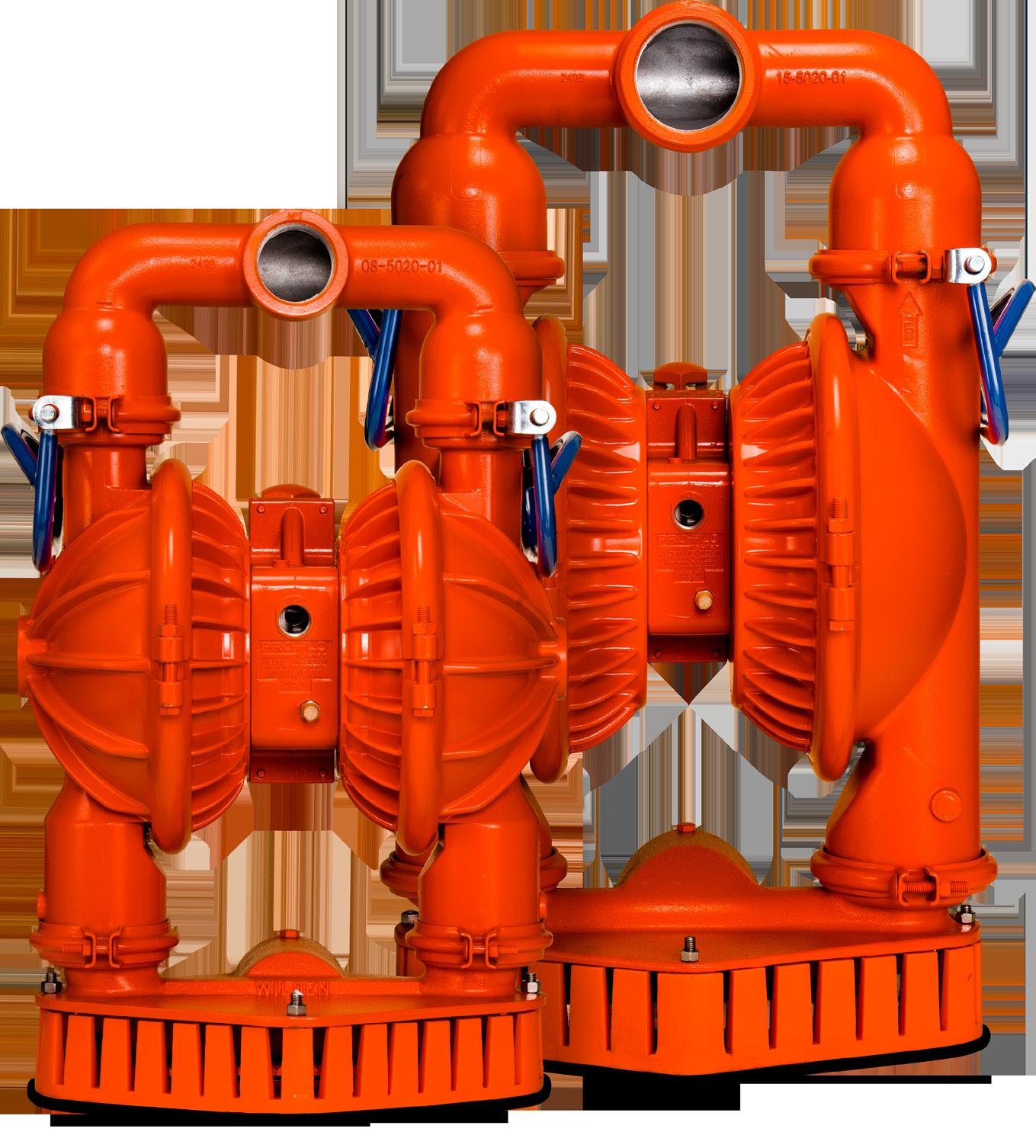

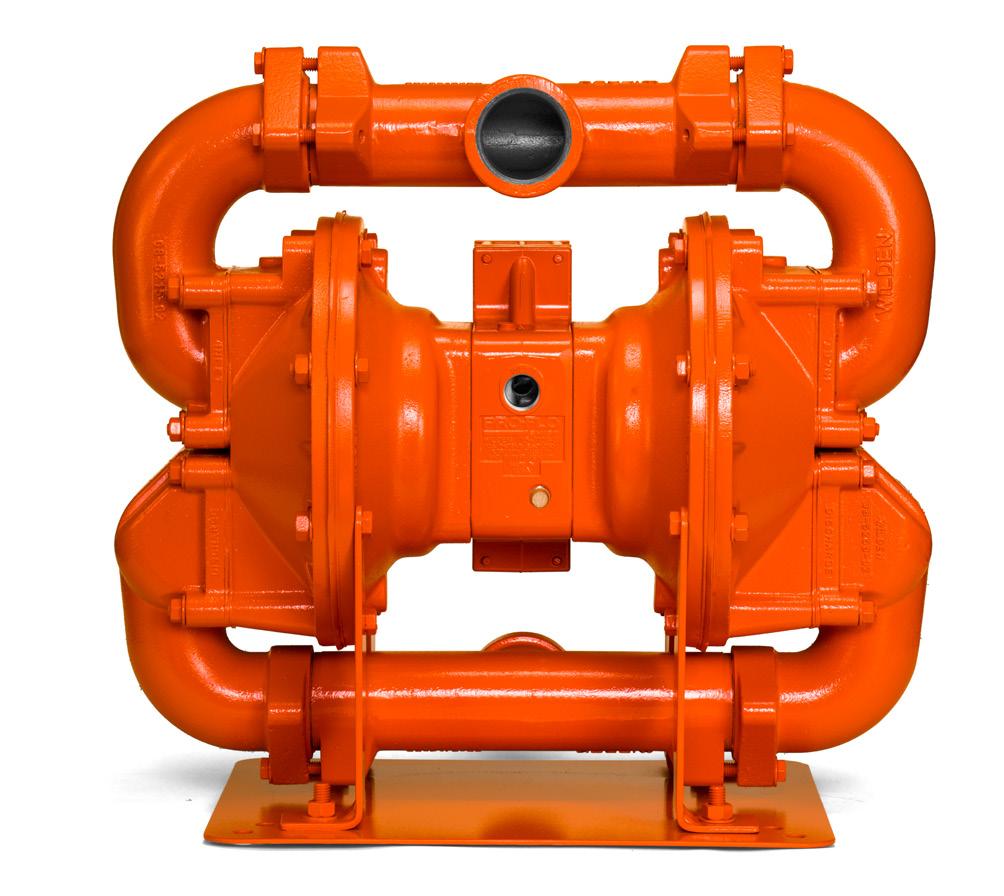

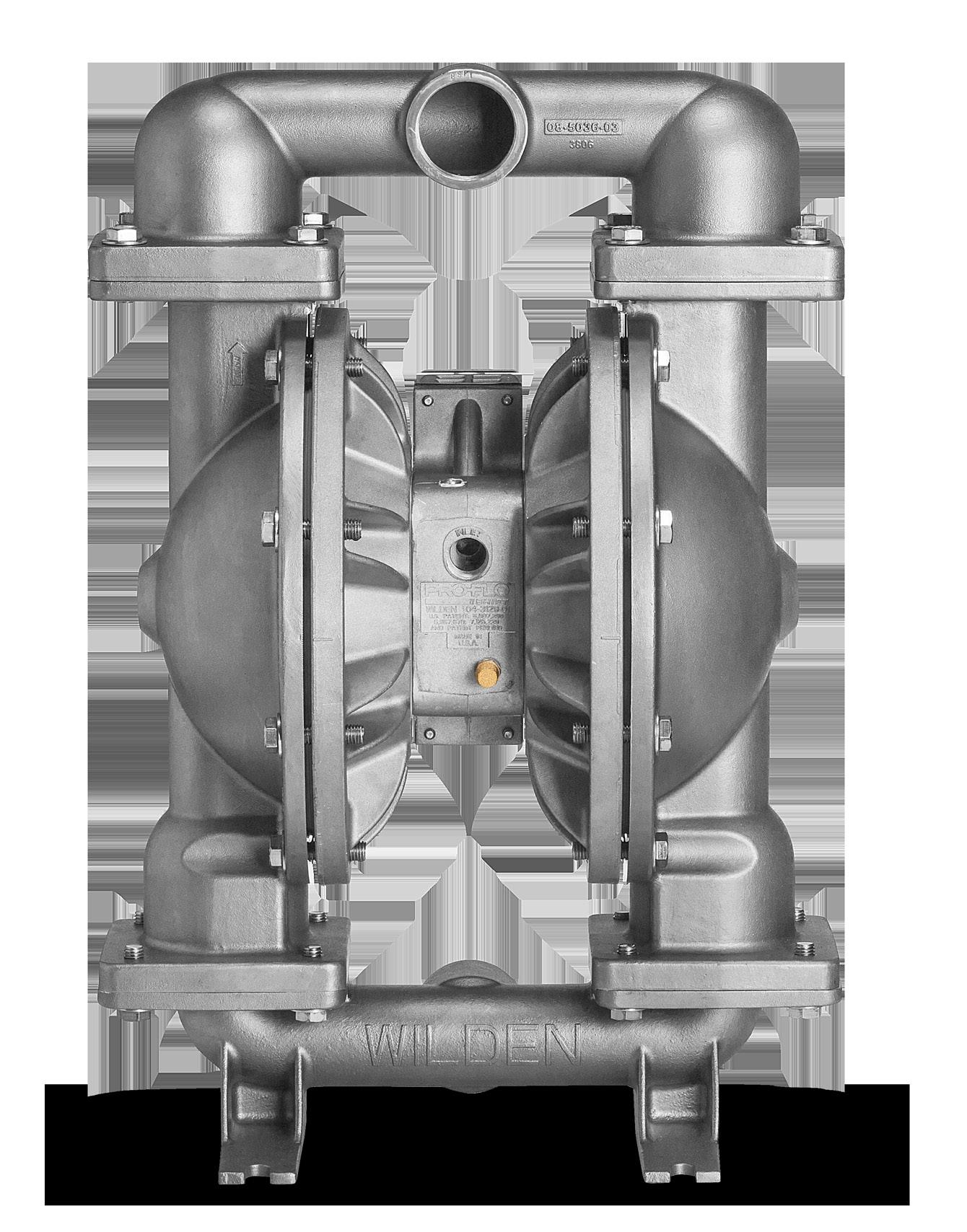

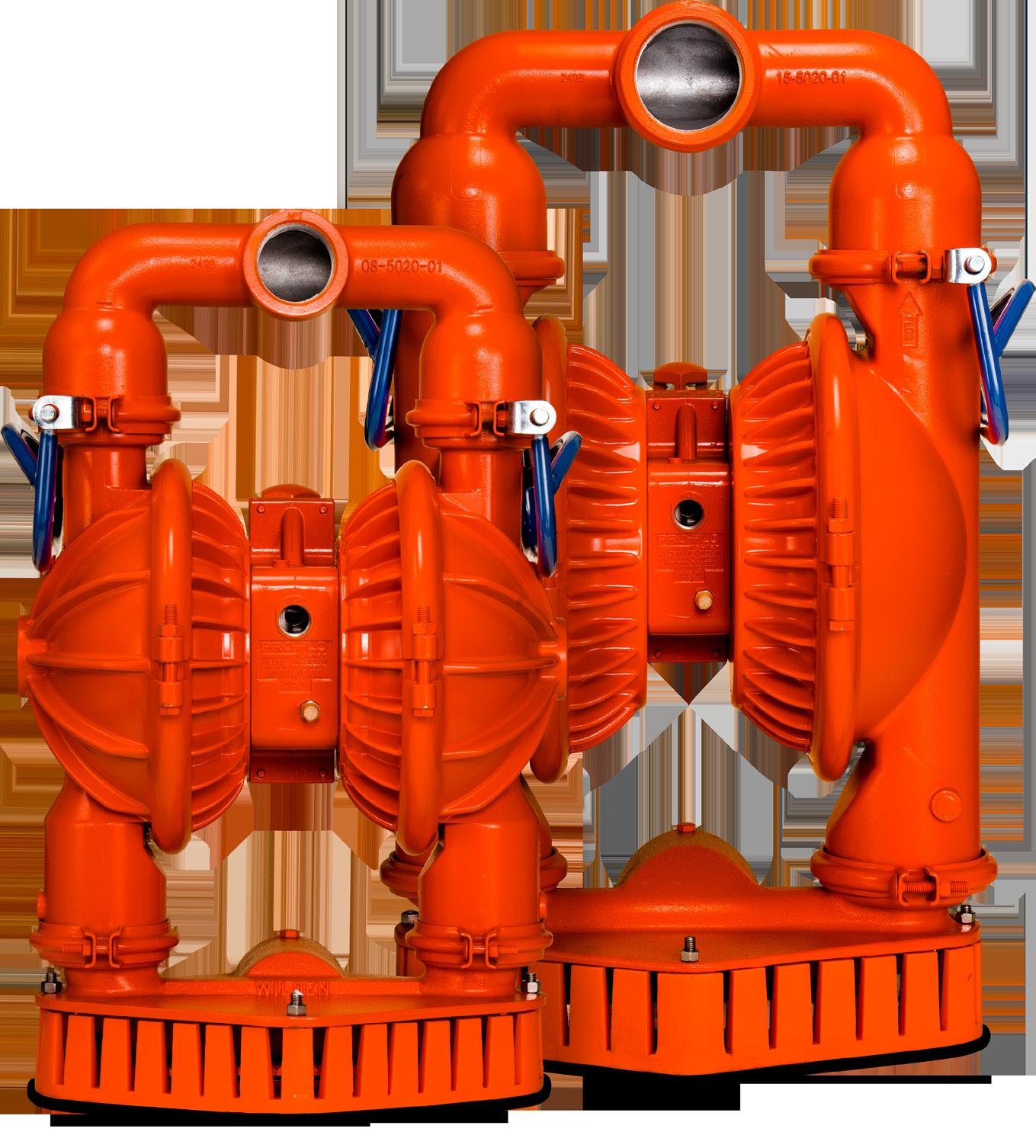

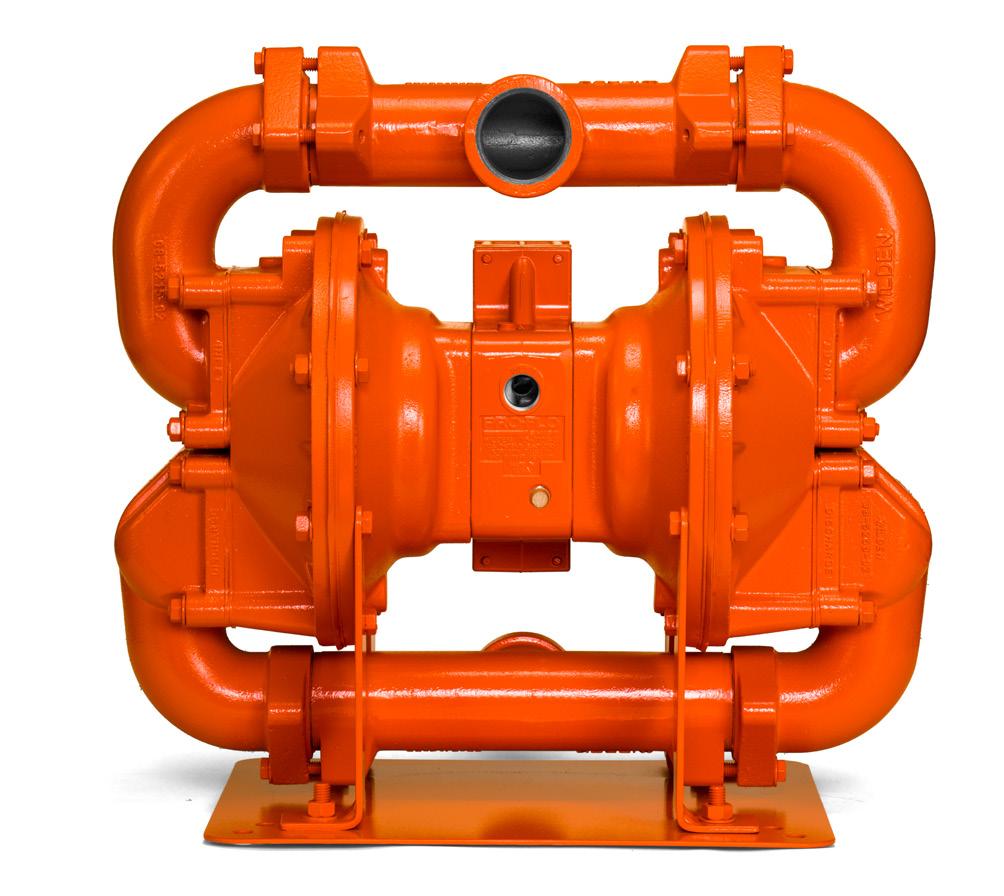

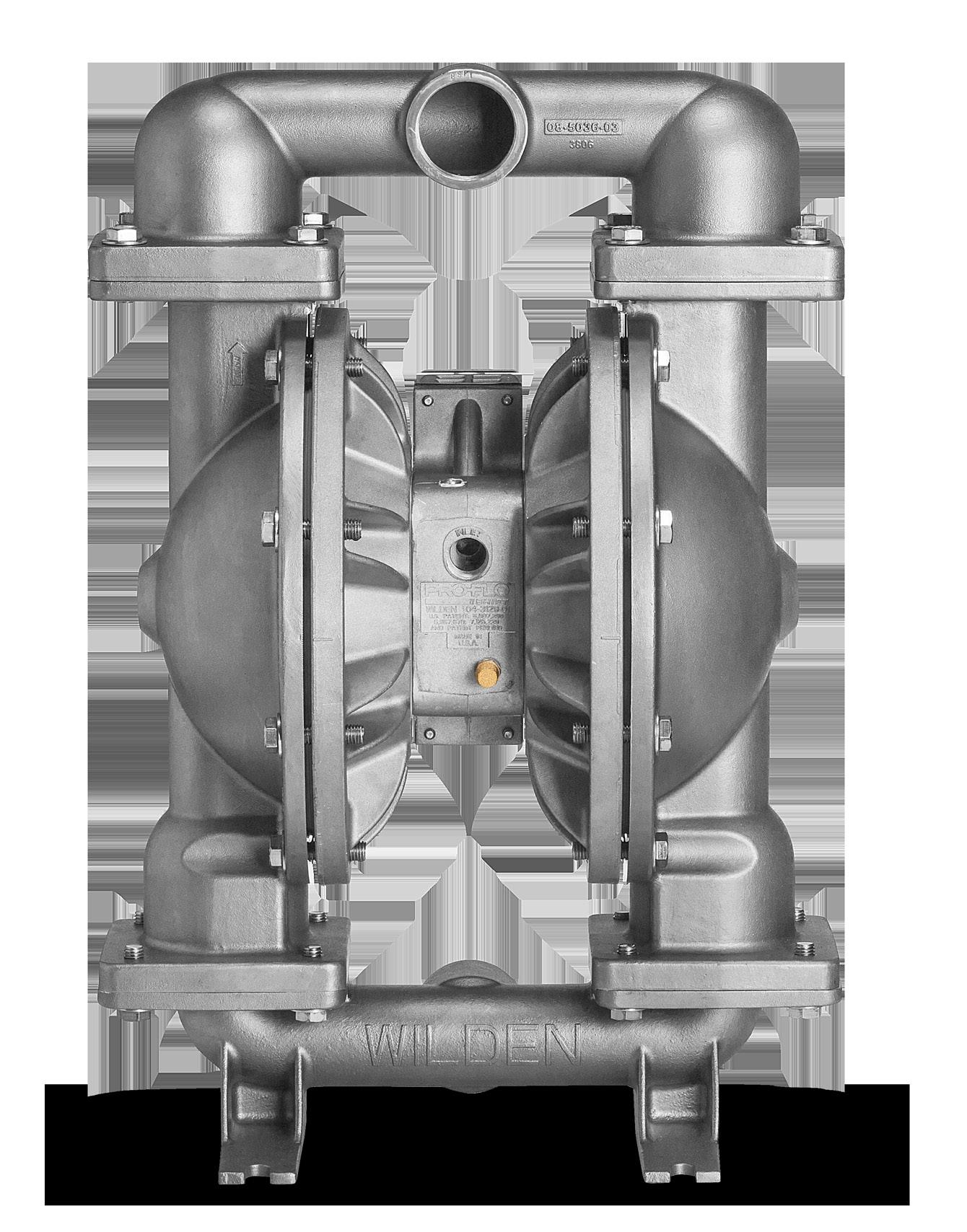

How AODD Pumps can satisfy all demands in mining operations

In an industry that features a number of harsh, but oftentimes delicate, liquidhandling challenges, Wilden® Air-Operated Double-Diaphragm (AODD) Pumps have consistently risen to the occasion

Mining is one of the world’s oldest industries, tracing its roots back to those prehistoric days when someone grabbed a digging instrument and began burrowing into the ground. In the many millennia since then, mining has grown into one of the world’s most important and widespread commercial enterprises, with mining operations spread across the globe while tasked with recovering an almost inexhaustible list of valuable commodities.

In fact, according to the World Mining Congress’s World Mining Data 2020 report, 17.7 billion metric tons of mined products were recovered in 2018, up from 11.3 billion metric tons in 2000 and nearly double the 9.6 billion metric tons in 1985. Asian countries accounted for 58% of the 2018 production, with North America second at 15.1%, followed by Europe (8%), Oceania (6.8%), Latin America (6.3%) and Africa (5.3%). Individually, China (23%), the United States (12.1%), Russia (9.2%) and Australia (7.2%) were the most prolific producers, with their total 51.1% of production more than the rest of the world combined.

This means that the mining industry is a strong one, with solid growth expected to continue in the coming years in many regions of the world. It also means that mining operations will continue to rely on pumping technologies that offer robust, reliable and safe service in a number of critical liquid-handling operations. This white paper will illustrate why positive displacement air-operated doublediaphragm (AODD) pumps can be the best choice for many of those applications.

The Challenge

While mining might appear to be nothing more than a rough-and-tumble operation – holes are dug by heavy machinery or with explosives, opening the hidden ode to access from above – there are, in fact, many complex and sometimes delicate operations that must be performed properly if the mining operation is to perform at its highest level of efficiency.

From a macro standpoint, this requires a pumping technology that can operate reliably in harsh and remote locations, even when submerged, or when tasked with handling particulate-laden liquids or toxic/corrosive products, and also one that is able to be maintained and repaired simply so downtime is lessened. The pumps must also be light enough to be manually moved from location to location within the mine itself.

For many years, a popular choice for use in these conditions was centrifugal pumps. While centrifugal pumps are able to create the high flow rates that are required, they have a number of operational “pain points” that hamper their use in mining applications: an inability to self-prime or run dry; special seals needed to prevent leaks; special linings needed to handle solids; high motor speeds of up to 1,800 rpm; and relatively high maintenance requirements and costs, especially when charged with transferring solidheavy liquids.

Another popular choice has been the progressive cavity pump, but, like centrifugal pumps, they have a number of operational shortcomings. These include an inability to consistently handle liquids with high

12 Pipes, Pumps and Valves Africa - Sep/Oct 2022

levels of abrasives, which leads to increased maintenance costs, wear on expensive stators and rotors that will eventually need to be replaced, and overall higher purchase, operating and repair/replacement costs.

Here are some of the specific liquid-transfer operations that take place in a mine and the ways that some pump technologies can fall short in satisfying them:

• Mine Dewatering: Removing excess produced water from the mine is a critical 24/7/365 operation and the water that is recovered is often full of particulates that can be as large as 3-4 mm (0.12-0.16") in size. If used in this application, centrifugal pumps require special materials of construction, which can be cost prohibitive, to protect against impeller wear caused by the abrasive particles. Centrifugal pumps are also not dry-run capable, which adversely affects their level of performance in this application.

• General Service: For common liquid-handling applications, you need an easy-to-operate pump that reliably can run dry, strip lines, operate at low speeds while still delivering high flow rates, and be easy to maintain and repair. Centrifugal pumps simply do not possess these capabilities.

• Corrosive Liquids: Much like solid-laden liquids, corrosive ones can wreak havoc on the wetted parts of centrifugal and progressive cavity pumps. This typically demands a need to use special mechanical seals, which can lead to exorbitant maintenance, repair and replacement costs.

• Press Filter: Press filters are used to clean the liquids that are produced in the mines and, again, centrifugal pumps can fall short in this application because the solid-laden liquid can damage the pump’s internals unless special, more expensive materials of construction or linings are used. Also, the nature of press-filter operation creates a strong discharge-pressure variation that can force the centrifugal pump to operate away from its Best Efficiency Point (BEP), resulting in high vibration and radial loads that can lead to shortened service life. A solution to this is the incorporation of variable frequency drives (VFDs) and controllers, but these are expensive and can negatively affect the cost-effectiveness of the operation.

• Product Transfer: This comes in all forms in a mining operation, from loading and unloading from transport trucks with new and used oil for the heavy machinery, fresh and fouled water, and any chemicals that are required. In every instance, there is the risk that the pump will be forced to run dry as the truck or storage vessel is emptied, while discharge-pressure variation can also generate high vibration and radial loads. As previously illustrated, centrifugal pumps cannot run dry, so they need protection from this condition or the addition of special seals. However, all of these upgrades still cannot totally protect against a catastrophic failure.

The Solution

While centrifugal pumps – despite their popularity – have proven to not be the most effective solution in many liquidhandling applications in mining, one pump technology that has proven to be an optimum choice is AODD – in terms of maximizing reliability, cost-effectiveness, ease of operation and maintenance, and safety for mining personnel and the environment. AODD pumps are able to perform effectively in mining applications because their method of operation allows them to easily handle variable flow rates and

pressures, while being dry-run and line-stripping capable, and nimble enough to transfer liquids that are shearsensitive or high-viscosity, as well as slurries laden with rocks, pebbles and other particulates.

The simple design of the AODD pump features few moving parts and comparably lower speeds than other pump technologies, which improves reliability and simplifies maintenance, while the pump’s seal-less construction results in fewer leaks, which is a critical consideration when handling the many hard-to-seal, corrosive or hazardous liquids that are prevalent in a mining operation. AODD pumps are available in both metal (most commonly aluminum, ductile iron and cast iron) and plastic (polypropylene and PVDF) housing constructions, while a wide array of elastomers can be used in the diaphragms, which eliminates many chemical-compatibility concerns.

A wide variety of AODD pump configurations provide operational flexibility that can also result in optimized performance at many levels. The ability to feature AODD pumps in a wide range of applications, from basic general use to delicate chemical-handling processes, allows operators to more cost-effectively outfit their mines. AODD pumps can also be less costly to operate, especially those models that are outfitted with a next-generation mechanically actuated Air Distribution System (ADS). At their most basic, AODD pumps excel in the typical rugged and harsh operating conditions found in the world’s mines, which reduces breakdown incidents along with corresponding downtime and repair costs.

Specifically, Wilden®, whose founder, Jim Wilden, conceived the AODD pumping principle 65 years ago, has been dedicated to developing technologies that meet the needs of mining operations. Today, Wilden offers three AODD pump models that are built to excel in mining applications, available in ductile iron, cast iron, aluminum, polypropylene and Kynar materials of construction:

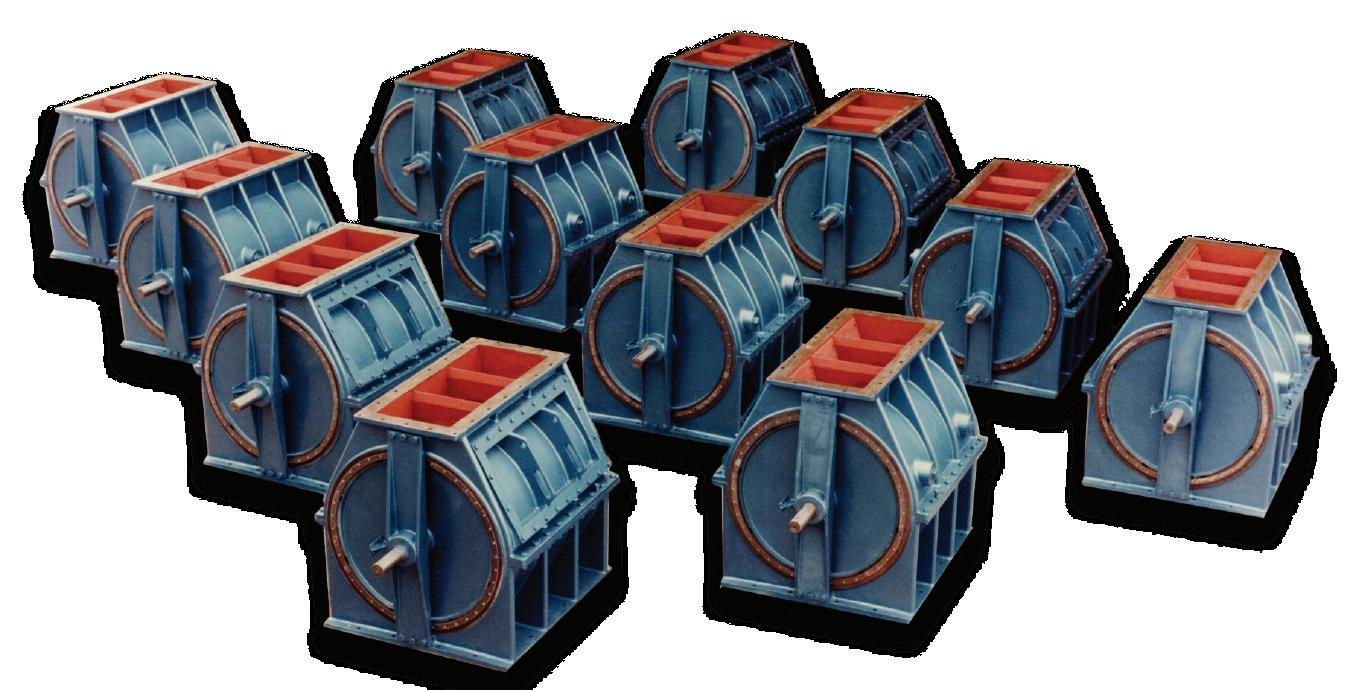

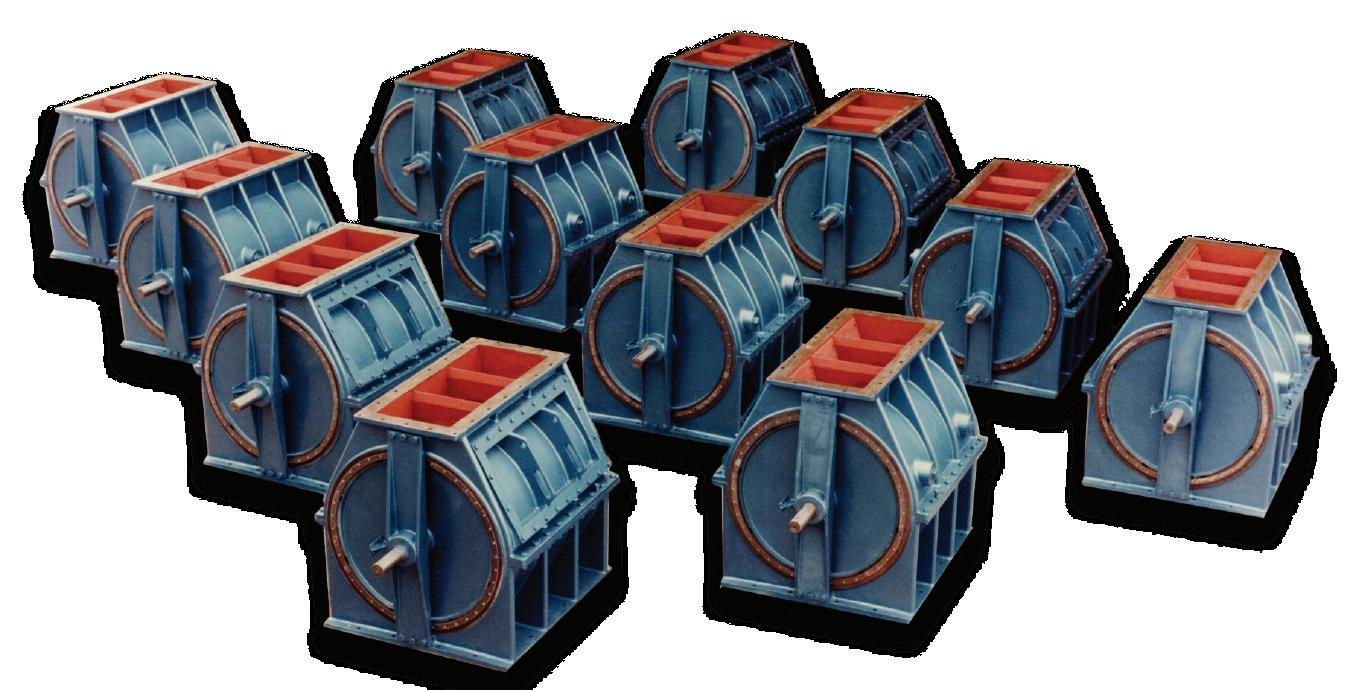

• Brahma® Series AODD Pumps: The Brahma pumps, which feature a bolted configuration, have been built for use in applications that require the handling of liquids featuring large solids. The Brahma pumps have a unique top-inlet/bottom-discharge flow orientation and flap valves that allow the passage of large solids with no risk that damage will occur as a result of product entrapment

Pipes, Pumps and Valves Africa -

Sep/Oct 2022 13 PUMPS

PUMPS

or the settling of solids within the pump’s internal flow paths. Brahma pumps are available in two models – PS810 (2"/51 mm) and PS1510 (3"/76 mm) – that are outfitted with the revolutionary Pro-Flo® SHIFT ADS, which has been designed to reduce air consumption by up to 60%. The T810 and T1510 models are powered by the Turbo-Flo™ ADS, the industry’s first air motor for AODD pumps. The flow-rate range for the four Brahma pumps is 166 to 258 gpm (628 to 882 l/min) at pressures up to 125 psi (8.6) with solids-handling capability ranging from 2"-3" (51-76 mm).

• Stallion® Series AODD Pumps: The Stallion pumps feature a clamped design with carrying handles for lightweight portability. Their design features large internal clearances and flow-through paths for easy passage of large solids with no chance for clogging. An altered ball/seat checkvalve assembly further enables solids passage, while a polyurethane screen base at the inlet increases the pump’s durability. The PS4, PS8 and PS15 (1.5", 2" and 3"/38, 51 and 76 mm) models are powered by a Pro-Flo SHIFT ADS, with the T4, T8 and T15 (1.5", 2” and 3"/38, 51 and 76 mm) pumps featuring the Turbo-Flo ADS, Wilden’s most robust ADS design for the toughest environments. Flow rates amongst the six models range from 57 gpm (216 l/min) to 232 gpm (878 l/ min) at working pressures up to 125 psi (8.6 bar). Solids sizes that can be handled range from 1/2" to 1" (13-26 mm).

• Pro-Flo SHIFT Series: Pro-Flo SHIFT pumps feature clamped or bolted configuration. Their design features different chamber materials, including metal and plastics,

even Kynar, which is capable of handling high levels of abrasive materials. The ProFlo SHIFT is also the most efficient AODD pump in the market, capable of reducing up to 60% air consumption.

This makes it the best option for handling corrosive and abrasive products in mining processes. The pumps have a product range that goes from 1.5" to 3" and flows from 2 to 271 gpm (8 to 1026 l/min).

All of the Brahma, Stallion and Pro-Flo SHIFT pumps are able to be outfitted with a wide array of diaphragm styles –including the newer Chem-Fuse, EZ-Install and Reduced-Stroke models – in a varying array of materials, such as Wil-Flex™ (Santoprene®), Geolast®, Polyurethane, Buna-N®, EPDM, Neoprene, FKM and PTFE.

This diaphragm range gives users the widest selection of diaphragms on the market, all of which are capable of providing extended mean time between failure (MTBF) for optimized uptime with reduced maintenance, repair and replacement costs.

All of these capabilities make AODD pumps the ideal choice for the aforementioned common liquid-handling applications in mining: dewatering, general service, corrosive-handling, filter press and daily product transfer.

Conclusion

In summary, Wilden AODD pumps are the best option for mining applications because they offer considerable operational advantages, like comparable low-speed operation, dry-run, line-stripping, self-priming and deadhead capability, along with increased operational safety and a reduction in maintenance/repair costs that can be incurred by pumps that are not designed to handle abrasive/corrosive or solid-laden liquids.

Wilden AODD pumps also outperform other AODD technologies in other significant ways: simple design with the lowest number of parts for faster, simpler and safer repairs and the lowest number of spare parts to stock; recent improvements in materials of construction that increase the pump’s MTBF; and improved efficiency through the use of the Pro-Flo SHIFT ADS, which ultimately results in faster product transfer with lower air consumption.

Wilden also continues to innovate through the development of the next-generation Chem-Fuse and EZInstall diaphragms, both of which increase service life and safety while not compromising the handling of challenging liquids.

Wilden Pumps, wilden@psgdover.com, www.psgdover.com

14 Pipes, Pumps and Valves Africa - Sep/Oct 2022

WE MAKE VALVE SUPPLY WORK

Bilfinger Intervalve Africa (Pty) Ltd. is one of the enterprises in Bilfinger Power Africa (Pty) Ltd., the South African subsidiary of German based Bilfinger SE. For years, we have been adding value to the power, mining, paper pulping and broader industry through comprehensive valve supply, valve maintenance and heat treatment solutions. www.intervalve.bilfinger.com

A business goes from smooth operations to an emptied bank account

SARS reviews old VAT returns, rejects all input VAT and demands millions. The business is on the brink of collapse when Cornerstone comes to the rescue.

In 2017 an enterprising young business was formed and quickly found growth and success within its community over the subsequent years. Common to young businesses the owner – and manager – did not have any familiarity with SARS, tax, or general principles.

Through a recommendation from a mutual friend, the owner found a company that offered to handle all the administrative and tedious requirements of tax compliance for the business.

As the business was still young and growing at the time, this third party negotiated to handle the tax compliance in exchange for a percentage of any VAT refunds that the company received as a result of its efforts.

As a result of unfortunate negligence, the business owner agreed to the negotiation, thus allowing the third party to load their contact details with SARS as if they were the business.

This way, any notifications or correspondence from SARS would go directly to the third party without the appropriate business owner being alerted.

With this arrangement in place, the business continued with its operations and trusted the third party to

handle all tax-related matters. The business had consistent growth, money was coming in, and life appeared to be good and bountiful.

The truth of the matter was that tax compliance was not actually going well. The third party had negotiated to be paid a percentage of all refunds, and as such, they were heavily incentivised to maximise refunds whenever possible.

Eventually, SARS noticed something strange going on with this growing business. SARS conducted an investigation and concluded that this growing business had a suspicious pattern of refunds, and that their VAT submissions of their years were littered with fraudulent errors.

As a result, SARS raised additional assessments on almost all the returns submitted in the past, denied all the input VAT, and demanded immediate payment for all the output VAT.

With all correspondence set up to go directly to the hired third party, the relevant business owner did not know the demands made by SARS.

The business owner was only alerted after the fraudulent third party failed to resolve the matter themselves. These alerts came a little too late, as the

16 Pipes,

- Sep/Oct 2022 ADVERTORIAL

Pumps and Valves

Africa

business owner was unable to timeously respond to the additional assessments raised by SARS.

SARS, becoming impatient with the business that seemed to be ignoring demand after demand, saw that the bank account of the business seemed to be slowly declining over time.

While this ebb and flow of the bank balance is a regular occurrence in business, SARS assumed the worst and decided to take what money they could before it disappeared. With an instruction to the bank, the business bank account was forcibly emptied and all funds were deposited to SARS.

The owner of the business, fortunately, had additional capital set aside and used this to seek out the services of a more reputable tax practitioner to help find a way forward. The newly appointed tax practitioner for the business was of course Cornerstone Tax and Accounting Services.

Using bank statements, slips, and various contacts Cornerstone has been able to arrange a more amicable situation with SARS, allowing the correction of the old VAT returns and the denied input VAT.

The business does still owe money to SARS as they were, strictly speaking, never supposed to receive any refunds. The money owed to SARS has however at least been reduced by an order of magnitude.

While the owner is not exactly happy that they will not be getting back the money that SARS emptied from their business account – in addition to the money still owed to SARS – they have at least learned the importance of having some involvement in their tax affairs and having a reputable practitioner guiding them along the way. How can Cornerstone help you?

Cornerstone Financial Services Group, marketing@cornerstonefsg.co.za, www.cornerstonefsg.co.za ADVERTORIAL

PUMPS

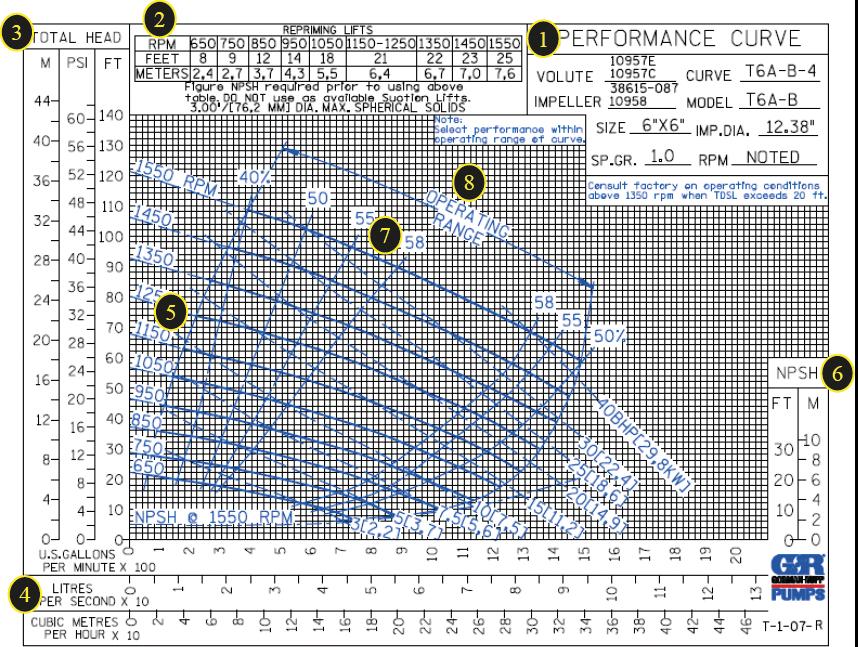

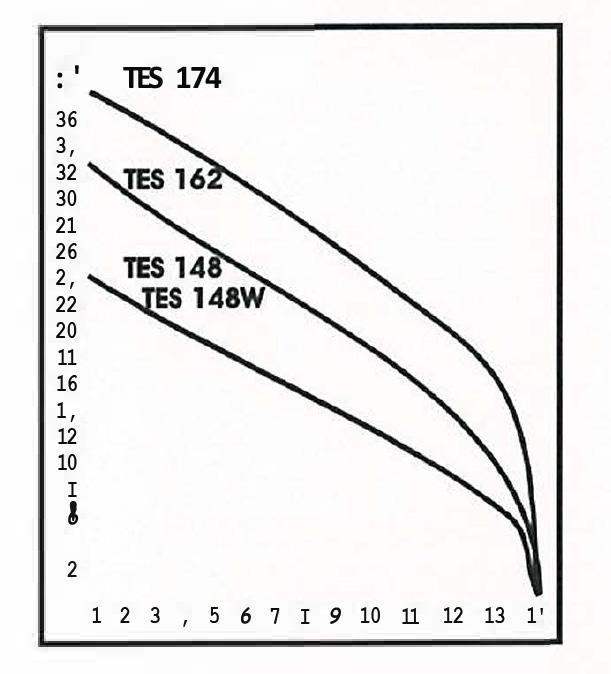

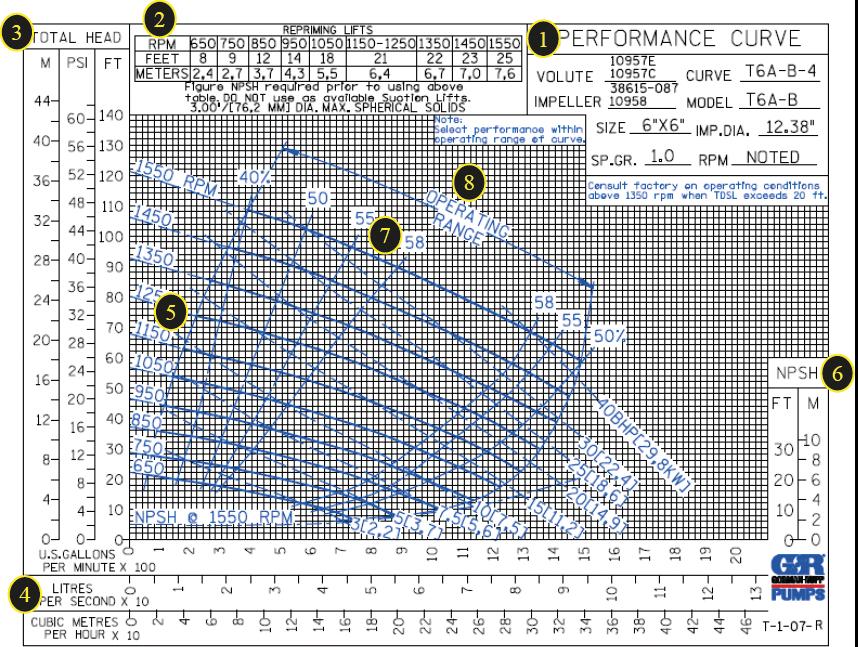

How to read a pump curve

A pump performance curve is defined as a manufacturer’s chart plotting head versus flow. While this is true, most curves include a wealth of additional information. This information may have to do with the subject of power consumption, efficiency, priming, solids capability, or pump parts information.

After design and fabrication of a pump, a prototype is tested to determine the pump’s capabilities from high pressure, low flow conditions to low pressure, high flow conditions.

After testing and documenting the pump’s capabilities at the extremes of pressure and flow, a pump performance curve is finalized.

1. The information provided in this area of the pump performance curve usually contains the performance curve number, pump volute casing part number, pump impeller part number and diameter, basic model number, the suction and discharge size openings, the specific gravity of the product that was used to test the pump, and the speed or speeds at which the pump is capable of operating.

2. The information provided in this area may vary. It may provide general specification information or reprime data.

3. The information provided in this area of the pump performance curve is total dynamic head. This value is found through the calculation of friction loss within the piping system added to the total static head.

This value is also the combination of dynamic gauge readings from the suction and discharge. The values within this area are noted in Meters (M), Pounds Per Square Inch (PSI), and Feet (ft).

4. The information provided in this area of the pump performance curve is flow. The values in the area are noted in U.S. Gallons Per Minute (GPM), Liters Per Second (l/s), and Cubic Meters Per Hour (m3/hr).

5. The information provided in this area of the pump performance curve is the performance of the pump.

It is shown in the form of H/Q or head/capacity lines. These head/capacity lines are noted by the speed required to achieve the head noted along the left side of the curve and capacity noted along the bottom.

6. The information provided in this area is the Net Positive Suction Head Required (NPSHr) by the pump. Its value is found to the right of the NPSHr curve in the chart labeled “NPSH”. The values in the chart are in feet and meters.

7. The information provided in this area is the efficiency. This particular pump ranges from 40 to 58 percent efficient.

8. This dimensional line denotes the full operating range or envelope of which the pump will perform satisfactorily.

A pump performance curve has basically three values, two of which like any mathematical equation have to be known to find the third.

While troubleshooting a pump, two of the three that can be measured and known are speed (tachometer reading of the pump) and the total dynamic head (suction and discharge gauge readings).

With these two known values, we can plot a condition point on the curve and find a flow rate from these two values.

If a design condition point is supplied, it usually is done so in the form of a total dynamic head and a flow rate.

Gorman-Rupp Africa, +27 (0) 11 3973536, www.grpumps.co.za

18 Pipes, Pumps and Valves Africa - Sep/Oct 2022

IPR boosts fleet ahead of rainy season

Disruption on work sites will grow in the next few months as rain returns to many of the country’s provinces, demanding a rapid dewatering solution.

Pump and dewatering specialist IPR – previously known as Integrated Pump Rental – has added capacity for the inevitable spike in urgent enquiries.

According to IPR operations manager Henru Strydom, renting of dewatering pumps remains a great option for dealing with emergencies.

“The high level of responsiveness that IPR offers is directly related to the available fleet that we have developed,” says Strydom.

“We have always been proactive about growing our rental capacity as we do not believe in leaving dewatering to chance during the rainy season.”

Having a rental fleet that is commensurate with the growing market demand has been vital to IPR’s ongoing success and interestingly most of these are trailer mounted. He explains that trailer mounted units allow optimum mobility and flexibility.

Pumping units can be deployed rapidly to sites when required and can also be easily moved on the site itself.

“Renting or leasing offers many advantages over buying your own pumping equipment for infrequent dewatering needs,” he says.

“This is especially the case if companies lack the staff or resources to regularly maintain equipment; they never know whether the equipment is serviceable when unexpectedly high rainfall leads to a sudden emergency.”

He notes that pump ownership inevitably incurs hidden costs related to labour, training, maintenance and spares. Many pump owners may not be aware of the attention that pumps need if they are to be ready for action at a moment’s notice.

“As a quick-response team that is completely focused on our equipment’s readiness, IPR of course handles all the maintenance requirements of rental pumps,” he says.

“We can also provide on-site training to customers’ staff, so that the equipment is employed to its fullest value.”

What this all adds up to, says Strydom, is better control of project costs. It also means that the right equipment is supplied for the job at hand, which is vital when heavy rains cause unexpected flooding.

IPR’s fleet of rental dewatering pump sets is large and diverse, ensuring that suitable units are always available when needed.

These cover the full range of submersible drainage, dewatering, slurry and sludge pumps.

Diesel driven dewatering pump sets are most often the solution of choice, as it is easy to get these units started

and operational even on remote sites where there is no access to power.

Integrated Pump Rental, +27 (0) 87 759 8654, admin@pumprental.co.za, www.pumprental.co.za

Pipes, Pumps

Valves Africa - Sep/Oct 2022 19 PUMPS

and

Accredited local support underpins Grindex pumps in Zambia

Local Zambian company IES has made rapid progress this year as Integrated Pump Technology’s distributor in that region, raising the service bar and expanding the footprint of the Grindex brand of submersible pumps.

Now operating its own authorised Grindex service centre and holding considerable stock to meet customer demand, IES is adding local value to the established Grindex reputation, says Integrated Pump Technology general manager Jordan Marsh. The Zambian Copperbelt has some of the wettest mines in the world, making dewatering a critical function on most mines. This places pump performance and reliability at a premium, says Marsh, hence the popularity of Grindex.

“As the official Grindex distributor in the Southern African Development Community (SADC) since 2014, Integrated Pump Rental’s priority is that these pumps are always well supported,” he says. “We are therefore excited to have tied up with IES as our distributor in Zambia, as they have a depth of experience both in the brand and the market.”

IES managing director Andrew Kansamba has 15 years of experience working with Grindex brand and with Integrated Pump Technology. Together the IES team has decades of combined experience working with this pump range, says Kansamba, making IES a natural fit to represent the brand in Zambia.

“Integrated Pump Technology and IES share the same operating style, with hands-on involvement from top management all the way down,” says Kansamba, an

electrical and mechanical engineer who began his career on a Zambian copper mine. “Our IES facility is centrally located in Kitwe, the strategic heart of the Zambian Copperbelt – so we can quickly reach the main mining and other operations within and outside of the Copperbelt region.”

The IES service centre improves the lead time on pump repairs and maintenance, giving customers access to a local source of technical expertise. This will reduce the need for pumps to be serviced by non-authorised workshops.

“Grindex pump owners can be confident that their pumps will be serviced to OEM standards,” says Marsh. “Mines will also appreciate the value that this service is creating within the local economy.”

Most of the product applications in the Zambian region relate to dewatering. Among the popular items in the range is the 90 kW Grindex Mega N and H pumps. Some of these units are successfully dewatering larger volumes in various underground and open pit mines, including applications at the bottom of shafts.

Other popular Grindex products in the region are the 37 kW Maxi N and H, 18kW Matador, 8 kW Master, 5.6 kW Major, 3.7 kW Minor and 2.2 kW Minette as well as the Bravo range of slurry pumps.

Integrated Pump Technology, +27 (0) 11 894 2906, sales@pumptechnology.co.za, www.pump-technology.com

20 Pipes, Pumps and Valves Africa - Sep/Oct 2022

PUMPS

MARCH 14-18 / 2023 / LAS VEGAS / NEVADA 250,000 sqm of Exhibits 130,000 Attendees 1,800 Exhibitors 150 Education Sessions REGISTER at conexpoconagg.com Save 20% with promo code SHOW20 TAKING CONSTRUCTION TO THE NEXT LEVEL. “ CONEXPO-CON/AGG PAYS DIVIDENDS ON YOUR TIME AND INVESTMENT BY BRINGING TOGETHER NEW TECH, BIG PLAYERS AND EDUCATION IN ONE PLACE.” — BREX ENTERPRISES, IRWIN, PA

VALVES

Digitalisation as a game changer

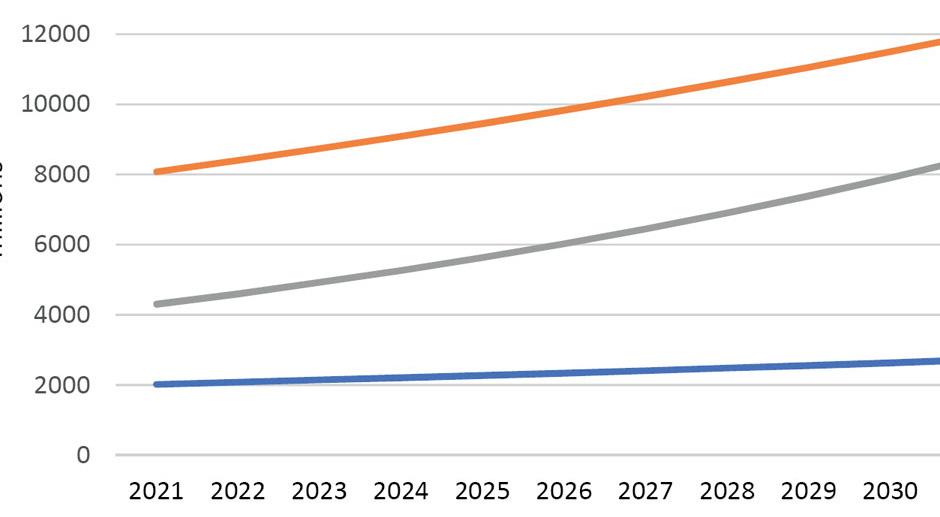

Digitalisation enables companies to act successfully, economically and ecologically. It optimises quality, safety, conservation of resources, energy savings and the reduction of CO2 emissions. Companies in the valve industry are using digital transformation to increase their competitiveness. It is turning out to be a real game changer.

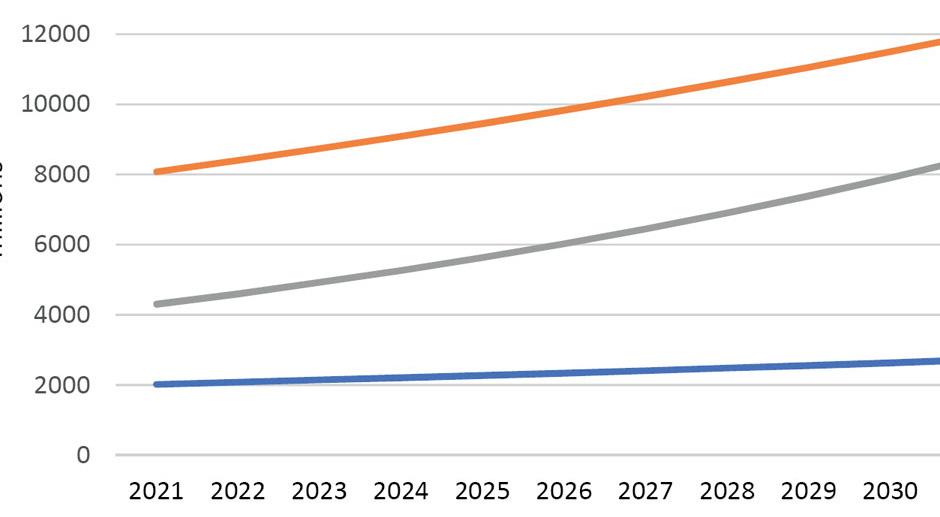

The trend is growing year by year. According to the Worldwide Digital Transformation Spending Guide of the International Data Corporation (IDC), spending on digital transformation will therefore have an average annual growth rate (CAGR) of 16.4 percent in the forecast period from 2021 to 2025. The reason for this is that companies are increasingly pursuing an end-to-end digital strategy for people, processes, technology, data and governance. Global spending on the digital transformation for business practices, products and organisations is projected to reach $2.8 trillion by 2025, more than twice as much as in 2020.

Connected production

The German plant and mechanical engineering industry has made high investments in digital transformation as well, so that it is already well positioned in productionrelated digitalisation. "For example, implementing interconnectivity within production as well as the integration of sensor technology to optimise production," explains Prof. Claus Oetter, Managing Director of the Software and Digitalization Association of the Association of German Mechanical and Plant Engineering (VDMA). The valve manufacturers have long since embarked on the

path of digitalisation. "In the past years, there has been a significant increase in decentralised automation of process valves, precisely in step with digital communication", confirms Sebastian Kundel, Product Manager Automation Process Valves at Bürkert. "Particularly important is digitalization of highly automated processes. Products with high quality standards demand validation of process operations".

The companies are aware that information technology already plays a decisive role today, but above all in the production of the future. AUMA therefore already offers its own cloud. The aim is to "make the asset management and condition-oriented maintenance of AUMA actuators efficient and cost-oriented and to ensure the long-term availability of the system".

Interactive platform

The AUMA Cloud is an interactive platform with which detailed device data can be collected and evaluated by all actuators in one system – made possible by intelligent algorithms.

"Our drives automatically collect and store process data

22 Pipes, Pumps and Valves Africa - Sep/Oct 2022

such as valve position, ambient temperature and vibrations as well as device data such as switching frequency, motor running time and warning messages," explains Marc Schmidt, Head of International Sales at AUMA. Plant operators can detect high loads or possible servicing and maintenance requirements at an early stage and thereby initiate the appropriate measures in order to prevent unexpected failures. Data is therefore used in a better way, and processes are optimised.

Digitalisation is important for all industries: It is not only increasingly shaping production processes as well as the onshore sector and offshore industry, but also, for example, the water industry. In addition to Industry 4.0, Water 4.0 also introduces a veritable revolution for purest water. A resource-efficient, flexible water management process can ensure an optimised water supply and disposal at all times – in a combination of measuring systems and control technology as well as actuators and valves.

Recording and evaluating data

Rotork also develops digital systems in order to prevent equipment faults, aging or inefficiencies which lead to production losses, reputational damage and financial losses. The intelligent electric Rotork actuators are equipped with a data logger which records and evaluates data. For example, the number of valve movements, alarms, torque profiles and unauthorised operating attempts. Torque profiles "provide valuable information about the condition of the valve, while sudden alterations in the average and peak temperature or vibration indicate a plant problem," explains Andreas Fuchs, Rotork Country Manager Germany. Data is analysed in asset management systems. These systems provide information at an early stage in order to ensure safe and reliable plant operation through measures and to prevent unforeseen costly and dangerous system failures.

Significant reduction of emissions

In addition to efficient processes, the digitisation of

industry also offers great potential for reducing CO₂ emissions. According to the Bitkom study "Climate Effects of Digitalisation", accelerating the use of digital technologies, in Germany alone could be saved up to 64 million tons of CO₂ in 2030 – that is 17 percent of the total planned CO₂ savings as part of the 2030 climate target. Furthermore, the use of digital twins, i.e. the simulation and optimisation of physical products or processes, could save 33 million tons of CO2. According to the Bitkom study, an additional 31 million tons could be avoided by increased automation in production, using digital technologies to reduce manual intervention and the use of materials as well as optimising processes.

Networks with added value

The concrete implementation of digitalisation on the ground has not yet been decided. For example, in pneumatic actuators. "So far, it has been outsourced to add-on parts," explains Mark Schmidt, Managing Director of Air Torque. The advantage of this solution is the simple interchangeability. However, there are now also all-in-one products. "It remains to be seen what the market decides on."

The digital possibilities appear complex for the market. Therefore, coordination – also in the form of corporate networks – offers added value. The open integration network has developed from this idea. Cooperation partners test and document the interaction of their products and the ways to fully utilise digitalisation in typical automated process environments.

"Users benefit from this in two ways: They can combine the best products of the respective product segment in their operating environments and also commission them quickly and easily, "explains Endress+Hauser. The company's partner programmes include Auma Riester, Bürkert, Flowserve, Pepperl+Fuchs and Rotork, among others.

AI as another pulse generator

The goal of implementing digital transformation has long been a priority for many companies. And that is why networks such as "open integration", but also cooperations with universities, are up-to-date. Also against the background that Artificial Intelligence (AI) provides additional strong impetus to digitalisation not only by collecting and interpreting data: AI intervenes in the process without human decision – machines react to each other. A development which companies can use for themselves – but also for the climate. However, it will take years to implement this trend consistently. But the way to this objective will be worthwhile.

From 29 November to 1 December 2022, the key players of the industrial valves sector will present themselves at VALVE WORLD EXPO with an accompanying conference in Düsseldorf.

Experts from all over the world will use the Düsseldorf Fairgrounds as an international fittings summit to present their innovations and discuss current research and production processes.

Valve World Expo, www.valveworldexpo.com

Pipes, Pumps and Valves Africa -

Sep/Oct 2022 23 VALVES

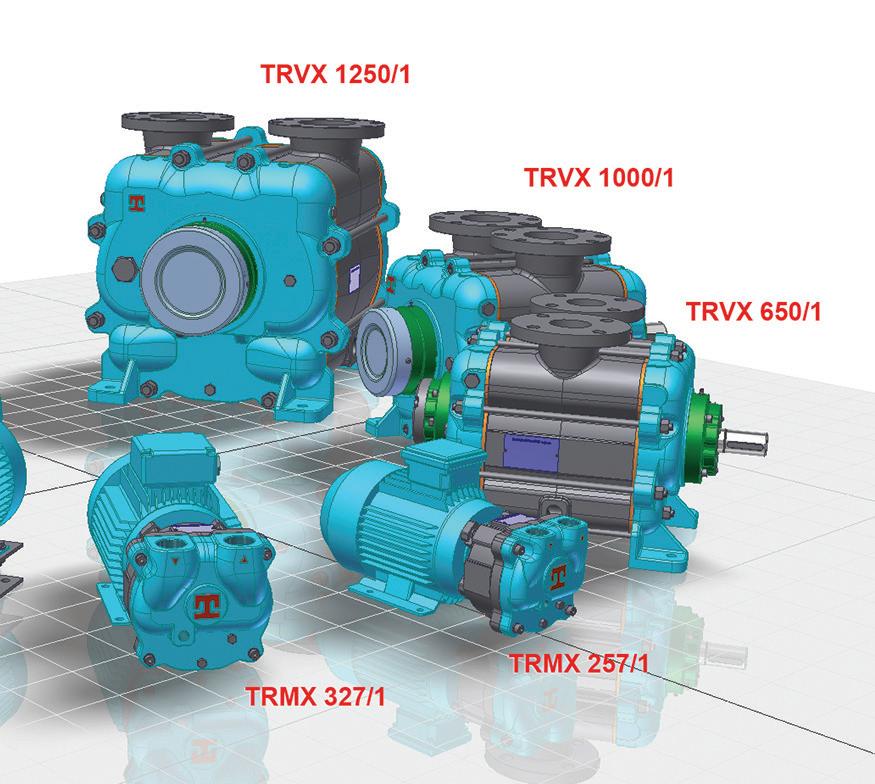

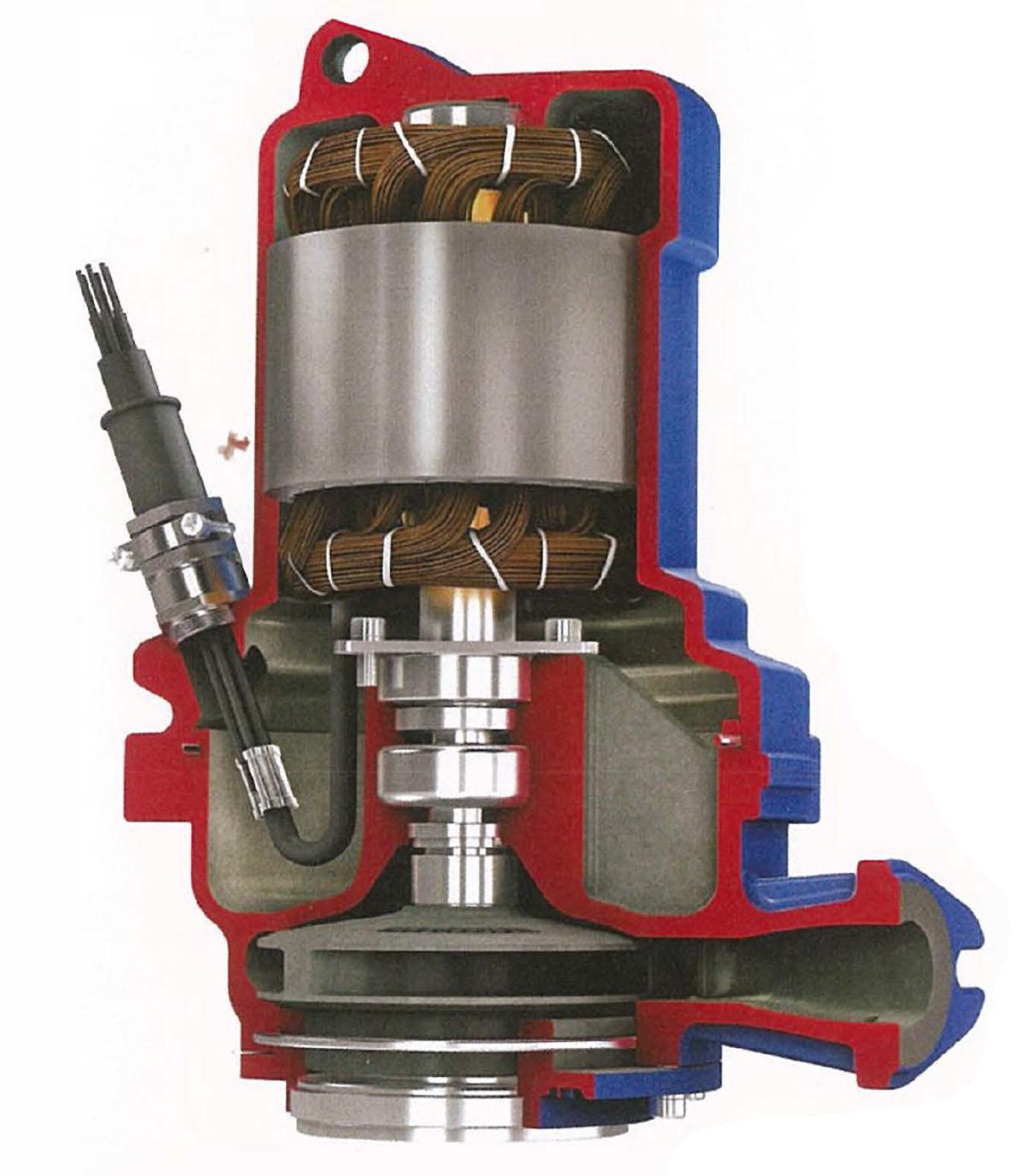

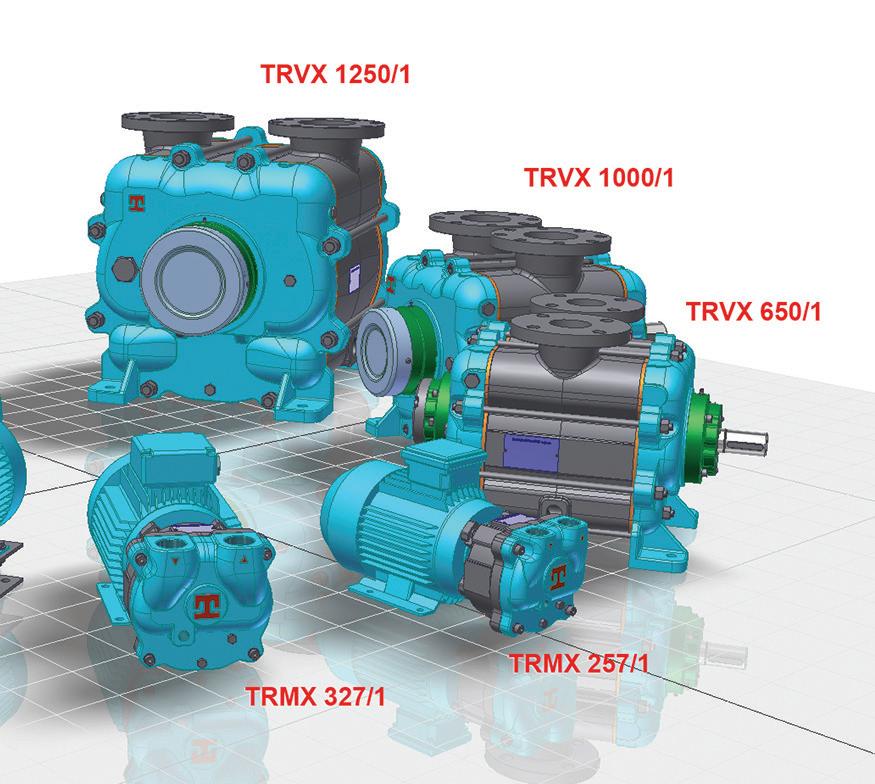

New generation liquid ring vacuum pumps

A range of single stage, variport liquid ring vacuum pumps is ushering in a fresh era in design performance and reliability.

TRVX Pompetravaini’s technology offers tangible benefits for food and beverage manufacturers. The new hydraulic profile allows performance increases of more than 10 per cent over traditional liquid ring designs. Increases in efficiency and operational cost savings can now be achieved over the entire pump life.

Advantages when compared to traditional liquid ring vacuum pumps:

• Pump weight is 30 per cent less on average compared to traditional designs

• Units are compact and dimension and volume is 40 per cent less than traditional designs

• Features single and direct service liquid connections

• Up to 50 per cent less service liquid usage reduction

• Central body impeller housing with integrated suction and discharge manifolds. This feature reduces pump components and increases robustness

• Suction, discharge port plates and impeller in stainless steel allows greater reliability.

• Standard ISO 3069/DIN 24960 mechanical seals are easily obtainable. This reduces component stocking

• Mechanical seals can be replaced without disassembly of the pump reducing downtime

• Features external precision regulation of the impeller shaft, resulting in easy maintenance, performance optimisation, assembly time and cost

• Length between bearing supports is 25 per cent less than traditional pump designs. This results in a reduction of eventual vibration and shaft deflection

• Connections are universally flanged to meet both DIN-EN and ANSI standards.

The TRVX is a true leader in its own class with capacities up to 2 000m³/h with a maximum vacuum of 33mbar abs.

24 Pipes, Pumps and Valves Africa - Sep/Oct 2022 ADVERTORIAL

A&VT = ADDING TOGETHER info@vactech.co.za 011 318 3241/2/3/4 www.vactech.co.za and the latest technology peristaltic hose with XXL roller technolog y, operation and maintenance saves on costs and downtime. Instruvac – a Division of Air & Vacuum Technologies (Pty) Ltd – are the sole agents for the Pompetravaini Liquid Ring Vacuum Pumps

VALVES

Setting a new benchmark in pneumatic actuators

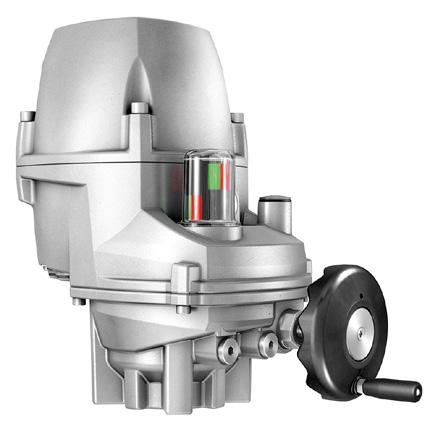

EMVAfrica, a trusted and renowned BBBE-E level 4 single-source supplier of worldclass industrial stainless steels and valves to Southern Africa’s mining and industry, proudly introduces the new V-ACT.

This superior quality pneumatic-operated rack and pinion actuator is suitable for the automation of new and existing quarter turn valves. V-ACT is the best choice for butterfly and ball valves and offers a proven solution for automated centralised control.

“The growing global trend by industry to move towards automation is driving a demand for actuated valves, with South Africa being no exception,” says Preshan Pillay, Valves Product Manager at EMVAfrica. “After identifying a great opportunity in the local market for high quality, reliable actuators, we searched for a suitable manufacturer whose product would match our valve portfolio in terms of quality and reliability. The V-ACT ticked all the boxes.

The actuator extends and complements our current comprehensive valve holding and is ideal for any industry that uses valves.” Pillay adds that the unit is particularly suitable for the manufacturing sector where automation is required to control different processes.

The V-ACT features a simple yet smart design that delivers several advantages. The compact dual piston rack and pinion design ensure a symmetric mounting position, a high life cycle and fast operation. Reverse rotation can be conveniently and rapidly accomplished in the field by simply inverting the pistons. Furthermore, the mounting of solenoids, limit switches and other accessories is easy.

The actuators boast an extruded aluminium (ASTM6005) body with internal as well as external corrosion protection. The honed cylinder delivers longer life and low coefficient of friction. The CE approved V-ACT is ISO5211 and Namur compliant and manufactured under ISO9001:2000 certification. The rugged reliability of these actuators reduces the chance of failure, thus maximising uptime and productivity for end users.

“We understand the importance of uptime for business sustainability which is underpinned not only by quality products but also by excellent after-market service,” notes Pillay. “To support our customers in the service space, we have employed a full-time qualified actuator technician and we carry stock of a full range of the fast-moving spares for the whole range of V-ACT actuators to ensure fast supply.”

Pillay further unpacks EMVAfrica’s commitment to assisting customers in solving business challenges. “In line with our 3-S factor - Stock, Service and Solutions - we source and supply superior quality products from reputable global manufacturers, provide support and industry experience and implement a 360° approach to problem-solving.”

The extensive valve offering from ISO 9001 certified EMVAfrica serves diverse applications within Southern Africa’s mining, mineral processing, water treatment, petrochemical, power generation, food & beverage, and general industrial sectors.

The V-ACT is currently available in a pneumatic quarter turn option and Pillay reveals that Energy valves will soon be expanding their offering to include a linear pneumatic actuator as well as an electric version.

EMVAfrica, +27 (0) 11 466 2480, sales@emvafrica.co.za, www.emvafrica.co.za

26 Pipes, Pumps and Valves Africa - Sep/Oct 2022

This will NOT happen with oddesse pumps

Telephone: (011) 792 9550/1/2 Fax: (011) 792 9553 e-mail: eeeaman@mweb.co.za Website: www.ernestee.co.za

VALVES

Valve trends in the global water and wastewater industry

The growing demand for water is mainly driven by population growth, which stimulates water consumption in various ways: as drinking water but also in agriculture, industry and power generation. Due to increased regulation and higher cost, municipalities and industries try to minimize waste water volumes and focus on waste water reuse.

Freshwater scarcity, one of the most critical global challenges of our time, poses a major threat to economic growth, water security, and ecosystem health. The challenge of providing adequate and safe drinking water is further complicated by climate change and the pressures of economic development and industrialization.

The public and industrial sectors consume substantial amounts of freshwater while producing vast quantities of wastewater. If inadequately treated, wastewater discharge into the aquatic environment causes severe pollution that adversely impacts aquatic ecosystems and public health.

Recovery and recycling

Recovery and recycling of wastewater has become a growing trend in the past decade due to rising water demand. Wastewater re-use not only minimizes the volume and environmental risk of discharged wastewater, but also alleviates the pressure on ecosystems resulting from freshwater withdrawal. Through reuse, wastewater is no longer considered a “pure waste” that potentially harms the environment, but rather an additional resource that can be harnessed to achieve water sustainability.

Communities across the country are incorporating water reuse into their water management strategies as a proven

method for ensuring a safe, reliable, locally controlled water supply-essential for liveable communities with healthy environments, robust economies and a high quality of life.

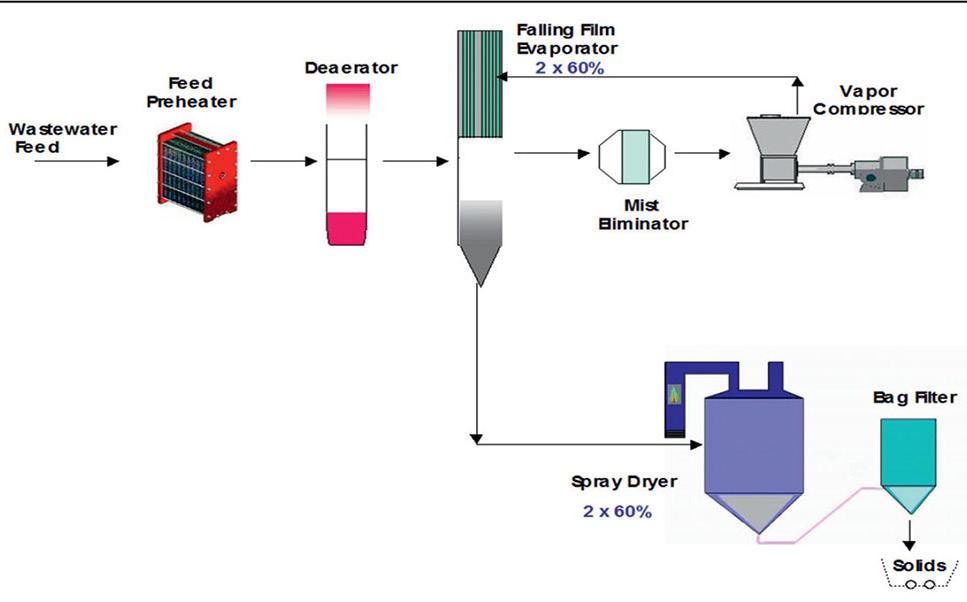

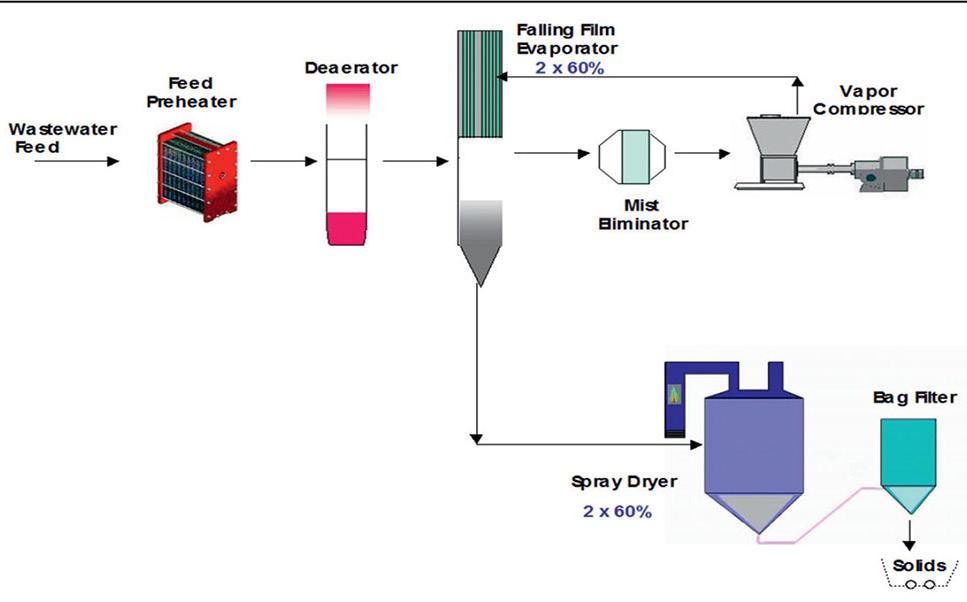

Zero liquid discharge

Zero liquid discharge (ZLD) eliminates any liquid waste leaving the plant or facility boundary, with the majority of water being recovered for reuse. There are several approaches to achieving ZLD; one involves reverse osmosis and evaporation. ZLD obviates the risk of pollution associated with wastewater discharge and maximizes water usage efficiency, thereby striking a balance between exploitation of freshwater resources and preservation of aquatic environments. More stringent regulations, rising expenses for wastewater disposal, and increasing value of freshwater are driving ZLD to become a beneficial or even a necessary option for wastewater management.

Areas of growth for water recycling include:

• Agricultural reuse

• Onsite non-potable water systems

• Industrial reuse

• Environmental restoration

• Potable (drinking water) reuse

28 Pipes, Pumps and Valves Africa - Sep/Oct 2022

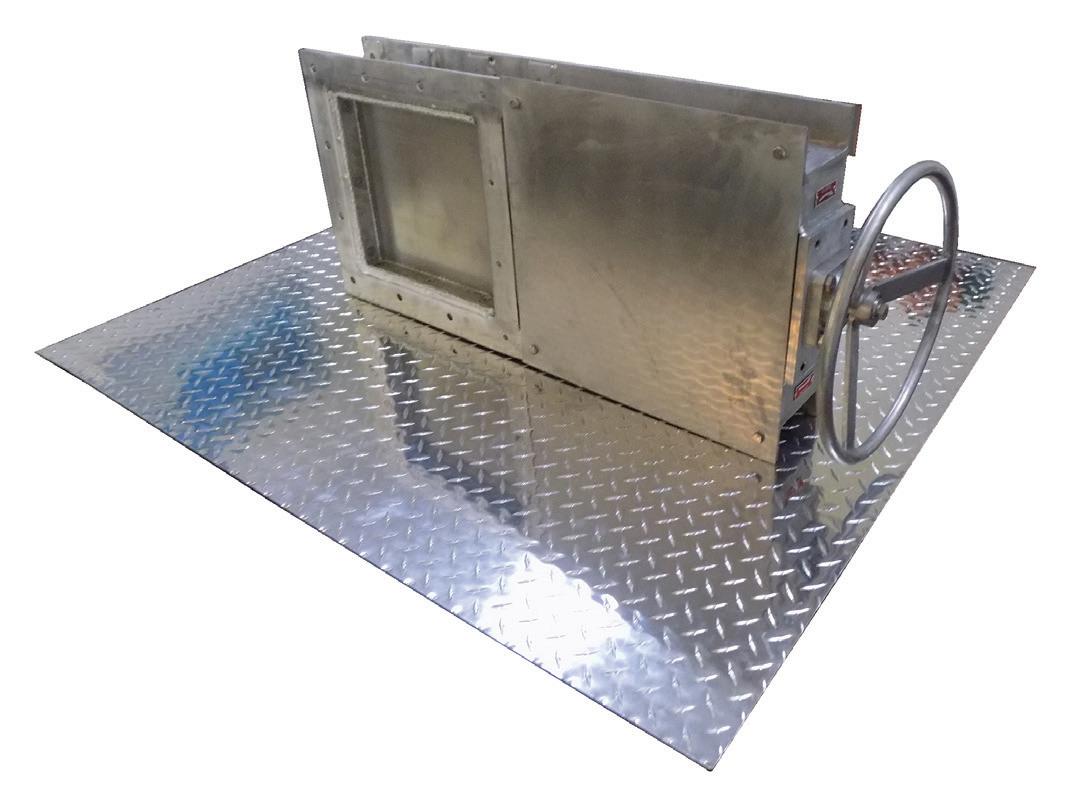

ZLD involves various process steps, for example reverse osmosis and evaporation Another involves using power plant heat to achieve the evaporation. Image courtesy of Aquatech Highperformance

From a global perspective, the global industrial market is more promising, with a growth rate of 7 per cent per annum. This high growth industrial market includes zero liquid discharge (see box text) and wastewater re-use. As mentioned before, the sanitation and re-use of water is an interesting growth market. Wastewater re-use also involves a bigger investment in high performance valves than normal wastewater treatment.

It can involve evaporation and reverse osmosis which

require special valve designs. One of the biggest present and potential uses is the power industry.

In China, re-use of municipal wastewater from power plants is standard practice.

In the U.S., municipal wastewater sources are convenient.

The average power plant is within 70 miles of a municipal wastewater plant.

This use of power plant heat involves a spray drier and a critical valve to control slurry injection into the dryer. To conclude, the market for valves for water and wastewater will be driven by population growth which will increase total use.

A bigger driver, however, will be the water scarcity that is in part due to climate change but also do to previous water management practices.

By Bob McIlvaine.

Valve World, www.valveworldexpo.com

Pipes, Pumps and Valves Africa - Sep/Oct 2022 29 VALVES Servicing our clients across the globe for over 35 years with high quality, high performance SAMCO® Pumps and OEM Spares

sameng.co.za sales@sameng co za +27 11 823 4250 • “Produced water” from oil and gas production • Stormwater capture and reuse

www.

VALVES

AR Controls well positioned to ride copper, cobalt and nickel wave in Africa and South America

With the global mining industry on the cusp of a commodity super cycle the likes of which was last seen in 2015, this remains the largest, most lucrative, and low risk market for valves in Africa.

“Copper has proven especially robust during a depressed financial market,” notes AR Controls Managing Director Julien van Niekerk. It has placed the spotlight firmly on the Central African Copperbelt, the largest copper and cobalt resource in the world, centred on Zambia and the Democratic Republic of Congo (DRC).

The leading importer and manufacturer of a comprehensive range of internationally recognised valves and instrumentation is successfully undertaking major work in the DRC.

“We had already made inroads into the DRC a decade ago when it was considered a difficult and closed market, and now it is one of the most favoured mining destinations on the continent, especially in terms of copper,” says van Niekerk.

Apart from its ongoing expansion in Africa, AR Controls continues to extend its global footprint.

This includes a strong focus on niche markets in Africa, Australia and Pacific Islands, and South America.

“Our international expansion is made possible due to our dual role as both a manufacturer and a stocking distributor, as well as the excellent supplychain management we leverage globally,” highlights van Niekerk.

The impact of the Covid-19 pandemic on the mining industry in particular has been increased lead times.

As the largest valve stockist of its type on the continent and possibly even in the Southern Hemisphere, AR Controls is hence in a unique position. “Having such a major inventory on hand is definitely a significant advantage against our competitors. Apart from supplying premium products, we also back this up with

exemplary service,” highlights van Niekerk.

A major challenge remains the influx of sub-par valves into Africa from low-cost manufacturing countries.

Quality is critical as it relates directly to gains in plant availability and revenue while operating in very arduous environments.

“It makes it challenging for us in that we have to be innovative and at the same time have boots on the ground to physically add value to our customers’ supply chains in terms of operations and their procurement processes,” adds van Niekerk.

“Extending our reach through our channel partners, our distributors have factory trained personnel, and our aggressive on-site support maximises availability and uptime and reduces production losses.”

“It goes a long way to forging very close relationships between ourselves and all our end users.”

AR Controls has been manufacturing the ARVALV® range since 1999 in its Vanderbijlpark factory, which has proven highly successful and has achieved a significant market penetration in critical process applications in the mining industry.

“Looking at our current market share, it is not inconceivable for us to double this in the foreseeable future,” says van Niekerk. In addition to ARVALV®, AR Controls owns the IncoValve and Controls® brand, which it acquired in 2016, and is the exclusive African and Central American distributor for international OEM DeZURIK.

“Our strategy is to break into new territories and industrial sectors, as well as continue to grow those markets where we are already entrenched.”

“We are aggressively involved in offering new product lines to complement our existing range and ensure our pricing

30 Pipes, Pumps and Valves Africa - Sep/Oct 2022

is competitive,” says van Niekerk. The range of valves and actuation accessories available is robust and ideal for harsh mining environments.

The core product lines are knife gate valves, concentric and high-performance butterfly valves, ball valves, non-return valves, control valves, actuation, and automation. A key product line that has seen significant growth in demand is pneumatic enclosures, which are supplied in various materials to house and protect-critical instrumentation. It also ensures that valves installed in hard-to-reach or hazardous areas can be operated with ease from an easily accessible and clearly marked safe remote area.

AR Controls will be a major presence at Electra Mining Africa 2022 from 5 to 9 September at the Johannesburg Expo Centre.

This is the first time the trade show has been held since Covid-19, with the OEM planning to take full advantage of displaying its full manufacturing and distribution capabilities and international presence.

“Our significant presence will communicate clearly that we are a major contender and the partner of choice when it comes to premium valve and actuation products and backup support and service for the mining industry,” concludes van Niekerk.

AR Controls, +27 (0) 16 981 4551, sales@arcontrols.com, www.arcontrols.com

- Sep/Oct 2022 31

Pipes, Pumps and Valves Africa

VALVES

GLOBAL LEADERS IN THE MANUFACTURE OF DURABLE THERMOPLASTIC VALVES AND PIPELINE SYSTEMS FOR CORROSIVE MEDIA

Since 1952, we have been the pioneers in this segment, setting new standards year by year through our brand: ASAHI AV. All the components of our products originate from our own production under the ASAHI YUKIZAI CORPORATION based in Tokyo, Japan. This guarantees a high-quality standard (ISO 9001) as well as exceptional flexibility and availability. Our knowledge of industrial applications (gained from over six decades of international experience) distinguishes us in particular.

As part of its ambitious focus on global expansion, the ASAHI YUKIZAI CORPORATION saw that the African market had great potential to benefit from our thermoplastic valves and decided to buy out Celtech Pipe Systems – our South African distributor founded in 1992. After the absorption of this company in its entirety, the future of ASAHI YUKIZAI’S presence within Africa was born: ASAHI Africa.

Established in 2019 as a subsidiary of the ASAHI YUKIZAI CORPORATION, ASAHI Africa has established relationships with many high-profile clients within South Africa such as Anglo Platinum, Columbus Stainless, Impala Platinum, Mondi, NCP Chlorchem, Sappi, Rand Refinery, Sasol, etc. Our continued business with these companies is a testament to

the quality of our products and customer service.

By working in partnership with us, our customers would be afforded the following benefits:

• A dedicated sales force based in our KwaZulu-Natal and Gauteng branches

• Access to an established brand of high-quality valves that are long-lasting and reliable

• Stock maintained within South Africa allowing for short lead times

• Direct communication with our factory in Japan to enable efficient response and tailored services when required

Outside of the Asahi range, we are also the proud distributors of the brands ChemValve-Schmid and Mecánica Prisma.

ChemValve-Schmid:

ChemValve-Schmid develops and produces high-quality valves (butterfly valves, ball valves, wafer check valves, nonreturn valves, etc.) in Welschenrohr, Switzerland.

Embedded in an environment that has been at the forefront of watch development and manufacture for over a century, they have developed and specialised into one of the leading manufacturers of PTFE-lined industrial valves in Europe.

Mecánica Prisma: Mecánica Prisma’s Spanish-manufactured actuators are known throughout the world for their robustness and reliability.

Prisma manufactures four families of pneumatic actuators according to their application: rilsanised aluminium, stainless steel, industrial plastic and for high-temperature actuators. These are all built under international standards: ISO, DIN, NAMUR, VDE, VDI, ATEX, CE, DNV, PCT, SIL2.

Mecánica Prisma is accredited by the quality standard ISO TS-29001, API Q1. They export roughly 65% of their production to more than 45 countries on five continents.

Through the combination of Asahi AV, ChemValve-Schmid and Mecánica Prisma, we look forward to finding a solution for your corrosive applications!

GAUTENG

Unit 34, Airborne Park, Taljaard Rd, Bartlett, Boksburg, 1459

T 011 397 4353/5 C 082 496 1089 F 011 397 4368

E info@asahi-africa.com

KWAZULU NATAL

P.O. Box 201053, Durban North, Kwazulu-Natal, 4016

T 031 563 3923 C 063 648 0724 F 031 563 3929

E joshua@asahi-africa.com

ASAHI Flow Control Valve PVC & PVDF available

ASAHI THERMOPLASTIC VALVES CHEMVALVE LINED VALVES PRISMA PNEUMATIC ACTUATORS

Leveraging better wastewater treatment to save the environment and ourselves

For water to truly be utilised without harm it needs to be clean, and the fact is that fresh water is not an infinite resource. Additionally, increasing urbanisation is placing strain on water resources and infrastructure networks alike across Southern Africa.

Fresh water used in industrial and process applications that is not remediated properly before being discharged back into local sewerage systems is also a heavy contributor to water pollution, placing further pressure on water treatment plants.

This is being further exacerbated by climate change, most particularly the potentially devastating drought that it can bring. This was plain to see in 2018, when Cape Town came within days of Day Zero, and becoming the first city in the world to run out of water.

Successful water treatment of wastewater is therefore essential for the sustainability of our planet, and our survival is dependent on responsible water management. Wastewater encompasses a broad spectrum, including drainage from households, commercial establishments, hospitals and industries. It also includes stormwater and urban runoff, along with agricultural, horticultural, and aquaculture effluent. Untreated, dirty water gets released into natural water reservoirs, where it wreaks havoc on fish, animals and crops. This water evaporates, and ultimately the resulting rainwater is also largely contaminated.

As it currently stands, however, wastewater treatment is not being fully leveraged. According to the UN, approximately 80% of wastewater is released into the environment without being recycled or adequately treated. This only increases the risk of contamination to potable and drinking water.

Furthermore, failing to fully utilise efficient wastewater treatment has a deleterious impact on socioeconomic issues, impeding sustainable economic development.

Effectively utilising wastewater is not only essential to environmental conservation and a smart way to address water shortages, but also potentially a resource, from which water, energy, nutrients and a variety of recoverable materials can be garnered.

Beyond that, it can also serve as a marketable commodity in its own right. According to the UN Environmental Programme, and the Global Wastewater Initiative, there is 330km³ of municipal wastewater being generated globally each year. If this wastewater could be managed effectively, the resources embedded in this water could be used to irrigate and fertilise millions of hectares of crops, as well as produce biogas that could supply energy for millions of households.