MAEDEH PARSIESFAHANI

I started to paint when I was 3 years old, as painting was a tool for me to connect to the world of imagination and creativity anytime. Later in life, in 2021, one of my paintings got nominated as one of the best paintings of the Decade in my home country.

I believe art can communicate the complicated and has the power to connect people together. Humanity, integrity, and peace are my values and I know myself morally responsible towards other people, before anything else in this world. I love to work with people and my ability to communicate with people and be an effective influencer, has always made me different, whether at the workplace or in life in general.

As a painter and architect, I have this dream to have a positive impact on people’s lives and emotions by creating unique pleasant spaces and artworks in society.

UNIVERSITY PROJECTS, RECOGNISED AS BEST DESIGNS

REVIT DOCUMENATIONS

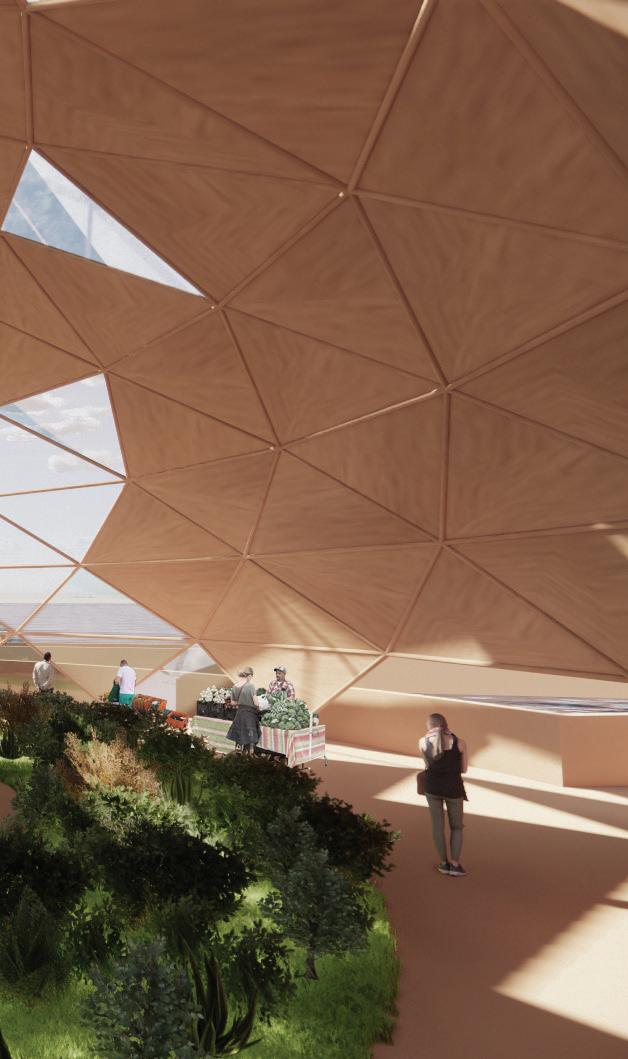

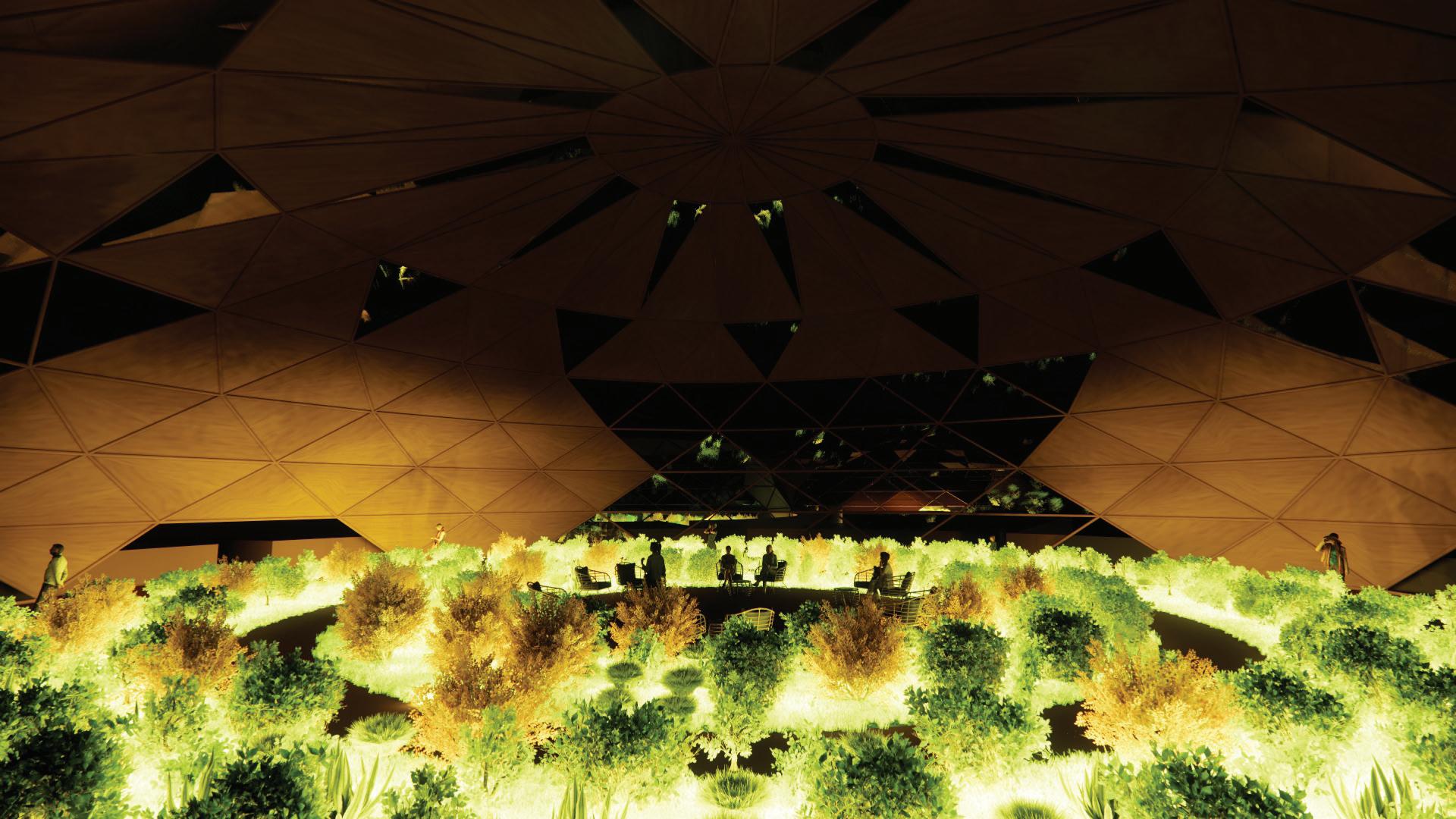

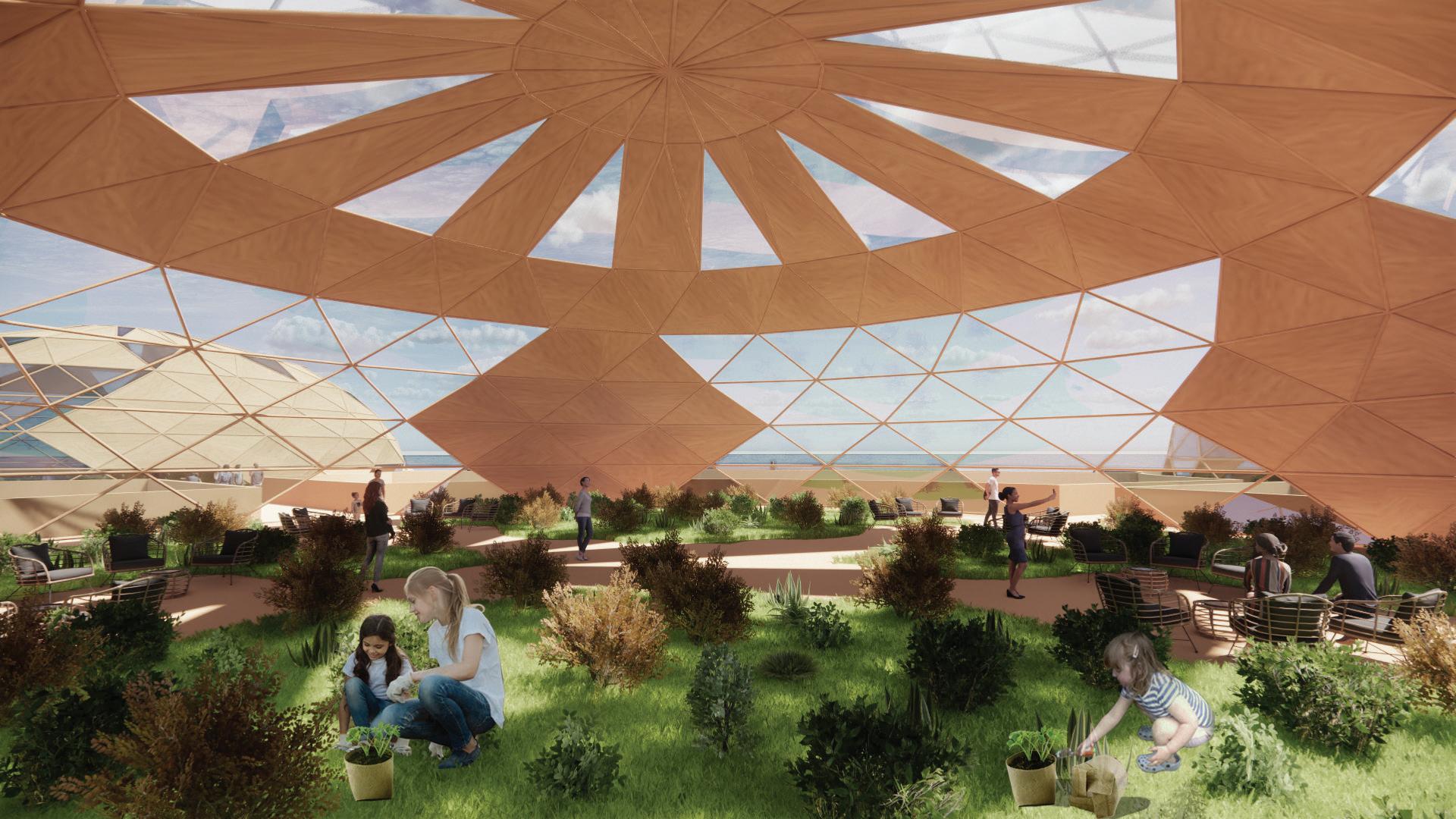

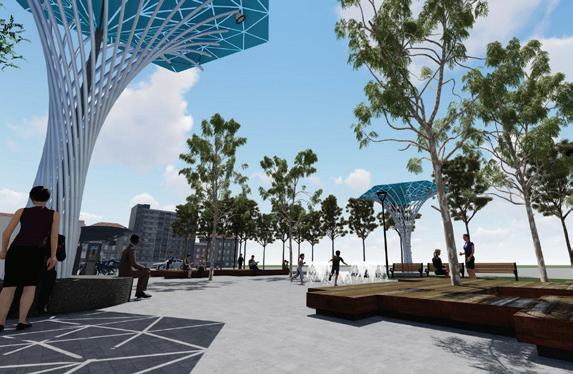

We are reusing the Garden Island, for designing a sustainable removable and movable structure. Glow plants, as starts at night, create a temporary special environment at night by lightening the space without electricity usage and in a sustainable way. In the morning the triangular glasses on the roof create temporary shades with cosmological shapes on the floor as well. The program also changes with the change of seasons and invites people to appreciate each season’s features and specific native plants. Glow land brings the SA community together in a sustainable space and engages them with landscape and nature that aims to improve the environment quality, diminish the negative impacts of climate change on our society, improve public knowledge about native plants and native medicinal plants and improve physical and mental wellbeing in different ways. Glow land provides multiple opportunities for creating positive human interventions in nature, through bringing the landscape in the heart of the ocean and inviting people to plant and garden in the outdoor landscape. This wooden floating structure consists of 4 sections which are connected to each other by wooden paths over the ocean. This sustainable environment and its programs welcome all people from SA, especially students, local farmers, and Garden Island community people. Approximately 150 people can be placed in.

My design changes through seasons and in the night. Change of seasons and existence of day and night are cosmological phenomenons. These astronomical phenomenons underpin my conceptual design.

Since this structure retrieves its main identity at the darkness of the night when the glowing plants start glowing as starts in the sky, my design has a cosmological concept. In the morning the triangular glasses on the roof create temporary shades with cosmological shapes on the floor as well. The triangular shapes on the dome are derived from the triangular shapes in the constellations.

Seasonal Plant Library

Seasonal Plant Library

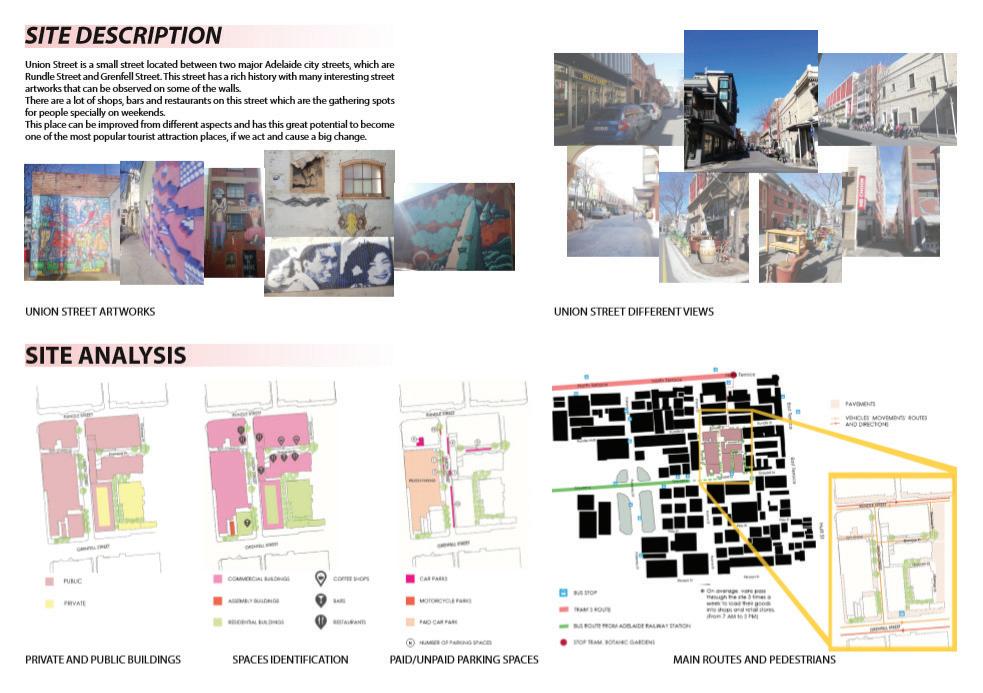

As we know, climate change has become a critical worldwide issue, which governments all around the world are trying to satisfy people with improving the sustainability factor in many things as much as possible. In all the design projects clients’ comfort and peace of mind is the priority for the designers. This design project is not only cost-effective, but also promotes Union Street in a way that it becomes more sustainable and environmentally friendly, providing people with more comfort and peace of mind while making it a safe and comfortable place. This street responds to peoples’ comfort by its suitable street furnitures, while providing people with shade and fresh air under its beautiful tall trees all over the street. As mentioned before, this project gives a lot of value to the environment, habitat by providing the street with trees, birdhouses and benches including beautiful planters beside them.

This group environment project’s goal was to improve the environmental quality of Bowen Street located in Adelaide CBD. Our team designed big shadings facilitated by solar panels, misting fans and rain water collection pipes. Based on our site thermal analysis done by envimet software, we increased the vegetaion on site by adding more trees and some green roofs on top of the surrounding buildings. We also changed the asphalt surfaces to concrete and grass. Then, we calculated the amount of water required on site and the amount of underground rain water collection tanks, based on our thermal analysis done by envi-met software.

PROJECT DESCRIPTION

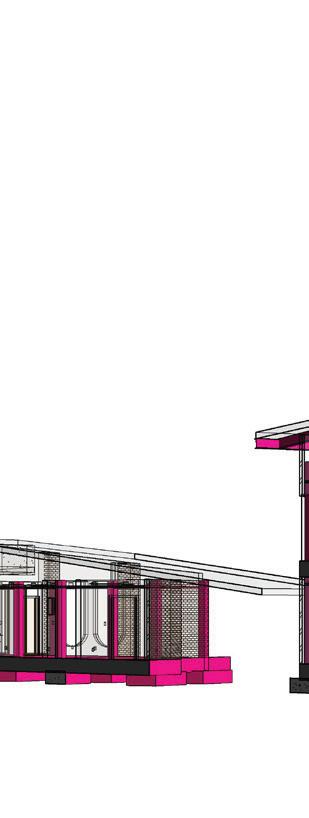

In this project we were asked to prepare the revit model and the documentations of a bridge located in the North Terrace Campus of the Adelaide University, connecting the State Library of South Australia to National Archives of Australia’s building.

We had to prepare construction details and structure analysis based on our assumptions achieved through our visual observations.

X 250 SHS COLUMN FIXED TO GROUND BY REINFORCED FOOTING

HANDRAIL BOLTED TO PFC BELOW (DIAMETER 50 MM)

GLASS WALLS (20 MM THICK) SUPPORTED STEEL PLATE BELOW

STEEL HANDRAIL BOLTED TO PFC BELOW

2O MM ALUMINIUM THICK PLATE

UNIVERSAL BEAM SCREWED TO C CHANNEL

CROSS TEE

EXPLOSIVE BOLT

HANGING POLE

MAIN HANGER

20 MM GLASS SUPPORTED BY STEEL PLATE BELOW

STEEL CONNECTION PLATE SCREWED TO THE ROOF

SPIDER FITTING

SPIDER ROUTEL FIXED TO 20 MM GLASS

PROJECT

GYPROCK

SUSPENDED CIELING

20 MM GLASS SUPPOERTED BY STEEL PLATE BELOW

STEEL HANDRAIL (50 MM DIAMETER) BOLTED TO PFC BELOW

20 MM GLASS SUPPORTED BY STEEL PLATE BELOW

6 MM ALUMINIUM SHEET

20 MM LAMINATE

STEEL MESH

CONNECTION PLATE

METAL DECK SCREWED TO UNIVERSAL BEAM BELOW

LIGHT WEIGHT CONCRETE

C CHANNEL C380 X 74 SCREWED TO U-BEAM

PURLINE FIXING U-BEAM TO C CHANNEL BY SCREWS

SUSPENSION ROD

SCREW

SCREW

20 MM ALUMINIUM THICK PLATE

GUTTTER SCREWED TO U-BEAM

UNIVERSAL BEAMS

SCREW FIXING 20 MM GLASS TO C CHANNEL C 380 X 74

UNIVERSAL BEAM

PURLINE

CONNECTION PLATE WELDED TO THE COLUMN

SCREW

SUSPENSION CLIP PLAIN TEE

CROSS TEE

GYPROCK

CROSS TEE

20 MM ALUMINIUM CLADDING

SUSPENDED CEILING

SCREW FIXING GUTTER TO U-BEAM PROJECT

EXPLOSIVE BOLT

HANGING POLE

MAIN HANGER

20 MM GLASS WALL SUPPORTED BY STEEL PLATE BELOW C CHANNEL C380X74 SCREWED TO U-BEAM

20 MM STEEL BAR 20 MM GLASS SHADE SUPPORTED BY STEEL PLATE ABOVE

20 MM STEEL PLATE SUPPORTING GLASS SHADE BELOW

SCREW FIXED TO 20 MM GLASS

SIDER ROUTEL

20 MM ALUMINIUM THICK PLATE

UNIVERSAL BEAM SCREWED TO C CHANNEL C380 X 74

PURLINE FIXING C CHANNEL TO U-BEAM BY SCREWS

SCREW FIXING U-BEAM TO C CHANNEL C380 X 74

EXPLOSIVE BOLT

SUSPENDED CEILING GYPROCK CROSS TEE

HANGING POLE

MAIN HANGER

LIGHT WEIGHT CONCRETE

MM LAMINATE METAL DECK SCREWED TO U-BEAM SCREW

UNIVERSAL BEAM SCREWED TO THE COLUMN

PURLINE ATTACHING TWO UNIVERSAL BEAMS BY SCREWS

SCREW FIXED TO PURLINE

SUSPENSION ROD

SUSPENSION CLIP

CONNECTION PLATE (WELDED TO COLUMN) FIXING UNIVERSAL BEAM TO COLUMN BY SCREWS PROJECT TITLE

TEE

BEAM

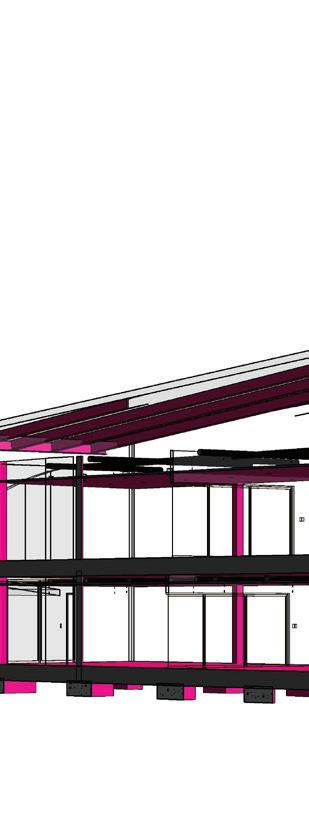

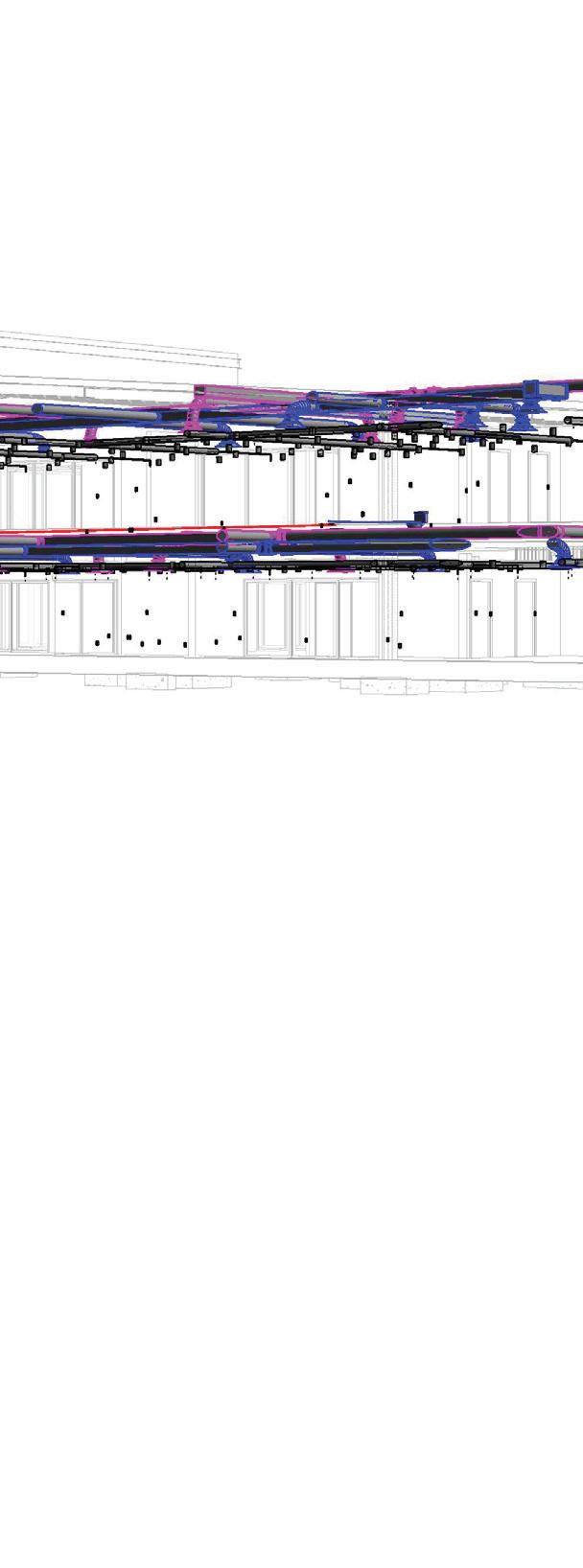

This project was about modeling an English Learning Center based on the client’s needs, in one of the Adelaide’s eastern suburbs, utilizing Revit. This building was a two storey building, with many rooms and different spaces with different functions.

In this task, we were asked to prepare all the design and construction documents and schedules, including the services, Hydralics, Mechanical, Electrical and structural plans. This was an informative task as we learnt how these systems are connected to eachother.

Diagram 1 1 Structural Diagram

PROJECT TITLE

Name

STUDENT NO. DRAWING TITLE

CONSTRUCTION III 2020 8/06/2020 4:15:33PM

CONSTRUCTION

PROJECT TITLE

STUDENT

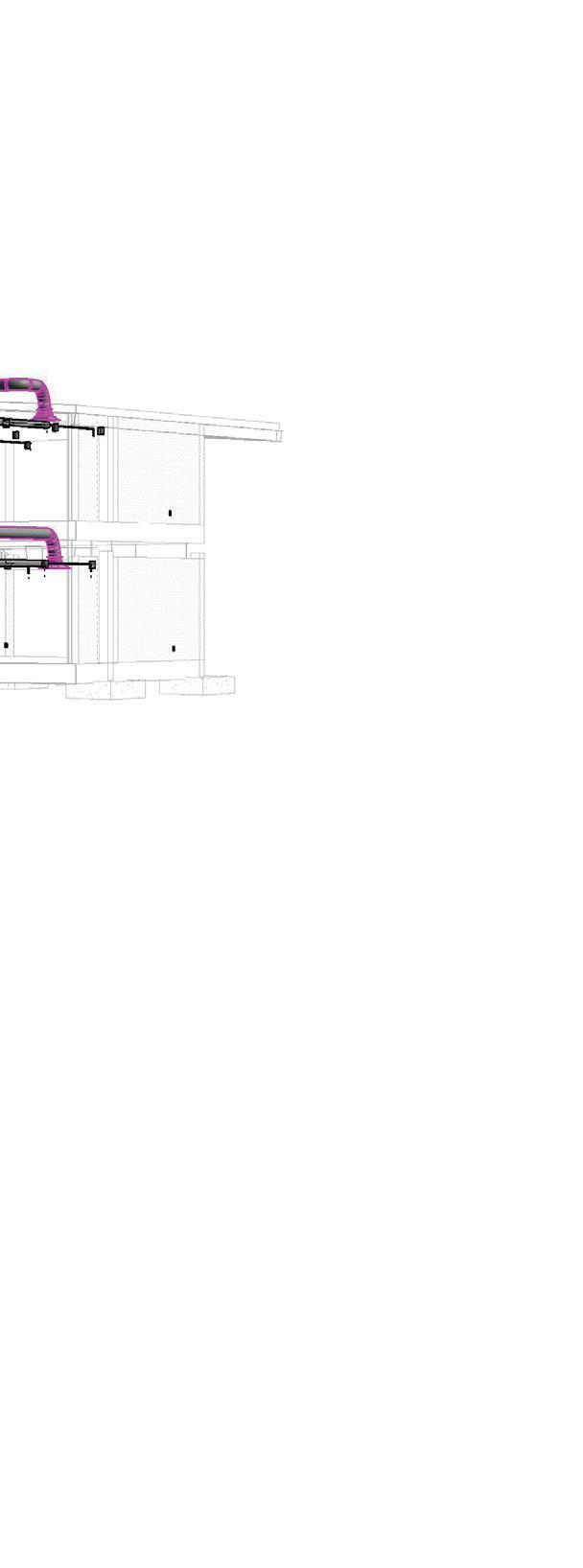

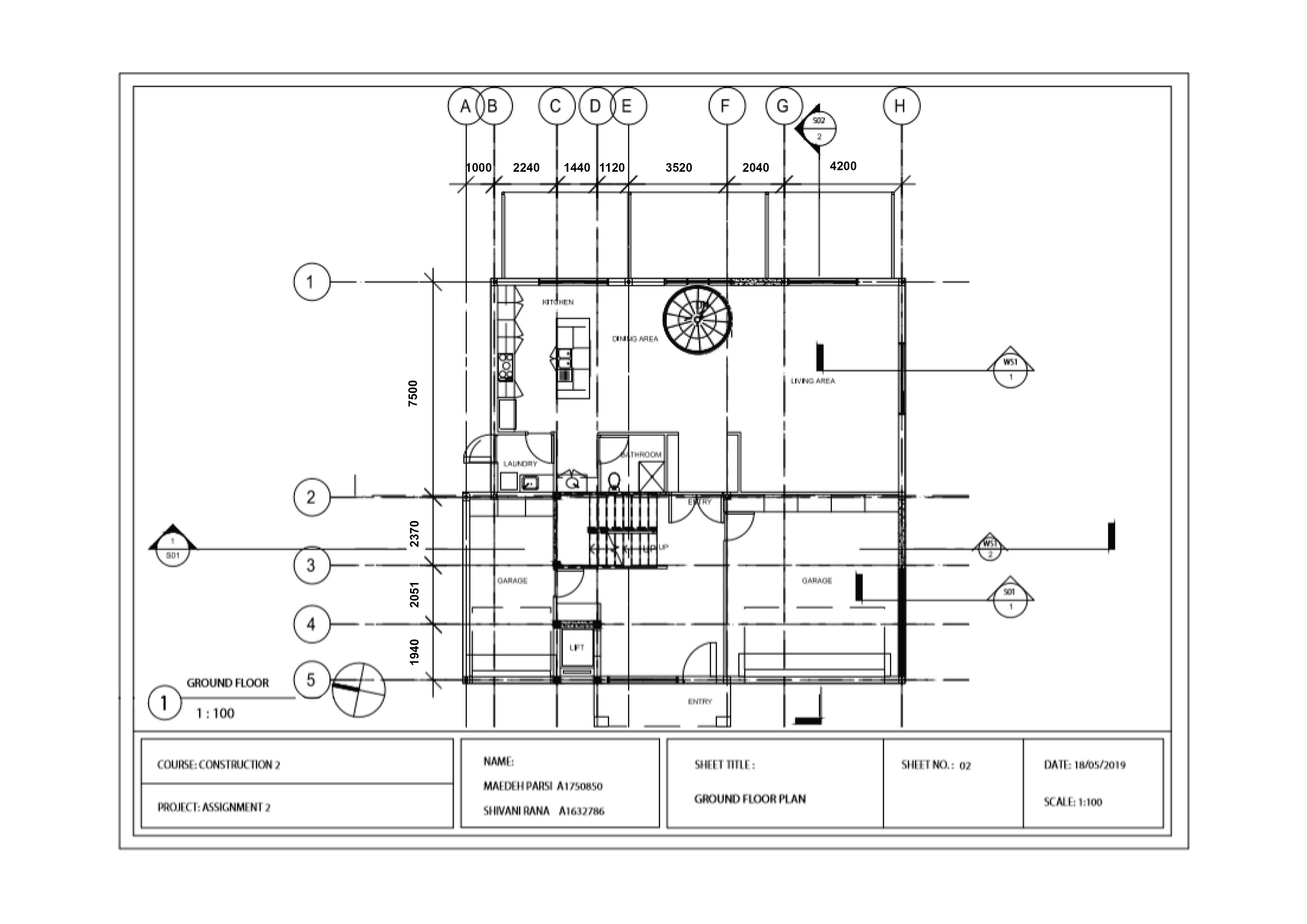

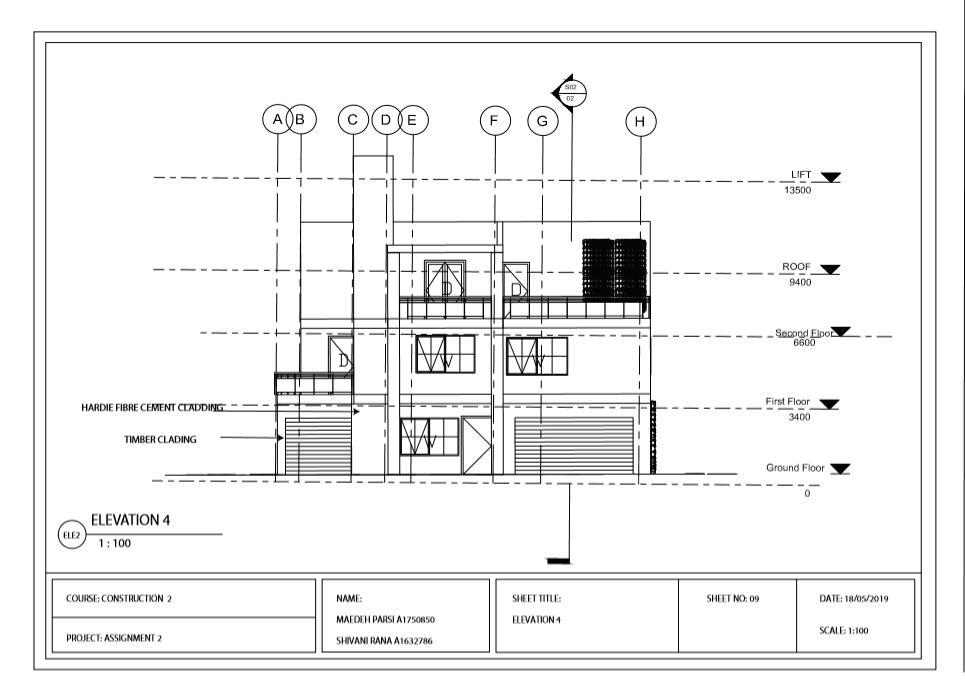

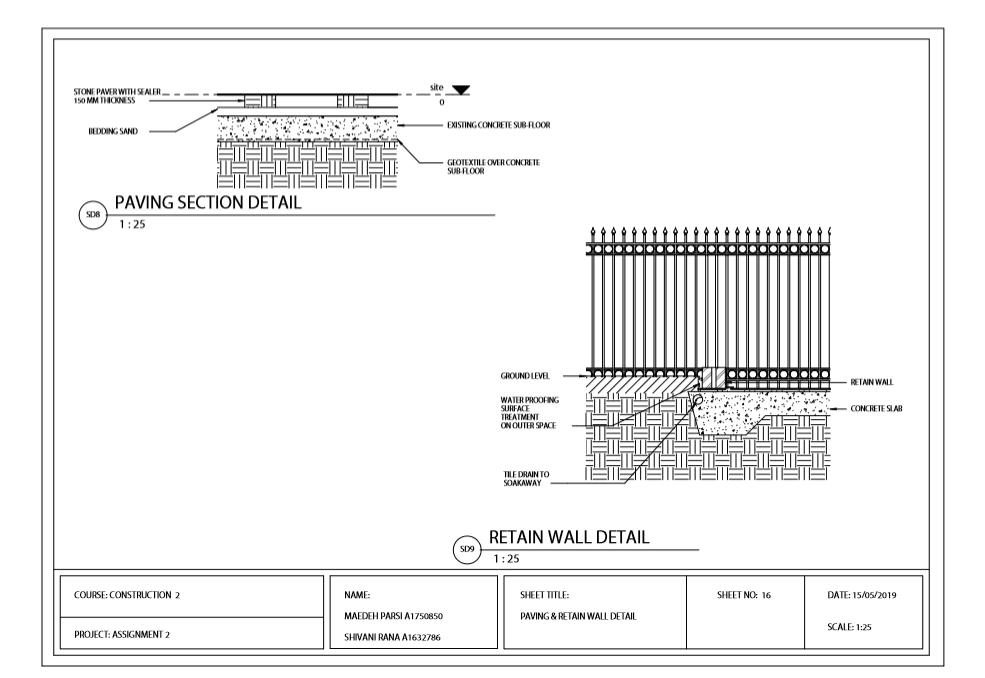

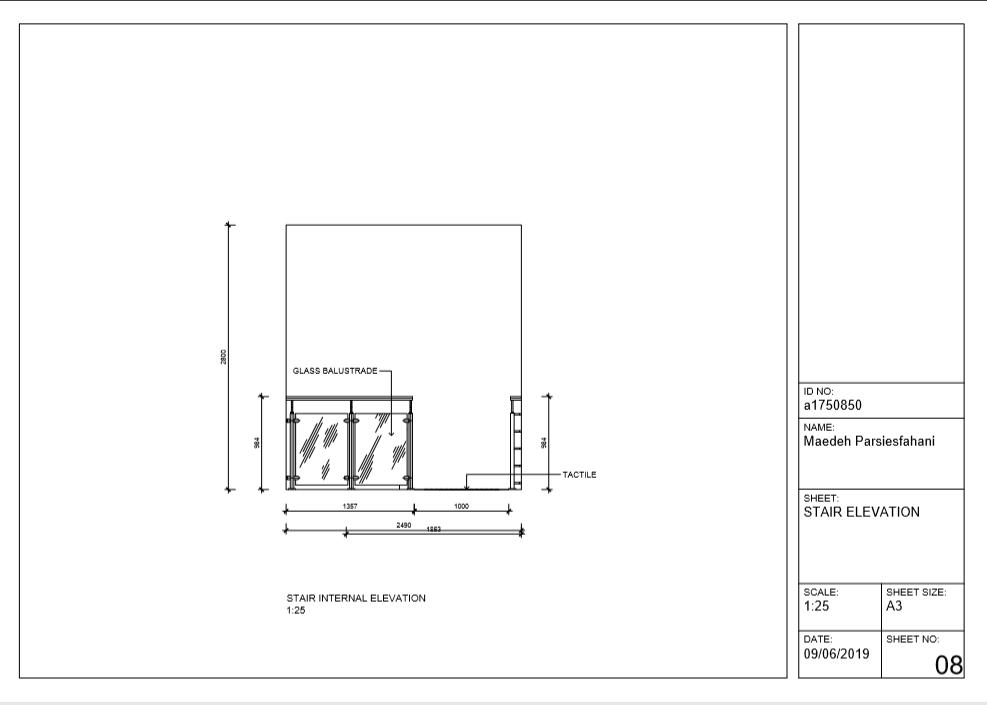

This project was about modeling a Home-Office building in one of the Adelaide’s eastern suburbs based on the client’s needs, utelising Revit. This task included the prepration of all the schematic design documents, construction drawings with joinery details.

This house was a three storey building, with 2 balconies in the front and a balcony with wooden deck in the backyard.

Your traces live longer than you. Leave good traces behind.