9 minute read

News in brief

KENC successfully wraps up engineering assignments for Jumbo

In December 2019, Jumbo awarded KENC with multiple engineering assignments. The scope entailed engineering and FEM calculations to prepare Jumbo’s Fairplayer, a DP2 heavy lift crane vessel, for an FPSO installation job offshore in Brazil. The assignments included the engineering of a 192t gypsy winch grillage and an overboarding tool to handle 120t torpedo piles. FEM calculations were performed on all constructions including the effects on local hull structure. Within four months, KENC successfully delivered all calculations and engineering work to full satisfaction of Jumbo.

Cranes of Sparrows Group to support Qatargas

Sparrows Group has secured a contract to manufacture three cranes for Qatargas’ North Field expansion project. The project, awarded through engineering firm McDermott International, will see the firm deliver two of its EC750 cranes for installation on wellhead platforms, as well as an EC1000 crane for a riser platform. North Field is the world’s biggest single non-associated natural gas field, located offshore north-east of the Qatar peninsula. The expansion project includes the development of four new LNG trains and eight wellhead platforms, where 80 new wells will be drilled. The cranes, which will be manufactured to API specification 2C 7 th edition, are expected to be completed in Q4 of this year.

i-Tech 7 and Shell collaborate

i-Tech 7, Subsea 7’s life of field business unit, and Shell International Exploration & Production have entered into a collaborative technology agreement to accelerate subsea digitalisation, initially for a period of five years from the fourth quarter of 2019. The agreement will help fast-track innovation and streamline the adoption of applied technologies in areas such as marine robotics, advanced sensing, artificial intelligence and autonomous systems to address the industry’s challenges to improve safety, costefficiency and sustainability.

KenzFigee introduces next generation subsea crane

KenzFigee is proud to introduce the next generation knuckle boom subsea crane. This next generation knuckle boom crane design is based on many interactive sessions with clients. During these sessions, the most important features were related to improvement of operational safety and workability. All these requirements are included in the new design: a Rope Actuated Knuckle Boom Subsea Crane featuring subsea requirements for optimised daily operations, safety and operability, without compromising lifting capacity from approximately 400t up to 2,000t.

Damen OSV 9020 answers calls for versatility in offshore support

Following calls for greater vessel versatility offshore, Damen has developed a new concept vessel – the Offshore Support Vessel (OSV) 9020. The vessel features a stable platform with plenty of accommodation, good station-keeping capability, low carbon emissions and a lot of flexibility to add mission-specific tools. The vessel has been designed to perform a variety of offshore tasks both at surface level and subsea. Accommodation is a key feature for the success of any offshore operation. The OSV 9020 provides living space for up to 120 persons on board. The interior design ensures those on board will quickly feel at home, with lots of possibilities to personalise their stay on board. A helicopter deck is integrated, further increasing the vessel’s flexibility. The vessel is primarily designed to operate on DP. First Subsea provides Cable Protection Systems

First Subsea has been awarded a major contract by DEME Offshore for the Cable Protection System for the inter-array cables at the Neart na Gaoithe offshore windfarm. The windfarm will consist of 54 turbines and will be located in the North Sea, approximately 15km off the coast of Fife in southeast Scotland. The cable protection system will be designed to protect the cable during installation and during the operating lifespan of the windfarm, significantly reducing cable fatigue at the point of entry into the wind turbine offshore structures. Engineering is in progress and offshore construction is due to start in June 2020, with full commissioning in 2023.

| Read more on offshore-industry.eu

WEAR ARE YOU SAFE? WEAR ARE YOU SAFE? WEAR ARE YOU SAFE?

for saferWire Rope Sheaves for saferWire Rope Sheaves for saferWire Rope Sheaves for saferWire Rope Sheaves

Constructive Solutions

Your Structural On- and Offshore Partner

Galloper Wind Farm base opens in Harwich

The Galloper Offshore Wind Farm team is starting 2020 on a high, having moved into its new, multi-millionpound, state-of-the-art Operations & Maintenance (O&M) facility at Harwich International Port in Essex. Galloper received consent for the base from the Marine Management Organisation and Tendring District Council in September 2018. Construction started immediately, and the purpose-built base has been delivered on budget and on schedule. Building was completed in December last year, and all O&M project personnel are now working from the base. Representing an investment of EUR 12 million, the facility includes offices, a 24/7 windfarm control room, a pontoon for project vessels, gym, canteen, and warehousing all in one location. It is accessible through a new access road off the A120.

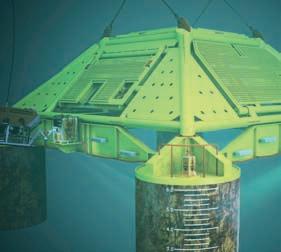

Ashtead Technology supports North Sea carbon capture development

Ashtead Technology has completed subsea installation monitoring work to support the Northern Lights Carbon Capture Storage project (CCS) in the North Sea. Developed by Equinor in partnership with Shell and Total, the Northern Lights project is the first of its kind in the region. The project aims to securely collect and transmit CO₂ from onshore sources and store this under the seabed. This project marks the first occasion Ashtead Technology has been involved in a CCS programme; providing a leading subsea services company with its integrated Deflection Monitoring System (DMS) and associated equipment. Using the DMS, Ashtead Technology personnel and equipment successfully monitored the installation of an Integrated Satellite Structure (ISS).

Airborne Oil & Gas secures 10km TCP flowline contract in Africa

Airborne Oil & Gas has been awarded its most significant flowlines contract to date which will see the manufacturer of thermoplastic composite pipe (TCP) deliver a record 10km length of its technology to a supermajor in West Africa. This is the second award for TCP flowline from the E&P organisation, and follows on from an earlier successful delivery of a 4km product, manufactured by Airborne Oil & Gas last year. The Netherlands headquartered company is producing the 10km TCP flowline to support the operator’s brownfield, tie-back development project in the same field and region.

| Read more on offshore-industry.eu

Large eet of spooling winches up to 350t Reeving of Crane Wire Ropes Inspections of Lifting & Rigging gear Crane Wire Ropes & Load Testing

People Product Performance Biggest Rigging Company in the world

Biggest Company in Rental of Heavy Lift Equipment

Modular Spreader Beams up to 3.000t - Shackles up to 2.000t Grommets & Roundslings - ROV Hooks & Shackles Cherry Pickers - Telehandlers - Waterpumps - Generators Waterbags - Testweights - Pontoons - Fenders - Gangways Snatchblocks - Lifting Frames - Multi Lugs - Hoists - Swivels Masterlinks - Hydraulics - Container Spreaders - Light Towers www.safelifting. eu rental@safelifting.eu +31 10 434 63 33

WWW.DEHOOP.NET

CREATIVITY

INNOVATION

Shipyard De Hoop concentrates on designing, engineering and building custom vessels, for both the inland and seagoing markets. The yard has all the core disciplines in house to provide clients with creative and innovative solutions, both in design and production. De Hoop is committed to a customer-oriented, goal based approach in which quality and flexibility are paramount.

CRAFTMANSHIP

Forum ROV to support Amundsen Science’s Arctic research

Forum Energy Technologies has secured an order from Amundsen Science (Université Laval, Canada) to supply a light work-class remotely operated vehicle (ROV) to support its Arctic scientific research activities. The vehicle will be installed on board the Canadian research icebreaker CCGS Amundsen and will support the exploration of arctic and sub-arctic seafloor eco-systems. Equipped with 85 scientific systems, the CCGS Amundsen gives Canadian researchers and their international collaborators unprecedented access to the Arctic Ocean. Forum’s Sub-Atlantic Comanche ROV system was selected due to its high thrust-to-drag ratio enabling it to operate in strong currents and replaces the organisation’s current Super Mohawk ROV, which was also supplied by Forum.

Skogul gets green light

The Norwegian Petroleum Directorate has granted its consent for start-up of the Skogul field in the North Sea. Consent is given to the licensees in production licence 460. Skogul was proven in 2010 and the Plan for Development and Operation (PDO) was approved in early 2018. Recoverable resources are estimated at 1.5m 3 million of oil (9.4 million bbls) in the PDO. That makes Skogul one of the smallest fields on the Norwegian shelf. The field is developed with a seabed template tied in to the Alvheim FPSO via the Vilje field. Operator Aker BP has planned the start-up for March 2020, in line with the PDO. When the PDO was submitted, development costs were estimated at approx. EUR 150 million.

28 May 2020 Navingo Career Event Rotterdam, Netherlands www.moce.biz 21 – 23 April 2020 MCE Deepwater Development London, UK mcedd.com 22 – 24 April 2020 FOWT Marseille, France www.fowt-conferences.com 4 – 7 May 2020 OTC Houston Houston, USA otcnet.org 12 – 13 May 2020 Windforce Bremen Bremerhaven, Germany windforce.info/windforce2020/ Offshore Events 24 – 27 March 2020 OTC Asia Kuala Lumpur, Malaysia 2020.otcasia.org