8 minute read

Hydrogen plan(t)s

the North Sea aS hydrogeN hub

the momeNtum for offShore wiNd coNtiNueS to grow. the coNtiNual iNcreaSe iN wiNd productioN (both on shore and off) brings new challenges to the table, particularly concerning the discrepancy between production peaks and electricity consumption. the solution may very well lie in joining forces with that other booming energy source: hydrogen.

By converti ng it into hydrogen, the energy surplus that is created during wind energy peaks can be temporarily stored. in turn, hydrogen can serve as a raw material for industrial purposes, fulfi lling the high energy demand that some industries have in their producti on process.

Grey, blue and green hydrogen to understand hydrogen’s full potenti al, it is vital to diff erenti ate between grey, blue, and green hydrogen. grey hydrogen is extracted from natural gas. among other things, this releases co 2 into the air. with blue hydrogen, the co 2 that is released during producti on is stored underneath bodies of water – in the empty gas fi elds under the north sea, for example. lastly, green hydrogen is even more promising. when water is split into hydrogen and oxygen via electrolysis, no co 2 is released in the process. in order for that hydrogen to be called ‘green’, the electricity used in the electrolysis has to be generated from renewable energy sources.

Between windfarm and industrial production since most ports bordering the north sea have both off shore windfarms and industrial producti on plants in their vicinity, they provide ideal locati ons for hydrogen plants. provide ideal locati ons for hydrogen plants. and indeed, port authoriti es seem parti cularly ambiti ous about hydrogen plants. nearly all of western europe’s larger ports have recently presented plans for the constructi on of hydrogen conversion plants, oft en in cooperati on with big players from both wind energy and other industries. this arti cle discusses the plans of some major dutch and belgian ports.

Djewels – Groningen Seaports on 24 January 2020, a consorti um comprising nouryon, gasunie, and four other partners announced that they have received an eUr 11 million european grant towards their 20Mw electrolyser project in delfzijl, the netherlands. the funding was granted by the fuel cells and hydrogen Joint Undertaking (fch-JU), a partnership of the european commission and industry that supports the development of innovati ve hydrogen technologies. other partners involved are McPhy, who will provide their innovati ve alkaline electrolysis technology to convert renewable electricity into 3,000t of green hydrogen per year; bioMcn, who will combine the hydrogen with co 2 from other processes to produce renewable methanol, reducing co 2 emissions by up to 27,000t per year; denora, a producer of electrodes, a key component of the electrolysis technology; >>

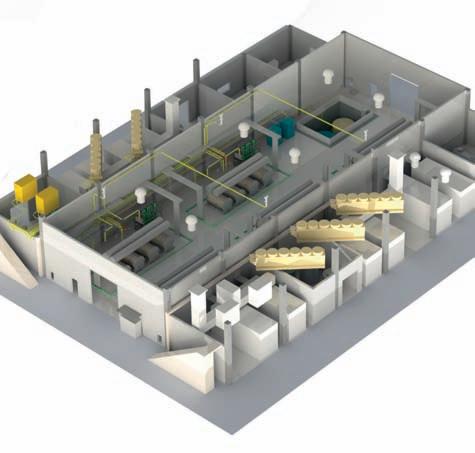

Building plan by McPhy for a large-scale electrolysis facility, such as the one that will be built in Delfzijl.

Hydrogen will become an essential building block in making industry in port areas CO 2 -neutral.

and sustainable energy consultant hinicio. nouryon and gasunie will make a final investment decision for the plant this year. in parallel, the two companies are studying options to increase the plant’s electrolyser capacity from 20Mw to 60Mw to make green hydrogen to produce sustainable jet fuel in a project with another group of partners. the project is also supported by an additional eUr 5 million in subsidies from waddenfonds, a fund that invests in projects in northern netherlands.

HyPort – Oostende Port of oostende, deMe concessions, and PMV on 27 January 2020 announced their exclusive partnership in the construction and operation of a plant for the production of green hydrogen. the green hydrogen will serve as an energy source for electricity, transport, heat, and fuel purposes, as well as a raw material for industrial purposes. by the end of 2020, 399 wind turbines will be operating off the belgian coast, with a combined installed capacity of 2.26gw. the new marine spatial plan leaves space for several hundred more wind turbines, which will generate around an extra 1.75gw. this amounts to a total green energy generating capacity of around 4gw, supplying half of belgian households with electricity. after initial demonstration setups, the rollout of a large-scale shore-based power project, running on green hydrogen, will start in 2022. the full plant should be operational in the Plassendale 1 port area by 2025, reducing co 2 emissions in flanders by around 500,000t to 1,000,000t per year.

North Sea Port on 25 november 2019, companies including north sea Port and local authorities hosted a hydrogen delta day, during which they issued a statement and presented their

Photo courtesy of Groningen Seaports | Fotografie Koos Boertjens.

Electrolyser by McPhy that uses alkaline electrolysis to produce hydrogen.

Aerial view of the port of Delfzijl, where a consortium of companies comprising Nouryon and Gasunie plan to build a green hydrogen plant.

Photo courtesy of Nouryon

Electrolyser in a hydrogen electrolysis facility in Rotterdam.

plans for a 1gw green hydrogen plant to be built and running by 2030. according to the parties involved, all conditions for the large-scale use of green hydrogen in the port area of north sea Port are in place. local companies offer lots of opportunities for its integration, and energy producers form a stable basis for change. since electricity from major windfarms at sea arrives on land in the port area of north sea Port, it is a highly suitable location to install electrolysers and further roll out a hydrogen grid. Moreover, smart delta resources provides a strong platform for collaboration. the statement specifies that the shared ambition of the companies and authorities is to be the biggest hydrogen cluster in the netherlands and flanders, as well as to remain frontrunners in this regard. the statement was supported by north sea Port, arcelorMittal, dow benelux, engie, fluxys, gasunie, icl-iP, impuls Zeeland, the dutch Ministry of economic affairs and climate Policy, Ørsted, the Province of east flanders, the Province of Zeeland, smart delta resources, Yara sluiskil, and Zeeland refinery.

Port of Amsterdam tata steel, Port of amsterdam, and nouryon joined forces in october 2018, stating that they wanted to form the biggest cluster for green hydrogen in europe. if everything goes to plan, the construction of the electrolysis plant will commence in 2021. fed with water and green wind energy from the north sea, it will supply green hydrogen that can be used as fuel, but also to turn waste gases such as co and co₂ into green chemical products. the hydrogen plant will have an output of 100Mw, saving 350,000t of co₂ annually. it is an essential intermediate step towards a subsequent scale-up. Ultimately, the whole region could be supplied with green hydrogen, which will become an essential building block in making the industry throughout the port area co₂-neutral, while simultaneously creating opportunities for new sustainable industry. Port of Rotterdam the Port of rotterdam authority, together with nouryon and bP, is also committed to setting up a large green hydrogen plant in europe. the plant they have in mind should annually produce 45,000t of green hydrogen, saving 350,000t of co 2 emissions. the partners have allocated three years to enable the infrastructure for the plant. the final decision on construction of the green hydrogen plant will be made in 2022.

Offshore hydrogen plant apart from the various plans within port areas, the north sea itself is the location for yet another hydrogen pilot project; building the world’s first offshore hydrogen plant. neptune energy’s Q13a oil & gas platform, located more than 10km off the coast of the hague, will house a plant producing green hydrogen from sustainable electricity generated by sun and wind. the plant should be operational in 2021, with a capacity of 1Mw. the conditions for producing sustainable >>

Photo courtesy of Neptune Energy.

hydrogen at sea are very diff erent to those on land: long distances, salt water, strong winds, more wear and tear, higher installati on costs, and more expensive maintenance. however, major cost advantages can on a large scale be expected in the transport and storage of wind energy. the electricity generated from off shore wind can be converted into hydrogen via the electrolysis of seawater and transported via existi ng gas pipelines. transporti ng these hydrogen gas molecules is much cheaper than transporti ng electrons via heavy electricity cables from windfarms on the north sea to land. as the constructi on of off shore windfarms conti nues at a sustained pace and they move further and further away from the coast, it is important to investi gate the most robust and inexpensive ways to get the electricity generated there to land. if the trial is successful, off shore hydrogen plants would open up lots of new possibiliti es. the north sea is home to many platf orms that have reached the end of their lifespan and need to be demolished, as well as numerous gas pipelines. these can have a second life, before being permanently disposed of. wind-generated electricity can be brought from sea to land without investi ng in expensive cables and other electricity infrastructure, as hydrogen can be transported via existi ng pipelines. the owners of the platf orms have the prospect of a new business case, now that gas producti on at sea is ending in many places. Manufacturers of electrolysers – devices that split water into water and oxygen, but which are currently exclusively used on land – will develop a new generati on to be used at sea. the biggest challenge for green hydrogen concerns the cost of electrolysis, which at present is very high. Yet companies such as nouryon believe that those costs can be cut in half in the foreseeable future – just like the price of wind energy has dropped over the last decade.

The Original and the Best

Efficient MODULAR design Adaptable | Compatible | Portable

Technical Experts A team of in-house engineers and specialists, with over 200 years combined experience

New State of the Art Factory Faster turnaround times, increased storage space and all of your technical experts under one roof

Global Distribution Network To find your nearest visit Modulift.com

For more information contact 00 44 1202 233 844 sales@modulift.com www.modulift.com