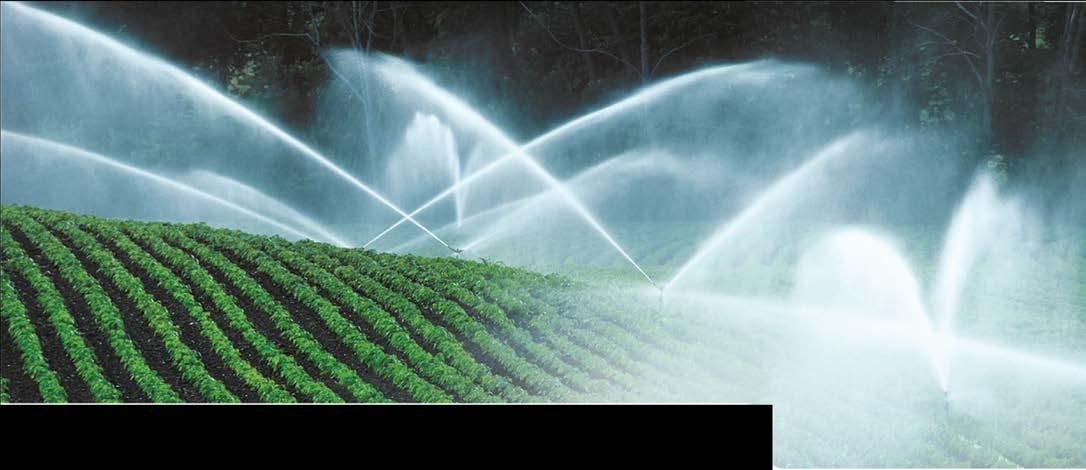

Zimmatic is an industryleading manufacturer of centre pivot and lateral move irrigation systems customised to varying terrains, crops and needs. Read more on page 3 how Zimmatic and FieldNET supports Namibian farmers.

H

ere we are. Spring. Seems like yes terday I was writing my letter just before winter started. We are moving towards a new season, one that brings hope and renewal. Spring is a muchanticipated season for all — longer days and warmer temperatures. Reawakening, planning and planting … It has been exactly three years since ProAgri BNZ made its first appearance. Thinking back, when our grandparents were our age, farms looked like those in children’s books. They raised a little of everything on their farm. Over the years, farms have changed. As farmers invested in tractors and other equip ment, they focused their efforts to make the most of those investments.

The same is true today. Just like the way farming has evolved, technology is also evolving, which enables farmers to be more efficient and farm smarter. Consumer needs and expectations drive the food value chain, and farming nowadays is a business.

One of the reasons why farming has been able to make such impressive strides in productivity in our lifetime, is that farmers today have the tools

and ability to access a vast quantity of knowledge that can be applied to make informed production decisions. We know that a farmer’s work never stops, so we shall continue to supply you with the latest information to help you grow your business.

In this month’s edition of ProA gri BNZ 36, in our cover article, we get to meet a very dynamic female farmer of the north-eastern parts of Namibia, who cultivates her dreams despite her hardships. Cultivating the soil and preserving the farm for her children to one day also enjoy an African sunset - what an inspiration, reminding me once again to appre ciate the little things in life. Read more on page 3.

We hope you enjoy this new edi tion of ProAgri BNZ. Now it is your turn: what do you wish people knew about farming? Or what would you like to know? Please contact us and let us know!

Bianca Henning

female farmer

research

farm

HOLLAND

more

production

Botswana / Namibia / Zimbabwe

577 Rossouw Street, Die Wilgers, Pretoria +27 (0)79 515 8708 www.proagri.co.za

Copyright © 2022. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

Editor

Bianca Henning

Reporters

Benine Ackermann

Maryna Steyn

Natasha Kruger

Specialist Writer

Bremner

+27 82-326-2572 bianca@proagri.co.za

+27 73-105-6938 benine@proagri.co.za +27 82-261-9177 maryna@proagri.co.za +27 81-736-4236 natasha@proagri.co.za

+27 82-320-3642 annemarie@proagri.co.za

Client Relations Manager

Swartz

Marketing Manager

Grobler

Marketing

Pieterse

Johan Swartz

Tiny Smith

Lynette van Tonder

Creative Director

Design

+27 84-233-0123 carin@proagri.co.za

+27 82-555-6866 diane@proagri.co.za

+27 79-524-0934 xander@proagri.co.za +27 71-599-9417 johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za

+27 72-419-3990 christiaan@proagri.co.za

Kruger & Lizelle Erasmus

Botha

+27 12-803-0782 engela@proagri.co.za

Distribution and subscription

Nita Volmer-van Zyl

Accounts

Schluter

Business Manager

Grobler

+27 79-515-8708 nita@proagri.co.za

+27 12-803-0782 accounts@proagri.co.za

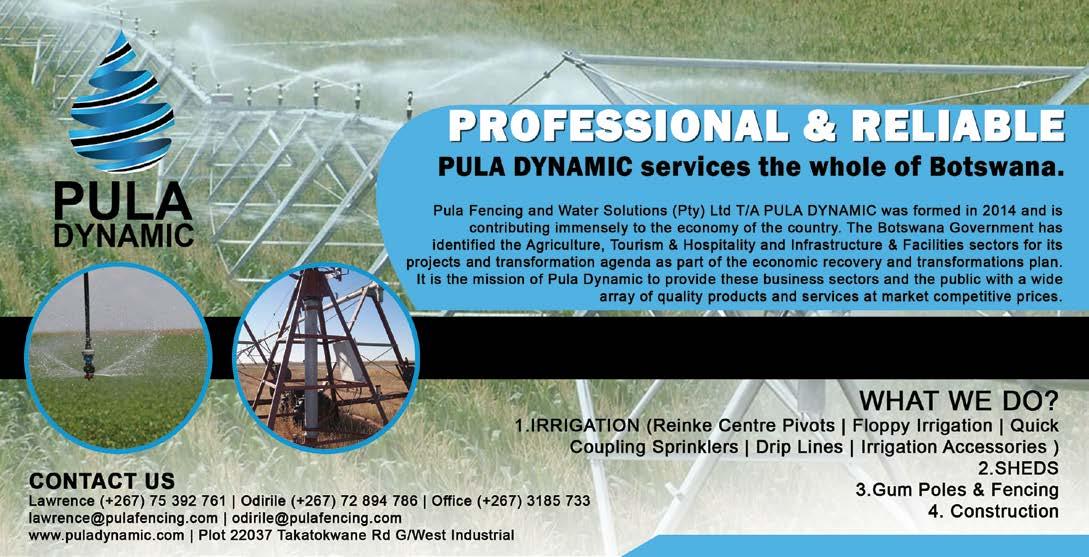

Solar energy offers numerous benefits for agricultural irrigation.

• EFFICIENCY – Crops require more water when the sun is shining, which is naturally when solar panels are most effective.

• ENERGY SAVINGS – Because the panels convert the sun’s rays to electricity, your operation will save on energy costs.

• REDUCED ENVIRONMENTAL IMPACT – Rely less on fossil fuels for power and pumping.

• NEW POSSIBILITIES – Where a traditional electric network does not exist, the pivot can be powered by the sun.

Ag Solar financing?

got you covered.

&

In the heart of the Northeastern parts of Namibia, 250 km from Windhoek, on the farm Springvale, is a passionate female farmer, Elize van Niekerk, who farms with cattle, goats, sheep, maize and wheat.

Elize started her career as a pilot in the early 2000’s. After facing devastat ing tragedies, Elize had to take over the farm in 2014. At that time her triplets were just born.

“I had no choice but to start farm ing, since I could raise my children and still generate an income. In my heart I’ve always wanted to be where the footprints of my people are, and I want to raise my children on the farm where family legacies were left,” says Elize.

As the years went by, Elize had to diversify and intensify her farming operation. She currently farms with 500 Dorper sheep, providing slaughter lambs to Windhoek, 500 head of cattle, and goats. During the summer months, she cultivates maize and in the winter months wheat.

“My goals and vision for the future are to farm more sustainably, obtaining an average yield of 16 tonnes of maize per hectare and 9 tonnes of wheat. My

dream is also to maintain a pregnancy percentage above 85% for my cattle and a weaning ratio percentage of 55%,” Elize explains.

“I think some of the biggest chal lenges that farmers, male or female, face, are environmental challenges and the fluctuation in nature, which makes it difficult to develop a stable financial platform. A farmer can truly be charac terised as an all-in-one, since you need to have knowledge of so many different facets, from mechanisation, biological aspects, and nutrition, to management and people skills. One advantage of being a female farmer, I would say, is that we are a bit more precise. It is of utmost importance to me that I work out my cash flow and fertiliser pro grammes very carefully.

“Despite all the challenges that we face, to me it is a privilege and inspira tion raising my children close to nature and on the farm. The sacrifices are worth it all. Seeing their eyes when catching a little lamb, or their faces when excitedly digging a hole in the ground to check whether the maize kernel has germinated yet. Grace upon grace, and having faith like a child gets me up every morning.

“My ultimate dream is to cultivate the soil and preserve the farm so that my children can one day also enjoy a beautiful Africa sunset.

“At the end of 2013, we purchased our first 13 ha Zimmatic pivot for the farm, which was set up by Brandberg, our local Zimmatic dealer. The next year, July 2014, we harvested our first maize irrigated with the 13-ha pivot. Today we

One of the seven Zimmatic pivots on Springvale.

have seven Zimmatic pivots on the farm, which irrigate 65 ha, and the eighth pivot will be set up soon,” says Elize.

Elize also plants 155 ha of dryland maize. Brandberg has set up five of Elize’s pivots and Aqualand two of them. “Brandberg is strongly involved in our area. They have good experience and know what they are doing,” Elize states.

Elize adds: “The biggest advantage that Zimmatic offers to me, is the FieldNET automation function. It helps me to manage my pivots remotely whenever I am not on the farm, being a mom for my children.”

“Looking back, one of the highlights will definitely be the Master Agronomist Award that I received in 2018. This award is presented to a farmer who is practicing an exceptional innovative scientific approach, good risk diversifi cation and community involvement.

“One thing that I have learned through the years, is that you have to be strong to stand alone, smart enough to know when you need help, and brave enough to ask for it,” Elize concludes.

For more information on Zimmatic and FieldNET products in Namibia, visit their website at www.lindsay.com.

F

ormerly known as the homelands in South Africa, the Mthatha region of the Eastern Cape has significant agri cultural potential. With ample room for development, and a community eager to learn, this was the perfect place for John Deere AME (Africa Middle East) to embark on a journey of growth that will change the lives of farmers in this area forever.

In collaboration with local farmer development groups who provide mentorship for farmers in the area, we identified a number of small-scale farmers in need of the right solutions and mechanisation to grow their farm ing operations.

"To assess the impact of mecha nisation on small-scale farmers, we identified two farmers with different needs and farming entities in South Africa. Some of the biggest challenges farmers in Africa face is access to finance and good mechanisation," says Zabion de Wee, New Business Devel opment Manager for John Deere AME.

"We decided to adapt the John Deere SMART initiative and custom-make it for Southern African farmers to help solve some of the challenges they face daily in crop production."

The John Deere SMART initiative has seen great success in Africa. Focused on providing farmers with the right solution for their operation, the mechanisation they need for better yields, access to finance making the un-bankable bank able, reliability at lower costs, and ac cess to training and technology.

"Once we introduce farmers to our products and proper mechanisation, we can provide them with the training and technology they need, specifically suit ed to their farming operations. That, in short, is what the SMART initiative is all about," continues Zabion.

Approximately eight months ago, the journey started with soil preparation on the rich earth of the Mthatha area (OR Thambo district). The farmers were provided with the specific equip ment they needed to optimise the

season: tractors, off-sets, ploughs and planters to better prepare their soil for optimum yields.

"We ensure that we provide the right tools and solutions for these farmers in order to assist them to reach optimal yields. We took into consideration what equipment they had, and only upgrad ed what was necessary, nothing more," says Zabion. "With SMART, we aim to grow the farmers to the level where they can make use of more technology and take advantage of our advanced equipment on offer, ultimately to get better yields.”

Traditionally, farming is done by hand or with very old equipment. The prob lem with older farming methods like harvesting by hand is that it is heavily time-consuming and small-scale farm ers can only produce a certain amount of work in a day. Farming by hand also limits the growth in hectares. Proper mechanisation is needed for small op erations to grow.

"We are dealing with farmers who have been farming for a long time and can’t reach their true potential. Our

farmer in the OR Thambo district.

"This mechanisation on my farm has put me in a position where I can purchase my own equipment for my business. It has also helped me de crease the timeframe, allowing me to do the work that usually took me three months in two to three days.

"I can now work more efficiently, and the equipment I use is top-notch; the same level as commercial farming equipment," concludes Mveleli.

This initiative places farmers in a position to get better prices for their products and move them to better markets. By assisting these farmers, John Deere enables them to move commercially.

At the end of this journey, John Deere was able to show the significant difference that mechanisation makes for small-scale farmers. Not only does it save time, but it increases produc tivity and efficiency. Mechanisation is an essential tool needed to grow in a world where agriculture is constantly evolving.

What comes next for this initiative? "The future is exciting, and there are a lot of opportunities in the area that need to be unlocked. With the John Deere SMART initiative's support, we can take more farmers to the next level, grow their profitability, and cre ate a more food secure province. We were able to show what good collabo rations with the private sector, NGO’s and the right farmers can do," con cludes Zabion.

John Deere is committed to empowering farmers in Africa and the Middle East to run successful opera tions. Keep an eye on the John Deere social pages as we explore this incred ible journey further.

goal was to expose them to mechani sation and technologies that they need, but have never used before, to en hance their production," states Zabion.

SMART supported the farmers through all the production steps of the season, knowing that harvesting is where most farmers experience their biggest challenges: a combine harvest er is one of a farmer's most expensive machines on a farm.

"We provided the farmers with a C120 John Deere Harvester, bringing the entire SMART project full circle. Harvesting by hand took these farm ers almost four months. In contrast, they could complete their harvesting in approximately three days, resulting in a better-quality produce, ready for market at better prices.

"The excitement of having a C120 Harvester in the field was incredible, and that is what we wanted to achieve; making technology accessible to farm ers who did not have access to these products in the past, and to show that there is a place for everyone in John Deere," concludes Zabion.

In the end, the group of Mthatha farmers agreed that SMART farming is a more efficient and sustainable way of farming that can help them im prove their yields, decrease their costs, and protect their land for generations to come.

"I started farming with vegetables on 5 hectares of land in Mthatha in 2015. I used equipment that gave many mechanical problems throughout the season due to it being old and difficult to find parts," states Mzimasi Jalisai, farmer in the OR Thambo district.

"In 2021, I was honoured to partici pate in this SMART initiative and re ceived assistance with mechanisation. The quality of my crop has improved, and where I used to get 3,5 tonnes per hectare, we harvested 8 tonnes this season," concludes Mzimasi.

"Through this initiative, I could plant with a good planter and not experience any downtime. Everything I needed to do, I was able to do on time, and it in creased my yield from 5 tonnes to 8,6 tonnes per hectare," explains Mveleli,

Contact or visit your nearest dealer today to discuss the various options offered by John Deere. Visit their website at www.deere.africa/en/.

It goes without saying that the welfare of your soil is intrinsic to agricultural health because when soil is healthy, it provides the nutrients and moisture crops need. A healthy soil can help to mitigate the impact of climate change by acting as a carbon store. In fact, soil is the second largest carbon sink after the ocean, capturing more CO2 than forests and holding three times more carbon than the earth’s at mosphere. You only need to look at the giant slab of carbon-rich peat, discov ered in central Africa and described as the 'lungs of humanity'; its demise with the release of some 30 billion tonnes of carbon will accelerate global change.

But our soil is under constant threat. Climate change and the increased oc currence of extreme weather has led to more droughts as well as more flood ing. Rising sea levels not only threaten our habitats, but can also contaminate our soils and cause erosion. Some ag ricultural practices have also reduced the quality and quantity of our topsoil.

It is easy to see why soil research has grown in importance in the agri cultural sector. Soil is a finite resource so we must conserve what we have. Sampling, measuring, and monitoring our soils is the foundation of bringing about change and improvements in agriculture.

Among other things, soil research addresses nutrient management, sus tainability, and agricultural efficiency. It can take many forms, but whatever your requirement is to investigate your soil, you will need the right equipment.

The Van Walt Group has been offer ing soil and sediment sampling equip ment for more than forty years. Now from five offices across three conti nents, we offer equipment for sampling and collecting soil and sediment sam ples, monitoring the chemical make-up of soils and, crucially, the moisture content of a soil — parameters vital for soil welfare.

“Equipment from our US manufactur er, AMS Samplers Inc, is the best avail able when it comes to soil sampling,” says Jani van Gend, Director, Van Walt SA (Pty) Ltd.

“When we first opened our new office in Stellenbosch just over two years ago, we were careful to find a supplier whom we could trust and who offered excellent equipment when it came to soil research. AMS not only has one of the largest selections, but the quality is excellent, their service is prompt, and the support and equipment advice is superb. We confidently offer this equipment to our customers knowing they are getting the best available.”

For basic soil research, Van Walt’s

augers for the collection of disturbed soil samples are strong and come in a variety of sizes and shaped heads for different soil types. Van Walt can help you choose the right auger or auger kit to make taking soil samples quick and easy.

Soil probes, including their range of step probes, have been designed to provide a simple, fast, and economic method of sample collection for soil profiling, moisture determination, and chemical analysis.

Their soil range also includes more specialised soil testing equipment like pH probes for continuous on-site moni toring, or their unique, highly accurate on-site Soil Redox Electrode to meas ure the redox potential in soils.

Jani says: "For soil moisture we have equipment from Rhizons for soil solu tion sampling – increasingly important in agriculture to check if plants can access the water and nutrients needed for healthy growth. Plus, we have a range of soil moisture sensors, many connected to our telemetry, to give accurate soil moisture data directly to your desktop, tablet or mobile."

For soil research where an undis turbed soil sample is needed, our selection of Soil Core Samplers allows samples to be collected in a liner or directly into the body of a soil core sampler for immediate examination of the sample. AMS’s Gas Powered Core Sampling Kit is a powerful, nondestructive, low disturbance site inves tigation tool for collecting soil samples down to 2,4 metres.

More specialised soil sampling kits are available, like AMS Bulk Density Soil Sampling Kits which come with everything required to take an accu rate interval specific core sample to a depth of 0,91 metres. The rings are ideal for laboratory studies and for undisturbed core samples.

For more information on Van Walt’s extensive range of soil research equipment visit: www.vanwalt. com/za or call them on (+27) 021518-1347.

The round bale hammermill is the larg est of the hammermills that Rumax produces. It is large enough to handle an entire round bale and only takes approx imately seven minutes to chop up the bale. It is powered by a 37 kW motor.

Rumax also produces a PTO-driven hammermill that can be paired with an auger that fills bags, containers, or feed mixers. It can attach to any trac tor with a three-point hitch.

As an addition to any of the hammer mills, an auger can be attached to the machine to move the milled product to where it needs to go, such as a storage facility or into a feed mixer. This means that it reduces the dust even more!

Steel pants can also be added to the outlet to assist with filling bags. It works with a simple flap that sends the material either left or right.

You can discuss the sieve require ments with Rumax when investing in your hammer mill.

Concentrate mixers are a great add-on product. Rumax produces a half tons mixer, powered by a single-phase 3 kW motor. There are also 1 t and 1,5 t mix ers that use 5,5 kW motors. In addition, for large operations such as factories or farmers that produce mineral licks, there is a mixer with two tonnes capac ity which has a 7,5 kW motor.

It mixes quickly, between two to eight minutes, and needs little maintenance. Farmers can request that a scale is mounted on it as well.

The BD 55 c is one of the most popular hammermills due to it being small, but having a high milling capacity.

Special auger attachments can be added to the hammermills to transport feed or milled food products to bags, containers, or mixers.

P

reparing feed for animals can be a tedious daily task, but with a ma chine manufacturer like Rumax in your corner, this task will be done efficiently and without hassles. Rumax manu factures hammermills, feed mixers, concentrate mixers, pellet machines, as well as muck spreaders and pruning machines.

Within each product category, Rumax offers a wide range of products to en sure you find the product that is right for your farming needs.

When milling, Rumax hammermills pro duce little to no dust – a characteristic unique to their machines. They also have a lower energy use, which means a lower electricity or diesel bill.

The smallest of the hammermills, the BD32, is has a 3 kW motor. It can be manufactured with a single-phase, three phase or diesel-powered motor. Due to its size, the BD32 is popular amongst households and smallholder farmers. It is also ideal for milling

spices or products for human con sumption. The BD32 is the only ham mermill Rumax produces with a 220 V single-phase motor.

This machine has a milling speed of approximately two tonnes per hour.

The most popular Rumax hammermill is equipped with a 7,4 kW motor. This machine has a milling speed of 3,5 t/h.

The BD55 has a motor of 22 kW and has a milling speed of 11 t/h. This machine is usually also paired with an auger because of its milling speed and capacity. Bags cannot be filled at a rate that meets the output; therefore, this hammermill is recommended to farm ers with larger farming operations and higher milling requirements.

The BD90 is the largest in the BD-se ries and offers a high output of milled materials. It runs on a 37 kW motor and produces 15 t/h, meaning it is mostly used in industrial settings.

The Rumax team regards it as a big honour when clients return to them for more machinery and advice, because it means they satisfied the farmer’s needs and understand his agri-busi ness. “We are proud of the relation ships we build with every client. We cherish that aspect in our customer service,” Jaco says.

He encourages everyone looking for a hammermill or concentrate mixer to call him and discuss the requirements for every machine. “You can even send a ‘please call me’ and I will phone back,” he laughs.

Every customer is like a friend to us, and we want to help that friend to find the right machine for him or her,” Jaco explains. “We want to have that con versation about what the farm needs, we want to talk about how to provide you with the machine that does the job you need it to do.”

Call Jaco today to discuss the needs of your farm! Reach him on +27(0)82-335-3970 or +27(0)-23-3426070. You can also send an e-mail to jaco@rumax.co.za. To find out more about Rumax machines, visit their website at www.rumax.co.za.

pany is also in the ETG stable. Through our fertiliser distribution points, for ex ample in Zambia, the agri input branch es can also bring in the mechanisation to deliver a complete presentation."

Whether you plough and plant from horizon to horizon, or just a small patch of green fodder or silage maize for your livestock, all farmers have one thing in common: they need reliable im plements that meet their unique needs.

ETG Logistics (ETGL) offers several implements to provide exactly what you need. In their collection of brand names, you will surely find an imple ment fit for your farm.

This distributor of farm implements has a large and growing footprint in Af rica. In the three months after NAMPO Bothaville, in South Africa, there are already a host of developments between the seven brand names that form part of the larger group.

At another expo in South Africa, namely KragDag, ETGL made their appearance once again. "We like what the KragDag expo stands for: inde pendence. Do something for yourself; don't just sit and wait for others. This is a theme that also runs through the product ranges of ETGL," explains Francois van Eeden, Marketing Lead for ETGL. "Whether it is a gigantic tractor for commercial farming or a small trac tor for your smallholding, we have both and more. There are even motorcycles for getting around on the farm." The distributor is a one-stop shop for all your farm's mechanisation needs.

At their exhibition at KragDag, various implements were on show: Big tractors from Belarus, small, compact tractors from VST, implements from Shaktiman, quad bikes from TGB and ordinary motorcycles from TVS. Even a modified tuc-tuc from TVS with good carrying capacities for short distances representing the Falcon Gas brand — another member of the ETG group.

"For us, it is about providing tools that help you be independent. That's why we're here at the expo," Francois explains.

by Maryna SteynAccording to Francois, one of the things that attracts people to ETGL's brand names is the various offers within which you can protect your risks: "You do not put all your eggs in one basket. You have different imple ments from reliable manufacturers that work for you."

Traders who would like to become agri-dealers can sell anything from a plough, right through to a tractor. You can then supplement this with quad bikes as an additional income stream.

VST delivers compact implements for smaller jobs on small or large farms.

ETGL's experts are at your service: They are Manhav Jadhu, Morne Tewitz, Francois van Eeden, Hans Greyling, Diyaksha Sebejan, Bray Hyland, and Brian Mumford.

Apart from KragDag 2022, they already have quite a few shows behind them for the year. During July there was the Chobe show in Botswana, and another show in Zambia. At the end of August, they were back in Botswana in Gabarone, and in September you can see them in Zimbabwe.

"This year, the compact tractors are more popular. The Shaktiman baler we have here is available at a special price of R170 000 including VAT. We have also received a lot of orders for motorcycles."

ETGL ensures that there are always experts at the shows to answer all your questions. "Farmers want to ask questions, so I have the respective brand heads here during the show. We respect our market — our farmers — and we ensure that we can offer them advice from the people who know the products best," says Francois.

"We recognise a farmer as an agri cultural businessman. He is an econo mist, a strategist, a financier; he is a smart, practical thinker; he is a doer. This is who you have to be able to ac commodate at a show.”

From NAMPO to now

Since NAMPO in May, several traders have joined the group. “Our network has grown across Southern Africa. We have opened a branch in Zambia, we are in the process of opening a branch in Botswana, and we have appointed dealers in Zimbabwe. We are also involved in discussions with people in Mozambique," says Francois.

"We are part of the Export Trading Group (ETG), which has existed since 1967. We have operations in 49 coun tries, and we originated in agriculture, including things like fertiliser production and distribution. Kynoch fertiliser com

On the horizon for ETGL ETGL recently successfully completed their discussions with Ashok Leyland as well. The Indian manufacturer has agreed with ETG to be their distributor in six African countries. The first units were shipped, and arrived in South Africa in early August.

"Pick-ups, trucks and buses will soon be introduced to the public. The pick-up is one of a kind, with a car rying capacity of two tonnes! Direct competitors cannot carry such loads. It remains within the gross vehicle mass limit of under 3,5 tonnes, which means that you do not need a heavy vehicle driving licence," said Francois.

It also features new-generation diesel technology with a three-cylinder supercharged engine. “This has not been seen before! Farmers who wish to invest in these pick-ups can also purchase optional service plans."

There are also trucks with a carrying capacity of between 4 and 20 tonnes on the horizon.

The yellow TVS King Kargo is spe cially designed for the sister brand, Falcon Gas.

To find out more about ETG's small, powerful and compact tools, as well as the wide variety of products they offer, visit their website at www.etgldistribution. com. Contact them at (+27)-65138-4567 or send an e-mail to info@etgldistribution.com.

The New Holland T7000 redefines agricultural innovation. Available with creeper transmission (330 m/hour) and high flow hydraulic system (150 l/pm). Intellishift system for optimal fuel consumption. Headland management for ultimate operators comfort. PLM ready or factory fitted steering systems, as well as various single or dual wheel options.

New Holland T6000

Maximum versatility. Ultimate comfort. Proven quality and reliability. Options to suit every application:

T6000 DELTA: 82-93 kW – Base model with 24x24 transmission and power shuttle.

T6000 PLUS: 93-104 kW – Increased versatility with 16x16 transmission and closed-centre hydraulic system.

T6000 R/C & P/C: 104-121 kW – High pressure common rail engine with 18x6 transmission.

Call your New Holland dealer today or Jaco du Preez at jacobus.du-preez@cnhind.com

Article supplied

The flexible T6000 tractor range satisfy the demands of many operations.

New Holland’s formula for outstand ing T6000 tractor performance involves mixing raw power and superior control with the ultimate in customer flex ibility. T6000 tractors are a natural choice for livestock, field or contracting applications.

Whether you are looking for proven performance in a value package, or a tractor that gives you the latest elec tronic conveniences and pushbutton simplicity, the T6000 Series tractors are built for you.

• Delta configuration models offer class-leading performance in a base-level configuration.

• Plus configuration models raise the bar for on-the-job performance, offering a range of options includ ing a semi-powershift transmis sion, higher capacity closed-center hydraulic system, and the Ho rizon™ cab with added comfort features.

Whether you choose a model with flatdeck ROPS platform or the all-weather comfort of the Horizon™ cab, you get space, comfort, control and view that make your work easier.

The throttle, transmission, hydrau lic and hitch controls are placed in an ergonomic position for easy, fingertip control. The sloped hood gives you an unobstructed view of the work area around you.

This Hi-Lo transmission with power

shuttle gives you the added conveni ence of clutchless forward-reverse shuttling, as well as twice the number of speed choices. Dual Command™ but tons are located right on the gearshift lever to allow you to powershift on-thego without clutching. This transmission provides the benefit of up to 11 speeds in the 3 to 12 km/h working range for maximum versatility. Transport speed is 40 km/h for FWD models.

This transmission with power shuttle gives you touch-button powershifting through the four gears of each range, plus a clutch-free shift between first and second range, and between the third and fourth range. You only need the clutch once in 16 gears. An electro-hy draulic power shuttle also lets you shift from forward to reverse without clutch ing for easier loader or grading work.

The powerful T6000 Range Command™ and Power Command™ models have a choice of rated power outputs from 104 to 121 kW (142 to 165 hp) and have been engineered by design to respond to your specific farming needs. With intelligent Engine Power Management these outputs can climb respectively to 131 and 148 kW (178 and 201 hp), but only when needed. The result? The New Holland T6000 series has all the power you need without the penalty of heavy fuel use.

You can choose a 19 x 6, 40 kph ECO transmission that not only provides 40 kph at a reduced engine speed, but also uses an ‘overdrive’ design to mini mise parasitic losses; the combined result, less fuel is used. For those

requiring specialist work we offer a 29 x 12 creeper transmission.

A modern tractor must be versatile. The traditional powerful but heavy tractor is compromised in several ap plications. The advantage of Series T7000 is that you get the power of a larger tractor but with considerably less overall weight. From transport and top work to ploughing and heavy draft applications - T7000 does it all.

T7000 tractors can tread lightly in the field for planting, reducing compac tion which can inhibit plant growth. For heavy draft work, the structurally strong T7000 tractors can add ballast quickly to make the most of its trac tive power. A light tractor is always the best choice for transport. New Hol land T7000 tractors have more power available to pull the load, they do not waste it on moving the tractor. A light haulage tractor also allows for larger payloads while still staying within any local road legislation limits.

Full Powershift — effortless drive — maximum power transfer. The Power Command™ transmission is designed to be robust and simple to use. Smart features like IntelliShift™ allow the operator to get the most out of the engine in the field and on the road.

perfect solution for

Balanced animal feed.

Chickens get sick very easily. Disease can kill your whole flock overnight, so it is important to make sure that you do everything you can to keep them healthy.

The two most significant diseases are Newcastle disease (ND) and avian influ enza (AI), also known as bird flu.

Newcastle disease is always present, and it becomes active at the beginning of the wet season. Day-old chickens are usually vaccinated with eye drops by the supplier, but they must be revaccinated at intervals throughout their lives.

When an outbreak is expected, a trained person must vaccinate the birds at least a month before the out break. The vaccination is inexpensive and if dosed correctly, it can save your flock. It is good to remain informed about diseases, as precautionary measures can save your business.

Different strains of the H5N1, a highly pathogenic or infective avian influ enza, referred to as AI or bird flu, are particularly dangerous to all poultry species, including chickens, ducks and geese. It even affects ostriches.

It also affects wild birds, which are believed to spread the disease. Espe cially migratory water birds can bring bird flu to your flock from far away.

Strict biosecurity measures must be

Healthy chickens appear alert and not listless, their eyes are clear and the colour of their wattles and comb in most species are bright red. (Source: Pixabay)

Left: The best way to ensure a healthy flock is to buy day-old chicks from a reputable supplier.

(Source: Pixabay)

Sick chickens lose their appetite and do not eat, which causes them to lose weight and condition. (Source: Pixabay)

Wild migratory waterbirds are be lieved to spread bird flu. (Source: Pixabay)

followed to prevent this disease from spreading, and infected birds must be culled and the carcasses destroyed. Thousands of chickens have been culled as a result of this disease, for which no vaccine exists.

Some of the strains can infect and kill humans. From January 2003 to 31 March 2022, altogether 863 cases of human infection with avian influenza A(H5N1) virus were reported to the World Health Organisation in eighteen countries. Of the 863 cases, 455 (53%) were fatal.

Prevention is better than cure

It is better, and cheaper, to prevent a disease, than to try and stop it once your flock is infected. In most cases all the birds will either die or will have to be culled.

Good management, which includes timely inoculations and biosecurity measures, can protect your birds from some diseases and help them to per form well, whether they are broilers or layers. Sick chickens do not grow at the rate they should, which means they will not turn feed into either meat or eggs, which means you will make a loss.

Good management includes a pro gramme on your farm to control disease and measure the growth of your chick ens against standards set by the indus try. Record-keeping is the way to know whether you are successful or not.

Controlling disease on your farm con sists of three steps, namely:

• disease prevention;

• early detection of sick birds; and

• treatment of identified disease conditions.

Start your flock with good quality chicks from a reputable and preferably only one supplier. If you must source chicks from more than one supplier, it is best to keep these day-old chicks in separate brooders.

The day-old chicks should already have had their first vaccination against Newcastle disease and bronchitis on the farm where they were hatched.

If they have not been inoculated against Newcastle disease, the vaccine must be administered at the age of ten days by means of their drinking water, and again at the age of twenty days. At the age of fourteen days, medication against gumboro disease must also be administered through the drinking water.

Gumboro is a highly infective viral disease that affects the immune system of young chickens. It can last more than fifty days in contami nated feed, water, manure and insects, and longer than four months in the poultry house after an infected flock had been removed.

This is only a directive, and a veteri narian or the suppliers of the vaccine must be consulted on the type of vaccines and methods and times of administering them.

Vaccination works best when the pos

sibility of disease is minimised through a properly designed management plan and biosecurity measures. On its own, vaccination won’t protect your chickens against devastating disease or poor management. It is therefore best to develop a vaccination programme for your chickens in consultation with a poultry veterinarian. The vaccination programme must be based on the local diseases and the availability of vac cines, and every bird must receive the correct dose of vaccine.

Here are some warning signs of the most common infectious diseases in your chickens, namely respiratory diseases, diarrhoea and nervous sys tem problems.

Respiratory problems are very com mon in chickens and can be caused by several pathogens like fungi, bacteria, viruses like avian influenza, and para sites like mites.

The chickens will display difficulty breathing with their beaks hang ing open, and they could be making wheezing, snoring or clicking noises. They may also sneeze or cough, have swollen sinuses and wetness around the nostrils and eyes.

If chickens do not have an appetite as a result of these respiratory diseas es, they may show weakness and lose weight and condition.

The sure signs of diarrhoea, also known as scours or dirty vent, is loose and watery droppings with a different colour than usual, and it may contain signs of blood. As a result of the loose droppings, the feathers around the vent (backside) become dirty and stick together.

Diarrhoea often leads to depression, lack of appetite, loss of weight and condition. If it is not properly man aged, the affected chickens may die.

Problems with the nervous system also cause problems with blood supply, mental problems like depression, and respiratory infections.

The legs of the poultry are affected, causing lameness or crippling, caus ing them to limp or refuse to move. It may also include paralysis, with heads and necks pulled over their backs or twisted to the side, while they stare upwards or limp around in circles.

These conditions may be caused by viral diseases such as Newcastle dis ease or Marek’s disease. This disease is caused by a highly contagious viral disease of the chicken herpes fam ily. It suppresses the bird’s immunity to other diseases such as coccidiosis. Coccidiosis is a common intestinal disease caused by several species of parasites, which damage the intesti nal lining and prevents chickens from absorbing nutrients from food.

Most often there is no treatment for these conditions, especially if they are caused by a pathogen-like virus.

It is therefore important to ensure that preventative measures like vac cinations and biosecurity measures are in place.

Disease problems can occur even under the best conditions. To detect disease at an early stage, you must measure your chickens’ growth by comparing it to known standards set by the industry. If they do not compare well, you will know that something is wrong, and you can investigate the reason. Once you have figured out what the problem is, or even before, call a veterinarian or state animal health services.

The birds must be inspected and measured against production stand ards. You can watch them to see any problems, but it is best to weigh sam ples and keep record of all information.

Chickens must be weighed on a weekly basis throughout the growth period.

About five to ten percent of the total number of chickens must be weighed at one time, so in a broiler with five hundred chickens, twenty-five to fifty chickens must be weighed.

weigh only the largest ones, but select them at random.

expected target mass of broilers at different ages:

Roosters Hens Assorted

40 40 40

135 135 135

405 395 400

790 720 755

1 200 1 055 1 125

1 640 1 410 1 525

2 105 1 770 1 940

Besides their body mass, you can check for these signs to find out if something is amiss:

• what did the day-old chicks look like when they arrive — were they perky and inquisitive, or listless?

• what was their average weight after one week?

• how many of your chickens died per day and per week?

• how much food did they eat?

• how much water did they drink?

• how much weight did they gain per day?

• how many eggs did your laying hens lay?

• how successful did they turn the feed they eat into growing?

• are they moulting (losing their feathers)?

• do your chickens seem dull and listless?

• do they cough?

• are they lame and cannot walk around; and

were the carcasses rejected at the abattoir?

To be able to detect disease, you must know what to expect from your chickens at each age. When you sus pect something is wrong, seek veteri nary advice as soon as possible so that pathogenic viruses and bacteria can be isolated.

for the age and function of the chickens must be provided.

only the best feed

It is important to keep up to date with local and regional health concerns in order to prepare for the unexpected.

Ill health in you birds can be caused by a variety of causes and in

teractions. Use a systematic approach when trying to determine the cause of health issues.

Feed: Do the chickens have the right quantity and type of feed suitable for their age and purpose, what is the nutritional content and how palatable is the feed, does the feed contain con taminants or toxins, how much are the chickens eating or have they stopped eating?

Light: Is there adequate lighting with the correct intensity in the poultry house, and are the birds uniformly ex posed to it so that they can grow and develop efficiently?

Litter: What type of litter is used, how thick is it and is it properly dis tributed to cover the whole floor, or is it wet and smelly and containing toxins and contaminants that can cause viral and bacterial growth?

Air: Is the poultry house well ventilated, but not draughty, is the temperature and humidity suitable, or does the air contain contaminants and toxins?

Water: Do the chickens have enough clean, cool water without any contami nants or toxins, and are they drinking enough water?

Space: Are there too many birds in the poultry house, are there enough feeders and waterers so all of them can reach the feed and water, and are

Sanitation: Is the inside and outside of the poultry house clean and well maintained, are there any pests and rodents and how are they controlled, are dead birds removed immediately, and is the wet litter regularly replaced with fresh material to avoid a build-up of worms and other parasites? How well is the poultry house and surround ings cleaned and disinfected before a new batch of chickens arrive?

References

Arbor Acres broiler management guide. (2009) Aviagen https://eu.aviagen.com/assets/ Tech_Center/AA_Broiler/AA-Broil erHandbook2018-EN.pdf

Cilliers, P.F. (July 2000) Smallscale poultry housing in South Af rica. ARC-Institute for Agricultural Engineering.

Cilliers, F. (Project manager) (2001) Small-scale broiler house (combined). ARC-Institute for Agri cultural Engineering.

Clarke, S. (n.d.) Ten things every chicken owner should know about Marek’s disease. thisNZlife. https://thisnzlife.co.nz/10-thingsevery-chicken-owner-knowmareks-disease/

Family poultry training course trainee’s manual. http://www. sapoultry.co.za/pdf-training/train ers-manual-poultry-course.pdf

Human infection with avian influ enza A(H5) viruses. (1 April 2022) Avian Influenza weekly update number 838 World Health Organi zation. www.who.int/docs/default-source/ wpro---documents/emergency/ surveillance/avian-influenza/ai20220401. pdf?sfvrsn=30d65594_220

Lera, R. (2020) Infectious Bursal Disease (Gumboro) in laying hens Hendrix Genetics layinghens.hendrix-genetics. com/en/articles/Infectious_Bur sal_Disease-IBD-Gumboro-Gum boro_disease-disease-poultrychickens-laying-hens-poultry_dis eases-black_chicken-brown-chick en-white-chicken/

Mormina, K. S. (n.d.) Coccidiosis: What backyard chicken keepers should know. The Chicken Chick.

cidiosis-what-backyard-chicken/ Warning signs of infectious dis eases in poultry (2021) Epol https://epol.co.za/warning-signsof-infectious-diseases-in-poultry/

Better Trees, Better Farmers, Better Industry

Fresh Avocado and Macadamia trees for Africa supplied from South Africa

A bonnet made from plastic bottles pulled from the Mississippi river, and a storage compartment made from ground coconut are only a couple of the surprising materials used to make this concept Gator.

The result of four years of collabora tion between John Deere and Ford’s sustainable materials team, the goal in developing the prototype was to exam ine ways of turning waste into viable machine components.

The brief was to build a Gator using renewable, recycled, and recyclable materials.

“It was difficult because we had to work within our current framework of production tooling,” says Keith Shanter, Senior Materials Engineer. “We weren’t going to invest in new tooling for a

product that won’t go to market, but we did everything we could to find sus tainable materials that were suitable replacements.”

In the end, the wide variety of differ ent materials used included soya beans for the roof, doors and seat foam. Flax and hemp fibre, wheat straw and maple wood were selected for interior panels, and exterior door panels were made from sugar cane with maize cob filler. A rice hull filler was used for the dash board, and the grab handles are made from recycled fishing nets.

Deere has no plans to take the concept to the production stage, but one compo nent from this project that is in Gators produced today is a defrost louvre made of recycled tyres. (Source: John Deere)

Kverneland introduces a flexible front hopper

Suitable for applying a wide range of fine to larger seeds and fertiliser, the

f-drill front hopper can be combined with different implements and for operation in various working widths. Seeding and fertilising in one pass is possible, as well as the combined appli cation of seeds and companion crops.

In spring, the f-drill can be used as a fertiliser hopper with the Optima F or, for example, in combination with the Kultistrip for strip tillage. When joined with a power harrow drill combina tion, it can be used as an additional seed hopper for sowing companion or spring crops. In summer and autumn, the hopper can be combined with a power harrow. Working width of the coulter bar is from 3 to 6 m and power requirements are from 78 to 127 kW.

Available in two sizes and two ver sions, the f-drill compact has a capacity of 1 600 litres and the f-drill maxi up to 2 200 litres. The standard version is equipped with one Eldos metering unit. Higher application rates can be

achieved by the duo version, as two El dos units distribute two times up to 400 kg/ha of one type of fertiliser or seed. The company says that high volumes are ensured by the venturi system with no need for a pressurised system.

The f-drill can be connected to any ISObus compatible tractor for fully func tional use by the tractor’s own terminal.

And more news from Kverneland: More maize with less fertiliser Pudama is the name of a technique that enables precision spot fertiliser placement below maize seed during planting. Kverneland says that it allows fertiliser rates to be reduced by up to 25% without affecting yields.

Developed in cooperation with the University of Applied Sciences in Co logne, and currently fitted to the Optima TFprofi SX precision drill, the Pudama

configuration sees seed and fertiliser ap plications synchronised by a sensor.

Suitable for operating at speeds of up to 15 km/h, at maximum speed it applies 25 fertiliser spots per second. Kverneland claims that the technique results in greater nutrient absorption because fertiliser is only applied where it is needed, and it prevents excess ni trate and phosphate from leaching into water systems.

A limited number of the Optima TF profi SX with Pudama will be available next season (fully available for 2024). Kverneland says that the technology will eventually migrate to other Optima models. (Source: Kverneland)

Massey Ferguson has introduced a range of limited edition S series trac

tors as part of its 175th anniversary celebrations. Customised at the Beau vais factory in France, all 175 'specials' are equipped with the top-spec Exclu sive specification.

Finished with bright red bonnets and fenders, the grey stripes put the iconic ‘Little Grey Fergie’ at the heart of the distinctive design. The tractors also come with a dedicated 3D metal lic chrome decal along with the 175 limited edition logo.

All top S series models are available as limited edition Exclusive versions. These include the 5S.145 Dyna-6, 6S.180 Dyna-VT, 7S.180 Dyna-6, 7S.210 Dyna-VT, 8S.265 Dyna-7 and 8S.305 Dyna-VT. Available to order now, the limited edition tractors also come with numerous personalised cab details and an individual gift pack for every customer.

“With strictly limited production, we expect these very special tractors to sell out quickly,” says Massey Ferguson Marketing Director Jérôme Aubrion. “Like many of our past iconic models, they will be treasured by owners and are set to be highly prized by collectors for years to come.” (Source: AGCO)

Legumes are a staple in many developing countries. Besides being a valuable source of protein, it also enriches the soil in which it grows. In this series, we highlight traditional crops that can contribute to providing nutritional meals to people.

The marama bean is a native of the de serts of Southern Africa, where it thrives in poor soil and harsh conditions.

The plant produces seeds that are on par with peanuts and soya bean regard ing nutritional value, while the high protein tuber below the earth is larger than sugar beans and more nutritious than yams or potatoes.

However, the plant has not been domesticated, and the valuable quali ties are therefore not utilised. It has a long way to go before anyone can truly capitalise on its qualities.

Roasted seeds have a nutty flavour like coffee beans or cashew nuts. It is also used as a substitute for almonds in cooking. The seeds are boiled with maize meal, or ground into flour for making porridge or as a drink that tastes like coffee or cocoa.

The seeds have a protein content of about 30%, much like the soy bean, while the edible oil content is about 40%, much like the peanut.

The plant occurs at an elevation of up to 1 500 m. it grows best at annual daytime temperatures of between 22 and 30 °C but can tolerate 16 to 50 °C. It prefers a mean annual rainfall of 300 to 600 mm, but can tolerate as little as 150 mm and an abundant 1 600 mm.

The plant is extremely drought re sistant and survives droughts by stor ing water in the tubers, which shrinks during dry years.

It grows best in a sunny spot in deep, loose, and sandy soil with a pH of 5,5 to 7, but it can tolerate 5 to 7,5.

Lablab bean (Lablab purpureus)

Lablab bean (Lablab purpureus)

The lablab bean (Lablab purpureus) is a climbing vine belonging to the family Leguminosae.

The lablab bean (Lablab purpureus) is a climbing vine belonging to the fam ily Leguminosae.

The bean is popular in southern India, where the pods and seeds sup ply much of the daily protein intake. Although its origins lie in Africa, it is quite unknown on the continent at present. It could, however, provide valuable nutrients in the African diet.

The leaves are either cooked like spinach or dried for future use. The flowers are eaten raw or cooked in soups or stews.

Young seedpods and immature seeds can be eaten raw or cooked as a green vegetable like French beans or in a vegetable curry.

The marama bean is

suited for drought conditions.

The immature seeds and stems are used as a vegetable or in soup. Young tubers have a pleasant, sweet taste that has been described as similar to artichoke, and it is either baked, boiled or roasted.

The mature seeds are edible but must be properly cooked. It has a mild flavour, is rich in protein and is a valu able staple food.

The seeds can be prepared as tofu or be fermented into tempeh in the same way that soya beans are used in Japan. The seeds can also be sprouted and eaten raw like mung bean sprouts.

The immature seedpod contains 3,2% protein, 0,8% fat, 5,4% carbohydrate, and it is rich in vitamin B1. The leaves contain up to 28% protein when dried.

The plant prefers well-drained soil that is rich in organic matter. It will tolerate fairly poor soil, as long as it is welldrained and with a pH of between 5,5 and 6.

It grows best in a warm, sheltered position at temperatures between 28 and 30 °C, but can tolerate a tempera ture of as low as 9 °C.

Some varieties are drought resistant. The plants grow quite fast, and young pods are ready to be harvested from 70 to 120 days after sowing.

Bambara bean (Vigna subterranean)

The bambara bean (Vigna subter ranean) is a member of the family Fabaceae. This plant, also known as bambara groundnut or nut, originated in West-Africa.

It has been cultivated through the ages in tropical regions south of the Sahara and is grown in Eastern Africa, Madagascar, and parts of South and Central America.

The beans are dug from the ground like peanuts and are usually boiled, roasted or fried, ground into flour and used in many traditional dishes.

At present the bambara groundnut is ignored and neglected, but the proteinrich, nutritional bean is a complete food with enough proteins, carbohy drates, and lipids to contribute greatly to the health of communities. The seed proteins contain more of the essential amino acid, methionine, than nearly all other beans.

It produces a food of exceptional nu tritional quality, so a little goes a long

way toward building and maintaining a solid foundation of good health.

All in all, this tasty protein-rich bean promises to benefit the people most in need and hardest to reach through con ventional development programmes.

The bambara groundnut thrives on any

well-drained soil, but light, sandy loam with a pH of 5 to 6,5 is most suitable. The crop also does well on poor soil that is low in nutrients. An abundance of soil nitrogen favours vegetative growth of the crop.

In Zambia, it gives the best yields on ploughed fields and a level seedbed, but in high rainfall areas with wet conditions, it can be planted on ridges. It is cultivated both as a single crop or intercropped with maize, cowpeas, and melons.

In Tanzania the plant is grown in small, mono-crop patches in traditional farming systems along with millet, sorghum, maize, beetroot, and tuber crops, as well as other legumes.

In Zimbabwe, the nuts are usually grown in sandy soils either as a single crop or in a mixed stand with maize, cotton, or sorghum.

Sussex cattle are one of the oldest and purest English breeds and are popu lar in Southern Africa's beef industry. The breed descended from horned red cows once found in Sussex and Kent in southern England. These cattle were draft animals for years before ultimate ly being slaughtered for beef at the age of 6 years.

The Sussex is a medium-sized, early maturing beef animal with a smooth, hereditary red coat and a white tail. The breed's easy-to-handle tempera ment has earned it the nickname "trou ble free." The breed is a part of the Bos taurus group.

The cows' maternal instincts, abun dant milk supply, high calving rates, and excellent fertility demonstrate their versatility. Cows’ average weight is 520 to 620 kg; bulls have muscle and depth, and their average weight is 850 kg.

Breeders must dehorn naturally horned Sussex animals. Breeders use polled bulls to introduce polled genet ics into their herds. Polled bull sperm has been imported, and polled genetics are available.

Sussex cattle mature early, so they can be sold right off the veld or pas tures. It is a good converter of concen trate feeds and gains weight quickly, so feedlot operators like them.

hardy, show a good weaning weight, and excellent post-weaning growth. Sussex bulls add weaning weight to crossbreeding programmes.

Sussex bulls with the $X brand mark on their left shoulder have been visu ally inspected by a senior inspector of the Society. When using Sussex bulls, farmers should make sure they have the $X brand.

A Sussex stud breeder gives com mercial beef producers high-quality bulls that work well to improve the quality and profitability of beef.

The Sussex breed produces high-qual ity meat.

African cattle are categorised by humps. Zebu cattle have humps on the thorax, while Sanga cattle have them on the neck. According to DNA tests, Tuli cattle are part of the Sanga group, which dates back over 2 000 years. Migrating tribes brought these early animals to Southern Africa, where they thrived south of the Zambezi. The Tuli is "fertile, profitable, range cattle", ac cording to the Society's logo.

This pure indigenous breed has quali ties that beef farmers value. It has a

medium body size, high fertility, is mostly polled, has easy birthing, lon gevity, hardiness, and adaptability that have been bred into it over at least 2 000 years by natural selection. This makes the breed naturally resistant to both internal and external parasites.

Scientific selection recently focused on economic value, resulting in the modern Tuli. Never has the breed’s har diness and adaptability been compro mised. They tend to have solid white, red, brown, and yellow coloration.

Tuli cows have good fertility, milk production, and low calf mortality with an average weight of 400 to 500 kg, and Tuli bulls have a good feed conver sion ratio and carcass quality with an average weight of 750 to 850 kg. The breed is a part of the Bos taurus afri canus group.

Southern Africa produces the Tuli breed because of its adaptability, hardiness, and capacity to produce high-quality meat from even the worst quality grazing.

The breed does well in sandy, semidesert areas like Namibia, Botswana, and the Northern Cape. It also does well in hot heartwater bushveld areas like Zimbabwe, Limpopo, and the Lowveld of Mpumalanga, as well as

In South Africa, Namibia, Zimbabwe, and Botswana, Sussex Stud breeders can meet the demands of commercial cattle farmers.

Sussex animals can tolerate the harsh cold of the Drakensberg and Eastern Cape mountains as well as the sands of the Kalahari Desert and the warm bushveld of Africa. This demon strates their extraordinary adaptability and superior heat resistance.

Purebred and crossbred Sussex cattle perform well. Bulls are pre-potency,

in high rainfall, sour veld, and highaltitude areas of Mpumalanga, and in KwaZulu-Natal, where redwater, gall sickness, and cold conditions with snow are common.

The Tuli is particularly effective in crossbreeding programmes due to its distinctive genetic make-up, which produces good hybrid vigour and a high proportion of polled calves. Addition ally, compared to many other breeds, Tuli steers and Tuli-cross calves finish quicker on the veld.

Of all the breeds in the world, the Tuli has the highest rib-eye to carcass ra tio. Due to the hardiness of the breed, their meat can actually be labelled as "grass fed" because it can be "fattened up" on the land.

The name Wagyu refers to two Japa nese cattle breeds and means "Japa nese cow". Buddhist leaders strictly forbid eating meat, so these cattle were chosen for their strength. Mar bling is the succulent, flavourful inter muscular fat. Wagyu beef used to only be eaten by royalty and samurais in Japan because it was so good.

International production accounts for 0,2% of premium meat breeds. Raising awareness of the excellent meat qual ity will continue to increase demand. South Africa produces both red and black wagyu. Akauishi has excellent marbling, fertility, and growth. They resemble South African red cattle. The Japanese black has even more mar bling than the Akauishi, and is ideal for the "boutique" meat market and exports. The cows weigh an average of around 450 to 560 kg and bulls can weigh up to 950 kg. The breed is a part of the Bos taurus group.

Due to their high adaptability, Wagyu

cattle are raised all over Southern Af rica. The Wagyu Society encourages its use in crossbreeding with native breeds like the Nguni, Bonsmara, and Beefmas ter, which are primarily British and in digenous, in order to improve the meat quality and fertility of these breeds.

In accordance with the breed defini tion, the term "Wagyu" may only be applied to cattle that are first-line crosses with a minimum of 50% breed content or to registered full-blood or purebred bulls. Farmers must follow a number of moral and animal wel fare rules, keep accurate production records, and castrate bull calves not intended for breeding before they are five months old.

The meat must be hormone-free and have a marbling score of at least three.

Ankole cattle are raised for beef in South Africa. This breed dates back to ancient Egyptian hieroglyphs and has been part of the longhorn cattle tribes for over 6 000 years. The breed migrated down the Nile to Uganda, the Pearl of Africa.

The Banyankole people of Western Uganda, after whom the Ankole was named, believe God created the breed and gave it to the Ankole Kingdom's founders. The Ankole are "Kings' Cattle".

Dual-breed cattle are known for their lean meat and high-quality milk. They have majestic, ivory-looking horns that point to the African sky. Horns con nected to airways help cattle regulate their body temperature.

Roan, strawberry, dark to light brown, and red are some of the coat colours. In the past, Ankoles were managed by their coat colours, body types, behaviour, and horn shapes. The cows weigh an average of around 400 to 540 kg, and bulls can weigh an average of 450 to 720 kg. The breed is a part of the Bos taurus group.

The breed can do well in most of Southern Africa because it can adapt to different climates.

They have the capacity to acclimate to harsh and extreme weather, from cold and rainy to hot and dry desert climates. They are a strong and use ful breed because they can survive on low-quality forage and have a high level of disease and tick resistance.

The breed may be used alone, but due to its extensive use in crossbreeding programmes in Uganda, it has come under threat over time. Lots of milk are produced by the cows, which are val ued in Uganda and is reportedly both tastier and healthier than milk from traditional dairy breeds.

The meat is tasty, lean, low in choles terol, and rich in omega-3 and ome ga-9 fatty acids. According to the An kole Cattle Breeders Society of South Africa, it will undoubtedly attract the attention of customers and markets who are concerned about their health.

Southafrica.co.za. (2022). South Af rican Beef Breeds. [online] Available at: https://southafrica.co.za/southafrican-beef-breeds.html

Loubser, A., Schutte, N. and Hofmeyr, I., (2007). Cattle breeds of South Africa. Pretoria, AgriCon nect, Pages 97-165.

The main asset utilised for farming in Africa is soil, a mixture of or ganic matter, minerals, gases, liquids, and organisms for that sustain plant growth.

The optimum use of this resource has however been minimised over the past years due to several dynamics, namely lack of structured funding from financial institutions for agricultural projects due to the absence of collateral from startup farmers; high costs of land prepara tion and posterior agronomic activities (fertigation, irrigation, nematode, in sect, pest control); the drastic effects of climate change; lack of well-developed market synergies to promote the sale of agricultural produce and the lack of properly qualified expertise to manage agricultural projects.

As technology is consistently changing, the emergence of hydroponic farming could provide the long-term sustainable solutions we have been seeking as a continent. Hydroponics is the practice of crop growth in mineral nutrient solutions, and it is a subset of soilless culture. Hydroponic systems can be subdivided into the following production technique categories: Nutrient Film Technique (NFT); Dutch/Bato Bucket Technique; Raft/Deep-Flow Technique (DFT); Slab/ Hanging Gutter Technique; Aeroponics and the Ebb and Flow Method.

Nutrient Film Technique (NFT) in volves the movement of a very shal low stream of water containing all the dissolved plant nutrients being recirculated past the roots of plants in a watertight gully (or channels).

The Dutch/Bato Bucket Method uses two or more growing containers con nected to the similar irrigation and drainage lines. This is an incredible water- and nutrient-efficient method, ideal for growing heavy-feeding and vining plants like tomatoes, peppers, and eggplants.

In the Raft/Deep-Flow Technique (DFT) water supplies nutrients to plants via ponds. Plants are grown in drainage channels with a 4 to 6 cm nutrient solution running continuously, and the roots of plants continually sub merged in the nutrient solution.

In the Slab/Hanging Gutter Technique soilless substrates in a gutter (plastic or metal) are placed in a support system or suspended above floor height with plant

roots growing in a nutrient solution.

The Aeroponics Technique involves being given nutrients from a mist that is sprayed onto the roots of plants. Crops are grown suspended in the air. The plants are contained in a humid atmos phere where frequent misting delivers a nutrient-rich solution right to the roots, keeping the crop from drying out.

The Ebb and Flow Method involves flooding the growing area with the nutrient solution at specific intervals, which then drains back into a reservoir containing a pump on a timer. This type of flood and drain hydroponics system is ideal for plants that are used to alter nating periods of dryness to wet.

The current global use of hydroponic systems is distributed as follows: 36% under the Nutrient Film Technique (NFT); 18% under Dutch/Bato Bucket Technique; 14% under the Raft/DeepFlow Technique (DFT); 8% under the Slab/Hanging Gutter Technique, 8% through Aeroponics; 3% utilising the Ebb and Flow Method and 13% of hydroponics is being done under other types of production systems.

Regions currently dominating the hydroponics market are North America, Western and Eastern Europe, as well as Northern Asia, followed by Southern Asia, the Middle East, Australia, and lastly South America and Africa.

For Africa to also compete on this global scale and reap the benefits of hydroponic production systems, the farmer should have access to loans corresponding to his level of opera tion. Financial institutions can disburse loans in which the collateral for the hy droponic project is fixed, and the sale of the produce is guaranteed by con tracts to the relevant wholesale, retail, and or direct buyers and middlemen.

Input supply companies and insur ance can collaborate to ensure that the project runs well. Input supply compa nies can have their products paid for by a financial institution or non-govern mental organisation funding the project, and the insurance firms can insure the project against catastrophes common in agricultural production systems.

• Allows large tracts of land to revert to the natural landscape, restoring ecosystem functions and services

• Remediates black water to create a much-needed new strategy for the conservation of drinking water

• Take advantage of abandoned and unused urban spaces

• Allows year-round food production without loss of yields due to climate change or weather-related events

• Eliminates the need for large-scale use of pesticides and herbicides, thus promoting organic farming

• Provide a major new role for agro chemical industries, for example, designing and producing safe, chemically defined diets for a wide variety of commercially viable plant species, and

• Creates an environment that encour ages sustainable urban life, promot ing a state of good health for all those who choose to live in cities.

The current market value of hydropon ics stands at 9,5 billion US dollars and is expected to have a market value of 12,1 billion US dollars by 2025. As a continent, we have to be able to participate in this space to spur the growth of gross domestic product (GDP), create employment and improve the functionality of agriculture within Africa’s countries.

Lerotho, Bangala, Spider flower, Delele, Jew’s mallow and kale are all part of the African leafy vegetables that can be commercially grown. These plants also help fight against malnutrition as they are rich in many minerals and vitamins.

We will be discussing these leafy greens as a group since the cultivation method is similar.

The popularity of these veggies are due to the speed at which they mature, and how easily a household can grow it in their home gardens or vegetable patch. It is well-suited as an intercrop or, if planted in a rotational system with other plants, a multicrop.

One of the African leafy vegetabels that is frequently cultivated is marogo or imfino. It is often enjoyed with stiff porridge. Like other leafy greens, it is rich in vitamins and minerals, especially vitamin A and iron.

Other kinds of leafy vegetables include:

• Amaranthus species (Amaranths, pigweed, marogo)

• Cleome gynandra (Spider plant)

• Corchorus spp (Gushe)

• Brasica carinata (Kale)

• Solanum retroflexum (Nightshade)

• Colocasia esculenta (Amadumbe)

African leafy vegetables fare best in climates where temperatures are usually between 15 and 30 °C, but each spe cies differs. Some, such as Cleome and Corchorus, prefer warm day tempera tures, and are sensitive to cold. Cleome requires full sun.

The vegetables grow well in sandy to loam soil. One of the reasons that African leafy vegetables are regarded as good crops and effective in fighting

malnutrition, is that it fares well in a wide variety of soil types. It is however a good rule not to plant it in soil that gets waterlogged, as this can cause rootrot.

Depending on the particular vegeta ble and the personal preference of the person preparing the food, these leaves are prepared in the same ways as spinach.

Prepare a fine seedbed. You can use a fork or rake to break any clods. A shov el can also be used. Take note of the fertilisation requirements the plants before planting.

Make shallow furrows in the soil bed, between 1,5 and 2,5 cm deep, and 25 to 35 cm apart.

Start by mixing the seed with some soil and sow evenly in the furrows. Irrigate lightly after sowing. Bigger seeds can be sown directly into the furrows,

Thin plants out when seedlings are 15 cm tall. Ensure there is 10 to 15 cm between plants.

Note that the germination of spider flower could be uneven. Corchorus seed also needs to be broken before sowing or it will remain dormant.

When it comes to intercropping, most

of the African leafy vegetables can be in tercropped with one other or with maize.

When preparing the seedbed, use rip ened manure and thoroughly work it into the seedbed. Use approximately 3 kg of manure per square metre of soil bed.

If you are using chicken manure, use half of the measurement (1,5 kg per square meter). Use manure with high levels of nitrogen to delay flowering and increase the leaf yield. You can also add 100 gram of ash per square metre of soil when planting corchorus. Give the manure chance to break down before you plant.

African leafy vegetables need water two or three times a week, depending on the temperature and rainfall. Heat stress and drought will cause plants to develop quicker through different stages. Effectively the plant jumps to developing flowers, and thus seed, quickly skipping past growing, affect ing the amount that is harvested. If day temperatures are extremely high, water daily.

Irrigate in the early mornings and late evening to ensure the water does not evaporate during the hot days.

When harvesting, there are three op tions: uprooting, cutting back (± 15 to 20 cm) or picking the leaves. Plants that are growing healthy and lavishly can be harvested often.

The best time to harvest is during the early mornings or late evenings Once plants are growing well, frequent harvesting of leaves or shoots can take place.

If plants are uprooted place them in water. If shoots and leaves are har vested wrap them in a wet cloth, or in a well-ventilated bag over night. Avoid excessive water as this will cause rot. You can dip the shoots in water for about 30 minutes to revive them again the next morning.

There are a few pests that attack Af rican leafy vegetables. Here are some examples:

Cleome: Flea beetle, nematodes, stem borer, pod borers and cutworms.

Kale: Aphids, mosaic virus, diamond back moth.

All of these pests and any viruses can be controlled by using registered chemicals to control them. Additionally, strict sanitation practices during the growing season should be practiced. You can monitor crops for important pests and diseases and prevent them before they cause serious damage.

The information provided in this article is credited to the Agricul tural Research Council Vegetable and Ornamental Plant Institute (ARC-VOPI). For more informa tion, contact +27(0)12-841-9611 or visit http://www.arc.agric.za.

ed sprayers have the same volume ap plication rates. Small-scale farmers can also benefit greatly from them.

Motorised knapsack sprayer

Motorised knapsack sprayers are great for LV and ULV. The engine operates a centrifugal blower that produces highspeed, low-volume air. Spray liquid is fed directly to the air outlet from the tank. The engine must always be at full power to atomize the spray liquid.

By Natasha KrugerThe methods used to apply plant pro tection chemicals are referred to as application techniques. There are many factors that contribute to good plant protection, including the substance it self and the time of its application. The instructions for mixing and applying a product can be found on the label of the container.

A plant-protection substance's biologi cal function is not dependent on water; rather, it serves as a vehicle for the product. The ratio of water to insecticide is critical to successful spraying. A large amount of the product flows off the plant when too much water is used. In addi tion, transporting signifi cant amounts of water to the field is very expensive.

The effective reduction of enormous amounts of water per hectare is now possible thanks to new technology. This is where ultra-low-volume equip ment comes in handy. Die sel oil can take the role of water as a vehicle in this technology, reducing the amount of liquid required per hectare to as little as two litres.

Lever-operated sprayer

For low-volume (LV) and high-volume (HV) applications, leveroperated sprayers are ideal. However, they are not suitable for ultra-low volume (ULV) applica tions. They're popular in vast orchards, but they're

(Image source: pixabay. com by hpgruesen)equally at home on a smaller scale.

Manual pump operation maintains spray pressure with lever-operated knapsack sprayers. By balancing the pressure in the chamber, an air cham ber keeps the pressure going to the nozzle steady.

Compression sprayers eliminate the need for pumping during spraying. This makes it easier to spray on uneven ground or crops that may need to be held with one hand. Make sure you don't fill the sprayer more than two-thirds full. After that, pump it up to a pressure of (typically) 5 bar and start spraying. Compression sprayers and lever-operat

Motorised knapsack sprayers treat trees conveniently without pumping. With a ULV attachment, production is five times faster. With a good breeze, the work rate is 20 times that of the other two sprayers. Motorised knapsack sprayers are great for controlling migra tory pests. A 20-m-wide swath is possi ble. When held vertically, it can cover 50 m and throw 10 m. Undiluted oil-based ULV formulations reduce application volume to 2,5 litre/ha.

For field crops, incline the air discharge tube. Swinging the air discharge tube left and right causes self-contamination.