No 38 Free ProAgri Botswana / Namibia / Zimbabwe www.proagri.co.za www.agri4all.com Borehole solutions with Carl Hamm and STÜWA Botswana Namibia Zimbabwe page 22 page 33 page 41 Renewable energy: The way forward?

You want to make decisions that improve your yield and bottom line. Valley® Irrigation is here to provide you with the equipment and technology you need to achieve maximum productivity and profitability. No matter your field size or budget, we have the best irrigation solution for you.

Whether you’re installing irrigation equipment for the first time, replacing an aging pivot or upgrading your current equipment, there’s no question that it’s a big investment – and a significant commitment. Determining exactly what you need is crucial to the way you farm. Contact us to help you design a

is

and

No matter

we

the best Invest in your

Invest Whether an that exactly that improve your yield and bottom Irrigation

here you with the equipment

you need to achieve maximum and profitability.

your or budget,

have

future.

+27(0)

7233

|

Finance Available

and C’s Apply)

customized solution for your operation.

60 048

marketingmea@valmont.com

www.valleyirrigation.com

(T’s

Power cuts: Looming crises in agriculture

Planting season is in full swing, and the concern of power cuts being imple mented result in farmers planting less, owing to rising costs and disruption in planting and irrigation schedules.

Just the other day, I was driving with a farmer on his farm, where he shared his concerns of power cuts with me and told me that he now has no choice but to install solar power on his farm if he is to survive in this business.

Power cuts are extremely detrimental to irrigation operators, as crop water requirements cannot be met. This leads to significant reductions in yields. The gross incompetence at Eskom has a ma jor cost implication to many farmers and their businesses. Implementing alterna tive energy sources on an average farm ing operation won’t be a cheap exercise.

It is not only the primary producers who are affected, but every operator in the value chain, from input suppliers to processors. Obviously, the more farm ers, processors and other players in the value chain are squeezed on their prof its, the more expensive food becomes and the greater the pressure on con sumers, especially the poor. Loadshed ding causes massive financial losses for farmers in Southern Africa, and contrib utes directly to a spike in food waste.

Electricity is a vital component for all

stages of the food production pro cess – without it, food spoils must be discarded. Food waste increases with load shedding, as refrigeration units stop working in our homes, our cold storage facilities, our dairies, our butcheries, in shops and in hotels, to name a few. Electricity is vital for all stages of the food production pro cess – without it, food spoils and must be discarded. Moreover, power cuts present security risks.

Alternative power from solar panels or from backup generators, is costly. If a farmer with a big operation com plains about the cost of setting him self up with solar power, we can only imagine how difficult things are for small-scale and emerging farmers.

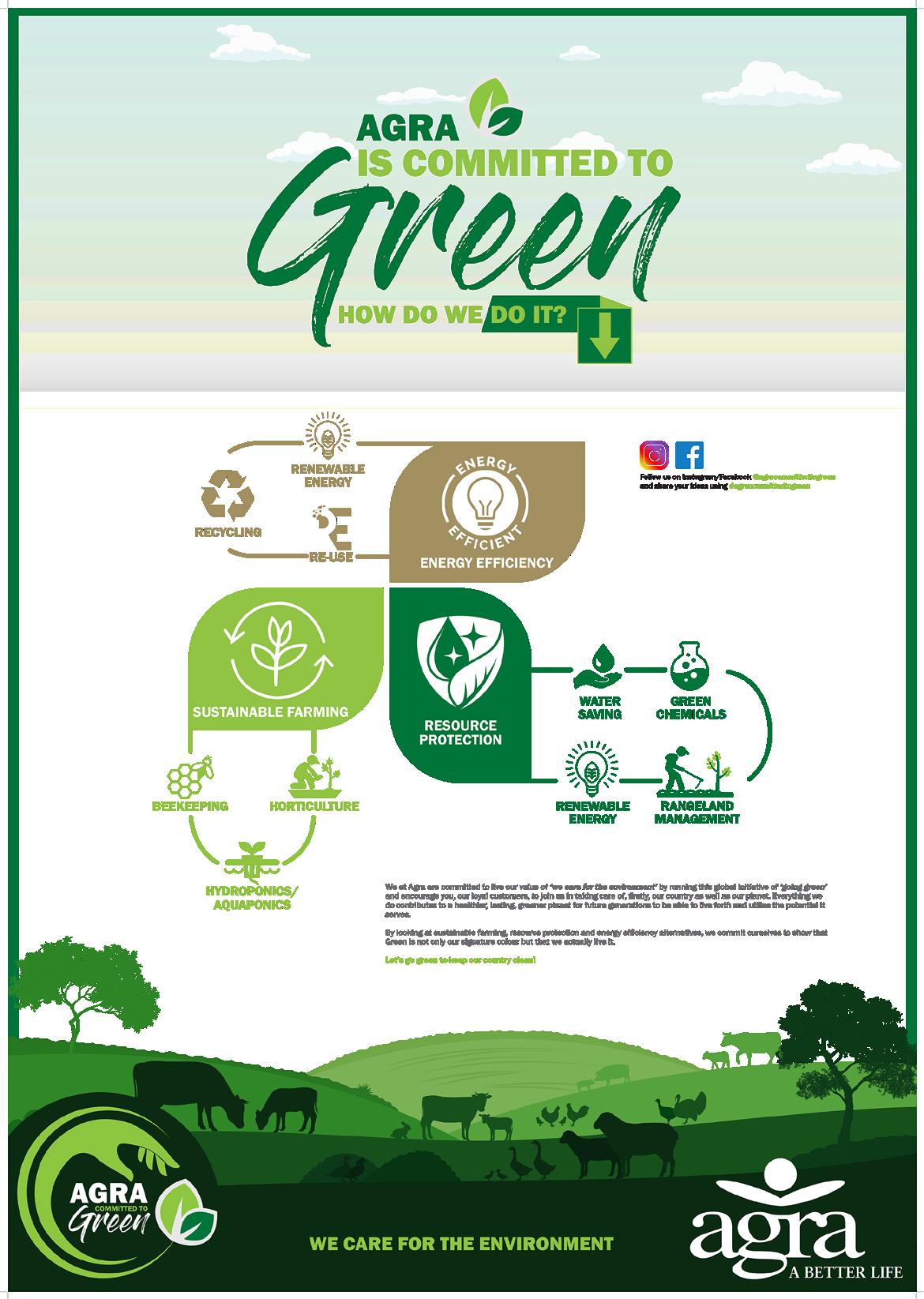

By using alternative energy sources farmers can free themselves from dealing with the woeful performance of government-run electricity providers, and it is much more sustain able. Farmers who switch to using renewable energy are taking action to mitigate climate change and keep the planet and its resources stable. Read more on page 40.

ProAgri greetings

Bianca Henning bianca@proagri.co.za

Cover

Carl Hamm pride themselves on superior quality borehole equipment. Apart from the highstrength material that they use in their products, they also design their products with safety, durability and longevity in mind.

ProAgri

Botswana / Namibia / Zimbabwe

577 Rossouw Street, Die Wilgers, Pretoria +27 (0)79 515 8708 www.proagri.co.za

Copyright © 2022. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

ProAgri BNZ

Editor

Bianca Henning >

Reporters

Benine Ackermann > Maryna Steyn > Natasha Kruger >

Specialist Writer Annemarie Bremner >

+27 82-326-2572 bianca@proagri.co.za

Client Relations Manager Carin Swartz >

Marketing Manager Diane Grobler > Marketing Xander Pieterse > Johan Swartz >

Tiny Smith >

Lynette van Tonder >

Creative Director

Christiaan Joubert >

Design Michelle Kruger

Enquiries

Engela Botha >

+27 73-105-6938 benine@proagri.co.za +27 82-261-9177 maryna@proagri.co.za +27 81-736-4236 natasha@proagri.co.za +27 82-320-3642 annemarie@proagri.co.za +27 84-233-0123 carin@proagri.co.za +27 82-555-6866 diane@proagri.co.za

+27 79-524-0934 xander@proagri.co.za +27 71-599-9417 johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za +27 72-419-3990 christiaan@proagri.co.za

Distribution and subscription Nita Volmer-van Zyl >

Accounts

Ronel Schluter >

Business Manager

George Grobler

+27 12-803-0782 engela@proagri.co.za +27 79-515-8708 nita@proagri.co.za +27 12-803-0782 accounts@proagri.co.za

Content

3. 5. 7. 9. 12. 15. 20. 22. 29. 33. 36. 38. 41. 44. 5 7 15 38

Carl

Hamm:

STÜWA

borehole

riser

pipes

and

well screens for

longevity and durability John Deere: The green keeps growing Ripper Tillage Equipment manufacture implements to your taste Poultry farming part 7: Record keeping Sheep breeds part 1: Sheep raised for mutton Beekeeping part 4: Inside the hive Technews: The latest in agricultural technology Vegetable planting part 19: Crop rotation and crop calendar Fighting a thorny issue Waste water treatment: Trapsuutjies makes a difference Choose greenhouses for maximised production Part 1 Renewable energy for farms Tree nut production in Sub-Saharan Africa part 2 Ancient African food Part 5.4: Cowpea

ProAgri

/

/

38 1

Botswana

Namibia

Zimbabwe

2 ProAgri BNZ 38 Contact any of our qualified staff members. NOW TRADING IN ALL AFRICAN COUNTRIES www.gallaghersa.co.za Coastal RegionGauteng / Limpopo / Mpumalanga / AfricaNorthern Cape / Free State / NorthwestOn-Line StoreDemi: demi.nel@gallagher.com / +27 73 001 4690 Mark: mark.smit@gallagher.com / +27 83 297 6079 Benard: benard.willemse@gallagher.com / +27 81 036 0173 Zinia: zinia.moloi@gallagher.com / +27 76 792 3737 sales.za@gallagher.com / 011 974 4740 Gallagher electric fencing systems for animal management all the fencing accessories you need in one place Weighscales Loadbars EID-Tag readers Portable/ Temporary fencing Insulators & Strainers Small or large scale farming, we have the solution for you. Complete fencing solutions which are efficient, reliable, and durable while still maintaining ease of use and practicality. We keep your animals safe and secure, providing you with peace of mind. THE iSERIES 24/7 remote monitoring and control + Multi-powered +Solar-powered + Battery-powered

Carl Hamm offers water solutions:

STÜWA borehole riser pipes and well screens for longevity and durability

by Maryna Steyn

by Maryna Steyn

B oreholes are vital for deep soil wa ter extraction. Much like everything else on your farm, taking care of your borehole will ensure that it takes care of you. That is why you need qual ity parts that are both effective and durable. Carl Hamm PPS, supplier of specialised pumps and pipes for the agricultural and mining industries, together with their German partner and manufacturer, STÜWA, is geared to ensure your borehole is well man aged and will continue to deliver pure water through superior equipment. Two products specifically produce proven effective results.

material quality,” says Chris Munnick, CEO of Carl Hamm PPS. By using a well screen, it stabilises the aquafer strata and helps water flow into the borehole at a consistent rate, therefore protect ing the area around it. Depending on wall thickness of each well screen, slot widths are approximately 0,5 mm or more. The wall itself can be up to a thickness of 12 mm. Screens are avail able in plastic and stainless steel, mak ing them rust resistant and durable.

The ZSM riser connection

The ZSM riser pipe connection has small slots into which chains are placed to create a strong, seamless seal.

A wide range of connec tions are available, but the ultimate decision rests on the techni cal requirements of your borehole or well. Depending on the circumstances in which these connections will be used, the following factors need to be consid ered:

• tensile strength,

• collapse resistance,

• outer diameter, and

• installation guidelines

“What makes this coupling strong and unique is that, unlike a screw-in pipe, it doesn’t need to be exactly straight to prevent a leak, and it is connected in seconds,” Chris explains. “The fact that there also aren’t screws that can damage the pipe is also a plus.” A ZSM connection has a restraining pin that slides into the slot to form a perfect seal. This pin acts as a hook that holds the opposite part of the connection in precisely the place it was made for. Since there are no grooves like with screw connections, the seal is tight and prevents sand from making its way into the thread. Furthermore, water cannot escape past this type of connection’s seal ring.

The slotted bridge well screen

A well screen is a part of the casing at the bottom of a well or borehole that stabilises the structure of the hole while also preventing debris such as rocks and dirt from the surrounding borehole wall from entering the water supply sys tem. What makes this product effective is the shape of the holes in the screen. The holes appear to have bridge-like structures over them, ensuring that water can still pass through the holes, but preventing any rocks and sand from doing the same. The slotted bridge well screen is produced according to internal STÜWA standards. “STÜWA bridge slot ted screens and casings are at the cut ting edge when it comes to stability and

The ZSM riser pipe connection has small slots into which chains are placed to create a strong, seamless seal.

The ZSM connection is quick and easy to install, and can handle a lot of pres sure — up to 40 bar! The pipes can fit into wells of up to 300 m deep and 250 mm in diameter. This slim, thin connec tion is the ideal choice for any project where there is little wiggle room. The couplings are made from stainless steel, meaning that they are durable and rust-resistant — you won’t need to replace tarnished connections because they last exceptionally long.

German engineering that offers durability and longevity

Carl Hamm and STÜWA share a similar beginning. Both are family businesses that are currently being managed by the fourth generation of their respec tive families. Together they strive to de liver customers with products of proven efficacy and durability. All products are developed in-house in Germany and shipped straight from the factory.

For more information on the prod ucts and services that Carl Hamm provides, contact Chris Munnick on +27(0)10-900-2005 or send an e-mail to chris@carl-hamm.co.za. Visit their website at www.carlhamm.co.za.

ProAgri Botswana / Namibia / Zimbabwe 38 3

Specialists installing the slotted bridge screen. The design prevents debris from entering the borehole.

4 ProAgri BNZ 38

John Deere: The green keeps growing

by Bianca Henning

At John Deere there is no time for sitting back and being idle. John Deere's smart people are constantly identifying and implementing strate gies to ensure that John Deere customers get the professional edge putting them in a winning position.

Today, in 2022, no one is unfamiliar with the world-famous agricultural equipment manufacturer, John Deere ... and no one speaks about the green stal warts without the necessary respect Pieter Pienaar, Tactical Marketing Planner at John Deere, says: "Tech nology is the key that can move agri culture forward to increase yields and decrease costs, but we can only do this if technology, people, equipment, data, and insights are connected for delivering better results. These con nections offer opportunities to apply sustainable farming practices.”

Add value to your livestock and orchard with smaller tractors

Every farmer, whether he farms with livestock, grain, or grapes, has differ ent needs. It is of the utmost impor tance for John Deere to understand and meet the needs of each farmer, in each section of the value chain.

"Over the past year, we have become deeply involved in production systems and also recently attended SAMAC and Veeskool's (Livestock School) farmers' days. These farmers' days are specifically focused on shar ing information with macadamia and livestock farmers," says Pieter.

John Deere's involvement with Veeskool

Pieter adds: “At Veeskool, we dis cussed John Deere’s role in livestock farming, which is really important for us to move closer to the farmer.

Cattle farmers at the famers’ day spoke highly of the adaptability, affordability, and productivity of John Deere's 6B tractors.

"When I think back to what farmers at Veeskool said, specifically about

our 6B and its suitability for the live stock industry, it becomes clear that livestock farmers do not always make use of all the technology of the trac tor, but they still want the reliability of this rugged tractor that lasts for years and completes the tasks easily," Pieter adds.

This ties in yet again with value for money. Pieter elaborates on the advantages of John Deere engines: "We manufacture the engines of our tractors ourselves. Their extended life can be contributed to the advanced mechanical technology available only on John Deere PowerTech engines.

Along with this, John Deere offers longer service intervals. Instead of required services every 250 hours, John Deere tractors are serviced every 500 hours. This means time and cost savings for the farmer!”

John Deere's involvement with SAMAC

John Deere also offers a range of tractors that are specifically designed and built to meet the challenges that an orchard, a vineyard, or a nursery presents to farmers. As John Deere moves closer to the farmers, their ex perts set a course for future solutions.

"Deere & Co recently invested in GUSS Automation, a company focused on bringing precision solutions to the market. This will give the farmer the opportunity to accurately apply fertilisers and treatments exactly where needed," says Pieter.

Farmers can rest assured knowing that there is enough power available for even the most difficult tasks.

"SAMAC was a wonderful op portunity for us to be part of such a professional organisation, not only to serve as a sponsor, but to share the necessary knowledge with macada mia farmers enabling them to move forward and make more informed decisions," says Pieter.

"John Deere is here for the long run, so we want to make sure that the farmer is also here for the long run by being sustainable from generation to generation," he concludes.

John Deere Financial also has cus tomised solutions for unique require ments. Whether it is big or small, they efficiently support you in the best financing solution.

From mid-November, John Deere will have a promotional offer for Black Friday. Keep an eye on their web pages and social media to get equip ment at affordable prices.

In addition to cost efficiency, a farmer wants to buy a tractor that can easily complete the necessary work on the farm. Here, too, John Deere offers attractive options.

Check with your closest dealer today to find out more about this year's Black Friday promotions and what they have to offer.

Visit John Deere's website for more information at www. deere.africa/en/index.html.

ProAgri Botswana / Namibia / Zimbabwe 38 5

Pieter says: "A farmer at SAMAC's farmers’ day told me and it will always stay with me; a farmer buys a John Deere that retires with him on his farm."

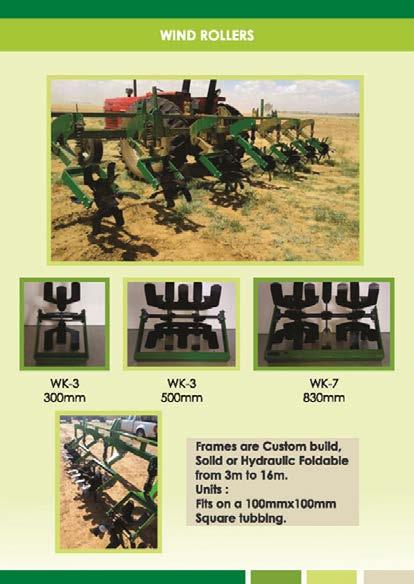

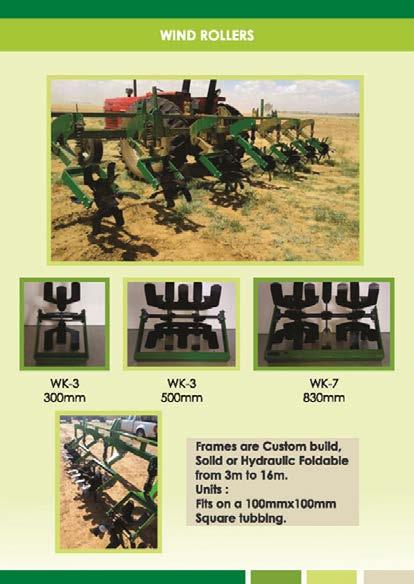

6 ProAgri BNZ 38 (+27) 82 773 9297 | info@rippertillage.co.za | sales@rippertillage.co.za | 12 Wessel Street, Hennenman, 9445, South Africa RIP WITH US! ROBUST, INNOVATIVE RIPPER TILLAGE EQUIPMENT Ideal for African soil Wind Rollers Rotary Hoes Harvester Trailer Design, manufacturing and development of agricultural equipment. Rip tills, Strip tills, Rotary hoes, Roller wheels & planter closing wheels.

The harvester trailer is manufactured in sizes 35 and 40 ft (10,6 - 12 m).

This

Ripper Tillage Equipment has an implement for every job through out the planting journey. The team specialises in custom-built equipment that ensures results in your crop, because a successful harvest does not only rely on fertiliser, water and the type of seed you use. It also relies on how the seed is planted in the particular soil type and how it is cared for.

Ripper Tillage Equipment pride themselves in identifying the needs of your soil bed. “We take into con sideration how the soil needs to be prepared,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains. “We also look at what you will need to close the soil after planting and ripping, such as rollers or closing coulters.”

Ripper Tillage Equipment manufac tures rip till and strip till equipment, rotary hoes and planting equipment

“We specialise in on the row ripping. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Because there is less soil ripped over a large area, the machinery –tractor included – has less wear. What is more, it also uses less fuel and requires less labour.

Tillage equipment backed by knowledge and support

Ripper Tillage Equipment employees are knowledgeable in soil require ments. “We come to your farm, do a

soil test with a demonstration and determine the implements you require to achieve the best culti vation,” Christine explains. “We look at the type of soil on your farm and take into consideration what your previous crop was – especially for farmers that practice conservation farming by tilling crop residues back into the soil. By looking at the soil condition and know ing what the farmer plans to plant next, we can see which implement is needed to do the job.”

That is the benefit of custom-made implements. Where your soil condi tions and the needs of every crop dif fer from area to area, you can invest in exactly the right tools to help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need.

Harvester trailers from Ripper Tillage Equipment

Harvester trailers are a handy piece of equipment that might not immedi ately jump to mind when thinking about harvesting season. The truth is that transporting headers can have many challenges, but with the right trailer, the problems are quickly solved.

Ripper Tillage Equipment manufac tures 35 to 40 ft (10,6 - 12 m) trailers that hook behind any bakkie or tractor. “It isn’t a heavy trailer, and it assists farmers with transporting har vester headers from the store to the field and back,” Christine explains.

This is just another way of solving a farmer’s need — one piece of equip ment at a time.

Ripper Tillage

Equipment is synonymous with effectiveness

We have successful clients who have used our equipment for more than eight years. “You can see how satisfied our clients are when they return next year for an even bigger order.

“We often hear that new clients heard about the effectiveness of our products from a neighbour or friend, and decided to invest in an implement themselves."

Ripper Tillage Equipment ensures excellent service by visiting clients on the farm and offering guidance on how to use the implements effec tively. “Maintenance is also fairly easy and inexpensive, because all parts are available at local hardware stores,” she adds.

Take

For more information about harvesting tables or custom ised equipment for your seedbed preparations, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbotharip till@gmail.com. Visit their website at: www.rippertillage.co.za or find them on Facebook: www.facebook. com/RipperTillage.

ProAgri Botswana / Namibia / Zimbabwe 38 7

your equipment needs … Ripper Tillage Equipment manufacture implements to your taste

Whatever

implement has the closing coulter and roller units for rip on the row soil preparation.

a closer look at the range of equipment from Ripper Tillage Equipment as displayed at the 2022 NAMPO Harvest day in Bothaville. https://www. proagrimedia.com/news-events/ nampo-2022-ripper-tillage-arespecialists-in-seedbed-preparationequipment/.

by Maryna Steyn

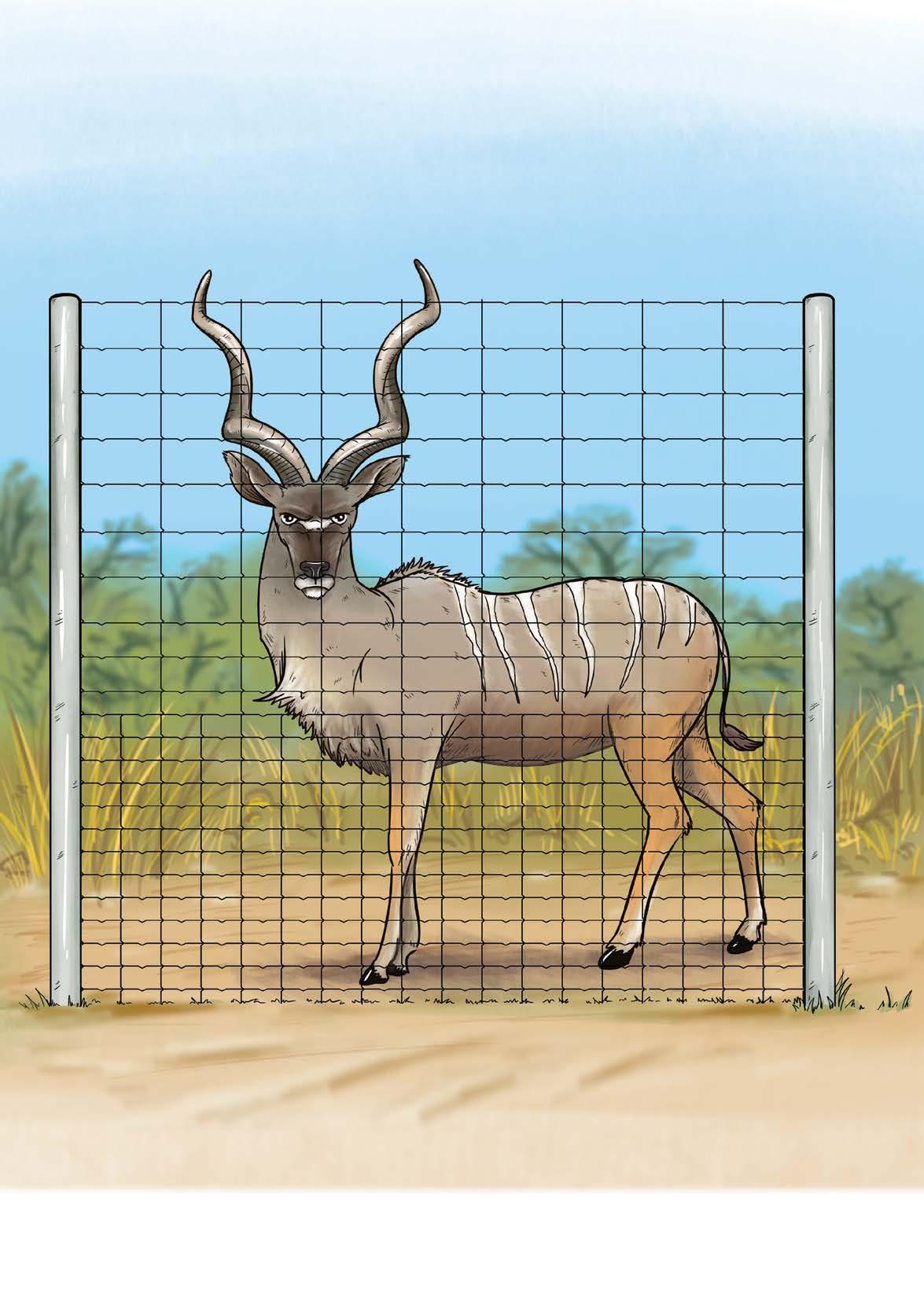

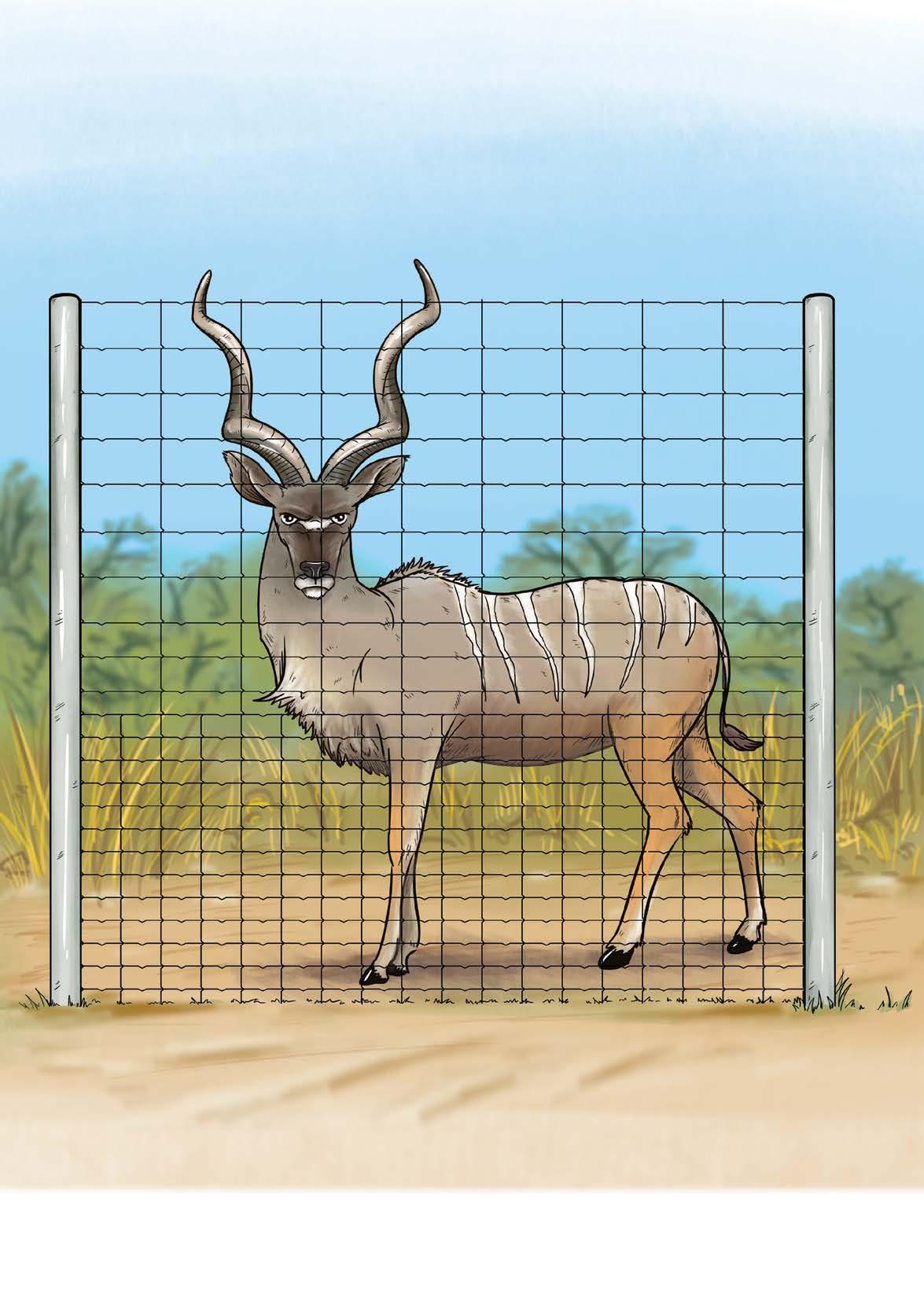

AVOID POOR IMITATIONS AND BUY DIRECTLY FROM THE ONLY BONNOX FACTORY, SITUATED IN SUNDERLAND RIDGE, CENTURION ONLY A BONNOX INVOICE SERVES AS A CERTIFICATE OF AUTHENTICITY. zane@bonnox.co.za • gerda@bonnox.co.za • linda@bonnox.co.za www.bonnox.co.za • 012 666 8717 3m WOW! Kudus can’t clear THIS fence! A FIRST FOR SOUTH AFRICA!!! KUDOS FOR B O N N OX ’S NEW 3METRE FENCE . 2.44m 1.2m 1.8m

Poultry farming part 7:

Record keeping

by Tisha Steyn

by Tisha Steyn

N

o business can survive without proper record keeping. The sys tem need not be complicated, but as a poultry farmer you must note down important information, such as the feed consumption, the number of sick and dead birds removed, and the type and date of medicine or vaccines.

It is good practice for all processes in a broiler operation to have standard operating protocols, which should include information on procedures, monitoring systems, records, and an analysis of these records.

The analysis will determine the ef fects of changes in the management and environment of the poultry house, as well as the nutrition and health sta tus of the birds.

Accurate production records, includ ing status of hygiene and diseases, are essential for effective management, assessing risks, the control of the sys tem and active response to developing problems.

Analysis and interpretation of pro duction data, including live weight, the efficiency of feed conversion, and mor

tality are necessary for the upgrading and improvement of your chickens’ performance.

When and what to record

At the start of the cycle

At the beginning of the cycle, it is im portant to state information about the day-old chickens you have received, such as the date, the number of chick ens, the breed, the particulars of the supplier, vaccines they have had, and the number of the cycle that is placed in the specific house.

ProAgri Botswana / Namibia / Zimbabwe 38 9

record keeping will show you whether you are farming at a profit or a loss.

Record all important information about your chickens from the day they arrive, until the day you have cleaned out the henhouse in anticipation of the next batch.

Good

(Source: Pixabay)

(Source: Pixabay)

(Source: Pixabay)

Take care of the pennies, and the

(Source: Pixabay)

Daily information

Daily information must be recorded, such as the minimum and maximum temperatures and humidity. Note down the type and quantity of feed that was given so that you can record how well the chickens have used the feed to grow. Note down the number of chick ens that have become sick or have died. For a beginner farmer, a mortality rate of ten percent is acceptable. Also write down the date and type of vaccines and medicine you have given the birds in case there is an outbreak of disease, and you must check your records.

At the end of the cycle If you have kept records diligently, you can calculate your success (or failure!).

Average live mass: Divide the total mass of all the chickens by the number of chickens alive at the end of the cycle.

The total loss: The total number of mortalities, or the chickens that have died at the end of the cycle, must be calculated as a percentage of the origi nal number of chickens that you placed in the house.

This is done by means of the fol lowing formula: Total losses (%) = (Mortalities × 100) / Number placed.

Feed conversion ratio: At the end of the cycle, you can calculate how much feed the chickens ate during their lifetime.

Use this formula: Feed conversion ratio = Total amount of feed used (kg) / Total live mass produced (kg).

A feed conversion ratio of 1,8 to 1,9 kg of feed used for each kilogram of meat produced is generally accept able. If you used more feed than that, you fed the chickens too much, which reduced your profit margin.

(Source: Pixabay)

10 ProAgri BNZ 38

Keep a close eye on your costs to minimise unnecessary expenses.

When you analyse your records, you will know what's going on in your business. (Source: Pixabay)

pounds will take care of themselves.

No matter how small your poultry business is, you have to keep good re cords. (Source: Pixabay)

Keep good records of your chickens' health and the medicine and vaccines you need for them.

Without good record keeping, your poultry business is as fragile as a box of chicken eggs. (Source: Pixabay)

Air

Number of birds removed

Multiple locations inside the poultry house should be monitored, especially in the litter area Daily cross-check automatic systems manually Ideally record dust, CO2, NH3, or at least observe levels of dust and NH³ Depletion

ProAgri Botswana / Namibia / Zimbabwe 38 11

Records Comments

placement Number of

Live weight Supplier Uniformity of

Date and

arrival Total

arrival Quality of

Mortality Daily Record by sex if possible Weekly Record of culls and reason for it Total Post-mortem records of excessive mortality Medication Date Amount Batch number As per veterinarian instruction Vaccination Vaccine type Vaccination date Batch number Expiry date Unexpected vaccine

weight Weekly average live weight Weekly uniformity rate More

needed when predicting slaughter weight or where

Quantity

Feed

feed

food

Event

Chick

day-olds

chicks

time of

dead upon

chicks

reaction Live

frequent weighing is

lighting is modified for better growth Feed Date of delivery

Date of starting feed Withdrawal before slaughter

type Accurate measurement of

consumed is essential to measure the

conversion rate and to determine the cost effectiveness of the business Water Daily consumption Water to feed ratio Water quality Level of chlorination Plot daily consumption per house Sudden fluctuation in consumption is an early indicator of problems Mineral and/or bacteriological count – especially with boreholes or open water Environment

Time and

from slaughterhouse

Carcass

Type

condemnations

out Total bacterial count After disinfection, salmonella, staphylococcus, or E. coli may be monitored if required House inspections Record the time of daily checks References: Arbor Acres broiler management guide. (2009) Aviagen https://eu.aviagen.com/assets/Tech_Center/AA_Broiler/AABroilerHandbook2018-EN.pdf Cilliers, P.F. (July 2000) Small-scale poultry housing in South Africa. ARC-Institute for Agricultural Engineering. Cilliers, F. (Project manager) (2001) Small-scale broiler house (combined). ARC-Institute for Agricultural Engineering. Family poultry training course trainee’s manual. http://www.sapoultry.co.za/pdf-training/trainers-manual-poultrycourse.pdf This is an example of the records that must be kept from the moment the day-old chickens arrive

Temperature inside: daily minimum and daily maximum during brooding, 4 to 5 times per day Litter during brooding Daily external temperature Daily relative humidity day the poultry house has been cleaned out.

quality Litter quality

date of removal Information

Carcass quality Health inspection

composition

and percentage of

Cleaning

to the

Sheep raised for mutton Sheep breeds part 1:

by Natasha Kruger

Dorper sheep

I n South Africa, the Persian sheep, the Dorset sheep, and the Van Rooy sheep were used to create the Dorper breed. This process produced a robust, quick-growing meat breed well suited to areas with insufficient precipitation.

Dorper sheep have white bodies and black heads, and they are very strong and sturdy. The White Dorper has a white head. Lambs of this rapidly ma turing, fertile breed are ready for the slaughter at only four months of age. The breed's skin, which has a smooth grain and no creasing, can be used for leather without the need for shearing. Mature Dorper rams weigh between 90 and 120 kg, and ewes between 50 and 80 kg.

In addition to being hornless, this breed of sheep is also quite long and has a relatively light coat of hair. Both black and white heads are present in the breed, but the black head is the most common. The ewes are also great mothers because of their strong maternal instincts, ability to adapt, hardiness, rate of reproduction, growth (reaching 36 kg at 3,5 to 4 months), and feed conversion rate.

The Dorper has a year-round breed ing season. A good manager can schedule lambing throughout the year. The breed is fertile, and the percent age of pregnant ewes is high. Eightmonth lambing periods are possible with good forage and management. In optimal conditions, lambing percent ages of 150% and 180% are possible. Under extensive conditions, lambing rates of 100% are expected. In a flock with many maiden ewes, the lambing

percentage is around 120% because they only have one lamb. If the lambing percentage is 150% and ewes can lamb three times in two years, a Dorper ewe will produce 1,5 lambs per year.

The Dorper adapts well to different climates and grazing conditions. This breed was originally developed for arid areas, but it is now widespread.

The Dorper is hardy and can thrive in conditions where other breeds cannot, and the ewe can raise a quality lamb in harsh conditions. As a strong and nonselective grazer, the Dorper is easy to manage.

Blackhead Persian

It is believed that Somalia or the Mid dle East were the original homes of the Blackheaded Persian sheep, an ancient meat breed. The Persian sheep has a hairy, fat tail and thrives in hot, dry climates. Long, floppy ears are another goat-like trait shared by hornless sheep. Blackheaded Persians make up the vast majority (90%) of the breed, with redheaded Persians (4%), and speckled Persians (6%). Persians are excellent mothers with an even temperament. There is a high rate of twin births and an eight month breeding period. Mature

rams and ewes weigh approximately 50 and 30 kg, respectively.

Although the Blackhead Persian va riety is raised solely for its meat, the skin can be used to create thin, highquality leather goods. The disease resistance of the Persian sheep breed has made it a favourite for cross breeding with other types of sheep in an effort to increase their overall pro ductivity as mutton sheep. The mature weights of Blackhead Persian rams are between 68 and 75 kg, and those of ewes are between 52 and 60 kg.

12 ProAgri BNZ 38

Dorper ram. (Source: alibaba.com)

Blackhead Persian ewe and lamb. (Source: persiansheep.com)

Blackhead Persian ram. (Source: persiansheep.com)

Dorper ewes (Source: rhyniepastoral.com.au)

Ile de France

The Ile de France sheep is a French mutton breed. Commercial farming with this breed only started in the 1970s in South Africa. The animals of this breed tend to be large and stocky. The face and lower legs are not covered in wool. The nose and lips are pink, and the rest of the face is white. Both rams and ewes are hornless (polled).

The Ile de France is a large, smoothbodied mutton breed, producing strong white wool of 23 to 27 microns. Wool can contribute up to 20% of this breed’s income. An average fleece weighs between 4 and 6 kilogrammes, and its staple length is between 7 and 8 centimetres.

However, most consider the Ile de France a meat breed only due to the rams’ use in crossbreeding to produce heavy, early maturing slaughter-ready lambs. The first lambing is at twentythree months, with few birthing prob lems. The Ile de France can be used for

Van Rooy ewe and lamb. (Source: learnnaturalfarming.com)

Meatmaster ewe and lamb. (Source: lasarusgamefarm.co.za)

Ile de France ram. (Source: chiledefrance.co.za)

Van Rooy rams. (Source: vanrooysa. co.za)

The Van Rooy is a large, hornless sheep, covered in white hair, and has a thin wool undercoat across its chest and shoulders. Its hefty tail and broad, rounded chest set it apart. Most of the body fat is concentrated in the back and tail.

The Van Rooy has a thick skin and is therefore less likely to be infected by parasites. The mature weights of Van Rooy rams are between 70 and 80 kg, and those of ewes between 50 and 60 kg.

The fertile Van Rooy is able to pro duce and raise lambs, even in harsh environments.

Due to their distinct genetic make up, they are frequently used in hybridi sation. The average age for a first birth is sixteen months.

Meatmaster

their milk and is classified as a dairy sheep in the USA. The mature weights of Ile de France rams are between 100 and 150 kg, and those of ewes between 70 and 90 kg.

Van Rooy

The fertile Van Rooy sheep is a type of meat sheep that was "developed" in South Africa and bred to perform well in the drier conditions typical of fat-tail breeds, such as those found in South ern Africa.

Another South African mutton sheep breed, the Meatmaster, is a cross be tween the Damara, Dorper, Van Rooy, and Ile de France. The objective was to create a meat sheep that could thrive in veld grazing systems and require minimal care and feeding. In 2007, the Meatmaster was recognised as a sepa rate breed, and in 2008, the Meatmas ter Breed Society was established to promote and protect the breed.

The Meatmaster is a medium-sized, non-fat-tailed sheep with a short, shiny outer coat and a short, woolly under coat. Weaning weight for a Meatmaster

Meatmaster ram. (Source: swartmodder.com)

is 27 kg at 100 days of age. At five months old, a Meatmaster lamb weighs about 38 kg, which means it can be slaughtered for a 17,5 kg carcass. A mature Meatmaster ram weighs between 85 and 105 kg, and an ewe between 60 and 70 kg.

References

Breeds of Livestock - Booroola Me rino Sheep — Breeds of Livestock, Department of Animal Science. (1996). Available at: http://afs.ok state.edu/breeds/sheep/booroolam erino/index.html

Ngcobo, J.N.; Nedambale, T.L.; Nephawe, K.A.; Mpofu, T.J.; Chokoe, T.C.; Ramukhithi, F.V. An Update on South African Indigenous Sheep Breeds’ Extinction Status and Difficulties during Conservation At tempts: A Review. Diversity 2022, 14, 516. Available at: https://doi. org/10.3390/d14070516

Sheep breeds. (2008). Department of Agriculture. Available at: https:// www.nda.agric.za/docs/Infopaks/ Sheep_breeds.pdf

Sheep Farming in South Africa. 2022. Available at: https://south africa.co.za/sheep-farming-southafrica.html

ProAgri Botswana / Namibia / Zimbabwe 38 13

Ile de France ewe and lambs. (Source: hasbargenlandcattle.com)

14 ProAgri BNZ 38 ET 66 EXC AVATOR ECONOMIC. POWERFUL. DURABLE. Tell: +267 311 0876 | info@afgriequipment.co.za An optimized drive concept of the latest generation enables precise, fast, and efficient work. The electronically controlled hydraulic pump permanently adapts the required hydraulic power to the available power of the diesel engine.

Beekeeping part 4:

Inside the hive

n the previous articles, we discussed beekeeping in general and the value of bees as pollinators.

I

In this article, we have a peek inside an active beehive to see who lives there and what they do.

Castes

A caste is a level of importance in the beehive, just like there are castes in many human societies. A beehive is all about social status, in short, some are created more equal than others …

The queen is, well, the queen, even though she has humble beginnings.

The drones are like a lot of men: fat, lazy and only interested in mating with a queen.

The workers are like womenfolk: They work from morn till night throughout their lives – and then they die.

A caste in social insects, such as bees, refer to different types of bees of the same sex but who have different bodies and do different jobs, like the worker bee and the queen. The drone is an additional caste in the hive.

All three castes have different duties, and the hive cannot survive without any one of them. It’s like they are dif ferent parts of a body, with the queen being the head who decides what the worker bees – the body – should do for the survival of the hive.

The worker bees are all females and work from dawn to dusk.

The queen Need for a queen

Let us start with a thriving hive that is fully functional. The main duty of the queen is to lay eggs – thousands of them to replace the vast number of worker bees that die each day, whether of old age, attacks by enemies like alien wasps, or herbicides that humans spray to get rid of harmful insects.

The queen is the brain of the hive. By releasing pheromones, a chemical sub stance produced and released into the environment, she controls the behaviour and physiology of all the bees in the hive. Without these pheromones, also referred to as her scent, there would be no order in any of the hive’s activities.

Worker bees work tirelessly to store the pollen and nectar brought to the hive by foraging bees returning from the fields.

She would, for instance, inhibit unnec essary queen cells to be built, or prevent the workers from laying eggs. She also uses her pheromones to attract drones during her mating flight. The bees know her scent and will guard against any intruders who do not smell familiar.

Without her pheromones, the workers will mill around helplessly. A failing or dead queen must be replaced as soon as possible, therefore workers act in stinctively. They choose several eggs or larvae to prepare a new queen, and so, the queen begins her life as an ordinary worker egg laid by the existing queen.

ProAgri Botswana / Namibia / Zimbabwe 38 15

During the third week of a worker bee’s life, she undertakes short flights to strengthen her wings. Later she will fly many kilometres a day to collect pollen and nectar.

Within a few days, the egg or larva is taken to a queen cell, where it will develop into a new queen with the help of the workers who feed her royal jelly that they produce with their glands.

Eventually, they seal up the larvae with wax. Sixteen days later a suitable queen emerges a few days sooner than if she were just another worker bee. After escaping from her peanut-shaped cell, she is cleaned and cared for by the royal court. She is fully developed and ready to take up her duties. For the rest of her life, she will be fed royal jelly.

Royal court

As the queen moves throughout the hive, she is surrounded by a group of workers known as the royal court. Nearly every bee at the age of two weeks gets a turn to be part of the royal court. They take care of the queen by feeding her royal jelly, and touching her by rubbing their antennae over her, and so spreading her scent throughout the hive. This helps the workers – and drones – to understand what they need to do.

16 ProAgri BNZ 38

Types of queen cells

The reason for a new queen could be that the old queen is at the end of her life and the hive needs to replace her, or the colony plans to swarm.

Two types of cells are suitable for a queen to be: a supersedure cell or a swarm cell. The queen cell has a peanut shape, is bigger than the other cells and is built away from them. A supersedure cell is situated along the centre of a given frame and is built for a queen that will supersede the failing or recently dead queen. There can be several of these cells at a time.

The swarm cells are attached to the bottom of the brood frame. The queen that emerges from these cells will leave the colony with half of the bees inside to form a new hive. This leaves room for thousands of new bees in the existing hive, and this is the bees’ nat ural ability to multiply at a superfast rate. A healthy hive can swarm four or more times during the warm season.

What does she look like?

The queen looks a bit like the worker –she is female after all, albeit a supe rior one. She is about one and a half times as large as a worker bee, with a slimmer and paler body with lightercoloured stripes on the abdomen.

She has a bald spot behind her head on the thorax, where six legs and four wings, which appear shorter than that of the workers, are attached.

Some beekeepers mark the queen with a dot on the bald spot so that they can distinguish her more easily from the workers. Usually, the colour of the dot will indicate the year the queen started her royal duties.

The queen has a curved sting without barbs, but rarely uses it except when she must get rid of another queen.

Mating

On her first day as queen, the royal court escorts her around the hive to where worker bees are cleaning cells into which she will lay her eggs after mating. This only happens after she has killed any other queens who may not have hatched yet!

On day three of her life, the queen’s wings are strong enough to support her body, and her mating organs are devel oped so she is ready for mating.

She leaves the hive and flies to about ten metres above the hive. Up to twelve drones from other colonies mate with her in flight. The drone’s sex organ snaps off inside the queen so that no sperm is wasted, and the drone falls to the ground and dies.

The queen may undertake up to twen ty flights, but when she returns to the hive, she has enough sperm to lay fertile eggs for up to five years. The sperm is kept alive by a protein substance pro duced by the queen’s body.

Laying eggs

Although she can lay up to 2 000 eggs per day throughout her life, she never has to mate again. This is quite as tounding if one considers that a colony can exist of between 10 000 individuals in winter and up to 60 000 or more in summer.

Soon after mating the queen starts

laying eggs. This is a most important job, because worker bees die at an alarming rate.

She needs to lay eggs to produce worker bees to do housekeeping du ties, guard the hive and collect nectar and pollen for the survival of the hive.

She inspects the cells to see if they are clean enough before putting her backside into the shallow cell to lay an egg. She produces a small bit of sticky substance in the bottom of a cell onto which the egg adheres, before moving to the next cell. She does this up to 1 500 times a day for five years, only taking short rests of five to ten min utes now and again.

The eggs and sperm are kept sepa rately in the queen’s body and she can control which eggs must be fertilised. The workers lead the queen to the cells where she must lay eggs. If she lays an egg in a worker cell, she allows one sperm to attach to the egg to produce a female worker.

If she doesn’t attach sperm, the egg will produce a drone. The drone cells, which are bigger than the worker cells, are usually found in the corners of the hive where the pollen and nectar are stored.

Division of labour

The workers

The workers are all female. The worker is the smallest in the hive but does all the work during her lifespan. She is well-equipped for her job, which changes as she gets older – she has a honey stomach, pollen baskets, wax glands, and a barbed sting for protect ing the hive against intruders.

The workers who are fresh from the uncapped cell work in complete dark ness inside the hive: they feed and cap

ProAgri Botswana / Namibia / Zimbabwe 38 17

Worker bees have many tasks in the hive. They feed and cap new larvae, store the pollen and nectar, and clean the hive.

18 ProAgri BNZ 38 Call Us In Gaborone, Botswana +267 3186 115 | +267 75 713 539 / 72 101 081 vlado@montgroup.co.bw | irrigation@montgroup.co.bw LOBATSE - TEL: 5332337 - FAX: 5332346 SEROWE - TEL/FAX: 4630755 MAHALAPYE - TEL: 4710730 - FAX: 4710734 F/TOWN - TEL: 2441526 - FAX: 2441527 TARA FARM TEL: 3957698 @ METSIMOTLHABE PALAPYE - TEL: 4924225 - FAX: 4924226 S/PHIKWE TEL: 2614662 - FAX: 2614662 / PANDAMATENGA TEL: 72333202 OR VISIT YOUR NEAREST BRANCH COUNTRYWIDE Graphics: MaruapulaA @TheAgriShop-2022 FEED CENTRE BW WHERE ONLY THE BEST QUALITY & AGRICULTURAL PRACTICES CAN DO fromP1600 Great Savings DRIPLINES Farming, The Future; a goal to improve a vulnerable community’s access to sustainable sources of food through competitive agricultural practices. we build SUPER SOLO TUNNELS 10MX36M SUBMERSIBLE PUMPS + motors | pc drippers & CONNECTORS All@ Sell eggs from your backyard chickens START YOUR OWN PRODUCE EGGS WITH THE AGRI SHOP PACKAGE INCLUDE•Chicken house (3.8mx3m) • 1x100g Stresspack •100 pullets Layer Cage •100 Pullets •8x50kg Layers Mash (1month feed) •1 egg bundle of cartons-2x6 •4 egg collecting trays - plastic (30 eggs size) AGROMONT ROUND FRAME DISC PLOUGH DP4 Working Depth: 250(mm) Space Between Bodies(B) 530 (mm) Number of Disc 4 Required Power 70-80 (hp) Total Weight 470 (kg) IMPORTANT: Transportation fees to different destinations varies 75 713 540 LAYERS Maize | Corn | Straw BLENDER THRESHER FORAGE GRINDER LUCERNE BALE & MOLASSES ANIMAL FEED

new larvae, they store the pollen and nectar brought to the hive by forag ing bees returning from the fields, and they clean the hive.

When they are older, they move to the hive’s entrance where they con tinue to receive the pollen and nectar from returning field bees, do guard duty, and cool the hive by fanning their wings for ventilation.

During the third week of the worker bee’s life, she undertakes short flights to strengthen her wings and to ori

entate herself to the location of the hive. When she starts foraging, she flies many kilometres a day and visits thousands of flowers to collect pollen and nectar. By doing so, she will polli nate fruit and nut trees, vegetables, oil producing plants and grains that form part of our diet.

During the roughly two weeks that she spends foraging, she will fly more than 650 km, wearing out her wings until she can fly no more. When she is about five weeks old, she will merely walk away from the hive to die a lonely death.

The drone

The drones are the only males in the hive, and usually, there are a few hun dred of them. Their hairy bodies are larger and more square-shaped than the workers. They do not have stings, so they are no good helping to protect the hive.

Their only purpose is to ensure ge netic variability of the hive by mating with a virgin queen of their own and other hives. Besides that, they are tolerated for emergency mating duties should something happen to the queen.

They usually live between 21 and 32 days before they are kicked out. In autumn, the worker bees pick them out and literally throw them out of the hive. If they try to return, the guard bees – also females – don’t allow them. Dejected, they try to find another vir gin queen to mate with, or just die.

References

Caste Differentiation: The Queen, the Worker & the Drone. (n.d.) BeeWare http://www.practicalbeekeeping.com

Anderson, R.H., Buys, B., Johanns meier, M. F. (2014). Byeboerdery in Suid-Afrika. Department van Land bou-tegniese Dienste Bulletin no. 394, 1978. Hersiene uitgawe.

ProAgri Botswana / Namibia / Zimbabwe 38 19

New larvae in cells.

Technews:

by Annemarie Bremner

The latest in agricultural technology

Cows get robot

waiters!

Automated milking has been around for a while, but now there is also an auto mated feeding machine, called Dairy Feed F4500, developed by GEA.

Feeding is the biggest cost factor in managing a farm. The quality, frequen cy, and optimisation of mixed rations for each group of cows are decisive to milk production. This is where the GEA DairyFeed F4500 feeding robot helps farmers to have more flexibility for their daily routines, as well as precise management of their feeding strategy.

Fitted with navigation sensors, the F4500 creates a precise map of the farm allowing it to work out the ideal routes for distributing feed. The robot

can constantly localise its position, recognise obstacles and avoid collisions, safely navigating between barns, on uneven floors and traveling on inclines of up to 10%. With the F4500, no ma jor farm modifications are needed!

Automatic 24/7 feeding routines

The autonomous feeding robot weighs, mixes and distributes up to 2,2 m3 of fresh TMR feed every hour for up to 300 animals in different nutritional groups. It ensures that customised rations are perfectly prepared in ac cordance with the feeding cycles set by you. The robot also takes over the work of feed pushing after and be tween cycles.

With the F4500 you can check feed

consumption and leftovers, and adjust the quantity of the next rations ac cordingly to minimize feed waste. It is also possible to analyse the nutritional composition of the ingredients and mix quality with sensors, allowing for adjustments of the mixture based on your feeding strategy for the best pos sible animal health.

GEA feeding and milking robots are digitally connected via DairyNet, enabling feeding and milk output and quality data to be synchronised roundthe-clock. This accurately optimizes feeding strategy and milk production.

(Source: GEA)

First electric Kubota tractors in Europe

Kubota will show its LXe-261 electrical ly powered compact tractor at several key events around Europe over the coming months, including SALTEX at the NEC and EIMA in Italy. The battery pow ered tractor will be available for rental in the UK from April 2023.

With an increasing number of Euro pean markets tightening regulations and implementing bans on diesel vehicles, many local authorities are actively seek ing alternatives to decarbonise power sources and reduce CO2 emissions.

One of the major challenges when developing an electric tractor, is range and operational time. Kubota reckons

ProAgri BNZ 38

to have provided sufficient range by equipping the LXe-261 with a large capacity battery that can provide rapid one-hour charging and three to four hours of continuous operation. This will allow operators to charge the batteries during lunch and continue working in the afternoon.

Described as an important strategic step for Kubota in the UK and Europe, the LXe-261 is suitable for a wide range of applications, including mowing and hauling. The specification includes an independent PTO, HST transmission (hydrostatic) and multiple hydraulic outlets. (Source: profi)

Amazone delivers 75 000th sprayer

A company that produces and sells 75 000 units of an implement must be doing something right! This mile stone Amazone sprayer driven off the production line, a 36 m boomed, selfpropelled Pantera 4502, was recently delivered to Robert Davidson & Son, who farm around 1 350 ha near Col chester, in England.

With a mix of cropping that includes continuous winter wheat, marrowfat peas, rye, and maize for both foraging

as well as for the combine, the farm also forages another 800 to 1 200 ha of maize and rye for neighbours.

A Pantera user since September 2015, their previous 40 m boomed 4502 clocked up 5 000 hours in seven years. Robert, the third generation and on the farm since the early 1970’s, confirms that the out-going model has given them sterling service.

“Although we looked at what else was on the market, its narrow road width, 50 km/h road speed and im

proved suspension makes it ideal for our further away contract farms. The service support from Amazone and our local dealer, RW Crawford, contributed to our continuation with the Amazone brand. Hopefully in a few years’ time when we are ready for the next one, we will get the 100 000th machine.”

Made in 1969, the first Amazone sprayer was the mounted S range, which was available with tank ca pacities of 400 and 600 litres. Today’s sprayers are made at a new, purposebuilt assembly facility at a 20 ha site at Bramsche, in Germany. (Source: Amazone)

Bale bigger with CLAAS

Why get stuck on 1,5 metre bales, if you can stretch it to 1,8 metres? The new Variant 500 variable chamber baler have two models, the 565RF and 560RC that can give your bales a slight increase to 1,6 m, or you can opt for the 585RF or 580RC that can stretch to 1,8 m.

Separate sensors mean the ten sion arms can be controlled indepen dently – one keeps the chamber belts tensioned, the other determines the bale pressure. This will allow users to determine if they want a soft centre in hay, for example, before increasing pressure as the bale nears full size. Likewise, it can create a hard centre straight from the start. Choosing one of the three crop types on the control box gives some pre-set densities that can then be fine-tuned.

The pick-up has gained the quick swing-in/out gauge wheels already seen on other CLAAS balers. There is a choice of 2,1 or 2,35 m pick-up widths.

The net binding system has also been given a makeover. Not only is it now positioned much lower with a new gravity controlled brake, and the net knife release uses the same trip mechanism as the knotters on the Quadrant square balers. And because there is a new chassis, Claas took the opportunity to design the baler to take larger tyres up to 560/45-22.5. (Source: profi)

ProAgri Botswana / Namibia / Zimbabwe 38 21

Kubota will launch its first electric tractor in Europe.

Handing over the 75 000th Amazone sprayer: Simon Brown, Managing Director, Amazone; James Faulkner and Robert Davidson, Robert Davidson & Son; Rupert Batho, Territory Manager, Amazone; and Tim Osbourne from RW Crawford.

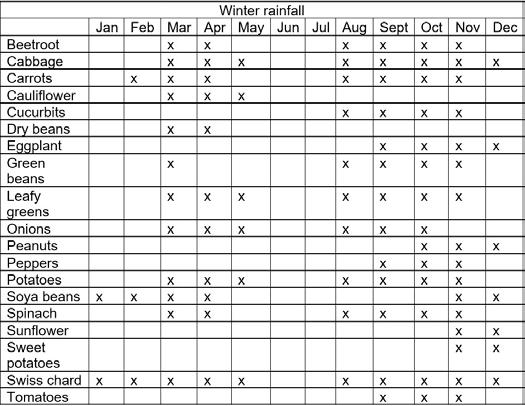

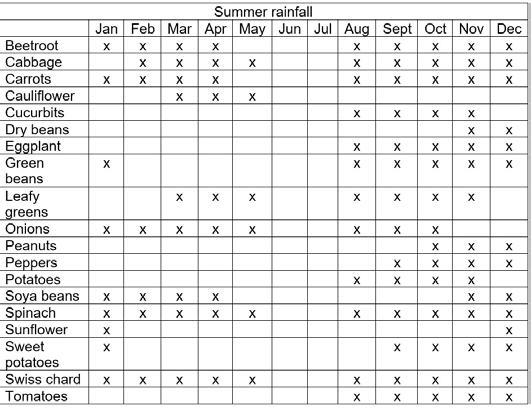

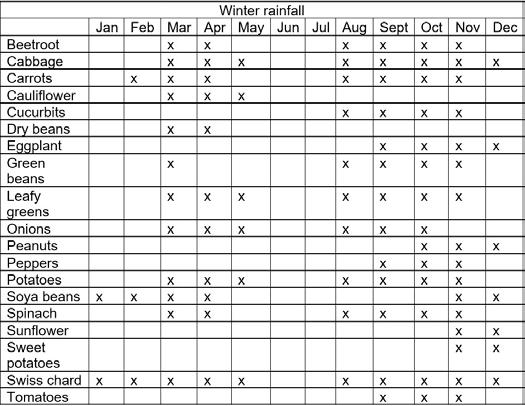

Vegetable planting part 19: Crop rotation and crop calendar

by Maryna Steyn

Vegetable crops offer a good source of income for both small- and largescale farmers. But it takes so much more than placing a seed in the soil and harvesting the plants at the end of the season. It takes care, diligence, nutrients, and knowledge on caring for crops.

Now that we have reached the end of our vegetable planting guide, there are still a few key points to keep in mind. These points are crop rotation and the crop calendar. Understanding these two points will enable you to find a production process that works best for you, either by rotating a specific selec

tion of crops over a certain period, or by planting multiple crops in one season while considering crop and soil health.

There are many benefits to plant ing various crops at the same time. It means that you can deliver more than one type of vegetable to market during one season, ensuring that there isn’t a surplus that is wasted or unpurchased. It also helps you be less reliant on the market price of only one type of crop. Seeing as the supply and demand per vegetable differs from season to season depending on a good (or bad) harvest, the inconsistent price can have a negative effect on your income.

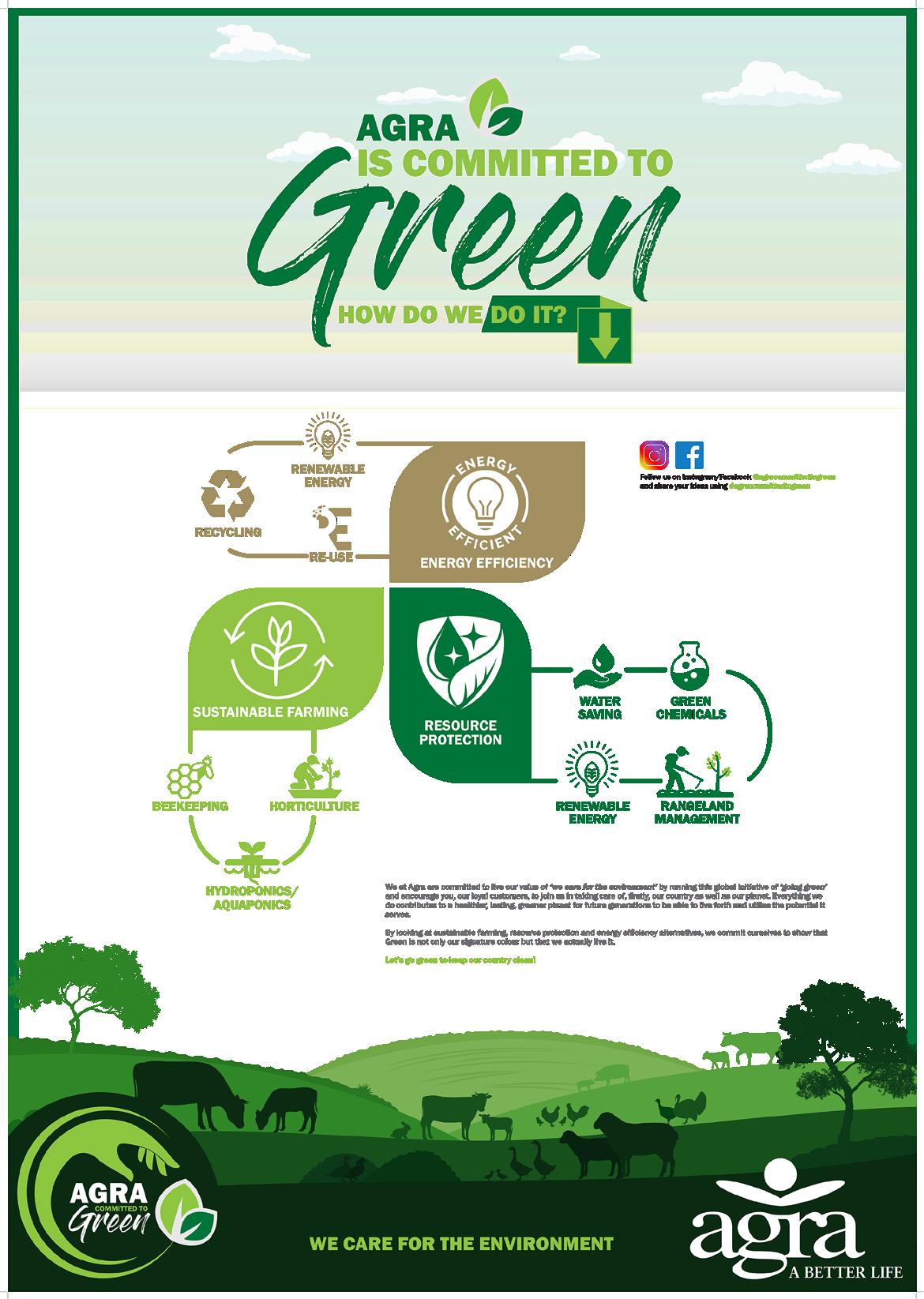

Crop rotation and the crop cycle

Crop rotation is a cultivation practice of growing a variety of crop types in succession on a specific plot or area over a few growing seasons.

To rotate your crops in one year, you can divide the area you want to cultivate into four sections. The area is divided into four because there are four crop types to keep in mind. Alternatively, you can rotate crops over a period of four years (or growing sea sons). One crop per crop group is then planted in each of the four areas. The following season, you will need to plant a different type of crop in the bed. You

22 ProAgri BNZ 38

Seedbed 1 Seedbed 2 Seedbed 3 Seedbed 4 Year 1 Legumes Shoots Roots Fruits Year 2 Fruits Legumes Shoots Roots Year 3 Roots Fruits Legumes Shoots Year 4 Shoots Roots Fruits Legumes The cycle that the crop rotation can take over a four-year period. Botswana

will continue to do this until you have completed the cycle.

Alternatively, a one-crop system can be used in which case the area that is being cultivated will be handled as a single seedbed. The cycle will then also be followed until it is completed over four years.

The four crop groups to keep in mind are as follows:

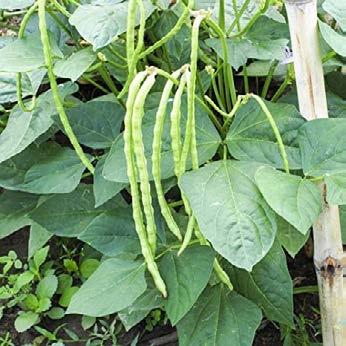

Category 1: Legumes

This group consists of legumes or vegetables that make pods. They add nitrogen to the soil, an important nutri ent that helps form plant proteins and enzymes. These types include green beans, peas, soya beans, chickpeas and peanuts. If it has a pod, it is from this plant category.

Category 2: Shoots

Shoots, or leaves, are the vegetables that grow leaves that humans con sume. These plants usually require a lot of nitrogen. Spinach, chard, lettuce, cabbage and broccoli are all part of this category.

Category 3: Roots

Root vegetables are light feeders. They generally require more potassium, a vi tal element for optimum plant growth. The vegetables in this category are anything harvested from below the soil, such as carrots, radishes, onions, garlic, turnips, and beetroot.

Category 4: Fruits

They extract a lot of phosphorus from the soil. These vegetables have fleshy structures in which they store nutrients and usually seeds, but tubers such as po tatoes or sweet potatoes also fall under this category. Under this type of vegeta ble, you will also find tomatoes, eggplant, maize, peppers, as well as cucurbits such as cucumbers, pumpkins, and melons.

The benefits of crop rotation for vegetable planting

Now we can take a closer look at the benefits of crop rotation:

1. Reduces pressure from pests that feed on one specific crop type in the soil

2. Prevents soil exhaustion by adding or subtracting different nutrients

3. Can help weed control

Pest are reduced through crop rotation because most pests and diseases are crop specific. This means that they feed on vegetables from a specific group. By replacing the crop with a different type effectively starves the specific pest when the insects cannot attack the new plants.

Some growers also question whether the soil can truly benefit from crop rotation, but conservation farm ers have already proved the positive effects that crop rotation has through improved yields. There is without a doubt less pressure on the soil nutri ents when the combination of nutrients that are being used is different from one season to the next. Certain plants such as legumes also place nitrogen and carbon back into the soil. This also influences the types of weeds that grow on the field. All in all, crop rotation leads to a reduced need for expensive fertiliser and pesticides.

With improved soil health, you can look forward to improvements in your yields and lowered costs on agricultural inputs. However, remember that this improvement is not a process that happens overnight and you may only see improvements after a few seasons of following these practices.

For the plants to benefit the most from crop rotation, it is important to cycle the crops in a specific order. Leg umes are always followed by leaves, then fruit and ending with roots.

Root

• This group consists of vegetables that stores nutrients below the ground in the root or bulb.

Fruit

•

This group consists of vegetables that form fleshy fruit.

Legumes

•

This group consists of legumes or vegeta bles that make pods.

Shoot (Leaves)

•

This group consists of vegetables from which humans con sume the leaves.

Crop rotation according to the crop calendar

ProAgri Botswana / Namibia / Zimbabwe 38 23

Using different seedbeds to plant different crop types is the first step to crop rotation. In the next season, you switch to the next crop category to plant in the individual beds. (Source: Pixabay)

(Source: Pixabay)

As important as it is to plant crops in succession, your plants will not grow properly if you don’t plant them at the required times. To find the cor rect planting dates, you can look at the articles for each individual crop as available on www.proagrimedia.com.

For a quick overview, you can refer

to the tables below. You will need to know whether you live in a summer or winter rainfall climate. You will be able to determine this by considering when your area receives its most rainfall. In Southern Africa, rain between Novem ber and March means it is a summer rainfall climate, whereas rain from

24 ProAgri BNZ 38

Botswana

Whether you are a small-scale or large-scale farmer, you can use crop rota tion in your vegetable production. (Source: Pixabay and Vecteezy)

(Source: Vecteezy)

May to August means it is a winter rainfall climate.

The two tables on the previous page indicate when to plant your crops. You will note that during June and July, no crops are planted. Due to winter in the Southern Hemisphere, there is little growth for any plants, and the microbial activity in the soil is also lower. Rest your soil in these months.

To prepare your soil to rest postharvest, you can either plant a cover crop or use mulch to keep the moisture in the soil during the winter. If you would like to know more about mulch ing, you can read our article Plants perform much better with mulch on our website.

ProAgri Botswana / Namibia / Zimbabwe 38 25

Crop rotation can help improve your yield. (Source:

Carefully note what time of the year is best for your planned crop. (Source: Vecteezy) Harvesting more than one type of vegetable per season means that you are less dependent on the market price for only one crop. (Source: pexels) References Cat, D. (2022). How to practice crop rotation (benefits explained) ~ Homestead and chill. Available at https://homesteadandchill.com/croprotation-benefits/. Crop rotations. (2020). Available at https://rodaleinstitute.org/whyorganic/organic-farming-practices/ crop-rotations/#:~:text=Crop%20 rotation%20helps%20return%20 nutrients,increase%20biodiver sity%20on%20the%20farm.

Garden Projects. n.d. Avail able at https://www.ufs.ac.za/ supportservices/departments/ service-learning-at-our-universityhome/links-for-community-projects/ food-garden-projects.

Saving your soils with crop rotation. Available: https:// www.fix.com/blog/three-yeargarden-crop-rotation-plan/. Crop rotation can improve soil health. (Source: Vecteezy)

Vecteezy)

Food

Lebo, N. (2015).

Valid 15 September - 15 October 2022

ProAgri Botswana / Namibia / Zimbabwe 38 27 Tel: +264 61 331 080 Faks: +264 61 255 820 www.whkla.com Lazarett Kommersiële Komplex, Eenheid 1 + 7, Suidelike Industriële Area, 64 Lazarett Straat, Windhoek, Namibië Maandag Dinsdag Woensdag Donderdag Vrydag Saterdag Sondag Windhoek Grootvee Hochfeld Grootvee Rehoboth Grootvee Windhoek Grootvee Gobabis Grootvee 1 2 3 4 5 12 6 13 6 7 8 15 9 16 10 17 11 18 OPKOMENDE DESEMBER VEILINGS 2 14 VERKOOP JOU VEE , die maklike manier Kommersiële groot- en kleinvee | Stoetveilings | Wildveilings | Skuifbare goedere | Speenkalfveilings

Now here’s a mouthful ...

... Kimtrafos is the perfect solution for your animals.

Kimtrafos 6 & 12 Grandé

Phosphate and trace mineral supplement or concentrate for phosphorous deficient areas.

• Available as a concentrate (P12) and ready-mixed product (P6).

• In a convenient granular form for a dust-free product.

• Enriched with the most important trace minerals in the correct ratio to phosphorous.

• Distinctive molasses smell and taste to promote intake.

• Promote production and fertility.

• Improves growth and skeletal development.

• Versatile application during the rainy season or throughout the year in phosphorous deficient areas.

• Suitable for cattle, sheep and goats.

Balanced animal feed.

www.yara.co.za/animal-nutrition animal.nutrition.sa@yara.com | Tel: +27 (0)31 910-5100

Kimtrafos 6 Grandé - Reg. No. V23311 (Act 36 of 1947), Kimtrafos 12 Grandé - Reg. No. V18670 (Act 36 of 1947)

Yara Animal Nutrition South Africa (Pty) Ltd. Reg. No. 2001/025850/07

ProAgri BNZ 38 uppe marketing A32970

Fighting a thorny issue

by Tisha Steyn

Two businessmen of George in the Southern Cape have tackled the thorny issue of invasive, alien cactus species that are adored as garden plants, but which are seriously threatening to destroy pasture and cultivated land.

Three years ago, Ken Coetzee, Wallie Stroebel and Bruce Taplin of Conserva tion Management Services (CMS) ex tended their soil conservation activities to also combat the rampant spreading of invasive alien cactus species.

These plants were imported and cultivated for use as livestock feed, but also as ornamental garden plants.

They tackle the invasive plants by means of biological control methods, which takes time. Where dense stands of impenetrable cacti are resistant to biological methods, chemicals with the least possible negative effect on the en vironment (soil, water, and air) are used. In extreme cases, mechanical methods are used to eradicate dense stands by chopping up the offensive aliens.

These cactus species, which include prickly pear species and others, were mostly imported to South Africa from arid areas of Southern America, Mexico, and parts of the USA. They spread rapidly

wherever the soil has been degraded to such an extent by drought, overgrazing and erosion that indigenous plant species cannot survive.

These cactus species are rapidly gaining ground in the Western, East ern, and Northern Cape, but also in other parts of the country.

Ken identified the top ten species that are already invasive and have the potential to develop into pest plants. According to the Conservation of Agri cultural Resources Act, as well as the National Environmental Management: Biodiversity Act, these plants are clas sified as pest plants and farmers are under an obligation to control it and preferably remove it.

Regeneration and distribution

All these plants, except the prickly pear and thornless prickly pear, were imported as ornamental plants for gardens. But many of them escaped from gardens and invaded large areas of land.

Top ten intruders

Opuntia ficus-indica – Prickly pear (gewone turksvy)

The prickly pear is a native plant of

Southern America. The fruit is eaten, and the leaves are used as animal feed. Because of the thorny leaves, these plants form a formidable, impenetrable hedge. In some countries, they are planted to stop desertification.

These species occur in dry, warm areas and are widely distributed throughout South Africa and Namibia. Although the fruit were once exported, these plants are at present mainly used as animal feed. It is highly digestible and tasty, and it is easy and cheap to establish.

Opuntia

monacantha – thornless prickly pear (doringlose turksvy)

The thornless prickly pear is also a native plant of Southern America. It easily encroaches and must be con trolled. The leaves are also used as animal feed.

Ornamental cactus species

The rest of these cactus species were imported as ornamental plants.

Opuntia aurantiaca – jointed cactus (litjieskaktus)

The stem of the low-growing jointed cactus consists of segments, which easily break off and spread, as the thorns attach in them to humans and animals, especially wool-bearing sheep. The thorns reduce the value of the wool, and where these plants grow profusely, it eventually becomes impossible to farm sheep.

Dense stands occur in the Eastern Cape, but also in other provinces, excluding the winter rainfall areas of the Western Cape.

ProAgri Botswana / Namibia / Zimbabwe 38 29

The torch cactus is regarded as the most serious invasive plant in the Eastern Cape and Karoo (Photo: Tisha Steyn).

Cochineal is used as a biological control on the thornless prickly pear (Photo: Tisha Steyn).

Opuntia stricta - Australian pest pear (suurturksvy)

The Australian pest pear is causing a massive problem in Australia where it has invaded large areas. It is gaining ground in the Karoo and on grass lands all over the country. The seed is distributed by baboons and elephants that eat the fruit. Leaves that break off propogate the plant vegetatively and quickly sprout roots.

This cactus must by law be eradicated, but even though a chemical herbicide has been registered for it, the only real solution is eradication by means of biological control with cochineal

(Dactylopius austrinus) or the cactus moth (Cactoblastis cactorum)

Opuntia microdasys – bunny-ears (haasoortjies)

The bunny-ear cactus with its short, yellow clusters of thorns, is a pest plant in the Western Cape, Eastern Cape, Northern Cape, and Gauteng.

It is spread by water, humans and vehicles, and poses a serious threat to indigenous plant species. Dense stands under trees rob livestock of shade in summer. Extensive stands push out indigenous species, and decrease the value of the land.

Animals and birds eat the fruits, which may be shades of red to purple, but basically the plant has no other value besides being pretty.

Opuntia humifusa – creeping prickly pear, devil’s tongue (kruipkaktus)

The low growing, spreading creeping prickly pear has small, pointed leaves and no thorns. It bears bright yellow, red, or purple fruit in summer. It is spread by means of seed and is becom ing a problem throughout South Africa.

Cylindropuntia imbricata - imbri cate cactus (imbrikaat-kaktus)

The imbricate cactus is difficult to control once it is established, as every shred of leaf that breaks off from the mother plant, forms a new plant. No chemical herbicide is effective, and it can only be controlled by cochineal.

The stems must be cut down at ground level, stacked and left to the insects to devour the leaves from the inside.

Cylindropuntia fulgida var. mammilata – boxing glove cactus (bokshandskoen-kaktus)

The boxing glove cactus occurs widely spread in the dry Northern and Eastern Cape, Limpopo province and Namibia. It grows up to a metre or a metre and a half. The tips break off and fall on the ground near the mother plant, where it takes root. It is also distributed by water or animals. The sharp thorns injure man and beast, and its presence dramatically lowers the value of the land.

There is no registered chemical herbicide that can effectively control it. It is also practically impossible to control it mechanically, as every inch of leaf that breaks off, immediately takes

30 ProAgri BNZ 38 Namibia

The imbricate cactus is difficult to control as each bit that breaks off, forms a new plant (Photo: Tisha Steyn).

Different cactus species invade the veld and grazing.

Prickly pear leaves with cochineal are placed in buckets to allow the insect to infest healthy leaves that will be put near plants in the veld.

The thornless prickly pear is used as livestock feed (Photo: Tisha Steyn).

A boxing glove cactus was dumped on the sidewalk by a homeowner who didn't want it in his garden any more (Photo: Tisha Steyn).

root. Biological control with cochineal or cactus moth are the only options for eradicating it.

Trichocereus spachianus – torch cactus (orrelkaktus)

The torch cactus with its thorny, cylindrical, tall, and upright stem is regarded as the most serious invasive plant in the Eastern Cape and Karoo.

Tephrocactus articulatus – pine cone cactus (dennebol-kaktus)

The pinecone cactus grows up to 30 cm tall and bears white flowers. The corklike, winged seeds are distributed by wind and water. The plant occurs along dry and seasonal waterways, drainage ditches and wherever the land

has been disturbed by human action. It is regarded as a pest plant, and it is rapidly spreading in the Western and Northern Cape.

Biological control

Cochineal (Dactylopius austrinus) spread from Central and Western Argentina, via Australia, to South Africa. It was intro duced to South Africa in the 1970s and has since been used to control prickly pears and other cacti in hot, dry areas.

In areas such as the Western Cape, where the winters are normally cold and wet, chemical herbicide is the only means to these species. The prickly pear moth (Cactoblastis cactorum), which is a native of South America, preys specifi cally on cactus species.

To eradicate dense stands of prickly

pear, CMS construct a greenhouse or a hutlike structure with plastic in the veld where these plants grow. Infected and healthy prickly pear leaves are placed in buckets inside the greenhouse, where the cochineal and cactus moths are allowed to spread from the infected leaves to the healthy ones. Once these leaves have been infected, they are placed near or on stands of prickly pear to allow the insects to invade the plants. By using this method, it takes about two years for a dense stand to be eradicated.

Mechanical control

CMS makes use of a mobile diesel chipper to mechanically fight invasive plants. The leaves of prickly pear plants are finely chopped up and used as a mulch to cover bare soil in the fight against soil erosion. The mulch protects and enriches degraded soil, allowing indigenous plants and pasture to reclaim the land.

The roots are treated with herbicide once the leaves have been removed from the prickly pear plant, and the fruits are treated separately to prevent further distribution by means of seed.

For more information contact Ken Coetzee at (+27)76-227-5056 or consken@mweb.co.za

ProAgri Botswana / Namibia / Zimbabwe 38 31

Imbricate cactus discarded next to an open field will take root and grow (Photo: Tisha Steyn).

The Australian pest pear must be biologically controlled with cochi neal or the cactus moth (Photo: Tisha Steyn).

A hut constructed with plastic in the veld acts as a greenhouse where prickly pear leaves can be infested with cochineal as part of the biological control process.

Namibia

Waste water treatment: Trapsuutjies makes a difference

by Tisha Steyn

Trapsuutjies is an environmental initiative owned by Susan Botha, who formerly worked at CapeNature. The name Trapsuutjies literally means ‘tread lightly’ and is the Afrikaans word for chameleon.

"The guiding principle of this ini tiative is to cultivate positive and focussed environmental behavioural change through value adding and inno vative partnerships,” says Susan.

Southern Africa has successfully integrated water resource policies, but some areas still lack sustainable water resources. The Water Research Commission (WRC) and its Research, Development and Innovation Road map for 2015 to 2025 suggested the use of alternative sources of water and the reuse of wastewater as one such intervention, if this water com plied with Green Drop requirements that would allow the use of this suit ably treated water.

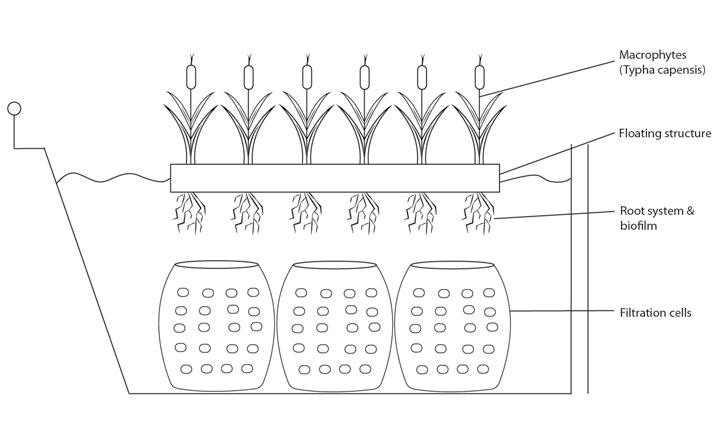

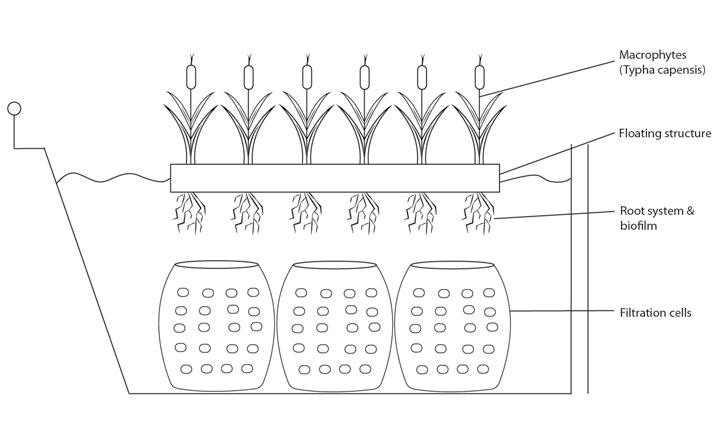

Trapsuutjies became involved with a pilot project at De Rust Wastewa ter Treatment Plant (WWTP) in 2017, when an artificial wetland was cre ated to improve water quality with the aim of releasing it into the natural water system.

This project involved the creation of floating islands on the fifth of six ponds at the plant. The islands consisted of pockets made with shade netting and filled with empty, recycled two-litre plastic bottles. Reeds and bulrushes were planted on the rafts.

In 2017, the UN Environmental Programme’s World Water Develop ment Report delivered in Durban noted that reclaiming wastewater could have environmental, economic, and social benefits, and contribute to better health

and well-being, water and food security, and support sustainable development.

According to the UNEP report, improved wastewater management should include the five Rs:

1. reducing pollution at the source; 2. removing contaminants from wastewater;

3. reusing the reclaimed water; 4. recovering useful by-products; and 5. raising social awareness that the use of reclaimed water is okay.

“While the South African government has been quite successful in providing water to most households, they have not been so successful in treating the sewage effluents from households,” said Dieks Theron, then a resident of De Rust, who designed the float.

“To expand the sewage works using conventional methods would cost bil lions of rands, and alternative natural methods should be tested.”

The wastewater plant at Blomnek outside de Rust consists of six waste water ponds, skirted with reeds and bulrushes growing along the edges. A chemical analysis of the reeds indicat ed that the plants on the edges were not effectively removing chemicals and unwanted bacteria from the water. The water in the last pond therefore did not comply with the standard required to release it into the natural water system or use it for anything else.

Dieks’s floating island design was novel. Here’s how to create it:

• make a pocket by sewing together the sides of a length of shade cloth with rope;

• fill the pocket with empty two-litre

plastic bottles;

• affix reeds and bulrushes to the float;

• position the raft on the pond, anchoring it to the edge for easy removal;

• once the reeds are overgrown, pull out the raft to cut leaves for composting.

How does the system work?

The roots hanging in the water be low the raft function as an anchor for useful bacteria which remove harmful bacteria (E-coli and Staphylococcus) and chemicals from the wastewater. Using an artificial wetland is a less expensive way than engineered ap proaches and greatly improves the quality of the water.