Zimmatic pivots have proven vital in driving the success of farms. An efficient irrigation system can benefit farmers through ease of use and improved water management. Read on page 3 how Zimmatic’s irrigation solutions opened new horizons for a Zimbabwean farmer.

This time of year, we often hear people say they can't believe it is December already, and they wonder where the time flew. Only yesterday day 2022 was still a dream; now the year has almost reached its end. Which made me think again: What is time?

Time is the single biggest factor affecting everybody's life. Everything is measured by time.

Life is sometimes shorter than we expect, and I realise it is a gift, a very precious gift and a privilege, and we have the choice to embrace each day and live it with integrity, passion and love.

When I look back at the year and all we wrote about, there were a lot of highlights and special events. Most of the agricultural shows took place again after two years of anticipation. Farmers and other role players in agriculture could reunite, and strengthen the ties of friendship in the interest of agriculture.

At certain times of the year, we had to take out candles, lamps and generators as Eskom's load shedding had left us in the dark.

Nevertheless, we have made it, and here we are at the end of yet another busy year.

During this time, we wish to acknowledge all the farmers – especially for their persistence in the responsibility to produce food sustainably.

To my ProAgri colleagues, I also thank you for your courage, passion and perseverance. Come what may, we make it work.

Let us not forget the lessons learnt this year when we relax during the big days; let us reflect on what we have learned, and how we can use this beneficially in the new year.

To all our farmers and the other role players in the industry, my sincere thanks to you for all your support this year. I wish you a blessed Christmas. Do not let opportunities pass, live with integrity, plan and work purposefully!

Our dreams and visions are the hope for a better future. May 2023 be the best year ever!

ProAgri greetings Bianca Henning bianca@proagri.co.za

Steps ahead in farming with Zimmatic by Lindsay New Holland TT-series: The strength behind you Ripper Tillage: Implements with your needs in mind De Haasenjagt Boerdery: Chicken farming done right Technews: Latest farming and agriculture news Sheep breeds part 2: Dual purpose sheep African agribusiness companies can still grow Ancient African food Part 5.5: Yam bean and horned melon Introduction to: Invasive alien vegetation Survival of bees depends on forage Greenhouses part 2: An option for maximised production Aquaculture, aquaponics the way forward Tree nut production in Sub-Saharan Africa Part 3 Dried fruits: Preserve and add value to your crop Interest rates and agriculture Beekeeping Part 5: Challenges that beekeepers face

577 Rossouw Street, Die Wilgers, Pretoria +27 (0)79 515 8708 www.proagri.co.za

Copyright © 2022. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

Editor

Bianca Henning >

Reporters Benine Ackermann > Maryna Steyn > Natasha Kruger > Specialist Writer Annemarie Bremner >

Client Relations Manager Carin Swartz >

Marketing Manager Diane Grobler > Marketing Xander Pieterse > Johan Swartz >

Tiny Smith >

Lynette van Tonder > Creative Director Christiaan Joubert >

Design Michelle Kruger Enquiries

Engela Botha >

+27 82-326-2572 bianca@proagri.co.za +27 73-105-6938 benine@proagri.co.za +27 82-261-9177 maryna@proagri.co.za +27 81-736-4236 natasha@proagri.co.za +27 82-320-3642 annemarie@proagri.co.za +27 84-233-0123 carin@proagri.co.za +27 82-555-6866 diane@proagri.co.za

+27 79-524-0934 xander@proagri.co.za +27 71-599-9417 johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za +27 72-419-3990 christiaan@proagri.co.za

Distribution and subscription Nita Volmer-van Zyl >

Accounts

Ronel Schluter >

Business Manager George Grobler

+27 12-803-0782 engela@proagri.co.za +27 79-515-8708 nita@proagri.co.za +27 12-803-0782 accounts@proagri.co.za

by Maryna Steyn

by Maryna Steyn

Z immatic centre pivots have proven vital in driving the success of farms. An efficient irrigation system can benefit the farmer through ease of use and better water management. This is exactly what Tobias Musariri from Zimbabwe experienced.

Tobias farms on Kwasamaita Farm, 10 km outside Chegutu, about 100 km from Harare.

“This is a second-generation farm. It was founded by my late father, Tobias Musariri senior, in 1979, after retiring from the motoring industry. I continued with the farm when he passed away in 2012,” Tobias says. “When he

initially purchased the land, there was absolutely nothing on the farm, except for one little building that was made of asbestos, but that was it. So, we built it from the ground up.”

Clearing the land took them a couple of years.

“We sunk some boreholes and started using a system with aluminium pipes for irrigation. Initially, we put 20 hectares under irrigation,” he elaborates.

Today, the successful farm cultivates

100 hectares of seed production for local seed houses, as well as 400 hectares of commercial maize. In total, there is 500 hectares under pivot irrigation.

“We provide seed to SeedCo, and grain which goes to the local Grain Marketing Board under commercial and government programmes. We used to specialise in the 727 cultivar, but now we also grow the 719 which takes longer to mature,” Tobias says. Other seed crops include barley and wheat.

The farm’s main source of water is the Mfure dam, and boreholes.

Back when Tobias and his family used the aluminium pipe sprayers, they had to move them every four to six hours, depending on the crop. “We must have done that for about 25 years,” he recalls. “As we expanded our fields,

we relied on this form of irrigation, because that was what we could afford at the time. But if you do not attach the rubbers correctly, it will not irrigate properly. We would get in trouble for over irrigating certain areas and wasting electricity and water.”

Later, at the turn of the century, they discovered the benefits of centre pivots. At that point they were cultivating just over 100 hectares. “We bought a second-hand Zimmatic pivot from a friend. When we first put it up, it gave us some problems, but it was such an amazing change. There was no need to wake up in the early hours anymore,” he recalls.

By 2012, we had 120 hectares under irrigation. “As our operation grew, we found pivots to be the most efficient. It changed the concept of farming for us, and it has increased our yields per hectare.”

Currently, there are twelve pivots on the farm.

“We have started changing our control panels to the 700 series. A part of this process is setting them up on FieldNET to ensure all our pivots can be remotely controlled and monitored,” Tobias explains. “Technology has greatly influenced our irrigation decisions. Our pivots are all communicating with us, and we are in the process of linking them up to a central farming system.”

This means that Tobias’ children who are studying abroad can even keep an eye on the pivots from where they are. “Even when they are not around, they can use the Zimmatic technology to get a glimpse of what is happening on the farm.”

Everything irrigation related is taken care of by Zimmatic. There are three pump stations that service the 500 hectares of irrigated fields.

Tobias praises the success he has

found with Zimmatic. “We can now confidently say our yields have doubled and our labour requirement has been cut down. Previously there were twelve labourers handling the irrigation, but now we have two who move around on their motorbikes.

“Before we upscale even more, we want to improve our yields. There are other products that we are bringing onto the farm such as potatoes and citrus, and Waterwright, our Zimmatic dealer, is walking us through it,” Tobias says. “Our plans involve using Zimmatic pivots for some of those crops as well.”

With this technology running smoothly on his farm, Tobias also has a student programme that educates students about the FieldNET technology. “Usually, we get top students from seven or eight universities across the country. They are very smart, tech savvy, and excellent with statistics. This shows how, in general, technology has made people’s lives easier, because helpful technology is something they easily understand,” he says.

During the years of expanding the farming operation, the Musariri family’s path crossed with Mr Graham Wright. “He is an amazing man who was keen to help us get his brand of pivots: Zimmatic by Lindsay,” Tobias states. Graham Wright is the Managing Director of WaterWright, the irrigation distributor and Zimmatic Dealer in Harare. “Mr Graham continuously visits our farm to advise us on the best decisions and to make suggestions. With his help and the advancing technology, he always keeps us one step ahead. It is this technology that will continue to make us more efficient and reduce labour costs.”

Tobias explains that the dealership

is very hands-on, and he can call them with a concern no matter what time of the night or day it is. “We are a happy farm thanks to our Zimmatic products. I continue to tell my dealer he needs to give me a Zimmatic sign so I can put it on my farm because I am so proud of the service and products,” he boasts.

“In our experience, the brand of machine makes a difference because it is not just about the machine, it is the long-term relationship you build with the brand supplier and the quality of service.”

This is not just in the purchase stage, but also afterwards.

“I would recommend Zimmatic pivots to other farmers because it is more than just a product; you also receive guidance on the various opportunities you could be maximising on your farm. You are also advised on how to best use the Zimmatic equipment, which is a plus. With advancements in technology, I think as a farmer you want to try and stay on top of new trends that will really be efficient and allow you to scale up.

“We have a very good relationship with our dealer, we quarrel a lot but we always get to the bottom of what we need to do,” he smiles. “We tease each other like that.”

To find your closest Zimmatic dealer or request a quote, visit www.lindsay.com. Talk to Tanya Brits on +27(0)21986-8900 or send an e-mail to tanya.brits@lindsayafrica.co.za today to learn more about the benefits of Zimmatic centre pivot technology.

New Holland Agricultural has a wide range of tractor units from 26,85 to 67 kW (36 to 90 hp) to meet the demands of the market.

The TT3 tractor range has been designed following extensive customer consultation, feedback, and input. Put simply, you could say the TT3 has been designed by farmers, for farmers. Characterised by smart design, rugged and robust construction, and efficient power, the TT3.50 simply delivers.

In order to meet the requirements of today’s demanding operators, the four-model TT3 range, delivering 26,85 to 36,6 kW (36 to 49 hp) offers modern styling, outstanding operator comfort, unsurpassed performance in its segment as well as the value and versatility customers have come to expect of New Holland. It is available in two- and four-wheel drive and 8x2 transmission.

Key New Holland styling cues have been integrated into the new TT3 range. New Holland’s iconic cat eye lights make it instantly recognisable as a New Holland tractor, as well as ensuring a bright, wide spread of light when working late into the night. The single piece hood can easily be opened for convenient access for routine maintenance.

The redesigned seat features integrated suspension and extra cushioning for ultimate comfort. When working on the most uneven ground, such as when working on cultivated soils, the undulations are counteracted for a smoother ride. The armrest further enhances day-long comfort.

All key controls have been positioned so they fall natural to hand for productive ergonomic operation and the semiflat platform offers more space and

greater day-long operator comfort.

The productive three-cylinder, 2,7 litre diesel engine packs a punch and enables you to complete the most demanding tasks with ease, especially those which are more commonly associated with more powerful machines. The mechanical PTO delivers robust and reliable performance. Furthermore, the large capacity fuel tank means that you can work even longer before filling up.

New Holland knows that you want your tractor to carry out as many tasks on your farm as possible. That is why versatility is in the TT3’s DNA. A threepoint linkage and easy maintenance complete the package.

When you are thinking of buying 41 to 55,9 kW (55 to 75 hp) tractors available in both 2- and 4-wheel drive, and stateof the-art performance, then the only tractors that fit the bill are the New Holland TT55, TT65 and TT75. Blessed with outstanding power, speed, lift capacity and pulling strength, these tractors far exceed expectations while maintaining high fuel efficiency. You get power and economy in one package. That is what we call a Global Performer.

All TT models are supplied with a 2-post ROPS and canopy, partial-synchro transmission plus optional creep speed and independent PTO. Rear axles feature multi-plate, wet disc brakes with a large surface area for safe and efficient braking. Equipped with New Holland engines; known for ruggedness, reliability, and excellent torque characteristics.

The design improves the operator zone, providing more legroom and better operator comfort. The levers have been specifically positioned so

that gear shifting becomes easier and needs less effort. The newly designed instrument cluster is not only aesthetically better but also provides better visibility of the gauges.

New Holland designed and developed the TT4 around you, effortlessly combining muscled-up performance with new appealing features, giving you, the farmer, the cutting edge in tractor technology.

Characterised by sturdy design, like the distinctive New Holland design cues that not only look good but enhance productivity and functional layout, the TT4 thrives on being pushed to the limit.

The TT4 engines offer more than just muscle. They set the highest standards for both dynamic performance and fuel economy, thanks to FPT (Fiat Powertrain Technologies) Industrial.

The TT4 range is simple to operate, easy to maintain and built to go the distance, offering maximum uptime and reduced maintenance cost, putting money back in your pocket.

Spending long hours in the field comes easy with the TT4, offering well-thoughtout comfort and space, featuring a true flat deck operating platform, steering column mounted shuttling and ergonomic controls, ensuring you work in comfort and keep alert for the job at hand.

Other features include a 3,5-ton maximum lift capacity, up to 60 litre per minute hydraulic flow and a 12 x 12 Power shuttle transmission.

For any inquiries, contact Jaco du Preez, at jacobus.du-preez@cnhind. com or visit their website at www. newholland.com/za.

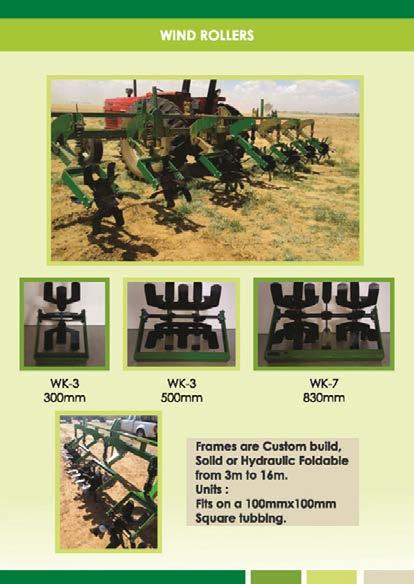

ipper Tillage Equipment offers more than robust and efficient implements; they start every customer journey with the question: What are your requirements? This includes the needs of your business according to the scale of your farming operation, the soil type, structure, and the crops you plan on planting.

R

By asking this question, Ripper Tillage Equipment is able to offer you, the farmer, the solution that fits your unique requirements. “We consider how the soil needs to be prepared for the type of crop the farmer wants to plant,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains.

This manufacturer designs and builds implements for every part of seedbed preparation and planting needs: before planting, during planting and after. This includes rip-till and strip-till equipment, rotary hoes and planting equipment.

“We specialise in rip-on the row. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Rip-Till equipment means the same seedbed, but different result Rip-till seedbed preparation means deeper tillage (deeper than 300 mm) that loosens the undersoil to ensure an even seedbed just like strip-till.

With conservation farming becoming more and more popular, conservation tillage is also increasingly popular. Rip-till implements from Ripper Tillage Equipment are ideal for this task, and what is more, their rip-on-the-row equipment delivers tillage that keeps soil moisture locked in.

On-the-row rip means you only till the soil in the row where your planter will carefully place the seeds. When, for example, using a 0,9 m (3 ft) 8-row planter, you will also use a 0,9 m 8-row ripper instead of ploughing the entire area of your field.

This process involves: • cutting of residue with a cutting coulter

• row cleaning

• rip and optional fertilize placements

• closing of furrow and compressing with a roller

Because there is less soil tilled over a large area, the machinery – tractor included – has less wear. What is more, you also use less fuel and require less labour.

“Our rotary hoe (rolegtand) is very popular for after-planting seedbed care when it comes to crumbling soil after heavy rain,” she adds.”

Tillage is more than implements, it is caring for the soil Ripper Tillage Equipment employees are skilled in identifying soil requirements. “We come to your farm, do a soil analysis with a demonstration, and determine the type of implement that will give you the best results,” Christine explains.

“We consider the type of soil on your farm as well as the last crop you planted – for example residue management.

When we look at the soil condition, we understand how to help the farmer plant his next crop in the best possible way. We can suggest the implement

with the right tines or closing coulters to get the job done.”

This is the added benefit of custommade implements: Guidance and expertise in what is best for your soil. Because soil conditions and crop needs differ from area to area, investing in exactly the right tools that give you the maximum results help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need. You won’t find a ready-made “one-sizefits-all” implement on a show floor.

“Maintenance is also fairly easy and inexpensive, because most parts are available locally,” she adds.

For more information on customised equipment for your seedbed preparation, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbothariptill@ gmail.com. Check out their visit website at: www.rippertillage. co.za or find them on Facebook: www.facebook.com/RipperTillage.

by Tisha Steyn

by Tisha Steyn

When a chicken farm sells all the eggs their 1 600 chickens lay per day within 24 hours, it is proof that they are doing something right.

Reyno Colyn and Belinda Hattingh farm with chickens on a farm in the Haasenjagt area some 20 km outside Oudtshoorn. They started chicken farming on a small scale two years ago, and they are doing exceptionally well in the heart of the Klein-Karoo.

Reyno grew up in the area and for the past ten years he has been a producer of vegetable seeds for the international market under the name De Haasenjagt Boerdery. These vegetables include onions, carrots, and pumpkins, as well as salad greens such as spring onions, rocket, and basil.

Reyno also used to keep ostriches, cattle, and sheep, but when his ostriches became financially unviable, he turned to chicken farming instead. As an extra source of income, he also keeps about 100 sheep, of which the offspring is sold at auctions.

When Reyno considered chicken farming about two years ago, he decided on broilers. Initially, he and Belinda drew up a budget to ensure that the chicken business was viable, sustainable, and profitable. “With the increase in the price of fuel and chicken feed, the budget basically flew out the window and alternative measures needed to be taken in order to keep farming chickens,” explains Belinda.

Initially, day-old broiler chickens were supplied by a certain Oom Gert, who provided good-quality, strong chickens.

It worked well for quite a while until Oom Gert retired. “Ever since, we have battled to find day-old chicks as good as those he provided, but to no avail.”

Eventually, Reyno decided to start focusing on layers to produce freerange eggs, and to incubate eggs to produce his own day-old chicks.

As he couldn’t stop selling broilers immediately, Reyno invested in 200 parent stock for hatching eggs for day-old chicks that could be raised as broilers. Later he started to hatch his own layers as well.

At present, De Haasenjagt Boerdery keeps about 300 broilers and 1 800

The doors of the shed remain open during the day to allow the chickens to move inside when temperatures soar outside.

layers. On average, the hens each lay an egg every other day, but Belinda, who does the bookkeeping, doesn’t keep exact track of every individual hen’s production. She does however keep count of the total number of eggs laid per day to pick up any problems indicated by a lower-than-usual number.

The farm provides eggs to restaurants, guest houses, bakeries, friends, or whoever learns about them and wants to buy eggs. “We are very lowkey as this is a small-scale business,” says Belinda. She does the marketing on Facebook and she also has quite a large WhatsApp group to which she adds new customers and announces any specials.

“This is a small community, and the news is also spread by word of mouth. It is not as if we have truckloads of eggs leaving the farm. The eggs are usually sold within 24 hours of being laid. Often someone will call in the morning ordering about ten trays of eggs, which we pack and deliver on the same day.”

To house the day-old chickens, they used custom-made wooden boxes. “We built custom-made wooden crates that are elevated above the ground, and sealed them,” explains Belinda.

A thick layer of very fine woodchips on the bottom keeps the chicks warm and dry.

The chickens remain in the nursery for fourteen days before they are moved to their sheds.

There are four sheds that can house approximately 500 chickens each – one for pullets of different ages, two for layers and one for broilers.

After the young chickens are moved to one of the sheds, they again remain behind closed doors for another week. Once the doors are opened, they roam freely. The doors are closed at night to keep them from prowling predators, which

include cats, mongooses, and snakes.

The sheds have massive windows for ventilation and are provided with canvas or hessian curtains that can be closed when it is windy or raining. Like the brooding boxes, the sheds also have a temperature regulator for controlling the heat.

The floor is cement for proper sterilisation between groups of hens. Finely chopped woodchips are used as bedding. “It is very important that the chickens are kept warm during winter, but equally important they are kept cool during summer when temperatures in the Klein-Karoo can soar to 40 °C or more.”

During the day the door remains open for the chickens to come and go as they please. When it is that hot outside and it is impossible to walk comfortably on the baked earth, it is important for the chickens to have a cool refuge inside.

“We try to contain them in a fenced yard adjacent to the sheds, but they fly over. Sometimes I find them on the couch in the house, and we have found eggs in the braai place – it must be those chickens that couldn’t make it back to their home-made wooden nesting boxes in time!

“The henhouses have a sleeping area, which is basically like a chicken jungle gym with perches at different heights.”

Water is provided by gravitation from tanks to either saucer drinkers for the day-olds, or drinkers suspended from the roof of which the height can be adjusted as the chickens grow.

They mix their own chicken feed, which contains a basic diet of soya, maize, barley, green lucerne and feed grade lime. “The exact recipe is a secret because it provides beautiful bright yellow yolks!”

Once the chickens are no longer viable to keep as layers, they are sold to backyard farmers who do not care how often eggs are produced.

Onions and other vegetables are grown for their seeds, which are sold to an international company.

All eggs that are laid are sold within 24 hours.

Contact Reyno Colyn on 072-9015650 or De Haasenjagt Farms on Facebook.

Same Deutz-Fahr has taken a majority stake in vineyard robotics start-up VitiBot. Based in Reims, in the heart of the Champagne region, the French company makes a 100% electric and autonomous straddle tractor called the Bakus. Described by SDF as an innovation accelerator, the move will allow VitiBot to accelerate its commercial development in vineyard equipment, and the two companies plan to develop a new range of precision farming solutions for a market that is expected to grow in the future.

SDF already owns the grape harvester and sprayer manufacturer, Grégoire. VitiBot will operate like this French subsidiary in that it will remain independent within the SDF Group.

SDF top man Lodovico Bussolati said that after a thorough search of available technologies, the company realised that VitiBot was the best solution for vineyards. “It allows us to enrich our tractor offer with self-driving and zero-emission electric vehicles,” he comments.

VitiBot was founded in 2016 by French wine grower Dominique Bache and his son Cedric, a robotics engineer. It took them five years to develop the roughly 2,4 t Bakus tool carrier, which is available as the S-model, for straddling 1,75 m high x 60 cm wide vines, and the L-version for 2,20 m high x 80 cm wide crops.

The Bakus can be equipped with a range of electric and non-electric

tools, including mowers, sprayers and mechanical weeders. More than 50 of these machines are already working in vineyards around the world. (Source: SDF)

make inroads, but most Dutch growers continue to cut cabbages and cauliflowers by hand, placing them on conveyors and a packing platform carried behind a tractor. Covering just 130 m/h, the tractor drives in the slowest creep speed. Most growers have long used a cable behind the tractor to operate it remotely. Van der Werf has gone a stage further and ditched the cable for a dedicated remote control unit.

Shown on a Case IH Maxxum 115 at the Bejo Zaden Machinery Show at Warmenhuizen (north of Amsterdam), the Dutch dealer has offered the conversion for some years now and has sold more than 100 systems, mainly to cauliflower growers. “It is a normal job for us,” comments Sander Klabbers of Van der Werf.

Activating the system is easy in three steps; start the tractor, engage the creeper and then turn on the remote unit (receiver connects to it). Engine speed is always set in idle for this type of work. The remote could be programmed to start the tractor and reverse it, but most growers opt for the six functions of stop, forward, gear change (up/down) and steering (left/ right). The tractor is always turned manually at the headland. The remote is only used when crossing a field.

The Maxxum is the most popular tractor for conversion, but the dealer has also installed the kit on a number of New Holland and Steyr tractors. The Dutch dealer reckons it is difficult to convert a CVT to remote control. The

Dutch Case IH and Steyr dealer Van der Werf Mechanisatie have developed a remote control unit that allows cabbages and cauliflowers to be harvested without a driver in the tractor cab.

Mechanical harvesters continue to

easiest is a mechanical transmission. It depends on the tractor and required functions, but the cost of the conversion is usually around €4 000. (Source: profi)

Fendt has returned to the 588 kW (800 hp+) self-propelled forage harvester market with the Katana 850. The new model is available to order now for the 2023 season in Europe.

Main features of the new machine include the redesigned CropFlow 2.0 system to maximise throughput and chop quality. Claimed as the largest on the market, the 720 mm diameter of the chopping cylinder with its high flywheel mass is said to ensure very smooth running and increased operator comfort. Optional chopping cylinders with 20, 28 or 40 knives are available to cover chop lengths from 2,6 to 41,4 mm.

The Katana 850 can be matched to the Kemper 490 Plus 12-row header to fully utilise the power of the 18-litre six-cylinder 623 kW (847 hp) Liebherr engine. The Liebherr block meets Stage V emissions with SCR, but there is no diesel particulate filter or exhaust gas recirculation. If the full power of the engine is not required, it can be operated in eco mode, which maintains the speed of the chopping cylinder, but then at reduced engine rpm.

Metal and stone detectors on the first of the six pre-compression rollers of the feed intake prevent damage to the chopping cylinder, and crop volume data recorded by a sensor in the rear area of the feed intake is available for yield monitoring and documentation.

Three different 300 mm diameter roller crackers are available. The standard R cracker with sawtooth profile is suitable

for chop lengths of up to 20 mm. The optional RS cracker with V-spiral groove has been developed for longer chop lengths. The speed difference of 30 or optionally 40 percent ensures thorough processing of the crop.

The loading height of the revised discharge chute is extended to 6,2 m. The Fill Control filling assistance option automatically controls the discharge flap if the discharge chute swivels, to

ensure trailers are filled more evenly. A camera is positioned next to the discharge flap.

Other options include a fully integrated silage additive system with 215-litre tank, the intelligent all-wheel drive BalancedGrip system, and an interface for an NIR sensor. This allows the dry matter content of the crop to be measured. An ISObus interface enables the use of different sensors. (Source: AGCO)

6 ranges. Suitable for tractors from 51 to 95 kW, the new low-draught model will be available early next year.

With a 110 mm box section frame and an underframe clearance of 80 cm, the Juwel 6 is available in versions with three to five furrows. The M version provides four mechanically adjusted working widths per body, while the 6MV provides infinitely variable hydraulic working width adjustment (hydraulic frame swivelling is optional). LEMKEN says that when combined with the iQblue Connect electronics kit, the implement can easily be transformed into a smart plough with ISObus control.

All LEMKEN mounted ploughs are equipped with the new pendulum wheel, the height of which can be adjusted without tools via a series of holes. For material protection and greater working comfort, hydraulic suspension is also fitted to the depth wheel. A simple conversion kit is available to upgrade to a Uni wheel for road transport.

Standard equipment on the Juwel 6 includes the tried-and-tested Dural bodies (DuraMaxx optional). Mechanical non-stop overload protection is recommended for stony soils, and as with all the company’s mounted reversible ploughs, the Juwel 6 comes with the Optiquick adjustment system for side draught-free work. (Source: www.world-agritech.com)

Raising sheep can be beneficial in many ways. Sheep can eat vegetation that is not fit for human consumption. Sheep populations tend to grow rapidly, and their gestation period is much shorter than that of cattle. A faster growth rate of the animal population is thus possible. Capital expenditures for sheep production systems are lower than those for cattle. Farmers can quickly see the results of their feeding, genetic, and management choices.

The Dormer and Dohne Merino both trace their ancestry back to the German Merino, a multipurpose sheep that served as a foundation for the development of those breeds. The Merino breed has been refined through generations of selective breeding in South Africa.

This large breed of sheep is a useful resource due to its fine 21 to 23 micron wool, and meat. The Mutton Merino was originally bred to take advantage of the Western Cape's winter grazing and to raise their lambs before the grazing

South African Mutton Merino ewes and lambs. (Source: savleismerino. net)

deteriorated in the summer. However, because it is so adaptable, it is now found all over the country.

In addition to being resistant to parasites like the hairworm, this breed is also less likely to contract diseases like Johne's. For the first time, ewes could give birth at the age of 22 months. At 100 days, the maximum weights that ewes and rams of the Mutton Merino breed can achieve is 35 kg, and they can produce good volumes (4 kg) of medium to strong wool. The Mutton Merino sheep gain weight as they age, allowing for a greater live weight to be slaughtered. There is no obvious fatty area on the carcass.

In South Africa, Dormer meat sheep were bred by crossbreeding Dorset Horn rams with German Merino ewes. Dormer comes from the combination of the names of its two parent breeds, Dorset and Merino. Even though the breed was developed in areas with winter rain in the Western Cape, it can be raised successfully in more temperate climates, both on natural veld and on cultivated pastures.

The Dormer is a hornless, whitewoolled sheep with a sleek body and excellent meat conformation. Multiple births are commonplace because of the breed's high fertility. Lambs are born very small but quickly mature into their full size. The mature weights of Dormer rams are between 100 and 110 kg, and those of ewes are between 70 and 80 kg.

Dormers typically have white wool averaging 27 microns in thickness and known for its strength. The wellmuscled sheep reaches reproductive maturity at a young age (first lambing at 18 months) and is extremely fertile, producing many small lambs.

South African

(Source: savleismerino.net)

It is not uncommon to see lambing rates of over 150%, and the ewes typically produce enough milk to nourish healthy, full-term lambs. The mature weights of SA mutton Merino rams are between 100 and 110 kg, and those of ewes are between 70 and 80 kg.

Dormer ram. (Source: dormersa. com)

Because of the breed's rapid growth and high feed conversion rate, lambs of this breed can be sold at a marketable weight of 16 to 22 kilogrammes at only three months of age. When it comes to the Muellerius lungworm, the Dormer has the upper hand.

Because of the harsh conditions of the Eastern Cape's sour grass veld, the Dohne Merino sheep were developed by crossing South African Mutton Merino rams with Merino ewes. Embryos of the Dohne have been shipped to Australia and Uruguay since the breed's inception in 1939 so that breeder communities there could begin developing.

The white, hornless Dohne is a versatile breed that can be used for both meat and fine to medium wool.

Dohne lambs can gain the 40-kilogram butchering weight in only four to six months. Dohne ewes wean at 29,9 kg and rams at 31,1 kg at 100 days of age. The mature weights of Dohne Merino rams are between 80 and 100 kg, and those of ewes are between 50 and 65 kg.

A locally developed dual-purpose sheep breed, the Afrino, has 25% Merino, 25% Ronderib Afrikaner and 50% SA Mutton Merino as its ancestors. It was bred to be a wool-producing sheep that would do well on large farms and grow up quickly so it could be used to produce lambs for slaughter.

The Afrino is a large breed with wool of 18 to 22 microns, which can contribute 20% of its income; the rest is from meat production. The age of first lambing is about 17 months, and the average marketing weight(42 kg) is achieved in 7 to 9 months under veld grazing conditions. Afrinos do well in feedlot farming systems as feed is converted to muscle rather than fat. The mature weights of Afrino rams are between 80 and 90 kg, and those of ewes between 60 and 70 kg.

Mature Suffolk rams can weigh between 113 and 159 kg, while ewes weigh between 81 and 113 kg. A mature ewe's average yield is between 50 and 62 percent, with fleece weights ranging from 2,25 to 3,6 kg. With a fibre diameter of 25,5 to 33 micron and a spinning count of 48 to 58, the fleeces fall into the category of medium wool type. Suffolk fleece has a staple length of about 8,75 centimetres.

The Suffolk sheep, originally from England, arrived in South Africa in the late 1890s. They are polled, meaning they do not have horns. Even though the Suffolk is mostly used to produce wool, it is also regarded as a mutton breed.

This large, muscular breed, distinguished by its black head and legs, not only yields a carcass with an excellent lean-to-fat ratio, but also wool of medium fineness. Birthing is simple for Suffolks, but they rarely have identical twins. Suffolk rams are popular for crossbreeding because they produce large, early-maturing lambs that are ready for sale after only two months.

Breeds of Livestock - Booroola Merino Sheep, Department of Animal Science. (1996). Available at: http://afs.okstate.edu/breeds/ sheep/booroolamerino/index.html

Ngcobo, J.N.; Nedambale, T.L.; Nephawe, K.A.; Mpofu, T.J.; Chokoe, T.C.; Ramukhithi, F.V. An Update on South African Indigenous Sheep Breeds’ Extinction Status and Difficulties during Conservation Attempts: A Review. Diversity 2022, 14, 516. Available at: https://doi. org/10.3390/d14070516

Sheep breeds. (2008). Department of Agriculture. Available at: https:// www.nda.agric.za/docs/Infopaks/ Sheep_breeds.pdf

Sheep Farming in South Africa 2022. Available at: https://southafrica.co.za/sheep-farming-southafrica.html

"Rome was not built in a day." The famous saying by John Heywood rings true in farming as well as business. Every large company today exists because of a growth plan that was laid out years ago. Right from the inception of its operation, the firm followed a strategic path that was flexible yet stubborn in its vision.

Most of the large international agricultural companies began their operations in the previous century when many companies currently operational in Africa were not yet established. There are still opportunities to penetrate the market, expand an asset and clientele base, increase expertise and focus on innovation. But to do so, smaller companies may need to overcome challenges such as the marginalisation of Africa from the global economy, poor healthcare and infrastructure, lack of financing, climate change, and weak governance.

The size of an agribusiness firm can be categorised by its sphere of operation such as seed production, bioenergy, artificial intelligence, pesticide production, and machinery and vehicle manufacturing. However, most companies function in multiple sectors.

Currently, the agribusiness industry is worth over USD 2,4 trillion and

employs over one billion people. Global companies dominating the top five agricultural spaces are Cargill, the Archer-Daniels-Midland Company (ADM), Bayer, John Deere, and CHN Industrial.

Cargill began operations in 1865 when William Wallace Cargill became the proprietor of a grain flat house in Conover, Iowa. The flat house, a type of warehouse that preceded country elevators, was at the end of the McGregor & Western Railroad line. Today, Cargill has interests in crops, livestock, food, raw materials, as well as industrial and financial risk management.

Cargill employs over 166 000 people in more than 66 countries. The company is responsible for about 25 percent of the grain exports from the USA. In 2020, their company revenue was USD 114,69 billion, making it the top agriculture company in the world.

Archer-Daniels-Midland Company (ADM) was founded in 1902 as ArcherDaniels Linseed Company by George A Archer and John W Daniels. The Minneapolis-based outfit processed linseed (also known as flaxseed) oil for ink, paints and linoleum. Currently, Archer-Daniels-Midland is the absolute leader in food processing and commodities trading.

Globally, ADM maintains a massive inventory of operating 270 plants, and over 400 procurement facilities, where food, beverage, industrial, animal feed, and nutraceutical products are manufactured by processing

oilseeds and cereal grains. The company’s revenues hit USD 64,34 billion in 2020, making it the second-largest agriculture company in the world.

Employing over 38 000 people, ADMs, products include high fructose corn syrup, ethanol, food and bioenergy.

There the company was making a thousand ploughs a year. Business boomed as Deere established a reputation for both his ploughs and his principles. Those same principles guide Deere and company to this day.

Currently, John Deere has strong footings in agriculture, forestry machinery, construction, drivetrains equipment, diesel engines, and lawn care equipment. The company’s agricultural products include: combine harvesters, tractors, cotton harvesters, silage machines, balers, sprayers, and planters. They supply machinery to industries such as agriculture, forestry, consumer and commercial equipment, as well as construction.

Valletta, E. (2018) Rome wasn’t built in a day. It took 8. Available at: https://www.sbs.com.au/guide/ article/2018/01/22/rome-wasnt-builtday-it-took-8 (Accessed: 4 5 March 2022)

Accelerating agricultural digital transformation through AI and IoT. (2022). Available at: https:// www.itu.int/en/ITU-T/webinars/ DT4CC/20220329/Pages/default. aspx#:~:text=The%20agricultural%20sector%20is%20 one,19%25%20of%20the%20 world's%20population. (Accessed: 4 March 2022)

Saud, D. (2022) Top 5 Biggest Agriculture Companies in The World 2022! Available at: https://dynamics. folio3.com/blog/top-agriculture-companies/ (Accessed: 5 March 2022)

Bayer is a German chemical and pharmaceutical company founded in 1863 by Friedrich Bayer (1825–80), who was a chemical salesman, and Johann Friedrich Weskott (1821–76), who owned a dye company.

Apart from being one of the largest agriculture companies in the world, it is also among the largest global pharmaceutical companies. The company also ranks at the top for its research in crop science, holding over 175 breeding sites globally. The company acquired Monsanto for USD 63 billion in 2018, further cementing its position as the largest global player in crop sciences and agriculture. The company’s revenues reached USD 51,18 billion in 2020.

Products Bayer specialises in are veterinary drugs, diagnostic imaging, women’s health products, general and speciality medicines, seeds, pesticides, plant biotechnology, over-the-counter drugs and diagnostic imaging.

CNH Industrial is an American-Italian multinational corporation with offices in Basildon and Amsterdam. Employing over 63 000 people in 67 manufacturing plants and 56 research and development centres, the company is one of the largest producers and sellers of agricultural and construction equipment. Their products include trucks, special vehicles (Iveco), buses, and powertrains (industrial and marine applications). The company generated over USD 28,1 billion in revenue last year.

These top five agribusiness firms based in developed countries represent a total revenue in 2020 of almost USD 275 billion. For Africa, more than 60 percent of the population of sub-Saharan Africa is smallholder farmers, and about 23 percent of the GDP comes from agriculture-roughly USD 621 billion.

This means that five companies can equal almost half of sub-Saharan Africa's agricultural-based GDP. It shows that there is a need for growth and participation of more companies.

Sekulich, T. (2019) Top Ten Agribusiness Companies in the World. Available at: https://www.tharawatmagazine.com/facts/top-ten-agribusiness-companies/ (Accessed: 5 March 2022)

Top agriculture companies. Available at: https://www.glassdoor.com/ Explore/top-agriculture-companies_ IS.4,15_ISEC10003.htm (Accessed: 5 March 2022)

Goedde, L., Ooko-Ombaka, A., Pais, G. (2019) Winning in Africa’s agricultural market. Available at: https:// www.mckinsey.com/industries/agriculture/our-insights/winning-in-africas-agricultural-market (Accessed: 5 March 2022)

Our History. Available at: https:// www.cargill.com/about/cargill-history (Accessed: 5 March 2022)

About Us. Available at: https://www. adm.com/en-us/about-adm/ (Accessed: 5 March 2022)

Overview. History of Bayer. Available at: https://www.bayer.com/en/ history/history (Accessed: 7 March 2022)

John Deere. Available at: https:// www.deere.com/en/index.html (Accessed: 7 March 2022)

John Deere was a blacksmith who developed the first commercially successful, self-scouring steel plough in 1837 and founded the company that still bears his name.

In 1848, Deere moved his growing operation to Moline, Illinois, on the east bank of the Mississippi River.

Deere & Company. American company. Available at: https://www.britannica.com/topic/Deere-and-Company (Accessed: 7 March 2022)

Our Brands. CNH Industrial. Available at: https://www.cnhindustrial.com/ en-US/Our-Company/Our-Brands (Accessed: 7 March 2022)

Modular design and easy clean nozzles that make maintenance easier and more efficient. Advanced brake technology ensures a smooth and consistent movement, offering optimum control for a wide and uniform application.

AGRICULTURAL IRRIGATION | A Hunter Industries Company Learn More. senninger.com

The African yam bean belongs to the family Leguminosae. The annual climbing or prostrate vine is mainly grown for its fleshy roots that looks like a sweet potato.

It flourishes throughout tropical Africa, where both seed and tuber are important components of the diet.

It is not well known as a food source outside Africa, although it is used as an ornamental plant in Europe and elsewhere. It is different from Mexican yam or yam bean that grows in Central and South America, and especially in Mexico and Brazil. There, this tuberous vine is grown mainly for the tuber because the seeds are toxic.

In nutritional terms, the African yam bean contains more than twice the protein of sweet potatoes, yams, or potatoes, and more than ten times that of cassava.

The protein is of exceptional nutritional quality, which complements the proteins of maize, sorghum, and the other staples.

The abundance of seeds and leaves are edible, and the plant seems capable of delivering record quantities of protein from soils normally considered marginal. In the traditional farm setting it is usually interplanted with yams and other vegetables in the traditional village farm setting.

The vine produces linear pods of between twenty and thirty centimetres long, each bearing twenty to thirty oval seeds that are usually cream, orangebrown, brown, or mottled brown.

Flowering occurs 80 to 130 days after planting, while the seeds reach maturity after 150 to 300 days.

In poor soil, the seed yield is about 300 to 500 kg/ha, but higher yields of between 2 000 and 3 000 kg/ha have been reported for fertile soils.

The plant yields tubers of 100 to 300 g/plant, with hectare yields estimated at about 2 000 kg in fertile soils.

The African yam bean grows best in areas where annual daytime temperatures are within the range of 23 to 29 ° Celsius, but it can tolerate 15 to 35 ° Celsius. It prefers a mean annual rainfall in the range 1 000 to 1 200 mm, but tolerates 800 to 1 400 mm.

The plant requires a dry period when it is flowering. It prefers a position in full sun. It grows best in a fertile,

sandy soil and prefers a pH in the range 5,5 to 6, but tolerates 4,5 to 7.

Although perennial, the plant is usually treated as an annual in cultivation. Plants are probably day length sensitive.

The seedpods can be harvested about five months after sowing and continue for another two months. The tubers mature seven to eight months after sowing.

It is best to leave the roots in the ground when removing plant material at the end of the growing season, as the decaying roots release their nitrogen.

Cucumis metalliferous, commonly called the African horned melon or horned cucumber, spiked melon, jelly melon, kiwano, or cuke-a-saurus is an annual vine in the cucumber and melon family, Cucurbitaceae

It is a traditional food plant indigenous to Southern and Central Africa and grows naturally in Namibia, Botswana, South Africa, and Swaziland.

It is nowadays also grown all over the world for its ornamental and edible fruits, including in New Zeeland where it was registered under the trademark Kiwano.

The horned melon is grown as an annual in cold areas and needs welldrained soil, regular watering, and support to climb on. A single vine can produce up to hundred fruits.

It is a self-fertile climber that does not need other similar plants for pollination. It has hairy leaves and stems, and bears white or yellow flowers. It attaches itself to a support by means of tendrils.

The soft-shelled fruit is about ten centimetres in length and is covered with prominent spines. It turns yellow orange when ripe.

The fruit can be eaten at any stage of development, from young, or mature but still green, or when ripe.

The juicy sweetish flesh is green and translucent and contains a lot of seeds covered in a gelatine-like substance. It tastes like a combination of cucumber and zucchini, or a combination of banana, cucumber, and lemon.

It can be eaten fresh when cut open and sprinkled with sugar or salt, scooped out of the shell, and used in a fruit salad, or juiced.

The leaves, fruit and seeds are edible. The fruit can be boiled until soft, strained and the liquid boiled with a cup of sugar for each cup of liquid to produce jelly. The fruit can also be cubed and pickled in vinegar.

The Khoisan roast the food and then strain the flesh. The leaves are either cooked like spinach or mixed with maize meal.

The fruit contains saponin, an oily glycoside that foams when shaken with water.

The skin is very rich in Vitamin C and fibre.

Plant the horned melon seeds in rich, well-drained soil in full sunlight near a trellis or fence to promote climbing.

The plant is not very particular regarding soils but prefers clay or loamy soil with a pH range of 6 to 6,5.

Sow seeds in the spring when temperatures are above 20° Celsius.

Plant two or three seeds at a depth of two to three centimetres, leaving sixty centimetres between groups of seeds. Allow about 1,8 m of space between rows.

Keep the soil moist down to about three centimetres to aid germination, which occurs within two or three weeks.

Once the plant is established, water slowly and deeply in the morning or afternoon. Provide it with two to five centimetres of water per week, soaking down to about fifteen centimetres, allowing the soil to dry between waterings.

General-use fertiliser with a 4-8-5 or 6-10-10 N-P-K ratio can be applied according to the manufacturer's instructions.

When the soil temperature is above 24 ° Celsius, you can apply organic mulch, such as straw or wood chips, around the base of the plant to help retain moisture and prevent weed growth. Weeds can be removed by hand.

S

ome plant species that have been brought to Southern Africa from other countries pose a serious threat to the environment, including water resources, indigenous vegetation, agriculture, and the economy.

Some of these plants were imported intentionally to address specific needs, like sand stabilisation or sylviculture, or as ornamental garden trees or shrubs, or unintentionally, like cosmos and khaki weed (kakiebos), which were brought in along with horse feed for the British army during the Anglo Boer War. The pretty pink, white, and sometimes purple or crimson cosmos flowers that adorn country roads in spring is an invasive alien plant, while khaki weed is regarded as a nuisance that sticks to everything, especially your socks!

Species that are alien to South Africa may have natural enemies that curb their spread in their countries of origin. Where there are no natural enemies, like insects or fungi, they rapidly reproduce and spread.

This poses a threat to their adoptive country

• They deprive indigenous plants of space by their rapid encroachment, threatening biodiversity

• As they usually consume more

water than indigenous plants, they deprive the local vegetation of water

• They deplete underground water resources and in heavily infested areas can reduce water run-off by up to 30%

• They provide fuel for intense veldfires that destroy vegetation and soil structure, infrastructure and threaten human and animal lives.

• As a result, they threaten biodiversity and disrupt the ecosystem services that we need for our livelihood, such as food, water, firewood, medicine, and clean air.

According to CapeNature the top 10 invasive alien plants affecting the Western Cape include rooikrans, black

wattle, Port Jackson, silky hakea, longleafed wattle, stinkbean, Australian myrtle, spider gum, cluster pine and blackwood.

Ken Coetzee of Conservation Management Services, believes that prosopis, or honey mesquite (Suidwesdoring) should head the list in the more arid areas such as Namaqualand and the northern Cape' as this invasive species has already invaded vast areas of the arid rangelands.

The South African government, CapeNature, the Gouritz Cluster Biosphere Reserve, and many other organisations provide for the management of these invasive plants by clearing land, making it available to agriculture, and to ensure a sustainable water supply. Clearing is done by biological, manual, mechanical and chemical methods.

Cut them down to size

Biological management involves the use of the alien plants’ natural enemies, such as beetles, flies, fungi, and pathogens that are sourced in the countries of origin.

Examples of this include the use of the cactus moth, Cactoblastis cactorum, and the cochineal insect, Dactylopius austrinus, on prickly pear, and the gall midge, Dasineura dielsi on rooikrans, to name a few.

Manual management involves removing small invaders or young plants from the soil by hand, while mechanical management involves chopping down plants with a hatchet or panga or using a bow saw or chainsaw to cut the plants down.

Ringbarking is also effective and involves removing a 30 to 40 cm strip of bark around the trunk. This prevents the plant from taking nutrients from the soil to the branches and leaves, and the plant dies.

Chemical management include the use of herbicides to kill the plant. The stumps of trees that had been cut down should in most instances be painted with a registered chemical agent to prevent it from sprouting again.

The following tips will help you do your bit to stop invasive aliens in their tracks while they are still manageable. These actions are suitable for controlling invasive alien plants on a small scale in your garden, as well as on a bigger scale on your smallholding or farm.

• find out which plants are aliens and how to control and remove them;

• share your knowledge with others;

• join or form a team to control alien plants in your area;

• remove small plants as they sprout in your area;

• get rid of the cuttings and make sure the roots don’t sprout again by painting it with a registered chemical;

• replace them with indigenous plants suitable for your area;

• plant only indigenous, waterwise plants in your garden or public area; and

• by removing aliens before they become a problem, you will promote not only indigenous plants, but also conserve water resources.

However, not all aliens are bad. Some eucalyptus species, native to Australia, are also a well-known feature of the South African landscape.

The eucalyptus is lauded for its benefits, including being a fast-growing source of wood, oil that is used in clean-

ing materials and an organic insecticide, and their ability to dry up a swamp. The latter is unfortunately also a negative feature, especially in a water scarce country such as South Africa.

Their most important feature is their ability to produce copious amounts of nectar, which is needed by honeybees.

According to the Alien and Invasive Species Regulations, which were promulgated under the National Environmental Management: Biodiversity Act, 2004 (NEMBA) published in the Government Gazette on August 1, 2014, these species include the river red gum (Eucalyptus camaldulensis), spider gum (Eucalyptus conferruminata), sugar gum (Eucalyptus cladocalyx), karri (Eucalyptus diversicolor), saligna gum

(Eucalyptus grandis), and forest red gum (Eucalyptus tereticornis)

Even though these species are listed as invaders in South Africa, they only need to be removed if they are in a place where they have a negative effect on the ecosystem, including biodiversity, water resources, erosion, and an increased risk of fire.

However, if these gum tree species on your property forms part of a bee forage area, a plantation or woodlot, a windrow or lining an avenue, you can apply for a Category 2 permit and keep them.

In the next issue, the thorny subject of prosopis invasion of vast areas of land will be under the microscope.

For more information contact Ken Coetzee at 076-227-5056 or consken@mweb.co.za.

References

Alien Vegetation Management (n.d.). CapeNature

https://www.capenature.co.za/ alien-vegetation-management

Gums and bees: A roadmap for landowners in South Africa. (2018). South African National Biodiversity Institute (SANBI)

https://www.sanbi.org/wp-content/ uploads/2018/05/gumsbees-webversion-hyperlinks.pdf

Inhibit® is ’n breëspektrum swamdoder met beide kontak- en translaminêr-sistemiese werking vir die beheer van verskeie siektes op aartappels en sojabone.

Inhibit® is ’n breëspektrum swamdoder met beide kontak- en translaminêr-sistemiese werking vir die beheer van verskeie siektes op aartappels en sojabone.

Inhibit® is ’n breëspektrum swamdoder met beide kontak- en translaminêr-sistemiese werking vir die beheer van verskeie siektes op aartappels en sojabone.

• Dit is ’n voorkomende, genesende en residuele swamdoder

• Dit is ’n voorkomende, genesende en residuele swamdoder

• Dit is ’n voorkomende, genesende en residuele swamdoder.

• Dit bevat twee aktiewe bestanddele wat ’n breë spekrum van swampatogene beheer Inhibit® is dus die ideale swamdoder in enige spuitprogram.

• Dit bevat twee aktiewe bestanddele wat ’n breë spekrum van swampatogene beheer Inhibit® is dus die ideale swamdoder in enige spuitprogram.

• Dit bevat twee aktiewe bestanddele wat ’n breë spekrum van swampatogene beheer. Inhibit® is dus die ideale swamdoder in enige spuitprogram.

• Voorkom swamdoderweerstand omdat dit aktiewe bestanddele bevat wat baie uiteenlopende metodes van werking het en in verskillende FRAC-groepe val.

• Voorkom swamdoderweerstand omdat dit aktiewe bestanddele bevat wat baie uiteenlopende metodes van werking het en in verskillende FRAC-groepe val.

• Dit is ’n oplosbare konsentraat-formulasie wat bo-gemiddelde benattingseienskappe toon.

• Voorkom swamdoderweerstand omdat dit aktiewe bestanddele bevat wat baie uiteenlopende metodes van werking het en in verskillende FRAC-groepe val.

• Dit is ’n oplosbare konsentraat-formulasie wat bo-gemiddelde benattingseienskappe toon.

• Goeie reën-en besproeïngsvastheid a.g.v. klein partikelgrootte.

• Goeie reën-en besproeïngsvastheid a.g.v. klein partikelgrootte.

• Bied ’n gewasveilige swamdoderopsie.

• Dit is ’n oplosbare konsentraat-formulasie wat bo-gemiddelde benattingseienskappe toon.

• Bied ’n gewasveilige swamdoderopsie.

• Goeie reën-en besproeïngsvastheid a.g.v. klein partikelgrootte.

• Bied ’n gewasveilige swamdoderopsie.

Namibiese Reg. Nr. N-AR1702 Reg. Nr. L10568, Wet Nr. 36 van 1947

Namibiese Reg. Nr. N-AR1702 Reg. Nr. L10568, Wet Nr. 36 van 1947

Namibiese Reg. Nr. N-AR1702 Reg. Nr. L10568, Wet Nr. 36 van 1947

Suitable forage is essential for the survival of honeybees. Strong, healthy bees are in turn needed to provide sufficient pollination for the country’s agriculture in general, and the growing fruit industry, which heavily relies on managed bees to supplement the service provided by wild bees.

Suitable forage is increasingly difficult to find, but bees still need nectar, which provides carbohydrates needed for activity. Pollen provides proteins, fats, lipids, and micronutrients, including sterols, vitamins, and minerals.

Bees cannot function optimally by feeding on just one kind of pollen, such as an apple or almond orchard, or a monoculture crop – they need a variety of crops to feed from.

Malnutrition of bees is not only the failure to get enough food, but the absence of the right mix of food. Bees cannot survive and function on just one type of nectar and pollen – they need a balanced menu. A lack of suitable forage – including a variety of wild flowering plants – leads to malnutrition. That in turn leads unhealthy bees that are more vulnerable to pests, disease, and

poison. Plant biodiversity is therefore extremely important for the survival of bees.

It is equally important for increasing pollination services. Statistics provided by Hortgro, a research institute for the deciduous fruit industry, show that 91 000 swarms (or hives) of honeybees are presently needed for commercial pollination of fruit orchards. This number is increasing by 15% per year. In five years, an expected 100 000 swarms will be needed to provide sufficient pollination.

Fruit growers in the Langkloof, Elgin-Grabouw-Vyeboom-Villiersdorp (EGVV), Ceres, and Klein-Karoo areas of the Western Cape, depend on commercial beekeepers to provide swarms for the pollination of their fruit, vegetables, nuts and edible oil crops.

Suitable forage is shrinking because of the following reasons, among others:

• natural veld must make way for agricultural to feed a growing human population;

• pesticides designed to make agriculture more profitable are taking their toll on pollinating insects, especially honeybees;

• the felling of blue gum trees in accordance with legislation for the control of alien plant species is removing valuable forage;

• The unsuitability of mountain fynbos means greater demand for bee forage elsewhere.

The reason why mountain fynbos does not provide sufficient forage for bees is because of the low nutrients in Table Mountain sandstone. Bees will survive, but with minimal honey and they struggle because the plants simply don’t secrete enough nectar. Those same plants growing in better Duineveld soils do supply adequate nectar.

Ahead of the pollination season during spring and early summer, the commercial hives need forage that is rich in pollen and nectar to build healthy and strong swarms for the pollinating task

ahead of them. Canola fields that offer an abundance of nectar and pollen provide good forage.

After the pollination season, these swarms need to rebuild the strength of the hive to help them survive through winter, and hives are often placed in or near areas where natural fynbos occur, such as conservation areas with indigenous plant species. At present, hives are not permitted to be placed inside conservation areas.

The placement of commercial hives near such a reserve gave rise to the concern that commercial swarms placed there may threaten the survival of wild bees and other pollinators.

An assumption was made that managed honeybees may be overstocked on fynbos, and therefore threaten the biodiversity of the fauna and flora.

The community of the Duineveld, a 50 km stretch of unspoiled fynbos along the Southern Cape coastline, expressed this concern regarding the unique type of fynbos, known as Strandveld dune thicket.

“The Duineveld is vitally important for forage to support the increasing number of bees necessary for commercial pollination,” said John Moodie of Honeywood Farm near Swellendam in the Western Cape. John has been keeping bees for more than fifty years and he is a recognized and knowledgeable role player in the bee industry.

Speaking at the annual general meeting of the Duineveld Conservation Group in 2021, John said very few beekeepers have their own land, so they depend on other landowners for forage sites. “Beekeepers always need sites for honey, but the need for increasing numbers of honeybees for agriculture, makes it even more important.”

On the question whether fynbos species and other pollinators were

threatened by overstocking of honeybees, John gave a resounding no.

Firstly, there are no alien bee species in Africa, as is the case in the USA, Australia, and Europe, where all honeybee species are exotic alien invaders. “In Europe and the UK, most of the indigenous honeybee species have died out because of bad management and disease,” said John.

Ten of the world’s 24 races of honeybees occur in South Africa. In the Western Cape, the Capensis is a unique honeybee in the fynbos area. It has recently been found that these bees can clone themselves, and for this reason there is a ban on moving bees from the southern provinces to the northern provinces, where the Scuttelata bees occur – hence the Scuttelata line, an imaginary border stretching from the town of Vredendal in the Western Cape to Willowvale in the Eastern Cape.

Secondly, he based his response on research done by Mariette Brand in 2009, while she was a doctoral student at the University of Stellenbosch. Mariette placed eight beehives in the De Hoop Nature Reserve for one month to determine the influence managed hives may have on wild bees and other pollinators. She found that these swarms had no negative effect on the activities or survival of wild bees or other insect pollinators.

Institute, in his studies on competition between African honeybees and other subspecies in South America, found that they affected only the alien European honeybee populations, but no other wild bee species. He also found that African honeybees did not change pollination stability or species decline.

The price of honey According to John, honeybees are not a threat to wild bees, as they belong to the same subspecies.

“Landowners should be much more concerned about the threat of alien Argentinian ants and alien vegetation, such as Acacia cyclops (rooikrans).”

Ants compete for nectar, while dense stands of rooikrans have invaded vast tracks of land, threatening the Duineveld fynbos. A gall-forming biological control insect, Cecidomyiid Dasineura Dielsi, was introduced into South Africa for biological control, but with limited success.

Beekeepers must by law register with the Department of Agriculture for

the control of disease. “Beekeepers do not comply easily, but regulations are in place,” says John.

“The real problem is that a functioning swarm of honeybees consumes 60 kg of honey per year to survive. Where is this going to come from if not from crops, Duineveld or gum trees? In real cash terms, that means R100 x 60 = R6 000 if fed honey, and a bit less if they are fed sugar, but this is still a considerable amount.

“Are growers even aware of the absolute bargain they are getting for pollination service, and are consumers aware of what a realistic price should be for a jar of honey?

“Beekeepers also totally underrate the value of their product or the valueadded service their bees provide.”

Bees

Growers of vegetable seed rely on bees to pollinate their crops.

Contact details John Moodie at john@honeywoodfarm.co.za

Pain, S. (2017, April 12) The whole food diet for bees. Knowable Magazine https://knowablemagazine.org/ article/sustainability/2017/wholefood-diet-bees

Melin A, Rouget M, Midgley J, Donaldson JS. Pollination ecosystem services in South African agricultural systems. S Afr J Sci. 2014;110(11/12), Art. #20140078, 9 pages. http://dx.doi. org/10.1590/ sajs.2014/20140078

Root, R.B. (2004, September 9). Argentine ants in the South African fynbos: effects on proteas and their arthropod visitors. Cornell University https://reeis.usda.gov/web/ crisprojectpages/0189503-argentine-ants-in-the-south-african-fynbos-effects-on-proteasand-their-arthropod-visitors.html

Roubik, D. (September 2009) Invasive Africanized honeybee impact on native solitary bees: a pollen resource and trap nest analysis: Responses to invasive honey bees. Biological Journal of the Linnean Society 98(1):152 – 160 DOI:10.1111/j.10958312.2009.01275.x

Now there’s honey for thought!

As the use of greenhouses spreads over Sub-Sahara Africa, it is more than paramount to ensure that the artificial climatic conditions created are optimally maintained. Not only does sustaining these conditions ensure that crops under protection have a higher yield, but it also improves the marketability of produce from the structure. In cases of high value produce smart greenhouse systems are extensively used.

According to the article Smart Greenhouse published on the United Kingdom Designing Buildings webpage, the smart greenhouse is a revolution in agriculture, creating a self-regulating, microclimate suitable for plant growth through the use of sensors, actuators, with monitoring and control systems

that optimise growth conditions and automate the growing process.

The global smart greenhouse market was valued at approximately USD 680,3 million in 2016 and is expected to reach approximately USD 1,31 billion in 2022, growing at a CAGR of 14,12% between 2017 and 2022.

Smart greenhouses are comprised of heating, ventilation, and air conditioning (HVAC) systems, light emitting diodes (LED) for grow lights, internet of things (IoT) and communication technology, irrigation systems, materials handling, valves and pumps, and control systems.

HVAC uses various technologies to control the temperature, humidity, and purity of the air in the greenhouse to

provide thermal comfort and acceptable indoor air quality. LEDs are luminaires utilised in an efficient way to produce the correct light for growing plants.

Communication technology equipped with current sensors automatically records and disseminates information on the greenhouse environment and crops on a continuous basis. The data is collected and supplied into an IoT platform, where analytical algorithms turn it into actionable insight to identify bottlenecks and anomalies. This process ensures that HVAC, lighting operations, irrigation and spraying operations may all be controlled on demand.

Irrigation systems usually employ an

autonomous irrigation controller that is useful in effectively managing water levels in the soil which is applied by use of drip irrigation, overhead sprinklers, or a boom system consisting of one or more pipes with nozzles that apply water as the system moves over the plants.

Materials handling equipment can be in the form of rolling belts and transport lines, and even harvesting robots, that are able to go down greenhouse aisles accurately identifying ripe produce, harvest them and place them in on-board boxing systems.

Valves and pumps control the pressure and quantity of water and respond to the recommended irrigation time for the smart green house. The control system uses soil moisture, temperature, and humidity sensors, light intensity, and carbon dioxide sensors to collect measurements and display them on a real time screen. The climate parameter values can be manually set online. The collected values from the sensors are then compared with the set of standard values, and then the lights, ventilation fans, warming lamps, water pumps and other facilities automatically start to adjust the climate by correcting the light intensity, carbon dioxide concentration, temperature, air humidity and soil moisture of the greenhouse to the required parameter values.

The major benefits of smart greenhouses are that it is able to maintain ideal micro-climate conditions. The complementary IoT sensors allow farmers to collect various data points

at unprecedented granularity.

They provide real-time information on critical climate factors such as temperature, humidity, light exposure, and carbon dioxide in the greenhouse.

These greenhouses enhance irrigation and fertilisation practices to be on par with the actual needs of cultivated plants for maximised yields. Parameters such as soil salinity are also well maintained.

The collaborative functionality of the machine learning platform, data regarding the greenhouse environment, external weather and soil characteristics reveal valuable insights into existing risks of pest and fungi infections enabling farmers to apply chemical

Smart greenhouses create a self-regulating, plant-growing microclimate using sensors, actuators, and monitoring and control systems to optimise growth conditions and automate the growing process.

(Source: postscapes.com)

treatments in a timely manner at the lowest cost.

IoT sensors in smart greenhouses provide an affordable infrastructure to monitor door status and detect suspicious activities preventing thefts and improving security. If they are connected to an automated alarm system, they instantly notify growers when a security issue arises.

Plant management can be done remotely as growers are notified of everything on any smart device through diverted alerts and notifications.

The downside of smart greenhouses are the high upfront and operating expenses, and the need of an expert to set up the greenhouse. The farmer also must have plenty of knowledge to grow crops successfully, there are high operational costs in maintaining the system, and significant efforts are required to keep the system running.

For farmers that desire to produce first grade produce, smart greenhouses are a viable option and as technology improves in Sub-Sahara Africa it can be expected that the number of specialist smart greenhouse farmers will grow.

Technology is the key that can unlock the potential of aquaculture. A conference on new and advanced techniques in aquaculture, aquaponics, and hydroponics was presented in collaboration with the University of Stellenbosch in Stellenbosch from 22 to 24 November.

Henk Stander, Principal Technical Manager at the Department of Aquaculture at the University, highlighted the development of aquaculture. His presentation provided some background, while others highlighted some aspects of the industry.

Aquaculture refers to the farming of aquatic organisms including fish, molluscs, crustaceans, and aquatic plants in all types of water environments. Farming implies a measure of intervention in the rearing process to enhance production, including regular stocking, feeding, and protection from predators. Farming also implies individual or corporate ownership of the stock being cultivated.

Aquaponics is a food production system that couples aquaculture (raising aquatic animals such as fish, crayfish, snails or prawns in tanks) while hydroponically cultivating plants in nutrient-rich water.

Hydroponics is a type of horticulture and a subset of hydroculture which involves growing crop plants without soil by using water-based mineral nutrient solutions in aqueous solvents, or with their roots mechanically supported in an inert medium such as perlite or gravel.

Aquaculture’s growth

Fisheries and aquaculture sectors have been increasingly recognized for their essential contribution to global food security and nutrition in the 21st century. The consumption of aquatic foods has increased at an average rate of 3% per year between 1961 and 2019.

With an annual growth rate of 5,8% since 2010, it is the fastest-growing food-producing sector. In 2018, 114,4 million tonnes of live weight, valued at US$ 263,6 million, was produced. Aquaculture provided more than 50% of the fish consumed globally, and it is expected to grow to 202 million tonnes by 2030.

Capture production or fishing has plateaued due to overfishing, but the demand is increasing, and aquaculture must fill the gap, especially in Africa.

In Africa, 2 196 million tonnes of aquatic species are produced annually, which is about 2,67% of global production. Nearly all of it (99%) is produced in inland waters. In 2018, Egypt, the largest producer since 1950, produced 71,10%, followed by Nigeria with 13,26% (mainly catfish). South Africa is the 10th largest producer at 0,28%.

In South Africa, production was 6 365,8 tonnes, worth approximately R1 billion, in 2018. These include mainly high-value species such as trout, abalone, oysters, and mussels. Trout is the dominant freshwater species (±1 503 tonnes, valued at about R98 million), followed by catfish (20 tonnes, valued at ± R0.5 million), and Tilapia (571,3 tonnes, valued at ± R25 million).

Marine species contributed about 67% of production by quantity and 85% by value. This is dominated by abalone, with 1 522,2 tonnes in 2018. The estimated value is US$48,98 million. In 2018, the total marine finfish production was about 73,8 tonnes valued at ± US$ 5 million, mussel production was about 2 182 tonnes valued at ± US$ 2 205 691, and oyster production was about 466,3 tonnes, worth approximately US$1 132 652.

Developing sectors in South Africa include tilapia, catfish, marron, seaweed (for abalone feed), and prawns. Marine species, including cob, yellow-

tail, tuna and sole, have high yields and high value, and are dependent on the development of offshore aquaculture technology.

The selection of a suitable species depends on the temperature and quality of water, control of reproduction and the efficiency thereof, the availability of infrastructure and feed technology, as well as marketability.