Every family needs a strong big brother to do the heavy lifting.

I might be small, but I am powerful for my size.

My passion is ensuring the farm animals are fed.

Harvest time is my time to shine.

Colour in this page to stand a chance to win a 9R Lego Set. Take a photo of you with your colouring picture showcasing your uniqueness and upload it onto social media with the hashtag #OKDeere and tag @JohnDeereAME. Make sure your profile is set to public.

The competition is open to anyone aged 12 or under living in South Africa. T’s and C’s Apply. Entries close 31 January 2023. Full competition rules are available at https://www.deere.africa/en/ our-company/news-media/news-releases/2022/nov/competitions-terms-and-conditions/.

Afresh, new year lies ahead of us, waiting to be welcomed, experienced, played, celebrated, explored, shared, deepened and enriched. Our sincere wish for all our farmers and advertisers is that it will be an especially good year!

The year 2022 was an eventful one, to say the least, especially in the agribusiness sector. Many challenges came to the fore, such as job creation, electricity supply, water availability and quality, climate change, to mention but a few.

Undoubtedly, we are entering 2023 with a number of these issues creating uncertainty, and they will require our undivided attention.

With the challenges of greater uncertainty, less control, and greater risk, more opportunities present themselves. I urge the agricultural sector and farmers to identify and exploit these opportunities, and to continue working smart and planning ahead to ensure that we manage the setbacks brought about by these challenges as best we can.

Despite the looming crises of power outages, on a positive note, farmers in Zimbabwe have reported that they have planted double the number of hectares of maize to date in 2022, compared with the same time the previous year. The maize planting target for the 2022/23 production season was just under two million hectares. Cotton plantings had also increased from almost 8 556 ha by December 2021 to 13 166 ha by December 2022.

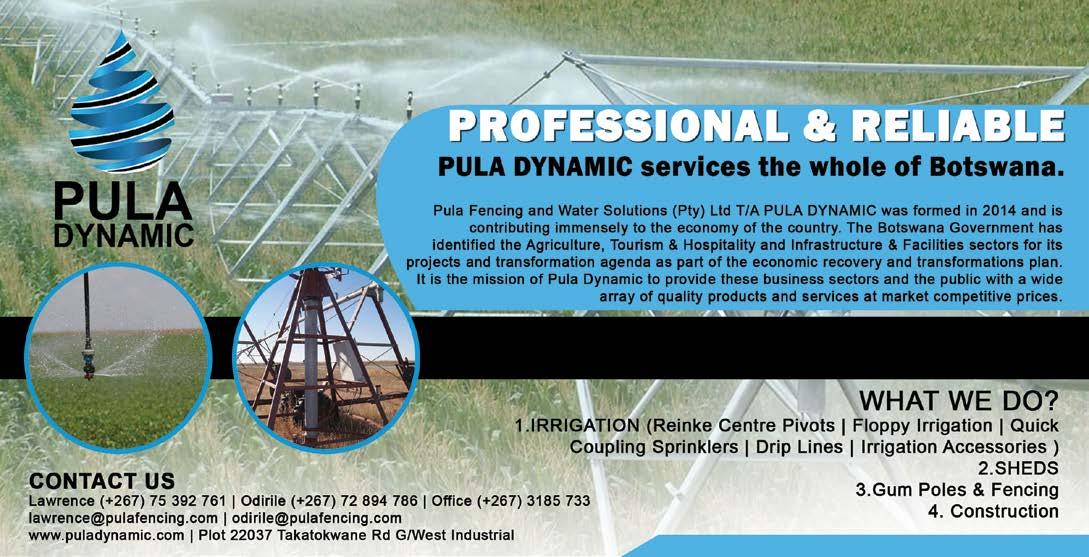

News from Botswana is that the United States (US) Conservation

International, United Nations (UN) Green Climate Fund, and Botswana’s Ministry of Agriculture recently launched a new initiative intended to restore communal rangelands and improve the grazing on farmland in Botswana. The project is expected to run until 2030 and will be funded by the Botswanan government to the tune of US$54 million (about R953 million), with another US$44 million (R776 million) coming from the US Conservation International & UN Green Climate Fund, according to Botswana’s Ministry of Agriculture.

It is vital for all African countries to become less dependent on the importation of food such as maize and other grains, and to become self-sufficient. Africa has the potential to feed itself and this potential needs to be developed. I truly believe that Africa is a slumbering economic giant that needed to be made aware of its own economic and agronomic potential in order to take care of its own, and to become a major global role player.

Let’s make 2023 the best year, yet! We are excited to present to you yet again another exclusive copy of ProAgri where we discuss everything in the farming space. We promise to keep the momentum going and give you the information that is vital for your business.

ProAgri greetings

Bianca Henning

bianca@proagri.co.za

Macadamia production is an increasingly competitive business and an excellent investment for farmers as it is very profitable. Precision irrigation is ideal for macadamia, as it delivers water at the same rate that the plant absorbs it, ensuring the soil moisture is always at the optimal level the tree needs.

577 Rossouw Street, Die Wilgers, Pretoria +27 (0)79 515 8708 www.proagri.co.za

Copyright © 2023. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

Editor Bianca Henning >

Reporters

Benine Ackermann >

Maryna Steyn >

Natasha Pansegrouw>

Specialist Writer Annemarie Bremner >

+27 82-326-2572

bianca@proagri.co.za

+27 73-105-6938

benine@proagri.co.za

+27 82-261-9177

maryna@proagri.co.za

+27 81-736-4236

natasha@proagri.co.za

+27 82-320-3642

annemarie@proagri.co.za

Client Relations Manager

Carin Swartz >

Marketing Manager

Diane Grobler >

Marketing

Xander Pieterse >

Johan Swartz >

Tiny Smith >

Agrico: Micro-irrigation that makes sense

JVA proudly introduces the Cloud Router App

Implements with your needs in mind from Ripper Tillage Equipment

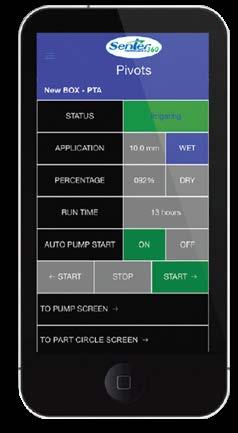

Irrigation without irritation: Senter360 pivots

Beekeeping Part 6: Feed

Silkworms to silk garments Part 1: Mulberry tree cultivation

Technews: The latest in agricultural technology from around the world

Fruit production Part 1: Glorious granadillas

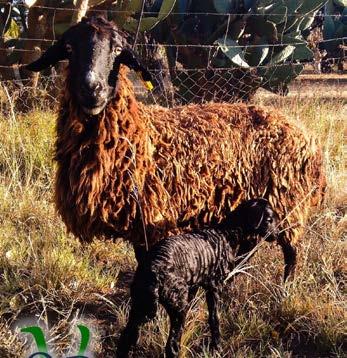

Sheep breeds Part 3: Native sheep breeds of Southern Africa

Introduction to spice and herb production in Africa

African agribusinesses can still grow Part 2

Plastic use in the agricultural sector

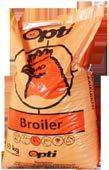

Greenhouses part 3: An option for maximised production

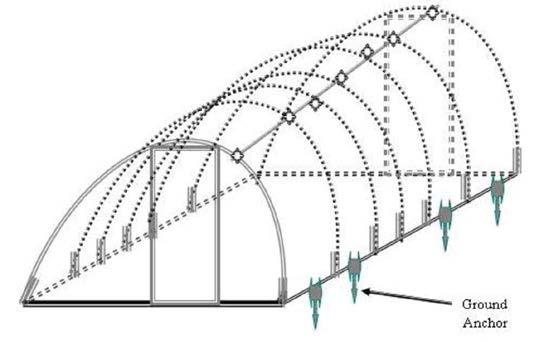

Invasive alien plants Part 1: Prosopis' rampant spread causes concern

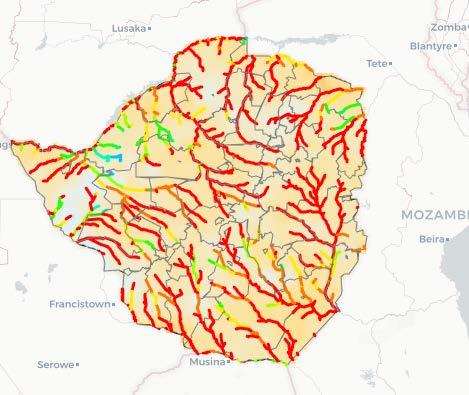

Power cuts cripple homes, businesses hard in Zimbabwe

Tree nut production in sub-Saharan Africa Part 4

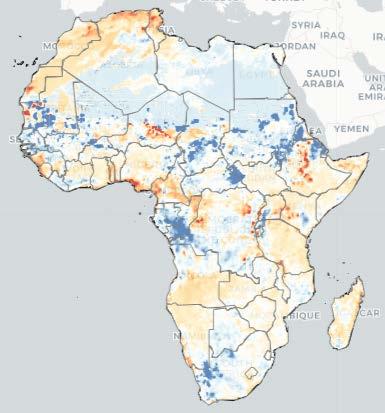

Drought effects in sub-Saharan Africa

Lynette van Tonder >

Creative Director

Christiaan Joubert >

Design

Michelle Kruger

Enquiries

Engela Botha >

+27 84-233-0123

carin@proagri.co.za

+27 82-555-6866

diane@proagri.co.za

+27 79-524-0934

xander@proagri.co.za

+27 71-599-9417

johan@proagri.co.za

+27 82-698-3353 tiny@proagri.co.za

+27 74-694-4422 lynette@proagri.co.za

+27 72-419-3990

christiaan@proagri.co.za

+27 12-803-0782

engela@proagri.co.za

Distribution and subscription

Nita Volmer-van Zyl >

Accounts

Ronel Schluter >

Business Manager

George Grobler

+27 79-515-8708 nita@proagri.co.za

+27 12-803-0782

accounts@proagri.co.za

A new year lies ahead: Hope for progress, despite uncertainty

Agood farmer does not randomly decide what he wants to farm with and how he wants to go about it. No, he investigates the most profitable practice and crop that grows in his area, as well as how much soil and water are needed — that makes sense!

Rob and Keegan Hughes of Thulani Macs feel that way too. This father and son duo farm 20 km outside Empangeni in the Heatonville area. Rob is a property developer and owns a game farm. In 2019, they decided to take on farming after being inspired by the success of macadamia farmers in the area.

They acquired land with a good source of water and then approached Willie Vosloo from Agrico in Empangeni. He helped determine exactly where the irrigation points — and therefore the orchards — should be established. Soil preparation started in the beginning of 2020, and the first tree was planted in 2021.

Today, the 105 hectares of high-density orchards consist of 43 780 trees.

Macadamia groves with micro irrigation that are sensibly laid out "We approached several macadamia farmers along the coast for information. They were eager to share advice," Rob recalls. "But before we did anything, we first thought about it and asked: Does it make sense? We approach everything that way.

"We asked Willie to help plan the water supply," says Rob. Agrico handles the design of the system, from surveying to layout. The farmer can install the system by himself or use contractors, but Agrico remains involved throughout.

For this farm, water is pumped from the Mhlatuze River and stored in an earth dam. It acts as a buffer dam and helps the silt settle down so cleaner water is pumped through the system.

Micro irrigation was set up for various reasons. A microsystem can easily be converted to drip irrigation if there is a water shortage in the future. One can also see when the apertures are blocked, and as a bonus, it helps to

protect the orchard against wildfires.

There are two 73 kW motors connected to KSB pumps which direct water to the various blocks. The blocks are divided according to the water requirement of the soil type and the slope on which it stands.

Each pump has variable speed drive (VSD) which helps control the pressure at the different slopes and lowers the general electricity costs.

The system is built to apply 3,5 mm of water per day. Cycle lengths vary from three to six days, depending on the soil characteristics and the weather conditions.

After the irrigation planning, the land was cleared, and tillage began. Lime and gypsum were worked into the soil under the recommendation of an agronomist who identified the varying soil types. Ridges were made with a plough on which the irrigation pipes were laid and the trees were planted.

Each tree can be identified with GPS guidance thanks to a system designed by Keegan. "We initially measured by hand where each tree should be in a block, but it was difficult to be accurate and time-consuming. This electronic system ensures that each tree stands three meters from its neighbours. It is quicker too," Keegan explains.

The varieties they plant are A4, 695, 816, 863, 8.4 and N2. "We alternate two varieties per block, with four rows of one variety and then four of another. Between each row, we plant Napier grass which acts as a wind buffer," he says. "These varieties are planted because the flowering periods overlap and ensure cross-pollination."

The Hughes follow an organic approach to their farming.

“We avoid chemical pesticides and fertilisers, and we have not yet needed to add any fertilisers. Leaf and sap tests indicated that our trees are happy," Keegan says.

Instead, they use cow manure that

by Maryna Steynhas broken down into compost to feed the roots naturally. The kraal manure is supplied to them by a local cattle farmer. When an extra boost is needed in the future, the piggy system – a stainless steel tank that withstands pressure up to 10 bar – will assist in fertiliser application. It is connected to the water that flows towards the orchard; soluble or liquid fertiliser is poured into the "piggy's" stomach and then the orchard is fertigated.

There are bees on the farm to help with pollination, a game fence that keeps bush pigs out and they have also erected posts for the forest buzzards that keep rats under control. Furthermore, they use mulching to keep the moisture in the soil, cool the irrigation pipes and create a favourable environment for micro-organisms. It also controls weeds.

To locate your nearest branch, visit Agrico's website at www. agrico.co.za or call Willie Vosloo on (+27)35-787-1949 or by mobile on +(27)82-571-2452.

The JVA Cloud Router™ App allows you to arm and disarm energizers, view your electric fence voltages, open and close relays through any Android or IOS device. The JVA Cloud Router™ App provides Real-time push notifications of Alarms, as and when they happen. With a touch of a button, you can see what is happening with your JVA sites and take the necessary steps to address any problems that may arise.

Control and monitor multiple sites such as your home, farm, factory, or office from the palm of your hand, anywhere in the world.

This is now all possible through the innovative JVA App development as a security and agricultural solution for our new and existing JVA clients at no additional monthly cost. The innovative dashboard allows you to view your sites at a glance and peruse historic event activity such as logs and

device graphs - keeping you in control of all your JVA sites.

The JVA Wi-Fi Gateway connects a group of JVA Z-Series devices to the Cloud Router™ App via an existing Wi-Fi network. The JVA Cloud Router™ App gives you a single dashboard to view and conveniently control your electric fence sites, gates, beams and alarm systems.

The JVA Wi-Fi Gateway enables any JVA Security Energizer, JVA Monitor or

• Site sharing with select user privileges

• History and event logs

• No monthly fees

• Available to download on Android and IOS devices

Test out the JVA Cloud Router™ App by following the below steps:

1. Download Cloud Router through the Android Playstore or Apple iStore.

JVA IP accessory to be added to the JVA Cloud Router system. The single dashboard to view and conveniently control your security sites makes it user-friendly, and the real-time push notifications allow for the most effective way to manage all your sites. One Wi-Fi Gateway can take register up to fourteen JVA Z-series devices, ensuring it can provide an economic offsite alternate gateway and backup for any large site. If Wi-Fi is not available, any of the JVA 3G or 4G GSM gateways can be used to ensure your sites remain connected.

The JVA "Cloud Router™" App:

• Controls and monitors multiple JVA sites

• Real-Time push notifications of events and alarms

2. Log into the JVA Cloud Router App: E-mail: cloud@pakton.com.au

Password: cloud1234!

3. Control and monitor the JVA Brisbane Office from halfway across the world!

The following link - https://www.jvafence.com/security/cloudrouter/ index.html will allow you to watch the real-time stream of the system you are controlling at our Brisbane office in Australia.

For more information on the JVA Cloud Router™ App or JVA Electric Fence Energizers and Devices, visit www.jvasecurity.com to locate your nearest dealer.

by Maryna Steyn

by Maryna Steyn

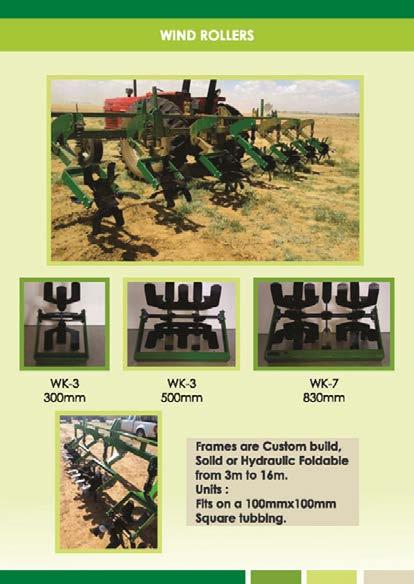

Ripper Tillage Equipment offers more than robust and efficient implements; they start every customer journey with the question: What are your requirements? This includes the needs of your business according to the scale of your farming operation, the soil type, structure, and the crops you plan on planting.

By asking this question, Ripper Tillage Equipment is able to offer you, the farmer, the solution that fits your unique requirements. “We consider how the soil needs to be prepared for the type of crop the farmer wants to plant,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains.

This manufacturer designs and builds implements for every part of seedbed preparation and planting needs: before planting, during planting and after. This includes rip-till and strip-till equipment, rotary hoes and planting equipment.

“We specialise in rip-on the row. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Rip-Till equipment means the same seedbed, but different result Rip-till seedbed preparation means deeper tillage (deeper than 300 mm) that loosens the undersoil to ensure an even seedbed just like strip-till.

With conservation farming becoming more and more popular, conservation tillage is also increasingly popular. Rip-till implements from Ripper Tillage Equipment are ideal for this task, and what is more, their rip-on-the-row equipment delivers tillage that keeps soil moisture locked in.

On-the-row rip means you only till the soil in the row where your planter will carefully place the seeds. When, for example, using a 0,9 m (3 ft) 8-row planter, you will also use a 0,9 m 8-row ripper instead of ploughing the entire area of your field.

This process involves:

• cutting of residue with a cutting coulter

• row cleaning

• rip and optional fertilize placements

• closing of furrow and compressing with a roller

Because there is less soil tilled over a large area, the machinery – tractor included – has less wear. What is more, you also use less fuel and require less labour.

“Our rotary hoe (rolegtand) is very popular for after-planting seedbed care when it comes to crumbling soil after heavy rain,” she adds.”

Tillage is more than implements, it is caring for the soil

Ripper Tillage Equipment employees are skilled in identifying soil requirements. “We come to your farm, do a soil analysis with a demonstration, and determine the type of implement that will give you the best results,” Christine explains.

“We consider the type of soil on your farm as well as the last crop you planted – for example residue management. When we look at the soil condition, we understand how to help the farmer plant his next crop in the best possible way. We can suggest the implement

with the right tines or closing coulters to get the job done.”

This is the added benefit of custommade implements: Guidance and expertise in what is best for your soil. Because soil conditions and crop needs differ from area to area, investing in exactly the right tools that give you the maximum results help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need. You won’t find a ready-made “one-sizefits-all” implement on a show floor.

“Maintenance is also fairly easy and inexpensive, because most parts are available locally,” she adds.

For more information on customised equipment for your seedbed preparation, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbothariptill@ gmail.com. Check out their visit website at: www.rippertillage. co.za or find them on Facebook: www.facebook.com/RipperTillage.

by Benine Ackermann

by Benine Ackermann

Satisfied farmers in more than half of the African continent’s countries depend on Senter360 for quality irrigation solutions.

Senter360’s policy is to not only sell the best possible products, but rather offering a long-term solution to their customers with a mutual win-win attitude.

“Over the years we have built good relationships with our customers in Southern Africa,” says Theuns Dreyer, Managing Director of Senter360. “We are excited about 2023, expecting even more growth. We also have an interesting addition to our product range to be introduced during 2023.”

Senter360 products are designed to be exceptionally strong. “They are designed to survive in tougher than usual conditions in remote areas, keeping them running reliably for longer. It is also interesting to note that pivots sold in Africa are usually larger than those sold in South Africa,” Theuns added.

A Senter360 pivot has a modular design throughout. This means a lower impact on the variety of spares required to build the machine, and therefore also to maintain it.

“The capital outlay for spares in remote areas is therefore smaller, making it easy to have a full range of spares ready in remote areas.”

"We have many dealers and knowledgeable contact people across the continent to support our clients. We also gladly visit farms where and whenever required,” he added.

“As mentioned before, our modular design with resulting advantages and outstanding structural falling strength of more than 2,5 times its own weight when filled with water, combined with its exceptional sideway stability withstanding winds above 158 km/h all add to its resistance to possible damage under extreme conditions. This is far more than any international competitor has to offer,” Theuns added.

Their centre pivots are made in South Africa and tailored to their client’s specific needs. “A pipe frame is used instead of the typical angle iron used for international centre pivots. With this method, we can increase the arc strength of our centre pivot while decreasing the wind resistance,” Theuns explains.

Senter360 also has an internet based application for farmers to use. With an internet connection, the centre pivot can therefore be controlled from a distance from the farmer’s phone, and the application can be used to track where the pivot is.

“Our modular design, combined with its exceptional sideway stability all add to its resistance to possible damage under extreme conditions.”

Please do not hesitate to contact Theuns Dreyer directly for more information and local support: Call Senter360 at (+27)82-564-5955, or visit their website at www.senter360.co.za.

In a previous chapter, we had a brief look at the need for suitable forage for bees and the value of placing your hives near such a source.

In this chapter, we look at what bees feed on and why they choose those foods. The honeybee’s basic nutritional requirements are like those of humans; namely, they need proteins (amino acids), carbohydrates (sugars), minerals, fats/lipids (fatty acids), vitamins, and water. To meet their nutritional requirements, honeybees collect nectar, pollen, and water.

Honeybees eat honey, which is processed nectar, and bee bread, which is processed pollen. The honey serves as a primary source of carbohydrates, which provides energy for flight, colony maintenance and general daily activities. Nectar, and thus honey, also provide minerals like calcium, copper, potassium, magnesium, and sodium, the presence and concentration of which depends on the source of nectar.

It is therefore very important that

the colony has sufficient stores of honey for the winter months, for, without it, the colony will grow weaker and die.

Bees forage for water at almost any source close to their colonies. These sources include ponds, streams, leaky taps, the neighbour’s pool, dog dishes, and bird baths. During hot weather, honeybees use water to cool the colony by fanning and evaporating water droplets inside the hive. Water may also provide essential minerals in addition to hydration.

Bees forage mainly for nectar and pollen provided by flowering plants but also for resinous flowers of trees, and, if it is available, they also make use of honeydew. Bees collect any sweet substance, including sugar water, cool drinks, even overripe fruit, and proteins from animal feeds. “One can often see bees feeding on the fine pollen dust emanating from grain mills, and bags of mixed pig feed,” says Charles Salmon of the Western Cape Department of Agriculture.

It is important to keep in mind that bees forage with the sole purpose of feeding themselves to keep the swarm healthy and productive. Seasons come and go and in times of plenty, these industrious insects will work hard to collect as much feed as possible so that they can survive during lean times.

The products of the hive give a good indication of why bees need specific food. Besides honey, other products found inside a hive include propolis, pollen and wax.

Honey is the primary product of a hive. The worker bee uses her long tongue to collect the flower’s nectar and store it in her nectar stomach. When she returns to the hive, she regurgitates the nectar and hands it over to a worker bee inside the hive. It is this second bee’s job to remove moisture from the nectar.

A physical process is used to remove most of the moisture, while a chemical

Wax cells filled with honey, which the bees produce from the nectar.

Wax cells filled with honey, which the bees produce from the nectar.

process uses enzymes to change the sugar in the nectar to honey sugar.

The bee that receives the nectar from the returning worker bee moves to a part of the hive where there is air circulation. The bee regurgitates the nectar to the point of the tongue to expose it to air. She swallows it again and repeats the process with the next drop of regurgitated honey. This continues until the moisture content is reduced from 60 to 80% to 16 to 20% before she deposits it into a cell on the honeycomb. If the moisture is not removed, the nectar will ferment and rot.

Bees whose job is to ventilate the hive by whirring their wings, circulate dry air in the hive to continue the evaporation process. Raw nectar con-

sists of three sugars: sucrose, glucose, and fructose. As the process nears its end, the honey is deposited into empty wax cells and covered with a layer of wax to store the honey.

Pollen is the male reproductive unit of plants and is essential for pollination. Bees do not produce pollen but collect it from plants and store it in the honeycomb cells. By mixing it with honey, the pollen is preserved so that it is available for the bees to feed on. Humans use pollen in some medicines and cosmetics.

Propolis is the third most important component of bee products. It is composed mainly of resin (50%), wax (30%), essential oils (10%), pollen (5%) and other organic compounds (5%).

It is a resin-like material made by bees which are collected from different plants like fynbos, the buds of poplar and cone-bearing trees. The bees use it to protect their nest against disease and pests; by repairing holes in the hives, they protect it against rain and wind. Propolis has antibiotic properties, and it is used for medicinal purposes.

Wax flakes are excreted by young worker bees. The bees chew, shape and use the wax to build the cells of the honeycomb. New wax is white in colour, but it turns darker when it is in contact with the brood. When the larva outgrows the cell, it leaves behind its skin in the wax cell filled with honey, pollen or propolis.

“The colour of pollen differs greatly and is not always bright yellow. An aloe species provides orange-red pollen,” says Charles. Some beekeepers believe that different colours of pollen in a hive

are an indication of a variety of feed plants, which is ideal.

Humans use wax for the manufacture of candles, cosmetics, food processing, polish, and medicine, among other things.

Bees use their poison to protect themselves. The poison is manufactured in bees between three- and 21 days old. It has medicinal value and is used as a medication for rheumatism.

Royal jelly is a white and viscous jelly-like substance secreted by worker bees. It is a superfood that is consumed by the queen bee, which probably contributes to her living much longer than other bees. It is also fed to immature young larvae in their first two to three days of maturation. Royalactin is the main compound in the royal jelly, which allows the morphological change of a larva into a queen bee.

Where does nectar come from, what does it consist of and why is it important for the bees?

Nectar is a sugar-rich liquid that is produced by plants’ nectar glands, called nectaries. These glands can be situated inside the flower, or on the leaves or stem, also called extrafloral nectaries. These provide a nutrient source to animal mutualists, such as ants, which in turn provide protection against herbivores. ‘

A nectary is a floral tissue that can be in different parts of the flower. It is one of the different secretary glands

that produce nectar, oil, or scent.

The function of these glands is to attract possible pollinators, such as bees, wasps, butterflies, moths, and mosquitos, as well as birds such as hummingbirds, honeyeaters and even bats.

Once a pollinator has visited the flower, the leftover nectar can be reabsorbed into the plant. Several factors influence the production of nectar, such as the age of the flowers, the location of the plant, whether the honeybee can reach the nectar, as well as the management of the habitat, such as enough water. According to Charles, the soil type, such as the lime content, also contributes to good honey production.

Pollen is a powdery substance produced by male plants. The pollen grains produce male sperm cells. When a sperm cell comes into touch with a female plant’s stigma, it moves down the style to the ovary, where they germinate.

Pollen in the form of bee bread is the honeybee’s main source of protein, while it also provides fats, minerals, and vitamins. The protein is important for brood production and the development of young bees.

Pollen consists of water, ether extract, carbohydrates, including reducing

sugars, nonreducing sugars, starch, lipids, ash, and some other contents. Because not all pollens are equally nutritious to bees, they need different sources of flowers to provide all the components.

Honeybees apparently choose pollen based on the odour, shape, and size of the pollen grains. A colony with a typical size of about 20 000 bees, collects about 57 kg of pollen per year. Between 15 and 30% of the colony’s foragers collect pollen and a single bee can bring back a pollen load of about 35% of the bee’s weight in the pollen baskets on its hind legs.

Bees collect pollen from pollen-bearing flowers for protein-rich feed.

The queen bee cells differ from ordinary cells in which eggs are laid.

Once the pollen has been brought to the hive, the workers condition it by adding glandular secretions that contain enzymes and acids. These secretions prevent harmful bacterial activity so that the pollen can be stored as bee bread.

The bees also add beneficial microbes to the pollen and produce enzymes that help the pollen release nutrients and amino acids, the building blocks of protein.

The colony consumes the bee bread relatively quickly and it is only stored for a couple of months, and only if there is a surplus. The colony requires about 15 to 55 kg of pollen per year. They use pollen for growth and development. Immature bees are fed a mixture of brood food and bee bread. Newly emerged bees eat bee bread to help their bodies reach maturity and the requirement of a single worker larva is about 124 to 145 mg, which contains about 30 g of protein. Pollen with a high protein content helps to grow strong and healthy worker bees that live longer, which is needed to grow a strong colony.

A beekeeper must make sure that the plants in the area have enough nectar and pollen to provide the bees with food. Plants that produce a lot of nectar, do not necessarily produce pollen for bees. It is important that bees have a large variety of plants to collect nectar and pollen from because no single pollen provides all the nutrition honeybees need. Just like humans, bees need a well-rounded diet, and the quality of the pollen is more important than the quantity.

The colony’s needs change according to the season and brood production. If there is a lack of pollen or the beekeeper thinks that the pollen is of poor quality, it is necessary to provide a pollen substitute or supplement.

In the next chapter, we will look at the additional feed to keep your bees healthy in lean times, such as winter.

Wax is a product of the hive.

Contact details

For more information contact Charles Salmon, Western Cape Department of Agriculture, at Charles. Salmon@westerncape.gov.za or 082-651-7466

References

Burger, P. Die heuningby: Handleiding vir die saadprodusent. Klein Karoo Saadproduksie (Edms) Bpk, Oudtshoorn

https://www.seedproduction.co.za/ wp-content/uploads/2015/10/Bye_ Handleiding.pdf

Ellis, A., Ellis, J.D., O’Malley, M.K., Zellen Nalen, C.M. (2020) The benefits of pollen to honey bees. The Institute of Food and Agricultural Sciences (IFAS).

https://edis.ifas.ufl.edu/pdf/IN/ IN86800.pdf

Nectar (2022) Wikipedia https://en.wikipedia.org/wiki/Nectar Pasupuleti, V.R., Sammugam, L., Ramesh, N., Gan, S.H. Honey, Propolis, and Royal Jelly: A Comprehensive Review of Their Biological Actions and Health Benefits. Oxid Med Cell Longev. 2017;2017:1259510. doi: 10.1155/2017/1259510. Epub 2017 Jul 26. PMID: 28814983; PMCID: PMC5549483. https://pubmed.ncbi.nlm.nih. gov/28814983/

Propolis – Uses, side effects, and more (n.d) WebMD.

https://www.webmd.com/vitamins/ ai/ingredientmono-390/propolis

Bees sometimes 'accidentally' collect pollen while they take nectar from flowers, but sometimes bees collect only pollen or nectar.

Propolis (2022) Wikipedia

https://en.wikipedia.org/wiki/Propolis

Sericulture is the process of raising silkworms to get raw silk and is the topic of this series.

The feed that an animal is given to sustain its growth and reproductive potential is the single most crucial aspect of any animal production system. Since mulberry trees are the exclusive source of nutrition for silkworms, we will cover their cultivation in this first part of the series.

Silk was a symbol of emperor homage in public ceremonies, according to the chronicles of Chou King (2200 BC). Migration helped the industry spread. Japan focused on the silk industry in the late 19th century, introducing processing machinery, improving techniques, and conducting intensive sericulture research. In India, silkworms were first domesticated in the Himalayas.

A mulberry tree leaf, specifically the white mulberry (Morus alba) leaf, is the food source for silkworms. Making sure good quality mulberry leaves are produced scientifically, is crucial for economically organised sericulture. Approximately 25 to 30 kilogrammes of high-quality cocoons can be harvested from a single case of eggs, but the rearing of the silkworms to spin those cocoons requires one tonne of mulberry leaves.

This plant has been grown in China for centuries and adapted elsewhere. It is a latex-producing woody plant, similar to figs and marijuana. The tropical tree bears red, black, or white clusters of seeds called mulberries. Black mulberry bears large purple fruit that resembles a long blackberry. Red mulberry produces soft red fruits, while white mulberry is used for silk. The red mulberry is called Morus rubra, the black mulberry is called Morus nigra, and the white mulberry is called Morus alba

The fruits can be used as pig food. Leftover mulberry leaves are fed to cattle to increase milk production. The leaves can improve egg production when used as a vitamin supplement in poultry diets. Mulberry bark is used for papermaking. The bark is both a worm treatment and a purgative. The fruits can be cooked into squashes, jams, jellies, and pickles. Mulberry wood is shock-resistant and hard. The sticks are used on fences or woven into baskets and silkworm trays.

Mulberry trees prefer welldrained, fertile soil and can be planted in rows along the

contour of less steep slopes (15 degrees), while on steeper slopes (15 to 30 degrees), the terrace system is used most effectively for single rows. High rates of soil erosion resulting in deficiency in nutrients, characterise extremely steep land.

Mulberry trees can thrive at altitudes up to 700 metres above sea level. Planting mulberries at a high altitude where frost is common is not economically viable.

by Natasha PansegrouwSoil is vital to plant health. Although roots make up only about a quarter of a typical seedling, they are often so finely divided that their mass exceeds the volume of air occupied by the shoot. As a result, there is a great deal of soil to root contact, demonstrating the plant's reliance on the soil for support, moisture, and nutrients.

The composition of the soil affects a variety of plant characteristics, including:

• The capacity of seeds to germinate.

• The plant's stature and straightness.

• Healthiness of the plant tissues.

• Hardness of the stem.

• Roots' descending depth.

• The duration of puberty.

• Vulnerability to environmental stresses such as drought, pests, and diseases.

• The yield or growth rate.

The quality of the soil in a mulberry field influences not only the growth and yield of the mulberry, but also the quality of the leaf, the rearing conditions of the silkworm, and thus the yield and quality of the cocoon. At least 50 cm of deep, friable, well-drained, aerated, rich soil is needed for mulberries. The following factors affect soils:

• Fertility

• Depth and profile

• Soil texture

• Soil pH, temperature, and moisture

Soil fertility is the soil’s ability to provide physical conditions favourable for root growth and enough water and nutrients to allow the crop to make the most of the area's environmental features. Soil fertility is the most important factor in determining the yield as well as the quality of the leaves produced.

Shallow soils do not allow crops to anchor and extract nutrients and water, and they are usually waterlogged or dry. Since mulberry is a perennial crop, it can root up to 4,5 to 6 metres in dry seasons.

The coarseness or fineness of soil particles is called soil texture. Soil texture is classified based on its equivalent spherical diameter. Mulberries thrive in clayey loam and sandy soils.

Mulberry bark has many uses, including in the production of paper pulp, as a purgative, and as a worm treatment. (Source: Pixabay by Stylidium)

Soils must be well-structured and accept water and rainfall without crusting, eroding, or eroding to yield well. It should also hold moisture at reasonable levels.

Root morphology determines the plant's pH response. The soil's acidity and alkalinity should be acceptable. Mulberry grows best in slightly acidic soils with a pH of 6,2 to 6,8. Applying gypsum or sulphur to alkaline soils and lime to acidic soils can correct them.

The temperature of the soil influences plant growth. Temperature dominates germination and growth in moist soils. This is because this temperature affects root growth, nutrient and water uptake, leaf expansion, and mulberry leaf yield. Mulberry trees grow best at 23 °C to 30 °C. High and low temperatures kill the plant. Organic matter increases specific heat (due to microbial reactions) and soil temperature. Dark soils absorb more heat than light soils, so they are warmer.

Plant growth depends on soil moisture. Soil particles and organic matter determine how much capillary or hygroscopic water soil can hold.

The fruiting Morus alba, or white mulberry. (Source: Pixabay by Emilian Robert Vicol)

Though drought-resistant, mulberry trees need water for growth and yield. They thrive in well-drained soils that receive 50 mm of water every 10 days in loamy soils and 15 days in clay soils. Finer soils hold more water. 50 to 60% (by weight) of the soil's maximum water-holding capacity is ideal for mulberry growth.

Water is crucial to plant physiology. It dissolves soil minerals and transports solutes through plant tissues. It increases the chemical reactivity of simple and complex compounds by allowing plant solutions and ionisation. It fuels photosynthesis. Turgidity is necessary for cell function and protoplasm survival.

All precipitation increases soil moisture, but not equally. Slower, gentler showers soak more water into the soil than heavy showers causing run-off. More water sinks below surface desiccation during a rainy period. Direct studies of soil moisture penetration and duration are best for measuring precipitation's efficiency as a plant water source. Mulberry trees need 800 mm or more of annual rainfall.

Biologic activity is minimal below 0 °C and above 50 °C. Mulberry thrives at 23 to 30 °C.

Mulberry cultivation requires the same manure components as most crops,

An orchard of mulberry trees. (Source: architecturelab.net)

Morus nigra, more commonly known as the black mulberry, is a fruit that changes from a white to a red to a black hue as it reaches ripening.

(Source: Pixabay by chulmin park)

but in much higher quantities. Mulberry, a woody plant, absorbs and uses fertiliser differently than annual herbaceous plants. It is grown for its leaves in terms of silk production, unlike other fruit trees.

References

Starovoytova, D. (2015). Mulberry and Silk Production in Kenya. Textile Science & Engineering. Volume 5. Pages 1-7.

SMEDA. (2020). Sericulture / Silk Production – Small Business. Ministry of Industries and Production (MoI&P) Government of Pakistan. Available at: https://smeda.org/phocadownload/OTC_Documents/ Sericulture%20-%20Silk%20 Production%20for%20Small%20 Business.pdf

Duraiswamy, D. (2019). The Origin of Silk Production. Silk- Road Universities Networks Online Journal.

CGSpace. (2007). Sericulture in East Africa. Japan Association for International Collaboration of Agriculture and Forestry. Available at: https://www.jaicaf. or.jp/fileadmin/user_upload/ publications/FY2007/report2007_1_e.pdf

New Holland has joined the ranks of tractor companies offering electrical and autonomous options to farmers.

The T4 Electric Power all-electric light utility tractor prototype was recently showcased in America.

It is being flagged as the ideal elec-

trical solution for mixed and livestock farms, and can work autonomously. Commercial production is expected to begin at the end of 2023. More models are planned for the future.

Producing a peak power of 88,26 kW (120 hp), maximum torque of 440 Nm and a top speed of 40 km/h, the battery is said to deliver up to a full day of operation, taking just one hour to reach 100% power when using a quick charger.

Electrical outlets support daily farm tasks such as welding and drilling.

Doubling as a backup power genera-

The T4 Electric Power’s roof houses sensors, cameras and control units. Detecting and avoiding obstacles, these allow the tractor to operate autonomously.

tor for daily or emergency needs, the outlets also power electric implements. Traditional mechanical, hydraulic and PTO implements can also be used.

In tests, the electric prototype is said to have shown exceptional performance compared to a conventional diesel tractor. Providing greater traction control and smoother shuttling and gear shifts, the saving in diesel costs and maintenance is said to reduce operating costs by up to 90%. The tractor is quiet, too, reducing noise levels by up to 90%, and vibration is also dampened.

It is possible to remotely activate the tractor via a smartphone app. Offboard digital services allows the tractor to be run from anywhere, at any time, while monitoring performance and battery level.

New holding in the AgTech company Track32

Modern image recognition is becoming more and more prevalent in agriculture and enables at least partially autonomous machine use in many fields. However, this requires powerful cameras or sensors combined with intelligent algorithms.

With its IC-Weeder AI, LEMKEN has already launched a hoeing machine which reliably distinguishes between sugar beets and weeds, even under high weed pressure. The relevant software was developed by the Dutch

AgTech specialist Track32, in which LEMKEN has now acquired a holding.

The intensive cooperation with Track32, a company based in Ede (Netherlands), has already proven highly successful in the development of camera-controlled hoeing machines. Anthony van der Ley, Managing Director of the LEMKEN Group, says: “This will accelerate the development of smart technologies and ensures continuity. For Track32, our cooperation delivers planning security and great potential for growth.”

Track 32’s founder, Joris IJsselmuiden explains: “As a company that specialises in software and artificial intelligence, we also develop solutions for arable farming and greenhouse processes. With LEMKEN as an investor and client, we shall be able to concentrate even more on the further development of our software and will benefit from closer proximity to end customers.”

Track32’s expertise will allow LEMKEN implements to be used even more precisely and in more versatile ways, so that intelligent machines can be controlled not only by human operators, but also by robots, for example.

During the Eurotier animal production trade show in Hanover, Germany, organiser German Agricultural Society (DLG) announced the winners of the Agrifuture Concepts Winner award.

In the field of farm machinery, an award goes to the remarkable Exos green fodder harvester from Lely. This fully electric vehicle harvests and takes fresh grass directly from the field into the cow shed.

Green fodder grown on the farm is the basis for profitable milk production and is essential to the health of the animals.

With Exos, Lely presents a concept for the fully autonomous harvest-

ing and feeding of fresh grass. Green feeding throughout the vegetation period offers multiple advantages. For instance, the loss of energy due to the silaging process is eliminated as is that part of the harvesting costs caused by silaging during time slots that are tight because of weather conditions.

The fully electric Lely Exos provides the daily green fodder ration for the entire herd autonomously. The robot detects obstacles and navigates smoothly in the interior and exterior area. It is also possible to spread fertiliser during harvesting.

Thanks to this and because mowing

takes place at the right point in time, quick regrowth of the grassland is promoted and the soil is protected due to the comparatively low weight of the machine. This enables the farm to benefit fully from the use of the entire vegetation period, to produce more milk from feed it has produced itself, and thereby to reduce labour, the number of machines needed and the purchase of additional feed.

Three giant Case IH Steiger Quadtrac tractors are on their last leg of a two year journey to prepare for a unique new home, far from the Australian paddocks in which they are usually seen.

(Source: www.world-agritech.com)

The Lely Exos enables the farm to benefit fully from the use of the entire vegetation period, to produce more milk from feed it has produced itself, and thereby to reduce labour, the number of machines needed and the purchase of additional feed.

The three Case IH Steiger Quadtrac 500s are currently in Tasmania, undergoing final preparations for their trip to Antarctica, where they will be used to support the Australian Antarctic Division’s (AAD) aviation operations at Wilkins Blue Ice Runway, 70 km inland

from Casey Station, and also at the Casey Ski Landing Area, 15 km from the station.

The tractors arrived in the Port of Melbourne from the United States in September, and then made the trip across Bass Strait to Tasmania, where

(Source: www.caseih.com)

they travelled by road to Case IH dealership TTMI at Longford, just south of Launceston, in preparation for their journey by ship to Antarctica.

Jason Wood, Case IH ANZ Steiger Product Manager, said the Steigers had been manufactured at Case IH’s plant

in Fargo, North Dakota, before undergoing some necessary modifications required to cope with the challenging conditions of Antarctica.

“This is a process that has taken several years because it’s not simply a case of delivering three of our regulation Steiger models. To withstand the unforgiving environment they are heading to, and carry out the work they are required to do to the very highest standard, they needed some critical modifications,” Jason said.

“They have had arctic hoses installed in key areas and heaters added for the warming of the coolant and engine oil each time before they are started. The fuel tanks have even been tripled in size to increase their versatility.”

Once in Antarctica, they will be involved in runway maintenance, fuel and cargo transport from Casey to Wilkins, and general sled towing and heavy vehicle recovery.

Pete McCann, General Manager of Case IH Australia/New Zealand, said the request had been a unique one for his team, who had enjoyed preparing the Steigers for something so far removed from their usual farming environment.

“It will be a proud moment when they are finally loaded onto the ship in Hobart for their new home and their new job on the frontline of the important scientific work being undertaken in Antarctica.”

(Source: www.caseih.com)

Granadillas, also known as passionfruit, is a vine species of passionflower that is native to Brazil. It belongs to the family Passiflora.

The centre of the fruit is filled with yellow gelatinous pulp and seeds. It is sweet yet acidic tasting. The thick outside rind is cut open to reveal the yellow insides. The plant itself grows lush green leaves, and the flowers are considered to also be ornamental as the unique blooms are quite interesting to look at.

Granadillas are ideal for commercial production or as an addition in your home garden. There are two commercially viable passion fruit types, namely the purple and the yellowskinned aromatic fruit.

It is mostly consumed in juices, salads or on its own, but the pulp is often used as a garnish.

The ideal climate to grow granadillas has a moderate temperature throughout the year. The purple variety is particularly susceptible to frost. To mitigate this temperature sensitivity, plants can be planted on cool slopes in hot areas, or warm slopes in cool areas. The temperature should be between 5 °C and 29 °C.

High humidity is preferred. These plants require high rainfall of up to 1 200 mm per year, preferably rain that is well distributed throughout the year.

Harvesting of the fruit occurs when they ripen, but have not yet reached their deep colour.

Granadillas have shallow roots. They are sensitive to waterlogging, so the soil needs to be sandy to loam soil. It is necessary to till the soil with a plough or ripper to break up the compacted soils. Cultivate no less than 800 mm deep.

Examine the soil closely. Add lime and phosphate to the root zone. Calcium and phosphorus can be worked into the soil as well.

You can harvest your own seed from healthy, ripe fruits. Cut the fruit open and scoop out the seeds and pulp. Separate the contents by washing the seed and pulp. Dry the seeds in the shade. It can later be planted in a soil mixture that has been sterilised. You can either use seed trays or bags.

Sow two seeds per hole. You will thin them out by selecting the stronger plants later.

Once the seedlings emerge and the additional plants have been removed, add a stake next to each so it can prepare to trail. Regularly remove side shoots.

The seedlings are ready for transplanting when they are between 300 and 400 mm in height (3 to 6 months

old). They should be healthy plants with dark green leaves. Ideally the best time to transplant is between August and September.

Plant the plants 1 to 2 m apart. Closer together means a higher risk of transmitting soil-borne disease and viruses but it also means a higher yield over a smaller area.

Granadillas are climbing plants. They therefore require trellis for the vines to

trail on. It needs to be strong enough to carry the weight of your developing fruits. Wooden posts can be used, but these need to be solid and treated to be termite resistant. Posts should be 2 m high. String 12-gauge wire across the poles. Add leader lines from the wire to the plant so the vines can be trained to grow towards the framework. You can assist it by wrapping the vines loosely around the wire.

Further care of your fruits may include pruning the vines to stimulate growth, removing dead materials and preventing overlap. Pruning, however, is not crucial, since most plantations only last three years, producing fruit for only 12 to 18 months of that period.

Since granadillas need annual rainfall of 1 000 – 1 200 for commercial cultivation, irrigation systems can be used to supplement the shortfall. Plants effectively require 15ℓ per plant per day in the summer and 8ℓ per plant per day in winter.

Be careful of not over irrigating as this creates an environment for fungi to thrive.

LAN can be added yearly, as well as phosphate and KCl. Further leaf analysis can show exactly how much, but the below table can be used as a guide.

Age LAN

Year 1 250 150 150

Year 2 350 300 300

Year 3 450 450 450

Zinc-oxide can be added as 200 g per 100 ℓ of water. Solubar for Boron deficiencies can also be added as 100 g per 100 ℓ of water.

For the health of your granadilla, there are a few diseases, viruses and pests to take note of.

Damping off Fungi causes damping off of seedlings. This is usually due to poor seedbed management. The good news is that it can be avoided by planting in welldrained, sanitised soil.

Footrot causes the base of the stem to thicken. This leads to cracks in the surface where other diseases and pests can enter. That, in turn, causes the stem to rot completely. Overirrigation and waterlogging usually are the main culprits. This can easily be

prevented by planting the granadillas in well-drained soil.

To identify a single virus that affects the plant is often difficult, but symptoms include spots, mosaics, and distortion. Control this by removing the affected shoots, disinfecting equipment and washing hands to prevent cross contamination.

Tip-wilters and stinkbugs are the most common pests in granadilla plantations. Frequent field inspections and collecting the insects by hand are the most effective control method.

by Natasha Kruger

by Natasha Kruger

Southern African native sheep breeds thrive in extreme environments. They are lean and muscular, with thick rump and tail fat. In times of scarce grazing, body fat is stored here for use as fuel. They are raised primarily for their meat.

Although the Damara is the most popular commercial sheep in South Africa, the BaPedi is also used by farmers to raise sheep for commercial meat production. The native sheep breeds do well in veld grazing systems.

The Damara can live well on both shrubland and leaves, which is different from other sheep breeds. It can also fight off both internal and external parasites and sheep sickness.

The average age at first lambing is 1 year and 5 months, and the average interval between births is 7,5 months. Lambs are typically born with fewer complications because of their small size. A Damara ewe is an excellent mother weighing around 30 to 55 kg, and adult rams weigh 50 to 85 kg.

In about seven months, the animal will reach the required 18 kg for slaughter. Damara meat has a low fat content, a fine texture, and no fat streaks. The fat on a Damara carcass is only 1 to 2 mm thick.

Damara sheep leather was found to be the strongest of nine different sheep breeds studied, thanks to its extremely fine grain and high tensile strength.

It is believed that Namaqua Afrikaner sheep descended from the Khoi-khoi (Hottentot) people who inhabited South Africa before colonisation. Located in the Northern Cape Department of Agriculture's Carnarvon Experimental Station, the Namaqua Afrikaner is now being saved from being one of South Africa's most endangered sheep breeds thanks to a conservation programme. Farmers buy surplus animals from conservation breeding programmes.

The Namaqua Afrikaner is characterised by long legs, a slim body, and a long, plump tail that can hold as much as 38 percent of its weight. The long, fat tail serves as an energy reserve for long dry seasons. It has a silky, whitehaired coat that is used for making gloves and other lightweight leather goods. Animals' heads can be either red or black. Rams and ewes have horns. A Namaqua Afrikaner first lamb is born at 16,5 months, and then every 8 to 9 months after that. The mature weight of rams can reach 75 kg, and ewes can reach a weight of 56 kg.

Damara ewe and lamb. (Source: GL

Damara

Large and native to Namibia, the Damara sheep stands out with its distinctive black face. It has a long, skinny body, short hair, and a thick, woolly undercoat that it only needs to shed during the summer. The colours can be brown, white, black, or a combination of those. The horns on both rams and ewes are spiralled.

Ronderib Afrikaner

This large, plump-tailed sheep breed gets its name from the shape of its ribs, which are oval. The Ronderib Afrikaner sheep is an old breed with possible roots in the Middle East or North Africa. It has adapted to live in South Africa's Northern Cape province, which is mostly desert.

When it needs to travel great distances in search of grazing and water,

the animal's long, thin legs are a great asset, and the fat stored in its huge, round tail can provide it with an extra 2 to 3 kilogrammes of energy. Mature rams weigh between 60 and 65 kg, and ewes between 50 and 55 kg.

It usually takes about 8 months before the first lamb is born. Lambs have a slow growth rate and are typically sold when they are 10 to 12 months old. As an additional breed of sheep, the "Ronderib" is frequently used due to the lean and compact nature of its carcass. Teaser rams, which are typically Ronderib rams, are used to prime ewes of other breeds for mating.

The substantial tail fat is often used for preparing boerewors and droëwors (droëwors is a preserved meat product made of finely minced meat and fat mixed with salt, spices, and then dried). The breed is prized for the soft, glossy, light-cream wool used to make blankets. The skin has a high value for the manufacture of luxury leather goods.

The Zulu sheep is a subspecies of the Nguni breed. Nguni sheep are well suited to the climate of KwaZulu-Natal thanks to the diversity of their ancestry. Tickborne diseases do not seem to bother them, and they do well even in harsh climates and communal grazing situations.

The Zulu sheep, along with the BaPedi, are members of the Nguni subspecies that have elongated fat tails for piling surplus fat. Some sheep in

the breed have extremely short ears (called "mouse ears" or "swelamadlebe" for short), but this is a rare occurrence due to a recessive gene. The mature weight of rams is up to 38 kg, and ewes weigh up to 32 kg.

The desire to increase carcass weight and mutton production has led to the risky practise of interbreeding with nonnative breeds, which threatens genetic purity. According to 1995 research, there were only about 3 000 remaining pure Nguni sheep in South Africa.

According to legend, the BaPedi sheep made their way south into the Limpopo province a few centuries ago. In this region, you will find the largest population of BaPedi sheep.

The BaPedi is a type of Nguni sheep characterised by a chubby tail, a mixture of white, brown, and red hair, a small body, and long legs. Because this breed is naturally resistant to ticks, there is no chance that it will get diseases like blue tongue, redwater, or heartwater, which are spread by ticks.

It is common knowledge that BaPedis reach adulthood quickly. The first lamb is born at 11 months, and there are two more lambings per year at sixmonth intervals. BaPedi ewes have been known to continue lambing up to

the age of eight years. Sheep can be slaughtered at their ideal weight of 30 kg after 12 months of age (12 months for ram lambs) (18 kg of meat). The mature rams weigh between 60 and 75 kg, and ewes between 40 and 50 kg.

Breeds of Livestock - Booroola Merino Sheep — Breeds of Livestock, Department of Animal Science. (1996). Available at: http://afs.okstate.edu/breeds/sheep/booroolamerino/index.html

Ngcobo, J.N.; Nedambale, T.L.; Nephawe, K.A.; Mpofu, T.J.; Chokoe, T.C.; Ramukhithi, F.V. An Update on South African Indigenous Sheep Breeds’ Extinction Status and Difficulties during Conservation Attempts: A Review. Diversity 2022, 14, 516. Available at: https://doi. org/10.3390/d14070516

Sheep breeds. (2008). Department of Agriculture. Available at: https:// www.nda.agric.za/docs/Infopaks/ Sheep_breeds.pdf

Sheep Farming in South Africa. 2022. Available at: https://southafrica.co.za/sheep-farming-southafrica.html

Arare production system farmers delve into in sub-Saharan Africa is herb and spice production. This may be due to the lack of knowledge of their value, supply chain and market linkages, production techniques and a general trend to follow traditional farming production systems. Their exploitation ranging from the medical field to the cosmetic industry make them a low-hanging fruit that a vast number of farmers and agribusinesses could benefit from.

Spices can be defined as “vegetable products used for flavouring, seasoning and imparting aroma in foods” (FAO, 2005). Herbs are leafy spices, and some, like dill and coriander, can provide both spice seeds and leafy herbs.

Examples of spices are parsley,

lavender, basil, mint, oregano, sage, rosemary, chives, French tarragon, marjoram, thyme, bay, fennel, lemon grass, lovage, anise, chervil, cumin, summer savoury, caraway, celery, garlic, lemon balm, dandelion, hibiscus flowers, lemon verbena, liquorice root, raspberry leaf, red clovers flowers, rosehips, stinging nettle, yarrow, calendula, chickweed, aloe, arnica, burdock, comfrey, plantain, St John’s wort, begarmot, bittersweet, orris root, patchouli, pine cones, rattlesnake master, scented geraniums, sumac, white sage, saffron, borage, chamomile, elderberry, hawthorn, evening primrose, milk thistle, alfalfa, bee balm, blue vervain, boneset, feverfew, gingko, heal all, heartsease, lemon verbena, mullein, round headed

lespedeza, sheep sorrel, skullcap, stevia, black cohosh, Chinese milk vetch, echinacea, ginseng, and gold seal, among others.

Spices and herbs are grown as trees, shrubs, perennials, annuals, wild and cultivated. Spice and herb plants provide seeds and fruits, leaves and stems, flowers and buds, roots and rhizomes, bark and resins that can all be commercialised in various forms: sold fresh, frozen, dried, whole or ground, distilled into oils or solvent extracted into oleoresins.

According to future market insights research, during the projected period, the global herb and spice extracts market is anticipated to thrive at an average CAGR of 5,1%. The market value is projected to increase from US$ 14,5 billion in 2022 to US$ 23,9 billion by 2032.

Demand for organic spices and herbs is being driven by increased interest in unusual flavours and growing healthcare consciousness among customers. Millennials are particularly interested in the many flavours and cuisine that reflect regional differences in culture.

Mordor Intelligence (2022) finds that the Africa spice and herb extracts market is consolidated, owing to the existence of few players holding majority of share in the market. Some of the key players in the market are Döhler GmbH, McCormick & Company, Inc, Kalsec Inc, Kerry Inc, and Olam International. Major players are opting for expansion strategies to expand their reach while focusing on producing purest and finest quality ingredients without any contaminations. They are investing in research and development activities to introduce ingredients in new flavours that are natural and safe for consumption. This, in turn, will increase sales of their ingredients among food and beverage companies in the region while garnering market dominance.

The common challenges faced by farmers in the herbs and spices value chain are the lack of networking arrangement between small-scale producers, and medium- and large-scale exporters/ producers; weak farmer organisation structures, especially in small-scale production, weak farmer organisation, unregistered groups; lack of suitable finance and credit facilities

to farmers; inadequate good quality seed and other planting materials and farm inputs; inadequate resources (financial and human resource) to support research and development of horticultural produce and low adoption of research outputs in support of horticultural development for export.

These challenges can be resolved through improving liaisons between the farmer and marketing associations, creating credit models that assist farmers begin spice and herb production at reasonable costs, solidification of unity among smallholder farmers for increased negotiating power with traders, and increased opportunities

to build long-term relationships with buyers, and collaboration between the public and private sector in executing sustainable policy reforms to create an enabling environment for competitive production and marketing.

Improved training, promotion and investment into herb and spice production systems would spur not only growth of the African continents, culinary, medicinal, cosmetic, agricultural and textile industry through the raw products and value-added inventions, but would bring new technology, improve employment opportunities and permit even the smallholder farmer to participate in a global multibillion dollar playing field.

In the next articles of this series, we shall look into spice and herb production in Africa, and how it works. Keep an eye out, and be sure not to miss out on some informative content.

References

Spices. Available at https://714493. smushcdn.com/1156533/wp-content/ uploads/2020/09/herbsspices-1536x864. jpg?lossy=1&strip=1&webp=1

Matthews, M., Jack, M. (2011) Spices and herbs for home and market. Available at: https://www.fao.org/3/i2476e/i2476e00. pdf

Pratiksha Supekar, P. (2017) Available at https://quickasianrecipes.com/drying-offruits-and-vegetables/

AFRICA SPICE AND HERB EXTRACTS

MARKET - GROWTH, TRENDS, COVID-19 IMPACT, AND FORECASTS (2022 - 2027) (2022). Available at: https://www.mordorintelligence.com/industry-reports/ africa-spice-and-herb-extracts-market

Mudau, F. N., Chimonyo, V. G. P., Modi, A. T., Mabhaudhi, T. Neglected and Underutilised Crops: A Systematic Review of Their Potential as Food and Herbal Medicinal Crops in South Africa. Available at: https://www.frontiersin.org/articles/10.3389/fphar.2021.809866/full Investment Opportunities in the Rwandan Herbs and Spices Sector TRAIDE Rwanda. (2020)

Herb & Spice Extracts Market Outlook (2022 - 2032) Available at: https:// www.futuremarketinsights.com/ reports/herb-and-spice-extractsmarket#:~:text=Herb%20%26%20 Spice%20Extracts%20Market%20 Outlook%20(2022%20%2D%20 2032)&text=The%20market%20 value%20is%20projected,US%24%20 23.9%20Bn%20by%202032.

Growth of African agribusinesses cannot be modelled around business strategies utilised by firms in first world countries (FWC). Economic policing characteristics such as interest rates, liquidity, agribusiness subsidies, rules and regulations surrounding the manufacturing, production, processing, export and import of agricultural products and services differ.

Despite the odds and different challenging economic environments in Africa, success has been achieved for agribusinesses.

According to AsokoInsight (2022) there are 14 African agribusinesses with an annual revenue of over USD10 billion. These are Cevital, Nigerian Breweries, FMN, BUA Group, Distell, Astral, Bidcorp, Tongaat-Hulett, Omnia, Pioneer Foods, Tiger Brands, TSB, PCL, and an Ethiopian company.

For this article’s sake we shall look at companies from different countries and sectors, namely Cevital, Nigerian Breweries, Omnia, Pioneer Foods, and Tiger Brands.

Cevital is a family-run group whose operations began in 1971 in the metal

construction business. It is the first private Algerian company to have invested in a wide variety of business sectors and has passed significant historical milestones to achieve the size and recognition it enjoys today.

They are involved in the food-processing and mass distribution industry, electronics and domestic appliances, the iron and steel industry, the flat glass industry, industrial construction, the automobile industry, services, and the media. As these investments have been made, the Cevital Group has focused on the key principle of creating an economic unit.

With the support of its 18 000 employees located on three continents, it is the flagship of the Algerian economy, working continuously to create jobs and wealth. Cevital has the largest

sugar refinery globally, with an annual production capacity of two million tonnes, and the biggest oil refinery in Africa, which produces 570 000 tonnes per year. Forbes Middle East (2021) states that its 26 subsidiaries generated USD4 billion in revenue in one year.

Nigerian Breweries began operation in 1949 with the introduction of Star Lager Beer. Since then, they have expanded their Lager portfolio to produce a wider range of Non-Alcoholic, Stout and Spirit Drinks comprised of over 21 brands enjoyed locally and globally.

According to African Financials, the company boasts one of the most modern brew houses in Nigeria. Nigerian Breweries has 11 breweries, two malting plants and 26 sales depots; enjoys a growing export market; and offers sales and logistic and marketing support to merchants and vendors. Brands

in the product portfolio are available in 13 countries including the United Kingdom, South Africa, the United States, and various countries in Middle East and West Company. Its company head office is in Lagos, Nigeria. Nigerian Breweries Plc recorded USD961,83 million revenue in the 2021 financial year.

Omnia is a diversified group that conducts research and development, manufactures and supplies chemicals and specialised services and solutions for the agriculture, mining, and chemicals application industries.

Based in Johannesburg, South Africa, with operations in 25 countries, Omnia has more than six decades’ experience in the business. Additionally, Omnia continues to grow its global footprint, with businesses in Australasia and Brazil, and clients in other regions such as North America and Canada.

Omnia provides customised, knowledge based, innovative solutions through its Agriculture, Mining and Chemicals divisions. These divisions include Omnia Nutriology, Axioteq™, BME, Protea Mining Chemicals and Protea Chemicals.

Operations began in 1953 as a family business with only £53 in capital. Today Omnia has grown to a market capitalisation of ±R12 billion.

Blackwell when it was divided between the JM Smucker Company Group and Tiger Brands. Today the Tiger Brands International team is dedicated to growing Tiger Brands’ footprint by continuing to explore new opportunities to bring quality brands to consumers in all corners of the globe.

Africa is a core focus for the Tiger Brands International team, driving growth across 25 countries with five priority markets: Cameroon, Mozambique, Zambia, Zimbabwe, and Nigeria. Companies Market Cap states that, according to Tiger Brands's latest financial reports, the company's current revenue (TTM) is $2,04 billion.

References

Revenue for Tiger Brands (TBS. JO). Available at: https://companiesmarketcap.com/tiger-brands/ revenue/#:~:text=Revenue%20 in%202021%3A%20%242.04%20 B,that%20were%20of%20 %241.76%20B

African top 20 Agribusiness Companies. Available at: https://www. howwemadeitinafrica.com/rankedafricas-top-20-agribusiness-companies/13532/

AsokoInsight. Africa's Largest Agribusiness Companies. Available at: https://www.asokoinsight.com/ content/market-insights/africa-slargest-agribusiness-companies

Forbes Middle East. (2021) Available at: https://www.forbesmiddleeast. com/lists/top-100-arab-familybusinesses-in-the-middle-east-2021/ cevital-group/

Pioneer Foods is one of the largest South African producers and distributors of a range of branded food and beverage products. The group operates mainly across South Africa, providing wholesale, retail, and informal trade customers with products of a consistently high standard. Pioneer Foods exports to more than 80 countries across the globe. The growing international business represents 21% of operating profit.

The company was formed in 1997 and is built on the foundation laid by two pioneering farming co-operatives, namely Bokomo and Sasko, and this journey began nearly 100 years ago.

Tiger Brands operations began in 1819 through the ownership of Crosse and

Nigerian Breweries PLC. Available at: https://www.nbplc.com/ourhistory/

African Financials. Available at: https://africanfinancials.com/company/ng-nb/

Pioneer Foods. Available at: https:// pioneerfoods.co.za/

Tiger Brands. Available at: https:// www.tigerbrands.com/

Omnia Holdings Limited. Available at: https://www.omnia.co.za/

Cevital. Available at: https://www. cevital.com/en/

by Tapuwa Mashangwa

by Tapuwa Mashangwa

There is a growing demand that all agricultural industries take into account the environmental consequences of whatever process they undertake. One of the areas of concern is the use of plastics. The use of plastics in agriculture has helped farmers to increase crop production, improve food quality, and reduce the geological footprint of their activities, but their negative impact cannot be ignored.

As versatile and economical as they are, plastics are found all over farms. They are used from machines to mulches, they are the stuff of bags and tubs, of tubes and tools, of tags and trays, and of pots and twine. Plastic films are used to cover greenhouses and hug plants around the root zone. Other kinds of plastics are used as ingredients in chemicals.

Rosanne (2021) states that world agriculture used 12,5 million metric tonnes of plastic for plant and animal

production and 37,3 million tonnes for food packaging in 2019.

Globally, packaging is the dominant generator of plastic waste, responsible for almost half of the global total. Plastics used in packaging have a very short ‘in-use’ lifetime (typically around six months or less). This is in contrast to building and construction, where plastic use has a mean lifetime of 35 years.

Plastics encompass a wide range of synthetic and naturally occurring substances that are capable of flow when heated, at which point they can be moulded, extruded, cast, spun, or applied as coating. Synthetic plastics, also known as plastic resins, refer to several dozen families of organic high polymers, which are large, chainlike molecules that contain carbon. Polymers are formed by causing shortchain hydrocarbon molecules, or monomers, to bond though a process known

as polymerization. These monomers are typically oil- or gas-derived, though bioplastics are derived from alternatives to fossil fuels such as vegetable fats and oils, plant starch, and microbiota. (World Bank Group).

In the agricultural sector, plastics are single-season use and sooner or later, nearly all plastics end up in landfills, incinerators, waste-to-energy plants, or places where they were never intended to go, or remain. Certain used plastics can be too costly to remove from farms, and hence are left to pollute the land.

Many plastic substances are endocrine-disrupting, and some are carcinogenic and harmful to the nervous and immune system, resulting in their unintended ingestion posing a risk to humans and animals alike. These risks often originate at the time of manufacture, when a range of chemicals including plasticizers, flame retardants, stabilizers, antimicrobials, and antioxidants are used to give plastics their unique properties or to enhance their performance.

Common additives such as bisphenol A (BPA), phthalates, and polybrominated diphenyl ethers (PBDE), for example, are known for their potential to act like a hormone in the body and may increase cancer and other risks.

According to Plastics Europe (2022), a number of European countries have

implemented National Collection Schemes (NCS) for the management of agri-plastics waste to increase the circular economy and to avoid having a negative impact on the environment.

The model of promoting National Collection Schemes ensures high collection rates as well as an improvement in the quality of the plastic waste collected, both prerequisites for recycling the plastic and the incorporation of recyclates into new products. Several countries have already implemented these NCS, namely France, Germany, Ireland, and Finland, or are starting with them such as the UK and Spain.

Once retrieved from the fields, plastics are usually washed to eliminate sand, herbs, and pesticides, before being grinded and extruded into pellets. The material can then be used again in the manufacturing of articles such as outdoor furniture. When mechanical recycling is not viable, chemical recycling and energy recovery are complementary options with different technologies available.

Rosanne (2021) states a FAO report called for improving the management of agricultural plastics through “the 6R model” – refuse, redesign, reduce, reuse, recycle and recover. More specifically, potential solutions could include changing practices to phase out plastic altogether, replacing plastics with biode-

gradable alternatives or designing better ways to manage or reuse plastic waste. Thus, as the global community moves forward in implementing research and solutions to reduce the effect of plastics, Africa’s farmers should also be aware that they can improve their methods to tackle the crisis.

References

The plastic waste issue: Everything British farmers need to know. Available at: https://bmcontent. affino.com/AcuCustom/Sitename/ DAM/298/260419P1213SUOGNP2532. jpg

Sustainable Agriculture. (2022) Available at: https://plasticseurope. org/sustainability/sustainable-use/ sustainable-agriculture/

Plastics. Agricultural Pollution. Available at: https://openknowledge.worldbank.org/bitstream/ handle/10986/29505/124346repl-WB-Knowledge-Plastic. pdf?sequence=1

Rosanne, O. (2021) Plastics in soil threaten health and agriculture. Available at: https://www.weforum.

org/agenda/2021/12/plastics-agriculture-soil-human-health-un-report/ Plastics in agriculture – an environmental challenge. (2022) Available at: https://www.unep. org/resources/emerging-issues/ plastics-agriculture-environmentalchallenge#:~:text=Plastics%20 are%20used%20extensively%20 in,which%20is%20spread%20on%20 fields

Ritchie, H., Roser, M. (2022) Plastic pollution, Available at: https://ourworldindata.org/plastic-pollution

Twenty firms produce 55% of world’s plastic waste, report reveals. (2021) Available at: https://www.theguardian.com/environment/2021/may/18/ twenty-firms-produce-55-of-worldsplastic-waste-report-reveals (Accessed: 13 November 2022)

The Role of Plastics in Agricultural Applications. (2021) Available at: https://www.plastivision.org/blog/ the-role-of-plastics-in-agriculturalapplications/ (Accessed: 13 November 2022)

The exploitation of greenhouses from their creation has contributed immensely to optimise agricultural production systems. Be it for fruit, nuts, crops, grain, horticulture, or herb production, yields and quality have improved. However, simply erecting a greenhouse will not miraculously improve yields. The greenhouse demands efficient management to attain the best results.