•

•

•

•

•

In a recent report by the Centre for Trade Policy and Development (CTPD) it was revealed that mindset and be havioural challenges are factors that impede the success of making agri culture a business among small-scale farmers. Negative cultural beliefs have the potential to frustrate the efforts of some small-scale farmers to work hard, as they believe that other farmers use charms or magic to steal their produce.

A question I frequently ask farm ers during interviews is what kind of relationships they have with the people in their community and the suppliers? Most farmers have positive stories to tell about their relationship with fellow community members and suppliers.

Behind every business, there are people, and people function in society through relationships. Establishing de cent relationships is of utmost impor tance since input suppliers know their products the best. Without the support and the relationship farmers have with the key role players and suppliers, it won’t be possible to make informed decisions or even save money.

Our suppliers play a crucial role pro viding us with useful information on the

latest technology, which fertilisers to use, trending equipment and sound advice on your farming operation whether it be crop-farming, poultry, livestock, or pig husbandry.

We at ProAgri also value the rela tionship we have with our farmers and suppliers in providing our read ers with the latest trends and news.

Stay up to date by signing on to receive our monthly newsletters, and visit our websites. Enjoy the latest edition ProAgri Zambia while pouring yourself a cup of coffee in the morning! Read how Agrico keeps growing in Southern Africa, Syngen ta’s potent new fungicide, ORONDIS® Ultra with two active ingredients for unsurpassed late blight and downy mildew control.

Relationships is the name of the game if you want to progress. In business, no man is an island. Let’s root for each other and watch each other grow.

greetings Bianca Henning bianca@proagri.co.zatechnology for the farmer Zambia

No. 10 Tito Road

Rhodespark, Lusaka +26 (0)97-769-9786 www.proagri.co.za

Copyright © 2022. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

+27 82-555-6866 diane@proagri.co.za +27 79-524-0934 xander@proagri.co.za +27 71-599-9417

johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za +27 72-419-3990 christiaan@proagri.co.za

+27 12-803-0782 engela@proagri.co.za +27 79-515-8708 nita@proagri.co.za +27 12-803-0782 accounts@proagri.co.za

by Tisha Steyn

by Tisha Steyn

What is the secret to more than 120 years of service?

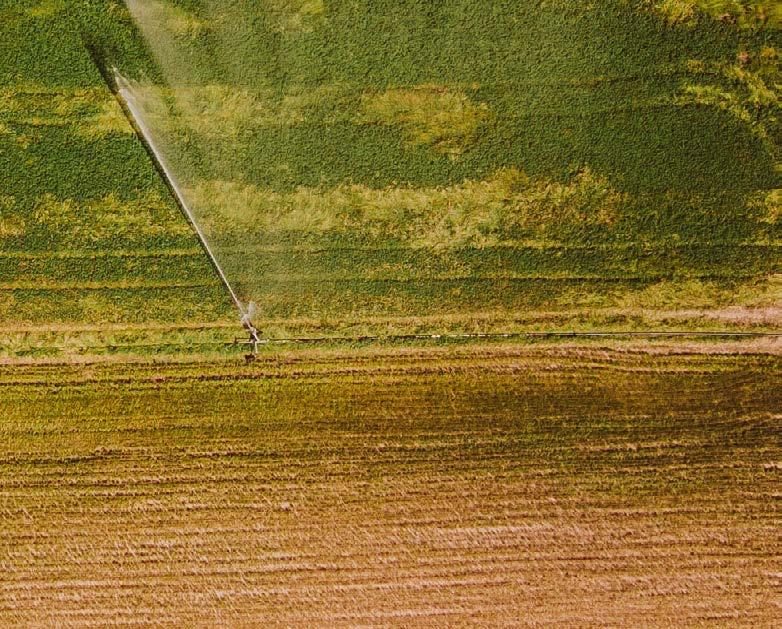

According to Johan Visser, drip- and micro-irrigation expert at Agrico, constant innovation and progress are fundamental to success. When serving a technologically developed irrigation market, one should not only be able to keep up, but you must always be one step ahead. That is how Agrico remains relevant. This is how Agrico grows.

From pivots to drip- and microirrigation, and everything in between Johan joined Agrico at the beginning of 2022. With 38 years’ experience in the irrigation industry, his mandate is to expand drip- and micro-irrigation expertise within Agrico, a name largely associated with pivots.

He says: "South Africa was one of the first countries to watch Israel tackle precision irrigation in the late sixties. South Africa is also a waterpoor country, so we also had to learn drip- and micro-irrigation techniques."

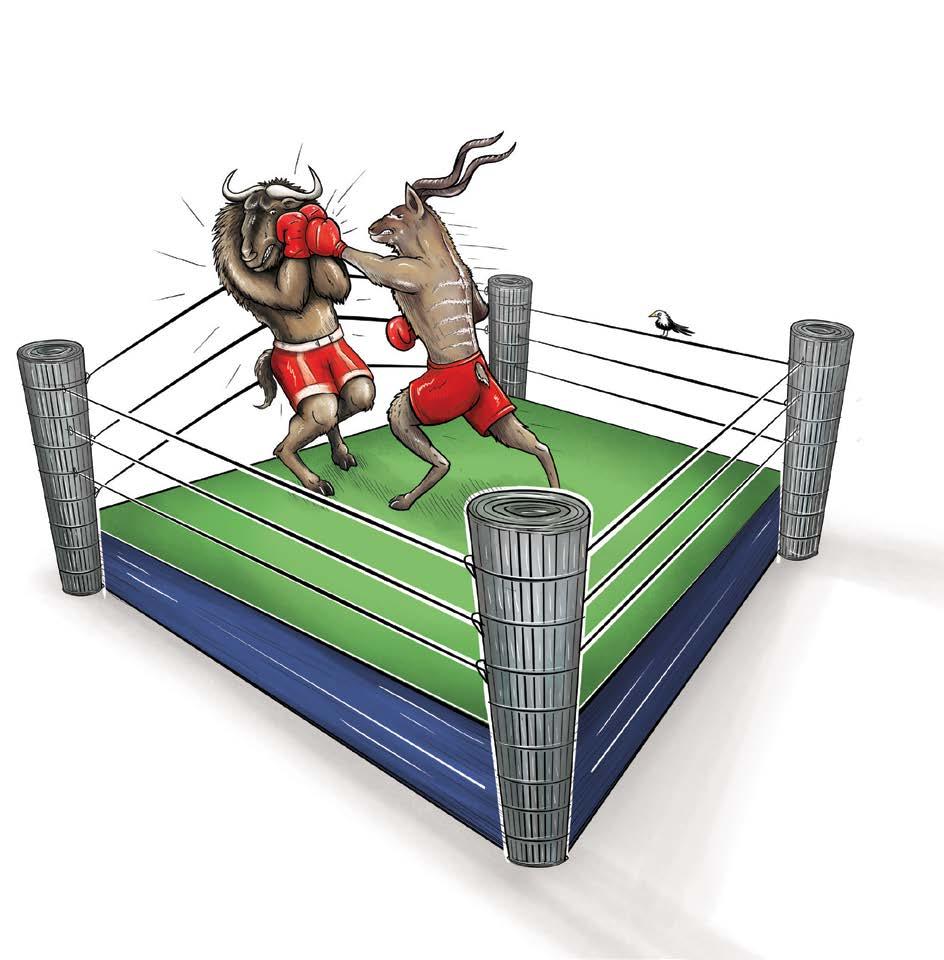

To compare drip- and micro-irriga tion to pivot irrigation is to compare apples with onions. According to Johan, the two methods are not in competition with each other at all. Each method has a specific application.

"The choice of system is based on the farmer’s needs," he explains. "With good planning and management of the systems, both are water-efficient methods of irrigation."

Establishing the application of dripand micro-irrigation within Agrico requires a plan of action. This includes further training of Agrico's designers and experts, as well as expanding the Agrico footprint across the country. In this way, every farmer can be assured that there is an Agrico expert nearby to provide the necessary support.

One step ahead of the rest: how to stay at the forefront of technological development

The South African irrigation market's de velopment over the decades is striking. The 21st century has shown the face of modern solutions and software such as Agrico Web Control, which allows a farm

er to control his entire irrigation system from his or her mobile phone. We live in a technological age, and that means swim or sink for irrigation suppliers.

“Many farmers, especially the younger ones, prefer high-tech sys tems. Agriculture is very dynamic, and the wheel of preferred products is con stantly spinning. That is why Agrico is working hard to remain at the forefront of technology," says Johan.

"South African farmers are among the best in the world. They produce under harsh conditions. Commercial farmers receive minimal or no support from the state, input costs are high, the roads are in appalling condition, and water is limited."

Fortunately, the expression, a farmer makes a plan, is still as appropriate to day as before. Farmers learned to face the challenges by farming more effec tively, economically, and scientifically.

Irrigation is no longer simply watering your crops; it is a transfer system that transports water, fertilisers and chemical or biological components to the crops.

The management of water is a pre requisite for success. An irrigation sup plier should know how to determine the farmer’s and farm's needs. Our farmers are well-informed, and it is the duty of the irrigation industry to ensure that we provide them with an economically workable system," says Johan.

The Agrico footprint grows non-stop "Agrico is a world leader in irriga tion. We aim to be the best irrigation company in the Southern Hemisphere," says Johan.

Therefore, growth and expansion are of utmost importance. It is criti cal to move, literally and figuratively, as close as possible to the farmer. By being present in a farmer’s area and demonstrating absolute expertise on all irrigation methods, the farmer can be assured that he or she is getting the optimal solution.

"Agrico wants to stay in touch with the farmer all the time. Our role is to be the bridge between farmers and the importers and manufacturers of irriga tion equipment."

Therefore, a salesperson should first of all determine who the customers are.

Thereafter, a solution should be proposed that the farmer is comfort able with, so that he can get the most out of it.

This is how Agrico offers efficient, economically feasible and sustainable irrigation solutions.

“Agriculture requires the farmer to be in charge of all aspects of his farm in his own way, with our help."

While Agrico sells products with repu table brand names such as Netafim, Agri plas and Azud, they also manufacture at least half of the equipment they offer inhouse. The factories in Bellville and Lichtenburg currently support 39 branches across South Africa and Zambia.

More than 70 marketers serve farm ers in Zimbabwe, Namibia, Botswana, Mozambique and Angola, as well as Nigeria and Ghana. A team of about 40 young engineers develops products and provides technical support.

"We employ young men and give them opportunities. With our existing experience and their innovative, pas sionate energy, we tackle agricultural challenges head-on."

For more information on how Agrico can assist you with the latest and greatest irrigation technology, contact sales@agrico. co.za or call +27-83-455 5423.

You can also visit Agrico's website at www.agrico.co.za.

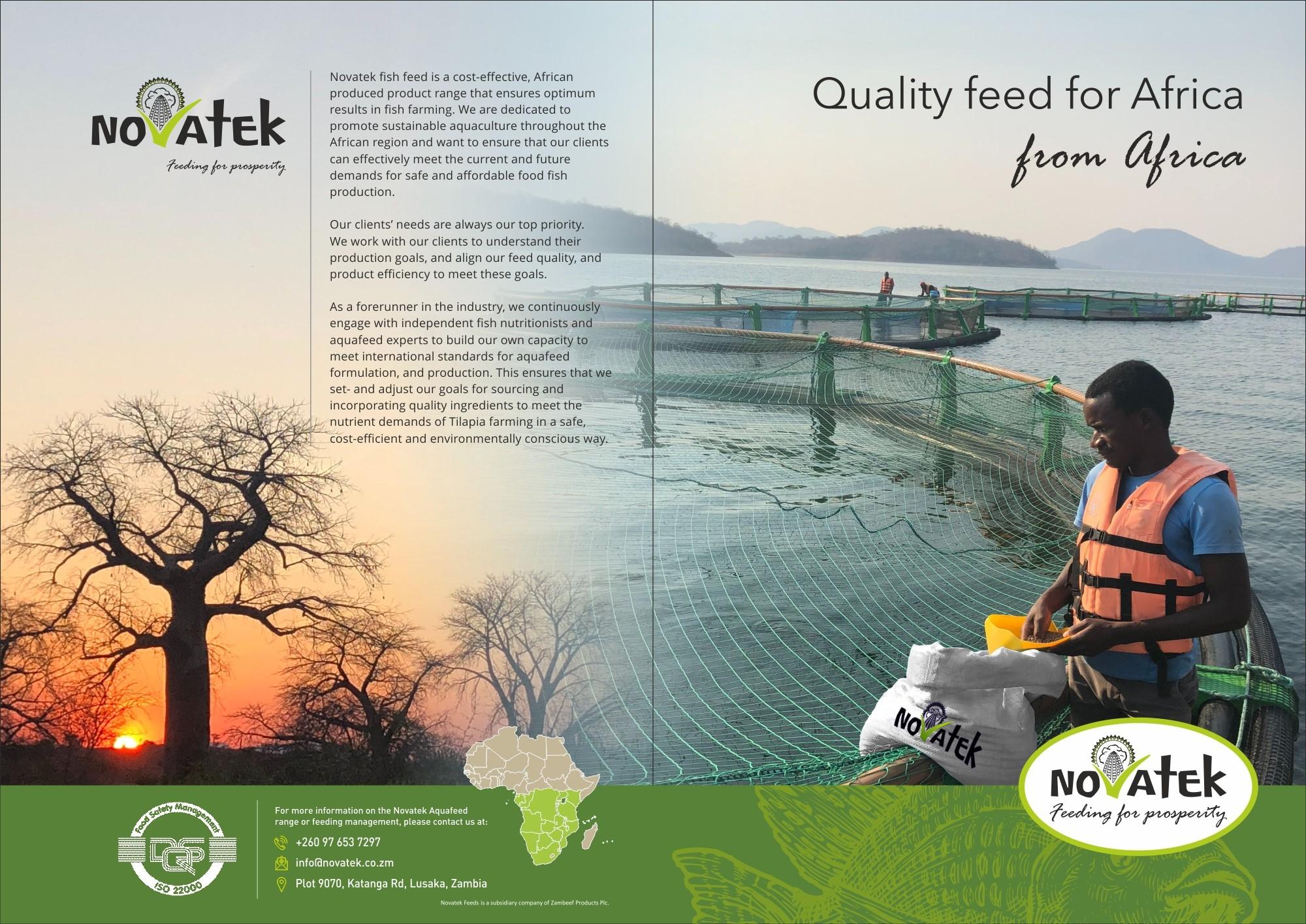

Aquaculture is becoming very popu lar amongst Zambians because it provides people with employment and a cheaper source of protein. The government, through the Ministry of Fisheries and Livestock, supported by other line ministries such as the Minis try of Small and Medium Enterprises, the Ministry of Commerce, Trade and Industry, and local government, are encouraging citizens to venture into fish farming.

Fish farming is a form of aquaculture specific to the growing of fish for business purposes. It is an industry on the rise, one that will play a pivotal role in scaling up nutrition for the local communities. To successfully raise fish in ponds, cages, tanks or raceways, there is a need to conduct a checklist.

Mostly in the Zambian scenario, fish farming is conducted in ponds and cages and placements of fingerlings occurs between August and April. This is due to the weather pattern. Between June to August, water temperatures drop to below 20 °C inhibiting growth as a result of the fish’s inability to consume enough feed. Once summer comes, fish farming activities restart, and it is then important to observe the following:

1. Check the status of the production system

Before you begin your fish farming cycle, ensure that you inspect your production facility very well. In ponds, ensure that the dykes, drainpipes, and liner (if it is lined) are without holes and all sieves are present. In cages; check all your fish nets and ensure they are without holes. For those using tanks, make sure all the aeration and filtration systems are working properly. Take time to observe your production systems before stocking, rather than doing amendments midway through the cycle. It will save you money.

2. Lime the ponds

Liming is important for disinfec tion. Ponds are usually limed to

by Robert Kanyembokill off pathogens that might have remained from the previous cycle. For newer ponds, it is not neces sary to lime unless the pH of the soil is acidic.

3. Filling the water

Begin filling in the water once you have checked for punctures or holes. Failure to spot the holes in your production system will lead to water loss in ponds and fingerling escapees in cages.

4. Fertilizing

Fertilizing helps with enriching the water to be able to produce natu ral food called plankton. Manure is commonly used as fertilizer. There is a misconception that manure is used as feed in fish farming. It is not! Manure is a catalyst for the growth of plankton in water which fish will eat. Plankton is natural food found in water that is made up of two components; zoo-plankton, which are minute animal-like organisms and phytoplankton, plant-like organisms. So, the concept of fertilisation is to enhance growth of natural food which provides extra nutrition to the newly introduced fingerlings. Do not feed manure, feed Novatek Fish Feeds.

A good seed source is essential in fish farming. Always get finger lings from a reputable fingerling supplier. There are a number of suppliers in Zambia that provide quality fingerlings. You can consult Novatek should you be looking for one.

Another important point to remember is to understand the species allowed in your area. Certain species are not allowed for farming in certain limnological systems. For example, Oreo chromis niloticus is not allowed in the Northern Region of Zambia and only allowed in the Southern

Region that includes Lake Kariba. Visit or consult the Fisheries Offic ers in your area.

6. Acquire feed

Fish feed makes up more than 50% of the total production ex penses. It is therefore important to pick the right feed that will in turn offer you better harvesting weights and profitability. Ensure you choose Novatek Fish Feeds today. At Novatek, we have a wide variety of fish feeds from fry stage to harvesting size; Prestarter to Grower and Finisher or Pond 18% for those in pond culture. Our fish feeds are afford able, of the highest quality and found country-wide at our many agents and Zambeef Macros.

A good fish farmer will always diligently monitor the water qual ity daily. Water quality parameter checks provide essential informa tion about the environment the fish is growing in. Parameters such as temperature, dissolved oxygen, pH, and ammonia need to be observed constantly as an imbalance may result in fatalities in the production systems.

Changes in temperature may lead to fish not eating or reduce the oxygen level in the water causing an anoxic environment, in which the fish will die. Increase in ammonia concentration will also kill fish. With a water qual ity testing kit, you will be able to measure the changes in these parameters.

All business decisions should be re lated to the market around you. Fish is popular in Zambia and currently, the country has a deficit. However, it is important to define your market before you start your business. Once you know your market, it will help you to plan the target weight you will grow your fish.

Most table-size fish in Zambia is grown to an average of 350 g but your market may require smaller or bigger fish. Your market will de fine the size. Listen to your market through your market research.

the event of rain. This rain-fastness, combined with the duration of control, provides excellent application flex ibility when less-than-ideal weather is an issue.

What type of protection does each active ingredient provide?

Applied preventatively, oxathiapiprolin (ORONDIS®) outperforms mandipropa mid, the current standard for late blight and downy mildew control.

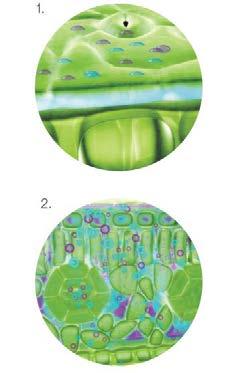

Mandipropamid and ORONDIS® both bind tightly to the waxy layer of the leaf surface (1) and flow steadily into the leaf tissue (2), where they provide disease protection on the upper and lower leaf surfaces.

Plasmopara viticola on grapevine

In grapes, ORONDIS® will provide ex cellent control at label rates regardless of rainfall.

F armers welcome Syngenta’s an nouncement of ORONDIS® Ultra fungicide with two active ingredients for unsurpassed late blight and downy mildew control.

ORONDIS® Ultra fungicide brings two highly effective modes of action together for powerful residual control.

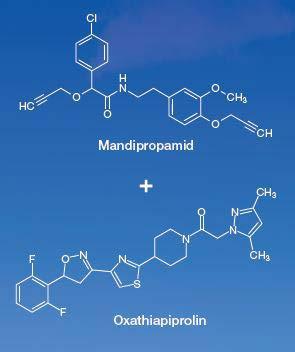

ORONDIS® Ultra combines man dipropamid (FRAC Group 40) with oxathiapiprolin (FRAC Group 49), a unique active ingredient that delivers highly effective residual protection against late blight and downy mildew.

Orondis® Ultra offers Oomycete control in vegetables and specialty crops, having:

• A new mode of action with no cross-resistance with other oomy cetes products.

• Local systemic and translaminar movement in the plant tissues to protect developing leaves.

• Durable and long-lasting disease control.

• Excellent preventive fungicidal activity, controlling all key life cycle stages of the pathogen.

• Rain-fast and protecting the plant from disease even after rain.

• Highly potent, with excellent ef ficacy and crop safety at very low application rates per hectare.

How does ORONDIS® Ultra work?

ORONDIS® Ultra provides translaminar and acropetal activity, meaning that it moves across the leaf surface as well as upwards into new growth via the plant’s xylem, or water-conducting vessels. Both modes of action work in tandem to protect the plant – even while it is actively growing.

Because ORONDIS® Ultra is taken up in the plant, it will not wash off in

Translaminar movement.

ORONDIS® Ultra protects new growth

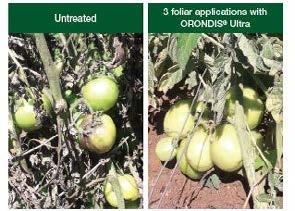

Applications of ORONDIS® Ultra pro tected new growth in tomatoes that were continuously inoculated.

Systemicity - biological activity outside of the treated area ORONDIS® can control pathogens outside the treated area in foliar application.

Xylem-systemic movement

ORONDIS® moves through the xylem – the plant’s water conducting vessels – and moves upward and outward to protect the plant as it grows.

Rain-fastness

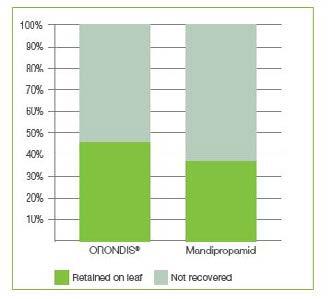

ORONDIS® has excellent retention properties providing unmatched oomy cete control even after heavy rainfalls.

Measuring retention on leaf surface

After 200 mm of rain 1 hour after ap plication, > 40% of ORONDIS® Ultra was recovered from grapes.

ORONDIS® Ultra is effective on key life cycle stages of the pathogen ORONDIS® Ultra targets oomycetes at several stages in the life cycle, and is most effective at key stages of sporula tion, germination and initial infection.

Stopping the pathogen at these points reduces the opportunity for disease cycles to develop.

Proven field performance

ORONDIS® Ultra brings a new era of protection against downy mildews and late blight diseases on vegetables and grapes with its two unique modes of action. Thanks to its unbeatable per formance, it is an elite and trustworthy solution, under all conditions, ensuring high yields of superb quality.

For more information about ORON DIS Ultra, visit www.syngenta.com

... Kimtrafos is the perfect solution for your animals.

Phosphate and trace mineral supplement or concentrate for phosphorous deficient areas.

• Available as a concentrate (P12) and ready-mixed product (P6).

• In a convenient granular form for a dust-free product.

• Enriched with the most important trace minerals in the correct ratio to phosphorous.

• Distinctive molasses smell and taste to promote intake.

• Promote production and fertility.

• Improves growth and skeletal development.

• Versatile application during the rainy season or throughout the year in phosphorous deficient areas.

• Suitable for cattle, sheep and goats.

Balanced animal feed.

www.yara.co.za/animal-nutrition animal.nutrition.sa@yara.com | Tel: +27 (0)31 910-5100

Kimtrafos 6 Grandé - Reg. No. V23311 (Act 36 of 1947), Kimtrafos 12 Grandé - Reg. No. V18670 (Act 36 of 1947)

Yara Animal Nutrition South Africa (Pty) Ltd. Reg. No. 2001/025850/07

At John Deere there is no time for sitting back and being idle. John Deere's smart people are constantly identifying and implementing strate gies to ensure that John Deere customers get the professional edge putting them in a winning position.

Today, in 2022, no one is unfamiliar with the world-famous agricultural equipment manufacturer, John Deere ... and no one speaks about the green stal warts without the necessary respect Pieter Pienaar, Tactical Marketing Planner at John Deere, says: "Tech nology is the key that can move agri culture forward to increase yields and decrease costs, but we can only do this if technology, people, equipment, data, and insights are connected for delivering better results. These con nections offer opportunities to apply sustainable farming practices.”

Add value to your livestock and orchard with smaller tractors

Every farmer, whether he farms with livestock, grain, or grapes, has differ ent needs. It is of the utmost impor tance for John Deere to understand and meet the needs of each farmer, in each section of the value chain.

"Over the past year, we have become deeply involved in production systems and also recently attended SAMAC and Veeskool's (Livestock School) farmers' days. These farmers' days are specifically focused on shar ing information with macadamia and livestock farmers," says Pieter.

John Deere's involvement with Veeskool

Pieter adds: “At Veeskool, we dis cussed John Deere’s role in livestock farming, which is really important for us to move closer to the farmer.

Cattle farmers at the famers’ day spoke highly of the adaptability, affordability, and productivity of John Deere's 6B tractors.

"When I think back to what farmers at Veeskool said, specifically about

our 6B and its suitability for the live stock industry, it becomes clear that livestock farmers do not always make use of all the technology of the trac tor, but they still want the reliability of this rugged tractor that lasts for years and completes the tasks easily," Pieter adds.

This ties in yet again with value for money. Pieter elaborates on the advantages of John Deere engines: "We manufacture the engines of our tractors ourselves. Their extended life can be contributed to the advanced mechanical technology available only on John Deere PowerTech engines.

Along with this, John Deere offers longer service intervals. Instead of required services every 250 hours, John Deere tractors are serviced every 500 hours. This means time and cost savings for the farmer!”

John Deere also offers a range of tractors that are specifically designed and built to meet the challenges that an orchard, a vineyard, or a nursery presents to farmers. As John Deere moves closer to the farmers, their ex perts set a course for future solutions.

"Deere & Co recently invested in GUSS Automation, a company focused on bringing precision solutions to the market. This will give the farmer the opportunity to accurately apply fertilisers and treatments exactly where needed," says Pieter.

Farmers can rest assured knowing that there is enough power available for even the most difficult tasks.

"SAMAC was a wonderful op portunity for us to be part of such a professional organisation, not only to serve as a sponsor, but to share the necessary knowledge with macada mia farmers enabling them to move forward and make more informed decisions," says Pieter.

"John Deere is here for the long run, so we want to make sure that the farmer is also here for the long run by being sustainable from generation to generation," he concludes.

John Deere Financial also has cus tomised solutions for unique require ments. Whether it is big or small, they efficiently support you in the best financing solution.

From mid-November, John Deere will have a promotional offer for Black Friday. Keep an eye on their web pages and social media to get equip ment at affordable prices.

In addition to cost efficiency, a farmer wants to buy a tractor that can easily complete the necessary work on the farm. Here, too, John Deere offers attractive options.

Check with your closest dealer today to find out more about this year's Black Friday promotions and what they have to offer.

Visit John Deere's website for more information at www. deere.africa/en/index.html.

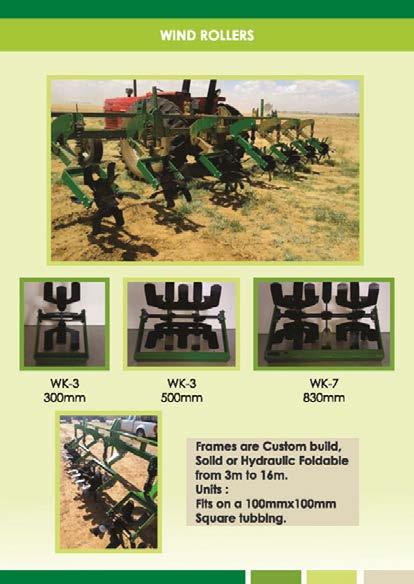

Ripper Tillage Equipment has an implement for every job through out the planting journey. The team specialises in custom-built equipment that ensures results in your crop, because a successful harvest does not only rely on fertiliser, water and the type of seed you use. It also relies on how the seed is planted in the particular soil type and how it is cared for.

Ripper Tillage Equipment pride themselves in identifying the needs of your soil bed. “We take into con sideration how the soil needs to be prepared,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains. “We also look at what you will need to close the soil after planting and ripping, such as rollers or closing coulters.”

Ripper Tillage Equipment manufac tures rip till and strip till equipment, rotary hoes and planting equipment

“We specialise in on the row ripping. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Because there is less soil ripped over a large area, the machinery –tractor included – has less wear. What is more, it also uses less fuel and requires less labour.

Tillage equipment backed by knowledge and support

Ripper Tillage Equipment employees are knowledgeable in soil require ments. “We come to your farm, do a

The harvester trailer is manufactured in sizes 35 and 40 ft (10,6 - 12 m).

This implement has the closing coulter and roller units for rip on the row soil preparation.

soil test with a demonstration and determine the implements you require to achieve the best culti vation,” Christine explains. “We look at the type of soil on your farm and take into consideration what your previous crop was – especially for farmers that practice conservation farming by tilling crop residues back into the soil. By looking at the soil condition and know ing what the farmer plans to plant next, we can see which implement is needed to do the job.”

That is the benefit of custom-made implements. Where your soil condi tions and the needs of every crop dif fer from area to area, you can invest in exactly the right tools to help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need.

Harvester trailers are a handy piece of equipment that might not immedi ately jump to mind when thinking about harvesting season. The truth is that transporting headers can have many challenges, but with the right trailer, the problems are quickly solved.

Ripper Tillage Equipment manufac tures 35 to 40 ft (10,6 - 12 m) trailers that hook behind any bakkie or tractor. “It isn’t a heavy trailer, and it assists farmers with transporting har vester headers from the store to the field and back,” Christine explains.

This is just another way of solving a farmer’s need — one piece of equip ment at a time.

Ripper Tillage

We have successful clients who have used our equipment for more than eight years. “You can see how satisfied our clients are when they return next year for an even bigger order.

“We often hear that new clients heard about the effectiveness of our products from a neighbour or friend, and decided to invest in an implement themselves."

Ripper Tillage Equipment ensures excellent service by visiting clients on the farm and offering guidance on how to use the implements effec tively. “Maintenance is also fairly easy and inexpensive, because all parts are available at local hardware stores,” she adds.

Take a closer look at the range of equipment from Ripper Tillage Equipment as displayed at the 2022 NAMPO Harvest day in Bothaville. https://www. proagrimedia.com/news-events/ nampo-2022-ripper-tillage-arespecialists-in-seedbed-preparationequipment/.

For more information about harvesting tables or custom ised equipment for your seedbed preparations, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbotharip till@gmail.com. Visit their website at: www.rippertillage.co.za or find them on Facebook: www.facebook. com/RipperTillage.

by Barbara Mulonda Simbaya, Tech nical Advisor, Tiger Animal Feeds

by Barbara Mulonda Simbaya, Tech nical Advisor, Tiger Animal Feeds

Biosecurity is a set of preventative measures designed to reduce the risks of infectious disease transmission to and among livestock. Biosecurity is important because the set of preventive measures put up will reduce the risks of infectious disease transmission and will help maintain the health of the birds. In poultry production, and broiler produc tion to be more specific, biosecurity refers to procedures used to prevent the introduction and spread of diseasecausing organisms in broiler flocks.

An effective and well-implemented disease prevention programme will ensure that chickens are healthy and grow rapidly. Healthy chickens do not require medicines to cure diseases, or expensive boosters to promote growth in poorly performing birds.

As we can see, disease is indeed a cost on the poultry business and will reduce the profit margin through delayed growth, poor quality birds and increased mortalities.

Prevention of diseases on a broiler farm can be achieved in two main ways:

1. Preventing the farm and the chick ens from coming into contact with disease agents, as well as getting rid of them if they are already there.

2. Preventing the disastrous effects of the disease agents on the chick ens by means of a well thought-out vaccination programme. However, for the disease prevention programme to be effective, it requires the right attitude from the person implementing it. A serious personal commitment to the importance of the broiler business has to be made. With this in mind, one should use the best resources at hand to keep the disease away from the chickens.

A good disease prevention pro gramme can be achieved by following the rules of biosecurity. The following are some of the rules that must be included when coming up with an ef fective biosecurity programme.

• The house must be cleaned prop erly and thoroughly before the chicks are placed. Clean by sweep ing out and dusting all hard materi als, followed by a thorough wash using detergents and clean water. Then disinfect the entire house with Virukil, Ultracide or any other effec tive disinfectant on the market.

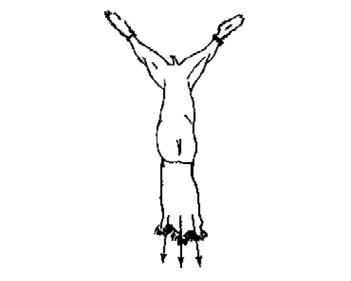

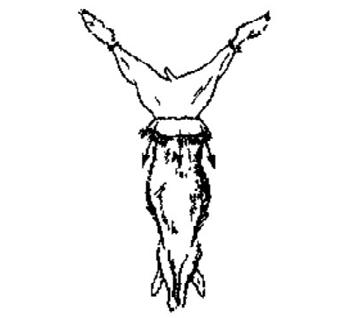

• Access to the poultry house by peo ple should be controlled. Humans and their equipment carry 95% of poultry diseases. Although diseases can spread naturally, the distance they travel is normally limited by environmental factors and their own physiology. Human activity has the potential to spread diseases much further and faster because of the speed and distances we travel. Therefore, equipment and human beings entering poultry houses, should be well-washed and disin fected to reduce the load of the germs they are carrying. Only one person should be allowed to take care of chickens in each house.

• All poultry house entrances should have footbaths with disinfectant for people. This helps to disinfect under the feet and shoes before entering the poultry house.

• Keep wild birds, village chickens, guinea fowls, ducks and rats out of the broiler house. These can carry pathogens that may cause diseases in your flock. Use traps or

rodent bait to keep rats out of the poultry house. All window openings should be covered with wire mesh.

• Sick and dead chickens should be removed from the house as soon as they are noticed, because they can easily and quickly spread the germs to the healthy birds. Sick chickens should be kept separately.

• Never let the bedding materials get wet and caked. Hard floors injure the feet of the birds and infection may follow. Wet litter is the breed ing ground for disease agents.

• Bury the manure removed from the poultry house as quickly as possible, because if left un checked, blowing winds may carry germs from the manure to healthy birds.

• Selling or dressing of chickens should not take place within the house, because it will make loose feathers fly around everywhere, thereby spreading germs to other chickens. Create a place where these activities should take place.

• Do not keep any other chickens, especially of local breeds, together with broilers. These birds carry a lot of diseases which they can eas ily transmit to the broilers.

• Follow a timely and strict vac cination programme. Do not wait until you see one chicken sick to vaccinate. In fact, never vaccinate sick chickens.

• It is not advisable to keep multi aged flocks in one house. This normally facilitates disease carry over from one batch to the next. However, if you are to keep flocks of different ages, let them be kept in different pens, and visitation of these groups should always be from the youngest to the oldest. If these rules are strictly observed, you will experience fewer problems with the chickens.

Tiger Animal Feeds provides free technical services to customers on all species of livestock. A strong technical team is available to offer help when ever the farmers require it. Take ad vantage of this service, and turn your enterprise into a successful business with Tiger Animal Feeds.

For more information or questions on biosecurity on your poultry farm, contact Barbara Mulonda Simbaya on +260)969-202-207 or send an e-mail to barbara. mulonda@tigerfeeds.com.zm

I

n the previous articles, we discussed beekeeping in general and the value of bees as pollinators.

In this article, we have a peek inside an active beehive to see who lives there and what they do.

A caste is a level of importance in the beehive, just like there are castes in many human societies. A beehive is all about social status, in short, some are created more equal than others …

The queen is, well, the queen, even though she has humble beginnings.

The drones are like a lot of men: fat, lazy and only interested in mating with a queen.

The workers are like womenfolk: They work from morn till night throughout their lives – and then they die.

A caste in social insects, such as bees, refer to different types of bees of the same sex but who have different bodies and do different jobs, like the worker bee and the queen. The drone is an additional caste in the hive.

All three castes have different duties, and the hive cannot survive without any one of them. It’s like they are dif ferent parts of a body, with the queen being the head who decides what the worker bees – the body – should do for the survival of the hive.

The worker bees are all females and work from dawn to dusk.

Let us start with a thriving hive that is fully functional. The main duty of the queen is to lay eggs – thousands of them to replace the vast number of worker bees that die each day, whether of old age, attacks by an enemies like alien wasps, or herbicides that humans spray to get rid of harmful insects.

The queen is the brain of the hive. By releasing pheromones, a chemical sub stance produced and released into the environment, she controls the behaviour and physiology of all the bees in the hive. Without these pheromones, also referred to as her scent, there would be no order in any of the hive’s activities.

Worker bees work tirelessly to store the pollen and nectar brought to the hive by foraging bees returning from the fields.

She would, for instance, inhibit unnec essary queen cells to be built, or prevent the workers from laying eggs. She also uses her pheromones to attract drones during her mating flight. The bees know her scent and will guard against any intruders who do not smell familiar.

Without her pheromones, the workers will mill around helplessly. A failing or dead queen must be replaced as soon as possible, therefore workers act in stinctively. They choose several eggs or larvae to prepare a new queen, and so, the queen begins her life as an ordinary worker egg laid by the existing queen.

During the third week of a worker bee’s life, she undertakes short flights to strengthen her wings. Later she will fly many kilometres a day to collect pollen and nectar.

Within a few days, the egg or larva is taken to a queen cell, where it will develop into a new queen with the help of the workers who feed her royal jelly that they produce with their glands. Eventually, they seal up the larvae with wax. Sixteen days later a suitable queen emerges a few days sooner than if she were just another worker bee. After escaping from her peanut-shaped cell, she is cleaned and cared for by the royal court. She is fully developed and ready to take up her duties. For the rest of her life, she will be fed royal jelly.

As the queen moves throughout the hive, she is surrounded by a group of workers known as the royal court. Nearly every bee at the age of two weeks gets a turn to be part of the royal court. They take care of the queen by feeding her royal jelly, and touching her by rubbing their antennae over her, and so spreading her scent throughout the hive. This helps the workers – and drones – to understand what they need to do.

The reason for a new queen could be that the old queen is at the end of her life and the hive needs to replace her, or the colony plans to swarm.

Two types of cells are suitable for a queen to be: a supersedure cell or a swarm cell. The queen cell has a peanut shape, is bigger than the other cells and is built away from them. A supersedure cell is situated along the centre of a given frame and is built for a queen that will supersede the failing or recently dead queen. There can be several of these cells at a time.

The swarm cells are attached to the bottom of the brood frame. The queen that emerges from these cells will leave the colony with half of the bees inside to form a new hive. This leaves room for thousands of new bees in the existing hive, and this is the bees’ nat ural ability to multiply at a superfast rate. A healthy hive can swarm four or more times during the warm season.

The queen looks a bit like the worker –she is female after all, albeit a supe rior one. She is about one and a half times as large as a worker bee, with a slimmer and paler body with lightercoloured stripes on the abdomen.

She has a bald spot behind her head on the thorax, where six legs and four wings, which appear shorter than that of the workers, are attached.

Some beekeepers mark the queen

with a dot on the bald spot so that they can distinguish her more easily from the workers. Usually, the colour of the dot will indicate the year the queen started her royal duties.

The queen has a curved sting without barbs, but rarely uses it except when she must get rid of another queen.

On her first day as queen, the royal court escorts her around the hive to where worker bees are cleaning cells into which she will lay her eggs after mating. This only happens after she has killed any other queens who may not have hatched yet!

On day three of her life, the queen’s wings are strong enough to support her body, and her mating organs are devel oped so she is ready for mating.

She leaves the hive and flies to about ten metres above the hive. Up to twelve drones from other colonies mate with her in flight. The drone’s sex organ snaps off inside the queen so that no sperm is wasted, and the drone falls to the ground and dies.

The queen may undertake up to twen ty flights, but when she returns to the hive, she has enough sperm to lay fertile eggs for up to five years. The sperm is kept alive by a protein substance pro duced by the queen’s body.

Although she can lay up to 2 000 eggs per day throughout her life, she never has to mate again. This is quite as tounding if one considers that a colony can exist of between 10 000 individuals in winter and up to 60 000 or more in summer.

Soon after mating the queen starts laying eggs. This is a most important

job, because worker bees die at an alarming rate.

She needs to lay eggs to produce worker bees to do housekeeping du ties, guard the hive and collect nectar and pollen for the survival of the hive.

She inspects the cells to see if they are clean enough before putting her backside into the shallow cell to lay an egg. She produces a small bit of sticky substance in the bottom of a cell onto which the egg adheres, before moving to the next cell. She does this up to 1 500 times a day for five years, only taking short rests of five to ten min utes now and again.

The eggs and sperm are kept sepa rately in the queen’s body and she can control which eggs must be fertilised. The workers lead the queen to the cells where she must lay eggs. If she lays an egg in a worker cell, she allows one sperm to attach to the egg to produce a female worker.

If she doesn’t attach sperm, the egg will produce a drone. The drone cells, which are bigger than the worker cells, are usually found in the corners of the hive where the pollen and nectar are stored.

The workers are all female. The worker is the smallest in the hive but does all the work during her lifespan. She is well-equipped for her job, which changes as she gets older – she has a honey stomach, pollen baskets, wax glands, and a barbed sting for protect ing the hive against intruders.

The workers who are fresh from the uncapped cell work in complete dark ness inside the hive: they feed and cap

New larvae in cells.

new larvae, they store the pollen and nectar brought to the hive by forag ing bees returning from the fields, and they clean the hive.

When they are older, they move to the hive’s entrance where they con tinue to receive the pollen and nectar from returning field bees, do guard duty, and cool the hive by fanning their wings for ventilation.

During the third week of the worker bee’s life, she undertakes short flights to strengthen her wings and to ori

entate herself to the location of the hive. When she starts foraging, she flies many kilometres a day and visits thousands of flowers to collect pollen and nectar. By doing so, she will polli nate fruit and nut trees, vegetables, oil producing plants and grains that form part of our diet.

During the roughly two weeks that she spends foraging, she will fly more than 650 km, wearing out her wings until she can fly no more. When she is about five weeks old, she will merely walk away from the hive to die a lonely death.

The drones are the only males in the hive, and usually there are a few hun dred of them. Their hairy bodies are larger and more square-shaped than the workers. They do not have stings, so they are no good helping to protect the hive.

Their only purpose is to ensure ge netic variability of the hive by mating with a virgin queen of their own and other hives. Besides that, they are tolerated for emergency mating duties should something happen to the queen.

They usually live between 21 and 32 days before they are kicked out. In autumn, the worker bees pick them out and literally throw them out of the hive. If they try to return, the guard bees – also females – don’t allow them. Dejected, they try to find another vir gin queen to mate with, or just die.

Caste Differentiation: The Queen, the Worker & the Drone. (n.d.) BeeWare http://www.practicalbeekeeping.com

Anderson, R.H., Buys, B., Johanns meier, M. F. (2014). Byeboerdery in Suid-Afrika. Department van Land bou-tegniese Dienste Bulletin no. 394, 1978. Hersiene uitgawe.

The need to put carbon back into the soil where it belongs instead of being released into the atmosphere as carbon dioxide that contribute to global warming, is very real. There is no time to waste while the world is seeking environmentally friendly alternatives to using fossil fuels as energy, says Ken Coetzee of Environmental Management Services.

The term ‘carbon sequestration’ has become a buzzword in discussions about environmental issues. Ken ex plains what it is:

“Modern mechanised industrial agriculture has caused the leaching of carbon from the soil in cultivated croplands. The importance of returning carbon to the soil is a relatively recent aspect of the global warming mitigation debate, but it can help mitigate the present dire conditions.

“Up to between fifty and seventy per cent of all cultivated soils in the world have lost most of their original carbon stocks. This is a result of exposure which causes the carbon stored in the soil to become oxidised and modified into atmospheric carbon dioxide (CO²).

“In addition, typical agricultural prac tices have resulted in an estimated loss of twenty billion tonnes of fertile topsoil every year and this represents a direct loss of carbon stored in the soil.

“Soil-carbon sequestration must thus be an essential part of global warm ing mitigation, and this can be partly achieved by restoring degraded and eroded landscapes.”

Unfortunately, there seems to be no urgency to stop and reverse these trends, which appear to continue unchecked. “We hear of the reforesta tion of tropical forests, the restoration of mangrove swamps, and the mass planting of trees in the Sahel in North Africa, but there is hardly ever a men tion of large-scale soil erosion control.

The frequent use of chemical fertilisers and pesticides has a negative impact on soil microbiology.(Source: Pixabay)A cover crop keeps the soil moist and protects it from the rays of the sun. (Source: Adele Payman, unsplash.com) Source: Pixabay

“If we do not collectively take effec tive and committed action with much more urgency than at present, we shall see the destruction of our home.”

How is carbon lost from the soil?

Ploughing, subsequent erosion and the uncontrolled use of non-organic chemi cal fertilisers and pesticides exacerbate the problem.

Frequent ploughing disrupts the habitat of micro-organisms below the surface of the soil where plant litter and carbon is stored. Deep ploughing destroys the root environment that is the habitat of micro-organisms necessary for maxim ised growth. When these systems are exposed to solar radiation and oxida tion, the soil loses its carbon.

“Therefore, a no-till or regenerative approach to crop production is a far better option for maintaining long term

soil health,” suggests Ken.

Ploughing also leads to erosion, whether caused by wind or water. When soil surfaces are exposed be cause of a lack of plant cover, either by planting monoculture crops, tilling or overgrazing, the soil carbon is oxidized and lost as CO² into the atmosphere.

The frequent use of chemical fertilisers and pesticides, which include herbi cides for plants, insecticides for insect pests and fungicides for unwanted fungi growth has a negative impact on soil microbiology. The loss of soil-form ing organisms is followed by a reduc tion of organic material in the soil, which leads to the soil’s reduced capacity to store carbon.

“This can be offset by stimulating natural soil recycling by encouraging the application of organic material, in cluding biochar and manure, to the soil

to improve productivity and help lay an effective foundation for improved carbon storage.”

The quantity of carbon in the soil can be determined by soil carbon experts in a laboratory. “The depth of the dark layer of soil near the soil surface is a good layman’s indicator of organic soil carbon. The deeper and darker the soil, the better the soil carbon content.”

Mitigate global warming

Putting carbon back into the soil not only helps to mitigate global warming, but also offsets the continuing nega tive impact of burning fossil fuels. In addition, it improves the fertility of the soil that is essential to feed a rapidly expanding human population.

“Recent research has shown that more carbon is stored in the soil than in the atmosphere and all the combined plant life on earth,” says Ken. “It follows that every possible opportunity to in crease soil carbon in all the ecosystems on earth should be explored and imple mented as a matter of great urgency.”

Ken believes the restoration of soilstored carbon is a relatively simple matter of returning the carbon to where it belongs, and one may ask why this is not being done more widely.

According to Ken it is a well-known fact that ancient civilizations of Central and South America manufactured and used biochar very successfully for increasing the fertility of the soil for food production.

“Why have we chosen to ignore this historical technology and think that we can instead continue to use chemical fertilisers to produce enough food for our needs? We now know that we were mistaken, and that returning organic carbon to the soil is not only necessary for improving soil fertility, but also for creating a critical carbon sink that is needed to counteract global warming.”

Biochar is a charcoal-like substance made by burning organic material from agricultural and forestry wastes, also called biomass, at a high temperature called pyrolysis.

It looks like ordinary charcoal, but reduces CO2 in the atmosphere. It contributes to the mitigation of climate change by enriching the soil, reduc ing the need for chemical fertilisers and thereby lowering greenhouse gas emissions.

Photosynthesis is the process by which plants use sunlight, water, and car bon dioxide from the atmosphere to create oxygen and energy in the form of sugar, which is necessary for the plant’s growth.

Carbon that the plant does not need for its own growth is transferred by the roots, where it is humidified and stabilized, and used to feed the organ isms in the soil. This improves water retention as well as the structure and fertility of the soil.

A primary vehicle for moving carbon into the soil is root fungi or mycorrhiza. Mycorrhizae is a symbiotic association between plant roots and fungi, and the term refers to the role of the fungus in the plant’s root system or rhizosphere.

Many plants have thread-like fila ments that extend the reach of the plant roots to access sufficient nutri ents and water. These filaments are coated with sticky glomalin, a sub stance that facilitates carbon storage in the soil.

“Plant roots, mycorrhizal fungi and glomalin are thus the key to carbon sequestration in the soil. A disturbance or loss of the plant cover on top of the soil, or of plant roots in the soil, will severely disrupt the ability of the soil to store carbon.”

What can we do about soil carbon storage?

“We need to incen tivise all land users, including landown ers, farmers, game ranchers, forest ers, conservation and agricultural authorities, as well as teachers, to change their ac tions towards a more regenerative approach in order to increase carbon sequestration

These actions can maximise carbon storage:

• effective landscape-scale soil ero sion control;

• replanting of degraded areas;

• improved grazing and pasture management;

• mulching crop biomass rather than burning it;

• large-scale production and use of biochar to improve soil health;

• reduction of ploughing in favour of regenerative agriculture;

• the informed and sparing use of fertilisers, herbicides and insecti cides;

• the restoration of important car bon sinks like peatlands, wetlands and grasslands.

Ken believes it would be easier to put carbon back into the soil instead of reducing in CO2 emissions caused by using fossil fuels. “In the short term, it will probably be more easily achiev able to put carbon back into the earth’s soils than to try to convert all the worlds’ fossil-fuelled vehicles into solar or hydrogen-powered machines.

“We need to actively work at restor ing soil carbon while the transformation to safer power sources for transport

is being considered, investigated, and implemented. It will still be a long time before we see the end of fossil fuels.

“We simply cannot allow the resto ration of soil carbon to be left behind while we search for ways to deal effec tively with the fossil fuel crisis; it has become clear that we now depend on maximum effective carbon sequestra tion for our ultimate survival.”

For more information contact Ken Coetzee at Conservation Management Services at +27 76227-5056 or consken@mweb.co.za

References

Bassham, J. A. (2022) Photosyn thesis. Britannica https://www. britannica.com/science/photosyn thesis

Mycorrhiza

Spears, S. (2018) What is bio char? Regeneration International. https://regenerationinternational. org/2018/05/16/what-is-biochar/

Tree harvesting has left the Miombo woodlands in northern Malawi de nuded of trees, resulting in major soil erosion.

Ken Coetzee of Conservation Man agement Services, based in George, visited the area, and concluded that an approach based on the Community Based Natural Resource Management (CBNRM) principles could be useful in solving the serious environmental and social problems caused by the unsus tainable harvesting of trees in the Miombo woodlands of Malawi.

While Malawians have been sustainably harvesting their forest trees for cen turies, increased charcoal demand by growing urban populations in cities has led to the depletion of these once abundant woodlands.

This is especially true of the Miombo woodlands in the hilly escarpment country west of Lake Malawi, and large mature trees are presently restricted to forest reserves and graveyards, ac cording to Ken.

“The demise of the woodlands began with the discovery that using charcoal for cooking food has benefits over the

use of firewood,” says Ken.

In many developing countries such as Malawi, charcoal is the preferred domestic fuel for cooking and heating. When used as a domestic fuel, it is easi er to light, it burns warmer and produces less smoke than wood, and leftover coals can be reused. In addition, it is easier to transport and store.

Charcoal is produced by burning stacked green wood in a pit covered with soil to prevent airflow in the under ground oven. Bigger trees are felled and cut up, and the roots are dug up before they are put in a hole, covered with soil, and set on fire. Once the charcoal is ready, it is bagged and carried out of the forest to the nearest village or collec tion point along a road from where it is transported to the nearest town or city.

Once the area has been stripped of large trees, the charcoal burners move to the next unharvested area. When there are no bigger trees left, the stumps that have coppiced (sprouted) are also harvested. As a result, most of the woodlands have been stripped of tall, mature trees and are left with coppice regrowth of between two and four metres high. Trees of which the roots have also been removed obviously have no chance of regrowth and are lost to the ecosystem.

Local people also harvest dry wood as a building material, for cooking and to fire brick-making ovens. This causes not as much damage as the harvesting of living trees for charcoal.

Where the tree canopy has been removed, increased sunlight allows grasses to flourish. This provides graz ing for cattle, but when these grasses are overgrazed, no grass seeds are produced for renewal. When the grass sward collapses, grass cover is re duced, and the soil becomes vulnerable to soil erosion.

The lack of a tree canopy and overgraz ing led to erosion of soil on the steeper slopes, causing gullies and eroded bad lands in the easily erodible granitic soils of the Miombo woodland areas.

Among the charcoal pits, which are a couple of hundred metres apart, multiple footpaths are formed by the harvesters between the trees, the firepits, and between farm settlements and villages. During every rainy sea son, water channelled along these paths widens and deepens the existing paths and creates new ones alongside

them. Eventually, these footpaths be come deep erosion gullies.

“An alternative solution to the growing need for fuelwood must be found as a matter of urgency,” says Ken.

This is not easy to find a solution in the face of traditional cultural prac tices, and poverty that forces com munities who live off the land with no alternative incomes but the burning and selling of charcoal, as well as poor governance.

Possible solutions include:

• Managing the harvesting of exist ing wood in a specially zoned rota tional harvesting system.

• Planting of alternative sources for fuel wood, such as plantations of gum and pine trees in managed woodlots near homesteads.

“Both of these alternatives will require complete buy-in and cooperation from the local authorities (chiefs) and the local communities. The success of these will require committed long-term management.”

Option 1: Rotational harvesting of existing woodland

“It is critically important that the harvesting of wood for charcoal must be done in a sustainable manner,” says Ken. “It will be preferable to have particular defined areas, heavily but sustainably harvested on rotation, and then rested to recover over the current unsustainable harvesting continue tak ing place across the entire landscape.”

Option one includes removing trees

for charcoal in rotating zones according to a planned harvesting sequence.

• The harvestable zones of three hectares each must be interlinked with patches of intact protected woodland or forests and surround ed by half a hectare of buffer zone from adjacent land use.

• Identify and map areas of wood land with suitable tree ages and density for the harvesting zones.

• Survey the area to determine tree species and age which can be used to determine rotational harvesting sequence and schedule.

• Exclude intact woodland forests with trees over twenty years old and keep them as undisturbed reserves for plant and animal bio diversity.

• Calculate the harvesting schedule to rest a zone for at least five to ten years before the next harvesting.

• Exclude three to five important slow-growing tree species that are representative of the Miombo woodland in the hilly escarpment areas from harvesting.

• Harvestable zones must be within walking distance from the villages, otherwise damaging harvesting may continue to take place.

• Leave enough mature trees of each species in each zone to permit for woodland recovery by means of root suckers and seeds.

• Do not harvest rare and vulner able species or trees with a stem circumference of 200 mm or more.

• Harvest trees to a minimum height of 300 to 500 mm and leave roots intact to allow regrowth.

• Do not harvest on extremely steep slopes.

• This process should be repeated for each broader area within the project area of influence so that each has its own map of harvest able zones with a suitable time schedule for harvesting.

Success with this harvesting method will require long-term commitment spanning up to 35 years and will re quire the total buy-in of the chiefs and communities that benefit from it. A system of monitoring and enforcement control will be necessary.

Some basic instruction and guidance will initially be necessary to set up the system. A restoration NGO could help with the establishment of harvestable zones and setting up harvesting schedules.

Charcoal-making ovens are a few hundred metres apart in a wood land area that has been stripped of mature trees.

Woodlots consisting of fast-growing indigenous or alien species could be established near villages or cities. Suit able species such as Eucalyptus and the indigenous Croton megalocarpus are preferred to alien invasive species such as Prosopis and the Australian Acacias.

Each woodlot should consist of about six blocks of about 3 ha each (3 000 m²),

Large volumes of charcoal are car ried out of the harvested areas every day, thereby creating numerous footpaths.

planted at about 10 000 trees per hec tare. Six blocks will contain 60 000 trees.

After five years, trees in two of the blocks can be harvested about one metre above the ground. After two years, an other two blocks can be harvested while the first two blocks are rested. After another two years, the last two blocks can be harvested. After that, the coppice

growth should be adequate for harvest. Harvesting must be controlled, and the schedule strictly honoured.

A nursery could be set up to supply seedlings to the woodlots and the com munity should be involved in plant ing, watering during the early stages, weeding, fire protection, containment and harvesting. All members in the participating community must share in the benefits.

As formal government agencies fall short of the requirement, charitable NGOs may like to get involved in the reforestation and management of the Miombo woodlands.

“The rural people of Malawi are ex tremely hardworking and with a little instruction are able to achieve exactly what is required in a relatively short time,” says Ken.

“We promoted low-cost but labourintensive methods of soil erosion con trol that will stabilise severely eroded slopes and gullies to the extent that the area can be replanted with lo cally indigenous woodland tree species where necessary.”

Most of the woodlands are under community-managed ownership, usually with a committee that is responsible for the utilisation of the woodland resources. This is not always

Copious amounts of dry wood is gathered for domestic use such as building, cooking fires, and firing brick kilns.

Water erosion washes out the many well-used footpaths.

Soil

very successful and is often influenced by the community’s economy or rather level of poverty.

A renewed approach to extension and education is needed, which can

be accomplished by an education or extension officer who cares about the people and the environment. He/she must be able to explain to the com munities why unrestrained removal of

trees cannot continue and how they should change their ways to ensure the future of these woodlands.

All education and extension pro grammes must be ongoing, followed up and evaluated to ensure they have the desired effect.

Contact Ken Coetzee at consken@ mweb.co.za or 076 227 5056, or visit the website at https://www. conservationmanagementservices. co.za/profile.php

Charcoal production for cooking and heating. UN Climate Technology Centre and Network. https://www.ctc-n.org/technolo gies/charcoal-production-cookingand-heating

Jones, B., Erdman, T. (2013)

Community-based natural resource management in Southern Africa: A decision-maker’s guide. USAID https://pdf.usaid.gov/pdf_docs/PA 00JRSF.pdf

Langat, M. K. (2019) The generous tree. Kew royal botanical gardens https://www.kew.org/read-andwatch/croton-megalocarpus-gener ous-tree

Steep hill slopes have been severely eroded after woodland and grass cover have been removed by cutting down the trees and overgrazing.

The initial steps in the preparation of Chinese soya sauce are essentially the same as for making Chinese soya paste (Jiang). The final stage of preparation involves the extraction of the sauce from the fermented mass.

Whole soya beans or defatted soy flour can be used. After cleaning, the soya beans or flour is soaked for 3 to 5 hours in water and drained before being steamed for 40 minutes. Cooking is a very important step that enhances starch and protein digestibility for the Koji starter culture and thus ensures the desired final texture of the paste. The cooked soya beans are then cooled to 80 °C before it is mixed with wheat.

Wheat bran or flour is steamed or roasted before being mixed with the hot soya beans. The ratio of soya to wheat is generally 60:40. The mixture is allowed to cool to 38 to 40°C before be ing inoculated with the starter culture.

S

oya sauce is the dark brown liquid extracted from a fermented soyawheat mixture. It has a salty taste and sharp flavour. It is used as an all-purpose seasoning. Soya sauce is prepared from soya beans mixed with other cereals such as wheat that undergoes two separate fermentation processes.

All the enzymatic and biological reac tions taking place during these two fermentation processes, together with concurrent chemical reactions, lead

to the formation of many volatile and non-volatile substances. These sub stances are responsible for the charac teristic colour, flavour and taste of soya sauce. A wide variety of traditional soya sauce recipes were passed on from one generation to the next.

All the different cultures of the East seem to have their signature soya sauce products. This report will de scribe a basic process for the manu facture of Chinese and Japanese soya sauce.

The treated soya and wheat mixture is inoculated with a special strain of Aspergillus that causes fermentation of the product and the formation of “Koji”. The concentration of starter used is be tween 0,1 and 0,2 %. The direct trans lation of “Koji” is “bloom of moulds”.

The Koji provides the spores of micro organisms needed to make soya sauce.

Fermentation takes place in open pans under controlled temperature (36 °C), airflow and relative humidity (>90%).

If defatted soya flakes are used, it should be cleaned and moistened with misters. The quantity of water used should be 30 % of the weight of the soya flakes. The moistened flakes are then pressure-cooked for 45 minutes. The cooked soya beans or flakes are rapidly cooled to below 40 °C. This is accom plished by constant stirring or spreading out on perforated belt/tray coolers.

brands of soya sauce. (Im age Source: seriouseats.com)

The mixture is occasionally stirred to release internal heat generated by fermentation, and to ensure sufficient aeration of the mixture. The first fer mentation stage is usually complete after 24 hours when the mixture turns olive green. The resulting product is known as mature Koji and is regarded as an intermediate product of soya paste and sauce manufacturing.

Koji moulds contain a great variety of enzymes that digest the starch, protein, and lipid components of the raw material. During the first fermen tation process, the major components of the raw materials are broken down to smaller components including pep tides, amino acids, maltose, glucose, free fatty acids and glycerol. These smaller components are fermentable substrates that support the growth of yeast and lactic bacteria that are active in the second (brine) fermentation.

The matured Koji is now mixed with a small quantity of warm brine and packed in fermentation vats or tanks. The anaerobic conditions favour yeast and lactic bacteria that originate from Koji starter culture. These organisms are responsible for the breakdown of the fermentable substrates (mainly sugars) to acid, alcohol, and other volatile and non-volatile substances that contribute to the quality of the final product.

Temperature is a particularly impor tant factor during fermentation, and determines not only the duration of the fermentation process but also the qual ity of the end product.

The mixture contains about half the volume of brine and 25% less salt compared to the mixture used for soya paste. These changes, along with high fermentation temperatures (40 to 45 °C), reduce the fermentation period to 3 weeks.

The fermented mash is transferred to another tank, mixed with additional brine, and heated to over 80 °C.

The heated mass is allowed to stand and settle before the supernatant is removed. This liquid is known as raw soya sauce.

The raw soya sauce is mixed with ben zoic acid to preserve it.

The sauce is clarified by passing it through filters.

The basic steps for the preparation of Japanese soya sauce are similar to Chi nese soya sauce, but the end products can differ significantly.

The process can be summarised as follows:

• Treatment of raw materials

• Koji preparation

• Brine fermentation

• Pressing and

• Refining

The soya beans and wheat are prepared separately but simultaneously. Whole soya beans are soaked in water for 8 to 12 hours (overnight) at 30 °C to increase the moisture content of the beans. The soak water should be changed every 2 to 3 hours to prevent the possible growth of undesirable Bacillus.

The soaked soya beans are then cooked in open pans or steam pressure pots until soft.

The treatment of the wheat is con current with that of the soya beans. Whole kernel wheat is roasted and cracked in rollers. Wheat flour and bran can also be used. The cracked wheat or flour is moistened and steamed.

The pre-treated soya beans and wheat flour is mixed in the desired propor tion, according to the recipe used and the type of end product desired. The ration can vary from 1:1 (soya beans: wheat) to as high as 9:1. The mixture is inoculated with Koji from a previous batch (seed Koji), or with pure cultures containing Aspergillus oryzea and/or A. sojae. Pure cultures are added at a concentration level of 0,1 to 0,2 %.

The inoculated mixture is placed in shallow, perforated vats and kept in incubating rooms with controlled condi tions. Temperatures are controlled at 30 to 35 °C initially, and reduced to 20 to 25 °C towards the end of the incubation period. Occasional stirring is necessary to aerate the mixture and release the heat generated inside the mix. The mixture turns green-yellow after 3 to 4 days and is now known as mature Koji.

Mature Koji is mixed with an equal volume of brine to form a liquid mash. The salt concentration of the mash should be 17 to 19%. The mash is kept in large fermentation tanks for several months for completion of the brine fermentation. The temperature of the mash inside the tanks can be

mechanically controlled. Although higher temperatures shorten the fermentation period, a better quality product is produced under lower temperatures.

A good quality soya sauce can be manufactured in six months by control ling the temperature at 15 °C for the first month, followed by 28 °C for four months and finally returned to 15 °C for the last month. Occasional stirring is necessary to provide enough aeration

to promote good yeast activity and pre vent the growth of undesirable anaero bic micro-organisms, and to facilitate the removal of carbon dioxide. The fermented mash should have a reddishbrown colour and pleasant aroma.

The mature mash is filtered through a cloth and pressed in a mechanical or hydraulic press. The filtrate that

is obtained is known as the raw soya sauce, and is stored in a tank to allow for precipitation of suspended matter and floating of oil on the top.

The salt and nitrogen concentration of the soya sauce can be adjusted at this point to meet standards of identity.

The sauce is pasteurised at 70 to 80 °C.

This heat treatment prior to clarifica tion is very important, and serves the following purposes:

• Inactivation of enzymes and micro-organisms, thus stabilising the product

• Enhancement of the unique product aroma

• Darkening of colour

• Induction of flock formation, which facilitates clarification

Soya sauce is clarified by sedimenta tion or filtration. Filter aids such as kaolin, diatomite, or alum may be added to enhance clarification before filtration.

Addition of chemical preservatives (optional)

Some processors prefer to add pre servatives such as sodium benzoate and paraoxybenzoate.

Packaging and labelling of soya sauce

The soya sauce is filled in bottles or cans, and labelled with the necessary information.

Published with acknowledge ment to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.

protein) mixed according to milk yield or stage of lactation. The breed is ge netically able to adapt to very different agro-ecological areas, but it cannot handle the heat in some areas.

The Holstein breed has a large number of potential artificial insemination sires due to its status as the world's most populous dairy breed. This means that it would be possible to maintain genetic progress for milk yield while improving traits like fertility.

Holsteins produce many calves that can be distinguished by their rapid growth, early maturing, and ease of care. The fine-fibred meat produced has a high growth percentage in the fattening sector.

Modern jerseys come in a wide variety of colours. Jerseys tend to be fawn in

Holsteins are easily recognisable due to their distinct markings, which are most often black and white, but can also be red and white. The breed originated in the Netherlands, where a few strains originated known as the Holstein, the British Friesian and the Dutch type. These dairy cattle form part of the Bos taurus group.

The average milk production for a lactating cow of this breed is 8 550 li tres over a lactation period of 305 days (or 28 litres per day). This robust and heavy cow weighs between 550 and 750 kilogrammes, and the bulls can exceed 1 tonne in weight. Milk typi cally has a fat content between 3,0 and 4,2% and a protein content between 2,5 and 3,8%. The butterfat is low and the milk yield is considered to be high.

Large-framed Holstein cows will not do well when feed is scarce or of low qual ity. Most often, Holsteins are utilised in intensive housing or open camp settings, both of which are examples of zero-grazing systems. They are fed a total mixed ration consisting of forages (hay, grass) and concentrates (boughtin pellets that are high in energy and

by Natasha Kruger

by Natasha Kruger

colour, but you might also see them in shades of grey, red, spotted white, or even near-black. In most cases, the underside of the cattle of this breed is a lighter colour than the top.

Jersey cows weigh between 350 and 550 kilogrammes and are smaller than Holsteins. The bulls can weigh between 600 and 700 kilogrammes. Jersey milk has higher levels of solid components

than Holstein milk, with fat levels of 4,0 to 5,5% and protein levels of 3,5 to 4,5%. This makes the milk rich with the highest percentage of butterfat and protein.

The Jersey produces more kilo grammes of milk per kilogramme of body weight than any other breed. However, their milk yield is lower than that of Holsteins, at around 5 000 litres per lactation. These dairy cattle form part of the Bos taurus group.

Jersey bulls are notoriously aggressive, but Jersey cows are known for their placid demeanour. Because of their superior grazing ability and lower milk yield requirements, Jerseys are com monly used in pasture-based systems. Jerseys are also the dairy cows with the highest heat tolerance. They can adapt to a wide range of climatic and geographical conditions.

An established breed since at least 1812, the Ayrshire can trace its roots all the way back to the district of Ayr in the southwest of Scotland.

duces milk with a fat and protein content that is somewhere between that of Hol steins and Jerseys. The fat particles in their milk are evenly distributed, giving it a smooth, creamy texture and a mild, sweet flavour. The milk is high in solids and gives exceptional cheese yields.

Because of its high grazing efficiency and high feed conversion ratio, the Ayrshire is a popular breed. Being able to produce in either hot or cold weather is one of its most appealing features.

The breed does well in a wide range of management systems, from inten sive stall systems to different kinds of grazing systems and even systems with no grazing.

Cattle from the Guernsey breed range in colour from a light yellow to a deep reddish brown with patches. The cows’ weight can be anywhere from 400 to 550 kg, and the bulls can weigh between 600 and 700 kilogrammes. High-quality milk can be produced by Guernseys despite the fact that they

A deep reddish brown Guernsey cow. (Image source: motherearth news.com)

the calving process. Their yield and milk quality (fat and protein content) fall somewhere between the Jersey and the Ayrshire.

The Scottish Ayrshire is a hardy breed with a wide range of reddish-brown and white coat tones. Ayrshire cows can have a weight of anywhere from 400 to 600 kg, and the bulls can weigh between 650 and 900 kilogrammes.

Their milk is referred to as “the ideal drinking milk”. This breed of cow pro

use 20 to 30% less feed than larger dairy breeds. These dairy cattle form part of the Bos taurus group.

The breed is wide awake and alert without being anxious or irritable. Physically, the Guernsey cow has good dairy conformation and presents the visual impression of a plain animal bred for utility rather than good looks.

Guernsey cattle are well-known for their extraordinary adaptability to a wide variety of environmental con ditions. This breed is known for its potential and easy-going nature.

Calves can be born to Guernseys as early as 22 months of age, making them a good investment due to their fast return on investment. Calves born to Guernsey cows are large and robust, and they present few problems during

References

Southafrica.co.za. (2022). South Af rican Beef Breeds. [online] Available at: https://southafrica.co.za/southafrican-beef-breeds.html

Loubser, A., Schutte, N. and Hofmeyr, I., (2007). Cattle breeds of South Africa. Pretoria, AgriConnect, Pages 184 - 201.

A n integral part of piggery is the feed the animals consume. The quality of the feed and feed uptake are closely related to parameters such as the Feed Conversion Ratio (FCR) of the animals, disease resistance, and repro duction. The optimum performance of the pigs regarding these three qualities determines the quality and eventu ally the price that will be placed on the product, and the income received.

The FCR is the quantity of feed consumed by an animal to be con verted into one kilo of live weight. This parameter of conversion of high-quality feed is paramount in modern pig pro duction, especially considering the ever-increasing feed costs. FCR is built into most feed and performance recording systems as an axiomatic and necessary parameter.

In a piggery, between 60 and 80% of the cost of production is directed to feed and usually around two to three kilogrammes of quality feed produces on average a kilogram of live weight gain. The lower this is or the closer to 2 kg the better the FCR is.

The health status of the pigs always affects the efficiency and effective ness of the conversion process, thus farmers may find that some healthy pigs will convert at 1:1,8 (1 kg weight for 1,8 kg of feed), but some will return figures of 10, that is 1 kg of weight

Sows require a balanced diet to ensure the health and vitality of their offspring. (Image source: pexels.com)

gain for 10 kg of feed input. This dis crepancy in performance indicates the health status of the herd. Pigs needing 10 kg of feed for a 1 kg weight gain will be clinically sick pigs. FCRs of four or five can be attained from sub-clinically sick pigs.

A myriad of factors affects the FCR in a piggery, chief among them being the environment, temperature, sickness, genetics, and quality of feed.

The ambient temperature of the pen should be maintained in the thermoneutral range from as low as 10 °C and up to 23,9 °C. Outside of this tempera ture range, pigs will want to eat either too much or too little.

Growers require temperatures of 20 °C to 23,9 °C, finisher’s need 10 °C to 15,6 °C and gestating sows need temperatures of 15,6 °C to 18,3 °C.

Cold pigs generally eat more due to the need to convert the feed into heat and hot pigs will eat less to keep their body temperatures lower. Other factors associated with a badly maintained environment are poor regulation of humidity and ventilation. High humid ity will reduce a pig’s appetite as does poor ventilation.

The stocking rate is also determined by the ambient temperature outside of a pig’s normal temperature range. A reduced area per animal intensifies stress and results in decreased feed intake. During feeding, pigs crowd ing together to stay warm means less space per pig at the trough, thus less consumption.

Generally, sick pigs do not eat much, or they may overeat without much positive weight gain. This is why it is important to implement disease pre vention strategies from project incep tion to closing to protect your animals and maintain a healthy herd.