Every family needs a strong big brother to do the heavy lifting.

I might be small, but I am powerful for my size.

My passion is ensuring the farm animals are fed.

Harvest time is my time to shine.

Colour in this page to stand a chance to win a 9R Lego Set. Take a photo of you with your colouring picture showcasing your uniqueness and upload it onto social media with the hashtag #OKDeere and tag @JohnDeereAME. Make sure your profile is set to public.

The competition is open to anyone aged 12 or under living in South Africa. T’s and C’s Apply. Entries close 31 January 2023. Full competition rules are available at https://www.deere.africa/en/ our-company/news-media/news-releases/2022/nov/competitions-terms-and-conditions/.

John Deere www.deere.africa | africa@johndeere.com | Customer Care: 0800 983 821 |

JohnDeereAME

John Deere Africa & Middle East

John Deere Africa & Middle East

Happy new year! I trust everyone had a lovely holiday season, and while you are about to dig into 2023, I wish to send you very hearty new year’s wishes from us all here at ProAgri.

Here we go, another trip around the sun in our rear-view mirror. Looking back is sometimes fun, but looking ahead can be really exciting. As we enter the new year, I remain optimistic about agriculture’s future. We still face difficult times ahead, the economy is shaky, inflation will stick around, the budget will need to be watched, and the list goes on.

But the truth is that growth – real growth – is not smooth; it is volatile; and the journey is not always a direct line: It is an up-and-down, back-and-forth, stopand-start process.

So, if ever there was a takeaway from this topsy turvy life we are living in right now, it is that we are growing. The volatility is proof. Now it is our turn to trust the process. Having faith means letting go of all expectations.

Does that mean we should not continue working towards our goals or fighting in what we believe is right? No. It means letting go of the need to control the outcome. It means putting in the work and having faith that what is supposed

to happen will happen. By letting go of that need to control the narrative, you make space for just enjoying the NOW.

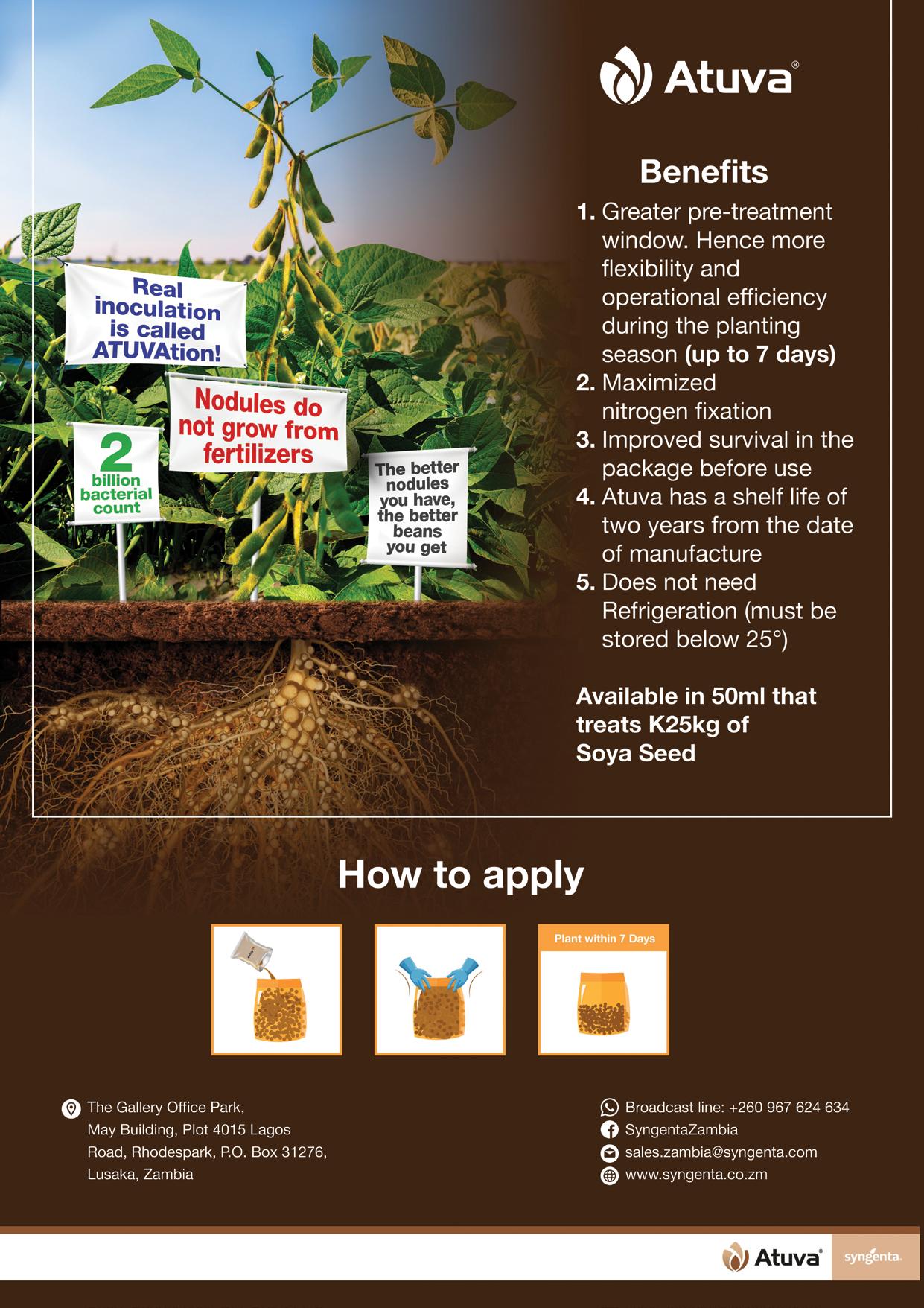

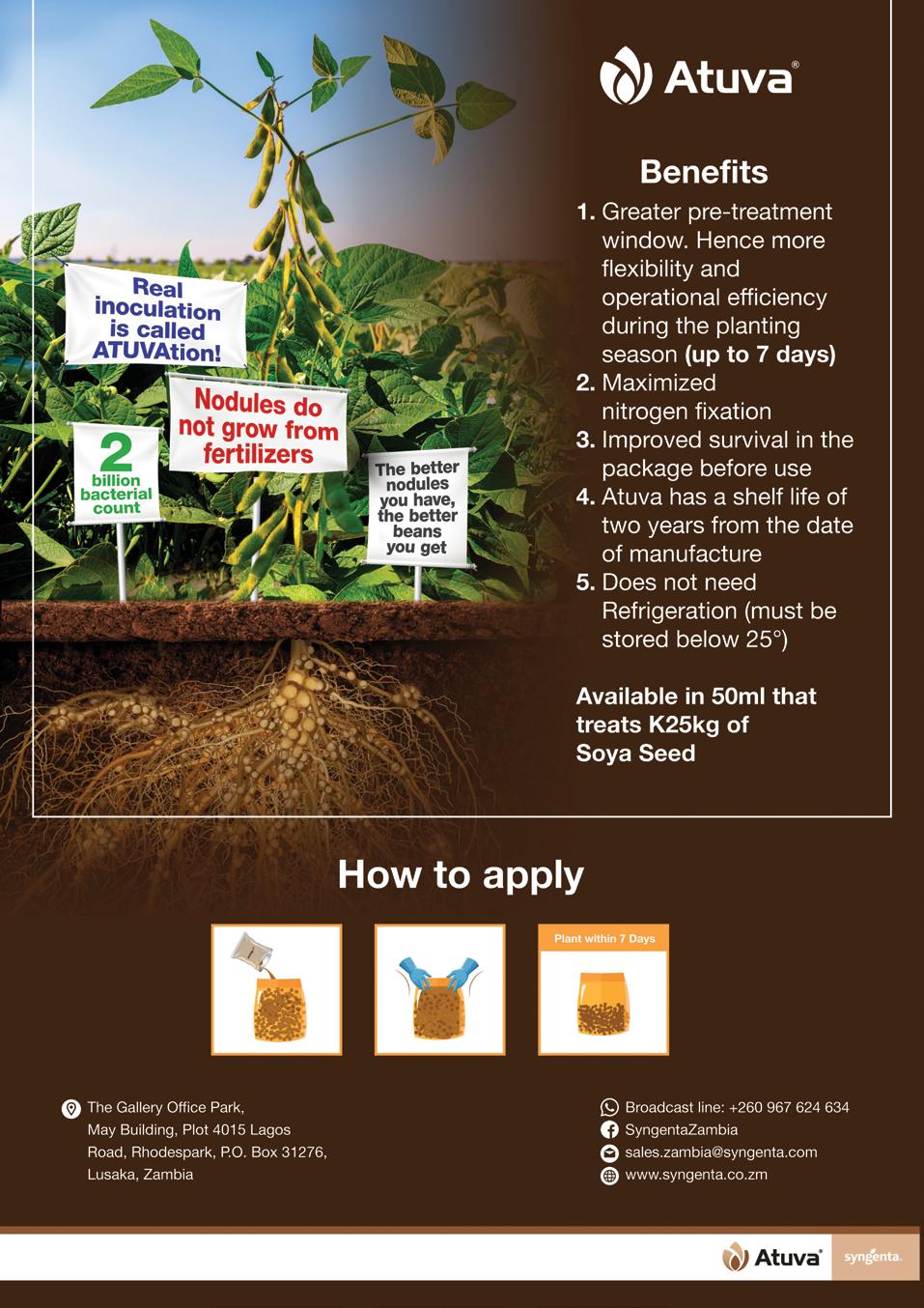

In this month’s edition of ProAgri, we kick off two brand-new series, on fruit production in Africa, and everything you need to know on silk production. We take a closer look at what bees feed on and why they choose those foods. In our front cover story, we learn what a macadamia farmer has to say about drip irrigation, and why this is the preferred method of irrigating your profitable crops. Syngenta is always one step ahead, offering solutions for crop farmers. Read more on soya bean inoculation at its best with ATUVA®.

We are excited for another jampacked year. Let’s make 2023 the best year yet! We take pleasure in presenting to you yet again another exclusive copy of ProAgri where we discuss everything in the farming space.

We promise to keep the momentum going and give you the information that is vital for your business.

greetings Bianca Henning bianca@proagri.co.za

Zambia

No. 10 Tito Road Rhodespark, Lusaka +26 (0)97-769-9786 www.proagri.co.za

Copyright © 2023. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

82-326-2572

+27 73-105-6938 benine@proagri.co.za +27 82-261-9177 maryna@proagri.co.za +27 81-736-4236 natasha@proagri.co.za +27 82-320-3642 annemarie@proagri.co.za +26 (0)97-769-9786 zainab@proagri.co.za +27 84-233-0123 carin@proagri.co.za +27 82-555-6866 diane@proagri.co.za +27 79-524-0934 xander@proagri.co.za +27 71-599-9417 johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za +27 72-419-3990 christiaan@proagri.co.za

+27 12-803-0782 engela@proagri.co.za +27 79-515-8708 nita@proagri.co.za +27 12-803-0782 accounts@proagri.co.za

A good farmer does not randomly decide what he wants to farm with and how he wants to go about it. No, he investigates the most profitable practice and crop that grows in his area, as well as how much soil and water are needed — that makes sense!

Rob and Keegan Hughes of Thulani Macs feel that way too. This father and son duo farm 20 km outside Empangeni in the Heatonville area. Rob is a property developer and owns a game farm. In 2019, they decided to take on farming after being inspired by the success of macadamia farmers in the area.

They acquired land with a good source of water and then approached Willie Vosloo from Agrico in Empangeni. He helped determine exactly where the irrigation points — and therefore the orchards — should be established. Soil preparation started in the beginning of 2020, and the first tree was planted in 2021.

Today, the 105 hectares of high-density orchards consist of 43 780 trees.

Macadamia groves with micro irrigation that are sensibly laid out "We approached several macadamia farmers along the coast for information. They were eager to share advice," Rob recalls. "But before we did anything, we first thought about it and asked: Does it make sense? We approach everything that way.

"We asked Willie to help plan the water supply," says Rob. Agrico handles the design of the system, from surveying to layout. The farmer can install the system by himself or use contractors, but Agrico remains involved throughout.

For this farm, water is pumped from the Mhlatuze River and stored in an earth dam. It acts as a buffer dam and helps the silt settle down so cleaner water is pumped through the system.

Micro irrigation was set up for various reasons. A microsystem can easily be converted to drip irrigation if there is a water shortage in the future. One can also see when the apertures are blocked, and as a bonus, it helps to

protect the orchard against wildfires.

There are two 73 kW motors connected to KSB pumps which direct water to the various blocks. The blocks are divided according to the water requirement of the soil type and the slope on which it stands.

Each pump has variable speed drive (VSD) which helps control the pressure at the different slopes and lowers the general electricity costs.

The system is built to apply 3,5 mm of water per day. Cycle lengths vary from three to six days, depending on the soil characteristics and the weather conditions.

After the irrigation planning, the land was cleared, and tillage began. Lime and gypsum were worked into the soil under the recommendation of an agronomist who identified the varying soil types. Ridges were made with a plough on which the irrigation pipes were laid and the trees were planted.

Each tree can be identified with GPS guidance thanks to a system designed by Keegan. "We initially measured by hand where each tree should be in a block, but it was difficult to be accurate and time-consuming. This electronic system ensures that each tree stands three meters from its neighbours. It is quicker too," Keegan explains.

The varieties they plant are A4, 695, 816, 863, 8.4 and N2. "We alternate two varieties per block, with four rows of one variety and then four of another. Between each row, we plant Napier grass which acts as a wind buffer," he says. "These varieties are planted because the flowering periods overlap and ensure cross-pollination."

The Hughes follow an organic approach to their farming.

“We avoid chemical pesticides and fertilisers, and we have not yet needed to add any fertilisers. Leaf and sap tests indicated that our trees are happy," Keegan says.

Instead, they use cow manure that

has broken down into compost to feed the roots naturally. The kraal manure is supplied to them by a local cattle farmer.

When an extra boost is needed in the future, the piggy system – a stainless steel tank that withstands pressure up to 10 bar – will assist in fertiliser application. It is connected to the water that flows towards the orchard; soluble or liquid fertiliser is poured into the "piggy's" stomach and then the orchard is fertigated.

There are bees on the farm to help with pollination, a game fence that keeps bush pigs out and they have also erected posts for the forest buzzards that keep rats under control.

Furthermore, they use mulching to keep the moisture in the soil, cool the irrigation pipes and create a favourable environment for micro-organisms. It also controls weeds.

To locate your nearest branch, visit Agrico's website at www. agrico.co.za or call Willie Vosloo on (+27)35-787-1949 or by mobile on +(27)82-571-2452.

by

by

affect plant population, crop establishment, and vigour.

Every farmer’s dream is to get a good yield; a yield above 2,5 tonnes per hectare. Farmers may not get a yield above this threshold if they do not protect their seed at planting and the seedling as it grows.

To effectively grow soya beans, they need to be fed with all the nutrients required for plant growth. These nutrients are obtained from the soil. However, the soil may not have the nutrients in the right amounts and forms. Therefore, farmers need to supplement nutrients by applying fertiliser.

One of the nutrients that is essential for soya bean production is nitrogen. This nutrient is supplied through synthetic fertiliser like D-Compound, urea, calcium nitrate, ammonium nitrate, and other blends of fertilisers.

S

ince the breakout of Covid-19, the prices of fertilisers have been rising monthly. This has been compounded with the war in Ukraine. Regardless whether the commodity prices of fertiliser rise, farmers must continue producing, because we all need food. Food is a necessity, and we all need to eat every day. Soya bean (Glycine max) is a very important food legume crop being cultivated extensively all over the world. It is needed for various food requirements for both humans and animals.

To cultivate it successfully, farmers must follow certain basic agronomic practices to maximise yields and get a better quality crop. Now that the planting season is upon us, it is our obligation as Syngenta to provide farmers with information that may help improve their farming enterprises.

The practice in Zambia by all seed companies is that they do not treat the seed before being put on the market for the farmer to procure. Some seeds may contain disease pathogens even before they are planted in the soil. Additionally, the soil in which the seed is planted contains thousands of different disease-causing pathogens. When the environment becomes conducive, these pathogens are ready to grow and infect the plants. It is therefore a must that the farmer treats the seed before planting to protect the genetic potential of the seed. This also gives the plant a good start in the critical times when they are susceptible to diseases.

Syngenta introduced a new product on the market called SoyaStarter+.

This is a combination pack comprising APRON® Plus Beans, Atuva® and Cruiser ®. This is a product combination that has done wonders for soyabean production in South Africa and Latin America. We are excited to introduce these innovative technologies to the Zambian farming community.

APRON® Plus Beans is a seed-applied fungicide (SAF) that will protect your seed and seedlings in the early establishment of the crop. This works in the first four to six weeks depending on the conditions. This is similar to what happens to human beings; when a child is born it is prone to be affected by different diseases because its immune system is not well developed. Doctors immunise babies against different diseases. This is the same principle that seed treatment provide; they give protection to the seed and seedling in the early stages of the crop.

Some farmers, especially small-scale farmers, plant the seed without treating. This leads to many problems, such as reduced germination. Because some seeds get infected as they germinate, they fail to germinate. Others that manage to germinate die back a few days or weeks after germination because the diseases kill the plant.

A number of those surviving beyond four weeks grow with less vigour, even after being provided with adequate fertilisers, because they have inherent diseases. Some of these diseases affect the plant at germination but only express symptoms later in the growth stages of the crop. All these factors contribute to low yields because they

However, soya beans, like many other legumes, can fix atmospheric nitrogen to plant-usable nitrogen. They do this by using bacteria that live in symbiosis with the plant. This bacterium is called Rhizobium japonicum. It can be found in the soil; however, it is commercially supplied through inoculants. Most of the bacteria found in the soil are survivors and are not effective in converting atmospheric nitrogen to plant usable nitrogen.

By using inoculants, farmers cut on the cost of using synthetic fertilisers, thereby, making their soya bean production more efficient. One of the most effective inoculants introduced by Syngenta is called Atuva®. It is one of the best inoculants you can find on the market; it is originally from Argentina and used extensively in commercial soya bean production there. Amongst the countries using Atuva® you will find Ukraine and Russia; both giants in grain production, including soya beans.

Zambia is the first country in Africa to register the product on soya beans and plans are underway to register it for other crops as well. Some of the attributes of Atuva® are that it has a low dosage rate of 0,2 ℓ per hectare. It has a high bacterial load per millilitre and has been produced using new osmo protection technology. This product does not need refrigeration but can be stored at room temperature and be used for two seasons. Atuva® is found in two pack sizes; a 50 ml that can treat 25 kg of seed and 2 ℓ that can treat ten hectares of soya bean fields or one tonne of seed.

wishes you the best season ever as you reap the rewards of quality products from your InnovationPowerhouse partner!

The JVA Cloud Router™ App allows you to arm and disarm energizers, view your electric fence voltages, open and close relays through any Android or IOS device. The JVA Cloud Router™ App provides Real-time push notifications of Alarms, as and when they happen. With a touch of a button, you can see what is happening with your JVA sites and take the necessary steps to address any problems that may arise.

Control and monitor multiple sites such as your home, farm, factory, or office from the palm of your hand, anywhere in the world.

This is now all possible through the innovative JVA App development as a security and agricultural solution for our new and existing JVA clients at no additional monthly cost. The innovative dashboard allows you to view your sites at a glance and peruse historic event activity such as logs and

device graphs - keeping you in control of all your JVA sites.

The JVA Wi-Fi Gateway connects a group of JVA Z-Series devices to the Cloud Router™ App via an existing Wi-Fi network. The JVA Cloud Router™ App gives you a single dashboard to view and conveniently control your electric fence sites, gates, beams and alarm systems.

The JVA Wi-Fi Gateway enables any JVA Security Energizer, JVA Monitor or

• Site sharing with select user privileges

• History and event logs

• No monthly fees

• Available to download on Android and IOS devices

Test out the JVA Cloud Router™ App by following the below steps:

1. Download Cloud Router through the Android Playstore or Apple iStore.

JVA IP accessory to be added to the JVA Cloud Router system. The single dashboard to view and conveniently control your security sites makes it user-friendly, and the real-time push notifications allow for the most effective way to manage all your sites.

One Wi-Fi Gateway can take register up to fourteen JVA Z-series devices, ensuring it can provide an economic offsite alternate gateway and backup for any large site. If Wi-Fi is not available, any of the JVA 3G or 4G GSM gateways can be used to ensure your sites remain connected.

The JVA "Cloud Router™" App:

• Controls and monitors multiple JVA sites

• Real-Time push notifications of events and alarms

2. Log into the JVA Cloud Router App: E-mail: cloud@pakton.com.au Password: cloud1234!

3. Control and monitor the JVA Brisbane Office from halfway across the world!

The following link - https://www.jvafence.com/security/cloudrouter/ index.html will allow you to watch the real-time stream of the system you are controlling at our Brisbane office in Australia.

For more information on the JVA Cloud Router™ App or JVA Electric Fence Energizers and Devices, visit www.jvasecurity.com to locate your nearest dealer.

Article supplied

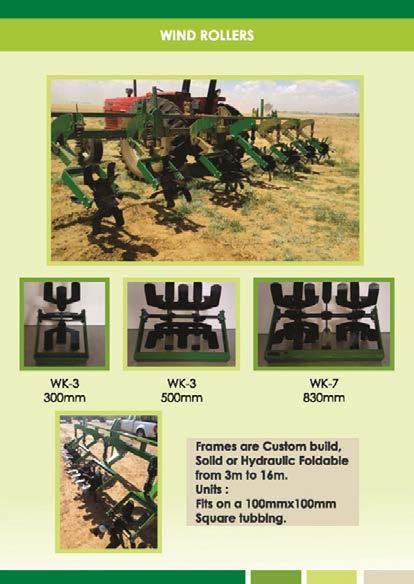

Ripper Tillage Equipment offers more than robust and efficient implements; they start every customer journey with the question: What are your requirements? This includes the needs of your business according to the scale of your farming operation, the soil type, structure, and the crops you plan on planting.

By asking this question, Ripper Tillage Equipment is able to offer you, the farmer, the solution that fits your unique requirements. “We consider how the soil needs to be prepared for the type of crop the farmer wants to plant,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains.

This manufacturer designs and builds implements for every part of seedbed preparation and planting needs: before planting, during planting and after. This includes rip-till and strip-till equipment, rotary hoes and planting equipment.

“We specialise in rip-on the row. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Rip-Till equipment means the same seedbed, but different result Rip-till seedbed preparation means deeper tillage (deeper than 300 mm) that loosens the undersoil to ensure an even seedbed just like strip-till.

With conservation farming becoming more and more popular, conservation tillage is also increasingly popular. Rip-till implements from Ripper Tillage Equipment are ideal for this task, and what is more, their rip-on-the-row equipment delivers tillage that keeps soil moisture locked in.

On-the-row rip means you only till the soil in the row where your planter will carefully place the seeds. When, for example, using a 0,9 m (3 ft) 8-row planter, you will also use a 0,9 m 8-row ripper instead of ploughing the entire area of your field.

This process involves: • cutting of residue with a cutting coulter

• row cleaning

• rip and optional fertilize placements

• closing of furrow and compressing with a roller

Because there is less soil tilled over a large area, the machinery – tractor included – has less wear. What is more, you also use less fuel and require less labour.

“Our rotary hoe (rolegtand) is very popular for after-planting seedbed care when it comes to crumbling soil after heavy rain,” she adds.”

Tillage is more than implements, it is caring for the soil Ripper Tillage Equipment employees are skilled in identifying soil requirements. “We come to your farm, do a soil analysis with a demonstration, and determine the type of implement that will give you the best results,” Christine explains.

“We consider the type of soil on your farm as well as the last crop you planted – for example residue management. When we look at the soil condition, we understand how to help the farmer plant his next crop in the best possible way. We can suggest the implement

with the right tines or closing coulters to get the job done.”

This is the added benefit of custommade implements: Guidance and expertise in what is best for your soil. Because soil conditions and crop needs differ from area to area, investing in exactly the right tools that give you the maximum results help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need. You won’t find a ready-made “one-sizefits-all” implement on a show floor.

“Maintenance is also fairly easy and inexpensive, because most parts are available locally,” she adds.

For more information on customised equipment for your seedbed preparation, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbothariptill@ gmail.com. Check out their visit website at: www.rippertillage. co.za or find them on Facebook: www.facebook.com/RipperTillage.

Left is an unclosed seedbed, and right with closing units.

Planter closing wheels.

by Benine Ackermann

by Benine Ackermann

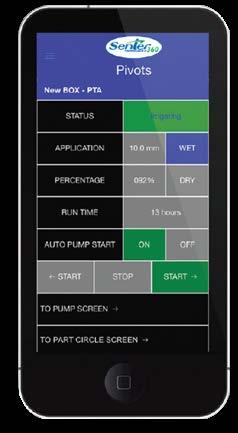

Satisfied farmers in more than half of the African continent’s countries depend on Senter360 for quality irrigation solutions.

Senter360’s policy is to not only sell the best possible products, but rather offering a long-term solution to their customers with a mutual win-win attitude.

“Over the years we have built good relationships with our customers in Southern Africa,” says Theuns Dreyer, Managing Director of Senter360. “We are excited about 2023, expecting even more growth. We also have an interesting addition to our product range to be introduced during 2023.”

Senter360 products are designed to be exceptionally strong. “They are designed to survive in tougher than usual conditions in remote areas, keeping them running reliably for longer. It is also interesting to note that pivots sold in Africa are usually larger than those sold in South Africa,” Theuns added.

A Senter360 pivot has a modular design throughout. This means a lower impact on the variety of spares required to build the machine, and therefore also to maintain it.

“The capital outlay for

remote areas is therefore smaller, making it easy to have a full range of spares ready in remote areas.”

"We have many dealers and knowledgeable contact people across the continent to support our clients. We also gladly visit farms where and whenever required,” he added.

Senter360 pivots are strong for farmers in Africa

“As mentioned before, our modular design with resulting advantages and outstanding structural falling strength of more than 2,5 times its own weight when filled with water, combined with its exceptional sideway stability withstanding winds above 158 km/h all add to its resistance to possible damage under extreme conditions. This is far more than any international competitor has to offer,” Theuns added.

Their centre pivots are made in South Africa and tailored to their client’s specific needs. “A pipe frame is used instead of the typical angle iron used for international centre pivots. With this method, we can increase the arc strength of our centre pivot while decreasing the wind resistance,” Theuns explains.

Senter360 also has an internet based application for farmers to use. With an internet connection, the centre pivot can therefore be controlled from a distance from the farmer’s phone, and the application can be used to track where the pivot is.

“Our modular design, combined with its exceptional sideway stability all add to its resistance to possible damage under extreme conditions.”

Please do not hesitate to contact Theuns Dreyer directly for more information and local support: Call Senter360 at (+27)82-564-5955, or visit their website at www.senter360.co.za.

spares in

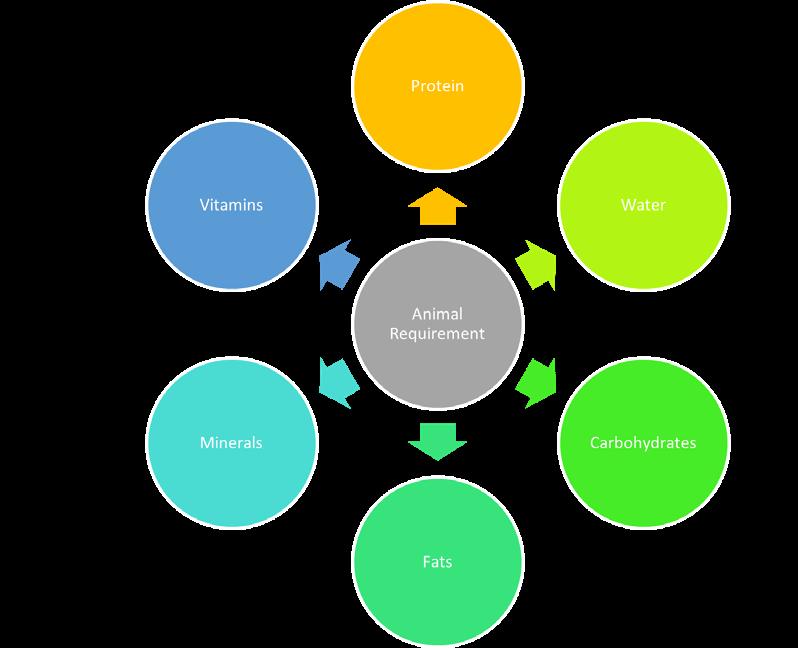

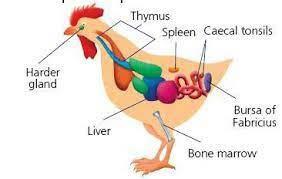

We often visit farms and acknowledge the challenges that are faced by many. There are often times where we have visited farmers and a number of questions have popped up relating to feed costs, production concerns etc. Often the basics of animal production are forgotten.

The 6 basic nutrients required by animals are as follows:

Protein is essential for growth, maintenance and reproductive processes. Lysine, Methionine, Threonine etc., are some examples of essential amino acids. These amino acids are building blocks for tissue formation. Protein in a diet can either be of plant or animal origin. Examples of plant origin sources are oilcakes, hay and straw. Examples of animal origin sources are meals made from fish or meat.

Carbohydrates are the main source of energy for animals and usually make up 60-70% of the cost of a diet. Grains such as maize, wheat, barley etc. are commonly used in the industry. Fats are important to animals and are required to a lesser extent in diets. Fats store energy and provide insulation to animals. The main sources of oil in diets are produced by the oilseeds sector.

Minerals play a role in bone and tissue formation and are known for regulation of chemical processes. Microminerals are those required in smaller amounts whereas macronutrients are required in larger amounts. Although minerals form a small portion of diet, an excess in terms of intake can result in toxicity.

Vitamins are also required in smaller amounts and play roles in metabolism, reproduction, growth, blood cell maturation, digestion, bone formation, and in the prevention of infection. The categories of vitamins are water soluble vitamins and fat-soluble vitamins.

Water is often the forgotten nutrient and makes up majority of a body mass. It is required for the regulation of body temperature, growth, reproduction etc.

We cannot say that the year that has passed has gone smoothly. There have indeed been a few speedhumps along the way. The hope is always that as the New Year comes along, that we can learn from the past.

All things in life may be considered lessons, or blessings. It just matters in which way one chooses to look at it.

Our hope is that we can walk alongside our clients in 2023. We are grateful for your business during the year that has passed and look forward to doing business with you all in 2023.

Please do not hesitate to contact the team should you require any advice or assistance.

"Success usually comes to those who are too busy looking for it" — Henry DavidFrom the left, Riyashna Rampersadh (Technical Manager), middle, Nelia Mbewe (Jnr Nutritionist) and Everett Pieterse (Nutritionist).

I n a previous chapter, we had a brief look at the need for suitable forage for bees and the value of placing your hives near such a source.

In this chapter, we look at what bees feed on and why they choose those foods. The honeybee’s basic nutritional requirements are like those of humans; namely, they need proteins (amino acids), carbohydrates (sugars), minerals, fats/lipids (fatty acids), vitamins, and water. To meet their nutritional requirements, honeybees collect nectar, pollen, and water.

Honeybees eat honey, which is processed nectar, and bee bread, which is processed pollen. The honey serves as a primary source of carbohydrates, which provides energy for flight, colony maintenance and general daily activities. Nectar, and thus honey, also provide minerals like calcium, copper, potassium, magnesium, and sodium, the presence and concentration of which depends on the source of nectar.

It is therefore very important that

the colony has sufficient stores of honey for the winter months, for, without it, the colony will grow weaker and die.

Bees forage for water at almost any source close to their colonies. These sources include ponds, streams, leaky taps, the neighbour’s pool, dog dishes, and bird baths. During hot weather, honeybees use water to cool the colony by fanning and evaporating water droplets inside the hive. Water may also provide essential minerals in addition to hydration.

Bees forage mainly for nectar and pollen provided by flowering plants but also for resinous flowers of trees, and, if it is available, they also make use of honeydew. Bees collect any sweet substance, including sugar water, cool drinks, even overripe fruit, and proteins from animal feeds. “One can often see bees feeding on the fine pollen dust emanating from grain mills, and bags of mixed pig feed,” says Charles Salmon of the Western Cape Department of Agriculture.

It is important to keep in mind that bees forage with the sole purpose of feeding themselves to keep the swarm healthy and productive. Seasons come and go and in times of plenty, these industrious insects will work hard to collect as much feed as possible so that they can survive during lean times.

The products of the hive give a good indication of why bees need specific food. Besides honey, other products found inside a hive include propolis, pollen and wax.

Honey is the primary product of a hive. The worker bee uses her long tongue to collect the flower’s nectar and store it in her nectar stomach. When she returns to the hive, she regurgitates the nectar and hands it over to a worker bee inside the hive. It is this second bee’s job to remove moisture from the nectar.

A physical process is used to remove most of the moisture, while a chemical

Wax cells filled with honey, which the bees produce from the nectar.

Wax cells filled with honey, which the bees produce from the nectar.

process uses enzymes to change the sugar in the nectar to honey sugar.

The bee that receives the nectar from the returning worker bee moves to a part of the hive where there is air circulation. The bee regurgitates the nectar to the point of the tongue to expose it to air. She swallows it again and repeats the process with the next drop of regurgitated honey. This continues until the moisture content is reduced from 60 to 80% to 16 to 20% before she deposits it into a cell on the honeycomb. If the moisture is not removed, the nectar will ferment and rot.

Bees whose job is to ventilate the hive by whirring their wings, circulate dry air in the hive to continue the evaporation process. Raw nectar consists of three sugars: sucrose, glucose, and fructose. As the process nears its end, the honey is deposited into empty wax cells and covered with a layer of wax to store the honey.

Pollen is the male reproductive unit of plants and is essential for pollination. Bees do not produce pollen but collect it from plants and store it in the honeycomb cells. By mixing it with honey, the pollen is preserved so that it is available for the bees to feed on. Humans use pollen in some medicines and cosmetics.

Propolis is the third most important component of bee products. It is composed mainly of resin (50%), wax (30%), essential oils (10%), pollen (5%) and other organic compounds (5%).

It is a resin-like material made by bees which are collected from different plants like fynbos, the buds of poplar and cone-bearing trees. The bees use it to protect their nest against disease and pests; by repairing holes in the hives, they protect it against rain and wind. Propolis has antibiotic properties, and it is used for medicinal purposes.

Wax flakes are excreted by young worker bees. The bees chew, shape and use the wax to build the cells of the honeycomb. New wax is white in colour, but it turns darker when it is in contact with the brood. When the larva outgrows the cell, it leaves behind its skin in the wax cell filled with honey, pollen or propolis.

“The colour of pollen differs greatly and is not always bright yellow. An aloe species provides orange-red pollen,” says Charles. Some beekeepers believe that different colours of pollen in a hive are an indication of a variety of feed plants, which is ideal.

Humans use wax for the manufacture of candles, cosmetics, food processing, polish, and medicine, among other things.

Bees use their poison to protect themselves. The poison is manufactured in bees between three- and 21 days old. It has medicinal value and is used as a medication for rheumatism.

Royal jelly is a white and viscous jelly-like substance secreted by worker bees. It is a superfood that is consumed by the queen bee, which probably contributes to her living much longer than other bees. It is also fed to immature young larvae in their first two to three days of maturation. Royalactin is the main compound in the royal jelly, which allows the morphological change of a larva into a queen bee.

is nectar?

Where does nectar come from, what does it consist of and why is it important for the bees?

Nectar is a sugar-rich liquid that is produced by plants’ nectar glands, called nectaries. These glands can be situated inside the flower, or on the leaves or stem, also called extrafloral nectaries. These provide a nutrient source to animal mutualists, such as ants, which in turn provide protection against herbivores. ‘

A nectary is a floral tissue that can be in different parts of the flower. It is one of the different secretary glands that produce nectar, oil, or scent.

The function of these glands is to attract possible pollinators, such as bees, wasps, butterflies, moths, and mosquitos, as well as birds such as hummingbirds, honeyeaters and even bats.

Once a pollinator has visited the flower, the leftover nectar can be reabsorbed into the plant. Several factors influence the production of nectar, such as the age of the flowers, the location of the plant, whether the honeybee can reach the nectar, as well as the management of the habitat, such as enough water. According to Charles, the soil type, such as the lime content, also contributes to good honey production.

Pollen is a powdery substance produced by male plants. The pollen grains produce male sperm cells. When a sperm cell comes into touch with a female plant’s stigma, it moves down the style to the ovary, where they germinate.

Pollen in the form of bee bread is the honeybee’s main source of protein, while it also provides fats, minerals, and vitamins. The protein is important for brood production and the development of young bees.

Pollen consists of water, ether extract, carbohydrates, including reducing sugars, non-reducing sugars, starch, lipids, ash, and some other contents. Because not all pollens are equally nutritious to bees, they need different sources of flowers to provide all the components.

Honeybees apparently choose pollen based on the odour, shape, and size of the pollen grains. A colony with a typical size of about 20 000 bees, collects about 57 kg of pollen per year. Between 15 and 30% of the colony’s foragers collect pollen and a single bee can bring back a pollen load of about 35% of the bee’s weight in the pollen baskets on its hind legs.

Once the pollen has been brought to the hive, the workers condition it by adding glandular secretions that contain

enzymes and acids. These secretions prevent harmful bacterial activity so that the pollen can be stored as bee bread.

The bees also add beneficial microbes to the pollen and produce enzymes that help the pollen release nutrients and amino acids, the building blocks of protein.

The colony consumes the bee bread relatively quickly and it is only stored for a couple of months, and only if there is a surplus. The colony requires about 15 to 55 kg of pollen per year. They use pollen for growth and development. Immature bees are fed a mixture of brood food and bee bread. Newly emerged bees eat bee bread to help their bodies reach maturity and the requirement of a single worker larva is about 124 to 145 mg, which contains about 30 g of protein. Pollen with a high protein content helps to grow strong and healthy worker bees that live longer, which is needed to grow a strong colony.

A beekeeper must make sure that the plants in the area have enough nectar and pollen to provide the bees with food. Plants that produce a lot of nectar, do not necessarily produce pollen for bees. It is important that bees have a large variety of plants to

The TOPIGS Tempo boar is ideally adapted for African environmental conditions, this proven by our client list, their production results and profitability. Many top farmers in Africa have invested in the breed with huge success. The excellent health status of our genetics is considered a major competitive advantage. Many producers choose to repopulate with Topigs Norsvin genetics to reap the benefits of this advantage.

• The TN70 is a cross between the Topigs Large White and the Norsvin Landrace.

• Highly prolific, easy in use sow

• Amazing weaning ability

• Top contribution to finishing pig quality

• Produces large litters of strong, uniform

TN70 & TN Tempo: The ultimate combination

• Tn Tempo brings robustness, uniformity and fast growth potential

• The TN70 is and excellent mother which strengthens these qualities by contributing the best feed efficiency to the finisher compared to any other sow in the world

• Together, the TN Tempo and TN70 offer you the potential to produce the most output against the lowest cost, combination unrivaled.

Zambian Pig Genetics is the distributor of Topigs Norsvin genetics in Central Africa. Built on our global research, innovation and absolute commitment to integrity and biosecurity, our close partnership approach means your farm benefits directly from our experience, energy and passion.

collect nectar and pollen from because no single pollen provides all the nutrition honeybees need. Just like humans, bees need a well-rounded diet, and the quality of the pollen is more important than the quantity.

The colony’s needs change according to the season and brood production. If there is a lack of pollen or the beekeeper thinks that the pollen is of

poor quality, it is necessary to provide a pollen substitute or supplement. In the next chapter, we will look at the additional feed to keep your bees healthy in lean times, such as winter.

S

uitable forage is essential for the survival of honeybees. Strong, healthy bees are in turn needed to provide sufficient pollination for the country’s agriculture in general, and the growing fruit industry, which heavily relies on managed bees to supplement the service provided by wild bees.

Suitable forage is increasingly difficult to find, but bees still need nectar, which provides carbohydrates needed for activity. Pollen provides proteins, fats, lipids, and micronutrients, including sterols, vitamins, and minerals.

Bees cannot function optimally by feeding on just one kind of pollen, such as an apple or almond orchard, or a monoculture crop – they need a variety of crops to feed from.

Malnutrition of bees is not only the failure to get enough food, but the absence of the right mix of food. Bees cannot survive and function on just one type of nectar and pollen – they need a balanced menu. A lack of suitable forage – including a variety of wild flowering plants – leads to malnutrition. That in turn leads unhealthy bees that are more vulnerable to pests, disease, and

poison. Plant biodiversity is therefore extremely important for the survival of bees.

It is equally important for increasing pollination services. Statistics provided by Hortgro, a research institute for the deciduous fruit industry, show that 91 000 swarms (or hives) of honeybees are presently needed for commercial pollination of fruit orchards. This number is increasing by 15% per year. In five years, an expected 100 000 swarms will be needed to provide sufficient pollination.

Fruit growers in the Langkloof, Elgin-Grabouw-Vyeboom-Villiersdorp (EGVV), Ceres, and Klein-Karoo areas of the Western Cape, depend on commercial beekeepers to provide swarms for the pollination of their fruit, vegetables, nuts and edible oil crops.

Suitable forage is shrinking because of the following reasons, among others:

• natural veld must make way for agricultural to feed a growing human population;

• pesticides designed to make agriculture more profitable are taking their toll on pollinating insects, especially honeybees;

• the felling of blue gum trees in accordance with legislation for the control of alien plant species is removing valuable forage;

• The unsuitability of mountain fynbos means greater demand for bee forage elsewhere.

The reason why mountain fynbos does not provide sufficient forage for bees is because of the low nutrients in Table Mountain sandstone. Bees will survive, but with minimal honey and they struggle because the plants simply don’t secrete enough nectar. Those same plants growing in better Duineveld soils do supply adequate nectar.

Ahead of the pollination season during spring and early summer, the commercial hives need forage that is rich in pollen and nectar to build healthy and strong swarms for the pollinating task

ahead of them. Canola fields that offer an abundance of nectar and pollen provide good forage.

After the pollination season, these swarms need to rebuild the strength of the hive to help them survive through winter, and hives are often placed in or near areas where natural fynbos occur, such as conservation areas with indigenous plant species. At present, hives are not permitted to be placed inside conservation areas.

The placement of commercial hives near such a reserve gave rise to the concern that commercial swarms placed there may threaten the survival of wild bees and other pollinators.

An assumption was made that managed honeybees may be overstocked on fynbos, and therefore threaten the biodiversity of the fauna and flora.

The community of the Duineveld, a 50 km stretch of unspoiled fynbos along the Southern Cape coastline, expressed this concern regarding the unique type of fynbos, known as Strandveld dune thicket.

“The Duineveld is vitally important for forage to support the increasing number of bees necessary for commercial pollination,” said John Moodie of Honeywood Farm near Swellendam in the Western Cape. John has been keeping bees for more than fifty years and he is a recognized and knowledgeable role player in the bee industry.

Speaking at the annual general meeting of the Duineveld Conservation Group in 2021, John said very few beekeepers have their own land, so they depend on other landowners for forage sites. “Beekeepers always need sites for honey, but the need for increasing numbers of honeybees for agriculture, makes it even more important.”

On the question whether fynbos species and other pollinators were Protective clothing is

threatened by overstocking of honeybees, John gave a resounding no.

Firstly, there are no alien bee species in Africa, as is the case in the USA, Australia, and Europe, where all honeybee species are exotic alien invaders. “In Europe and the UK, most of the indigenous honeybee species have died out because of bad management and disease,” said John.

Ten of the world’s 24 races of honeybees occur in South Africa. In the Western Cape, the Capensis is a unique honeybee in the fynbos area. It has recently been found that these bees can clone themselves, and for this reason there is a ban on moving bees from the southern provinces to the northern provinces, where the Scuttelata bees occur – hence the Scuttelata line, an imaginary border stretching from the town of Vredendal in the Western Cape to Willowvale in the Eastern Cape.

Secondly, he based his response on research done by Mariette Brand in 2009, while she was a doctoral student at the University of Stellenbosch. Mariette placed eight beehives in the De Hoop Nature Reserve for one month to determine the influence managed hives may have on wild bees and other pollinators. She found that these swarms had no negative effect on the activities or survival of wild bees or other insect pollinators.

Institute, in his studies on competition between African honeybees and other subspecies in South America, found that they affected only the alien European honeybee populations, but no other wild bee species. He also found that African honeybees did not change pollination stability or species decline.

The price of honey According to John, honeybees are not a threat to wild bees, as they belong to the same subspecies.

“Landowners should be much more concerned about the threat of alien Argentinian ants and alien vegetation, such as Acacia cyclops (rooikrans).”

Ants compete for nectar, while dense stands of rooikrans have invaded vast tracks of land, threatening the Duineveld fynbos. A gall-forming biological control insect, Cecidomyiid Dasineura Dielsi, was introduced into South Africa for biological control, but with limited success.

Beekeepers must by law register with the Department of Agriculture for

the control of disease. “Beekeepers do not comply easily, but regulations are in place,” says John.

“The real problem is that a functioning swarm of honeybees consumes 60 kg of honey per year to survive. Where is this going to come from if not from crops, Duineveld or gum trees? In real cash terms, that means R100 x 60 = R6 000 if fed honey, and a bit less if they are fed sugar, but this is still a considerable amount.

“Are growers even aware of the absolute bargain they are getting for pollination service, and are consumers aware of what a realistic price should be for a jar of honey?

“Beekeepers also totally underrate the value of their product or the valueadded service their bees provide.”

Bees need a variety of forage plants and wild flowers to provide nutrition that monoculture crops cannot.

Growers of vegetable seed rely on bees to pollinate their crops.

Contact details John Moodie at john@honeywoodfarm.co.za

Pain, S. (2017, April 12) The whole food diet for bees. Knowable Magazine https://knowablemagazine.org/ article/sustainability/2017/wholefood-diet-bees

Melin A, Rouget M, Midgley J, Donaldson JS. Pollination ecosystem services in South African agricultural systems. S Afr J Sci. 2014;110(11/12), Art. #20140078, 9 pages. http://dx.doi. org/10.1590/ sajs.2014/20140078

Root, R.B. (2004, September 9). Argentine ants in the South African fynbos: effects on proteas and their arthropod visitors. Cornell University https://reeis.usda.gov/web/ crisprojectpages/0189503-argentine-ants-in-the-south-african-fynbos-effects-on-proteasand-their-arthropod-visitors.html

Roubik, D. (September 2009)

Invasive Africanized honeybee impact on native solitary bees: a pollen resource and trap nest analysis: Responses to invasive honey bees. Biological Journal of the Linnean Society 98(1):152 – 160 DOI:10.1111/j.10958312.2009.01275.x

Now there’s honey for thought!

Sericulture is the process of raising silkworms to get raw silk and is the topic of this series.

The feed that an animal is given to sustain its growth and reproductive potential is the single most crucial aspect of any animal production system. Since mulberry trees are the exclusive source of nutrition for silkworms, we will cover their cultivation in this first part of the series.

Silk was a symbol of emperor homage in public ceremonies, according to the chronicles of Chou King (2200 BC). Migration helped the industry spread. Japan focused on the silk industry in the late 19th century, introducing processing machinery, improving techniques, and conducting intensive sericulture research. In India, silkworms were first domesticated in the Himalayas.

A mulberry tree leaf, specifically the white mulberry (Morus alba) leaf, is the food source for silkworms. Making sure good quality mulberry leaves are produced scientifically, is crucial for economically organised sericulture.

Approximately 25 to 30 kilogrammes of high-quality cocoons can be harvested from a single case of eggs, but the rearing of the silkworms to spin those cocoons requires one tonne of mulberry leaves.

This plant has been grown in China for centuries and adapted elsewhere. It is a latex-producing woody plant, similar to figs and marijuana. The tropical tree bears red, black, or white clusters of seeds called mulberries. Black mulberry bears large purple fruit that resembles a long blackberry. Red mulberry produces soft red fruits, while white mulberry is used for silk. The red mulberry is called Morus rubra, the black mulberry is called Morus nigra, and the white mulberry is called Morus alba

The fruits can be used as pig food. Leftover mulberry leaves are fed to cattle to increase milk production. The leaves can improve egg production when used as a vitamin supplement in poultry diets. Mulberry bark is used for papermaking. The bark is both a worm treatment and a purgative. The fruits can be cooked into squashes, jams, jellies, and pickles. Mulberry wood is shock-resistant and hard. The sticks are used on fences or woven into baskets and silkworm trays.

Mulberry trees prefer welldrained, fertile soil and can be planted in rows along the contour of less steep slopes (15 degrees), while on steeper slopes (15 to 30 degrees), the terrace system is used most effectively for single rows. High rates of soil erosion resulting in deficiency in nutrients, characterise extremely steep land.

Mulberry trees can thrive at altitudes up to 700 metres above sea level. Planting mulberries at a high altitude where frost is common is not economically viable.

Soil is vital to plant health. Although roots make up only about a quarter of a typical seedling, they are often so finely divided that their mass exceeds the volume of air occupied by the shoot. As a result, there is a great deal of soil to root contact, demonstrating the plant's reliance on the soil for support, moisture, and nutrients.

The composition of the soil affects a variety of plant characteristics, including:

• The capacity of seeds to germinate.

• The plant's stature and straightness.

• Healthiness of the plant tissues.

• Hardness of the stem.

• Roots' descending depth.

• The duration of puberty.

• Vulnerability to environmental stresses such as drought, pests, and diseases.

• The yield or growth rate.

The quality of the soil in a mulberry field influences not only the growth and yield of the mulberry, but also the quality of the leaf, the rearing conditions of the silkworm, and thus the yield and quality of the cocoon. At least 50 cm of deep, friable, well-drained, aerated, rich soil is needed for mulberries. The following factors affect soils:

• Fertility

• Depth and profile

• Soil texture

• Soil pH, temperature, and moisture

Soil fertility is the soil’s ability to provide physical conditions favourable for root growth and enough water and nutrients to allow the crop to make the most of the area's environmental features. Soil fertility is the most important factor in determining the yield as well as the quality of the leaves produced.

Shallow soils do not allow crops to anchor and extract nutrients and water, and they are usually waterlogged or dry. Since mulberry is a perennial crop, it can root up to 4,5 to 6 metres in dry seasons.

The coarseness or fineness of soil particles is called soil texture. Soil texture is classified based on its equivalent spherical diameter. Mulberries thrive in clayey loam and sandy soils.

Soils must be well-structured and accept water and rainfall without crusting, eroding, or eroding to yield well. It should also hold moisture at reasonable levels.

Root morphology determines the plant's pH response. The soil's acidity and alkalinity should be acceptable. Mulberry grows best in slightly acidic soils with a pH of 6,2 to 6,8. Applying gypsum or sulphur to alkaline soils and lime to acidic soils can correct them.

The temperature of the soil influences plant growth. Temperature dominates germination and growth in moist soils. This is because this temperature affects root growth, nutrient and water uptake, leaf expansion, and mulberry leaf yield. Mulberry trees grow best at

23 °C to 30 °C. High and low temperatures kill the plant. Organic matter increases specific heat (due to microbial reactions) and soil temperature. Dark soils absorb more heat than light soils, so they are warmer.

Plant growth depends on soil moisture. Soil particles and organic matter determine how much capillary or hygroscopic water soil can hold.

Though drought-resistant, mulberry trees need water for growth and yield.

They thrive in well-drained soils that receive 50 mm of water every 10 days in loamy soils and 15 days in clay soils. Finer soils hold more water. 50 to 60% (by weight) of the soil's maximum water-holding capacity is ideal for mulberry growth.

Water is crucial to plant physiology. It dissolves soil minerals and transports solutes through plant tissues.

Bee visiting mulberry blossoms to spread pollen. (Source: Pixabay by Wisa)

It increases the chemical reactivity of simple and complex compounds by allowing plant solutions and ionisation. It fuels photosynthesis. Turgidity is necessary for cell function and protoplasm survival.

All precipitation increases soil moisture, but not equally. Slower, gentler showers soak more water into the soil than heavy showers causing run-off. More water sinks below surface desiccation during a rainy period. Direct studies of soil moisture penetration and duration are best for measuring precipitation's efficiency as a plant water source. Mulberry trees need 800 mm or more of annual rainfall.

Biologic activity is minimal below 0 °C and above 50 °C. Mulberry thrives at 23 to 30 °C.

Mulberry bark has many uses, including in the production of paper pulp, as a purgative, and as a worm treatment. (Source:

Mulberry cultivation requires the same manure components as most crops, but in much higher quantities. Mulberry, a woody plant, absorbs and uses fertiliser differently than annual herbaceous plants. It is grown for its leaves in terms of silk production, unlike other fruit trees.

Maize sweeteners and syrups are manufactured from the starchy endosperm of maize using a conversion process known as hydrolysis.

This hydrolysis process can be chemical (by means of strong acids), or enzymatic, or a combination of the two. Various types of maize syrups can be produced, including glucose, maltose, dextrose and fructose. The type of sweetener produced depends on the processing conditions and hydrolysis agents used. This article will deal primarily with the production of glucose syrups and powders.

Starch is composed of thousands of glucose units that are linked together to form long chains. When these links are broken, starch is broken down to smaller units which can be single glucose units, two glucose units combined (maltose) or more than two glucose units combined (dextrose).

Single glucose units may also be converted into its isomer, fructose, which is much sweeter than glucose.

This conversion process is also done by enzymes. The various products formed from starch during hydrolysis are classified according to their dextrose equivalent (DE) value. This is a measurement of the reducing sugar content that is expressed as a percentage of the total dry matter content.

Before maize starch can be converted into syrups, the maize needs to be wet milled and the endosperm separated from the rest of the components.

Strong mineral acids such as hydrochloric or sulphuric acid are used to acidify the starch slurry to pH 2,0. This is done in a reactor. Once the optimum pH has been reached, the steam pressure is increased. This causes the gelatinisation and depolymerisation of the starch to facilitate hydrolysis. The mixture is then left to react under controlled temperature and pressure conditions until the desired DE value is reached.

The process is stopped by adding alkali to raise the pH to between 4 and 5. The acid hydrolysis process was the traditional method of preparing maize syrups, but has been replaced by enzyme hydrolysis. There are several reasons for this. First, the acid process is a random process; in that it causes random hydrolysis of the links between glucose units, and thus produces unpredictable products through an uncontrollable process. Second, it requires various purification treatments to separate the chemicals from the syrup.

Various starch hydrolysing enzymes are available to the processor, such as alpha- and beta-amylase, glucoamylase, amyloglucosidase and glucoisomerase enzymes. Each enzyme has a different hydrolysis pattern and specific optimum operation conditions. These enzymes can be used alone or in combination on fresh maize starch or partially acid-hydrolysed starch.

The enzymes are added to the gelatinised and depolymerised starch slurry in a powder or capsule form and left to react until the desired DE value is reached. The enzyme activity is stopped by a high heat treatment.

The drastic improvements in enzyme technology have made enzymatic hydrolysis the more popular choice today. Enzymes are very specific and can overcome the limitations of acid hydrolysis. They can produce a wide spectrum of syrup products that vary in composition and functional properties. In this way, syrups can be tailormade for a specific purpose.

It is necessary to remove the chemical agent used in acid hydrolysis as well as various non-carbohydrate components that detract from the clarity, colour, and stability of the syrup. A centrifugation or filtration process is applied first to remove large impurities. Inorganic ions

may be removed by a demineralisation or ion exchange treatment.

Protein impurities are considered serious impurities with regard to the colour of the syrup. These need to be removed by adsorption on activated carbon. Two types of activated carbon may be used; steam activated or chemically activated carbon.

The purified syrup is concentrated to about 60 to 80% dry matter content (weight basis) to give the required concentration and viscosity of the syrup. At this stage, various additions such as sulphur dioxide or anti-foam agents may be added to improve its handling characteristics. The syrup may also be dehydrated and crystallised to produce a powder.

Maize syrups are inexpensive sweeteners (compared to cane and beet sugar) with various functional properties that make them popular for application in the chocolate, sweet and confectionary industry. Their sweetness value and functional properties vary according to their composition, making it a very versatile ingredient.

Modern image recognition is becoming more and more prevalent in agriculture and enables at least partially autonomous machine use in many fields. However, this requires powerful cameras or sensors combined with intelligent algorithms.

With its IC-Weeder AI, LEMKEN has already launched a hoeing machine which reliably distinguishes between sugar beets and weeds, even under high weed pressure. The relevant software was developed by the Dutch AgTech specialist Track32, in which LEMKEN has now acquired a holding.

ew Holland has joined the ranks of tractor companies offering electrical and autonomous options to farmers.

The T4 Electric Power all-electric light utility tractor prototype was recently showcased in America.

It is being flagged as the ideal electrical solution for mixed and livestock farms, and can work autonomously. Commercial production is expected to begin at the end of 2023. More models are planned for the future.

Producing a peak power of 88,26 kW (120 hp), maximum torque of 440 Nm and a top speed of 40 km/h, the battery is said to deliver up to a full day of operation, taking just one hour to reach 100% power when using a quick charger.

Electrical outlets support daily farm tasks such as welding and drilling. Doubling as a backup power generator for daily or emergency needs, the outlets also power electric implements. Traditional mechanical, hydraulic and PTO implements can also be used.

In tests, the electric prototype is said to have shown exceptional performance compared to a conventional diesel tractor. Providing greater traction control and smoother shuttling and gear shifts, the saving in diesel costs and maintenance is said to reduce operating costs by up to 90%. The tractor is quiet, too, reducing noise levels by up to 90%, and vibration is also dampened.

It is possible to remotely activate the tractor via a smartphone app. Offboard digital services allows the tractor to be run from anywhere, at any time, while monitoring performance and battery level.

The T4 Electric Power’s roof houses sensors, cameras and control units. Detecting and avoiding obstacles, these allow the tractor to operate autonomously.

The intensive cooperation with Track32, a company based in Ede (Netherlands), has already proven highly successful in the development of camera-controlled hoeing machines. Anthony van der Ley, Managing Director of the LEMKEN Group, says: “This will accelerate the development of smart technologies and ensures continuity. For Track32, our cooperation delivers planning security and great potential for growth.”

Track 32’s founder, Joris IJsselmuiden explains: “As a company that specialises in software and artificial intelligence, we also develop solutions for arable farming and greenhouse processes. With LEMKEN as an investor and client, we shall be able to concentrate even more on the further development of our software and will benefit from closer proximity to end customers.”

Track32’s expertise will allow LEMKEN implements to be used even more precisely and in more versatile ways, so that intelligent machines can be controlled not only by human operators, but also by robots, for example.

During the Eurotier animal production trade show in Hanover, Germany, organiser German Agricultural Society (DLG) announced the winners of the Agrifuture Concepts Winner award.

In the field of farm machinery, an award goes to the remarkable Exos green fodder harvester from Lely. This fully electric vehicle harvests and takes fresh grass directly from the field into the cow shed.

Green fodder grown on the farm is the basis for profitable milk production and is essential to the health of the animals.

With Exos, Lely presents a concept for the fully autonomous harvesting and feeding of fresh grass. Green feeding throughout the vegetation period offers multiple advantages. For instance, the loss of energy due to the silaging process is eliminated as is that

part of the harvesting costs caused by silaging during time slots that are tight because of weather conditions.

The fully electric Lely Exos provides the daily green fodder ration for the entire herd autonomously. The robot detects obstacles and navigates smoothly in the interior and exterior area. It is also possible to spread fertiliser during harvesting.

Thanks to this and because mowing takes place at the right point in time, quick regrowth of the grassland is promoted and the soil is protected due to the comparatively low weight of the machine.

This enables the farm to benefit fully from the use of the entire vegetation period, to produce more milk from feed it has produced itself, and thereby to reduce labour, the number of machines needed and the purchase of additional feed.

Three giant Case IH Steiger Quadtrac tractors are on their last leg of a two year journey to prepare for a unique new home, far from the Australian paddocks in which they are usually seen.

The three Case IH Steiger Quadtrac 500s are currently in Tasmania, undergoing final preparations for their trip to Antarctica, where they will be used to support the Australian Antarctic Division’s (AAD) aviation operations at Wilkins Blue Ice Runway, 70 km inland from Casey Station, and also at the Casey Ski Landing Area, 15 km from the station.

The tractors arrived in the Port of Melbourne from the United States in September, and then made the trip across Bass Strait to Tasmania, where they travelled by road to Case IH dealership TTMI at Longford, just south of Launceston, in preparation for their journey by ship to Antarctica.

Jason Wood, Case IH ANZ Steiger Product Manager, said the Steigers had been manufactured at Case IH’s plant in Fargo, North Dakota, before undergoing some necessary modifications required to cope with the challenging conditions of Antarctica.

“This is a process that has taken several years because it’s not simply a case of delivering three of our regulation Steiger models. To withstand the unforgiving environment they are heading to, and carry out the work they are required to do to the very

highest standard, they needed some critical modifications,” Jason said.

“They have had arctic hoses installed in key areas and heaters added for the warming of the coolant and engine oil each time before they are started. The fuel tanks have even been tripled in size to increase their versatility.”

Once in Antarctica, they will be involved in runway maintenance, fuel and cargo transport from Casey to Wilkins, and general sled towing and

heavy vehicle recovery.

Pete McCann, General Manager of Case IH Australia/New Zealand, said the request had been a unique one for his team, who had enjoyed preparing the Steigers for something so far removed from their usual farming environment.

“It will be a proud moment when they are finally loaded onto the ship in Hobart for their new home and their new job on the frontline of the important scientific work being undertaken in Antarctica.”

www.caseih.com)

Granadillas, also known as passionfruit, is a vine species of passionflower that is native to Brazil. It belongs to the family Passiflora.

The centre of the fruit is filled with yellow gelatinous pulp and seeds. It is sweet yet acidic tasting. The thick outside rind is cut open to reveal the yellow insides. The plant itself grows lush green leaves, and the flowers are considered to also be ornamental as the unique blooms are quite interesting to look at.

Granadillas are ideal for commercial production or as an addition in your home garden. There are two commercially viable passion fruit types, namely the purple and the yellowskinned aromatic fruit.

It is mostly consumed in juices, salads or on its own, but the pulp is often used as a garnish.

The ideal climate to grow granadillas has a moderate temperature throughout the year. The purple variety is particularly susceptible to frost. To mitigate this temperature sensitivity, plants can be planted on cool slopes in hot areas, or warm slopes in cool areas. The temperature should be between 5 °C and 29 °C.

High humidity is preferred. These plants require high rainfall of up to 1 200 mm per year, preferably rain that is well distributed throughout the year.

Harvesting of the fruit occurs when they ripen, but have not yet reached their deep colour.

Granadillas have shallow roots. They are sensitive to waterlogging, so the soil needs to be sandy to loam soil. It is necessary to till the soil with a plough or ripper to break up the compacted soils. Cultivate no less than 800 mm deep.

Examine the soil closely. Add lime and phosphate to the root zone. Calcium and phosphorus can be worked into the soil as well.

You can harvest your own seed from healthy, ripe fruits. Cut the fruit open and scoop out the seeds and pulp. Separate the contents by washing the seed and pulp. Dry the seeds in the shade. It can later be planted in a soil mixture that has been sterilised. You can either use seed trays or bags.

Sow two seeds per hole. You will thin them out by selecting the stronger plants later.

Once the seedlings emerge and the additional plants have been removed, add a stake next to each so it can prepare to trail. Regularly remove side shoots.

The seedlings are ready for transplanting when they are between 300 and 400 mm in height (3 to 6 months old). They should be healthy plants with dark green leaves. Ideally the best time to transplant is between August and September.

Plant the plants 1 to 2 m apart. Closer together means a higher risk of transmitting soil-borne disease and viruses but it also means a higher yield over a smaller area.

Granadillas are climbing plants. They therefore require trellis for the vines to trail on. It needs to be strong enough to carry the weight of your developing fruits. Wooden posts can be used, but these need to be solid and treated to be termite resistant. Posts should be 2 m high. String 12-gauge wire across the poles. Add leader lines from the wire to the plant so the vines can be trained to grow towards the framework. You can assist it by wrapping the vines loosely around the wire.

The thin vines require support from posts and trellis to carry the forming fruit. (Source: Pixabay)

Further care of your fruits may include pruning the vines to stimulate growth, removing dead materials and preventing overlap. Pruning, however, is not crucial, since most plantations only last three years, producing fruit for only 12 to 18 months of that period.

Since granadillas need annual rainfall of 1 000 – 1 200 for commercial cultivation, irrigation systems can be used to supplement the shortfall. Plants effectively require 15ℓ per plant per day in the summer and 8ℓ per plant per day in winter.

Be careful of not over irrigating as this creates an environment for fungi to thrive.

LAN can be added yearly, as well as phosphate and KCl. Further leaf analysis can show exactly how much, but the below table can be used as a guide. Age

For the health of your granadilla, there are a few diseases, viruses and pests to take note of.

Fungi causes damping off of seedlings. This is usually due to poor seedbed management. The good news is that it can be avoided by planting in welldrained, sanitised soil.

Footrot causes the base of the stem to thicken. This leads to cracks in the surface where other diseases and pests can enter. That, in turn, causes the stem to rot completely. Overirrigation and waterlogging usually are the main culprits. This can easily be prevented by planting the granadillas in well-drained soil.

To identify a single virus that affects the plant is often difficult, but symptoms include spots, mosaics, and distortion. Control this by removing the affected shoots, disinfecting equipment and washing hands to prevent cross contamination.

Zinc-oxide can be added as 200 g per 100 ℓ of water. Solubar for Boron deficiencies can also be added as 100 g per 100 ℓ of water.

Tip-wilters and stinkbugs are the most common pests in granadilla plantations. Frequent field inspections and collecting the insects by hand are the most effective control method.

There is also a yellow-skinned granadilla. (Source: Vecteezy)

The information provided in this article is credited to the Agricultural Research Council (ARC) ÚRC Tropical and Subtropical Crops. For more information, contact +27(0)13-7537000 or visit http://www.arc.agric. za.

There is nothing that excites pig farmers more than seeing their herd healthy and having attained the ideal slaughter weight they sought for. It means their arduous labour put into rearing the animals will have paid off and the investment made from project inception, feeding, health, and project management can be finally recouped through sales. However, if the slaughter process is not properly executed, losses can still be experienced.

The final product of the slaughtered pig depends on the market demands such as suckling, porker, baconer, grower or finisher. The general slaughter process starts with ante-mortem inspection, to stunning, dehairing, skinning, washing of the carcass, evisceration, post-mortem inspection, and then finally refrigeration, handling and transport of carcasses and meat to the desired market.

Prior to slaughtering, it is paramount that the pigs are not stressed in any manner as it affects the meat quality. Farmers should avoid deprivation of water or food, rough handling, and exhaustion of pigs due to transporting over long distances. Furthermore, mixing of animals reared separately can result in fighting.

The main purpose of inspection during the slaughter process is to assess the health of pigs before death

(ante-mortem) and after death (post-mortem). This guarantees safety and quality of meat for the market. Observing the animals’ behaviour to check for signs and symptoms of disease, isolating animals that show signs of disease, illness, or injury and verifying identification records and tags are some of the methods employed during this process.

Ante-mortem inspection averts infection of premises, equipment, carcasses, and personnel, thus enabling the implementation of control, disinfection, and preventive methods to contain diseases.

Stunning is the most common method used during the slaughter of pigs for commercial production systems. For subsistence and smallholder systems throat slitting is usually employed. There are other methods for killing the animal such as the lethal injection and bullet-free firearms. Methods of stunning are captivebolt stunning followed by bleeding or pithing, percussion stunning, electrical stunning and carbon dioxide gas stunning.

The dehairing process is done by first scalding the pig in water at around 60 °C for about six minutes, which loosens the hair in the follicles. If the temperature is too low, the hair will not come loose properly, and if it is too

high the skin will be cooked, and hair removal will be difficult. Dipping the pig into a water tank works better.

Dehairing can be done using a bell scraper or knife, or a mechanical dehairing machine. In cases where the skin is required for leather production, the pig is dipped in a bath containing a hot resin adhesive. After the adhesive has set, the resin adhesive is then peeled off pulling the hair with it from the roots.

Skinning, as the name implies, is the removal of the skin from the carcass. Usually, two operators work together on a pig to slit open the skin on the legs and opening the skin to the stage where it can be pulled off the back. Skinning is usually done with the carcass hanging.

Evisceration, also known as gutting, requires a longitudinal incision from the pubis to the neck to remove the offal. The rectum is loosened and tied off. The incision cuts through the pelvis, and the bladder and sexual organs are removed. The foreskin in male pigs must not be punctured as it is a source of infection. Depending on the market requirements, the pig can be split down the backbone.

The carcass is washed to remove

visible soiling and blood stains to improve its appearance. It is imperative to ensure that stains of gut contents are cut off, and wiping cloths are not used.

According to the Techniques and Hygiene Practices in Slaughtering and Meat Handling guide produced by the Food and Agricultural organisation (FAO), a wet surface favours bacterial growth so only the minimum amount of water should be used, and chilling should start immediately.

A well-designed cooler will dry out the carcass quickly, inhibiting bacterial growth.

The post-mortem inspection is done on the organs, lymph nodes, and the entire carcass to investigate indications of unwholesome conditions. If the meat is approved for human consumption, an inspection stamp is put along the length of the carcass.

Refrigeration is done to delay bacterial growth and extend the shelf-life of the meat. A deep muscle temperature

of 6 to 7 °C should be achieved in 12 to 16 hours for the carcass, and the chilled meat must be kept cold until it is sold or cooked. Pigs kept at -1 °C attain an expected storage life of 1 to 2 weeks.

The pig carcasses and offal are transported to retail outlets only by meat delivery vehicles that maintain the meat temperature at or near 0 °C. Meat inside the trucks should be suspended on rails and if stockinettes are used, the farmer or company should ensure their cleanliness.

Raising sheep can be beneficial in many ways. Sheep can eat vegetation that is not fit for human consumption. Sheep populations tend to grow rapidly, and their gestation period is much shorter than that of cattle. A faster growth rate of the animal population is thus possible. Capital expenditures for sheep production systems are lower than those for cattle. Farmers can quickly see the results of their feeding, genetic, and management choices.

The Dormer and Dohne Merino both trace their ancestry back to the German Merino, a multipurpose sheep that served as a foundation for the development of those breeds. The Merino breed has been refined through generations of selective breeding in South Africa.

This large breed of sheep is a useful resource due to its fine 21 to 23 micron wool, and meat. The Mutton Merino was originally bred to take advantage of the Western Cape's winter grazing and to raise their lambs before the grazing

South African Mutton Merino ewes and lambs. (Source: savleismerino. net)

deteriorated in the summer. However, because it is so adaptable, it is now found all over the country.

In addition to being resistant to parasites like the hairworm, this breed is also less likely to contract diseases like Johne's. For the first time, ewes could give birth at the age of 22 months. At 100 days, the maximum weights that ewes and rams of the Mutton Merino breed can achieve is 35 kg, and they can produce good volumes (4 kg) of medium to strong wool. The Mutton Merino sheep gain weight as they age, allowing for a greater live weight to be slaughtered. There is no obvious fatty area on the carcass.

In South Africa, Dormer meat sheep were bred by crossbreeding Dorset Horn rams with German Merino ewes. Dormer comes from the combination of the names of its two parent breeds, Dorset and Merino. Even though the breed was developed in areas with winter rain in the Western Cape, it can be raised successfully in more temperate climates, both on natural veld and on cultivated pastures.

The Dormer is a hornless, whitewoolled sheep with a sleek body and excellent meat conformation. Multiple births are commonplace because of the breed's high fertility. Lambs are born very small but quickly mature into their full size. The mature weights of Dormer rams are between 100 and 110 kg, and those of ewes are between 70 and 80 kg.

Dormers typically have white wool averaging 27 microns in thickness and known for its strength. The wellmuscled sheep reaches reproductive maturity at a young age (first lambing at 18 months) and is extremely fertile, producing many small lambs.

South

(Source: savleismerino.net)