A post emergence herbicide targeting weeds, ensuring a high yield and good grain quality. Available in 5 litres (water dispersible granule).

ProAgri really appreciated the opportunity and experience of being welcomed warmheartedly at the Agritech Expo, and happy to see it being back in full swing.

Agritech Expo Zambia is indeed Zambia’s leading professional agriculture trade fair; a very solid agricultural platform in Zambia showcasing advanced farming mechanisation equipment, seed varieties, plant protection and fertilisers, irrigation tools, animal husbandry equipment, and much more … like solar technologies. Agritech Expo contributes to the future of the Zambian farmer.

Mechanisation is the key to the farming business of the 21st century, and will definitely have positive effects like higher outputs, and generating more income for the farmer itself and the society.

I can write a book with all the information gathered and about my experience at Agritech 2023. Truly a surprise around every corner! Unfortunately, there is only space for so much in every issue, but we hope you enjoy our report on the expo from page 8 onwards.

The future of the Zambian farmer Zambia still has a stable policy environment, which means the government supports the agricultural sector and promotes commercial farming. We see contrary tendencies happening in South Africa, as already happened in the past in Zimbabwe. Commercial or emerging farmers are more likely to invest in a country with stable policies. Zambia is still a good place to grow crops and raise animals, with enough fresh water for irrigation.

Information is the key to success, and the drastic increase in attendance numbers at this year’s Expo confirms that farmers understand this truth. It is true that representatives of companies have to punt and sell their products, but I have never come across one that is not prepared to share what he knows or even what he has learned from the experience of other farmers who found solutions to problems. An expo such as Agritech, as well as farmers’ days, offers the ideal opportunity for farmers to pick the brains and share in the experience of those who know.

ProAgri firmly believes that information should be freely available, and we would like to hear your opinion on our contents. Please let us know whether we are on track, or what you would like to read about.

We look forward to more visits in Zambia, and please feel free to reach out to me!

ProAgri greetings Bianca Henning bianca@proagri.co.za

Carl Hamm and Stüwa are leading suppliers of drilling and pump equipment with more than 90 years of experience in the industry. Their products are known for their reliability, durability, and innovative designs. Read more on page 3.

Carl Hamm and Stüwa: Meet your water partners

Tips from Novatek: Looking after your wiggly tail companions

Choose Senter360 for local quality

Agritech Expo: A paradise for Zambian farmers

Saro Agro puts the small-scale farmer first

Advanta Seeds International's superior genetics

Apimondia: For the love of honeybees

From silkworms to silk garments Part 4.1: Silk reeling methods

The latest in agricultural technology from around the world

Processing of condiments Part 29: Pickled baby marrows

Tiger Animal Feeds: More than just feed

Goat breeds part 2: Milk and mohair breeds

Fruit production part 5:The cape gooseberry is a golden crop

Farm management and planning Part 2: Camp sizes

Beekeeping part 10: Harvesting and marketing of honey

Snail production – Part 1

Manage your cattle’s grazing better for a higher production rate

Editor Bianca Henning >

Reporters

Benine Ackermann >

Maryna Steyn >

Natasha Pansegrouw>

Specialist Writer

Annemarie Bremner >

+27 82-326-2572

bianca@proagri.co.za

+27 73-105-6938

benine@proagri.co.za

+27 82-261-9177

maryna@proagri.co.za

+27 81-736-4236

natasha@proagri.co.za

+27 82-320-3642

annemarie@proagri.co.za

Senior Production Manager

Zainab Pandor >

+26 (0)97-769-9786

zainab@proagri.co.za

Client Relations Manager

Carin Swartz >

Marketing Manager

Diane Grobler >

Marketing

Xander Pieterse >

Johan Swartz >

Tiny Smith >

Lynette van Tonder >

Creative Director

Christiaan Joubert >

Design

Michelle Kruger & Enquiries

Engela Botha >

+27 84-233-0123

carin@proagri.co.za

+27 82-555-6866

diane@proagri.co.za

+27 79-524-0934

xander@proagri.co.za

+27 71-599-9417

johan@proagri.co.za

+27 82-698-3353

tiny@proagri.co.za

+27 74-694-4422

lynette@proagri.co.za

+27 72-419-3990

christiaan@proagri.co.za

Jamie-Lee Tromp

+27 12-803-0782

engela@proagri.co.za

Distribution and subscription

Nita Volmer-van Zyl >

Accounts

Ronel Schluter >

Business Manager

George Grobler

+27 79-515-8708

nita@proagri.co.za

+27 12-803-0782

accounts@proagri.co.za

Carl Hamm, a renowned supplier of high-quality pipe and pump equipment, partners with Stüwa, a leading manufacturer of well and borehole screens and casings, to offer customers innovative solutions for effective borehole construction and maintenance.

Carl Hamm / Stüwa are leading suppliers of drilling and pump equipment with over 90 years of experience in the industry. Their products are known for their reliability, durability, and innovative designs. Carl Hamm’s ZSM connector is a patented coupling system that provides a secure, leak-proof connection between sections of casing. The ZSM connector is designed to reduce the risk of groundwater contamination and to provide a long-lasting, effective borehole. The system is easy to install and requires no special tools or equipment.

Stüwa has been providing the drilling industry with reliable well screens and casings for decades. Their products are made of top-quality materials and are designed to meet the specific needs of each project. Their screens and casings are known for their durability and their ability to withstand harsh conditions. Stüwa offers a wide range of products to fit any application, from standard designs to custom solutions.

Together, Stüwa and Carl Hamm provide customers with a comprehensive range of products for borehole construction and maintenance. Their combined expertise and innovative solutions make them the ideal partners for any project. Whether you need a standard well screen or a custom casing design, Stüwa and Carl Hamm have the knowledge and experience to help you find the perfect solution.

Stüwa’s well screens and casings are made from a variety of materials, including stainless steel, PVC, and fibreglass, to provide customers with a wide range of options to fit their specific needs. The screens and casings are available in a variety of sizes and configurations to fit any application. Stüwa’s engineers work closely with customers to develop custom solutions when needed, ensuring that every project is a success.

In summary, Stüwa and Carl Hamm are the ideal partners for borehole construction and maintenance. Their innovative solutions, combined expertise, and top-quality products

make them the perfect choice for any project. Stüwa’s well screens and casings, coupled with Carl Hamm’s ZSM connector, provide customers with a complete range of products for effective and long-lasting boreholes. Contact us today to learn more about our partnership and how we can help you with your next project. For more information on the products

For services that Carl Hamm PPS provides, contact Desmond Enslin on (+27) 83 556 4642 or send an e-mail to desmond@carl-hamm. co.za. Visit our the website at www.carl-hamm.co.za.

Dogs are known as man’s best friend and have that title for a reason. They are your loyal companions and are always there when you need them. Caring for your companions is a responsibility of all pet owners, which takes effort and commitment.

We will discuss some important tips to ensure they are kept healthy and happy:

A well-balanced healthy diet is essential to your companion’s well-being and health. The food you choose needs to meet their nutritional requirements. A puppy’s needs are significantly different from an adult dog’s needs and your choice of food should be made with that in mind.

Additionally, it’s important to follow the instructions on how and how much to feed them. This ensures that your companions do not become obese and that they receive a well-balanced amount of nutrients to support health and optimal growth.

easy access to clean cool water. The water and feeding bowls should be cleaned between each meal to ensure there are no harmful bacteria present.

by Everett PieterseA sudden change in your companion’s diet can cause gastrointestinal upset, leading to symptoms such as diarrhoea and decreased appetite. Therefore, when changing to your companion’s choice of food it’s important to transition them over slowly as seen in Figure 2. This allows the digestive system enough time to adjust to the new ingredients.

Dogs should be fed at least one to two times a day at approximately 8 to 12-hour intervals. It is important to always provide your companion with

It’s essential for your pet’s health and the health of your local community to ensure that your companions are fully vaccinated. Serious diseases such as rabies, distempe r, and parvovirus

can be avoided by doing so. A regular check-up with your vet helps keep your companion’s vaccines up to date.

Your companions require regular exercise to stay healthy and happy. Depending on the breed, age, and size of the dog, the level of exercise will differ. Activities such as playing fetch and taking them on walks are good ways to ensure that your best friend and you stay fit and healthy.

Training and socialisation are important parts of looking after your companion. These help to reduce aggressive behaviour by developing boundaries and teaching them social skills. Training should start at a young age as younger dogs will respond better to training than older dogs.

In conclusion, taking care of your companion requires time, effort, and commitment. Dogs bring us so much joy, and we must ensure that they live happy and healthy lives. We at Novatek always endeavour to provide quality dog food for both adults and puppies. Our unique blend of botanical extracts offers extra antioxidant support to your dog’s natural defence against harmful stressors and premature ageing.

For information on Novatek’s dog feed contact Robert Kanyembo, Novatek National Sales Manager on (+260) 97-125-2522.

AtSENTER360 we are proud to not only supply products, but build long-term relations with our clients by delivering a package of high-quality products and excellent service. The SENTER360 centre pivot, manufactured since 1994, is known for its excellent quality and strength above industry standards. We have been part of the irrigation industry for more than 25 years and have interests in South Africa, Africa and in the rest of the world.

AtSENTER360 we are proud to not only supply products, but build long-term relations with our clients by delivering a package of high-quality products and excellent service. The SENTER360 centre pivot, manufactured since 1994, is known for its excellent quality and strength above industry standards. We have been part of the irrigation industry for more than 25 years and have interests in South Africa, Africa and in the rest of the world.

We are passionate about our centre pivots. We do not only build a tough, extremely strong structure but also give attention to small details to make a big difference in your everyday life.

We are passionate about our centre pivots. We do not only build a tough, extremely strong structure but also give attention to small details to make a big difference in your everyday life.

SENTER360 tower trusses are manufactured from pipe and not angle iron as is commonly used by other brands. The advantage of the lighter and structurally stronger material enables us to use two more sets of trusses per tower than is possible with angle iron trusses, ensuring an exceptionally strong structure. An added advantage of the pipe truss structure is its aerodynamic superiority above angle iron as a structural material. That is the reason why a SENTER360 machine can withstand a windstorm of 158 km hour (actual field data) without any damage. This claim is borne out by the fact that no SENTER360 was blown over in the recent storms (the only brand not to topple over).

SENTER360 tower trusses are manufactured from pipe and not angle iron as is commonly used by other brands. The advantage of the lighter and structurally stronger material enables us to use two more sets of trusses per tower than is possible with angle iron trusses, ensuring an exceptionally strong structure. An added advantage of the pipe truss structure is its aerodynamic superiority above angle iron as a structural material. That is the reason why a SENTER360 machine can withstand a windstorm of 158 km hour (actual field data) without any damage. This claim is borne out by the fact that no SENTER360 was blown over in the recent storms (the only brand not to topple over).

Firstly, the pipe structure, but also the standard long base beams, sturdy tower supports, stabilizing rods, diagonals, and a low centre of gravity, all contribute to the exceptional stability.

Firstly, the pipe structure, but also the standard long base beams, sturdy tower supports, stabilizing rods, diagonals, and a low centre of gravity, all contribute to the exceptional stability.

• feedback when the machine stops

and stop feedback communication.

• direct water application adjustment

• feedback when the machine stops

and stop feedback communication.

Last sprinkler solutions

• direct water application adjustment

• showing the position of the pivot

• low pressure stopping and pressure starting

• showing the position of the pivot

• low pressure stopping and pressure starting

• part circle and sector adjustment with variable water application per sector

• part circle and sector adjustment with variable water application per sector

• sector control of the end water cannon

• sector control of the end water cannon

• auto-reverse with variable water application on return

• auto-reverse with variable water application on return

• pre-programmable scheduling options

• and many more!

• pre-programmable scheduling options

• and many more!

All new and old** SENTER360 panels can be controlled by your cell phone*, tablet*, computer or base station by adding a simple plug-in communication unit of your choice, such as GPRS/cell network, Wi Fi, or radio unit.

Last

One of the common problems with centre pivot irrigators is the regular blockage of the last nozzle. We have solved this problem in a simple innovative way, constantly keeping the last nozzle clean throughout the irrigation cycle.

One of the common problems with centre pivot irrigators is the regular blockage of the last nozzle. We have solved this problem in a simple innovative way, constantly keeping the last nozzle clean throughout the irrigation cycle.

SENTER360 centre pivots are equipped as standard with high quality, high performance Komet Twister sprinklers operating at 10 psi (0,7 bar) or optional 6 psi (0,42 bar), mounted on drop pipes. This top-quality product ensures outstanding water distribution, even in trying climatic conditions.

SENTER360 centre pivots are equipped as standard with high quality, high performance Komet Twister sprinklers operating at 10 psi (0,7 bar) or optional 6 psi (0,42 bar), mounted on drop pipes. This top-quality product ensures outstanding water distribution, even in trying climatic conditions.

The same modular principals used throughout the entire SENTER360 design is also visible in our control panel design. Our entry level control panel is similar in functionality to the top panels of most other brands.

The same modular principals used throughout the entire SENTER360 design is also visible in our control panel design. Our entry level control panel is similar in functionality to the top panels of most other brands.

Standard functions include:

• on/ off

Standard functions include:

• on/ off

All new and old** SENTER360 panels can be controlled by your cell phone*, tablet*, computer or base station by adding a simple plug-in communication unit of your choice, such as GPRS/cell network, Wi Fi, or radio unit.

Full pump control, VSD control and feedback are also available on the same system. New panels have full function internet controls, record keeping, and graphs.

Full pump control, VSD control and feedback are also available on the same system. New panels have full function internet controls, record keeping, and graphs.

*Android, IOS and other **Older panel controls are limited to on/off, direct water adjustment, run

*Android, IOS and other

**Older panel controls are limited to on/off, direct water adjustment, run

The standard drivetrain of a SENTER360 centre pivot is made up of heavy-duty wheel gearboxes, driven by a 0,56 kW (40:1) motor gearbox combination (30:1 and others are optional.) An optional five-year extended warranty is available (T’s and C’s apply).

The standard drivetrain of a SENTER360 centre pivot is made up of heavy-duty wheel gearboxes, driven by a 0,56 kW (40:1) motor gearbox combination (30:1 and others are optional.) An optional five-year extended warranty is available (T’s and C’s apply).

by Bianca Henning

by Bianca Henning

During the mid-month of April, all roads in Zambia lead to Chisamba as this is a highlight event on the calendars of all Zambian farmers, providers of farming equipment, and citizens.

The Agritech Expo is the biggest agricultural show in Zambia with an attendance of farmers of all sizes from all the parts of the country.

This is a platform where farmers get the opportunity of gaining and sharing information, and meet with international and local suppliers for all aspects of the agriculture industry and all elements of the farming process. Agritech offers farmers the opportunity to talk

to qualified agronomists, livestock and crop experts, and many more in the position to sort out or clarify any issues they are facing in their farming operations.

Agritech Expo is a professionally led event that serves the needs of all the agri-value chains in Zambia and neighbouring countries. Expo attendees include large-scale commercial farmers, as well as emerging and smaller farmers. Agritech Expo Zambia offers something for everyone.

Bringing international solutions to the farming community of Zambia, the show attracts more than 20 000 farming professionals, 240+ local and

An impressive array of field trials sown and planted by exhibitors showed which crops and varieties are best suited for cultivation in specific regions.

energy, inputs, irrigation and water management, machinery and implements, livestock and veterinary services, petroleum and lubricants, seed producers, storage, technology, utility vehicles and many more are there!

Expo attendees are happy to be part of the Agritech experience.

international exhibitors and seven international country pavilions - all in one location and with the goal of driving Zambia's agri sector forward.

Agritech Expo Zambia 2023 is the ultimate business-to-business buying platform for agricultural professionals, from small-scale farmers to commercial enterprises, to engage and conduct business with some of the world's leading suppliers to the agricultural industry. From live crop trials and machinery demonstrations to technical and practical workshops and business lounges for commercial players, Agritech Expo presents the gateway to industry innovations with the leading outdoor exhibition in the region for the agri community.

Agritech expo Zambia: Overview of exhibitors and visitors

Agrochemicals and fertilisers, agroprocessing, construction, finance and insurance, distribution and logistics,

Promising business start-up in Zambia Zambia continues to have great agricultural potential and a politically stable market environment that is increasingly attracting professional investors from abroad. The country's new leadership has initiated a rapid reorientation towards building a highly productive agricultural industry in Zambia.

Farmers just love to feel, experience and look at farming equipment, tools and accessories. The Agritech Expo offers farmers this opportunity. No wonder that large numbers of farmers flocked to the show to see the live demonstrations and equipment on display.

Many new exhibitors who attended the show for the first time were impressed by the discussions with potential customers, and have confirmed their participation for next year as well. Armed with new information, a deeper understanding, and products developed for farming in Zambia, farmers can now face the new season with confidence. Make sure you do not miss the upcoming Expo in 2024.

Saro Agro is dedicated to making farming easier. This distributor of agricultural equipment aims to make the small-scale farmer’s task easier, thereby making their farming more efficient and more profitable. To achieve this, Saro Agro offers a variety of solutions such as mechanisation in the form of tractors, machinery, irrigation, electricity generation, and construction.

Just because you are a small-scale farmer, does not mean you need to struggle with ploughing, planting, harvesting, processing, or transporting yields. Thanks to Saro Agro, there is a solution to meet your needs. This was proven at the recent Agritech Expo Zambia which was held from 17 to 19 April 2023.

Along with the equipment, various experts from the different divisions within Saro Agro were on hand to assist farmers with advice and guidance about the machines that will solve their farming problems.

Construction

In the construction division, the distributor provides farmers vital equipment. These are the PY 220 hp, six-cylinder motor grader, as well as the 20-tonne compactor that is arriving soon. Both these machines are from SINOMACH.

The BULL Tractor Loader Backhoe (TLB) from India is a 96 hp machine that has four-wheel drive. It does the job of five machines in one:

1. Forklift

2. Loader

3. Backhoe

4. Tractor

5. Auxiliary for other attachments such as a jack

Electricity generation

This division is focused on providing farmers with solar systems and generators.

“Under solar products, we have a Focus smart inverter. It is a hybrid that can be powered by the grid or solar energy,” explains Kafula Kabwibwi, from the Genset and Solar division at Saro Agro. “Connected to it is a lithium battery with a lifespan of 10 years. A farmer can easily use this for a decade without issue.”

The inverter can be used in the house to cook with, boil water, and even iron. “It is a smart inverter that means that you can connect to it via Bluetooth to see with an app how the inverter is performing,” she explains. “If you choose to rather connect tubular batteries, you can as well.”

They also distribute regular invert-

ers, including Microtek that can be used either on the grid or on solar. These require external charge controllers for solar systems.

They also offer solar geysers from 100 to 150 litres, streetlights, and spotlights.

The range of generators they supply range from 2,5 kVA to 100 kVA. Generators for domestic use are the 2,5, 5, 6,5 and 7,5 kVA models that can power your home’s lights, plugs, or a water pump. The industrial generators range from 15 to 100 kVA.

To help farmers improve their yields, Saro Agro has a water division that provides farmers with pumps and irrigation systems such as drip, micro sprinklers, centre pivots, and inline irrigation.

It is ideal for horticulture to use drip irrigation, and for orchards, micro sprinklers can assist farmers. The centre pivots provided by Saro Agro can be used with solar power or with

Tractors, land preparation, or hay making and harvesting, Saro Agro aims to assist the small-scale farmer in reaching his mechanisation dreams.

Not only are there wide ranges of well-needed equipment, but there is also expert knowledge to draw from. Here the team is gathered at Agritech expo in Zambia.

electricity provided via the grid. Rotrix travelling irrigators are supplied, installed, and serviced by this company as well.

In addition, the water division has sand filters for farmers who use open sources of water such as rivers and dams.

The variety of pumps include electric submersible pumps, booster pumps, hybrid pumps that work on AC or DC, as well as pure solar pumps. Power ranges from 0,5 hp (0,37 kW) to 5 hp (3,7 kW).

All infrastructure that a farmer might need for fertigation is also available.

Other products available include:

• Food processing machines such as dehullers and hammer mills

• Land preparation equipment such as ploughs, harrows, and disk harrows

• Forage equipment such as hay rakes and ballers,

• Farming machinery such as combine harvesters and a variety of tractors.

To get your hands on one of these many products, visit their website at https:// www.sarozambia.com/

Advanta Seeds International is a plant genetics company with a global presence across Africa, Asia, Australia, South America, North America and Europe. Advanta is a subsidiary of the Indian Multinational Agrochemical gian UPL Limited (5th largest agribusiness company in the world). In Africa, Advanta is present in 30 countries at different stages of its evolution. In Zambia, Advanta Seeds has been operational since 2018, with presentment and a supporting team in Copper-belt province, Central province, Southern province, Lusaka province, Eastern province, Western province. Advanta seeds Zambia supplies hybrid Maize Seed and Vegetable Seeds of both Hybrid and OPV, which are currently being sold in Agro dealers across Zambia.

HYRID SEEDS

VEGETABLE PRODUCTS

OPV

Okra Hybrid 814 & 820 Onion Texas Grano Carrot Nantes

Red Okra Red Magic F1 Pepper Cal Wonder Chinese Cabbage Michilli

Tomato 1247 F1 determinateOval Rape Hobson Cucumber Ashley

Tomato 1299a F1 determinate-Round Spinach Swiss Chard Okra Clemson Spineless

Tomato 12139 F1 indeterminate-Round Onion Red Creole Okra Clemson Spineless

Watermelon Candy F1 Watermelon Crimson Sweet Tomato Tengeru 97

The third African Regional Apimondia Symposium (ARAS 2023), hosted by the SA Bee Industry Organisation (SABIO), took place at the International Convention Centre in Durban from 22 to 24 March.

Apimondia is the International Federation of Beekeepers' Associations and other organisations working within the apiculture sector since 1895. The first African regional symposium was held in Arusha, Tanzania, in November 2014, and the second in Addis Ababa in Ethiopia in December 2018, and stakeholders in Africa once again embraced the opportunity to come together and engage in information-sharing in Durban.

“Apimondia symposia are meant to bring stakeholders, from beekeepers, equipment manufacturers, scientists and academia, policymakers, and development partners, to honey processors and traders under one roof to exchange information, ideas, and experiences on how to develop the apiculture sector within the respective regions,” said David Mukomana, President of the Apimondia Regional Commission for Africa.

(1), Kenya (3), Lesotho (14), Malawi (9), Mozambique (13), Namibia (1), Tanzania (15), Togo (1), Turkey (2), United Arab Emirates (2), United States (2), and Zimbabwe (16).

“The Durban symposium was designed to generate a beekeeping revolution that will create a vibrant and sustainable apicultural economy on the continent,” said Kai Hichert, who co-chaired the symposium with Tumi Mobi. “The aim was to develop a value chain that ranges over the whole spectrum of beekeeping activities from subsistence beekeeping to commercial pollination of agricultural crops.”

The Africa Regional Apimondia Symposium, which was presented by the South African Bee Industry Organisation (SABIO) in Durban from 22 to 24 March, was attended by 322 people, 30% of which hailed from elsewhere.

The symposium was attended by 322 bee enthusiasts, of which 30% were from outside South Africa. Besides the 229 South Africans, visitors from outside the country’s borders included apiculturists from Argentina (1), Belgium (1), Botswana (2), Burkina Faso (6), Democratic Republic of the Congo (1), Eswatini (2), Germany (1), Greece

The symposium offered an opportunity for apiculturists to share research, challenges, and commercial opportunities at workshops and roundtable discussions.

In addition, the first-ever continental honey, mead, and bee products competition was held. It showed that there is ample scope for marketing these products, thereby further developing a viable industry.

Seven themes were discussed, including bee biology, bee conservation, bee products, beekeeping technology, policy development, and pollination. Bee products and beekeeping in rural areas will be discussed in separate articles.

Kenamelang Mooketsi from Northwest Province, judging the honey on merit as no names were displayed, only numbers.

Under this theme, the ‘language’ of drones, killer pesticides, the genetics of Ethiopian bees, and the value of honeyguides were discussed.

Eloise Butcher of the Social Insects Research Group at the University of Pretoria discussed her research into the chemical signals in the communication of drones of Apis Mellifera Scutellata with each other and the rest of the hive.

“I am interested in the role drones play within the hive as they are often overlooked or misunderstood. Investigating their communication could lead us to ask fascinating new questions involving drones,” said Eloise.

The long and short-term effects of neonicotinoid pesticides were discussed by Gamze Ertem of the Ege Üniversitesi in Izmir, Turkey. Gamze is researching the negative effects of these pesticides on the nervous system of bees. Since the

early 1990s, they have become the most widely used class of insecticide and are presently used in at least 140 products in more than 120 countries. As a result of the pesticide’s negative effect on bee colonies, prohibitions and restrictions have been imposed on their use in European Union countries.

A presentation on the genetic diversity of Apis mellifera and beekeeping development in Ethiopia was offered by Dr Teweldemedhn Gebretinsae Hailu, whose PhD research focused on the classification and characterisation of Ethiopian honeybees. Dr Hailu and his co-researchers used integrated methods to classify and characterise the highly debated Ethiopian honeybee lineages and subspecies.

David Lloyd-Jones of the University of Cape Town discussed honeyguides and honey-hunting which provides insight into wild honeybee ecology.

David lives in Tanzania and is a beekeeper and ornithologist who is completing a PhD on greater honey-

guides and their cooperative behaviour with human honey-hunters. He spent six years doing research in Niassa Special Reserve in northern Mozambique where he collected data on thousands of wild bee colonies.

Two papers were presented on this topic. Dr Lynne Hepplestone, a full-time small animal veterinarian at Ikhala Veterinary Clinic in Makhanda in the Eastern Cape, presented a paper on the use of honey in wound management. A series of case studies of multiple trauma patients comprising, among others, wounds from vehicle accidents, bite wounds, toxic tick and spider bites, tissue necrolysis, injuries caused by wire snares, and domestic accidents, were successfully treated with honey. Makhosi Lepheana of the National University of Lesotho in Maseru, Lesotho, presented a paper on the physiochemical elements of honey from the three agroecological zones, namely lowlands, foothills, and the mountains of the country, as well as a comparison to international honey standards. These elements influence the honey’s storage,

granulation, texture, flavour, nutritional, and medicinal values.

The development of an automated system for monitoring and optimising beehive parameters for honey quality improvement was presented by Antoni Bairo, a researcher at the University of Dodoma, Tanzania, who is working on electrochemical sensing technology and developing monitoring software for chemical analysis.

Albert Mutangiri of Blue Bean Software in Johannesburg, South Africa, presented a paper on the HivePulse smart beehive monitoring device that has been designed to fight vandalism and theft while increasing hive health awareness through intuitive technology.

Shingirirayi Mugabe, a student at the University of Zimbabwe in Harare, Zimbabwe presented an overview of postcolonial beekeeping in Zimbabwe from 1980 to 2022.

His study explored the development of apiculture in Zimbabwe from 1980 when the country gained independence and offered an interesting view of how political independency shaped apiculture and how it contributed to economic growth.

Pollination

Heroes and villains

Dr Robin Crewe, Senior Research Fellow at the Centre for the Advancement of Scholarship at the University of Pretoria, presented a paper on “Heroes or

Villains: honeybees and pollination”.

He described the Cape honeybee (Apis mellifera capensis), the indigenous honeybee subspecies, which is the only managed pollinator in Cape floristic region. One of the unique properties of this bee is the ability of the workers to lay eggs without fertilisation, and hence their ability to produce laying workers that act as social parasites in other honeybee colonies.

Water, bees, and onion flowers Charles Salmon, a postgraduate stu-

dent at CPUT, discussed the influence of water application rates on visitation by the South African honeybee (Apis mellifera capensis) and the seed yield of Texas Grano onions. A separate article is dedicated to this subject.

Blueberry pollination

Dr Hannelie Human, an extraordinary lecturer in the Department of Zoology and Entomology in the Faculty of Natural and Agricultural Sciences at the University of Pretoria, said pollination by honeybees played a crucial role in ensuring an increased yield, better shelf-life, and flavour of blueberries. Albeit costly, pollination is crucial.

She discussed the many challenges facing the pollination of blueberries under netting. The results of new technology for appraisal of hive quality to ensure that growers get what they are paying for, is showing promise.

The bumblebee alternative

Dr Keanu Martin, a pollination biologist, is one of the primary researchers of blueberry pollination in South Africa.

In the absence of their native pollinator, bumblebees, blueberry pollination in Africa is performed primarily by honeybees. He said there was increasing pressure to import bumblebees in many African countries as honeybees are seen as inefficient blueberry pollinators.

For more information, contact Kai Hichert at +27 82-561-0346 or send an e-mail to kai@sabio.org. za. Some of the presentations are available for reading at this link: https://www.apimondiaafrica2023. org.za/scientific-programme/

In industry and trade, the term "raw silk" typically refers to raw mulberry silk. Reeling is a technique for extracting the silk filaments from cocoons to weave them together to create compact, untwisted, and degummed silk thread.

To reel raw silk, you have to find the right end of the cocoon filament and join a few ends together. A reeling machine is used to unwind the silk filament from the cocoon. In all cases the process starts with cooking the cocoons and keeping them in a basin with warm water.

Cocoons can be reeled in directly on standard reels or indirectly on small reels. The reeling machines' water temperatures are optimised for the type of appliance, water, and cocoons.

The reeling basin and reeler receive cooked and brushed cocoons with filaments. Clear filaments are tied to a reel bench hook near the reeling basin.

There are several ways to reel silk:

1. Traditional charka

The Indian cottage reeling industry uses the charka, a manually operated reeling machine. Charkas are usually installed in backyards or in simple, roofed shelters.

Charkas have mud platforms, distributors, and reels. The dimensions are usually 60 x 120 cm with a 90 cm-high mud platform that is rectangular in shape with a basin that covers the builtin fireplace. This basin, which is a 45 to 50 cm oval mud pot or copper vessel, cooks and holds the silk cocoons. The reeler sits on the mud platform, which covers the basin to its brim.

The basin has a metal thread guide (tharpatti) with apertures. It is securely attached to a thin, long stick leaning against the front edge of the mud platform near the basin.

Firewood or dry twigs are burned to heat the basin water in the fireplace or oven. Paddy husks and peanut shells are used as fuel in some places, and a chimney vents smoke.

A wheel on a vertical axis drives the wooden traverse rod in a distributor. The traverse rod is parallel to the platform's front and 20 to 25 cm away. The reel's cord belt drives the wheel's constricted part. The traverse rod has regular wire loops to guide threads to the reel. The traverse rod rapidly crosses the reel's silk while reeling. Each reel holds four ends. The cocoon ends are collected with a stick

Cooked and brushed cocoons with filaments enter the reeling basin and reeler. A reel bench hook near the basin holds clear filaments. (Source: blog.paradisefibers.com)

after cooking the floss. The charka gathers the cocoon filaments in one hand and passes them through the tharapatti. After passing through the tharapatti, two threads are crossed and fed to the charka reel through the distributor guide. A separate turner manually rotates the thread on the reel.

Cooked and brushed cocoons with filaments enter the reeling basin and reeler. A reel bench hook near the basin holds clear filaments. (Source: blog.paradisefibers.com)

Due to its uneven denier, this reeling method cannot produce high-quality silk. Since cocoons are kept in large numbers at high temperatures in the basin, reeling cannot be maintained uniformly. This method reels in even inferior cocoons, resulting in inferior silk.

The Charka gives a higher silk yield and a lower renditta (the number of cocoons needed to produce 1 kg silk). (Source: YouTube by Our Collection)

The disadvantages are that the boiling and reeling processes cause the basin water to become dirty and coloured, making the raw silk dull. Therefore, the reeler must refill the basin four to five times a day and these breaks result in loose ends.

a. Domestic Basin

The domestic basin improves raw silk quality to compensate for charka reeling system flaws. The domestic basin unit has two reeling basins and one cooking basin on a convenient height platform. To cook and transfer cocoons to the reeling basin, the cooking basin is placed directly in front of the tworeeling basin unit. The reeling basin receives cooked cocoons from singlepan cooking.

Distributor Guide

Threadguide

Baloon

Cluster (Rose) of Cocoons Reeling Water Reeling Basin

Cottage basins are widely used in reeling, and the cooking unit has three or four basins in a row. Cooking does not disturb reelers, and the table holds 4 to 6 reel basins.

Copper sheet reeling basins measure 45 x 25 x 7,5 cm. A tap from the cooking unit's water drum supplies hot water for the reeling basin. The transmission shaft, drive wheels, and croissure frame are made of wood or iron.

Each basin reel has four to six ends. Each basin has jettebouts for filamet attachment. Each basin has its own travellette croissure frame. The reel frame is a one-metre-long, angle iron or wooden frame parallel to the reel bench.

Reel benches are 150 to 170 cm tall from the ground, so the knotter can move freely in the passage and knot threads. Drive wheels on a transmission shaft turn the power reels. The

transmission shaft has a handle for reel rotation and a traverse mechanism with gears and a cam to move the traverse bar.

This multi-end basin is slightly better than the domestic basin. The cottage basin has small overhead reels and rereeling equipment. The rest resembles a domestic basin machine.

3. Multi-end reeling basins

Multi-end reeling machines produce thread on small reels at a slow speed. Reeling slowly breaks the thread, resulting in less waste and easier re-reel-

ing. It helps make better silk mechanically, and the reeling does not strain the reeler. This reeling technique has revolutionised design and operation.

The multi-end unit automatically cooks cocoons. The reeling unit has two parallel rows of basins with small overhand reels. The reel bench is tall enough for workers to sit on stools and reel.

Deep rectangular reeling basins with a copper and tin interior, 10 to 12 cm wide are used. Jetterbouts with equal reeling ending in each basin, an overflow drain, and a travellette croissure

are all required. Reels on the multi-end machine range in diameter from 60 to 75 cm.

The light metal or hard frame machine has six hard wood reel bars. Each reel has a round stainless steel or brass rim around the reel bars.

Connecting gears from the main shaft drive the reels over a carrier shaft. A mechanical brake on the shaft stops all reels when needed. Each reel has a stop motion device that automatically stops when encountering large slugs and waste in raw silk thread.

All reeling machines have porcelain button thread guides with a tiny thread aperture. It has speed regulators, and the vibration-free machines last longer. The multi-end machine improves reeled silk quality, productivity, and waste.

References

CGSpace. (2007). Sericulture in East Africa. Japan Association for International Collaboration of Agriculture and Forestry. Available at: https:// www.jaicaf.or.jp/fileadmin/ user_upload/publications/

FY2007/report-2007_1_e.pdf

Agarwal, A. (2014) 1 silk reeling, Academia.edu. Available at: https://www.academia. edu/7988066/1_SILK_REELING

The range of DeLaval robots is now being expanded with an autonomous feed distribution robot – OptiWagon. Feeding is one of the biggest costs on a dairy farm and, in addition, the most labour-intensive activity after milking. DeLaval is launching the new robot as a module in its complete automated feeding solution, DeLaval Optimat™.

This total feeding solution provides everything from weighing, cutting, and mixing to delivering the feed to the feed table. It will be available in most European markets shortly.

This latest robot is designed as a module for use with the firm’s Optimat stationary automatic feeding system. This mixes the ingredients, which are then conveyed into the tub of the OptiWagon for feeding.

“The new feed distribution robot helps to optimise the conversion of the roughage dry matter into milk. Being able to do this efficiently is a great benefit on a dairy farm,” says Ludo Bols, Feeding Systems Specialist at DeLaval. “By including the OptiWagon as part of the Optimat system you have an efficient and flexible feeding system that can help to save valuable time and limit energy costs on farms,” Ludo says.

DeLaval stands by its concept of having separate products for mixing and cutting, and distributing the feed. “This

way we develop the product to do the job it is meant to do in the best possible way,” says Ludo.

Capable of providing various animal groups with a different feed mix up to 12 times a day, the recipes and routes are set up and adjusted via the firm’s DelPro farm management system.

by Annemarie BremnerDeLaval says that the Optimat system is installed on more than 600 farms, mainly in Europe. Described as simple and effective, the standard version is suitable for feeding 120 to 130 cows. The master version is a fully automatic feeding solution for dairy herds of up to 1 000 animals. (Source: Delaval.com)

Valtra celebrates another achievement as their Q Series ‘Beast’ received the prestigious Red Dot Award for Product Design. The announcement comes less than six months after their newest tractor, the Q Series was released. The new series suits the higher horsepower segment.

The Q Series was released in September 2022, and quickly garnered industry attention, picking up the Farm Machine 2023 Jury Award at the SIMA show in Paris, last November. The Farm Machine jury praised the Q Series for its agricultural contractor focused approach.

At 171 to 227,5 kW (230 to 305 hp), the Q Series fills the gap between Valtra’s T Series and their S Series. In test drives, customers have praised the Q Series’ smooth CVT transmission, manoeuvrability, and high level of visibility for such a high-horsepower tractor. To achieve this, careful consideration has been given to the design of the Q Series.

Industrial Design and User Experience Department Lead, Kimmo Wihinen, explains that the best tractor experience comes from listening to the customer: “Customers have been asking for a bigger T Series. We have delivered a completely new tractor. Large farms and agricultural contractors need an efficient higher horsepower tractor but with good manoeuvrability and visibility. Everything from the easy access via the aluminium steps, the all-new powerful integrated front work lights, cab comfort, new roof design, and easy-touse, fully integrated technology via the SmartTouch user interface, responds to customer feedback. Everything is

designed to make the Q Series a comfortable, and well-equipped tractor. It is the best tractor we have ever designed and built here in Suolahti in Finland. We are very happy that the Q Series continues Valtra’s history of winning Red Dot Design Awards.”

Valtra’s previous successes with Red Dot Awards included an award for the T Series in 2016, an Honourable Mention for the N Series in 2017, a win for the A Series in 2018, for the G Series in 2021, and, more recently, a Red Dot Award for the N Series in 2022.

Valtra’s Q Series will be on the road heading to various locations across Europe as part of Valtra’s SmartTour 2023. (world-agritech.com)

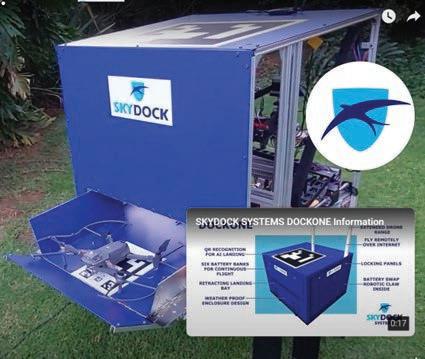

Drones can be very useful tools for farm security and crop protection, but short work times with manual intervention due to limited battery power is problematic. Dock-One is Skydock Systems’ automatic drone battery swapping and mission planning solution for DJI Mavic; with other drones to follow shortly.

Dock-one is an affordable drone battery swapping station developed in South Africa for the local and international market.

24/7 in an automated fashion.

The docking station design was incubated by Roelf Diedericks and Wikus Combrinck during Covid, when a family farm near Mabalingwe Game Reserve in the Limpopo province of South Africa was struck by a spate of night-time burglaries in the surrounding lodges. Manual patrols by the reserve, using a thermal drone, resulted in several arrests, and served as a deterrent for would-be criminals reducing security incidents by 99%.

The challenge with staff needed for manual drone surveillance and manual

battery swapping is solved by the DockOne docking station.

Paired with the DJI Mavic 2 Enterprise drone, DockOne allows you to automatically patrol day and night, and using the drone’s accessories such as the spotlight, or loudspeaker, nefarious activities can be stopped in its tracks.

Drones used for crop monitoring and protection in orchards will also be able to continue with their work non-stop.

Using the SkyDock/Flight Now system, you can create automated missions and monitor the drone from a centralised location over the internet.

The DockOne solution comprises

three components, the DockOne docking station, FlytNow mission planning and remote-control software, and the DJI Mavic 2 Enterprise drone.

DockOne quick info

• Quick battery swapping docking station.

• 5 batteries on constant charge.

• Weather resistant enclosure, 200W thermo-electric heating and cooling.

• Built-in camera for remote monitoring.

• External LED landing light support.

• 2 x 12v back-up batteries for safe landing in power-outage situations.

• Automated precision landing.

• Dual extended range drone antennas (up to 10 km)

• Built-in 4G/LTE, WiFi, or Ethernet Internet router.

• Remotely accessible dashboard.

• Dimensions (H x W x Depth) : 690mm x 970mm x 920mm

• Weight: 70kg

• Material: Mild steel, powder coated.

SkyDock Systems is a division of ByteHeavy Industries (Pty) Ltd, a South African based software and robotics engineering firm. For more information, visit https://skydock.systems/ dock-one/.

Farmers

The Swedish innovation platform, Agtech 2030, hosted by Linköping University, has created a digital control room for agriculture. It is called the Agtech Dashboard, AGDA for short, and includes digital twins of farms.

Martin Stenmarck at the technology company HiQ says: “Farmers today have many systems to manage: tractors, machines, milking robots, and silos. Although some integration of the systems has been done, there is still more to be desired. Furthermore, userfriendly interfaces are often missing.”

Fredrik Gustafsson, professor of sensor informatics at Linköping University, says: “We have been inspired by the needs of park rangers in Kenya. In the Ngulia project, new technology was developed for increased protection of rhinos. It is about digitisation, appbased field reports, sensor networks and positioning systems. A central part

has been positioning and movement analysis in real time. We have now transferred and adapted this to the Swedish agricultural context.”

The team has tested advanced functions in the model, for example maps where you can see exactly where each cow has gone in the last 24 hours.

The team has also created digital twins. The idea is that the farmer should be able to bring up the entire farm as an interactive 3D model.

The model will enable a farmer to get a good overview of his farm and he can more easily plan the work with his team. The information is visual and easy to absorb, you can even see it through VR glasses.

Mikael Pettersson, Farm Manager at Rotenberg Manor and part of the team behind AGDA, comments: “The 3D model consists of two models, one overview that includes the fields, and

one that focuses on the farm centre. Through this, you can quickly and clearly point to something you want to discuss, for example which solar cells need to be fixed. It will be easy to plan the work and coordinate tasks.”

Oscar Hoffmann of Linköping University, who created the 3D model, explains: “The model is based on approximately 4 000 still images photographed with drones, as well as images from the ground with a hand-held camera to capture details. The compilation of the images into a 3D model is called photogrammetry. The 3D models also have focal points. Clicking on them brings up photographs and in some cases video in real time.

“This concept gives a foretaste of how future farm management will be possible,” Per Frankelius, Innovation Leader in Agtech 2030 concludes. (world-agritech.com)

can now manage their farms remotely by using 3D-technology.Baby marrows (courgette or zucchini) are common ingredients in vegetable pickles. It can either be pickled alone or in combination with other vegetables such as onion, gherkins, cauliflower, green beans, or carrots.

The product is preserved by the low pH (<4,5) of the packaging liquid and a pasteurisation treatment. It is sealed in suitable containers such as glass jars.

1. Harvesting of baby marrows

Baby marrows are harvested at a very immature stage when the rind is tender and seeds are underdeveloped. The fruit reach harvestable size 4 to 6 days after pollination and therefore require regular picking. Baby marrows are harvested by hand, every other day, for several months.

Harvesting should be done by cutting rather than snapping off the fruit to minimize physical damage of the fruit. Poorly trimmed stem-ends promote post-harvest decay. Pickers also remove the attached blossom in the field. Pickers often wear gloves for protection against the thorny leaves and stalks, but also to reduce the damage caused to fruits by fingernails. The baby marrows are placed in plastic crates for easy transport and should be removed from the field as soon as possible.

2. Inspection and sorting

This is done to select the best suitable raw materials for manufacturing the value-added end product. The harvested baby marrows are inspected and any damaged, infested, rotten or off-colour baby marrows are removed along with any foreign matter such as sticks and blossoms.

3.

Baby marrows are washed to remove adhering dirt, soil and any other unwanted deposits. Water baths filled with potable water or agitated washing drums must be used.

4. Trimming and sorting

The baby marrows are inspected for damage. Any damaged, immature or misshaped areas are trimmed away using sharp stainless steel knives. The baby marrows are size sorted according to length and diameter.

5. Cutting

The baby marrows are sliced, diced or cut into strips, according to requirements. Manually operated apparatus or automatic cutting equipment can be used.

6. Inspection

The pieces are inspected to ensure that only the correct length and thickness is

selected. No defects, black spot, slivers or pieces of stalk may be present.

7. Blanching

Blanching is a short heating process whereby food products are heated to a certain temperature that is high enough to inactivate the enzymes responsible for undesirable changes in colour and flavour.

Vegetables are living plants that continue to respire after harvest. Enzymes start to break down tissues as soon as the vegetable is removed from the plant, producing waste products which are an ideal growth medium for micro-organisms, which causes change in the taste and flavour of the product. Blanching prevents enzymatic and microbiological deterioration by inactivating enzymes and killing plant tissue. The main disadvantages of blanching are the loss of water-soluble vitamins and minerals.

This should be controlled by keeping the exposure time as short as possible. During commercial blanching, the product should be heated to the required temperature as quickly as possible to minimize the softening of the tissue.

There is a variety of blanching methods to choose from, including water blanching and steam blanching, individual quick blanching (IQB), vacuum steam blanching, microwaves and

integrated blancher-coolers. Steam and IQF blanching would be a good choice for baby marrow pieces, since water blanching tends to make the product soggy.

8. Drying and cooling of blanched pieces

The blanched pieces are dried to maintain uniform colour of the product, and to prevent it from becoming soggy. Moisture is first removed by using dewatering screens where the product is spread out in a thin layer on mesh screens and the moisture is allowed to evaporate. To increase the drying efficiency, cool air can be blown over the product. This not only dries but also cools the product and preserves the texture of the blanched pieces by preventing extended heating.

9. Brining

The baby marrow pieces are brined by immersing in a 10 to 15% salt solution. The brine may be slightly acidified with lactic acid (0,5%). Brining may continue for 1 to 5 days before the vegetable pieces are removed and rinsed with potable water to reduce the salt content of the pieces to 5 to 6%.

10. Mixing baby marrow pieces with additional ingredients (optional) Popular additions to baby marrow pickles are cauliflower, green or red peppers, and onions.

11. Filling and sealing

The baby marrow/vegetable mixture is packed tightly into suitable, wide mouthed glass jars that have been properly cleaned. The packaging liquid is added, ensuring that all the ingredients are completely covered to prevent deterioration of the vegetables.

The packaging liquid is prepared from natural malt vinegar, spirit vinegar, acetic acid or any desired combination according to the final product requirements. The addition of spices, such as turmeric and caramel, to the vinegar for added flavour is optional. The addition of a sweetener in the form of granular sugar, glucose syrup or artificial sweetener is also optional. Artificial sweeteners are useful in creating a product suitable for diabetics. The quantity of sweetener to be added is judged according to taste. The addition of sweetener should be declared on the packaging label.

The containers are hermetically sealed with self-venting, acid resistant lacquered metal closures capable of forming a vacuum seal. A small headspace is left at the top of the jar. Heating the packing liquid prior to filling does slightly raise the temperature of the product, but is not necessarily effective in decreasing the required heat dosage of pasteurisation since the majority of the pack consists of the vegetable pieces which are filled at room temperature. The final acidity of

the product should be below pH of 4,5 and thus only requires pasteurisation for long term preservation.

12.

Pasteurisation entails the controlled and limited heating of the pickle in sealed containers that are capable of forming a headspace vacuum upon cooling. It is impossible to give specific time and temperature requirements in a general report like this since sufficient pasteurisation depends on the size and dimensions of the container, the starting temperature, the type of equipment used, the type of product and pH.

Processing

baby marrow

Baby marrow

Harvesting

Inspection

Washing

Trimming & Sorting

Cutting, dicing & slicing

Inspection

Blanching

Cooling

(Brining)

Brine Solution

Mixing

Vegetable Selection

Filling & Sealing

Jar preparation

Liquid preparation

Pasteurisation

Cooling & drying

Labelling

Pickled baby marrow

As a general rule, the point of slowest heating in a mixed pickle with a pH below 4,5 should be held at 71 °C for 15 minutes. However, it is essential to institute the most rapid and efficient heating method possible to ensure that the product is not overheated, resulting in softening of the vegetables and a generally poor quality product.

Pasteurisation is necessary to ensure a long shelf-life product. This is achieved by the heat destruction of spoilage micro-organisms and heat inactivation of most enzymes that cause darkening, softening, clouding, sedimentation and flavour deterioration in a pickled product. Pasteurisation also removes air in the product, thus minimising oxygen dependent spoilage mechanisms.

Pasteurisation can be performed by various methods and equipment. Batch operations commonly use steam cabinets or batch retorts while continuous operations use continuous steam cabinets or hydrostatic retorts. The hydrostatic retort consists of a “U” tube with an enlarged lower section where the pressure is maintained by a column of water at the inlet and outlet (the two arms of the “U”). Hot water fills one of the legs while cold water fills the other. The containers are placed on a chain conveyor and fed into the hydrostatic retort via one of the arms.

The containers are progressively heated by hot water rising in the tube. At the bottom of the inlet tube, the containers are moved into the sterilisation section where the temperature is increased to 115 to 121 °C. The containers follow an undulating path through this section to ensure sufficient contact time and temperature exposure. After the required time in the sterilisation section, the containers are transported to the outlet column where they are progressively cooled.

13. Cooling of pasteurised pickles

Pasteurisation should be followed by rapid cooling. Cooling prevents overheating that would result in loss of sensory quality. The jars are cooled to below 50 °C with cold water. The first stage of cooling takes place in the cabinet/retort by replacing the hot water with cooled and progressively cooler water. Further cooling takes place once the containers have been removed. Alternatively, the containers can be quickly cooled by passing them through misting tunnels.

Cooling of glass jars should be gradual to prevent thermal shock that would result in cracking of the jars. The containers are allowed to dry naturally or blow-dried with hot air blowers prior to labelling.

Broiler farming is a very important farming business. For the farmer to be successful and achieve maximum results in the broiler business, certain pieces of equipment are necessary.

Heat stress decreases the productivity of broilers and thus farm profitability. Proper brooding temperatures are necessary for chicks to be healthy and to rapidly feather. The brooder temperature will decrease with each week of age. Therefore the thermometer is an important tool in broiler production.

Every farmer should have weighing scales in order to accurately determine productivity in broiler farming. Monitoring the weights of broilers from day one is an important management tool in poultry farming. Scales can be used in a farm’s economic analysis to estimate overall profitability by measuring the input and output of production.

Every broiler farmer must monitor the bird weight progress. This detects any aberrant growth rate fluctuation in your broilers at an early age, and in time to take corrective steps. Furthermore, knowing how much your broilers weigh on a daily basis is critical if the farmer wants to get them to market age at the lowest possible cost. The following are important parameters to track:

• The daily minimum weights

• Maximum daily weight

• Uniformity of average weight

• Weight gain

A hygrometer is a device used to measure the volume of water vapour in the air, soil or any confined space. The humidity meter is useful for various sectors like manufacturing, agriculture, construction, restoration, heating, ventilation.

Broiler birds are characterized by fast growth. Humidity is an extremely important factor during their growth. Unmonitored and uncontrolled temperature and humidity within the pen can lead to reduced productivity and high rate of mortality.

An ammonia meter is an instrument used to measure ammonium levels in the poultry house. Ammonium in a poultry house comes from the birds themselves. Unused nitrogen is excreted as uric acid (80%), ammonia (10%), and urea (5%).

When ammonia gas is exposed to moisture, it reacts and forms a basic, corrosive solution called ammonium. This aqueous ammonium solution causes harm to birds. The ammonium corrodes the lining of chickens’ respiratory tracts and paralyses or even destroys the cilia of the epithelial cells. In such conditions, the mucus on the surface of the trachea cannot be cleared by the cilia and thus bacteria become trapped. When the bacteria reach the lungs or the air sacs, they cause infections.

Measures to reduce ammonia levels, including gut performance management, can promote the good health and performance of the birds. A high concentration of ammonium in the poultry house has adverse effects on the health and performance of birds. Keep levels low to stay naturally ahead.

For more information, contact Barbara Mulonda Simbaya on barbara.mulonda@tigerfeeds. com.zm or (+260)969-202-207.

Goats that are good for both milk production and mohair production make excellent livestock. They are easy to care for and maintain, and they generate steady income. Mohair from these animals is highly sought after due to its softness and resilience, and their milk is a nutritious and delicious substitute for cow's milk. As an added bonus, they are sociable and simple to care for, making them an excellent addition to any farm.

Both the Saanen and Angora goat breeds are excellent choices for milk and mohair production. They are hardy, easygoing animals that are capable of producing high-quality products. With proper care and management, these breeds can provide a steady supply of milk and mohair for many years to come.

The Saanen goat is a large, white or cream goat that is known for its high milk production. It is one of the most popular dairy goat breeds, especially for its mild-mannered temperament and easy-going nature. Saanen goats are also known for their ability to produce large amounts of milk, with some goats producing up to 15 litres of milk per day.

The Saanen dairy goat can be traced back to Switzerland's Saanen Valley, where they originated. Saanen does are prolific milk producers and typically produce between three and four percent milk fat in their milk. The does weigh about 65 kilogrammes and the buck can

weigh up to 75 kilogrammes, and range in size from medium to large.

There is no prejudice against goats that have spots on their skin. It is acceptable for the hair to have a few streaks of colour, but this is not something to strive for. The hair should be kept short and fine, although it is common to have a fringe that falls over the spine and thighs. The ears should be held in a perceptive and alert position, preferably with a forward tilt, and should be long and floppy. The face can be either straight or dished.

The Saanen goat is a domestic goat breed renowned for its superior grazing prowess. They are hardy animals that can graze on a wide range of vegetation, including grasses, shrubs, and some kinds of trees. They are also capable of consuming a variety of forages, includ-

by Natasha Pansegrouw

by Natasha Pansegrouw

ing hay and silage. They are therefore a fantastic option for farmers who need to feed their animals a variety of foods.

Saanen goats are renowned for their capacity to adjust to various climatic conditions. They can endure extremes of heat and cold, and they can even endure high levels of humidity. They are therefore a fantastic option for farmers who need to feed their animals a variety of foods in various climates. The breed is, however, vulnerable to overexposure to sunlight and tends to do better when kept in cooler environments. Therefore it is absolutely necessary to provide shade.

This breed is about the size of a medium sized dog and appears to be ro

bust, active, and alert. The does weigh at least 60 kilogrammes, and the bucks can weigh 90 kilogrammes.

The goat’s hair is either short or medium in length, and it is extremely fine, soft, and lays completely flat. Its colour is consistent all the way from a light fawn to a dark chocolate, and it does not favour any particular shade.

The following is a list of the distinct white markings: white ears with a dark spot in the middle; two white stripes down the face from above each eye to the muzzle; hind legs white from the hocks to the hooves; forelegs white from the knees downward with a dark

The ears are held in an upright and forward position. Lines on the face can be dishy or straight.

When temperatures are lower, Toggenburgs are at their peak performance. They have excellent udder development, which contributes to their high milk production, and their milk has an average fat test percentage of 3,7 percent. In addition to its use in dairy products, goat milk has also found its way into products for the body and skin.

The Toggenburg goat is renowned for its adaptability and hardiness. They can survive in environments with few resources and can withstand cold

temperatures. They are a great option for farmers in a variety of regions due to their adaptability to various climates and environments.

The Toggenburg goat has a reputation for being a superior grazer. They can graze on a range of grasses and forages, such as weeds, alfalfa, and clover. They can also graze in areas with rocky soil and steep terrain. This makes them perfect for mountainous areas where they can graze on the rocky outcroppings and steep slopes.

The Angora goat is a medium-sized goat that is known for its long, silky mohair. Angora goats are one of the oldest breeds of goats and are known for their hardiness and ability to thrive in a variety of climates. Angora goats produce high-quality mohair that is used in a variety of products, including sweaters, hats, and scarves.

The typical goat is sheared twice a year and can shear about 2,5 kilogrammes of mohair per shearing. They generate fibre with a 12 to 15 cm staple length.

The Angora is a very appealing animal with horns on both sexes. The bucks usually have a pronounced spiral to the horn, which comes back and away from the head; the horns of mature bucks sometimes reach two or more feet in length. The female's horn, on the other hand, is considerably shorter, smaller, and only slightly inclined to spiral. The female's horn rarely measures more than nine or ten inches. The ears are heavy and drooping.

When compared to sheep, common goats, or milk goats, the Angora goat is a small animal. There is considerable variation in the size of goats, but mature bucks will usually fall in a weight range of 80 to 102 kilogrammes but do not reach their maximum weight until after five years of age. When fully grown, does will weigh between 32 and 50 kilogrammes.

Because the Angora likes to graze, it has been very useful in some fields of agriculture. Goats are excellent "browse" consumers who frequently stand on their hind legs to eat as high as they can. Goats are adapted to graze in areas where sheep struggle.

On land that is unsuitable for conventional agricultural activities, Angoras have been able to generate a profit.

References

lien (band) below the knee acceptable; a white triangle on either side of the tail; a white spot may be present at the root of the wattles or in that area if there are no wattles present.

It is acceptable to have varying degrees of cream markings rather than pure white, but this is not desirable.

Toggenburg

Goat Farming in South Africa (2022). Available at: https://southafrica.co.za/goat-breeds-in-southafrica.html

Breeds of Livestock, Department of Animal Science (1996). Available at: http://afs.okstate.edu/ breeds/goats

The sweet cape gooseberry is gaining popularity due to its high value as the next big superfood. Its name is derived from its look, as the ripe fruit looks like it is wrapped in a paperlike “cape” that resembles a Chinese lantern.

A multitude of varieties are available. They differ in colour, size and shape. It is, however, important to note that the cape gooseberries are a completely different species to regular gooseberries.

Originating from Peru, the cape gooseberry (Physalis Peruviana) is part of the nightshade family such as tomatoes, peppers and potatoes.

Immigrants introduced the cape gooseberry to Southern Africa in the 1770s. Today, South Africa’s Western Cape and Northwest provinces are some of the largest local producers.

Columbia dominates the international market because the input costs are so low and it can be produced on small scale by family farms, which means that you can invest in your own cape gooseberry production, especially since setting up a production system is so

affordable compared to other berry crops. Within the first 100 days of being planted, these berries start to produce a crop. This means that there is a fairly quick return on investment.

The fruit is sweet, nutritious, and has a high market value. Part of what makes these berries so healthy is that they are high in fat. It may sound strange to think that fat is healthy, but it enables the fruit to carry fat soluble vitamins such as vitamin A, D, E and K. It also contains betacarotene, calcium, copper, magnesium, manganese, iron, phosphorus, potassium, bioflavonoids, protein, and fibre. No wonder it is viewed as the next super food!

Cape gooseberries are used to make jams or juice, but they can also be dried, cooked or consumed raw.

These plants are relatively hardy. They can survive temperatures of -4 °C,

by Maryna Steynand recover quickly from frost. Young plants, however, dislike frost. The ideal climate for these berries range between 10 and 25 °C.

Arid to semi-arid areas are best for your cape gooseberry farm as they prefer full sun and warmth all year round.

The soil pH level needed for these fruits is between 5,5 and 7,0. One of the benefits of planting cape gooseberries is that they grow extremely well in poor soils. Higher soil fertility may result in unnecessary vegetative growth – too many leaves and stems with no significant improvement in fruit yield.

The berry is also drought tolerant, but this characteristic also means that it does not fare well when it is waterlogged. To avoid this, start your soil preparation by preparing a fine soil bed.

Mix in the residue from the previous

crops with a fork. Use a disk to improve the aeration of the soil and distribute the organic matter throughout the seedbed. Break up any clods. Soil preparation should be aimed at improving the drainage of the soil and reduce compaction.

Soil preparation needs to be done between 200 and 400 mm deep to assist optimal root growth. Create ridges in the seedbed, approximately 600 mm wide.

Farmers usually plant seedlings rather than cuttings. This is more effective and affordable. Seeds can also be planted

directly into the soil, but planting seedlings gives your plants the best chance for survival. You can make your own seedlings, or buy them from a trusted vendor or nursery.

Cape gooseberry is a shrub that grows to a metre high. That means that you need space for it to grow. Larger plants can even grow up to a metre wide in some cases.

Space plants 0,75 m apart. You can place rows approximately 2,2 m or up to 2,8 m apart. This will entirely depend on whether you will need machinery to fit in between the rows or not.

Plant density can vary between 4 000 and 6 000 plants per hectare, depending on the size of land you have available. You can expect that a healthy plant will produce approximately 300 berries in its lifetime.

Cape gooseberries are water wise plants. They do not require a lot of water, in fact, only 800 millilitres of water a day.

The plant does need consistent watering during the growing season to set a good fruit crop. Irrigation can be reduced when the fruits are maturing. The plants become dormant during drought.

You can water the plants twice a week in hot months to ensure the soil is moist, but avoid over-watering by checking the soil moisture before watering. Irrigate close to the soil and avoid watering the leaves as this can lead to pests and disease.

Another benefit of cape gooseberry production is that there is no need to fertilise the crop at all. This saves you input costs on fertiliser as well as labour. Where necessary before the next crop, you can correct the pH level of the soil.

The main threats to cape gooseberry production are cutworm and caterpillars. Inspect your crop regularly to act early. Insecticides can mitigate the effects of these pests if you discover an infestation.

The plants bear fruit 4 to 5 months after being planted.

Harvesting is done by hand when the golden berries are ripe. Berries should not be picked before then, as they stop ripening once picked. This can affect the taste.

Prune any dead vegetation after the first harvest.

Sources:

Cape gooseberries: The next big superfood trend? (2019) Magzter. Farmer's Weekly. Available at https://www.magzter.com/stories/Business/Farmers-Weekly/ Cape-Gooseberries-The-NextBig-Superfood-Trend

Commercial gooseberry farming (2022) Berries for Africa. Available at https://www.berriesforafrica.co.za/commercial-gooseberry-farming/

Gardenate - growing Cape Gooseberry ( 2012) Gardenate. Available at https://gardenate.com/plant/Cape%20

Gooseberry?zone=

Kriel, G. (2023) Cape gooseberries: Fruit farming in South Africa, South Africa Online. Available at https://southafrica.co.za/ cape-gooseberries.html

on labour expenses and to ensure a good pregnancy rate, it will pay off to use smaller camps.

The maximum number of camps depends on the size of the herd, the size of the farm and the grazing capacity of the farm. It can be calculated as follows:

Herd size x grazing capacity

Camp size = Number of camps per herd

Size of farm

Number of camps = Size of camps

Shape of camps

The ideal shape will be a square. Where homogeneous veld types prevail and water could be distributed without any troubles, square camps would be an easy option. The fact is that veld types are usually not homogeneous, roads and railway lines are present and even the shape of the farm could hamper the construction of square camps.

In the previous article on farm management and planning we focused on optimal resource utilisation and farm planning. When planning for the provision of a sufficient number of camps, the ultimate question is how many camps are needed for each herd?

With camps, it will be possible to maintain the condition of the veld and even improve it, provided that animal numbers are kept within reasonable limits. With six camps or more per herd, it is much easier to comply to the requirements of short grazing and long resting periods.

On most farms there are small herds or rams, bulls, dairy cows and calves, sick animals, animals for slaughtering, horses, and donkeys. Make special provision for these different herds to continuously practice good veld management. A few smaller camps will provide the solution. It is crucial that no camp, not even the so-called house camp, should ever be subjected to overgrazing.

When a farm is divided into camps, the sizes of camps should be considered. The sizes of camps should be limited in order to graze the camps as evenly as possible. The accessibility of the terrain also has an influence on the size of a camp. The more inaccessible the terrain,