VOLUME 57 | NO 1 APRIL 2024 ISSN 1037-7107 Official Publication of the Institute of Materials Engineering Australasia Limited Trading as Materials Australia | A Technical Society of Engineers Australia www.materialsaustralia.com.au UNIVERSITY SPOTLIGHT UNSW PAGE 36 Online Short Courses PAGE 54 CONFERENCES CAMS2024 PAGE 9 ENERGY MATERIALS 2024 PAGE 31 Metals May Hold the Key: Australia’s Clean Energy Transformation CL I C K A B LE L I N K S

buckyballs

MOFs

Nd:YAG

palladium catalysts nickel foam

perovskite crystals

europium phosphors

alternative energy

thin lm

diamond micropowder

additive manufacturing

organometallics

nanogels surface functionalized nanoparticles

YBCO

nanodispersions

glassy carbon isotopes

3D graphene foam

metamaterials

AuNPs

EuFOD

silver nanoparticles

quantum dots

transparent ceramics

sputtering targets

endohedral fullerenes

gold nanocubes

tungsten carbide

osmium

mischmetal ultralight aerospace alloys

scandium powder

biosynthetics

III-IV semiconductors ITO

NMC

CIGS

InAs wafers platinum ink

OLED lighting

The Next Generation of Material Science Catalogs

photovoltaics

graphene oxide exible electronics

chalcogenides laser crystals

CVD precursors

deposition slugs

MOCVD Invar InGaAs GDC

superconductors

Over 35,000 certi ed high purity laboratory chemicals, metals, & advanced materials and a state-of-the-art Research Center. Printable GHS-compliant Safety Data Sheets. Thousands of new products. And much more. All on a secure multi-language "Mobile Responsive” platform.

ultra high purity materials

pyrolitic graphite

zeolites

Ti-6Al-4V h-BN

metallocenes

mesoporus silica

99.99999% mercury

Now Invent. TM

www.americanelements.com © 2001-2023. American Elements is a U.S.Registered Trademark 140.116 Cerium 58 8 18 19 9 2 Ce 140.90765 Praseodymium 59 8 18 21 8 2 Pr 144.242 Neodymium 60 8 18 22 8 2 Nd (145) Promethium 61 8 18 23 8 2 Pm 150.36 Samarium 62 18 24 Sm 151.964 Europium 63 8 18 25 8 2 Eu 157.25 Gadolinium 64 8 18 25 9 2 Gd 158.92535 Terbium 65 8 18 27 8 2 Tb 162.5 Dysprosium 66 8 18 28 8 2 Dy 164.93032 Holmium 67 8 18 29 8 2 Ho 167.259 Erbium 68 8 18 30 8 2 Er 168.93421 Thulium 69 8 18 31 8 2 Tm 173.054 Ytterbium 70 8 18 32 8 2 Yb 174.9668 Lutetium 71 8 18 32 9 2 Lu 232.03806 Thorium 90 2 8 18 10 2 Th 231.03588 Protactinium 91 2 8 18 9 2 Pa 238.02891 Uranium 92 2 8 18 9 2 U (237) Neptunium 93 2 8 18 9 2 Np (244) Plutonium 94 18 Pu (243) Americium 95 2 8 18 8 2 Am (247) Curium 96 2 8 18 9 2 Cm (247) Berkelium 97 2 8 18 8 2 Bk (251) Californium 98 2 8 18 8 2 Cf (252) Einsteinium 99 2 8 18 8 2 Es (257) Fermium 100 2 8 18 8 2 Fm (258) Mendelevium 101 2 8 18 8 2 Md (259) Nobelium 102 2 8 18 8 2 No (262) Lawrencium 103 2 8 18 8 3 Lr 1.00794 Hydrogen 1 1 H 6.941 Lithium 3 2 1 Li 9.012182 Beryllium 4 2 2 Be 22.98976928 Sodium 11 2 8 1 Na 24.305 Magnesium 12 2 8 2 Mg 39.0983 Potassium 19 2 8 K 40.078 Calcium 20 2 8 Ca 85.4678 Rubidium 37 2 8 18 8 1 Rb 87.62 Strontium 38 2 8 18 8 2 Sr 132.9054 Cesium 55 2 8 18 18 8 1 Cs 137.327 Barium 56 2 8 18 18 8 2 Ba (223) Francium 87 8 18 32 18 8 1 Fr (226) Radium 88 8 18 32 18 8 2 Ra 44.955912 Scandium 21 2 8 Sc 47.867 Titanium 22 2 8 Ti 50.9415 Vanadium 23 2 8 V 51.9961 Chromium 24 2 8 Cr 54.938045 Manganese 25 Mn 55.845 Iron 26 2 8 Fe 58.933195 Cobalt 27 2 8 Co 58.6934 Nickel 28 2 8 Ni 63.546 Copper 29 2 8 Cu 65.38 Zinc 30 2 8 Zn 88.90585 Yttrium 39 2 8 18 9 2 Y 91.224 Zirconium 40 2 8 18 10 2 Zr 92.90638 Niobium 41 2 8 18 12 1 Nb 95.96 Molybdenum 42 2 8 18 13 1 Mo (98.0) Technetium 43 18 13 Tc 101.07 Ruthenium 44 2 8 18 15 1 Ru 102.9055 Rhodium 45 2 8 18 16 1 Rh 106.42 Palladium 46 2 8 18 18 Pd 107.8682 Silver 47 2 8 18 18 1 Ag 112.411 Cadmium 48 2 8 18 18 2 Cd 138.90547 Lanthanum 57 2 8 18 18 9 2 La 178.48 Hafnium 72 2 8 18 32 10 2 Hf 180.9488 Tantalum 73 2 8 18 32 11 2 Ta 183.84 Tungsten 74 2 8 18 32 12 2 W 186.207 Rhenium 75 18 32 13 Re 190.23 Osmium 76 2 8 18 32 14 2 Os 192.217 Iridium 77 2 8 18 32 15 2 Ir 195.084 Platinum 78 2 8 18 32 17 1 Pt 196.966569 Gold 79 2 8 18 32 18 1 Au 200.59 Mercury 80 2 8 18 32 18 2 Hg (227) Actinium 89 8 18 32 18 9 2 Ac (267) Rutherfordium 104 8 18 32 32 10 2 Rf (268) Dubnium 105 8 18 32 32 11 2 Db (271) Seaborgium 106 8 18 32 32 12 2 Sg (272) Bohrium 107 18 32 32 13 Bh (270) Hassium 108 8 18 32 32 14 2 Hs (276) Meitnerium 109 8 18 32 32 15 2 Mt (281) Darmstadtium 110 8 18 32 32 17 1 Ds (280) Roentgenium 111 8 18 32 32 18 1 Rg (285) Copernicium 112 8 18 32 32 18 2 Cn 4.002602 Helium 2 2 He 10.811 Boron 5 2 3 B 12.0107 Carbon 6 2 4 C 14.0067 Nitrogen 7 2 5 N 15.9994 Oxygen 8 2 6 O 18.9984032 Fluorine 9 2 7 F 20.1797 Neon 10 2 8 Ne 26.9815386 Aluminum 13 2 8 3 Al 28.0855 Silicon 14 2 8 4 Si 30.973762 Phosphorus 15 2 8 5 P 32.065 Sulfur 16 2 8 6 S 35.453 Chlorine 17 2 8 7 Cl 39.948 Argon 18 2 8 8 Ar 69.723 Gallium 31 2 8 Ga 72.64 Germanium 32 2 8 Ge 74.9216 Arsenic 33 2 8 As 78.96 Selenium 34 2 8 Se 79.904 Bromine 35 2 8 Br 83.798 Krypton 36 2 8 Kr 114.818 Indium 49 2 8 18 18 3 In 118.71 Tin 50 2 8 18 18 4 Sn 121.76 Antimony 51 2 8 18 18 5 Sb 127.6 Tellurium 52 2 8 18 18 6 Te 126.90447 Iodine 53 2 8 18 18 7 I 131.293 Xenon 54 2 8 18 18 8 Xe 204.3833 Thallium 81 2 8 18 32 18 3 Tl 207.2 Lead 82 2 8 18 32 18 4 Pb 208.9804 Bismuth 83 2 8 18 32 18 5 Bi (209) Polonium 84 2 8 18 32 18 6 Po (210) Astatine 85 2 8 18 32 18 7 At (222) Radon 86 2 8 18 32 18 8 Rn (284) Nihonium 113 8 18 32 32 18 3 (289) Flerovium 114 8 18 32 32 18 4 Fl (288) Moscovium 115 8 18 32 32 18 5 (293) Livermorium 116 8 18 32 32 18 6 Lv (294) Tennessine 117 8 18 32 32 18 7 (294) Oganesson 118 8 18 32 32 18 8 Nh Mc Ts Og

SOFC

borophene

Elements Opens a World of Possibilities..... Now Invent! A MERICA N E LEMENTS A N N I V ER S A RY 199 7 - 2 023

radiation shielding zircaloy -4 tantaloy 60 metallic glass titanium aluminum carbide rare earth optical ber dopants niobium C103 UHP uorides

powder rare earth metals carbon nanotubes 99.9999% aluminum oxide molybdenum TZM li-ion battery materials

American

CONTENTS 8 12 37 22 Reports Contents 3 From the President 4 Corporate Sponsors 6 Advertisers 7 Materials Australia News WA Branch Reports 8 CAMS 2024 9 VIC Branch Reports 10 Professor Graham Schaffer Retirement 14 Profile: Dr Michael Bermingham 16 Swinburne University of Technology, SEAM CMatP Profile: Igor A. Chaves 18 Our Certified Materials Professionals (CMatPs) 20 Why You Should Become a CMatP 21 Industry News Profile: Dr Michael Bermingham 22 ARC Future Fellow Reflective Materials and Irrigated Trees: 24 Study Shows How to Cool One of the World’s Hottest Cities By 4.5°C Graphene Oxide Study Strengthens the Case 25 for Smart Concrete Powder Characterisation: Reliable methods for 26 consistent quality in Additive Manufacturing Research Begins to Reduce Shed of Microplastic 28 During Laundering Ultra-Thin Lithium Strips Show Great Promise as 30 Anode Material for Enhanced Lithium Ion Batteries ENERGY MATERIALS 2024 31 AXT Now Offer Aconity3D Metal 3D Printing Solutions 32 High Resolution 3D Printing on a Budget 33 Profile: Dr Yuman Zhu 34 ARC Future Fellow University Spotlight – UNSW 36 Breaking News 38 Feature – Materials for Clean Energy Production - Metallic 44 MA - Short Courses 54 Join Now 56 VOLUME 57 | NO 1 MARCH 2024 WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 3 osmium semiconductors

From the President - Professor Nikki Stanford B.Eng(Hons) Ph.D. CMatP

Welcome to the April 2024 edition of Materials Australia.

This is my first message as the President of Materials Australia, and I am very honoured to be joining our fantastic team.

I would like to take this opportunity to extend a special thanks to the immediate past President, Dr Roger Lumley for providing mentorship throughout my years as Vice President, and giving me a very gentle landing as the new President.

Appointment of a New Vice President

I’d also like to announce that we have just confirmed that Professor Gwénaëlle Proust will be our new Vice President.

Gwen completed her PhD at Drexel University in the USA, before undertaking a post-doctoral project at Los Alamos National Laboratory. While working with Professor Carlos Tomé, Gwen became an expert in the plasticity of hexagonal metals, and is world-renowned for her work on deformation twins.

Gwen came to Australia in 2008 to join the School of Civil Engineering at the University of Sydney. After many successful years as an academic, Gwen was recently appointed to a new role at Sydney University; she is now the Academic Director of the Sydney Manufacturing Hub.

Gwen has been a member of the organising committee for many of our conferences over the years, and cohosted APICAM in Sydney last July.

We are very excited to have her on the Materials Australia Executive Committee, and wish her every success as our new Vice President.

Appointment of a New Treasurer

We also have a new Treasurer, Leon Prentice.

Leon is the Chief Research and Development Officer at SDI Limited. In this role, he leads a team of engineers and scientists to deliver cutting-edge medical devices and technologies that improve health outcomes and quality of life for millions of people.

He has over 15 years of experience in materials-based research and development, process engineering, and biomaterials. Leon has contributed to multiple patents, publications, and awards in the field of

metallurgy and materials science.

Leon was at CSIRO for many years, and brings his years of experience and extensive scientific network to the Executive Committee of Materials Australia.

He has wasted no time throwing himself head-first into the inner workings of our finances and admin, and appears to be enjoying his important role very much!

Calendar of Events

We have a huge calendar of events in motion for the coming months and years. Preparations for CAMS 2024 are in full swing. This year will be the first year that CAMS has left the eastern seaboard, and is heading to Adelaide for the first time. The CAMS 2024 website is up and running, and calls for abstracts are now open. You can access it via: www.cams2024.com.au

Finally, I would like to thank the army of volunteers that keep Materials Australia running. Our individual branches in each of the states run fantastic local events for our members, and keep us connected to each other and to developments in the world of Materials. And to the National Executive Council, my sincere thanks for your support.

This magazine is the official journal of Materials Australia and is distributed to members and interested parties throughout Australia and internationally. Materials Australia welcomes editorial contributions from interested parties, however it does not accept responsibility for the content of those contributions, and the views contained therein are not necessarily those of Materials Australia. Materials Australia does not accept responsibility for any claims made by advertisers. All communication should be directed to Materials Australia. Materials Australia National Office PO Box 19 Parkville Victoria 3052 Australia T: +61 3 9326 7266 E: imea@materialsaustralia.com.au W: www.materialsaustralia.com.au NATIONAL PRESIDENT Nikki Stanford MANAGING EDITOR Gloss Creative Media Pty Ltd EDITORIAL COMMITTEE Prof. Ma Qian RMIT University Dr. Jonathan Tran RMIT University Tanya Smith MATERIALS AUSTRALIA ADVERTISING & DESIGN MANAGER Gloss Creative Media Pty Ltd Rod Kelloway 0418 114 624 PUBLISHER Materials Australia Technical articles are reviewed on the Editor’s behalf PUBLISHED BY Institute of Materials Engineering Australasia Ltd. Trading as Materials Australia ACN: 004 249 183 ABN: 40 004 249 183 Cover Image From feature article on page 44. Letters to the editor; info@ glosscreativemedia.com.au VOLUME 57 | NO APRIL 2024 Trading as Materials Australia Technical Society of Engineers Australia UNIVERSITY SPOTLIGHT UNSW PAGE 36 Online Short Courses PAGE 54 CONFERENCES CAMS2024 ENERGY MATERIALS 2024 Metals May Hold the Key: Australia’s Clean Energy Transformation A L S CLI C K A B LE L I N K S 4 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

MATERIALS AUSTRALIA

6 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU MATERIALS AUSTRALIA Corporate Premium Corporate Premium Plus

Advertisers - April 2024

MATERIALS AUSTRALIA Corporate

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 7 AdvancingMaterialsandManufacturing 202

WA Branch Technical Meeting - 11 March 2024

Prediction of Pitting Corrosion in Corrosion-Resistant Alloys

Source: Dr Ke Wang, Curtin Corrosion Centre

Ke Wang has more than ten years’ experience in materials and corrosion engineering. He gained his PhD for research at Deakin University on cathodic protection and coating disbondment. Since joining the Curtin Corrosion Centre at Curtin University four years ago, he his research has had a focus on prediction of pitting corrosion in orrosion resistance alloys. The objective of improved prediction is improved lifetime asset management, more intelligent materials selection, and cost-effective alloy design.

Dr Wang started his presentation by explaining that corrosion resistance alloys (CRAs) are extensively employed in corrosive media due to their excellent corrosion resistance to various reducing and oxidizing environments. However, the occurrence of pitting corrosion is a common issue when CRAs are exposed to aggressive conditions. It is therefore of great practical importance to be able to predict whether a CRA can be expected to withstand its intended operating conditions.

He then gave examples of how commonly used approaches to pitting prediction, such as those based on alloy content (e.g., PREN – pitting resistance equivalence number) or limits on dissolved oxygen content, are often overly conservative. This leads

to unnecessarily expensive process equipment or placing unnecessary restrictions on operating conditions. However, in the absence of better ways of predicting pitting, a conservative approach is understandable as pitting is very hard to detect non-destructively, and pitting is common initiation of corrosion-induced cracking.

The corrosion resistance of CRAs depends on a passive oxide film on the surface. However, local breakdown of the film leads to anodic areas rapid oxidation can occur, driven by the relatively much larger cathodic area provided by the passivated surface. Depending on conditions, incipient pits may either fail to grow (metastable pitting) or continue to propagate (stable pitting). Eventually, if a pit grows to a depth at which the potential at the base of the bit falls to level where the surface at the base of the pit re-passivates (which it will do, since the metal is a CRA), the pit will cease to grow. This, however, may be beyond the critical depth for cracking.

Dr Wang summarised three general approaches to predictive modelling approach as empirical, correlative and mechanistic; a fourth approach combines all three. His own approach to pitting prediction is of the mechanistic type and is essentially analytical rather than empirical. That is, experimental

L to R: Ehsan Karaji, Dr Ke Wang

measurements are used to test and validate the model, rather than serving as basis for the model.

Following this approach, he is developing a mathematical model of electrochemical and mass transfer processes inside a growing pit. The model is based on idealised 1-D (one-dimensional) pit. Experimental testing and validation of predictions is undertaken using a novel experimental arrangement comprising a wire sandwiched between glass plates, bonded with epoxy resin. Pit growth is modelled as the exposed end of the wire is dissolved producing a circular metal surface at the bottom of the epoxy-walled cylindrical hole, The glass plates allow observation of the corrosion processes.

The mathematical model combines diffusion of ions between the metal surface and the solution at the exterior of the pit with migration of charged ions in the electric field produced by the potential difference between inside and outside. Changes in species concentration are large enough to require chemical activities to be taken into account.

A key parameter that is useful in rationalising experimental and predicted behaviour is the ‘pit stability product’ denoted x.i, being the product of the depth of the pit (x) and the corrosion current density (i), expressed in units of Amperes/metre. There is a critical value of the pit stability product (in the range 0.98-0.9 A/m) for pit growth to continue. The model allows calculation of the potential at the base of the pit, and hence when the re-passivation potential is reached and growth ceases. It also allows prediction of the effect of chloride ion concentration on pit propagation. It has provided a tool for the next stages of research into pitting, which has a focus on critical values for potential, temperature, and time to establish stable pit growth.

The audience was very appreciative of the opportunity to be given an insight into Ke Wang’s ongoing research, some of which has not yet been published.

MATERIALS AUSTRALIA 8 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

4-6 December 2024 | University of South Australia |

The 8th conference of the Combined Australian Materials Societies, incorporating Materials

Australia and the Australian Ceramic Society. Our technical program will cover a range of themes identified by researchers and industry as issues of topical interest.

Symposia Themes

> Additive manufacturing

> Advances in materials characterisation

> Metals, alloys, casting & thermomechanical processing

> Biomaterials & nanomaterials for medicine

> Ceramics, glass and refractories

> Corrosion & wear

> Materials for energy generation, conversion and storage

> Computational materials science - simulation & modelling

> Nanostructured/nanoscale materials and interfaces

> Progress in cements, geopolymers and innovative building materials

> Surfaces, thin films & coatings

> Polymer technology

> Composite technology

> Waste materials and environmental remediation/recycling

> Semiconductors and electronic materials

> Materials for nuclear and extreme environments

> Advances in Science and Technology of Ceramics (AOCF) Advancing

Materials andManufacturing

www.cams2024.com.au

for

exhibitions are available. Conference Secretariat: Tanya Smith tanya@materialsaustralia.com.au | +61 3 9326 7266

Nikki Stanford

of South Australia

Professor Pramod Koshy UNSW Sydney koshy@unsw.edu.au CO CHAIRS ABSTRACTS CLOSE 1 JULY 2024 Conference Hosts Destination Host Conference Partner

Opportunities

sponsorships and

Professor

University

Nikki.Stanford@unisa.edu.au Associate

VIC and TAS Branch Technical Meeting Molecular Modelling Explained to MA Members

Source: Ivan Cole

In February, Dr Ernane de Freitas Martins (ICN2, Barcelona/Spain) presented to over 40 Materials Australia Victoria and Tasmania Branch and guests. Ernane is from ICN2 or Centre for Nanoscience and Nano-engineering which has a world leading reputation in both nano-technology and molecular modelling.

Dr Ernane showed attendees the most recent results obtained in collaboration with the Rapid Discovery and Fabrication team at RMIT University. He also presented the innovative molecular modelling method (NEGF-QM/MM) developed in ICN2, where both solvent and voltage effects can be taken into account in the simulations, which are

being applied to corrosion science for the first time.

The results obtained by Dr Martins and our shared PhD students (José María Castillo, Mazhar Iqbal, and Michael Morgan), led by Dr Pablo Ordejón in ICN2, demonstrate the capabilities of the new method and its potential applications to electrochemistry problems.

The work is capable of building models that represent the real physical environment but can describe processes at the molecular and so lead to new understanding and chemical design principles. It is hoped that in time we will be able to virtually and rapidly design not just corrosion inhibitors but a wide range of active molecules.

2023 POF End of Year Function

Source: Rob ODonnell

Since 2011, patent attorney firm Phillips Ormonde Fitzpatrick has generously sponsored the Materials Australia End of Year function in Victoria. This is a free event, open to both our members, and members of sister professional societies. The function has become a highlight of the combined technical calendar for each of the participating

professional bodies.

The function was an opportunity for attendees to enjoy an informal mix of networking, social conversation, and technical presentations related to new technologies or new challenges in technical areas. All this was conducted over some first class refreshments provided by the hosts, while enjoying a spectacular view over the north-eastern end of Melbourne afforded from Phillips Ormonde Fitzpatrick's premises at 333 Collins Street.

Professor Mike Tan, Ivan Cole (President Materials Australia Victoria and Tasmania Branch) Bruno Angelico and Edwin Patterson (Phillips Ormonde Fitzpatrick).

Attendees were treated to engaging presentations.

Professor Mike Yongjun Tan (Professor of Applied Electrochemistry and Corrosion Technologies, Deakin University Institute for Frontier Materials) spoke on

the topic New Challenges to Materials and Infrastructure Engineering in the Renewable Energy Age.

Professor Tan covered the array of challenges confronting materials science in the renewable energy age and highlighted the important role corrosion science will play in the sustainability and durability of renewable energy infrastructures.

Bruno Angelico (Managing Director, Steele Environment Solutions) then presented on the topic Emerging Energy Technology and the Need for New Materials.

Bruno identified further materials related problems confronting containment vessels and infrastructure that will be required for next generation of energy generation systems (including nuclear, hydrogen and even fusion systems).

The End of Year event is scheduled again for late 2024, information will be forthcoming on the Materials Australia website and through all sister societies.

MATERIALS AUSTRALIA

Dr Ernane de Freitas Martins

10 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Making Sure They Have a Safe Ride

HYPERSONIC MATERIALS CHARACTERISATION UP TO 2000°C AND BEYOND

∙ Thermal conductivity determination for temperatures up to 2800°C using laser flash analysis

∙ Determination of specific heat and degradation behaviour up to 2400°C and beyond

∙ Analyzing thermal expansion up to 2800°C with dilatometry

∙ Characterizing dynamic mechanical properties with forces up to 500N and 1500°C using DMA

NETZSCH Australia Pty Ltd. Unit 9/10 Anella Avenue, Castle Hill 2154 NSW, Australia www.analyzing-testing.netzsch.com/en-AU

2023 Victoria and Tasmania Branch Borland Forum

Source: Ivan Cole

The Borland Forum honours the memory of Dr Doug Borland who made a significant contribution to the study and teaching of metallurgy and materials engineering during his long and distinguished career. This Forum showcases high calibre postgraduate students nominated by their tertiary institution, who give a short presentation on their materials-related research project. The top presenter receives the Borland Forum Award and a cash prize.

This year the Borland Forum was hosted by RMIT University Advanced Manufacturing Precinct. Once again Victoria’s five top Universities were represented. The presentations were of a high calibre and represented a broad mix of materials research activities. The presenters and their respective topics were:

RMIT University – Jordan Noronha: High strength hollow-strut titanium lattice metamaterials by laser powder bed fusion

Monash University – Jaydeep Das: Synthetic tunable matrices for immune cell culture

University of Melbourne – Nicholas Collins: GrapheneEnhanced Single Ion Detectors for Deterministic Near-Surface Dopant Implantation in Diamond

Deakin University – Piers Coia: Multifunctional Structural Supercapacitors

Swinburne University of Technology – Daniel Ricardo: From Micro to Macro : the relationship between ice morphology and geotechnical behaviour for lunar regolith

A large crowd of Materials Australia members, post-graduate students and numerous friends and colleagues came from as far afield as Geelong and enjoyed networking and discussions

over a selection of warm savouries and refreshments provided by the host venue.

Rosy Borland (Doug’s daughter) was joined by two other independent judges from private industry to determine the best presentation on the night. While the competition was fierce due to the high quality of the science and presentations, the judges determined a winner and awarded the Borland Forum Award to Piers Coia of Deakin University for his presentation on Multifunctional Structural Supercapacitors

Materials Australia would like to express our appreciation to RMIT University for hosting an excellent evening.

All five Borland Forum presenters alongside Materials Australia Victoria and Tasmania Branch Vice President Rou Jun Toh.

MATERIALS AUSTRALIA 12 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

The Borland Forum winner Piers Coia with Materials Australia Victoria and Tasmania Branch Vice President Rou Jun Toh.

Unlock the Power of Purity: High Purity Metal Salts

Available product types:

• Alkali & Alkaline Metal Salts

• Transition Metal Salts

• Rare Earth Metal Salts

• Precious Metal Salts

• Metaloid salts

Specialized salt offerings:

• Redi Dri™

• AnhydroBeads™

• Technipur®

Maximize Research Reliability, Minimize Waste with Improved Product Packaging

Metal salts play a vital role in research, development, and the production of advanced technologies that require exceptional properties, performance, and quality. Designed to optimize your research outcomes, our diverse collection of metal salts includes both anhydrous and hydrated forms, with purities ranging from 99.9% to 99.999% based on ICP-Mass and ICP-OES analysis.

sigmaaldrich.com/metalsalts

The Life Science business of Merck operates as MilliporeSigma in the U.S. and Canada.

Decades of Discovery: The Enduring Legacy of Professor Graham Schaffer

Professor Graham Schaffer from The University of Melbourne recently retired after a decorated career in materials science and engineering, and academic leadership. Graham has made a significant contribution to the field of materials science and engineering for over three decades, particularly in the fields of powder metallurgy, rapid prototyping or additive manufacturing, material design and processing, engineering design, composites and nanomaterials.

Graham’s academic career began at the University of Cape Town, where he completed a Bachelor of Science and Master of Science supervised by Tony Ball. He then completed a PhD with Ray Smallman and Mike Loretto at the University of Birmingham. He relocated to Perth in 1988 and worked with Paul McCormick at the University of Western Australia.

In 1991, Graham moved to Brisbane,

and worked at The University of Queensland from 1991 to 2014. During this time, Graham held numerous academic and executive leadership positions. Following his time at UQ, Graham was appointed as the Pro Vice-Chancellor for College of Science, Health and Engineering at La Trobe University in Melbourne.

Graham then moved to The University of Melbourne in 2016 and served as the Melbourne School of Engineering Dean in 2018, before completing his career in a professorial role from mid-2018 to August 2023.

Graham reshaped the field of aluminium powder metallurgy and pioneered titanium powder metallurgy and metal injection moulding research in Australia. In particular, Graham and his students and postdoctoral fellows identified the critical role of magnesium, micro-alloying and nitrogen in the sintering of aluminium. Graham was an early adopter of additive manufacturing research in Australia and published his findings on “Rapid manufacturing of aluminium components” in Science in 2003.

During his time at The University of Melbourne, Graham researched multi-objective genetic algorithm in alloy design, as well as knowledge management in social networks and communities of practice. During his career, Graham published 143 journal papers, 3 scholarly book chapters and holds five patents.

Graham holds numerous fellowships, including with Australian Academy of Technology and Engineering (ATSE), Engineers Australia, and the American Powder Metallurgy Institute (APMI) International, as well as four honorary university appointments. He supervised 16 PhD students and 19 postdoctoral fellows, and raised over $14 million in materials-related research income. Many of his former group members have become high-flying academics or successful entrepreneurs in Australia and China.

Graham will have lasting impact on us all; professionally and personally. He will be known for his scientific rigour (including asking difficult and needed questions), encouragement, thoughtful guidance and friendship.

In the future, Graham will be establishing a foundation for retired academics to volunteer travel to tertiary institutions in the South Pacific to share their experience and enable academic excellence.

Friends, family and former colleagues celebrated Graham’s career at a surprise retirement farewell on Friday 11 August 2023, hosted by the Department of Mechanical Engineering at The University of Melbourne. Three colleagues travelled from as far as China to pay tribute to Graham for his achievements and friendship, while colleagues from other parts of the world sent recorded videos honouring Graham.

MATERIALS AUSTRALIA 14 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

NDT EQUIPMENT SALES - UNIT 21, 3 BOX ROAD TAREN POINT NSW 2229 TEL: (61-2) 9524-0558 • FAX: (61-2) 9524-0560 • Email: ndt@ndt.com.au • Web: www.ndt.com.au www.NOVO-DR.com

SEAM Profile: Hsin-hui Huang

Hsin-hui Huang is a PhD Candidate with the Australian Research Council (ARC) Industrial Transformation Training Centre in the Surface Engineering for Advanced Materials (SEAM) at Swinburne University of Technology.

From a young age, Hsin-hui has been driven by a deep curiosity to understand the 'why' behind everything around her and the curiosity to unravel the mysteries of the world we inhabit. This innate passion naturally led her into the realm of Science, Technology, Engineering, and Mathematics (STEM) studies.

Hsin-hui earned her Bachelor's degree from the University of Colorado at Boulder in the US with a double major in chemistry and biochemistry and a minor in mathematics. Her focus was physical chemistry and inorganic chemistry, and during her university years, she studied electron transfer to mimic photosynthesis for hydrogen generation and synthesized inorganic compounds for water splitting. She found fundamental sciences along with mathematics to be captivating and intelligible. She was guided to examine the fundamental principles of the world of natural and artificial systems. These passions led her to further studies in advanced materials focused on nanomaterials at the University of Ulm in Germany. At this University, Hsin-hui delved into the realm of surface chemistry. Her thesis was part of a project that aims to improve lithium-ion batteries with advanced atomic imaging techniques to study the interaction between ionic liquids and metal surfaces. This experience gave her an edge, not only in improving her research and analytical skills but also in broadening her mind to the fields of

applied sciences.

After earning her Master’s degree, Hsin-hui had the privilege of working at the Taiwan Semiconductor Manufacturing Company (TSMC) in the advanced processing team that was pioneering making smaller yet more powerful semiconductor chips for smartphones, cars, and other day-to-day items. This was the first time Hsin-hui saw her studies being applied in the real world and on an industrial scale. Seeing the real-world applications of science reignited her passion for research and led her back to academia to work in an intense femtosecond laser laboratory at Academia Sinica in Taipei, Taiwan. Her research topic was the interaction between intense femtosecond lasers and matter, which results in highly nonlinear optical processes. This photon conversion made the generation and control of terahertz (THz) and X-rays possible, and with this knowledge, we not only get to understand the fundamental mechanisms but also improve the current spectroscopy techniques or communication technology.

As Aristotle astutely noted, "The more you know, the more you realize you don't know." Once she set foot on this path, there was no turning back. The educational and practical experiences have uniquely prepared her for the challenge of joining the PhD program with the ARC research team called SEAM.

ARC-SEAM excites Hsin-hui the most due to the faculty, the equipment facilities, the diverse team, and the balance between fundamental science and real-world applications. This is a great opportunity to combine out-of-the-box creative thinking and a real-world solution. In this new role, she is working on understanding the fundamentals of a new class of alloy materials called High-Entropy Alloys (HEAs) with the help of THz spectroscopy methods.

As a woman in SEAM, Hsin-hui is grateful for the platform they have provided for her to speak up and show young girls that women have a wealth of capabilities to excel in STEM studies and achieve remarkable feats.

Acknowledgement: This work has been supported by the Australian Research Council (ARC). The ARC Training Centre in Surface Engineering for Advanced Materials, SEAM, has been funded under Award IC180100005. The additional support from industrial, university and other partners is critical for our success.

For more information about SEAM, please visit www.arcseam.com.au/ or email seam@swinburne.edu.au

MATERIALS AUSTRALIA 16 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Founded in 2019 as a partnership between three universities, SEAM’s mission is to help solve critical surface engineering problems faced by industry, while training up talented industry-ready graduates for our future

During the partnership with SEAM, CSIRO has been actively involved in the development of a cold spray process to manufacture anti-microbial coatings CSIRO has also contributed to the supervision and mentoring of two earlycareer scientists, providing them with valuable lab experience

DMTC Ltd has had a long and successful relationship with the SEAM partners in their project. It continues the evolution of developing advanced coatings for Defence applications, and most importantly, giving industrial context to training the next generation of scientists to continue this important work into the future

Experience the synergy of SCG Chemicals (SCGC) and SEAM who craft cutting-edge thermal spray coatings for boiler tubes Leveraging SEAM’s elite thermal spray facilities, SCGC boasts superhydrophobicity and anti-slagging functionalities, setting a benchmark in global competitiveness Elevate your boiler performance with SCGC – where excellence meets evolution!

more: https://arcseam.com.au

See

CMatP Profile: Igor A. Chaves

For Igor A. Chaves, science has always been a passion. Technological and scientific research has always been the main goal in his professional career plan. Allied to the need of specialised learning, Igor understands that academic research can provide a level of knowledge to face the professional challenges of the present world.

Igor is currently an Associate Professor in Civil Structural Materials Engineering at the University of Newcastle, School of Engineering, where he was awarded a PhD in 2013 for developing novel approaches to structural steel corrosion analysis and prediction. He initiated his studies on steel structures as a research trainee in 2004 at the Federal University of Vicosa, Brazil, where he graduated as a civil engineer in 2007.

Igor’s interest for engineering scientific research lead him to the EESC University of Sao Paulo, Brazil, and as result of completing a master’s degree in structural engineering in 2009, design guidelines for cold-formed composite steel and concrete beams were added to the Brazilian Standard of Steel Design.

Where do you work?

Describe your job.

I’m an Associate Professor in Civil Structural Materials Engineering at the University of Newcastle, School of Engineering.

My role includes delivering technological and scientific innovation through research grants for both government and private industry partners, post-graduate research training and supervision, coordinating and teaching construction material science and structural engineering design undergraduate courses, coordinating formal industrial placement experiences for undergraduates, and professionally collaborating with various national and international organisations and industries.

What inspired you to choose a career in materials science and engineering?

After working many years in various large civil construction projects, I learnt to value specialised learning. I understood that higher education and focused academic research can provide a unique commercial advantage and level of knowledge to face larger sector challenges.

Through my applied structural research design experience, I learnt that material science underpins the mechanical properties of design choices and their constraints. Being able to understand material behaviour, and therefore how to optimise infrastructure structural material service life, can be pivotal to many industries and societies.

Who or what has influenced you most professionally?

The rare few applied academics whom I had the pleasure of meeting or having as mentors, have been the main influence on my professional academic career strategy. Like my mentors, it is a pleasure to be able to blend my teaching, research, and service roles to create new knowledge of scientific value that also provides relevant, applicable, solutions to industry nationally and internationally. It is also very

rewarding to be able to disseminate that knowledge and understanding to others, including students, industry, and wider society for the greater good.

What has been the most challenging job or project you've worked on to date and why?

It is challenging to be able to simultaneously cater for various commercial, political, and societal goals. During my former role of National President of the Australasian Corrosion Association (ACA), and Chairman of the National Council, it was important to be able to impartially advocate and professionally represent the wider membership through their voiced concerns, ideas, and requests. Fortunately, this was been a very challenging yet rewarding growth experience, considering that since 1955 the ACA has had a long history of strong collegiality, professionalism, and service excellence.

What does being a CMatP mean to you?

Being recognised as CMatP means that I can expand my network and share expertise with colleagues for our mutual benefit. It means that as an organised and formally certified group of experts, our current and future partners have an extra level of trust for the quality and professionalism the CMatP group can deliver.

I would encourage all material professionals to consider pursuing this status as it is earned, not purchased, by demonstrating continuous professional development and commitment to the sector. It is also, in my view, a convenient way to set professional goals and an organised pathway to obtain senior mentorship or succession planning support.

What gives you the most satisfaction at work?

To pass it forward. To receive news, either in person or anecdotally, that one of my former students has

18 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU MATERIALS

AUSTRALIA

achieved success in their careers. That my former students are now in a leadership position and able to return with project ideas, promote further collaboration, and create further channels for dissemination of knowledge through new students.

What is the best piece of advice you have ever received?

That success is not defined by anyone but ourselves. That success is being where you want to be, doing what you believe is right. Pursuing and fulfilling goals of personal value, albeit not always clear, is very much one of the most important lessons I have learnt. Example outcomes of this lesson include realising that political boundaries often restrict potential; that scientific publication metrics are relative to the end user; that true excellence comes from genuine collaboration. What are you optimistic about?

I am optimistic about the future of the energy infrastructure sector. Industry and academia have been very prudent in steadily pursuing future sustainability goals, whilst carefully considering infrastructure requirements. Change should not be feared, but pragmatically accounted for. Built infrastructure, and the future smart materials used for such developments, underpins the transition in how societies will live, adapt to new modes of transport, and utilise energy resources or commodities. I am optimistic about the technological advances made so far, and those shortly to come for the greater good.

What have been your greatest professional and personal achievements?

To have been approached for a deputy director role of a large multidisciplinary research centre

whilst, having no family support and still being able to be present as an involved father and husband to a loving and hardworking family.

What are the top three things on your “bucket list”?

To support and enable my wife to resume her ambitious professional career aspirations following maternity leave.

To support my daughters at their Scouts Australia, and Surf Life Saving endeavours.

To help establish Newcastle University and its partners as one of the main national research, development, and upskilling hubs for the offshore wind sector.

systems that enable us to offer you off-the-shelf and custom solu�ons made in USA. No compromises.

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 19 MATERIALS AUSTRALIA “making the invisible visible” PO Box 2383 Taren Point NSW 2229 Australia Unit 21, 3 Box Road Taren Point NSW 2229 Australia T: 61 2 9524 0558 E: ndt@ndt.com.au W: www.ndt.com.au

Prime Fusion

Our Certified Materials Professionals (CMatPs)

The following members of Materials Australia have been certified by the Certification Panel of Materials Australia as Certified Materials Professionals.

They can now use the post nominal ‘CMatP‘ after their name. These individuals have demonstrated the required level of qualification and experience to obtain this status. They are also required to regularly maintain their professional standing through ongoing education and commitment to the materials community.

We now have nearly 200 Certified Materials Professionals, who are being called upon to lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

A/Prof Alexey Glushenkov ACT

Dr Syed Islam ACT

Prof Yun Liu ACT

Dr Karthika Prasad ACT

Dr Avik Sarker ACT

Dr Olga Zinovieva ACT

Prof Klaus-Dieter Liss CHINA

Mr Debdutta Mallik MALAYSIA

Prof Valerie Linton NEW ZEALAND

Prof. Jamie Quinton NEW ZEALAND

Dr Rumana Akhter NSW

Ms Maree Anast NSW

Dr Edohamen Awannegbe NSW

Ms Megan Blamires NSW

Dr Phillip Carter NSW

A/Prof Igor Chaves NSW

Dr Evan Copland NSW

Mr Peter Crick NSW

Prof Madeleine Du Toit NSW

Dr Ehsan Farabi NSW

Prof Michael Ferry NSW

Dr Yixiang Gan NSW

Mr Michele Gimona NSW

Dr Bernd Gludovatz NSW

Dr Andrew Gregory NSW

Mr Buluc Guner NSW

Dr Ali Hadigheh NSW

Dr Alan Hellier NSW

Prof Mark Hoffman NSW

Mr Simon Krismer NSW

Prof Jamie Kruzic NSW

Prof Huijun Li NSW

Dr Yanan Li NSW

A/Prof Xiaopeng Li NSW

Dr Hong Lu NSW

Mr Rodney Mackay-Sim NSW

Dr Matthew Mansell NSW

Dr Warren McKenzie NSW

Mr Edgar Mendez NSW

Mr Sam Moricca NSW

Dr Ranming Niu NSW

Dr Anna Paradowska NSW

Prof Elena Pereloma NSW

A/Prof Sophie Primig NSW

Dr Gwenaelle Proust NSW

Miss Zhijun Qiu NSW

Dr Blake Regan NSW

Mr Ehsan Rahafrouz NSW

Dr Mark Reid NSW

Prof Simon Ringer NSW

Dr Richard Roest NSW

Mr Sameer Sameen NSW

Dr Luming Shen NSW

Mr Sasanka Sinha NSW

Mr Frank Soto NSW

Mr Michael Stefulj NSW

Mr Carl Strautins NSW

Mr Alan Todhunter NSW

Ms Judy Turnbull NSW

Mr Jeremy Unsworth NSW

Dr Philip Walls NSW

Dr Alan Whittle NSW

Dr Richard Wuhrer NSW

Mr Deniz Yalniz NSW

Mr Michael Chan QLD

Prof Richard Clegg QLD

Mr Andrew Dark QLD

Dr Ian Dover QLD

Mr Oscar Duyvestyn QLD

Mr John Edgley QLD

Dr Jayantha Epaarachchi QLD

Dr Jeff Gates QLD

Mr Payam Ghafoori QLD

Mr Mo Golbahar QLD

Dr David Harrison QLD

Dr Janitha Jeewantha QLD

Dr Damon Kent QLD

Mr Jaewon Lee QLD

Mr Jeezreel Malacad QLD

Mr Sadiq Nawaz QLD

Dr Saeed Nemati QLD

Mr Bhavin Panchal QLD

Mr Bob Samuels QLD

Mr Ashley Bell SA

Ms Ingrid Brundin SA

Mr Neville Cornish SA

A/Prof Colin Hall SA

Mr Brendan Dunstall SA

Mr Nikolas Hildebrand SA

Mr Mikael Johansson SA

Mr Rahim Kurji SA

Mr Andrew Sales SA

Dr Thomas Schläfer SA

Dr Christiane Schulz SA

Prof Nikki Stanford SA

Prof Youhong Tang SA

Mr Kok Toong Leong SINGAPORE

Mr Devadoss Suresh Kumar UAE

Dr Ossama Badr VIC

Dr Qi Chao VIC

Dr Ivan Cole VIC

Dr John Cookson VIC

Miss Ana Celine Del Rosario VIC

Dr Yvonne Durandet VIC

Dr Mark Easton VIC

Dr Rajiv Edavan VIC

Dr Reza Emdad VIC

Dr Peter Ford VIC

Mr Bruce Ham VIC

Ms Edith Hamilton VIC

Dr Shu Huang VIC

Mr Long Huynh VIC

Dr Jithin Joseph VIC

Mr. Akesh Babu Kakarla VIC

Mr Russell Kennedy VIC

Mr Daniel Lim VIC

Dr Amita Iyer VIC

Mr Robert Le Hunt VIC

Dr Thomas Ludwig VIC

Dr Roger Lumley VIC

Mr Michael Mansfield VIC

Dr Gary Martin VIC

Dr Siao Ming (Andrew) Ang VIC

Mr Glen Morrissey VIC

Dr Eustathios Petinakis VIC

Dr Leon Prentice VIC

Dr Dong Qiu VIC

Mr John Rea VIC

Miss Reyhaneh Sahraeian VIC

Dr Christine Scala VIC

Mr Khan Sharp VIC

Dr Vadim Shterner VIC

Dr Antonella Sola VIC

Mr Mark Stephens VIC

Dr Graham Sussex VIC

Dr Kishore Venkatesan VIC

Mr Pranay Wadyalkar VIC

Dr Wei Xu VIC

Dr Ramdayal Yadav VIC

Dr Sam Yang VIC

Dr Matthew Young VIC

Mr Angelo Zaccari VIC

Dr Yuman Zhu VIC

Mr Mohsen Sabbagh Alvani WA

Dr Murusemy Annasamy WA

Mr Graeme Brown WA

Mr Graham Carlisle WA

Mr John Carroll WA

Mr Sridharan Chandran WA

Mr Conrad Classen WA

Mr Chris Cobain WA

Mr Adam Dunning WA

Mr Jeff Dunning WA

Dr Olubayode Ero-Phillips WA

Mr Stuart Folkard WA

Mr Toby Garrod WA

Prof Vladimir Golovanevskiy WA

Mr Chris Grant WA

Mr Paul Howard WA

Dr Paul Huggett WA

Mr Ivo Kalcic WA

Mr Srikanth Kambhampati WA

Mr Ehsan Karaji WA

Mr Ka-Seng Leung WA

Mr Mathieu Lancien WA

Dr Evelyn Ng WA

Mr Deny Nugraha WA

Mrs Mary Louise Petrick WA

Mr Johann Petrick WA

Mr Biju Kurian Pottayil WA

Dr Mobin Salasi WA

Mr Daniel Swanepoel WA

Mr James Travers WA

MATERIALS AUSTRALIA 20 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Why You Should Become a Certified Materials Professional

Source: Materials Australia

Accreditation as a Certified Materials Professional (CMatP) gives you recognition, not only amongst your peers, but within the materials engineering industry at large. You will be recognised as a materials scientist who maintains professional integrity, keeps up to date with developments in technology, and strives for continued personal development.

The CMatP, like a Certified Practicing Accountant or CPA, is promoted globally as the recognised standard for professionals working in the field of materials science.

There are now well over one hundred CMatPs who lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Benefits of Becoming a CMatP

• A Certificate of Membership, often presented by the State Chapter, together with a unique Materials Australia badge.

• Access to exclusive CMatP resources and website content.

• The opportunity to attend CMatP only networking meetings.

• Promotion through Materials Australia magazine, website, social media and other public channels.

• A Certified Materials Professional can use the post nominal CMatP.

• Materials Australia will actively promote the CMatP status to the community and employers and internationally, through our partner organisations.

• A CMatP may be requested to represent Materials Australia throughout Australia and overseas, with Government, media and other important activities.

• A CMatP may be offered an opportunity as a mentor for student members.

• Networking directly with other CMatPs who have recognised levels of qualifications and experience.

• The opportunity to assume leadership roles in Special Interest Networks, to assist in the facilitation of new knowledge amongst peers and members.

What is a Certified Materials Professional?

A Certified Materials Professional is a person to whom Materials Australia has issued a certificate declaring they have attained all required professional standards. They are recognised as demonstrating excellence, and

possessing special knowledge in the practice of materials science and engineering, through their profession or workplace. A CMatP is prepared to share their knowledge and skills in the interest of others, and promote excellence and innovation in all their professional endeavours.

The Criteria

The criteria for recognition as a CMatP are structured around the applicant demonstrating substantial and sustained practice in a field of materials science and engineering. The criteria are measured by qualifications, years of employment and relevant experience, as evidenced by the applicant’s CV or submitted documentation.

Certification will be retained as long as there is evidence of continuing professional development and adherence to the Code of Ethics and Professional behaviour.

Further Information

Contact Materials Australia today: on +61 3 9326 7266 or imea@materialsaustralia.com.au or visit our website: www.materialsaustralia.com.au

•

•

•

•

MATERIALS AUSTRALIA WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 21 Advertise with Materials Australia! Advertising with Materials Australia will give you the opportunity to: • Maintain and build on professional relationships

Connect with a highly targeted audience

Showcase your new products and services

•

•

Gain instant market feedback

Increase and strengthen brand awareness

Stay at the forefront of industry developments and innovations

Show your dedication to, and support of, the industry Email rod@materialsaustralia.com.au for more information

Profile: Dr Michael Bermingham ARC Future Fellow

Dr Michael Bermingham's research is primarily concerned with advanced manufacturing of metal materials. This also involves metal alloy development including understanding how the manufacturing process influences the structure and behaviour of the material and how alloy design can be optimised for the process. He has research expertise in solidification processing (including casting, welding, soldering and additive manufacturing), as well as subtractive metal machining technologies.

Michael was awarded his PhD from the University of Queensland in 2010 with a Dean's Award for Outstanding Higher Degree Theses. From 2010 to 2015 he completed a post-doctoral appointment sponsored by the then Defence Materials Research Centre (now DMTC Ltd) working with Australian manufacturers in the F-35 Joint Strike Fighter supply chain. This work principally centred on developing advanced machining technologies for titanium fabrication.

During this time Michael also completed a post-doctoral appointment investigating new materials and design solutions for implantable medical devices in collaboration with a multinational medical device manufacturer.

Michael became a Lecturer in the School of Mechanical and Mining Engineering at the University of Queensland in 2016 and has been a Senior Lecturer since 2020. He teaches into undergraduate and postgraduate courses in materials, manufacturing and design and has won a number of teaching awards including a 2020 Australian Award for University Teaching Citation for Outstanding Contribution to Student Learning.

Can you provide brief summary of your research career?

My research career began as a PhD candidate in the former CAST CRC trying to understand grain refinement science in cast titanium products. I was fortunate to be well supported in this research environment and had some incredible times and formed lifelong friendships.

After completing my PhD I joined the then Defence Materials Research Centre (now DMTC Ltd) working alongside SMEs in the F-35 Joint Strike Fighter supply chain to develop advanced machining techniques for fabricating aircraft parts.

I also held other postdoc appointments including working with Cook Medical Australia looking at materials and manufacturing related issues associated with medical devices.

In late 2015, I was fortunate to secure a continuing academic (teaching and research) position at the University of Queensland and a few days later an ARC Discovery Early Career Researcher Award (DECRA) – a truly fantastic week! Since then, my research in physical metallurgy has continued, and just recently I was awarded an ARC Future Fellowship.

What has been the most productive period in your research career and why?

During my ARC DECRA fellowship I had the opportunity to pursue my research interests in additive manufacturing (AM), which proved to be a productive period. I was able to grow and mentor a team that was working to understand how to control microstructure and properties during metal additive manufacturing. The flexibility afforded by the fellowship provided me with opportunities to travel and collaborate with others in the field.

How do you balance your time?

In a life before research, I worked in the brick manufacturing industry where among other things I learned to value my time and work efficiently. When my research journey started, I applied these same principles and found a healthy work-life balance that I still practice today.

My role has since evolved and there are more pressures on my time than previously, but I maintain a healthy balance. I have learned that it’s okay to say no to things that don’t bring value and joy.

What do you think are your

most significant research accomplishments?

I’m proud of my research contributions to the field of grain size control in titanium alloys during solidification processing. I was fortunate that when I commenced my study in this area back in 2006 I had many world class solidification experts available to mentor me along this journey including Professor David StJohn.

The research we did in grain refining cast titanium product later proved useful in addressing the pressing issue of how to control large grain sizes and textures that develop during additive manufacturing.

Additionally, the cyclic heating and cooling associated with AM can embed microstructure and phase heterogeneity which creates issues in part-to-part consistency.

Recently, our team published our work in Science which outlined a pathway toward alloy design that incorporates methods to simultaneously control grain size, texture and phase heterogeneity which resulted in uniform properties in a class of titanium alloys.

What are the big issues in your research area?

My future fellowship focuses on understanding how we can develop fit-for-purpose products directly from AM by closely examining alloys. Most

INDUSTRY NEWS

22 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Dr Bermingham demonstrates martensitic transformations to students by heat treating steels live in a lecture.

alloys used in AM were not developed for this process and some, including titanium alloys, were originally designed for thermomechanical processing.

However, AM is unique in its nature and offers the potential to unlock new possibilities. For instance, recent research has shown that certain compositions can be successfully processed by AM without forming deleterious segregation defects which is not achievable through conventional production routes. As a result, some of the traditional rules for how we approach alloy design can be redefined, taking advantage of the novel opportunities presented by metal AM. Exploring these possibilities is a key aspect of my fellowship.

If you were starting your project or research again today, what would you do differently?

I do not harbour any regrets towards the research career I’ve had. I have

been very fortunate to have had long term supportive mentors and collaborators, particularly Professor Matthew Dargusch who has taught me so much about research and industry translation.

How do you feel about translating research outcomes to industry?

I am a firm believer that the research we do must add value to industry, and I am a strong proponent of translation. Some of my proudest research outcomes have never been published but have been directly adopted by the industry partner because the research has addressed critical issues facing them. As a researcher it is rewarding knowing that the discoveries we make are valuable to industry.

How do you feel about teaching? What is your teaching philosophy? Good teaching is critical and can profoundly influence students. Attracting students to materials

engineering is an ongoing challenge that our discipline faces and I believe that all of us in teaching roles should do our best in attracting and educating the next generation of young materials engineers. When I was a student I didn’t initially know what materials engineering was and I never contemplated a career in it.

However, thanks to an exceptional teacher, Professor Arne Dahle, I became fascinated. I remember Arne would demonstrate material properties live in class by smashing ceramic mugs and throwing (and shattering) cryogenically frozen squash balls at the wall in a lecture theatre. I’ve been inspired by Arne to make materials and manufacturing interesting and I try to implement best practice pedagogies into my classes. I’m honoured to have won several teaching awards at the university and national level.

INDUSTRY NEWS

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 23

Dr Bermingham with postgraduate researcher Dr Chi-Ho Ng and PhD candidate Mandeep Singh explore issues in wire arc additive manufacturing (WAAM).

Reflective Materials and Irrigated Trees: Study Shows How to Cool One of the World’s Hottest Cities By 4.5°C

Source: Sally Wood

New cooling technologies could reduce the energy needs of one of the hottest places in the world.

Riyadh, the capital of Saudi Arabia, is situated in the centre of a desert, with temperatures that can exceed 50°C during summer.

Those temperatures are tipped to rise, as climate change and rapid urbanisation increase the magnitude of overheating.

However, a recent UNSW Sydney study combined highly reflective ‘super cool’ buildings with irrigated greenery and energy retrofitting measures, which could cool the city by 4.5°C.

The study, which was conducted in collaboration with the Royal Commission of Riyadh, is the first to investigate the large-scale energy benefits of modern heat mitigation technologies when implemented in a city.

The materials were developed by Australian researchers at UNSW’s High-Performance Architecture Lab.

“The project demonstrates the tremendous impact advanced heat mitigation technologies and techniques can have to reduce urban overheating, decrease cooling needs, and improve lives,” said UNSW Scientia Professor Mattheos Santamouris, who is the Anita

Lawrence Chair in High-Performance Architecture and senior author of the study.

Extreme urban heat affects more than 450 cities worldwide. It increases energy consumption needs and adversely impacts health, including heat-related illness and death.

“Limited greenery and large artificial surfaces made of conventional building materials like asphalt and concrete trap heat, meaning the city continues to heat up.”

“Additional heat from car pollution and industrial activities also increases the city’s temperature,” Professor Santamouris said.the potential of this novel edge transport in electronic and spintronic applications.

Simulating City-Scale Heat Mitigation Scenarios

The team of researchers ran large-scale cooling climatic and energy simulations of the Al Masiaf precinct of Riyadh, including the energy performance of 3,323 urban buildings, under eight different heat mitigation scenarios.

This method was designed evaluate optimal strategies for lowering the temperature of the city and reducing cooling needs.

The modelling considered different combinations of super cool materials, vegetation types and energy retrofitting levels.

It opened the possibility of decreasing the outdoor temperature in the city during summer, and improve cooling energy conservation by up to 16%.

The recommended heat mitigation (or cooling) scenario for Riyadh includes using super cool materials implemented in the roof of the buildings, and more than doubling the number of irrigated trees to improve transpiration cooling.

“By implementing the right combination of advanced heat mitigation technologies and techniques, it is possible to decrease the ambient temperature at the precinct scale.”

“For a sweltering city the size of Riyadh, significantly reducing cooling needs is also tremendous for sustainability,” Professor Santamouris said.

The researchers hope to work with the Royal Commission of Riyadh to begin implementing the tailored heat mitigation plan across the city, which would be the largest of its kind in the world.

24 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

INDUSTRY NEWS

More irrigated greenery is crucial to heat mitigation in Riyadh. Photo: Getty Images.

Temperatures can exceed 50°C during the summer in Riyadh, Saudi Arabia. Photo: Getty Images.

Graphene Oxide Study Strengthens the Case for Smart Concrete

Source: Sally Wood

Engineers recently made stronger 3D printed concrete by adding graphene oxide to cement mixture.

The research, conducted by RMIT University and the University of Melbourne, is the first to investigate the effects of graphene oxide on the printability and compressive properties of 3D printed concrete.

Researchers found the addition of graphene oxide, a nanomaterial commonly used in batteries and electronic gadgets, gave concrete electrical conductivity and increased its strength by up to 10%.

Research supervisor and RMIT Associate Professor Jonathan Tran said it had the potential to create ‘smart’ buildings, where walls act as sensors to detect and monitor small cracks.

“The equipment for these methods is often bulky, making it difficult to regularly use for monitoring very large structures like bridges or tall buildings.”

“But the addition of graphene oxide creates the possibility of an electrical circuit in concrete structures, which could help detect structural issues, changes in temperature and other environmental factors.”

Current detection methods, such as ultrasonic or acoustic sensors, are non-destructive and widely used in the construction industry to detect large cracks in concrete structures. However, detecting smaller cracks early is still a challenge.

Professor Tran said graphene oxide has the potential to make 3D printed concrete more viable in the construction industry, leading to positive impacts on cost and sustainability.

“Current concrete structures are created using formwork, which is where you create a mold before pouring fresh concrete mixture into it.”

As 3D printed concrete uses layer-by-

layer printing, it can potentially lead to weaker bonds between each layer. However, the addition of graphene oxide in concrete makes it easier to extrude, creating better interlayer bonding, which can also help maximise strength.

“Graphene oxide has functional groups on its surface, which are like sticky spots on the surface of a material that can grab onto other things,” Professor Tran said.

“These 'sticky spots' are mainly made of various functional groups containing oxygen, which play a crucial role in facilitating its stronger bonds with other materials like cement. This strong bonding can improve the overall strength of the concrete.”

“However, more research is needed to

Left:

Above Left to right: RMIT Engineering students

Hoang Khieu, Wen Si, Thanh Ha Nguyen, Junli Liu and Shuai Li. Left: Graphene oxide in concrete has the potential to create ‘smart’ buildings where walls can act as sensors to detect and monitor small cracks. Image credits: Jonathan Tran.

test if concrete with graphene oxide can match or surpass the strength of traditionally cast concrete.”

The research assessed two dosages of graphene oxide in cement and found the lower dosage (0.015% of the weight of cement) was stronger than the higher one (0.03% of the weight of cement).

Professor Tran believes adding too much graphene oxide could impact the strength and workability of the concrete mix, which can cause potential issues with printability, strength and durability.

“Concrete is a carefully balanced mixture. Adding too much graphene oxide can disrupt this balance, particularly the hydration process, which is crucial for concrete strength,” he said.

A 3D printed concrete structure created by RMIT Engineering students.

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 25 INDUSTRY NEWS

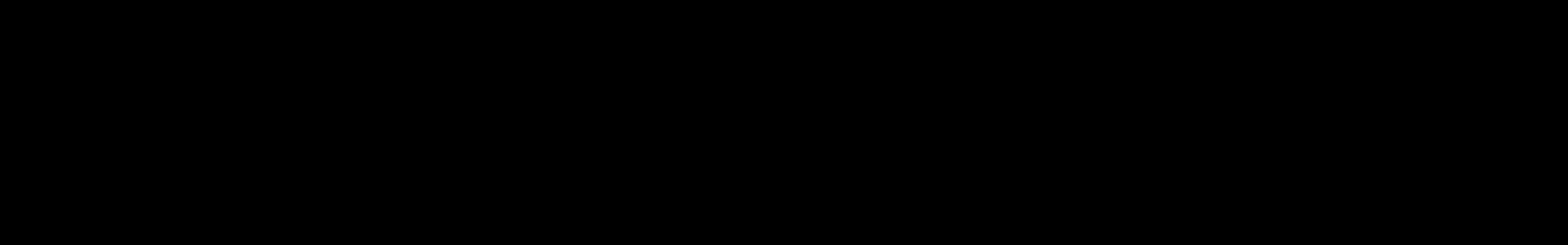

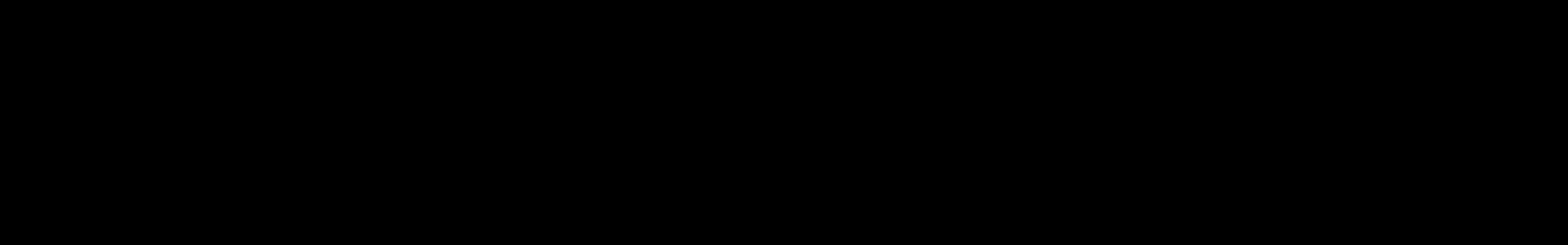

Powder Characterisation: Reliable methods for consistent quality in Additive Manufacturing

Source: ATA Scientific Pty Ltd

Additive Manufacturing (AM) describes the methods that convert a 3D model into a real part by the layer upon layer addition of material. AM is ideal for rapid prototyping and can enable the faster, cheaper and more efficient manufacturing of complex parts like customised medical components or engine parts, often with improved strength and durability.

As exciting as the possibilities are in AM, the process itself is not without its challenges. Problems with final product consistency and a narrow range of expensive raw materials are some of the biggest obstacles to the widespread adoption of AM. Up to one-third of the production cost is the cost of the powder used, while poor powder quality or contaminants can lead to pores, cracks and inclusions, severely impacting the end product. To maintain consistent high quality components it is necessary to not only certify manufactured parts for their physical and chemical properties, but also to certify raw material.

Laser Diffraction and Image Analysis are essential techniques for certifying both feedstock powders and printed parts, as cited in ISO/ASTM 52907 standard Additive manufacturing — Feedstock materials — Methods to characterise metal powders. This is the main standard for metal powder characterisation for AM and can be applied across the entire AM value chain including academic research, metal powder manufacture and component manufacture.

Particle size distribution - choose Mastersizer 3000

Particle size distribution is critical for powder bed AM processes since it affects several characteristics of the powder including bulk density, flowability, moldability and compressibility, which impact final component properties. Figure 1 illustrates the packing density of different sized balls in a box. Too many large particles will reduce the packing density, while too many small particles can be problematic for health and safety as well as reduce flowability due to the cohesion of the powder particles. Additionally, there is a compromise for additive layer manufacturing as it’s important to ensure a consistent layer thickness and for that reason, a narrower particle size distribution is usually preferred.

The Malvern Mastersizer 3000 uses laser diffraction, an established technique for measuring the particle size distribution of metal, ceramic and polymer powders for additive manufacturing, and is employed by powder producers, component manufacturers and machine manufacturers worldwide to qualify and optimise powder

properties. A complete high-resolution particle size distribution is provided in a matter of minutes (from 10 nm to 3.5 mm) using either wet or dry dispersion. Closely matching results between dry and wet measurements of the same sample can be obtained and comparing the two allows the primary particle size, and indeed the whole size distribution, to be validated. The technique can also be integrated into a process line (Insitec) to provide real-time particle sizing.

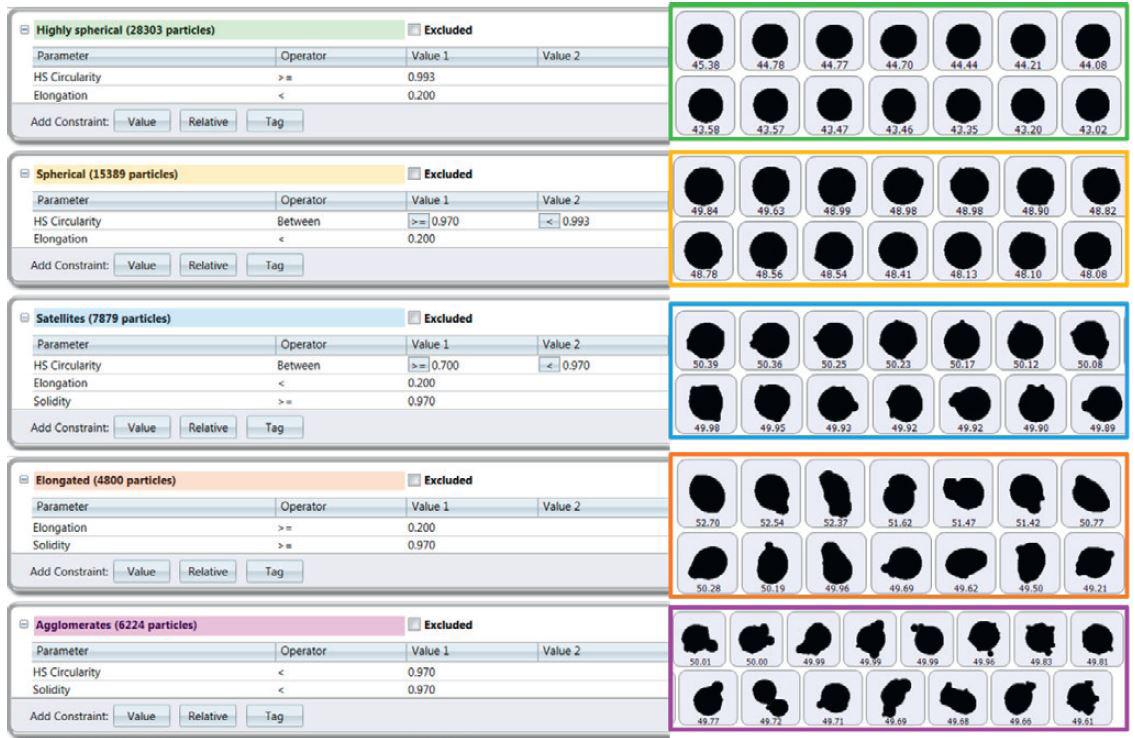

Particle shape and compositionMalvern Morphologi 4-ID

Powder bed density and powder flowability are influenced by particle size and shape. Particle morphology is therefore another important metric for powder bed additive manufacturing, with smooth, regular-shaped particles preferable as they can flow and pack more easily than those with a rough surface and irregular shape which reduce flowability via interparticle friction and mechanical interlocking.

Suitable for particles from approximately 0.5 μm to > 1 mm, the Malvern Morphologi 4-ID enables automated optical image analysis to classify and quantify the size and shape of metal, ceramic and polymer powders. It provides a range of different shape parameters, including circularity, elongation, convexity, and solidity. It can also support customised classifications to examine features such as satelliting. The fully integrated Raman spectrometer also enables component-specific morphological descriptions of chemical species.

INDUSTRY NEWS 26 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Figure 1: Particle size distribution versus packing density.

The Phenom ParticleX AM is a specialised high-resolution desktop scanning electron microscope (SEM) dedicated to optimising AM metal powders and final product quality. This fully integrated system is simple to operate and eliminates the need for outsourcing for quality checks, speeding up time-to-market. By combining an imaging resolution of <8nm and magnifications up to 200,000x together with X-ray analysis (EDS) for elemental composition, properties such as structural integrity, print resolution, surface uniformity, phases and the presence of impurities or defects can be identified and their location logged to contribute unique insights not possible with other systems. A scanning area of 100x100mm grants a large degree of freedom to image and assess the size and shape of whole parts or sections

of a larger component simultaneously.

Molecular structure, Malvern OMNISEC Multidetector GPC/SEC

The physical properties and behaviour of polymeric powders and photopolymer resins depends on the properties of the polymer molecules themselves. By assessing their molecular weight and distribution, molecular size and structure and controlling these properties, manufacturers can control polymer production and quality. Historically, accurate measurement of polymer molecular weight via Gel Permeation Chromatography (GPC) has been dependent on having standards of the same polymer but the introduction of advanced detection techniques such as light scattering and intrinsic viscosity have made absolute measurements possible.

Malvern’s OMNISEC system is a multi-detector GPC system that combines light scattering (RALS/ LALS), refractive index (RI), ultraviolet (UV) and intrinsic viscosity (IV) detectors to generate a large amount of information about a sample simultaneously enabling

measurements using less sample with lower molecular weights than ever before.

In figure 4, the light scattering chromatogram (RALS) indicates a shoulder at low retention volume (ca.15mL) for Nylon 12-recycle sample only. As no corresponding peak in the RI is observed, a high molecular weight species is likely present in the recycle sample at very low concentrations which can indicate chemical modifications may be occurring during processing.

These analyses facilitate a deeper understanding of how many times a powder can be recycled, as well as the optimum powder refresh rate (used/new powder ratio) to use in the process. This helps to ensure the quality of the powder bed, and therefore the quality of the final part is not compromised.

Go further together

At ATA Scientific, we don’t just sell our instruments – through collaboration with a broad range of industries and academic institutions, we play a key role in the AM ecosystem. We support our customers by providing optimal material characterisation techniques used in AM together with key insights into the application, measurements and analysis to fully understand material behaviour.

Contact us for more information today!

ATA Scientific Pty Ltd

+61 2 9541 3500

enquiries@atascientific. com.au

INDUSTRY NEWS

High resolution and fine surface detail - Phenom Desktop SEM

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS APRIL 2024 | 27

Figure 2: Particle classifications for an AM metal powder with corresponding particle images.

Figure 3: Spherical, satellite and deformed metal powder particles

Figure 4: Overlay of the RI and RALS chromatograms for duplicate injections of Nylon 12-new (red and purple) and Nylon 12-recycle (green and black).

Research Begins to Reduce Shed of Microplastics During Laundering

Source: Sally Wood

A new collaboration between Deakin University researchers and Australia's largest commercial linen supplier is tackling a global issue.

Researchers worked with Simba Global, a global textile manufacturing company, to manage the spread of harmful microplastics through our laundry.

Clothing and textiles are estimated to generate up to 35% of the microplastics found in the world's oceans.

But there is still a lot to be learnt about the characteristics of these microplastics and exactly how and why they are generated.

Simba Global is the major linen supplier to Australia's hospitals, hotels and mining camps, resulting in 950,000 tonnes of textile products going through the commercial laundering process each year.

The company wants to lead the charge to reduce the environmental impact of textiles. As such, they partnered with researchers at the ARC Research Hub for Future Fibres in Deakin's Institute for Frontier Materials (IFM).

Associate Professor Maryam Naebe, who is a lead scientist at IFM, said researchers are focussed on potential

solutions including the pre-treatment of textiles to reduce the shedding of microplastics.

"Microplastics are now ubiquitous in the environment, they're in the air we breathe, the food we eat and the earth we walk on. The magnitude of the problem is bigger than previously thought.”

"Of serious concern is the mounting evidence that microplastics are having a negative impact on human and animal health. There are not just physical, but chemical and biological impacts,” Associate Professor Naebe said.

Bringing Research to Life

The team recently presented their science at the Association of Universities for Textiles (AUTEX) Conference 2023, which started important conversations of formally categorising these types of microplastics.

"We need to have a standard definition of what is a microplastic.

Up to this point that has been lacking, which makes it difficult to compare and incorporate other studies in this area.”

"We are now developing a systematic method for sampling and identifying microplastics in laundry wastewater. It has been tricky to measure the different sizes, but this is important information to have,” Associate Professor Naebe said.

Simba Global Executive Chair Hiten Somaia said the company had a strong focus on sustainability, driven by the business's purpose statement.

"We work to contribute to a better world—for every person, every relationship, and every community.”

"But as the major supplier to the Australian commercial industry, the converse is also true—that we are part of the problem. So, to stay true to our purpose, it wasn't a difficult decision at all for Simba to take a leadership role and commit significant resources to this research," Mr Somaia said.

INDUSTRY NEWS 28 | APRIL 2024 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Shervin Ranjbar (Services Engineer, Simba Global) and David Tester (Head of Innovation, Simba Global) with a Deakin University researcher. Image credit: Deakin University.