2

1

REPLACEMENT PARTS

Quality Imaging parts for CT, Mammography, MRI, Cath labs, and general X-Ray

Hands-on technical training for all imaging modalities in Nashville, TN. Now offering an Apprentice program! 4 PRE-OWNED

Inspected, tested, and certified by our team in our 60k square foot facility in Nashville, TN.

3

Service support for all major imaging manufacturers including GE, Philips, Siemens, Hologic and Toshiba/Canon.

can’t

Supply chain issues and low-quality parts from offshore vendors can wreak havoc on your timeline and bottom line. You need a support team who understands the pressures you face and provides solutions — from new and T.Certified pre-owned products to top-quality repair parts — that fit your budget.

We’re in YOUR corner. Call today to schedule repairs or to purchase parts and equipment.

“We appreciate the opportunity to support the training needs of the imaging service industry,” RSTI CEO Todd Boyland, CRES, CPSM, said. “It was equally as fun getting to share this with the RSTI team and the group of students in classes that week too.”

SINCE 1985, RSTI HAS PROVIDED DIAGNOSTIC IMAGING TRAINING. OFFERING A WIDE SELECTION OF OVER 60 COURSES EACH YEAR, RSTI HAS TRAINED MORE THAN 15,000 SERVICE PROFESSIONALS FROM OVER 50 COUNTRIES IN RADIOLOGY, MAMMOGRAPHY, MR, CT, ULTRASOUND, NETWORKING, PACS AND DICOM.

CONTACT US: 23/24 CALENDAR:

ISO 9001:2015 CERTIFIED (IQC CERTIFICATE NO. Q-1158) STATE OF OHIO REG. NO. 93-09-1377T

P.12 SPOTLIGHT

p.12 Department of the Month: The St. Elizabeth Healthcare Clinical Engineering Department

p.14 Company Showcase: Collaborative Medical Solutions

p.18 Professional of the Month: Broderick Richard

p.20 Shifting Gears: The Big Reveal

p.22 Next Gen: Bryant Hawkins Jr.

P.24 INDUSTRY UPDATES

p.24 News & Notes

p.30 [Sponsored Content] Medical Equipment Doctor Is In

p.32 Welcome to TechNation

p.34 AAMI Update

p.36 Ribbon Cutting: NVRT Labs

p.38 ECRI Update

52 46

P.41 THE BENCH

p.41 Tools of the Trade

p.42 Biomed 101

p.45 Webinar Wednesday

P.46 FEATURE ARTICLES

p.46 Roundtable: Endoscopes

p.52 Cover Story: Women in the Industry

P.58 EXPERT ADVICE

p.58 Career Center

p.60 [Sponsored Content] Innovatus Imaging

p.63 The Future

P.64 CONNECTED

p.64 Cybersecurity

p.68 HIMSS

p.71 Networking Notes

p.73 Get Connected Company Directory

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey OF SALES

EDITORIAL John Wallace

CONTRIBUTORS

Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Connor Walsh

David Witt

Steven J. Yelton

ACCOUNT

EXECUTIVES

ART DEPARTMENT

Megan Cabot

Emily Hise

Karlee Gower

Taylor Hayes

Kameryn Johnson

DIGITAL SERVICES

Cindy Galindo

Kennedy Krieg

Haley Wells

EVENTS Kristin Leavoy

WEBINARS

HTMJOBS.COM

ACCOUNTING

CIRCULATION

Linda Hasluem

Kristen Register

Sydney Krieg

Diane Costea

Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Jim Fedele, CBET, Senior Director of Clinical Engineering, UPMC

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Benjamin Scoggin, MBA, MMCi, Director, Clinical Engineering | Biomedical Operations, Equipment Distribution, Clinical IT, DHTS, Duke Health Technology Solutions

Allison Woollford, Biomedical Equipment Specialist at Duke University Health System

Register now for the next DNV CHOP-B Certification Course

- Starts September 18 - 3-Weeks Online

- Live Webinars

Fall 1 Cohort begins September 18

Fall 2 Cohort begins October 20

At the beginning of the Civil War, in Covington, Kentucky, Henrietta Cleveland and Sarah Peter, with the support of the Catholic church, turned a grocery store in the city into a hospital. It was the first St. Elizabeth Hospital. The new hospital was staffed by nuns and named after St. Elizabeth of Hungary.

A second location was established in Covington after the end of the war. Those two locations grew into a health care system that today serves Northern Kentucky and Southeastern Indiana.

The St. Elizabeth Healthcare Clinical Engineering Department manages the medical equipment inventory for the health system including more than 30,000 medical devices, including radiology, biomedical equipment, laboratory and CE/IT medical device integration.

The CE team includes Director D’Juan James, MBA; Imaging Specialist Aaron Fischer; CE Supervisor Penny Frederick, CBET, MBA; CE Supervisor Brad Swecker; CE/IT Specialist Nathan Fischer; Service Logistics Coordinator Gina Loudermilk and 20 technical professionals.

The department includes six imaging specialists and two OR equipment specialists.

“St. Elizabeth Healthcare operates five hospital facilities throughout Northern Kentucky and Southeast Indiana: St. Elizabeth Dearborn, St. Elizabeth Edgewood, St. Elizabeth Florence, St. Elizabeth Ft. Thomas, and St. Elizabeth Grant, for a combined total of 1,200 patient beds,” James says.

He says the system also operates an ambulatory care center, hospice center, three freestanding

imaging centers and is in partnership with St. Elizabeth Physicians (SEP), which includes a network of over 185 physician offices located in Kentucky, Indiana and Ohio.

The CE team manages and negotiates service contracts to determine if a service agreement is necessary based on financial and service history data, proprietary equipment, department request, number of devices within the organization and equipment to technician sustainability ratio (ETSR), which is used to determine if the department has the full-time employee capacity to support the device in-house or outsource service contract.

James says that the vast majority of the department’s data collection is from its CMMS database (Medimizer). He says that this includes financial and service history data, service contract management and preventative maintenance compliance.

“In addition, we are now using Internet of Things (IOT) among other resources to track IP addresses, MAC addresses, operating systems, medical device vulnerabilities, remediations, alerts and recalls, and equipment utilization management,” he says.

James adds that there is a high level of integration between CE and IT.

“All medical device integration projects typically go through a technical/security discovery meeting with either our ancillary care or acute care subgroups within IT depending on the device type, network configurations, infrastructure type (on premises or cloud based), licensing requirements and security parameters,” he says.

As is the case with all biomed departments, there are projects and challenges that the St. Elizabeth’s team has tackled.

“St. Elizabeth outsources their telemetry monitoring and Tele-ICU services (virtual health). Technical

challenges come along with that. The vendor uses their own computer hardware to integrate with our Philips patient monitoring system, gaining remote access to view/surveillance our patients,” James says.

He says that CE manages the installation, integration and troubleshooting of the remote hardware system.

“We experience intermittent or hard done network dropouts which causes the vendor to lose visibility to patient vitals momentarily. Our team works diligently troubleshooting by immediately enlisting the help of a nurse to assist us in gaining remote access to allow us to reboot the PC or reseating hardware connections, and sometimes, reconfiguring the display settings on the remote screen resolves the issue,” James says.

He says that the CE department is involved in many projects such as capital planning for a new cancer center, slated to open in late 2024, business plan proposals; providing ROI contributions and maintenance strategies, standardizing infusion pump management at the most recently acquired hospital, as well as upgrading the Philips patient monitoring system software to the latest software revision.

“Philips offers a software application called patient information center (PIC iX) that provides visibility into patient data and enhancing clinical workflow. Our central station monitoring across the system are on two different software revisions; Rev B and C. Revision B has been end of life for several years and C will soon follow. We are

currently upgrading our monitoring system in stages to Philips newest 4.1 revision platform,” James says.

He says that the project required effective communication to nursing leaders without impacting patient care as it resulted in equipment downtime.

“CE assisted Philips with the deinstallation of the old MP series monitors (non-compatible) as part of the upgrade as well as staging, incoming inspection and inventory of the new MX series monitors into CMMS database,” James says.

The team also put its resources into a telemetry department remodel project that included a complete remodel of the telemetry unit and reduction from 32 to 26 beds.

“Our department worked with an outside vendor and IT department to run all new cabling and secure network drops. Installed and programmed the central monitoring PCs. Installed wireless access points and configuration of telemetry transmitters to communicate with the wireless network. In addition, installed patient overview hallway monitors for better visibility for the nursing staff to view patient vitals,” James says.

As a result of its efforts, the CE team carries on Henrietta Cleveland’s vision of helping ensure quality health care services to the residents of Covington and the Northern Kentucky/Southeastern Indiana region the health care system serves.

ollaborative Medical Solutions Principal Trey McIntyre explains that the company was formed after nearly 20 years in the pre-owned medical imaging equipment space.

“Actually, about four years ago, it was an international client from those early days in that business who came to us with an endoscopy opportunity. We had become friends over the years, and it was great to connect again and work together,” McIntyre says.

“While endoscopy equipment was somewhat of a new category, many of the same principles apply,” he adds. “People want someone reliable when buying pre-owned equipment; someone who will provide quality solutions and follow through. Relationships matter to us, and good relationships require product quality and availability, and ongoing support. We work hard to build long-lasting partnerships around the world by growing our inventory, improving our quality processes and being consistent in communication.”

TechNation found out more about Collaborative Medical Solutions during a recent Q&A with McIntyre.

Q: WHAT ARE SOME ADVANTAGES THAT YOUR COMPANY HAS OVER THE COMPETITION?

MCINTYRE: Our global reach and experience in international sales and support has been a key to our success and will be the biggest part of our growth in future. Our team has served more than 30 countries around the world, and we’re proud that nearly all our clients are repeat customers.

Q: WHAT ARE SOME CHALLENGES THAT YOUR COMPANY FACED LAST YEAR?

MCINTYRE: It may sound absurd to say, but the slowdowns of the pandemic still influence our industry. Project

timelines for delivering new equipment to hospitals and outpatient facilities have been pushed out or otherwise interrupted, and that has effects everywhere in the endoscopy market, from service and repair lead-times to pre-owned equipment availability, and so on. By offering many different brands of endoscopy equipment – from Olympus, Fuji, Pentax, and many others – we’ve managed to maintain inventory levels and still offer great opportunities and solutions.

Everyone is still challenged to find staff to meet demand, and this industry is no different. We’re happy to have grown our team and be able to help find creative ways to work together.

Q: CAN YOU EXPLAIN YOUR COMPANY’S CORE COMPETENCIES AND UNIQUE SELLING POINTS?

MCINTYRE: We take a consultative approach with our clients, and really try to understand everyone’s unique needs and challenges. Our focus is on the best brands and technology that can help our global client base with the equipment they need for their practice. Previously owned scopes and towers can add a lot of value as part of an overall strategy to manage and upgrade endoscopy equipment.

The great partnerships and other relationships we’ve formed with organizations and people who share our values have been an incredible resource we can bring together to offer unique and powerful solutions.

Q: CAN YOU SHARE SOME COMPANY SUCCESS — ONE TIME THAT YOU “SAVED THE DAY” FOR A CUSTOMER?

MCINTYRE: Endoscopy asset managers deal with tight budgets and compressed timelines quite a lot in today’s health care industry. There was a facility that was struggling to find a solution to update their technology. We were able to lay out a strategy that showed exactly how they could get the technology they needed, including customizable warranty options, which was a significant concern. What made it all work was that we were able to give value for the much older scopes and equipment that they’ve been using – they were surprised to be

able to reduce their purchase price with what they considered “outdated” assets. Beyond that, it was important to them to keep their patient schedule intact while finalizing financing options. We were able to provide loaner scopes and processors so there were no interruptions at all.

It’s a common case, but another example we’re proud of. We received a request for older model scopes from a very small country that seems to struggle to purchase the endoscopy equipment they need from reputable providers. The commerce and logistics challenges often make people shy away, which can be understandable, but that’s where our international experience shows best. To be able to deliver quality scopes to them, at a price that makes sense for their budget, means a lot. Those are the customers who need support, and we know we’ll work together on the next opportunity when it comes, as well.

MCINTYRE: As part of our international growth, we’ve brought on Barney Greig to oversee sales, marketing, and sourcing in the European and other markets. Barney comes with a wealth of experience in used medical devices, crucial in such a specialized niche market,

where product and market knowledge is vital.

To understand its challenges, its nuances, its players and its often-underestimated value within the health care landscape has been incredibly helpful.

More importantly, he’s immediately shown that he shares our key values: always focused on long-term relationships, creating an excellent customer experience, and offering technical and customer support long after the point of sale. He is based in England, but loves to travel and meet with clients, vendors and partners in person from Germany to New Zealand where he was born and raised.

Q: CAN YOU DESCRIBE YOUR COMPANY’S FACILITY?

MCINTYRE: Our big news is that we’re opening a new U.S. headquarters this fall. We are in the later stages of the construction project, and the whole team is excited about what’s coming. It’s larger than our current space, and will better fit the growth we’ve seen, as well as our expansion plans for the future. We’ll almost double the QA/QC capability, carry more endoscopy inventory that’s ready to ship, plus give the new faces on our customer support and operations teams some elbow room.

For more infomation, visit cmsscopes.com.

LIVE:

SEPT 13 | Kontakt.io

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

SEPT 20 | Chronos Imaging

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

SEPT 27 | Phoenix Data

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

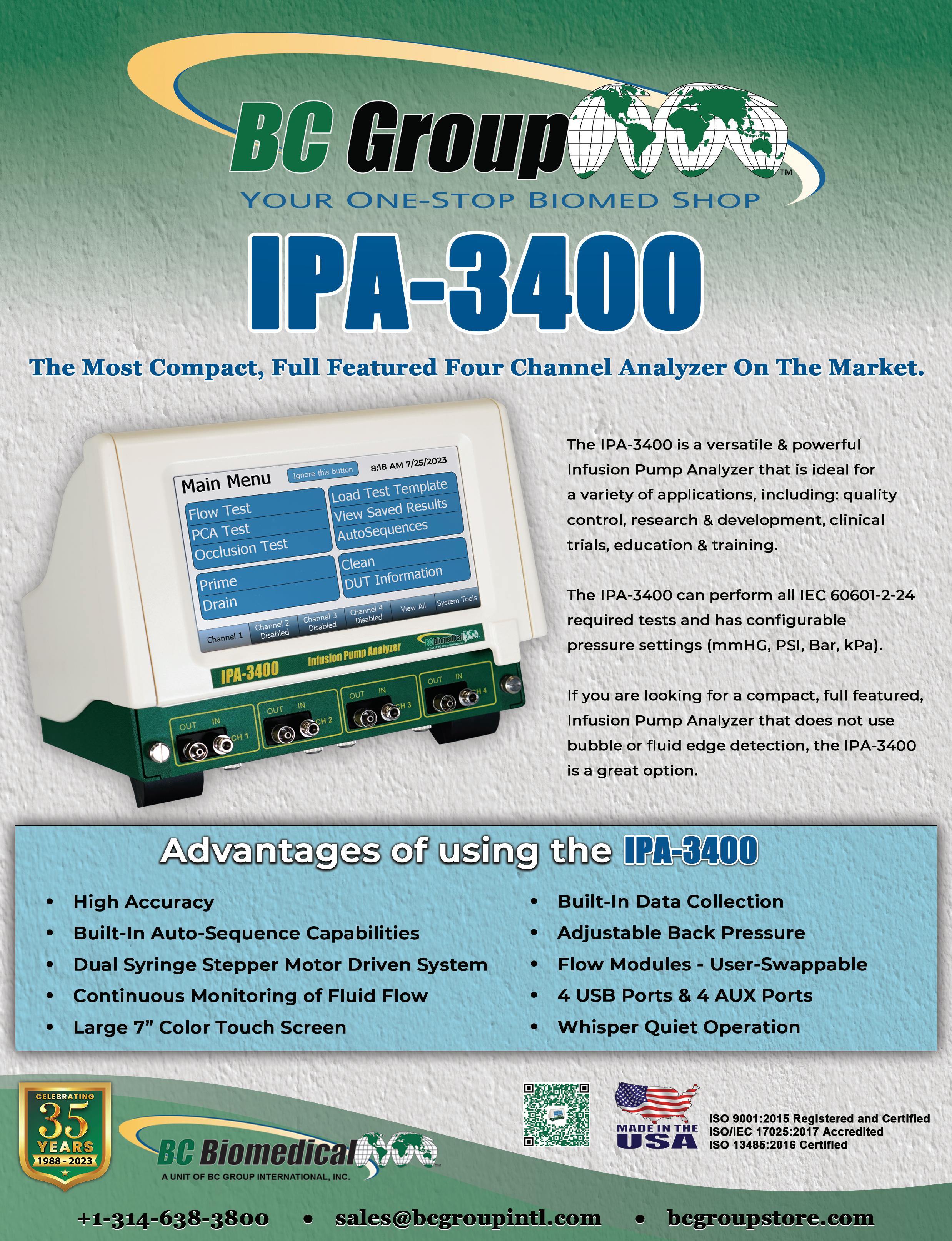

SEPT 28 | Tools of the Trade LIVE Demo with BC Group

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

ON-DEMAND:

sponsored by HTMJobs

“HTM Jobs: The Future of HTM Careers”

sponsored by BC Group “Infusion Pump Testing with the IPA-3100”

sponsored by Cynerio

“Generative AI: The Future of Healthcare Cybersecurity”

sponsored by Cynch!

“Solid Productivity Gains with Best of Breed CMMS and Asset Management Platform”

PODCASTS:

sponsored by Healthmark

“Fire in the OR! Why Checking Cords for Integrity & Continuity is Important”

sponsored by MMS

“Learning Marketable Skills as a Biomed”

All webinars, podcast, and product demos are eligible for 1 CE credit from the ACI.

The greater Houston area represents one of the largest population centers in the U.S. and the largest economic and cultural center in the South. The city’s port is the second largest in the U.S. Working in this vibrant area offers residents many avenues for employment and many bedroom communities to choose from.

One of the region’s health care providers is CHI St. Luke’s The Woodlands Hospital in Conroe, north of Houston. The hospital’s CE department has previously been spotlighted in TechNation

Broderick Richard is a Senior BMET in the clinical engineering department at The Woodlands.

Richard was already making a contribution to health care in another hospital system when he discovered biomed.

“Actually, I started off in EMS at Harris Health Systems LBJ Hospital and while transporting patients to and from Ben Taub I ran across a gentleman name Joe Boone. I asked him, ‘I always see you in scrubs but never see you with a patient. What do you do?’ He replied, ‘biomed.’ I was like, ‘what is that?’ So, the next morning while at LBJ before I started my shift, I started asking around about biomed and a co-worker offered to take me to the manager of biomed at LBJ; Coreaun

Jackson. Coreaun showed me the shop and we talked about biomed for almost an hour, and from that moment, I knew I wanted to change professions. I didn’t realize they would pay me to play with electronics all day,” Richard says.

To facilitate his new career, Richard obtained an associate degree in electronic engineering technology with a specialization in biomedical electronics from Houston Community College.

Since entering the field, Richard has been a Clinical Engineer I and Clinical Engineer II, before his 2023 promotion to Senior BMET.

His specialty area is anesthesia. He is manufacturer-trained by GE for the GE Carestation 600 Series, GE Avance CS2, GE Avance as well as Draeger Fabius GS Premium, GS/OS, Fabius Plus, Fabius Plus XL, Fabius Tiro and Fabius MRI. He has also received OEM training on Philips PIC IX System and Philips MX Monitors.

Richard says that any challenges he has experienced are simply the ones to be expected.

“Challenges in biomed, I feel, are pretty much the same for most biomeds; getting to the equipment once it is down. There are times you get called to repair a machine and you have no clue what it does. My go to question in this case is ‘Show me what you did?’ About 75 percent of the time, the machine works just fine and the error is fixed and then they say it’s only working because you are here,” Richard says.

Away from work, Richard spends time with his family or involved in high school football; a Texas tradition.

“On Friday nights during football season, you can catch me on the sidelines refereeing high school football,” he says.

He says that “Friday Night Lights” refers to high school football.

“I normally don’t attend games outside of the ones I’m working. Trying to get to college football. It’s a sport I love and played growing up. Once I had the opportunity to get back on the field, I jumped at it. Also, standing on the sidelines, I get a pretty good view of the game,” Richard says.

He says that he also likes to spend time “cheering my kiddos” as they participate in their prospective sports.

This biomed keeps the Texas tradition alive by not only cheering on his local high school football team but taking an active part in the sport as well.

FAVORITE FOOD: Snow crabs

HIDDEN TALENT: Refereeing

WHAT’S ON MY BENCH?

My trusty certifier and manometer. Most of my calls can be resolved with these items and my screwdriver.

My favorite part about being a biomed is the fact I can be the hero in the background without having to be in the limelight. The satisfaction of knowing just about every person that walks through my hospital door for treatment plays a role in getting them back to their family safe and ready to enjoy life. I always look at it like a music producer, everybody always knows the singer but the producer behind the song plays just as big of a part as the singer.

or fans of college sports, the team’s mascot is as well-known as any star player on the team. Real college sports fans can reel off a list of popular mascots. What is less known, is the amount of work and commitment these mascots make. The person, hidden below the costume, is as committed to the team and its success as any other team member. The person in the costume is also an athlete like the players in uniform.

During the 2023 graduation season, when most colleges and high schools were immersed in milestone days for thousands of students, one event may have stood out as extra unique and exciting for participants and sports fans.

At the 2023 University of South Carolina (USC) graduation ceremony participants were in for a big reveal as the student beneath the school’s beloved mascot “Cocky” costume would be unveiled for the first time. Sports is a big part of college life at the University of South Carolina. The Gamecocks compete in 21 varsity sports.

The student who was revealed at this year’s commencement ceremony just happened to be receiving her degree in biomedical engineering. But, before continuing her studies in the school’s master’s degree in biomedical engineering program, Sarah Sylvester surprised everyone at the graduation ceremony and created a viral video in the process.

Yet, after two years of donning the costume and thrilling college sports fans, what originally drew her to become a famous mascot?

“Believe it or not, I was never a mascot in the past, nor did I ever want to become a mascot. As cliche as it sounds, I just wanted to be ‘Cocky.’ I always knew I wanted to go to the University of South Carolina. My mother and sister are alumni and so I grew up visiting, exploring the campus, and going to football games. It was the only place I applied for college. My freshman year I went to every single event and sporting game possible. Oftentimes, I would find myself watching Cocky, in

love with his character, the way he interacted with others, and the joy and laughter he always brought to the environment,” Sylvester says.

She says that one day she told some close friends, “I am going to figure out how and I am going to do that one day.” The rest was history.

“I made the proper connections, auditioned and here we are. My pure passion and love for the character and university led me to the position,” she adds.

From ringing the opening bell on the New York Stock Exchange on College Colors Day to doing a nationwide televised interview with David Muir on ABC World News, Sylvester as Cocky or herself, has had some incredible experiences.

“Holding the position as Cocky has given me invaluable opportunities and the memories of a lifetime. Even the smallest experiences such as high-fiving or hugging a student when they might be having a tough day hold the biggest places in my heart. There were also many larger experiences that were proven to be once-in-a-lifetime opportunities. One of the most memorable experiences for me has been ‘coming out of the box’ in the middle of the football field at home football games. At USC, the pregame tradition for years has been for the song ‘2001: A Space Odyssey’ to play as ‘Cocky’s magic box’ is in the center of the football field, where at the big crescendo, the curtains drop to reveal Cocky jumping around, to then jump out of the box and down to the end zone to lead the entrance of the football team onto the field,” Sylvester says.

She says that the first time she got to lead this experience was absolutely magical and she wouldn’t trade it for the world.

“In addition to partaking in countless memorable experiences at home in Columbia, South Carolina, I also got to travel abroad to represent the university in countless ways as well. One of the most unique experiences was being invited to ring the opening bell on the floor of the New York Stock Exchange. In September of 2022, Cocky as well as a few other notable SEC mascots were invited to come to New York City. There, they wanted us to lead the ceremonious ringing of the opening bell to spark the beginning of the day in the New York Stock

Exchange to represent national College Colors Day. We got to stand up on the platform and ring that large famous bell. Afterwards, we got to sign the wall of celebrities that have gotten to do the same over the years,” she remembers.

Sylvester describes that experience as “absolutely surreal.” “Another experience that will always be one of my most treasured is competing and placing in my own national’s competition. Every year in Daytona, Florida, there is the NCA and NDA national’s competition where cheer and dance teams, and their mascots, compete for a national title. For mascots to compete, they have to receive a bid to go, either at camp or via submitting a video to audition. I did the latter and beat out several mascots for a chance to compete at nationals,” Sylvester says.

She says that mascots compete by creating a skit with a soundtrack and props, the theme of which is entirely up to the performer’s choice and perform it in front of judges and a large audience.

“They then only announce the ones who ‘place,’ which are the top five. Being that Cocky hadn’t placed in several years, and that I was creating the skit and props entirely by myself with the help of one close friend and my father, my goal that I had set for myself was to place, and that I did. Hearing my (or Cocky’s, rather) name called as a placer on that big stage fulfilled a goal of mine and re-established my knowledge that I can do anything I set my mind to. All of these experiences have proven nothing short of that,” Sylvester says.

Running parallel to all of the functions she fulfilled as Cocky, there was still the primary reason that Sylvester enrolled at USC. It was the reputation of the degree program

she participated in.

What led Sylvester to pursue a biomedical engineering degree and an interest in medical devices?

“Growing up I always knew I wanted to be in engineering. I always loved STEM, and math in particular, and excelled at it; although, I wasn’t always sure of which pathway I wanted to take with it. In high school, I became part of a volunteer program where I shadowed departments all over the local hospital, most notably the biomedical engineering department, the emergency room and the operating room,” she says.

Sylvester says that it was there that she learned of her passion for the medical field and how it operates as well.

“After some research, I discovered the field of biomedical engineering and specifically that I could take that pathway to focus on developing medical devices to further enhance the medical field. I knew that the University of South Carolina offered that program, and it was history from there,” she adds Because she was part of an accelerated master’s program during her senior year, her pursuit of a Master of Engineering degree in Biomedical Engineering at USC will only take her one year.

Future patients may never realize that they are benefiting from a medical device that in whole, or in part, was developed by an engineer who was once also a college mascot known to fans far and wide. That may be fitting, since for two years, USC fans had no idea who was underneath the costume of their beloved mascot Cocky. For Sylvester, either way, she has a lifetime of stories to tell.

For more photos, view this article online at 1TechNation.com.

ryant Hawkins Jr. was introduced to the world of healthcare technology management by his father and namesake Bryant Hawkins. His father is a successful HTM professional with 30 years of experience. Bryant Hawkins Jr. holds an associate degree in biomedical equipment technology and is currently a biomedical technician with AdventHealth Fish Memorial Hospital in Florida.

TechNation found out more about this Next Gen HTM pro via a recent question-and-answer session.

Q: WHERE DID YOU GROW UP?

A: I grew up in Slidell, Louisiana.

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: I received my college education at the College of Biomedical Equipment Technology and before starting in the field I also did an internship and AdventHealth Palm Coast.

Q: WHY DID YOU CHOOSE TO GET INTO THIS FIELD?

A: My father was the one who introduced me into this field. I was unsure what I wanted to pursue when I was finishing my tenure in high school. He told me that I should go into this field as he felt like it would be something I would enjoy and that even if I did not enjoy it I could use it to fund my education. Fortunately for me, I greatly enjoy this field.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: I enjoy the fact that I help people by doing my job correctly. It is a very fulfilling feeling.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: All the different kinds of medical equipment there are. Before starting, I never realized how ignorant I

was to just how many kinds of machines there are to help save people’s lives.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: My greatest accomplishment has to be seeing how far I’ve grown intellectually in the field from when I started to now. In the beginning, my knowledge was minimum on the workings on the equipment and hospital environment, but now I can say I feel quite comfortable navigating myself through issues. Whether it’s a call from the OR or having to troubleshoot with the telemetry system, I always find myself being able to find a solution to the problems.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: One goal I have for myself in the next 5 years is to advance to Tech 2 status and go to some training sessions.

FAVORITE HOBBY: Piano and photography

FAVORITE SHOW OR MOVIE: “That ‘70s Show”

FAVORITE MEAL: Pizza

WHAT WOULD YOUR SUPERPOWER BE? Flight

1 THING ON YOUR BUCKET LIST: Travel to a different continent.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU: I can play 5 musical instruments.

The Insulation tester, Leak Tester Tester and Cable Continuity Tester are easy-to-use devices for verifying the functionality of equipment for safety

Detect & locate defects such as pinholes, cracks and bare spots in the jacket or coating of laparoscopic and bi-polar electrosurgical instruments

Test the functionality of automated & handheld endoscope leakage testers with healthmark’s new Leak Tester Tester.

Test the quality of monopolar and bipolar cords with this user-friendly, durable device. A green light notifies the user that the cable passed testing.

For more of Healthmark’s intelligent solutions for instrument care and infection control, visit HMARK.COM

TechNation delivers a new video series that empowers healthcare technology management (HTM) professionals. The series highlights the tools that biomeds can use to do their jobs more efficiently.

The video series builds on the longstanding and popular “Tools of the Trade” magazine feature. The series will have live broadcast and on-demand recordings, similar to the current Webinar Wednesday series. Viewing live broadcast will be eligible for 1 CE credit from the ACI.

The Philips MX40 IntelliVue was featured as the Tool of the Trade in the May issue of TechNation. In the inaugural broadcast, Glenn Schneider, MHSA, chief service officer of Elite Biomedical Solutions, provided a live demo on the Philips MX40 IntelliVue.

The next installment of the Tools of the Trade video series brought over 40 registrations and featured Voytek Medical’s Bear Trap and URSA product lines.

“This will save so much money on equipment leads and keep the inventory up,” attendee Douglas Booth, BMET III, Southern NH Medical Center, shared after the live presentation. July brought another broadcast for this series, featuring

J.C. Newell of NRC LLC. Newell discussed candidate services provided by her company, also featured as the Tool of the Trade in the July issue of TechNation.

Details for upcoming Tools of the Trade broadcasts can be found on WebinarWednesday.live. Each month a new tool will be featured in print and with a live demo.

For more information, scan the QR code below:

In its continued effort to promote and applaud the men and women of healthcare technology management (HTM), TechNation magazine introduces the Tech Choice Awards also known as the Wrenchies!

The award categories are:

• Professional of the Year

• Department of the Year

• YP of the Year

• ISO Employee of the Year

• Director/Manager of the Year

• Lifetime Achievement Award

• Military BMET of the Year

• Humanitarian Award

• Women in Leadership Award

• Ingenuity Award

• Outstanding Vendor of the Year

• Association of the Year

• Industry Influencer of the Year

The inaugural awards will be announced in the March 2024 issue of TechNation. Nominations are being accepted in a variety of categories through November 3, 2023. Up to 13 Wrenchies will be awarded with the winners selected based 100% on votes from those who make up the HTM industry.

The top nominations for each category will be highlighted in the January 2024 issue of TechNation with voting allowed until January 12, 2024. Winners will be announced in the March issue of TechNation and highlighted in a special digital supplement.

Nominations are open online at 1technation.com/ tech-choice-awards.

MD Expo, the signature healthcare technology management (HTM) conference hosted by MD Publishing, returns to the Sunshine State this fall. Registration is now open for the October 29-31 conference and is FREE for hospital employees, students and active military members.

MD Expo strives to provide HTM professionals with a unique, intimate and rewarding conference second to none. Clinical engineers, biomedical technicians, directors and managers, procurement/asset managers and others responsible for medical technology will gather in a one-of-a-kind warm and welcoming environment to network with peers, learn the latest technologies and advances in HTM. Find out what everyone has been talking about; this is one event you can’t afford to miss!

MD Expo features:

• Industry-leading speakers covering the hottest topics in HTM, compliance, IT, cybersecurity, management and equipment service

• Certified education approved for 36 CEU credits

• The industry’s most unique networking events to connect and share best practices with other leading HTM professionals

• World-class exhibit hall with the latest technology, products and services

Several of the top-flight presenters recently took some time to share more about their presentations and MD Expo.

University of Chicago Medical Center System Director of Clinical Engineering Shawn Molloy will present the session “Developing a Family Out of a Team – Know your role and your place” at the MD Expo. He described it as “a playful and inspirational dive into developing a strong family-like environment in your CE department through understanding your role and everyone else around you.”

He described MD Expo as an out-of-this-world event.

“MD Expo is an essential experience to reinforce the support structure and backbone of our career field. It gives you the true visibility of the scope of our career field. I compare it to when astronauts see the Earth for the first time and their feeling of one humanity. That is the same feeling I get when I attend the MD Expo and it revitalizes my engagement in the field,” Molloy said.

“I am always humbled by seeing and conversing with my HTM heroes and also speaking with the new blood to the organization and seeing the ideas and new life they bring to the HTM community,” he added. “I love to see our leaders and communicators sharing their love, experience and knowledge with the HTM community.”

Children’s Health (Dallas) Healthcare Technology Management Senior Director Andrea Brainard, CBET, CHTM, is slated to host a panel discussion on women in HTM.

“This will be a questions-and-answers forum with questions garnered from LinkedIn, past presentations and audience questions,” she explained. “My panelists include women that are in various disciplines within HTM. We get down to the nitty gritty of being a woman in HTM in hopes to not only get more women into HTM, but to allow everyone to share in our experiences and knowledge.”

When asked what attendees can expect at MD Expo, Brainard spoke from experience having attended several in recent years.

“Attendees can expect a vast array of educational opportunities, seminars, panel discussion and product demos in the exhibit hall. There are also great networking opportunities to meet both vendors and HTM colleagues in the industry,” she shared. “MD Expo is great way to collaborate with other HTM colleagues, make new connections, learn a lot of new stuff and have some fun doing all it.”

Intermountain Health’s Director of Field Service for the HTM Department Mike Powers, MBA, AAMIF, CHTM, CDP, will present on the Health Sector Coordinating Council’s (an advisory group to HHS for Cybersecurity) “Health Industry Cybersecurity – Managing Legacy Technology Security (HIC-MaLTS)” document. After three years of efforts this 117-page document helps organizations have concrete guidance to deal with technologies that have aged to the point that the risk posed by their software cannot be reasonably mitigated.

He said, “An MD Expo is a trade show/educational seminar series opportunity to learn from industry experts, meet new vendors for unique solutions to operational challenges and catch up with friends and colleagues in the field.”

Milwaukee School of Engineering Adjunct Professor in Electrical Engineering and Computer Science

Larry Fennigkoh, Ph.D., PE, is another veteran MD Expo presenter who will share his knowledge in Orlando.

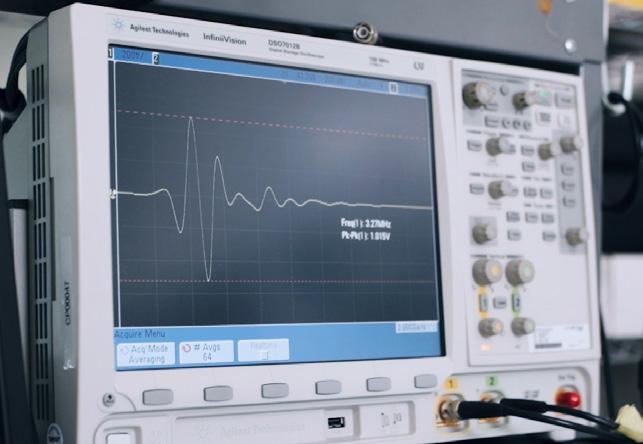

He shared that his presentation will benefit anyone involved in the support and maintenance of physiological monitors, electrocardiographs, heart-lung machines or intra-aortic balloon pumps.

For anyone thinking about attending MD Expo Orlando, Fennigkoh said to find a way.

“Stop just considering attending but start planning to attend now. Beg, plead, or negotiate with your employer to let and help you attend – even paying some or all the costs needed to do so. These conferences remain some of the absolute best value-added and most needed PM that you can give yourself,” he said. “One of the reasons so many others start to lose the passion, excitement, and fun for a job that they once loved, is because they didn’t nurture, regularly feed, and take care of their career-related bodies. Attending the upcoming MD Expo may be just the professional and personal health spa experience that you need.”

The elite members of the HTM community will be on hand for the education, exhibit hall and networking events including the Boos & Brews Halloween Party.

Attendees won’t want to miss the finale event with the MD Expo Halloween Costume Contest. Ghosts and goblins beware, the staff boasts some scary good prizes that will be awarded for the best costumes. With great music, food and a signature cocktail it would be ghoulish to miss this party!

Register today at MDExpoShow.com.

FSI Services has partnered with health care management professional, Theodore Pappas, to help health care systems re-evaluate their space management approach from a cost-savings and software perspective.

“Space is the largest, most valuable asset within a health care organization,” said Pappas, healthcare facility information specialist, of FSI. “All departments are impacted, from design and construction, finance, compliance and safety, real estate, and property management. Within those teams, I see space managed at a very basic level within hospitals. What they need is the right tools to make educated, cost-effective decisions before jumping to – let’s build, expand, buy.”

In the past, hospitals relied on a physical pen and paper process – large scale paper plots in tubes, binders, disks with files. The industry has since evolved, with several cloud-based solutions that allow technicians to access information on their phone, tablet or computer – regardless of their location.

“Ted’s experience was exactly what we needed to elevate our space management product – CMS Space Manager – in the market,” explained Chris Lang, director of strategic business development at FSI. “We’re hearing more from customers and at industry events that hospital staff are expected to do more with less. Taking advantage of a comprehensive tool that reduces manual tasks and saves money is how teams solve for this expectation.”

With Space Manager, benefits include:

• Reduce overspend on materials: Users can import polylined CAD drawings and instantly calculate square

footage to help accurately estimate remodeling costs.

• 100% regulatory reimbursement: Easily maintain accurate rooms, floors, and utilization square footage calculations to ensure 100% Medicare and Medicaid reimbursement.

• Eliminate manual square footage calculations: With a few mouse clicks, calculate square feet.

• Maintain a centralized database with every building’s CAD drawings in one place.

Vizzia Technologies has announced new technology partnerships to expand its portfolio of digital solutions for smart, connected hospitals.

“Vizzia is proud to collaborate with these world-class technology leaders,” said Dave Wiedman, chief commercial officer of Vizzia Technologies. “We are committed to delivering innovative solutions that improve healthcare efficiency and patient care.”

The new technology partners are:

• Zebra Technologies offers health care-grade hardware solutions that are used by 14 of the top 20 hospitals on the U.S. News & World Report 2022-2023 “Best Hospitals” honor roll. Vizzia has joined the Zebra PartnerConnect program and added its Bluetooth Low Energy (BLE) devices.

• ElectrifAi is a global leader in machine learning (ML) and artificial intelligence (AI) and its Inventory Optimization module generates predictive PAR levels of critical

hospital equipment. Vizzia has piloted ElectrifAi at a 500-bed hospital, which yielded a 52% improvement in key metrics.

• Sonicu is an IoT provider of critical environmental monitoring solutions, trusted by more than 500 health care customers in all 50 states to meet CDC and Joint Commission compliance. Vizzia has verified the Sonicu technology at the Vizzia IoT Lab onsite at the University of New Mexico.

• HCI provides digital patient engagement solutions to transform the patient experience and streamline caregiver workflows for more than 900 hospitals and 1,500 clinics in all 50 states. Vizzia clients have requested integration with patient communication systems to include Digital Whiteboards.

Meet Vizzia executives and partners at HIMSS Georgia annual conference in Atlanta (Oct. 3) and MD Expo Fall conference in Orlando (Oct. 29-30).

Radiological Service Training Institute (RSTI) recently celebrated a record-breaking enrollment milestone! It is said that a picture is worth a thousand words and the video crew, photographers and drone footage captured that and more.

Surpassing enrollment numbers since their doors opened almost 40 years ago, was a special moment to capture

“We appreciate the opportunity to support the training needs of the imaging service industry,” RSTI CEO Todd

Boyland, CRES, CPSM, said. “It was equally as fun getting to share this with the RSTI team and the group of students in classes that week too.”

Since 1985, RSTI has provided diagnostic imaging training. Offering a wide selection of over 60 courses each year, RSTI has trained more than 15,000 service professionals from over 50 countries in radiology, mammography, MR, CT, ultrasound, networking, PACS and DICOM.

626 recently acquired Custom X-Ray Services in Arizona, according to a press release.

“We are ecstatic to welcome Custom X-Ray to the 626 family,” shared Philip Revien, chief executive officer of 626. “Our longstanding strategy of acquiring respected, founder-run brands that are family-oriented, profitable, growth-oriented companies in markets where 626 needs deeper FSE coverage and deeper-rooted customer relationships has always served us well.”

“We endeavored to strengthen our presence in Arizona; and see Custom X-Ray as the perfect fit to immediately improve our service delivery to 626’s and Custom X-Ray’s current and future customers,” he added.

Established in 1968, Custom X-Ray is a veteran- and woman-owned legacy business that provides depend -

able, knowledgeable and dedicated customer service. Custom X-Ray offers a variety of analog and digital medical imaging technologies to its customers and represents the leading manufacturers of medical imaging systems.

“My parents founded this company to provide the highest quality products and services,” shared Shawna Wiertzema, chief operating officer for Custom X-Ray.

“We firmly believe that service, not the product, should be considered the most important factor when selecting an imaging equipment sales and service company to handle critical applications and project planning. Both the team behind the service and our focus on the customer have enabled Custom X-Ray’s sustained growth and lasting customer relationships,” she added.

Rigel Medical has invested further in the expansion and growth of its U.S. operations with a senior appointment.

Lewis Lennard has joined the U.S. operation in Tampa, Florida, as a product manager. Bringing eight years’ experience to the role, he will be responsible for managing the medical product portfolio and supporting brand sales across North America.

He will also be involved in analyzing market trends and identifying opportunities to support new business development as well as monitoring and reporting on market behaviors and trends to inform strategic planning and marketing.

The move by Lennard, who was previously an application engineer with Rigel Medical based in the United Kingdom, comes at a time when the market for electrical safety test products in North America continues to show huge potential for growth, according to a news release.

“Rigel Medical is fast building a reputation and presence in the industry at a time when the market is rapidly growing,” Lennard said. “I look forward to working alongside a team focused on providing high-quality products, unsurpassed customer service and innovation that adapts and expands to meet market standards.”

Seaward is part of Metrawatt’s GMC Instrumentation Group, a collaboration of separate specialist test equipment manufacturing businesses based in Germany, Switzerland and the USA.

“I very much look forward to working with Lewis as we continue to strengthen our U.S. team. He has excelled throughout his time in Seaward, going above and beyond in many areas,” Sean Daley, vice president and chief operating officer at Seaward USA, said. “The growth opportunities in the North American marketplace align with his ambition and will add further success to Rigel Medical’s growth in the territory.”

Getinge has announced clearance from the U.S. FDA for Servo-air Lite, a wall gas independent non-invasive mechanical ventilator.

“We are happy to broaden our ventilator product offering for the U.S. market,” says Elin Frostehav, president acute care therapies at Getinge. “This significantly increases our addressable ventilation market in the U.S., by now being able to target the non-invasive hospital segment with our ventilation offering.”

Servo-air Lite is Getinge’s turbine-driven ventilator for

non-invasive ventilation. Like all Servo ventilators, it offers ICU-quality ventilation but is more geared towards spontaneously breathing patients in need of extra breathing support. With its powerful turbine and long-lasting battery backup power, it can also be operated independent of wall gas and is suitable for intrahospital transports. It features embedded workflows, support for high flow therapy, CO2 monitoring option and tools to support escalation of therapy if needed.

The product is expected to be available for customers in the U.S. from this month.

• REPAIR AND PM SERVICE

• HIGHLY TRAINED AND CERTIFIED TECHNICIANS

• OEM NEW AND RECERTIFIED PARTS

• QUICK TURNAROUND TIMES

• COMPREHENSIVE PARTS AND LABOR WARRANTY

MAKE CARDIOTRONIX YOUR NEXT SERVICE CALL (855)-4DEFIBS IF IT’S MEDICAL EQUIPMENT RELATED, WE HAVE YOUR SOLUTION!

CARDIOTRONIXHEALTH.COM

Located in Orange County, California, Medical Equipment Doctor (MED) specializes in the sale, purchase, rental, and repair of refurbished medical devices and instruments. In 2017, industry veteran and the Doctor himself, Albert Negron, set out on his own to start a company in his garage with nothing but one plastic folding table, two Home Depot orange buckets, and 10 years of medical device sales experience. He made a logo, applied his expertise and with that, Operation: MED was underway.

Today, gone are the times wherein going to work involves pressing a clicker to reveal orange buckets hiding behind a garage door. In fact, the company augmented in a second unit within its HQ building in Tustin, California, earlier this year.

The most exciting facet of MED’s expansion is an in-house endoscope and ultrasound probes repair depot, which celebrated its launch in April 2023. At the hands of industry-renowned technicians, several with notably over 20 years of repair experience, Medical Equipment Doctor will sell and repair both large and small scopes, not to forget your rigid models as well.

In all domestic hospitals, GI labs, and surgery centers alike, MED knows how vital functioning endoscopes are to not only facilities’ revenue, but to their patients moreover. Because of this, they are dedicated to making sure when equipment, you don’t have to miss a step. When you send in for a repair, Medical Equipment Doctor provides you with an interim loaner device, offering same-day delivery or next-day shipping for centers outside of the local region.

In conjunction with its competitive pricing, MED’s endoscope repair depot offers free evaluations and some of the quickest return times in the industry. Above all, they do everything they can to ensure you don’t have to halt any procedures at the hands of broken equipment.

In the five short years since setting up shop, Albert has instituted an eminent company founded on a basis that centralizes culture, growth and community. MED’s holistic scope of service, from rental to repair, is dedicated to helping hospitals and surgery centers sustain and fulfill their working needs. With the Doctor’s help, clinicians are able to stay fully equipped so they can continue to provide the best patient care possible.

“Our focus at Medical Equipment Doctor is to partner with you to keep your budget and costs in check through providing top-level pre-owned equipment sales, service and rental, for all your medical equipment needs. This has our company being recognized nationally as the affordable solution to purchasing new. Over the years we have had the good fortune to get to know many of you in the health care and medical equipment industry,” Albert said. “It has been a true pleasure. “

“The name of our company came from people referring to us at trade shows and gatherings as their; ‘Medical Equipment Doctor’ so we carried it forward into our name and brand,” he added. “We are passionate about what we do and always keep the safety and comfort of the patients that use our equipment at the forefront of every step we take and the care with which we approach it. Let’s connect and discuss your needs and how we can partner up with you on all your medical equipment needs.”

Included in the different kinds of equipment MED services are:

• Patient monitoring

• Infusion pumps

• Surgical equipment

• Respiratory equipment

• Cables

• Imaging equipment

As we approach the back half of the year, Medical Equipment Doctor is excited to announce that the company is currently on track to have its ISO 13485 certification by the end of 2023. Each month, the MED team members continue to surpass their goals and reach new heights. The aim remains to serve the community to the highest of their ability. One thing that sets them apart from all of the others is their dedication to customer service. All salesmen, technicians, and everything in between are all under the same roof, working tirelessly to ensure the best quality and the quickest turnaround times possible for biomedical equipment.

Above all, Medical Equipment Doctor cares. Though not working directly with the patients themselves, the main driver in being motivated for success is the role they get to play in helping people. Healthcare takes a village, and from the mouth of the Doctor and former Home-Depot-bucket-in-garage owner himself, “You take care of the patient, we’ll take care of the equipment!”

CRAIG HARMON PRINCIPAL/FOUNDER

CRAIG HARMON PRINCIPAL/FOUNDER

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Products: New and ReCertified Defibrillators and AED’s, Ventilators, CPR assist devices, and IV Therapy devices

Services: Single-Source bundled services, On-Site Maintenance, Equipment “refresh” programs, service all brands, legacy equipment supported

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Without a doubt, it is our commitment to customer service deliverables. We are not a break/fix organization, we are a relationship driven company. We create cost effective solutions that deliver long term financial results.

For more information, visit cardiotronixhealth.com.

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

We are a global provider of pre-owned endoscopy equipment focused on Olympus, Fuji, and Pentax scopes and towers, as well as Stryker and Karl Storz. By working together, we can help find value in your excess equipment or older technology as part of an overall upgrade strategy.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

We take a collaborative approach with the goal of long-term relationships by offering quality equipment and creative solutions, beyond the usual buy-sell model.

For more information, visit cmsscopes.com.

Any builder can attest to the fact that a strong foundation is needed for a sturdy house. Neglect the groundwork, and the walls and roof will never hold. Everything is bound to come tumbling down. For the members of the AAMI Medical Device Security Working Group, some form of this maxim must have been top of mind. The group recently developed a new standard on security risk management for device manufacturers – ANSI/AAMI SW96 – building it on the cement and steel already laid down by two technical information reports (TIRs) on the same subject.

ANSI/AAMI SW96:2023, Standard for medical device security—Security risk management for device manufacturers, is the first consensus standard to provide specific requirements for managing security across a product’s entire life cycle. The document, released earlier this year, is based on guidance previously published in AAMI’s TIR57:2016 and TIR97:2019.

• AAMI TIR57:2016/(R)2023; Principles for medical device security—Risk management, is primarily focused on addressing security risk during product design.

• AAMI TIR97:2019/(R)2023; Principles for medical device security—Postmarket risk management for device manufacturers, offers guidance related to managing security risk during and after product production.

The two TIRs are meant to be used together and within the risk management framework defined by the

International Organization for Standardization’s global standard, ISO 14971:2019.

The publication of ANSI/AAMI SW96:2023 comes at a time when managing medical device security risks is becoming more difficult by the day. A study from 2022 in The Journal of the American Medical Association found that ransomware attacks against health care organizations more than doubled between 2016 and 2021, for example. And a 2023 cybersecurity report by the U.S. Department of Health and Human Service’s Office of Information Security noted that health care data breaches “have consistently trended upward” over the past decade. Cybercriminals, the HHS reports, “are continuously seeking to make their attacks more resilient, more disruptive and harder to counter.”

The issue of cybersecurity has become so critical that the 2023 “omnibus” bill signed into law by President Joe Biden includes a section on “Ensuring Cybersecurity of Medical Devices” that amends product submission requirements spelled out in the Federal Food, Drug and Cosmetic Act. Responding to the amendment this March, the FDA published new guidance on medical device security that advises manufacturers to submit “a plan to monitor, identify and address … postmarket cybersecurity vulnerabilities and exploits” and to “design, develop and maintain processes and procedures to provide a reasonable assurance that the device and related systems are cybersecure.”

While SW96 was developed before the FDA guidance came out, the standard provides device manufacturers with a roadmap to comply with its recommendations. Postmarket monitoring of device vulnerabilities and exploits, for example, is among the topics addressed in SW96, as are important cybersecurity measures like patching and creating a software bill of materials (SBOM).

In a summary of the standard and its implications

written by four industry leaders who played major roles in its development (Charles S. Farlow, et al., Biomedical Instrumentation & Technology), the authors say SW96 strengthens security risk management by focusing on several “elements” that are key to the risk management process. Summarizing the group’s research, Charles Farlow stated, “SW96 advances the state of the art and provides a set of well-documented requirements for security risk management.” One section of the standard, for example, is all about security risk analysis, while another covers the evaluation of “overall security residual risk acceptability.” Under “General Requirements for Security Risk Management,” it explains what manufacturers need to include in their security risk management plans. And within clause 10, “Production and Post-production Activities,” it specifies that device makers must establish “a process for identifying and managing security incidents.”

The authors of the BI&T analysis also point to the

standard’s supporting annexes and explain how they were developed to expand on topics “of particular interest to practitioners in the security risk management field.” The annexes include detailed information on everything from working with third-party service organizations to best practices in threat modeling.

The BI&T authors note that TIR57 and TIR97 “have been widely successful” as resources for industry stakeholders, but that TIRs are limited by the simple fact of their status as TIRs rather than standards. These guidance documents are reviews of technical issues and statements of expert opinion, but because they are TIRs, they do not include any requirements that medical device manufacturers must follow.

Now, with ANSI/AAMI SW96:2023, device makers have a playbook they can use to stay ahead of existing and emerging cyberthreats while adhering to federal guidance on the subject. For years, manufacturers had their foundation, but now they finally have a house built to last.

Founder and CEO Matthew Bassuk explains that his company’s name “NVRT Labs” is pronounced “Invert Labs.” It is a company on the cutting-edge of virtual reality training for healthcare technology management (HTM) professionals.

TechNation found out more about the company in a recent question-and-answer session with Bassuk.

Q: WHAT ARE SOME OF THE SERVICES AND PRODUCTS YOU OFFER? IS THERE A SPECIFIC OR NEW ONE YOU ARE EXCITED ABOUT RIGHT NOW?

BASSUK : We just launched our VR training platform for HTM professionals as of July. We couldn’t be more excited to be the first and only extended reality company to bring virtual reality training to our industry. At a time when technicians everywhere are being required to have more and more skill sets yet training budgets are constantly being tightened, we are thrilled to be offering a truly innovative solution to close the skill gap and save organizations training dollars. Our platform launched with an already amazing library of procedural modules, and we are continuing to add more and more BMET content monthly on everything from defibrillators and fluid warmers to imaging and ultrasound, etc.

Q: HOW DOES YOUR COMPANY STAND OUT?

BASSUK : I think NVRT Labs is starting to be noticed in the industry for the focus we have on future technologies in the HTM space. Truthfully, we are the ones who are doing the really cool and cutting-edge

development that this industry has been craving for years. Whether it’s our VR training content, our AR design services, or the AI projects we are working on, we think about technology from an HTM industry perspective first and that should stand out. I think applying emerging technologies specifically to the medical device repair space is filling a void that’s been open for too long. Hopefully that continues to turn some heads.

BASSUK : In the short-term we are continuing to ramp up our platform adoption and add content as fast as physically possible. Our internal goal is to get a VR headset to every BMET student and into every biomed shop in the country. Thinking about the future, I envision that we leave no stone unturned with regards to technology driven products. We want NVRT Labs to be synonymous not only with extended realities and VR training but with anything related to paradigm-shifting technology in the HTM space.

BASSUK : I am beyond excited for us to be launching our journey in the TechNation community. We have been part of this audience for a long time, attending all the MD Expos and events, and working with amazing organizations and professionals who are also a part of this community. I primarily want the readers to know that we are a resource that is cut from the same cloth. Should anyone in this space have a technology idea or need, our lines are always open for collaborations and partnerships.

For more information, visit nvrtlabs.com and check out the content library.

Amid increasing electricity prices and increased emphasis on sustainability, health care organizations are looking for ways to reduce their energy consumption. Medical imaging departments are among the larger energy consumers in health care, so substantially reducing power consumption in these areas could result in considerable cost savings.

Health care organizations are large consumers of energy, making them particularly vulnerable to energy supply shortages and price increases, as experienced in recent years. In addition to affecting the financial health of the institution, high energy usage also has a societal impact, making it harder for organizations or communities to meet carbon neutrality goals. Facilities therefore have clear incentives to scrutinize their electricity usage.

“Historically, hospitals have focused on patient care and high-quality service regardless of the energy toll,” notes Francisco Rodriguez-Campos, MSc, Ph.D., MRSO (MRSC), a principal project officer in ECRI’s Device Evaluation group. “But today, we’re seeing interest in finding ways to reduce energy use without compromising care. The imaging suite is a good place to start.”

A common target for energy-saving improvements is one of the bigger consumers of electricity within a health care facility: the imaging suite. CT and MR imaging scanners in particular require a great deal of electricity.

In addition to the energy demand during scans, a large amount of energy is required to keep these systems cool, even when they are not in active use.

“The climatization requirements of the devices in the imaging suite are a key driver for high energy use,” explains Rodriguez-Campos.

Most imaging systems have dedicated water cooling systems that run independently of the institution’s climate control, while some now use air cooling systems that use the air in the imaging suite for cooling, placing demand on the facility’s heating, ventilating and air conditioning (HVAC) systems.

To help organizations save money and work toward sustainability goals, ECRI summarizes below research showing the amount of energy used by different imaging systems, then offers tips for reducing energy consumption.

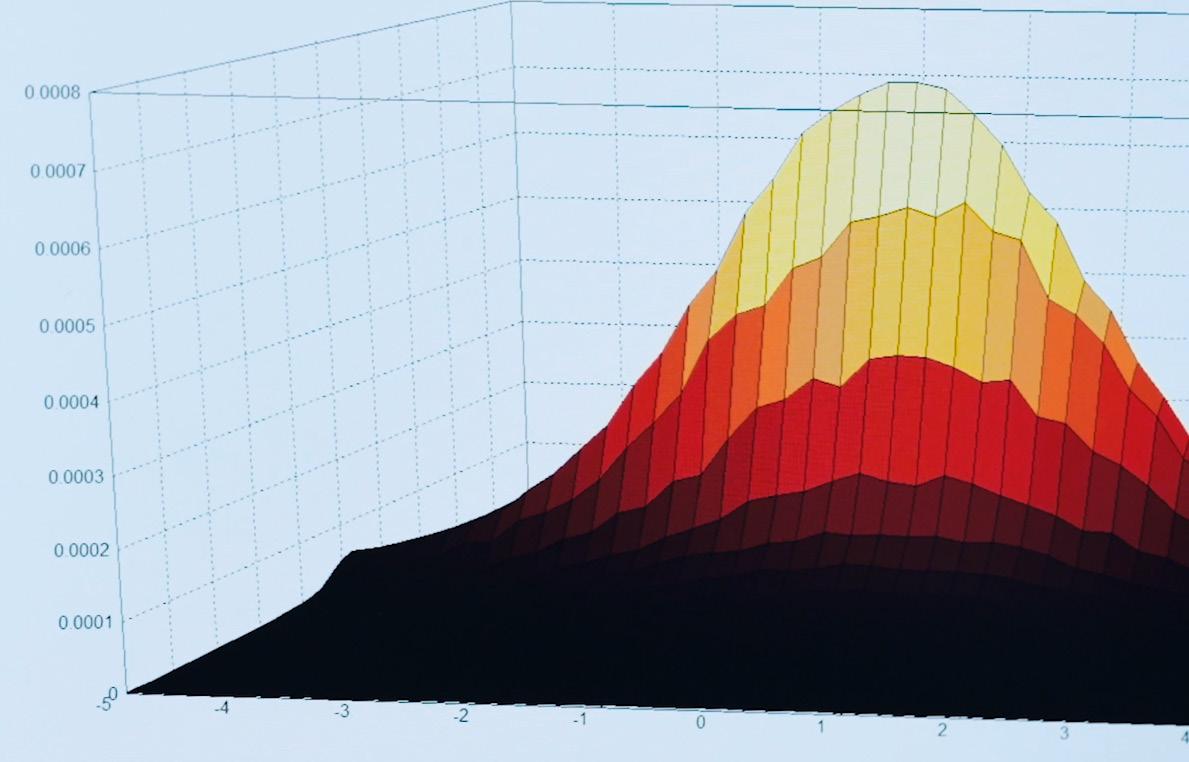

In a 2015 study, researchers directly monitored the energy usage of three CT scanners, four MR scanners, and their cooling systems at a health care facility in Switzerland for one year (Heye et al. 2020). The total energy consumption of the imaging and cooling systems represented 4% of the facility’s total yearly consumption. Of the energy used for these systems, 44% was to power cooling systems and 56% was for patient imaging exams.

The three CT scanners used 78,679 kWh over the course of the year. Energy usage was broken down into categories based on periods of use: (1) Active periods (includes patient preparation, planning, net scan and reconstruction time): 23,797 kWh. The net scan portion (actual patient scan time during which energy consumption increases) was 10,741 kWh. And (2) Idle periods (time between patients): 42,867 kWh (about four times the amount of power used for scanning patients). During the remaining time, the scanners were off,

though ancillary systems continued to consume power.

The four MR scanners – one 3.0-tesla (T) system and three 1.5 T systems – used 467,348 kWh in one year, including 265,334 kWh for active periods and 36,268 kWh for idle periods. In addition, more than a third of the power consumption of the MR scanners was during the off state. Unlike CT scanners, which aren’t associated with significant amounts of energy use when shut down, MR scanners require constant magnet cooling even when the system is off. For CT scanners, nearly two-thirds of electricity was used during idle time, which includes the demand of adjunct cooling systems, and only one-third of power consumption was used during actual imaging exams.

Note that the scanners in this 2015 study did not have certain power-saving technology that is more widely available today. For example, today’s users can take advantage of newer off/standby states that reduce the use of electricity. Also, new technology is downsizing the magnet cooling systems in MR scanners to help reduce electricity usage. MR scanners’ use of electricity is largely driven by the helium cooling heads. Plus, there’s room for new developments. Rodriguez-Campos notes that “novel device designs could be devised to, for example, generate

electricity from the moving parts within an imaging device, like the internal tube and detector that keep spinning after a CT scanner exposure.”

Heye T, Knoerl R, Wehrle T, et al. The energy consumption of radiology: energy- and cost-saving opportunities for CT and MRI operation. Radiology. 2020;295(3):593-605. doi:10.1148/radiol.2020192084

Furlan L, Di Francesco P, Tobaldini E, et al. The environmental cost of unwarranted variation in the use of magnetic resonance imaging and computed tomography scans. Eur J Intern Med. 2023;111:47-53. doi:10.1016/j.ejim.2023.01.016

COCIR. COCIR Self-Regulatory Initiative for the Ecodesign of Medical Equipment. Status Report 2018. COCIR European Coordination Committee of Radiological, Electromedical and Healthcare IT Industry. COCIR Self-Regulatory Initiative for the Ecodesign of Medical Equipment Steering Committee; June 2018. Accessed May 23, 2023. https://www.cocir.org/ fileadmin/6_Initiatives_SRI/SRI_Status_Report/ COCIR_SRI_Status_Report_2018_-_June_2019.pdf

1. For CT scanners, use optimized schedulers (orchestrators) to maximize time spent performing exams and minimize idle periods.

2. For MR scanners, explore the possibility of using waste heat recovery methods that recycle the heat produced by the system rather than spending additional energy to neutralize the excess heat.

3. Explore the implementation of a smart cooling system that uses a scanner’s status to adjust the operation of adjunct cooling capabilities.

4. Use a modular configuration for cooling systems that allows scalability of ancillary systems instead of each newly installed scanner requiring its own system.

5. During the procurement process, request information from the vendor regarding the energy consumed during scanning as well as during the idle and system-off states.

6. Replace outdated HVAC systems in the imaging suite with more efficient equipment.

7. Monitor energy usage with energy management solutions that can provide granular, real-time information about energy usage. Some applications can give real-time consumption by specific areas of the hospital.

8. Ask vendors to modify the scanner’s defaults and other parameters to minimize energy use in idle and system-off states, which is something only manufacturers can do.

9. Ask vendors if they take any measures to reduce greenhouse gas (GHG) emissions and if they are implementing features in their equipment to help facilities achieve their GHG goals. A study by Furlan et al. published in February 2023 found that the use of CT and MR is a major contributor to GHG emissions.

10. Avoid refurbished devices, which are older and therefore may not have the highest energy efficiency; about 5% of medical imaging devices sold in 2016 were refurbished. There has been a reduction of about 20% in energy usage from 2005 to 2012 in medical devices (COCIR 2018), which indicates that manufacturers are making their devices more energy efficient, and refurbished equipment may not be able to match these improvements.

SEPT. 28, 2023 @ 2PM ET Register at webinarwednesday.live

The IPA-3100 is the most compact, feature dense single channel analyzer on the market. It is a high accuracy and easy-to-use system incorporating full touch screen control with an intuitive interface. It has built-in Bluetooth wireless technology and is myBC mobile compatible. The patented design uses a dual syringe stepper motor driven system that provides continuous monitoring of the fluid flow without the need to stop and perform intermittent drains. This provides a more realistic flow path for the infusion device under test and therefore more accurate readings.

The IPA-3100 has configurable test parameters which allows for specific test routines specified by

various manufacturers. Tests can be stored manually or automatically with up to 250 different records. These test records can be downloaded to a computer to then create reports that can be printed.

The IPA-3100’s Bluetooth wireless technology syncs to myBC mobile and allows for wireless testing and control. With the use of myBC mobile or BC Flow, multiple test configurations can be stored for quick testing. Records of each test can be created and then saved for later viewing and analysis. Reports can also be generated from test records for in-depth analysis and/or traceability.

For more information, visit bcgroupintl.com.

Medical equipment cybersecurity is the hot topic in the healthcare technology management (HTM) industry these days and with good reason. Cyber threats against health care providers have increased significantly in recent years forcing medical equipment manufacturers and those who maintain the equipment to develop products, tools and processes to mitigate the risks.

Based on discussions occurring within the government and accreditation organizations like The Joint Commission, many leaders in the HTM industry speculate that it is only a matter of time before regulatory agencies will begin to move more of their cybersecurity recommendations for hospitals from “nonbinding” to regulated requirements.

“The HTM community has known for years that it’s necessary for hospitals to protect their clinical equipment from hackers and malware, but there is general agreement among those that follow the topic that we will soon see more suggestions and standards become regulations,” says Barbara Maguire, vice president of quality and healthcare technology management at ISS Solutions Inc.

While many in the HTM industry feel overwhelmed by this prospect, ignoring the issue will not make it go away. Fortunately, developing an effective medical equipment cybersecurity program can be accomplished with a tool you should already have – your computerized maintenance management software (CMMS).

“The first and maybe most important step in setting up an effective medical equipment cybersecurity program is to make sure all the medical equipment your hospital owns or leases long-term is inventoried in your CMMS, especially if it is networked,” Maguire says. “That includes often forgotten devices in your

medical offices and ambulatory care centers.”

Along with a complete and accurate inventory, hospitals should capture pertinent security information for each device so that when vulnerabilities or alerts are found, affected devices can quickly be identified. This includes whether the device is networked, its IP and MAC address, its ePHI capabilities, and its operating system.

Emphasizing this point, the U.S. Federal Bureau of Investigation (FBI) conducted its own research into how hospitals should protect their medical equipment and released a report last year that listed a number of cybersecurity recommendations including:

• Maintain an electronic inventory management system for all medical devices and associated software, including vendor-developed software components, operating systems, version and model numbers.

• Use inventory results to identify critical medical devices, operational properties and maintenance timeframes.

• Consider replacement options for affected medical devices as part of purchasing process; if replacing the medical device is not feasible, take other mitigation precautions, such as isolating the device from network or auditing the device’s network activities.

Those in HTM know that it’s much easier said than done to capture all this data, and even more difficult to keep it up to date. There are different “checkpoints” in a device’s life cycle that are particularly important in collecting the pertinent data to help protect it.

• Onboarding – working with supply chain, the receiving dock, and other departments involved in equipment purchasing, all HTM departments should have a process in place to be notified when new equipment arrives and is being installed so that it can be inventoried, tagged and added to the CMMS with all required information.

• During Maintenance – anytime a device receives

maintenance – whether it’s planned maintenance (PM) or corrective – the technician should verify that the CMMS contains up-to-date information about the device, including its IT components. This data check should be part of maintenance checklists to ensure this task is not forgotten. Remember that it’s always easier to get the information when the device is in front of you versus having to go find it later when missing data is identified.

• Regular Scheduled Inventory Audits – it’s now considered a best practice to do a manual sweep of the hospital’s medical equipment at least every few years to verify the inventory and associated data is accurate. If your validation process during checkpoints one and two are being followed closely, you can limit this manual audit just to devices that have not been seen since the last audit and perform visual audits in departments to look for un-inventoried devices that slipped through the cracks.

• Disposal – an often-forgotten but critical step in a device’s life cycle is to document its proper disposal in the CMMS. This includes documenting that ePHI stored in the equipment was properly removed. No matter how important accurate data is, finding and entering the data is not always a technician’s favorite part of his/her job. Therefore, you want to make sure certain fields are required in your CMMS so that pertinent data is captured and/or verified during each of these checkpoints. Depending on which CMMS you use, you also may be able to build in workflows and checklists that automatically instruct your technicians what data they need to collect and/or validate during each checkpoint, as well as automatically fill in certain data points associated with the make/model.

“We spent a lot of time configuring our CMMS – Nuvolo – to streamline collection of this data and to develop risk criteria so we can focus our resources on the riskiest devices,” Maguire says. “This has helped us tremendously in keeping the inventory accurate.”

Once your inventory and its data are accurate, you can then begin the process of assessing the equipment’s cybersecurity risk and documenting it in your CMMS. Don’t forget about those non-networked mobile devices that store ePHI. If they go missing, you still need to report it to the Office of Inspector General (OIG) if enough patient records go missing with them.