Need

P.12 SPOTLIGHT

p.12 Professional of the Month: Ashley O’Mara, MS, CCE

p.14 Department of the Month: The AHN West Penn Hospital Clinical Engineering Department

p.16 Next Gen: Josh Ablian

p.18 Association of the Month: Association of Medical Engineering of Kenya (AMEK)

P.22 INDUSTRY UPDATES

p.22 MD Expo New England Among the Best Ever

p.25 News & Notes

p.32 AAMI Update

p.34 Ribbon Cutting: UptimeServices

p.36 ECRI Update

P.39 THE BENCH

p.39 Tools of the Trade

p.40 Biomed 101

p.42 Webinar Wednesday

P.46 FEATURE ARTICLES

p.46 Roundtable: Infusion Pumps

p.50 Cover Story: The Real Value of Real-Time Location Systems

P.57 EXPERT ADVICE

p.57 Career Now

p.58 SPONSORED: Innovatus Imaging

p.60 Networking Notes

p.62 Cybersecurity

p.64 Right to Repair

p.67 The Future

p.68 Health ISAC

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey OF SALES

EDITORIAL John Wallace

CONTRIBUTORS Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Steven J. Yelton

ACCOUNT Megan Cabot

EXECUTIVES Emily Hise

ART DEPARTMENT Karlee Gower

Taylor Hayes

Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy

WEBINARS Linda Hasluem

HTMJOBS.COM Kristen Register Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Jim Fedele, CBET, Senior Director of Clinical Engineering, UPMC

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Benjamin Scoggin, MBA, MMCi, Director, Clinical Engineering | Biomedical Operations, Equipment Distribution, Clinical IT, DHTS, Duke Health Technology Solutions

Allison Woollford, Biomedical Equipment Specialist at Duke University Health System

Bryant Hawkins Sr., HTM on the Line, Trimedx Site Manager at Children’s of New Orleans

Dr. Brian Bell, HTM Workshop, Faculty Biomedical Engineering at St. Petersburg College in St. Petersburg, Florida

Carlos Villafane, BMET Latino, Certified Biomedical Engineering Technician III, Baycare Health Systems

Chace Torres, Bearded Biomed, Lead Technician SPBS, Dallas-Fort Worth Metroplex

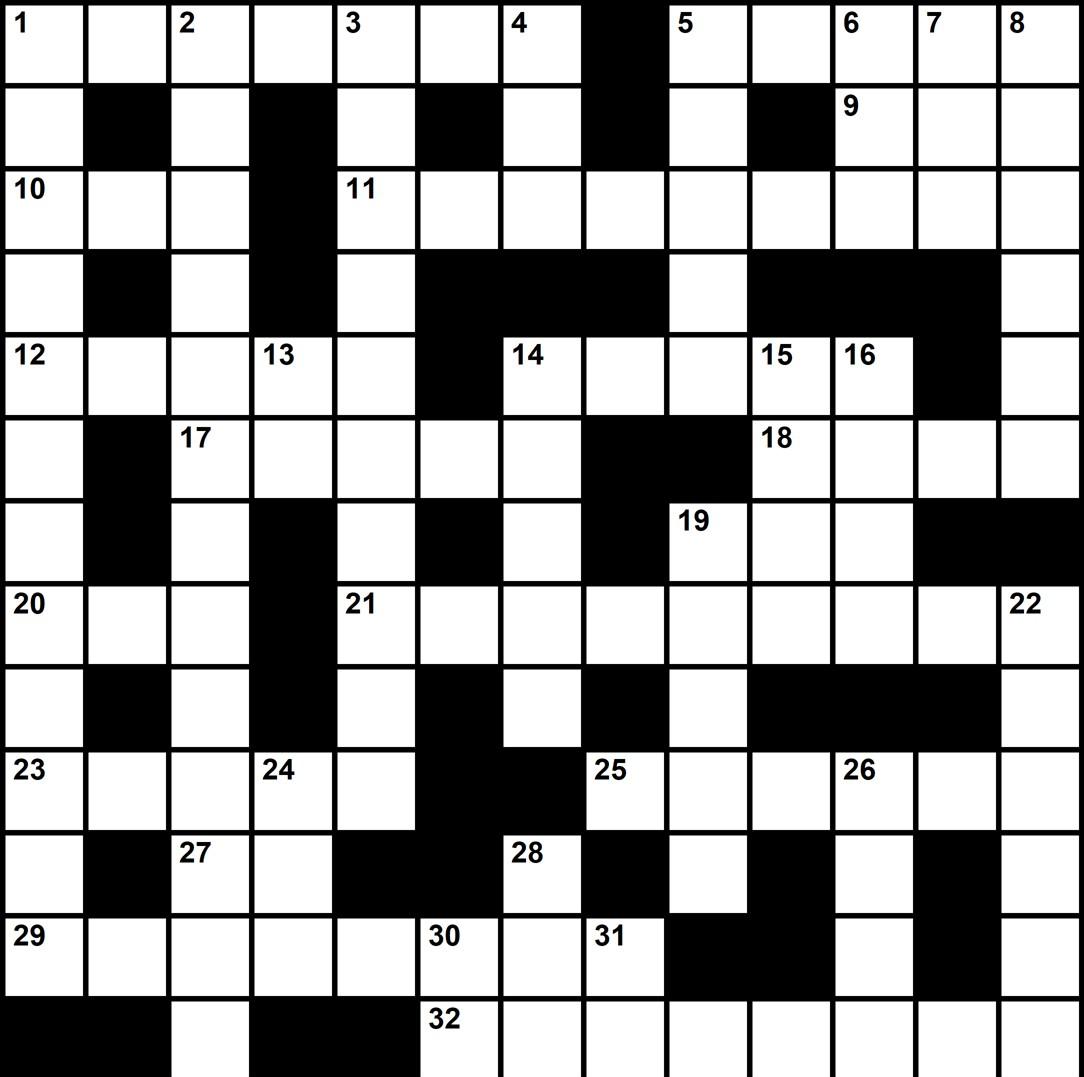

p.71 Biomed Brainbuster

p.72 MedWrench Bulletin Board

p.73 CEAI Scrapbook

p.74 MD Expo New England Scrapbook

p.76 Preferred Vendors

p.82 #HTMLife

p.78 Service Index

p.81 Alphabetical Index

As

As we look forward to a new year, now is the perfect time to plan your next career move. CBET’s online programs in Healthcare Technology Management are designed for anyone eager to gain essential skills and secure a future in this high-demand field. Join a growing community of professionals, access flexible learning, and start strong in 2025.

With

BY K. RICHARD DOUGLAS

As hley O’Mara is the VA New England Healthcare System Chief of Healthcare Technology Management (HTM). She is also president of the New England Society of Clinical Engineering .

O’Mara’s interest in the HTM field was fueled during her undergrad studies when she did volunteer work at a local hospital.

“I attended an education session on clinical engineering as a profession during my undergraduate studies. After learning about this job field, I reached out to a local hospital and volunteered during my last year of undergraduate studies while I applied for a master’s in clinical engineering. I loved the idea of working closely with clinical staff to solve problems and implementing the latest and greatest medical technologies,” she says.

She took night classes to earn her master’s degree while working at a hospital 30-plus hours a week.

“During this training program I worked alongside highly trained clinical engineers and biomedical equipment technicians,” O’Mara says.

After graduating with a master’s degree in clinical engineering, O’Mara worked as a staff biomedical engineer at a hospital in Buffalo, New York for two years. She then took a promotional opportunity to work as a supervisory biomedical engineer at a hospital in North Florida/South Georgia for three years.

“A wonderful opportunity to relocate to [the] Northeast and become the chief biomedical engineer in Connecticut, which was closer to family as I started to consider growing

our family. Currently, I’ve been in the VA New England Healthcare System Chief HTM position for 7-plus years and oversee eight medical centers’ HTM program and HTM staff,” she says.

With the exodus of retirement-age baby-boomer biomeds, any effort to replenish the field with qualified replacements is a noble undertaking. O’Mara helps by spearheading one of the efforts to recruit new HTM talent.

“I serve as the co-chair for the National HTM Biomedical Engineering Recruitment and Retention Workgroup which focuses on developing guides/tools for the field to aid in facility recruitment/retention strategies,” she says.

She says that the Biomedical Engineering Recruitment and Retention (BERR) Workgroup is the principal advisory body to the VHA Healthcare Technology Management (HTM) Program Office (PO) for the development of recruitment and retention processes and practices to attract and keep highly qualified biomedical engineering support specialists (BESS) and biomedical engineers (BME).

“This group will focus on three critical positions for recruitment and retention: (1) BESS; (2) BME; and (3) Technical Career Field (TCF) BME trainees. The overall BERR workgroup, along with three (3) subgroups, each focusing on one of the critical roles within the organization (i.e., BESS, BME and TCF trainees), aim to make VHA the employer of choice for professionals in the field,” O’Mara says.

The BERR Workgroup is responsible for developing recommendations in tandem with field feedback for improving recruitment and retention for biomedical engineering positions: (1) BESS; (2) BME; and (3) TCF trainees.

Ashley O’Mara co-presents a session for “VA HTM 403 Leadership Training.” This is a three-day course for new chief/ supervisory biomedical engineers and supervisory biomedical equipment support specialists.

O’Mara says that they also formulate and document best practices for highly effective recruiting methods, support the professional development of our existing biomedical engineering staff and recognize high performing members of the biomedical engineering professional community, recruit TCF trainees and additional high-qualified personnel from the industry-atlarge for roles within VHA.

Some projects that O’Mara has been involved in have helped guide her team to update and manage the assets they manage.

“When I began in the regional HTM chief role, the team and I outlined and wrote a comprehensive region-wide medical equipment management program (MEMP) which allowed for us to update one document annually with changes. Though it does allow for local variation when needed, any variation is documented in their local plan.

She says that they also rolled out a new HTM CMMS system during calendar year 2023 which involved the team reviewing, mapping, validating data on top of their normal duties as HTM professionals.

“Thankfully our regional MEMP was able to be updated with all the CMMS changes versus eight separate MEMPs (this system change affected over 30 percent of our SOPs),” O’Mara says.

Away from work, she enjoys running and coaching.

“I recently took up running and finished my first 5k! I am coaching my daughters’ ‘Girls on the Run’ group in our local town,” O’Mara says.

“I lead third- to fifth-grade girls through a bi-weekly physical activity-based positive youth development program developed/designed by ‘Girls on the Run (GOTR).’ We use running and other physical activities to teach life skills. This group also selects a community impact project that helps make the world a better place, so I’m excited to see what ideas the girls have this year. At the end of the season, the teams participate in a 5k to

celebrate all they’ve learned and the progress they’ve made over the eight-week program,” she adds.

On the home front, O’Mara has been married almost 15 years and has a 10-year-old daughter.

In November of 2021, she was named the 2021 “VHA Supervisory Biomedical Engineer of the Year.” While serving as NESCE president, the society received AAMIs “2020 HTM Association of the Year” award.

“I am passionate about the healthcare technology management profession. I have a fantastic team that works tirelessly in the medical centers to ensure safe, effective medical equipment for their clinicians and veterans,” O’Mara says.

She says that she stays involved in both VA national initiatives and external organizations like ACCE Board member-at-large and planning the 2024 ACCE/AAMI mini symposium program topic and format as well as planning quarterly webinars, symposiums and education opportunities for the New England Society of Clinical Engineering (NESCE).

“This involvement allows me to learn from my colleagues and share experiences/resources that we’ve developed along the way,” O’Mara says.

As a very active member of leadership, both on the job and in the greater HTM community, O’Mara has devoted her time and talent to bettering the field.

BY K. RICHARD DOUGLAS

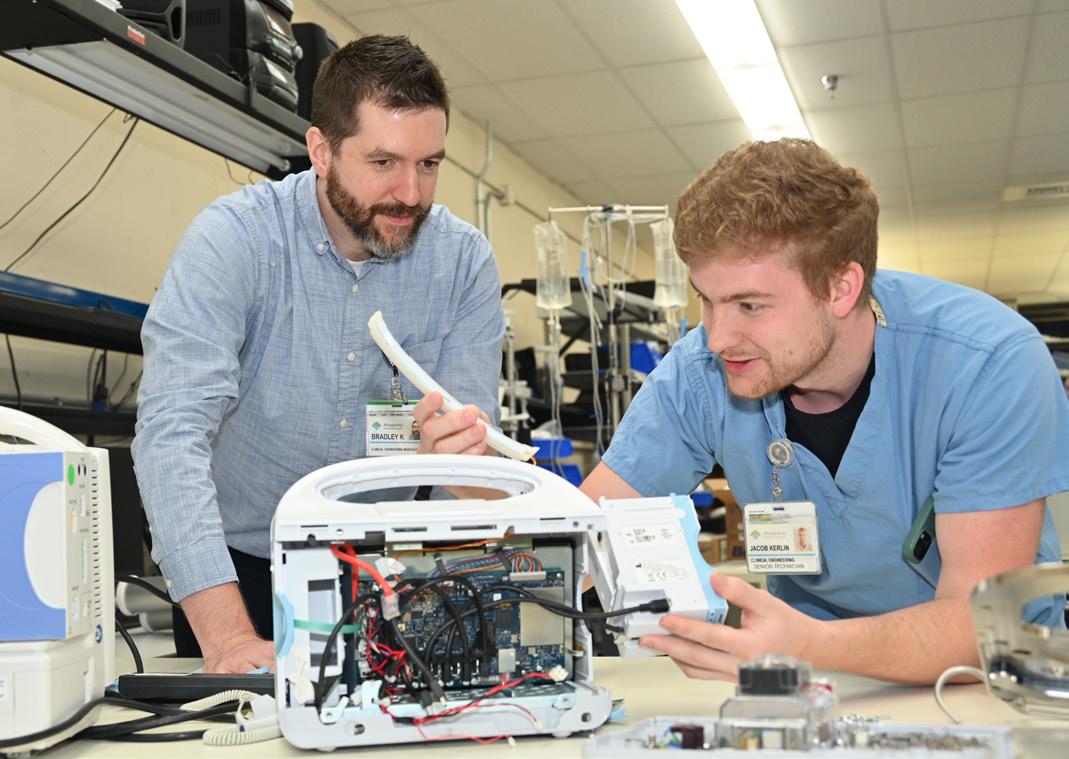

The Allegheny Health Network (AHN) operates 14 hospitals in western Pennsylvania, serving counties in portions of New York, Ohio and West Virginia. One of those hospitals is the West Penn Hospital in Pittsburgh.

West Penn hospital is a 356-bed facility, primarily offering oncology and women’s health services. It was named the 30th best hospital in the nation for obstetrics and gynecology by U.S. News, according to Brad Klauss, clinical engineering manager in AHNs clinical engineering department.

“West Penn Hospital and Clinical Engineering are both part of Allegheny Health Network, a system of 14 hospitals and numerous offsite locations in Western Pennsylvania. Clinical

Engineering is responsible for repairs and maintenance of medical equipment at all of these locations,” Klauss says.

In addition to Klauss, the CE team is made up of Network Director Dave Petrosky, five biomeds and two rad techs.

“All our techs are assigned to special areas,” Klauss says.

He says that Jake Kerlin primarily takes care of the NICU department and infant respiratory equipment.

“As one of the largest NICU departments in Pennsylvania, we have a substantial amount of specialty equipment. Everything from infant specific transport beds to multiple types of infant ventilators,” Klauss says.

Joe Shybloski is responsible for anesthesia.

“This involves PMs and repairs on 27 gas machines in addition to patient monitoring. He assists Glen with the OR PMs as well. He also has patient monitor floors that he is responsible for,” Klauss says.

He says that Dave Herron primarily takes care of vital signs machines and patient monitoring throughout the hospital. This

year he will start working on our adult respiratory equipment.

“Nick Hwostow is one of our rad techs. He has a hand in all our rad equipment repairs and will be specializing in angio equipment soon,” Klauss says.

He says that another biomed is responsible for the OR, which has 18 main rooms. He works on all the OR equipment such as ESUs, surgical towers, surgical tables, and surgical lights. He also assists Joe Shybloski with anesthesia machines.

“Dan Quast was a former biomed tech for us until earlier this year. He used to be responsible for respiratory and anesthesia equipment and has at some point worked on pretty much everything we have in the hospital,” Klauss says.

He says that the department also has one open clinical engineering technician position and that the team includes an intern from the PSU (Penn State University) biomed program, which started in August.

“Clinical Engineering and IT are separate departments but work closely with each other. Together, we are responsible for getting vitals to go from our devices to our EMR. With the increased importance of cyber security, we work together to identify and remediate any network vulnerabilities and reduce the risk of cyber-attacks,” Klauss explains.

He says that service contracts are reviewed on a system wide basis.

“As a cost saving initiative, AHN Clinical Engineering has determined the use of single service agreements are less cost efficient. We have determined that utilizing network wide master service agreements prove the greatest cost savings,” Klauss says.

He also states that the team collaborates with procurement to utilize the technology life cycle for all assets.

“We use our CMMS TruAsset to organize and analyze this data to decide capital equipment purchases,” Klauss adds.

The department plays an important role in capital purchases of the assets they manage along with reorganizing departments.

“West Penn Hospital is the oldest secular hospital in Pittsburgh, originally founded in 1848. With this comes a lot of old infrastructure. Our department plays a critical role in prioritizing updates to our equipment. We’ve recently been instrumental in deciding updates to equipment in our radiology department as well as updates to our OR surgical lights,” Klauss says.

He says that the team has become extremely good at reorganizing departments.

“As an example, during COVID, we were crucial in changing our unused pediatric department into a 16-bay expansion to our ICU and a 20-bay stepdown unit in an old, unused floor. This involved reconfiguring all patient monitors, work with IT to ensure all vitals are captured by our EMR, and guaranteeing each room is properly equipped to use ventilators,” Klauss says.

He says that now that the pandemic is past, they have used these skills to open and rearrange units throughout the hospital.

“When our NICU was at capacity, we were tasked with quickly converting the COVID ICU back into the peds unit. The same goes with other floors as well,” Klauss adds.

In addition to dealing effectively with equipment and infrastructure changes, the team has proven adept at problem solving.

“Jake identified an issue with the replacement fans we were receiving for our incubators. The fans being produced by the vendor were no longer compatible with the incubators. He worked with the vendor, who sent a design engineer on site to assess the issue. As a result, the vendor changed their design for all fans they were producing,” Klauss says.

He says that there have been issues with the wiring for the telemetry network.

“Dan, during his time as a biomed tech, poured over the schematics and traced the issue to a single splitter in one of our network closets. This is notable because our telemetry network covers approximately 150,000 square feet,” Klauss says.

“However, I believe since every tech works closely with their departments to help with equipment problems, purchases, or upgrades we avoid many ‘major’ issues. We do have our share of equipment malfunctions, but overall, because of the diligence of our technicians we do not run into many catastrophic issues. This includes maintaining regulatory compliance to meet the Joint Commission standards,” Klauss adds.

He says that the CE team works closely with local biomed educational programs.

“Staffing is an issue across the nation, and we’ve developed close relationships with both the PSU BMET and RMU biomedical programs. We regularly host interns as part of both programs,” Klauss says.

Josh Ablian, CBET, is a senior biomed with UCHealth (University of Colorado). TechNation recently caught with him and learned more about his HTM journey.

Q: Where did you grow up?

A: Lee’s Summit, Missouri

Q: Where did you receive your HTM training/ education?

A: On the job and from good mentors.

Q: How did you first discover HTM?

A: My parents who work in health care told me about HTM when I was trying to find a different job other than software development.

Q: Why did you choose to get into this field?

A: Out of college, my first job was for a big health care software corporation. I couldn’t stand sitting in a drab cubicle all day and wanted something more hands on but still in health care. HTM it was!

Q: What do you like most about your position?

A: Creating a positive vibe with the team around me while bettering patient care.

Q: What interests you the most about HTM?

A: The future of AI technology with medical equipment, it’s so interesting and could truly change how we do what we do.

Q: What has been your greatest accomplishment in your field thus far?

A: Collaborating with my team and anesthesiologists during COVID to retrofit anesthesia machines to be ready for multiple patients at one time. This was a scary time and the vent shortage across the U.S. was tough.

Q: What goals do you have for yourself in the next 5 years?

A: I want to be in an HTM leadership role that allows me to mentor others, grow the field and be a changemaker.

FAVORITE HOBBY: Snowboarding

FAVORITE SHOW OR MOVIE: Transformers “Autobots ROLL OUT!”

FAVORITE MEAL: Burnt ends and fries

WHAT WOULD YOUR SUPERPOWER BE: Super speed

ONE THING ON YOUR BUCKET LIST: Attend an Olympics. Summer or winter, doesn’t matter

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I grew up a farmboy; drove tractors and showed animals at the fair.

BY K. RICHARD DOUGLAS

Home to the African elephant, the East African lion, the Cape buffalo and the black rhinoceros, the country of Kenya, on Africa’s east coast, offers endless vistas within its national park and game reserves. The country sits on the Indian Ocean and borders Uganda, Tanzania, Somalia and South Sudan.

A place known for rhinos, elephants and safaris may not be the first place thought of when it comes to biomed associations, but Kenya also has the capital city of Nairobi, with its national park, the third largest sub-Saharan economy, a strong agriculture sector and 12,375 public and private hospitals.

The hospitals fall under six categories according to guidelines in the country’s Health Act.

The Association of Medical Engineering of Kenya (AMEK) brings biomeds across the country together in one organization.

“The Association has now grown from a small number of members of less than 50 members at the start to now over 1,500 registered members, but with at least 300 members who are active (fully paid members),” says the group’s chairman, the Honorary Symon Mbakah.

Mbakah is the group’s sixth chairman.

He says that the Association of Medical Engineering of Kenya (AMEK) is a national professional association registered under Cap.108 section 10 of the laws of Kenya on July 9, 1998 and officially launched in November of 1998.

“The Association was started in Mombasa by the then head of Medical Engineering Department at the then

Mombasa Polytechnic, now Technical University of Mombasa (TUM) by the name Andrew Oscar Obura who was also made the first chairman. His vice chairman was Philip Amoko, currently doing private practice and later became the second chairman of the Association after the death of Oscar Obura,” Mbakah says.

The group provides many benefits to members including conferences and workshops, increasing member’s knowledge, including virtual training through partners, professional development and reporting and management tools review.

“AMEK has eight types of meetings which may be virtual or physical,” Mbakah says

He says that this includes full council meetings every quarter, executive meetings monthly, an annual general meeting for all members, special general meetings for all members; held when there is need to pass an agenda, usually with only one agenda item.

There are also planning meetings, which are held to organize an event such as for training, workshop, conference or any other matter as guided by the constitution.

There are some specialty events as well.

“Women in Biomedical Engineering Day symposium; specifically for women to empower and motivate them in the profession,” Mbakah says. He says that this symposium usually occurs annually on June 23.

There is also the World Biomedical Engineering Symposium for all members and held in December every year as well as the Global Clinical Engineers’ Week.

“This is an activity carried out globally and AMEK participates in the activities in October every year,” Mbakah adds.

The group works with local training programs to help new biomeds enter the field.

“The association collaborates with Kenyatta University (KU), Technical University of Mombasa (TUM), Kenya Medical Training College (KMTC) and North Coast Medical Training College (NMTC),” Mbakah says.

The group has very specific goals and initiatives during its annual meetings. These initiatives aim to increase the competency, professionalism and standards within the biomed profession countrywide.

“The Association usually holds one scientific conference on a yearly basis. The association has partnered with other associations in East Africa as part of the Federation of East Africa Healthcare Engineering Associations (FEAHEA) which organizes rotational conferences referred [to] as [the] East Africa Regional Conference (EARC). AMEK was the first to hold the first EARC in 2008. This year, Tanzania will be hosting the 7th EARC in Mwanza, Tanzania, on November 20 to 22, 2024,” Mbakah says.

He says that during the first African Regional Biomedical Engineering Conference and Healthcare Technology event hosted by AMEK in 2023, there were several resolutions decided on.

regulated and now the association has taken an initiative to develop a biomedical engineering profession bill to regulate training, registration, licensing and practice,” Mbakah says.

The group has also engaged in a review of reporting and management tools.

“The biomedical engineering professional management tools were developed over 20 years ago and since then there are many issues that have emerged such as oxygen ecosystem management, artificial intelligence, noting that technology is not dynamic. Therefore, there is a need to have these tools improved to enhance capturing the necessary data during maintenance of the various medical devices,” Mbakah explains.

“Women in Biomedical Engineering Day symposium; specifcally for women to empower and motivate them in the profession.”

“There is need to harmonize and regulate programs and professional training for [the] biomedical engineering profession in Africa. Advocacy for countries to adhere to World Health Organization (WHO) staffing norms for biomedical engineering in Africa. Promote translation of local innovations/inventions to market-level in African countries and strengthening healthcare technology management, Health Technology Assessment (HTA), and regulations of medical devices in African countries,” Mbakah says.

The group is working on a professional regulatory bill.

“Currently [the] biomedical engineering profession is not

He points out that the COVID-19 pandemic highlighted the important work that biomeds do every day.

“The pandemic in one way or the other opened avenues for biomedical engineering professionals. This is because their role in health care service delivery came into the limelight and many organizations, managers and institutions became appreciative [of] the role biomedical engineers play in health care service delivery,” Mbakah says.

He says that in a nutshell, the pandemic changed the way biomedical engineers operate because now there is a lot of involvement in planning and managing the health care sector.

“Additionally, the association has also been able to carry out capacity building to its members through various partners as a result of the pandemic,” Mbakah says, referring to staffing.

Kenya is much more than safaris; it is home to a vibrant and proactive biomed association that is guiding the profession to be the best it can be.

All webinars, podcast, and product demos are eligible for 1 CE credit from the ACI.

ON-DEMAND:

FSI’s Flow Tool Tools of the Trade demo

Solve the 6 Toughest Problems in HTM + HFM – The CMMS in 2025

How AI location intelligence can aid PAR level automation and Equipment Distribution with RTLS (Real-Time Locating Systems)

TUNE IN TO ANY LIVE WEBINAR TO WIN A $100 LOWE’S GIFT CARD

LIVE:

DEC. 4 | Pronk Technologies Tools of the Trade

DEC. 11 | Kontakt.io

Save the date for this live webinar.

sponsored by Healthmark

AI and Automation Inspection for Sterile Processing & Endoscopy

sponsored by MMS

Zen and The Art of Medical Equipment Maintenance

sponsored by MMS

The Key to Growth in the HTM Industry

New England • October 8-10, 2024

early 1,000 HTM professionals came together for amazing networking events, ACIapproved education, an exhibit hall packed with the latest solutions and more.

The Mohegan Sun was the perfect venue with lots of space, restaurants and entertainment options. The MD Expo was proudly supported by the New England Society of Clinical Engineering (NESCE).

The 2024 MD Expo New Englad Fall conference has it all. “MD Expo New England continues to set the standard for conferences in the HTM industry,” MD Publishing President John Krieg said. “We were fortunate enough to be able to bring our world-class show to a part of the country that is ripe for continuing education, networking, and displaying the latest in medical equipment technology.”

“By partnering with the incredible team at NESCE, we brought together over 800 clinical engineers, students and directors of the leading health care facilities in the country, for three days of personal and professional

growth,” Krieg added. “We look forward to returning to New England as part of our regular MD Expo rotation.”

MD Publishing Vice President Kristin Leavoy, CMP, said the local support for MD Expo was amazing.

“It had been eight years since MD Expo was held in New England, so seeing so many new faces was great! Support from the local hospitals, the VA and the New England Society of Clinical Engineering (NESCE) was tremendous! We will be sure to return to Connecticut sooner rather than later!” she shared.

One of the many highlights was the first-ever H.O.T. Workshop (hands-on training workshop). In this workshop, Glenn Schneider, chief service officer with Elite Biomedical Solutions, showed attendees how to disassemble, inspect, reassemble and test the MX-40 patient monitor. A review of the options, parts availability, common failures and proper maintenance were presented. Schneider introduced a patentpending tool that can be used to open and work on the MX-40. Attendees were also invited to get their hands inside the device.

Another highlight was a keynote panel discussion on the Right to Repair medical devices. Mike Busdicker, Binseng Wang, Nathan Proctor and Rob Kerwin took the stage as Chris Nowak moderated the discussion. After prepared remarks, the panel fielded questions from the more than 200 HTM professionals in attendance at the

session sponsored by Zopec Medical.

Attendees praised the MD Expo venue and complimented TechNation magazine and MD Publishing for providing top-tier education and networking. Recordings of the educational sessions are available for on-demand viewing at MDExpoShow.com

Nicole Ruffin, BMET II, described MD Expo as “inspiring and educational.” She added that three words she would use to describe MD Expo are “community, support and diversity.”

Luis Pimentel, a BMET with CME, said this was his first MD Expo.

“The MD Expo is the perfect event for professionals in the field who want to expand their knowledge and find their calling,” he said. “The most valuable aspect of the conference for me was the networking opportunities and the educational sessions. I also enjoyed the keynote speakers.”

“What inspired me the most during my time was the passion and expertise shared by industry leaders and fellow professionals,” he added.

When asked to describe MD Expo in three words, Pimentel said “innovative, collaborative, educational.”

Bob Larkin, the director of HTM at University Hospitals Healthcare/Sodexo HTM, described MD Expo as “immersive, productive, fun.” However, he could not stop with just a threeword description.

Larkin said MD Expo is “an immersive experience into our HTM universe and its many facets, functions and services.”

He explained that MD Expo presented an opportunity to network and have “direct contact with vendors I use every day but didn’t know face-to-face.”

Hartford Hospital Biomed Technician

Dominic Cianciolo’s three words to describe MD Expo are “educational, fun, exciting.”

“Fun” is a word that comes up often when discussing MD Expo and the finale party sponsored by USOC is one reason why. The party featured food, drink, games, fire pits and live music!

Next up, is MD Expo SoCal in April. Sign up for the newsletter at MDExpoShow.com.

The Insulation tester, Leak Tester Tester, Shaver Leak Tester and Cable Continuity Tester are easy-to-use devices for verifying the functionality of equipment for safety

McGan Insulation Tester

Detect & locate defects such as pinholes, cracks and bare spots in the jacket or coating of laparoscopic and bi-polar electrosurgical instruments

Cable Continuity Tester

Test the functionality of automated & handheld endoscope leakage testers with healthmark’s new Leak Tester Tester.

Test the quality of monopolar and bipolar cords with this user-friendly, durable device. A green light noti es the user that the cable passed testing.

Shaver Leak Tester

Designed for pressure testing arthroscopic shavers to help identify leaks caused by failing seals that degrade over time from repeated use and processing.

For more of Healthmark’s intelligent solutions for instrument care & infection control, visit hmark.com hmark.com | 800.521.6224 | healthmark@hmark.com

The North Carolina Biomedical Association is actively raising funds to support local communities impacted by Hurricane Helene. The NCBA is accepting donations toward a Hurricane Helene relief fund. The 2024 Board of Directors voted unanimously to donate to the recovery efforts in North Carolina. All the funds collected will be donated to hurricane relief efforts in the area!

“We invite you to join us in this vital mission by making a

Frazier Healthcare Partners, a Seattle-based, healthcarefocused investment firm, has completed the acquisition of DirectMed Imaging, a leading provider of aftermarket parts and component repairs for diagnostic imaging equipment, from NMS Capital.

The partnership will leverage Frazier’s growth-oriented investment experience and health care industry expertise to build upon DirectMed’s success as a leading solution provider in the aftermarket imaging parts and repairs market. DirectMed supports provider organizations by extending the life of medical imaging equipment to improve patient access, reduce waste, and lower healthcare costs. The company will continue to invest in its people and capabilities organically and through acquisition as it expands its expertise in existing and new imaging modalities.

“Frazier is an ideal partner for DirectMed, and we are fortunate to be working with a firm that has 30 years of experience building companies,” said Brad de Koning, CEO of DirectMed. “We looked for a partner with deep healthcare experience and a proven ability to bring resources that will allow us to accelerate our growth initiatives and better serve our customers. This partnership marks the beginning of an

donation. Your contribution will directly assist families and organizations in need of essential resources such as food, shelter, medical supplies, and recovery support. Every dollar you donate helps us provide hope and relief to those affected by this disaster. Together, we can make a meaningful difference in the lives of our neighbors during this challenging time,” the NCBA said.

Donations can be made at tinyurl.com/ys8mcuah

exciting chapter for our organization.”

Tanner LoRusso, co-founder and vice president of sales, said “We are excited to partner with Frazier to build our capabilities in interventional radiology, mammography, and ultrasound modalities, reinforcing our commitment to becoming the one-stop supplier of diagnostic imaging solutions for customers around the world.”

“Brad, Tanner, and the DirectMed leadership team have built a differentiated Company in an increasingly important part of the healthcare ecosystem, and we are thrilled to have the opportunity to partner with them in the company’s next phase of growth,” said Kent Berkley, partner at Frazier. “We look forward to supporting the DirectMed team’s vision with incremental capital and experienced resources, including several members of our Center of Excellence team, to accelerate growth and further solidify its leadership position in the market.”

UptimeHealth, in collaboration with the College of Biomedical Equipment Technology (CBET), kicked off the Dental Fix Summit 2024 in early October at the Embassy Suites by Hilton Nashville Airport. This four-day event is designed to equip independent dental equipment repair technicians and biomedical technicians with the latest technical training, business strategies, and networking opportunities in the dental industry.

CBET President Richard “Monty” Gonzales was among the speakers at the opening session. He discussed health care silos and the need to eliminate them. He shared a vision where biomeds and dental repair technicians work together to create an expert who can work on all health care equipment including dental equipment.

“The military long ago got rid of the distinction between dental and medical equipment,” Gonzales said.

He explained that CBET is working on the creation of a dental repair technician training program.

He also expressed a desire to work with AAMI and ADA to create a Certified Dental Repair Technician (CDRT) certification. Danielle McGeary from AAMI, who was in attendance at the

conference along with AAMI Chief Learning and Development Officer Robert Burroughs, said the CDRT is something being considered but that it will take time to develop.

At least one HTM insider in attendance at the summit said he expects the new certification to be available in 2025.

The Dental Fix Summit 2024 was an opportunity for technicians to advance their skills and knowledge through hands-on workshops, insightful sessions, and interaction with industry leaders. Attendees had access to OEM technical training and business solutions tailored to the needs of independent service organizations. The event also offered a chance to earn continuing education units (CEUs), enhancing the professional growth of participants.

“We are thrilled to bring together such a dynamic group of professionals for the Dental Fix Summit 2024,” said Darrine Miller, vice president of operations at UptimeServices, in a press release leading up to the event. “This event is all about empowering technicians with the tools, knowledge, and connections they need to thrive in the industry. We look forward to seeing the impact this summit will have on their businesses and careers.”

As hospitals across the United States navigate the challenges of delivering patient care in increasingly high-acuity environments, a new partnership between US Med-Equip (USME), a leading provider of medical equipment rentals and services, and Sentec, a global leader in respiratory monitoring technology, is set to help more clinicians with real-time insights into the conditions of critically ill respiratory patients, including newborns in Neonatal Intensive Care Units (NICUs).

Under the new partnership, USME added Sentec’s transcutaneous monitoring (TCM) devices as part of its extensive portfolio of life-saving medical equipment. Sentec’s TCM devices provide continuous, non-invasive monitoring of a patient’s carbon dioxide levels and oxygen saturation to help clinicians make better-informed decisions in real-time – particularly vital in the care of patients, such as those in the NICU, where precise monitoring of respiratory function is crucial.

In addition to transcutaneous monitoring, Sentec’s Intrapulmonary Percussive Ventilation (IPV) technology will also be available through this partnership. IPV therapy supports the front-line care of critically ill respiratory patients as a management tool to restore lung function and mobilize secretions.

By adding TCM and IPV technology into USME’s rental and service offerings, health care providers gain greater access to non-invasive equipment often preferred by clinicians, especially in intensive care units, emergency departments, and during transport of critically ill patients.

“Partnering with US Med-Equip enables us to better support our shared hospital customers dedicated to providing the highest quality care for respiratorycompromised patients, especially during periods of high patient census and urgent capital needs,” Sentec CEO Bob Cormier said.

This partnership reflects a growing trend in health care, where the integration of advanced technology with on-demand service is increasingly essential. Under the new partnership, US Med-Equip, known for its rapid response and high-quality service, is offering Sentec’s devices with the level of support that has made them a trusted partner for hospitals nationwide.

“Sentec shares our unwavering commitment to supporting clinicians in delivering exceptional patient care,” Greg Salario, CEO of USME, said. “This collaboration enhances our ability to provide health care partners with access to the most advanced patient monitoring solutions, precisely when they need them most.”

The U.S. News recently released its 100 Best Jobs list for 2024.

“No single job suits all of us, but many of the best ones have a few attributes in common: They pay well, challenge us year after year, match our talents and skills, aren’t too stressful, offer room to advance throughout our careers, and provide a satisfying work-life balance. Job seekers also often consider whether a position is in demand. U.S. News used these qualities to rank the 100 Best Jobs of 2024. You can also explore the Best-Paying Jobs and other more specific career rankings,” the website states.

Biomed, which is listed as Medical Equipment Repairer is #1 in Best Maintenance and Repair Jobs and #26 in 100 Best Jobs.

Nurse Practitioner tops the list with an overall score of 7.4 out of 10. It is listed as the #1 in 100 Best Jobs, #1 in Best STEM Jobs, #1 in Best Health Care Jobs and #23 in Best-Paying Jobs.

Physician Assistant is #5 in the Best Jobs list and #2 in Best Health Care Jobs, #4 in Best STEM Jobs, and #21 in Best-Paying Jobs.

Medical and Health Services Manager is #2 in Best Business Jobs, #5 in Best STEM Jobs and #6 in 100 Best Jobs.

EQ2 HEMS – is focused entirely on healthcare maintenance management

Management and Technicians achieve more in less time

Integrate with all of your existing systems

Compliance and AEM made easier with the right tools and reports

Our system helps you keep your devices protected

Data and information that shows leadership how your department saves the hospital money

ISS SOLUTIONS INC. ACHIEVES ISO 13485:2016

CERTIFICATION

ISS Solutions Inc., a leading provider of customized technology life cycle services for health care and other mission-critical industries, recently announced its achievement of ISO 13485:2016 certification. This internationally recognized certification demonstrates the company’s commitment to the highest standards of quality management systems (QMS) specific to medical devices and related services.

ISO 13485:2016 is the globally accepted standard for organizations involved in the design, production, installation, and servicing of medical devices. By achieving this certification, ISS Solutions affirms its dedication to consistently meeting customer expectations, regulatory requirements, and ensuring the safety and reliability of the medical devices it services.

“Achieving ISO 13485:2016 certification is a significant milestone for ISS Solutions,” said Barbara Maguire, vice president quality and healthcare technology management, ISS Solutions. “This accomplishment underscores our unwavering commitment to delivering the highest quality services to the healthcare industry while ensuring the safety of patients and caregivers. We are proud to provide the peace of mind that comes with adhering to internationally recognized best practices.”

The certification process involved a comprehensive review and audit of ISS Solutions’ quality management systems, operational processes and commitment to continuous improvement. Achieving this certification positions ISS Solutions as a trusted partner for health care providers looking to enhance their medical device management and ensure compliance with the latest industry standards.

With this certification, ISS Solutions continues to strengthen its role as an industry leader, offering a wide range of medical equipment services, including repair, preventive maintenance, and asset management, all backed by a proven commitment to quality and regulatory compliance.

TechNation magazine turns 15 in 2025! And, who better to celebrate with than the readers?

TechNation invites readers old and new to help celebrate its 15th anniversary with 15 prizes and a monthly time capsule in the magazine.

Enter the contest and help TechNation celebrate. Visit 1TechNation.com/contest and fill out the short form for a chance to win. Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo.

Each month, a winner will be selected and featured in TechNation magazine!

An expert panel convened for an informative discussion regarding medical Right to Repair at the MD Expo New England. Mike Busdicker, Binseng Wang, Nathan Proctor and Rob Kerwin took the stage as Chris Nowak moderated the discussion.

After prepared remarks, the panel fielded questions from the more than 200 HTM professionals in attendance at the session sponsored by Zopec Medical.

A brief history of Right to Repair and landmark moments were shared by panel members.

Overall, the key takeaways were how HTM professionals need to raise their voice to be heard in the nation’s capital while at the same time educating and encouraging C-suite level decision

makers at hospitals to also ring the bell.

Collaboration among ISOs, in-house biomeds and OEMs was another hot topic during the discussion.

It was pointed out that many of the OEMs stated concerns in the United States do not seem to be a hinderance in the European Union or in the middle of a pandemic. Questions were raised as to why that is the case.

References were also made to FDA, FTC and other decisions and communications that indicate that third-party repairs are not a safety issue.

The January 2025 issue of TechNation will include a cover story on the Right to Repair with additional insights from industry experts.

MD Expo introduced hands-on-training workshops, or H.O.T. Workshops, at the New England conference.

The inaugural H.O.T. Workshop: Patient Monitors, approved for 6 CEUs by ACI, was presented by Glenn Schneider, chief service officer with Elite Biomedical Solutions.

In this workshop, he showed attendees how to disassemble, inspect, reassemble, and test the MX-40 patient monitor. A review of the options, parts availability, common failures, and proper maintenance were presented. Attendees were also invited to get their hands inside the device.

Schneider also introduced a patent-pending tool that can be used to open and work on the MX-40.

Kristin Leavoy, vice president at MD Publishing, said the H.O.T.

Workshop was the result of feedback from MD Expo attendees and TechNation readers.

“We heard from attendees and they want more in-depth training on equipment,” Leavoy said. “We worked with our vendor partners who would have enough equipment for attendees to work on.”

James Dubois said the H.O.T. Workshop was interesting to him because “we get to tear the thing apart, so that’s good.”

Larry Lamourine from MGB-Cooley Dickinson Hospital enjoyed the hands-on aspect of the training and said it was a “great experience.”

He said everyone learned from the presenter and from each other during the session.

MD EXPO SOCAL DATES ANNOUNCED

The next MD Expo is set for Southern California this spring!

MD Expo SoCal will be held April 15-17 at Pechanga Casino & Resort in Temecula, California.

The spring event is already shaping up to be a can’t-miss

conference for HTM professionals with H.O.T. Workshops, Leadership Summit, Keynote, Exhibit Hall, Young Professionals at MD Expo, 7 hours of education and a finale party! Find

The Association for the Advancement of Medical Instrumentation (AAMI) has signed a memorandum of understanding with the Global Clinical Engineering Alliance (GCEA). The agreement establishes a joint effort from AAMI and GCEA to strengthen the healthcare technology management (HTM) field, known globally as clinical engineering (CE).

AAMI’s core mission is to promote the safe and effective use of healthcare technology. To that end, AAMI produces industry standards related to medical devices and their use, and strives to elevate, standardize, and promote the HTM field. GCEA was founded to support and empower the clinical engineering profession across the world and to contribute to international harmonization efforts.

This MOU is a natural fit for the missions of both organizations and is expected to yield multiple new initiatives that will support the HTM/CE community around the globe. This will include:

• Co-marketing of events like AAMI eXchange and the International Clinical Engineering and Health Technology Management Congress (ICEHTMC).

• Creation, translation, and distribution of educational materials, guides, and other resources for HTM/CE professionals.

• Expanding the network of HTM professionals internationally.

After the signing of the MOU, AAMI’s Vice President of HTM Danielle McGeary stated, “The signing of this MOU with the

Global Clinical Engineering Alliance is a key opportunity to bring AAMI’s HTM work to an international audience with the goal of creating international HTM standards and guidance that will further harmonize the field globally.”

According to GCEA President Yadin David, “This collaboration creates a powerful framework for advancing healthcare technology innovation, safety, and management on a global scale. Through this agreement, both organizations can strategically align their expertise and resources, enabling the development of global guidelines, best practices, and educational programs in clinical engineering across the world. Ultimately, this partnership will ensure that the global health care community benefits from improved medical technologies, elevated standards, and enhanced health care delivery systems. Our shared commitment to safety, innovation, and education will play a pivotal role in improving patient outcomes and enhancing health equity worldwide.”

A statement of work from AAMI and GCEA related to forthcoming collaborations between AAMI and GCEA is expected later this year.

As artificial intelligence (AI) becomes more integrated into the health care sector, there is a pressing need for industry standards that will protect patients and promote best practices.

The Association for the Advancement of Medical Instrumentation (AAMI) has signed a memorandum of understanding with the Consumer Technology Association (CTA) that will enable the production of new industry standards related to the use of AI and machine learning (ML) in health care products.

“The signing of this MOU is a key opportunity to bring AAMI’s HTM work to an international audience with the goal of creating international HTM standards and guidance that will further harmonize the field globally.”

The new MOU establishes a framework for AAMI and CTA to collaborate on efforts like the production of new standards documents. Any forthcoming projects will promote the safe, effective use of AI and ML-enabled tools and are expected to impact medical device manufacturers and end users, and the health IT field.

Pat Baird, senior regulatory specialist at Philips, and longtime member of both associations said, “Standards are a great way to share good practices and warn about common pitfalls for a particular topic; I’m happy that AAMI and CTA are starting down a path where even more people can share their perspectives, experiences, and ideas of what good looks like.”

The MOU states that AAMI and CTA intend to coordinate standardization activities related to digital health products and solutions that have AI or ML capabilities. This may include:

1. Post-market surveillance methodology for over the counter (OTC) health devices.

2. Evaluation and assessment criteria for AI and MLenabled products.

3. Other activities such as mutual recognition of standards, information sharing, and workshops.

4. The potential for additional collaborative projects.

Collaboration with CTA and its members is an opportunity for AAMI to advance its core mission of producing regulatory ready standards. Since 1967, AAMI has used its voluntary industry standards to ensure medical devices and products promote optimal patient outcomes. This new relationship with CTA is a continuation of that mission.

According to Matt Williams, Vice President of Standards at AAMI, “This MOU with CTA is a major milestone in AAMI’s ongoing work related to artificial intelligence. I look forward to the opportunities that this joint endeavor will bring to both our organizations in the future.”

“As health technologies develop at an unprecedented rate, industry-driven standards will be crucial to ensuring the efficacy, safety, and innovation of these products and services,” said Kerri Haresign, Sr. Director of Technology and Standards at CTA. “For CTA, collaborating with AAMI marks an important step in creating the standards needed to guide the responsible development of AI in health care.”

AAMI members interested in the specifics of the new relationship can learn more by reaching out at standards@aami.org.

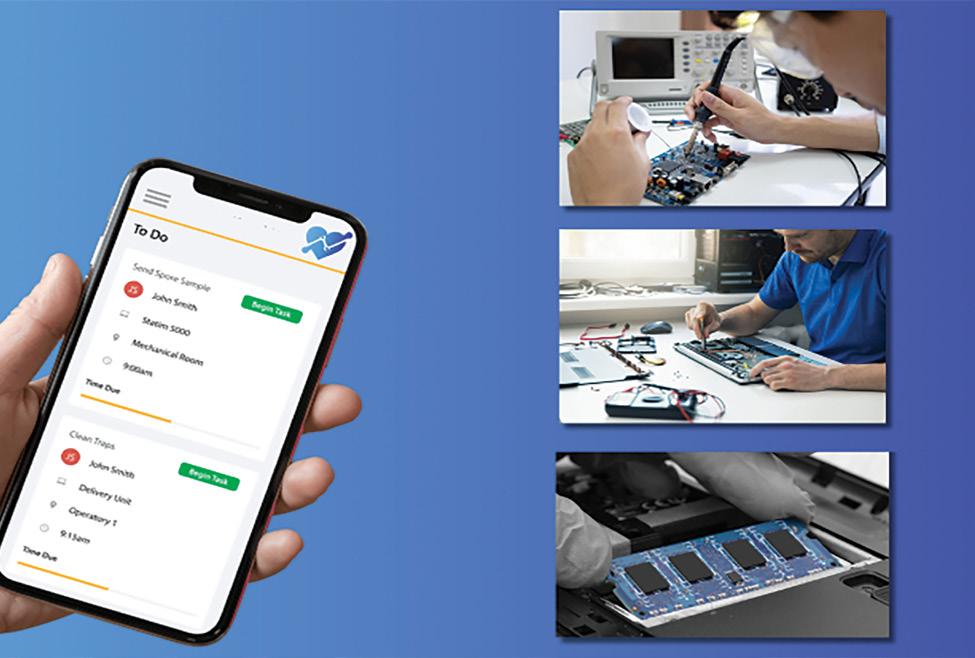

UptimeServices was created to support technicians by providing them with job opportunities, education and career development. Its technician education program is one of the most exciting offerings, providing hands-on training and certifications to help technicians sharpen their skills and grow in their careers. Additionally, the platform offers software that helps technicians manage their jobs, schedules, certifications and career progression seamlessly.

UptimeServices CEO and Founder Tamara Dhanda recently took some time to share more information about the company.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

DHANDA: We stand out by focusing on empowering technicians with the tools and resources they need to succeed. UptimeServices bridges education and career advancement through job placement, ongoing learning opportunities, and intuitive software that makes it easier for techs to manage their work. Our approach puts the technician at the center of everything we do, helping them thrive in their roles.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

DHANDA: We aim to expand our Technician School and strengthen partnerships with health care facilities to provide more job opportunities for technicians. We’re also working on enhancing our software to further streamline how technicians manage their tasks and career growth, providing an even better experience.

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE TECHNATION READERS TO KNOW?

DHANDA: UptimeServices is committed to the success of medical equipment technicians. We offer education, career support and powerful tools that help techs stay ahead in the fast-paced healthcare environment.

For more information, visit uptimehealth.com/uptimeservices.

BY MARC SCHLESSINGER, RRT, MBA, FACHE, LSSGB

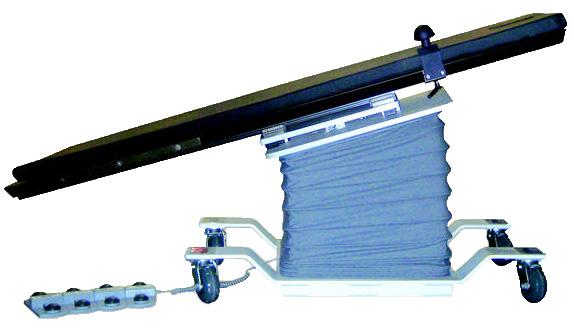

In the rapidly changing field of health care, the planning and procurement of capital medical devices are critical for hospitals and other medical facilities. Capital equipment planning in health care enhances workforce and patient safety and reduces preventable harm by providing reliable, up-to-date tools that improve care quality. Biomedical engineers play a vital role in this process, ensuring that medical devices are not only effective but also align with the institution’s needs, budget and regulatory requirements.

Given the experience and training of biomedical engineers, no one is more qualified to assist in this planning. This article will explore how biomedical engineers can assist with the capital equipment planning process for medical devices and highlight their contributions to the process in several key areas.

Capital equipment planning involves the strategic and objective assessment of a medical facility’s current and future needs for medical devices and equipment. This process includes identifying the types of equipment required, estimating costs, analyzing vendor options, understanding cybersecurity risks, and ensuring compliance with health regulations. These tasks are essential for maintaining a facility’s operational efficiency and quality of care.

The first step in capital equipment planning is to conduct a comprehensive needs assessment. Biomedical engineers collaborate with clinical stakeholders to understand the specific requirements of different departments. This might involve:

• Identifying Gaps: Biomedical engineers should assess current equipment and identify any gaps in functionality or capacity. For instance, if a hospital’s imaging department lacks newer 3D breast tomography units, engineers can pinpoint this need based on available current technology and diagnostic requirements.

• Futureproofing: They should also consider future trends in health care, such as emerging technologies, to ensure that the planned equipment will meet long-term clinical needs.

Once needs are identified, biomedical engineers can assist in performing a TCO analysis of potential equipment purchases. Cost of ownership for a medical device refers to the comprehensive assessment of all costs associated with acquiring, operating, and maintaining that device over its entire life cycle. This goes beyond just the initial purchase price and includes several key components including:

• Acquisition Costs: The upfront cost of purchasing the medical device, including any taxes, shipping and installation fees.

• Operational Costs: Ongoing expenses related to the device’s use, such as:

• Supplies and Consumables: Items required for the device to function (e.g., syringes, sensors).

• Energy Costs: Electricity or other energy sources needed to operate the device.

• Maintenance and Support: Costs associated with regular maintenance, repairs and technical support. This includes:

• Preventive maintenance

• Unforeseen repair costs

• Warranty and service contracts

• Training Costs: Expenses related to training staff to use the device effectively, which can include time, materials and external training programs.

Choosing the right vendor is crucial in capital equipment planning. Biomedical engineers should play a significant role in this selection process by:

• Conducting Hands-On Evaluations: The technical specifications of available medical devices need to be researched, ensuring that they meet the facility’s clinical needs. This should involve detailed comparisons of features, performance metrics and human factor considerations.

• Facilitating Demos and Trials: Biomedical engineers often coordinate equipment demonstrations and trials, allowing clinical staff to evaluate equipment firsthand. Their technical expertise helps in analyzing performance data during these trials.

• Explore Product Evaluations: ECRI provides firsthand deep-dive evaluations of various medical devices. These evaluations are objective and provide industry leading information useful to both the biomedical engineer and clinician.

Health care facilities must adhere to stringent regulations regarding medical devices. Biomedical engineers are essential in navigating these complexities by:

• Ensuring Compliance with Standards: They can ensure that all equipment meets regulatory standards set by organizations such as the Food and Drug Administration (FDA). This involves verifying that devices have the necessary certifications and have undergone proper testing.

• Risk Assessment: Biomedical engineers conduct risk assessments to identify potential safety concerns associated with new equipment. This proactive approach helps mitigate risks that could impact patient safety or lead to costly legal issues. Searching for recall information on the device in addition to exploring the FDA’s MAUDE (https://www. accessdata.fda.gov/scripts/cdrh/cfdocs/cfmaude/search.cfm) database to help determine reported incidents.

The integration of new medical devices into existing systems is another critical phase where biomedical engineers contribute significantly. Their involvement includes:

• Interoperability Assessment: Ensuring that new equipment can seamlessly integrate with existing systems, such as electronic health records (EHR) or other medical devices, is crucial for efficient operations. Biomedical engineers can analyze compatibility and recommend solutions to any integration challenges.

• Training and Support: They provide training sessions for clinical staff, ensuring that users are comfortable and competent in operating new devices. This training is vital for maximizing the benefits of the new technology and minimizing the risk of errors, thereby improving patient care.

Biomedical engineers help manage the life cycle of medical devices, from maintenance schedules to replacement planning. By keeping track of a device’s performance over time, including repair history and costs, they can recommend upgrades or replacements when necessary.

Biomedical engineers are integral to the capital equipment planning process for medical devices in health care settings. Their expertise ensures that medical facilities can make informed decisions that enhance patient care, reduce preventable harm, comply with regulations and optimize costs. As the health care landscape continues to evolve, the role of biomedical engineers will become even more crucial in navigating the complexities of medical devices, cybersecurity and equipment planning.

Marc Schlessinger, RRT, MBA, FACHE, LSSGB, is a principal consultant and investigator with ECRI.

PartsSource PRO® is the only comprehensive, clinical management platform built for the specialized workflow and procurement needs of clinical engineering and supply chain teams. Discover why over 1,600 health systems across the country rely on PartsSource PRO® to maximize their time and cost savings.

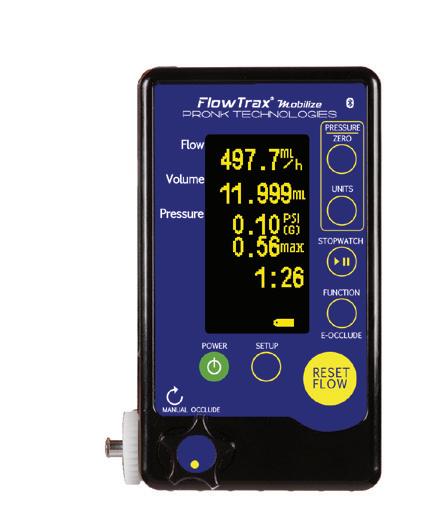

Pronk Mobilize is a multi-level solution that provides flexibility to streamline and automate medical device testing. Mobilize is easy to use and can be adapted to fit specific testing and documentation needs.

Pronk’s Mobilize App connects with Mobilize-compatible test equipment – automated electrical safety, vital signs simulation, IV pump, defibrillator, and ventilator testing – individually or in combination. Testing protocols/procedures can be generated in an intuitive and user-definable way.

Mobilize includes automated step-by-step electronic procedure features. It includes user-controllable options to adapt procedures according to the particular configuration of the medical device and test equipment at hand.

A third operating mode provides the ability for a biomed to create a library of test protocols that can be loaded instantly for executing automated testing with wireless connectivity to the test equipment.

Mobilize also has the capability of conducting automated tests directly from the CMMS in Direct Control Mode. This provides the added feature of capturing the test results live into the CMMS. Mobilize provides a complete automation solution as well as providing the capability of integration to a wide range of CMMS to transfer all the electronic reports right into a work order.

For more information, visit pronktech.com

BY ZACHARY SILAS

The year 2023 was a big journey for me. I was supposed to start my job as a site manager with TRIMEDX on Jan. 3, but I found out during my relocation that my cousin was reported to have committed suicide. As the co-executive producer of Ellen DeGeneres Show, he was a very public figure. But to me, he was a family member who I admired and appreciated. To be so genuine and humble while navigating from Montgomery, Alabama all the way to Los Angeles while maintaining your roots. He was just remarkable. It was a huge blow to find out.

During my grieving process, the first order of business was doing something I had never done and really exposing myself to therapy in a way that required vulnerability. It also helped me work through some life changes, like my new role as a site manager. In the midst of everything, I was trying to build a team and motivate others, but I realized you also have to be motivated yourself.

I realized my leadership was an extension of Stephen’s legacy and what he was able to accomplish in this world. I want people I meet, regardless of the relationship, to feel empowered in some way. I want them to be better than they were before. I felt that way prior to Stephen, but I think it’s more intentional now. I had a friend who would ask “Are you happy?” instead of “How are you?” and it always got a more truthful response. I think that’s the one question I wish I was more intentional about asking Stephen. I wholeheartedly believe he was happy when we were together, but I wish I had asked him how he felt when he wasn’t surrounded by loved ones. We assume because you have goals and aspirations, you’re still moving towards something. We assume because you’re moving, you’re in a good place, but that might not be the case.

Even more than before, I think my purpose is to shed positive light on the people I encounter. I took that into my new role as a site manager. Since the account is in a rural location, we have had to get creative with hiring some people who didn’t have any background in the medical field whatsoever. With such a new team, we really had to focus on team building with lunches, team activities and ways to just get to know each other outside of the shop. We try to be creative. We have had team lunches where we each bring in dishes traditional to our ethnicities, which is always a fun way to learn about others. This past Halloween, we needed some last-minute costumes and one of the team members loves drawing. He came up with the Ghostbusters idea, so we got some OR bunny suits and made the designs. Sometimes it’s important to do something fun and memorable for the team to look back on and laugh. That’s really the dynamic the team has formed over time and it’s cool to see.

To any new incoming leader, I would offer the following advice:

1. Be patient. This phase is about learning, not necessarily doing.

2. Trust the process. When you make yourself available, the training and exposure will make you capable. Availability is sometimes as valuable as capability.

3. Become familiar with how you are being measured internally and externally and prioritize often.

4. Determine a plan that will deliver results while giving the entire team ownership. The approach to goal attainment should be sustainable, so no cutting corners. Do the right thing.

Illinois.

WORLD’S LARGEST RTLS DEPLOYMENT: HCA’S 75% REDUCTION IN RENTAL

The Webinar Wednesday session “World’s Largest RTLS Deployment: HCA’s 75% reduction in rental fleet” was sponsored by Kontakt.io. Presenters Rom Eizenberg, Kontakt. io’s CRO, and Noel Hodges, HCA’s South Atlantic Supply Chain CEO, shared valuable information and insights during the webinar.

What if you could reduce your medical device fleet and CapEx? Give nurses more bedside time and generally operate more efficiently, responding in real time?

That’s exactly what HCA accomplished in just a few months. With Kontakt.io’s asset management solution, HCA increased their equipment utilization and reduced their active rental fleet by 75% with 7x annualized ROI.

Attendees walked away with details about the HCA success storyas well as how health systems, big and small, can leverage enterprise technology at a price point that achieves 7x annualized ROI. Attendees also learned about best practices from a real-world example of optimizing care operations and cutting costs.

Winston Henry, a Sodexo program support manager in Ohio won a $100 Amazon gift card as part of Webinar Wednesday’s 10th anniversary during the session.

Attendees were asked “How much new information did you receive from today’s webinar?”

“I was familiar with the RTLS applications mentioned. What I learned was building upon the technology to make sure we have the people, technology and processes to ensure a successful program,” said Winston Henry, Program Support Manager, HTM, Sodexo.

“Great bit of information about rental fleets,” said Alec Hadley, Field Service Manager, ReNew Biomedical.

Watch these webinars on-demand

Webinar Wednesday’s session “Enhancing Device Management and Extending Cyber Protections with Cynerio + AiRISTA” presented by Tim Bloomer, Cynerio director of sales engineering, and Vince Grove, AiRISTA vice president of product marketing, is eligible for 1 CE credit from the ACI. Registration was free and a recording is available for on-demand viewing thanks to sponsor Cynerio.

Cybersecurity and asset management have become inextricably linked in the complex landscape of modern health care. As biomedical engineering teams grapple with the challenges of tracking assets, they are increasingly tasked with contributing to the prevention of escalating cyber threats. The result is a much-needed unified approach to asset management and security implementation. This webinar explored how the integration of AiRISTA Flow and Cynerio empowers health care organizations to effectively manage medical devices, mitigate risks and ensure patient safety.

Bloomer and Grove provided a guided tour of the powerful combination of these solutions. Attendees were able to discover how a real time location system (RTLS) can revolutionize asset management by providing real-time visibility, status updates and location tracking. They illustrated how this enhanced visibility directly impacts patient experience, improves operational efficiency and helps meet stringent compliance mandates. The duo also fielded questions from attendees.

The webinar was a hit with attendees, especially Dakota Brown-Goodwin, CBET, in California. He won a $100 Amazon gift card as part of the Webinar Wednesday 10th anniversary celebration!

Attendees were asked “Excluding CE credits, why do you attend Webinar Wednesday?”

“I enjoy the new learning experience,” ReNew Biomedical Field Service Manager Alec Hadley said.

“Learn about new things in our field,” said Jason Chaffin, the lead BMET at St. Luke’s Vintage.

The Webinar Wednesday Tools of the Trade Live Demo featuring the Fluke Biomedical IDA-6 Infusion Device Analyzer was presenter Justin Ross, a Fluke Biomedical sales engineer. The webinar is eligible for 1 CE credit from the ACI. The webinar was sponsored by Fluke Biomedical.

The IDA-6 Infusion Device Analyzer is the next generation of infusion device analyzers.

The IDA-6 elevates medical device testing, providing simplicity and efficiency. Ross discussed how biomeds can embrace the transformative power of the IDA-6 Infusion Device Analyzer, equipped with the exclusive OneQA workflow automation software. This groundbreaking analyzer is the solution to common pain points including extended periods dedicated to testing and documenting results. With IDA-6, biomeds can effortlessly modify pre-set procedures. Plus, the results are automatically recorded on the device and seamlessly synced to a PC, making PM completions a breeze with its user-friendly interface. Recognized worldwide for its excellence in infusion pump testing for decades, the IDA-6 allows biomeds to focus on protecting lives. Ross invited attendees to incorporate the IDA-6 Infusion Device Analyzer into their organization and experience the change.

More than 100 people attended the live presentation and a recording of the webinar is available for on-demand viewing at WebinarWednesday.live.

Attendees were asked, “What was your single biggest takeaway from today’s product demo?”

“The ability to accurately test the pumps and individually calibrating of the tester,” said Helen Brazen, biomedical manager with Blount Memorial Hospital.

“The ability to store any tests that were done internally/within the IDA-6 using either the work order or asset number of the device. This is handy for me as I visit multiple sites where I have to service infusion pumps, specifically from Baxter,” shared Bruce Wan, biomedical technologist, Ottawa Hospital, Civic Campus.

“That Fluke is putting a lot of thought into the future of medical equipment testing,” said Robert Wentworth, vice president of biomedical operations for VIKAND Solutions Inc.

All webinars, podcast, and product demos are eligible for 1 CE credit from the ACI.

The Webinar Wednesday session “HHS’ Top 3 Cyber Attack Vectors: HTM’s New Compliance Challenge” sponsored by Claroty delivered valuable insights. The webinar was presented by Ty Greenhalgh, industry principal-healthcare, Medigate by Claroty, and Skip Sorrels, senior director healthcare at Claroty.

This webinar explored the top 3 cybersecurity attack vectors for the health care industry and their critical impact on medical device cybersecurity. Health care experienced a 156% increase in records breached from 2022 to 2023. The experts broke down health care’s 3 primary attack vectors, what they mean for HTM teams, and how upcoming regulations will require proactive risk reduction.

Attendees were able to learn actionable strategies for mitigation and remediation, tailored specifically for health care environments. This session is a must for anyone involved in HTM, healthcare IT, or medical device security.

Attendees also had the opportunity to ask the experts questions during the Q&A portion of the webinar.

Common Spirit Health’s James Whitaker won a $100 Amazon gift card as part of the ongoing Webinar Wednesday 10th anniversary celebration.

Attendees were asked “How did today’s webinar meet your expectations?”

“Excellent updated information,” said David Banister, a field service technician with Clinical Engineering Services.

“I was particularly interested in hearing more about the cyber risk with medical devices,” shared Vince DiFranco, CEO with WJ Mangold Memorial Hospital.

“Provided great insight into potential HTM attack vectors,” said Jalil El, a biomedical equipment support specialist with Edward Hines Jr. VA Hospital.

“By providing a peek beyond the usual cyber posture, this expanded the scope from a holistic approach,” said Lee Woodruff, regional operations senior manager, Genesis Healthcare.

“Being in the Clinical Engineering world I appreciate the way the information is relayed and explained,” said Summa Health System HTM Manager Sandra Munsey.

Featured Employers: Agiliti, Renovo Solutions, TRIMEDX, SP Associates, Erbe USA Incorporated, and more!

htmjobs@mdpublishing.com for posting inquiries htmjobs.com to register today

A niche job board for the HTM and imaging communities

350+ open job opportunities

Single-job postings to 12-month unlimited memberships

3200+ biomedical and imaging candidates

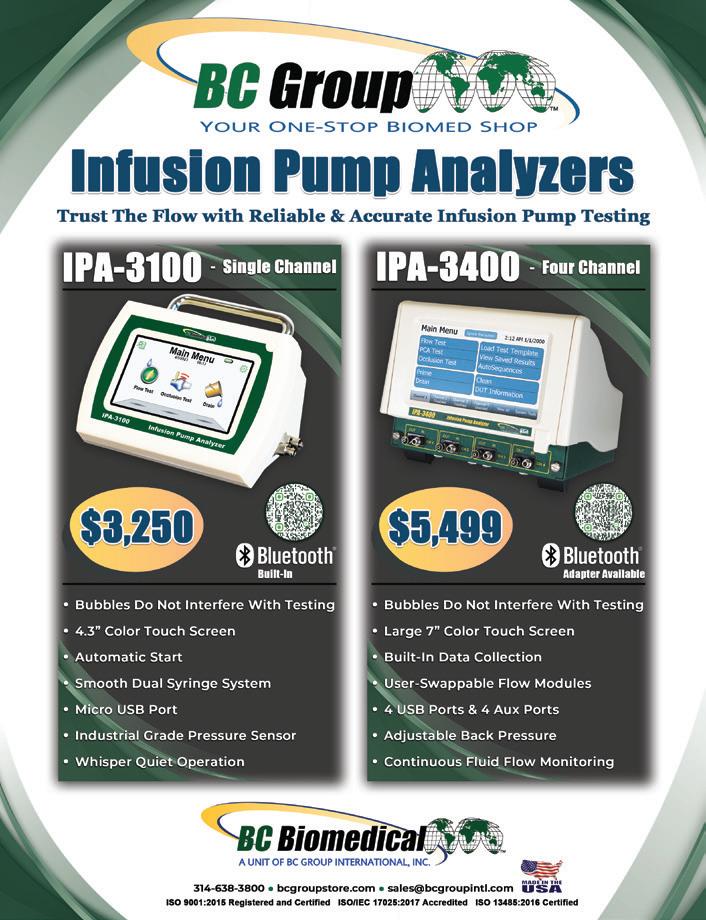

Infusion pumps are everywhere in health care facility. Infusion pumps and patient monitors might be the most common and abundant devices when it comes to health care delivery. Maintaining infusion pumps in good working order is a huge task for HTM departments everywhere. TechNation reached out to HTM experts for the tips and advice regarding infusion pumps in this month’s Roundtable article.

Participants in the article are:

• Soma Tech Intl Biomedical Engineer Schleshin Molly David

• MMS Regional Service Manager Jose Jimenez

• ECRI Senior Project Officer Mukui Mutunga

• USOC IV Pump Lead Technician Jeremy Sommer

• ECRI HII-Tech Consultant Dustin Telford

Q: WHAT IS MOST COMMON ISSUE BIOMEDS ENCOUNTER WHEN IT COMES TO INFUSION PUMPS?

DAVID: The most common issue biomeds face with infusion pumps is occlusion alarms, which indicate a blockage in the flow of fluids and often require troubleshooting. Battery failures or charging problems are also frequent, especially in older or heavily used devices, leading to interruptions in operation. Additionally, calibration errors and software issues can result in inaccurate flow rates and dosages, necessitating maintenance or software updates.

JIMENEZ: Flow rate, low battery life, air-in-line (AIL) codes, and cosmetic damage. The bad battery problems are usually cause the AIL and flow rate.

MUTUNGA: Field serviceability: a. Some infusion pumps on the market are not easy to repair in-house. b. Parts are difficult to obtain from the manufacturer.

SOMMER: Insufficient training of staff. With the constant advancement of IV technologies, device compatibility and operation can be confusing. While the user interface or design may only have minor changes, these changes can easily shake up the confidence of the most seasoned staff member. Training is key to avoiding this.

TELFORD: User errors and usability issues are common challenges, often causing unnecessary alarms or improper setups. While mechanical problems like occlusion alarms and battery failures are frequent, poorly designed interfaces can make these issues worse. Simplifying user workflows and keeping firmware up to date helps reduce both mechanical and user-driven problems.

Q: WHAT TOOLS OR TECHNOLOGIES ARE INDISPENSABLE WHEN IT COMES TO INFUSION PUMPS?

DAVID: Flow and pressure sensors are essential for monitoring fluid delivery and detecting occlusions or blockages in infusion pumps. Battery management systems are also crucial, as they ensure uninterrupted operation, making rechargeable batteries and efficient charging

circuits vital for mobile or long-term use. Additionally, software and wireless connectivity play a key role in updating pump settings, tracking performance, and integrating with hospital systems for real-time monitoring and alerts.

JIMENEZ: There are a few main aspects to infusion pumps that need to be tested. These are flow rate and pressure of occlusion. The flow rate can be determined with a scale and the occlusion for the upper and low lines can be analyzed with a pressure meter.

MUTUNGA: 1) Wireless firmware and software updates/ upgrades – reduce the need for physical interaction with each device to update.

2) Log extraction and interpretation – infusion pump logs that can be extracted through a wired connection and wirelessly, and that are easy to understand (without consulting the IFU for error codes), make the troubleshooting process faster and aid in accident investigations.

3) Built-in asset tracking – especially across hospital enterprises that consist of smaller hospitals transferring patients to larger hospitals in the network.

4) Unified software for multiple types of infusion pumps (e.g., syringe and large volume) – reduces the burden on biomeds to maintain multiple software licenses. Provides a centralized location for tracking all infusion pumps across a network.

SOMMER: Quite possibly a cliché, but a calm and clear thought process. Taking a step back and analyzing an issue carefully and methodically almost always ensures a successful outcome. Besides that, access to the endless available amount of information on the Internet.

TELFORD: Precision tools such as feeler gauges, force and pressure gauges, and syringe jigs are crucial for maintaining infusion pumps. Air-in-line injection methods and diagnostic software help verify pump performance and ensure safety. Additionally, precision and torque drivers play a critical role in ensuring accurate repairs.

Q: HOW HAVE ADVANCEMENTS IN TECHNOLOGY CHANGED THE WAY YOU APPROACH REPAIRS?

DAVID: Advancements in diagnostic tools and software have streamlined the process of identifying and troubleshooting issues, reducing repair times and improving accuracy. Remote monitoring and connectivity features also enable technicians to access device data and perform firmware updates without needing to be on-site, which boosts efficiency. Meanwhile, the introduction of more complex electronic components and automated systems has increased the demand for specialized training and expertise to handle sophisticated repairs.

JIMENEZ: Before the use of scales, the flow rate was determined with graduated cylinders. This was fine for the time being, but not entirely accurate due to the measurement being taken at the curve of the water in the cylinder. The change to

the scale has given a much more accurate reading.

SOMMER: Biomeds have now become junior IT personnel. With more and more IV pumps connecting to hospital networks and the Internet, troubleshooting has gone from simple mechanical to a full spectrum of wireless issues.

TELFORD: Modern infusion pumps now have diagnostic tools that allow biomeds to track usage patterns and flag issues before they become critical. This proactive approach helps prevent breakdowns by identifying problems early through built-in logs and usage data. These advancements allow for more effective preventive maintenance, minimizing downtime.