MedWrench is your online community to ask questions and share information about specific medical equipment you work with every day.

MedWrench is your online community to ask questions and share information about specific medical equipment you work with every day.

Since 2010, the face of MedWrench is Ben Calibrating or Ben C. for short. While he may just be a small logo figure, you can find him all over the world.

Is he helping fix broken equipment at your facility?

Is he fighting off sharks at the beach?

Is he crowd surfing at a concert?

The possibilities are endless!

How does Ben C. do these amazing things?

That’s where you come into play. MedWrench has an ongoing photo contest to see where Ben Calibrating is traveling to and what he has been up to.

Follow MedWrench of Facebook and LinkedIn and checkout the Expos and Events section on the Bulletin Board to find us at an upcoming show!

Post your pics with #BenC and tag @MedWrench.

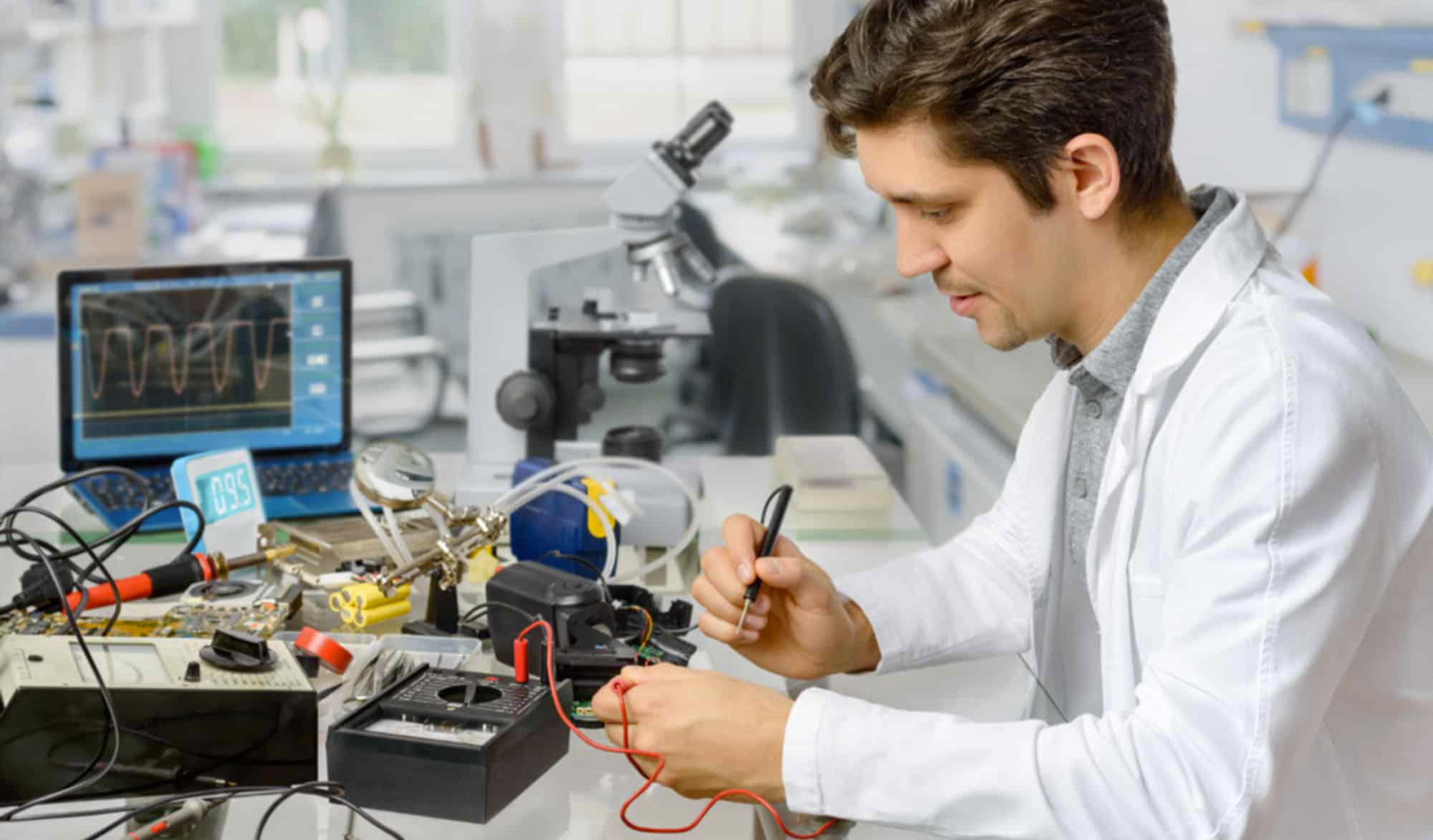

One of the key tools to aid a health care organization in controlling its medical equipment support costs is by having its in-house healthcare technology manage ment (HTM) team attend technical service training for the product it purchases. This training, provided by a manufacturer or an independent service company, helps to ad dress concerns around operating costs and total cost of ownership, timeliness of support, and flexibility in when planned or unplanned service can be performed. It also helps to provide options for how to extend the life of equipment when the original manufacturer may limit or end support. This access to technical training is an important part of the right to repair movement and enables health care organizations to have better control of their overall equipment and relat ed support costs.

The real challenge is when access to this tool is taken away, such as when a manufacturer uses the premise of a new product releases as the rationale for them to discontinue offering any technical service training to customers even though that type of training was readily available for the last model product. Other manufactures may even mention how a recent company merger or the acquisition of a new product line prevents them from offering technical service training. In practice, what those manufacturers fail to mention is that they still have a process to train their own

factory field service staff, especially when they want a health care organization to still buy its products. They may also not inform the health care organization that they will train an authorized distributor or service provider, but not the employees of the health care system that is buying the equipment.

The arguments typically presented by manufacturers generally revolve around how they are “suddenly in flux for their customer-facing training program due to restructuring” or “how they are moving to a new support model for customers due to a shift in corporate business strategy.” What this usually means is that they are no longer offering technical training as there is no longer any compelling compet itive advantage for them to do so, especially if they absorbed their competition and they now hold the

market share for a particular product type. In health care, when a product is established in the industry as the standard, physicians are not likely to consider other options, in turn leaving health care organizational leadership with zero room for demanding or negotiating something different.

One common problem that you may see is that many manufacturers will try to do a “divide and conquer” approach with customers. They will try to manage the interests of the physician and/or clinical user separately from that of the supply chain team, and what seems more and more, separate both groups from the HTM team. End of the day, a clinical user is using the equipment to treat the patient, and in turn let the health care organization generate revenue. If capital pricing is not negotiated in conjunction with software and service offerings, to include technical training, then the post-purchase support options and costs over the term of ownership generally end up unfavorable to the health care organization. Presenting and maintaining a unified front is the ongoing challenge that faces many health care organiza tions. Some do much better than others, thankfully. Many health care organiza tions are working more and more with their respective group purchasing organizations as well to help gain leverage when dealing with manufactur ers and in turn raise awareness to this issue.

Over the last 20 years, the ongoing intertwining of medical equipment with network connectivity and software is driving the need for ensuring compatibil ity with network infrastructure and applications, cybersecurity needs, and the ongoing cost of software support and product licenses needed for interfacing with software applications. The unified effort of a health care organization’s supply chain, HTM and information services is becoming ever important.

Sales and service have to be addressed concurrently for a health care organiza tion to have the most purchasing power and control the total cost of ownership.

For HTM, as more organizations bring that team to the negotiating and capital planning table, the simple message to share with manufacturers is that, “the simpler and easier it is to support a product means the easier it is for healthcare technology management to be the champion for recommending one vendor over another during the final selection process.” The health care organization holds the funds to buy the new equipment. It’s during the time of evaluating and comparing manufacturer products and service offerings that the health care organization has the most leverage; it’s also when the manufactur ers will make the most concessions to win the sale and the related downstream revenues.

Some manufacturers are starting to listen to this message and, in turn, are starting to reconsider offering technical training, while other manufacturers don’t appear to care. This seems especially true with those manufacturers who have overwhelming market share and see their customer as a captive audience. In those situations, the manufacturer sets itself to be a price-set ter versus a price-taker.

A health care organization having cost and time effective options on how it supports and maintains its patient care equipment is very critical. The right to repair is a right all health care organiza tions need to fight for, be it when doing a competitive bid between manufacturers while assessing total cost of ownership, when replacing old equipment with newer models, and when talking with its own government liaison staff for raising awareness with state and federal officials.

Eventually insurance providers and the state and federal government may wake up and realize they too are paying too much for procedure reimbursements when a health care provider cannot readily and economically service the equipment it owns. Maybe that is when real change will happen. Until then, HTM profession als need to keep raising awareness around the value of technical service training and the right to repair.

MARK NEWELL Director, Operations Support, Healthcare Technology Management/Clinical Engineering

“A health care organization having cost and time effective options on how it supports and maintains its patient care equipment is very critical.”

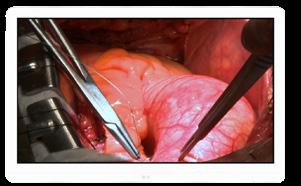

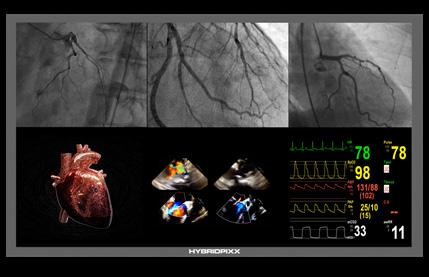

Ampronix is the LEADER in Medical Imaging Technology. We are your go-to Resource for Cath Lab Displays, Surgical Displays, Clinical Displays, Diagnostic Displays, Medical Recorders, Ultrasound Machines, Medical Video Converters, Digitizers, Printers, & Media.

We offer Sales, Service, Repair, Replacement, & Exchanges both Domestically and in 154 countries worldwide. Our extensive outreach allows us to extend our Direct Pricing from OEM’s, such as Sony, Barco, Eizo, LG, JVC, NDS, Mitsubishi, among others.

Whether replacing your unit, repairing it, or searching for a new product, Ampronix Can Help.

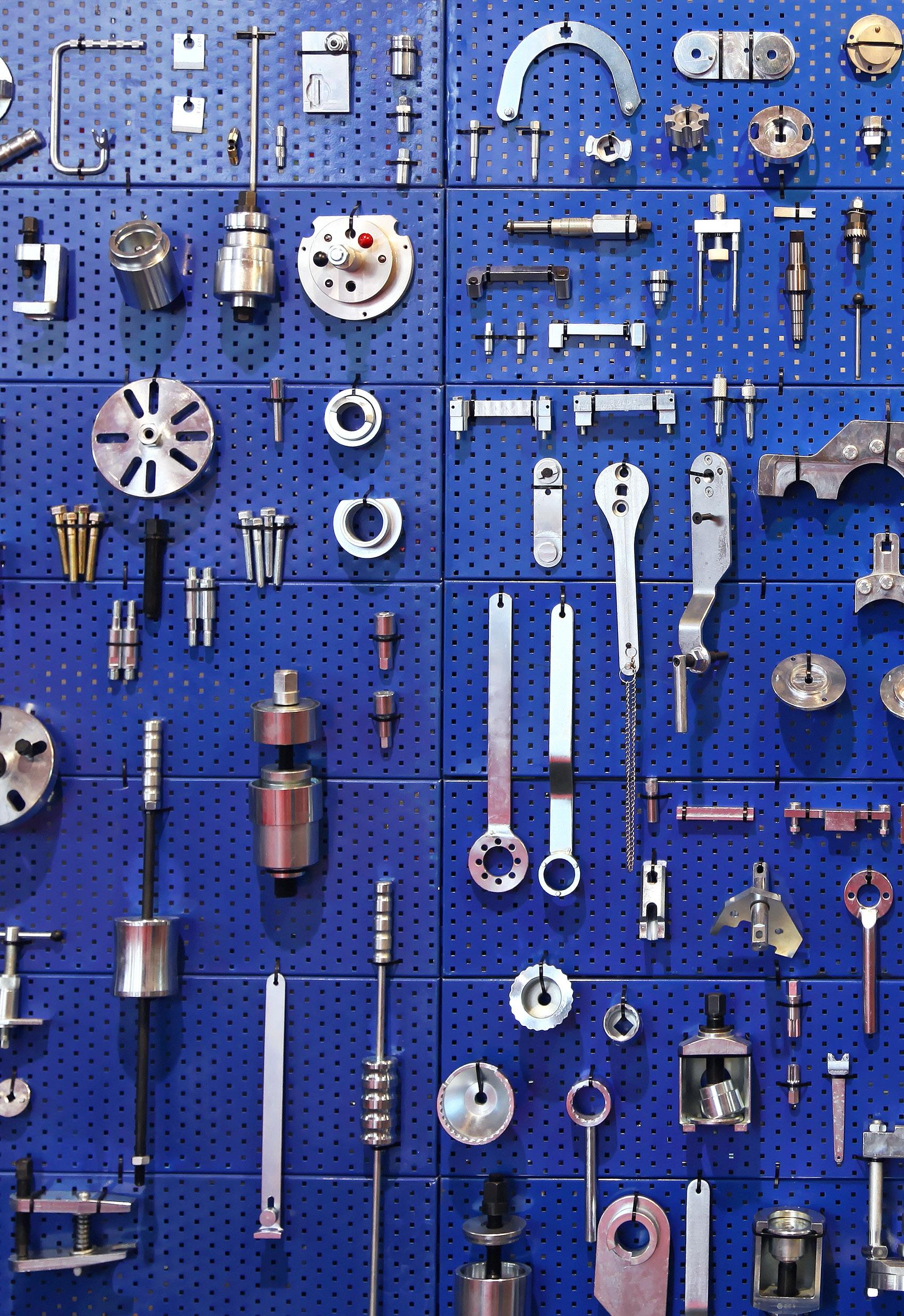

Healthcare Components Group (HCG) is dedicated to the design, manufacturing, and supply of quality components and solutions for the healthcare industry. With almost 100 years of combined expertise serving the medical and dental industries, HCG’s founding brands incorporate their vast knowl edge, experience, and global con nections to provide a wide range of components and solutions for the repair of mission critical medical and dental devices.

HCG was formed by the unification of a network of healthcare compo nent brands: American OpticsEndoscope Replacement Parts (AO-ERP), Endoscopy Development Company (EDC), Micro Optics Europe (MOE), and Replacement Parts Industries, Inc. (RPI). With robust engineering facilities and precision manufacturing across the globe, HCG strives to offer faster product releases as well as a more streamlined purchasing experience for their global customers. Quality, performance, and attention to detail are paramount.

The focus of HCG is to ease the effort of sourcing components and

repair parts for the industry. These parts are principal to maintaining healthcare devices and equipment including flexible and rigid endo scopes, biomedical equipment, and dental equipment. To HCG, quality is of the utmost importance, their manufacturing sites are ISO certified and one of their sites is an FDA medical device establishment. What separates HCG, is they deliver a network of top-of-the-line health care components and solutions under one entity. Their in-house

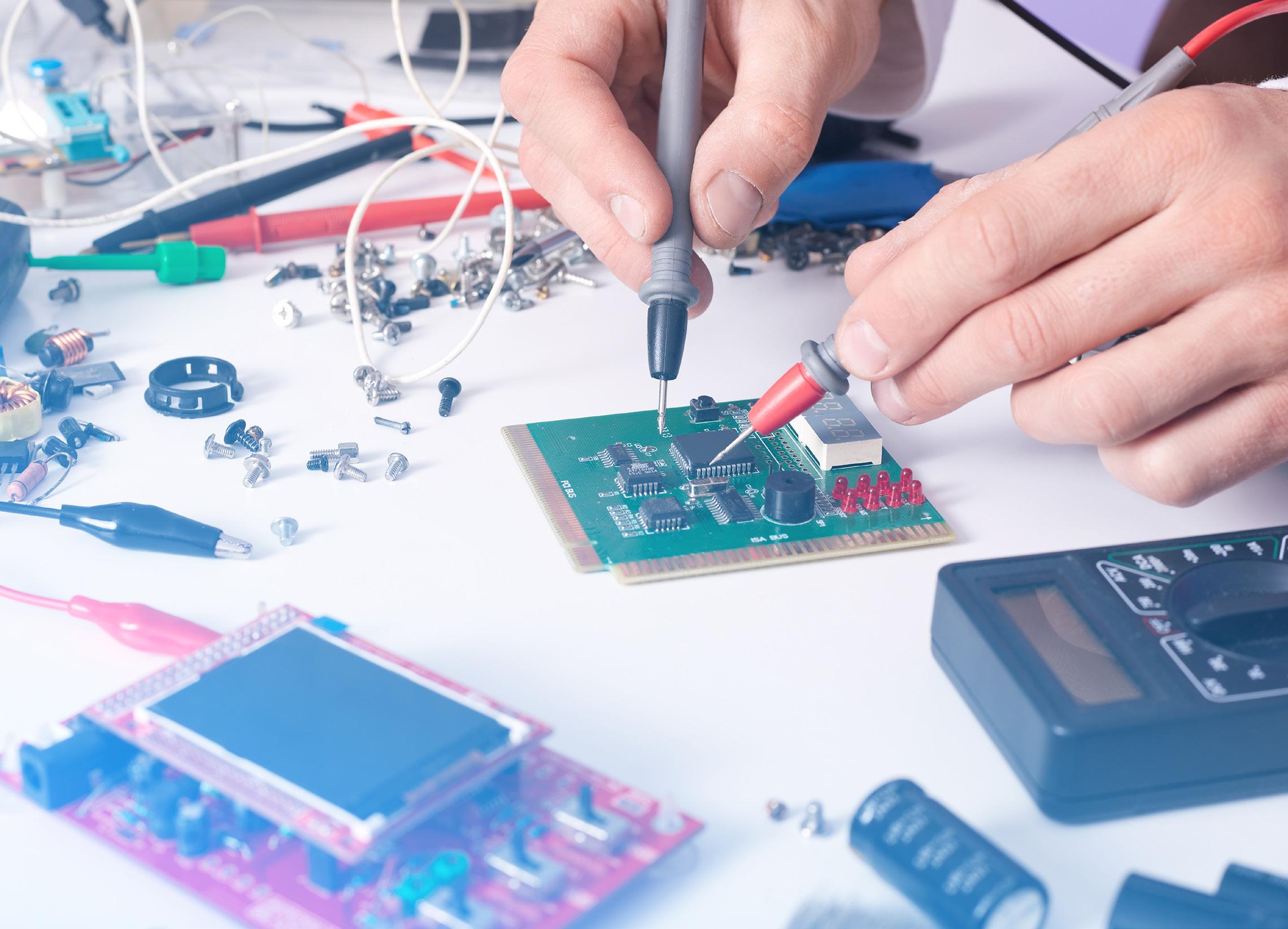

MedWrench reached out to several experienced healthcare technol ogy management (HTM) professionals for an informative look at medical equipment parts. The panel was asked what to look for when buying parts, if the OEM is always the best option and more. Panel members participating in the roundtable are Dan Germanotta from GE Healthcare, Ira Lapides from HCG, Michael Lipson from MIT/MedEquip, Michael Thomas from Ampronix and Chace Torres from Bearded Biomed.

GERMANOTTA: While price is an important factor to consider when buying parts, we encourage buyers to think about other factors including ensuring they have the right part to fix their system. OEM tech support may assist with part selection, as well as confirmation of part revisions that may have occurred. New part revisions are regularly introduced to help improve the performance of OEM parts. Another consideration should be the quality or condition of the part. This can include a new, refurbished, used or aftermarket (clone) part. A third consideration is to evaluate the supplier, including its quality management systems, warran ties, and other delivery metrics.

LAPIDES: Here are a number of things to look for when buying parts for

medical equipment:

• Whether it be from the OEM or a third-party supplier, the purchaser needs to have a good comfort level with the quality of the parts they are purchasing.

• Does the supplier have a good track record of quality with their parts?

• Are they ISO certified and/or FDA registered?

• What is the warranty on their parts?

• Does the supplier provide good customer service with a smooth and easy purchasing experience, and are the parts available to ship as needed to minimize equipment downtime?

• Does the supplier provide good and easily accessible technical support?

• And, of course, the cost of the part should be considered.

LIPSON: When buying parts, quality is key. Price, part availability and delivery

time are also key factors in buying parts. I would suggest looking for companies that have some sort of quality system in place, for example, ISO 9001 or more specifically, ISO 13485. Make sure the parts, if not brand new, have been recently tested and are backed by a solid warranty. Look for short lead times on shipping.

T HOMAS: I would start by asking what the availability and warranty on the parts are. Establishing a timeline for the repair will allow the facility to deter mine if a loaner unit would be needed until the repair is completed. It would also be helpful to know the return policy in the event the part does not function properly.

TORRES: What is the cost and is the part economically feasible to purchase in regards to total value of the unit your trying to repair? Is the part in stock or on backorder? Do the parts have warranty with them? If it’s an aftermar ket part what is the quality compared to OEM original?

2. SHOULD HOSPITALS ONLY BUY PARTS FROM OEMS?

GERMANOTTA: We use distribution partners (channel partners) to increase access to our parts and solve unique customer buying preferences. Impor tantly, we’ve chosen partners who uphold our commitment to quality and

customer experience.

LAPIDES: In many cases, third party suppliers provide just as good an alternative to the OEM when it comes to parts, and sometimes better. Often, the part purchased from a third-party supplier will be literally identical to that provided by the OEM, as both are sourcing the part from the same manufacturer. Price, quality, service, delivery are also areas where third-party parts companies can excel. For third-party parts suppliers, their parts sales are the core of their business, so they tend to pay great attention to the entire parts purchasing experience for their customers.

LAPIDES: There can be several advantages to buying from a third-party supplier, including availability, price, customer service and support. Remember, for the third-party supplier, the parts are their livelihood and so their primary focus is on the parts. Price can be a significant advantage due to lower overhead, and a good third-party supplier will ensure excellent quality and ease of purchase.

LIPSON: Price is an advantage when buying from third-party providers. Typically, third-party companies offer significant savings over the OEM, offering the same or better warranty. Ease of transacting can also be an advantage of dealing with third parties. Another advantage is the that some third-party companies can rapidly source hard to find parts when unavailable from the OEM.

providers who are committed to your success. Do they work to ensure you are buying only the parts you need? Are they delivering quality parts with low out-of-box failures and, if a part does fail early, what is the warranty commitment? Do they maintain inventory or is there a markup cost to connect you with another party who is selling the part? Ask about a provider’s quality management systems and the reliability of their sourcing channels.

T HOMAS: I would not recommend buying ONLY from the OEMs. OEMs do not manufacture all of their parts typically and lead times, on average, seem to take longer than a third party as the third party might heavily stock specific parts with a higher failure rate.

TORRES: I typically go to the OEMs for parts first, however, if you factor the first question’s answers it may lead you to another alternative. There are several aftermarket solutions that have just as good or better quality part offerings. It truly depends on cost, availability and lead time for me.

T HOMAS: Generally, to get the most for your money, buying parts from a third party can save the average buyer between 25 to 50 percent in most instances compared to purchas ing directly through the OEM. Additionally, some third-party providers might also offer a more extended warranty period on the part compared to the OEM.

TORRES: I typically go to the OEMs for parts first, however, if you factor the first question’s answers it may lead you to another alternative. There are several aftermarket solutions that have just as good or better quality part offerings. It truly depends on cost, availability and lead time for me.

4. WHAT ARE SOME TIPS FOR FINDING A REPUTABLE PARTS PROVIDER?

GERMANOTTA: Look for

MICHAEL LIPSON MIT / MedEquipLAPIDES: There are several ways to find a reliable parts provider. Attending industry conferences is a good place to start, including state biomed association conferences, MD Expos and the AAMI Exchange. At those exhibit halls there will be many parts suppliers and the prospective purchaser will be able to ask questions of the supplier to get a good feel for the company. Buyers guides such as the MD Publishing Buyers Guide and industry websites are another good place to search. Asking the supplier for some references as well as copies of

IRA LAPIDES HCGcertifications like ISO are good ways to assess a supplier.

LIPSON: Word of mouth is always a good place to start. Ask your fellow HTMs or industry peers for suggestions on parts providers. Browsing through trade magazines, online trade related sites and even Google search and then doing your research on any companies you find. Looking at reviews from customers and end users can shed some light on how that provider holds up. Make sure the provider has a quality system in place.

T HOMAS: If considering utilizing a new company for purchasing parts, I would encourage them to do some due diligence. Ask companies how long they have been in business and if they are authorized resellers of the equipment needing to be purchased or repaired. You can also confirm the parts provider has experience in selling the specific type of part requested.

GERMANOTTA: We believe there are multiple factors to consider. Time lost due to ordering the wrong part, shipping delays or early part failure often erodes the savings a low-price alternative might offer.

LAPIDES: When it comes to parts for medical equipment, cost should never be the only factor. Quality metrics are key, such as DOA rates for parts, on-time shipping performance, warranty, technical support and customer service are key factors as well. Asking the supplier how they engineer, source and/or manufacture the parts to get a good feel for their processes for producing the parts is essential as well.

LIPSON: Cost is not the only factor. Always consider the reputation of the third party. Evaluate their warranty policy. Look for companies that are committed to customer satisfaction, maybe they offer surveys. Make sure they have a quality system in place. Also consider the technical expertise of their service department. Always look for a company that has a good post sales service/process.

TORRES: The first step is to always get the OEM part number if you can because most reputable third-party providers will be able to reference that part and give you their alternative. Reputation is everything! Ask your fellow biomeds their thoughts and experiences with parts providers. Consider who the OEM is of that device and recognize their may not be a third-party solution because they have kept that device entirely propri etary, i.e. no parts, literature, nothing made available outside their net.

T HOMAS: Cost should not be the only factor considered, as you should also confirm the warranty on the part being serviced or replaced. Next, establish a timeline of expectations of when the part will be delivered or the unit will be serviced. This will limit issues down the road, such as receiving an incorrect part or resending a unit for repair that was not fixed properly initially.

LIPSON: No, I believe hospitals should also look at third parties when search ing for parts. In many cases these are the same parts that the OEM is selling, whether new or refurbished. Third-par ty companies can offer the same quality parts, backed by a quality system and a good or better warranty policy.

LIPSON: Cost is not the only factor. Always consider the reputation of the third party. Evaluate their warranty policy. Look for companies that are committed to customer satisfaction, maybe they offer surveys. Make sure they have a quality system in place. Also consider the technical expertise of their service department. Always look for a company that has a good post sales service/process.

T HOMAS: Cost should not be the only factor considered, as you should also confirm the warranty on the part being serviced or replaced. Next, establish a timeline of expectations of when the part will be delivered or the unit will be serviced. This will limit issues down the road, such as receiv ing an incorrect part or resending a unit for repair that was not fixed properly initially.

TORRES: Cost is the driving force in decision making, but it is not the only factor to consider. Compatability, quality of build, is there a warranty, is it returnable, what is availability, what is the lead time are all critical things to consider.

GERMANOTTA: Key data points should include OEM part number and description (including when purchasing from a third party), purchase price and on-time delivery metrics. Additionally, some key parts are likely to be serial ized, such as CT tubes, and this information should be recorded.

LAPIDES: Tracking DOA rates and failure rates once the part is in use are two good measures to track for deter mining the quality of a supplier. On-time shipping is another key factor, as this can help a hospital keep invento ry down and minimize equipment down time.

LIPSON: Collect data on cost, warranty policies, failure rates, inventory lead times and the availability of buying the same parts over time. Any information on the companies you are buying from, including their quality policy, quality metrics and their history fulfilling your parts needs.

T HOMAS: I would record the follow ing: supplier, who the part was sourced from, part manufacturer, model and/or part number, the system that will be connected or installed, and warranty terms. This way, you could easily reference this information as needed.

TORRES: Did the part solve the problem? What was the OEM/ third-party part number? What was the availability/lead time to get it? What was the cost of the part and how much longer will the part remain available?

GERMANOTTA: Be diligent in evaluat ing the best option to ensure your success. Consider all the “costs” in the sourcing process to ensure the savings are real or

the price premiums provide a benefit toward other cost avoidance. At the end of the day, system uptime is the final measure of success for sourcing decisions.

LAPIDES: One other key feature for a parts supplier, whether it be the OEM or a third-party supplier, is how they respond when there is a problem. If the part is DOA or fails prematurely, or if there is a trend or issue with a batch of parts, does the supplier handle the situation well? Do they offer support to the hospital, providing different potential solutions and a commitment to address the issue with a root cause analysis and long term solution? Do they follow up with the customer to be sure the problem was resolved to the customer’s satisfac tion? This, to me, is very critical. Hospi tals want partners that they can rely on, who will work with them to solve problems, even anticipate potential problems, and look ahead to help the hospital achieve its goals. Hospitals do not want transactional suppliers who are simply there for the sale.

copy of their quality policy. Reach out to the quality manager with any questions you may have and any feedback, positive or negative. Let your supplier know how they are doing.

T HOMAS: Some companies will offer free technical support for customers. This would be helpful initially to get feedback on the issue the unit is experi encing and sometimes can resolve the issue without parts needing to be purchased. At Ampronix, we have resolved problems over the phone while troubleshooting due to settings that needed to be updated or firmware that was not installed correctly. Also, if the part required is becoming end of life, it would be beneficial to order multiple quantities of the part needed, especially if the facility has other units that could be affected.

TORRES: I will always check with the OEM first because what you learn at that point will set you on a course for searching elsewhere, recommendations to end user and serviceability of that device. Also, as a community, we need to hold our part distributors, aftermar ket and OEMs accountable for the quality of service, availability of parts and support they provide. If they aren’t meeting our needs, then their reputa tion and usage should reflect that. Last ly, if you’re stuck and cannot find a solution go to MedWrench, LinkedIn, Facebook Groups and Discord groups for support. We move as we do because we have a strong community dedicated to patient safety!

LIPSON: Ask the companies you are buying from if they have a process in place for testing the parts they are offering. Use surveys when available to let third parties know how they are doing. Or when working with ISO certified companies feel free to ask for a

An online resource where medical equipment professionals can find all the information needed to help them be more successful! The easy to navigate Bulletin Board gives you access to informative blogs, expos and events, con tinuing education opportunities, and a job board. Visit www.MedWrench.com/BulletinBoard to find out more about this resource. Follow MedWrench on twitter @medwrench, facebook.com/medwrench & linkedin.com/company/medwrench!

An online resource where medical equipment professionals can find all the information needed to help them be more successful! The easy to navigate Bulletin Board gives you access to informative blogs, expos and events, continuing education opportunities, and a job board. Visit www.MedWrench.com/BulletinBoard to find out more about this resource. Follow MedWrench on twitter @medwrench, facebook.com/medwrench & linkedin.com/company/medwrench!

Get ready for these events coming soon!

“ ” SAVE the DATE The Woodlands Waterway Marriott Hotel & Convention Center | Houston, TX REGISTER FOR FREE AT HTMJOBS.COM

I bought EPIQ 5 (Elite) two years ago. Recently, when I use linear probe (e 18-4), it’s very noisy, it was upgraded from 5.0 to 9.0.2. How should I deal with this problem? Thank you very much.

become an illegal monopoly to service your equipment and keeps you from being able to do basic service such as reload software after replacing a bad hard drive.

When upgraded, did they (Philips), bring in an apps specialist? If not, I would request that first. If they did complete apps:

1. Compare with a different L18-4.

2. Replace the Acquisition Module. (The channel board resides here)

Philips has removed the key base login which has disabled anyone without a Philips IST key from accessing the service area of an ultrasound system. They pressure customers into this upgrade by stating the system is vulnerable to being hacked. However, the “hacking” is only done by someone with access to the system aka third-party service orgs or a biomed that has retained outside service orgs that have the ability to give them access to the service platform of the system. However, as soon as an organization decides to upgrade to a revision higher than 5.0.3, Philips has now

Additionally, when you upgrade from any revision software, you will pay for the software upgrade but they will not give you a copy of the software after the upgrade. Even if you have purchased the software, you can reload it onto the new hard drives but without an IST ongle or a Philips parts contract that allows a first responder access, you can’t load the necessary Licensed Options File from your newly created Preset backup and the system will continuously display a 014 error code after the reload until a Philips FSE is dispatched for a service call.

You now still have a non-working medical device after the hard drive replacement which is hindering patient care until a Philips engineer can come onsite to log into the Service Platform and load the LO file which takes about two minutes and can cost the facility a trip charge upwards of more than $1,200.

If you had access to the system’s Service Platform, the patients needing scans would not have to be rescheduled and be able to receive

their diagnosis in a timely manner. However, Philips, unlike GE and Siemens that leave software on their systems and make it possible to complete most service, such as part replacement without the need of proprietary service tools, HDD replacement without the need of proprietary service told to load Licensed Files after the software reload and finally, having to purchase software separately that is already licensed for you system.

My recommendation as a third-party service organization would be to steer away from purchasing a Philips ultrasound system running the software that violates fair business practices and forces you to utilize the overpriced OEM field service monopoly. Find an OEM that practices in a more open-minded service platform that doesn’t hinder your ability to service your equipment that you paid for or having the choice to use someone other than the OEM that is qualified and able to do so while still keeping patient safety and patient care as a whole in mind without causing more cost to the hospital/ organization.

is compiled from MedWrench.com. Go to MedWrench.com community forums to find out how you can join and be part of the discussion.

1. Cybersecurity Attacks Can Disrupt Healthcare Delivery, Impacting Patient Safety 2. Supply Chain Shortfalls Pose Risks to Patient Care 3. Damaged Infusion Pumps Can Cause Medication Errors 4. Inadequate Emergency Stockpiles Could Disrupt Patient Care during a Public

Health Emergency 5. Telehealth Workflow and Human Factors Shortcomings Can Cause Poor Outcomes 6. Failure to Adhere to Syringe Pump Best Practices Can Lead to Dangerous Medication Delivery Errors 7. AI-Based Reconstruction Can Distort Images, Threatening Diagnostic Outcomes

8. Poor Duodenoscope Repro cessing Ergonomics and Workflows Put Healthcare Workers and Patients at Risk 9. Disposable Gowns with Insufficient Barrier Protection Put Wearers at Risk 10. Wi-Fi Dropouts and Dead Zones Can Lead to Patient Care Delays, Injuries, and Deaths

YP at MD is a group of young professionals in the HTM industry. Gather with your fellow up-and-coming colleagues at our MD Expos, HTM mixers and on social media to network, share ideas and discuss our bright future in the HTM industry!

Gather with your fellow up-andcoming collagues to network, share ideas and discuss our bright future in the HTM industry!

DECEMBER 7 | Althea

DECEMBER 14 | Cynerio

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

“This is easily one of the BEST resources available for day to day questions, particularly technical. What I enjoy the most is the accumulated brain power and experience for those legacy systems and devices that tend to linger and reference material is not available in e-form.”

“It is a great resource for troubleshooting problems, finding parts and introducing us to new vendors that help keep things going at our hospital. An extra bonus is the network of people that I have made friends with during research and troubleshooting. Sometimes I help them solve problems and sometimes they help me.”

“MedWrench provides a one-stop shop for information on a vast array of medical devices. It provides needed documentation when it is difficult to find elsewhere. It also provides a place for technicians to use the HTS community to address known issues or help troubleshoot something they were stumped on. 100% necessary bookmark for any HTS professional regardless of title or position.”

- Lee Woodruff, HTM Director

“I use it as a source of information , technical information and to establish contact with companies that supply medical equipment parts.”

- M Carlos Velasco Vivas, Engineer

“Love the access to service manuals and the ability to ask questions of other HTM professionals.”

- Tammy Sosa, Site manager ssm st Mary’ Jefferson City

“I have found MedWrench to be the go to place for equipment manuals that I am unable to locate online. The website is full of useful information and the download process is fast and convenient.”

- Sheryl Blount, Biomed Systems Analyst

“ Solved many issues before work was started.”

- Jeff Robinson, Owner

- Christopher Brown/ Service Engineer ll

- Eric Clark, Manager, HTS

“I use MedWrench nearly everyday. Such a great resource!”

- Jimmie Lee Norman, Biomedical Equipment Technician

is a product focused support network where medical professionals, purchasing administrators, manufacturers, dealers and industry experts can provide opinions, share ideas, and gather relevant information on medical technology and equipment. We want to say thank you for all of our users over the years. MedWrench wouldn’t be here if it wasn’t for our users!