EFFORTNEEDEDTOCREATESTANDARDIZED HTMTITLESACROSSTHEINDUSTRY

The Insulation tester, Leak Tester Tester and Cable Continuity Tester are easy-to-use devices for verifying the functionality of equipment for safety

Detect & locate defects such as pinholes, cracks and bare spots in the jacket or coating of laparoscopic and bi-polar electrosurgical instruments

Test the functionality of automated & handheld endoscope leakage testers with healthmark’s new Leak Tester Tester.

Test the quality of monopolar and bipolar cords with this user-friendly, durable device. A green light notifies the user that the cable passed testing.

For more of Healthmark’s intelligent solutions for instrument care and infection control, visit HMARK.COM

RSTI is committed to improving the quality of diagnostic imaging service and helping students advance their careers through knowledge, education and hands-on, technical learning.

“Having completed Phase I: Principles to Servicing Diagnostic X-Ray Systems at RSTI was a large factor in getting selected for my current position with Mayo Clinic in the Medical Imaging Department.”

“RSTI teaches you how to work on a modality, not single machines…learning the theory then the process of how the machine works and how to service it gives you a good foundation and makes you ready for any model.”

COMPLETE SUPPORT PARTNERFOR OUR SERVICE CUSTOMER:

• Hands-On, Technical Training

• Imaging Parts Inventory – Tested and Ready to Ship!

• Service Support – Tube Installs, PMs, etc.

• Technical Support – Access to 174+ years of Instructor Technical Expertise

• Equipment Options – Including Mobiles

P.12 SPOTLIGHT

p.12 Department of the Month: The Keck Medicine of USC Biomedical Engineering Department

p.14 Company Showcase: CBET

p.18 Professional of the Month: Brian Inphouva, CBET, CHTM

p.20 Company Showcase: The Intermed Group

p.23 Next Gen: Paul Rasche

p.24 Shifting Gears: The Ultimate Escape; Free Falling to Earth

p.28 Company Showcase: Bird Technologies

P.30 INDUSTRY UPDATES

p.30 MD Expo Recap

p.32 News & Notes

p.38 Welcome to TechNation

p.41 AAMI

p.42 ECRI

p.44 Ribbon Cutting: CompliaMED

P.46 THE BENCH

p.46 Biomed 101

p.49 Tools of the Trade

p.51 Webinar Wednesday

P.52 FEATURE ARTICLES

p.52 Roundtable: Training and Education

p.58 Corporate Profile: Elite Biomedical Solutions

p.62 All Aboard: Effort Needed to Create Standardized HTM Titles Across the Industry

P.66 EXPERT ADVICE

p.66 [Sponsored Content] Avante Health Solutions

p.69 Career Center

62 52

p.70 [Sponsored Content] NVRT Labs

p.72 Right to Repair

p.74 [Sponsored Content] Innovatus Imaging

p.76 The Future

p.78 [Sponsored Content] Block Imaging

p.80 [Sponsored Content] Renew Biomedical

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey OF SALES

EDITORIAL John Wallace

CONTRIBUTORS

Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Connor Walsh

David Witt

Steven J. Yelton

ACCOUNT

EXECUTIVES

ART DEPARTMENT

Megan Cabot

Emily Hise

Karlee Gower

Taylor Hayes

Kameryn Johnson

DIGITAL SERVICES

Cindy Galindo

Kennedy Krieg

Haley Wells

EVENTS Kristin Leavoy

WEBINARS

HTMJOBS.COM

ACCOUNTING

CIRCULATION

Linda Hasluem

Kristen Register

Sydney Krieg

Diane Costea

Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Jim Fedele, CBET, Senior Director of Clinical Engineering, UPMC

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Benjamin Scoggin, MBA, MMCi, Director, Clinical Engineering | Biomedical Operations, Equipment Distribution, Clinical IT, DHTS, Duke Health Technology Solutions

Allison Woollford, Biomedical Equipment Specialist at Duke University Health System

The Keck School of Medicine of the University of Southern California (USC) was established in 1885. In 1999, USC received a gift of $110 million from the W.M. Keck Foundation. That gift prompted the school to rename itself in honor of the generous gift.

That is how Keck Medicine of the University of Southern California’s medical enterprise got its name also.

Keck Medicine is comprised of the USC Norris Cancer Hospital, USC Verdugo Hills Hospital, USC Arcadia Hospital and more than 100 unique clinics in Los Angeles, Orange, Kern, Tulare and Ventura counties.

The health system’s biomedical engineering department manages the many medical devices spread across the facilities that serve patients in southern California.

“Keck is a 400-bed acute care hospital, Norris Cancer Center is a 100-bed cancer center, and we have over 70 clinics throughout the Los Angeles and Orange country,” says Jesus “Jesse” Lopez, director of operations of the biomedical engineering department.

He says that Keck and Norris are equipped with state-ofthe-art medical equipment, including diagnostic imaging equipment, patient monitoring systems and surgical equipment.

“Our biomedical engineering department is responsible for maintaining and servicing this equipment to ensure that patients receive the best possible care,” he adds.

In addition to Lopez, the department staff includes USC Biomed Administrator Sandra Paredes; Keck Biomed Supervisor Rene Pulido; Keck Biomed Techs Adrian Banuelos, Anthony Contreras, Ericka Contreras, Gabriel Luque, Michael Velarde, Nelson Figueroa and Fernando Ruezga.

Other members of the department include Norris Cancer Center Biomed Supervisor Derik Davoudian and Norris Biomed Techs Chris Su and Christ Khodaverdy. There is also Ambulatory Services Biomed Supervisor Rot Tutam and

Ambulatory Biomed Techs Victor Azurdia and Jerson Alvarez.

The team members work closely with their colleagues in IT to harden the surface of their networks from external threats.

“Our biomedical engineering team works closely with our IT department to ensure that all medical devices and systems are secure and fully integrated into our network. We regularly conduct risk assessments and vulnerability testing to identify potential weaknesses in our systems and address them proactively,” Lopez says.

He says that the department has implemented a variety of technical controls, including firewalls, intrusion detection and prevention systems, and multi-factor authentication to help protect their systems and data from external threats. Lopez says that they also conduct regular penetration testing to identify potential vulnerabilities in their systems and address them proactively.

“Overall, our biomedical engineering department supports almost 19,000 pieces of equipment in a 500-bed environment and several outpatient clinics and medical offices,” he adds.

The team members also participate in various continuing education and training programs to ensure that they are up to date with the latest advances in medical technology and equipment management.

Working in conjunction with clinical staff, administrators, manufacturers and vendors, the biomed team has participated in several special projects aimed at improving patient care and health care operations.

“One notable project that our department was involved in was the upgrading of our electronic health record (EHR) system. Our team worked closely with the IT department and health care providers to ensure that the new system was properly integrated with our medical equipment and that all data was accurately captured and stored,” Lopez says.

He says that the project required extensive planning and coordination, as well as training and support for staff members throughout the organization.

“The successful upgrade of the EHR system has led to

more efficient documentation and communication of patient data, which has improved patient care and outcomes,” Lopez says.

He says that the department has also participated in several research studies and quality improvement initiatives aimed at improving patient care and outcomes.

“These projects have included the development of new protocols for equipment maintenance, the implementation of new technology and the evaluation of new medical devices,” Lopez says.

“We are committed to staying at the forefront of healthcare technology management and contributing to the advancement of the field,” Lopez adds.

In the area of problem-solving the biomed team has developed a prioritization protocol with input from clinicians.

“We have developed a system for prioritizing maintenance and repairs based on the urgency of the issue and the impact on patient care. Our team works closely with clinical staff to understand the needs of each department and to ensure that equipment is maintained and repaired in a timely manner to minimize downtime and ensure that patients have access to the equipment they need. We also utilize data analytics and performance metrics to identify trends and issues before they become major problems, allowing us to proactively address issues and prevent downtime,” Lopez says.

He says that the team is highly skilled in troubleshooting and

resolving issues with medical equipment quickly and efficiently.

“We understand that downtime can have a significant impact on patient care and outcomes, and we work diligently to resolve issues as quickly as possible to minimize disruption and ensure that patients receive the care they need. We are also constantly seeking new ways to improve our processes and procedures to reduce downtime and improve efficiency,” Lopez says.

Team members are active in the HTM community outside of work.

“As the director of our biomedical engineering department, I am proud to say that our team is actively involved in several professional association activities aimed at advancing the field of healthcare technology management and improving patient care,” Lopez says.

“Here at USC, we are involved in the California Medical Instrumentation Association (CMIA) which is dedicated to the promotion, education and information exchange of the state’s clinical biomedical engineering community,” he adds.

Working for one of the leading research and health care providers in the country requires an equally competent team of HTM professionals. The biomedical engineering team at Keck prove that they are up to the task.

“We are committed to staying at the forefront of healthcare technology management and contributing to the advancement of the field.”

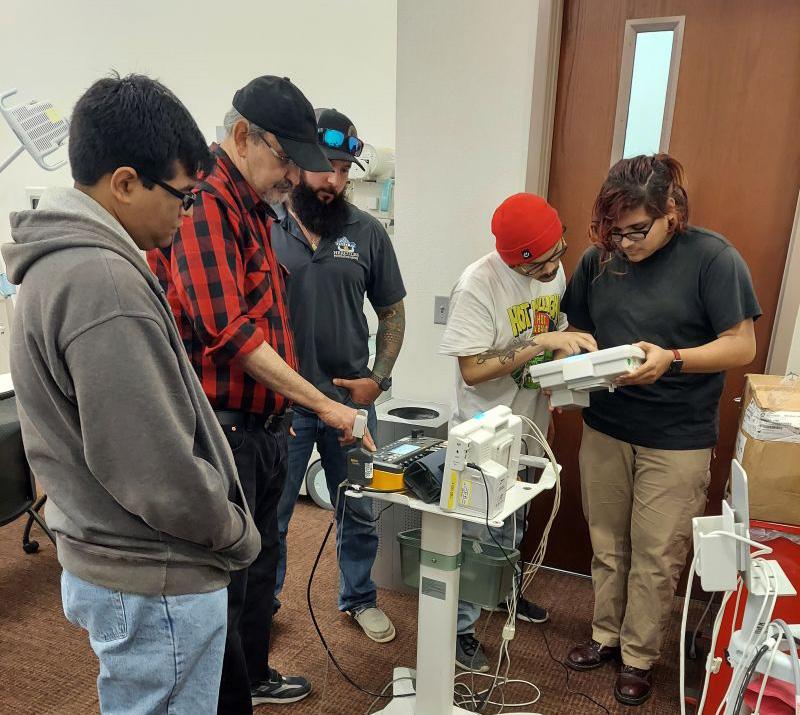

The College of Biomedical Equipment Technology (CBET) was formed to address the growing demand for skilled biomedical equipment technicians.

“Since our founding, demand for skilled technicians has only grown, exacerbated by the effects of the ‘silver tsunami,’ the pandemic and other factors. Additionally, the health care industry is facing a skills gap, driven largely by rapidly advancing technologies and limited access to quality education and training,” said Richard L. “Monty” Gonzales, Ed.D., President, College of Biomedical Equipment Technology (CBET).

“Our success in addressing these issues can be attributed to the relationships of trust we have formed with HTM leaders across the country. By working closely with medical device manufacturers, independent service providers, hospitals and other health care organizations to design our programs, we can ensure students receive training and develop the necessary skills that meet evolving employment needs,” he added. “The most important measure of our success continues to be our ability to educate, train and place students with respected health care organizations across the country and internationally. In 2022, we provided education and training to more than 600 students, the overwhelming majority of whom are working in the healthcare technology management (HTM) industry today.”

TechNation found out more about CBET with a question-and-answer session with Gonzales.

GONZALES: One of the main advantages of being a college that offers its programs via interactive distance learning is the

flexibility it offers. Online classes can be completed from anywhere with an Internet connection, allowing students to work on their own schedule. This is particularly beneficial for students who have work, family or other obligations that make attending traditional classes difficult. In addition, online courses often offer a wider range of options and can be significantly more affordable than on-campus classes. Flexibility and affordability are too often barriers to meeting applicant needs, and being an online college allows us to bring down those barriers.

CBET is also an accredited college, which means that all our operations, programs, online educational delivery and hybrid offerings are subject to rigorous peer and accreditor review and independently held to the highest benchmarks for completion and placement.

Perhaps the most important advantage we possess is the relationship we have with the health care community. The unique relationship with the industry we serve enables our team to constantly improve the education and training our students receive consistent with real-time and evolving industry needs. Our relationship with industry also enables our career services team to better support graduates seeking employment or advanced career opportunities.

GONZALES: The biggest challenge we face, and a recurring theme in our conversations with our industry colleagues, is related to our goal of maintaining curriculum and programs aligned with industry demands. There are the “steady state” challenges, the day-to-day work of ensuring regulatory compliance and accreditation to maintain standards consistent with Department of Education guidelines. And there are the other challenges, like those driven by accelerated rates of change associated with technology, or simply aligning programs and content with the trends and needs of the health care sector. Our goal – to keep no light between us and those that we serve – has served us well in addressing this challenge.

Q: CAN YOU EXPLAIN CBET’S CORE COMPETENCIES?

GONZALES: The College of Biomedical Equipment Technology (CBET) is an accredited educational institution offering Biomedical, Healthcare Information Systems Management (HISM), Imaging, Cybersecurity, and other technically oriented courses and programs. Our core competencies revolve around the types of education and training we deliver and the instructional team responsible for delivering them.

In addition to our accredited certificate and degree programs, we work directly with health care organizations to design customized education and training to assess and address skills gaps. We don’t believe in “cookie cutter” solutions or a “one-size-fits-all” approach. We have discovered that flexibility and working with health care organizations in an iterative manner to customize high value targeted training is extremely beneficial.

A third unique competency we possess is our ability to develop customized XR training content. Several years ago, we began exploring paths into the XR development arena and made a commitment to establish an organic capability to develop XR content to improve the quality and expand the delivery options of education and training. We believe that the future of HTM education and training is going to be closely linked to this sort of technology and are committed to its full development and adoption.

Q: WHAT OFFERS ARE YOU MOST EXCITED ABOUT RIGHT NOW?

GONZALES: The college is thrilled to announce the unveiling of a new degree program, Healthcare Information Systems Management. This program was designed to meet the growing need for health care professionals who possess a unique combination of skills in Medical Device Integration (MDI), Cybersecurity, Information Technology, and Healthcare Technology Management. The program will prepare students to manage the complex information systems used in health care organizations, with a particular focus on cybersecurity and medical device integration.

The program concept was conceived from a years-long collaboration with the HTM team at Sodexo, and the development of a Biomedical and Imaging Information Systems (BIIS) training course designed to up-skill their technicians to better address cybersecurity risks in the health care organizations they serve. The collaboration, led by Tyler Chaney and Christopher Faulkner at Sodexo, and John Schmidt, from the College of Biomedical Equipment Technology, has proven an incredibly effective model for conceiving, developing, and delivering relevant and valuable training.

GONZALES: The College of Biomedical Equipment Technology (CBET) is in San Antonio, Texas, a few miles away from the Department of Defense Medical Education and Training Campus (METC) and epicenter of the military biomedical training program at Fort Sam Houston. Suffice it to say, the fact that we are in San Antonio is not by accident. As a majority

Veteran owned and operated company, there were too many obvious advantages to locating in San Antonio.

Additionally, through a partnership with 626, we have been able to establish a state-of-the-art imaging training facility just outside of Atlanta, Georgia. The 15,000-square-foot imaging training center enables us to provide hands-on training for students in the imaging technology program. The center includes classrooms, labs and simulation rooms that allow students to obtain hands-on experience in maintaining, operating, troubleshooting and diagnosing imaging equipment. The imaging training center is staffed by experienced instructors who are experts in imaging technology and are dedicated to providing students with the highest level of training and education.

As a college that provides much of its education and training online to a national student population, we have also invested heavily in a quality learning management system and other software infrastructure to ensure quality interaction between faculty and students, as well as students and their peers, and students and all of the career, academic and other services we provide to ensure their success. Our commitment to the development of XR training content and incorporation of this into curricula is a truly exciting opportunity to expand the value and delivery of online training.

GONZALES: In the near future, CBET plans to expand its offerings in several key areas. One area of focus is expanding accreditation and compliance training by introducing approved Certified Healthcare Operations Professional (CHOP) certification preparation courses. Working in concert with DNV, the college will be offering individual and group sessions designed to better equip technicians and managers with the skill necessary to address health care accreditation and compliance demands.

Another interesting area of expansion is our initiative to develop a new program for dental repair technicians. For the past year we have been working with representatives from Dental Whale, an ISO specializing in dental equipment repair, and Dexis, a leading provider of dental imaging equipment, to design a certificate program addressing the specific needs of the dental industry.

Lastly, we have been working with the widely regarded Al Gresch over the past year to develop a leadership training series. The series, which I hope will present much like the popular Master Class Series you see advertised, is intended to serve as a series of professional development seminars focusing on topics of critical importance that are under-addressed in formal education. Topics like “Lean Concepts and Performance Measures: Instruments to Optimize Performance and Customer Satisfaction” and “CMMS Use and Application: Keys to Demonstrating and Building Your Value” will be included in the series. We are excited to see where these seminars take us next.

For more information, visit cbet.edu.

leasanton, California sits east of the San Francisco Bay in Alameda County in northern California. It is northeast of the city of San Jose. Pleasanton is headquarters to several major corporations. It is also the location for Stanford Health Care Tri-Valley.

Stanford Health Care Tri-Valley is a part of Stanford Medicine and has locations in the cities of Dublin, Pleasanton and Livermore, California.

The health system’s biomedical engineering department includes Assistant Manager of Biomed and IT Brian Inphouva, CBET, CHTM.

Like many successful members of the HTM community, Inphouva got his start in the military.

“Before separating from the military in 2013, I found an article talking about the trajectory and demand for more HTM professionals. It was the perfect field for me to translate my aviation electronics experience into, given that I acquire the supplemental education and certifications,” he says.

Inphouva attended the military’s Aviation Electronics Intermediate Level Training and Calibration school, which provided the foundation for his technology/electronics knowledge.

“From there, I attended DeVry’s Biomedical Engineering Technology program in Fremont, California, where we topped it off with a six-month internship to really witness the day-today of HTM operations,” he says.

Inphouva worked his way up from starting out as an intern to a lead biomed, supervisor and into his current position as an assistant manager. His area of specialty is managing service contracts.

It is managing service contracts that Inphouva says can present some challenges. He says that managing every specialty device’s service contract in the hospital can be daunting at first.

“But, with the strategic approach of consolidating with a multi-year master service agreement, has helped reduce the itemization of each task and eased the hassle of adding devices in the future. Tracking these contracts via Smartsheets has been a tremendous hack for me. I am able to create intake forms for vendor quotes, track the life cycle of a contract from beginning to end and create rollup spreads for my leadership to see firsthand live the data they need, i.e., aggregates, number of contracts, lapses in service and savings,” Inphouva says.

Although he has an experienced team of HTM professionals, there are times when putting everyone’s head together can help with problem-solving.

“My team is a pretty veteran team with five-plus years of experience now, especially at our extension of Stanford. And seldom do they request for any technical assistance. I also respect their knack as natural problem solvers and love to encourage empowerment at the front lines. Most of the time nowadays, the team is educating me on technical issues and resolutions for our newest and updated medical systems,” Inphouva says.

He recalls one day, the team was tasked with assisting the cath lab, along with collaborating with many other vendors, to set up the room for different EP configurations.

“Two of our most technical biomeds were assisting the cath team for almost four hours, running mock setups for upcoming cases. They did great! They even drew a diagram and explained how the room was configured for the rest of our team,” Inphouva explains.

He says that midway through the day, they ran into an

issue where they were unable to get the video on the boom monitor even though they were able to bridge the connection with adapters.

“I hadn’t stepped out of the office all day, and due to the high visibility of this mock setup for the upcoming EP case, I decided to scrub up and peek my head into the room to see if I could be of any assistance of my team. After getting fully briefed, and seeing with my own eyes the adapters used, I can see that we were going from digital to analog, and if anyone has ever had experience with audio/video, that would not be possible without some kind of converter. Luckily, we had ordered five of these and had them stored in the shop from a few years back,” Inphouva says.

He says that once the DVI to VGA converter was installed, they were able to get a clean and crisp live feed from the source.

“Thinking I was out of my element for some time, I was glad I could still be of some technical use to my team and still tell them about a scenario I encountered years ago. Which just proves that a biomed’s experience will always be an accumulation of problem-solving scenarios along with the decisions and steps to remediate those issues. Thus, the importance of sharing our wealth of knowledge amongst colleagues and peers,” Inphouva adds.

When not on the job, Inphouva enjoys fitness activities.

“I occasionally go snowboarding when there are good deals, partake in the bowling summer league, pickup basketball at the local 24 Hour Fitness and ride my road bike in the really tight suits,” he jokes.

“I have an amazing wife that has blessed us with two wonderful children,” he adds.

Many people from Southeast Asia, who left to escape communism, have worked hard and discovered success in the U.S. Inphouva’s parents were among those immigrants.

“I am second generation Asian-American, born to Laotian refugees who arrived during the Vietnam war,” he says.

Inphouva says that one of the things he likes best about work is the people.

“I honestly care and look out for their well-being. I need to know that I did my best to make sure you are loving what you do, feel safe and are always supported, even outside of the workplace. Whatever I can do in my power to make work worth looking forward to everyday, will always pay itself back ten-fold,” he says.

Some of that life-view may have come out of Inphouva’s background. He is a U.S. Navy veteran who served a five-year term overseas on the USS George Washington at the time homebased in Yokosuka, Japan.

It is an attitude that helped him earn the attention of others to be nominated as a professional of the month.

FAVORITE BOOK: “Think and Grow Rich” by Napoleon Hill

FAVORITE MOVIE: “Harold and Kumar go to White Castle”

HIDDEN TALENT:

I am the chef at home.

FAVORITE FOOD:

Malaysian Nasi Goreng, fried rice with chicken satay and peanut sauce.

WHAT’S ON MY BENCH?

A cup of coffee, water flask, photos of my family, desk heater and a box of Costco size protein bars.

FAVORITE PART OF BEING A BIOMED?

The relief in the eyes of clinical staff when biomed saves the day.

The InterMed Group is a dynamic provider of comprehensive healthcare technology management (HTM) services covering a broad range of client needs. InterMed’s deep-rooted partnership philosophy drives all its offerings, helping to ensure everything it does moves clients closer to achieving their goals.

The most encompassing of their offerings is their HTM services. InterMed acts as the client’s “one-stop shop” for their medical devices –whether that is filling in the gaps for the health care facility’s existing program or implementing a new one. They always bring the best to the client’s devices ranging from the linear accelerators, MRIs and CTs through anesthesia, dialysis, and respiratory therapy, to the patient monitors, infusion pumps and beds and everything in between.

Expanding on this, InterMed also provides field service-based contracts on medical equipment. Roughly 50% of its technical team members are specialized in diagnostic imaging where it provides service contracts for specific devices in hospitals, imaging centers and veterinary hospitals. In service and support of their cli -

ents InterMed team members abide by the “Sundown Rule” – they address every challenge or customer service concern by sundown each day, so their clients know their response and when to expect a resolution.

To add value, InterMed is also able to offer new and pre-owned equipment to clients. InterMed provides clients with capital planning reports, through its Technology Planning Solutions (TPS) offering, along with assessments of existing equipment to identify capital replacements that will best benefit the client. InterMed then also provides the clients with options to consider if they choose to move forward with a replacement.

Many years ago, InterMed established the JumpTeams program as it saw the demand for temporary, highly skilled technical talent. Whether a facility is trying to fill in for vacation time, adding skills for a recall or supplementing staff until a full-time technician is hired, the InterMed JumpTeams can provide partners with qualified staff.

There is not a day that goes by without the industry hearing about another health care cyber security attack. The FDA has even issued a warning that health care is being targeted. In addition to their other offerings, InterMed has solutions to create and implement cybersecurity plans for clients, no matter their size or current status in security – a plan that

“Every organization has its own mission, and its employees thrive when there is alignment. InterMed is about making health care better and about helping our partners achieve their goals.

If you are passionate about health care, it’s a perfect place to grow.”

– Larry Hertzler, COO of InterMed

encompasses the life cycle of all medical devices, from procurement onward.

The industry has been facing a shortage of qualified technical talent for many years, with a large population approaching retirement age and a shortage of new technicians joining the workforce. However, due to the pandemic, those highly experienced technicians of retirement age chose to retire. Now, post-pandemic, InterMed has an increased focus on addressing staffing challenges, and continues to successfully recruit and maintain the most qualified individuals as part of the InterMed team. InterMed’s internal philosophy of constant and never-ending improvement is really highlighted by its training,

where each employee has a hand in creating their annual training plan, while also educating all employees to be the best at what they do.

At The InterMed Group, the team knows the industry will continue to evolve, so InterMed will continue to create solutions for tomorrow’s challenges. That is why their goal is to be the number one independent service organization in the healthcare technology management services industry – bringing the best to as many health care providers as they can, so their partners can focus on what’s important – the patients and their families.

For more information, visit intermed1.com.

Paul Rasche has an associate degree in applied science and is currently a biomed technician at Pioneer Biomedical.

TechNation recently learned more about this up-and-coming HTM professional.

Q: WHERE DID YOU GROW UP?

A: Belle, Missouri

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/EDUCATION?

A: State Technical College of Missouri

Q: HOW DID YOU FIRST DISCOVER HTM?

A: I first discovered HTM from a roommate explaining what he was going to school for.

Q: WHY DID YOU CHOOSE TO GET INTO THIS FIELD?

A: I chose this field because a roommate going to school for biomedical engineering told me what he would be doing as a biomed tech. As someone who enjoyed taking electronics apart, I was immediately interested.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: What I like most is that every day is different.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: What interests me the most is that it allows me to work behind the scenes in the medical field. I love

playing a role in helping patients without actually being right in front of them.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: My greatest accomplishment thus far, a year in this field, would be gaining the knowledge to troubleshoot and repair complex medical devices.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: My goals in the next five years would be expanding my knowledge on different medical devices, acquiring AAMI certifications and figuring out which part of biomed I am most passionate about.

FAVORITE HOBBY: Soccer

FAVORITE SHOW OR MOVIE: “The Vikings”

FAVORITE MEAL:

A fat ribeye steak with roasted Brussel sprouts and truffle fries.

WHAT WOULD YOUR SUPERPOWER BE?

I would want Flash’s super powers.

1 THING ON YOUR BUCKET LIST: Visit the gladiator colosseum in Rome.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I’ve competed in a bodybuilding competition.

Jumping out of a plane may be on some people’s bucket list, but it is likely on many other “no-way in the world” lists as well. It takes a special personality with an adventurous and unconventional spirit to strap on a parachute and step out of a plane at 5,000 feet.

One biomed and business owner has dared to take that leap.

Curtis R. Shaw, owner and operations manager of Innovatrix Biomedical LLC in Colorado, has strapped on a parachute many times and stepped out of a plane.

“I have always been a fan of extreme sports; skydiving was just something I didn’t think ‘normal’ people got into. When I was really young, my friends and I were into skateboarding, snowboarding, bikes, etcetera, and we always tried to push the edge. As we got older, we got more into building fast cars, racing motorcycles, street luge; really anything that made me feel ‘alive.’ When a friend of mine called me to go do a tandem with them, I didn’t even have to think about it. ‘Yes, send me the time and place,’ ” Shaw says.

He says that when they got to the dropzone (DZ) that day, the group of six was down to a group of three.

“We were on a wind hold – winds gusting too much to be safe for landing – and we spent about four hours waiting to go. During those four hours, I talked to everyone; the owner of the DZ, the DZ staff, the packers, the tandem instructors, the students taking their AFF (a class to get your skydiving license), and even just other tandem students that were there that day,” Shaw says.

He says that he has always been interested in gear/ mechanics and how things work, and in his spare time, before skydiving, he built a lot of engines for cars, diesels and rotary engine vehicles.

“I spent a lot of those four hours at the DZ asking

about the gear and how it all worked. Before we went up to do our tandem, I was enrolled in a class the next day at Skydive Ricks in Petersburgh, Ohio. I knew before ever having gone that these people were more than just skydivers, they were a family. I was hooked already,” Shaw says.

It was that experience that started Shaw on his skydiving adventure, along with graduating to more advanced techniques and maneuvers. After a large number of jumps, Shaw moved into Canopy Relative Work (CRW), a more intricate version of skydiving, compared with the more common “free fall,” and which requires additional training and safety procedures.

While the more common singular, free fall skydive comes with instructions to avoid other parachutes and separate from others, CRW is all about bringing the skydivers together in the sky with a much more prolonged period of free fall. Shaw says the difference can vary by as much as 50 seconds compared to 13-15 minutes.

“CRW comes with a whole other set of emergency procedures and a whole other unique set of gear. The reserve we use is the same as normal skydiving, the main parachutes we use are specifically designed to be used for CRW and are not that good for much else. They land differently than any other parachute I’ve ever used, they open very abruptly — sometimes it hurts — but they do stay pressurized well and are great for CRW. We, like most skydivers, carry hook knives (like a seatbelt cutter knife) but we have several of them. The joke is: ‘Why does the CRW dog (what they call us) have five hook knives?’ ‘Because they didn’t have room for six.’ We use open face helmets, like you’d see someone skateboarding wear so our ears aren’t covered and we can hear each other yelling,” Shaw explains.

He says that some parachute containers, the back-

pack worn that contains the main/reserve parachutes, are better for CRW than others.

“Oftentimes, we have a lot of lines on us and we want a ‘rig’ – the whole parachute container/reserve/main – all together, that doesn’t have very many snag points on it,” Shaw says.

He says that CRW only represents about two percent of skydivers and that those who practice the sport have become like family.

When his feet are planted on the ground, Shaw is focused on the biomed business he started in 2020.

“I formed Innovatrix Biomedical LLC in January 2020, but didn’t tell anyone for about a year. December 3, 2021, was when I put in my two-week notice and four days later, I had my first meeting with the CNO and plant ops director of another, larger critical access hospital in Colorado. They asked me for a proposal; all I had was a blank Word document. I spent the next four days writing my own contract and paid my lawyer thousands to get it proofread/corrected over the weekend. A few days after that, we had an agreement and now this is the third year I’ve been there,” Shaw says.

He says that since that time, his company now works in three different states, has hired an employee and paid for his CABT certification through AAMI.

“We have full-service contracts with two critical access hospitals in Colorado, work for some local health care offices, seven nursing homes across Colorado, a lot of urgent care clinics in Wyoming and we add more every day,” Shaw says.

He says that it is his mission for his company to be the best healthcare technology management company in Colorado and surrounding states; maybe even the entire U.S. and beyond.

“All the goals I’ve set for five years, I’ve exceeded in less than three. My competitiveness as a skydiver translates very well to owning a business. A lot of skydivers are also coincidently business owners, too,” Shaw says.

He finds many parallels between the challenges of skydiving and the work of biomeds and running a business.

“If I can be calm entangled in one of my friend’s parachutes, falling towards the ground at a rate of speed high enough to kill me on impact, I can be calm when OR equipment breaks with a patient in the room. It takes a special breed of person to take that chance and possibly fail; for me I’d rather fail than regret. As of now, I have no regrets in life and my only fear is to ‘peak,’” Shaw adds.

LIVE:

JUNE 14 | Healthmark

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

JUNE 21 | RLDatix

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

JUNE 28 | Phoenix Data

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

PODCASTS:

sponsored by MMS “Continuing Your Education as a Biomed”

All webinars and podcast are eligible for 1 CE credit from the ACI.

ON-DEMAND:

sponsored by RTI Group “The Importance of Traceability in X-ray QA and Testing Performance”

sponsored by Cynerio “5 Ways HTM Teams Are Leading Healthcare Cybersecurity”

sponsored by Claroty “The Contractual Cure for Cybersecurity Pain: The Power of Medical Device Negotiations”

Bird Technologies is a global provider of radio frequency measurement and management solutions. The company was founded in 1942 as Bird Electronic Corporation by J. Raymond Bird in Cleveland, Ohio. He was a pioneer in the field of radio frequency (RF) power measurements, and his innovative work laid the foundation for the company’s success.

In the 1940s, RF power measurements were in their infancy, and there was a lack of accurate and reliable instrumentation available. Bird recognized this need and began to develop a new type of power meter that was more accurate, reliable and versatile than any existing instrument.

One of Bird’s first products was the Model 43 Wattmeter, which was introduced in 1952. The Model 43 was the world’s first portable, dual-range RF wattmeter and became the de facto standard worldwide. Still used today, the instrument helps engineers and technicians measure forward and reflected RF power in a coaxial transmission line.

Bird continued to innovate in the field of RF power measurement, developing new instruments and techniques that helped to establish the company as a leading provider of high-quality RF measurement solutions.

Today, Bird continues to innovate and develop new products and technologies that help customers manage, calibrate and optimize their RF systems, test, measure, monitor and invent on a broader and deeper scale. Its newest products have been developed with ingenuity, precision and simplicity in mind to meet the emerging challenges for a wide range of industries, including medical.

Bird Technologies Director of Strategic Development Katie Wright recently shared more information about the company.

WRIGHT: Unlike competing products, Bird has built our reputation on impeccable accuracy and simplicity for making RF power measurements. Radio frequency (RF) power measurements can be challenging to make because RF signals are complex and have many different parameters that need to be accurately measured. RF signals can be affected by a variety of factors such as interference, reflections and other environmental factors, which can make accurate power measurements more difficult.

Thru-line radio frequency (RF) power meters offer several advantages, including:

• Accuracy: Thru-line RF power meters provide highly accurate measurements of RF power, allowing for precise power measurement in an MRI system.

• High power handling capacity: Thru-line RF power meters are capable of measuring high power levels without being damaged or affecting the performance of the RF MRI system. This is especially important when measuring MRI pulse signals.

• Wide frequency range: Thru-line RF power meters can measure RF power across a wide frequency range, making them suitable for use in many different types of RF systems.

• Low insertion loss: Thru-line RF power meters have very low insertion loss, which means that they do not significantly impact the performance of the RF system they are measuring.

• Low VSWR: Thru-line RF power meters have a low voltage standing wave ratio (VSWR), which means that they do not introduce significant reflections into the RF system they are measuring.

YEAR?

WRIGHT: Bird designs and manufactures our products in the United States. This was a significant advantage during COVID as our business was deemed essential to remain open to

produce products for mission-critical markets such as medical, public safety and semiconductor. The challenges, however, surrounded the ability to receive raw material. Being a small company, Bird was able to be extremely flexible and pivot with our manufacturing by prioritizing critical products, rethinking logistics and diversifying suppliers.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

Q:

WRIGHT: Bird’s core competence is the ability to measure in-line, continuous or pulsed, RF energy with precision and simplicity. Bird is able to calibrate the MRI RF power to ensure the best diagnostic image without causing harm to the patient.

Bird’s solution would benefit MRI equipment that does not have the calibration procedure built into the unit. We have an easy-to-read display that will plug into the directional power sensor through a USB cable and our sensor that uses an element with a frequency range of 10MHz to 130MHz and load with peak power of 37kW and pulse width, max. of 10ms. This kit also is carefully calibrated at our factory to support the accuracy for MRI calibration.

• Simple and quick way to measure pulse power during MRI testing and calibration.

• Does not require a technician to use an oscilloscope.

• The sensor package is calibrated using the same pulse amplifiers used for the MRI machine.

• RF power and all the additional sources of uncertainty are eliminated.

WRIGHT: Data harnessing in RF products will make possible actionable insights that can inform decision-making and drive better performance outcomes. One example of how data harnessing in RF MRI sensors can lead to actionable insights is in the area of predictive maintenance. By collecting data from sensors embedded in RF products, it is possible to monitor performance and detect potential issues before they become major problems. This can help companies schedule maintenance activities proactively, reducing downtime and saving money on repairs.

Q: CAN YOU TELL TECHNATION READERS MORE ABOUT YOUR ON-SITE TEST EQUIPMENT FOR MRI CALIBRATION?

WRIGHT: RF power plays an important role in the medical industry that requires high precision RF power measurement. Most major manufacturers of magnetic resonance imaging (MRI) machines purchase Bird equipment for the research and development and field calibration of their MRIs.

Bird’s new MRI test kit provides a complete set of equipment to carry out precise and independent measurements of RF power encountered. It also determines if the equipment is not in the appropriate exposure limits during device or pulse sequencing test.

Our goal is to provide companies with an easier way to test MRI safety for RF exposure levels and to make independent RF power measurements to test the accuracy of the specific absorption rate over the range of operating conditions encountered in MRI.

Q:

WRIGHT: We are excited to expand our RF power measurement capabilities into the medical market, capitalizing on years of RF experience and our portable test equipment products. Bird’s new MRI kit is specially designed for MRI testing that directly samples and measures the RF power during MRI calibration. It is perfect for MRI equipment resellers, MRI and imaging service providers, field service managers and engineers.

These kits are deployed to hospitals all over the globe where technicians will disconnect the RF cabling connected to the MRI machine and use our test kit to determine the power output. Technologists, radiologists and facility staff all work hard to ensure MRI safety for every patient they treat and rely on service technicians, MRI providers and maintenance teams to have the proper test equipment to make sure their MR equipment is calibrated and safe.

For more information. visit birdrf.com

Record-breaking attendance, top notch educational offerings, signature networking events and a jammed exhibit hall marked the 2023 MD Expo in Houston, Texas. The final numbers from the healthcare technology management (HTM) conference included 659 attendees and 359 exhibit personnel for a total of 1,018 individuals not including MD Expo staff. The conference was strongly supported by HTMA-TX and HTMA-NTX.

“The 2023 MD Expo Houston is one from which all others will be measured! Every attendance record was broken, including booths, class sizes, etc., the list goes on and on,” MD Publishing President John Krieg said. “For the first time in our 20-plus year history, we had over 1,000 total attendance, and almost 700 attendees.

The HTMA-TX and HTMA-NTX societies were instrumental in getting the word out to the local community, and the national exposure the TechNation brand brought just added to the show’s huge success.”

“We are already looking at 2027 dates to return to the Houston area,” he added.

MD Publishing Vice President Kristin Leavoy, CMP, echoed Krieg’s excitement.

“Having helped organize and plan every MD Expo

since our inception in 2002, I can honestly say this MD Expo was one of the best. Not only was it the highest attendance, but the energy amongst everyone there was upbeat and positive,” Leavoy said. “Everyone was so glad to be together!”

“We anticipated this being a home run show so we started planning from day one and put the tools in place to ensure that we could hold this event with minimal hiccups. It was one of the smoothest shows we’ve ever planned,” she added. “From the moment the attendees walked up to registration to when we bid farewell at the Disco Rodeo!”

- John Krieg, MD Publishing PresidentLeavoy applauded everyone involved with the conference.

“The MD Publishing team onsite and behind the scenes truly puts their all into making every event a success. It’s not just a business event for us, it’s bringing together our friends and colleagues,” she said.

“The 2023 MD Expo Houston is one from which all others will be measured! Every attendance record was broken, including booths, class sizes, etc., the list goes on and on.”

“It’s practically a family reunion we hold twice a year!”

Health-ISAC Inc. Vice President of Medical Device Security Phil Englert said he always enjoys the networking opportunities at MD Expo.

“I get to spend more quality time with attendees and learn so much from those conversations,” he said.

“This is where you go to meet with and learn from peers,” is what Englert said he would tell anyone considering attendance at a future MD Expo.

Garrett Seeley, who presented at MD Expo Houston, said three words that describe the conference are, “vital, informative, fun.”

He added that his favorite part of the conference is catching up with friends and meeting new peers.

“It still has to be the interaction with people from the field. It is really what makes any tradeshow valuable. MD Expo provides a great opportunity to connect to other technicians and vendors,” Seeley said.

Krieg said the MD Expo team is already preparing for a successful fall conference in Florida.

“The momentum from Houston is already in full swing as we are busy gearing up for a phenomenal MD Expo Orlando,” Krieg said. “We always have an incredible turnout when we return to Florida, and the FBS support always helps with our local and regional attendance. Our education and speaker line up is once again second to none, and we expect another memorable return to Florida!”

See the MD Expo Scrapbook on page 98.

For more information, visit MDExpoShow.com.

The Joint Commission has released its Sentinel Event Data 2022 Annual Review on serious adverse events from Jan. 1 through Dec. 31, 2022. A sentinel event is a patient safety event that results in death, permanent harm or severe temporary harm. Sentinel events are debilitating to both patients and health care providers involved in the event.

The Joint Commission reviewed 1,441 sentinel events in 2022. The most prevalent sentinel event types were:

• Falls (42%)

• Delay in treatment (6%)

• Unintended retention of foreign object (6%)

• Wrong surgery (6%)

• Suicide (5%)

Failures in communications, teamwork and consistently following polices were the leading causes for reported sentinel events. Most reported sentinel events occurred in a hospital (88%). Of all the sentinel events, 20% were associated with patient death, 44% with severe temporary harm and 13% with unexpected additional care/extended stay.

“COVID-19 continued to present challenges to healthcare organizations throughout 2022, and we saw the number of

sentinel events increase above pre-pandemic levels,” notes Haytham Kaafarani, MD, MPH, FACS, chief patient safety officer and medical director, The Joint Commission. “For each sentinel event, a Joint Commission patient safety specialist worked with the impacted health care organization to identify underlying causes and improvement strategies. Our goal is to help prevent these types of adverse events from occurring again.”

The majority of sentinel events (90%) were voluntarily self-reported to The Joint Commission by an accredited or certified health care organization. The remaining sentinel events were reported either by patients or their families, or employees of a health care organization.

Reporting of sentinel events to The Joint Commission is a voluntary process, and no conclusions should be drawn about the actual relative frequency of events or trends in events over time.

The full sentinel event data summary is available at: jointcommission.org/resources/sentinel-event/sentinel-event-data-summary

Paramount Bed has selected US Med-Equip (USME) to become the exclusive U.S. distributor of its medical equipment.

USME now offers thousands of hospitals and clinicians around the country Paramount’s beds, built stronger for a lifespan surpassing many others in the industry, according to a press release. The bed’s Japanese-engineered design helps accelerate early mobility and makes preventative maintenance and repairs simple and easy, the release adds.

“The portfolio of top-quality paramount equipment for sale includes the A6 Series Medical Surgical Bed and ALiUS Medical Surgical/ICU Bed, a sought-after low-height bed with an early mobilization tool. Both have a 562-pound capacity and include advanced patient features such as simple controls and buttons for ease-of-use, grip assists for patients to hold on to support mobility and help keep them safe, stable, and balanced when standing, and built-in USB ports to charge their phones,” the release states.

Other available mobility equipment for rent includes the Sittan Rehabilitation Table, which promotes early, upright ambulation by helping patients balance when sitting on the side of their bed, and Paramount’s walking aid, which comes with two sets of brakes for enhanced safety and an adjustable height to suit most patients. All overbed tables come with an auto or a manual-locking brake to reduce the risk of patient falls when they lean on them while getting out of the bed.

“We chose USME as our partner because of their proven record providing the best service to top clinicians and staff seeking

the best equipment for their patients,” Paramount Bed USA President Kazuya Takahashi said. “We are excited to work with a dedicated team working from more than 90 locations, USME has the best resources and processes to best serve hospital partners nationwide.”

US Med-Equip partners with thousands of hospitals across the nation for the rental, sale, service and asset management of medical equipment – diagnostic and clinical devices ranging from ventilators to therapeutic patient beds. In 2022, US Med-Equip acquired Freedom Medical, known for its beds and Page 1 therapeutic mattresses with WAVE technology, which helps protect patients’ skin from pressure injuries.

“We continue to align ourselves with the best partners in the industry to bolster support for hospital partners focused on their patients’ healing,” said US Med-Equip CEO Greg Salario. “As a leader in patient bed safety, quality and durability, we share with PARAMOUNT an unwavering commitment to helping health care heroes.”

On December 29, 2022, the bipartisan $1.7 trillion Omnibus Appropriations Act was signed into law. A measure in the new bill provides the FDA with the authority to require medical device manufacturers to take additional cybersecurity protection measures, such as the inclusion of a Software Bill of Materials (SBOM) with each device brought to market through future pre-market submissions.

As of March 22, 2023, what were once cybersecurity control guidelines are now enforceable requirements. Walt Szablowski, founder and executive chairman of Eracent, which has provided complete visibility into its large enterprise clients’ networks for over two decades, suggests, “These new cybersecurity regulations tend to have a cascade effect that may sneak up on some unsuspecting entities in and around the aggregate medical-industrial complex. The good news is that Eracent can help catch everyone up to speed and is offering free access to Eracent’s Supply Chain Risk Management application (SBOM Management Application) to hospitals, health care facilities and medical device software developers.”

It’s getting harder to underestimate the evil genius of the modern-day cybercriminal. The FBI has been sounding the alarm regarding the vulnerabilities of “unpatched” or outdated medical devices that run on legacy software and those with substandard security features. Medical devices, such as insulin pumps, defibrillators, mobile cardiac telemetry, pacemakers, and intrathecal pain pumps, can be appropriated by malicious hackers who could endanger a patient’s health by changing a monitor’s reading or administering a drug overdose. A skilled hacker can exploit unsecured devices, interfere with a medical facility’s operational

activity, and compromise data confidentiality and integrity.

An SBOM essentially contains a listing of items that make up the ingredients of a hardware/software device. It comes into play when tracking security vulnerabilities and updates for each software component. The SBOM is also used for the verification and management of software licenses. Szablowski elaborates, “An SBOM by itself is impotent and ineffective if it is not constantly scrutinized by an automated, proactive process with instant visibility and vigilance in mitigating and resolving any component-level security weaknesses across the life cycle of the hardware/software device. Eracent’s cutting-edge Intelligent Cybersecurity Platform (ICSP) Cyber Supply Chain Risk Management (C-SCRM) module is unique in that it provides an additional, critical level of protection to minimize software-based security risks.”

The ICSP C-SCRM recognizes obsolete components that can increase security risks; it offers up-to-the-minute protection by independently scanning the itemized details within the SBOM and matching each listed component to the most up-to-date vulnerability data using Eracent’s IT-Pedia IT Product Data Library – a single, authoritative source for essential data concerning millions of IT hardware and software products. Medical device software developers frequently utilize open-source software (OSS) to produce products faster to hasten their release into the market. OSS is pre-coded, real-world-tested, and often free to use. An astounding 92% of applications contain open-source software. Standard vulnerability analysis tools do not scan individual OSS components within applications.

MW Imaging Corp, a leading ultrasound parts, probes, systems and service provider, recently announced the achievement of ISO 13485:2016 recertification for its business operations based out of St. Charles, Missouri.

MW Imaging’s facility was audited by DEKRA Certification Inc., an accredited ANAB Certification body. They were presented with their certificate on March 21, 2023. The St. Charles facility repairs ultrasound probes, systems and equipment from all leading manufacturers. The company has implemented standardized in-house processes and testing methods that ensure a high quality of repairs for their products and services.

ISO 13485:2016 is the world’s most widely recognized medical device quality management standard, developed and published by the International Organization for Standardization (ISO) for medical device companies. It provides a framework to establish a rigorous quality management system that aligns with FDA regulatory requirements laid out in 21CFR, Part 820. It predominantly focuses on

mandatory regulatory requirements, compliance, evidence-based decision-making, risk management and accountability across all organizational processes. It ensures that medical devices placed on the market are safe and effective.

“The core values of MW Imaging have always been to achieve the highest standards in all that we do. This recertification is a direct result of the collective efforts of the MW Imaging team. Without the dedication of our employees, this achievement would have been impossible. These efforts have led to improved efficiency, productivity and most importantly customer satisfaction. We believe this certification demonstrates our dedication to quality, continuous improvement, patient safety and both employee and customer satisfaction.” said Amber Sportsman, vice president of operations/ quality manager.

MW Imaging has been certified since March 2020, and has been audited yearly for conformance to ISO 13485:2016 standards despite the challenges of the COVID-19 pandemic.

ReNew Biomedical recently celebrated Josh Weatherford and instructor Richard Woods. Josh Weatherford, ReNew’s shop manager, was recognized as the first-ever technician to complete a biomedical apprenticeship program in association with AAMI (Association for the Advancement of Medical Instrumentation) and the U.S. Department of Labor. As part of this two-year course, he achieved his CABT and CBET certifications under the instruction of Richard Woods.

AAMI Vice President of HTM Danielle McGeary presented Weatherford with his apprenticeship completion certificate from the Department of Labor. Also in attendance was Robert Burroughs, AAMI’s Chief Learning and Development Officer. As the first individual to recieve this recognition, Weatherford’s certification has been specially recorded in the Federal

Department of Labor Archives.

The ReNew Biomedical Training Academy was announced by Governor Bill Lee and Commissioner Bob Rolfe in October of 2020, and aims to train Certified Biomedical Equipment Technicians (CBET) in West Tennessee. With the growing need for medical equipment service, ReNew is comitting to revitalize the healthcare technology management and biomedical workforce to maintain, service and repair life-saving medical equipment around the country. The RBTA program is aimed at facing labor challenges head-on and creating local skilled jobs. The academy is set to create 43 new skilled jobs over its first five years. The ReNew Biomedical Training Academy, and newly refurbished facilities, officially launched in January of 2021.

Royal Philips and Northwell Health, the largest healthcare provider in the state of New York, announced that they have entered into a seven-year agreement to help the health system standardize patient monitoring, enhance patient care and improve patient outcomes while driving interoperability and data innovation. This will not only allow Northwell Health to lay the foundation for a future-proof, enterprise-wide platform, but the system will also allow them to support innovative technologies as they evolve and give them the flexibility to scale their patient monitoring systems quickly and efficiently.

Northwell Health has 83,000 employees at 21 hospitals, including flagship facilities North Shore University Hospital and Long Island Jewish Medical Center, 850 outpatient facilities and one of the largest residency programs in the U.S. with over 1,900 residents and fellows. All of this to help them address a service area of 12 million people, treating over two million patients a year, delivering over 30,000 babies, and treating more New Yorkers for cancer than any other care provider. Northwell Health is also pioneering research at the Feinstein Institutes, including national clinical trial sites for treating lupus, rheumatoid arthritis and paralysis.

“With the new system, we wanted something that could

leverage our existing IT infrastructure and allow Northwell to offer cybersecurity, while also building in redundancy with local availability,” said Phyllis McCready, vice president and chief procurement officer for Northwell Health. “The new Philips system gives us an enterprise-wide platform that centralizes our patient monitoring and allows us to see what is happening at each bedside. The innovative approach is extensible and allows us to give the communities we serve the very latest technology, while helping us to deliver a better patient and staff experience and better outcomes.”

“As forward-thinking health systems like Northwell Health take an enterprise-wide approach to healthcare IT, we can help take the guesswork out of the technology and help them to standardize their systems, with an open, interoperable architecture that can break down barriers to integration and simplify workflow for care providers,” said Jeff DiLullo, chief market leader of Philips North America. “Their new patient monitoring system can help minimize manual tasks, give staff a centralized view of patients, and harness the power of massive amounts of data by using AI to provide actionable clinical insights – all of which are helping them to deliver a better patient and staff experience, lower costs and contribute toward the goal of improving outcomes.”

Tenacore provides immediate access to highquality, pre-owned medical equipment at a greatly reduced price. Typically, you can realize a savings of over 50% compared to new!

• Ten-step process ensures that all equipment is tested and cosmetically like new

• Six to twelve-month warranty on all equipment provides peace of mind with your purchase

• Ongoing inventory allows immediate shipment on most orders

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

NVRT Labs is an XR development company singularly focused on the creation of XR content to train healthcare technology technicians and students on various medical device procedures and repairs. NVRT Labs provides customized content development services to healthcare organizations, medical device manufacturers, educational institutions, and independent service organizations looking to scale their service capabilities and streamline their training budgets.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Each of NVRT Labs’ modules is designed to be a highly-interactive and immersive learning experience that places technicians in virtual environments with photorealistic 3D models to simulate real-world scenarios and develop real-life competencies. With a constantly growing catalogue ranging from general biomedical equipment procedures to extremely sophisticated radiology device installations and calibrations, NVRT Labs’ platform is the only XR content library created specifically for HTMs.

For more information, visit nvrtlabs.com.

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

With over 80 years of experience, Bird provides highly accurate and elegantly simple, high power radio frequency (RF) measurements and calibration kits for MRI and RF ablation equipment.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Bird has the unique ability to measure in-line, continuous or pulsed RF energy, with accuracy traceable to NIST. We provide peace of mind that the applied RF power will provide the best diagnostic image and/or accurate targeted RF therapy without causing harm to the patient.

For more information, visit birdrf.com.

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Cynch brings a digital revolution to MRO operations by automating the resource intensive maintenance and repair work order processes in the cloud. With automated MRO, our customers save time and eliminate rework using fully guided procedural instructions (checklists) and live reporting features. Cynch customers maximize up-time for manufacturing assets, medical devices, and aircraft using proactive maintenance schedules that increase overall profitability.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Alfredo Rey, Market Development

Alfredo Rey, Market Development

Cynch is a unified ERP platform offering Computerized Maintenance Management (CMMS) plus asset management, purchasing, inventory management, subcontracting and warranty claims. Customers can log-in to Cynch through their own website to manage their entire operation in one place. Technicians can see their work queue, follow a guided inspection and maintenance process, add notes, upload photos, add MRO inventory parts to the order, see asset specific user/repair manuals and so much more. Cynch also offers lightning fast filtering and searching of enormous asset catalogs by customer location, asset type, asset status, work order status, plus your custom requirements. Cynch has everything you need. Call 720-939-8467 or email Alfredo@Cynch.me to schedule your personalized demo.

For more information, visit cynch.me.

Your Ultrasound Partner

Your Ultrasound Partner

QUALITY, TESTED PARTS

QUALITY, TESTED PARTS

ULTRASOUND SERVICE TRAINING

ULTRASOUND SERVICE TRAINING

PROBE REPAIR WITH FREE LOANERS

PROBE REPAIR WITH FREE LOANERS

NEXT DAY RENTALS

NEXT DAY RENTALS

SERVICE ACROSS THE US

SERVICE ACROSS THE US

Mention this ad for 10% OFF your next part or repair.

Mention this ad for 10% OFF your next part or repair.

HAVING PROBLEMS WITH YOUR ULTRASOUND PROBE?

HAVING PROBLEMS WITH YOUR ULTRASOUND PROBE?

Scan the QR code and get an instant quote by using our free ultrasound probe evaluation tool.

Scan the QR code and get an instant quote by using our free ultrasound probe evaluation tool.

AAMI and the British Standards Institute (BSI) have jointly published guidance documents on performing risk management for machine learning (ML) or artificial intelligence (AI) incorporating medical devices.

AAMI Technical Information Report (TIR)34971:2023, Application of ISO 14971 to machine learning in artificial intelligence – Guide, derives from a 2022 AAMI consensus report (CR). The U.S. Food and Drug Administration recognized the CR as a guidance document “appropriate for meeting requirements for medical devices under the Federal Food, Drug, and Cosmetic Act.” Developed in collaboration with BSI, the CR was the first AI-related guidance to receive this level of recognition from the agency.

“The key difference about the TIR is that we’re doing it jointly with BSI,” said Hae Choe, principal director of standards at AAMI. “It is a dual-logo document. The documents are a little different because BSI doesn’t have technical information reports. They’re publishing theirs as a British Standard.”

Notably, the content of the TIR is substantively the same as the CR content, with only minor spelling and formatting differences between the U.S. and British versions. “The technical content is the same,” Choe said. But the TIR and Standard designations carry more weight – and the British Standard will extend the reach of the guidance.

To develop the CR and TIR, AAMI’s Artificial Intelligence Committee piggybacked on ISO 14971:2019, Medical Devices-Application of risk management to medical devices, and

the AAMI/ANSI/ISO 14971:2019, which is the U.S. adoption of the standard. This widely used standard details how manufacturers can implement the risk management process of assessing and mitigating potential risks to protect the health and safety of patients as well as data and system security.

Rather than reinvent the wheel, the AAMI Artificial Intelligence Committee applied the standard risk management process to the elevated or unique safety-related vulnerabilities and risks of AI- and ML-enabled medical devices, including:

• Data management

• Bias

• Data storage, security and privacy

• Overtrust

• Adaptive systems

“The risk management process is the same, but there are new ways to fail, different concerns and different risk controls to consider,” said Pat Baird, senior regulatory specialist at Philips and co-chair of the AAMI Artificial Intelligence Committee, in AAMI’s inaugural Medical Device Safety in Focus report, Artificial intelligence: The Trust Issue. “Recognize the fact that AI systems, data and clouds are going to change and that is outside your control. Plan for it. Don’t wait until something bad happens and then try to figure out what you’re going to do about that. Have the infrastructure and mechanisms in place.”

In the near future, AAMI and BSI are planning to propose TIR34971 as in international standard through International Organization for Standardization (ISO) Technical Committee (TC) 210, Quality management and corresponding general aspects for products with a health purpose including medical devices, and IEC (International Electrotechnical Commission) Subcommittee (SC) 62A/Common aspects of medical equipment, software and systems.

For more information, visit aami.org.

ecall management remains challenging for health care providers, as the number of hazard alerts involving medical devices, pharmaceuticals and other products continues to increase. From cybersecurity vulnerabilities involving complex medical technologies, to sterility issues with various consumables, to shortages across the industry, managing product recalls and corrections becomes more complex every year.

An analysis of 2022 data from the ECRI Alerts Workflow system, which facilitates efficient recall and technology risk management for medical equipment, supplies and pharmaceuticals, highlights the scale of the challenge that providers are facing:

In 2022, the number of ECRI medical device alerts and related recalls kept pace with the prior year; however, reports from providers point to a higher volume of impacted units and increased burden on the provider. The 2022 alerts breakdown as follows:

• 1,923 total medical device alerts – 62% of these were related to supplies, while the rest were related to capital equipment

• 636 alerts related to pharmaceuticals

• 546 alerts related to food products

As an indicator of risk, ECRI assigns a priority level to

each alert to help members prioritize. In 2022:

• 5% of device alerts were classified as “critical,” indicating the potential for serious injury or death

• 77% were classified as “high” priority,” indicating the potential for serious injury, temporary illness or harm

• 18% were classified as “normal priority,” based on regulatory or other risks that are unlikely to cause injury or illness

Medical device alerts classified as “critical” priority included a range of technologies, with specific types being represented multiple times:

• Several alerts related to cardiac circulatory assist units, which are used to improve blood circulation in patients with a debilitated heart

• Multiple alerts involved infusion pumps, which remain a common device affected by recalls and corrections

• As in previous years, issues involving continuous positive airway pressure and bi-level continuous positive airway pressure technologies continued to arise

• COVID tests continue to be a hot topic, as inaccurate or unapproved tests continue to cause issues for patients

In addition to the many alerts that require review and the diverse group of technologies affected, health care providers experienced several high-profile recalls that garnered much industry attention:

• Recalls involving Philips continuous positive-airway pressure devices and ventilators, stretching back to 2021, continued to be a big issue in 2022

• Contamination and resulting shortages of infant formula placed a large burden on providers and parents

• A production disruption of GE Healthcare Omnipaque (Iohexol) and Visipaque (Iodixanol) contrast media led to shortages and diagnostic imaging delays

With the large volume of recalls shown above and the complexities of recall management and supply chain sourcing, management of recalled medical devices, pharmaceuticals and food products remains a complex problem for health care providers. To ensure the safety of patients and staff, providers should have appropriate resources and technologies working seamlessly together for more effective and efficient recall management.

Some best practices are as follows:

• Ensure that recall notifications are being received and

distributed in a timely fashion.

• Confirm that recall information is properly communicated to all organizational stakeholders.

• Make sure that staff takes appropriate action to isolate affected products to help keep patients safe.

• Validate that proper information is communicated back to the manufacturer to close the recall loop. Track all recalls to closure and record actions taken for regulatory compliance and audit.

• Incorporate reporting and related dashboards to support quarterly updates and to confirm complete enterprise-wide recall compliance. ECRI can help you ensure the removal of harmful products before they reach the patient and reduce the time spent on recalls by 50% to 90%.

For information, visit ecri.org/solutions/alerts-workflow.

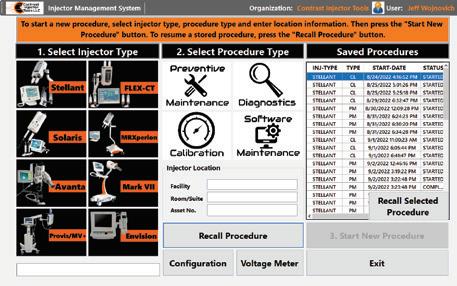

ompliaMED is highly specialized business and CMMS software engineered for the biomed service industry. It offers an end-to-end CRM, asset and inventory management system, with companion mobile inspection and work order apps.

CompliaMED COO Chris Zulliger recently shared more information about the company.

Q: WHAT ARE SOME OF THE SERVICES AND PRODUCTS YOU OFFER? IS THERE A SPECIFIC OR NEW ONE YOU ARE EXCITED ABOUT RIGHT NOW?

ZULLIGER: CompliaMED has officially launched its computerized maintenance management system (CMMS) software. It is designed by biomed technicians and built specifically for the biomed service industry which enables any size company to capture and report test documentation from start to finish on an iPad and produce compliant reports all in one application. CompliaMED also integrates with QuickBooks Online for an all-in-one CRM, CMMS and financial solution for efficiently operating biomed service companies.

Q: HOW DOES YOUR COMPANY’S STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

ZULLIGER: CompliaMED is a complete solution for operating a biomed service company. We know of no other all-in-one application for managing biomed service companies. Our mobile inspection and service order applications allow for offline operation. Freeing technicians from unstable cell service and slow Wi-Fi makes working remotely fast, reliable and accurate. Integration with Pronk Technologies testing and simulation devices produces traceable, compliant test and simulation results. We offer easily shared comprehensive inspection certificates and service reports.

Q: DO YOU HAVE ANY GOALS YOU WOULD LIKE TO ACHIEVE IN THE NEAR FUTURE?

ZULLIGER: Our goal is to provide technology to independent biomed service companies that will allow them to compete in an ever changing and competitive market.

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE OUR READERS TO KNOW?