47 Global Brie

ng

Ecotug agreement; Solar power; driving biofuels

49 Product News

Mobile port; O

shore charging; Ammonia tugboat

10 Congress pro

The Port of Antwerp Bruges talks about its future plans

12 Technology

Yara Marine Technologies discusses how shore power has its place

Monitoring

OceanWise discusses how environmental monitoring is changing

ABP discusses how it’s enabling green hydrogen production

22 Monitoring

RightShip talks tailoring its GHG Ratings tool for ports

32 Pollution

An innovative new remote waste collection device

Michele Witthaus talks greener cruise with Galveston

Hydrogen by rail; Electrofuels hub; Green ammonia

Shem Oirere on South Africa’s renewable energy plan

Dave MacIntyre examines a NZ port come penguin sanctuary

31 Opinion

Isabelle Ryckbost from ESPO details green port goals

It’s hard to believe that October has come round again and once again it’s time for the annual GreenPort Congress and Cruise conference.

As the sister event tied to GreenPort magazine, it cannot be emphasised enough how important the event is to the industry, especially during these challenging times.

The conference is an opportunity to learn about the current environmental issues that are shaping the industry and regulation coming into force and it’s a chance to network with peers and swap ideas on how to save energy, emissions and costs.

Editor: Anne-Marie Causer editor@greenport.com

News Reporter: Rebecca Strong rstrong@mercatormedia.com

Dave MacIntyre, Australia Shem Oirere, Africa Michele Witthaus, Cruise

Jon Lane, RightShip

Simon Nadin, P&D Marine Group

Jon Halvard Bolstad Olsen, Yara Marine Technologies

Isabelle Ryckbost, ESPO

Dries De Smet, Port of Antwerp-Bruges Amy Thompson, OceanWise Ralph Windeatt, ABP

David Blake, Paul Dunnington production@mercatormedia.com

SALES & MARKETING

t +44 1329 825335

f +44 1329 550192

The conference is an opportunity to learn about the current environmental issues that are shaping the industry and it’s a chance to network with peers and swap ideas on how to save energy, emissions and costs

This year we are fortunate enough to have the newly merged Port of Antwerp-Bruges as our host. As a combined entity, the port is the prime example of building resilience to tackle the challenges of tomorrow.

Delegates at the conference will be enlightened on the port’s plans for green hydrogen production at Zeebrugge which it plans to ship across Europe via the hub port of Antwerp. It will also talk about how it is working to clean up its fleet with a hydrogen and a methanol powered tugboat.

Away from the conference, we cover some really innovative topics in this issue of the magazine which largely centre around building resilience.

Monitoring is a really big topic for this issue with Oceanwise taking us through the various options for forecasting in bathymetric terms, getting better with predicting the weather and the tides to boost operational efficiency.

RightShip tells us how it has adapted its GHG Ratings tool to develop a specific emissions monitoring solution for ports and terminals.

Yara Marine Technologies talks to us about the benefits of shore power and how it fits into the overall new energy mix that is helping making ports leaner and greener than ever before.

And on the energy mix front, we talk to the UK’s ABP about their project to bring the first large-scale green hydrogen production facility to the UK, the Immingham Green Energy Terminal.

Our cruise focus this time is on the US Port of Galveston and how it is working to provide turnkey LNG fuelling solutions to its vessels.

Whatever you are focused on at your operation at the moment, hopefully you’ll learn something from this issue which could make a difference to how your operation performs on the environmental front.

Share your news with us online by searching @greenportbiz on Twitter and Facebook or email editor@greenport.com

Media Sales Manager: Arrate Landera alandera@greenport.com

Sales Executive: Rhys Lawton rlawton@mercatormedia.com

Chief Executive: Andrew Webster awebster@mercatormedia.com

Published quarterly by Mercator Media Ltd, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD

Tel: +44 1329 825335

Fax: +44 1329 550192

E-mail: sales@greenport.com Website: www.greenport.com

Registered in England Company Number 2427909

Registered office address: c/o Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD

Digital Edition: Subscription Rates: £73.00 pa

For subscriptions contact amccartney@mercatormedia.com

©Mercator Media Limited 2021

ISSN: 2045-6085 (print) ISSN: 2633-4488 (online)

Cover image: Photo: Port of Antwerp-Bruges

A Scandinavian cargo transporter is switching its tugs to biofuel use.

UECC, a provider of short sea transportation services for cars and other rolling cargo in Europe, has signed a three-year contract for Svitzer’s EcoTow product, through which fossil fuels are replaced with biofuels on Svitzer’s tugs.

“With this agreement, UECC once again positions itself in front of the market, demonstrating that decarbonisation projects are scalable and available,” said Daniel Gent, energy & sustainability manager, UECC.

”This project aligns with our own supplier policy, which looks to holistically reduce the environmental impact of our business operation, far beyond regulatory requirements.”

Mr Gent added that biofuels are among the most effective fuels for decarbonisation in the short term as these are readily available and can deliver easy, immediate cuts of as much as 100% in tank-to-wake emissions for existing vessels.

The new partnership will result in a reduction of almost 25% in UECC’s seaborne Scope 3 emissions covering indirect emissions associated with business operations across IUCC’s value chain.

It is estimated that CO2 emissions from UECC’s towage operations at the ports

The Port of Barcelona and cruise operators are joining forces to speed up access to shore-based power. The working group is part of an agreement signed by the Port of Barcelona, Barcelona Cruise Port, Carnival Corp & PLC, Royal Caribbean Group, MSC Cruises, NCL Holding LTD, Viking Cruises and Virgin Voyages. This collaboration aims to accelerate the EU requirements for onshore power for ships in 2030.

of Esbjerg, Gothenburg and Malmo will be reduced by more than 300,000kg over the term of the agreement with Svitzer.

Sven Lumber, head of EcoTow at Svitzer, added:

“We are extremely pleased to see UECC among the first-movers on EcoTow in Scandinavia. With this agreement they join other global Svitzer customers who partner with us

around decarbonisation, gaining the ability to include externally audited CO2 emission savings in their reporting.”

Shipowners will have to meet more stringent environmental performance standards with implementation of the IMO’s Carbon Intensity Indicator from 1 January 2023 and the Fuel EU Maritime regulation due to be phased in from 2025.

A ground-breaking solar and battery system at the UK’s Portsmouth International Port has reached a major milestone with 2660 solar panels now installed.

It’s a project which has broken new ground in the national context as it’s the first UK port to have solar canopies and will have a 1.2 mega-watt sized battery installed as part of a renewable installation.

“The port is owned by the people of Portsmouth, so we have a obligation to reduce the impact of our operations on the environment, whilst reaching the ambitions set out in our 20 year Masterplan,” said Jerry Clarke, pilot and senior project manager at Portsmouth International Port.

“Combined with other sustainability initiatives, it will help us achieve our ambition of reaching net-zero carbon by 2030, and becoming one of the UK’s first zero emission ports by 2050.”

The project began in February

A new Scottish port decommissioning hub looks set to deliver a boost to both jobs and the circular economy. CessCon Decom will launch a decommissioning hub at the Port of Aberdeen’s GB£400 million South Harbour expansion in the latter part of 2022, creating up to 50 new jobs. “There are growing opportunities to reuse, repurpose and recycle material during the decommissioning process,” said Bob Sanguinetti, chief executive, Port of Aberdeen.

2022 and incorporates roofmounted solar panels across a number of buildings, a large battery and solar canopies.

Power produced by the 2,660 solar panels will contribute around 35% of the site’s power; a significant step in the port’s ambition to be the UK’s first net zero carbon port.

It’s all part of an integrated approach that will also help the port offer shore power for smaller ships, without having to take extra power from the local electricity grid.

The Port Authority of Valencia (PAV) has expanded its fleet of electric vehicles and added new charging points for both employees and visitors. The port now runs ten electric cars, a van and two motorbikes and has plans to add a further four hybrid cars, in line with the Valenciaport 2030 net-zero initiative. A charger with two outlets has been installed for visitors in addition to four chargers with two outlets each in the employees’ car park.

As well as generating carbonfree power, the solar canopies will provide shade for cars waiting to board ferries; allowing them to stay cooler for longer, without having to run their engines.

The battery, with a capacity of 1.5 megawatt hours (enough to run a typical home for four months), will capture green power that would otherwise be exported from the site, which can be used then used at the port when needed.

The new battery will work in tandem with a previously announced battery storage pilot, which will balance services to the national grid and storing power during lower pricing periods. When complete, it is estimated that in peak conditions that 98% of the electricity consumed by the port will come from the solar and battery, combined.

The work is the latest in a series of solar and battery projects being managed by the council’s in-house energy services team.

A new ‘playbook for ports’ has launched challenging ports to take ambitious action across three lines of eff ort, with a focus on bold commitments, progressive policies and demonstrable progress. Developed by Pacific Environment and Opportunity Green, the ‘Ports Playbook for Zero-Emission Shipping’ lay outs nine actions to end port pollution and ensure reliable access to zero-emission fuels.

An American port has been awarded a US$1m grant to further its biofuels development.

The Port of Columbia, home to the Louisiana Green Fuels project (LGF) has been awarded the Department of Homeland Security (DHS) and FEMA grant through the Port Security Grant Program (PSGP).

“This funding commitment from DHS and FEMA recognises our deeply carbon negative footprint LGF project as a key contributor to our country’s energy transition and worthy of federal investment into its security,” said Dr Paul Schubert, CEO of Strategic Biofuels, which is the project developer.

“The Columbia Port Commission’s leaders have been strong advocates for us from the beginning and have been exceptionally effective in securing state and federal funds that enhance the port’s infrastructure and support our project.”

The PSGP is part of a series of grant programs created by the US Congress and implemented by DHS to help strengthen defenses around the nation’s critical infrastructure.

Port of Columbia’s grant was the largest award to the 15 Louisiana recipients and was in the top 8% of all awards granted. Notably, it was greater than the grants to the Port of New Orleans, the Port of Baton Rouge and the Port Authority of New York and New Jersey.

The plant and its accompanying Class VI Carbon Capture and Sequestration (CCS) Wells will produce about 88% renewable diesel and 12% renewable naphtha. Both renewable fuels are ‘drop-in fuels’ that are chemically identical to fossil-derived diesel and naphtha.

Once completed, the Louisiana Green Fuels Plant is expected to produce approximately 33 million gallons of renewable fuels. The aim is for the plant to be operational in late 2025 or early 2026.

The project is the first of a series of projects by Strategic Biofuels to produce renewable diesel fuel from Renewable Fuel Standard compliant forestry waste which will produce all its own green power from sawmill and forestry waste materials.

Sweden is aiming to install its first cruise ship onshore power facility.

Ports of Stockholm is building onshore power connection facilities for cruise ships at two city centre quays in order to lower air pollution emissions in the Baltic Sea.

“It feels really good that we will also be able to connect cruise ships to onshore power next season. This will be the first facility of its kind in Sweden and one of only a few in Europe. The cruise passengers are very important to Stockholm financially and generate over 1,000 jobs in the region,” said Thomas Andersson, CEO Ports of Stockholm.

Building the facilities at Stadsgården quay berths 167 and 160 will make Ports of Stockholm

the first port in Sweden to offer cruise ships onshore power connection.

The environmental initiative is a collaboration with other Baltic Sea ports. Ports of Stockholm is working with the ports in Copenhagen, Aarhus and Helsinki to enable cruise ships and shipping companies to connect to onshore power with a common international standard in each port.

It’s hoped this will encourage

more shipping companies to make the major investments in equipment that the ships need to connect to onshore power.

Work to equip the two city centre quays with onshore power connections will be completed, respectively, in 2023 and 2024. These cruise quay-berths are two of Ports of Stockholm’s most visited. It is estimated that at least 45% of the cruise ship calls will be able to connect to onshore power when the facilities are in place.

The total reduction in greenhouse gas emissions will be at least 6,000 tonnes each year as a result of connecting to onshore power. This environmental investment for cruise ships in Stockholm is a top priority and has been awarded grant funding from both the EU and the Swedish Environmental Protection Agency’s Climate Leap program.

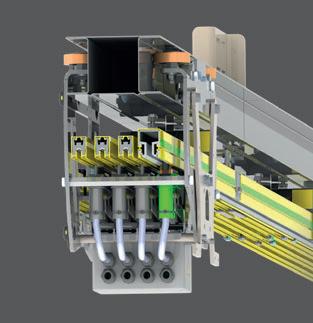

A German handling facility has completed its electric vehicle charging project. The final charging station for Automatic Guided Vehicles (AGV) at the climate-neutral handling facility, HHLA Container Terminal Altenwerder (CTA), has gone into regular operation. This means that 18 electric charging stations are now available for charging the automatically driven AGVs that transport containers between the quayside and the container block storage area at the terminal.

Six key northern European ports for offshore wind have joined forces in a bid to expand capacity. Under the terms of the Esbjerg Declaration, Germany, Denmark, Belgium, and the Netherlands have a combined target of delivering at least 65 GW offshore wind by 2030.

KIZAD and green mobility company, NWTN, have joined forces to establish the first electric vehicle (EV) assembly facility in Abu Dhabi to serve growing demand for sustainable transport options.Under the agreement, NWTN plans to initially operate a 25,000m² manufacturing, research and development, vehicle testing and logistics facility. Constructed by KIZAD, it will have an annual capacity of 5,000 to 10,000 units for the assembly of semiknocked-down EVs. In phase two, NWTN plans to introduce several new EV models and expand capacity to 50,000 units per year.

Cromarty Firth’s green freeport bid includes plans for an innovative mobile port solution.

Fred Olsen 1848, a renewable energy innovation company, is exploring the deployment of a mobile quayside, known as the Mobile Port Solution, as part of Opportunity Cromarty Firth’s (OCF) bid to become a green freeport.

“By setting up the Mobile Port Solution in the Firth, Fred. Olsen 1848 would provide an immediate solution for the rapid and cost-efficient installation of floating offshore wind, enabling the creation of new attractive green job opportunities, not only to the Firth but also for the UK in general,” said Sofie Olsen Jebsen, CEO, Fred. Olsen 1848.

Building upon the existing infrastructure and competencies for manufacturing, assembly and integration of large industrial scale floating offshore wind structures, the Mobile Port Solution aims to enhance the floating offshore wind supply chain and infrastructure in Scotland and contribute to

establishing a floating offshore wind cluster in Inverness and the Cromarty Firth.

In addition, it aims to have minimal environmental impact and builds on existing infrastructure.

A wind turbine installation vessel combined with a storage barge, will be located at a suitable location within Cromarty Firth, creating sufficient space and working conditions during the pre-assembly, pre-commissioning and wind turbine installation on the floating foundation.

Bob Buskie, chief executive of

8 The Mobile Port Solution aims to enhance the floating offshore wind supply chain and infrastructure in Scotland

the Port of Cromarty Firth, speaking on behalf of OCF, said: “The Fred. Olsen 1848 Mobile Port Solution would increase available infrastructure and, used in conjunction with the excellent existing port facilities at Invergordon and Nigg, would enable the Firth to support a larger number of offshore wind projects and accelerate the shift to green energy.”

platform for vessels to use either wind-generated or grid electricity whilst on standby outside port, thereby reducing the use of fossil fuels whilst vessels idle.

“Innovative thinking and practices are crucial if we’re to achieve a green maritime industry,” said Bob Sanguinetti, chief executive, Port of Aberdeen.

NYK Group company, Keihin Dock Co., has won a contract to convert a tugboat to run on ammonia fuel. Owned by NYK subsidiary, ShinNippon Kaiyosha, and operating in Tokyo Bay, the Sakigake currently runs on LNG and will be converted to run instead on ammonia by 2024. This initiative is part of work to develop a domestically produced ammonia-fuelled engine begun in October 2021 by NYK and IHI Power Systems (IPS) as part of the Green Innovation Fund Project of the New Energy and Industrial Technology Development Organisation.

Automated mooring is playing an important role in port decarbonisation by improving operational efficiency and reducing harmful emissions.One example is Cavotec’s project APM Terminals

MedPort Tangier where it’s providing next generation vacuum mooring system MoorMaster NxG.

Stillstrom and the Port of Aberdeen are joining forces to explore the feasibility of an offshore renewable charging hub to significantly reduce emissions from vessels waiting to enter port.

The study, which will run until the end of the year, will develop a

roadmap for the potential introduction of offshore charging infrastructure developed by Maersk Supply Service-owned Stillstrom.

The company’s ocean clean-tech concept provides a

“We look forward to working with Stillstrom to develop low carbon power supply and reduce emissions from vessels on standby outside our port. Pioneering projects, like renewable offshore charging, will help to make our vision of becoming Scotland’s premier net zero port a reality.”

Just recently, the port invited interested parties to submit responses for a request for information to explore the provision of shore power to vessels at berth.

DaChan Bay Terminals has begun operating two electric empty container stackers helping further the company’s decarbonisation efforts. This is the first batch of pure electric empty container stackers in operation at the terminal. The empty container stacker is capable of running continuously for more than 12 hours and takes just one hour to fully recharge. Average power consumption for handling one teu is 1 kWh with a CO2 emission of 0.96kg, a reduction of around 45% per teu compared with a diesel-powered equivalent.

Why is the Port of Antwerp-Bruges well placed to host the GreenPort Congress and Cruise conference this year?

Port of Antwerp-Bruges is more than a port, more than transport, more than tonnes, more than teus. And it’s not just about profit, money and jobs. As one of Europe’s most important ports, we have an essential social role to play: we are a port made up of people, for people. We intend to become the first port in the world to reconcile people, climate and economy.

Port of Antwerp-Bruges is transitioning from being a passive landlord to an active community builder, becoming the ‘glue’ in ambitious sustainability projects starting out from Antwerp and Zeebrugge and with the potential to become international trailblazers. Our ultimate goal? To become Europe’s green energy gateway. This is why we are working on pioneering flagship projects focused on carbon capture and storage (CCS), the circular economy, waste heat, alternative marine fuels and green hydrogen, the energy of the future.

What does the port hope to facilitate by holding the conference?

Except from sharing our expertise on different topics, we also want to increase the importance of strategic partnerships. We are the first world port to reconcile people, climate and economy, but we don’t want and don’t can do this on our own. We strongly believe in partnerships. We must tackle the challenges of tomorrow together.

Can you please explain how since the two ports have merged in April 22, the ports’ environmental strategies have been amalgamated?

Every now and then, one plus one is three. Achieving further added value is also the stated ambition of the recently merged Port of Antwerp-Bruges. In the long run, we

want to become the green energy gateway to Western Europe – thanks to the expertise and complementarity of both platforms. In the long run, we need to completely move away from all fossil fuels. It’s the only way we can achieve a climate-neutral society. While we can obviously generate large amounts of green energy here in Europe, for a highly energy-intensive region like ours, the local supply of wind and solar energy will not be enough to complete the transition in time. We thus need to get that green energy from outside Europe also. This is where an energy source such as hydrogen comes into the picture.

Our recently merged port has several aces in its hand when it comes to importing large volumes of hydrogen. In Zeebrugge, thanks to its location right by the sea, we can take in very large volumes of hydrogen for shipping to users in neighbouring countries. Antwerp not only has several hydrogen receiving terminals, but also several very large industrial companies operating in the port area which use hydrogen as an energy source. Whereas Antwerp can immediately receive hydrogen carriers such as ammonia or methanol with its existing terminals, Zeebrugge has the advantage of its direct access to the sea. Large volumes of both gaseous and liquefied hydrogen can be unloaded here with just a few adjustments to the infrastructure. Once they arrive in Zeebrugge, liquefied hydrogen can be reconverted into hydrogen and oxygen, after which the hydrogen can be transported to end users via pipelines.

Which key green targets are next on the agenda for the port?

In Zeebrugge, we want to develop a site to produce green hydrogen locally by 2024. To this end, the Colruyt Group and Fluxys, among others, have joined forces. They hope to ultimately produce 25 megawatts using green energy. This is set to be a true pioneering project for mainland

GreenPort talks to Dries De Smet, sustainable transition expert at Port of Antwerp-Bruges about why it is well placed to host this year’s GreenPort Congress & Cruise conference8 The port is working on greening its fleet with a hydrogen and methanol powered tugboat, pictured HydrotugPhoto: Port of Antwerp-Bruges

Europe. This hydrogen will also be transported from Zeebrugge to Antwerp and beyond. We also have ambitious plans to substantially reduce CO2 emissions in the port of Antwerp through the massive capture and storage of CO.

In terms of future green fuels, can you please explain the port’s strategy?

Every year, ships are estimated to bunker more than six million tonnes of fuel at Port of Antwerp-Bruges. With this position, we want to take a leading role in getting ships to run more and more on more environmentally-friendly fuel. For example, we are working on the transition to a multi-fuel port with alternative fuels that generate fewer CO2 emissions and are better for the climate and air quality. LNG is already a reality today and we are working to provide ample supply of methanol, hydrogen and electric power. We’re also working on shore power for seagoing vessels and barges.

Shore power allows ships ashore to shut down their engines or generator and connect to the grid. Where shore power is available, it is prohibited to use the generator. This reduces emissions (NOx, SOx and particulate matter), improves air quality and reduces noise pollution.

Barges have been able to connect to shore power when berthed for several years now. Not that many seagoing vessels are yet equipped for shore power. Substantial technical facilities are required for it, both on board the ship and on the quay. So by offering shore power for seagoing vessels, we want to break the ‘chicken or egg’ situation. That’s why we are working on rolling out shore power for seagoing vessels in the near future.

What is the port’s position on green hydrogen, does it feel that it is the answer to green energy autonomy in Europe?

If we want to play an important role in the long term as a green energy gateway for Western Europe, we should not just be looking at supplying green energy to industry in and around Antwerp. We intend to import much larger volumes of green energy through our merged port, subsequently making it available to a very large hinterland, for instance the German industrial regions. The large volumes required just by Antwerp’s chemicals cluster are set to become a lever driving a hydrogen economy outside the port.

What other green projects are on the horizon for the port?

We are working on greening our fleet with a hydrogen powered tugboat and a methanol powered tugboat.

We’re also involved with the Antwerp@C project which also involves Air Liquide, BASF, Borealis, ExxonMobil, INEOS, Fluxys and Total. We are joining together to investigate Carbon Capture Utilisation & Storage (CCUS) in Antwerp@C . The aim of this project is to capture half of the CO2 emissions at the port with CCUS by 2030.

The port is also part of the PIONEERS project. PIONEERS is an international consortium of 46 partners, led by Port of Antwerp-Bruges. This PIONEERS consortium brings together ports, terminal operators, carriers, freight forwarders, knowledge institutions, technology developers, innovators and government agencies to tackle greenhouse gas emissions.

We’re also involved with the Hydrogen Import Coalition and the Antwerp North residual heat network, among many other projects.

Lastly, can you please impart some words of wisdom about how other ports and terminals can embrace and make the most of opportunities arising from this period of transition that we now find ourselves in?

We have to do this together. We can not solve these challenges on our own, but by building strong partnerships we will be more resilient to tackle the challenges of tomorrow. The port is taking a leading roll in this. Together, we devise concrete solutions to reduce greenhouse gas emissions at ports while safeguarding our competitive position.

8 In Zeebrugge, the plan is to produce green hydrogen locally by 2024. At Antwerp, there are ambitious plans to use capture and storage of CO2

We intend to become the first port in the world to reconcile people, climate and economy. Port of Antwerp-Bruges is transitioning from being a passive landlord to an active community builder

The shipping industry must undertake urgent action and use all the tools in its belt, to meet decarbonisation targets and achieve a net zero future.

EEXI and CII regulations, prospective carbon taxes for shipping and the development of alternative fuels are all vital steps to push forward progress towards a greener maritime industry. Nevertheless, shore power is a viable option available right now and can play a pivotal role in cutting maritime emissions and improving air quality at ports.

Promisingly, while discussions on market-based measures roll on and deals continue to be hashed out with governments, energy suppliers and ports to supply the maritime industry with the necessary volumes of alternative fuels, shore power initiatives are on the rise.

Installations of shore power systems offer a present solution for fuel optimisation and emission reduction strategies, in line with upcoming regulation requirements. Ports can utilise and expand their existing shore power installations to reduce GHG emissions on land. Whilst vessels connecting to the power grid at port would eliminate emissions, directly impacting the vessels’ CII result. As a result, portside communities can benefit from a reduction in noise and air pollution, as well as an improvement in water conditions.

The EU, as part of their ‘Fit for 55’ green legislative strategy proposed a Fuel-EU Maritime regulation. The inclusion of onshore power in this regulation acknowledges the timescale problem shipping faces when relying on the creation of viable

alternative fuels. Pragmatic steps to cut emissions must be taken now and the regulation is a clear sign that maritime cannot wait for decarbonisation strategies to develop or for future technologies and fuels to be made available.

In response to the Fuel-EU Maritime regulation, a specific shore power declaration was agreed upon at the One Ocean Summit in February 2022. The European Investment Bank alongside ports and ministers agreed to make efforts to deploy a shore-side electricity supply by 2028. Signatories of the declaration further agreed to reward environmentally friendly ship stopovers, and to also promote actions which improve the environment around ports. This includes reducing stopover fees for these vessels.

The shore power declaration has been supported by global port signatories such as the Port of Busan, the Port of Los Angeles, and the Port of Rotterdam, and signifies the start of a wider initiative to utilise current technologies for decarbonization purposes.

Using shore power at port operations alone is estimated to reduce annual emissions by 2-6%. These numbers could be increased by making shore connections available at anchor ports such as Singapore. Nevertheless, regardless of the availability of future fuels, connecting a vessel to the electricity grid will remain a more efficient way of powering a vessel due to the minimal efficiency loss in the process.

To ensure emissions reduction via shore power on a large scale, green electricity must be available at ports. Promisingly, many ports are already providing energy from renewable sources and several others are investing in the infrastructure.

Jon Halvard Bolstad Olsen, strategy & business development director at Yara Marine Technologies, explains why we have to use tools available now to meet decarbonisation targets8 Finnlines and Stena Line are already leading the change by installing Yara Marine’s turnkey shore power solution Photo: Yara Marine Technologies

This holistic approach by ports and ship owners is already foregrounding shore power as a key factor for shipping’s decarbonization journey.

Shore power can also help companies to achieve their environmental, social and governance (ESG) strategies.

Competitive advantage no longer solely means profits or the quality of a product or service. A competitive edge means having a company ethos that aligns with consumer and supplier beliefs. These beliefs are increasingly environmentally focused, making environmental and equitable practices more important than ever.

Companies that take clear and proactive measures to reduce their emissions using all resources that are available to them now, like shore power, will help them to reap ESG benefits, including greater reputation, relationships with customers and stakeholders, and unlocking green finance.

Ensuring your efforts to cut emissions should be a core consideration of your ESG strategies. It is essential that we use the opportunity of the enormous transformation to our port and maritime operations to ‘bake in’ greater workers’ rights, social justice and responsible working practices. A big part of this is to ensure that new green operating methods do not have unforeseen negative impacts on the marine environment and local port communities. Shore power can help by reducing shipping’s damaging emissions and noise pollution in ports.

Engaging with port communities and demonstrating the efforts being made to protect their health and quality of life is not only a moral duty but will help foster positive relationships and smooth the process for further infrastructure development. Demonstrating such commitment also helps boost the attractiveness of ports and shipping to prospective employees, a valuable thing at a time when maritime needs a technologically savvy workforce.

As cruise and other ship operators shift towards the use of shore power solutions, it has become imperative for ports to look to the future of port-side infrastructures and uptake the opportunity for expansion.

Ports not offering clean electricity to vessels in the future will only be able to cater to older vessels without onboard systems to connect to the grid. These older vessels will likely be top polluters and result in higher taxation rates for ports when carbon tax regulations come into effect.

We as an industry must keep in line with progress and follow the steps being taken by ports and governments around the world. Governments in Denmark, France, Germany, Norway and Sweden are helping the deployment of shore power at their ports with subsidies, grants for investments and reductions in electricity taxes.

Ports which are already deploying shore power services are ahead of the trend. By offering the necessary services now, you can consolidate your standing as a port aiming for clean port operations in the shipping industry. As a selffulfilling prophecy, this reputation will enable you to attract compliant vessels which in turn will increase the uptake in use of these installations.

As conventional fuel prices and availability of fuel fluctuate due to ongoing geopolitical conflicts, market instability jeopardises the shipping industry and pushes greater emphasis on the need for alternative fuels. However, the creation, production, and stability of alternative fuels are still a work in progress.

We as an industry cannot afford to wait for the

implementation of long-term strategies. Currently, there are viable solutions which do not diminish pre-existing strategies nor make vessels obsolete if industry transformation goals were to change in the future.

That said, ensuring the cost-effectiveness of using the electricity grid at berth versus fuel would increase the spread of the use of the technology. Promisingly, many ports are investing in infrastructure to provide clean electricity at competitive prices. Therefore, retrofitting vessels to make them shore power compliant is a proactive and economically viable approach to reducing fuel use.

Equipping turnkey solutions onboard allows vessels to connect to local power grids when in port, switching to electricity rather than using auxiliary engines which run on fuel.

Finnlines and Stena Line are already leading the change by installing Yara Marine’s turnkey shore power solutions on board to reduce fuel consumption, emissions, and noise in port. The solution mitigates any technical challenges that may arise for operators. A turnkey solution allows for easy installation and guarantees a compatible system onboard.

There is no excuse not to follow industry emission standards. Such a simple and effective solution of reducing fuel consumption will make clear cuts to your emissions and is something every port and ship operator can implement today. The benefits are clear, let’s use every tool in our belt to get closer to achieving net zero by 2050.

Installations of shore power systems offer a present solution for fuel optimisation and emission reduction strategies, in line with upcoming regulation requirements

‘‘

8 Jon Halvard Bolstad Olsen, strategy & business development director at Yara Marine TechnologiesPhoto: Yara Marine Technologies

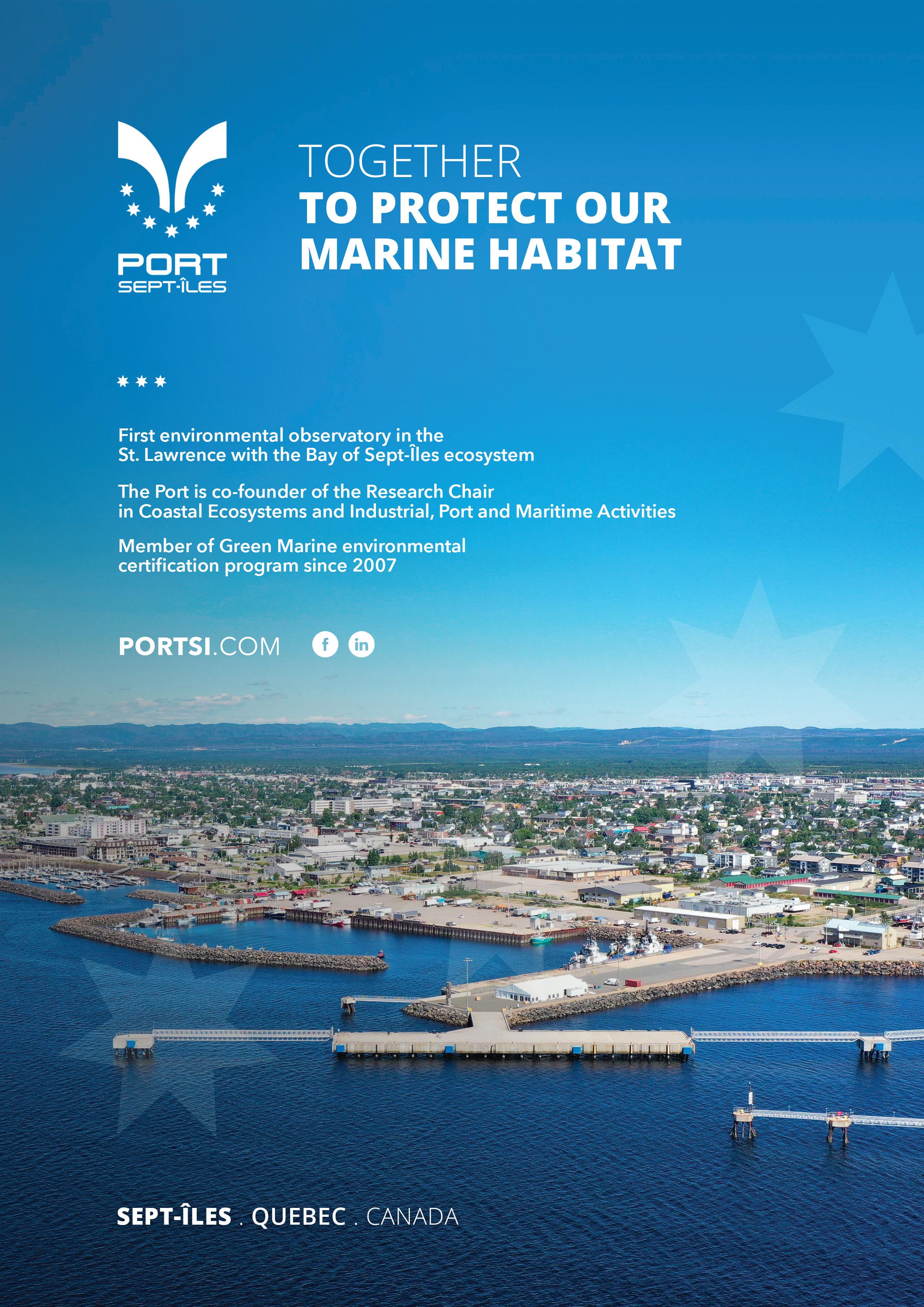

As a Green Marine-certified port since 2021, the Galveston Wharves and its partners are making progress in realising long-term changes to protect the environment, says Rodger Rees, Galveston Wharves Port Director and CEO.

The voluntary Green Marine environmental programme for North America’s maritime industry is helping the port staff to identify and implement best practices, manage environmental initiatives, measure progress and strive for continuous improvement.

“Cleaner energy sources and air quality initiatives are just two examples,” says Mr Rees. Green Marine’s environmental programmes are guiding the port as it plans for cruise growth. In November, we will open our third cruise terminal. In 2023, we are forecasting a record year with 360 cruise ships and more than 1 million passengers.”

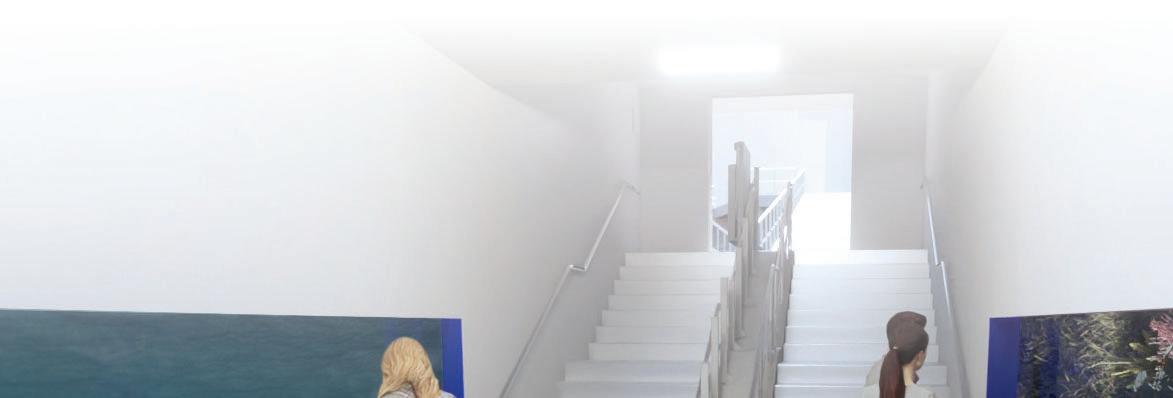

As 2022 draws to a close, a major investment by the Port of Galveston in the new terminal, together with Royal Caribbean International, will come to fruition, bringing brand new facilities to Pier 10 at Galveston Wharves.

Work started in summer 2021 on the US$125 million project, a collaboration between Galveston Wharves, Royal Caribbean International and Ceres Terminal Holdings. The new facilities are designed to provide customised home port facilities for the cruise brand’s Oasis-class ship, Allure of the Seas, with the 161,300-square-foot terminal occupying 10 acres on the east side of the port.

Sustainability is at the heart of the new infrastructure. In line with the requirements of the port’s Green Marine

certification, Royal Caribbean has designed the new terminal to meet Leadership in Energy and Environmental Design (LEED) certification standards.

“We view a new terminal as an opportunity to future proof our operations,” says a spokesperson for Royal Caribbean International. “As a result, we have spent a considerable time designing our new facility in Galveston to be LEED certified, in fact, it will be the first LEED Gold certified cruise terminal in Texas. Building any new cruise terminal comes with its challenges, that’s why we pursued LEED as the recognised leader in sustainable building standards. The facility was designed from concept to operation with sustainability in mind.”

The inaugural sailing of Allure of the Seas from the expanded facilities at the port is set for November 13 and will coincide with the opening of Terminal 10.

One year down the line, in November 2023, the Port of Galveston will see the completion of significant modifications to existing berthing facilities for another cruise industry giant and its mega ships. The planned upgrades will enable Carnival Cruise Line to provide LNG bunkering for Carnival Jubilee, the line’s third ship to run on an LNG technology platform.

The move to ready the port for LNG bunkering for this purpose follows the port’s announcement in August 2021 that it would partner with energy transition services provider Stabilis to provide turnkey LNG fuelling solutions to vessels at the port. The LNG facilities resulting from this collaboration will also serve many other vessels calling at Galveston in future.

Michele Witthaus finds out how ambitious partnerships with two of the world’s largest cruise companies are enhancing the Port of Galveston’s sustainable passenger shipping future8 A Carnival Cruise Line ship berthed at Cruise Terminal 25. Planned modifications will enable homeporting for the line’s new LNG shipPhoto: Port of Galveston

“Enhancing Carnival’s port facilities in Galveston is a key part of our plan to operate Carnival Jubilee there and accommodate the new technologies and processes needed to bunker a ship powered by LNG,” says a Carnival Cruise Line spokesperson. “Carnival introduced the first LNG-powered ship in North America when it debuted Mardi Gras in Port Canaveral last year, and Carnival Jubilee will be the first LNGpowered ship to homeport in Galveston.

“Galveston is an important port for us, and among our busiest. Extending the use of LNG technology to the Port of Galveston and homeporting one of our new and innovative Excel-class ships there underscores our commitment to the Galveston community.”

The Port of Galveston is the fourth most popular cruise home port in the US and only cruise port in Texas. The Galveston Wharves is a self-sustaining city entity, whose mission is to generate and reinvest port revenues to benefit the Galveston community with economic growth, jobs and sales tax revenues.

Greener fuels and fuelling opportunities are crucial to the environmental ambitions of the port, says Mr Rees. “As liquified natural gas (LNG) continues to gain traction globally as a commercial marine fuel, the Port of Galveston and the community will reap environmental and economic benefits,” says Mr Rees. “Fuelling more ships with safe, clean-burning LNG improves air quality. Providing LNG fuelling services will create more jobs and ship calls for our port.”

The newly built Carnival Jubilee is scheduled to call Galveston home beginning in November 2023. Now under construction at Meyer Werft in Germany, the ship will have a capacity of 5,374 passengers and 1,735 crew. It is the company’s third Excel-class vessel.

“The Port of Galveston is proud to be a leader in homeporting an LNG-fuelled cruise ship. It will be the port’s first LNG-fuelled cruise ship, which aligns with our environmental initiatives,” says Mr Rees. “By using LNG fuel, sulphur emissions are reduced by nearly 99 percent and nitrogen oxide emissions are reduced by 85 percent. This is a huge step toward a greener future for the cruise industry.”

Future proofing

Shore power is integral to the new facilities, providing another opportunity to reduce air emissions, says Mr Rees. “We have aligned with cruise and energy partners to explore the potential of connecting docked ships to shore-side electricity. Docked ships are typically powered by diesel auxiliary engines, which produce air emissions. As a Green Marinecertified port, we recognise shore power as an opportunity to

improve air quality and reduce greenhouse gases associated with maritime activities.”

The scale of investment the Port of Galveston is making in future cruise growth and sustainability is considerable. The port budgeted US$20 million for an internal roadway, utilities, sustainable landscaping and cruise parking for the new terminal. The port and Royal Caribbean International shared the US$15 million cost for Pier 10 improvements, including berthing and mooring structures.

To support the investments at its cruise terminals, the port is improving local and regional links to make both inbound and outbound travel more environmentally friendly. Mr Rees explains: “We are building an interior roadway to accommodate cruise and cargo traffic and relieve traffic congestion and idling time on Harborside Drive, the main access road to the port and historic downtown Galveston.

“We are also employing technologies to reduce travel and idling times for the hundreds of thousands of cruise-related vehicles at the port each year. Navigation apps with real-time data updates, texts with current travel conditions, and automated license plate readers will contribute to a better cruise experience.”

In addition, the port partners with community and business stakeholders to promote shared environmental goals. There are plans to install 28 electric vehicle charging stations at five of its cruise parking lots in 2023. The stations are funded in part by a US$35,000 Texas Volkswagen Environmental Mitigation Program grant through the Texas Commission on Environmental Quality.

Community engagement in sustainability initiatives is also encouraged. “In September more than 30 volunteers with the Galveston Wharves and Ceres Terminals Galveston picked up litter and debris at Stewart Beach,” says Mr Rees. “Ceres Terminals, in partnership with Royal Caribbean Group, will operate the new cruise terminal opening in November. The clean-up was one way the port and Ceres, both Green Marine-certified entities, demonstrate their commitments to environmental stewardship.”

Earlier this year the Galveston Wharves was awarded a US$5,000 grant from Clean Galveston to sustainably landscape the port’s new Royal Caribbean cruise terminal with native plantings. “This project has many benefits,” remarks Mr Rees. “It’s good for the environment, it advances our Green Marine environmental programme, it promotes sustainable landscaping, and will inform cruise terminal visitors about the beauty and benefits of native plants. Landscaping with native plants that are resistant to drought and pests also aligns with the cruise terminal’s sustainability objectives.”

Powering shipping’s emissions-cutting ambitions

Propulsion stream | Alternative fuels stream | Technical visit

Two days of conference streams exploring compliant technology & fuel solutions to meet the IMO’s 2050 milestone and EU’s Fit for 55 proposed tandem regulation, specifically the journey to 2030 with Shorepower. This year the programme will also feature sessions on eFuels & Bio Fuels, Ammonia, Methanol and Multifuel engines. While providing industry leaders a space to network and knowledge share.

Chairmen: Lars Robert Pedersen, Deputy Secretary General, BIMCO Reinhard Lüken, Managing Director, VSM German Shipbuilding and Ocean Industries Association

08:00 Coffee & Registration

09:00 Chairmen’s welcome

Lars Robert Pedersen, Deputy Secretary General, BIMCO

Reinhard Lüken, Managing Director, VSM German Shipbuilding And Ocean Industries Association

Rasmus Stute, Area Manager, DNV SE

Moderator: Lars Robert Pedersen, Deputy Secretary General, BIMCO

Under the Fitfor55 legislative package shore-side electricity has been given particular attention. Requirements for shore-power infrastructure development under the Alternative Fuels Infrastructure Regulation (AFIR), and for zero-emissions from ships at berth under FuelEU Maritime, will give shape to a new ecosystem in Europe aimed at improving the air quality in EU ports and supporting the Energy Transition/ decarbonisation in shipping.

Ricardo Batista, Policy Officer, Directorate-General for Mobility and Transport European Commission Isabelle Ryckbost, Secretary General, ESPO

Martin Kröger, Chief Executive Officer, VDR German Shipowners’ Association

Kai-Dieter Classen, Deputy Director External Affairs, Hamburg Port Authority Wolfram Guntermann, Director Regulatory Affairs Fleet, Hapag-Lloyd AG Christos Chryssakis, Business Development Manager Maritime, DNV SE

10:30-10:50 Coffee break

Moderator: Reinhard Lüken, Managing Director, VSM German Shipbuilding And Ocean Industries Association

10:50

Charging for the future: The rise of hybrid propulsion systems

Dr. Torsten Büssow, Managing Director, Electrical & Power Systems Business, Wärtsilä

The marine market is in a move. The decarbonization targets are changing the way we look at a ship propulsion system, that have been like this for decades now. What is the future operational profile? What is the future power source? Will there be more than one? What fuels do we burn? All or these uncertainties you can address already today with a alternative propulsion systems, which will in most cases be hybrid. The presentation explains several hybrid systems we are building at the moment and summarizes our experience of 70 hybrid vessels from Wartsila.

11:05 Enhancing energy efficiency of merchant ships through system-wide control

Stefan Goranov – General Manager, Sustainability Solutions, WinGD The presentation discusses the importance of integrating all the components of the hybrid ship’s energy system on control level, so it functions as a coordinated whole. Particular attention is dawn on the two-stroke engine integration as a crucial factor for maximising the energy efficiency onboard.

11:20

Simone Bernasconi, Head of Global Product Line Upgrades, Accelleron To support shipping’s journey towards decarbonization, easy-to-implement turbocharger technology can play an important role in reducing the CO2 footprint of existing installations. But to achieve any significant impact, wide market adoption is key. Combining greater efficiency with a sound business case will be vital to maintaining a competitive edge in a low carbon world.

11:35

11:50-12:10

12:10-13:40

Title & Speaker tbc

& Networking

Moderator: Sebastian Ebbing, Technical Advisor, Climate, Marine fuels, Innovation, Funding, German Shipowners’ Association (VDR)

Mia Elg, R&D Manager, Deltamarin

This presentation focuses on showcasing a realistic pathway to decarbonized shipping with practical examples from our ongoing projects. We discuss about the related digital modelling and optimization methods and about their application and validation.

Gregory Puckett, Head of Group Digital, MAN Energy Solutions

In his presentation, Mr. Puckett describes the “digital wave” within MAN-ES. From connectivity, to cloud, from data to artificial intelligence. The digital wave is continuous, it is variable, it can be calm one moment, and stormy the next. Most interesting it will never not turn back.

14:10 Digital tool to ensure engine efficiency

Matthias Winkler, Managing Director, CM Technologies

Digitalisation for engine performance measurement including automated data transfer between ships and ashore. Important is the possibility to have all data at one place allowing access from everywhere at any time for anyone. Useful assistance for ship and shore personnel.

14:25 The significance of data in achieving sustainable performance

Pascal Reolon, Head of Digital Product Management, Digital Customer Solutions, Accelleron

A closer look at the analytics layer sitting on top of the electronic logbook and continuous operational data. How enhanced data provides deeper insights into key performance indicators and supports proactive decision making for managing decarbonization.

14:40-15:00 Q&A

15:00-15:30 Coffee break

Moderator: Lars Robert Pedersen, Deputy Secretary General, BIMCO

15:30 With Orca; Norwegian zero-emission bulk carrier project

Michael North, Sales & Marketing Manager for Norway & Iceland, Lloyd’s register Earlier this year, Lloyd’s Register awarded Approval in Principle to Norwegian ship owner Egil Ulvan Rederi AS for its zero-emission self-discharging hydrogen-fuelled bulk carrier, With Orca. The innovative vessel will be fitted with two large rotor sails and is planned to enter into a long-term transport contract with cargo owners Felleskjøpet Agri SA and HeidelbergCement. It was designed by Norwegian Ship Design.

15:45 The Aurora Class - the future of deep sea shipping

Henrik Andersson, Head of Sustainability, Hoegh Designed to carry up to 9100 cars, the multi-fuel and zero carbon ready Aurora Class vessels will be the first in the PCTC segment to be able to operate on zero carbon ammonia, signifying a breakthrough in reaching Höegh Autoliners’ ambitious net zero emissions target by 2040.

16:00 Solutions for groundbreaking carbon-transport-and-storage project

Kristian Mogensen, Promotion Manager, MAN-ES

16:15 Wärtsilä Two-Stroke Future Fuels Conversion platform

Stam Achillas, Head of Business Development & Sales, 2-Stroke Fuel Conversions, Wärtsilä

A retrofit-optimised solution to convert existing 2-stroke electronicallycontrolled engines to run on either LNG, methanol or ammonia.

The ground-breaking technology will be applied on a 13’000 TEU

MSC containership to convert it first (2023) to LNG and later (2024) to ammonia.

16:30 NYK Line newbuilds set for net zero with WinGD system integration

Andreas Schmid - General Manager Technology Development, WinGD

Four PCTC vessels for NYK Line will meet IMO’s 2030 target seven years early – and be ready to reach net-zero by 2050 – when they enter service next year. WinGD is integrating battery-hybrid technology, energy management and LNG-fuelled X-DF2.0 engines.

16:45-17:00

Q&A

17:00 Conference close

17:00 Pre Dinner Drinks Reception

18:30 Conference Dinner - Gröninger Privatbrauerei Hamburg, Willy-Brandt-Straße 47, 20457 Hamburg, Germany

Announcement of the Motorship Award winner, Presented by Nick Edström, Editor, The Motorship

08:30 Coffee & Registration

09:15-09:30 Recap of day 1 by Chairmen

Lars Robert Pedersen, Deputy Secretary General, BIMCO

Reinhard Lüken, Managing Director,VSM German Shipbuilding And Ocean Industries Association

Moderator: Lars Robert Pedersen, Deputy Secretary General, BIMCO

09:15 The Future of Bunker Fuels for world’s Shipping Fleet

Jon Buckingham, Chief Mechanical Engineer, BMT

09:30 Sebastian Ebbing, Technical Advisor, Climate, Marine fuels, Innovation, Funding, German Shipowners’ Association (VDR)

09:45 Development of IMO’s Market Based Measure

Chris Waddington, Technical Director, International Chamber of Shipping

With the coming into effect of the CII and EEXI requirements in January 2023, the first phase of IMO’s workplan for GHG reduction will be in place. Within the second phase, IMO is now considering a Market Based Measure (MBM). This presentation will outline the various MBM proposals under consideration, and will summarise the remaining processes for finalisation of this measure.

10:00 Christos Chryssakis, Business Development Manager Maritime, DNV SE

10:15-10:35 Q&A

10:35-10:55 Coffee Break

Moderator: Lars Robert Pedersen, Deputy Secretary General, BIMCO

Franciska Kjellström, Global Application Manager, Marine Fuels, Alfa Laval

There is currently a high interest in biofuels including FAME and HVO as well as methanol. Ships can already bunker these fuels and engine combustion technology is available. We will discuss the impact of various new fuel types on the ship’s fuel cleaning and fuel supply systems.

Daniel Chatterjee, Director Technology

Management & Regulatory Affairs Head of the Green-and High-Tech and NetZero @ PowerSystems Program, Rolls-Royce

Lex Nijsen, Senior Vice President and Head of Sales, 4-Stroke engines, Man ES

The various fuels in gaseous or liquid forms have impacts on fulfilling rules and regulations. In the presentation pathways to decarbonization are highlighted and the value of having options to adapt vessels to fuel supply developments.

11:40 Moving biofuels into the mainstream

Monique Vermeire, Fuels Technologist, Chevron Biofuels can offer a carbon-free alternative to other non-fossil fuels, if considered on a lifecycle basis. Monique Vermeire will also discuss the impact of biofuels on NOx emissions and consider their operational and technical implications alongside the regulatory approach to their use.

11:55-12.15 Q&A

Moderator: Reinhard Lüken, Managing Director, VSM German Shipbuilding And Ocean Industries Association

10.55 Carbon Levy – Why Advanced Coatings will be Essential to Success in the Age of the Carbon Levy Philip Chaabane, CEO of I-Tech

11.10 Who can improve energy efficiency in ship operations and bring down emissions?

Rene Taudal Poulsen, PhD, programme director for BSc Program in international shipping and trade, Copenhagen Business School, Denmark We study how a large network of decisionsmakers, including cargo-owners, commercial managers, ship operators, port stakeholders and public actors influence voyage planning and execution. We find that they often pusue commercial objectives, which undermine energy efficiency in ship operations.

11:25 Wärtsilä 2-Stroke Radical Derating Stam Achillas, Head of Business Development & Sales, 2-Stroke Fuel Conversions, Wärtsilä A solution to significantly reduce an existing 2-stroke engine’s emissions by modernising its combustion while preparing it for future fuels.

11:40 Hydrocat the world’s first dual-fuel CTV Benjamin Weinacht, Managing Director, Compagnie Maritime Belge (CMB) Hydrocat is the first crew transfer vessel operating based on dual fuel, i.e., diesel and hydrogen generating up to 50% of emissions. Hydrocat is operated by Windcat Workboats which is part of the CMB Group.

Moderator: Lars Robert Pedersen, Deputy Secretary General, BIMCO

Peter Morsbach is Vice President Sales Operations at Høglund Marine Solutions

This presentation will examine the technological considerations that must be overcome on board a ship before widespread adoption of green ammonia as a marine fuel can begin, looking at the technical, operational, commercial, regulatory and environmental aspects such as health and safety (toxicity), materials elections (corrosiveness), engine requirements (combustibility), and emission prevention (engines and fuel system).

14.00 René Sejer Laursen, Director Fuels & Technology, Global Sustainability Copenhagen, ABS

14.15 Development cycles towards ammoniafuelled two-stroke engines

Dr Andreas Schmid, General Manager Technology Development, WinGD Industry interest in carbon-free fuels has reanimated development towards ammonia-fuelled ship engines. In this presentation, Andreas Schmid will explore the many areas that engine designers and builders are working on to bring safe, reliable and efficient ammonia-fuelled engines to market.

14.30 Engineering the ammonia engine of the future

Kristian Mogensen, Promotion Manager, MAN-ES

The development of MAN Energy Solutions’ first two-stroke ammonia engine is well underway. We share our learnings from designing and commissioning an ammonia fuel supply for our test engine facility, along with experiences from initial testing.

14:45-15.05 Q&A

Moderator: Sebastian Ebbing, Technical Advisor, Climate, Marine fuels, Innovation, Funding, German Shipowners’ Association (VDR)

13.45 Methanol: A Future Proof Marine Fuel

Matthias Ólafsson, Chief EU Representative, Methanol Institute

14.00 Development of worlds 1st methanol engine for very large container ships

Dr Gwang-Hyeon Yu, Senior Researcher Green Oiwer & engine Systems research, Hyundai Heavy Industries

14:45-15.05 Q&A

Moderator: Sebastian Ebbing, Technical Advisor, Climate, Marine fuels, Innovation, Funding, German Shipowners’ Association (VDR)

15.35 Will “multi-fuel” propulsion engines be the solution to solve the “future fuel” uncertainty?

Rolf Stiefel, Regional Chief Executive, Bureau Veritas Marine & Offshore

The advent of multi-fuel systems is a key step towards 2030 and 2050 decarbonisation targets, yet a number of challenges must be addressed – from the safety and control of fuels with different properties, to storage, bunkering, infrastructure and regulatory considerations.

15:50 The Multi fuel engine, the main corner stone of a successful fuel transition

Maikel Arts, General Manager Market Innovation / Marine Power Sales Central Europe & Nordics

The Multi-fuel engine technology enables the transition from fossil to renewable fuels through its built in technical feasibilities and economic viability. Infrastructure and availability of green fuels need time to mature while Multi-fuel engine technology enables shipowners a safe transition journey starting already today.

16.05 Alternative Fuels – Preparing for the impact on marine lubricants

Harriet Brice, Technology Manager Marine Engine Oils, Lubrizol

This presentation will discuss approaches to formulating effective marine cylinder lubricants for use with new alternative fuels. This requires gaining the best possible understanding of new engine designs, fuel and combustion characteristics and the challenges they may present.

16.20 What will a multi-fuel, low carbon future look like?

Eddie Fish, Market Development Advisor, ExxonMobil Marine & Aviation Fuels

The IMO’s ambition to reduce international shipping’s carbon footprint creates new challenges for the entire maritime ecosystem. To overcome them and lead the energy transition, advanced solutions will be needed to meet society’s needs. 16:35-16:55 Q&A

Moderator: Reinhard Lüken, Managing Director, VSM German Shipbuilding And Ocean Industries Association

15.35 Combining efficiency technologies with wind to deliver results beyond compliance

Tuomas Riski, CEO, Norsepower

Norsepower’s Rotor Sails improve environmental performance and reduce fuel consumption, especially alongside other clean technology solutions such as hydrodynamic hull optimisation or hybrid electric propulsion systems Regulation, including EU ETS, is driving shipowners to choose proven solutions, demonstrated by Scandlines’ M/V Copenhagen.

15.50 The role of retrofitting in the Clean Fuel Transition

Jan P. Brugger - Co-Founder& COO, FuelSave

The use of hydrogen & methanol retrofit echnology can help shipowners to meet IMO Tier III standards. An alternative to urea or ammonia, these solutions achieve substantial emission reductions and cost savings, whilst curbing OPEX.

16.05 Retrofitting to Methanol DF operation – an Owners experience

Per Westling, Managing Director, Stena RoRo AB

16:20 Economic and Ecological Considerations for Wind-Assisted Ship Propulsion Systems

Karsten Hochkirch, Head of Ship Performance Center, DNV SE

Wind propulsion is well known and has propelled ships for millennia. However, with the advent of fossil-fuel powered ships, wind energy lost its importance for cargo transport almost 100 years ago. Rising fuel prices and a society being more aware of the consequences of CO2 emissions fuels the revitalization this energy source and a variety of wind assisted propulsion systems are on the market today. Key factors for success of wind assisted propulsion are discussed and a case study for a multipurpose vessel is used as illustration.

16:35-16:55 Q&A

Lars Robert Pedersen, Deputy Secretary General, BIMCO

Reinhard Lüken, Managing Director, VSM German Shipbuilding And Ocean Industries Association

Sebastian Ebbing, Technical Advisor, Climate, Marine fuels, Innovation, Funding, German Shipowners’ Association (VDR)

For further information please call +44 1329 825335 or email conferences@propulsionconference.com

Conference Fee

Cost per delegate Premium rate:

fee includes:

Conference Attendance

at drinks reception

lunch and

November)

Place at conference dinner (22 November)

Place at technical visit (24

Cost per delegate Standard rate: €2259/

• Group booking discounts available

rate available for recognised

Booking Online

or complete and fax the booking form below to +44 1329 550192. On receipt of your registration, you will be sent

For further information on exhibiting, sponsoring, or attending the conference, contact the Events team on: +44 1329

Le Méridien Hotel, Hamburg

d. Alster 52, 20099 Hamburg, Germany

propulsionconference.com

BOOK ONLINE OR COMPLETE THIS FORM AND FAX TO +44 1329 550192 (Please copy this form for additional delegates)

Please tick all that apply :

Please register me for the Propulsion and Future Fuels Conference 2022. I will attend the following: Conference Dinner (22nd November 2022) No additional cost

Technical Visit (24 November 2022) No additional cost

Members of supporting associations will receive up to 50% off your delegate booking.

I am a member of

Family Name

First Name

Title Mr/Mrs/Ms/Dr/Other

Company

Job Title

Company Address

Country Telephone Fax Email Signature

Company VAT No.

HOW TO PAY *UK registered companies will be charged the standard rate UK VAT

Bank Transfer: Mercator Media Ltd,

Prepayment

Credit/Debit

I have paid by bank transfer

Please

Please charge my card (delete as appropriate) Mastercard/Visa/Amex

Card Number

Expiry Date

Name on Card

Credit Card Billing AddressSecurity Code

SPACE AT THE CONFERENCE IS LIMITED – RESERVE YOUR PLACE TODAY!

Book online at propulsionconference.com or fax booking form to +44 1329 550192

Registered in England. Company Number 2427909. Mercator Media Ltd reserve the right to alter the timing, content or speeches of this conference at any time. Full terms & conditions are available at https://www.mercatormedia.com/terms-conditions-1

Book online at motorship.com/PFFBOOK or fax form to +44 1329 550192

Maintaining the safety and efficiency of marine operations year-round has never been more imperative.

With increased investment being put into offshore renewable energy (including wind, tidal and even marine solar in some areas of the globe), there is now a higher demand for marine and offshore movements than at any time previously.

The Covid-19 pandemic has highlighted how intrinsic maritime operations are to global supply chains and the transit of commodities to meet consumer requirements.

Whilst the marine environment is being utilised in ever more ways, marine operators must contend with increasingly extreme and unpredictable weather conditions due in part to climate change, including an increase in disruption and potential damage caused by waves and swells during storms and more severe surges and cuts associated with tidal level.

These contribute to operational safety concerns but also have a major impact on efficiency and hence profitability. As vessel size and the quantity of marine traffic continues to increase, accurate real-time meteorological and oceanographic (metocean) data is vital to ensure efficient cargo loading and unloading, the safe berthing of commercial ships and subsequently the smoothglobal transportation of goods throughout the world’s ports, preventing backlogs and shortages.

The ability to forecast the tides many years in advance has historically been possible due to the trackable and measurable influence of various physical factors within the solar system (including the harmonic influences of the moon, sun, and other celestial objects). Ports, harbours and marine

operators have historically been able to plan vessel movements in detail, based on this. This predictability also makes, for example, tidal-stream energy a highly exciting and lucrative opportunity, as energy production can be planned well in advance based upon the tidal stream predictions for a given location and forecasted energy demand.

For today’s real-time operations where individual centimetres can make the difference between bringing a ship into port or not, relying on predictions alone is no longer a viable option. Whilst the impact of, for example, atmospheric pressure on sea level is well known (the inverse-barometer effect), the increase in frequency and severity of wind events and storms have an exaggerated effect on the local conditions of a port, harbour, or marine resource.

Storm surges and cuts (i.e. a lowering in tidal level thus reducing the depth of water available to vessels) are becoming increasingly extreme, often exceeding the predicted values given by forecasting organisations. Accurate real-time data is required to allow marine operations to take place efficiently.

Installing real-time monitoring systems for tidal level, meteorological parameters, waves and currents at strategic

Amy Thompson, oceanographic data engineer at OceanWise discusses how environmental monitoring is changing and improving safety in an unpredictable world

With global meteorological conditions becoming more and more uncertain due to climate change, it has never been more important to have real-time, accurate data informing decision making

‘‘

locations allows port operators to make informed decisions in relation to vessel movement and operational safety, allowing near-instantaneous decision-making with regards to pilotage.

For example, our customer Associated British Ports maximises its environmental monitoring data by having a suite of tide and weather sensors installed across their UK sites. In addition to these sensors, it utilises data from wave buoys at key locations, to make informed decisions on both port operations (for example where a surge or cut in tide will impact the size of vessel they can berth) and pilotage, with wave height thresholds used to make decisions on whether a pilot can safely board a vessel to bring it into port.

Real-time monitoring also allows ports and harbours to operate more efficiently with regards to personnel and assists with staff absences where required – for instance, during pandemic-related lockdowns. Having multiple sources of real-time environmental monitoring data colocated in a centralised location significantly reduces the time required to make informed decisions in support of safe navigation and marine operations within a port.

This data can easily be fed into Portable Pilotage Units (PPUs), alongside bathymetric data and electronic navigational charts, to give pilots and crews as much information as possible to assist with vessel movements with limited time and space to operate. This combined approach to data dissemination is used by Peel Ports and several of our other customers.

When it comes to choosing the best monitoring system for your port there is no “One size fits all” approach. In fact, it is quite the opposite. Each port, harbour or marine operator will have their own unique set of influencing factors, which will determine what system, sensors and software will be most suited.

A small harbour for example may have minimal large vessel traffic but require a higher amount of data around environmental impact such as air pollution, turbidity or marine noise. Ports are also equally individual as they have a different marine approaches, scope and size of vessel traffic, range of marine users, environmental conditions and different land-side infrastructure and layouts.

To select the right system, first make sure you understand what you already have, what you need and importantly who requires the data. A wide variety of people can benefit from your data, inside and outside of your organisation, so consulting with other departments within your organisation and external stakeholders brings a wider benefit. Where you can, future proof your system and make sure that you can add, build and develop the system as you go.

Lastly, and arguably just as important, ensure it has good data management and interoperability at its heart. Why?

Creating the data is only half the battle, how it is organised, stored, managed and maintained has a direct impact on how any business will function. We are constantly creating, storing and sharing data even when we don’t realise that we are doing it and often this data exists in ‘silos’ which cannot or do

not enable data sharing. The result of this leads to data inconsistencies, replication, inefficiencies and ultimately confusion.

Translate this into port scenarios and it could mean that despite the data being available, a pilot may not have realtime access to critical tide and wind data on their hand-held device (tablet/PPU etc). A bathymetric survey may be duplicated unnecessarily because the metadata is missing. An individual spends valuable time retrieving and sending files to other team members when they could find this information quicker by locating and accessing it themselves.

Bad data management can cost time and money and cause unnecessary confusion and frustration. In terms of metocean data, better understanding and efficiency is achieved only when data from multiple sources is combined and communicated in a way that makes it relevant, interesting and digestible by the non-expert.

Unfortunately, there is not an easy fix – good data management requires policies, procedures, information systems and architectures to be established. However, some of these may already be in place. Small incremental steps can be taken relatively cheaply and painlessly. ‘Smart’ technologies can also support good data management and interoperability is now becoming a ‘must have’ feature of any new policy, system or software.

With global meteorological conditions becoming more and more uncertain due to climate change, it has never been more important to have real-time, accurate data informing decision making. Being able to monitor the weather and sea conditions in real-time ensures that windows for marine operations, such as pilot boarding/disembarking and vessel berthing, are optimised and taken full advantage of whilst maintaining personnel safety.

As the pressures of the global economy and consumer demand continues to increase, having reliable and accurate data to aid decision making will continue to become increasingly important in our changing world. I believe that technology can also support this with the ongoing development of smart technologies, improvements in telemetry and the notion that data and data sharing are now being taken seriously and at all levels, not just by the IT department.

Help is out there. You can find more information on marine data management for ports, help guides and even request a free training course from OceanWise - we’re dedicated to supporting the marine and maritime sectors improve the way they govern and manage their data.

8 When it comes to choosing the best monitoring system there is no “One size fits all” approach

Creating the data is only half the battle, how it is organised, stored, managed, and maintained has a direct impact on how any business will function

Associated British Ports (ABP) is the UK’s leading ports group with a network of 21 ports across Britain, including four ports on the Humber, which is the UK’s largest industrial cluster. As such, the Humber offers the biggest decarbonisation opportunity in the country and achieving net zero is critical to supporting jobs and delivering economic growth for the region.

The Humber as a region has delivered for the UK before, with extensive recent history and experience in supporting large scale green energy projects, including the world’s largest installed windfarm, the 1.3GW Hornsea 2, as well as five other arrays. Together ABP’s ports on the Humber at Grimsby, Hull and Goole, Immingham provide a gateway for the trade and prime locations for green energy generation projects, connecting businesses across the UK, Europe, and beyond.

The need for renewable energy generation has never been clearer, with the UK adopting the role as a global leader in addressing climate change and achieving greater sustainability to ensure that we can preserve the world for future generations.

As part of its commitment to combating climate change,

the UK Government has committed to reaching Net Zero greenhouse gas (GHG) emissions by 2050. To achieve this, support from traditional industry sectors is critical, to be able to save the planet whilst creating new jobs through innovation and green technologies. On the Humber, there are multiple nationally critical energy and decarbonisation projects, which need to be delivered for the UK to achieve its ambitious target. These include a wide range of projects, from carbon capture and storage to green hydrogen. ABP recognises the vital role ports must play as enablers in the UK clean energy transition.

In addition, in 2019, the UK Government published its ‘Clean Maritime Plan’, which provides a route map for achieving zero emissions from shipping. The plan reflects the need to respond to the challenges of climate change and air pollution to meet the International Maritime Organization (IMO)’s target of halving total annual GHG emissions from international shipping by 2050. To deliver these plans, major investments in infrastructure and incentives are needed, to help transform the maritime industry. When it comes to finding the best locations for onshore wind and solar projects, ports are increasingly important with 17 of ABP’s 21 ports now hosting onsite renewable energy projects helping to reduce emissions and generate clean energy for port users and the grid.

Ralph Windeatt, ABP head of business development, discusses how the port group is enabling green hydrogen production8 The Immingham Green Energy Terminal will contribute at least 150MW of hydrogen production capacityPhoto: ABP/David Lee Photography Ltd

The Humber is also among the leading areas in developing carbon capture, utilisation, and storage (CCUS) technology that will be critical for reducing industrial emissions. An example of this is Zero Carbon Humber, a consortium of energy and industrial companies and academic institutions seeking to turn the Humber into the UK’s first net zero carbon region by 2040.

Ports have a crucial role to play in CCUS by providing a solution for shipping CO2, which is critical for regions of the UK that do not have direct access to geological storage. It also provides an opportunity for the UK to exploit the storage potential on the continental shelf for CO2 captured within the EU, where the plans for capture exceed the capacity of available storage.

Accelerating the development of the hydrogen economy is a vital component of achieving net zero and indeed, hydrogen production is an important element of the UK’s clean energy transition. The UK Government’s hydrogen strategy seeks to achieve 10 GW of low carbon hydrogen production capacity by 2030. In relation to this, the primary challenge is that currently there is no significant domestic production of such hydrogen in the UK.