Saturday, Feb. 22, 2025 I Sunday, Feb. 23, 2025 I Friday, Feb. 28, 2025

Saturday, Feb. 22, 2025 I Sunday, Feb. 23, 2025 I Friday, Feb. 28, 2025

MUCH OF NORTHWEST IOWA received nearly a year’s worth of rainfall from April through June, with approximately 11 inches falling in a short period of time in the month of June. This resulted in historic flooding, which devastated hard-hit Iowa communities like Rock Valley, Spencer, Sioux Rapids,

Correctionville, Hawarden, and points further south.

Weather service: Some areas received a year's worth of rain in 3 days' time

By KAREN SCHWALLER

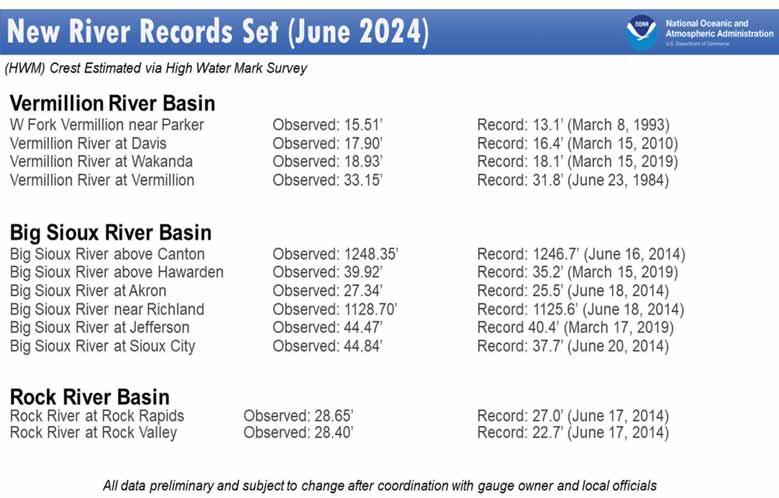

MILFORD — Northwest Iowa continues to recover from record-breaking flooding which occurred over the weekend of June 22-23, 2024. According to the National Weather Service (NWS), a multi-day heavy rainfall event led to widespread heavy rain across the region. Rainfall totals over a three-day period exceeded two inches in nearly all areas, with widespread totals between five and 10 inches. Rain totals in pockets of southeastern South Dakota and northwest Iowa were between 10 and 20 inches — nearly a year’s worth of rainfall in that amount of time.

The NWS said these rainfall amounts exceeded the 500- to 1,000-year annual exceedance probability in some areas.

While many cities were impacted, more widespread flooding took place in the communities of Rock Rapids, Rock Valley, Hawarden, Spencer, Sioux Rapids and Cherokee in Iowa; Windom and Jackson in Minnesota, and

Sioux Falls, Canton, and McCook Lake in South Dakota, according to the NWS. Gov. Kim Reynolds issued a disaster declaration that weekend for 21 Iowa counties affected by the nearly unimaginable amount of flood water inundating those areas.

Two especially hard-hit areas included Clay and Sioux counties, where frequent rain events brought river levels to the breaking point, creating levee failures and sending flood waters over their banks. They included (primarily) the Rock, Floyd and West Branch of the Floyd River in Sioux County, and the Little Sioux and Ocheyedan rivers near Spencer in Clay County, along with other contributing smaller rivers and creeks that were also deluged with rain waters.

Flood waters damaged or destroyed countless homes and businesses all over northwest Iowa, washed roads and bridges out and left farm land under water for days or weeks at a time. Reports of basements filled with water — some completely, with more

See FLOODS, Page 2D

FLOOD WATERS took a harsh toll on farm fields. This corn field, located west

as it appeared after widespread flooding in June.

Continued from Page 1D

on the main floor — were common. Basement walls gave way under the pressure — some from home owners pumping water out of their basements too quickly.

Downtown and residential areas in both counties were flooded, with people evacuating, and otherwise being rescued from roof tops by boat and helicopter. Sewage systems backed up as well due to excessive flood water, and utilities were down for a time.

Temporary large-group housing needed to be set up, and donation centers opened for people to give items or money for those who had lost so much — or everything. Recovery efforts have been underway since then, and are ongoing eight months later.

S IOUX C OUNTY A G P ICTURE

Joel Sikkema, Sioux County engineer, said damage in his county was widespread, with

the heaviest in the northwest parts of Sioux County near Rock Valley.

“There were also substantial impacts in the northeast parts of the county and in areas east of Sioux Center and near Alton as well,” he said.

Sikkema said the damages to rural roads and bridges was extensive, but what has taken the most time to repair are scouring of bridge embankments (approaches to bridges).

“A lot of those bridge em-

bankments, because of the amount and speed of the water, were washed away, so we had to get those put back into place,” he said.

Sikkema said there are still two gravel road bridges near Rock Valley that are closed, with the likelihood that they will have to be replaced entirely instead of repaired.

Sikkema said the financial impact to the county budget for repairs has come in at $1.4 million.

“Looking ahead at some bridges and culverts that were severely damaged that need to be replaced, it could cost $1.5 to $2 million more,” he said, adding that the county could see reimbursements from the federal government amounting to 85 percent of costs the county incurs. “Our crews hauled more than 4,000 loads of dirt to repair bridge embankments and road

shoulders and bare ditches — it’s an immense figure,” he said. “There were 340 locations where we had to do debris removal or blade it or add gravel because water had either washed over the roads or damaged the shoulders.”

Sikkema said the county ran out of barricades and had to garner help from the farm community using round bales as barricades, as well as dumping loads of gravel to help close roads to keep people safe.

He said one month brought the completion of much damage repair, mostly for more highly-traveled areas of Sioux County.

Sikkema said he was reminded of how powerful water can be.

“When you look at a bridge and normally there’s a little stream flowing through it, and then you come up to it and the roadway is totally gone … the bridge is still there, but the roadway is totally gone, and when you look down, the hole is 20 feet deep … it’s amazing the destruction that water can cause.”

S IOUX C OUNTY FSA

Teresa Van Sloten, executive director of the Farm Service Agency in Sioux County (based in Orange City), said flood damage there was more extensive than anticipated from the Rock River, Floyd River and Big Sioux River (on the western border).

“The West Branch of the Floyd River that goes down the middle of the county was more extensive than we thought; we drove around and saw it, and heard reports that the water was more than 20 feet high on the West Branch going right down the middle of the county,” she said.

Van Sloten said she and her crew saw damage to pastures and cropland due in part to excessive sand that washed into those areas.

“Some guys might have 10 or 20 acres covered in sand maybe two feet high, and the next

See FLOODS, Page 4D

field might not have any,” she said, “… but another field might have two acres covered in rock and debris. Some had holes in their field that were 12 feet deep. There was overturned irrigation equipment … just extensive crop land damage with gulleys and holes.”

She said she heard of places in the northern part of Sioux County that received 21 inches of rain that week.

“A lot of people got that sand and debris cleared off of their cropland in a hurry, but their struggle is finding a place to put it,” said Van Sloten. “Some farmers have 100 side dump trucks worth of sand that they don’t know what to do with because nobody wants it. A lot of waterways filled up with silt and were level with the field, so a lot of them had to scrape that out.”

Van Sloten said producers are looking at the Emergency Conservation Program (ECP) to help with expenses of restoring their ground to where it was before the flood. The funding might include minor grading and shaping to dig up waterways or fill in gulleys. It also helps pay for fence repair expense.

“A lot of guys have their pastures along a river or a waterway or creek and it all got wiped out or full of junk and it ruined their fences. ECP will help pay for some of that,” said Van Sloten, adding that ECP can also help with damaged crop land that needs a temporary cover crop in order to keep weeds down.

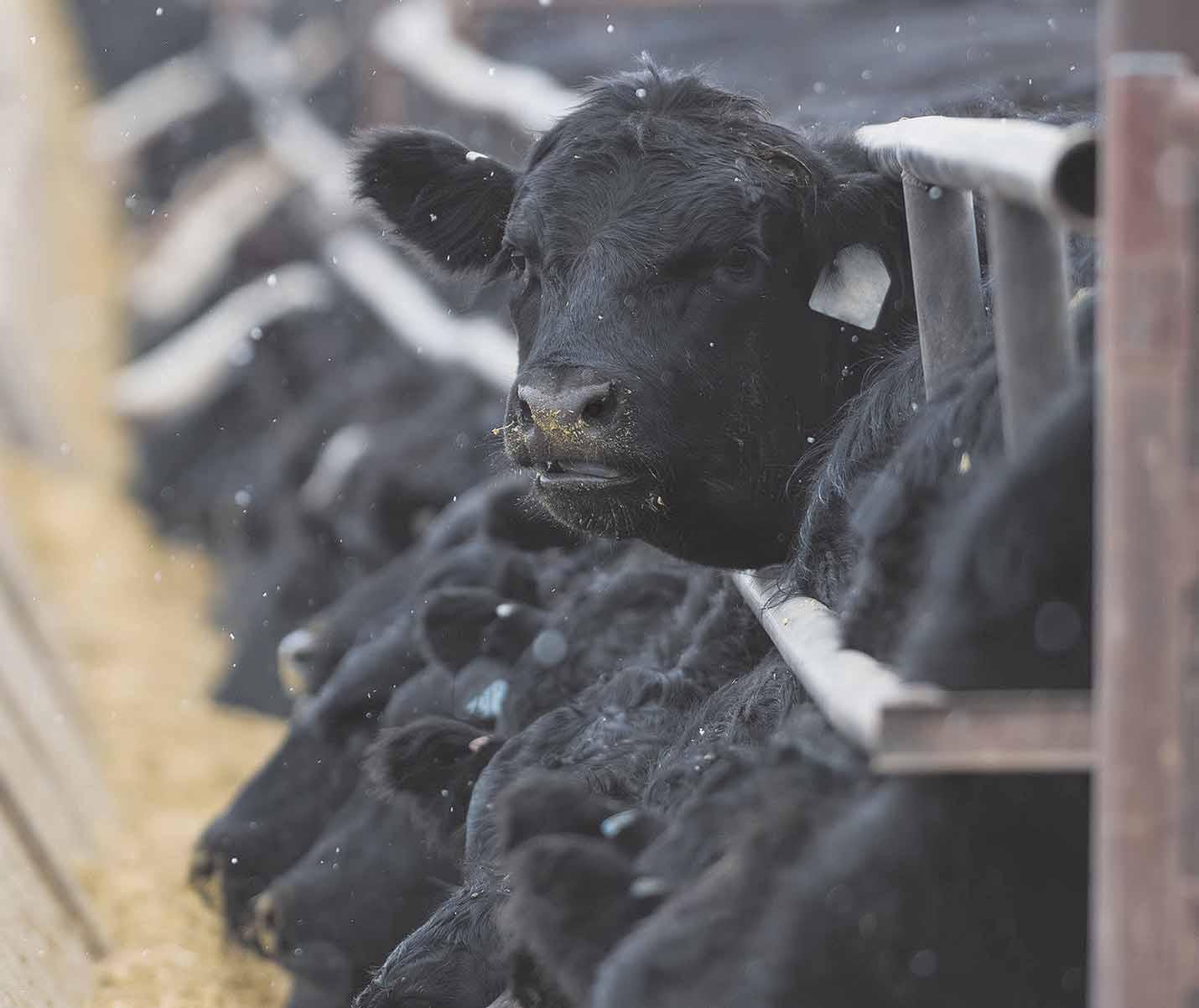

She said producers can also seek out the Emergency Livestock Indemnity Program if they lost livestock in the flood. The funds also helped a beekeeper whose hives floated away.

“Some producers couldn’t get to their hogs and maybe lost electricity; some died in the heat, and some cattle were washed away down the river,” said Van Sloten. “The stories

are unbelievable.”

She said the Emergency Livestock Assistance Program (ELAP) has been needed by Sioux County producers who have had to fix pasture fences, have pulled their cattle off of pasture because there is no grass left, or their hay bales floated away. Those funds help pay for feed for the number of days they were off pasture.

“You don’t find livestock numbers like you find in Sioux County,” said Van Sloten. “We had a lot of applications for those two livestock programs.”

Van Sloten said FSA and NRCS staff traveled together the Monday after the flood, surveying crop land, pasture and livestock damages, and while she said it was difficult to find a comprehensive dollar amount

for that, she said they came up with an initial figure of $25 million or more for total ag damages in Sioux County.

“It will be a long time before we’re done paying everybody for that (ECP) program,” she said, adding that some producers wanted to wait until spring to fully assess the damages they received, especially those who had CRP acres along the river. “We’ll be working on this program for another year or so yet.”

Cole Budach, Clay County engineer, said significant damage occurred on secondary roads there, especially in low places with culverts where water wants to drain naturally, and with gravel eroded away, and

road sub-bases being washed away.

“We were able to build the gravel roads all back before the fall,” said Budach. “We saw a few paved roads that lost the asphalt, and some paved roads that lost the shoulder. Those have been restored now.”

He said damage to roads and bridges was consistent throughout the whole of Clay County, with no area seeming worse than another.

Budach said one heavily-damaged county bridge over the Little Sioux River in Southeast Clay County (Herdland Township) will not reopen. To date, that is the only Clay County rural bridge that will not be repaired or replaced.

Budach said some bridges had banks washed out adjacent to the bridges, and in the more severely-damaged areas, they have been backfilled with large rocks. Road beds that were washed away have been repaired in Clay County and southern Dickinson County.

He said all Clay County roads are back in service, but debris removal is still on the docket.

“Conservatively, we’re over 60 percent done with that (debris removal) — removing corn stalks, sediment, soil that ended up in a ditch, we’re cleaning that out and stockpiling it,” he said. “We’ll continue that once the ground thaws.”

Budach didn’t have a dol-

lar figure for what repairs have cost Clay County’s road department, but he said once all figures are compiled, they’ll be turned in to FEMA, and the federal government will reimburse up to 75 percent of that cost for labor, materials and equipment cost. He said they will also receive an additional 10 percent reimbursement from Iowa Homeland Security (state).

Budach said his crews initially worked overtime hours in order to take care of those issues that were an immediate threat to public safety, and after that, have been working regular 40-hour weeks to continue flood recovery efforts and keep the roads open and safe.

The flood stage for the Little Sioux River near Spencer is 10 feet, according to the National Oceanic and Atmospheric Association (NOAA). The previous record water level on the Little Sioux River near Spencer was 20.2 feet, and on June 22, 2024, it crested at 22.10 feet — nearly two feet higher than the previous record water level. The flood stage for the Ocheyedan River running through Spencer is eight feet. The previous record water level for the Ocheyedan River there was 12.9 feet, and last June it crested at 16.9 feet. Both rivers met the criteria for the 500-year flood plain for Clay County.

Woods, Clay County FSA executive director, said the county saw lots of pasture damage and much grazing loss in the weeks and months (90 days at least) post-flood.

“Some basically lost the entire grazing season up until frost,” said Woods. “I had producers whose pastures were completely destroyed, or were under water for a month.”

Clay County livestock producers have been signing up for the ECP and ELAP programs, which help with pasture and crop land repairs, and grazing losses.

Woods said Clay County saw between 20 and 30 percent of

See FLOODS, Page 6D

MUCH OF NORTHWEST IOWA received nearly a year's worth of rainfall before 2024 was even half over, with approximately 11 inches falling in a short period of time in the month of June. That resulted in historic flooding, which devastated hard-hit Iowa communities like Rock Valley, Spencer, Sioux Rapids, Cherokee, Correctionville, Hawarden, and points further south. Here the water flows from the field and over the roadway.

row crops heavily damaged to the extent that they would raise a low-yield to no-yield crop.

He anticipates some producers putting some of their pasture into CRP in the future, or some placing more buffer between them and the river, or some who will reduce grazing or abandon pastures along some areas of the river.

But he said plenty are planning to go back and repair pasture damages, redesign fences and put more distance between fences and rivers, or replace woven wire fences that were destroyed with electric fences as a cheaper option.

Woods said repairs will most likely take into next year, with some cow producers doing some reseeding or burning off their pastures, etc. Most crop producers have done something about working their ground and getting fields back to pre-flood condition.

“Some of these cattle producers will be here again next year by the time they can get everything put back together,” said Woods.

He said reimbursements with FSA relief programs are a cost-share situation. The ECP program is scenario-based, he said, with fences being reimbursed at 75 to 90 percent depending on the severity of damage.

Woods said he saw a 10,000- to 15,000-bushel grain bin washed into a field in northern Clay County, and at least one field near Peterson and one north of Spencer where sand was two feet deep in draws and waterways.

Sand removal atop rich farm soil has been a tricky process, Woods said, and added that producers also need to be careful about where they place unwanted sand. He said they cannot take it to local wetlands, nor place it back in the river.

“Producers will need to place that sand where it will have the least environmental impact,” said Woods.

He said he anticipates more

assistance programs coming out for flood losses similar to what they’ve had in the past, including programs tied to crop insurance losses. He said he is not aware of major livestock losses, but knows of livestock wandering out of pastures.

Woods said Clay County FSA requested relief funds in the amount of $1.1 million, as a starting point.

“I’m going to say that 20 to

30 percent of crops were destroyed or damaged beyond repair,” said Woods. “Some soybeans came out of that, and some producers had been waiting to plant with all the spring rains, so a lot of them planted after the flood too, if they could get in. So there were a lot of soybeans planted late, and that actually turned out OK here.”

Woods said producers have been frustrated with the way

“things have been.” But he said there is $31 billion in national economic disaster aid for farmers and ranchers in the second extension of the 2018 Farm Bill, as well as $21 billion in agricultural disaster aid from the American Relief Act of 2025 to be distributed by USDA to cover expenses due to loss of revenue, and quality of production of crops in 2023 and 2024. Woods said there will also be $10 billion in economic aid and response coming in some form of payment for commodities of corn and soybeans. He encourages producers to apply for disaster assistance when programs and deadlines are announced, and check with FSA offices to know when those deadlines are. For now, he said producers need to come in and sign up for ARC/ PLC before April 15.

Deere technology turns sprayers into targeted weed weapons

By DARCY DOUGHERTY MAULSBY

Increasing input costs. Narrow application windows. Tighter margins. It’s never been more important to do more with less in farming.

That’s why more producers are investing in high-tech solutions to manage weeds more effectively, including See & Spray technology from John Deere.

With a combination of on-board cameras and computers, See & Spray turns sprayers into targeted, weed-killing machines, only applying crop-protection products where they are needed.

“Blink your eyes — you’re too slow,” said Josh Ladd, go-to-market manager/application for John Deere. “See & Spray works at lightning speed.”

He’s referring to See & Spray’s ability to scan 2,500 square feet per second, thanks to on-board cameras, as the sprayer moves across the field.

“The technology makes decisions in 200 milliseconds or less about when and where to apply crop-protection products in the field,” Ladd said.

See SPRAYERS, Page 8D

& Spray technology was used.

Continued from Page 7D

See & Spray uses 36 onboard cameras, including 16 on each side, and four in the center. “There’s a camera about every three feet,” Ladd said. The technology is available as a factory-installed system on a variety of John Deere and Hagie sprayers. See & Spray is also available as an upgrade kit to retrofit existing sprayers. See & Spray technology works with a variety of crops, including corn, soybeans and cotton, as well as fallow ground. See & Spray Premium is an entry-level product that starts at $25,000. It’s available as a factory install or a preci-

sion upgrade that turns a grower’s current sprayer into a precision machine. By target spraying only where necessary, Deere notes that farmers and custom applicators can: Cut herbicide usage by more than 50%. (These savings refer to volume application savings. Individual results will vary, based on weed pressure, crop types, machine settings and environmental conditions.) “This past year, we covered over a million acres,” Ladd said. “On average, we

“This

past year, we covered over a million

acres. On average, we saw a 59% savings in non-residual herbicide products. The return on investment is definitely there.”

Josh

Ladd, go-to-market manager/ application for John Deere

DEERE’S SEE & SPRAY TECHNOLOGY uses 36 on-board cameras, including 16 on each side, and four in the center. There’s a camera about every three feet. By target spraying only where necessary, Deere notes that farmers and applicators can cut herbicide usage by more than 50%.

saw a 59% savings in non-residual herbicide products. The return on investment is definitely there.”

Reduce water use and crop stress. See & Spray reduces crop stress by providing an effective weed-kill strategy, eliminating weeds that rob plants of valuable nutrients and moisture.

Improve cost efficiencies and boost profit potential.

Deere has developed a variety of See & Spray options. See & Spray Ultimate, for example, is available for select 400 and 600 Series John Deere sprayers. The sprayer’s two tanks help growers manage herbicide resistance by using two independent tank mixes in one pass.

The dual-tank configuration lets farmers and custom applicators apply targeted spray and traditional broadcast at the same time. Applicators can target-spray weeds and broadcast fungicide, or better manage weeds by applying a non-residual targeted spray and residual broadcast, all in one pass.

“Combining two passes in one saves time and money,” Ladd said.

Soybean trials show 3- to 4-bushel yield boost

See & Spray technology isn’t just for large farms or big custom applicators.

“We’re seeing utilization from all different sizes of farms all over the country that want to be as efficient as possible,” Ladd said.

How does See & Spray “know” when to spray?

Deere has designed the technology to recognize what a healthy corn, soybean or cotton crop looks like at every stage of growth. When a sprayer is working in a corn field, for example, the cameras and computers are basically answering the question “Is it corn, or is

it not corn?” for each plant the technology “sees.”

“That’s how it knows to spray volunteer soybeans, for example, or Palmer amaranth,” said Ladd, who noted that the technology incorporates computer vision and machine learning.

See & Spray technology has proven to be a great fit for producers who want to farm more sustainably, Ladd added.

“We’re driving towards individual weed identification. We’ve

got a long list of features we want to bring to market to make this technology

even better.”

Josh Ladd Go-to-market manager/application for John Deere

“Along with less product you have to apply, less water is used, as well,” he said.

Doing more with less could be the motto of this technology, which contributes to higher yield potential. Beck’s Hybrids put See & Spray technology to the test and documented the results in its 2024 Practical Farm Research report. The data showed a 3.3- to 4.2-bushel-acre soybean yield advantage where See & Spray technology was used.

“These yield increases give us a lot of optimism,” Ladd said. After the numbers were

crunched, the savings per acre with See & Spray technology ranged from $12.80 to $24.84, according to the Beck’s Hybrids report. (All See & Spray calculations included the herbicide cost for the acres sprayed and a $5/acre tech fee for the non-sprayed acres.)

“John Deere’s See & Spray technology allows farmers to target specific weeds, reducing herbicide use,” noted the Beck’s Hybrids report. “Using less herbicide can minimize crop stress, which may offer yield benefits. In our first year of testing this technology, we witnessed both benefits. We plan to continue testing this technology in the future.”

While there’s a bit of a learning curve associated with See & Spray technology, it’s designed to be user-friendly. Deere also offers a quick reference guide in the cab.

“This technology does a phenomenal job, from needing less product to giving you more application flexibility,” Ladd said.

If this all sounds too good to be true, that’s understandable, Ladd noted.

“There’s a lot of ‘I want to see it to believe it.’ Growers and applicators want to make sure not only that the technology works, but that it works in their geography.”

More Deere dealers across the country are demonstrating the technology, Ladd said. The John Deere team continues to refine the See & Spray technology to make it even more useful, he noted.

“We’re driving towards individual weed identification,” Ladd said. “We’ve got a long list of features we want to bring to market to make this technology even better.”

Josh Ladd on See & Spray technology

“This technology does a phenomenal job, from needing less product to giving you more application flexibility.”

“There’s a lot of ‘I want to see it to believe it.’ Growers and applicators want to make sure not only that the technology works, but that it works in their geography.”

•

•

By LORI BERGLUND

WEBSTER CITY — “Trial by fire” may be a cliche, but for Nick Willwerth in his first year as general manager at UnitedCo-op, it’s more than appropriate.

Willwerth took over the role of general manager in December 2023 after the retirement of long-time United Co-op General Manager Tim Scott. Barely four months later, United Co-op would face perhaps its greatest challenge since coming together from five existing grain elevators in 1977.

It was barely past midnight on April 7, 2024, when flames engulfed the woodhouse bin at United Co-op’s Stonega site. The fire was so intense that flames could be seen from miles away. A camera located at a nearby farm captured a lightning strike that appeared to be the source that ignited the wind-whipped blaze.

As horrific as the blaze and resulting damage were, it is ultimately not what will stay with Willwerth the longest.

“Looking back, I would just say that the way everyone came together in a time of adversity, is what really mattered,” Willwerth said. “That’s the cooperative spirit; that we can do things together that we couldn’t do by ourselves. That’s what stands out to me the most.”

Willwerth, who grew up near Vincent, is a graduate of the University of Iowa with a degree in business management. He came to United Co-op six years ago, having worked for Consolidated Grain and Barge in Kentucky. Prior to being named general manager, Willwerth served as controller for United Co-op.

His appreciation is deep for the many area fire departments that responded quickly to help, to law enforcement, railroad crews, fellow employees, and even members of United Coop who were quick to volunteer their time and equipment as well.

“We had every fire department from 20 miles around, probably more,” Willwerth recalled. Volunteers from those departments had not only a very long day on the day of the fire, but continued to keep watch for several days, lest smoldering grain reignite. Likewise, employees and customers of United Co-op rallied around to do whatever they could.

“When this happened, it was all hands on deck,” Willwerth said. “All the different departments, all of our employees, everyone just rallied around — and that includes our customers. They were more than willing to work with us.”

He gave his appreciation to employees, board members, customers, and neighbors who, like in the history of all great rural communities, were quick to lend a hand.

There were farm customers who called to offer their own backhoes and endloaders to assist in the clean-up. Perhaps even more importantly, farm

customers worked logistically with United Co-op to get their grain to other elevators within the United Co-op family, taking the strain off the heavily damaged Stonega site.

The number of farmers who regularly haul grain to United Co-op’s Webster City elevator has declined in recent years. Taking larger equipment through the downtown, coupled with faster unloading equipment at the rural sites, means the vast majority of grain comes in at the Stonega, Kamrar, Highview and Stratford sites.

While farmers did make more use of Webster City this year, Stonega also used temporary on-site storage to accommodate farmers who needed to haul there. The grain was then shipped by United Co-op to sites such as Highview.

“It’s a testament to the customers who stayed loyal to us,” Willwerth said. “They were willing to dump downtown, which is slower.”

In the end, the physical loss at Stonega included the 1970s-era woodhouse, an ad-

jacent wood annex, and two smaller metal bins. Some 330,000 bushels of soybeans were lost in the blaze, but there was no financial loss for farmers.

At first, it was feared that two new bins that got extremely hot during the fire may also have to be taken down. The bins were later inspected and found to be in top condition. During the active blaze, firefighters had used infrared detectors to measure the heat on the new bins and began dousing them to cool them down.

“Three years ago, we put up a 550,000-bushel bin and a 140,000-bushel bin, plus a dryer, a receiving pit and a receiving leg,” said Stonega Location Manager Rich Lura. None of those facilities were lost.

To replace the woodhouse and smaller metal bins that were a total loss, United Coop worked quickly to come up with a building plan to construct a new 550,000-bushel bin.

“We went from shock when we first got the call, to prob-

lem solving, and then to figuring out what we do next,” Willwerth explained. “It was A, get the fire out; B, get it cleaned up; C, rebuild.”

With the new bin joining those put up three years ago, Stonega is well positioned to continue providing services for area farmers for decades to come.

Stratford sees growth

At the outset of 2024, Stratford was the site where most of the building action was slated to take place. The fire vastly added to the construction work, but all of the work went forward at Stratford as originally planned.

In Stratford, a new office and scale were constructed, along with two, 500,000-bushel steel bins. The challenge for the Stratford site is that the elevator is located in town, with nearby neighbors. Building a new office and scale down the street on the other side of Shakespeare Avenue, allowed the new bins and grain leg to go up on the existing footprint of the old facility.

UNITED CO-OP GENERAL MANAGER Nick

said it was a group effort that sped recovery for the Stonega location. With him, continuing from left are; Anita Witte; Rich Lura, location manager; and Clint

-Submitted photo

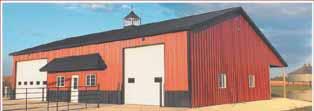

THE ALUMINUM-CLAD WOODHOUSE that was destroyed in the April 2024 fire is shown at right in this photo of the Stonega location of United Co-op.

“One of our board members down there, Rick Carlson, had that idea,” Willwerth said. “Our scale was right there, it was getting old, and if we moved that office across the street to the east, it gave us the room when we needed to expand.”

The project greatly sped up the time it takes to unload, helping farmers get back to the field faster during harvest season.

After several busy years of major capital improvements at several different locations, United Co-op is looking forward to perhaps a less eventful year in 2025. Improvements to the rolling stock and regular equipment replacements are planned for the year ahead. This spring, farmers can expect to see a new self-propelled sprayer in the fields served by United Co-op.

“We still have other projects in mind for the future,” Willwerth said. “But we’re going to build up the balance sheet first.”

By DARCY DOUGHERTY MAULSBY

LATIMER — Market demand for oats is growing, and more farmers are integrating this useful small grain into their crop rotations. A new market for oats is also on the way, thanks to Iowa farmer/entrepreneur Landon Plagge and other farmers who’ve invested in a new oat processing plant in Albert Lea, Minnesota.

Landon Plagge spearheads new processing plant See PLAGGE, Page 2E

“The brands are paying oat millers 22% more than they were a few years ago,” said Plagge, 43, a corn, soybean and oat grower from Latimer in north-central Iowa.

Plagge is the driving force behind Green Acres Milling, a farmer-owned business that’s preparing to break ground in the spring of 2025 on a new $55 million processing facility on the south side of Albert Lea. The mill is also a partnership with

Plagge’s wife, Anne, an assistant professor of family services at the University of Northern Iowa.

The timing for this new plant is right, as demand for oat-based products like oat milk, bread and cereal continues to grow. Plagge and 65 farmers from Minnesota, Iowa, South Dakota and Wisconsin who’ve invested in Green Acres Milling are excited to help grow the Midwestern oats industry.

Canada currently grows the vast majority of oats processed and consumed in the United States. “About 95% of the oat products you see in the grocery store are made with Canadian oats,” Plagge said.

Green Acres Milling plans to process 3 million bushels of oats per year. Project leaders expect the plant to be operational by the early fall of 2026. “Our transportation costs will be significantly lower than shipping oats from Canada,” Plagge noted.

Traceability is another huge advantage, he added.

“With farmers delivering direct to Green Acres, we can offer traceability — something the large mills can’t offer with their business model.”

Where did all the oats go?

Plagge farms 4,000 acres in northern Iowa with his father and uncle. Among their fields are many acres of oats, a rarity among the nearly endless rows of corn and soybeans in the region.

While oats were once an integral part of Midwestern crop production, this small grain has all but disappeared in the U.S. — a trend that started decades ago.

The second half of the 20th century brought a myriad of changes to Midwest agriculture, including the near disappearance of work animals, the development of modern confinement barns to house

pigs and chickens, and readily-available synthetic nitrogen fertilizer. Federal policy incentives also evolved to favor corn and soybean production. The bottom line? It became easier and more profitable to grow only corn and soybeans.

Oat demand is growing

More farmers are taking a new look at oats, however. The unprecedented demand for oats in recent years continues to grow, driven by the popularity of oat-based products like oat milk, breakfast cereals, yogurt and more.

Europeans consume 30 pounds of oats per capita per year. While Americans only

consume 5.2 pounds per capita per year, this is up from 4 pounds per capita a decade ago, said Plagge, who noted that oats are naturally gluten free and allergen free.

The U.S. Food and Drug Administration (FDA) recognizes that oats are good for heart health. “The market potential for oats is there, especially as consumer demand for healthier food grows,” Plagge said.

Oatly, the Swedish company that took North America by storm in 2017, buys a lot of food-grade oats, primarily from Canada, the world’s largest exporter of oats. Oatly’s sustainability goals have spurred the company to ex-

plore sourcing more oats from the Midwest. In recent years, the company has connected with Practical Farmers of Iowa (PFI), a nonprofit group that supports farmer-led innovation.

Plagge is one of a handful of farmers who’ve participated in an oat-growing pilot program that PFI launched in Minnesota and Iowa in 2019 to help growers diversify their corn and soybean rotations. Diversification makes sense to Plagge, whose travels have taken him around the world.

“When I spent a year after high school working on farms and ranches in Australia, I saw

See PLAGGE, Page 3E

but disappeared in the U.S. — a trend that started decades ago. But oat demand is beginning to grow again, driven by the popularity of oatbased products like oat

how those producers used no-till and planted a diversity of crops, including oats,” Plagge said.

Oats help farms change for the better

The value of oats isn’t just in the crop itself. Some farmers report a yield bump in corn and soybeans by adding oats to the rotation. Plagge has seen many other things change for the better when small grains join a crop rotation.

“If you seed the oats early enough, they help choke out weeds,” Plagge said. Oats also break up pest cycles, making it harder for yield-robbing insects like corn rootworms and soybean cyst nematodes to wreak havoc.

While crown rust and the DON vomitoxin can impact oats, these fungal diseases haven’t been a major problem on Plagge’s farm.

“We haven’t had to use fungicides or insecticides on our oats for the past six years,” said Plagge, who has grown oats for 10 years. “By growing oats and cover crops, we’ve cut our use of pre-emerge herbicides on corn and soybeans and have been able to reduce our total chemical use by one third.”

In addition, oats are a less nitrogen-dependent option that can help build soil health. Research is showing that including oats in a crop rotation reduces erosion and helps protect water quality. “We’ve seen better water infiltration in our fields where we’ve grown oats,” Plagge said.

He isn’t alone. Martin Larsen, who farms near Rochester, Minnesota, participated in the PFI/Oatly pilot project and has conducted a lot of testing.

“He found that nitrate levels are reduced about four-fold with an oat crop,” Plagge said.

Corn that grows in soil where oats grew the previous year typically doesn’t need as much nitrogen fertilizer as a crop in a corn-only or corn-soybean system. Oats can also be part of a double cropping system with soybeans and can fit well with a grazing system (along with sorghum sudangrass and millet) for cattle.

Plagge, who has expanded his oat production to 2,500 acres in the last five years, stresses that management is important.

“You must treat oats like a primary crop, meaning you need to plant the right varieties and fertilize the crop,” said Plagge, who strives to produce oats with a test weight of 38 pounds per bushel.

Since oats mature in the upper Midwest around June/July, while corn and soybeans mature in September/October,

this impacts crop insurance.

“We’ve been able to cut our crop insurance by about half,” Plagge said. “A more diverse crop rotation offers a lot of benefits, removes a lot of risk and adds more resilience to a farming operation.”

“We’re confident this is going to work” Plagge and his fellow Green Acres investors hope the new Albert Lea plant encourages more farmers to grow oats.

“By

Landon Plagge

The facility will have an agronomist on site to help growers learn more about growing oats.

While that reflects Plagge’s mindset as a farmer, his experience in the food business also helps him bring a unique skill set to Green Acres Milling. When the local grocery store in Latimer (population 471) closed permanently, Plagge and his family reopened it nine years ago.

“Our goal was to provide competitive prices and pay competitive wages,” Plagge said. “The store gave us a lot of experience with the grocery business and working with big brands.”

After Plagge and his family sold the grocery store a year ago to other community members, he shifted his focus to Green Acres Milling. To help this new venture succeed, he’s done his homework. He’s toured oat-milling plants in Finland, Sweden and Switzerland to study best practices to incorporate into Green Acres Milling.

“We’re confident this is going to work. We’ll be providing actual food for consumers, and I’m excited about how oats can help farms become more resilient and profitable.”

ARTIFICIAL INTELLIGENCE (AI) TOOLS are able to collect and analyze data and make predictions, such as soil analysis, through the use of soil

-Photo

By KAREN SCHWALLER

Alexis Stevens said the “wave of the future is already here.”

She’s talking about the use of artificial intelligence (AI) in agriculture, and the importance of governing it with cybersecurity.

Stevens, Iowa State University Extension and Outreach farm management specialist from Jefferson, said the use of cybersecurity and AI among ag producers was at less than 10 percent in 2015, and has grown to more than 60 percent across the ag sector as of 2023.

“I am incredibly excited about the future of agriculture,” said Stevens. “I call myself an ‘ag futurist’ because I think about how agriculture is going to change so much, and how it’s already changed.”

She said AI tools are able to collect and analyze data and make predictions, such as soil analysis, through the use of soil sensors. It evaluates soil composition, pH levels and moisture to recommend the best planting strategies. Sensors can also monitor soil moisture, and AI can

schedule watering to reduce waste and ensure adequate hydration.

Fertilizer can also be managed through AI, avoiding overapplication and minimizing environmental impact.

Stevens said AI can help farmers choose seeds that will work best in their growing conditions through genetic analysis and recommendations of planting densities.

“AI takes all of a farm’s history and all the genetic information that an agronomist or seed dealer might have, so you have the best agronomist in your back pocket when you use AI,” she said, adding that AI can help with genetic selections to match specific growing areas, which can be useful for people with less knowledge of agronomic issues.

She said AI is especially useful for crop monitoring with tools like drones, satellites and sensors to help see under the canopy to detect possible diseases and pest issues before they become a big problem, and nutrient deficiency.

“By the time you recognize some diseases in the field when you go out and walk

“AI (artificial intelligence) takes all of a farm’s history and all the genetic information that an agronomist or seed dealer might have, so you have the best agronomist in your back pocket when you use AI.”

Alexis Stevens Iowa State University Extension and Outreach farm management specialist

them, it’s too late — you’ve got yield loss or have lost a whole field,” she said. “Imagine if you had 10 extra days to decide if you needed to spray. AI can return yield back to the farmer because disease issues can be caught a lot sooner.”

Stevens said the wave of the future will include more drones applying fertilizer and chemicals and fewer tractors and sprayers. She went as far as to say that, while that kind of drone might be an investment of $50,000, a tractor and sprayer might cost hundreds of thousands of dollars. She said less labor is needed when using AI to apply fertilizer and chemicals — a cost-saver for producers. This also eliminates the stress of finding farm labor and someone who is confident

in their ability to run a sprayer.

“AI also takes a human being out of the driver’s seat, which takes them away from the chemicals so there is less exposure to those operating the equipment,” she said.

Stevens said yield prediction technology is here already, with tools that analyze historical data, weather patterns and soil health to predict crop yields.

“Right now there are companies that have AI modeling tools that can go out into your corn field in early August and can predict within 3 percent accuracy what your yields will be, if all things were constant and weather patterns were similar to what they normally are,” she said. “They may even be more accurate than USDA yield predictions.”

She said being able to predict with that degree of accuracy what corn and soybean yields might be would give producers an edge in being able to confidently market their grain.

Stevens, a fifth-generation farmer, said having access to

a field’s history is something that doesn’t have to go away with AI.

“Typically, when someone passes, all those years of agronomic knowledge are gone,” she said.

“With AI, you can still have all that information in one tiny device or app, and that’s powerful. That will be incredibly beneficial to young people as they move into farming — they may not have that long history, but they can have that tool to give them the history.”

Stevens said automation is present in nearly every area of agriculture today. Autonomous farm equipment is in use, but she said it still needs some improvements before being widely used — such as the ability to override the automation to drive a piece of equipment manually if necessary. Inability to connect to the cloud from everywhere is also a problem in many areas of Iowa.

The up side to operator automation in equipment is that it can detect if debris is in the way of a machine, and in another area, can also give a producer more time with his/ her family if they don’t have to be in the tractor all the time.

“We don’t have to work such long hours and work ourselves to death at harvest time,” Stevens said.

She said AI allocates resources efficiently for areas such as energy use, optimizing the use of power for equipment and irrigation systems, labor

management, forecasting labor needs based on workload predictions, and scheduling tasks accordingly.

Stevens said AI identifies risks to crop production and suggests risk mitigation strategies, such as for climate change and market analysis. She said

it doesn’t matter whether or not producers believe climate change is real, since the government is forging ahead in their charge that it is real.

She said AI can integrate data from all devices across the farm.

“It brings all kinds of apps together to cre-

ate one big farm brain to connect all things together for best decision-making,” said Stevens.

Livestock

She said AI can help in meat production with health monitoring and early disease detection, nutrition management, op-

timal breeding schedules, precision livestock farming (smart barns); disease outbreak prediction/control, and financial optimization.

To learn more Some resources for more cybersecurity information can be found at: ISU Ag Decision Maker (www.agdecisionmaker.iastate.edu); the ISU Center For Cybersecurity Innovation and Outreach (which Stevens highly recommended): www.cyio.iastate.edu; Iowa Cyber Hub at http:// www.iowacyberhub.org, or people could contact the FBI if necessary.

“Once you click in the link they send, they’re in,” Stevens said of personal bank accounts.

She advised people to know what phishing is, and to be cautious about clicking on email attachments — cyber criminals often convincingly pose as people with whom business is done.

Stevens said passwords are important, along with any two-step process to access account information, since it’s all to help protect against cyber criminals. She said passwords need to be long and or complex, changed every so often, and never reused.

Stevens said dairy farms have outpaced most of production agriculture in terms of getting on board with AI because they have had to. She said with so much happening at dairy farms, it helps with optimizing feeding schedules, monitoring health and detecting disease, along with boosting production.

Automated milking tracks milk quality and quantity, pays attention to the needs of each cow specifically, and that smart breeding improves milk yield, fertility and herd longevity.

“You guys are light years ahead of the rest of us,” she said, adding that (especially with dairy milk), people want to know their food is safe.

“People think, ‘It’s all poison,’ or ‘We’ve been lied to.’ AI allows traceability of what’s actually in the (food) supply, and there’s power in that.”

“It’s not a matter of IF it happens, but WHEN,” she warned. “Have a plan for if you somehow have no access to your smartphone, and backup your information often. Have a plan for a time when the internet is down and you can’t get to your planting data — things like that.”

She said people should work with a cybersecurity firm if possible, develop a plan to become more secure, become security literate and develop a level of trust with the people with whom business is done. She also said not everyone on the farm needs to have access to all data.

Fraud Stevens said agriculturalists must be vigilant about cybersecurity on their farms, since cyber criminals don’t typically go after the large box stores or internet chains. She said they usually target businesses with fewer than 10 employees because they think they are too small for someone to go after them.

She encouraged producers to start small with AI tools tailored for specific agricultural needs, working with a trusted company with a history in agriculture and an understanding of a producer’s needs, and establishing that crisis management plan in the event of a cyber incident.

She said AI and cybersecurity together can detect cyber threats with predictive analytics to anticipate vulnerabilities. It can help secure AI systems, protect data integrity/prevent misuse, and ensure ethical AI use to prevent unintended consequences.

Overall, Stevens asked producers if they could imagine making 10 percent more money than they did the year before, and what they would do with it.

Often, she said, a cyber criminal may have hacked into a bank account without the owner knowing it, and it might take most of the year before anyone notices it.

“An antivirus system may not always catch a financial breach — the average cost of a data breach could be more than $4 million,” she said. “If that happens, you would have to start selling farms.”

Alarmingly, she said 82 percent of cybersecurity data breaches involve human error.

“I may have done something wrong that I didn’t know,” she said, adding that people should always check in personally with financial institutions or places of business that ask for personal information, and to think twice before giving that information out over the internet.

“That strengthens rural America, and the use of AI reduces the carbon footprint,” she said, adding that if producers sign up for carbon sequestering programs, an AI tool can help them show or prove that they have done so.

Stevens said producers can look into a website called, “There’s An AI For That” — a clearinghouse of sorts to find an AI for almost anything they might need, complete with associated costs. She said as of late January there were nearly 29,000 AI tools available, and that the number has and will increase substantially in a short time, simply because technology is developing that rapidly.

By KAREN SCHWALLER

TERRIL — Improvements

at Pro Cooperative in Terril have yielded a new agronomy complex and office, streamlined traffic flow in and out of (and throughout) the elevator grounds, put the scale system under roof, and centralized company operations.

These renovations began in the fall of 2023 and ended in the fall of 2024. The new systems were in place and used for the 2024 harvest.

“We outgrew our old facility. We couldn’t grow anymore because our old facility couldn’t handle it, and we couldn’t take on any new business,” said Pro Cooperative Location Manager Todd Nissen. “Nothing was automated; it was all done by hand.”

Nissen said renovations called for the demolition of several old buildings that once stood on the grounds. They were replaced with a new EPS agronomy center measuring 385 feet by 88 feet, with an office attached to the front.

The center features all needs under one roof — including large areas for chemicals, seed storage and a new 60-foot shop for maintaining and repairing company equipment.

“The agronomy complex has two load-out bays for liquid fertilizer, and one of them is a 24-hour bay, so all of our growers can access it anytime with their code so they can get water or fertilizer or whatever they need,” said Nissen. “They only need to punch in their order number (arranged ahead of time) and come in at any time

— we don’t even have to be here.”

Farmers can load liquid nitrogen, starter fertilizer, ammonium thiosulfate and more, along with any chemical, which can be premixed and ready to load onto tankers and brought to the field.

“With this facility we have 14 bulk product tanks and 10 other products on mini-bulk stands, so we have access to 24 bulk products at one time,” said Nissen. “Anything people use that we don’t have in bulk we

can add with an inductor cone.”

The new campus also features a repack area, where farmers can bring in their mini-bulk and get it filled with any chemical they need. The new state-ofthe-art system measures chemicals by the pound instead of gallons; Nissen said that results in a more accurate measurement and is fast.

The complex renovation also added an additional UAN (32 percent liquid nitrogen) tank that holds 1.5 million gallons.

“Before, we only were able to store about a third of that — about half a million gallons,” said Nissen. “Now we can order more at a time and store it here, and pass along a better price to our growers.” He said these improvements are enhancing the work of their producers.

“With this system, recipes are made up on the work order, and then it’s pulled into the system. Once you click on that order, the system pulls everything in and mixes it all for you,” said Nissen.

“People are catching onto it, and it’s so efficient,” he said. “We can fill a full tanker load (in and out) in 10 minutes because it’s all automation.” The seed area features five bulk bins for five bulk products, along with other needed varieties, a new load-out for bulk seed, and a truck loading ramp to help move product where it needs to go. Seed treatment can now all be done under roof as well.

New scale

Nissen said the previous Pro Cooperative campus featured a scale system that created bottlenecks every year, which he said would sometimes frustrate people who had to spend time waiting in line at harvest time.

The new design features inbound and outbound lanes with a probe sitting between them, which is able to swing to both sides. Farmers can come in with their grain, have it probed, then drive ahead to the new scale house, which features two new sideby-side truck scales (14 feet by 80 feet) that are under roof. Producers now use a radio frequency identification (RFID) card to check in and out of the scale process using scanners there. Intercoms are available if someone needs to contact the office.

Nissen said elevator grain capacity is at 3.7 million bushels. This renovation did not add any new grain storage. The last grain storage improvements at Pro Cooperative were an 800,000bushel bin in 2018-2019, and another one of the same size two years before that.

“We’re way more efficient now. (Elevators) are all going to be this way eventually. This is the future. Who wouldn’t want to do business at a place where there are stateof-the-art facilities?”

Todd

Nissen

Location manager, Pro Cooperative

Nissen said the scale being under roof will render more accurate readings of grain weights, without the problems associated with wind moving the scale or snow sitting on the scale. The new card readers allow farmers to check in and out of that process without having to check in person with anyone. They can just be on their way, saving time.

He also said this improvement has reduced the bottleneck situation they had previously, with only one scale.

“All the pits would be empty, but everybody was waiting to get on the scale,” said Nissen. “We have four pits to dump at this facility and we can do it in a hurry. Three of them are 15,000 bushels per hour, and one is 20,000 bushels per hour.”

Pro Cooperative installed a new road leading into the elevator campus, keeping truck and tractor traffic out of the city streets. That access road improved traffic getting to the elevator, while improving safety for the citizens of Terril.

Pro Cooperative has 14 locations. The Terril location now serves as a regional hub for the northern region of the company, and the other similar hub is in Rolfe, which serves the company’s southern region. Farmers can go to their local Pro Cooperative elevators to do their business, but all seed and chemicals come from one of those two hub locations.

“Everything is in one spot — you’re not doing inventory on five locations because all the agronomy products are in (the two main hubs),” said Nissen.

The cost of this renovation, Nissen said, was a very substantial commitment by the Pro Cooperative Board of Directors, and indicated their commitment to the farmers they serve, Nissen said.

“It was needed,” he said. “We’re way more efficient now. (Elevators) are all going to be this way eventually. This is the future. Who wouldn’t want to do business at a place where there are state-ofthe-art facilities?”

COOPERATIVE now features a scale system that is all under roof, which gives a more accurate reading without wind issues or snow sitting on the scale. With streamlined inbound and outbound roads and larger sideby-side scales, Location Manager

said the scale system is state-of-the-art, with reduced or almost no waiting in line to unload grain.

By DARCY DOUGHERTY MAULSBY

GOWRIE — Drones continue to revolutionize crop production and help farmers boost their profit potential — and a Gowrie-based company has been on the leading edge of this new frontier from the start.

“We’ve come a long ways in a short time,” said Duane Davis, founder of SkyDronesUSA, a Gowrie-based distributor of drones and drone accessories. “It’s not uncommon for today’s drone technology to help farmers save 50% with crop inputs, while being better stewards of the land.”

SkyDronesUSA has evolved as technology has evolved. “When we started in this business 14 years ago, we were strapping cameras on the belly of the drone,” Davis said. “Then it would take days to ‘stitch’ all the images together in software to make the data useful. The capabilities of today’s high-tech drones have gone far beyond that.”

SkyDronesUSA, a veteran-owned, family-operated business with more than 40 years of consumer electronics experience, specializes in unmanned aerial vehicles (UAVs) for agricultural use. An-

“We’ve come a long ways in a

“You

Duane Davis Founder, SkyDronesUSA

swerAg, a partner of SkyDronesUSA, helps optimize applications (from cover-crop seeding to foliar feeding and other inputs) and multi-spectral mapping, which helps farmers and agronomists spot areas of nutrient deficiencies, weed pressure and disease challenges.

“Today’s drones can apply foliar fertilizer, dry fertilizer, crop scouting, cover-crop seeding and crop-protection products,” said Davis, a lifelong aviation enthusiast and Vietnam veteran who was a crew chief on fighter aircraft during his military service.

“You can watch the health of your crop throughout the growing season and determine where you can cut back on inputs and where you need to add more,” Davis said. “The data gathered by the drone also becomes a valuable record to help you track the changes you make and fine-tune your farm management year after year.”

The precision inherent with this technology allows much more accurate, judicious use of inputs.

“We can do spot-spraying at a very low rate, if that’s the best solution,” Davis said. “We can treat 20 acres, for example, instead of the whole 80-acre field.”

Drones can also provide better coverage and less risk of drift.

“Drones fly about 12 feet over the corn tassels and can fly even closer at the V2 or V3 stage,” said Davis, who added that drones also offer advantages in terms of safety and insurance issues, compared to crop-duster planes.

Covering more acres faster

It helps that the FAA approved a number of new regulations in 2024. Drone pilots now can legally fly their drones at night to apply fertilizers and crop-protection products. (This is a plus, since there’s usually little or no wind at night.) New FAA regulations also permit swarming, where multiple drones operate at the same time and cover more acres quickly.

“Also, you can now fly drones out of the line of sight,” said Davis, who noted that GPS and RTK satellite technologies guide the drones.

Some of the latest, most powerful drone models can go 40 miles per hour.

“These drones can generally cover 50 to 60 acres an hour, although you might be able to cover 70 acres an hour on a good day,” said Davis, who added that large, spray drones cost roughly $30,000 to $45,000.

About 60% of the farmers Davis interacts with choose to buy their own drone and fly it themselves, while about 40% want to hire AnswerAg to do custom work.

“Some farmers don’t want to go through all the steps to get licensed, and that’s fine,” said Davis, who noted there are more registered drone pilots than commercial pilots, according to the Federal Aviation Administration (FAA).

Agriculture has become a leading market segment for drone technology. This sector is also poised for significant growth, according to a March 2024 article (“The Flourishing of Drones in Agriculture”) on Commercial UAV News.com. Based on the latest research by Drone Industry Insights, this sector is set to expand from $3.6 billion in 2024 to $5.7 billion by 2030.

“As technology evolves and regulations adapt, drones are set to become an integral part of agricultural innovation, optimizing workflows and enhancing the sector’s overall productivity and efficiency,” noted Commercial UAV News. Drone technology is advancing at a rapid rate, making it much more viable for farmers.

“We’re here to help, whether you want to buy a drone and need training, or you prefer custom application services by our partner AnswerAg.”

“This technology is only going to get better” Drones offer timely applications of fertilizer and crop protection products.

“You can fly when ground rigs might not be able to go, due to wet soil conditions,” Davis said.

Not only does this help

By KRISTIN DANLEY GREINER

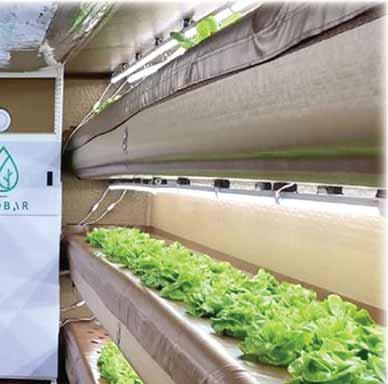

Growing fresh, local produce in areas without healthy water sources or fertile soil can seem impossible, until now — with AirFarm.

Described as the world’s first inflatable farm, AirFarm was named a CES 2024 Best of Innovation Honoree, the second time it’s earned that honor. It’s a technological tool that allows for cultivation with minimal water.

Developed by Midbar, AirFarm comes in two sizes and has been sold primarily in countries like Korea, Japan, Jordan and the United Arab Emirates.

“While we haven’t made sales in the U.S. yet, we are actively exploring opportunities there,” said Jenna Kim, business manager at Midbar.

Company leaders have shared that the business name, Midbar, means desert in Hebrew. Jordan happens to be one of the most water-scarce countries in the world. The high sodium concentration in the ground water there also makes it unsuitable for agricultural uses.

So Midbar rolled out the AirFarm in Mafraq, where farming efforts have been virtually impossible. The refugees there were trained to operate AirFarm systems, which brought them gainful employment and allowed them to grow fresh produce for local residents who had limited access to such food.

“AirFarm, as a scalable indoor farm, is designed to grow a wide range of crops, including leafy greens, root vegetables like carrots, seed potatoes and herbs. However, large fruit-bearing trees and crops with extensive root systems are less suited for our system,” Kim

a technological tool that allows for cultivation with minimal water.

told Farm News. AirFarm comes in two sizes — a 10-foot model that is primarily used for education, research and home use, and a 20-foot Airfarm that can create a large yield if someone plans to sell the crops.

AirFarm units also have been installed at Al al-Bayt University in Mafraq, Jordan, in collaboration with KOICA (Korea International Cooperation Agen-

cy). The aeroponic container is described as quick and easy to install. The lightweight system also doesn’t need heavy steel frames like greenhouses.

“We have successfully made our journey to the UAE, and they have successfully grown leafy greens in there,” Kim said. “They’re using it in school cafeterias to provide salads. We

See AIRFARM, Page 11E

“AirFarm, as a scalable indoor farm, is designed to grow a wide range of crops, including leafy greens, root vegetables like carrots, seed potatoes and herbs.”

Jenna Kim Business manager for Midbar

The Broad Spectrum Disease Prevention

General information: BioEmpruv is a biological fermentation extract containing a host of different substances that accomplish numerous actions within a corn plant. BioEmpruv contains biologically derived extracts, enzymes, vitamins, minerals, natural growth regulators and simulators, antioxidants, amino acids and bases and more. It also contains natural phytoalexins to boost the corn plants’ immune system and to increase the resistance to disease and pathogens as well as to environmental stresses. BioEmpruv contains natural and biodegradable ingredients. No chemicals or residues. BioEmpruv will be your best line of defense against Goss’s Wilt and other bacterial leaf diseases. Curative & very systemic. Much wider application window. Developed by PhD biochemist Dr Awada, Logan, UT.

Bio-Empruv

* Commercially applied to spuds, sweet and field corn since 2014. It has increased corn yields from 10-90 Bu/A, depending on application timing and infection rate. Keeps plants green and filling until natural maturity (BL) is reached. Drydown with normal senescent plants let the healthy ears dry faster and earlier than corn and grain from a die down plant.

Contact: Marv Mortensen 515-370-3381 • Bob Strelt 515-709-0143

-Submitted photo

DRONES OFFER TIMELY APPLICATIONS of fertilizer and crop protection products. “You can fly when ground rigs might not be able to go, due to wet soil conditions,” said Duane Davis, founder of SkyDronesUSA.

Drones Continued from Page 9E

control soil compaction, but it also helps protect the crop.

“The national average is 7% damage when groundrig sprayers run over crops,” Davis said. “Farmers tell me it’s way worse than 7%, though.”

In dry conditions, the big tires on ground spray rigs kick up a lot of dust.

“When the liquid being applied mixes with that dust, the heavy particles fall to the ground, which doesn’t help the plants,” said Davis, who noted that plugged spray nozzles can also create challenges.

Drones can work especially well for foliar feeding. Some drone pilots prefer to complete foliar feeding jobs at night, when plants are respiring and are under less stress, since the temperatures are cooler.

With any application, from foliar feeding to crop-protection products, timing is everything. Drones make it much easier to hit narrow application windows — something that’s critical with herbicide applications to control weeds much more effectively.

“Drones are here to stay, and this technology is only going to get better. This will be a game changer for agriculture going forward.”

Duane Davis Founder, SkyDronesUSA

Drones can also work well in a range of geographies. Drones can handle the tight spots and oddshaped parts of a field that might be tough for airplanes or ground applicators to access, Davis noted. In addition, drones can provide a practical solution where there’s a need to apply crop-protection products with a high level of precision, like a farm field near a residential subdivision. If farmers want to increase their profit potential, it’s time to take a serious look at drone technology, Davis said. “Drones are here to stay, and this technology is only going to get better. This will be a game changer for agriculture going forward.”

-Photo courtesy of Midbar

AIRFARM COMES IN TWO SIZES — a 10-foot model that is primarily used for education, research and home use, and a 20-foot Airfarm that can create a large yield if someone plans to sell the crops.

Continued from Page 10E

have installed units in Japan.” AirFarm converts moisture from the air into water in real-time. It recirculates the moisture produced by crops back to the roots, making it the world’s first farm that operates without water infrastructure. Midbar touts AirFarm as using 99 percent less water than conventional farming, 90 percent less water than a traditional hydroponics system, offers 10 times the productivity that conventional farming does and only takes half a day to set up. Fertilizer usage is reduced by 60 percent and pesticide usage by 100 percent, all while crop yields are maximized, the company stated.

AirFarm’s micro mist aeroponic system offers advantages over other hy-

droponic systems by allowing for the cultivation of various crop types, including root vegetables like seed potatoes and carrots, as well as leafy greens and fruits. The smart farming system also is data driven and pairs with a smartphone app. From EC and pH levels to temperature, humidity and VPD, all essential factors for cultivation are integrated into a single application monitored from a smartphone. Instead of a few cycles per year, the AirFarm allows a farmer to grow and harvest dozens of times per year because seasons don’t matter inside the Airfarm. It creates whatever season is needed for a particular crop at any time of the year.

At Van Diest Supply Company, . We have a sincere interest in our customers’ business and a genuine desire to help. We strive for l with our customers, suppliers and Team Members.

At Van Diest Supply Company, people make the difference. We have a sincere interest in our customers’ business and a genuine desire to help. We strive for long-lasting relationships with our customers, suppliers and Team Members.

Our tradition revolves around providing products and services that consistently exceed expectations. Serving Agriculture since 1956, a family owned business, we are know for our longevity, stability and continued growth.

Our tradition revolves around providing products and services that consistently exceed expectations. Serving Agriculture since 1956, a three generation family owned business, we are known for our longevity, stability and continued growth.

Van Diest Supply Company employs over 600 people, has 55 buildings on approximately 270 acres in Webster City, Iowa, has 20 outlying Distribution Centers and serves over 6,000 customers across the Midwest.

Van Diest Supply Company employs 00 people, has over buildings on approximately 270 acres in Webster City, Iowa, has outlying Distribution Centers and serves over 6,000 customers across the Midwest. Join us as a part of our Winning Team by filling out an application today!

By DARCY DOUGHERTY MAULSBY

FARNHAMVILLE — What is the secret behind most successful small businesses? Family.

While some of these businesses don’t last beyond the first generation or two, a Farnhamville-based tiling and excavating company is helping a new generation of young families to grow their future in rural Iowa.

“It’s great to work in a family business like this,” said Trevor Larson, 35, who owns The Larson Corporation with his younger brother, Brett.

In September 2022, the Larson brothers purchased Vosberg Enterprises Inc. from another pair of brothers — Jeff and Gary Vosberg.

Trevor Larson had worked with Vosberg

Enterprises for a number of years, learning the ins and outs of both the farm drainage and machining sides of the company from the Vosbergs. The summer after he graduated from high school, he got a summer job at Vosberg Enterprises, building anhydrous trailers.

“FC Cooperative, which used to be based here in Farnhamville, ordered the trailers,” said Larson, a 2008 Prairie Valley High School graduate who grew up near Moorland. “We were assembling and painting three a day.”

After that summer, Larson enrolled at Iowa State University and planned to become a high school biology teacher. His ties to Vosberg Enterprises, however, continued to open up more opportunities.

“I liked how there’s always something new,” said Larson, who decided a teaching career wasn’t in his future. “We’re always solving the next challenge or building the next thing.”

Building on 90 years of success

Vosberg Enterprises’ roots run deep in the Farnhamville area. George Vosberg founded the company in the 1930s, and it was a family business from the start.

“My Grandma Sally ran the machine, and Grandpa George installed the tile,” said Gary Vosberg, whose father, Erwin, became the next generation of the family to own the business. Through the years, the Vosbergs also bought Buske Manufacturing, a Gowrie-area business that fit well with the machine shop division of Vosberg Enterprises.

Today, The Larson Corporation, housed on the northeast edge of Farnhamville in a former Massey Ferguson dealership, carries on a tradition of manufacturing, tiling/ farm drainage and excavating for clients in Calhoun County, Pocahontas County, Webster County, Boone

-Photo by Darcy Dougherty Maulsby

TREVOR LARSON, who co-owns The Larson Corporation in Farnhamville, is shown here in the shop. The Larson team uses the machines in the spacious shop to repair equipment and fabricate a variety of items, including Gator Spacers. Gator Spacers are bolted to the wheels of all-terrain utility vehicles to track row crops better.

County and beyond. “They’re carrying on where we left off,” Gary Vosberg said. “It’s great to have a new generation take over the business and support more families in the area.”

Conservation to innovation

Shortly after Vosberg Enterprises became The Larson Company, the Larson team worked with the Iowa Soybean Association on an oxbow restoration project in west-central Iowa in the fall of 2022. Oxbow restoration is part of the Iowa Nutrient Re-

duction Strategy, a statewide plan to improve water quality. Oxbows can reduce nitrate in the water by around 50 percent, according to the Iowa Agriculture Water Alliance. Oxbow scars are “u-shaped” stream beds that fill with eroded sediment. They often end up being wet spots in a field. They typically have consistently low yields, or they fill with water part of the season, only to dry up later. Restoring oxbows means digging out sediment back to where the creek bed used to be. Restored oxbows provide fish

and wildlife habitat, plus they help improve water quality, which impacts drinking-water supplies.

“This kind of work can play a big role in conservation,” Larson said.

The Larson Corporation also assists farmers and landowners with their ag drainage/tiling needs. “We’re tiling whenever the crops aren’t in the field and the ground isn’t frozen,” said Larson, who noted that tile’s durability depends on the soil type and how the tile was installed.

To identify the best locations for tile lines, Larson’s team uses LiDAR (Light Detection and Ranging) technology to create detailed elevation maps of fields. Along with modern technology, tiling involves a fair amount of history.

“You never know what you’re going to dig up. Some of it hasn’t moved since the days of the glaciers. We’ve also dug up plenty of old whiskey bottles, cow and horse bones, and foundations of old barns and houses.”

Trevor

Larson Co-owner, The Larson Corporation

“You never know what you’re going to dig up,” Larson said. “Some of it hasn’t moved since the days of the glaciers. We’ve also dug up plen-

ty of old whiskey bottles, cow and horse bones, and foundations of old barns and houses.”

PhysicianAssistantToniaOdden tailorstreatmentplansbasedona person'sspecifichormonalneeds, determinedthroughblood/salivatests andotherdiagnosticassessments. Toniaseespatientsinthe JewellandStratfordclinics. Formoreinformation,ortoschedule anappointmentwithToniainJewell orStratford,

While some tiling companies charge per acre or by the line, The Larson Corporation charges by foot of tile installed. Every junction is an add-on.

“We give customers their tiling maps,” said Larson, who added that The Larson Corporation uses a drone to take photos of the field after the tiling project is complete. “It’s their field, and we figure they deserve to have this information.”

When the team isn’t working on tiling or excavating projects, they’re probably working inside.

The Larson Corporation’s spacious shop has an array of machines, including MIG (metal inert gas) welding, a variety of hydraulic presses, a CNC-guided press brake and CNC-guided plasma cutting table, a Stamco 8-foot sheer capable of cutting quarter-inch sheet steel, and a “Little Iron Worker” with a variety of hole-punching dies.

The team uses these machines to repair equipment and fabricate

a variety of items, including aluminum Gator Spacers. Available in a variety of styles and sizes, Gator Spacers are bolted to the wheels of all-terrain utility vehicles to track row crops better.

“We’ve got them on our Gators,” said Larson, who noted

that Gator Spacers make it easier to drive down 30-inch rows.

“They’re really helpful when we’re doing tile fixes in the spring and don’t want to break off the young corn.”

The Larson Corporation works with a variety of John

Deere dealerships to market Gator Spacers to customers in Iowa and surrounding states. The Larson Corporation also sells Green Mountain Grills (GMG) wood-pellet barbecue grills and smokers, along with barbecue seasonings and wood pellets.

The company has been an authorized GMG dealer since the spring of 2024.

The Larson Corporation’s team appreciates the chance to build their business, raise their young families in rural Iowa and serve area farmers.

“We have customers who’ve worked with this company for years,” Larson said. “It’s great to grow with them.”

By KRISTIN DANLEY GREINER

Two years ago, John Deere launched its ExactShot technology designed to allow farmers to reduce the amount of starter fertilizer needed during planting by more than 60%.

According to the company, the technology uses sensors and robotics to place starter fertilizer precisely onto seeds as they are planted in the soil, rather than applying a continuous flow of fertilizer to the entire row of seeds.

ExactShot uses a sensor to register when each individual seed

is in the process of going into the soil. As this happens, a robot will spray only the amount of fertilizer needed, about 0.2 milliliters, directly onto the seed at the exact moment it goes into the ground. Farmers can switch between dosing and continuous mode from the tractor cab.

“Paired with ExactEmerge BrushBelt technology, the system tracks each seed from the meter to seed trench, synchronizing each dose with the exact timing of the seed drop. Placing the solenoid and nozzle tip, below the row-unit, directly above the seed

trench adds an additional level of accuracy with each dose. ExactShot can save farmers up to twothirds of in-furrow input costs by applying nutrients directly on the seed to be used most efficiently.

With this technology, farmers can switch between dosing and continuous mode from the cab. Since this technology reduces in-furrow usage it also allows farmers to go further between fills so they can get more acres done in a day,” said Jenni Badding, a spokesperson for the production and precision ag division of John Deere.

Across the U.S. corn crop, ExactShot could save more than 93 million gallons of starter fertilizer annually and prevent wasted fertilizer from encouraging weed growth or increasing the risk of running off the field into a waterway, John Deere stated. ExactShot is available from the factory or as a precision upgrade.

“We’re putting that much less fertilizer out, which reduces the chances for runoff and other things that are negatively impacting the environment,” the company stated.

-Submitted photo

EXACTSHOT USES a sensor to register when each individual seed is in the process of going into the soil. As this happens, a robot will spray only the amount of fertilizer needed.

INNERPLANT HAS CREATED PLANTS THAT EMIT LIGHT that’s detectable as far away as outer space. The plants emit light when under attack by pests or are short of water or nutrients. Test plots will be established in Iowa this growing season.