18 minute read

ISHIDA

New Ishida X-ray offers enhanced sensitivity for difficult to detect items

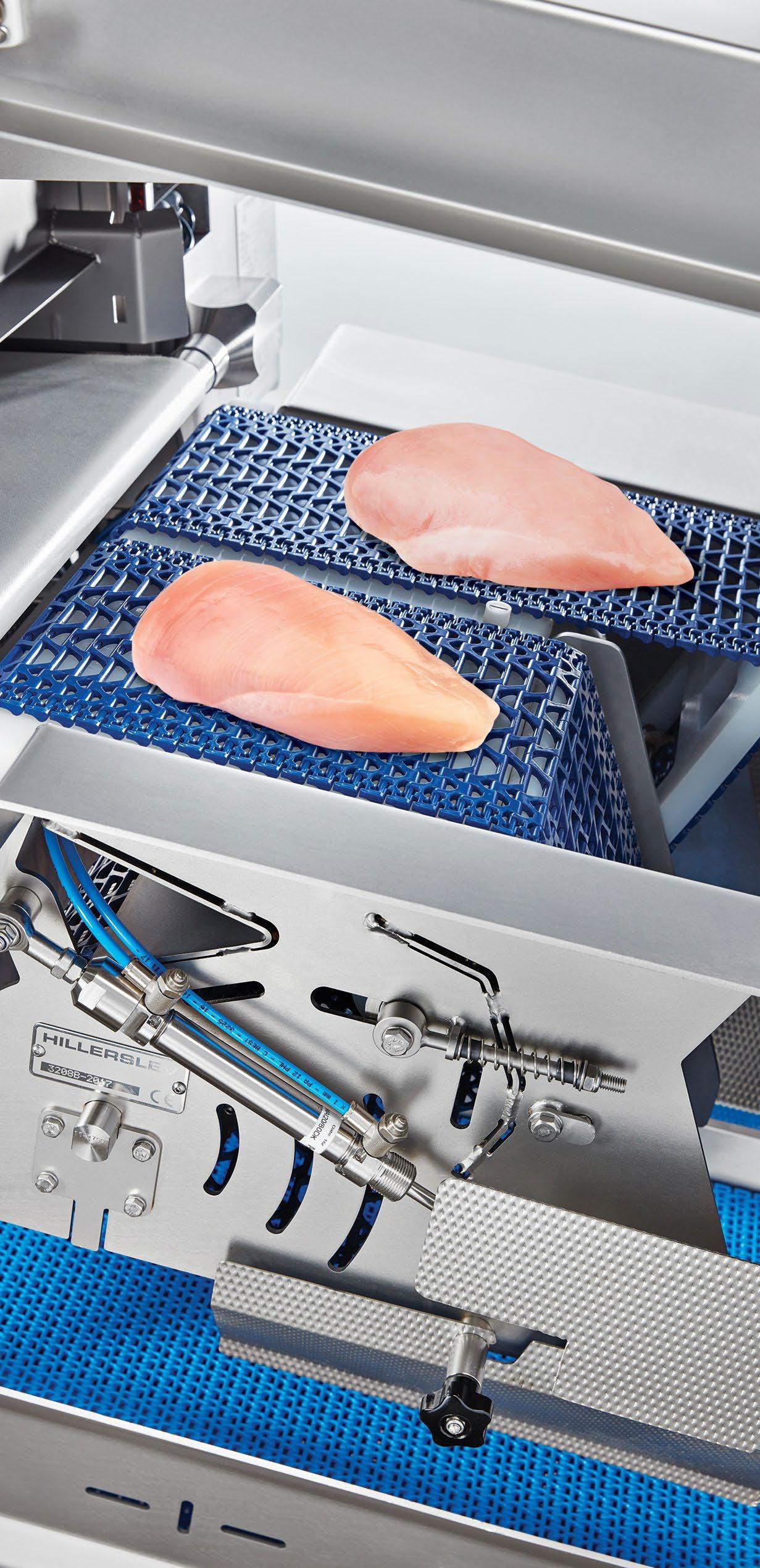

Ishida Europe is launching its next generation IX-G2 dual energy X-ray inspection system which offers significantly enhanced sensitivities for the detection of low-density and difficult to spot foreign bodies, including bone.

The Ishida IX-G2-F incorporates a new line sensor that provides a high-quality X-ray image through an enhanced signal to noise ratio which has increased the ability to detect bone fragments by a factor of four compared with previous X-ray models. This further increases the ability of the machine to identify contaminants, in particular when handling thicker and denser products such as chicken fillets, chicken breasts and a wide range of poultry products where they can often be overlapped or presented with uneven surfaces.

The enhanced sensitivity of the machine also greatly reduces the risk of false detections, which helps to maximise throughput and avoids the costs associated with unnecessary waste and the repacking of products.

The high performance of the IX-G2-F is supported by Ishida’s unique self-learning Genetic Algorithm (GA) technology which combines with the new line sensor to deliver maximum detection sensitivity and reliability.

The GA technology focuses the X-ray machine to identify difficult to detect contaminants with a high degree of accuracy, even at high throughput rates, using image data analysis over a number of trial runs. As it is common in food production for similar contamination problems to recur, data logging can help to build up a more precise calibration protocol with each trial. This enables permanent or recurring defects to be easily identified during the inspection process.

Ishida’s dual energy technology incorporates two line sensors, one which takes images at high energy and one at low energy. These are then compared, which provides a better overall image of the product with a clearer contrast between the product and any low-density foreign bodies, such as bone fragments.

“The next generation IX-G2-F X-ray inspection system offers unrivalled performance and with its improved line sensor and software capabilities it has already delivered significant benefits on production lines,” comments Sibtain Naqvi, Ishida Europe’s X-ray Product Manager.

“The enhanced sensitivity provides poultry processors with even greater reassurance that their high product quality standards are being maintained, and by minimising the number of false rejects, production can be maximised. We believe our IX-G2-F models represent another major advance in our X-ray inspection portfolio,”

A sticky situation results in business benefits

Caramel can be a challenging material to extract, particularly when delivered in one tonne totes. One of the ways the Burtons Biscuits came up with, was to put totes into a warm room to enable the caramel to flow easier from the tote via a pump then into a hopper. However, they found that one of the main drawbacks on this process of totes was that the caramel would stick to the inside walls of the tote as the pump sucked out the caramel. At times this would mean that between 10% to 30% of the caramel would be left in the tote, unable to be extracted. The method was to connect a pump to the bottom outlet of the tote and transfer the caramel to a hopper, which worked well until the level of caramel in the tote fell to between 10% and 30%. From this point the pump cavitated and could not draw the caramel in, resulting in between 10% and 30% of the contents of the tote being returned to the supplier, costing anything between £50,000 and £140,000 per annum in unused caramel.

One idea that came from the Continuous Improvement team while looking at available options to reduce this waste or increase the yield was to revert to 200L drums of caramel rather than the tote. Kecol were asked to make proposals for transferring the caramel from the 200L drums to the line hopper and offered a Kecol H800SN Maxiprime unit c/w 10:1 ratio piston pump.

Kecol supplied a trial unit to Burtons for a two-week trial period to enable evaluation of the proposed system. Whilst the system transferred the caramel at the required rate and reduced the waste, the drum loader used by Burtons could not place the drum into the Maxiprime in the correct position. To resolve this, Kecol worked with Burtons Engineers and modified the standard Maxiprime to suit the existing drum loader. Burtons purchased 2 x H800SN Maxiprime systems and have reduced the waste caramel to less than 1%, significantly reducing expenditure and increasing yield.

Web: www.kecol.co.uk E-mail: sales@kecol.co.uk Tel: 01746 764311

CUT COSTS CUT COSTS 4 4 WAYS WAYS

With VIBRO-BED Circular Vibratory With VIBRO-BED Circular Vibratory Fluid Bed Dyers, Coolers, and Moisturizers Fluid Bed Dyers, Coolers, and Moisturizers

Kason o ers circular vibratory fl uid bed Kason o ers circular vibratory fl uid bed systems in diameters from 18 inches (457 mm) systems in diameters from 18 inches (457 mm) to 84 inches (2134 mm) for drying or cooling to 84 inches (2134 mm) for drying or cooling of bulk foods, pharmaceuticals, and chemicals— of bulk foods, pharmaceuticals, and chemicals— rapidly and uniformly, in batches or in-line, on rapidly and uniformly, in batches or in-line, on laboratory or production scale. laboratory or production scale.

kason.com kason.com

1. Cut Purchase Costs 1. Cut Purchase Costs

The inherent strength of the VIBRO-BED’s The inherent strength of the VIBRO-BED’s circular design eliminates the need for heavy circular design eliminates the need for heavy sidewalls and braces. Lighter gauge shell, sidewalls and braces. Lighter gauge shell, downsized motors, fewer weld seams, and downsized motors, fewer weld seams, and only one air inlet and outlet dramatically only one air inlet and outlet dramatically reduce material and labor costs, especially reduce material and labor costs, especially when fi nishes to FDA, BISSC, 3-A, or other when fi nishes to FDA, BISSC, 3-A, or other sanitary standards. sanitary standards.

2. Cut Cleaning Costs 2. Cut Cleaning Costs

No internal cross-members, fewer seams No internal cross-members, fewer seams and corners, and quick-disconnect shell allow and corners, and quick-disconnect shell allow for fast, thorough cleaning of the machine. for fast, thorough cleaning of the machine.

3. Cut Energy Costs 3. Cut Energy Costs

The light weight of the high-strength circular The light weight of the high-strength circular shell signifi cantly reduces HP/kW and power shell signifi cantly reduces HP/kW and power consumption of gyratory motors. E cient consumption of gyratory motors. E cient fl ow of fl uidized material and heated or cooled fl ow of fl uidized material and heated or cooled air within the circular chamber maximizes air within the circular chamber maximizes heating/cooling per kWh. heating/cooling per kWh.

4. Cut Engineering Costs 4. Cut Engineering Costs

Complete skid-mounted systems are preComplete skid-mounted systems are preengineered, lab tested using your material, engineered, lab tested using your material, and ready to plug in and run. and ready to plug in and run.

Sift, Scalp, De-Lump, and De-Water with Sift, Scalp, De-Lump, and De-Water with Quick-Clean CENTRI-SIFTER Centrifugal Sifter Quick-Clean CENTRI-SIFTER Centrifugal Sifter

CENTRI-SIFTER Centrifugal Sifters with hinged end covers with hinged end covers CENTRI-SIFTER Centrifugal Sifters with hinged end covers with hinged end covers and 2-bearing cantilevered shafts and 2-bearing cantilevered shafts allow quick pull-out of allow quick pull-out of internal components, internal components, facilitating rapid, facilitating rapid, thorough cleaning. thorough cleaning. Rotating helical paddles Rotating helical paddles propel on-size material through propel on-size material through the sidewall of a screen cylinder, the sidewall of a screen cylinder, ejecting overs through the cylinder ejecting overs through the cylinder end. CENTRI-SIFTER units are also e ective end. CENTRI-SIFTER units are also e ective at dewatering slurries and de-lumping materials. at dewatering slurries and de-lumping materials.

Scalp In-Line with Scalp In-Line with PNEUMATI-SIFTER Separator PNEUMATI-SIFTER Separator

VIBROSCREEN PNEUMATI-SIFTER VIBROSCREEN PNEUMATI-SIFTER Circular Vibratory Separators Circular Vibratory Separators

scalp free-fl owing materials in-line scalp free-fl owing materials in-line with dilute-phase pneumatic conveying with dilute-phase pneumatic conveying systems, removing oversize particles systems, removing oversize particles and foreign materials from plastic resin, and foreign materials from plastic resin, fl our, starch, sugar, and numerous food fl our, starch, sugar, and numerous food and chemical products at ultra-high rates. and chemical products at ultra-high rates.

Change Screens Quickly and Meet Change Screens Quickly and Meet Low Headroom Requirements with Low Headroom Requirements with VIBROSCREEN Flo-Thru Separator VIBROSCREEN Flo-Thru Separator

VIBROSCREEN Flo-Thru Low-Profi le VIBROSCREEN Flo-Thru Low-Profi le Circular Vibratory Sifters have two Circular Vibratory Sifters have two motors on opposing exterior sidewalls, motors on opposing exterior sidewalls, reducing height requirements reducing height requirements signifi cantly. The bottom outlet is signifi cantly. The bottom outlet is positioned directly below the top positioned directly below the top inlet, allowing material to descend in inlet, allowing material to descend in a straight-through path at extremely a straight-through path at extremely high rates. An optional Air-Lift device high rates. An optional Air-Lift device promotes fast access for screen changes and inspection. promotes fast access for screen changes and inspection.

Separate Contamination-Sensitive Separate Contamination-Sensitive Solids with VIBROSCREEN UltraSolids with VIBROSCREEN UltraSanitary Gap-Free Screener Sanitary Gap-Free Screener

VIBROSCREEN Ultra-Sanitary GapVIBROSCREEN Ultra-Sanitary GapFree Circular Vibratory Screeners Free Circular Vibratory Screeners

meet cGMP, 3-A, USDA, and FDA meet cGMP, 3-A, USDA, and FDA standards and are an ideal fi t for standards and are an ideal fi t for food, pharmaceutical, nutraceutical, food, pharmaceutical, nutraceutical, and other applications with strict and other applications with strict sanitary compliance requirements. Unit sanitary compliance requirements. Unit design considerations include gap-free design considerations include gap-free screen frames, quick-release “U” clamps, screen frames, quick-release “U” clamps, radius corners, a domed lid, an Air-Lift radius corners, a domed lid, an Air-Lift device to raise the frames, continuous ground and device to raise the frames, continuous ground and polished welds, a gap-free and crevice-free interior polished welds, a gap-free and crevice-free interior fi nished to sanitary standards, and a washable underside. fi nished to sanitary standards, and a washable underside.

Contain Dust and Remove Contain Dust and Remove Scraps with VIBROSCREEN Scraps with VIBROSCREEN Bag Dump Screener Bag Dump Screener

VIBROSCREEN Circular Vibratory VIBROSCREEN Circular Vibratory

Back Dump Screeners draw dust from Back Dump Screeners draw dust from dumping activities onto cartridge dumping activities onto cartridge fi lters that derive vacuum from a fi lters that derive vacuum from a top-mounted exhaust fan. Short top-mounted exhaust fan. Short blasts of air from pulsejet nozzles blasts of air from pulsejet nozzles located within the fi lters dislodge located within the fi lters dislodge accumulated dust hat falls onto accumulated dust hat falls onto the ultra-low-profi le vibratory the ultra-low-profi le vibratory screener. Screeners o er highscreener. Screeners o er highcapacity screening of product capacity screening of product while eliminating dust contamination while eliminating dust contamination risk and reducing labor requirements. risk and reducing labor requirements.

Replacement Screens Compatible with Replacement Screens Compatible with Virtually any Round Vibratory Screener Virtually any Round Vibratory Screener or Centrifugal Sifter or Centrifugal Sifter

K-SERIES round replacement K-SERIES round replacement

screens are available in 18 inch screens are available in 18 inch (457 mm) to 100 inch (457 mm) to 100 inch (2540 mm) diameter (2540 mm) diameter options in stainless steel options in stainless steel and synthetic meshes, and synthetic meshes, compatible with most compatible with most makes and models of makes and models of circular vibratory screeners. circular vibratory screeners. Customizable to meet your Customizable to meet your process needs, including process needs, including sanitary fi nishes, heavy-duty sanitary fi nishes, heavy-duty supported screen rings, screen supported screen rings, screen trays with anti-blinding devices, and more. trays with anti-blinding devices, and more. Replacement screen cylinders for centrifugal sifters are Replacement screen cylinders for centrifugal sifters are available in stainless steel or synthetic mesh options. available in stainless steel or synthetic mesh options. Heavy-duty, high-performance wedge wire or perforated Heavy-duty, high-performance wedge wire or perforated plate screen baskets are also available. plate screen baskets are also available. In-stock options are available for next- or same-day In-stock options are available for next- or same-day shipment, with Quick-Ship options available upon request. shipment, with Quick-Ship options available upon request.

kason.com kason.com

Don’t take a chance on corrosion-Change!

Harvesters Way, EDINBURGH , making the case for a sustainable and environmentally friendly heating system

The implementation of an alternative approach to water treatment and the use of continuous monitoring in the prevention of corrosion in closed systems is not always obvious. The approach used by James Culbertson of the Keenan Consultancy at Harvesters Way explains the operation of such systems, the minimal initial cost and sustainable savings associated with this enhanced process.

Control of corrosion of any closed-circuit heating or cooling system is critical as it imposes a considerable energy load on the system if fouling and debris accumulates. Premature component failure or pipework penetrations can cause catastrophic financial and reputational damage to manufacturers, contractors, designers, and owners alike.

Greater knowledge of the fundamentals of pressurisation and alternative methods to controlling oxygen corrosion can result in substantially lowering of the environmental impact of systems. CIBSE CP1 2020 on Heat Networks has recently recognised the approach of alternative standards such as the German VDI 2035 Part 1* in this regard.

The introduction of the Northern European guidance leads to better sustainable outcomes based on minimizing oxygen entry and water conditioning such as demineralisation as opposed to the use of chemical inhibition. This approach has been used very successfully in Germany, Switzerland, Austria, the Benelux, Scandinavia etc. for decades. In many parts of the UK the mains water quality is good enough to fill systems without any further treatment or conditioning.

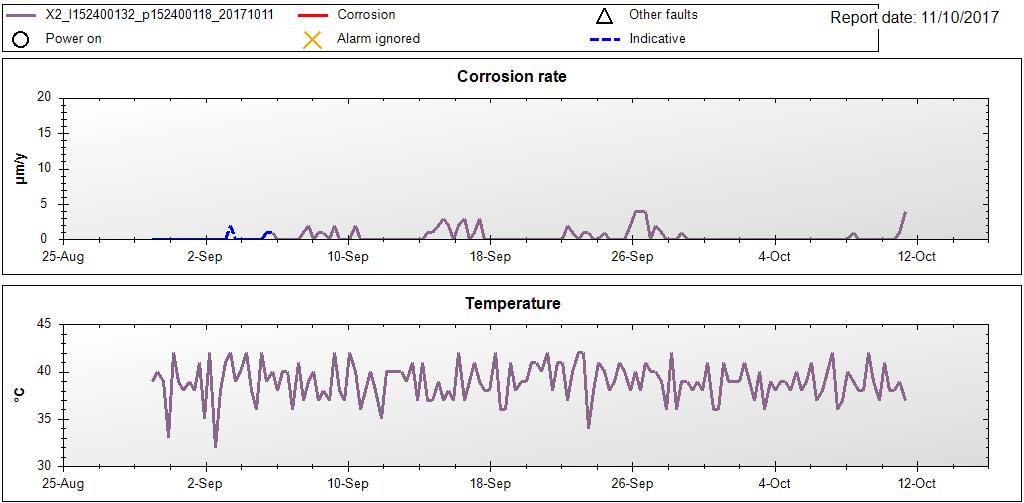

The key to controlling corrosion in closed systems is to control the level of oxygen entry. The case of Harvesters Way and many others show that correct pressure control, limiting water make up and the use of steel pipework lead to corrosion levels below 5µm/y.This is well below the level where damage due to corrosion or corrosion products could occur.

Continuous corrosion monitoring will monitor the system condition and alert the building operator if events occur that will cause an increase in corrosion. Realtime corrosion monitors are low cost and will pay for themselves within 2-4 years thus CAPEX neutral and truly OPEX beneficial.

Harvesters Way Project - Edinburgh

TRADITIONAL WATER TREATMENT VS WATER CONDITIONING

is adding chemicals to the water to change its properties, in water conditioning the properties of the water are altered by processes such as demineralisation or softening. No chemicals are added.

The traditional UK method of protecting heating systems from corrosion is through the use of chemical inhibitors. Standards such as BS7593:2019 or BSRIA BG29:2021 / BG 50:2013 leave very little option for an alternative approach. The problem is that many people think that because the system has been inhibited it is fully protected regardless of all other parameters. But nothing could be further from the truth. It is the amount of oxygen that enters the system that determines the amount of corrosion that takes place. Even the best inhibitors cannot cope with large amounts of oxygen entering the system.

Therefore, most continental standards are based on minimising the oxygen entry and using water with a conductivity below 100µS/cm (VDI2035 Part1). In some parts of the UK mains water would meet these requirements without any further conditioning. The low conductivity slows down corrosion and microbiological processes. Any corrosion that may occur would not be damaging and can easily be monitored.

A non-chemical approach is not only better for our environment but also offers more sustainable results and a lower overall cost The CIBSE Heat Networks Code of Practice in the UK (CP1) should be commended in its adoption of alternative approaches such as VDI 2035Part1.

CASE STUDY

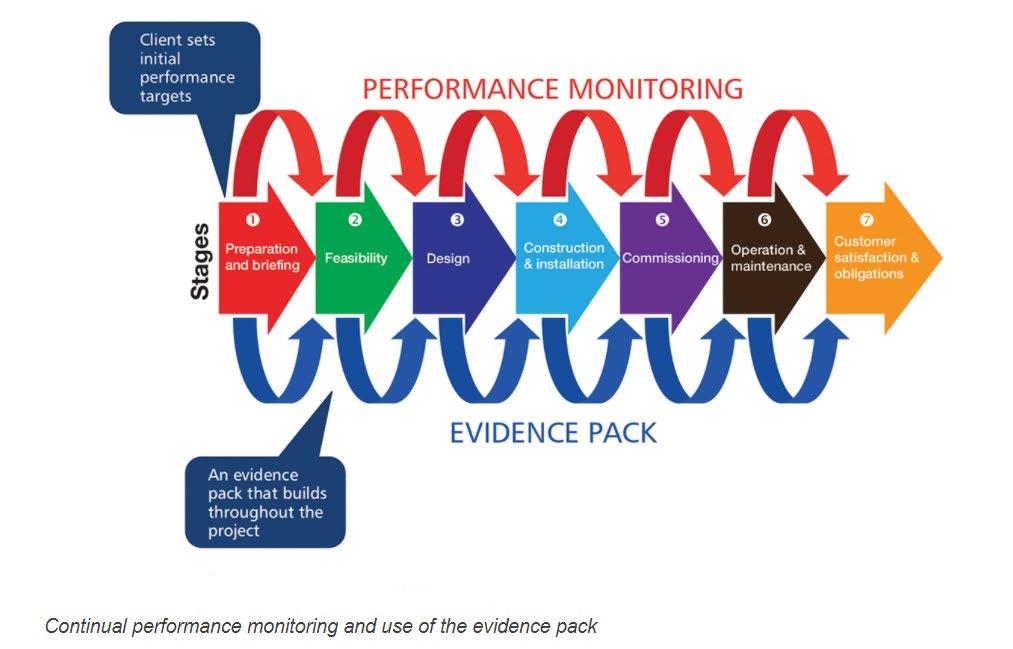

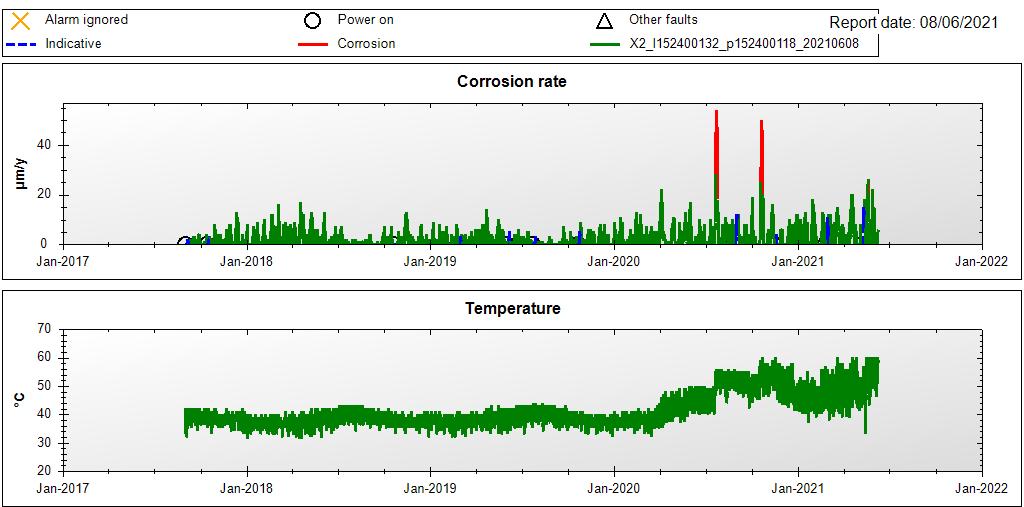

The heat network at Harvesters Way in Edinburgh used the approach in CIBSE document CP1. It consists of 183 maisonettes, flats and town houses with HIUs and no hydraulic break. By using a central boiler plant of only 400kW the efficiency of the system in comparison to decentralised boilers is around 15% better. The inclusion of a Risycor electronic corrosion coupon monitor allows systematic performance monitoring and to provide data for the evidence pack at hand over. The Risycor electronic corrosion monitor alarmed twice in 3 years when maintenance on system was being carried out.

The corrosion data recorded by the monitor shows otherwise vey low levels of corrosion meaning the system runs efficiently and reliably.

Post Practical Completion introduction of Electronic Coupon Corrosion Monitoring initial 6 weeks forming evidence of a stable system in the handover pack Figure 1 Continual performance monitoring and use of the evidence pack has arrived in CP1

CONCLUSION

The case identifies the benefits of adopting a considered design approach to water conditioning opposed to water treatment combined with performance monitoring where quality & quantity of incoming water, enhanced design of system pressurisation and commissioning offers substantial economic justification in terms of ROI.

“Corrosion tends to be the greatest mystery and astonishment of both stakeholders and FM contractors, who historically just rely on inhibitor levels as their standard bearer whether a system is going to be okay. An online corrosion monitor such as Risycor provides transparent real time and proactive assistance to the process to allow better financial, educated and long term planning for any system.” James Culbertson of The Keenan Consultancy

This new technology has been widely used in other systems for a few years now, particularly where clients and manufacturers have sought greater transparency on system performance at commissioning and beyond. The benefits of the monitoring technology can be applied in all such systems regardless if the water comes straight from the tap, has been conditioned or chemically inhibited with minimal capital expenditure.

On-Demand acccess to: The case for sustainable, environmentally friendly heating and cooling systems

Gastrace from ESS - the ultimate tool in food grade gases monitoring

SSV CHECKWEIGHER

XR75 X-RAY M6 METAL DETECTOR

Trusted worldwide for superior product inspection and contaminant detection.

Anritsu systems deliver performance,

reliability and low total cost of

ownership. Plus, we back our longlasting equipment with unparalleled service and support.

Over 175,000 installations worldwide.

Discover what you’ve been missing.

Learn how to advance your product quality and operational efficiency at anritsu.com/infivis.

Fast, accurate detection of contamination in Food Grade Gases.

Food grade gases are subject to highly stringent control measures and the likelihood is that these controls will tighten.

GasTrace from ESS offers the perfect solution for monitoring impurities in food grade gases. With low parts per billion detection limits and a response time of just 120mS all results are in real time.

GasTrace is capable of monitoring up to 64 individual contaminants in gases such as CO2 and N2, and has the capability for automated operation from up to 64 sample points with time and date stamped individual data files for each.

The ability to provide fully quantitative measurements in real time gives you the assurance that the gas you are using in food and drink packing is free from harmful impurities and reinforces the quality control that you need.

www.essco.com | 01606 49400 Sales@essco.com

THE JDN MINI FOOD GRADE

The JDN Mini Food Grade is an air hoist specifically designed to meet the requirements of the food and beverage industry. This includes a motor housing of uncoated cast aluminium, along with stainless steel components. The motor is lubricated by a physiologically safe fully synthetic special grease. The chain lubricant is food grade approved.

ADVANTAGES AT A GLANCE

• Corrosion resistant • Resistant to high levels of humidity • Easy to clean • Suitable for high pressure cleaners • Ex-proof

YOUR BENEFITS

• Decrease of the total costs of ownership (TCO) • Safe processes in the production • Availability 24/7 • Easy and quick maintenance direct at the operation site