10 minute read

SUMITOMO

Protecting premium Food & Beverage brand integrity

Counterfeiting in the luxury food and drinks industry has long been a multimillion pound industry. The pandemic added to these pressures, with high demand for premium products coupled with interrupted supply chains and fewer physical audits amplifying the risks of opportunists and illicit bootleggers taking advantage of the disruptions.

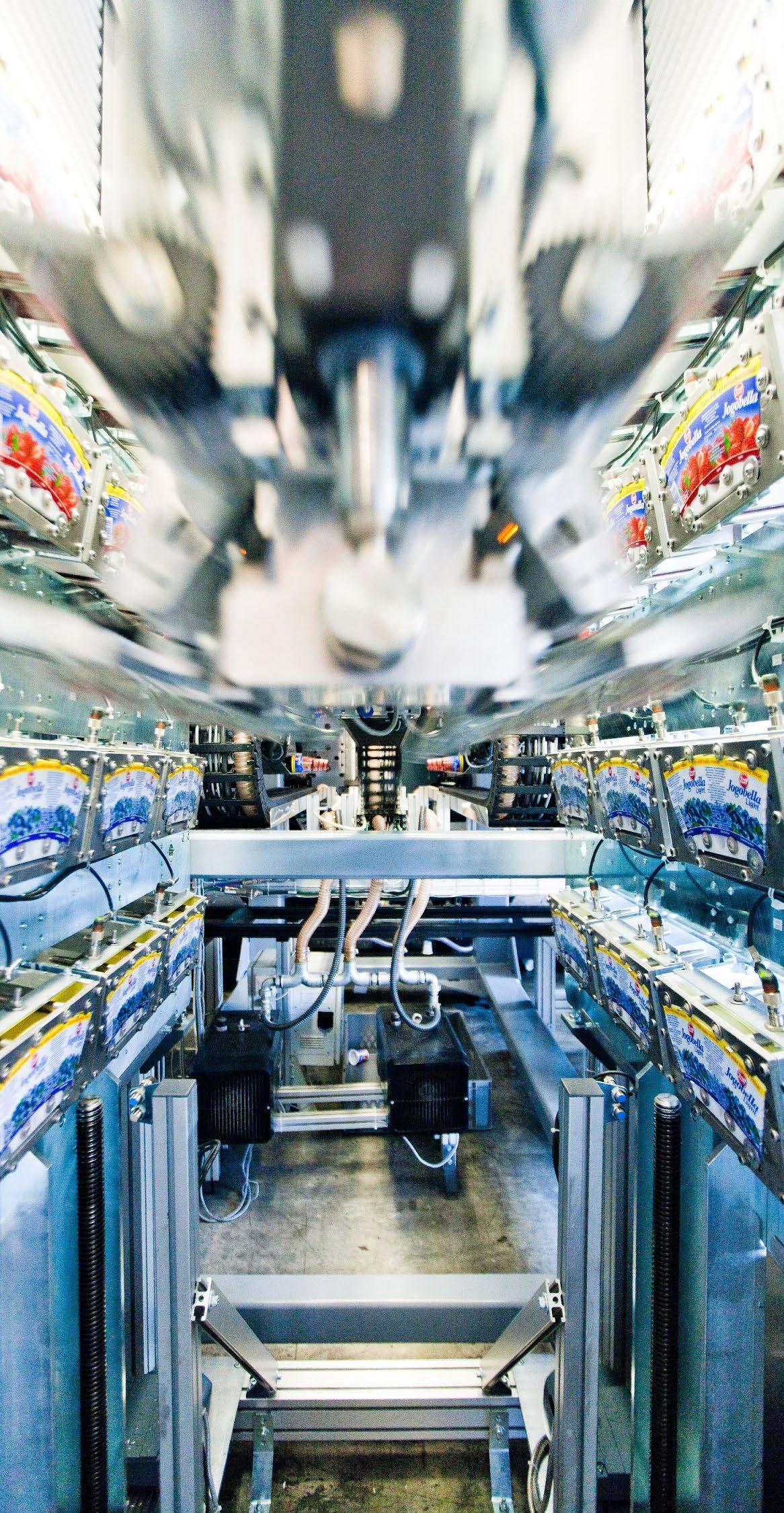

Packaging specialist at Sumitomo (SHI) Demag UK Ashlee Gough examines how specialist closure and thin wall moulders are applying the latest injection moulding precision and In Mould Labelling (IML) techniques to step up their fight against the creative food and drink fakers to mitigate risks and safeguard brand integrity.

In a recent survey of senior food and drink execs by assurance specialists The Lloyd’s Register, only a third admitted to vetting suppliers against a recognised GFSI standard. One in five declared that no checks were made as part of sourcing decisionsi. Yet, despite these prevalent risks - 97 percent stated that they’d been affected by food fraud in the last 12 months - few in the industry regard authenticating products as their highest priority.

Against this backdrop, the UK food and drink market remains one of the worst affected by counterfeiting. Deliberately

Ashlee Gough, Packaging Specialist, Sumitomo (SHI) Demag UK

Tamper evident closures is one method deployed by packaging manufacturers to counteract fraud in the premium drinks, wellbeing and pharmaceutical markets (iStock.com/bert_phantana) packaged to deceive consumers, the Food Standard Agency’s National Food Crime Unit estimates that the combination of adulteration, substitution, theft, misrepresentation, illegal processing, waste diversion and document fraud costs £11.97bn per annumii.

Seizures of counterfeit products provide a good indication of the scale of the problem. In 2020, Operation OPSON IX seized 12 000 tonnes of illegal and potentially harmful products, including 1.2m litres of alcohol.

In a converted effort to crackdown on groups profiting from illicit versions of branded spirits and premium foods, manufacturers are making labels more difficult to copy and bottles harder to refill. “One way to counteract counterfeiting and product tampering is through the innovative design of packaging that cannot be easily copied,” highlights Ashlee.

“Until recently, this may have involved putting shrink or foil sleeve around a luxury drink brand, for example. Closure moulders especially are stepping up their efforts and investing in dedicated cells to produce high quality and anti-refill closures made up of a number of complex parts.” Due to the intricacy of these closures, moulding precision is paramount.

Significant investment in high quality tooling, automation, machinery and expertise can be another major deterrent, highlights Ashlee. “Realistically, few counterfeit operators would make the level of investment required to replicate this level of technical precision.”

Other overt packaging methods to deter counterfeits include concealing unique identifiers, such as a QR code, holograms or tags within the IML. While these can assist with track and tracing, Ashlee claims that they only really help to validate the origin of a container and tend to be more widely deployed by luxury food, cosmetics, pharmaceutical and wellbeing brands.

“To outsmart quick-witted counterfeiters, manufacturers may need to deploy several tactics simultaneously to prevent brand value being diluted, including tamper evident bands, secure closures, snap buttons, barcoded labels and batch codes, and even chemical markers.”

For packaging moulders producing thin walled containers, caps and closures by the millions, cost effectiveness remains vital. Sumitomo (SHI) Demag’s El-Exis SP range typically achieves between three and five percent more productivity when benchmarked against other packaging machines on the market. Now in its fourth generation and always aligned to evolving market trends, the EL-Exis SP series is designed to withstand the higher stresses and injection pressures that are so critical in achieving repeatability in closures and thin walled packaging products, while maintaining comparable mechanical properties. Centralised monitoring of real time machine performance and energy consumption is equally critical to reducing machine downtime.

Seeley International industrial cooler wins two coveted awards

Seeley International – world leading Evaporative Cooler Manufacturer are celebrating winning, not one but two highly prestigious awards in the UK. Both accolades have been given for our latest addition & innovation to the Climate Wizard range of Indirect evaporative coolers, the CW3 which is a compact adiabatic air conditioner, ideal for industrial plants involving food production, packaging or storage facilities.

The winners of The Energy Awards 2021 were revealed on the 22nd September at Grosvenor House Hotel, London.

Seeley won in the category Innovation of the year: Buildings technology (HVAC, systems and lighting) and were praised by the expert judging panel, who are drawn from across the energy sector.

The Energy Awards Judging Panel 2021 said “The new approach demonstrated in the development and engineering of their system impressed the judges, resulting in significant savings of energy over traditional cooling systems and refrigerant-free running”.

Meanwhile the winners of the H&V News Awards 2021 were revealed on the 11th November. On this occasion, Seeley International won in the category of Commercial HVAC Product of the Year – Cooling Technology, sponsored by Smith Brothers Stores. The Judges said “Seeley have perfected a very efficient design through years of research and dedication which suits the sustainable needs of today and of future installations”.

In fact, Climate Wizard CW3 industrial cooler can reduce carbon emissions by 87%. Because of the reduced running costs (-88%) it is particularly suitable in industrial plants where air conditioning is not an option. Most industries with high heat loads, such as bakeries, packaging facilities or premises where ovens are involved, have no cooling system installed, and this impacts on the workers’ morale and productivity, as well as on their health. Climate Wizard CW3 uses 100% fresh outside air, significantly improving Indoor Air Quality in the building, which these days is not a minor factor.

Crucially, premises such as warehouses or big storage rooms, especially when dealing with food or drinks, have specific temperature requirements. In all these scenarios CW3 could be the right solution because it doesn’t use any sort of chemical refrigerants to cool the air.

If you’d like to learn more about environmentally friendly cooling solutions for commercial and industrial spaces, please contact uksales@ seeleyinternational.com or call 0115 963 5630.

Seeley International Website Climate Wizard In-direct Evaporative Cooling Breezair Direct Evaporative Cooling CW3 Video - the Future of Cooling

Cost-effective cooling for production plants and storage areas

Evaporative cooling is the perfect solution when cooling large buldings with high heat loads, to improve thermal comfort and Indoor Air Quality (IAQ)

Green technology Easy installation 100% fresh, filtered air Low running costs

Contact us for a free survey, we will suggest the solution that best suits your needs.

Improving production processes and cutting costs

INSPIRON SYSTEMS LTD are leading suppliers of Weighing, Labelling and Inspection systems and we have over 25 years’ experience. Inspiron is a privately run, family business who take pride in everything related to weighing, labelling and inspection, focusing on quality, value for money, customer support and building lasting partnerships with our clients.

The Isle of Man Creamery are celebrated cheese makers who use locally sourced milk to make their award-winning cheeses, which are then exported worldwide. They replaced their existing Delford machine with an Espera Nova due to its high performance, excellent print quality, superior level of accuracy, ease of use and on-board Predictive Maintenance software which helps reduce unnecessary downtime.

The ESPERA NOVA ES-R Automatic Weigh Price Labeller with Checkweigher functionality is now installed at the creamery and being used to weigh and label top and bottom flow wrapped cheese, ranging from 100g up to 1.7Kg, reaching speeds of more than 90 packages per minute.

“The Espera Nova has been a massive upgrade to the weighing and labelling operation of our award-winning Manx Cheese.” Andy Thornton, Manufacturing Manager Isle of Man Creamery Ltd.

Granby, renowned producer of Sausages in Dublin, upgraded their Weigh Price Labellers to the ESPERA NOVA ESR, equipped with Top, Bottom and a Total Label Printer. An Espera user for years, Granby invested in the latest technology to enable higher accuracy of label positioning, improved throughput speeds and increasing OEE, using the latest 4.0 technology.

Granby followed-up their initial purchase of 2 x ESPERA NOVA ES-R machines with 7 x ES-M Manual Weigh Price Labellers. This investment by Granby in the new generation of Espera machines shows a great commitment to the new Industry 4.0 Smart factory technology and strengthens our partnership with Granby.

“Everyone at Granby, management & operators are extremely impressed with the ESPERA Nova systems which have advanced our labelling capability to a much higher level than we ever had before.” Eoin Kavanagh, Managing Director Granby Ltd.

Other features installed on the ESPERA NOVA ES-R include online barcode verification, Automatic Reject device (to sort non-conforming packs) and EspromNG, a central software solution for database management and reporting, which captures average weight reports and production statistics.

If you are looking to update your production lines with technical advanced weighing, labelling or inspection machinery, or simply need an advanced software solution, please get in touch and find out how we can help.

INS-MDINS-MD IIII INS-CWINS-CW ES-RES-R NOVANOVA

Silverson Machines launch three Laboratory scale mixers including a Laboratory scale version of the Silverson Flashmix Powder/Liquid mixer

With advances in design and manufacturing technology, Silverson Machines have added three Laboratory mixers to their product range for high viscosity, hygienic and powder/ liquid mixing applications.

The most exciting of the developments in the range is the FMX5, a laboratory scale version of Silverson’s production scale Flashmix powder/liquid mixers. The FMX5 provides a simple, effective and hygienic means of powder/liquid mixing on a Laboratory scale and is able to process higher viscosity mixes.

The FMX5 is suitable for small scale manufacturing and R&D work and offers an accurate means of predicting the performance of the production scale Flashmix, making the scale-up process a simple task.

Offering proven performance on a wide range of powders including Gelatine, Guar Gum, Pectin, and Xanthan gum, as well as Sugars, flours, milk powder etc. the introduction of this new Powder/ Liquid mixer to the Silverson product ranges opens up the possibility of many more applications than were previously possible at laboratory scale.

For higher viscosity mixing at a laboratory scale Silverson has developed the Verso-HV, a pilot scale In-Line mixer which matches the capabilities of the production scale Silverson HV In-Line mixers. The Verso-HV incorporates a unique and innovative “pumping rotor” design that substantially increases its self-pumping capacity.

High flow rates are maintained as viscosity rises, often eliminating the need for an additional feed pump when processing many higher viscosity products in the food industry including gums and thickening agents and Mayonnaise. Ideal for R&D and small scale production, the Verso-HV facilitates easy scale up to Silverson’s production scale UHS-HV Series In-Line mixers as it is built to the same fine tolerances.

For applications with more stringent and demanding hygiene requirements, Silverson has developed the new Verso UHS. The Verso UHS is an UltraHygienic version of the standard machine and is manufactured with Silverson-designed hygienic single mechanical shaft seals, which can be converted to hygienic double mechanical shaft seals. It has a crevicefree construction and is designed for Cleaning-InPlace (CIP) and Sterilise-InPlace (SIP) operation.

All three mixers can be supplied with a Vessel Package, comprising of a vessel, stand, valve and pipework, and conversion kits are available allowing the standard Verso to be upgraded to a Verso-HV and an FMX5, allowing further flexibility within this new series of mixers.

FMX5

To find out more contact sales@silverson.co.uk