10 minute read

Recent advances in fiber optic sensing systems

INSIGHTS

PLANT OPTIMIZATION

Advertisement

to keep building capabilities in the “new normal” environment. It does not stop there. We also ask our plant leadership about skills needed for the next two to three years so we can start developing training now to make ourselves future proof.

Makes associates’ jobs more practical

For associates, PO makes their jobs more practical and even easier in some cases. It gives them the capability to apply knowledge and skills on the shop floor and improve their plant’s key performance indicators (KPIs) day in and day out (see Figure 1). An example is our Daily-Weekly-Monthly management system, which is a standard way to manage plants’ ongoing planning activities, standardizing, reviewing and taking action that supports a dashboard of cascading KPIs and targets. Since PO is embedded into this system, associates have a clear understanding of expectations, follow-ups and where to focus efforts. PO is part of the “way they work” and not an isolated workstream or improvement project. PO does not become, “one more thing I need to do.”

While operationalizing and optimization does impact the hard skills, it is the PO mindset and behaviors

to keep building capabilities in the “new normal” envi- that end up emerging stronger. We tested a formula of four variables to see what kind of outcome they produced: Capabilities + clarity + recognition + walking the talk = (how would you solve this equation?). Capabilities.We ensure associates are clear on the why, what and how of PO as well as their roles and value add. Clarity.We equip associates with information and skills they can apply to their jobs daily. Recognition. We put recognition systems in place for when associates go above and beyond and when a red flag is raised to identify an obstacle. Walking the Talk. Plant leadership — at all levels — is visible and publicly models PO values and behaviors. What we found: Capabilities + clarity + recognition + walking the talk = A path to increased empowerment for problem solving and performance improvement. Together, we are building a work environment that is producing the right products for customers as well as focusing on producing people, culture and teams committed to operational excellence. PE

Ricardo Estokis the director of plant optimization transformation at The Goodyear Tire & Rubber Company.

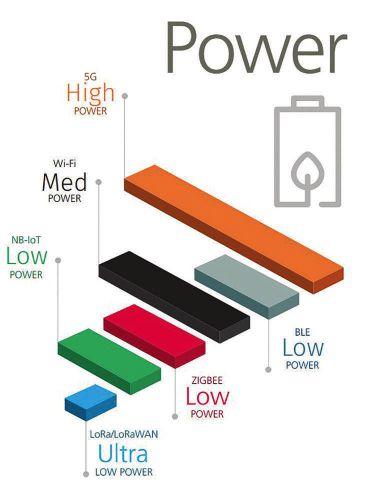

A Practical Use Guide To Wireless Technologies

Daniel Phillips | Technical Director, PTS Monitoring and Diagnostics

To ensure that your operation is performing at optimal levels with the lowest possible total cost of ownership, IoT-connected wireless monitoring technology can help to save both money and time. However, not all equipment necessarily needs to be monitored, and not all monitoring systems are financially viable.

This white paper explores the factors to consider when exploring whether your maintenance team and your equipment could benefit from wireless monitoring technology. For example, how much time is needed to prepare spare parts and labor when a machine fails? How much does lost production time cost? What resources are available to analyze the data generated from monitoring devices? For equipment that has a high cost for lost production, is located in remote locations, or is not stationary, the benefits of wireless systems are explored. The strengths and weaknesses of both wireless and wired systems are also briefly explored.

Register to download the paper at: https://bit.ly/2QIhqFA

SOLUTIONS

2020 PRODUCT OF YEAR AWARD WINNERS

By Kevin Parker

Innovative solutions address needs of today’s U.S. manufacturers

Unconventional approaches suit readers’ choices

AutomationDirect.com, the first industrial controls company to successfully use a direct sales catalog for PLC products, and now an online superstore, received the grand prize in the 2020 Plant Engineering Product of the Year awards competition for its ProductivityOpen platform.

That Plant Engineering readers chose an Arduinocompatible open-source hardware and software platform from a company that can deliver that winning product (or almost any industrial control product) direct to your doorstep says something about the last year’s stresses and strains, as well as perhaps indicating the way forward as the U.S. economy surges.

“We believe this way of doing business is especially attractive to the younger generations just entering the industrial workforce,” said Bill Dehner, technical marketing manager, AutomationDirect. “As an online supplier our mission is to provide a better shopping experience with 24/7/365 product ordering and fast delivery. Our product engineers stay in tune with industry trends. An industrialized open-source controller was a rising need we felt we could definitely meet.” The ProductivityOpen platform provides all the features of a standard Arduino plus the added power and reliability of an industrial controller. With the growing popularity of single-board controllers and the risks of implementing them in industrial applications, AutomationDirect says an open-source controller is needed that holds up in extreme industrial conditions. The processor circuit of the P1AM-100 Arduino-compatible CPU mimics the Arduino MKRZero

microcontroller. It is compatible with most available Arduino MKR format shields and industrially hardened ProductivityOpen shields and can utilize most Arduino sketch programs found on open-source websites. Using the Arduino integrated development environment, the P1AM-100 is programmed using C++ code; the ProductivityBlocks graphical programming interface uses a more visual approach that simplifies coding and reduces syntax errors. Produced in conjunction with FACTS Engineering, the ProductivityOpen platform combines the ingenuity and the proven reliability of the AutomationDirect Productivity controller family. “FACTS Engineering has worked with us on many successful product lines. Their knowledgeable staff and dedication to quality always produces reliable products. Working together with FACTS to produce the ProductivityOpen controller and ensure it lives up to its promise of reliability was well worth the effort and we’re pleased that The ProductivityOpen Plant Engineering’s readers are happy with the outcome,” platform from Dehner concluded. AutomationDirect provides all the Asset management rules features of a standard In total, the awards program identified three winners Arduino plus the across each of 12 categories for a total of 36 gold, silver added power and and bronze award winners, besides the grand prize. reliability of an Unfortunately, this year as well as last, winners of the industrial controller. Plant EngineeringProduct of the Year awards would likely have attended the CFE Media & Technology Engineering Awards in Manufacturing event traditionally held in April in Chicago. The event brings together representatives from a wide range of companies focused on furnishing the manufacturing industries with innovative products, services and solutions. CFE Media sister publicationControl Engineering has a similar awards program, and the Plant Engineering Plant of the Year award is also presented at the event. Postponed because of Coronavirus restrictions, CFE Media is hoping to begin scheduling live events again soon. Please refer to the chart following to see all the 37 award winners in all 12 product categories.

SOLUTIONS

2020 PRODUCT OF YEAR AWARD WINNERS 2020 PRODUCT OF YEAR AWARD WINNERS

For the important category of asset management, readers’ awarded the gold to Endress + Hauser America’s solution for the IIoT ecosystem, called Netilion. Instrument makers have software that uses that data from the edge to diagnose problems and schedule maintenance. While smart instruments provide diagnostics to indicate problems with electronics or subcomponents, this is often done by way of the automation system. “This type of solution presents problems. Networks can be unduly burdened with data transmissions, historians can become bloated, and there can be time lags between data collection and recognition by the IIoT software,” said Ryan Williams, product manager for solutions & services, Endress + Hauser America. A better solution, Williams suggested, is to deliver all of the edge data to IIoT software via the cloud, thus bypassing the automation system completely. By connecting instruments to an Ethernet-based network, the data can be captured by an edge device to transmit it to IIoT software in the cloud.

Software and hardware are needed to extract data from the plant’s Ethernet network or devices and transmit it to that cloud-based software. Netilion Connect includes the edge devices, cloud platform and application programmable interfaces (API) to do that. “The Netilion ecosystem is based on an open-source technology platform that includes analytics software, process health diagnostics and the means to access appropriate documentation,” said Williams, thus providing technicians what they will have increasing need for in the future.

Avoid analysis paralysis

The gold award in the analytics & design category went to PTC ThingWorx Kepware server industrial connectivity software. Industry 4.0’s benefits make it a critical pursuit for manufacturers who want to

remain competitive. But for many companies, the prospect of connecting to their myriad of factory assets — particularly trusted older equipment — is simply too daunting. Industrial connectivity helps manufacturers break widely implemented operational technology systems like MES, SCADA, PLCs and CNCs out of niche-protocol silos. Doing so means manufacturers get more out of valuable machine data, making it actionable, preventing maintenance and downtime, and ensuring equipment compliance. A gold medal winner in PTC Kepware is probably best known for its comprethe energy management hensive library of device drivers. category, Eaton’s Smart However, besides drivers, other tools are relevant based EBMX enclosure combines on the type of connectivity involved. One example would an explosion-proof clamping be a bespoke proprietary format. In fact, Kepware’s latest enclosure design for universal device driver includes scripting capability to hazardous environments allow connection to a wide range of ancillary devices. with IoT-enabled circuit This approach to connectivity culminates in Thingbreakers and intelligent Worx Kepware Server. motor management relays. ThingWorx Kepware Server provides a single source for industrial automation data to all of an enterprise’s applications. Users connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface. ThingWorx Kepware Server leverages OPC — the automation industry’s standard for interoperability — and ITcentric communication protocols, such as SNMP, ODBC, and web services, to act as a single source for industrial data.

Efficient, reduced frame motors meet requirements for pump and compressor applications Seek and you shall find Another winner in the analytics category was Seeq Corp. for the R22 release of its advanced analytics software for process manufacturing. New R22 features support enterprise data governance initiatives and priorities to support

The SIMOTICS Advantage Series medium Seeq expansion in large organizations. For example, Seeq voltage, totally enclosed fan-cooled motors Integrated Security honors OSIsoft PI security restriccombine flexibility and performance to meet or exceed basic application requirements. tions for PI data access and enables administrators to set signal-level permissions on data in historians and other

With three new frame sizes, this motor series time-series data stores. Users therefore only have access is configured with all necessary standard to the data they need, facilitating data access compliance. features and pre-engineered modifications to Additional R22 features include: power general industrial applications such as large compressors, blowers, coolers, mixers, conveyors, extruders and pumps, among many • Improved Scatterplot in Workbench: conditional filtering and more display options help users find others. Not only do these motors have up relationships among signals more quickly to 33% more power as a result of innovative • NOAA Weather Service Connector: data from the cooling technology, but they are also up to National Weather Service API can be easily integrated38% smaller compared to into Seeq analytics other frames in the market. In this introduction, we’ve been able to highlight only Less space a few of the award winners. All of them, however, are means better worthy of your attention. To examine them in detail, plant layout utilization. These motors feel free to visit the CFE Media Products for Engineers Database. In future, our editors predict that the proviare NEMA Premium Efficient as well as sion of managed services by automation suppliers will optimized for motor efficiency and reduced become an increasingly powerful force in the manufacelectrical power consumption. turing industries. PE