7 minute read

How to test for absence of voltage

SOLUTIONS

ELECTRICAL SAFETY

Advertisement

By Rachel Bugaris

How to test for absence of voltage

NFPA 70E and CSA Z462 harmonize absence of voltage testing requirements

Awork condition is not considered safe just by turning a system off. According to updated NFPA and CSA standards, a work condition is not even considered safe once lockout devices are put in place. The 2021 editions of NFPA 70E: Standard for Electrical Safety in the Workplace and CSA Z462-18: Workplace electrical safety updated critical language that describes the process of establishing and verifying an electrically safe work condition to now include the crucial step of testing for the absence of voltage.

The updated, harmonized standards now agree on important requirements for permanently mounted absence of voltage testers, providing manufacturers and businesses operating across North America with unified guidance on design solutions that helps reduce risk during the testing process. A closer look clearly demonstrates how these harmonized exceptions on absence of voltage testing present an opportunity to ensure consistent and efficient electrical safety in the workplace.

From information to exception

For both standards, an “exception” is a fully approved method, an alternate for meeting a requirement; as opposed to the more common meaning of an allowance for a rare circumstance, as if it’s something to be avoided. Before 2018, testing for absence of voltage required an adequately rated test instrument, with no distinction made between portable testers and permanently mounted testers. That meant somebody had to physically check for the absence of voltage, a procedure that typically involved a qualified person with personal protective equipment (PPE) opening an electrical enclosure to test with a handheld tester.

In 2018, an exception was introduced in NFPA 70E that described how permanently mounted absence of voltage testers also meet the requirement without the need for additional verification with a handheld, or portable tester. The 2018 edition of CSA Z462, however, added complementary language as an informational note, not an exception. The 2021 harmonization updates the CSA language from an informational note to an exception.

What’s the difference?

Exception 1 to NFPA 70E-2021 120.5 (7) describes how a permanently mounted absence of voltage tester meets the requirement by itself, without further use of a handheld tester. That empowers facilities to forego the complexity and added exposure to electrical hazards of a handheld testing procedure, and design in permanently mounted testers as an engineered control for reducing risk.

The 2018 informational note in CSA Z462 did not have the same power as an exception, meaning that facilities following that standard could

Figure 1: Electrical enclosures protected by VeriSafe remain locked until absence of voltage is verified. Courtesy: Panduit Corp.

SOLUTIONS

ELECTRICAL SAFETY

Figure 2: The visual display makes it easy for anyone to determine voltage levels in electrical units protected by VeriSafe. Courtesy: Panduit Corp.

only supplement verification with a permanently mounted absence of voltage tester, not replace it.

While such supplementation obviously added a layer of safety, it deprived facilities of the ability to build safety procedures to fully take advantage of a permanently mounted tester.

Now that CSA Z462-2021 has added Exception 2 to 4.2.5(g), permanently mounted absence of voltage testers are an approved alternative to the handheld test instrument.

Even more agreement

NFPA 70E and CSA Z462 also harmonize in two other important ways. First, they list requirements an adequately rated permanently mounted absence of voltage tester must meet. The second is they include an informational note to help interpret whether such a device meets the requirements in the exception by referring to UL 1436, or Underwriters Laboratories’ Standard for Outlet Circuit Testers and Similar Indicating Devices.

To satisfy the requirements of the process for verifying an electrically safe work condition, an absence of voltage tester must test the conductors and circuit points at the point of work, must test for both ac and dc voltage, phase-to-phase and phase-to-ground, must be verified as operating satisfactorily before and after testing and must be listed and labeled for the purpose of verifying the absence of voltage. The informational note is important because the requirements given in NFPA 70E and CSA Z462 do not include any technical specifications, ratings or design standards that would indicate a device’s acceptability under the exception.

Together with the requirement the tester be listed and labeled for the purpose of absence of voltage testing, the reference to UL 1436 clarifies what testers qualify as adequately rated and permitted to be used for the purpose. In addition, UL 1436 provides requirements for other features necessary for reliably determining the absence of voltage with a permanently mounted tester. This includes features such as an installation test, active indicators and functional safety requirements, among others.

It’s important to note that if a facility plans to use permanently mounted absence of voltage testers to improve their safety procedures, the tester chosen must meet the requirements of being listed and labeled for the purpose. NFPA 70E and CSA Z462 harmonize on this language, and it’s crucial to point out there are other permanently mounted products that may measure voltage, or in the case of voltage test portals, facilitate voltage measurement, but do not meet the requirements described in the exception.

Devices that aren’t absence of voltage testers

The requirements help clarify which devices may have useful functions, but don’t actually verify an electrically safe work condition. For instance, panel meters and voltage indicators should alert a person to the presence of voltage, but neither is sufficient for verifying absence of voltage. Wary (and experienced) engineers are already ahead of the game here. A test designed to indicate something is present isn’t the same as a test designed to tell us something is absent.

In the case of a panel meter, absence of voltage is not guaranteed because of several failure points, including how the sensors are connected to the source. In addition, the panel meter fails crucial

requirements for the exception: It does not have a self-test function and (most likely) only measures phase-to-ground, not phase-tophase. Voltage indicators suffer similarly: They don’t self-test, don’t test phase-to-phase and don’t test the conductors and circuit parts at the point of work. Not only aren’t voltage indicators listed and labeled for the purpose of verifying absence of voltage, OSHA has stated its position that voltage indicators cannot be used to verify de-energization of equipment.

What about voltage test portals?

A test portal seems like it would help verify the absence of voltage before a panel has to be opened. However, where they seem to help is where they hurt — when testing through the portals, a person can’t confirm the probes are in proper contact. A false negative is therefore possible, and exactly what we’re trying to guard against.

Similarly, test portal leads bring voltage to the door and are often fused, which for other safety purposes is ideal, but in the case of verifying absence of voltage, a negative test could be the result of those fuses acting as designed, verifying that the safety equipment of the test portal has operated correctly, instead of verifying that the source is de-energized.

Actual absence of voltage testers

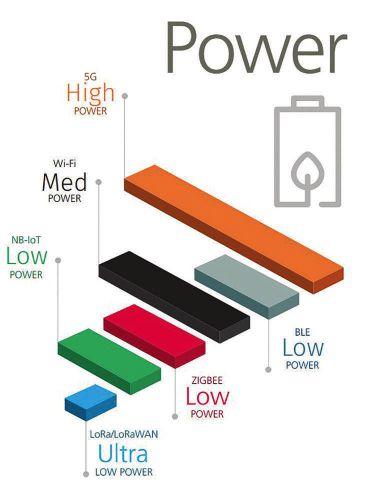

An absence of voltage tester (AVT) is specifically designed to prove absence of voltage, without requiring a qualified person to open equipment doors and potentially expose themselves to electrical hazards (see Figure 1). AVTs allow a person to push a button that starts a test sequence that meets all the requirements for verifying the absence of voltage. The AVT automatically self-tests with a known voltage source and checks for direct contact with the circuit at time of testing (see Figure 2). It then tests for absence of ac and dc voltage — phase-to-ground and phase-to-phase.

The push-to-test capability of AVTs allows a facility to build in efficiency, and unlike manual testing, is performed without exposure to electrical hazards. Ensuring the efficient process is also safe is the purpose of UL 1436, which is beyond the scope of this article to fully describe, but it includes a number of fail-safes and extensive reliability functions.

Looking ahead

The 2021 editions of NFPA 70E and CSA Z462 help manufacturing and commercial facilities looking to improve electrical safety procedures by providing clear and harmonized standards for using permanently mounted absence of voltage testers as part of the process for establishing an electrically safe work condition (see Figure 3).

As more facilities look to implement safety procedures less susceptible to human error, engineered solutions like AVTs help facilities reduce risk. For more information on using AVTs for a more efficient, engineered approach to safety, reach out to your electrical infrastructure solution partner. PE

Figure 3: Ease of installation and maintenance make VeriSafe a low-cost, high-value safety enhancement. Courtesy: Panduit Corp.

Rachel Bugaris is a business development manager at Panduit Corp., where her work focuses on electrical safety solutions for the workplace. She has a background in R&D, designing products ranging from absence of voltage testers to arc resistant equipment, has multiple patents and has written several technical papers on electrical safety topics. Bugaris has a Bachelor of Science in mechanical engineering from the University of Notre Dame. She is a member of IEEE and SWE.