6 minute read

Research

Award-winning teamwork in the digital sphere RESEARCH

Building 310 at DTU has set new standards for cooperation and the use of BIM.

Advertisement

In 2019, Peder Schiønning entered the stage twice to receive awards for his efforts regarding the newest research building at the Technical University of Denmark (DTU). The first time was Peder achieving the title of Young FRI Consultant of the Year for his role as the project manager for the building. The second time was when Building 310 was named Building of the Year. This award is given by leading representatives of all the major organisations in the construction industry. At the award ceremony, it was pointed out that this is the first time that a building has primarily won based on the process. The project is also a success, since the ambitions were achieved for all the parameters.

But the cooperation is unique. DTU chose to operate with a form of procurement in which the contractor was involved early on in cooperation on equal footing with the consultants. All knowledge was to be used in the project as early as possible, and this is where technology played a major part. 5D project The digital tools played a crucial role in the successful cooperation. From start to finish, a common BIM model was the preferred communication platform. At several stages of the project, it was possible for all parties to use the model to visualise the building. The researchers were able to get a real spatial feel for their future laboratories, both by means of Dalux and in a virtual reality studio. Since this was a 5D project, in which the metadata on price, time and quantities were coded into the model, all the parties were given access to a very detailed decision-making basis. Last but not least, BIM had a directly practical importance, since the craftsmen could use tabelts at the construction site to check the details in the model. An interesting detail illustrating the use of BIM is that DTU saved over DKK 1 million in paper and printing.

Complex research unit In order to understand the challenges we have resolved in Building 310, the complexity of the building must be taken into consideration. The research building is to house DTU Energy and 3D Imaging Centre. DTU Energy conducts research in sustainable and environmentally correct energy technologies and 30 individual gas systems have been designed. The gases include flammable and toxic gases that must be handled with great care, why a gas alarm system was established.

Material research through 3D imaging is performed by using X-ray and neutron canons to create images at nano level. Work on this scale requires that all external influences are completely eliminated, and special VCD constructions have been planned, while custom ventilation systems and climate chambers have been designed to control the climatic conditions.

20 The handover of Building 310 took place the agreed date on August 15, 2019, where the research building was fully operational.

The team behind Building 310 receives the Building of The Year-award

Laboratory ceilings 30 individual gas systems

User involvement with virtual reality

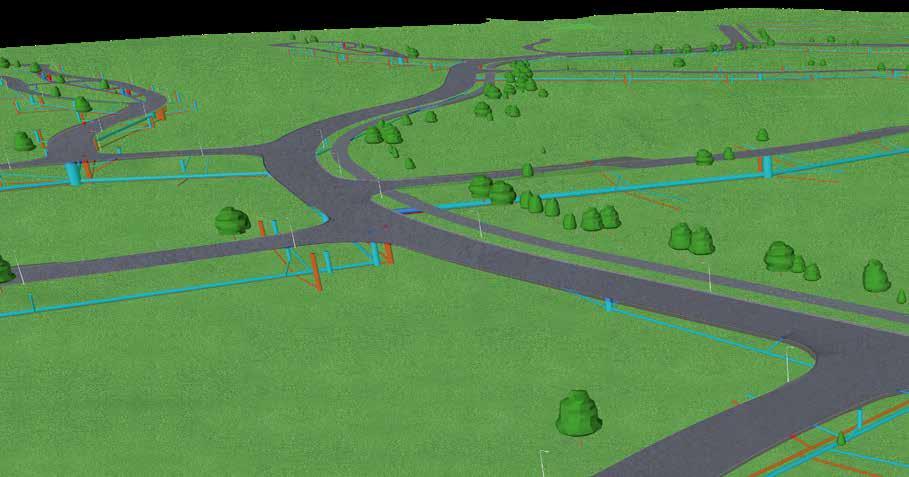

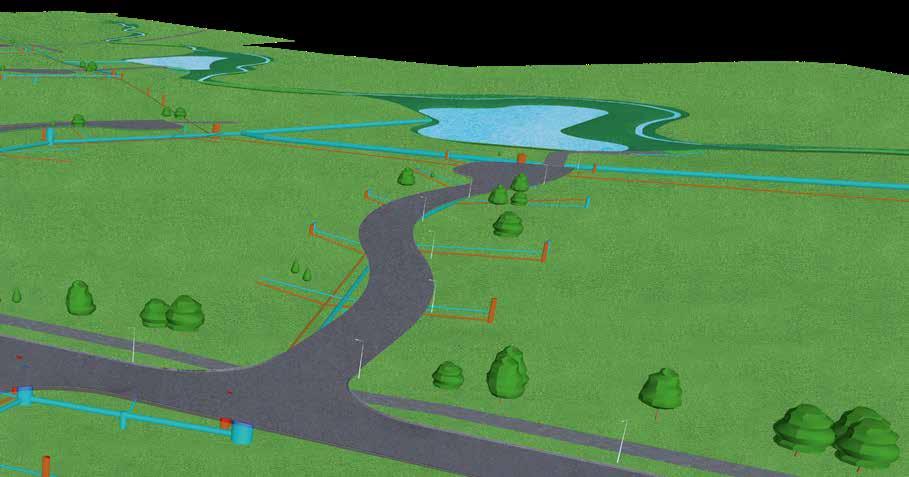

LAND DEVELOPMENT 200 trees and a revitalised stream

A new residential area rich in nature is on its way at Fuglsang Vest in Fredericia Municipality. We are responsible for the preparation of a fully digital project for developing a site, where a stream which has been piped will be opened up to contribute to the green element of the site.

The plans for Fredericia's residential area at Fuglsang Vest consist of 101 parcels of land. The entire process started with the client inviting the parties involved on an inspirational tour of various sites to promote the development of ideas.

One of the outcomes was the choice of winding roads rather than a grid-like network, which often characterises such districts. The organic expression also harmonises well with Fredericia Municipality's vision that nature should blend into the residential area.

At our office in Southern Denmark, we have BIM specialists with experience from complex construction projects, such as the New North Zealand Hospital. Our digital ambitions quickly rose and the entire site development was prepared in 3D, down to the smallest detail. Since projects at MOE are carried out across our various offices, Mathias Bisgaard from Aarhus is responsible for the road project.

Each road should have its own expression and wind through the development. Since good technical road solutions are also to be ensured, it is a great advantage to have a 3D model that can help visualise the special courses of the roads. This has also made the construction contractor's work much easier.

Mathias Bisgaard Design Engineer Infrastructure Aarhus

A life-giving vein Under ground in the western part of the construction site there is a stream that has been rerouted in a pipe, which we will open up and release with a new winding course to help create a natural area. This so-called remeandering, in which the stream will be given a naturally meandering course, has been designed in 3D. The stream will also connect two new recipient basins, which will delay the runoff of rainwater before it discharges into the river at Himmerigshuse. The stream and the two basins form a natural area that acts like a climate adaptation. The entire design for this solution is prepared using a combination of AutoCAD Civil 3D, PowerCivil, Microstation and Mike Urban. There is no plan for planting in the area surrounding the stream, which will be left as virgin soil so that nature is given free rein.

The landscape will be drawn into the development at the same time, by creating green wedges that will integrate the organic expression in the residential area and create a harmonious transition to the wild nature. This part of the project will, however, include a large-scale planting plan with 200 new trees. Even though the trees will be planted in a sporadic fashion to contribute to the wild expression, the actual placement is far from random. On the contrary, they are drawn into the model, so the underground utilities and infrastructure in general are taken into account. Computer control The contractor at Fuglsang Vest is using our 3D model for computer control. This expertise is one of our focus areas when speeding up the digital approach to civil works.

In the case of excavation work that requires a high degree of precision and needs to be carried out efficiently, computer control has clear advantages. As we are among the pioneers in the digital field and master several BIM tools, we can provide solid and wellprepared input for computer control systems. Among the most commonly used are Leica and Trimble.

Jan Richard Christensen Corporate Technical Director GIS & Data Processing in Utilities Næstved