❖❖ THE ORIGINAL MAGAZINE FOR MODEL ENGINEERS Vol. 230 No. 4717 19 May – 1 June 2023 Join our online community www.model-engineer.co.uk

CIRCUITS Where’s our train? Gauge 2 Can it be revived? Braking How do we make them stop? Machines Do they have a soul? COVER FEATURE

TRACK

Published by Mor tons Media Group Ltd, Media Centre, Morton Way, Horncastle, Lincs LN9 6JR Tel: 01507 529589 Fax: 01507 371066

© 2023 Mor tons Media ISSN 0026-7325

www model-engineer co uk

EDITORIAL

Editor: Mar tin R Evans

Deputy editor: Diane Carney

Designer: Druck Media Pvt Ltd

Club News: Geoff Theasby

Illustrator: Grahame Chambers

Publisher: Steve O’Hara

CUSTOMER SERVICES

General Queries and Back Issues

01507 529529

Monday-Friday: 8 30am-5pm

Answerphone 24hr

help@classicmagazines co uk

www classicmagazines co uk

ADVERTISING

Group adver tising manager: Sue Keily

Adver tising: Angela Price

aprice@mor tons co uk Tel: 01507 529411

Ad production: Andy Tompkins

By post: Model Engineer adver tising, Mor tons Media Group, Media Centre, Mor ton Way, Horncastle, Lincs LN9 6JR

PUBLISHING

Sales and distribution manager: Carl Smith

Marketing manager: Charlotte Park

Commercial director: Nigel Hole

Publishing director: Dan Savage

SUBSCRIPTION

Full subscription rates (but see page 666 for offer): (12 months, 26 issues, inc post and packing) –

UK £128 70 Expor t rates are also available, UK subscriptions are zero-rated for the purposes of Value Added Tax

Enquiries: subscriptions@mor tons co uk

PRINT AND DISTRIBUTIONS

Printed by: Acorn Web Offset Ltd , W Yorkshire

Distribution by: Seymour Distribution Limited, 2 East Poultry Avenue, London EC1A 9PT

EDITORIAL CONTRIBUTION

Accepted photographs and articles will be paid for upon publication Items we cannot use will be returned if accompanied by a stamped addressed envelope and recorded delivery must clearly state so and enclose sufficient postage In common with practice on other periodicals, all material is sent or returned at the contributor’s own risk and neither Model Engineer, the editor, the staff nor Mortons Media Ltd can be held responsible for loss or damage, howsoever caused The opinions expressed in Model Engineer are not necessarily those of the editor or staff This periodical must not, without the written consent of the publishers first being given, be lent, sold, hired out or otherwise disposed of in a mutilated condition or in other unauthorised cover by way of trade or annexed to or as part of any publication or advertising, literary or pictorial manner whatsoever

Vol. 230 No. 4717 19 May – 1 June 2023

668 SMOKE RINGS

News, views and comment on the world of model engineering

669 THE FORGOTTEN RAILWAY SYSTEM - GAUGE 2

John Arrowsmith discovers that Gauge 2 is still with us and awaiting a revival

672 RAILWAY BRAKING FOR MODEL ENGINEERS

Bob Bramson explains the science and the practicalities of stopping trains

676 GRASSHOPPER BEAM ENGINE

Mar tin Gearing describes a half beam engine suitable for a beginner

678 BASIC OSCILLATOR STEAM ENGINE IN CAD

Luis Trincão leads us through the creation of a 3D CAD model of an oscillating steam engine

682 A FIVE-INCH GAUGE 0-4-0 PADARN RAILWAY TENDER LOCOMOTIVE

Luker presents Fire Queen, a Welsh slate quarry locomotive

686 THE STATIONARY STEAM ENGINE

Ron Fitzgerald tells the story of the development of the stationary steam engine

689 CLUB DIARY

Future Events

http://www facebook com/modelengineersworkshop

http://twitter com/ modelengineers

SUBSCRIBE & SAVE UP TO 49%

See page 666 for details

690 BEER HEIGHTS LIGHT RAILWAY SIGNALLING

Mike Hanscomb describes the signalling system at the Beer Heights Light Railway at Pecorama in Devon

692 BOOK REVIEW

Roger Backhouse reads John Hannavy’s history of the gas tramcar

693 ABOUT MACHINES AND THEIR CREATORS

Mikhail Chernyshev sees the magic in the mundane

694 SLOTTING ON THE LATHE

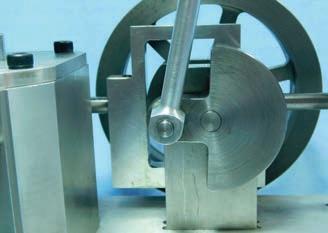

Jacques Maurel presents an attachment for creating slots on a small lathe

698 LNER B1 LOCOMOTIVE

Doug Hewson presents a true to scale 5 inch gauge model of Thompson’s B1

702 POSTBAG

Readers’ letters

704 KMYCA – A NEW RAISED MINIATURE RAILWAY

Luc Hoorelbeke tells the story of the relocation of the Koninklijke Model Yacht Club’s track in Antwerp

709 THE EATING OF ELEPHANTS

Steve Goodbody argues that anything is possible if you take it a bite at a time

712 CLUB NEWS

Geoff Theasby compiles the latest from model engineering clubs around the world

O N T H E C O V E R

Henry Greenly’s 0-6-0-6-0 ar ticulated shunting engine in Gauge 2 (photo: John Arrowsmith)

www.model-engineer.co.uk

. . .

This issue was published on May 19, 2023 The next will be on sale on June 2, 2023 ❖❖ THE OR G NAL MAGAZINE FOR MODEL ENG NEERS –Jo n o r on ne ommunity www mo e -e g nee co uk T R A C K C I R C U I T S Whe e o t n? Gauge 2 Can it be ev ved? Braking How do we make them stop? Machines Do they have a soul?

663 www.model-engineer.co.uk 676 712

P R I N T O N LY Q u a r t e r l y d i r e c t d e b i t fo r £18.00 1 ye a r d i r e c t d e b i t fo r £65.00 1 ye a r c r e d i t / d e b i t c a r d fo r £70.00 P R I NT + D I G ITA L Q u a r t e r l y d i r e c t d e b i t fo r £21.00* 1 ye a r d i r e c t d e b i t fo r £82.99* 1 ye a r c r e d i t / d e b i t c a r d fo r £84.99* D I G I TA L O N LY 1 ye a r d i r e c t d e b i t fo r £49.00* 1 ye a r c r e d i t / d e b i t c a r d fo r £52.95* *Any digital subscription package includes access to the online archive Enjoy 12 months for just £65 GREAT REASONS TO SUBSCRIBE > Free UK deliver y to your door or instant download to your device > Great Savings on the shop price > Never miss an issue > Receive your issue before it goes on sale in the shop SUBSCRIBE AND SAVE L MAGAZINE FOR MODEL ENGINEERS V 9 N 70 4 - 1 m ou online community www m del-enginee c uk EDERATION AGM d Autumn Rally at Little Hay Midlands Show First impressions ❖❖ THE ORIGINAL MAGAZINE FOR M V 3 4 11 J n our n ne c mmu SCOT IMLEC 2023 We invite entries for this year s efficiency compeition We visit a bobb ❖❖ THE ORIGINAL MAGAZINE FOR MODEL ENGINEERS 4712Jo n ou on ne commun ty mode -eng nee Lincolnshire Line Exploring the history of the Lincolnshire Coast Light Railway h u r c h the 150th the s EC 2023 rd to the small ficiency competit on We V t Rye d a l e We tak p Nor th Yorksh re SAVE 49%

w w w.classicmagazines.co.uk /MEDPS 01507 529529 and quote MEDPS Lines open Monday to Friday 8 30am – 5 00pm GMT Offer ends December 31, 2023 Subscriptions will start with the next available issue Direct Debit payments will continue on the agreed plan unless you tell us otherwise To view the privacy policy for MMG Ltd (publisher of Model Engineer), please visit www mortons co uk/privacy Please visit www classicmagazines co uk/terms for full terms & conditions

Jaw Regrinding - Pete Barker

EVANS Editor

Steam Traction World

Well known miniature traction engine kit company Steam Traction World continues to grow as a business and has recently invested significantly in new machinery for their Daventry factory The company supplies traction engine kits that are fully machined and ready for assembly after final de-burring, sanding and then painting Most models tend to be purchased over a fixed period of time so the kits arrive at regular intervals to enable the builder to build as they pay for each kit

DIANE CARNEY Assistant Editor

To continue to back their operation in January 2023 year managing director Dean Rogers decided to invest capital into the purchase of a new £100,000 CNC lathe, a Puma GT2600L With a gap of 1 2 meters between turret and spindle this lathe will enable work to be completed on all the longer items in the production process such as axles and boiler barrels With the previous lathe being over 25 years old it has clearly been a great oppor tunity to benefit from new technology too This now takes their number of CNC machines to nine, as well have having manual machines too such as their gear cutter

Since the leaving of the EU, Steam Traction World have

been required to resubmit each of the 20 different boiler designs for reapproval, as dual cer tification is now need –CA for the UK, and CE for the rest of the world, which was a significant piece of work to under take. All of this has been completed with a backdrop of continued business growth, as more and more people have joined the ranks of miniature engine builders So much enthusiasm has been shown that Steam Traction World has introduced a ‘fast track’ purchase scheme, where kits are provided in three stages over a 12 month period to respond to customers wanting to complete a build at pace

One area that Steam Traction World has previously faced criticism from customers about has been the supply of spare par ts A key advantage of their engines is that all the par ts are catalogued with the vast majority available ‘off the shelf’ However, the business struggled to find a way to service this area in an efficient way for their customers They have now introduced an online shop for par ts and have a dedicated member of staff, Traci, who oversees matters regarding spares. Feedback is now much more positive for this impor tant area of the business, and with over £400,000 of stock in spare par ts most are available via the shop or by email query

Their biggest selling engine remains their four inch Burrell agricultural traction engine, of which they have sold a staggering 524 kits, but their

current most popular is the double crank compound four inch Burrell road locomotive which has 38 being built currently compared to 14 of the Showman’s variant in build

In total now 1343 Steam Traction World engines have been built, or are the process of being built, which is a remarkable achievement, and a tribute to the way the company has responded to their customers’ requirements and created good quality products

Fire Queen

In Fire Queen, par t 2 (M E 4714, April 7) fig 2 omits some of the dimensions for the plate above the axleboxes in the front frames The key missing dimension is the width of the plate, which is 58 8 mm, as shown in the figure above The holes shown in blue are positioned as in the original drawing but the positioning of the holes shown in red is discretionary Some suggested positions for these holes are shown in the figure The material is 1 6 mm bright mild steel and all holes are 2mm diameter

Model Engineer 19 May 2023

MARTIN

can be contacted on the mobile number or email below and would be delighted to receive your contributions, in the form of items of correspondence, comment or ar ticles.

Mar tin Evans

07710-192953 MEeditor@mor tons co uk

668

Dimensions of the plate above the axleboxes in Fire Queen’s front frame

Joe Simon’s four inch double crank compound Burrell, seen in his tidy workshop, is well advanced now on its build Joe didn’t opt for the ‘fast track’ option but has taken his time to create a fine-looking engine finished in Oxford Blue livery and it will be a striking exhibit on the rally field once completed

T h e F o r g o t t e n R a i l w a y S y s t e m - G a u g e 2

John Arrowsmith explores a short-lived gauge that expired about a century ago but hopes for a revival one day.

This relatively unknown gauge was first introduced by the German company Märklin at the 1891 Leipzig Toy Fair Gauge 2 is equivalent to a scale of 1:22 5 or 7/16 inch to 1 foot It was originally built to 64mm or 2½ inch gauge but in 1909 was standardised to 2 inch or 50 8mm, often described as 54mm when measured between the rail centres, and this is how it has stayed through all the years Its use was strongly discouraged by Bassett Lowke, Greenly and others in 1917 in the interests of post war standardisation and it has fallen into disuse but collectors have maintained a small selection of rolling stock and locomotives in the hope that one day it might be revived.

A new group of modellers have now built a new 2 inch gauge 40 x 20 foot oval layout and this was demonstrated recently at the G1MRA75 event held at Bicester in October 2022 by kind permission of the G1 Association who

669 www.model-engineer.co.uk >>

The main station on the Gauge 2 layout at Bicester

Another view of the Bicester event with a rake of six coaches built by H B Jervis in 1912

David Viewing prepares the Carson Precursor for its turn on the track

2 1 3

were the organisers of the event It was perhaps the largest gathering of Gauge 2 locomotives and rolling stock since the First World War and

where most of the world’s operating locomotives were in action The photographs show almost all of these locomotives located at the shed on the new

David Viewing is the prime mover in this resurgence and he was highly delighted to

7 8

be able to use a new layout to demonstrate this (almost) long-lost system. The track was scratch built using code 330 rail (similar to the modern LGB rail) so that a wide range of both locomotives and stock, from early tinplate to later scale models, could run Most of the small amount of surviving original Gauge 2 track was deployed in extensive sidings

Scale Gauge 2 engines and carriages need a minimum of 10 foot radius track to operate successfully The other consideration was the provision of electricity for other locomotives and a powered track did not seem feasible so the electric models have been converted for R/C use using lithium batteries, which obviate the need for powered rails It is appreciated that this method is perhaps not in keeping with the history of the models but it

670 Model Engineer 19 May 2023

A good head of steam as the Precursor waits for the signal

The Greenly engine operating at Bicester.

Pages from Greenly’s book and the construction details of his engine

The 0-6-0-6-0 on a 40 wagon goods train in a suitable garden layout

4

Greenley’s 0-6-0-6-0 Tank locomotive (circa 1911)

5 6

layout displayed at the Bicester exhibition

does mean that they can now be operated on any suitable track, either indoors or out

The two operating steam locomotives have a very interesting history which can be traced back to their original owners The Jubb Atlantic is the engine described by Mr W H Jubb in Henry Greenly’s Models, Locomotives And Railways and was built in 1911. It is still running today in original condition. The other steam engine operating at this event was the Carson 4-4-0 Precursor locomotive which is now 110 years old and still going strong Probably the most unusual locomotive performing at the show was Henry Greenly’s 0-6-0-6-0 articulated shunting engine (circa 1911) which he never completed but which now runs in this configuration

The engine is the only known example of a model locomotive built by Greenly himself.

A majority of the world’s surviving serviceable Gauge 2 locomotives. From left, clockwise:

• Saint George, Bing for Bassett Lowke, 1913 (live steam, awaiting restoration);

• a pair of LNWR Bowen Cooke 4-6-2 tanks, Bing for Bassett Lowke, 1912;

• Great Central 9N 4-6-2 Tank, Bing for Bassett Lowke, clockwork;

is based on the LB&SC J1 class This engine has been refurbished and is fitted with lithium batteries It has also been fitted with an intermediate bevel gear, 3D printed in SLS Nylon to replace the one lost in the 1920s To preserve the original paintwork it has been clothed in a printed vinyl covering displaying the colours of the original locomotive

The weekend event at Bicester has appeared to give this forgotten gauge system a new lease of life, so it will be interesting to see if it has generated additional interest and can move the gauge forward towards being as popular as Gauge 1, or Gauge 3 which is the ‘scenic’ version of the 2½ inch gauge

More information on the Gauge 2 Model Railway can be found by scanning the QR code

• (in shed) 4-4-0 Metropolitan Tank, modern, Ned Williams;

• Peckett 0-4-0 Tank, Carette for B-L 1910

• (on turntable) Experiment 4-6-0, Bassett Lowke

• (on road behind) 0-6-6-0 Tank, Greenly, 1911

• 0-4-0 Tank, F W Jubb for B-L, c 1910

riginally it was fitted with twin clockwork mechanisms but today it is powered by two 3D printed lithium powered engine units Working well, it can pull 40 Gauge 2 wagons, without difficulty, for two hours non-stop

• Abergavenny - LBSC 4-6-2 Tank, Butcher & Co , c 1911

• (turntable road) Sydney, Bing for Bassett Lowke, c 1908

• GNR N1 Tank, Bing for Bassett Lowke, c 1910

• Precursor 4-4-0, James Carson, 1911 now named Carson (live steam)

• 4-4-2 Atlantic, F W Jubb 1911, live steam

Another unique survivor from those early days is the 4-6-2 tank locomotive Abergavenny by C Butcher & Co which

671 G A U G E 2 www.model-engineer.co.uk

The Jubb Atlantic and a 4-4-2 in the siding with the J1 passing through the station.

A superb example from the 1920s based on a LB&SR J1 Class.

com/2p96myd9 ME 9 10 11

tinyurl

Introduction

Throughout the past century of our hobby, there have been many developments in improving the performance and reliability of miniature steam locomotives but very little on the subject of braking A relatively small number of articles have appeared in the model engineering press but no real efforts have been made to adopt continuous and automatic braking, possibly because the additional effort needed to equip miniatures with a well-engineered braking system adds quite a significant number of hours to

P

R a i l w a y B r a k i n g f o r M o d e l E n g i n e e r s

the completion process Not only that but it is evident that there is a knowledge gap and this article is intended to help bridge that gap and stimulate interest in the subject

Throughout this article, the Imperial system of weights and measures is used

Why adopt power braking?

The author’s first experience with the business of braking was after constructing his 3½ inch gauge tank locomotive Jubilee He set up about 30 feet of track in the garden and steamed the engine He was fairly young then and naturally eager to see it go. Bystander No.1, elder brother, remarked, “Now you’ve made it go how do you stop it?” This was followed by both heels digging two tramlines into his dad’s fondly manicured lawn, not to mention hot ash setting it on fire The experiment came to an abrupt conclusion but the lesson had been well and truly learned Given the small scale of model locomotives and the light loads of the day, braking was generally achieved using hand brakes on drivers’ trollies, which is still the norm today in the smaller gauges. In 1966, the author visited the ‘Surrey Hills Live Steamers’ in Melbourne, Australia and was offered a drive of a five-inch gauge petrol driven locomotive fitted with air brakes Two things stuck in his mind about that experience the hospitality and friendship of the club members extended to a seafaring ‘pommie’ and the superb braking control of the engine and its train

Since those early days the hobby has graduated to larger and larger scales Nature decrees that as the linear dimension of an object increases, its volume expands in relation to its cube On this principle, a 3½ inch gauge standard gauge type engine might weigh say 70 lb and doubling this to 7¼ inch gauge the weight goes up to around 600 lbs A 3½ inch gauge passenger engine might pull four passengers and a couple of cars with an all up weight of some 800 lb Its 7¼ inc h gauge counterpart could be hauling an all up weight of some 5,000 lb at speeds up to 10 mph Under those conditions, it is uite impossible to expect a trolley brake to dissipate the considerable amount of kinetic energy of such a train - an effective braking system acting on all vehicles is essential

In the late 1970s, our society became set on the road of the so called ‘service economy’ with the litigation industry forming a prime ‘service’ This has bred plenty of opportunity for claims against clubs, societies and even individual drivers if accidents occur Our legal framework rightly requires us to exercise a duty of care to limit risks to the safety of ourselves and our fellow citizens

The rules

The regulatory framework for the operation of miniature railways is predicated on the Health and Safety at Work Regulations 1974 In pursuance of this legislation, the current ‘Guidance’ HS2020

672 Model Engineer 19 May 2023

Bob Bramson explains the important business of bringing trains to a halt in a controlled manner A R T 1

Brake system continuity

for ‘Managing the health and safety at passenger carrying miniature railways’ is now in place. On the subject of braking, Clause 41(d) states ‘the vehicle has adequate braking provisions for parking, normal and emergency braking’ Whilst the author considers this statement rather feeble it is the effective law that attends should an enquiry or prosecution be brought in the event of a mis hap (Author’s note The former TN produced by HMRI was more specific on this topic and is worthy of consultation )

So now we know the rules which apply to our gauges. This puts the onus on us all to ensure that our operating practices are safe Let’s keep it that way

Braking principles

The scientific principles which govern the braking of miniature trains are in essence no different to that of their main line counterparts For main line operation the theoretical and practical lessons have been well learned resulting in the publication of the ‘Railway Group Standards’ which mandate how safety of operation on Network Rail is achieved Braking is covered in several of these standards (available on the web at www rssb co uk) the most relevant being GM/RT2045 ‘Braking Principles for Rail Vehicles’ This document sets out some prime requirements which apply equally to miniature gauges, these are

● Brake systems must be safe and reliable

● Continuous and automatic operation of the power brake must be provided.

● The system must operate in all foreseeable weather and climatic conditions

● A parking brake must be provided

It should thus be obvious that whatever medium is used to power a braking system, it must be safe and always work when required

‘Continuous’ means there is a series of brake system connections throughout the train as shown in fg 1

‘Automatic’ means whenever there is any interruption of the continuity system, the train is automatically brought to a stand For instance, if a train division occurs, the ‘ pass comm (communication cord)’ is operated or the guard applies his brake valve

‘Fail Safe’ means that if any critical system component fails, the system cannot be rendered inoperative In all safety systems, the principle of ‘de-energise to apply’ is adopted to ensure fail safe operation.

ther relevant provisions are

● A guard’s brake valve must be fitted to enable the brake to be applied by the guard and the brake continuity proved

● The normal convention for operation of the driver’s brake valve on steam locomotives is anticlockwise to apply and clockwise to release or

towards you to apply and away for release (different on modern trains!)

Friction

Friction is the primary means used to dissipate the energy of motion What is friction?

● It is difficult to define precisely but we can observe its effect

● It occurs when materials are either in contact or rub together in sliding contact under the influence of a mechanical force

● Different materials exhibit varying frictional characteristics

● Friction varies with speed, pressure and temperature.

● The energy due to motion (kinetic and wheel rotational energy) is

normally dissipated by FRICTION The principle of ‘Conservation of Energy’ applies (heat is work and work is heat)

● With electric drives, the energy can also be dissipated by dynamic braking but a friction medium is still necessary to provide braking to a stand

● The rate at which a train can be braked depends on three main variables friction, brake force and speed

The coefficient of friction (pronounced mu) is simply the force applied to a material in contact with another divided by the normal reaction

For example, if a force of 20 lb is applied to one of the materials and a force of 100 lb is applied normally (at 90 degrees) to both of them, the coefficient of friction would be 0 2 The friction at the point where sliding just takes place is known as the coefficient of limiting friction

Figure 2 shows a rail vehicle brake block applied to a wheel When the product of brake force F and the coefficient of friction between the brake block and the wheel rim is less than the product of the coefficient of friction between the wheel rim and the rail and the normal force on the wheel Q – wheel slide will not occur For this reason, it is always necessary

673 B R A K I N G www.model-engineer.co.uk >>

Friction and braking forces

Direction of travel Q Block retarding force Retarding force at rail Brake force μB x F μR = Mu at rail μR x Q has to be greater than μB x F to avoid wheel slide μB = Mu at block μR x Q F

2

Fig

At 80mph, wheel F has a peripheral speed of 7040ft/min

At 10mph, wheel S rotates at 360rpm

Both wheels have the same rim speed at the rail - 880ft/min

to limit the brake force F so that wheel sliding and consequent wheel flats do not occur This limit is referred to as the ‘brake percentage’

In fg 3, an essential truth by which we, as model engineers benefit, is the fact that a model 7¼ inch gauge wheel, of say 9¼ inches diameter, would be the th scale e uivalent of a 6 foot 2 inch full size wheel.

The rim speed of the model wheel at 10 mph works out at 880 ft per minute and it rotates at 360 rpm The full size wheel at this speed has the same peripheral speed but only rotates at 45 4 rpm

At eighty mph the wheel revolves at 360 rpm and has a rim speed of 7,040 ft per mi nute The issue here is that friction at the higher speeds is much reduced and the model operates at a speed where the available friction is comparatively high.

Figure 4 illustrates how the friction force varies with speed At high speeds (above 60 mph) the friction is low, both between the rail and block interfaces with the wheel and thus the rate of retardation is correspondingly low To the left of the diagram, the friction effect can be seen to be significantly

increased, a gr eat advantage for miniatures One downside however, is that during a prolonged brake application, the temperature of the brake block/wheel interface will increase leading to lower effective brake force and possible wheel damage, a plague in full size but hardly an issue with miniatures

So now the influence of friction, brake force and speed on the rate of braking can be appreciated.

Brake systems

A b r a k e s y s t e m i s t h e a r r a n g e m e n t o f t h e v a r i o u s

c o n t r o l a n d f u n c t i o n a l i t y o f

t h e b r a k e s

e

There are basically three systems which can practicably be used for the braking of miniature trains

● Vacuum (atmospheric air)

● Compressed air

● Spring applied.

Each system has its own advantages and disadvantages Spring applied brakes are not considered in this article because the means of isolating this type of brake adds complication when working trains

The vacuum brake system is eminently suited to steam locomotives Vacuum is easily created by use of an ejector worked by a small flow of live steam Provided the system is well engineered, it should be very safe and reliable. There are a number of dos and don’ts to observe in designing and making such a system and if these are satisfied the result will prove most acceptable

A (simple) air brake system is perhaps better suited to battery or I C engined locomotives There are a few more components to make for an air operated system but it can be just as safe and reliable as an equivalent vacuum system

The advantage of the vacuum system lies in its simplicity but it does require relatively large brake cylinders since a system operating at 21 inches of mercury only has a maximum air pressure of 10 lb/in2 to work the brake An air brake system may work at any safe desired pressure and the brake cylinders may be correspondingly small yet provide the same brake force as an equivalent vacuum system

The crunch comes when considering the rolling stock that needs to be compatible with the installed system. British Railways spent a significant fortune in fitting dual braked systems in the 1950s and 60s during the change over from vacuum to air braking So, which system do you fit The choice

he variability of brake retarding force with speed

674 Model Engineer 19 May 2023

o m p o n e n t s w h i c h a r e i n t e r c o n n e c t e d t o p r o v i d e t h

c

Ø6' 2"

Ø9 25” Wheel S (1 1/2” : 1’)

Wheel F (Full size)

3

Fig

he benefit of scale.

B l o c k R e t a r d i n g F o r c e Train Speed Adhesion envelope at rail μ at rail - low speed μ at rail - high speed μB x F

4

Fig

depends on several factors and should be well thought out by individual clubs and societies

Figure 5 shows a typical system for a trailer car

T h e b r a k e c y l i n d e r s o f b o t h v a c u u m a n d a i r o p e r a t e d s y s t e m s d e s c r i b e d h e r e i n e m p l o y a b a l a n c e d p i s t o n p r i n c i p l e W h e n t h e b r a k e i s r e l e a s e d , b o t h s i d e s o f t h e p i s t o n ( i g n o r i n g t h e s m a l l a r e a o f t h e p i s t o n r o d ) a r e b a l a n c e d e i t h e r b y e q u a l v a c u u m o r e q u a l a i r p r e s s u r e W h e n o n e s i d e i s ‘ r e l e a s e d ’ a i r p r e s s u r e o f t h e a t m o s p h e r e o r f r o m t h e a i r b r a k e r e s e r v o i r a p p l i e s t h e b r a k e

Figure 6 shows a vacuum brake scheme for a steam locomotive The resistance to leakage of any vacuum system is a key requirement. It should be remembered that the old axiom, nature abhors a vacuum’ applies absolutely

Figure 7 illustrates a simple air brake system, the heart of which is the air compressor

The air brake system described differs greatly from that used in full si e being simplified to work in the inverse manner as the vacuum brake

I t w i l l b e n o t e d t h a t o n a l l t h r e e d i a g r a m s a r e l e a s e v a l v e i s s h o w n T h e p u r p o s e o f t h i s i s t o a l l o w a t r a i n t o b e m o v e d w h e n t h e r e i s a s y s t e m f a i l u r e o r t h e t r a i n r e q u i r e s t o b e s h u n t e d w i t h t h e b r a k e i s o l a t e d T h i s i s a c c o m p l i s h e d b y v e n t i n g t h e r e s e r v o i r s i d e t o a t m o s p h e r e w h e n e i t h e r t h e v a c u u m o r c o m p r e s s e d a i r i s v e n t e d f r o m t h e t r a i n p i p e W i t h o u t t h i s t h e b r a k e w o u l d r e m a i n a p p l i e d w h i l s t e i t h e r t h e v a c u u m o r a i r r e s e r v o i r s r e m a i n c h a r g e d T h e s e r e s e r v o i r s p r o v i d e t h e e n e r g y s o u r c e w h i c h o p e r a t e s t h e b r a k e s .

NEXT TIME

We discover how we can create a vacuum

simple brake system for an powered locomotive

675 B R A K I N G www.model-engineer.co.uk >>

Brake diagram for a trailer vehicle

acuum brake system for a miniature steam locomotive.

To be continued Brake cylinder Release cords Continuous brake pipe Guard’s brake valve Stored energy (air/vacuum) NRV

5 2 4 Vacuum reservoir Brake cylinder Ejector steam valve Vacuum ejector Exhaust elbow Non-return valve Driver’s brake valve Vacuum release valve 1 2 3 4 5 6 Drain valves Non-return valve Train pipe Chamber Gauges 3 1 5 6 1 2 4 3 6 5 9 10 11 8 7 Prime mover Brake cylinder Air compressor Electric clutch Electric decompressor Non-return valve 1 2 3 4 Safety valve Pressure switch Auto-drain valve Non-return valve 5 6 7 8 Pressure regulator Driver’s brake valve Release valve 9 10 11 Brake reservoir Main reservoir Air brake pipe MR BC ABP

Fig

Fig

6

Fig

7

Martin Gearing presents an ideal beginner’s project with great potential for the more experienced builder.

r a s s h o p p e r B e a m E n g i n e

676 Model Engineer 19 May 2023

G

P A R T 20 Continued from p 621 M E 4716 May 5 Valve setting = = Sectioned view showing spool in valve block Sectioned view showing spool in valve block Setting of Valve CAM Position crank at top dead centre Adjust cam peaks to be equal below top face of cam follower, then secure 1 Setting of Valve SPOOL Position crank at 90° Adjust spool to be flush with lower face of top por t 2 Double checking Valve SPOOL setting Position crank at 270° Check spool to be flush with upper face of lower por t 3 Fig 69

Valve setting

Having satisfied yourself that the assembled parts all move freely with one another the last ob is to set the valve timing (fg 69) This is done in two stages

Setting the

cam

Note that because of the mechanism of the beam, the centre of the clevis in the connecting rod will N T be in line with the shaft and pin of the crank at 0 degrees to the base – so do not bother to try and position all three centres in a straight line

Turn the crankshaft until the crankpin is at its highest point in relation to the base Another way to look at this statement is that the centres of the crankshaft and crankpin need to lie on a line at 0 degrees to the base

hen that position has been achieved turn the cam so that the two e ual peaks on the profile are exactly the same amount distance below the face of the top surfa ce of the cam follower The cam should now be secured by tightening the M x 10 grub screw (photo 144)

Setting the valve spool

Tighten the clamp screw in the valve lever cam

Turn the crankshaft until the crankpin centre is at 0 degrees on from T C, and on the same hori ontal centre as the crankshaft

Coincidentally this is the same centreline as the cam follower shafts 52 5 above the base (photo 145)

ith the crankshaft in this position, carefully rotate the spool valve lever on the cross shaft until the upper face of the spool is exactly flush with the lower face of the ports in the top of the cylinder block Nip up’ the clamp screw otate the engine at least a full turn and bring the crankpin back to the 0 degree position

Check to see the spool is still in the correct position, resetting if necessary hen this is the case tighten the clamp screw (photo 146)

f g spool setting

otate the crankshaft until the crankpin centre is at 270 degrees from T C, and on the same hori ontal centre as the crankshaft and cam follower shafts (photo 147). ith the crankshaft in this position, without moving the crankshaft, turn the engine on its cylinder block end until you can see into the end of the valve block

The end of the spool should be exactly flush with the upper face of the lower port in the cylinder block If not, slacken the clamp bolt and ad ust until the spool faces are in exactly e ual positions in relation t o the ports at both 0 and 270 degree crankpin positions. etighten the clamp bolt (photo 148)

First test run

For the least amount of noise it is a great help if the vacuum cleaner you use as a power source has a variable speed, or at least high and low speeds, which should be set to the lowest - otherwise ust accept the noise

ush the control valve handle so the top is fully over towards the cylinder block Connect your chosen cleaner hose to the inlet port of the control valve and swi tch the cleaner on ou should now hear the sound of the vacuum being drawn through the Spill’ port in the control valve base, as the supply of vacuum to the engine valve block is closed Slowly rotate the control valve turning the flywheel away from either of the dead centres if it doesn’t start to rotate ou should find the engine speed

responds to the rotation of the control valve

Hopefully you have arrived at this point with an engine that responds to the position of the control valve and most importantly will run slowly, so that the mechanism’s movement may be observed ou will have experienced a pleasure that is becoming increasingly rare The skills experienced are transferable to most forms of mechanical engineering, sadly once commonplace

677 G R A S S H O P P E R www.model-engineer.co.uk

Setting the valve spool

Setting the cam

Valve spool clamp screw

onfirming the valve spool setting

Valve spool clamp bolt

144 145

ME 146 147 148

B a s i c O s c i l l a t o r S t e a m E n g i n e i n CA D

Luis

Continued from p 625 M E 4716 May 5

P A R T 2

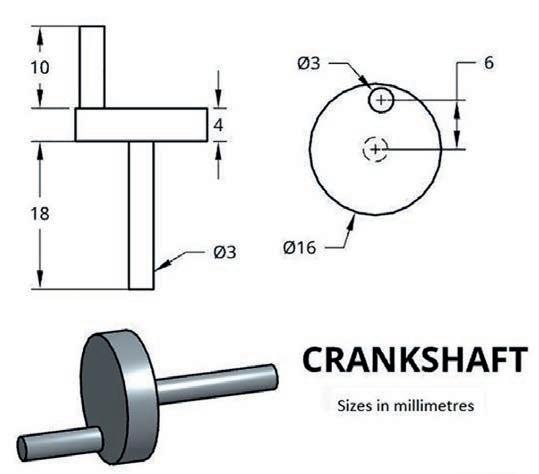

its basic form Perform the following operations:

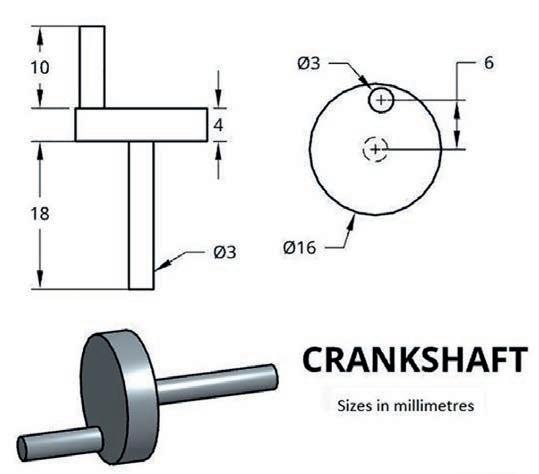

Step C1 – Create a Part studio and make the sketch of fg 3 Select the Top plane Use the Dimension tool to define the position and diameter of the circles

Step C2 – Make a 4mm Extrude-New of the 16mm circle in the positive Z direction – fg

Step C3 – ExtrudeAdd 14mm of crankpin circumference in the same direction You need 14mm to compensate for the 4mm of the part made in Step C2 and get the final 10mm crankpin dimension

Step C4 – Extrude-Add 18mm from the 3mm centre circumference to create the Axle This extrude is made in the opposite direction to the crankpin.

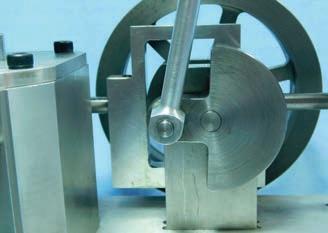

Crankshaft

The next part is the crankshaft It is an easy part to draw and is represented in fg in

Step C5 – Change the default part name to Crankshaft and assign the colour and material In my case I selected cast iron See fg In the Properties option you can see that this part will weigh 6 99g

678 Model Engineer 19 May 2023

Trincão takes us through the CAD process step by step.

Crankshaft.

Fig 22

Crankshaft extrude

Fig 24

Crankshaft sketch

Fig 23

N o w I p r o p o s e t h e c h a l l e n g e o f t r a n s f o r m i n g t h e c r a n k s h a f t m a d e t o t h e o n e i n g I w o n ’ t d e s c r i b e i n d e t a i l h o w i t ’ s d o n e , j u s t s a y i n g t h a t o n e o p t i o n i s t o c r e a t e a n e w s k e t c h o n o n e o f t h e c r a n k w e b f a c e s , d r a w t h e p a r t t o b e r e m o v e d a n d m a k e a n E x t r u d e - R e m o v e o f t h e s e p a r t s . O f c o u r s e , y o u c o u l d h a v e d o n e i t i n s t e p C 1 , d r a w i n g t h e i n t e n d e d s h a p e i n s t e a d o f u s i n g t h e c i r c u m f e r e n c e A t a n y t i m e , y o u c a n e d i t a p r e v i o u s s k e t c h b u t t h e r e c a n b e n e g a t i v e c o n s e q u e n c e s T h e r e m a y b e i n c o r r e c t e x t r u s i o n s o r o t h e r l a t e r a c t i o n s t h a t r e l i e d o n s e c t i o n s r e m o v e d f r o m t h e o r i g i n a l s k e t c h U s u a l l y , a f i x i n o t h e r a c t i o n s c a n s o l v e t h e p r o b l e m

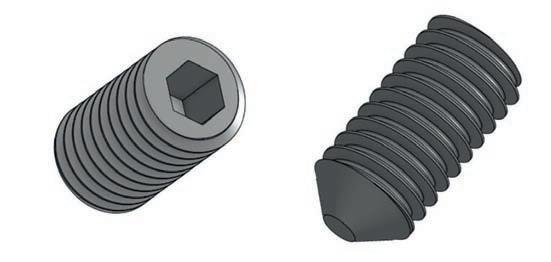

Flywheel and set screw are the next parts to be created Note that all parts of this engine could have been generated in the same Part Studio I chose to create several Part Studios to facilitate the explanation

I suggest you watch a tutorial reading QR Code 5 You can also search on the Internet for ‘Onshape patterns’.

The dimensions of these parts are shown in fg

Step F1 - Create a Part studio where you will make the sketch for the Flywheel – fg Use

Top Plane Draw from the rigin point The 0 degree

angle is set to allow placing the set screw in line between hole 1 and hole 6 Draw hole 1, leaving the remaining holes to be created with the Circular patterns tool

You may have noticed that the circles are not fully constrained because they are in blue. That is no problem if you do not move them Not wanting to complicate things at this stage, there are ways to make the drawing fully constrained, turning all the lines black

Step F2 – Create a plane parallel to the right pane with an offset of 12mm It will be tangent do the Flywheel between holes 1 and 6 This plan will be used to set the hole centre for the grub-screw – fg

QR Code 5 - www youtube com/ watch?v=BFURYp4Rgck Grub screw plane

679 C A D g >>

Crankshaft rename.

Fig 25

New crankshaft.

Fig 26

Fig 27

Fig 28

Flywheel

Flywheel sketch

Fig 29

Set screw sketch.

Step F3 – Extrude-New your sketch, leaving out the circumferences of the holes and axis – fg 3 Use Symmetric Extrude option as shown

Step F4 – You will now make a sketch just to mark the centre of the set screw hole aligned with the centre of the drawing – fg 31

Step F5 – Drill a counterbore hole – details in fg 3 . It could be also a straight hole You can thread the set screw hole or leave it as is

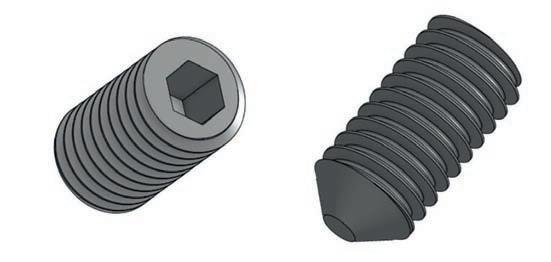

Now let’s create the set screw in the same part studio

Step G1 – Create the sketch – fg 33 Use the polygon tool to draw the hex hole

Step G2 – Extrude-New a 6mm high cylinder Include the polygonal part

Step G3 – Extrude-remove the

polygon with a height of 2mm

Step G4 – Use the Chamfer tool to obtain the result of fg 3 on the opposite face of the hex hole

Step G5 – Thread set screw as explained for the ports on the Base part using the ‘Thread Creator’ custom feature You will achieve result from fg 3

Step G6 – Name your parts, set the material and colour.

I could avoid creating the Grub Screw, Nut and Washer because there is a library with these and other standard parts This library is accessible in the model assembly under the “Insert-Standard content” option For pedagogical reasons I decided to explain the creation of these components

80 Model Engineer 19 May 2023

Fig 30

Fig 31

xtrude ywheel

Set screw chamfer.

Set screw

Set screw hole centre

To be continued

Set screw hole

Fig 32

Fig 33

Fig 34

Fig 35