www.africamininginsight.co.za AF RI CA MI NI NG I NS I GHT Pg16 Pg25 26 COVER Pg28 Africa’sOwn MiningJournal September-October2022>Issue5.Vol#4 TECHNOFAST HYDRAULIC HEAD NUTS PROVIDE FASTER AND SAFER LINER CHANGES FOR GYRATORY ORE CRUSHERS Reducing Fuels Bills and Equipment Downtime with ECOCLEAN Fuel Additive Technology ® SA Tube & Honing Screening Division Accurate GNSS Data Collection for Precise Drilling Locations

Africa’sOwn MiningJournal September-October2022>Issue5 Vol#4 TECHNOFAST HYDRAULIC HEAD NUTS

Reducing Fuels Bills and Equipment Downtime with ECOCLEAN Fuel Additive Technology SA Tube & Honing Screening Division Accurate GNSS Data Collection for Precise Drilling Locations

Cover Pg28

www.technofast.com Pg16 Pg25 26 COVER

Editor Goodwill Sibanda editor@africamininginsight.co.za Writer Kennedy Chamu writer@africamininginsight.co.za Sales Daren daren@africamininginsight.co.za Leon Jaure leon@africamininginsight.co.za Cleopas Moyo cleopas@africamininginsight.co.za Jacob White jacob@africamininginsight.co.za Samuel Ndlovu samuel@africamininginsight.co.za Design and Layout Kelvin Munash design@africamininginsight.co.za Accounts Lenon Chirimuta accounts@africamininginsight.co.za Subscription Thatho Ndlovu subscrip�on@ fricamininginsight.co.za General info@africamininginsight.co.za sales@africamininginsight.co.za Call: +27 84 744 4593 +27 79 499 2268 www.africamininginsight.co.za

This issue of Africa mining Insight tries to bring together this wide range of perspec� es in mining on the con�ne t. It is my sincere hope that you will appreciate the insights given. Our publica�on ocuses on the developmennts and ac�vi�e aking place in the mining sector through out Africa. As you are aware the con�ne t is a haven of minerals which are in demand world wide. The diamonds of Botswana, the South African gold, and the oil of Angola, to men�on jut a few. Zimbabwe boasts of coal which is in abundance, with Zambia renowned for its copper. Unfortunately despite its mineral wealth, Africa s�ll lags behind in de elopment as compared to the rest of the world. It seems the Interna�onal ompanies mining on the conn�n t are only interested in extrac�on of the mineals and working on them outside the conn�n t.

Minerals mined in Africa leave the con�ne t in their raw state. This has deprived Africa in terms of developing the country's mining industry and from earnings which accrue from the minerals once value is added on to them. It is �me th t Africa holds on to its minerals and only dispose of them afer vvalue addi�ono enable it to fully benefit from its produce.

Beneficiaa�on is aactor African governments should impose on their resources before expor�ng their mineals. It is believed that in the purificaca�on of pla�num e are over seven by minerals which are also found in the process. These are not brought back to Africa by the mining companies but sold as finished products through out the world. This process has led to few jobs being created within the industry. In the case the products come back to Africa, they are sold at very exorbitant costs. Zimbabwe' diamond is cleaned out of the country and sold at treble the price by its buyers afer value addi�on. This occurence has led to few jobs being created, with industries being built overseas to benefit foreigners. Saudi Arabia does not have a diamond mine but boasts of a 25 billion dollar diamond industry. Most of its diamonds are procured from Africa. The following example illustrates clearly what I am wri�ng about. The ganite that was used to build the Royal Danish Library was mined in Mutoko, Zimbabwe. The Italian company paid US$150 per ton as mining rights and extracted 6500 tons. The Zimbabwean government made US975 000 from this venture. The Italian firm cut and polished the stones and sold them to the Danish for US$18 million. The country lost almost US$17 million in possible revenue.

It is very sad to con�nue o watch our people wallow in poverty and live in slums when wealth can be kept on the con�ne t. Countries in Africa should not only be eager to sell their raw products but should strive to add value to it. The pla�num mining firms in Zimbabwe should build a smel�ng pla t to avoid the product being sold raw outside the country. This will create more jobs and increase the tax basket of the country at the same �me witness a gowth in mining infrastructure.

Your comments and contribu�ons will be mot appreciated.

www.africamininginsight.co.za

Editor’s Note Disclaimer: All material is strictly copyright. The magazine or any part thereof may not be reproduced or adapted without writen permission from the publisher: - Africa Mining Insight welcomes material submited for publicaa�on butetains the right to edit copy. The views expressed in the publicaca�one not considered those of the publisher, which accepts no liability of any nature arising out of or in connec�on with the contents of this magazine. While every effort has been taken in compiling this publica�on, the publisher does not give warranty as to the completeness or accuracy of its content. The publisher and the editor cannot accept responsibility for any loss inconvenience & damage that may occur there from.

04

Best regards Goodwill Sibanda .africamininginsight.co.za

CONTENTS www.africamininginsight.co.za 05 DEALING WITH FIRE RISK IN A MINING ENVIRONMENT PAGE 06 Safe and simultaneous tensioning p42 Accurate GNSS Data Collection p40 SA Tube & Honing Screening Division p25 Reducing Fuels Bills, Equipment Downtime p16 SOLVING THE CHALLENGES OF MINING COMMUNICATIONS PAGE 07 A.N. SOLUTIONS ENABLES SMART MINING APPLICATIONS PAGE 10 THE SAFE AND CLEAN DIRECT IN-LINE PUMPING SYSTEM PAGE 12 VARIANT MINING TECHNOLOGIES PAGE 14 PAGE 16 SWEEPER PRODUCT DEVELOPMENT PAGE 18 SEPURA'S VHF TETRA SOLUTION IMPROVES SITE SAFETY FOR MINING ORGANISATIONS PAGE 20 TOMRA SORTING MINING BREAKS NEW GROUND WITH UNIQUE XRT PAGE 22 SA TUBE & HONING SCREENING DIVISIONPAGE 25 TECHNOFAST HYDRAULIC HEAD NUTS PAGE 26 TRACKS AND DRIVE SPROCKETS FOR MINING PAGE 30 LUBRICATION SOLUTIONS TO WEAR RATE REDUCTION PAGE 32 ROYAL IHC'S EXPERTISE INVALUABLE FOR WATER MANAGEMENT IN DREDGE MININGPAGE 34 LIBS CHEMICAL SENSING APPLICATIONS IN THE MINING AND MINERALS INDUSTRY PAGE 36 ACCURATE GNSS DATA COLLECTION PAGE 40 SAFE AND SIMULTANEOUS TENSIONING PAGE 42 REDUCING FUELS BILLS AND EQUIPMENT DOWNTIME

Solving the challenges of mining communications

Modern mine operators are increasingly recognizing the need for technologically advanced communica�on systems for both worker safety and opera�onal efficiency Keeping workers connected and informed is key to a safe and efficient workplace and communica�ons play a vital role in ensuring opera�onal coordina�on.

We have asked Regional Director Carsten Laursen and Regional Sales Director Stuart Will from DAMM Cellular Systems how their communica�on solu�ons conform to these requirements.

Fail-safe voice and data communica�ons

Why should mining companies consider a DAMM radio communica�on solu�on?

“DAMM fully understands the cri�cal importance of fail-safe voice and data communica�ons. We specialise in providing equipment perfectly suited to the remote, harsh environments and severe working condi�ons of mining opera�ons. Our solu�ons provide crucial communica�ons integra�on between the mining site, rail and port opera�ons and centralised administra�on, enhancing both efficiency and the safety of personnel,” says Carsten. When communica�on systems fail, mining companies have to stop opera�ons, which costs millions a day. The decentralized architecture of the DAMM system combined with a fully redundant setup prevent down�me, even if the network is hit by lightning.

Along with high availability, DAMM's system includes a wide range of other safetyenhancing features, including clear voice quality even in noisy environments, emergency calls, man-down func�onality, geo-loca�on services, mul�ple pre-emp�ve calls, broadcast messaging alerts and direct alarm dispatch to emergency units.

How are DAMM's products specifically useful for the mining sector?

“Our IP65-protected outdoor base sta�ons are built for remote areas, harsh

environments from high heat and dust to rain and low temperatures. Their compact design and low weight make them easy to mount directly in masts, providing coverage for the en�re mining site. In addi�on, their design

Mining-Tech

07

www.africamininginsight.co.za

Easy to deploy, move and maintain

Carsten Laursen Regional Director

makes them suitable for portable deployment, e.g. on trailers that can be moved to adapt to changing mining loca�ons or along haul roads. Thanks to the simple and self-configuring setup, you can quickly and seamlessly expand your system when needed,” Stuart explains.

Breakthrough TCO and proven success

What makes DAMM's products especially suitable for the African region?

“Not only are our products built for harsh environments and for improving opera�onal efficiency and safety. We are commi�ed to offering solu�ons that ensure low CAPEX and OPEX. One of the key features of our outdoor base sta�ons is their cost efficiency. The low power consump�on saves on electricity costs and even allows a completely solar-powered solu�on providing portability saving costs every day

In addi�on, the base sta�ons are designed with passive cooling, which means there is no addi�onal cooling systems requiring a power source, maintenance, or repair – indeed low maintenance is a key trait of our products. Our system is not only cost-efficient when it comes to purchasing and opera�ng it. Due to the high reliability, you are also guaranteed a minimum of costly down�me with opera�ons coming to a stands�ll,” says Carsten.

Stuart adds, “We have many years of experience in providing costeffec�ve solu�ons to major players within the mining industry around the world and have delivered systems for huge opera�ons run by Rio Tinto, BHP, Glencore and Fortescue Metals Group (Australia), New Gold (Canada) and BUMA (Indonesia) to name but a few. We therefore have the know-how and the exper�se needed to support similar large-scale opera�ons in Africa.”

About DAMM

With its nearly 40 years in the industry, DAMM is a well-established name within TETRA radio communica�on and has built up extensive experience in delivering products that can endure the harsh environments that characterise the mining industry. DAMM's TetraFlex® solu�on is 100% IP-based and comes with complete outdoor and/or indoor base sta�ons and comprehensive features as well as integrated so�ware such as network management, voice and data recording and full dispatch applica�ons.

To learn more about our products and solu�ons and how we can help you, please contact Carsten Laursen Regional Director cl@damm.dk

Stuart Will Regional Sales Director sw@damm.dk

www.africamininginsight.co.za

08

Stuart Will Regional Sales Director

Solving the challenges of mining communica�ons

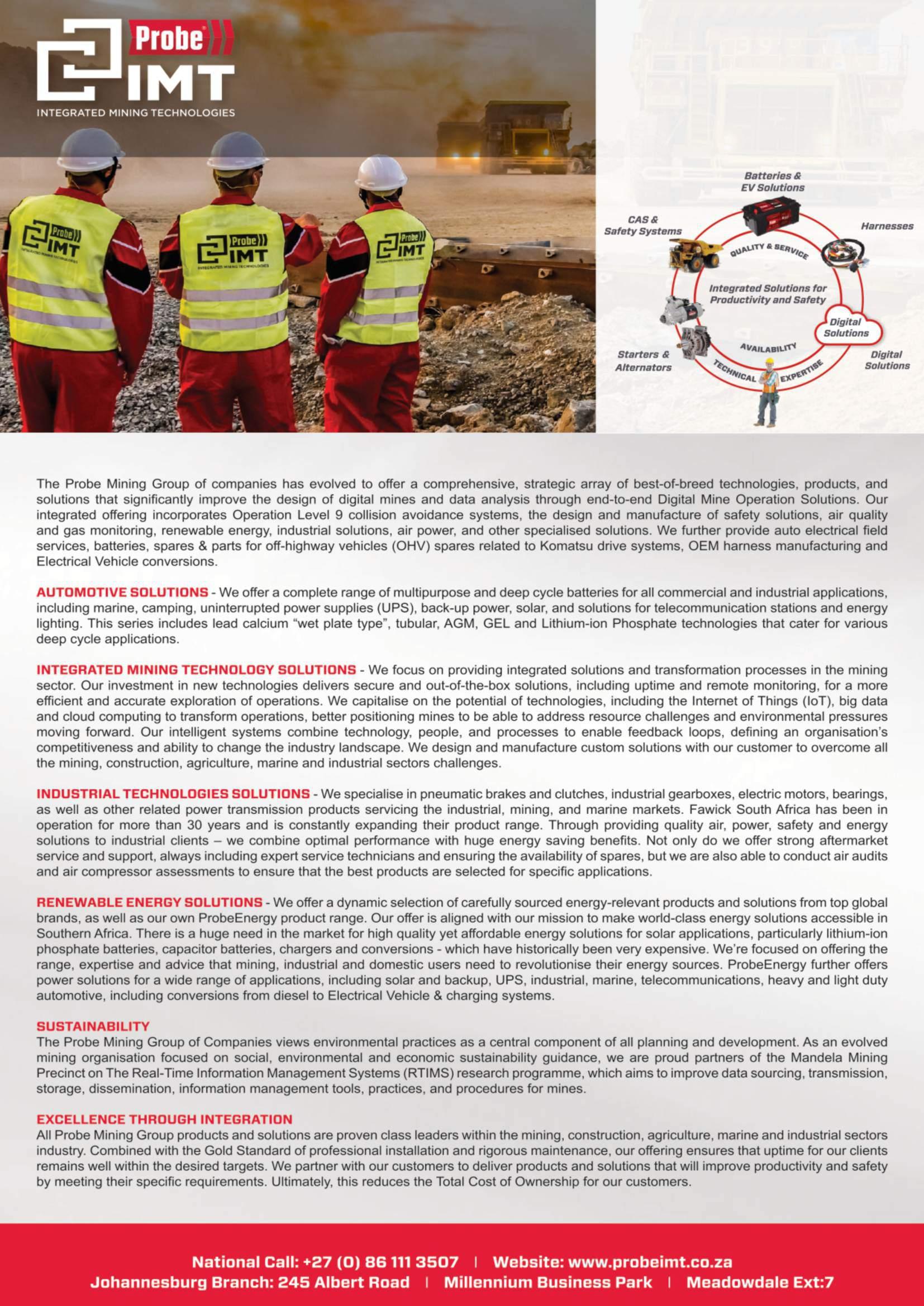

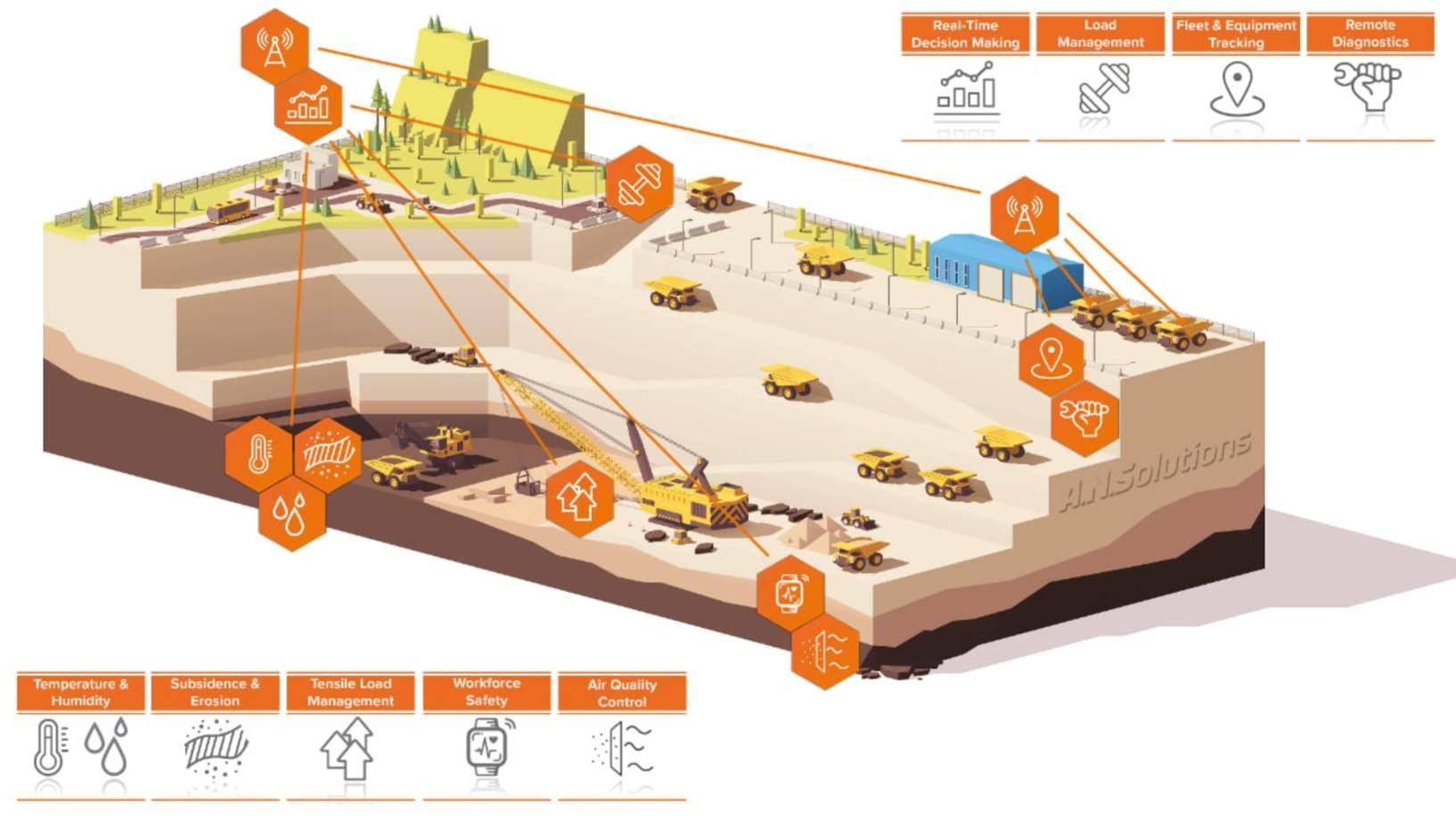

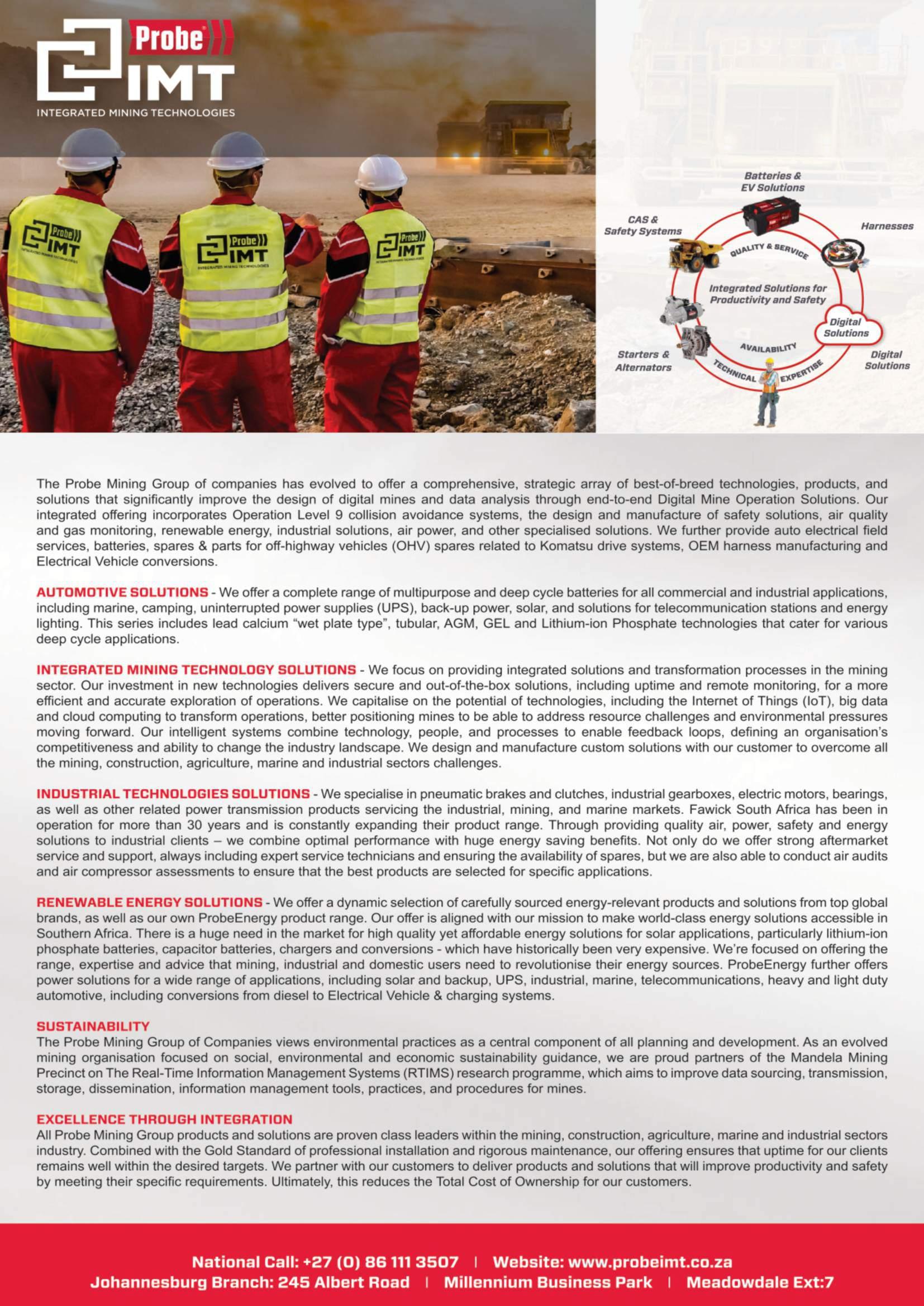

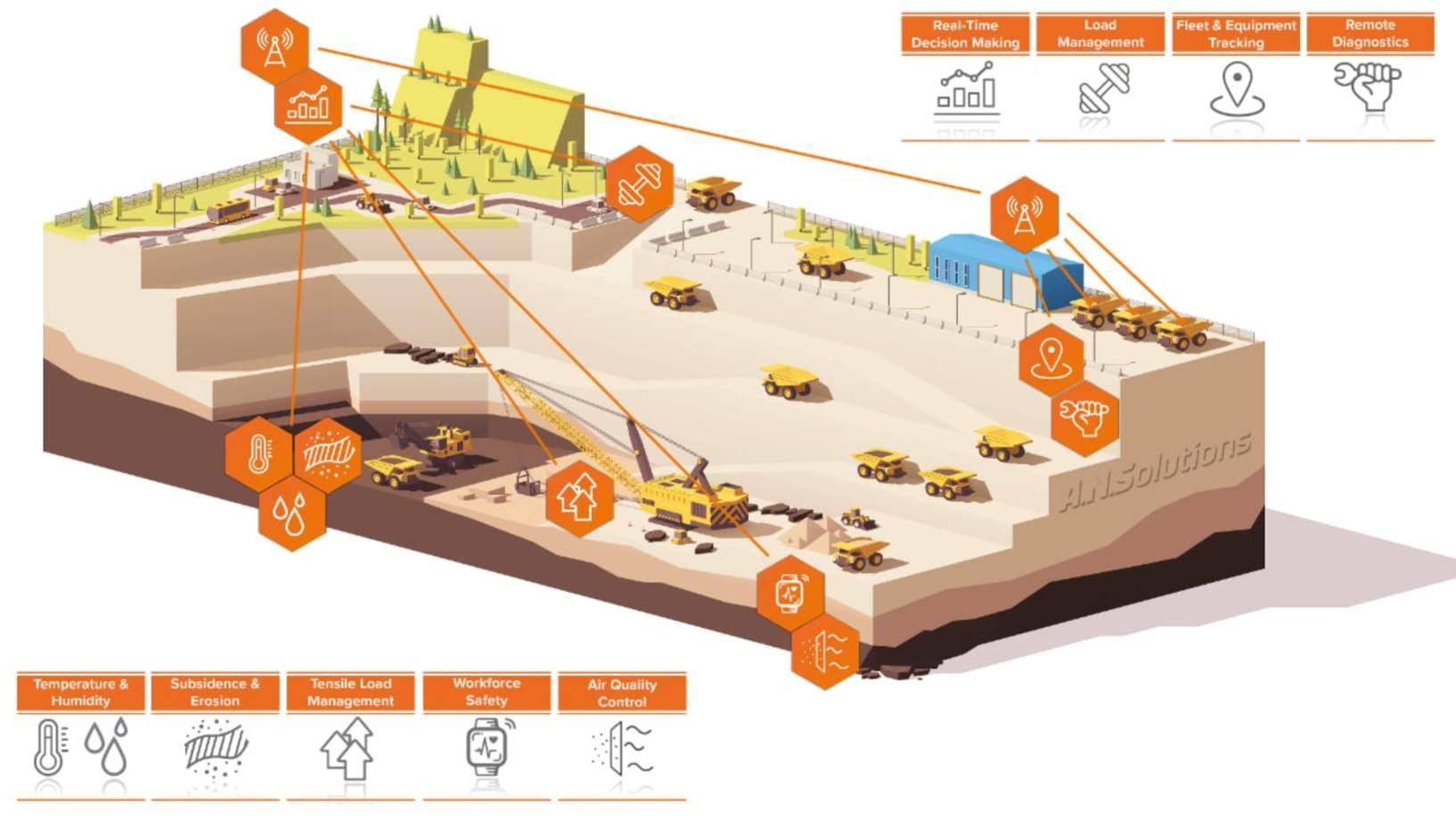

A.N. Solutions Enables Smart Mining Applications with Reliable Wireless Connectivity

Smart Sensors Improve Efficiency and Cut Costs

The mining industry has come a long way from pickaxes and shovels to sophis�cated machines and tools. Yet another revolu�on is sweeping the industry. Powered by wireless sensor technology, the Internet of Things (IoT) brings connec�vity to every piece of equipment in the field while offering significant benefits, from enhanced safety to cost reduc�on and increased efficiency. Whether it's an underground or a surface mine, the miners' safety is of paramount importance. Methane gas buildup may cause an explosion. Contaminated dust and vola�le organic compounds (VOCs) are toxic and pose a significant health hazard. Machine operator's fa�gue can cause an accident. By keeping a watchful eye on air quality and worker's vital signs, wireless sensor devices spring into ac�on when cri�cal condi�ons are detected. They help prevent accidents and

save lives 24/7.

Mining opera�ons require a lot of sophis�cated tools and equipment. Open-pit mining requires a fleet of dump trucks and earth-moving equipment. Every mechanical failure results in costly down�me and may affect many other links in the produc�on chain, snowballing the losses. Smart connec�vity allows a company to diagnose each vehicle's health remotely, and schedule maintenance proac�vely. Vehicle usage can be op�mized by tracking and analyzing its performance.

Ground subsidence and erosion are extremely dangerous while being everpresent in open-cast mining. By detec�ng minute shi�s, �lt sensors monitor ground subsidence and provide advance warning. It is also important that the dump trucks do not get overloaded. Wheel load scales help ensure that the truck load is within the acceptable range. Fi�ed with radio

transmi�ers, they relay real-�me data to the opera�ons control center

How Sensor Network Operates

Mines use a wide variety of sensors that measure all kinds of parameters, from temperature and humidity to �lt and accelera�on. However, all this valuable sensor data needs to be harvested and transmi�ed, o�en in real-�me, so that it can be analyzed and visualized, and ac�ons can be taken in a �mely manner. Wireless technologies hold the key to solving this challenge.

Each sensor node is equipped with a �ny radio transceiver and antenna. An embedded microcontroller is its “brains.” So�ware determines the mode of opera�on of a sensor node and the frequency of data transmission. A sensor node can serve as a pure monitoring device or when equipped by an actuator, will perform a control func�on.

Mining-Tech 10 www.africamininginsight.co.za

Ba�ery-powered sensor nodes can operate autonomously for years and are easily fi�ed even into the most hard-to-reach loca�ons. They offer the ul�mate flexibility in the network configura�on.

and A.N. Solu�ons has mastered different ba�ery technologies, including industrialgrade rechargeable cells, and more.

Many mines have wired or wireless legacy systems in place. Replacing them completely is prohibi�vely expensive. A.N. Solu�ons' experts will be able to seamlessly integrate a new wireless network with the legacy system, and combine the data collected. A.N. Solu�ons offers comprehensive expert services for every stage of wireless product development - from a thorough review of the current architecture and the need assessment to mapping out a migra�on plan and crea�ng a proof of concept. Combining in-depth knowledge of wireless protocols, such as IEEE 802.15.4/Zigbee, 6LowPAN, and LoRa, and their compa�bility, with all aspects of connec�vity and device management, network security, and sensor data acquisi�on, A.N. Solu�ons experts will provide step-by-step guidance.

with Reliable

● Extensive partner ecosystem of industry leading vendors and service providers, incl. Bosch Sensortec, Microchip, Nordic, Qorvo, Sensirion, and more;

● Flexible engagement op�ons and support packages;

● Uncompromising “Made in Germany” quality

Explore our IoT solu�ons and contact our engineers at www.an-solu�ons.de

Thomas Lerm, Founder & CEO thomas.lerm@an-solutions.de

Tel: +49 351 30900 195

The advantages of working with A.N. Solu�ons are many:

● In-depth exper�se in all facets of IoT design;

● Its own product line of rugged IoT components;

● Rapid prototyping using 3D modeling;

● Safety and compliance cer�fica�on assistance;

Wireless Solu�ons that Work Reliably A.N. Solu�ons specializes in developing reliable and rugged wireless sensing solu�ons that work in the environments that are most “unfriendly” to a radio signal, from trains to industrial equipment to mines. A.N. Solu�ons has been building ATEX compliant solu�ons and designs capable of opera�ng in the -85°C to 145°C temperature range, which far exceeds IP67 requirements. With a large por�olio of reference designs from different industries, A.N. Solu�ons can create a futureproof system quickly and cost-effec�vely The recent prolifera�on of wireless standards makes it difficult to select the one that best fits the applica�on. A.N. Solu�ons will help you select the wireless protocols and components spanning 169MHz up to 5.2GHz radio spectrum to achieve an op�mum range vs. signal strength, ba�ery life, and important characteris�cs, according to your requirements. So�ware fine-tuning is important for a secure and efficient sensor data acquisi�on and storage process, as well as ba�ery life. Antenna design is a cri�cal factor for reliable data transmission. Long ba�ery life is the key to smooth opera�ons, www.africamininginsight.co.za

Connec�vity

A.N. Solu�ons Enables Smart Mining Applica�ons

Wireless

11

The safe and clean Direct In-line Pumping System for economic & environmental wastewater lift stations

Mining- Pumps

12 www.africamininginsight.co.za

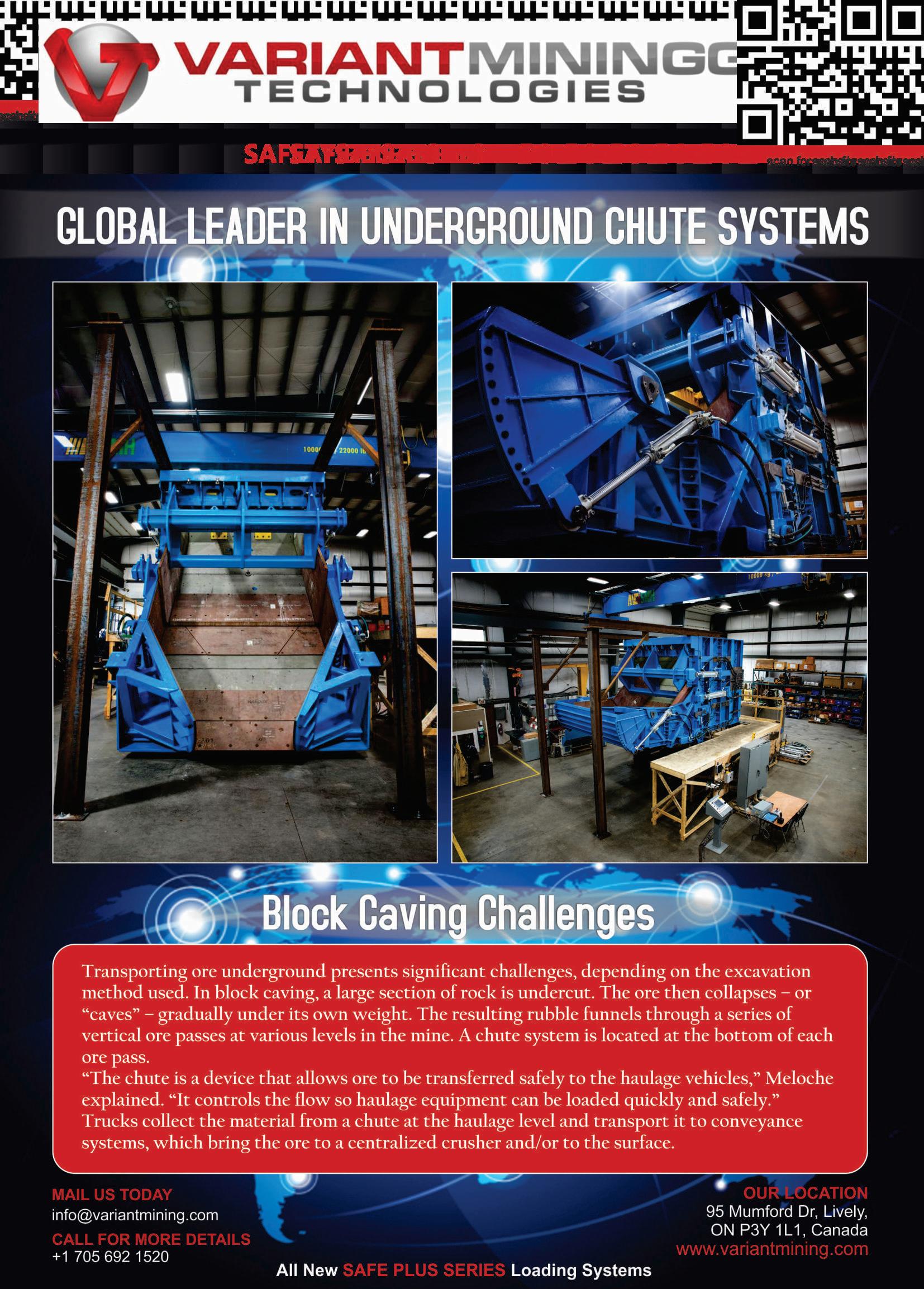

Variant Mining Technologies

SAFETY RELIABILITY ACCURACY

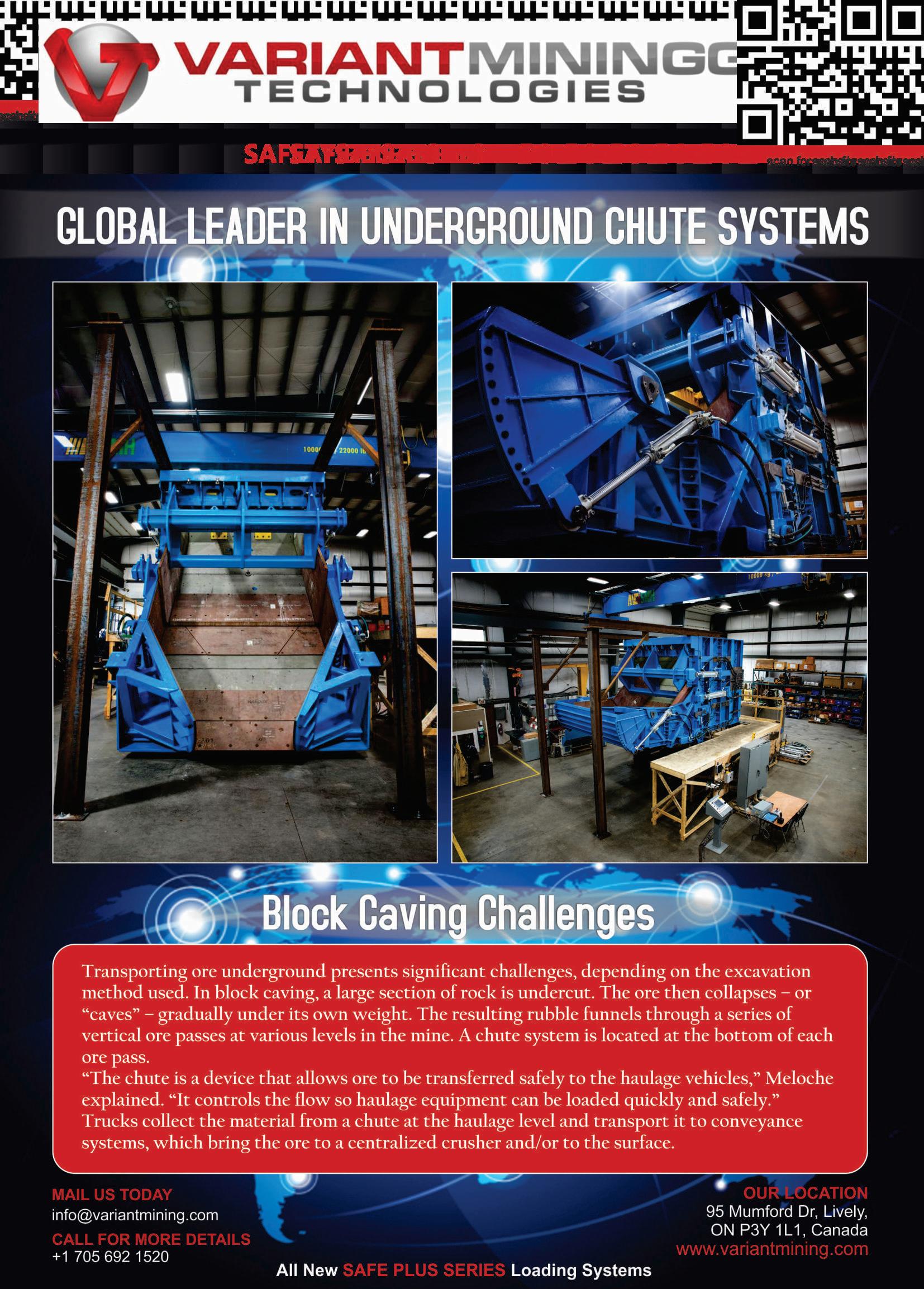

First-of-its-kind ore handling solu�on puts safety first

Mining companies are digging deeper than ever to maximize output, what starts as an open-pit mine ofen extends underground. “As mines get deeper, extrac�on of aluable ore becomes more costly,” said Derek Meloche, manager of business development, Variant Mining Technologies. “In addi�on, safeguarding personnel from underground hazards is a cri� al concern.”

Located in the Sudbury basin in Ontario, Canada, Variant Mining Technologies specialize in solu�ons or underground hard rock mining. The company works to solve one of the industry's biggest challenges – moving material underground safely and efficiently

Block Caving Challenges

Transpor�ng oe underground presents significant challenges, depending on the excava�on m thod used. In block caving, a large sec�on of ock is undercut. The ore then collapses – or “caves” – gradually under its own weight. The resul�ng rubble funnels through a series of ver� al ore passes at various levels in the mine. A chute system is located at the botom of each ore pass.

“The chute is a device that allows ore to be transferred safely to the haulage vehicles,” Meloche explained. “It controls the flow so haulage equipment can be loaded quickly and safely”

Trucks collect the material from a chute at the haulage level and transport it to conveyance systems, which bring the ore to a centralized crusher and/or to the surface.

Safety First

We are focused on crea�ng a producte mining environment that mi� ates and eliminates risk – and is an a�racte place to work. Tradi�onall, underground ore chute systems have been viewed as steel fabrica�ons, with ery limited control. However, Variant brings control technology to the forefront to help make equipment safer, more efficient, and more reliable.

A Two-Fold Control Solu�on

Successful opera�on of the oe loading system depends on the coordinated control of the ore chutes and haulage vehicles. Variant is charged with supplying the ore chutes – and a safety control system that meets func�onal s fety requirements. To achieve a func�onally s fe system, in this case a system that meets SIL 3 ra�ngs, the design considered the process that encompasses the bin, chutes and trucks.

The control system is built on platorm Featuring, designs that eliminate hazards, safety-rated controllers, and HMI interfaces. The system is designed with a controller and HMI in each chute and aboard each truck. For fail-safe communica�on, the i tegrated system uses safety-rated protocols running on an Ethernet wireless network.

Enabling Smart Technology

To op�mie the system, Variant incorporated several technologies that are not new in other industries but new to underground mining. For example, the vehicle detec�on system in the chute loading area detects a truck's presence and posi�on – while RFID technology determines the vehicle model and type.

“This technology allows operators in the truck cabs to control the chutes in a safer manner,” Meloche said. “The chute will not operate unless a haulage truck is present and in the correct posi�on. Jeeps or other ehicle types cannot trigger opera�on” The system also includes fallen object protec�on. A ate at the end of the chute contains any loose rocks from the previous load to help safeguard approaching vehicles and personnel. “And our system monitors the ore bins associated with each chute to make sure they don't run empty,” Meloche said. “We keep material in the bins at all �mes o serve as a buffer – so ore falling 150 feet doesn't come out of the chute like a rocket.”

Exceeding Expecta�ons

Our Team of Cer�fied Machine fety Experts CMSE™ design ore handling systems that improve operator safety while op�mizing mine throughput. Variant an�cip tes the system will enable significantly beeer traffic control and equipment u�liaa�on than other systems on the market. “Overall, mining companies are most concerned about safety – and produc�vit,” said Meloche. “Our safety-rated SIL 3 system is designed to improve both.” This truck loading control system is currently patent pending.

14

www.africamininginsight.co.za

Mining-Solution

Reducing Fuels Bills and Equipment Downtime with ECOCLEAN Fuel Additive Technology

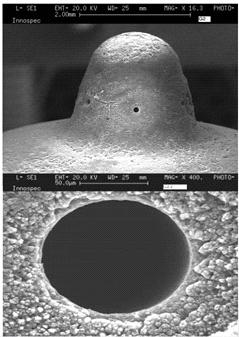

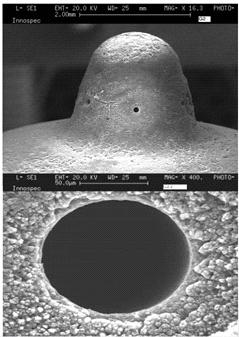

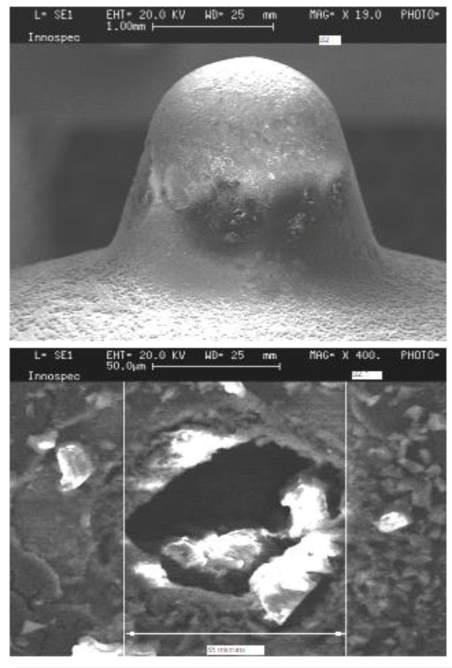

The heavy-duty diesel engines typically used in today's mining industry are complex machines that generate high temperatures and pressures. When paired with basic untreated diesel, mine operators o�en experience a range of issues with their equipment, ranging from loss of power and poor fuel economy, to difficul�es in star�ng, rough running, increased exhaust emissions and unexpected repair costs. The problem is that basic untreated diesel fuels become thermally stressed and unstable in these type of engines. This causes fuel to break down and create a black soot-like material. These deposits quickly accumulate in the fuel

system resul�ng in injector failures, filter plugging, loss of power, poor fuel economy and premature wear

Under these condi�ons, carefully engineered engine components may no longer work as intended and the fuel is not atomized correctly Deposits le� on injector nozzles lead to loss of power and increased fuel consump�on. Deposits on the inside of the injectors create difficul�es with engine star�ng and running. These deposits also get returned to the saddle tank via the return fuel line. This circulates dirty fuel throughout the fuel system, causing

www.africamininginsight.co.za

premature fuel filter plugging. Innospec was the first company to develop and patent ECOCLEAN® fuel addi�ve technology

This high-performance diesel fuel addi�ve can improve fuel economy, minimise equipment down�me and cut emissions. It has been specifically designed to meet the demands of diesel engines in heavy-duty mining equipment.

The ECOCLEAN® range works by stabilising diesel fuel so it can withstand the extreme temperatures and pressures of today's fuel injec�on systems. Advanced diesel detergents

Mining-Tech 16

®

and an�foulants create a powerful formula that is effec�ve at removing and preven�ng deposits on both the injector �ps and inside the injectors. It cleans the fuel system and returns an engine to an 'as new' condi�on, preven�ng injector failure.

The benefits of using ECOCLEAN® products can be summarised in improved fuel economy, lower fuel bills, smooth reliable running, less chance of equipment failure and down�me, less maintenance costs, and reduced emissions.

Over the years we have conducted numerous field trials to demonstrate how ECOCLEAN® performs in real-world applica�ons. As well as working in partnership with mul�ple mines all over the world, we have assisted large trucking companies in the US, Mexico, Brazil, Europe, and Asia.

These trials confirm that using ECOCLEAN® results in an improvement in fuel economy by 5% or more, enhanced maintenance cycles and reduced equipment down�me by up to 50%. The trials also demonstrate an 18% reduc�on in vehicular CO emissions, alongside a 39% drop in par�culate ma�er output. Contact us for more informa�on on the specific results of our field trials and to discuss how we can create the best fuel treatment for your mining applica�on.

Innospec is a global specialty chemical company and the largest dedicated fuel treatment company in the world. We are the market leader in fuel addi�ve technology. As a business, we are commi�ed to developing fuel addi�ves geared to the specific requirements of our customers. That is why we work in partnership with the major oil companies, refineries, industry bodies and leading OEMs to help solve the issues facing fuel distributors, fleet operators and the end-users of fuel. Through our offices in Africa and partnerships with the major mine operators, we have developed an in-depth understanding of the region's mining sector and the necessary exper�se to help customers reduce opera�ng costs and increase efficiency across all types of mining applica�ons.

Please contact mining-fuel@innospecinc.com

www.africamininginsight.co.za

technology

Reducing fuels bills and equipment down�me with ECOCLEAN® fuel addi�ve

17

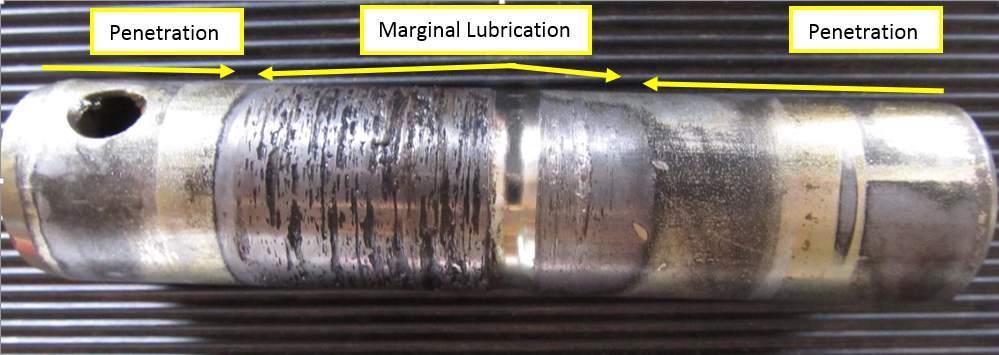

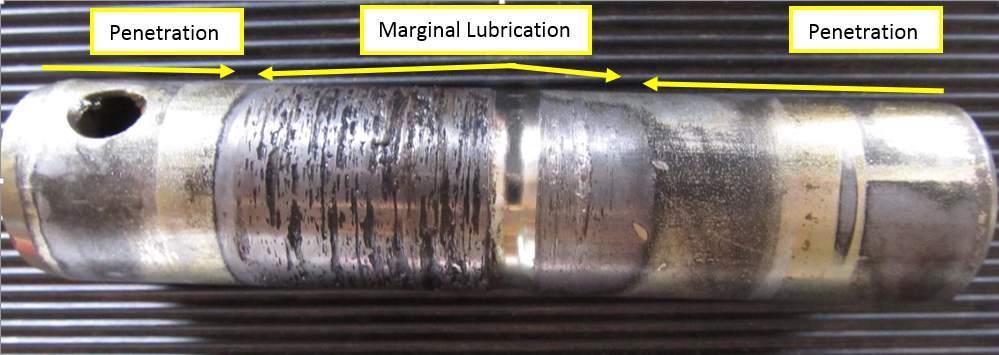

Injector

Removing and preven�ng deposits on both the injector �ps and inside the injectors Injector spray penetration without ECOCLEAN® Injector spray penetration with ECOCLEAN® All images are copyright Innospec 2022

Injector nozzle without ECOCLEAN®

nozzle with ECOCLEAN®

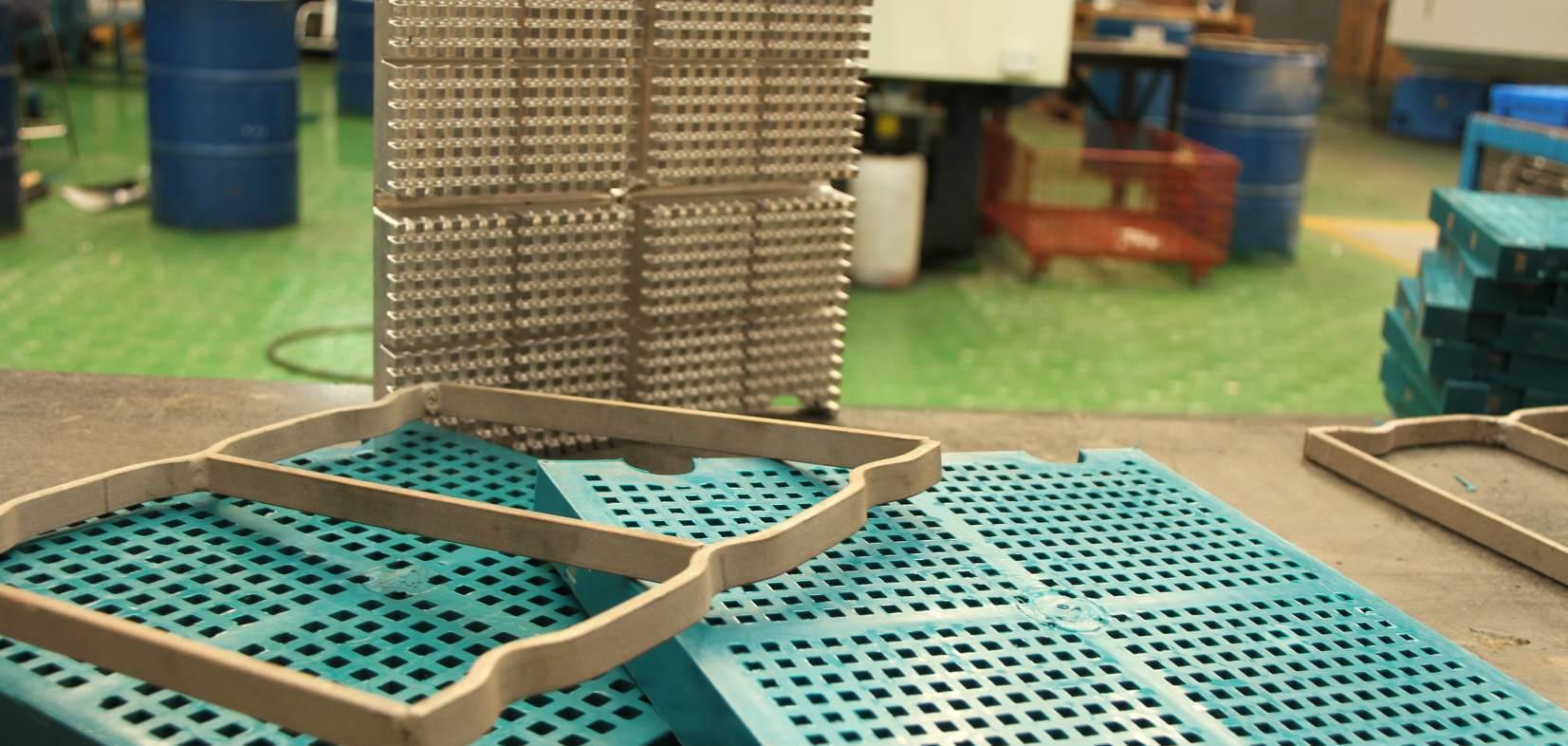

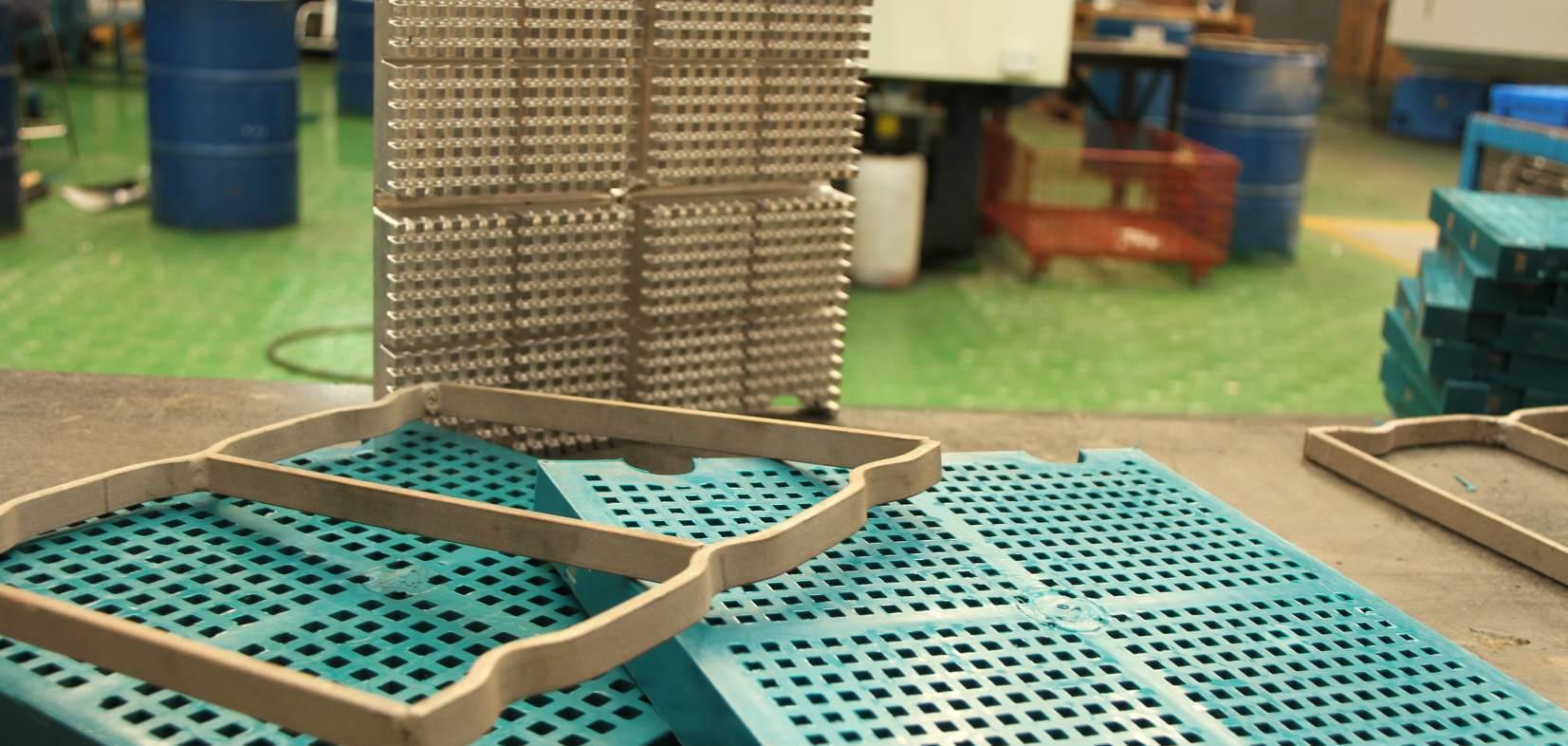

SA Tube & Honing Screening Division

SA Tube and Honing Screening Division is a specialized manufacturer and supplier of screening surfaces and accessories and is part of the SA Tube and Honing Group of companies situated in Wadeville, Germiston. We have been manufacturing and supplying a full range of modular injec�on moulded polyurethane and rubber screen panels to local and interna�onal Mining and Aggregate markets since 2018. We offer a large range of aperture configura�ons to suit any screening applica�on in the industry. We have access to a state of the art engineering facility within the SA Tube Group of Companies that offers us flexibility in design and allows us to manufacture any special aperture requirements in a very short turnaround �me. Our modular polyurethane and rubber screen media range from 0.3mm Aperture to 110mm Aperture in various thicknesses, shore hardness's and fixing methods. In 2019 SA Tube and Honing Screening Division started the process of expanding its product range to include woven wire screens

for the Mining and Quarrying Industries. We started introducing our woven wire screens into the market in July 2020 and since the have shown incredible growth month on month. We are able to weave wire diameters from 0.9mm up to 12.5mm, with aperture sizes up to 200mm in various configura�ons. SA Tube and Honing Screening Division understands the challenges faced in today's tough mining and economic climate, and acknowledge that for any opera�on to remain profitable and sustainable, we need to look at ways of reducing opera�onal costs without nega�vely impac�ng on the mining processes involved. Our team has spent a lot of �me focusing on the work at hand and fully understand our purpose to add value and reduce costs for our customers. We have invested extensively in the latest equipment over the last 18 months and systems have been put into place to ensure that our exis�ng quality management systems cer�fica�on will be applied across our total range of services and products

supplied to the mining and aggregate markets.

The SA Tube and Honing Screening Team has more than 100 years of collec�ve industry experience in the design, manufacture, supply and commissioning of various screen media. We are ac�vely involved on a large scale with various Mining and Aggregate Houses and have built up an excellent reputa�on in the industry with regards to customer service and technical exper�se. Over the years we have 'added value' by introducing innova�ve screening media as well as impar�ng knowledge to improve through put, 'up �me' and reducing cost per tonne.

One of our main focus areas for 2023 is to increase our footprint both locally and interna�onally. Our dedicated and experienced team of technical sales professionals is standing by to assist with all your screening and opera�onal needs.

www.africamininginsight.co.za 25 Mining- Solutions

Technofast hydraulic head nuts provide faster and safer liner changes for gyratory ore crushers

Gyratory crushers handle some of the toughest ore and materials, and are therefore subject to rapid deteriora�on from abrasion, which means their internal wearing components need to be replaced regularly In order to change the mantle, which can happen as frequently as every 10 days in

harsher environments, the retaining “head nut” has to be unfastened to allow removal of the worn component – a process previously done in a �me-consuming and poten�ally hazardous way

“The mantles are usually secured with standard nuts, which are o�en installed with

26

Mining-Tech

www.africamininginsight.co.za

hydraulic jacking hammers or flogging spanners, and removed by oxy cu�ng the burn ring below the nut to release the excessive force, which generally builds up during opera�on of the crusher,” explains Technofast Technical Solu�ons Manager, Ma� Blundell.

Technofast's EziTite Hydraulic Head Nut being installed on a gyratory crusher

“This method is not only physically demanding, but the cu�ng of the burn ring can be hazardous, and requires replacement a�er each use. Addi�onally, bolt load cannot be measured accurately,” he said.

A faster, safer method

To address the issues mining and quarrying opera�ons were having with crusher mantle and liner changes, Technofast developed its ® EziTite Hydraulic Head Nut, which has received an Australian Manufacturing Growth Centre grant, to commercialise the technology in Australia.

The EziTite Hydraulic Head Nut provides precise clamping forces generated by hydraulic pressure ac�ng on a constrained area within the assembly. It is fi�ed with mul�ple in-built locking screws to retain these tensile loads a�er the hydraulic pressure is released.

“The old method used to take five or six personnel approximately five hours to complete the mantle change, which is a big chunk of down�me. With the EziTite Head Nut in place, the same job can be done in under an hour, with only two or three personnel. It really adds up when you consider that when they aren't crushing, they aren't making money,” says Ma�.

The EziTite Head Nut is �ghtened using hydraulic force supplied through a pump, which means minimal physical effort is required and extremely accurate and even bolt loads can be achieved.

A maintenance supervisor for a the gold mine that implemented the Technofast EziTite Head Nut technology commented on its safety and �me-saving features, saying “The EziTite Head Nut has made the job a lot easier labour-wise, faster, and also has eliminated any OH&S concerns by ge�ng away from using our jacking ram for the installa�on of Head Nuts. Using a hydraulic pump to achieve the load is also a nobrainer”

How it works

1. The EziTite Hydraulic Head Nut assembly is screwed by hand onto the crusher sha� (replacing the original nut) un�l the base is �ght against the working face of the mantle.

2. Hydraulic pressure is then applied through the nipple fi�ng on top of the nut body into the sealed chamber, forcing the piston and the nut body apart, thus sea�ng the mantle on to the machine's taper.

3. The force generated by the hydraulics is maintained by an array of locking screws which are �ghtened to take the load. The hydraulic pressure is relieved and the Sacrificial Cover which protects the mechanism against abrasion and corrosion can be easily fi�ed.

4. When it is �me to remove the EziTite Hydraulic Head Nut, the installa�on procedure is reversed and the nut is removed by hand elimina�ng the need for large

hammers and flame cu�ng of the burn ring, dras�cally reducing maintenance �me and improving site safety

5. In the unlikely situa�on that there is a hydraulic malfunc�on, the lockscrews can be released manually, and the assembly unscrewed by hand.

“The EziTite Head Nut reduces machine down�me and increases opera�onal safety for workers. It is designed to work with all major brands of gyratory crusher, and the protec�ve cover can be customised to suit the abrasiveness of the material being crushed,” says Ma�.

www.technofast.com

Industries is a worldwide leader and specialist in Bolt Tensioning, providing innovative and effective technical solutions along with uncompromising customer service.

About Technofast Technofast

A large diameter EziTite Head Nut at Technofast's warehouse in Queensland, as it is prepared for dispatch to a mining customer

27

Technofast hydraulic head nuts provide faster and safer liner changes for gyratory ore crushers

www.africamininginsight.co.za

Tracks and drive sprockets for mining

Synergy Undercarriage Components supplies high quality, market leading tracks and drive sprockets for most popular mining size hydraulic excavators and electric rope shovels to end users throughout Australia, the Asia / Pacific region and Africa. Our strategic partnerships with blue chip mining contractors and companies over the years has afforded us the opportunity to develop a broad range of designs, materials and

processes to provide unique, cost effec�ve solu�ons that are applica�on specific –whether it's hard rock copper and gold, coking and thermal coal or iron ore. We understand no two ore bodies are the same and that opera�ng condi�ons can vary greatly - which a standard design & material from an OEM may not stand up to.

Our unique, long standing and technology driven partnership with our manufacturer,

who has been manufacturing steel cas�ngs for over 80 years, enables us to provide quality solu�on based, differen�ated products.

All Synergy Undercarriage tracks and drive sprockets are manufactured in superior grade quench and tempered alloy steels then induc�on hardened on the high wearing surfaces u�lising state of the art, purpose designed and built equipment. Hardness

Mining- Solutions

30

www.africamininginsight.co.za

www.africamininginsight.co.za 31

levels of the wear surfaces are matched to the ma�ng components

that is able to provide significant impact resistance. Our capabili�es: · Computer-aided engineering, design and manufacture · FEA · Virtual prototyping / CNC pa�ern making · Solidifica�on simula�on · Concurrent engineering · Fast track prototyping · CMM dimensional verifica�on · In-house mechanical tes�ng · On site prototype tes�ng and monitoring

Tracks and drive sprockets for mining

whilst ensuring a duc�le core

Lubrication Solutions to Wear Rate Reduction

By Chuck Strait

By Chuck Strait

Petron Corpora�on, located in New Berlin, Wisconsin, USA, has over 50 Years of experience manufacturing high performance lubricants focusing on surface mining, underground mining, and ore processing. Petron Corpora�on's specialty lubricants excel in lubrica�ng equipment such as Draglines, Electric/Hydraulic Shovels, Loaders, Haul Trucks, and any other mobile pit equipment, as well as Crushers and all types of Mills.

Let's face it

Mining Equipment is designed to have parts wear out while s�ll maintaining the machine integrity. While it is beneficial that high wear items can simply be replaced, it is also detrimental if these parts wear out too o�en. Early wear causes loss of up�me and throughput, which nega�vely impacts the company's bo�om line.

A classic example of this would be the pins and bushings used in almost all mining equipment. Petron Corpora�on has recognized that the tradi�onal lubrica�on techniques and products no longer provide the protec�on needed in modern mining

equipment owing to their ever-increasing demands.

Some historians call pin and bushing joints the first type of bearings. They have been around for thousands of years and were originally used in applica�ons such as rota�ng wheels on wooden axles. However, in today's mining world there are hundreds of machines that use various materials and configura�ons for their pins and bushings. Though material construc�on has changed from the original plain wood pins and bushings, providing a lubrica�ng film and elimina�ng contamina�on between the pin and bushing has not.

How is Petron Corpora�on different? Petron has pioneered the development of specific high viscosity lubricants that greatly reduce wear on slow moving gears, pins, and bushings. Tradi�onally, these applica�ons were lubricated with a Mul�-Purpose Grease with a soap addi�ve. This soap, much like a sponge, holds the base oil and addi�ves in suspension un�l sufficient force is applied to squeeze out the oil into the load zone. By their nature Mul�-Purpose Greases do not flow due to their high soap content.

Formula�ng our products with primarily heavy viscous oils, in many cases above 50,000 cSt, along with a light carrier oil, allows Petron lubricants to have the characteris�cs of a much lower “apparent” viscosity lubricant. This lower “apparent” viscosity lubricant will flow readily into a load zone, deposi�ng select addi�ves and high viscous oil molecules right where they are needed the most, while remaining viscous enough to eliminate the need for large amounts of soap to hold the oil in suspension.

This lubricant film then separates even the highest loaded surfaces, greatly reducing the possibility of contact wear, while the light carrier oil washes the would-be contamina�on out of the load zone and safely away

Wear reduc�on is the key

Today's mining equipment uses the most sophis�cated form of bronze pin bushings, and their ability to reduce wear is impressive. Even though bronze is extremely reliable and durable, it is s�ll designed to be a “wear” material. The purpose of wearing is to

Mining- Solutions

32 www.africamininginsight.co.za

reduce the damage to structural steel components. The bronze bushing is much less expensive to replace than something like the loader boom arm, and, therefore, it is used as a wear material to reduce damage to the other rota�ng components.

Typically, in these applica�ons there are two types of wear on pins and bushings:

A. Galling - is when excessive contamina�on builds up between the pin and the bushing surface and the load pressure forces the contamina�on into the bronze bushing.

B. Impact loading – is when a sudden impact is applied to the bushing surface greater than the lubricant film can withstand causing a rupture. If proper lubrica�on maintenance is prac�ced, the replacement and/or repair of pins and bushings can be greatly reduced. Most pins and bushings today have “lubricant grooves” on the inner diameter that aid in purging contamina�on from the bushing by forcing out unwanted materials while

As seen in the photo above, tradi�onal lubricants only penetrate a par�al distance from the end of the pin toward the load zone, leaving the heaviest loaded sec�on of the pin with marginal protec�on.

providing a film thickness for the pin to rotate on. These lubricant grooves can also capture contamina�on if the proper lubrica�on intervals are not maintained. Therefore, wear can occur if the bushings are not purged adequately The use of Petron Open Gear Lubricants on your pins and bushings will form the thickest lubricant film possible allowing most contaminants to remain suspended in the film un�l they are purged out. This very thick film will also cushion the blow of a sudden

impact keeping the surfaces apart greatly reducing the wear rate on those parts designed to “wear out.”

Petron Corpora�on is ac�vely seeking new distributors for Africa region. If you are interested in becoming a Petron Distributor, please contact Chandrasekar at rchandrasekar@petroncorp.com

For more informa�on about Petron Corpora�on's products or services, feel free to visit our website at or www.petroncorp.com email – info@petroncorp.com

www.africamininginsight.co.za

33

to Wear Rate Reduc�on

Lubrica�on Solu�ons

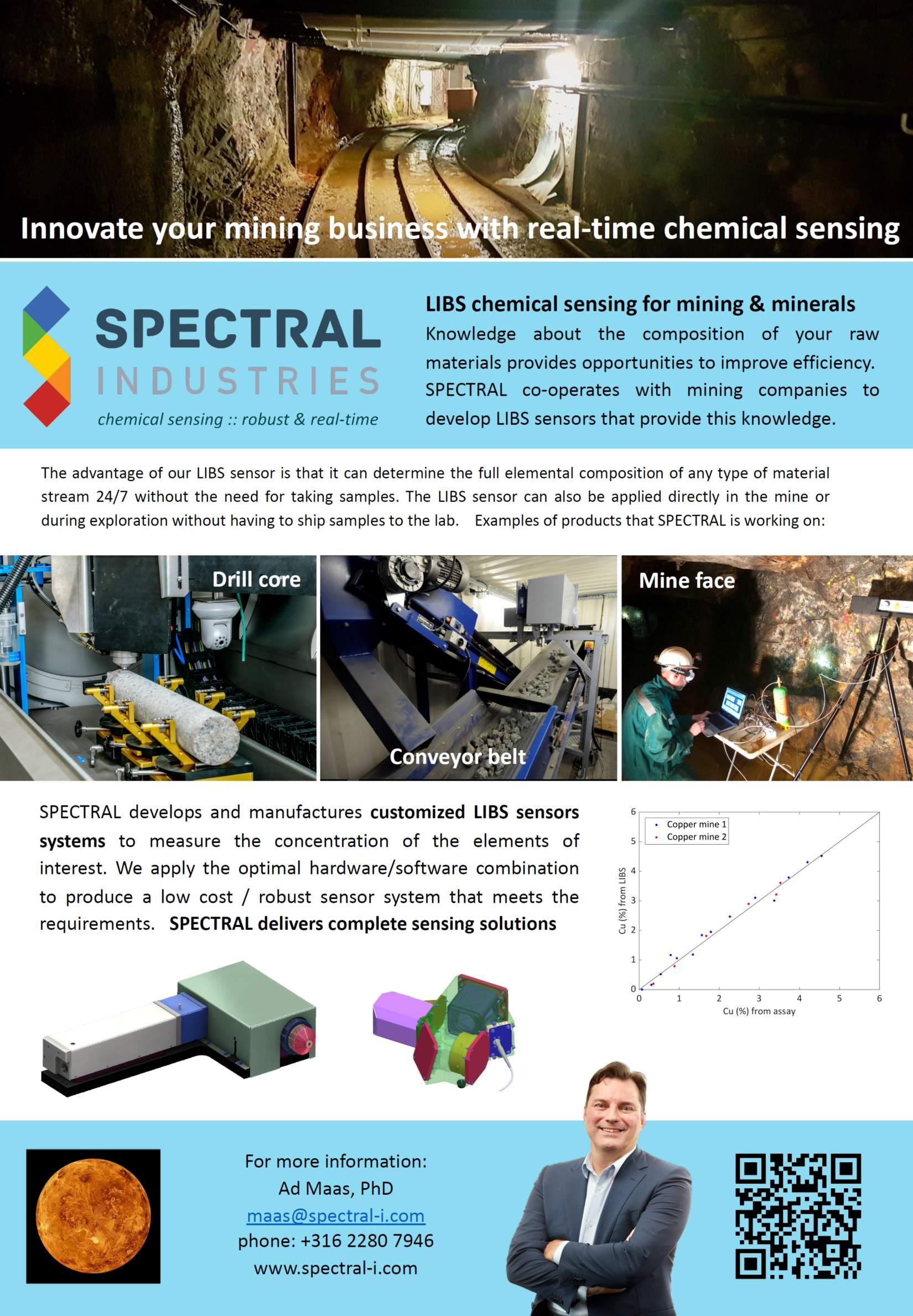

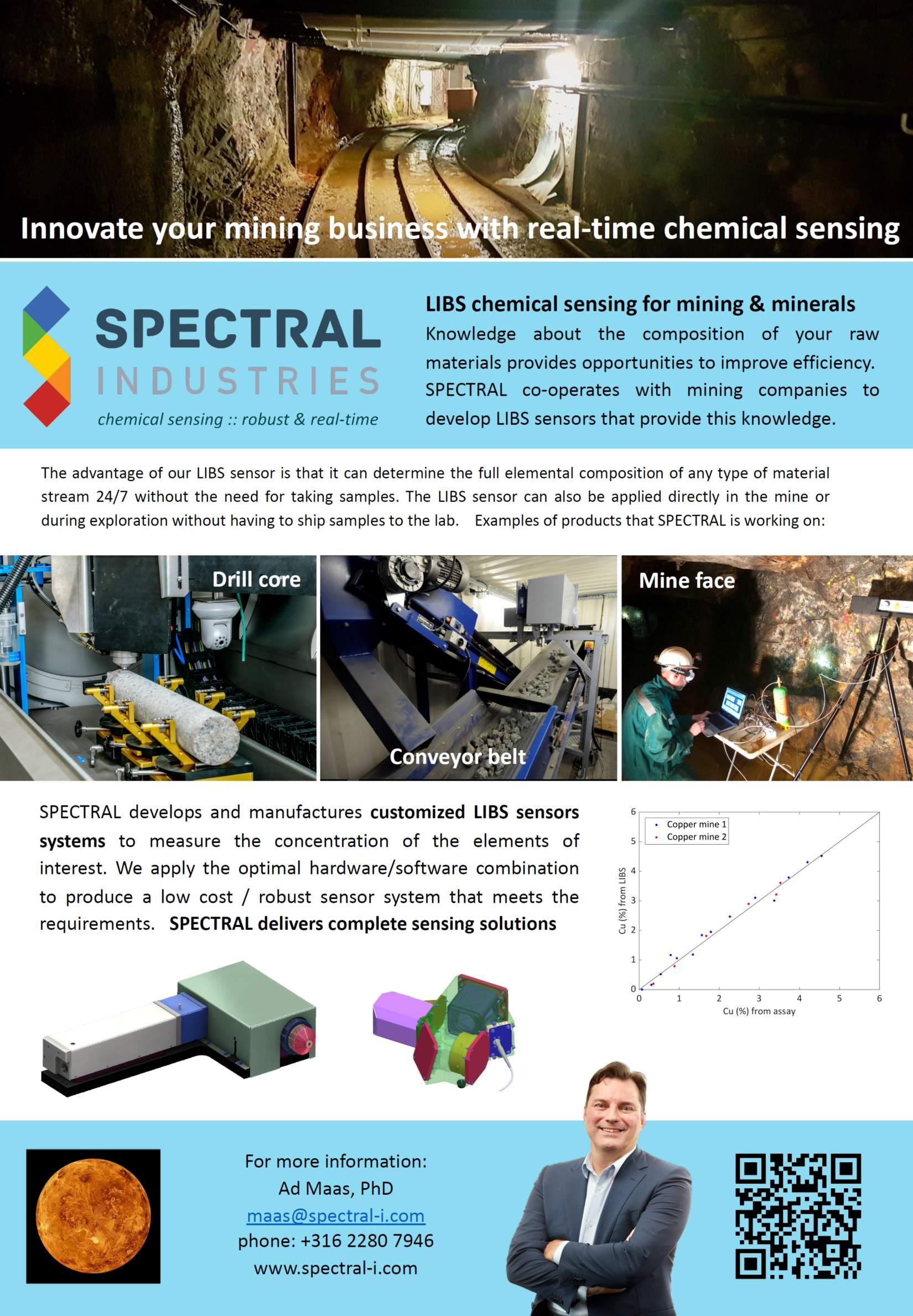

LIBS chemical sensing applications in the mining and minerals industry

The mining industry is faced with an increasing scarcityofnaturalresources.Atthesame�me, the global demand for resources keeps growing and the requirement to reduce the environmental footprint of mining becomes more important This creates the need to develop innova�ve solu�ons that increase the efficiency and sustainability of mining natural resources.

Miningopera�onsdealwithhugequan��esof excavated material with varying mineral concentra�ons and economic value. Increased knowledge about the composi�on of this material provides opportuni�es to improve decision making for stockpiling, sor�ng, and mineral processing However, no systems currentlyexistthatcanbeusedtomeasurethe chemical composi�on of large material quan��es in real-�me. LIBS chemical sensor technology provides a solu�on, because no sample prepara�on is required and measurements can be performed at rela�vely highspeeds.

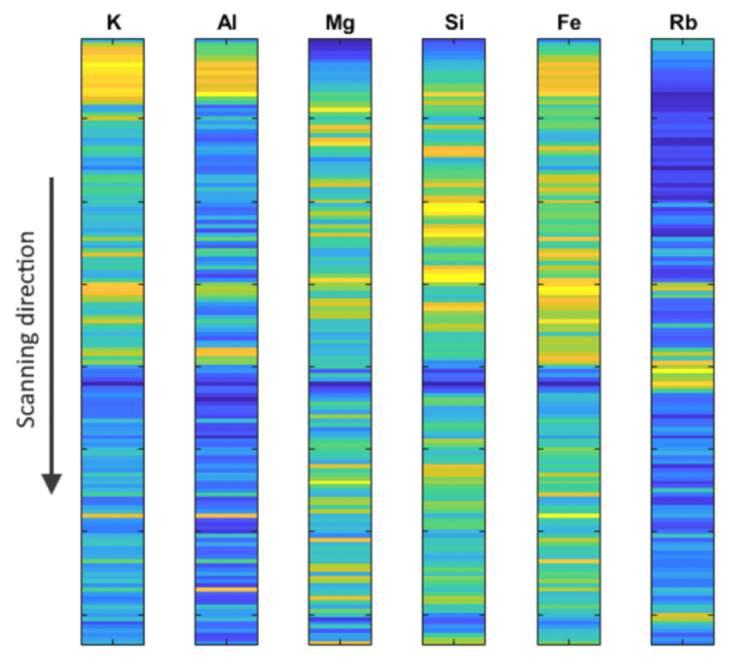

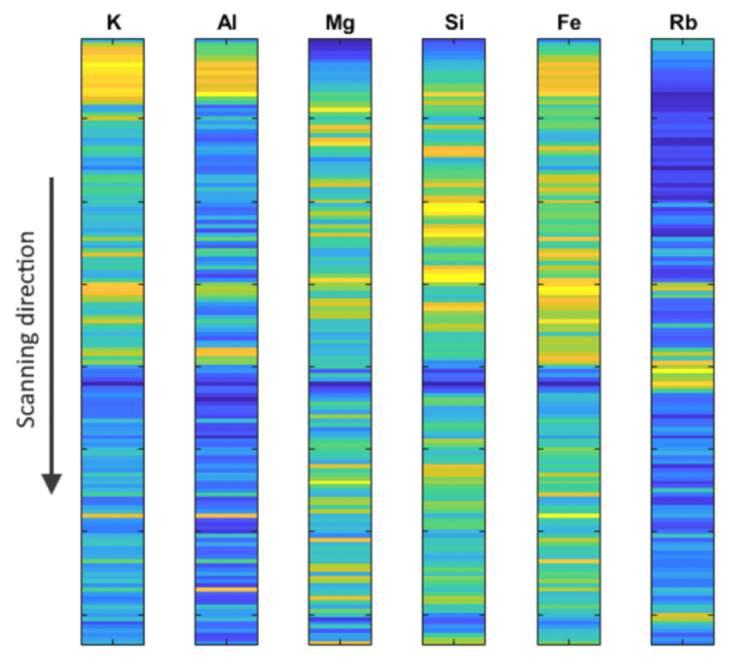

At SPECTRAL Industries we work together with the mining industry to develop LIBS-based sensor applica�ons for the mining environment. Examples of applica�ons are inline conveyor belt analysis, scanning exposed rock surfaces (see Figure 1) and scanning drill chips from blasthole drilling. Addi�onally, we also work on applica�ons that improve the explora�on for new mineral deposits such as the scanning of drill cores (see Figure 2). We develop the best LIBS sensor for a specific applica�on using our in-depth exper�se of lasers, spectrometersanddataprocessing.

One of the major challenges of using LIBS for characterizing the mineral quan�ty in rocks is the heterogeneity of this material. Rocks are composed of many different minerals with various grain sizes. Each mineral consists of

several different elements and for some minerals the rela�ve quan�ty of these elements can vary Depending on the size of the mineral grains, a single LIBS measurement can represent one or several minerals Development of advanced data processing techniques is therefore required in order to provide quan�ta�ve composi�onal informa�on that meets the required accuracy. Addi�onally,calibra�onsneedtobetailoredto the geological se�ng of a specific mineral deposit to take all the varia�on between rock typesandmineralogyintoaccount.

The results obtained using LIBS chemical sensing on ore samples from ac�ve mining opera�ons show that LIBS can be used to provide the informa�on that is needed to improve the efficiency and sustainability of futuremining.

SPECTRAL Industries is a new chemical sensor developer and manufacturer, with a focus on applica�ons in the mining and minerals industry. SPECTRAL's chemical sensors are robust, mobile & fast: they can be applied on

Example of part of the output of a drill core scan (warmer colors are higher concentrations)

(fast) moving raw material. The sensor features our unique IRIS spectrometer with world-class signal-to-noise (S/N) ra�o, rugged pulse laser source and highly efficient op�cs. The design allows for flexible integra�on into industrial equipment and can be mounted in any orienta�on. Suitable for a wide range of environmental condi�ons, it offers low maintenance cost and improves processes by delivering real-�me informa�on. SPECTRAL delivers its unique sensor systems for the following applica�ons:

• Drill core scanning

• Rock surface mapping

• Drill cu�ngs analysis

• Ore, concentrate and slag characteriza�on

• Muck pile characteriza�on

The LIBX sensor can be applied for automated ore sor�ng, that separates valuable from non-valuable rocks to prevent unnecessary cost for processing worthless ore and maximize return on investment. The technology is highly scalable as the hardware is suitable for any type of ore and materials.

Mining- Solutions

36

www.africamininginsight.co.za

A “STABLE” HAUL ROAD HAS MANY BENEFITS

CLAYCRETE IS THE SOLUTION

Haul Roads are the life blood of any mine. Every part of a haul vehicle is subjected to stresses that result in wear or damage. This can ofen be caused by badly designed and or badly maintained haul roads. The easiest way to reduce those stresses is to improve the road surface, reduce rolling resistance and limi�ng dust.

This is the value of strong, smooth, clean haul road surfaces. Astute miners focus on removing the cause of problems before they add to downstream costs. Haul roads are the arteries of every mine, and the condi�onof the running surface influences much of the cost of moving product.

If you build good roads, you want them to work and you want them to last.

CLAYCRETE is the answer to Road Stabalisa�on and to dust and mud problems. CLAYCRETE is a liquid chemical soil stabiliser which increases road pavement strength by changing the propertes of clay parrcles to improve compac�on,weather resistance and trrac�on. By u�lizingthe unique chemistry of clay, the density and bending resistance of pavements are increased without the need for expensive cement treatments.

The treatment is economical and efficient. CLAYCRETE is a liquid which is simply added to the water used for road construc�onor surface maintenance. During the process of mixing with the soil CLAYCRETE reacts with the clay frac�on and the rreac�o consumes all the product. Treated clay has different prroper�es to untreated clay. The changes to clay are permanent and irreversible, no further treatment is required. The chemically altered clay becomes the binder and the perfect void filler

Proper�es th t make clay cause mud and dust are evidence of the unique nature of clay, which atracts water because of an over nega� e charge on the surface of the clay platelet. Balancing that chemical property is the process of stabilisa�onwith CLAYCRETE.

Older forms of stabilisa�onaaempt to restrain the forces and fight the problem of clay by adding as much as 5% of the volume in cement or other expensive materials. CLAYCRETE simply treats the problem.

CLAYCRETE is efficient, one drum of 200 litres will replace 150 tonnes of cement which is commonly used to stabilise road pavements. One twenty-foot container of CLAYCRETE is enough to stabilise 80,000m3 of clay soil or build 400,000m2 of 200mm pavement. (Equivalent cement stabilisa�onat 5% would require 7,200tonnes of cement which would fill more than 250 containers).

CLAYCRETE is safe to use in all environments. It is cer�fie by SGS as no threat to fauna. This is partly due to the unique chemistry and partly due to the complete exhaus�onof the product in reac�onwith the soil.

Wherever produc�onis adversely impacted by dust in dry weather, mud in wet weather, high rolling resistance, high maintenance costs, high suspension maintenance, short tyre life, ru� , corrugaga�onhigh fuel cl consump�on, or other haul road related problems the answer is stabilisa�onwith CLAYCRETE.

CLAYCRETE is also suitable for access roads, hardstands, storage areas, workshop floors, ramps, helipads, runways, taxiways, and any area where high strength low-cost pavement is needed.

The largest haul packs in the world are already running on CLAYCRETE stabilised haul roads. It costs nothing to find out what CLAYCRETE can offer. Phone, or email, we have access to experience in more than thirty countries and your problems have already been experienced on one of the sites where we have helped.

Mining-Solution 38

www.africamininginsight.co.za

· POTHOLES - One litre of CLAYCRETE will treat 5 cubic meters of Road Material.

· GRAIN STAGE – Whether it is open air or emergency storage having a proper floor CLAYCRETE allows you to keep more product and lose less. Claycrete is environmentally safe and will not contaminate the food product.

· STRUCTURAL FLOORS – CLAYCRETE will stabilize the ground that your founda�ons will o on. This leads to less issues around the founda�on s e�lingeducing foundada�onacking.

· AIR STRIPS & HELIPADS – CLAYCRETE drama� ally reduce dust and leave a smooth surface eradica�ng “Bown Outs”

· FLOCCULANT FOR TAILING PONDS – When CLAYCRETE bonds with free clay par�cles th y take on hydrophobic proper�es. These n w water repellent prroper�es helpo rapidly separate any water from the treated materials.

· DAMS, DIKES & LEVEES – Small leaks lead to big leaks and big leaks lead to failure. Stop leaks in the first place and keep water at bay with CLAYCRETE.

APART FROM ROADS CLAYCRETE HAS MANY OTHER APPLICATIONS WHICH INCLUDE:

T284

► ► ► ► ► ►

scan for web

COBRE PANAMA OPERATE LIEBHERR

UNITS ON CLAYCRETE HAUL ROADS Jack James CLAYCRETE Johannesburg - Email: jack@claycreteglobal.com (Johannesburg South Africa) – Mobile Number: +27 (0) 796175328 Brian JackmanCLAYCRETE Global – Email: info@claycreteglobal.com www.claycreteglobal.com

Contact

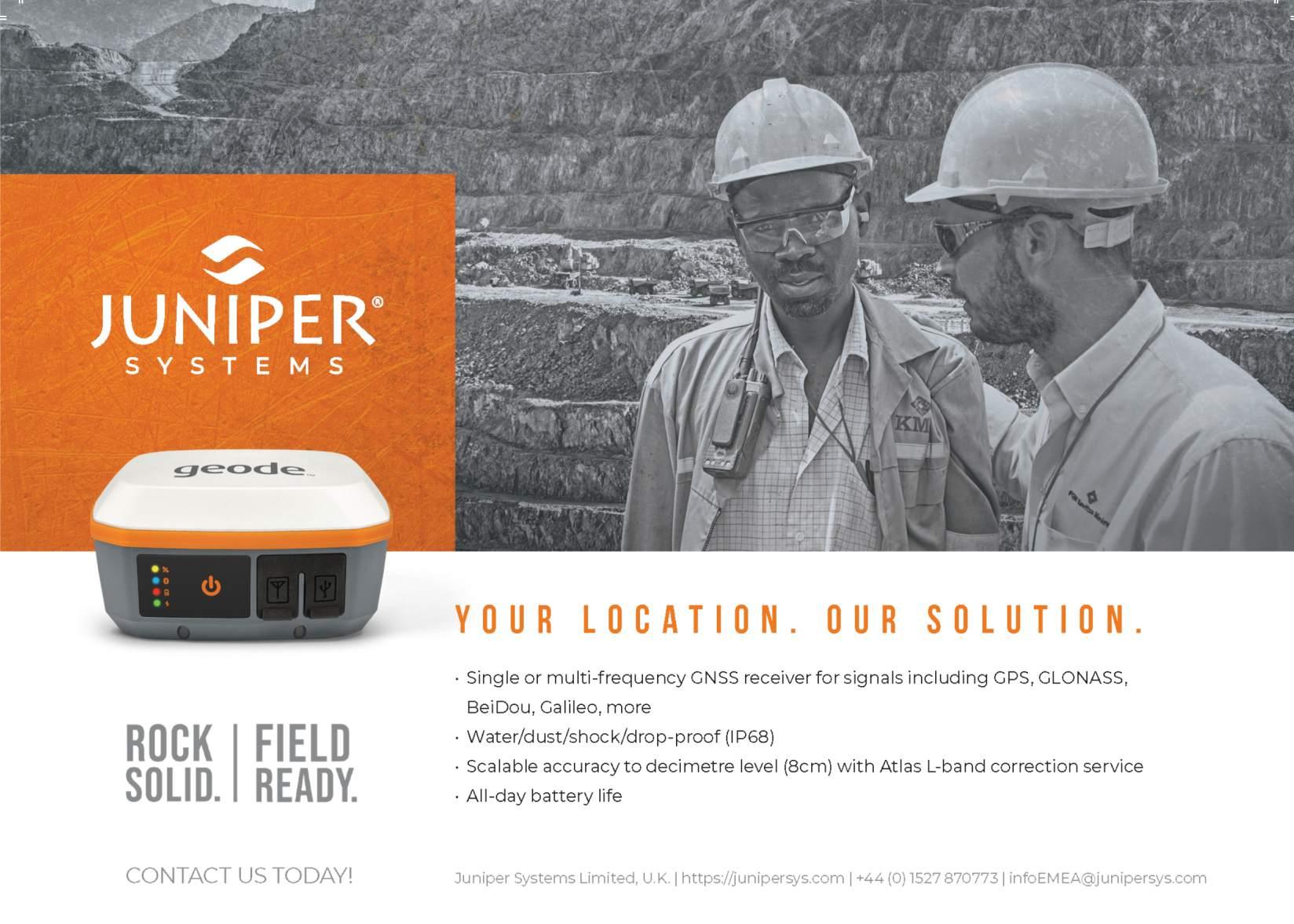

Accurate GNSS Data Collection for Precise Drilling Locations

Whether mining below ground or above, collec�ng accurate and relevant data is a core element of mining work. Inaccuracies in measurements can lead to re-work, project delays, cost overruns and – most frightening – wrong drilling loca�ons.

Acquiring precise loca�on data can be both complicated and expensive. There are many GNSS receivers and data collectors available in the marketplace, but many are difficult to use, cannot achieve low-level accuracy, or are cost-prohibi�ve. Even if the hardware is intui�ve, o�en the so�ware is not.

Add in rapidly-changing weather condi�ons and extreme environments with water, wind and dust, and the day's work gets even more complicated.

Juniper Systems set out to solve all these problems with one affordable GNSS receiver that delivers low-level accuracy, is intui�ve to use, works with mul�ple data collectors, and stands up to extreme condi�ons.

The new Geode™ GNS3 Receiver is scalable, simple to use, and provides a variety of accuracy levels – including sub-meter (50cm), sub-foot (30cm) and decimeter (10cm).

Designed with versa�lity in mind, the Geode GNS3 collects real-�me GNSS data without the huge price tag or complexity of other precision receivers.

Geode GNS3 Receiver

Compared to Juniper Systems' previous GNSS receivers, the significantly-upgraded Geode GNS3 is available in either single or mul�frequency models. The internal antenna delivers precision, mul�-GNSS/mul�frequency with integrated ground plane. The mul�-frequency model is capable of

Mining-Solution 40

www.africamininginsight.co.za

accuracies to 8cm with the Atlas L-band H10 correc�on service.

Scalable Accuracy

Collect precision, mul�-frequency, mul�constella�on GNSS data with more than 800 channels and through a variety of signals, including GPS, GLONASS, BeiDou, Galileo and others.

SBAS correc�ons are supported with 3channel parallel tracking in North America, Europe, India and Japan, reducing ionospheric error in GPS data. Addi�onal correc�on services using RTK/CORS NTRIP GNSS are supported to achieve even greater accuracy

Where SBAS and network correc�ons are not available, a supported Atlas Worldwide subscrip�on will provide L-Band correc�on. With mul�ple accuracy levels and a tolerance for signal interrup�on, data can be collected anywhere in the world.

For every job, select the accuracy op�ons for the data needed, at the sub-metre (50cm),

sub-foot (30cm) or decimetre (10cm) levels.

Open Interface

The Geode GNS3 works with a wide range of data collectors, handheld computers, tablets and smartphones, and is especially useful for bring-your-own-device (BYOD) work situa�ons. It's compa�ble with Juniper Systems' handheld computers, including the new Mesa Pro 10-inch Rugged Tablet, Mesa® 3 Rugged Tablet (7-inch), and Cedar™ CT8X2 Rugged Tablet.

Many other data collectors can also be paired with the Geode GNS3, including devices running on Microso�® Windows PC or Android™ 7 (and above) opera�ng systems, and a broad range of Apple® iPhone® and iPad® devices. Easily connect to any of these using Juniper Systems' GeodeConnect™ so�ware, designed to configure the device and set up communica�ons with the receiver

Juniper Rugged™

Like all products from Juniper Systems, rugged features are inherent to the Geode

GNS3 design. Tested against U.S. standard MIL-STD-810G, it withstands drops, shock, vibra�on and temperature extremes. The enclosure is rated IP68, sealed against moisture and dust ingress.

The Geode GNS3 is perfect for a mul�tude of applica�ons, such as construc�on, survey planning, water u�lity loca�on, agricultural mapping and planning opera�ons, seed research plots, and rural popula�on and census studies. It's also the logical solu�on for remote mapping projects where correc�on services are not available, such as in strip mining, archaeology, environmental sciences or wildlife management.

Take the affordable Geode GNS3 with you mounted on a pole, in a pack, or held in your hand to easily collect real-�me, precision GNSS data in harsh environments.

Learn more: h�ps://junipersys.com/products/geode

Accurate GNSS Data Collec�on for Precise Drilling Loca�ons

Safe and simultaneous tensioning of crusher outer shell nuts saves time and cost

Changing the outer shell on rock and ore crushers can be a �me-consuming process, involving many poten�al OH&S issues. Too o�en, large hammers or flogging spanners are used to loosen the nuts, so that the outer shell can be replaced.

To avoid risks of injury, and to save �me and ® cost, Technofast's latest EziTite hydraulic nuts and bolts have been designed to tension all nuts simultaneously using hydraulic pressure.

The hydraulic pressure tensions the bolt to the precise tension required and then locks it in place mechanically with a locking device.

“These crushers are processing hard materials, so these outer shells need to be replaced frequently. And any �me they aren't crushing, they aren't making money,” says Technofast Founder and CEO, John Bucknell. EziTite hydraulic nuts and bolts provide simple assembly, and they can be daisy

chained together so that all nuts are tensioned to the exact requirements simultaneously

“Mining opera�ons that have used our EziTite products have found that the job can be done in half the �me, with fewer personnel,” said Mr Bucknell.

“Not only are they saving �me and cost, but worker safety is priori�sed too, because EziTite eliminates the risk of injuries

Mining-Solution

42 www.africamininginsight.co.za

associated with flogging hammers,” he said.

The EziTite outer shell replacement process

With Technofast's EziTite hydraulic nuts and bolts in place, changing the outer shell of crushers can be a simple, safe process, which typically involves:

1. Placing the EziTite nut down un�l it meets the washer

2. Connec�ng a hydraulic hose to the hydraulic fi�ng, ensuring the hose is capable of delivering the required pressure

3. Using hydraulic force to �ghten the nut to the required pressure, no�ng par�cularly that all EziTite nuts can be tensioned simultaneously to provide precise, even pressure.

4. Locking the unit in place with a mechanical lock-ring once the desired pressure is reached. This means the unit is mechanically locked, so no sustained pressure is required.

5. Removal is equally rapid and simple, using hydraulic pressure to release the lock ring, and then relieving the pressure from the nut.

“Linking the units together has received very posi�ve feedback from mine site supervisors, who are impressed with the tension accuracy, and ease of installa�on. One also pointed out that simultaneous tensioning removes the possibility of jamming the taper,” said Mr Bucknell.

“The use of EziTite hydraulic nuts has made the job much faster and simpler, and has also eliminated many OH&S concerns with previous methods. With reduced down�me, labour requirements and costs, crushing applica�ons that have installed EziTite nuts have con�nued to benefit with each outer shell change,” he said.

and cost

Safe and simultaneous tensioning of crusher outer shell nuts saves �me

About Technofast Technofast Industries is a worldwide leader and specialist in Bolt Tensioning, providing innova�ve and effec�ve technical solu�ons along with uncompromising customer service. www.technofast.com www.africamininginsight.co.za 43

Advertisers Index 02 WILLARD 03 IMT 09 DAMM 11 A.N.S Solutions 13 Side-industrie 15 VARIANTMININGTECH 18 INNOSPEC INC 21 SEPURA 24 Escape Chute Systems 29 SSBS 31 Synergy Undercarriage Components 33 Petron Corporation 35 Royal IHC 37 Spectral 39 CLAYCRETE 41 JUNIPER SYSTEMS 45 WMITC 46 VERMEER 47 VEGA 48 FUTURE MINERALS FORUM

www.vega.com

By Chuck Strait

By Chuck Strait