COBRE PANAMA OPERATE LIEBHERR T284 UNITS ON CLAYCRETE HAUL ROADS

· POTHOLES - One litre of CLAYCRETE will treat 5 cubic meters of Road Material.

· GRAIN STAGE – Whether it is open air or emergency storage having a proper floor CLAYCRETE allows you to keep more product and lose less. Claycrete is environmentally safe and will not contaminate the food product.

· STRUCTURAL FLOORS – CLAYCRETE will stabilize the ground that your founda�ons will o on. This leads to less issues around the founda�on s e�lingeducing foundada�onacking.

· AIR STRIPS & HELIPADS – CLAYCRETE drama� ally reduce dust and leave a smooth surface eradica�ng “Bown Outs”

· FLOCCULANT FOR TAILING PONDS – When CLAYCRETE bonds with free clay par�cles th y take on hydrophobic proper�es. These n w water repellent prroper�es helpo rapidly separate any water from the treated materials.

· DAMS, DIKES & LEVEES – Small leaks lead to big leaks and big leaks lead to failure. Stop leaks in the first place and keep water at bay with CLAYCRETE.

www.naue.com

EDITOR

Goodwill Sibanda editor@africamininginsight.co.za

WRITER Kennedy Chamu writer@africamininginsight.co.za

SALES

Leon Jaure leon@africamininginsight.co.za

Cleopas Moyo cleopas@africamininginsight.co.za

Emmanuel Chipeta emmanuel@africamininginsight.co.za

Godrick Jere godrick@africamininginsight.co.za

Roslyne Mangena roslyne@africamininginsight.co.za

Design and Layout

Qhawe Maphosa design@africamininginsight.co.za

Subscrip�on

Thatho Ndlovu subscrip�on@ fricamininginsight.co.za

General info@africamininginsight.co.za sales@africamininginsight.co.za

Call: +27 11 0257 031

+27 67 7677 393 www.africamininginsight.co.za

Welcome to another informa�ve edi�on of Africa's favourite Bi Monthly magazine; bringing you all the latest news about construc�on equipment, industrial machinery, mining projects, technologies, investment opportuni�es you'll want to get your hands on in 2023.

Africa Mining Insight is a marketplace, a communica�on hub and news source for advancing mining Industry businesses in the region. Abundant resources, an advanced mining sector, robust financial systems, a progressive legal framework are the gateway to African markets.

A robust mining sector is broadly understood as a fundamental path to economic growth and development. The key boon of mining is that it absorbs large swaths of workers and places them into produc�ve and decent paying jobs. Throughout history, this exact recipe has transformed the United States, United Kingdom, France, Japan, and Germany into some of the world's wealthiest na�ons.

However, this narra�ve seems to exclude many African na�ons. Despite their manufacturing poten�al and promising trajectories, most African countries have remained rela�vely dearth of factories. This limited industrial development represents a missed opportunity for economic transforma�on and quality employment genera�on that alleviates poverty

Today, leaders are increasingly realizing that the mining industry is a major factor in helping Africa achieve its goals and successfully reaching the next stage of economic development.

In this edi�on we will look at Mines and Money Connect London which th will take place on the 25-26 April 2023, being Europe's premier mining investment event, connec�ng miners with money and investors with opportunity. This issue will also include geosynthe�c solu�ons from Naue, Carima's produc�on and formula�on of water-based lubricants, for the installa�on of op�cal fibers and electrical cables. Çlean-in-Place Electrowinning from Cadia systems, Redeployable Turnkey Explora�on Camps, air scrap dust control and heavy minerals mining are some of the top headlines.

Thank you to all our authors, subscribers and adver�sers for helping to shape not only this edi�on, but also the very fabric of the magazine.

Best regards Goodwill Sibanda

Disclaimer: All material is strictly copyright. The magazine or any part thereof may not be reproduced or adapted without writen permission from the publisher: - Africa Mining Insight welcomes material submi�ed for publica�on but retains the right to edit copy. The views expressed in the publica�on are not considered those of the publisher, which accepts no liability of any nature arising out of or in connec�on with the contents of this magazine. While every effort has been taken in compiling this publica�on, the publisher does not give warranty as to the completeness or accuracy of its content. The publisher and the editor cannot accept responsibility for any loss inconvenience & damage that may occur there from.

ÇLEAN-IN-PLACE ELECTROWINNING

OFFICIAL ARPOL PARTNER IN AFRICA

MINES AND MONEY CONNECT

RELOCATABLE STRUCTURES

WATER-BASED LUBRICANTS

MITIGATE ARC-FLASH HAZARDS

GEOSYNTHETICS IN MINING WORKS

SURFACE AND CORROSION PROTECTION

AIRSCRAPE DUST CONTROL

HEAVY MINERALS MINING

CONTRACT MINING

MACHINE HEALTH MONITORING

COLLISION AVOIDANCE AND NAVIGATION

ENERGY IS A COMMODITY AND A NEED

ANTIWEAR COATINGS

FIBERTEX GEOSYNTHETIC SOLUTIONS

PAGE 06

PAGE 08

PAGE 10

PAGE 11

PAGE 12

PAGE 14

PAGE 16

PAGE 20

PAGE 22

PAGE 24

PAGE 26

PAGE 28

PAGE 30

PAGE 32

PAGE 34

PAGE 38

Relocatable structures p11

Water-based lubricants P12

Heavy Minerals Mining P24

Solutions for road maintenance p38

Çlean-in-Place Electrowinning. It's a concept that when you see it in ac�on seems obvious. But for years the process used in ADR plant goldrooms in gold mines around the world, has involved the removal of individual cathodes from the electrowinning cell by means of overhead gantry to a dedicated wash-bay for recovery of gold sludges.

“It's �me consuming, ergonomically demanding on operators and fraught with the poten�al for gold sludges loses to the goldroom floor” says Sean Galvin, Engineering Manager at Cadia Systems – a Perth based mining equipment manufacturer

Mr. Galvin was, for over a decade, formerly manager and designer at the Equipment Division of Como Engineers – another Perth based Engineering Consultancy and Equipment manufacturer. Having been responsible for design and commissioning of goldroom equipment and modular elu�on systems worldwide, he first hand experienced the short comings of cell cleaning - even on the electrowinning cell designs he had been responsible for

Issues common in goldroom cell cleaning ac�vi�es include dealing with heavy lids requiring either counter balances for winches to li� open, slow movement of overhead gantry cranes when reloca�ng cathodes or anodes, heavy cathodes which were o�en man handled in and out during cleaning processes, and problema�c connec�ons of

cathodes and anodes to the main busbars.

“I remember commissioning a system for Metso in Finland in 2011 on Christmas day” he states, “they were 800 sized cathodes with 40 cathodes over two split cell designs.”

“A�er moving the first few to the wash-bay using the overhead monorail I just gave up”.

Mr Galvin instead proceeded manually hauling the cathodes out of the cell one by one and laying them on top of the remaining anodes and cathodes in the cell. “That was my version of clean-on-top of cell”, he laughs. Cadia Systems specialises in the development of innova�ve technologies for the gold processing industry. The business has a strong focus on cleanroom style technologies that bring safety improvements for operators. The equipment also has a clear design focus on improving recoveries and op�mising performance.

Their proprietary protected EC Clean-in-Place Electrowinning Cell was developed a year a�er Mr Galvin started Cadia Systems.

U�lising a novel automated li�ing mechanism, the cell li�s the anodes and cathodes away from the main connec�ng busbar connec�ons, allowing the anodes and cathodes to be slid one by one across the cell to provide access to the cathode face for insitu, in-cell washing.

An addi�onal clever addi�on to the cell designs include a near neutral-pivot, low

weight/high rigidity cell lid. The lid simply slides back with a minimal operator pressure to the front of the lid. For larger cells, which can be as large as 1200mm cathodes in size, the lids are also available with automated opening and closing.

The cells also have front mounted busbars that are located out of the vapour zone to minimise corrosion from ammonia fumes. The busbar contains stud connec�ons which provide �ght inter-busbar connec�on �ghtness to avoid hot-spot connec�ons. So no more losing those pesky nuts. A guard protects the busbars when in opera�on, but also forms part of an inbuilt keyed locking mechanism for security of the precious metals while in opera�on. Anodes are manufactured to provide longer design life�me, and cathodes can accommodate either mild steel or stainless mesh or more common pre-made pillows.

“The product has really been a great success with clients!” says Mr Galvin, “Goldroom operators love them and site management love the enhanced safety and recovery aspects”

Cadia Systems has also entered a collabora�ve arrangement with Gekko Systems for the design and supply of modular elu�on systems using Cadia's equipment and design experience and Gekko's world-class engineering, manufacturing and support services.

Fluid Systems Africa has recently been appointed as the official partner of Arpol flexible pipe couplings in Africa. Arpol designs and manufactures flexible joints for the connec�on and repair of all types of pipes and industries.

Arpol flexible couplings connect pipes be�er, faster, safer and at a lower overall cost than conven�onal systems.

Our Scope of Supply

Arpol was founded in 1976 in Barcelona and specialises in design and manufacturing of flexible couplings for all types of pipes and applica�ons.

We supply a wide range of couplings for many applica�ons. Our size range is 48mm to 3000mm and pressures from PN16 up to 1300mm, and PN10 up to 2000mm

Some of the sectors that put their trust in our flexible couplings are water purifica�on and treatment plants, chemical industry, power sta�ons, domes�c installa�ons, civil

construc�on and engineering, mining, and bo�ling plants. But they are not all, as we con�nue to seek out new sectors where we can be of assistance.

In many cases, new pipelines involve pipe materials that are different from the previously installed pipes, and can create diameter differences that even though minimal, can become an inconvenience when old and new lines are to be connected.

Arpol couplings can be used to repair any point of the line, but also to connect dismantling pipes to different hydraulic pieces (valves, pumps, etc.) as well as different material pipes.

Arpol couplings are a great solu�on to connect different diameters and make them the most reliable tool for hydraulic sealing. All Arpol couplings allow certain tolerance to solve common old-line problems like angular deflec�ons, pipe separa�ons, se�lement correc�ons, rough surfaces etc.

Quality is our guarantee. Our mission is to offer our customers the best possible solu�on to the problem they face. To us every project is unique, and we do our best to offer the flexible coupling that best meets the customer's needs. Our products are guaranteed by the constant quality inspec�on they undergo in our Barcelona factory

Solu�ons are our iden�ty.

We a�ach great importance to our R&D&I department. Our goal has always been to offer solu�ons to the challenges that arise in the market. The world evolves and we evolve with it, so we are in a constant process of innova�on.

“Because connec�ng ma�ers” is not just a slogan, it is a way of working. We take the �me to listen to and understand the individual needs of all our customers.

We are present in more than 40 countries, and we aim to be in many more including Africa.

Europe's premier mining investment event, connec�ng miners with money and investors with opportunity

Long Event Descrip�on:

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest. See who is exhibi�ng here

The 70+ speakers will talk in various formats from in�mate fireside chats, to project spotlights, mining pitch ba�les and panel sessions. Expect to take away ac�onable insights you can deliver to your team to help deliver your business objec�ves. The key topics covered throughout the two-day program include what's next for the energy transi�on, government policy on cri�cal minerals and implica�ons for the mining field, new thinking in ECG, and sustainability and metal prices in 2023. View the program speakers here and .

Across two days, there are thousands of opportuni�es to network, brainstorm, and share knowledge, providing the perfect pla�orm to obtain invaluable new business contacts, connect with the industry's leading figureheads and explore new ideas.

Mee�ngs are at the heart of what we do. To ensure your �me is maximised onsite, there is an AI-driven mee�ng planner, allowing you to pre-schedule all of your mee�ngs, depending on your needs. Find out more here

There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at to connect@minesandmoney.com discuss your par�cipa�on or register for your pass here

For more informa�on on the event, visit the event website here or contact connect@minesandmoney.com

Quick reference links and informa�on

Dates: 25 – 26 April 2023

Loca�on: County Hall, London, SE1

Website: Minesandmoney.com/connect

Ticket Link:

h�ps://minesandmoney.com/connect/register

Email: connect@minesandmoney.com

LinkedIn: h�ps://www.linkedin.com/company/mines-andmoney/

Twi�er: h�ps://twi�er.com/minesandmoney

YouTube: h�ps://wwwyoutube.com/c/minesandmoney

Facebook: h�ps://wwwfacebook.com/minesandmoney/

Short Event Descrip�on:

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest. See who is exhibi�ng here

There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at to connect@minesandmoney.com discuss your par�cipa�on or register for your pass here

Plain Text Event Descrip�on:

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest.

The 70+ speakers will talk in various formats from in�mate fireside chats to project spotlights, mining pitch ba�les and panel sessions. Expect to take away ac�onable insights you can deliver to your team to help deliver your business objec�ves. The key topics covered throughout the two-day program include what's next for the energy transi�on, government policy on cri�cal minerals and implica�ons for the mining field, new thinking in ECG, and sustainability and metal prices in 2023. Across two days, there are thousands of opportuni�es to network, brainstorm, and share knowledge, providing the perfect pla�orm to obtain invaluable new business contacts, connect with the industry's leading figureheads and explore new ideas.

Mee�ngs are at the heart of what we do. To ensure your �me is maximised onsite, there is an AI-driven mee�ng planner, allowing you to pre-schedule all of your mee�ngs, depending on your needs.

There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at connect@minesandmoney.com to discuss your par�cipa�on.

Due to the modular design, our Redeployable Turnkey Explora�on Camps can be easily dismantled and rebuilt at another loca�on. This means they are the ideal solu�on for explora�on camps. They can be used on a temporary or semi-permanent basis and can even be extended or reduced in size. They feature so� roofs with a choice of hard or so� sides, adaptability makes it simple to remodel our enclosures when required to meet your opera�onal needs.

h�ps://wwwturnkeymobilecamps.com/#abo ut-us

Since our Redeployable Turnkey Explora�on Camp buildings are anchored to the ground via stakes, they do not require founda�ons and can be installed quickly with reduced civil works and ground prepara�on. When you need solu�ons fast to meet strict opera�onal �melines, our structures offer you the

advantage of efficient project scheduling and process profitability

Rent, lease of purchase heavy-duty, an�-skid access mats and other temporary roadway solu�ons that transform rough, so�, or unstable ground condi�ons into stable and weatherproof surfaces. Install our composite mats to easily transport specialized service vehicles and components, or create a staging and storage area for equipment, mobile offices, or trailers. F3 Group, h�ps://www.f3group.co.za/composite-baserig-mats.html offers ma�ng solu�ons for any

construc�on work site, climate, or terrain with weight-bearing capaci�es of up to 1000 psi. The mats are made of High-Density Polyethylene (HDPE) with specialized fillers for strength, plus UV and an�-sta�c addi�ves to withstand the rigors of heavy construc�on.

Rent, lease of purchase aircra� landing mats for all remote projects, reduced civil works by installing Redeployable landing mats available in Composite or Aluminium. The Pro Aero mats are modular in design and can be moved from site to site.

h�ps://www.compositebaserigmats.com/pro -aero-mat/

Carima is a leading company on the European market in the produc�on and formula�on of water-based lubricants, for the installa�on of op�cal fibers and electrical cables.

Carima is a chemical company located in Gessate, near Milan (Italy), which has always tried to sa�sfy its customers with innova�ve products and short delivery �mes, in a con�nuous process of quality assessment and improvement.

We support our customers by producing various types of lubricants that meet the working methods of each installer. For example, if a technician has always worked with a gel lubricant, Carima will make sure to provide him with the most correct gel for his needs. We don't want to change the habits of technical installers, on the contrary we want to help them in their daily ac�vi�es. We can offer an op�mal solu�on for every request.

All our products are Made in Italy and, through a qualified industrial process, they are a guarantee of op�mal performances in all sectors: industrial, civil and construc�on. S�ll with regard to our awareness of the environment that surrounds us, we take all the energy we need from the sun; numerous photovoltaic panels have been installed on our roofs in order to give energy to our daily work.

We also care a lot about the environment: that's why all our products are water-based and do not contain petroleum deriva�ves. Furthermore, all the electricity that CARIMA needs comes from the sun. For transparency,

the produc�on data of our photovoltaic system is updated in real �me every 15 minutes on our website at the link h�p://fv.carima.biz.

Carima produces and sells different products: Slips and lubricants

Specific slips and lubricants for laying electric cables and op�cal fibers such as GLISS® F, GLISS® GEL, GLISS® W, or S LUB 20, S LUB 100XL, etc. They allow to reduce the fric�on generated during installa�on opera�ons of cables and fibers in pipelines

Mono and bi-component products for electrical insula�on, such as SOFT SIL GEL 32, SOFT GUM, etc.

Solvents and detergents for removing plugging grease (jelly) from cables and for cleaning the fibers before splicing, such as FO Cleaner, Biosol 19

Technical spray products and water-based marking paints for usual work opera�ons, such as IDRO SPRAY, etc.

Various accessories for a be�er and simpler use and applica�on of our products, such as Duct Cleaner, ICE Mel�ng, Mass effect etc…

Chemical products developed, produced and sold by us for special needs, Green Glass, solar and photovoltaic panel cleaner, silicone and PAG-based greases, etc.

Why so many products?

Why do you need so many different types of slips and lubricants to solve a seemingly simple problem?

The answer is simple and precise Carima is able to offer the best solu�ons for every need. To do this, it supports the customer by producing various types of products to sa�sfy the "modus operandi" of each installer

So if a technician has always worked with a gel product, Carima will certainly have the right gel product in its wide range for him. Carima does not want to change the installa�on technician's work habits, but to help him in his daily ac�vi�es.

The produc�on lines are able to package the various products from the 100ml tube, up to the 1000kg IBC, passing through 500ml and 1lt bo�les, 5, 10, 20 and 25 liter tanks and buckets also including 50 liter drums, 100 and 200lt.

Special packaging requested by customers is possible.

Manufacturer of “Made in Italy” lubricants and anti-friction agents for fibre optic cables and power cables.

Carima

With the use of electrical equipment comes the real risk of arc-flash incidents. Recent advancements in arc-flash mi�ga�on technology now enable mines around the world to cost-effec�vely mi�gate arc-flash hazards to protect both personnel and equipment. One pulp and paper customer recently reduced their arc-flash incident energy by more than 90% by using a highspeed arc-flash mi�ga�on solu�on from Schweitzer Engineering Laboratories (SEL) that included feeder protec�on relays with op�cal sensors.

However, when making capital investments, the sporadic nature of arc-flash events can cloud the issue. When everything is working properly, it's easy to take arc-flash safety for granted. You're not alone if you some�mes wonder if arc-flash dangers are overstated when months or even years pass without incident.

This was the case for an electrical engineer at a North American mining opera�on who always wondered if the investment he was making in arc-flash technology would pay off One Monday morning, upon returning to inspect the plant's new switchgear installa�on, he learned that an arc-flash event had occurred over the weekend. However, as he surveyed the affected

switchgear, he no�ced that only a small layer of dust covered the equipment. The power protec�on scheme from SEL had operated correctly, and provided event informa�on that enabled them to understand what had occurred. Knowing the poten�al havoc that an arc-flash event could have caused, the lack of damage surprised the engineer “What was humbling was that the unexpected happened,” said the engineer, “…and [the relays] protected our equipment from poten�ally devasta�ng damage.”

The primary objec�ve of installing arc-flash protec�on equipment at the mine had been to ensure worker safety. But, the protec�on scheme also protected the mine's newly installed switchgear and prevented an expensive disrup�on to the mine's opera�ons.

As he reflected on the calamity that had been avoided, the engineer felt fortunate to have incorporated arc-flash mi�ga�on technology from SEL for many years throughout his facility. Regardless of how rarely arc-flash events occur, given the poten�al consequences, it is cri�cal to be prepared. For this engineer, protec�ng personnel, equipment, and ongoing opera�ons proved to be a solid investment. For further details about this customer and his arc-flash

protec�on scheme, please read the SEL customer case study at h�ps://selinc.com/Solu�ons/Success -Stories/Mining-Arc-Flash/ SEL understands that it's cri�cal for mines to stay up and running, and we design our solu�ons to help ensure reliable and con�nuous power for mining opera�ons around the world. You don't have to experience an arc-flash event firsthand to understand the severe consequences that can occur. To learn more about SEL's arc-flash mi�ga�on solu�ons, visit www.selinc.com\solu�ons\arc flashsolu�ons

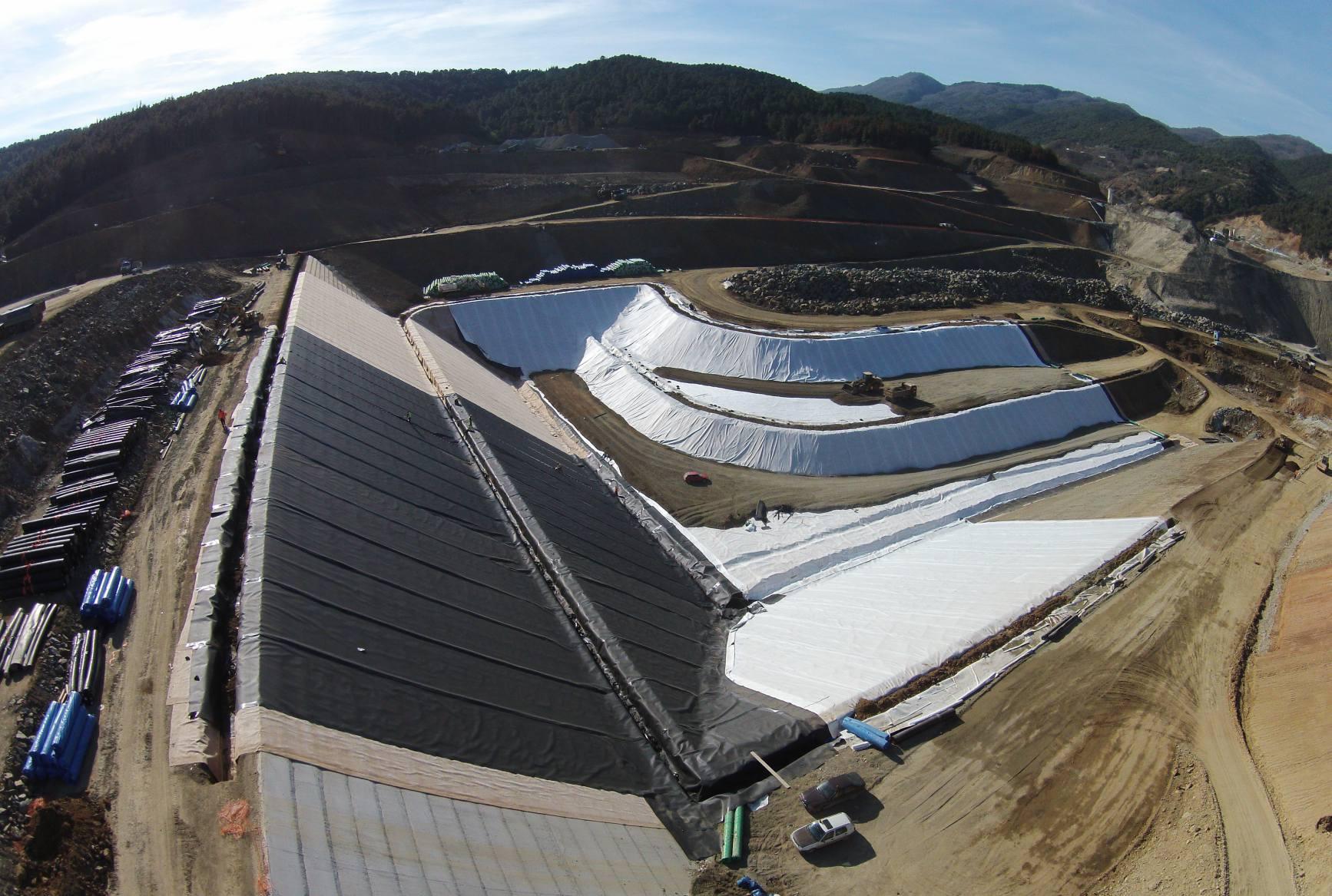

The use of geosynthe�cs in mining opera�ons grows annually as mining companies focus on the technical and economic advantages of geosynthe�cs. In this regard, Naue can

· support the economic extrac�on of valuable resources in heap leaching,

· offer engineering solu�ons for mine waste and water management in tailings facili�es,

· provide sealing, drainage, filtra�on or separa�on materials for all kinds of ponds or mine remedia�on of old mining opera�ons,

· deliver reinforcement and stabilisa�on products and systems for embankments, haul and access roads or steep slopes and walls.

This means that our polymeric materials enable more efficient barriers, stronger access roads, space-saving and safety-enhancing retaining structures and much more. But mining projects are o�en sensi�ve to the environment and are located in remote areas. Therefore, our geosynthe�cs can not only offer cost and �me savings but also reduce the environmental impact (carbon footprint, energy consump�on) on most projects involving geotechnical work compared to conven�onal methods.

® Our HDPE geomembranes Naue Carbofol are extremely durable with a great cost-benefit ra�o. And in parallel, they are an important line of defence to protect the environment. The applica�on of our reinforcement and stabilisa�on

®

® products Naue Secugrid and Naue Combigrid results in a reduced need for quality engineered fill material for sub-base reinforcement. Our ® geosynthe�c clay liner Naue Bentofix or mul�component GCL Bentofix X can replace clay

In both cases, the transport costs to the site will be

reduced, and the speed of construc�on will be increased. To sum up, the costs of construc�on materials such as aggregates or concrete, construc�on �me and environmental impact will be reduced significantly

You can use our geosynthe�cs individually or combined as an intelligent system solu�on. They are built to last for long-term usage when properly designed and installed. Naue can provide

· engineering, specifica�on and design support,

· so�ware tools (for base courses, slopes and walls or working pla�orms),

· tes�ng (e.g., shear box tes�ng, leachate tes�ng),

· training and supervision,

· installa�on.

Design and specifica�on of the solu�on should be carried out as early as possible within the scheme's development and guided by appropriate ground inves�ga�on.

For example, heap leaching. Without ques�on, heap leach has become an enormous driver of the growth of mining opera�ons wordwide. 25 years ago, only about 3% of copper and gold supplies were produced through heap leaching. Today, the volume surpasses 30% annually. Valuable chalcopyrite copper, previously not considered economical in heap leach development, is now heap leached, as is nickel laterite, uranium, and even rare earths. Heap leach stacks can be up to 200m, as opera�ons look to prove site yield more quickly. Heap leaching accomplishes this – but only with the containment support of geosynthe�cs. Geomembranes and geosynthe�c clay liners (GCLs) are used in lining system solu�ons as heap leach pad liners, pregnant solu�on trench liners,

processing pits, onsite water storage, “raincoat” covers over ore stacks to shed stormwater – rather than dilute the leach heap solu�on – and onsite wastewater management. Geomembranes are not all that mining sites require. Nonwoven geotex�les provide long-term, robust protec�on of and fric�onal stability for geomembranes on difficult terrain and in tall ore stack scenarios.

The second example is TSF. When an ore's valuable deposit is extracted, what remains of the ore is waste. O�en, it is a high percentage of the ore handled at the mine. Poten�ally contaminated from the extrac�on process or containing environmentally harmful components, tailings must be isolated to prevent long-term environmental damage. As mine sites increase in size, the engineering needed to properly contain the volume of tailings has intensified. This scaling up of containment frequently requires not just lining systems but reinforcement and sealing systems for perimeter berms on tailings pond. Weaker, earthen-only berms are at risk of satura�on, erosion and failure.

Furthermore, the increasing depth of tailings storage ponds requires a stronger containment engineering design. With the environmental security of the site relying on these environmental protec�on systems, the geosynthe�cs selected must be trusted. Here, geosynthe�c solu�ons ® include our HDPE geomembrane Carbofol , our GCLs Bentofix and Bentofix X, our nonwoven geotex�le Secutex and our reinforcing geogrids Secugrid and Combigrid

Naue has more than 50 years of experience in geosynthe�cs development, produc�on and installa�on. We can be your single point of contact to find a proper solu�on for your geotechnical challenges in your mining projects.

BMG's range of NORD aluminium drives is available with the nsd tupH (Sealed Surface Conversion System) an�corrosion treatment, which has been developed by NORD DRIVESYSTEMS, for improved process reliability in extreme environmental condi�ons and for hygienically cri�cal applica�ons.

“NORD's nsd tupH surface and corrosion protec�on system, which is resistant to acids and alkalis, is a highly efficient an�corrosion treatment for gear units, smooth motors, frequency inverters and motor starters in washdown-op�mised cast aluminium housings,” explains Derrick Louw, NORD product specialist, Electromechanical Division, BMG.

“BMG's NORD nsd tupH drive units are a robust alterna�ve to painted geared motors or Stainless Steel versions. The nsd tupH cataly�c surface treatment process permanently bonds a high hardness layer to the aluminium substrate, to offer the same corrosionresistance as Stainless Steel. Advantages include extended surface life, a substan�ally lower mass, improved

installa�on op�ons and cost efficiency

“NORD's easy-to-clean surface treatment is not a coa�ng like a paint layer, that can detach or flake off. This durable protec�ve layer offers op�mum protec�on against scratching, blistering and the penetra�on of corrosion, even if the unit is damaged. This surface conversion system is highly resistant to extreme environments and aggressive cleaning chemicals, even under high pressure washdown condi�ons.”

NORD drives with nsd tupH comply with FDA Title 21 CFR 175.300 and for this reason are suitable for food applica�ons. They have been successfully tested according to ASTM D714 (blistering), ASTM D610-08 (corrosion), ASTM D1654-08 according to DIN EN ISO 2409 (scratching), ASTM B117-09 according to DIN EN ISO 9227 (salt spray test) and ASTM D3170 (Gravelometer). In addi�on, resistance to common cleaning agents, which are used in the food industry, has been confirmed in tests.

All DIN and standard components for BMG's NORD nsd tupH aluminium drive

units, including drive sha�s, are made from Stainless Steel. Fan-less smooth motors, which run quietly, do not spread germs. They are available as synchronous and asynchronous motors and comply with efficiency classes IE2 and IE3 (asynchronous motors) and IE4 (synchronous motors).

Typical applica�ons for NORD drives with nsd tupH surface treatment, include the food and beverage industry, bo�ling and canning plants, water treatment and sewage plants, as well as offshore and onshore applica�ons. This range is suitable for use in any plant that requires a washdown a�er produc�on.

The NORD range, which is assembled locally by BMG according to stringent interna�onal quality and safety specifica�ons, has earned recogni�on by the local market for reliability, high efficiency, reduced noise levels, extended service life and minimal maintenance requirements.

New to the range of bulk handling systems from BLTWORLD, is the contact-free AirScrape® conveyor belt skir�ng system, which significantly reduces material spill, dust forma�on and explosion hazards at transfer points and other cri�cal sec�ons in the conveyor chain.

Because this system hovers freely above the conveyor belt, skirt fric�on and belt damage is eliminated and service life is extended.

“The AirScrape system - which encompasses inward facing, hardened-steel diagonal blades - operates according to a new principle where it hovers 1-2 mm, on the le� and right side above the conveyor belt. These blades deflect larger par�cles inwards, while using the airflow of the conveyor belt and conveyed material to create an inward suc�on, flowing any dust and fine par�cles back into the product flow,” explains Ken Mouritzen, managing director, BLTWORLD. “Through these diagonally fi�ed plates and the speed of the running belt, air is drawn from the outside inwards. As a result, neither the dust nor material can escape.

“Conven�onal skir�ng is pressed against a

conveyor belt to keep dust and material in the middle of the belt, but a�er a period, wear of the skir�ng and belt can be so severe, that material and dust escapes. Material spillage at transfer points needs to be removed and regular maintenance of belt skir�ng and transfer points is necessary “With the AirScrape dust-free and contactfree, side sealing system for belt conveyors, there is no skirt contact and therefore no belt wear or damage. Motor power requirements are reduced as there is no belt-skirt fric�on and because there is con�nuous skir�ng with no gaps, product loss is minimal.

“Studies show, that even three years a�er installa�on and with con�nuous use in harsh condi�ons, the AirScrape system hardly shows any signs of wear. Opera�onal costs are also reduced because there is no need for spillage collec�on, regular maintenance, or replacement parts.”

This system is available in pairs of le� and right hand 2 m, inter-connectable pieces, to form any required length and is available in two different base widths of 90 mm and 60 mm, to suit various belt widths and chute sizes. For flexibility on site, this system is

completely extendable.

AirScrape is fi�ed using spacers, floa�ng the blades just above the belt and is a�ached to the outside of the chute by u�lising exis�ng skirt clamps or a simple bolt and nut system. It is longitudinally adjustable to follow the contours of conveyor belt rollers and the belt trough angle.

This durable system consists of nonflammable and an�-sta�c Polyurethane materials and blades made from Hardox/ Stainless Steel. FDA-approved materials are also available for specific conveyor handling applica�ons.

This system - designed and manufactured in Germany by ScapeTec Trading, to the highest quality standards – is available from BLTWORLD throughout Africa and the Indian Ocean Islands. The BLTWORLD team provides an assessment and solu�ons service for planning and implemen�ng each project. Correct installa�on of suitable equipment, ensures cost efficiency, op�mum performance and safety, reduced risk of breakdown and extended service life of the conveyor system.

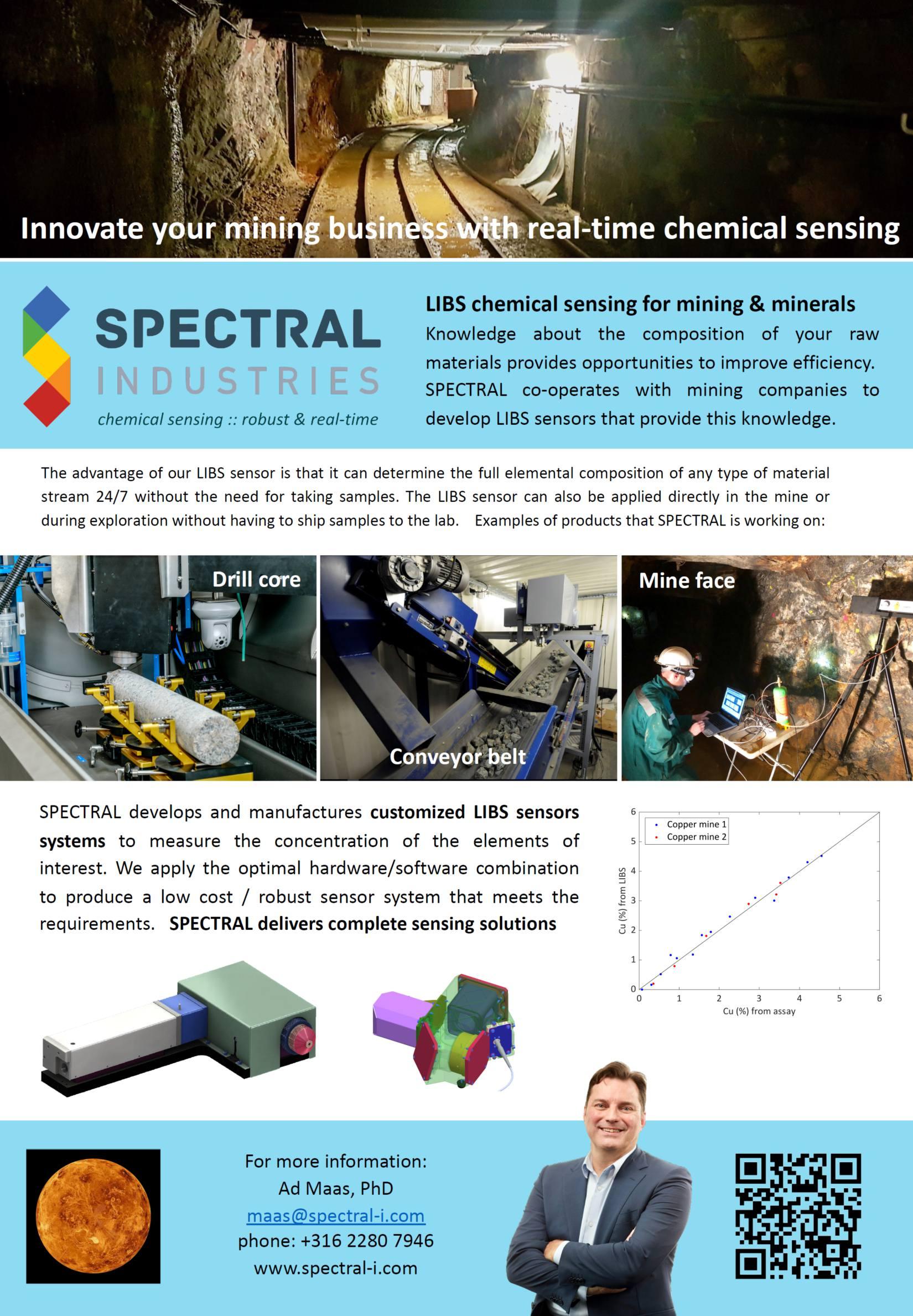

Africa is a con�nent richly endowed with a variety of economically viable mineral deposits. The con�nued discoveries of these mineral deposits have made the con�nent a beehive of ac�vity in the recent past with mul�na�onal mining companies seeking to have a piece of the pie.

Heavy Minerals Mining is one of the numerous explora�on ac�vi�es currently being undertaken on the con�nent. They are called heavy minerals because they have a

density greater than 2.9 g/cm3. 75 percent of the world's �tanium is produced from heavy mineral sands. Various African countries have huge deposits of this mineral with South Africa being the second largest producer of �tanium and zircon in the world a�er Australia.

Kenya will see its first bulk shipment of �tanium minerals come online in January 2014 from Base Titanium's Kwale project while other countries like Namibia,

Mozambique, Senegal, Tanzania, Sierra Leone, Gambia and Mauritania also have heavy mineral poten�al.

Heavy mineral sands are an accumula�on of valuable minerals, normally called placer deposits, formed by gravity separa�on during sedimentary processes.

Upon deposi�ng of sand on the coastline by waves heavy minerals are concentrated as backwash carries some of the lighter minerals back to sea. Onshore winds which

preferen�ally blow lighter grains inland some�mes lead to higher concentra�ons of heavy minerals at the front of coastal dunes and as a result strandlines, old fossil shorelines, can now be found a li�le distance inland. Heavy mineral sands are an important source of �tanium, rare earth elements, thorium, zirconium and tungsten and industrial minerals such as diamond, sapphire, garnet and occasionally gemstones.

Heavy minerals have vital economic applica�ons. Even though the strength and chemical inertness of �tanium allows it to be used in defense, medical and aerospace industries more than 95 per cent of total �tanium supply is for pigment produc�on. Zircon is used in TV screens due to its ability

to absorb X-rays. Its hardness, high mel�ng point and low expansion coefficient when heated enables it to be used in foundry sand and as an abrasive.

It is also used as a source of zirconia for the chemical industry in adhesives, an�perspirants, catalysts, aqueous polymers, gela�n hardening and dyes. Zircon is also used mostly in the ceramics industry to glaze finishes of �les, crockery and bathware for durability and resistance to discolora�on.

As a metal Zirconium is fairly so�, malleable and easily worked. Its high density and high mel�ng point makes it suitable to be used in modern superconductors. The oxide is also used in fuel cells, transducers in audio equipment and oxygen sensors. In the paper coa�ng industry, Zr-carbonate acts as an

insolubilizer while in tex�les potassium hexafluorozirconate acts as a flame retardant.

Heavy mineral mining has both economic and social benefits to the host countries. Mining of these minerals creates employment for thousands of ci�zenry. This significantly improves the social status of the people in the third world countries. It also leads to development of various infrastructure projects such as roads, ports, dams e.t.c. An ideal example of how these mining ac�vi�es can benefit the local people and play an important role in advancing the na�onal economy well beyond the life of the mining opera�on is Base's Kwale project in Kenya.

There is a direct correla�on between the market size of contract mining and the commodi�es cycle/prices and investment pa�erns in capital projects Historically, mining was a highly protected industry and had a low propensity for outsourcing, but more opera�ons are being outsourced across Africa, says global consultant and adviser Deloi�e.

This is owing to mines not having access to robust mining systems and processes, exper�se and the ability to control the en�re mining value chain, limi�ng the realisa�on of a project's opera�onal poten�al, asserts Deloi�e associate director Mahendra Dedasaniya. “There is a direct correla�on between the market size of contract mining and the commodi�es cycle/prices and investment pa�erns in capital projects.

Amid current market condi�ons, many mining opera�ons have started to consider outsourcing part of or all their opera�ons to the best contractor to achieve the best

cost and produc�vity possible,” Dedasaniya comments. He notes that using contractbased mining services is a strategic, longterm decision and must be integrated into a mining company's business and opera�onal strategy to achieve the best possible outcome.

Contract mining is used not only to implement rapid strategic change but also to assist in providing a compe��ve edge in the global market, Dedasaniya points out. He illustrates that many mining companies in South Africa, Namibia, Botswana, the Democra�c Republic of Congo and Zambia have outsourced their mining opera�ons, such as Kimberley Diamonds, Kalagadi Manganese and Langer Heinrich, as well as the zinc mines of Black Mountain.

The decision to outsource is normally based on opera�onal cost, capital efficiency, flexibility, rela�onship and competency, as well as the owner's current status in terms of the age of the fleet, required skills availability, produc�vity,

overhead cost, the type of mining opera�ons and the mining method employed, Dedasaniya adds.

He emphasises that, when considering outsourcing mining services, it is important to weigh the organisa�on's op�ons in terms of the type of contract, selec�on of the right contractor and the measurable output requirements while balancing socioeconomic considera�ons. The selec�on of a contractor should be based on their past safety sta�s�cs, alignment with business and corporate strategy, shared values and cultural fit, as well as understanding the poten�al risks associated with contract mining and the probability of mi�ga�ng these risks based on actual requirements.

He puts forward that selec�ng the right business partner, in terms of the type and form of contract, will result in defining balanced commercial terms involving the

incen�ve of shared benefits between owner and contractor and flexibility with regard to changing the contract scope. In terms of output control, Dedasaniya says defining the mining company's objec�ves and goals in terms of outsourcing plays an important role in ensuring that the contractor will be able to perform accordingly. He notes that by defining the dependencies that other opera�ons could have on a contractor's performance and how to reduce this reliance when output is at risk, will also assist in preparing recovery plans. “Once you enter into a contract, it's very difficult to exit without disturbing opera�ons. It is, therefore, of great importance to chose the right business partner who shares a company's values and envisions the same end goal,” he declares.

Dedasaniya asserts that there are various models available when selec�ng contractors that will best meet the requirements of a project and those of a company. These models can be iden�fied as full outsourcing or par�al outsourcing models, he says, explaining that full outsourcing includes all project needs such

as equipment, labour, materials and infrastructure. Par�al outsourcing is when the equipment and infrastructure is supplied by the owner, with the contractor supplying labour and, at �mes, maintaining equipment.

Dedasaniya notes that, if outsourced mining is not part of a business's opera�onal plans, it could result in the cost of mining being higher by as much as 15% to 20%, adding that there could also be a loss of intellectual property since there is no con�nuity in knowledge, which ul�mately affects the decision-making process. Therefore, should the contract be prematurely terminated, the en�re opera�ons cycle will be disrupted, resul�ng in revenue loss. He also notes that an inadequately defined scope and responsibility matrix leads to conflict and unhealthy rela�ons between the par�es, affec�ng the targeted outcome of the outsourcing business case.

Dedasaniya highlights that, when contract criteria are met and the best model has been selected for an opera�on, outsourcing

has many advantages, such as the achievement of produc�on targets within budget and on schedule. Addi�onally, he says contracts can also be structured to allow for opera�onal costs to be converted from fixed costs into variable costs during �mes of low produc�on volumes, reducing the risk of nega�ve profit margins.

“The mining environment has an influence on many variables, such as ground condi�ons and market condi�ons, which some�mes erodes the business case; however, outsourcing provides flexibility and scalability in [a mining company's] model to meet ever-changing produc�on requirements, resul�ng in a smooth transi�on between mining methods such as openpit to underground mining.”

Dedasaniya points out that the effec�ve use of resources and the deputa�on of a subject-ma�er expert from one opera�on to another is also an added advantage. “Outsourcing should emphasise and create bonds and networking in an organisa�on to ensure it achieves the best possible produc�on at the pre-agreed produc�on cost, while achieving higher capital efficiency and flexibility [at] mining opera�ons,” concludes Dedasaniya.

Bearings and rota�on specialist, SKF, is empowering customers to monitor machine health without the need for extensive training or diagnos�c exper�se through its innova�ve Enlight QuickCollect.

Designed to make it easy to collect and interpret valuable machine data, SKF Enlight QuickCollect is helping customers to op�mise their rota�ng equipment performance.

Previously, in order to collect machine and process data customers needed expensive equipment and had to depend on in-house exper�se to understand the data and diagnose machine problems effec�vely. The SKF Enlight QuickCollect makes it easy for customers to get started and its entrylevel setup costs means that the capital expenditure is eliminated. As an affordable addi�on to the maintenance program, customers can collect valuable machine data and inspect and process this data swi�ly and simply

This advanced innova�on combines a user-friendly SKF QuickCollect Sensor with mobile SKF QuickCollect apps to simplify inspec�on, process and machine health data collec�on and analysis. By u�lising the sensor and the apps, customers can easily start checking the 'on the spot' condi�on of their rota�ng machinery. In addi�on to rapid and effortless iden�fica�on of machine condi�on, this solu�on assists customers to also capture, share and store inspec�on as well as process machine health data across the company

The simple and rugged SKF QuickCollect handheld sensor monitors a wide array of issues rela�ng to vibra�on and temperature. The sensor transmits data wirelessly to an app on a mobile device, providing instant machine diagnos�cs with the ability to store and share data for further analysis.

Customers can upgrade from the SKF QuickCollect app which delivers entry level, on-the-spot analysis, to the SKF DataCollect app to receive extended diagnos�c capabili�es, more detailed, colour-coded machine condi�on feedback based on ISO standards, customised forms for collec�ng all types of inspec�on and process data as well as guided measurement support.

The SKF DataCollect app also delivers customised forms to collect a wide range of useful data from around the customer's facility. In addi�on to machine monitoring, opera�ons employees can perform visual inspec�ons guided by instruc�ons and record informa�on such as pressures, lows, lubrica�on levels, etc. Instruc�ons can also be provided for operators to clean and inspect equipment and to tell them when

and how to seek help when needed. This type of inspec�on data is invaluable to complement customers' maintenance programmes and can also be u�lised to automate support for ac�vi�es such as plant safety and EHS audits, environmental /quality/air leak inspec�ons, equipment checks and lubrica�on rounds. SKF QuickCollect assists the workforce to monitor plant machinery as limited training and no specialist skills are required.

There are a limited number of organisa�ons that hold a large body of inhouse exper�se on preventa�ve maintenance, rota�ng equipment performance op�misa�on and root cause analysis. SKF Enlight QuickCollect provides a solu�on to this dilemma as SKF DataCollect also gives customers the ability to connect with SKF expert remote services with access to SKF's industry-leading diagnos�c personnel and resources. In the event of customers requiring advanced support such as automated diagnos�cs for example, they can conveniently connect directly with SKF remote diagnos�c services giving them access to worldleading machine and bearing performance analysts – industry-leading exper�se and benchmark data at the customers' finger�ps.

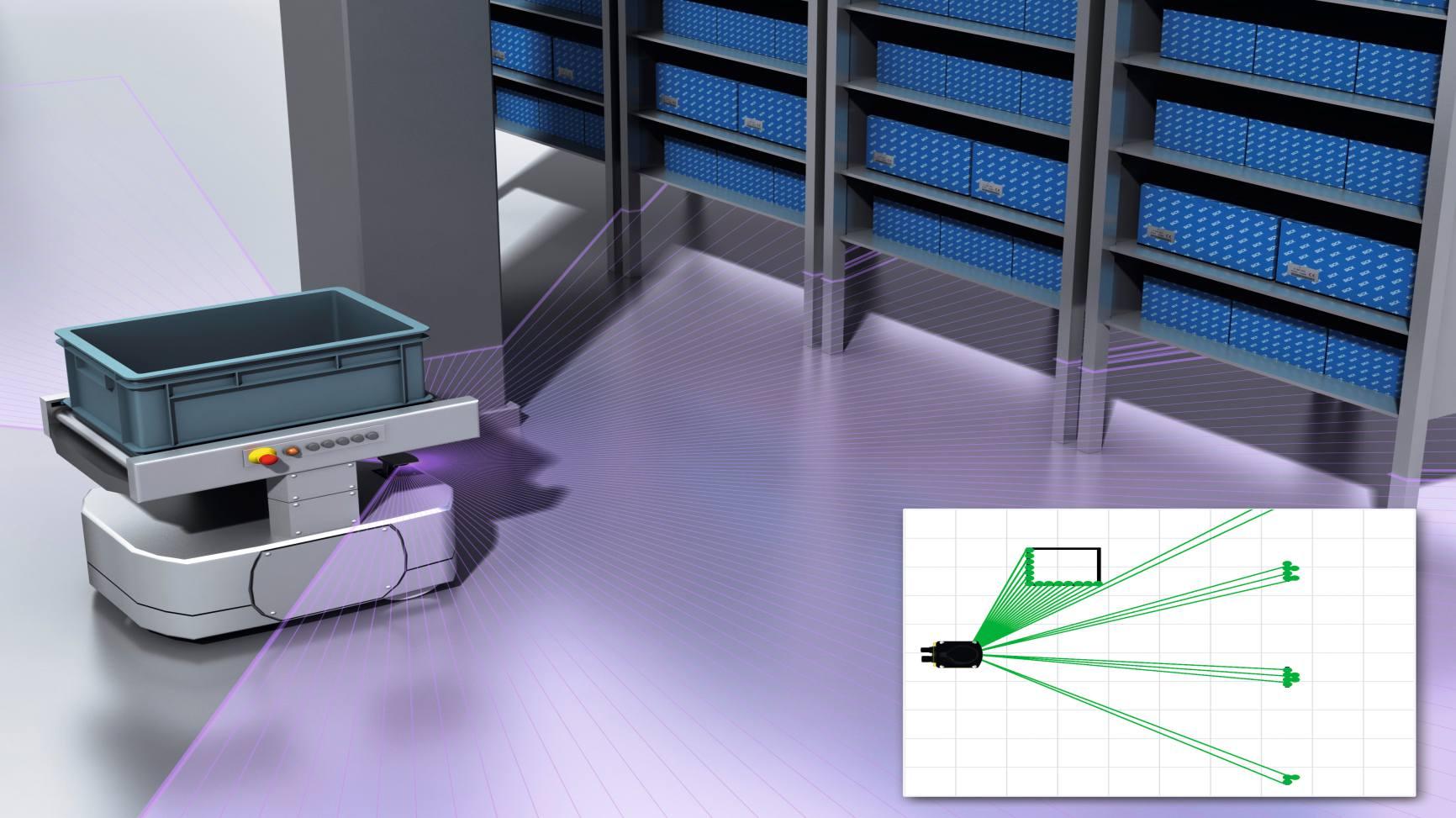

From electric li�ing trucks and order pickers to tugs and mobile transport pla�orms, warehouses are benefi�ng from SICK Automa�on's2D LiDAR sensors. These sensors from the TiM series ensure collision-free manoeuvring and precise measurement data fornaviga�on.

To enable transport and picking vehicles to operate autonomously they must be protected against collisions and equipped with the op�on for self-naviga�on. SICK's TiM 2D LiDAR sensors sa�sfy requirements for integra�on capacity, course-plo�ng and rou�ng, obstacle detec�on, and cater to safety-related applica�ons.

The 2D LiDAR sensors in the TiM series are designed for quick and simple plug-and-play integra�on,with a design that takes shock and vibra�on resistance and ambient light immunity into account. All 2D LiDAR products

feature innova�ve HDDM technology which enables both mobile and sta�onary obstacles to be reliably detected. Detec�on is reliable regardless of material, surface structures, colour or ligh�ng. Eye-safe infrared light and High Defini�on Distance Measurement (HDDM) technology were designed, developed and patented by SICK.

SICK Automa�on's TiM range offers applica�on-orientated solu�ons that meet key device-related requirements. The Tim1xx weighs just 90 grams and requires only 2.2W of power. This compact, energy efficient model delivers long, interrup�on-free opera�on. The TiM361S is safety-cer�fied in accordance with EN ISO 13849-1:2015 and is the perfect combina�on of measurement performance and func�onal safety. Opera�ng in the safety range from 0.05cm to 4m, it has up to 48 independent monitoring fields and

as many monitoring scenarios and protec�ve field geometries can be set up as needed.The compact TiM5xx has a height of only 86 millimetres making it ideal for object detec�on, posi�on detec�on and naviga�on in confined installa�on spaces with a working range up to 25m. These are just a few examples from SICK's wide range of 2D LiDAR scanner op�ons.

The world of autonomous-mobile intralogis�cs requires intelligent sensors that are able to deliver real-�me naviga�onal and environmental informa�on to self-driving vehicles, pla�orms and robots.SICK's 2D LiDAR Sensors in the TiM range deliver precision, reliability and speed to effec�vely support naviga�on and posi�on determina�on data and consistently avoid collisions.

IF “GREED” WAS THE BUZZWORD 20 YEARS AGO, one could argue that today it is “choice.” In choice, there is power

When our founder, Jerry Dyess, had the vision for Choose Energy, his goal was to demys�fy the u�li�es business for the average consumer. Quite simply, energy is a commodity and a need. And, the more choices, the be�er it is for everyone involved. Tradi�onal retail companies have long thrived by providing consumers with op�ons. The prolifera�on of online marketplaces has given consumers the ability to make smart choices and save money on everything from car insurance to healthcare. However, un�l recently, consumers didn't have a choice when it came to energy – one of the few things that they literally can't live without. In states where energy deregula�on is becoming more and more prevalent as it has in other countries, many of the consumers in these states either do not know that they have op�ons, and if they are aware, they likely do not know what or how to choose. That is where the power of the energy marketplace comes in.

At Choose Energy, we not only provide the online pla�orm to purchase the commodity

of energy, but we act as a connector and facilitator, allowing customers to compare and shop for their electric, natural gas and other energy providers. Energy marketplaces provide consumers the ability to see all of the energy supplier's offers in one convenient place so they can compare one offer with another, side by side. O�en these same consumers receive offers from energy companies that sound like a good deal but there is no way for them to compare the costs or the benefits with alterna�ve op�ons. We help them find the right place and the right planwhether they are looking for a fixed plan, a shor�erm op�on, cost savings or a greener choice. Finally, the consumer doesn't have to blindly pay their energy bill and feel like they have no choice when it comes to the provider who keeps their lights and their heat on.

We also help the energy suppliers communicate their services through a trustworthy pla�orm so they can a�ract and retain the right consumers. Suppliers now are compe�ng for the customer's business, which puts the consumer in the driver's seat. Energy marketplaces benefit the consumer

and the provider, by offering services such as comparison, transparency, ease of enrollment and strong customer service while guiding consumers through the decision-making process of comparing and/or switching suppliers. Imagine 20 years ago – even 10 –being able to go online and shop for energy needs. We are currently in eight deregulated electricity states and just announced in January that we have expanded into six deregulated natural gas states, with plans to launch our services in three more states this month.

Educa�on is a key factor in the expansion of energy choices and the deregula�on process. In deregulated energy states in the United States (in which more than half the U.S. popula�on lives), once consumers were given a choice in energy providers, they may have found themselves overwhelmed with monthly mail inserts, door hangers, or mul�level marke�ng agents ringing doorbells and phones. These channels were the only op�on the energy companies had – but now retail energy suppliers are reviewing their marke�ng budget alloca�ons and realizing that the changes in regula�on have brought new op�ons and new marke�ng channels,

Since energy is a commodity and a need, more choices are better for all parties in the industry

which benefit them.

This complexity behind the energy sales and marke�ng processes create confusion for the consumer, and is the reason that educa�on is paramount. In addi�on, educa�on varies by market. For example, Texas, Pennsylvania, Connec�cut and Illinois have reached greater than 50 percent deregulated electricity market adop�on over the past few years. There is currently more educa�on in these deregulated states on electricity op�ons, so we are building on that awareness to inform consumers that natural gas choices are also available. One of the great things about Choose Energy is that people can switch electricity and natural gas in one place, at one �me (in states where available).

With this winter's energy bills substan�ally higher due to the much-reported “Polar

Vortex” and other weather extremes across the country – consumers are paying more a�en�on to their energy bills.

Many states are also experiencing rate hike announcements, so we expect more and more consumers to take control of their energy op�ons. Choose Energy is growing over 100 percent a year in all of our markets. While cost is important, energy choices aren't limited to price. Some consumers have made the decision to change providers because they want a renewable plan as part of the “green movement.” Un�l fairly recently, renewable choices were challenging for consumers to access. Today, up to 20 percent of Choose Energy's customers have chosen offerings that come from renewable sources. While not always the least expensive, it is perfect for those who are commi�ed to

making environmentally conscious shopping decisions.

Others are searching for the best price or a way to manage their budgets, removing the risk of energy price increases. The typical consumer in a deregulated market can save as much as much 25 percent on their yearly energy bill.

This is truly a game changer for the u�li�es business. Deregula�on has provided people with the ability to choose energy providers. With the pla�orm to pair the consumer with the provider based on their individual needs down to the details of region, climate, psychographics, demographics, economics and priori�es – energy marketplaces have the power to personalize that choice.

With over 20 years of experience in the field, EGI Industries has a department that specializes in automated applica�on of thermal coa�ngs to extend the life of cri�cal industrial mechanical parts. EGI Industries serves various types of industries at all stages from prototyping to high-volume parts produc�on. EGI Industries acquired an ultra modern thermal spray system that builds coa�ngs with excep�onal proper�es. We are equipped with a metallography laboratory to

In addi�on, EGI Industries', services are based on internal and external R&D to create, improve and develop processes that serve to provide solu�ons tailored to the needs of each and every client. It is also one way in which we respect one of our biggest corporate values: being open to innova�on. With machining and finishing, EGI Industries offers turnkey solu�ons for all of your failing,

and wearing parts inside your equipment. Our process is quite unique. Clients in various industries mostly all experience parts and equipment failures such as valves, pumps, air locks, sha�s and so forth; all of which could not withstand either the chemicals being used, temperature or abrasive materials they are in contact with. Replacing parts, and equipment is extremely costly and not forge�ng the cri�cal and expensive down�me that is incurred.

Valves/Pumps are an example, which are commonly found in mine sites all around the world. Certain makes and models can cost within the range of tens to hundreds of thousands of dollars. These name brand valves do not always have an�-wear coa�ngs, which is needed to withstand the abrasive chemicals passing through. We rebuild all makes, models, and sizes for valves/pump housings and other components back to the original manufacturers' specifica�ons at a frac�on of the cost for a new replacement. Our warrantee backs all of our parts and work.

As solu�on experts, our goals are to produce the longest las�ng parts with excep�onal quality. We customize every gear, pinion, and gearbox internals with the best steeltreatments currently available. We cer�fy every gear and gearbox refurbishment/upgrade with test bench reports and include a warranty to our clients assuring them they're well taken care of. We teach our clients that many gears may look similar; however, looks are deceiving to the untrained eye. Gear steel quality, origin of the steel, treatments perhaps used, chemical composi�on before and a�er treatments, and overall strength all are ponderous factors to

be considered when bearing in mind the reliability of your gears inside your crucial equipment. Higher quality generally means higher price-per-item. Clients looking only at price sa�sfying their budget numbers unfortunately discover catastrophic and/or even premature failure that ends up cos�ng the plant numerous hours or days of costly down�me. This unacceptable predicament is one we simply cannot stand for and we will do everything in our power to prevent our clients from falling vic�m to it. It may be simple and fast to cut corners and produce inferior components; however, at EGI, you will never need to worry about that; guaranteed.

We are a direct OEM factory which manufactures directly for you the end user. We have all available machinery to build your requirements. We design, and build in

accordance to approved drawings.

1. Spare parts commonly for the mining industry such as mills, crushers, mine hoisters, and mobile equipment such as excavators, cranes and dozers.

2. Spare parts for wellhead equipment found in the oil and gas industry, such as semi-finished Stabilizers and BOP bodies.

3. Design and manufacture whatever your requirements call for. Our engineering department will work with you and your team to gather all the cri�cal details and build accordingly.

4. Forging & Cas�ng, Machining, Heat Treatment service are offered.

Fibertex geosynthe�c solu�ons for road maintenance, include Fibertex AM-2, which is a flexible needle punched nonwoven paving fabric. This robust product, was specifically developed by Fibertex, for African road engineering condi�ons.

“The func�ons of Fibertex AM-2 are twofold: To avoid reflec�ve cracking of new asphalt. This material is used to prevent the propaga�on of cracking from an old pavement surface being transferred into a new re-sealed surface - stress relief,” says Lionel Kistan, export sales manager, Fibertex South Africa –manufacturers of geosynthe�c products.

“The second func�on of Fibertex AM-2 is to protect the subsoil from water intrusion and thereby loss of bearing capacity. In this case it is used to create an impermeable membrane layer – a seal - to prevent the ingress of surface water into road layer works through exis�ng cracks in the pavement.

“When water saturates the load bearing layers under a road surface, the bearing capacity of such layers reduce and crack forma�ons could eventually propagate and lead to pothole forma�on under the dynamic loads of heavy traffic.

“This membrane also act as a Stress

Absorbing Membrane Interlayer (SAMI) to prevent surface stress cracking by absorbing stresses imposed by differen�al loads.”

The Fibertex AM-2 system can be applied mechanically for large volume installa�ons, as well as manually in cases where narrow width installa�ons are required. By using Fibertex AM-2 paving fabric in road maintenance projects, future maintenance cycles can be reduced; full road rehabilita�on projects can be postponed and pavement life can be extended, which means substan�al cost savings.

Addi�onally, when using Fibertex F-grade geotex�les in a basal separa�on applica�on below the road prism, the road design can be adjusted to decrease the thickness of load bearing layers, while s�ll maintaining or even increasing its load bearing capacity. This results in a more cost effec�ve design. Alterna�vely, without the use of a separa�on fabric in weak subgrade condi�ons, punching of engineered aggregate into the weak subgrade could occur, as well as ingress of the below subgrade into the engineered fill material. As a result, the bearing capacity of the base course could be reduced over �me, which could lead to basal failure of the road. Virgin PP geotex�les have a high level of chemical stability over a wide pH range and are thus suitable for applica�on in most civil engineering environmental condi�ons. This characteris�c ensures its durability, where product failure might not only impact on project cost, but could have a long term environmental impact.

Fibertex UV stabilised virgin PP geotex�les are the only nonwoven geotex�les produced in Africa with cer�fica�on for durability of over 100 years, in accordance with the latest EN standards.

This range of environmentally-friendly geosynthe�c materials encompasses nonwoven and woven geotex�les, gabions and ma�resses, drainage pipes and fi�ngs and erosion control and cellular confinement solu�ons. The company also supplies soil reinforcement and stabilisa�on products, including geogrids and geocells, as well as geosynthe�c clay liners (GCL) and geomembranes (GMB) that can be used as part of composite lining systems in waste containment solu�ons.

Fibertex South Africa's team of experts from branches in KwaZulu-Natal, Gauteng and the Western Cape offers a technical advisory and support service, to ensure correct specifica�on of durable and safe materials for every project.

Originated