RISKMANAGEMENT Africa’sown RiskManagementJournal Nov-Dec2022>Issue6>Vol.#8 www.riskmanagementinsight.co.za R I S K MA N A G E ME N T I N S I G H T 7 Weighing up risk Pg10 Building design must incorporate effective disaster management Pg18 A unique, innovative concept for the ultimate solution of material ow problems Pg26 RISK MANAGEMENT Insight

C O N T E N T S 13 16 18 26 42 www.riskmanagementinsight.co.za 04 06 Minister Pandor gives a boost to COS initiative … … SAIW to play major role in the welding sector Businesses can make a difference through correct separation-at-source SMART-100 Tramp Metal Detector Building design must incorporate effective disaster management A unique, innovative concept for the ultimate solution of material ow problems WolfPack Nov - Dec 2022

Front cover SAIW

Editor

Goodwill Sibanda

Lenox Marufu lenox@riskmanagementinsight.co.za

Kelvin Nkonhla kelvin@riskmanagementinsight.co.za

Frank Spick Frank@riskmanagementinsight.co.za

Muthulisi Nkiwa muthulisi@riskmanagementinsight.co.za

Kennedy Chama kennedy@riskmanagementinsight.co.za

Peter Johnson

Editor’s Comments

Ladies and gentlemen welcome to this edition of this wonderful magazine. Our aim is to keep you informed on risks which we encounter everyday as we do business. In this issue I will talk about cybercrime which is a concern to governments and the cooperate world. The Oxford dictionary denes cybercrime as criminal activities carried out by means of a computer on the internet. Others dene it as crime which a computer is the object of the crime or is used as tool to commit the offence. This could be child phonography, hate crime or hacking of organizational computers. With the amount of data stored in data bases around the world, this has made the use of the internet very important. Data can be easily accessed at the press of a button. The infusion of the internet has changed the way we handle data and at the same time more threats to held information has arose with this infusion. Fraudsters have managed to transfer money from different bank accounts and have remained unapprehended. Cooperate data has disappeared when computer induced viruses and malware attacked company data bases. In the USA a teenager boy managed to hack into the Pentagon computer system for fun. This exposed the data security of the Pentagon. Software designed to disturb or cause damage to computers have been designed and are being sent out to different computers through emails which once opened pass the virus to the computer leading to its malfunction. In the last year cybercrime has been rmly established as one of the biggest threats to democracy, privacy and health and safety Terrorists groups are also now using the internet to champion their cause. While money laundering is at a huge scale on the internet. Child phonography is also a huge concern as children are targeted by unruly elements and subjected to horric pictures aimed at inuencing their behavior Recently cyber criminals have been demonstrating that their activities are becoming more about nancial gain and recognition. Although this was always the motivation, after all the easiest means of making money is to get hold of personal records and sell them on the dark web. We are witnessing a notable increase of attacks for this purpose. To prevent cybercrime from taking place in organisations there is need to employ cyber security Cyber security is the body of technologies, processes and and practices designed to protect networks, computer programs and data from attack, damage and unauthorized access. This include Application security, Information security, Network security, Operational security Business continuity plans and End user education. One of the most problematic elements of cyber security is the quality and constantly evolving nature of security risks. In other words the threat is advancing quicker than we can keep up with it. As a result cyber criminals always change their ways and continue to commit crimes and untold damages to unsuspecting people, In conclusion the risk of cybercrime is real and as risk personnel should be able to come up with

Editor G. Sibanda

www.riskmanagementinsight.co.za 05

Nov - Dec 2022

Accounts Sharon Moyo accounts@riskmanagementinsight.co.za Subscription Thato Ndlovu subscription@riskmanagementinsight.co.za Disclaimer: All material is strictly copyright. The magazine or any part thereof may not be reproduced or adapted without writen permission from the publisher: Risk Management Insight welcomes material submi�ed for publica�on retains the right to edit copy. The views expressed in the publica�on not considered those of the publisher (CLEOPAS PROJECTS), which accepts no liability of any nature arising out of or in connec�on with the contents of this magazine. While every effort has been taken in compiling this publica�on, the publisher does not gi e warranty as to the completeness or accuracy of its content. The publisher and the editor cannot accept responsibility for any loss inconvenience & damage that may occur there from. info@riskmanagementinsight.co.za sales@riskmanagement.co.za landline +27 11 058 0879 www.riskmanagementinsight.co.za Like us on our facebook page RISKMANAGEMENT own ManagementJournal July-August2017 Issue Vol.6# www.riskmanagementinsight.co.za RISKMANAGEMENT Africa’ RiskManagementJournal July-August2017 Issue2> ol.6# www.riskmanagementinsight.co.za Seaco Tank Containers For Liquids And Gases Pg20 Beyond complexity customized solutions through collaboration Pg23

RISKMANAGEMENT Africa’ RiskManagementJournal Jan-Feb2018>Issue ol.#7 Biological Infectious Waste Disposal Systems Pg10 tank containers for and gases Pg30 RISKMANAGEMENT Africa’ RiskManagementJournal Mar-Apr2018>Issue6>Vol.#7 www.riskmanagementinsight.co.za Weighing up risk Pg10 design incorporate effective management Pg18 A unique, innovative concept the solution material ow problems Previous publications RISK MANAGEMENT Insight

security measures to minimise this risk. Best Regards

https:www.facebook.com/riskmanagement.co.za

Design & layout

editor@riskmanagementinsight.co.za Sales

RISKMANAGEMENT Africa’sown RiskManagementJournal Nov-Dec2022>Issue6>Vol.#8 .riskmanagementinsight.co.za Weighing up risk Pg10 Building design must incorporate effective disaster management Pg18 A unique, innovative concept for the ultimate solution of material ow problems Pg26 RISK Insight

Minister Pandor gives a boost to COS initiative …

… SAIW to play major role in the welding sector

Department of Higher Education and Training (DHET) Minister, Naledi Pandor, at a recent meeting with captains of industry, has emphasised the importance of the department's training initiative to boost youth employment in South Africa Referred to as the Centres of Specialisation (COS), the programme aims to secure partnerships between the industry and 26 Technical and Vocational Education and Training (TVET) colleges, countrywide, for the training of top artisans in 13 priority trade sectors.

One of these sectors is welding and the Southern African Institute of Welding (SAIW), the leading welding training organisation in Africa, has been awarded the contract from the DHET to act as the 'Quality Custodian' of the process in the welding industry Moreover, SAIW's Etienne Nell has been appointed the industry's Occupational Team Convener for the implementation of the Quality Council for Trades and Occupations (QCTO) Artisan Welder Curriculum (NOCC –

A21 which is aimed at producing: a skilled and capable workforce to support economic growth; an increased availability of intermediate skills and an increased delivery of properly qualied artisan welders, at the Centres of Specialisation.

“The Minister is fully committed to the QCTO programme, which ultimately puts pay to the failed 'Learnership' idea. This is an excellent thing for the welding industry and all other trades in South Africa,” Nell says.

One of Nell's rst tasks was to nd the two welding TVET partners and, after visiting several colleges, the Boland College in Worcester and the East Midlands College in Uitenhage were selected. These colleges will run the QCTO's 'dual' training system, which combines technical education and practical training with authentic work experience in a fabricator's workshop.

Meanwhile the National Skills Fund has set aside R150 million to support the partner colleges across all the sectors to ensure they are up-to-date and ready for

training. For the welding industry, it will be Nell's responsibility to help the two chosen colleges to procure the equipment, train the trainers and generally ensure that their infrastructures are in the appropriate condition for training

SAIW executive director, Sean Blake, says that Minister Pandor's support of this programme is wonderful news for the welding industry “The Minister has said that national associations have a key role to play in modernising TVET colleges' system for the production of intermediate-level skills and the SAIW is certainly ready to rise to the challenge,” he says.

He adds that bringing together of all the right players, including the various industries, government and business, in a cohesive programme will do wonders in helping to improve the skills situation in this country “This is long overdue and the SAIW commits to doing all it can to make the initiative a success,” he concluded.

06 www.riskmanagementinsight.co.za

Nov - Dec 2022

Carl Hamm embarks on an aggressive growth strategy

Germany-based pipe and pump solutions provider Carl Hamm has embarked on an aggressive growth strategy which has seen it establish a South African subsidiary Carl Hamm Pipes Pumps Solutions (Pty) ltd business to focus on mining-related dewatering opportunities on the African continent using its proven ZSM coupling system. It offers a safe, quick and angeless installation solution which is ideally suited to managing acid mine drainage (AMD)

While Carl Hamm has not largely focused on the South African/African market over its 90 year history, Munnick recognised the potential its ZSM coupling system offered in heavy-duty, hanging AMD applications and oversaw its successful implementation in all three of the country's AMD treatment plants across the three Witwatersrand Basins.

The design and advantages of the ZSM coupling, noting that ZSM is a German acronym for 'Zo spoedig mogelijk', which in English simply translates to 'as quickly as possible'. “This is the core benet of our system, which is

far quicker to install and maintain than the alternate ange pipe connection,” he highlights.

ZSM is an axial, non-positive and detachable tight sleeve pipe connection which is ideally suited to hanging pipe/pumping vertical shaft dewatering applications. The patent-protected tight sleeve connection is, according to the company, a “unique” alternative to other conventional connection systems thanks to its quick and easy assembly/disassembly, space-saving design. The design is available from 50 nb to 1.4 m nb and can be installed in from surface over 1 400 m.

Basically, the combination of a spigot end, sleeve, O-rings and shearing elements enable pipes to be joined quickly, securely and are also electrically safe – unlike a ange which takes a signicant time to install and requires attention to detail to ensure accuracy

The ZSM connection excels owing to its cost effectiveness, especially when used with high-performance submersible pumps where time-saving assembly and disassembly

deliver major impacts on heavy-duty pumping requirements. The uncomplicated disassembly of the pipe section guarantees shorter times (up to a third less time) when changing a pump which in an AMD application is critical. This is highly relevant to the South African environment when AMD generated from the enormous underground workings of historic gold mines requires intensive pipe and pumping activity to prevent millions of litres of water from decanting to surface every day The system is safe in that staff no longer have to enter the mine to work on equipment. All is controlled, installed and removed from surface.

Outside of dewatering applications, the hanging pipe/pump system is perfectly suited to concrete batch pumping systems which are used for shaft sinking projects Munnick explains that pumping concrete underground works optimally with a perfectly straight pipe system – which is exactly what ZSM delivers.

For more info visit: www.carl-hamm.co.za

07 www.riskmanagementinsight.co.za

Nov - Dec 2022

Dekka is the industry leader in packaging machinery tape heads

Dekka is the industry leader in packaging machinery tape heads with technological advances like the no break tape advance system and an open design for easy threading Being one of the few companies dedicated to tape head manufacturing, we are able to keep a high standard of quality with exible solutions with a variety of tab sizes, lengths and speeds.

Dekka offers over 400 unique tape heads to t on almost every case sealer, erector, former or packer in the market. This versatility extends to the types of packaging tape and cases that our tape heads are able to handle as well including hot melt, acrylic, rubber, and other types of tapes for cases, boxes, recycled cartons and more. The wide range of our products has driven and been driven by the overwhelming demand for our product. Dekka customers understand the importance of the quality, reliability and service that comes with each Dekka tape head.

Dekka has also recently introduced its new machinery line, bringing the same level of quality and reliability from our tape heads to case sealing and erecting machinery These machines have been designed and built to synergize with Dekka tape heads to bring the highest level of performance and reliability to our customers.

Main Products:

DEKKA SE

The DEKKA SE is our agship tape head and the majority of our products are based around this design. This tape head is built with premium stainless-steel materials, open side wall for easy tape threading, and our exclusive No Break Tape Advance for reliable performance. The success of this tape head is in the details as although the tape head design is relatively simple, it reliably gets the job done every single time.

DEKKA 100

The DEKKA 100 is a pressure sensitive, bottom belt, semiautomatic case sealer It is designed to be the perfect pairing for the Dekka tape-head, providing an economic and reliable case sealing solution. It is designed with a heavy-duty structure and space saving design.

The DEKKA 100 is able to handle a wide range of case

sizes and can easily be changed to adapt different cases with a quick 2 point size change over The machine is simple and easy to use with helpful pictorial guides and color-coded size change labels The machine was designed with maintenance in mind with easy access to belt and tape head changes.

08 www.riskmanagementinsight.co.za

Nov - Dec 2022

Benets and uses of redeployable devices –Body Worn Camera, Speed Dome and Site Tower

There are multiple benets to implementing a Redeployable CCTV programme. With reduced set-up costs and ease of installation through to scalability and future-proong, WCCTV's clients across both the public and private sectors have benetted from integrating Redeployable CCTV into their monitoring strategy

The simple yet functional design of the WCCTV Body Worn Camera lends itself to ease of use, with a simple onebutton record mechanism. The award-winning Body Worn Camera's video solutions are fully scalable, making them suitable for the largest complex law enforcement deployments down to single-use cameras. It offers live transmission of video, audio, real-time alerts and GPS information via 4G/3G and Wi-Fi connectivity It enables an operator to connect to the Body Worn Camera in the eld, view the live video, communicate with the wearer and understand their position via GPS Alternatively, the wearer can send an alert back to the control room.

The Body Worn Cameras has been named as a nalist in the Safety and Health Excellence Awards (SHE). The WCCTV Body Worn Camera has previously been awarded 3

ASIS Accolades (Security's Best, Judge's Choice, People's Choice), a SIA New Product Showcase Award for Best HD Surveillance Camera and was a nalist for CCTV Camera Equipment of the Year at the IFSEC Security and Fire Awards.

The WCCTV 4G HD Speed Dome Camera is a day to night camera with 360° movement, offering the best view and capturing of events. The camera has no blind spots and is used for middle to large scale surveillance areas. The low streaming bandwidth allows high-quality live video with no delay The Speed Dome Camera is mainly useful in terms of safety, but it has other uses as well. Trafc disruption patterns and antisocial behaviour reduction are two ways in which the Speed Dome Camera is necessary for maintaining a safe and secure environment. Receive email alarms and notications of possible interferences or trafc sent directly to you. The Speed Dome Camera is an essential safety must have with a complete, lightweight integrated unit. The portable and rapidly deployable dome is perfect to move anywhere, inside or outside, because it has a 2MP day/night camera.

The WCCTV Site Tower is specically designed to provide all-in-one site surveillance for temporary sites such as construction, demolition and highways infrastructure projects. The Site Tower is a rapid-deployment CCTV system which means that it can be fully operational in minutes. The exible power methods make it suitable for deployment even in the most remote location because it doesn't require any supporting infrastructure. The Site Tower is ideal for any temporary, mobile or semipermanent applications and it can be installed and moved for short to long-term purposes, making it a very convenient health and safety measure. The Site Tower is used for health and safety, which will control any losses on site, by providing surveillance.

WCCTV's continuous product development and customer focused approach has lead to ongoing improvements in its redeployable CCTV systems WCCTV prides itself on providing unrivalled customer support and focuses on continual technical product development to meet its customers changing requirements.

09 www.riskmanagementinsight.co.za

Nov - Dec 2022

Weighing up risk

In excess of 60% of the SADC group of countries combined GDP comprises goods that are weighed at some point in their transition to market, whether locally or as exports. Weighing is therefore profoundly important.

Risks are Higher in Industrial Sectors

Weighing breaks down into basically retail weighing, comprising goods sold through large and small retail outlets, and the much larger component termed industrial weighing The risks associated with decient weighing within the retail sector are comparatively low, but the same cannot be said for industrial weighing and these risks have been growing

Prior to the advent of the digital age, globalization, expanding trade within the SADC region, the introduction of axle weighing overloading regulations throughout SADC, the introduction of SOLAS regulations which has impacted all global containers exports by sea, industrial weighing was a mundane process involving trucks driving over weighbridges with the results being written down, and eventually captured into an accounting system.

In this “mundane age” of industrial weighing risks of decient weighing were low, and the scale companies providing industrial weighing equipment and services were equally mundane The business of these participants was essential the installation of scales and the maintenance and repair thereof

Changing Dynamics are Increasing the Risks

The term “decient weighing”, includes weighing done on devices that are unapproved, weighing done on devices that are inaccurate, weighing software that is not compliant and weighing software that does not enable real time weighing data to be supplied.

Understanding the signicant risks associated with “decient weighing” in today's rapidly changing market place requires one to dissect the associated risks that arise from directly from the new trade dynamics, laws and regulations and technologies that impact on and shape our industrial trade ows in today's global economy

Each of these dynamics and the associated risks can be

summarized as follows:

1. Introduction of axle weighing overloading regulation: nd In South Africa, the Road Trafc Act 22 Amendment requires that, for every load, the transporter and or consignor must produce and retain proof that each vehicle in question is loaded to within permissible limits Government weighing stations both in South Africa and the rest of SADC then weigh vehicles to ensure they are within limits.

Failure to be able to prove full compliance with the Road nd Trafc Act 22 amendment will result in large potential nes for non- compliance, potential nes for overloading at government weighing stations, the possible required discharging of cargoes at government weighing stations so as remedy overloading causing resultant delays and added costs and nally the possibility of insurance cover being rendered null and void in the event of an accidents.

2. Compliance with SOLAS regulations on containers shipped by sea:

10 www.riskmanagementinsight.co.za

Nov - Dec 2022

Weighing up risk

Validity of Transporter's Third Party insurance cover called into question without proof of compliant axle loading and total loading.

IMO SOLAS regulations require that, for every container to be transported by sea, the owner of that cargo must determine the gross mass of the container on an approved weighing device, and must generate documentary proof thereof in a specied format.

Failure to comply with these regulations will prevent containers being allowed into departure ports risking delays and added costs.

3. Controlling in transit stock losses

The volume and value of goods transported around SADC countries by road are vast.

Stock losses in transit can only be controlled and managed if volumes of goods load and the point of loading and the volume of goods discharged at the point of loading are determined with great accuracy

Weighing is the obvious way of establishing these values, and is highly effective when these values are integrated into an overall ERP system so as to make real time reconciliations possible.

Solutions to Mitigate Weighing Related Risks

Weighing related risks can only be mitigated through management having access to accurate and compete weighing data on a real-time basis. The provision of these types of solutions are therefore key

While a number of software companies have sought to provide these solutions, they have generally lacked the base weighing knowledge and understanding of weighing devices, which has curtailed their success.

With one notable exception, most of the scale companies that historically focused on the supply, servicing and

repair of scales, in the “mundane age” of weighing have continued to focus on service and repair of scales.

The notable exception is Sasco, which traded as during the mundane age” of weighing as the South African Scale Company Sasco commenced trading in 1910 and was the market leader during both the mechanical age of weighing and in the in subsequent electronic analogue age of weighing

Sasco transformation into the leading weighing data systems provider has been achieved by securing rights to the most advanced digital weighing technologies, integrating these devices with micro-computer systems capable of providing fully automated weighing solutions and the complete integration of this data to real- time ERP and cloud based solutions.

11 www.riskmanagementinsight.co.za

Nov - Dec 2022

Businesses can make a difference through correct separation-at-source

South Africa's paper recovery rate is well above the global average at 68.4% of recoverable paper This means that 1.4 million tonnes of paper and paper packaging was diverted from landll in 2016, with a majority of this being paper packaging This would cover 254 soccer elds.

However, it is estimated that less than 10% of businesses recycle their used paper and cardboard. “This represent a signicant opportunity for business, commercial ofce parks and retail outlets to make a difference by not only recycling but setting up systems and infrastructure to make it happen,” says Ursula Henneberry, operations director for the Paper Recycling Association of South Africa (PRASA).

Recycling reduces waste going to landll, provides raw material for new products and sustains jobs - in the formal sector, for small enterprises and waste pickers.

Four common recycling mistakes in an ofce environment Henneberry outlines four common recycling blunders with helpful tips to make sure that paper and board remain in a clean and dry condition for effective reprocessing

Mistake 1: Putting non-recyclable paper products into the recycling bin

Some paper-based items should not be recycled due to contamination and elements like waxes, foils and glues: dirty paper plates, cigarette butts, tissues, toilet paper, paper towel, sticky notes, carbon paper, as well as foillined, wax-coated and laminated paper

Educate and empower:

· Educate employees and cleaning teams around what is recyclable and what is not.

·Use printable material available on www.recyclepaper.co.za

· Appoint a recycling champion to manage the programme.

Mistake 2: Putting wet waste into the recycling bin

Wet waste – food, tea bags, cigarette butts and soiled take-away containers – contaminates the paper and reduces its value. Paper also starts to degrade once wet.

Keep it separate:

· Set-up a two-bin system – receptacles for paper-only and bins for food, liquid and non-recyclable waste.

Mistake 3: Making it difcult and time-consuming for employees to recycle

We are all human. Nobody likes to walk too far to throw something away

An Australian study showed that paper recycling rose from 28% with one bin per ofce to 94% when paper trays were located on desks.

Make it easier:

· Ensure that each desk has a paper-only bin.

· Install paper-only bins in key locations: printing/copying stations, meeting and break rooms, kitchen areas and reception.

· For every paper-only bin, there should be a general bin alongside it.

Mistake 4: Not knowing what to do with your recyclables

Your ofce has collected all this paper but doesn't know what to do with it.

How to correct these mistakes:

· Assign a sheltered area to keep recycled paper clean and dry

· Partner with a collection agent – a big company, a smaller business or an informal collector

· Support a local school or charity's recycling fundraising initiatives.

www.recyclepaper.co.za

13 www.riskmanagementinsight.co.za

Nov - Dec 2022

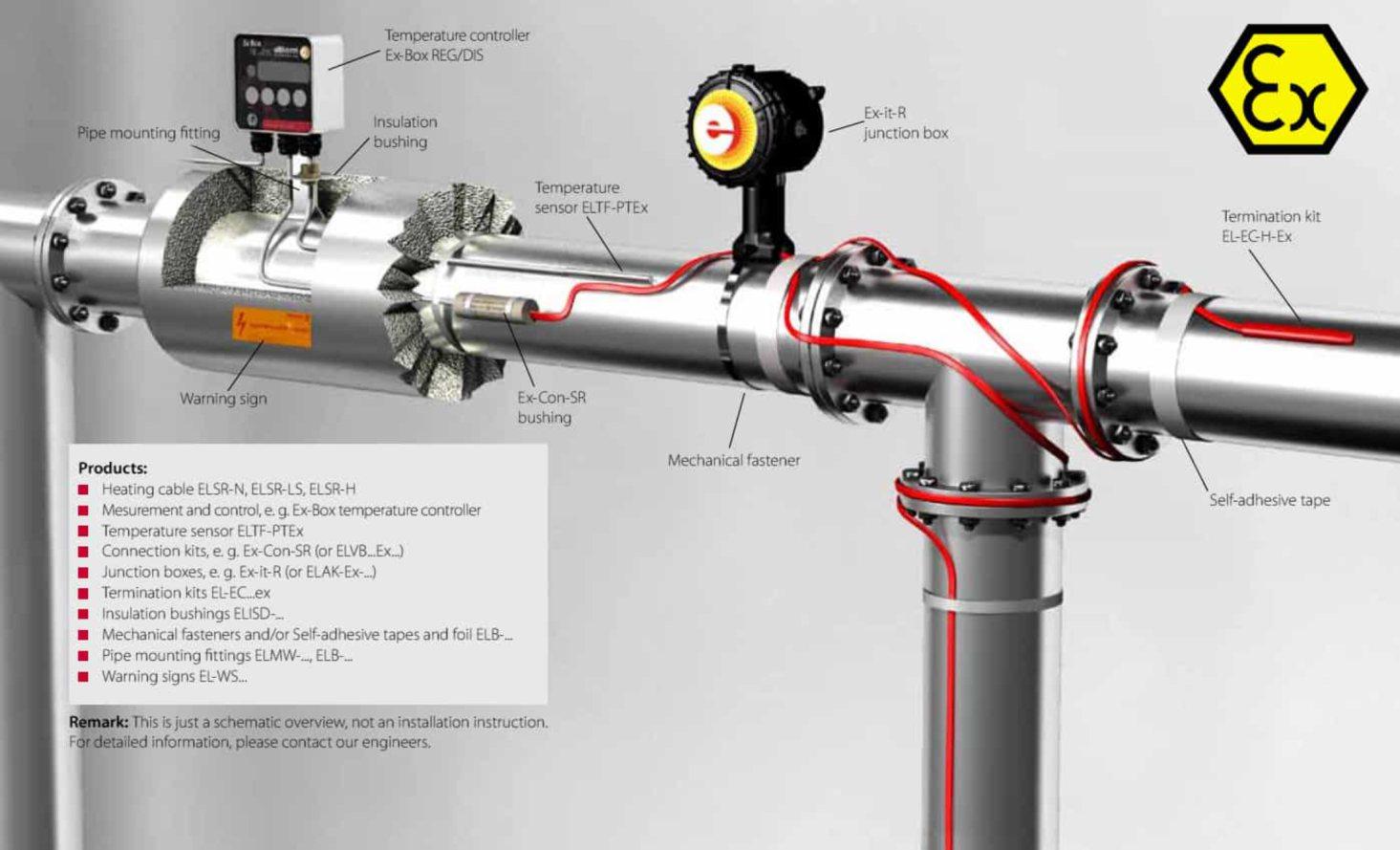

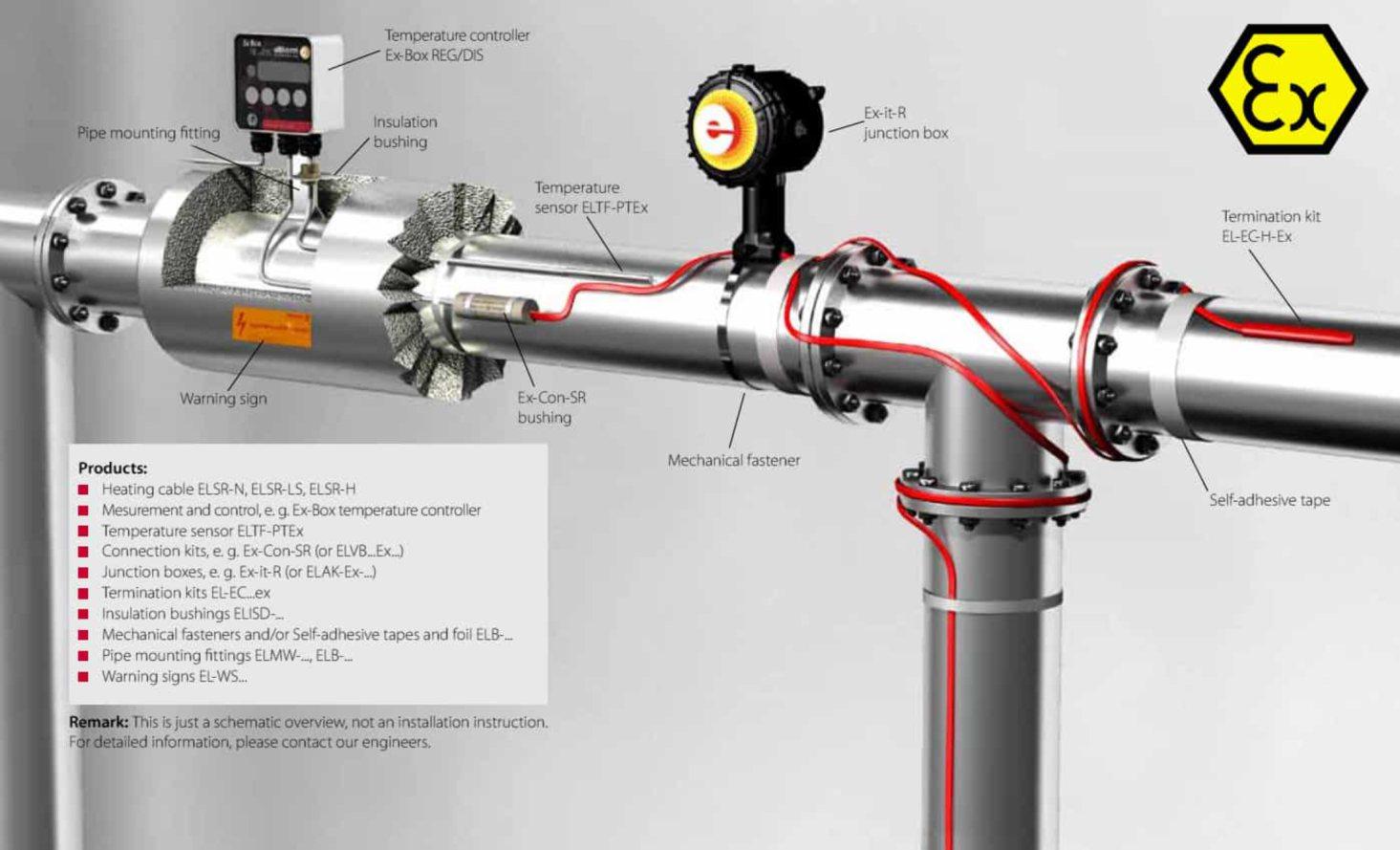

Electrical heat tracing for Ex areas

Electrical heat tracing (EHT), heat tape or cable, is a system used to maintain or raise the temperature on vessels, tanks, pipes and valves. Essentially, it uses an electrical heating element that runs the length of a pipe; this heating element is then used to regulate temperature. “Electrical heat tracing can assist plant and process managers to alleviate stubborn viscosity sensitive products and processes. This also ensures that pumps don't malfunction due to cavitation and pipes don't get blocked, mitigating costly repairs and maintenance.” explains, Peter Stone, Managing Director of eltherm South Africa.

eltherm, as an ATEX and IECEx-certied company, fullls the increased safety standards according to the latest Exguidelines.

Whether it is heating cables, heated hoses, heating mats and jackets, measurement and control appliances or ancillaries – for all its products eltherm has approved equivalents for heat tracing systems in hazardous locations.

Self-regulating Heating Cable

The versatile self-regulating heating cable ELSR-N is suited for frost protection and temperature maintenance in the low temperature range of industrial applications. It is approved for use in hazardous areas. The BOT version of this heating cable even withstands aggressive chemicals, oil and fuel and, thanks to this high chemical resistance, stands out for a long lifetime.

Advantages:

· Self-regulating

· Four nominal outputs

· Can be cut to length off the roll

· Moisture proof

· UV-resistant

· Approved for use in hazardous areas

Applications:

· Frost protection

· Heat tracing on level indicators

· Chemical & petrochemical industries

· Tank bottom heating of LNG storage tanks

· Pipe heat tracing

· Vessels and tanks

· Automotive

· Food processing industry

Constant Wattage Heating Cable with Resistance Wire

These parallel heating cables offer tremendous exibility in use, as they can easily be cut to the required length off the roll, with the assurance of constant power output. There is no need for a connecting cable and input can be unilateral.

It is quick and easy to assemble; this saves a lot of time, and reduces costs considerably as a result. Since output of up to 60 W/m is possible for lengths laid to piping, ELP parallel heating cables are particularly suitable for piping with high output requirements such as in industrial process technology

The particularly temperature resistant outer shell in Fluoropolymer and the high level of chemical resistance of the Fluoropolymer ensure a long useful life.

Advantages:

· Single end power input

· Can be cut off the roll

· Constant power output per meter

· Long life cycle

· Laying without exact measuring possible

· High chemical resistance

· UV resistance

Applications:

· Vessels, piping, valves

· Building construction

· Food processing industry

· Paper industry

Ex-Box Temperature Controller with Display

Ex-Box REG/DIS: Complying with latest Ex-protection directives 94/9/CE (ATEX 95) this electronic temperature controller has been designed and developed especially for its use in hazardous areas. Programming and operation is done via the integrated operating panel with display

Advantages:

· Rugged enclosure IP 65

· Operation and programming in hazardous area

· Increased safety through fail alarm

· Integrated heating circuit monitoring

· Display

Applications:

· Hazardous areas

· Power plants

14 www.riskmanagementinsight.co.za Nov - Dec 2022

Electrical heat tracing for Ex areas

· Chemical & petrochemical

· industries

· Oil & gas industries

· Pharmaceutical industry

· Plastics industry

· Wastewater treatment plants

Ex-Box Temperature Controller with LED-Display

Ex-Box REG/LED: Complying with latest Ex-protection directives 94/9/CE (ATEX 95) this electronic temperature controller has been designed and developed especially for its use in hazardous areas. Programming and operation is done via external Ex-Control manual control.

Advantages:

· Rugged enclosure IP 65

· Increased safety, tamperproof, no unauthorized adjustments

· Increased safety through fail alarm

· Integrated heating circuit monitoring

Applications:

· Hazardous areas

· Power plants

· Chemical & petrochemical industries

· Oil & gas industries

· Pharmaceutical industry

· Plastics industry

· Wastewater treatment plants

Ex-Box Limiter with Display

The Ex-Box LIM/DIS is a limiter for switching off heating circuits in case of excess temperature or current overload.

Output signal values for maximum and minimum temperatures are programmable Programming and operation is done via the integrated operating panel with display

Advantages:

· Rugged enclosure IP 65

· Operation and programming in hazardous areas

· Increased safety through fail alarm

· Integrated heating circuit monitoring

· Display

Applications:

· Hazardous areas

· Power plants

· Chemical & petrochemical industries

· Oil & gas industries

· Pharmaceutical industry

· Plastics industry

· Wastewater treatment plants

Temperature Sensor

This temperature sensor has been designed according to Ex standard 94/9/EG especially for use in explosive gas and dust atmosphere. An emphasis on safety, simple installation and tting accuracy were the requirements that our development engineers met.

Advantages:

· Impact protection (U-prole) for sensor protection

· Strain relief by hexagon-swaging

· Bend protection

· Decrease of parasitic coupling from surrounding electrical components because of uoropolymer shielded sensor cable

Applications:

· Hazardous areas

· Power plants

· Chemical and petrochemical plants

· Oil and gas industry

· Varnish and paint

· Heating of instruments, devices and plants

· Pipe, pump and valve heating

For more information about eltherms full range of electrical heat tracing products, go to www.eltherm.co.za, email: info@elthern.co.za or call 011 326 6475.

15 www.riskmanagementinsight.co.za Nov - Dec 2022

SMART-100 Tramp Metal Detector

A technically advanced Tramp Metal Detection system is vital in assisting mining companies in eliminating the damage caused to machinery by a tramp metal. Such system would save mines costly downtime and repairs to damaged processing equipment such as crushers and mills Unfortunately, many available tramp metal detectors false trip on ores such as copper, iron ore, manganese, vanadium, coal with pyrite, etc. due to conductive and sometimes magnetic properties of the ores.

PJ Tech has just the solution to address such challenges faced by the mines in detecting tramp metal in the form of their SMART-100 Tramp Metal Detector This technologically advanced system detects magnetic and non-magnetic pieces of tramp metal while ignoring

conductive and even some magnetic properties of various ores.

This detector has latest technology set of basic features and is designed to operate in a very wide and difcult range of applications. It is compatible with steel corded belts as well as the belts where the steel clips are used for splicing

SMART 100 tramp metal detector systems are custom made to suit each user's particular application. Each detector system is subjected to extensive testing both at the sub-assembly level and after nal assembly to ensure best performance and complience of electrical safety standards.

The transmitter and receiver antennas are manufactured

to withstand even the harshest environments. They are encased in impact resistant, weatherproof breglass. The upper antenna swings away to protect from large overburdens.

Marking device marks the exact location of metal which trips the detector by means of bright colorant spray. This feature helps to nd buried metals and saves search time thus improving production.

Overall it is the most advanced tramp metal detection system available worldwide that can be used in a very wide and difcult range of applications.

Average production lead time per detector is less than a week.

16 www.riskmanagementinsight.co.za

Nov - Dec 2022

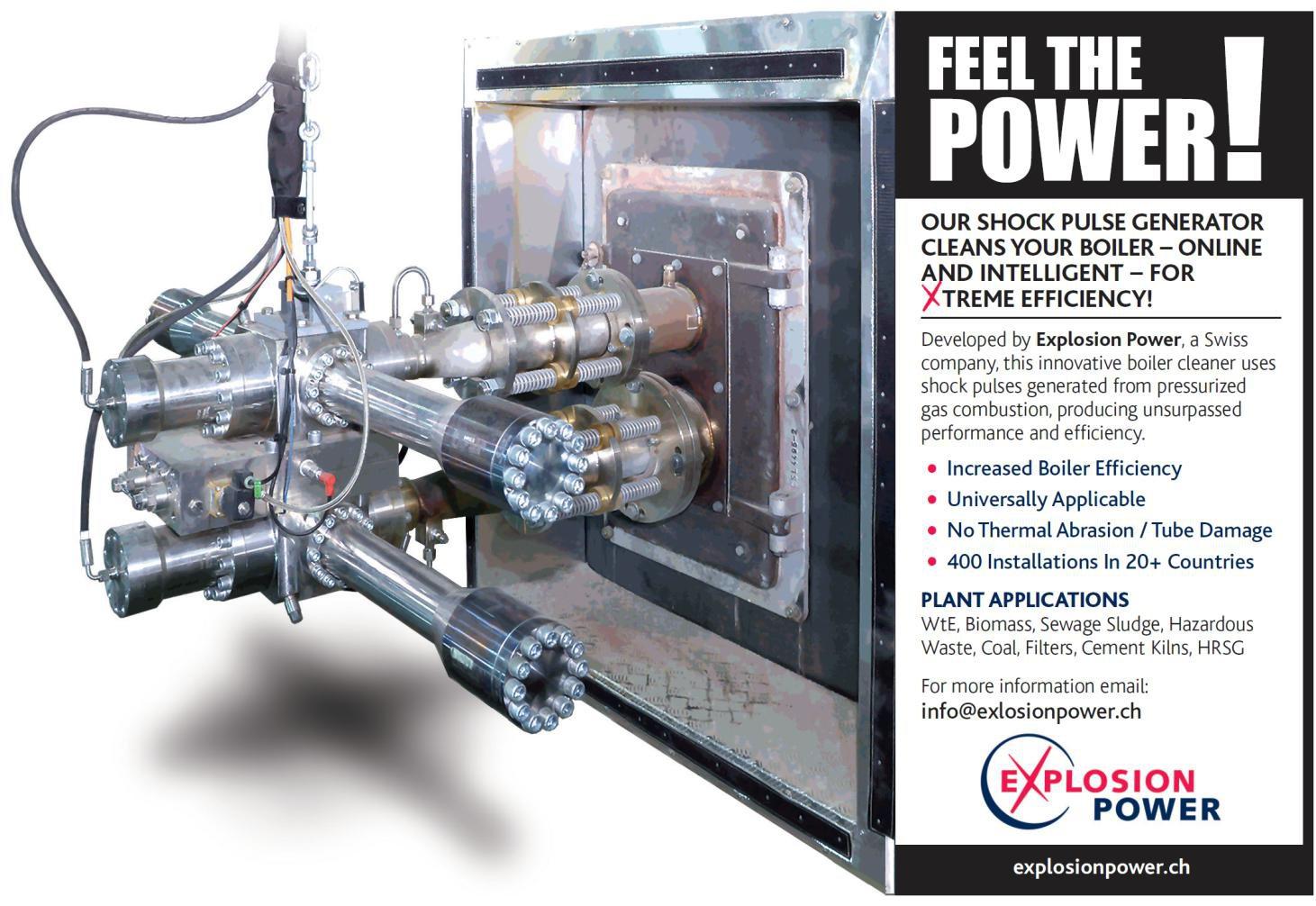

Solutions for Recovery boilers and Coal red boilers

The solutions used by Heat Management are:

· Infrasound fouling prevention

· Optimized steam soot blowing

Infrasound fouling prevention

Recovery boilers typically suffer from build-up of deposits in the duct between ECO and ESP (electrostatic precipitator). Infrasound cleaning (low frequency acoustic cleaning) is a fouling prevention method with unique power and cleaning range.

Typical results are:

-Solving clogging issues

-Drastically reduced need for manual cleaning -Stable pressure drop over the duct

In coal red boilers the applications are mainly Economizers, Rotating Air Preheaters (RAPH) and SCR catalysts.

Typical results are:

-Stable pressure drop over RAPHs and SCRs

-Heavily reduced or eliminated use of steam soot blowing -Reduced wear of heat exchanging surfaces

Infrasound system operation

The infrasound (15-30 Hz sound) is typically generated for 2 seconds every 4 minutes, keeping the heat transfer surfaces of catalyst surfaces clean continuously during boiler operation.

Compressed air, 6-8 bar(g) (85-115 pis(g)) is used.

The powerful infrasound waves are transferred to the ue gas, increasing the turbulence temporarily and ushing ash from surfaces before it has accumulated/sintered into thick layers.

The infrasound has a cleaning range and cleaning effect far superior to other types of acoustic cleaning, typically using 75-300 Hz. 12 infrasound generator are enough to cover a large cleaning area, such as a whole goose-neck duct after a recovery boiler or a whole SCR reactor on a coal red boiler

Optimized steam soot blowing of retractable soot blowers

Soot blowers in recovery boilers are generally operated non-stop, to keep the ue gas path clean and prevent the fouling and sintering of accumulations on heat exchanger surfaces. In many cases this is not enough, with resulting downtime for manual cleaning. Heat Management's optimization can increase soot blowing capacity by 100 %, without installing more soot blowers or steam headers. By introducing a simple local control on each soot blower steam (poppet) valve, existing soot blowers can be upgraded to one-way soot blowing, without taken the boiler down and disrupting the chemical recovery process. During boiler shutdown, the control system is upgraded to achieve overlapping operation of soot blowers. The

technology constitutes a step-change in soot blowing technology, doubling the capacity (starts per day) without installing more soot blowers or consuming more steam. If more starts is not top priority, the technology can be used for saving 50 % of the steam consumed by sootblowers.

To sum up, by equipping the sootblowers with our actuators for regulating the steam ow locally we can obtain:

-Up to 50 % reduced steam consumption of the steam soot blowers

-Double the soot blowing frequency

-A combination of above

17 www.riskmanagementinsight.co.za Nov - Dec 2022

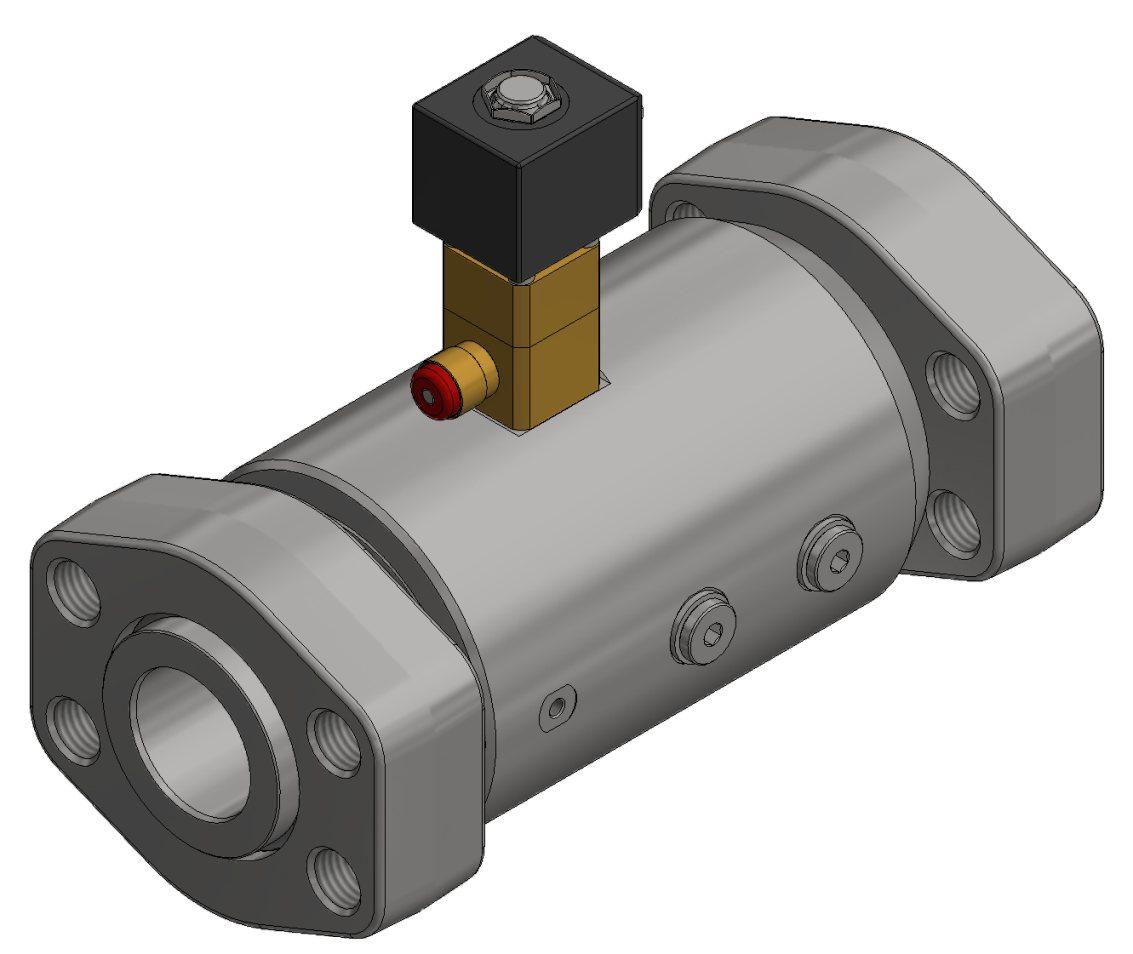

Local actuator on sootblower poppet valve

Building design must incorporate effective disaster management

All building designs must incorporate effective disastermanagement systems to allow for safe escape and the control of re and smoke. A minor design aw could potentially place people, equipment, and property at risk of death and destruction, ASP Fire CEO Michael van Niekerk warns.

All buildings in South Africa need to comply with the requirements of the National Building Regulations and Building Standards Act, 1977 (Act No. 103 of 1977), Fire Protection, as set out in SANS 10400 Part T: 2011 Effective re-safety solutions take into account the dimensions and construction of the building, the materials used, and the occupancy and storage of items. These all fall within the prescriptive requirements set out in SANS 10400-T

Any digression from the prescriptive requirements requires a rational design to be completed in accordance with the re engineering methodology framework requirements of BS 7974. The Application of Fire Safety Engineering Principles to the Design of Buildings, supported by the published documents form an integral , part of the BS 7974 framework.

A rational design is the performance-based design of re safety and prevention mechanisms and strategies in a building in order to provide the same or better re safety levels of the National Building Regulations, where the prescriptive requirements cannot be applied. This process is not elective, inasmuch as that only certain parts of the framework may be used, or that the results of the process are subjective or optional.

A rational design commences with a re risk consultantsuch as ASP Fire visiting the premises, or reviewing a set of new building plans, to undertake a comprehensive evaluation of all areas of the property to inspect all areas of re safety and risk in detail.

Correct and proper re engineering principles are appliedto ensure that the design complies with the life, building, re behavioural and environmental re safety objectives ,required by law According to Van Niekerk, the three main causes of re are electrical, arson and heating equipment.

“In the event of a major re that results in immense damage and the possible death of occupants, the re engineer will be held liable. Rational design takes into account the behaviour of a building during a re, meaning the structure must be designed accordingly, thereby minimising any potentially devastating impact.”

Fires can be dealt with through three main actions. The rst is controlling the growth of the re to prevent it from spreading. The next is suppression, which involves cooling the re rapidly Finally, extinguishing the re means that there is no heated substance remaining Evacuation should also be safe and easy while allowing , unrestricted access for emergency services. The installed re detection system must be able to detect the re assoon as possible, warn occupants and allow them to , escape in time

The qualitative review under rational design includes an architectural review, re safety objectives, re hazardsand risks, trial re safety designs, and worst-case rescenarios for analysis. For example, consultants often ignore the building roof's geometry and the required ,

substitute rectangular volume used in smoke-ll formulae.

The next step is quantitative analysis according to BS7974. Here the main focus is on the development of re within the enclosure of origin, the spread of smoke, structural response and re spread beyond the enclosure of origin, detection of re and activation of re-protection systems, re services intervention, and evacuation ofoccupants.

Assessment against criteria is the nal step, where the re safety designs developed during the engineeringanalysis are assessed to ensure that the objectives established at the beginning of the process are in fact , , met.

Upon the completion of the re risk assessment anddrafting the rational design report, ASP Fire provides the client with practical actions to implement The report comprises a detailed and documented objective re-risk assessment, as well as re engineering calculations andanalysis where required, covering all aspects of re risk and safety

“This guides the client in protecting its business, employees, and customers by providing prioritised recommendations for action, in order to rectify problem areas and strengthen existing re-safety procedures. This also ensures that the client complies with re-safety regulations for the protection of life, property, and the environment,” Van Niekerk elaborates.

As part of its value-added service, ASP Fire also works closely with insurance brokers and underwriters to address a client's re risk based on the outcomes of the

18 www.riskmanagementinsight.co.za

Nov - Dec 2022

Building design must incorporate effective disaster management

re safety risk assessment report This assists inpreventing damage to property and products, loss of life, nancial loss, consequential loss of prot, loss of productivity and insurance repercussions. ,

“We also provide ammable liquid store designs and certication, special-risk re protection systems, visual safety awareness programs, SHEQ safety le drafting and implementation, emergency response and business continuity plans, emergency evacuation plan design,

emergency evacuation drills, and re equipment training,” adds Van Niekerk.

ASP Fire also offers standardised and customised client training “The client has the option to select a standard re risk and safety course, or have a customised training programme developed around individually specic needs, or the areas indicated in the re safety risk assessment report,” he states.

ASP Fire Contact

Michael van Niekerk

ASP Fire CEO

Phone: +27 (0) 11 452 2169

Cell: +27 (0) 83 779 1701 Fax: +27 (0) 86 505 1030

Email: michael@aspre.co.za Web: www.aspre.co.za

19

www.riskmanagementinsight.co.za

Nov - Dec 2022

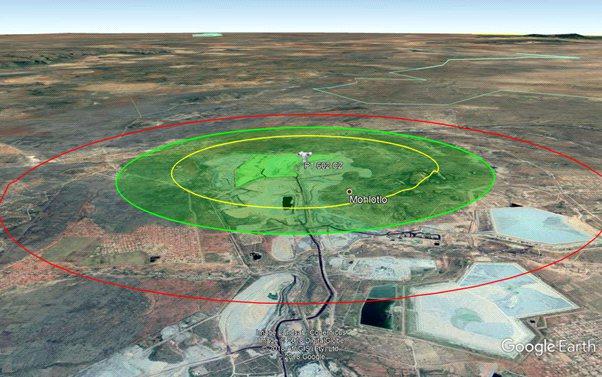

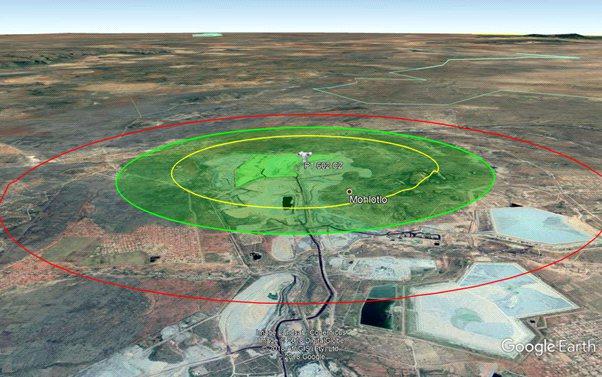

Surveillance System from Secu-Systems

Charles Harrison of Secu-Systems says that in essence there has been a fundamental change from traditional perimeter intruder detection systems. Typically, mining operations now tend to spend less money on installing physical barriers such as fences and have moved towards investment in bre based technology, wireless point to point , camera following camera or beams, typical intrusion solutions on critical infrastructure internally, due to the complexity of operations and the sheer distances that need to be covered.

He adds that another prompting factor towards additional technology adoption is that once an intrusion has been detected, the time taken for a reaction team to nd and reach that point is often excessive, with criminals having entered the facility and further detection proving nigh impossible due to the vast area to be covered. The trend is to institute the peeling-onion strategy from the

inside out , says Harrison. This allows for 360° wide area surveillance solutions On large sites that include opencast mines or even country borders, physical barriers do still play a role but detection options such as high-end thermal and day/night HD camera solutions are being strategically deployed in high-site locations.

This deployment is often coupled with Australiandeveloped Panoptes military type Moving Target Indication software This allows long-range ground-based surveillance sensors to cover 20 to 30 times more area with the same assets. Further, it allows for multiple target identication and tracking autonomously and simultaneously Cameras can easily detect movement down to 4 pixels.

This software can also be coupled with ground radar in areas that allow for it, such as fairly at areas whereby slew to cue options can be used. The cost benets are that it is the surveillance system cheapest per square

kilometre available on the market.

Thermal tags issued to enrolled users and utilised in conjunction with thermal cameras, allow mines to differentiate friend from foe Harrison cautions that because this is a military application, end user certication is required.

He adds that commercial cameras can attain detection radiuses of only 2.5 km, whereas military-spec cameras, such as the FLIR HRC-X, can attain detection distances of up to 17.8 km or the FLIR PT-602CZ can attain target detections up to 9.2km. This makes these cameras extremely benecial on large sites and in ambient conditions of total darkness, smoke, dust and light fog

Worth noting is that while thermal cameras give users the ability to see what is going on, irrespective of the level of light and in adverse weather conditions (since they rely on heat to detect movement or motion), they cannot be used

20 www.riskmanagementinsight.co.za

Nov - Dec 2022

Surveillance System from Secu-Systems

for personal identication purposes Therefore, a combination of thermal and traditional cameras is suggested as best practice.

Return on investment through surveillance camera adoption is guaranteed. Harrison cites the case of a mine that is currently installing new cameras. “The actuaries have performed calculations on the four new cameras in terms of their cost effectiveness and in only three weeks the cameras paid for themselves twice over This was primarily due to the fact that each week their footage led to the arrest of between 80 and 100 Illegal miners. Incurred losses from illegal mining have been totally obliterated. The successes we have experienced here have led to us embarking on a drive to enter the anti-poaching arena with our technology solutions.”

https://www.youtube.com/watch?v=7Fc7GIVMfmc www.secusystems.co.za www.secuexports.com

www.riskmanagementinsight.co.za

21

Nov - Dec 2022

GMAW Automated pipe spool welding solution:

“Rotoweld”

Rotoweld 3.0,( Twin Bay)

Automated pipe spool welding machine

The Rotoweld is a fully automated pipe welding work cell developed specically for industrial pipe prefabrication, small pressure vessels manufacturing or other similar 1G welding

It integrates machine vision, adaptive control and robotics technology in a complete dedicated solution that is fast and offers full penetration 1G high quality welding This system is up to 5 times faster than SMAW and uses GMAW for the root, the hot pass and the cap. The work cell will process spools from 4” to 42”. The Rotoweld welding torch is standing still and the pipe spool rotates on the idler rollers. It can weld pipe to pipe and pipe to tting connections and welds carbon steel pipes with standard wall in one dia-inch per minute!! Not only is it fast also it is easy to operate and erases human errors in the welding process by its adaptive control. This results that even not experienced welders can perform quality welds after training by us.

“Welding one dia-inch per minute with the Rotoweld”

The Rotoweld can completely weld for example 12” carbon steel pipe with standard wall in only 12 minutes. The Rotoweld 3.0 welds the root with GMAW and the ll and the cap with GMAW, FCAW or SAW

Optional you can choose to work with a single bay or twin bay, obviously the twin bay system has major advantages and it also is the most sold one. The twin bay is the most efcient and most obvious one to purchase because of the efcient way of work on two bays at the same time and the higher output this leads too.

Adaptive control during welding

The vision based welding technology enables the operator to control the complete process.

The system continuously analyses the image of the root weld pool picked up by a video camera incorporated in the welding arm. Unique algorithms use this information to adjust welding parameters such as

travel speed, wire feed rate, arc voltage and weaving width, constantly adapting the process to varying conditions such as changes in gap, alignment, root face, or temperature.

full-penetration root pass in an open bevel joint represents the epitome of pipe welding skill, and this applies in the fabrication of pipe spools; that is, a subassembly of pipes and ttings welded in pipe shops and then sent into the eld. If the welder deposits metal too far above the weld pool, it sinks and cools prematurely, so fusion is incomplete. But if the welder keeps the arc in front of the weld pool, and at just the right height, hot metal ows toward the root and, voila! he gets a full-penetration root pass that should pass muster The Rotoweld has the knowledge of highly experienced welder and will therefore for come lack of fusion by it's adaptive control. The operator should only monitor the welding process and might now and then correct the welding process when the system provides a signal.

22 www.riskmanagementinsight.co.za

Nov - Dec 2022

GMAW Automated pipe spool welding solution:

In 2014 the company released the third iteration of the technology, Rotoweld 3.0, which uses a custom robot to perform 1G girth welds. The robot arm performs the root, ll, and cap passes with one welding gun, though the system still can be congured with multiple processes. For instance, a thick walled pipe might call for gas metal arc welding (GMAW) for the root pass and submerged arc welding (SAW) for the ll and cap passes.

Visit our dedicated website for this machine on www.pipespoolwelding.com

The main advantage of the Rotoweld 3.0:

· High quality welding: the machine offers awless root welding automatically

· Root, ll and cap can be done with GMAW in one set up.

· High productivity : The GMAW is much faster than TIG welding processes

· The machine has a large range of pipe diameters : from OD 4” to 42”

· For root welding the LINCOLN STT welding source is available

Copier Bevel Machines (C.B.M) sells the Rotoweld as an agent in EUROPE, AFRICA and MIDDLE EAST countries for the Canadian company TECNAR Further more Copier Bevel Machines is a machine manufacturer based in the Netherlands and focusses on stationary equipment for the pipe fabrication industry. Copier Bevelmachines manufacturers and sells worldwide pipe bevelling machines, pipe cutting and bevelling machines, pipe end working machines, cnc pipe machining centres and pipe roll grooving machines We also sell custom made machinery for machining ends of ttings, cylinders, axis and shafts.

The Rotoweld is a machine that belongs to our portfolio of machinery and really has major competitive advantages compared to other automated welding station. The main advantage is that it adaptive control is incorporated in the machine, the positive aspect of this feature is that the welding parameters are adapted on the situation the camera encounters during the welding process and in the weld pool.

Telephone :+31-(0)183441313

Contact sales : Mr Bertels E-Mail : jbertels@copierbv.com

Websites: www.pipespoolwelding.com www.bevelmachines.com www.endworking.com www.rollgrooving.com

www.riskmanagementinsight.co.za

23

Nov - Dec 2022

“Rotoweld”

Biological Infectious Waste Disposal Systems

Cradle to Grave Waste Management

One of Averda South Africa's key offerings is end-to-end Health Care Risk Waste (HCRW) management that is compliant with the strictest industry regulations. An endto-end solution is important because, according to the Waste Act, generators have a legal duty to ensure their waste is responsibly managed. Therefore, it is essential to know a reputable provider is in charge of the whole process, from segregation, containerisation and collection of waste to treatment and nal disposal.

Waste Treatment

Averda South Africa prescribes the same treatment methods to sanitary waste that are prescribed to HCRW, going beyond-compliance in the treatment of potentially infectious materials. While most sanitary waste providers treat waste on-site using chemical processes, Averda South Africa either incinerates or uses high-tech non-burn electro-thermal deactivation (ETD) facilities to ensure all inherent pathogens are neutralised from waste prior to disposal.

Averda South Africa is a national leader in the safe collection, transport and treatment of infectious, pathological, sharps and pharmaceutical waste streams.

We offer a range of thermal and non-thermal destruction and treatment solutions at Averda South Africa's owned and operated facilities to satisfy both your regulatory demands and the rigorous legislative requirements associated with this waste stream.

Waste Receptacles

We supply the top of the range certied waste receptacles, specic to our clients' requirements, to ensure that healthcare waste is safely contained, easy to transport and easy to identify

Tracking and Control

All waste output is recorded, itemised, weighed, scanned

and veried. We are in the process of introducing radio frequency identication (RFID) tracking which will automate tracking and record keeping processes. Weight and location details will automatically be recorded along all phases of the waste management journey The automation of this process will enhance data integrity and assist our clients with record keeping according to strict legislative requirements.

Weighing and tracking waste is important to ensure that all waste is accounted for as it progresses from the point of origin to nal disposal at landll The effective management of this process is essential to ensure that hazardous waste is dealt with safely and effectively

24

www.riskmanagementinsight.co.za Nov - Dec 2022

refrigerant-recovery service

The company is achieving this through its association with Rapid Recovery of the US, which it acquired in 2016. A-Gas South Africa introduced its Rapid Recovery service offering for the local market at a media event held on the 1st and 2nd November 2017 at supplier Metraclark in Cape town and Johannesburg respectively

The event was attended by Rapid Recovery MD Adam Dykstra. The company is not only the largest refrigerant recovery company in the US, but in the world. “We recover more refrigerant than any other single company globally,” he reveals.

“Anywhere there is a regulatory compliance for a contractor, or a demand for such compliance from a customer, there is a need for high-speed refrigerant recovery solutions,' Dykstra explains. He adds that the recovery equipment available to contractors today is offthe-shelf and bulky “We offer a service that essentially encompasses both a technical, compliance and legal solution. We not only assist contractors in complying with the law, but also give their own customers peace-of-mind that they are dealing with professionals well-versed in the latest technology and trends.”

One of these latest trends is the A-Gas Rapid Recovery

service, which offers contractors the latest equipment. “Our machines are based on the simple concept of a compressor and a condenser. It basically recovers refrigerant from one unit to another really fast, in order to prevent it from venting to the atmosphere.”

“SANS 10147 regulations have specic refrigerant recovery, tracking, handling, and documentation requirements. A-Gas Rapid Recovery provides all necessary documentation electronically to clients,” A-Gas South Africa National Sales Manager Michael Labacher explains.

“Rapid Recovery is performed by us, while the contractor team can utilise its specialised skills to diagnose and repair the equipment, rather than handling empty and full recovery cylinders, and waiting on traditional recovery equipment.

Custom-made petrol-operated machines are typically ten times faster than a contractor's 'buzz box' (recovery machine),” Labacher elaborates.

Dykstra cautions that venting occurs when a line to a machine is simply cut, or it develops a leak, allowing the refrigerant to escape into the atmosphere. “The correct thing to do is to capture that refrigerant, keep it from damaging the ozone layer and also from causing global warming, clean it, and bring it back onto the market.”

The A-Gas Rapid Recovery solution “stops that one-way

train from refrigerant coming in and going straight to the atmosphere through a piece of equipment that is not properly maintained or inefcient. By recapturing it and bringing it back onto the market, we also reduce the quantity of new refrigerant that needs to be produced, thereby lowering the global footprint.”

Dykstra highlights that Rapid Recovery launched in the UK and Europe earlier this year, and will launch in Australia in 2018, as part of its overall globalisation strategy. “South Africa is now compatible with the US as far as refrigerant recovery speed is concerned. The playing eld has denitely been levelled here with the advent of the A-Gas South Africa Rapid Recovery service.”

Dykstra stresses that extensive technical support is provided to all Rapid Recovery technicians, who receive two-week' intensive training in the US, followed by four-weeks local training, which includes legal and technical aspects. The A-Gas Rapid Recovery service is applicable to the heating, ventilation, air conditioning, refrigeration, demolition, and marine industries.

A-Gas

US

South Africa launches

www.riskmanagementinsight.co.za 25 Nov - Dec 2022

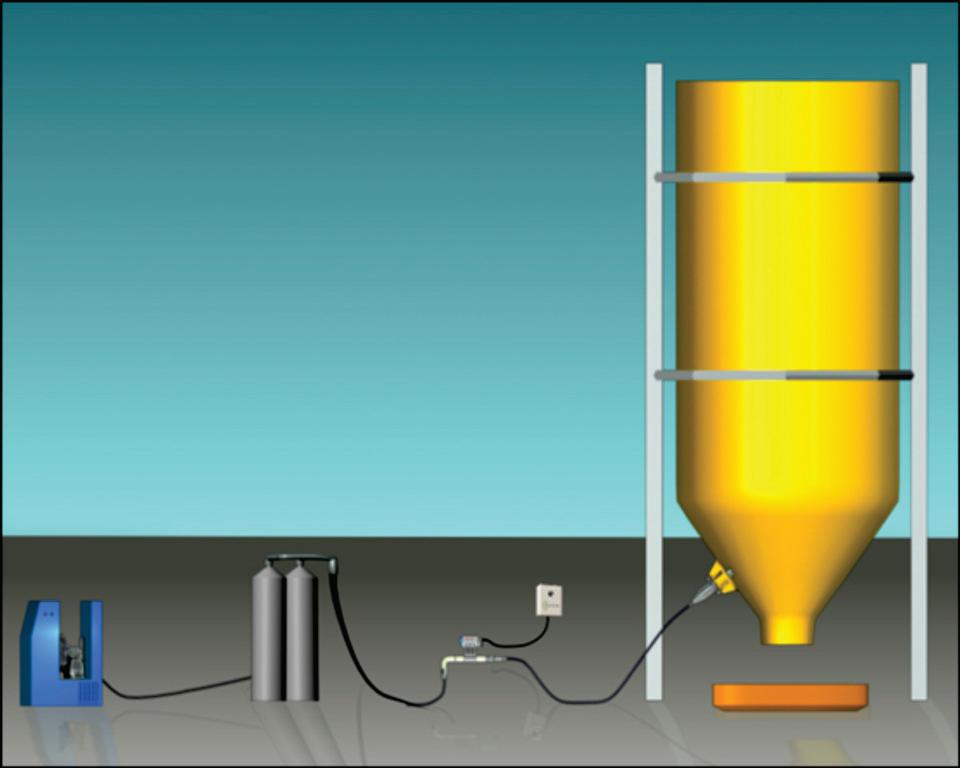

A unique, innovative concept for the ultimate solution of material ow problems

Flow Industries' Silo-Flow system employ a technology using a new, proven concept of cyclical sudden, highpressure air discharges (up to 3000 PSI or 200 bars) for eliminating blockages and accumulations in all types of silos, hoppers, bins and bunkers at cement, chemical and steel plants as well as at power stations.

Limitation of existing solutions

Existing solutions of bulk material ow are usually air blasters or cannons and Cardox. An air cannon consists of a fast-acting normally-closed valve and a pressure tank. The tank may be of various capacities and is lled with air

compressed up to 100 PSI (7 bar). The cannon releases the compressed air from the pressure tank into a storage or process vessel and this discharge is supposed to break down accumulations and blockages.

In many cases, the maximum pressure amplitude of 100 psi of traditional air blasters is not sufcient to do the job effectively To overcome the disadvantage of low power discharges, plants usually install a great number of cannons. Since bulk material has usually cracks and holes, a part of the air released by the cannon immediately escapes over the paths of the least resistance, causing immediate pressure drop and making the process even

less efcient. For hard buildups like in high-temperature facilities, air cannons slightly reduce the rate of buildup formation but are very inefcient to clean them or maintain the surface clean.

Cardox is a method of converting liquid carbon dioxide into gas inside the tube containing at one end a bursting disc. Gas rapidly expanding in the tube breaks the disc and creates a blast outside the tube. The method is used mostly to clean hard buildups in high-temperature facilities and creates only a single blast per charge. The method is inconvenient and expensive while has a potential to damage the refractory

26

www.riskmanagementinsight.co.za

Nov - Dec 2022

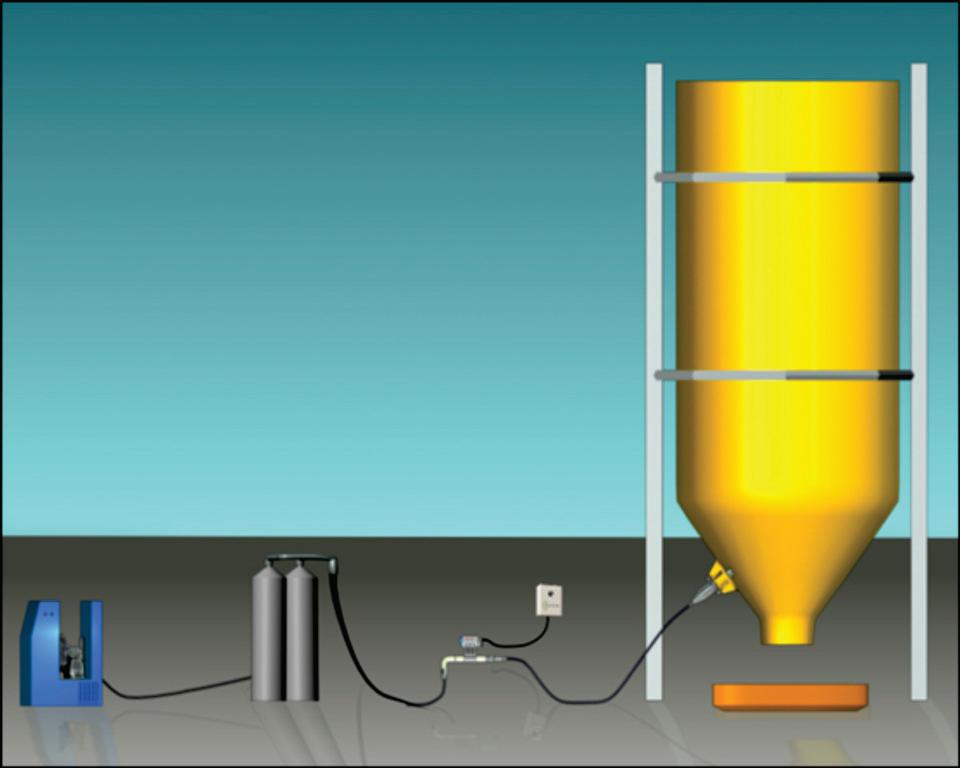

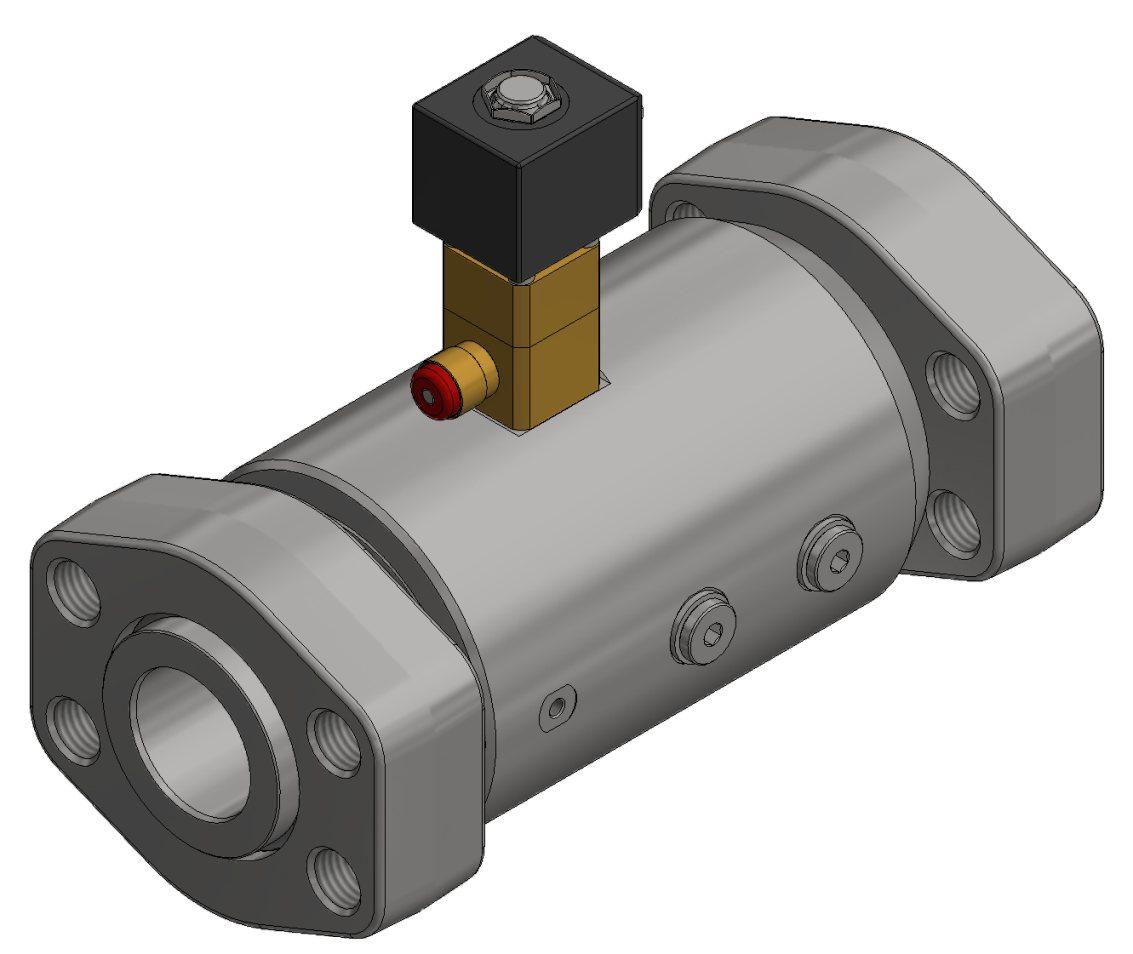

Silo-Flow™

General. The Silo-Flow™ patented technology has been developed and marketed worldwide by Flow Industries Ltd. Silo-Flow™ devices (SFDs) are pneumatic devices for sudden multi-pulse release of air compressed at up to 3000 psi (200 bar) into the plant storage or process vessel to meet unique application requirements.

Operation. Silo-Flow™ system consists of SFD, a control panel (CP), one or two standard high-pressure tanks and a dedicated high-pressure compressor (Figure 1) The compressor supplies air to the high-pressure tanks, which are connected to the SFD by a high-pressure tubing through a normally closed CP valve, so that in the standby mode the SFD is not under pressure. The SFD is attached to the vessel wall by a mounting socket enabling insertion of the SFD nozzle into the vessel. The system can be activated from the control room by a standalone timer or manually by opening the CP valve and allowing the compressed air from the cylinders to ow freely into the SFD As soon as compressed air reaches the SFD, it continuously creates powerful air pulses (blasts) with the frequency of one pulse per three or four seconds as long as the air supply is activated. Each such pulse results in a shock wave followed by a high velocity air stream. The shock wave and air stream inside the plant vessel dislodge any blockage or build-ups inside. The SFD is programmed to 're' at predetermined intervals, depending on the application. In addition, air pressure is fully controlled from as low as 300 psi (20 bar) to 3000 psi (200 bar).

Silo-Flow™ Device working principle. The SFD working principle is based on a of unique innovative concept continuous ring of blasts triggered by the incoming high-pressure gas. Pressure of the gas owing into the device governs the ring power. The higher the gas pressure, the stronger the ring pulse. In general, the SFD consists of two chambers separated by a piston. When air is fed into the device, the inlet chamber is lled more quickly and has a higher pressure than the pressurized chamber. This keeps the piston in a closed (charged) position (See Figure 2A). As gas continues to ll the SFD, the pressure in the pressurized chamber increases and becomes close to that of the Inlet chamber. Because of the different piston surfaces exposed to the chambers, the piston is eventually forced towards the inlet chamber and opens the discharge ports releasing the energized compressed air stored in the pressurized chamber (See Figure 2B). This burst of air is directed into the storage or process vessel through release tunnels alongside the SFD body. When the compressed air reaches the vessel and atmospheric pressure inside, the sudden jump in pressure inside the vessel creates an instant shock wave and a strong turbulent air ow throughout the material inside.

Silo-Flow replacing natural gypsum with synthetic gypsum

The availability and low cost of synthetic gypsum (a byproduct of power plant activity) has enabled cement producers to reduce the demand for mined (natural) gypsum. But synthetic gypsum is a cohesive material and has much more problematic properties than natural

gypsum, causing severe ow and operational problems industrywide, regardless of the gypsum bin design or cover These signicantly impact ow problems productivity, to the extent that cement manufacturers avoid replacing natural gypsum with synthetic.

Like many other cement plants, the Lehigh plant in Alabama tried to replace natural gypsum with synthetic, but experienced severe problems with the ow of synthetic gypsum in its feeder bins although there was no problem with natural gypsum ow Despite the installed air cannons (several per bin), the gypsum bins would severely clog with the synthetic gypsum, so the plant continued using the more expensive natural material. The plant engineers were frustrated with the continued inability to use to the synthetic gypsum. When they heard that Silo-Flow technology assured continuous and stable material ow, they decided to try it at the plant.

The plant had the device re for 25 seconds (5 'shots') every 20 min at about half its maximum power (1500 psi). After several trials with various mixtures of synthetic and natural gypsum, they moved to 100% synthetic gypsum. The SFD maintained continuous material ow of 100% synthetic gypsum at all times. The plant achieved huge savings with the move to 100% synthetic gypsum and paid back the investment in less than a year

Silo-Flow eliminates y ash and coal blockage in power plant hoppers.

Ashkelon power station in Israel, like many other plants, experienced severe ow problems with their y ash and coal hoppers These problems affected process efciency, raised maintenance expenses, and caused costly process interruptions. Air cannons (several per hopper) couldn't solve the problem. The plant searched for an efcient and safe method to prevent such problems, and chose Silo-Flow system.

The plant installed one Silo-Flow device per hopper and that was enough to solve completely the plant material ow problems. gypsum and paid back the investment in less than a year

www.riskmanagementinsight.co.za 27

unique, innovative concept for the ultimate

material

Silo-Flow™ Device Typical Silo-Flow™ System Configuration Control Panel High-pressure Air Tanks High-pressure compressor Nov - Dec 2022

A

solution of

ow problems

Powder King®

Powder King®, founded in 2003 by respected industry professional Jim Hummel, has provided over 40 years of fabricating services, including manufacturing and corporate services. Powder King® has been producing our unique design of Single and Dual Mill Pulverizers for over 15 years. In that short period of time they have rmly taken the lead in the design and capability of Pulverizing Machinery With machines installed and producing consistent product worldwide, Powder King's reputation for quality and dependability has grown as fast as our customer base.

Powder King® has been at the forefront of machine design, now with 4 generations of our pulverizing system designs we have the ultimate pulverizing system for all our customer requirements. Our last design change, our Velocity Series® is a game changer in this industry and

looks as if the future is very promising for those numbers to substantially increase.

The Powder King® line of Pulverizing systems have been proven to be the workhorse of the Plastics Industry throughout the world. Powder King® has always been a company that looks forward to the future and also listens to their customers. “The only way to be the best is to listen and gather great ideas from your employees, a customer, or your piers within the industry We need to constantly be aware of any opportunity to learn something new and improve or services,” says Hummel. Powder King® has and will always be on the forefront of the Pulverizing Industry The future for Powder King® will continue to be innovative and remain a wise investment to their customers.

The pulverizers are manufactured in Anthem, AZ, in a modern, well equipped facility with many contemporary tooling centers, support equipment and disk sharpening machines. We are sure you recognize how important it is to have the in-house capability to quickly produce replacement parts should it become necessary. Additional service and technical expertise is provided by skilled professionals that are very well versed in all aspects of the pulverizing technology

For more information, please contact Jim Hummel at sales@powder-king com or visit our website at www.powder-king.com

28 www.riskmanagementinsight.co.za

Nov - Dec 2022

Tubebarrier

The Tubebarrier is a temporary ood defence; quick and easy to deploy to prevent ooding of water in urban and rural environments As well in case of industrial leakage/seepage or temporary water storage.

Which hazard(s) is the innovation designed to mitigate?

Fluvial oods: resulting from discharges that exceed ood protection levels; the high-river discharges are caused by heavy precipitation in the river basin.

Heavy local precipitation (rainfall events): results in 1) (urban) oods due to exceedance of drainage capacity, and 2) ash oods, dened as rapid ooding of low-lying areas, generally within a few hours after heavy rainfall events such as thunderstorms.

How does the innovation work?

The Tubebarrier is an innovative temporary exible ood barrier that can be installed without the use of electricity, pumps, compressed air and / or a lot of manpower The Tubebarrier consists of elements of 10 meters that can easily be connected to each other, by a special design zipper, making the temporary dike as long as necessary

The principle is that we use the upcoming water from the ood to stop the same water So "Fighting water with water".

The Tube consists of a hollow tunnel that is held up by reinforcing slats, with a stability ap in front of it. When the water rises, the water runs on the ap and also in the Tube itself, because there are inlet holes at the bottom of the Tube. Due to the weight and therefore the pressure of the water, the Tubebarrier gets its stability The innovation works through so-called communicating vessels: when the water is high the tube lls up and as soon as the water is gone the tube empties itself

The Tubebarrier is capable for overow (not turning over once the water reaches a level higher than its capacity), which increases the safeguarding properties The Tubebarrier is stored like an accordion (compact) and installed quick with a short installation guideline. The barrier is xed into the ground with ground plates or anchors (depends on the surface), and operates independent from electricity After usage, the Tubebarrier

can be folded back together in the box and easily be transported to a storage facility for reusing This way 100 meter Tubebarrier can fold back to 6 meter

Added value / main differentiating element from conventional approach(es)

Quickly to deploy (100 m/hr with 4 people) and to remove. Cheap, efcient and secure. Alternatives are slower, more difcult to organize during times of oods and less exible for different surface conditions.

Critical success factors

Success factors:

- Quick to place; installation doesn't need much people and equipment.

- Relatively cheap; for installation of a permanent ood defence is more complex.

- Reusable; can be used more than once.

- Multi-use on different locations; one Tubebarrier can be used at multiple locations.

www.tubebarrier.com info@tubebarrier.com

www.riskmanagementinsight.co.za 29 Nov - Dec 2022

Gt Sonic Cleaning

Guangdong G T Ultrasonic Co, Ltd (GT Sonic) was established in 2003 and is a unique public company in ultrasonic cleaning The company boasts of more than 50 patents with more than 12 years' experience in the industry It is this experience which has enabled the company to come up with different series of products to carter for the different needs of the different industries. The following are the product series offered by the company: Household ultrasonic cleaner, Ultrasonic sterilising cleaner, Tabletop ultrasonic cleaner, Industrial Ultrasonic cleaner, Ultrasonic medical equipment and Ultrasonic environmental protection equipment.

The GT Sonic –T Series ultrasonic cleaner is designed to carter for optical, mechanical, electronic, jewelery, metal parts, assembles, electronic tools, circuits boards and other cleaning applications. It is the best choice for object cleaning slits, grooves, deep hole, blind hole, surface cleaning removing oil, rust oxide and many other

unwanted matter In addition it is used to clean Applications mainly for extraction of agriculture, food, cosmetics, and other industry specic cleaning utensils and ingredients for extraction of emulsication applications.

The D Series ultrasonic cleaner is used widely in laboratory, medical/dental, gem/jewelery, optics, electronics, automotive, industry, pharmaceutical to provide simple effective results for cleaning objects. The whole range of G Sonic ultra-sonic products are designed to give the best in cleaning Those who have used the application have highly recommended it as a very effective cleaning application.

The Household Ultrasonic cleaner VGT-800/VGT200/VGT1000 is produced to carter for the home. Its function is to clean CD, VCD and DVD It has the following features: countdown digital display, a transparent lid with blue light for viewing the cleaning process, stainless steel

tank ARS housing It also comes with a basket and watch holder After cleaning the subjects will be as clean as new All the products offered by the company re certied ensuring that they meet the industrial standards for such applications.

All these products come highly recommended. I only spoke of 3 series however they are several series offered by the company For more details you can visit their website. www.gtsonic.net

30 www.riskmanagementinsight.co.za Nov - Dec 2022

www.riskmanagementinsight.co.za 31 Nov - Dec 2022

Fire & Security Techniques introduces new range of local zone valves

Fire & Security Techniques CEO Neil Hughes explains that the valve acts as a selector valve, directing the gas to the correct zone. Controlled electrically, the valve is used to control the ow of Inergen re-extinguishing agent. Made of brass and stainless steel, the ZSV-25 weighs 2.3 kg, with a 62 mm diameter, and measuring 135 mm by 155 mm.

“The valve uses system pressure to operate the valve mechanism. When the solenoid is powered, the system pressure will force the valve open until the system pressure drops below 0 2 MPa, when it closes automatically,” Hughes explains.

The valve must be pressurised on the inlet in order to be able to function properly The valve's state can be monitored electrically when it is open and pressurised. Monitoring with additional equipment is also possible via the 3.5 mm activation ports.

The pneumatic activation chamber is designed with a small leakage to protect the valve from unwanted activation caused by small leakages into the activation chamber Once the valve is open, it remains so until the system pressure has dropped below 2 bar It closes

automatically after discharge.

Hughes highlights that using a main and reserve bank with a sequence of zone valves, the system can discharge Inergen agent into the desired area, and thereby extinguish any re. Following this, the system will reset automatically, with the reserve bank cylinders now on

standby, in order to protect all the affected areas from re damage.

“This process will also allow for cylinders to be removed and relled without any system redundancies occurring,” Hughes concludes.

32 www.riskmanagementinsight.co.za Nov - Dec 2022

Fire & Security Techniques CEO Neil Hughes

I-CAT can customise re-suppression systems for mining environments

Poor maintenance and bad operator practice are some of the biggest contributors to res in mining vehicles, I-CAT's Head of the Fire division, Andro Gibhard points out. In some cases, the re suppression system installation itself was deemed erroneously to be the cause of a re, as the suppression hoses allegedly chafed against the fuel or hydraulic lines, thus causing them to rupture and spray fuel on hot engine surfaces.

One of the biggest underground res in South Africa to date was attributed to an operator running a vehicle with the emergency brake engaged. Parked next to other vehicles during a shift change, the brakes overheated to the point where the tyres began to burn. With no one present to douse the re early enough, it spread quickly to other vehicles, leading to the nightmare scenario of the mine having to close the shaft due to the danger posed.

“The fact that a mining vehicle is tted with a resuppression system is meaningless if it is not accompanied by an action plan in the event of an incident, as well as proper training of operators on how to respond in the event of any re incidents.” A major problem in the mining industry is that customers often install resuppression systems simply in order to be compliant, without proper understanding of the system itself, or its specic requirements.

“Most procurement decisions about what to install are based on cost, which often means the cheapest system is installed, and not necessarily the correct system for that particular application,” Gibhard highlights. I-CAT strongly recommends a proper risk assessment, especially given that the same mining vehicle might have a totally different risk assessment in two different environments.