Offshore Energy Magazine

3 Editor’s note

Guest Column: Martin van Onna 6 Rotterdam on track to becoming truly sustainable port 10 ‘World’s largest tidal scheme’ takes next step toward realization

12 2023 was ‘transformational year

16 'Partnership with Maersk will help Hapag double down on its sustainability targets'

20 16 European partners kick off project to scale up offshore

36 Letting energy growth spring free with AI 40 The clock is ticking for fossil fuel era in shipping

42 North Sea platform electrification ‘key’ to unlock emission cuts from oil & gas production, says NSTA

44 DCS Moerdijk: innovative coating specialist for the offshore sector

48 Looking ahead to the cable laying vessels of tomorrow 51 What is happening

Colofon

Advertisers index

Unmatched maneuverability

Our fully integrated Volvo Penta Inboard Performance System (IPS) packages are there for you, for excellence in all conditions. Enjoy unrivalled maneuverability, high productivity and low fuel consumption. Maximum power, maximum precision.

volvopenta.com

Editor's note

by

Energy is grabbing the headlines daily. When it comes to fighting climate change or from the viewpoint of foreign dependency, energy plays a pivotal role. The offshore energy sector is in the middle of all these developments. In this magazine we give an overview on what is going in this sector.

The magazine provides you with market insights in the form of articles and guest columns. The whole of the offshore energy sector is covered in the magazine. From renewables like marine energy and offshore wind, the traditional offshore energy industry, but there is also focus on the supply chain also the maritime sector and subsea sector.

All sectors of the industry share the same ambitions when it comes to energy security and the transition to renewable energy. To fulfil these ambition, collaboration is much needed. Offshore Energy Exhibition & Conference in Amsterdam, part of the media company that also publishes this magazine, is a place where stakeholders meet. It is a platform for companies that focus on future proof business opportunities for the offshore energy industry. The conference program provides unique insights into the latest trends, all in a world that is changing fast.

Please visit www.oeec.biz for more information.

The editorial team

Look no further!

With Headway’s BWTU, Reikon supplies one of the lowest power consumers available. Add that to Headways ‘single treatment’ solution and you can save thousands of euros on fuel costs on an annual basis compared to other BWT solutions. And did we mention that in ten years time, we haven’t replaced a single core treatment element?

Innovation holds the key to overcoming Europe’s CCS challenges

Despite its huge potential as a means for decarbonising hard-to-abate sectors, carbon capture and storage (CCS) still has its detractors. Some see it as a distraction, one that’s eating up capital that would be better spent on boosting electrification and green hydrogen production.

What has become increasingly clear though is that countries must use all the tools in their arsenal to hit net zero, and that includes CCS. Renewable energy will of course be vital too, but it has its own unique challenges that are putting the brakes on deployment.

If CCS is to play a key role in the transition though, the IEA’s latest report on the subject finds the technology must scale up and accelerate rapidly. If all planned projects deliver, some 420 megatonnes of CO2 a year (MtCO2/annum) will be captured in 2030, more than eight times current capacity. But that’s less than half of the 1 gigatonne of CO2 a year (GtCO2/annum) required for the Net Zero Emissions by 2050 Scenario (NZE Scenario). Current project lead times average six years, but that’s no longer acceptable and there is scope to reduce this by around three to four years.

For storage, offshore locations are ideal for permanently locking away emissions; in Europe, the North Sea’s numerous depleted gas fields are perfectly deigned to hold large volumes of CO2. For scale, in a report released last year global energy consultancy Xodus said: “The volume of CO2 being injected into the North Sea by 2050 will be equivalent to the natural gas currently being extracted from the basin.”

There are still operational challenges to overcome though, both onshore and offshore, and especially around the issue of corrosion. Strohm’s Thermoplastic Composite Pipe (TCP), which doesn’t corrode, offers an answer to this issue challenge, while its flexibility streamlines the offshore installation process, meaning projects can progress more quickly.

Where capture is carried out at onshore locations with a high concentration of CO2, the resulting gas often carries with it a range of impurities, like hydrogen sulfide (H2S). Purifying CO2 so that it can travel through steel pipelines is extremely expensive, especially when done on a small, individual scale. As such Transmission System Operators (TSOs) plan to use non-corrosive materials to develop a smaller gathering network, before purifying CO2 en masse and sending it to larger transmission lines. For this to be successful, TCP will be key as it means purification can be carried out centrally and at the pressures and sizes required.

Once this has happened, large pipelines are needed to export CO2 from land to offshore reservoirs and aquifers. Typically these pipes are carbon steel and require dry CO2. Here, the issue is around infield infrastructure in systems that use subsea wells and

valves, where even the tiniest bit of water can spark major corrosion challenges. Again TCP can provide the solution by linking manifolds to injection trees, meaning the last mile of transport is fully non-corroding.

Flexible pipes also simplify the offshore installation process, slashing project lead times, a must for the NZE Scenario. Moreover, TCP is lightweight enough that developers can use small vessels, again reducing installation time, as well as the environmental impact of delivering CCS - research carried out by DNV has shown that TCP can reduce the total carbon footprint of a given offshore pipeline solution by more than 50%.

There is little doubt that the scale and pace of deployment of CCS must significantly increase to keep decarbonisation targets within reach. In turn industry will need to embrace technologies like TCP to overcome operational challenges and speed up project execution, while ensuring sequestration is affordable. It is unquestionably an exciting time for the burgeoning CCS sector, but we mustn’t let this excitement distract from the gaps that still need to be bridged.

Martin van Onna CEO Strohm

Rotterdam on track to becoming truly sustainable port

Despite a slight decline in total cargo throughput, 2023 was a year of success for the Port of Rotterdam which is making significant strides in becoming more sustainable.

Last year saw major investment decisions that are contributing to making the port and the logistics chain to and from Rotterdam greener. The financial results were stable with revenues rising by 1.9% to €841.5 million year-onyear. This puts the port authority in a position to commit to further investments for a future-resilient port in the years to come as well.

Total cargo throughput in the Port of Rotterdam amounted to 438.8 million tonnes in 2023, 6.1% less compared to

467.4 million tonnes seen in 2022. The fall was mainly seen in coal throughput, containers and other dry bulk. Throughput rose in the agribulk, iron ore & scrap, and LNG segments. The decline was due to the ongoing geopolitical unrest, low economic growth and high inflation, as explained by the port authority.

“2023 saw ongoing geopolitical unrest, low economic growth due to higher interest rates and faltering global trade, all of which had a logical effect on

throughput in the port of Rotterdam,” Boudewijn Siemons, CEO of the Port of Rotterdam Authority, commented.

“However, the year also saw many major investment decisions and milestones in the transition to a sustainable port. We made the final investment decision for the construction of the CO2 transport and storage project, Porthos. Construction work also began on the national hydrogen network in the port of Rotterdam. And we celebrated a number of significant devel-

opments in the logistics segment this year, such as the announcement of the expansions of the APMT and RWG container terminals, and the opening of the CER. All these developments will take us a step closer to a successful and future-resilient port and industrial complex.”

Progress on the energy transition

The definitive investment decision was made for Porthos in mid-October 2023. The Porthos system for the transport and storage of CO2 consists of an onshore pipeline running from Botlek through the port area to a compressor station on the Maasvlakte. From the compressor station, the CO2 pipeline goes to empty gas fields under the bed of the North Sea.

Most of this ‘backbone’ will be positioned in the existing pipeline strips. Valve or connection locations are planned at ten strategic locations to allow companies in the port to bring their captured CO2 into the system.

Thanks to Porthos, 2.5 million tonnes of CO2 a year will soon be captured and permanently stored. CO2 storage is therefore a meaningful measure that will allow industry to contribute to the Dutch climate goals.

What is more, the construction of the national hydrogen network began officially in the port of Rotterdam on October 27. The network, which is open to all hydrogen suppliers and buyers, will soon be 1,200 kilometers long and

it will provide five Dutch industrial clusters with access to green hydrogen.

Another initiative — the construction of the shore power installation for cruise vessels at the Holland America Quay — began in early June 2023. The Ministry of Infrastructure & Water Management, the Municipality of Rotterdam and the Port of Rotterdam Authority are providing the financing for the building work.

Boskalis commissioned a large-scale shore power facility at its Waalhaven location in November. Some of the DFDS vessels that dock in Vlaardingen have been supplied with electricity from a shore power installation since late 2023. Using shore power reduces emissions of CO2, nitrogen and particulate matter. It also reduces noise levels from ships significantly.

Last year, Distro Energy, a scale-up of the Port of Rotterdam Authority, was launched. Distro Energy developed an intelligent and fully automated trading platform that allows companies to trade the green energy they produce between themselves locally and to optimise consumption. Initially, the marketplace will grow over the next year, primarily with the arrival of users in the Rotterdam industrial and port cluster. They include not only customers and producers but also energy suppliers and grid operators.

The energy transition is generating a lot of demand for locations in the port area. The number of locations available for issue in the current port area

'The Port of Rotterdam expects 2024 to be an unpredictable year'

is scarce. The Port of Rotterdam Authority is therefore making some areas around the Princess Alexiahaven suitable to accommodate new clients. Just under 10 million cubic meters of sand will be used to reclaim 85 hectares of land. Work began in July 2023 and it will continue until the summer of 2024.

In 2023, container terminals APM Terminals and Rotterdam World Gateway (RWG) announced plans to expand their terminals in the Princess Amaliahaven. Both terminals will be prepared for the use of shore power and will operate in carbon-neutral ways, contributing to the port’s overall sustainability goals. Last year, the Container Exchange Route (CER) went into operation in Rotterdam. The 17-kilometer closed road network currently connects the container terminals of RWG, the Delta terminal of Hutchison Ports ECT Rotterdam (ECT), the terminals and depots of QTerminals Kramer Rotterdam (KDD, RCT and DCS) and the State Inspection Terminal of the Customs

Authority. The CER is making a major contribution to security, integrity, efficiency and sustainability in the Port of Rotterdam.

In the years to come, more and increasingly larger container vessels are expected to pass through the Yangtzekanaal to the Maasvlakte terminals. To provide more space for the current vessels and also to allow the ever-larger vessels to pass each other properly, the navigable channel of the Yangtze Canal will be widened along its entire length in the years ahead. The first subproject began in September 2023 and it involves the construction of 500 meters of quay immediately alongside the entrance to the port of Rotterdam. Berths, including shore power, are being established at this quay for twelve tugs.

What to expect in 2024?

The Port of Rotterdam expects 2024 to be an unpredictable year due to geopolitical developments and upcoming elections in several countries. It is

important in these turbulent times for the port to maintain a steady course and implement plans that will further the transition, the port said.

Construction work will begin on Porthos in 2024 and the development of the second conversion facility will continue. Investment decisions are expected for hydrogen plants, bio-refineries, the Maasvlakte-Zuid rail yard and the Princess Alexia Viaduct on the Maasvlakte.

Furthermore, new steps are being taken to establish shore power facilities for cruise vessels, container vessels and RoRo vessels, among others.

Work will also continue in 2024 on the deployment and availability of new, renewable fuels, and investments will be made in charging infrastructure for electric trucks to meet the expected demand for sustainable road transportation.

By Naida Hakirevic Prevljak

A NEW BUSINESS TO BREAK THE MODEL

We are NIM

NIM is a highly specialized company focussing on practical technological innovations that make sense today. We derive our power through cooperation. At this moment NIM has diverse ownership from shipyard through ensurance companies. A total of 17 companies have ownership stakes in NIM.

Founded by 5 partners with a heart for innovation and technology in the maritime sectors, we aim to establish a realistic path forward with a client-centered focus.

NIM is a pioneer in developing sustainable solutions. We can help you regardless of what value you add to the innovation landscape.

Methanol

NIM, backed by the large Dutch consortium MENENS, is moving toward the quick implementation of methanol dual fuel retrofit kits.

With a soon to be operational engine testbench with a capacity of 3.5MW and fully equipped with the latest technology, NIM will develop the first easy to install methanol solution with a 100% fallback to conventional gas-oil.

Our methanol timeline is now well established and runs until 2030. By that time the assumption of methanol is more wide spread and NIM will have solutions based on advanced dual fuel combustion methods with 95% methanol as a fuel.

Hydrogen

True zero-emission fuels like hydrogen are growing in attention and luckily also in implementation. NIM builds, develops and assists in certification of hydrogen technologies and services.

No matter where you are in the value-chain, NIM has expertise in production, technology on-board, financing, certification and ensurance of your project.

Join the NIM

Our commitment to sustainability, collaboration and progress sets us apart. Let's pave the way forward together. There is a place for you at our round table.

More Information

More info about NIM or want to contact us? Visit our website www.nim-bv.nl or stop by our stand H116 .

‘World’s largest tidal scheme’ takes next

step toward realization

Liverpool City Region’s Mayor has presented the UK’s “first of a kind” barrage scheme between Wirral and Liverpool for the city region’s flagship Mersey Tidal Power project.

Said to have the potential to become the “world’s largest” tidal scheme, the Mersey Tidal Power project would potentially create thousands of local jobs, bringing economic and resilience benefits to the Liverpool City Region, in an asset that could operate for more than 120 years. According to the Liverpool City Mayor, the project could manage environmental issues that are associated with climate

change. However, to complete the development stage, the scheme would need government backing.

“Mersey Tidal Power has the potential to generate clean, predictable energy for 120 years, create thousands of green jobs and apprenticeships – and all but seal our area’s status as Britain’s Renewable Energy Coast,” said Steve Rotheram, Mayor of the Liverpool City

Region. “Beyond the banks of the River Mersey, this is a national infrastructure asset that could position the UK as a global leader in the renewables race and help to turbocharge our net zero ambitions.”

Planning phase

The announcement to pursue a barrage between the Wirral and Liverpool as the preferred option

for the Mersey Tidal Power project coincides with the multi-billion pound scheme advancing into the formal planning consent phase. This decision could create a cycling and pedestrian route over the river, connecting Liverpool and Wirral for the first time. Additionally, it may serve as a defense against future flooding risks linked to climate change.

The Liverpool City Region Combined Authority will seek approval at its March meeting to submit a scoping opinion to the Planning Inspectorate

later this year for what could become the world’s largest tidal power scheme. Over the past three years, the authority has conducted preliminary technical work to develop the potential scope of the scheme, aiming for it to be operational within a decade. This initiative aligns with the region’s goal to achieve net-zero carbon emissions by 2040.

“Existing strengths in wind and solar power and emerging strengths in hydrogen mean that our city region is already leading the way in developing

a cleaner and greener economy. Harnessing the power of the River Mersey to generate green and predictable energy for the next 100 years and more would be an incredible addition to our clean energy mix,” said Councillor David Baines.

“We need to ensure we are extremely aware of our sensitive local ecology but just reaching this stage in the Mersey Tidal Power project has taken a huge amount of hard work allied with vision and would be a big step towards it becoming a reality.”

If agreed upon, the Combined Authority would conduct a period of engagement with stakeholders, both regionally and nationally, before submitting the scoping opinion. Following the scoping opinion, formal consultations would be held across communities and stakeholder groups. The scoping opinion would focus on the construction of a barrage across the river.

Highlights

The report presented to the Combined Authority highlights that opting for a barrage would lower costs compared to a lagoon, necessitating less material and reduced government support. Submitting a scoping opinion marks the initial phase in the preparation of a development control order (DCO) submission, a process that usually spans two to three years.

The scoping opinion submission outlines the project and requests guidance from the Planning Inspector regarding the necessary scope and extent of surveys required to compile documents detailing the environmental impact of the scheme.

By Zerina MaksumicDiamond Offshore’s CEO designates 2023 as ‘transformational year’

Offshore drilling contractor Diamond Offshore Drilling is looking forward to reaping the benefits of higher day rates, once its rigs move to their new contracts that poured in during 2023. With $245 million in backlog added in the fourth quarter of 2023, the rig owner’s fleet utilization level rose to 69% while its revenue efficiency remained the same as during the previous quarter.

Diamond Offshore’s contract drilling revenue for 4Q 2023 totaled $298 million compared to $245 million in the third quarter of 2023. The increase in revenue quarter-over-quarter was primarily due to the start of the Ocean BlackHawk drillship’s contract in the Gulf of Mexico in the fourth quarter, after the completion of an MPD installation, special periodical survey, and contract preparation work.

This increase was also driven by new contract commencements for the Ocean Patriot and Ocean Apex semi-submersible rigs, partially offset by lower revenue for the Ocean Courage semi-sub due to contract preparation activities related to its new multi-year contract in Brazil.

Furthermore, the rig owner’s contract drilling expense for 4Q 2023 was $189

million, or a $7 million increase from the prior quarter, largely due to higher charter rental costs associated with the managed rigs and the annual bonus expense related to the drillships’ BOP service agreement. This was partially offset by the deferral of certain costs associated with contract preparation activities for the Ocean Courage, as the firm continued to prepare the rig for a new contract that began

during the quarter, and the absence of costs associated with the Ocean Apex shipyard project in 3Q.

The offshore drilling contractor noted that the general and administrative expenses were $19 million in the fourth quarter, or a $3 million increase compared to the prior quarter, primarily due to an adjustment in accrued expenses associated with the company’s incentive compensation plan.

The rig owner’s tax expense for the fourth quarter was $174 million, compared to a $125 million expense in the prior quarter. The non-cash tax ex-

pense in the fourth quarter reflected the expected continued normalization of Diamond Offshore’s tax expense and the reversal of the tax benefit recorded earlier in 2023.

Bernie Wolford, Jr., Diamond Offshore’s President and CEO, highlighted: “2023 was a transformational year for Diamond Offshore. We marked our one-year anniversary of re-listing on the New York Stock Exchange, made measurable improvements in our capital structure, secured $485 million dollars in new contract awards throughout the year, safely completed special periodical surveys on five rigs, and completed eight contract start-ups, including four contract commencements in the fourth quarter, one in each of the regions in which we operate.“

Notable improvements

Diamond Offshore underscored that its rigs continued to perform well, achieving revenue efficiency of around 95% across the fleet for the second successive quarter. The rig owner sees this as “a notable achievement” given its fleet’s high amount of shipyard activity and the start-up of contracts during the quarter. The company confirms that the Ocean BlackHawk and Ocean Courage rigs completed contract preparation activities in 4Q and are now operating under new contracts in the Gulf of Mexico and Brazil, respectively.

“In the first quarter of 2024, as previously announced, we secured a twoyear contract extension for the Ocean BlackLion in the Gulf of Mexico at a leading edge day rate and secured additional P&A work for the Ocean Patriot to fill a portion of the gap prior to commencement of a long-term P&A campaign in 2025. The recent $362 million in contract awards are in addition to our reported backlog of $1.4 billion as of January 1, which

will result in notable average day rate improvement as we transition to new contracts,” added Wolford.

Running contracts

In the meantime, an equipment incident was reported on February 1, 2024, for the Ocean GreatWhite semi-submersible rig west of the Shetland Islands. The rig’s lower marine riser package (LMRP) had been disconnected from the rig’s BOP on the well while waiting in harsh weather. Subsequently, the LMRP and the deployed riser string unintentionally separated from the rig and dropped to the seabed.

As Diamond Offshore estimates 90100 days of out-of-service time for the rig due to this incident, the drilling campaign with BP is anticipated to resume by the end of April or early May. The rig is expected to remain under contract until at least late November or early December 2024.

Moreover, the end of the Vela drillship’s current campaign is estimated to be in mid-August while the Auriga drillship is expected to return to the rig owner, following the completion of its drilling contract, which is expected to occur in early March.

In addition, the Ocean Apex semi-submersible rig’s final campaign is slated to run until late February 2025. Aside from this, the firm earned an additional bonus in 4Q for efficient, injury-free operations in Senegal.

With rig demand set to grow further due to the ongoing offshore drilling upcycle, Diamond Offshore’s peers –Transocean, Valaris, and Noble – also anticipate more work for their rigs in the future, which will increase their contract backlog while boosting fleet utilization and day rates.

By Melisa Cavcic

No. When it comes to offshore services and green ambitions, we don’t believe in coincidence. We believe in great expertise and the right equipment. At Rohde Nielsen, we have both. Together with you and our specialised fleet, we execute advanced offshore projects – from landfalls and trenches to rock installation – all to safely bring power ashore and safeguard tomorrow. Rock, paper, scissors?

'Partnership with Maersk will help Hapag double down on its sustainability targets'

Yesterday, container shipping heavyweights Hapag-Lloyd and Maersk made waves in the liner shipping industry after revealing a groundbreaking operational cooperation deal, leading to Hapag’s withdrawal from THE Alliance. The move marks a strategic shift that promises to reshape the dynamics of the global shipping landscape.

The long-term operational cooperation, named Gemini Cooperation, aims to enhance schedule reliability and sustainability starting from February 2025, mainly focusing on several East-West trades.

The new cooperation will comprise a fleet pool of around 290 vessels with a combined capacity of 3.4 million containers (TEU); Maersk will deploy 60% and Hapag-Lloyd 40%. Many of these ships will be ready to adopt cleaner fuels.

The network will comprise 26 mainline services, complemented by a global network of dedicated shuttles centered

around owned and/ or controlled transshipment hubs.

The cooperation still has to be approved by anti-trust bodies in various jurisdictions including the U.S., Europe, and China.

The duo plans to file the final documents with the relevant authorities within the next few months, with hopes pinned on all approvals received in the third quarter of 2024. Based on the completed research, Hapag-Lloyd is confident that the corporation is fully compliant with the existing regulatory framework.

Unlike other alliances in the industry, this one has been dubbed ‘cooperation’ basically due to its more open operating model. It has no expiration date, as the duo plans to stay together for the ‘long run’.

On the legal side, the binding period for the partnership is 36 months, followed by a 12-month rolling notice period.

The decision of Hapag-Lloyd and Maersk to forge an operational cooperation deal is rooted in their recognition of the significance of shared business values and culture. Speaking yesterday in a press briefing Rolf Habben Jansen, CEO of

Hapag-Lloyd, stressed the importance of a similar business culture of the two companies and mindset on two major points: reliability, and sustainability.

“We believe this will bring improved schedule reliability for our customers, competitive transit times, and very good coverage. We also believe that because the companies are very well aligned on the ambition to deliver better quality and accelerate decarbonization that that is an area where we will make more progress and that as two partners we should also be able to adapt flexibly to whatever is happening in the market,” Jansen said.

“On the sustainability front, we have to double down. It’s important to do our utmost to bring those emissions down and that means you have to work with a like-minded partner.”

Hapag-Lloyd attributes its decision to partner with Maersk to the company’s overarching strategy for 2030, where its mission of becoming the unequivocal leader in quality necessitates a significant enhancement in operational efficiency. The strategy includes three key targets: improving schedule reliability, cost competitiveness, and cutting emissions.

Hapag-Lloyd CEO underscored that progress in this direction over the past five years has been insufficient with its existing partners. Therefore, the move to join forces with Maersk is seen as a strategic step to accelerate progress and attain the ambitious goal of being the foremost industry leader in quality.

With that in mind, the German liner major ruled out a move into the integrated logistics solutions business, stressing its strategy to remain a pure-play-plus liner and terminal infrastructure player, and keeping its business essence unchanged.

Jansen sees the strategic alliance with Maersk as a key enabler of its schedule reliability improvement and a major opportunity to create scale to drive down costs.

He added that to have an efficient network at scale it was critical to have control over the hubs and the terminals, especially those where the transshipment will take place. The Gemini Cooperation will control five transshipment terminal hubs, which is a key difference in the partnership when compared to existing networks.

“All of the loops will have two to three main port calls per region, where they will also call the hubs. That means that the risk of delays will be significantly less and since we control the hub terminals we can also control priorities and waiting times,” he pointed out.

German ports to benefit considerably Commenting on the potential impact of the partnership on German ports, Jansen

noted that the new setup is expected to strengthen the role of German ports.

“If we look at the Hapag-Lloyd’s cargo being handled in German post, we expect that once the network is fully rolled out that volume will be up to 20%. The ports in Germany that will benefit the most from that are Williamshafen and Bremenhafen due to more transshipment that will be done in Germany,” Jansen said.

As explained, Hamburg may experience a decrease in volume, but it is expected to be compensated partly with more transshipment from Maersk, resulting in an estimated 10% type of impact.

Decarbonization

While addressing sustainability plans, Hapag-Lloyd’s CEO said that with Maersk these goals could be achieved quicker and more effectively with great strategic and operational alignment.

“If you want to bring your emissions down, then of course, we can do some of that by using more alternative fuels and other things. However, there is also something to be said about how you use your assets and how to reduce the overall emissions of the network as much as possible. When thinking about that, of course, one also thinks about what are the possibilities to do that together with others,” Jansen noted.

Hapag-Lloyd confirmed to Offshore Energy that it plans to integrate its LNG dual-fuel 24,000 TEU vessels in the collaboration. The company has a dozen 23,600 TEU containerships powered by LNG on order, which are set to be put into service by 2025. Biofuels are a significant part of the company’s sustainability efforts, and the shipowner was scheduled to use more than 150,000 tons of biofuel in 2023. That being said, the company has expressed openness to alternative fuels, stating that while LNG has been a significant focus, Hapag-Lloyd is actively looking into the potential of methanol and ammonia. With

an eye on the future, the company believes that multiple fuel options will play a role in decarbonizing the industry. On the other hand, Maersk has been a strong opponent of LNG as a transitional fuel for the maritime industry, due to its well-towake methane emissions profile.

“We all see that there are various alternatives to decarbonize and we all think that there’s not one way to get there,” Jansen commented when asked whether this topic was discussed with Maersk.

“Maersk (Net Zero 2040) and Hapag-Lloyd (Net Zero 2045) have the most ambitious decarbonization targets in the industry, and they remain unchanged. However, the new network aims to provide a more fuel-efficient setup that will reduce the greenhouse emissions per transported container already in 2025 and both parties are committed to continue to drive further efficiency in the years to come,” a Maersk spokesperson said in a statement to Offshore Energy.

“Maersk has set a Net-Zero greenhouse gas emissions target for 2040 across the entire business and has also set tangible and ambitious near-term targets for 2030 to ensure significant progress, and that remains unchanged. Since 2021, Maersk has had a policy of only ordering new ves-

sels able to operate on green fuels. All 24 Maersk vessels currently on order will be equipped with dual-fuel engines and will be able to operate on green methanol,” the statement added, saying that Maersk could not comment on Hapag-Lloyd’s strategy for new vessels/fuels.

Nevertheless, both Maersk and Hapag-Lloyd CEOs joined a recent joint declaration issued at COP 28 calling for an end date for fossil-only powered newbuilds and urging the International Maritime Organization (IMO) to create the regulatory conditions to accelerate the transition to green fuels.

Departure from THE Alliance

Hapag-Lloyd’s departure from THE Alliance is a significant development, as the German liner major had been planning to stay in the alliance by 2030.

The announcement took other members of THE Alliance by surprise, prompting inquiries into the departure. Hapag-Lloyd noted that they informed their partners in the alliance on the day of the announcement.

Questions arose about potential compensation, with Hapag-Lloyd emphasizing its commitment to honoring all contracts until February 2025, and that its withdrawal had no legal repercussions.

Hapag-Lloyd clarified that the decision was not a result of dissatisfaction with existing partners. Instead, the move is seen as an opportunity to bring operational quality and schedule reliability to the next level. He noted that in terms of capacity provision in the Alliance, Hapag-Lloyd’s contribution was comparable to ONE, providing around 25 % of capacity, while in the new set-up it will provide 40%, ensuring a staretgicaly more beneficial position for the company.

“We have made an agreement where both partners have equal rights, and we believe that with two partners it’s easier to make decisions than with four,” Jansen added.

The Gemini cooperation aims to achieve industry-leading schedule reliability above 90%, an Jansen is confident this is a realistic target.

“We believe that the 90% is doable, and that has a to do with the fact that that we will have a slightly different operating model, with much less ports on both ends than most of traditional corporations, and a stronger role for the hubs that we by and large control. So we believe that that’s a realistic target,” he pointed out.

By Jasmina Ovcina Mandra

REINTJES Gearboxesthe best choice for your vessel!

For over 75 years already, REINTJES Benelux –based in Antwerp – handles sales and services of REINTJES gearboxes and reversing gears for Dutch shipping for short-sea, sea going, dredging, fishery, inland vessels and luxurious yachts.

Our service department is available for all spare parts as well as repairs. Whether it is an inspection or repair, our team of experienced service engineers is always there for you and assures you the reliability and quality REINTJES represents.

2x ZWVSA 440 U 1081 kW @ 2000 rpm

REINTJES Benelux BVBA | Luithagen Haven 2 | Unit F | 2030 Antwerpen Tel +32 (0)3 541 92 33 | www.reintjes-gears.com

16 European partners kick off project to scale up offshore solar

Sixteen European partners have started an EU joint industry project (JIP) where floating solar technology is scaled up to standard formats of 150 MW enabling to build gigawatt scale farms.

The BAMBOO project (Building scAlable Modular Bamboo-inspired Offshore sOlar systems) aims to resolve challenges for the rollout of large-scale offshore solar into new and existing wind farms.

This also involves proving the robustness and performance of the floating solar panels in offshore conditions, alongside researching their environmental impact to ensure sustainability across the whole value chain of this industry.

This collaboration is coordinated by RINA and gathers offshore

solar developer Oceans of Energy, technology developers Solarge, TKF, Pauwels Transformers, SolarCleano, technical and environmental consultancies RINA, ABS, Aquatera Ltd, Aquatera Atlantico, and WavEC, testing laboratories MARIN, Fraunhofer CSP, SIRRIS, the marine science-policy think-tank European Marine Board, and offshore wind farm developer Vattenfall as potential client for implementation.

“This project will contribute to enable feasible business cases of solar renewable energy offshore”, said Andrea Bombardi, Carbon Reduction

Excellence Executive Vice President of RINA.

“RINA, thanks to the leading experience in the provision of energy yield assessment services for solar plants and in floating offshore systems, will pioneer the development of a new predictive yield model applicable to this emerging technology. We will bring to the project our competence in groundnative solutions offshore, in static and dynamic analysis on dynamic export cables, in comparative analysis between different power export layouts, in the definition of recycling strategies for

PVs and electrical components at the end of their life, and in the coordination of EU-funded projects.”

Envisioned results

The desired outcome for the BAMBOO project is to mature the technologies and allow for attracting the funds for the pioneering 100-200 MW offshore solar farm within a Vattenfall offshore wind farm by the end of the decade.

The specific wind farm for this development is yet to be determined.

Lower investments

According to Oceans of Energy, the complementarity between energy patterns of a co-located offshore solar and wind farm enables more efficient utilization of the same grid connection,

reducing the need for investments in expanding the energy system. By utilizing offshore wind farm space for floating solars, the required space for generating renewable energy on both land and at sea can be significantly reduced.

As reported in January 2024, the industry needs to start shifting its focus from wind farms to energy farms, as we have limited space that needs to be used efficiently – synergy of offshore wind and floating solar wind is the way to go.

“Oceans of Energy is proud to advance offshore solar further towards a real gamechanger in the renewable energy transition, by bringing these standardized, large scale offshore solar

farms to the world,” said Allard van Hoeken, Founder and CEO of Oceans of Energy.

“Offshore solar is becoming a major contributor to the energy transition in the North Sea. We are kickstarting the development of a standardized offshore solar building block, which fits right in-between four offshore wind turbines. This allows for optimized multi-source offshore energy farms without competing for scarce and limited land space.”

The increased scale of floating solar farms can reduce their environmental impacts per installed capacity, as there is reduced reliance on seabed anchors and the electricity export cable can be centralized on a larger floating platform, said Oceans of Energy.

International standards

This project is expected to play a role in advancing international standards and testing methods for floating solar technology.

The innovation program is set to conduct hydrodynamic assessments at MARIN, climate chamber tests at SIRRIS, tests for PV panels at Fraunhofer, as well as accelerated lifetime tests based on offshore measurements & operations.

Further research is to be conducted on predicting and improving lifetime energy performance. There will also be an emphasis on measuring and predicting the environmental impact of this technology, such as methods for contributing to nature enhancement and end-of-life management.

These efforts are geared towards internationally aligned policies including environmental assessment criteria frameworks.

By Zerina Maksumic

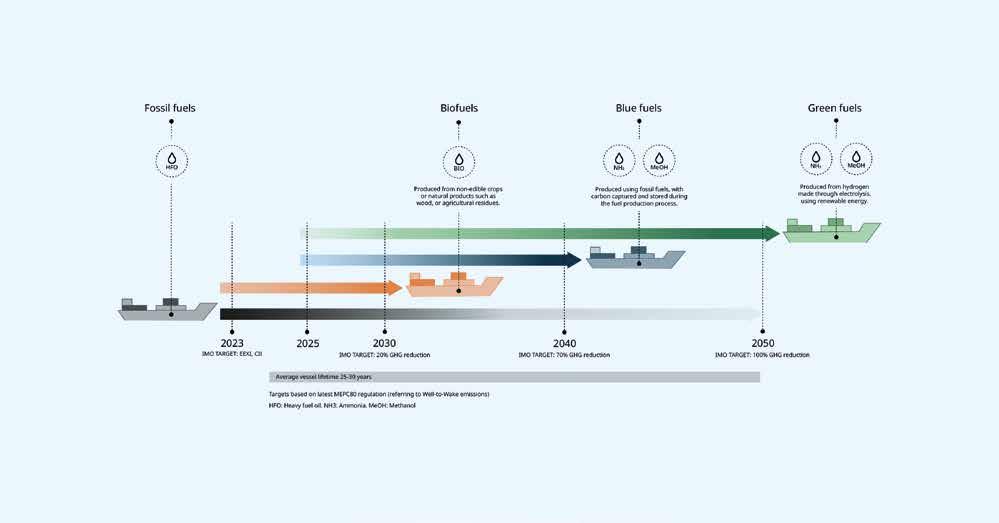

EU ETS and FuelEU Maritime to close price gap between green and fossil fuels, report finds

Sustainable shipping fuels could reach cost parity with fossil fuels as early as 2035 with the help of decisive emissions policy such as carbon taxes and emissions limits, according to a new report launched by Finnish technology group Wärtsilä.

The report, titled ‘Sustainable fuels for shipping by 2050 – the 3 key elements of success’, reveals that the EU Emissions Trading Scheme (ETS) and FuelEU Maritime Initiative (FEUM) will see the cost of using fossil fuels more than double by 2030. By 2035, they

will close the price gap between fossil fuels and sustainable fuels for the very first time.

Transporting 80% of world trade, shipping is the engine room of the global economy. However, despite being

the most efficient and environmental way to transport goods, it emits 2% of global emissions, equivalent to the annual emissions of Japan. Without action, this could increase by more than 45% by 2050.

In 2023, the International Maritime Organization (IMO) set a target of achieving net zero emissions by 2050. Existing decarbonization solutions, such as fuel efficiency measures, could cut up to 27% of emissions. Wärtsilä’s report argues that sustainable fuels will be a critical step in eliminating the remaining 73% but radical action is needed to scale them.

The industry suffers from a “chicken and egg” challenge – ship owners won’t commit to a fuel today that is

expensive, only produced in small quantities, and may be usurped by another fuel that scales faster and more affordably. Meanwhile, it is difficult for suppliers to scale production without clear demand signals.

Policy, collaboration and action

Wärtsilä has produced new modelling that shows a timeline of which fuels are likely to become widely available on a global scale, when and at what cost. To accelerate this timeline, the report argues that decisive policy im-

plementation, industry collaboration, and individual operator action must coalesce to scale the production of these fuels.

“Achieving net zero in shipping by 2050 will require all the tools in the toolbox, including sustainable fuels. As an industry, we must focus on coordinating action across policymakers, industry and individual operators to bring about the broad system change required to quickly and affordably produce a mix of sustainable fuels. Policy in Europe is showing just how impactful action at the international level can be, closing the cost gap between fossil- and low-carbon fuels for the first time,” Roger Holm, President of Wärtsilä Marine & Executive Vice President at Wärtsilä Corporation, commented.

Wärtsilä’s modeling shows sustainable fuels will be 3-5 times more expensive than today’s fossil fuels in 2030. As ETS and FEUM show, policy is key to closing the price gap. The report argues that policymakers should maximise certainty: Set an internationally agreed science-based pathway for phasing out fossil fuels from the marine sector, in line with IMO targets. Boost cost competitiveness: Adopt a global industry standard for marine fuel carbon pricing. Collaborate: Increase global collaboration between governments on the innovation and infrastructure necessary to deliver sustainable fuels at scale worldwide.

Next to that the sector must collaborate with stakeholders from inside and outside shipping. The report calls on industry to pool buying power and initiate sector-wide procurement agree-

'Roadmap for the future of sustainable fuels'

ments to pool demand from multiple shipping operators.

Improving fuel efficiency

Collaborate with other sectors: Convene with leaders in aviation, heavy transport, and industry to establish a globally recognised framework for the production and allocation of sustainable fuels. Share skills: Establish an industry-wide knowledge hub for the purpose of sharing expertise, skills and insights.

Every euro an operator saves in fuel costs at today’s prices, could be worth 3-5 times that by 2030. That means companies such as Carnival Corporation, which made a 5-10% efficiency gain through its Service Power Upgrade Program, could cut its fleetwide fuel costs by as much as $750 million per year in 2030. All operators can benefit from improving the efficien-

cy of their vessels – the technology is readily available today, according to the report.

“If there is one take away from our report, it is that smaller operators need not feel powerless. They have a major role in accelerating towards net-zero emissions shipping. Taking steps to improve fuel efficiency and invest in fuel flexibility can deliver immediate returns, reducing both emissions and operating costs. But action must be swift – we have the lifecycle of just a single vessel to get this right,” Holm added. Investing in fuel flexibility is said to be the most financially viable way to avoid the risk of stranded assets.

The report provides a roadmap for the future of sustainable fuels, identifying how the industry can more rapidly and affordably scale these fuels and achieve full decarbonization by

mid-century – within the lifetime of just a single vessel.

Recently, the World Shipping Council (WSC) proposed a solution to the challenge of crafting a global greenhouse gas pricing regulation that encourages investment in green fuels. This proposal, named the WSC Green Balance Mechanism, will be brought to the table during negotiations at the IMO MEPC 81 this week.

Specifically, the WSC Green Balance Mechanism introduces a novel approach to greenhouse gas pricing, aiming to minimize the cost disparity between fossil fuels and green alternatives by implementing a fee structure that reallocates fees from fossil fuels to green fuels, ensuring an equal average fuel cost.

By Naida Hakirevic Prevljak

Seawork

Vigo, Spain 21 - 23 May

Greece 3 - 7 June Southampton, United Kingdom 11 t/m 13 June

Germany 3 - 6 September

PASSER eyeing floating wind

The work on the vertical lay-up machine (VLM) for JDR’s new cable factory in the UK is now well underway in Klaipeda, Lithuania, where Norway-headquartered PASSER Group recently opened a new fabrication facility. The Group has revealed that, besides expanding its production capacity, it is also looking into areas for future business expansion, with floating wind being one of them, primarily due to the capabilities at PASSER SIDC in Lithuania.

Orders in renewable energy, including offshore wind, and interconnector markets now account for over half of PASSER’s turnover, PASSER Group’s Business Development Director, Espen Brudal, said in an interview with our sibling news site offshoreWIND.biz.

Klaipeda-based PASSER SIDC witnessed a 30 per cent growth in 2023,

mostly as a result of PASSER Products rolling out the vertical lay-up machine and the market starting to boom in terms of deliveries of other products such as smaller carousels, reels and transportation baskets, according to PASSER SIDC’s CEO, Aivaras Kamas.

The Group’s portfolio of companies spans beyond the production of cable

manufacturing and handling equipment and includes shipbuilding and vessel design, fabrication of steel structures, as well as engineering and project management. Having a multidisciplinary setup also enables both the Group and a single company within it to offer one-stop-shop solutions, Brudal and Kamas pointed out.

“Our range of products stretches across multiple areas, from equipment for cable manufacturing and handling to everything that has to do with steel – and we have full welding certification so we can deliver the highest standard possible in this regard,” Aivaras Kamas said.

“When it comes to our capabilities, here too we are able to cover the full range, from engineering, project management, fabrication, installation, to final documentation and commissioning.”

Kamas further added that being part of the PASSER Group gives PASSER SIDC the advantage of having the full value chain under one roof, which ensures providing the highest quality possible.

“Following mechanical installation, we’re now adding E&I to our offering, so the full scope will be in-house. By not depending on external suppliers and having full control over things such as delivery terms, we can mitigate delays that were previously not under our control and better coordinate on executing our contracts more efficiently.”

Vertical lay-up machine

At the moment, PASSER is working on the production of the vertical layup machine (VLM) for JDR Cable Systems’ new subsea cable manufacturing facility in Blyth, UK.

JDR is building the new plant to be able to meet an expected increase in demand for high-voltage cables in the middle of the decade, the cable manufacturer said in November 2023, when the company announced that all piling for the foundations of the VLM and continuous catenary vulcanization towers (CCV) had been completed.

Once operational, the factory will become the only facility in the UK capable of full start-to-finish manufacturing of high-voltage subsea cables, according to the company.

At PASSER, the majority of the job of fabricating the vertical lay-up machine for JDR’s new factory has been assigned to the fabrication facility in Klaipeda, Lithuania, which officially went into operation in October 2023.

The new workshop has been built to A+ energy class, with energy efficiency and metal dust collectors and other filter systems in place, and solar panels planned to be installed in due course.

The aim for the workshop in Klaipeda from the start was to make it as ‘green’ as possible, as part of PASSER’s strategy for decarbonization and the Group’s ESG goals.

The Lithuania-based company is set to start its ESG reporting in 2025, but it already began with some activities last year. Group-wide, PASSER is at the beginning of its ESG reporting journey and is currently setting up a system to encompass all its companies and value chains in one place.

“This is the challenge of being a global group. We need to align with local regulations and requirements which are not necessarily the same across all the locations where our companies are, such as Lithuania, Norway, and the Netherlands. We need to include all the local requirements, ’pulling everything together into one system and that is what we are currently working on,” said Espen Brudal, Business Development Director at PASSER Group.

Offshore wind, interconnector market growth driving PASSER’s capacity expansion

The decision to build the new environmentally friendly workshop in Klaipeda came as the need to set up large enough in-house fabrication capacity arose, which was also driven by the significant increase in offshore wind, other renewable energy, and interconnector projects, according to Brudal.

OW PASSER SIDC’s hydrogen-powered wind farm service vessel design'The zero-emission vessel is designed for the transport of personnel, spare parts and components'

With the new facility, PASSER went from 2,000 square metres to around 7,000 square metres of space to house its fabrication capacity.

“One of the main drivers is certainly the increasing demand in the subsea cable market, including interconnector and offshore wind industries which are seeing unprecedented growth. In offshore wind, wind farm development is ramping up with ever-increasing capacities. We see more and more demand for longer and larger cable,” Espen Brudal said.

Now that cable manufacturers need to expand their capacities, many are currently building new subsea cable plants. As they expand their capacities, PASSER also needs to follow suit as the requirement for cable manufacturing equipment, as well as that for cable handling and storage products, grows together with the market.

“As the demand in the cable market continues to increase, cable manufacturing plants see that they need to expand to meet the demand. With the energy transition underway and ambi-

tious national targets, cable manufacturers are also pressed to the max and are selling cables out of factories they haven’t built yet,” Brudal said.

“This includes offshore wind as well as interconnector projects since there are now many cross-border connection plans, and there are also other energy markets in demand of subsea cables.”

The market situation combined with PASSER’s product portfolio makes the Group well set to meet the upcoming demand, according to Espen Brudal.

Exploratory talks

In addition to interconnectors and fixed-bottom offshore wind, the future growth of floating wind is also expected to further increase the cable demand and subsequently the requirement for cable manufacturing capacities.

For floating wind, PASSER Group says it is not only well-positioned to deliver its existing cable handling and manufacturing equipment – but also mooring transportation solutions by tapping into the Group’s experience with serving the FPSO market.

The shift from providing mooring rope reels for FPSOs to reels for floating wind mooring ropes requires some development since floating wind turbines to be installed in deeper waters will be secured to the seabed by much longer mooring lines, so the cost efficiency of producing the reels and the transportation to farther locations such as Asia need to be worked on.

Nevertheless, this is not the only floating wind area which PASSER has its

eye on, as the Group is also looking into leveraging its capabilities to build floating wind foundations.

PASSER SIDC’s CEO Aivaras Kamas revealed the company is currently in exploratory talks with Gazelle Wind Power, the Ireland-based developer of a hybrid modular floating wind platform

Kamas did not disclose any further details about the collaboration with the floating wind tech developer, saying the companies are in an early talks stage.

“We’ve been working in shipbuilding and building steel structures for a pretty long time, so we are able to add construction of steel floating wind foundations by building upon these capabilities,” Aivaras Kamas said.

Hydrogen-powered vessel

PASSER’s company in Klaipeda is also in talks with a potential client for its clean fuel-powered vessel specifically designed for the servicing of offshore wind farms.

The zero-emission vessel is designed for the transport of personnel, spare parts and components required during the maintenance, repair or installation activities at offshore wind farms.

Kamas left the potential client unnamed but provided a few details about the new vessel, whose concept design the company introduced in 2021.

The new design is an upgrade to the company’s vessel designed for oil spill recovery and fish farming, with the hull and the bow of the vessel redesigned and other capabilities added to enable it to serve the offshore wind industry.

The service vessel can be powered by hydrogen or methanol and also includes additional electricity generators which can be used in the cases of high energy demand.

By Adrijana Buljan PASSER’s new fabrication facility in KlaipedaTürkiye puts wind in Black Sea oil & gas exploration sails while chasing energy independence

Türkiye, which is working on shoring up different energy sources to fortify its domestic production and end its reliance on imports, is in the same boat as most other nations, thus, the country has set its cap on boosting its search for more oil and gas. In the hopes of finding more hydrocarbons, the country plans to embark on further drilling activities in the Black Sea this year. Türkiye will not set coal aside either while leaving no stone unturned in its quest to expand its energy arsenal with renewables and nuclear.

With multiple forces at play, the complex global energy landscape is shaped by many factors, including geopolitical woes and upheavals. However, energy security is still the dominant concern among countries worldwide. The opening of its first underground natural gas storage facility and the start-up of a giant gas project in the Black Sea enabled Türkiye

to strengthen its energy independence. However, more work needs to be done to ensure the country can say goodbye to imports by replacing them with domestic energy resources.

While emphasizing that Türkiye should put its own domestic and renewable resources to use as one-third of the electric-

ity produced in the country comes from coal with half of this still stemming from imported coal, Alparslan Bayraktar, Türkiye’s Minister of Energy and Natural Resources, underlined: “This country needs energy. We need to use our own resources to reduce the current account deficit. We cannot turn our back on coal.”

As a result, Bayraktar points out that it is necessary to take advantage of around 20 billion tons of coal reserves in the country without compromising occupational health and safety, adding: “We need to use it in a way that is compatible with the environment. Therefore, we need to bring this understanding into our economy with both our coal and other mines.”

With the green shift in full swing around the globe, some people have expressed opposition to electricity production from coal, however, Bayraktar is adamant that

the use of domestic coal is directly related to energy security and therefore national security.

“Coal consumption increased in Europe in both 2002 and 2023. Therefore, we say that if there is to be a transformation, it must be smart,” he remarked while noting that “coal must continue to be in the economy for a certain period of time.”

Türkiye’s Minister of Energy and Natural Resources, who explained that almost 99% of the new capacity the country pro-

duced last year came from renewable energy, is convinced that throwing coal out of the energy mix while pursuing renewables would be the wrong move.

Bayraktar elaborated: “Our main goal is to save Türkiye from foreign dependency in energy. We want to use our domestic and renewable resources to the maximum extent for this purpose.”

More Black Sea drilling activities on Türkiye’s horizon

According to Bayraktar, the natural gas produced in the Sakarya gas field has reached 3.7 million cubic meters. The country intends to speed up exploration in three locations, especially in the Black Sea, throughout 2024 to produce more value-added products and reduce its foreign dependency in the energy arena. At least three more exploration wells in the Black Sea are on the country’s agenda this year.

Foreign dependency

“We are working with the aim of absolutely ending foreign dependency in the field of energy and natural resources in the next 30 years in the Century of Türkiye,” underscored Bayraktar. “We predict that the demand in Türkiye will continue to increase in the coming period until the 2040s. Our per capita electricity consumption is approximately 4 thousand kilowatt hours. Therefore, our demand is increasing.”

Furthermore, Türkiye has already put forward some strategies, especially renewable energy, to lower its reliance on imports. With this at the forefront, Bayraktar claims the country needs to scale up its domestic and renewable resources, including coal while amplifying energy efficiency.

In line with this, Bayraktar stated: “We will produce more. We will make more discoveries. This year, we will hopefully declare 2024 as the year of exploration. With future discoveries, we will reduce Türkiye’s

foreign dependency on energy and natural gas. We will become a fully independent Turkish energy market in the next 30 years.”

Since the energy transition game plays an important part in this, Bayraktar outlined: “As the trend towards greener resources continues, we know that oil and natural gas will continue to have a place in economies in the coming decades. Therefore, since these will not be reset in one day, Türkiye must find its own oil and natural gas.”

With nearly 70% of the energy currently being covered by imports, the country’s President Recep Tayyip Erdoğan put forward his vision of the Century of Türkiye to strengthen the country in many areas and free it from foreign dependency, turning it into a fully independent energy player. The country’s natural gas reserves in the Black Sea rose to 710 bcm following exploration activities.

Bayraktar reminded: “In 2016, we put forward a vision we called the National Energy and Mining Policy and said we will now search for our own oil and natural gas with our own ships and our own engineers, and hopefully we will find it.”

“We added the Fatih, Yavuz, Kanuni, and Abdülhamid Han drillships to our fleet. Today, I am proud to say that Türkiye is a country with a fleet of the most advanced deepwater drilling and seismic ships in the world. I can say that it is among the top ten countries in the world.”

In a bid to curb its dependence on foreign oil, the country is also exploring previously avoided geographies such as Gabar. Currently, Türkiye produces 37,000 barrels of oil in Şırnak Gabar and plans to increase this to 100,000 barrels.

Bayraktar continued: “We are searching for natural gas in the Mediterranean and the Black Sea with our Fatih, Yavuz, Kanuni and Abdülhamid Han drillships. Thank God, we made the largest natural gas discovery in the history of the country in August 2020. In this field, which we call the Sakarya gas field, we have now produced natural gas used in the homes of 1.4 million households.”

“This is just the beginning. Hopefully, we will increase our production there. We strive day and night for this. We are working day and night to find other discoveries in the Black Sea and other places, hopefully in 2024.”

Nuclear power

Embracing nuclear and green energy

As nuclear energy has been Türkiye’s 70-year-old dream, Bayraktar underlined that some steps had been taken to bring the dream to reality in almost every period. Currently, four nuclear power plants are being built simultaneously in Akkuyu. Upon completion, 10% of Türkiye’s energy is anticipated to be met from this power plant, bringing the country into the nuclear energy player’s club.

With great potential for renewable energy still on the table, Bayraktar notes that once Türkiye uses the sun, wind, and renewable resources; produces its own oil and natural gas; and makes nuclear energy, it will eliminate the problem of foreign dependency, which is currently permeating its energy sector.

“When we realize all these projects, Türkiye will move forward economically,” concluded Bayraktar while elaborating that once the country’s dependence on foreign sources is over, it would become “a country that is much stronger geopolitically, more listened to in its region, and can be pointed out in the world.”

By Melisa Cavcic

It’s time for the rise of Global South in maritime decarbonization

So far, maritime decarbonization has been focused almost solely on the Global North rather than the Global South. In order to enable a just and equitable energy transition, policymakers and other maritime stakeholders would need to ensure that countries in the Global South are not omitted. This could be achieved with the help of green shipping corridors.

Maritime decarbonization is believed to be critical to decarbonizing the global economy as a whole, including both the Global North and South. However, the progress of maritime decarbonization is clearly uneven.

Advanced economies would need to deepen their engagement with developing countries to overcome a new “North/South divide” on the pace and priorities of energy transition, last year’s report by the International Energy Forum in collaboration with S&P Global Commodity Insights said.

As defined by the United Nations Conference on Trade and Development (UNCTAD), the Global South broadly comprises Africa, Latin America and the Caribbean, Asia (excluding Israel, Japan, and South Korea), and Oceania (excluding Australia and New Zealand).

The full decarbonization until 2050 has attracted much attention, however only a few attempts were made to include the Global South in the potential and actual projects gathering maritime community. One of the promising attempts is a joint US-Danish project to resource

and execute pre-feasibility studies for green corridors in five countries in the Global South.

The “Global South Green Corridors” project aims to support sustainable green growth and job creation in developing countries by identifying and supporting the development of green corridor projects. The project is expected to conduct pre-feasibility studies in Namibia, Panama, Fiji, and two more countries to be announced soon. In July 2023, the International Maritime Organization (IMO) agreed on a 2023 green-

house gas (GHG) strategy signaling early industry commitment to phasing out GHG emissions from international shipping as well as promoting a just and equitable transition. As the IMO delegates meet this week in London for the Marine Environment Protection Committee (MEPC), 81st session, to discuss the 2023 IMO GHG Strategy, the focus will be, among other things, on stimulating the adoption of scalable zero-emission fuels and ramping up the use of such fuels to achieve the medium- and longterm GHG emission targets.

Here, the green corridors come into play as they can simplify zero-emission challenges, help the industry achieve the IMO GHG emission targets and result in numerous other benefits such as un-

locking economic development of less developed countries.

The Global South and the potential of green corridors

Green corridors are shipping routes on which there are commercially operating ships using alternative fuels. These maritime routes have the potential to accelerate the green transition in a country or region.

What is more, they can support infrastructure development and green transition in developing countries.

Furthermore, green shipping corridors are recognized by the signatories of the Clydebank Declaration as a key accelerator of early transition.

Currently, there are 44 announced green shipping corridor projects around the world, according to Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping’s and Global Maritime Forum’s data. Each of these corridors is in a different stage of development, with the more developed being those that completed their respective feasibility studies.

One of the successful ongoing green corridor projects includes the Chilean Green Corridors Network Project. The Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping cooperates with the Chilean Government on establishing a network of green corridors allowing for green maritime transportation of goods in and out of Chile. The aim of the project is to establish green corridors between ports where vessels can access, and bunker low-carbon fuels.

Against this background, the Global South has been recognized as a promising market for green fuels. By implementing the concept of green shipping

corridors, countries in the Global South could be supplying much-needed green fuels to the developed countries of the Global North.

Places on the map of the Global South have the opportunity to become new bunkering hubs. This was stressed in the webinar “Leveraging Maritime Green Corridors in Your Climate Strategy” organized by Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping on March 20.

The center has been creating methodologies to cover any potential green corridor in the world, from the pre-feasibility phase to feasibility. According to the center, green corridors can be used not only to demonstrate technical and regulatory feasibility but also to better understand the socio-economic opportunities and risks for people, communities and countries.

For countries, they leverage wider transition aims including improved access to clean energy, economic diversification, knowledge and technology transfer and capacity building. They also ensure decent, sustainable jobs and workforce up-skilling.

Speakers of the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping’s webinar concluded that investments in the countries of the Global South (e.g. South Africa) are necessary to stimulate production and further develop the region.

Such investments could change the global prospects of (green) bunkering.

“We need to use green corridors to move the world in a better position,” it was concluded in the webinar.

By Naida Hakirevic Prevljak

'Letting energy growth spring free with AI as key to sorting out challenges in oil & gas and renewables'

As countries around the globe speed up their evolution, artificial intelligence (AI) is becoming an integral part of daily life across a wide range of disciplines, including the energy landscape. What lies ahead for oil, gas, and renewable energy in the AI-oriented environment and how will these sources of supply be revolutionized? What role will AI play in the decarbonization game and can it up the energy transition ante?

Bringing the benefits of AI to oil, gas, renewable energy, and decarbonization technologies is perceived to be a crucial tool in the energy industry’s arsenal to unleash new growth in the offshore energy industry and reach net zero aspirations, according to Kumar Narayanan, Vice President (VP) & Head of Energy & Resources for Americas at Tata Consultancy Services (TCS), a part of the Tata Group, which is said to be India’s largest multinational business group.

Aiming to help businesses transform through technology, TCS has a proac-

tive stance on climate change, earning a place in leading sustainability indices such as the MSCI Global Sustainability Index and the FTSE4Good Emerging Index. The company has worked with many international players, including Italy’s Saipem, and offshore drilling giants, such as Seadrill, which hired the firm in 2019 to transform and maintain its onshore and offshore digital infrastructure.

With over 30 years of total experience under his belt, out of which 28 have been spent with TCS, Narayanan has held several different management

roles, including Country Director for TCS in Singapore and France, Client Partner for a large banking relationship in NA, Global Head of sales and solutions for the Intelligent Automation practice and now the Head of Energy & Resources for Americas.

From digital twin technology to robotics and many other innovations in the AI toolbox, Narayanan was adamant during our interview that artificial intelligence was affecting all things not just in the oil and gas industry but also in green and clean energy departments.

He believes that AI deployment can have a real impact on all energy players, helping them tackle current headwinds and woes while also giving them the tools to meet their climate goals.

No one can deny that AI is reshaping the fossil fuel industry’s landscape while also optimizing the supply chain. Aside from giving operators insight into the value of specific reservoirs and customizing drilling and completion plans, AI is also often used for offshore maintenance. With so many diverse applications at the oil and gas industry’s disposal, could you tell us more about the benefits of AI deployment across the industry?

Kumar Narayanan: AI will be one of the most important technologies for the petroleum industry in the next several

years. You will see AI agents assisting human geoscientists in exploring new frontiers not open to us today. AI will assist human operators in upstream, midstream, and downstream to operate wells and plants at much higher levels of efficiency than can be imagined today resulting in lower-cost energy and products for consumers.

AI will help solve the sustainability problems in the petroleum industry by reducing emissions and discovering new processes. Every aspect of the petroleum industry will benefit from the deployment of AI.

How can AI assist fossil energy companies in optimizing production and overall operations? Can AI help operators to

slash project costs and improve overall safety?

Kumar Narayanan: AI will accomplish this in myriad ways. Two of the most important are as follows. First, it will allow greater precision in operations. As control systems become more pervasive and more intelligent wells, refineries, LNG plants, and retail operations will all be able to operate at much higher levels of efficiency and productivity.

For example, more precise control in refineries can result in a higher product yield per barrel. An improvement of as little as 1% delivers millions in savings and an improved carbon footprint. Secondly, in the area of safety, AI will make truly autonomous robots possible, allowing a vision of unmanned facilities – which the industry has been pursuing for decades – to become reality. The best way to keep workers safe is to remove them from hazardous conditions, and AI will finally allow this.

What are the biggest challenges for artificial intelligence suppliers in the oil and gas industry?

Kumar Narayanan: Perhaps the biggest challenge faced by AI players in this space is the ability to create solution ecosystems. No one supplier can provide all the technology knowledge, oil and gas industry know-how, and the skills to bring AI to life in solutions that deliver real value. Fortunately, TCS has the structural approach through our long-established Co-Innovation Networks – ‘COIN’ – as we call them, that allow customers, TCS, academic institutions, independent researchers, and start-up entrepreneurs to work together to deliver oil and gas solutions that are deeply contextualized.

Algorithms, hardware, AI platforms, oil and gas engineering knowledge may all come from different members of the COIN, but they come together in a single solution, such as daily refinery mass balance, or refined product distribution command centers, all powered by AI.

Hywind Tampen wind farm in the North Sea (for illustration purposes).

Since AI has proven to be a useful tool in monitoring offshore oil and gas infrastructure, how can operators unlock its full potential?

Kumar Narayanan: The next movement in offshore development is in the deployment of AI in edge computing devices. Even with the power of 5G and IoT technology, some operational tasks are subject to latency issues. By the time data and commands are transmitted from the seabed to the platform and then back to the shore base and onto the cloud, things can change very rapidly.

In-situ devices with embedded cooperative AI can allow technology to be driven deeper literally and figuratively offshore. Deep sea autonomous submersibles are one specific example where TCS is at work. The next generation of seabed control devices will also have AI working ‘at the edge.’

What is coming up next on the AI horizon for oil and gas operations?

Kumar Narayanan: AI co-workers will soon be empowering operations engineers and crews both in plant and remote field settings. Already AI applications are being developed as a part of Agile Minimum Viable Products (MVPs) and delivered in handheld devices and smart helmets. The ability of AI engines to rapidly survey operational and maintenance histories and then recommend solutions to operational problems can

reduce or eliminate unplanned downtime and speed the return to service in all cases.

AI engines become the glue that allows every operator to operate every well or plant, sharing experience and applying talent across multiple assets. In the near future, every piece of equipment on a well or facility will be considered ‘smart’ – that is to say, empowered by embedded AI.

Will AI innovations push the decarbonization of oil and gas assets forward?

Kumar Narayanan: Decarbonizing the hydrocarbon industry will be impossible without AI. Today cognitive AI engines are at work optimizing operations with complex dashboards that now include sustainability, in addition to safety and efficiency.

In the near future, AI generative engines will suggest generative well and facility designs that have lower carbon footprints both in construction and operation. Achieving sustainability long-term is a learning journey, a continuing process of ‘learn better, do better.’ Therefore adaptive, learning technology – such as AI – will be essential on this journey.

Is AI one of the key tools in the energy transition toolbox for oil and gas players?

Kumar Narayanan: Yes, AI plays a very

important role in the energy transition. One emerging area that is not often thought about is the role generative AI will play in future products such as advanced materials. As less petroleum is used for transportation, more hydrocarbon will be available for making advanced materials.

Amazingly enough, the overall carbon footprint of carbon fiber material is lower than the overall carbon footprint of aluminum. AI generative platforms will suggest the formulation and manufacturing of these new advanced materials similar to the way they have been used to design new drugs. This will include evaluating the sustainability impact of these suggested materials.

Digital twin technology is very popular in the oil and gas industry, however, it is also being adopted for assets in other energy sectors, like renewables. Do you expect this trend to continue in the future? Can you tell us a bit more about this?

Kumar Narayanan: Digital Twin technology has already proven extremely valuable in all segments of the energy industry – across electric power, renewables, and the entire oil and gas value chain. This trend will expand as digital twins become richer in content and broader in scope. They have grown from modeling pieces of equipment to units in a refinery, to entire plants – and now