PUBLISHER

FAX: 973-235-1963

Thomas Greco | thomas@grecopublishing.com

SALES DIRECTOR

Alicia Figurelli | alicia@grecopublishing.com

EDITORIAL & CREATIVE COORDINATOR

Alana Quartuccio | alana@grecopublishing.com

MANAGING EDITOR

Chasidy Rae Sisk | chasidy@grecopublishing.com

OFFICE MANAGER

Donna Greco | donna@grecopublishing.com

PRODUCTION COORDINATOR

Joe Greco | joe@grecopublishing.com

www.grecopublishing.com

@grecopublishing

First Wednesday Each Month, 8:00–9:30am Southern Metro Collision Shop Meeting Dakota County Technical College, Rosemount

Second Wednesday Each Month, 7:30–9:30am St. Cloud Area Collision Repair Alliance Meeting APH Headquarters, St. Cloud

Third Tuesday Each Month, 12:30-1:30pm Mechanical Monthly Morning Zoom Meetup

Third Thursday Each Month, 12:30-1:30pm Collision Monthly Morning Zoom Meetup

June 14 Body Shop Session St. Cloud Technical & Community College, St. Cloud

June 21

28th Annual AASP-MN Golf Outing Majestic Oaks Golf Club, Ham Lake

Hello, my name is Dan and I am happy to be taking on the role of Mechanical Division Director. I have worked alongside my father, Tom Gleason at Pro-Tech Auto Repair in the northwestern suburb of Corcoran, full-time for 21 years. Before that, I spent my summers mowing the lawn and sweeping the floors at the shop. We are proud to be celebrating our 40th year in business this year. Although a lot has changed over the years, our purpose has stayed the same.

I have had the privilege of being able to learn the ropes from my dad, who taught me how to change oil, write estimates, set goals, hire new team members and how to continually improve the shop. My roles have changed throughout the years, but the hard work ethic instilled in me has helped me to continue to succeed. Like you, we have faced many challenges. Sometimes they are put there to teach us a lesson; others test our skills at adapting and overcoming.

I am blessed to have a great team that continues to impress me with their hard work and dedication. One challenge that continues for our shop is trying to grow to meet our goals. We have had people come and go that just weren’t the right fit but helped fill a gap. We have taken chances on people with zero experience but were willing to train. And we’ve taken in technicians with very little training and waited for them to grow, like planting a seed and waiting for its fruits.

We had hired a junior in high school that was in the local vo-tech program as a shop helper for two summers. We were very excited when he said he wanted to go to technical school, also nervous that he would get eaten up by the dealerships throwing around big offers. We decided to pay for his tools and stayed in frequent contact with him. He would work for us during his school

breaks and throughout the summers. Now he will be graduating in a few weeks and will return to us full-time as a fully trained technician. I can finally see the fruit from the seed that we planted four years ago. It has not been an easy wait, but it is worth it.

So, with the continued labor shortages, how will you continue to survive? Do you have a plan to start farming your own technicians instead of hunting for them? Maybe now is the time to start growing your own employees. Creating and updating your procedures, policies and employee handbooks are all essential tools. You have all figured out how to succeed, now WRITE IT DOWN. Having a playbook helps you to duplicate your successes. Be as detailed as you can. You could even have your “A” technicians and experienced service writers help you by writing down their successful actions.

The dealerships already have their own in-house training programs that we must compete with. But there are some tools, like the NAPA Autocare apprenticeship program, with tons of online training modules, followed by hands-on training to demonstrate what was learned in the shop to move on. Look into vendors, tool guys and other suppliers for help with training materials. Who in the shop handles the training is another hurdle – technician training mentor or shadowing? This hat usually falls on the owner or manager. Could there be a retired mechanic who could help part-time?

Growing our own technicians takes time, but when they are ready they will be trained the way you want them to be. We must start looking at the candidates who are available and try to see their potential. These are some ideas that hopefully can help you take on someone who may not be your ideal candidate today and make them part of your success in the future.

Last fall, AASP-MN’s legislative article featured a “Back to Basics” list, which detailed some basic legal rights regarding auto repairs and insurance claims. Many members were familiar with some or all of the rights listed, but didn’t have the statutory language to easily cite. Knowing your rights (and the customers’ rights) is increasingly important as the claims and reimbursement process become more challenging.

In this article, we’ll do something similar, but with a different topic – timelines, adjustments and claim approvals/denials. We want to touch on this because during this year’s legislative session, AASP-MN, based on member feedback, pursued changes that would require insurance companies to respond within three business days to approve or deny a claim. An outcome of this advocacy is the formation of a joint working group of shop owners and adjusters, to determine solutions that get at the root of the problem, without having unintended consequences that could harm shop owners or their customers.

As this group works on solutions, AASP-MN members should be aware of current timelines in Minnesota statutes that may be helpful. Some of you may note that unfortunately, these statutes are not always followed, but it is important for AASP-MN members to be aware of the

existing laws as they advise customers, and to help

by Sam Richie & Shannon K. Mitchell, AASP-MN Lobbyists

by Sam Richie & Shannon K. Mitchell, AASP-MN Lobbyists

AASP-MN leadership gather feedback on what statutes aren’t being followed, or how they could be strengthened.

To that end, Minnesota Statute outlines a right to an inspection and a corresponding timeline.1

The right to inspection is something insurance companies do when there is an accident, but becomes even more important when there is disagreement over the estimated cost of a repair submitted by the auto shop to the insurance company. Policyholders have a right to have an agent conduct an in-person vehicle inspection and do not have to do this at an insurance drive-in center. The holder can request this inspection be done at the auto shop of their choice. This inspection must be done within five days of request for a car that cannot safely be driven, and within 15 days for a car that can be driven.2

Reinspection is required “promptly” after there is an adjustment to the estimate, and if supplementary allowances are requested by the repair shop or the amount is in dispute.3 Additionally, insurance adjusters cannot legally adjust a damage appraisal of a repair shop when

AASP-MN is pleased to announce it has awarded 22 scholarships totaling $20,000 to help automotive service and collision repair students pay for tuition or tools during the 2023-24 school year. The scholarships are in the amounts of $500 - $1,500 and are made possible by the generous donation from the Minnesota State I-CAR Committee, as well as proceeds from AASP-MN’s Annual Race for Automotive Education fundraiser.

Thirty college and high school students from 10 schools submitted completed applications. Applications were reviewed by a committee of industry representatives, with consideration given to scholastic achievement, education and career goals, financial need and written recommendations.

The recipients are:

• Gregory Arreola, Dakota County Technical College, Rosemount – Auto Body Collision Repair

• Jonathan Broenen, Dakota County Technical College, Rosemount – Auto Body Collision Repair

• Isaac DeBilzan, Hennepin Technical College, Brooklyn Park – Automotive Service Technology

• Matthew Foster, Lake Superior College, Duluth –Automotive Service Technology

• Mason Frank, Dakota County Technical College, Rosemount – Automotive Service Technology

• Ty Gregor, St. Cloud Technical & Community College, St. Cloud – Automotive Service Technology

• Jonathan Herrera-Martinez, Hennepin Technical College, Eden Prairie – Automotive Service Technology

• Joshua Hogan, Century College, White Bear Lake –Automotive Service Technology

• Catherine Jacobs, Dunwoody College of Technology, Minneapolis – Auto Body Collision Repair

• Lex Lewison, Riverland Community College, Albert Lea – Automotive Service Technology

• Sydnie Mailer-Kelly, Dakota County Technical College, Rosemount – Automotive Service Technology

• Cindy McCulley, Hennepin Technical College, Eden Prairie – Auto Body Collision Repair

MNCARS

• Zack McLaughlin, Dakota County Technical College, Rosemount – Automotive Service Technology

• Eric Otam, Dakota County Technical College, Rosemount – Automotive Service Technology

• Jacob Lee Marwyn Paulson, Century College, White Bear Lake – Automotive Service Technology

• Peter Rozeboom, Dunwoody College of Technology, Minneapolis – Auto Body Collision Repair

• Margaret Sager, Lake Superior College, Duluth –Automotive Service Technology

• Landon Stookey, Dakota County Technical College, Rosemount – Automotive Service Technology

• Julia Swanson, Dakota County Technical College, Rosemount – Auto Body Collision Repair

• Tomas Szambelan, Dakota County Technical College, Rosemount – Auto Body Collision Repair

• Samweil Tawfik, Century College, White Bear Lake –Automotive Service Technology

• Joshua Taylor, Hennepin Technical College, Eden Prairie – Automotive Service Technology

Congratulations to all this year’s recipients!

The scholarship awards are the centerpiece of AASP-MN’s Automotive Education Fund, which was established to provide financial resources to support automotive students, enhance automotive programs and raise awareness of career opportunities in the independent automotive service industry.

Attention AASP-MN Members!

Complete Your Member Profile

The AASP-MN website was designed to help you seek out other AASP-MN members when looking for services, tools/equipment or general advice and has search capabilities to facilitate those connections. However, in order for the search results to include information about your shop, you must complete your member profile on the website.

To do that, go to aaspmn.org and click on the “Members Only” button in the upper right corner. You will be prompted for a username and password. (If you don’t know this information, contact the AASP-MN office.)

Once you are logged into the site, click on “Members Only” on the navigation bar. A drop-down menu will appear. The first option on that menu is “My Profile.” Click on the “My Profile” option to update your company profile. Once you’ve completed editing your profile, hit the save button at the top of the page.

Please take the time to check out all of the great information and resources on the AASP-MN website, including:

Information about:

• Association news

• Member benefit programs

• Current/past legislative activities & find your legislators

• Industry training and upcoming events

Member shops, tools and equipment:

• Search our database to find a member shop in your

area, see what diagnostic or other equipment they own, what repair information they subscribe to, which management system they use and more! Our extensive database was designed to help members connect with – and be a resource to – other members. So be sure to login and complete your member profile!

Resources/links:

• Regulation of Claims Practices & Prohibition on Insurers Statutes

• Truth in Repairs Act

• Insurer Unfair Claims Practices Report

• MN Motor Vehicle Damage Disclosure & Reporting Requirements

• P-Pages, DEG & other estimating resources

• OEM service information

• MPCA Fact Sheets and other regulatory compliance information

Sample documents:

• Complaint Letter to Department of Commerce

• Loaner Car Agreement

• Repair Authorization form

• Notice of Hazardous Defects

• Assignment of Insurance Proceeds

• Sheriff’s sale instructions and documents

Consumer info:

• Find a Shop

• Auto Insurance Claims & Claimants’ Rights “Nuts & Bolts” brochure

• Consumers’ “Know Your Rights” (after submitting an automobile accident claim to your insurance company)

• Motor Vehicle Service Contracts: FTC, MN Attorney General and Consumer Reports

• FTC Consumer Alerts on auto warranties and warranty scams

Other:

• Automotive career and scholarship info, including links to state college automotive programs

• AASP-MN News Magazine – Check out the current or past issues of the Association’s monthly magazine, AASP-MN News

• And, much more!

The Do-It-For-Me (DIFM) light vehicle aftermarket in the U.S. has two major segments: products and purchased service. Purchased service is the labor cost of product installation and diagnostics performed by automotive technicians.

Purchased service generated over half of total car and light truck aftermarket product growth (products and purchased service) during the five years prior to COVID19. Over the next five years, Lang Marketing expects that the purchased service share of light vehicle product growth will increase.

DIFM is the Dominant Aftermarket Driver

DIFM products and purchased service generated over 85 percent of light vehicle aftermarket growth between 2011 and 2021. During this period of DIFM aftermarket dominance, purchased service (product installation and diagnostics) climbed at a faster annual pace than DIFM products.

DIFM products (products installed by automotive technicians) increased by an estimated $16 billion at userprice between 2011 and 2021.

Preliminary findings by Lang Marketing indicate that DIFM products and purchased service generated over 90 percent of the 2022 aftermarket product growth, at userprice. More details will be available in a few months.

Products Climb by 22 Percent

Lang Marketing estimates that the 2021 DIFM product volume was nearly 22 percent higher than 10 years earlier. This represents a 2.0 percent average annual growth.

While DIFM products recorded a strong growth rate over the past 10 years, light vehicle purchased service climbed even faster.

Light vehicle purchased service soared from $53.9 billion in 2011 to $71.1 billion in 2016 at user-price.

Lang Marketing estimates that light vehicle purchased service topped $83 billion in 2021.

Purchased service for light vehicles averaged 3.5 percent annual growth over these ten years.

Light vehicle purchased service climbed at a threequarters faster annual pace than DIFM products between 2011 and 2021.

The total light vehicle aftermarket in the U.S. (DIFM & DIY products plus purchased service) surged by over $46 billion between 2011 and 2021.

Car and light truck purchased service accounted for 52 percent of this gain, and products (DIFM and DIY) were responsible for 48 percent of light vehicle

Preliminary findings of Lang Marketing indicate that purchased service exceeded DIFM and DIY product volume growth during 2022.

The DIFM market (DIFM products and purchased service) generated over $40 billion of light vehicle aftermarket growth between 2011 and 2021.

Lang Marketing estimates that purchased service growth expanded the DIFM market by 60 percent between 2011 and 2021.

Three factors have boosted the annual growth of purchased service: diagnostics, pricing pressure on parts margins and the cost of tools and equipment required by the growing complexity of vehicle repair.

Vehicle complexity has increased the need for more diagnostics to determine the repairs and parts required. For many repair jobs, diagnostics exceed product installation in the amount of purchased service required by automotive technicians.

The internet has increased the visibility of parts costs to consumers and boosted their sensitivity to parts prices charged by repair outlets. To counter this pressure on repair parts’ gross margins, many outlets are increasing charges for purchased service.

Increased diagnostics and the growing complexity of vehicles require repair outlets to purchase additional and more expensive tools and equipment. To offset rising tool and equipment costs, many outlets are increasing the hourly rates charged for the work of automotive technicians.

Lang Marketing expects that factors boosting purchase service growth will intensify over the next five years.

Diagnostics will become more pervasive and expensive. The visibility of parts costs to consumers through the Internet and other sources will increase downward pressure on prices that repair outlets can charge for parts.

Purchased service will increasingly be used to maintain gross margins threatened by parts pricing pressures and to offset the cost of tools and equipment needed to perform the increasingly complex vehicle repairs.

Accordingly, Lang Marketing expects that purchased

service volume will increase at about twice the annual growth pace of light vehicle DIFM products, at user-price, from 2023 through 2027.

• The purchased service is the cost of product installation and diagnostics performed by automotive technicians.

• DIFM products and purchased service generated over 85 percent of total light vehicle aftermarket product growth between 2011 and 2021.

• Preliminary findings by Lang Marketing indicate that DIFM products and purchased service accounted for over 90 percent of light vehicle aftermarket product growth in 2022.

• Purchased service averaged 3.5 percent annual growth in the light vehicle aftermarket between 2011 and 2021, stronger than the 2.0 percent average annual increase of DIFM products.

• Purchased service has increased its annual growth rate for three primary reasons: the increased need for diagnostics, growing pressure on parts pricing, and the requirement for additional and more expensive tools and equipment to perform increasingly complex vehicle repairs.

• See the 2023 Lang Aftermarket Annual for a 10-year analysis of the growth of DIFM products and purchased service in the light vehicle aftermarket.

Car and light truck product sales in the U.S. from 2019 through 2022 increased much faster than the growth of vehicles in operation (VIO) and light vehicle annual mileage. This was the result of increased aftermarket product use per mile.

Greater product use per mile, especially among older vehicles, will generate the continued aftermarket product growth of Internal Combustion Engine (ICE) cars and light trucks as they dominate the older vehicle age groups in the U.S. through this decade and for many years beyond.

Factors driving car and light truck aftermarket product growth have shifted during the last three years. Traditionally, light vehicle aftermarket product use was driven primarily by the increasing number of vehicles in operation (VIO) and the corresponding mileage growth.

The situation changed from 2019 through 2022. Despite record-high automotive sales from 2016 through 2019, the new car and light truck annual volume faltered over the next three years. Accordingly, the VIO gain averaged less than 1.5 percent annually over these seven years and even less over the next three years

Following a 2.5 million gain during 2020, the car and light truck VIO was not much higher in 2022 than two years earlier. From 2019 to 2022, light vehicles averaged less than 1.0 percent annual growth.

In 2020, light vehicle mileage suffered a double-digit plunge from the onslaught of COVID-19, followed by a sharp rebound in 2021. Light vehicle mileage climbed moderately in 2022, but annual miles rose less than 1.0 percent from 2019 through 2022.

Annual light vehicle mileage recorded lower growth than the VIO from 2019 through 2022. The average car and light truck traveled approximately 150 fewer miles last year than in 2016, the result of light vehicle mileage climbing at a rate less than one-half the mileage growth over the previous seven years.

While final results for 2022 will not be available for a few months, preliminary findings by Lang Marketing suggest that average product volume per mile rose significantly from 2019 through 2022. This resulted from three factors: the rising average age of vehicles, the population growth of older cars and light trucks and the increasing share of light vehicles represented by light trucks.

Lang Marketing estimates that the average age of all types of vehicles (cars, light trucks, domestic nameplates and foreign nameplates) climbed significantly from 2019 through 2022, prompted by the downturn in new vehicle sales and the increased durability of vehicles in operation.

The number of older vehicles among all types of cars and light trucks increased last year, boosting overall vehicle average age. Since older vehicles use more aftermarket products per mile than younger models, the aging vehicle population and the increasing average age of cars and light trucks in operation were significant factors in generating aftermarket product growth over the past several years.

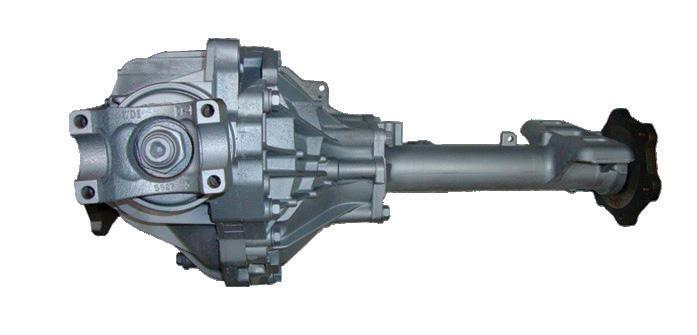

Light trucks average greater annual product use per vehicle than cars. This reflects expensive replacement parts (especially drivetrain components) that are unique to light trucks, the greater use of accessories on light trucks, and the higher prices of some light truck components than comparable car parts.

With their increasing share of the light vehicle population and miles driven, light trucks are boosting product use per mile.

The ability of the aftermarket to generate product growth from increased product use per mile and the expanding share of light trucks in operation is good news for Internal Combustion Engine (ICE) aftermarket volume in the coming years. Virtually all light trucks and vehicles in older age categories will be fossil-fueled for a long time.

continued on pg. 21

At the end of April, state affiliate leaders of the Alliance of Automotive Service Providers (AASP) gathered at the I-CAR Chicago Technical Center (CTC) in Vernon Hills, Illinois for a full day of learning, sharing and interacting during the national association’s first meeting of 2023.

AASP-MN Executive Director Linden Wicklund and the National Board’s current President Dan Sjolseth (Superior Service Center; Eagan) made the trip out to connect with fellow members of AASP National, tour I-CAR’s newly unveiled CTC and to share the goals and efforts of the Alliance with colleagues from around the country including New Jersey, Pennsylvania, Massachusetts, New York, North Carolina and Illinois.

Conversation went back and forth around the room as Wicklund and other leaders shared their experiences within their own membership groups along with information and education related to ADAS, Right to Appraisal, photo estimating, storage and administration fees and the liability repairers face if cars are not fixed to OEM standards.

Wicklund shared AASP-MN’s efforts to keep members supplied with resources and information, making sure they know how to properly document line items and recognize state statute violations, while not being afraid to speak up and file complaints.

Providing high quality educational opportunities continues to be a strong suit of the association and now it’s going even deeper with the addition of what Wicklund calls “more casual” opportunities as a way to get more people to engage. The group meets twice in person and twice online each month.

Wicklund noted that many people who have shown up admit to having never participated in the past. “It often almost becomes a group coaching session for the shops that have been on the sidelines,” she said. Using the analogy of a “Bible Study,” the gatherings bring

people together in a casual networking environment so even those who may not be as active can feel more comfortable taking part.

“It’s a great collaboration, just like we’ve had in this room today,” commented Sjolseth. “The meetings don’t get too technical; it’s a lot about sharing best practices and experiences.”

During her report, AASP National Administrator Judell Anderson shared the recent success of the AASP-supported Database Enhancement Gateway (DEG), supplied by its administrator Danny Gredinberg. Highlights included the DEG’s newly refurbished website and the significant corrections made to the estimating systems as a result of the DEG’s efforts. She applauded the DEG for its large impact on body shops all across the country that will benefit from those corrections.

“I don’t think you can point to anything else that has the impact the DEG has,” Anderson praised, adding that if more repair professionals took the time to submit inquiries, it would be even greater.

Meeting at the I-CAR training center allowed affiliate leaders the opportunity to walk through the new facility courtesy of a tour led by Bud Center, director of technical products and curriculum.

Center relayed the specific design requirements that were needed for the facility, especially for its ADAS calibration training area. I-CAR worked closely with the contractor to make sure the floor was completely level and flat as per requirements of many manufacturers when it comes to their ADAS calibrations.

“A self-leveling product had to be poured, a little at a time, and then 3D lasers were put all over the floor to make sure it stayed level,” Center explained. In fact, the contractor they worked with admitted he had never been asked to produce a completely flat and level surface previously.

Lighting is another key factor in ADAS calibrations. The lighting in the room is designed to be dimmed, so it can be adjusted to match daylight. According to Center, there are many situations that require lighting to match outdoor lighting, and without it, it can take a lot longer to set a dynamic calibration.

As AASP members stopped to look at the equipment, tools and vehicles used in EV training, Center reviewed the five-day process that starts with understanding the basics of electricity through the teaching of building electrical circuits. Once the trainees have developed an understanding about the different things involved in high voltage vehicles, they will be able to test and diagnose so they know what to expect when working on a live vehicle. Once that understanding is reached, trainees can work on a live vehicle with the proper PPE.

“We have people coming through here and saying, ‘My head hurts trying to take in all this information and understand it all,’” Center said of the intense program, adding that people will comment that EVs are not widely seen. “It only takes one vehicle to kill somebody,” he noted.

An overview led by I-CAR’s Mike Mertes and Jeff Peevy on how “cutting edge” innovations like AI can be possibly utilized in training evolved into an eye-opening discussion on technology advancements as a recruitment tool as the group considered the future of collision repair.

I-CAR is also in the early stages of developing a

by Alana Quartuccio

by Alana Quartuccio

virtual repair planning game that, once mastered, would put that technician in a more advantageous position over the average tech entering the field.

Cars are more computerized than ever before. Although most of the world may not realize it, technical process skills are needed in addition to hands-on skills, Peevy stressed. “Once someone envisions something with wheels on it, they automatically think one has to be good with their hands.”

Changing the look of the industry is necessary in getting a new generation into the fold, but the biggest hurdle with this might be changing which skill sets shops are focused on when recruiting new employees.

Wicklund shared that she recently asked shop owners if any had considered looking at young IT professionals as a source of future employment, as individuals possessing the skill set necessary to diagnose computerized physical objects (like vehicles) and “may not want to work in a basement” could be a good fit for this industry. She shared that responses received indicated that these individuals “don’t know how to turn a wrench.” She noted that teaching the hands-on skills related to automotive repair might be easier than teaching some computer diagnostics.

Economic uncertainty can be terrifying for small business owners, but as discussed in the April issue of AASP-MN News (available at grecopublishing.com/aaspnews-april-2023), what may be a detrimental downturn for other industries actually opens up the door to many opportunities for automotive and collision repair shops.

While the possibility of a nationwide recession still looms, this industry is fortunate to be a bit more recessionproof than most. Why? Well, for starters, while Americans continue to rely heavily on their personal vehicles (especially in the wake of COVID which has enhanced distrust of public transportation), consumers are less apt to take on more debt by making large purchases like new cars. Inflation and increasing interest rates have collaboratively created a situation where buying a new car is incredibly prohibitive: by the end of 2022, new cars were averaging over $48,000 with an average interest rate of 6.5 percent and a $700 monthly payment!

“People worry about going into debt with such high car payments being financed for long periods of time,” explained Maylan Newton (Educational Seminars Institute). “Rising interest rates also causes people to hang onto their cars longer, investing in engine replacements and major repairs to avoid a new car payment. They’re more willing to invest in what they have to avoid the hassle of buying a new car; between surcharges and premiums, some dealerships are charging more than $30,000 above sticker price! The average consumer cannot afford that and would rather repair their current car instead of going into such massive debt for six years with high rates, especially with the way they’re rushing to complete vehicles now. I expect a lot of recalls in the coming years because they aren’t taking the time to build cars correctly. It’s going to be a good couple years for repair shops because of all these reasons.”

“With new car loans averaging 77 months and 14 percent of new car loans over $1,000 per month, this is the easiest time to take advantage of the opportunities that exist in the repair world,” agreed Rick White (180BIZ). “Consumers often resist investing in repairs, but why throw a $60,000 solution at a $4,000 problem? Service advisors can sell the repair by demonstrating the cost for a new car in payments and interest over a seven to eight year note. Help them understand that their vehicle is an investment and that we’re selling the ability to get more miles out of their car. The next 10-12 years will be one of the best times we’ve seen in the auto repair industry in a long time. People will keep their cars and invest in them

because they understand that’s a better use of their money. Even a $3,000 repair costs less than six months’ worth of payments!”

Shops may need to spell this out for consumers because “a lot of consumers are not very intelligent about their cars,” Newton observed. “Our job is to help them understand the value of fixing the vehicle as opposed to replacing it. I use statements like ‘protect your investment’ and encourage them to make sure their car ‘lasts longer than the car payments do.’ Emphasize that neglecting to care for their car means it won’t last the length of time that they finance the car for. We have to change our mindset to focus on the customer’s needs, and that means talking less about the technical side. Instead, we need to explain how we’re protecting their investment and making it last as long as possible.”

From a collision perspective, the decreased demand for new cars creates different opportunities.

“Customers are more apt to fix their car instead of buying new, whether that means filing insurance claims or bringing the car in themselves,” suggested Mike Anderson (Collision Advice). “Shops are likely to see more customer pay vehicles which are usually the most profitable jobs since they mean more labor, less parts and a higher gross profit, plus there’s the added benefit of working directly with the consumer instead of a third-party payer.”

He also pointed out that people tend to focus on collision repairs cyclically. “After income tax season, there’s that time of year when people slow down and start preparing for summer vacations, so it’s likely that they’ll invest in their cars at that point to make sure they’re running properly and that they’re looking their best.”

With that in mind, this may also be the perfect opportunity for shops to re-evaluate their offerings.

“It’s important for any entrepreneur to be nimble and able to pivot and change their strategy,” indicated Rachel James (Torque Financial Group). “Could you market detailing services to help make that old car feel like new again? Or maybe, a conventional collision shop might consider offering some à la carte maintenance and service items to add some line items to their blueprints while creating convenience for their customers. Adding a band of business you’ve never engaged with before, such as glass repair or calibrations, could add an additional stream of revenue and more security.”

Selling customers on those additional maintenance items requires convincing them to agree to those services.

Since the majority of collision repair costs are typically covered by insurers, it may be more difficult to sell those add-ons unless shops are able to establish repairs as an investment, instead of an additional cost.

“It truly can be an investment to the consumer, so that’s how shops need to position it,” James insisted. “As a consumer who doesn’t want to spend additional money on a monthly car payment, you’ll have to accept that there will be expenses associated with maintaining that vehicle. From a shop’s perspective, it all comes down to communication, and a qualified customer service representative can effectively have that conversation to explain how maintenance prevents bigger repairs down the road and reduces the overall costs by sustaining the vehicle through some due diligence and a little TLC.”

Communicating with customers can make a huge difference for forward-thinking shops, especially as it pertains to advancing technology. “Shops should be holding car care classes to educate people and teach them how to be involved in protecting their investments,” Newton recommended. “It’s amazing how many cars we see without oil in them because people don’t even know how to check their own oil! Attend meetings of the local rotary clubs and chambers of commerce to explain how much technology exists in today’s vehicles.

“Cars aren’t cars any longer,” he continued. “Multiple systems and modules are communicating with each other electronically via airwaves. Most people don’t even know their car is hackable. We need to educate consumers so they stop learning from Google and YouTube. They think it’s easy, and then we make it sound easy by advertising prices or quoting prices over the phone. We need to educate customers and talk about how it takes special knowledge and tools to even know WHAT to fix before it can be fixed.”

White believes that advancing technology is one of the reasons that people are keeping their vehicles

longer, but “as technology continues to grow, the do-it-yourself market is going to get smaller and smaller because they can’t keep up with the technology. And although there are early electric vehicle (EV) adopters, a lot of people are resistant to EVs, plus there are still enough bugs in the infrastructure that I think internal combustion engines are going to be around for a while, even after they stop being made. So, while shops need to start investing in future technology to repair tomorrow’s cars, today’s vehicles are already complex and will be around for a long time, offering plenty of opportunities for us all.”

“No one has all the answers, but I definitely believe there are lots of opportunities for our industry,” Anderson said. “This whole EV revolution provides opportunities and will likely separate some shops in a way that aluminum never did. We haven’t even scratched the surface in regard to ADAS and calibrations, which will continue to grow, and I suspect more shops will embrace it and bring it in-house. COVID jump-started the utilization of some technology, but we’re not quite where we need to be in terms of researching repair procedures or utilizing software…There may even be a place for 3D printing in our industry’s future! We just need to stay open-minded and willing to accept the opportunities when they come knocking.

“Too often, we kick new software solutions to the curb because they don’t offer 100 percent of what we need, but we all need to learn to crawl before we walk before we run,” he encouraged. “Instead of penalizing them for what they can’t do today, understand that we need traction to advance along even further and consider what that software might be capable of in the future.”

Despite the existence of those opportunities, many shop owners still express fears related to rising costs, but rising costs are nothing new.

“We have increasing costs every year, whether there’s a recession or not,” Newton pointed out. “Shops need to stop being afraid to charge what’s correct. Reevaluate your hourly rate every year – or preferably every quarter – and increase it as needed. Quarterly increases allow you to keep up with inflation, plus it’s easier to raise that number a little at a time instead of a lot all at once. It’s important to do the math and calculate your true cost of doing business, but understand: your hourly rate isn’t as important as your effective labor rate, which is the amount you’re actually charging based on productivity. You need to understand your numbers in order to make money, and we also need to sell

value, not repairs. Sell knowledge, not what our hands can do for us. We’re selling peace of mind and safety, not just parts and labor.”

Anderson concurred that shops should be looking at their labor rates more often. “Most people do it yearly, but I recommend evaluating your cost of doing business every quarter in order to build budgets and pro formas for the upcoming year. Surround yourself with experts like your 20 group peers and other knowledgeable people that can help you better understand what expenses you should be considering and what rates you should be charging. We need to be monitoring our expenses and our overhead, especially as we look at repairing EVs due to the investment we’ll need to make in training and equipment for those vehicles. It’s a good rule of thumb to have at least six months’ of expenses saved in cash reserves; that’s the sign of a healthy business.”

White shared a similar viewpoint. “We should be watching inflation all the time because it averages around three percent each year. It’s the silent killer of profit since people don’t always pay attention, but it’s about buying power. Something that cost $100 in 2019 now costs $117. Prices go up constantly, so shops should be adjusting their rates quarterly or even monthly. Realize that these increases don’t allow you to make more money; they’re simply giving you the same buying power. And when you’re thinking about that, you also need to be giving employees a cost of living increase because if you’re worried about inflation, so are they. As the shop owner, you need to be taking care of them. No matter how hard things get, it won’t last forever. Know that it may be tough, but you can thrive if you keep a

positive attitude and work smarter.”

James offered some financial advice for all business owners: “Over the next 12 months, look at your budget and develop a plan. Many look at their checkbook as an indicator of success, but in reality, that’s not the whole picture. Evaluate your P&L for the past year to see what it costs to run your operation. Are there any discretionary expenses that can be eliminated to free up cash flow? If you’re unsure, now is the perfect time to get a better understanding of your monthly financials so you can remove any unnecessary costs and better position yourself for financial success.”

At the same time, shops must recognize the difference between necessary and unnecessary costs, and in a time of financial uncertainty, it’s easy to make the wrong decisions on which expenses should be cut…and which should be increased.

“Market when you’re busy to stay busy,” Anderson recommended. “We need to market now more than ever before, but don’t overextend yourself. You can’t overspend in your personal life and ask your business to support that. It’s not about what you make; it’s about what you spend.”

“Struggling shops may not make it through a recession, leaving only stronger shops to survive, and that gives those shops an opportunity to increase their market share,” White noted, citing the example of AirBnB’s decision to decrease marketing during COVID. In contrast, Vrbo increased marketing 10 times, and by the end of the pandemic, AirBnB had lost 15 percent of the market, while Vrbo had picked up 61 percent. “Go big! When it’s really busy, the audience isn’t watching the stage, but during something like the pandemic, people are watching. And if 98 of 100 shops hide to ride out the recession, that leaves two shops trying to get the audience’s attention…and they’re going to get it! This is a great time to record videos to help people get to know and trust you. When no one else is marketing, now’s the time to build credibility. Increase your marketing, grow your market share, and you’re going to do really well.”

“The hardest part of financial planning is the emotional aspect,” James acknowledged. “It’s challenging to navigate because it’s so easy to fall into the fear of scarcity versus abundance, but more pressure equates to better results. Sure, issues occur, but you buff it out or realign it. There’s no perfect day in a collision shop, so you need to plan for the good times and the bad. Develop options for abundance and a contingency plan for when things get tight. There’s no crystal ball telling us if the next 12 months will be horrible or not, but we can rest assured that some point in the future will hold a difficulty for every business, whether that be economic, market or product driven. Being prepared is key.”

“Most people reading this article aren’t the cheapest shop in town, yet they’re busy,” Newton emphasized. “We worry too much about price due to fear, but we need to stop advertising and quoting prices and start charging a fair amount based on the cost of doing business. Fear causes us to stop marketing when times get tight, but we should continue advertising, just redirecting our focus on service, quality and value. If we convince ourselves that the sky is falling, our employees will believe and perpetuate that; if we tell them it’s slow every day, they’ll slow down and create productivity problems. We need to be optimistic because there’s plenty of opportunity. Charge the correct amount, do the best job you can, constantly build value, and you’ll have a good year!”

Fire extinguishers are designed to fight fires in their early stages when the fire presents a relatively small hazard. An extinguisher can be used when the fire possesses the following characteristics:

• Small

closes and the discharge stops

S=Sweep

• Sweep the nozzle by moving your arm at the elbow. Direct the discharge to cover the entire width of the base of the fire.

• Small

• Slow growing

• Slow growing

Fire extinguishers are designed to fight fires in their early stages when the fire presents a relatively small hazard. An extinguisher can be used when the fire possesses the following characteristics:

• Giving off minimal smoke

• Emitting minimal heat

If a fire is too large, if there is too much smoke or if you are too frightened, evacuate immediately.

PASS

• Giving off minimal smoke

• Emitting minimal heat

Use the PASS method:

P=Pull

If a fire is too large, if there is too much smoke or if you are too frightened, evacuate immediately.

• The safety pin is usually held in place by a plastic seal and will pull off. Do not push down on the operating lever while pulling the pin, it won’t come out.

PASS

Use the PASS method:

P=Pull

A=Aim

• Aim at the base of the fire, the lowest flame closest to you. The base of the fire will recede from you as you use the extinguisher, so you must adjust your aim.

Know Your A, B, Cs

Using the wrong fire extinguisher can result in more damage than the fire itself. All extinguishers have nameplates identifying their usage instructions, as outlined below.

Class A Fires

• Only use Class A extinguishers for wood, paper, trash and other items that produce glowing embers as they burn. Class A extinguishers should never be used on gas or electrical fires.

Class B Fires

Be safe and healthy on the job with these helpful tips provided and fight a fire. If, at any point,

• The safety pin is usually held in place by a plastic seal and will pull off. Do not push down on the operating lever while pulling the pin, it won’t come out.

A=Aim

S=Squeeze

• The operating lever is above the carrying handle. The operating lever opens the valve when you squeeze it down. When you let go, the valve

• Aim at the base of the fire, the lowest flame closest to you. The base of the fire will recede from you as you use the extinguisher, so you must adjust your aim.

S=Squeeze

• The operating lever is above the carrying handle. The operating lever opens the valve when you squeeze it down. When you let go, the valve closes and the discharge stops

S=Sweep

• Sweep the nozzle by moving your arm at the elbow. Direct the discharge to cover the entire width of the base of the fire.

Know Your A, B, Cs

Using the wrong fire extinguisher can result in more damage than the fire itself. All extinguishers have nameplates identifying their usage instructions, as outlined below.

Class A Fires

• Only use Class A extinguishers for wood, paper, trash and other

• Only use Class B extinguishers to fight fires caused by flammable liquid and gas (gasoline, paint thinners, solvents, grease and acetylene).

Class C Fires

• Use a Class C extinguisher only to fight energized electrical equipment fires

This flyer is for informational purposes only and is not intended as medical or legal advice. © 2007-2010, 2017 Zywave, Inc. All rights reserved.

Be safe and healthy on the job with these helpful tips provided by CBIZ…

Never feel like you must stay and fight a fire. If, at any point, you feel like your safety is threatened while using a fire extinguisher get out immediately. For more information, contact Brad Schmid at bschmid@cbiz.com or 763-549-2247.

Visit degweb.org to submit a Database Inquiry and contribute to database accuracy!

The Database Enhancement Gateway (DEG) helps improve the information in collision repair estimates through repairer feedback about vehiclespecific errors, omissions and inaccuracies in the databasae and labor times. If you are performing automotive repairs of any kind - collision or mechanical - you need to utilize the DEG! Check out some recent Database Inquiries - and their resolutions - below!

All Three Systems: Structural repairs requiring rocker pinch weld clamps, truck frame or fixture anchor points may require repair and refinishing after removing the vehicle from the structural bench. The labor to repair and refinish anchor points is NOT INCLUDED and would be an on-thespot evaluation for labor and material cost.

CCC/MOTOR: Adjusting Door Glass Frameless Windows – Recent DEG Inquiry 30633 states, “After review of the concern, adjustment/alignment of the Door Glass is not included with the estimated work time and would be addressed through an on-the-spot evaluation.”

GM Wiring Pigtails & Socket Catalog: Repair businesses can easily locate OEM wiring pigtails and socket part numbers using this free website directly from GM Genuine Parts|ACDelco: acdelco-connectors.dstcloud.com/v2/#!/ catalog

Note: The estimating databases are all intended to be used as a GUIDE ONLY. View these tips and others at DEGWEB.ORG

continued from pg. 5

the extent of damage is in dispute without conducting a physical inspection of the vehicle.4

Unlike the original inspection timeline, “promptly” is not defined. The Department of Commerce has not defined “promptly” but will investigate complaints about reinspections that are not happening “promptly” when shops are experiencing unreasonable delays.

AASP-MN has clarified that auto repair shops can make these complaints directly to the Department of Commerce on behalf of customers. AASP-MN leadership can assist with the complaint process and contacting us helps establish broader trends which help with our ongoing discussions with Commerce. Regardless, the first step is to know and cite the statutes that require the original inspection to be within five days for a vehicle that can’t be driven and 15 days for a vehicle that is drivable5 and that reinspection must happen promptly in cases of supplements or price disputes.6

Over the coming months AASP-MN will continue to make use of current laws and bundle complaints to submit to the Department of Commerce. We will also work with AASP-MN members to determine the most impactful policy chances to pursue next legislative session, during the “policy year” where legislators seek policy changes as opposed to setting a budget.

1 Minnesota Statute 72A.201, see Subd. (6) section (3)

2 Minnesota Statute 72A.201, see Subd. (6) section (4)

3 Minnesota Statute 72B.091, see Subd. (4)

4 Minnesota Statute 72B.091, see Subd. (1) section (5)

5 Minnesota Statute 72A.201, see Subd. (6) section (3)

6 Minnesota Statute 72B.091, see Subd. (4)

By Janet L. Keyes, CIH

By Janet L. Keyes, CIH

What kills in automotive shops?

Being crushed by vehicles. Taking cars for test drives. As we were perusing OSHA inspections for car dealers, we were struck by the number of fatality reports. That led to a search for OSHA-reported vehicle fatalities, such as these:

• A year ago, an employee started up a pickup truck to move it out of the repair shop. It immediately shot forward, crushing another employee against another vehicle. The truck had been left in gear because the parking brake wasn’t working.

• In July 2021, an employee put an RV on jacks to fix a flat tire. The RV shifted and fell, crushing the mechanic.

• Again in 2021, two different shops used forklifts to raise and move cars. When a car at each of those shops fell off the forklift, it crushed an employee to death.

• August 2021 – This time, the car wasn’t on a forklift. It was on an ordinary hydraulic lift when, for unexplained reasons, it rocked and then fell, killing the employee.

Don’t stand between vehicles and fixed objects. Inspect your lifts and jacks. Never rely on hydraulics – use jack stands; make sure the safety latches for vehicle lifts work. Don’t take shortcuts when working under vehicles.

We recently saved a company $18,367. How? We recommended that they contest some OSHA violations. The company didn’t question the citations. They hadn’t been doing Right to Know/Hazard Communication training. They weren’t using respirators correctly. Employees were overexposed to a substance. Equipment wasn’t guarded. They hired us to help correct those problems. But we still recommended contesting because if you contest the citation, there’s a good chance you’ll pay less. If you don’t contest the citation, you’ll pay the full amount.

OSHA isn’t in the money-making business. Penalties assessed against employers go to Minnesota’s general fund, not MN/OSHA. MN/OSHA prefers to get corrections in place and come to a settlement agreement than to try to get every last penny out of an employer. OSHA doesn’t get mad or offended if you contest citations. Instead, our clients have usually been offered a 40 percent penalty reduction, once OSHA sees the companies are trying to correct the problems.

The company that saved $18,000 in OSHA penalties ended up paying a lot of money anyway. They had to pay us to get them on the right track with training and control measures. They paid for ventilation system upgrades and machine guarding fixes. It would have been cheaper to have fixed the problems before OSHA came in.

If you want to pay even more, don’t contest the citation and don’t correct the problem. In 2018, a car

dealer in Duluth was cited for respirator program problems and lack of carbon monoxide monitoring. They paid the full amount of $2,400. This past February, OSHA cited them for the same problems. This time, the dealer paid the full penalty of $4,500. If it happens again, their penalties would jump substantially. For Minnesota to be able to continue to run its own OSHA program, it must raise its penalties to be in line with federal OSHA. Federal OSHA charges a minimum of $11,162 for repeated violations. $22,324 may not buy a new car, but it still is a good chunk of change.

Painters need to wear respirators because of the isocyanates and solvents in the products they spray. Do body techs need respirators?

We don’t think they usually do, but they may want to. Dust levels may be uncomfortable, but are not likely to be close to legal or recommended exposure limits. Styrene, the solvent in body filler, is also likely to be well below limits. Respirators may be needed for priming or spraying poly, but those tasks need to be done in a spray booth or prep station to control the fire hazards.

If body techs are using N95 filtering facepieces, all you need to do to comply with OSHA’s respirator requirements is to hand out Appendix D to OSHA’s respirator standard. That cautions that users should read and follow manufacturers’ instructions, use NIOSHapproved respirators, wear the respirators only for protection against relatively low levels of particulates and keep track of their respirator.

But when we walk through body shops, we often see elastomeric (rubber-type) respirators, such as the bodyman’s mask. You can’t get by with just handing out Appendix D if employees use that type of respirator, even if use isn’t mandatory. You need to do three things to ensure use of the respirator won’t harm the employee:

• Get medical clearance. Anyone who is required to wear any type of respirator, including N95 filtering facepieces, must have medical approval to wear the

respirator. But that’s also required for voluntary users of elastomeric respirators. Your occupational health clinic can handle this for you. There are also online options.

• Have standard procedures addressing how to take care of the respirator, so it doesn’t harm the user.

• Train users on those standard procedures, so they know how to take care of their respirators. They need to keep their respirators clean and in good condition. We shouldn’t see dirty masks with worn-out straps left on top of body techs’ tool chests.

As long as respirator use is not required, body technicians don’t need annual fit testing and training and they can be as hairy as they want. If they need to wear a respirator, though, they must be clean-shaven where the respirator seals to their face. If they aren’t, the respirator won’t give them enough protection.

continued from pg. 9

ICE vehicles will disproportionately contribute to aftermarket product volume per mile compared to their percentage of the total light vehicle population and total miles driven.This will be an aftermarket sales multiplier for ICE cars and light trucks over the next 10 to 20 years.

ICE vehicles will generate strong aftermarket product sales for many years, even if the robust (and questionable) estimates of Electric Vehicle new sales materialize.

• Light vehicle aftermarket product use traditionally has been driven by VIO growth and increasing annual miles.

• The situation changed from 2019 through 2022, as COVID-19 prompted a sharp reduction in new vehicle sales and stagnated VIO growth and annual mileage.

• Product use per mile has been a key factor driving aftermarket product growth, given the slowing of VIO and total miles.

• With older vehicle age groups recording the fastest population growth among cars and light trucks, the aging vehicle population is generating substantial aftermarket product growth.

• Light trucks average greater aftermarket product use per mile than cars. The surge in the light truck share of the nation’s VIO is a major factor in increasing aftermarket product growth.

• Virtually all light trucks and vehicles in older age categories will be fossilfueled for a long time in the U.S. This will help to sustain the strength of the U.S. ICE aftermarket for decades.

Complete Health, Environmental & Safety Services, Inc. (C.H.E.S.S.) offers AASP-MN members a 20 percent discount on the following services:

Right to Know (RTK)/Hazard Communication

You must train employees before they start work and annually. You must have a written program. CHESS’ Right to Know Written Program and Training Guide is customized for your facility, whether you offer collision or mechanical repair. The written program and training guide is available exclusively to AASP-MN members for $515.

Safety Data Sheet Management

As part of the Right to Know/ Hazard Communication OSHA law, you must provide your employees access to Safety Data Sheets (SDS) for

PROPERTY/LIABILITY AND WORKERS’ COMP INSURANCE

CBIZ

Contact: Brad Schmid 763-549-2247 / bschmid@cbiz.com

the products in your shop. CHESS’s SDSLinks, an online SDS management tool, makes them easy to find. CHESS also provides support 24/7 if you cannot locate one. SDSLinks is available exclusively to AASP-MN members for $325 per year.

A Workplace Accident and Injury Reduction Program (AWAIR)

As of February 2020, you must have a program that outlines who has responsibility for safety, how safety is communicated, how hazards are identified, how accidents are investigated and how safety is enforced. AASP-MN member discounted price: $760.

Safety Reminder Posters

OSHA has some regulations, such as walking and working surfaces and ladder use that require training.

Keeping safety in front of employees on a regular basis is one way to help reduce injuries. CHESS will email you a poster on a different topic each month relating to safety issues found in your shop. You can post it or review it with employees in a shop meeting. The Safety Reminder Posters program is available exclusively to AASP-MN members for $285 per year.

All of these services can be bundled for a fee of $1,500, with annual renewal of the SDSLinks and posters for $575.

In addition, CHESS offers up to one hour of free phone consultation to any AASP-MN member with safety or environmental questions.

For more information, contact Carol Keyes at (651) 481-9787 or carkey@ chess-safety.com

WEBSITE AND INTERNET MARKETING SOLUTIONS

Autoshop Solutions

Contact: Tony Mercury 919-267-1731 / tony@autoshopsolutions.com

BUSINESS FORMS/CALENDARS

AASP-MN

Contact: Jodi Pillsbury 612-623-1110 / jodi@aaspmn.org

CBIZ AIA and United Fire Group (UFG) have created a program for members that includes a special premium discount, exclusive coverage and potential safety group dividend. CBIZ AIA can present quotes from multiple carriers and, as an added bonus, offer members an exclusive 10% discount on their property/liability insurance premiums.

EMPLOYEE BENEFITS

Business Planning Professionals

Contact: Dennis Begley 612-308-6577 / dennis@begley-group.com

Business Planning Professionals will provide AASP-MN members with quotes from multiple carriers for life insurance, health insurance, long-term care and disability insurance.

EMPLOYEE VOLUNTARY BENEFITS

Colonial Life

Contact: Deb Ferrao 612-600-4135 / deb.ferrao@coloniallifesales.com or Tracy Bailey 612-801-0139 / tracy.coloniallife@gmail.com

Dedicated representatives can help members transform their benefit package with competitive rates, value added services at no cost and complimentary legal document preparation service. Colonial Life has the tools and flexibility to create a plan to fit everyone’s needs.

UNIFORM & LINEN SUPPLIES

Aramark

Contact: Rick Krenz

612-616-5290 / krenz-richard@aramark.com

Discounted pricing to members on rental of uniforms, entrance mats, shop rags, etc. Purchases are also discounted. Members receive annual rebate equal to 10% of their business with AmeriPride/Aramark each year.

CREDIT CARD PROCESSING

Association BankCard Services

Contact: Mac Hardin

952-933-2026 / mach@retailfinancialservices.biz

Competitive rates for AASP-MN members. Terminals and printers sold at cost. Monthly rental of equipment is also available.

LEGAL CONSULTATION

Fryberger, Buchanan, Smith & Frederick

800-496-6789

Members receive free, over-the-phone legal assessment and consultation (some restrictions apply) with an attorney who specializes in the area of law that is the subject of the call.

Autoshop Solutions has developed the most cutting-edge marketing platform for AASP members. Really Powerful Marketing (RPM) is an all-in-one program that bundles your website, pay-per-click, search engine optimization, social media, and much more! With five levels of RPM to match your budget, goals, and competition, it’s built to drive your shop forward!

REPAIR SHOP PRODUCTS/SERVICES DISCOUNTS

CARS COOPERATIVE

Contact: Stephenie Sheppard 405-547-4077 / membersupport@cars.coop Members receive discounts on a variety of products and services they use every day! From discounts on paint and rental cars to office supplies and phone services. Over 50 programs available!

INFORMATION PROVIDERS

Mitchell 1

Contact: Mitchell 1 Representative 888-724-6742 ext. 6986 Mitchell 1 offers AASP members a $10 per month discount on any eligible Mitchell 1 subscription.

Mitchell International

Contact: Mitchell International Representative 800-238-9111 AASP members receive $350 off Mitchell's MD-500 allin-one solution for scanning, calibration, estimating, and blueprinting.

TECHNICAL INFORMATION HOTLINE

IDENTIFIX

800-745-9649

Members enjoy a 20% annual savings on Direct-Hit and Direct-Help subscriptions, the industry's most reliable source for experience-based repair information.

CHECK GUARANTEE SERVICES

Certegy Check Services

877-520-2987

Discount rate of .75% to AASP-MN members. Use existing credit card terminal. Fast claim payments.

AUTO EMPLOYEE ASSESSMENT

Assessment Associates International

Contact: Nate Page 952-854-6551 / nate@aai-assessment.com

Designed to help facilitate and enhance hiring decisions. AASP-MN members receive 50% off retail price, starting as low as $15 per assessment.

Discounted rates on printed business forms and calendars.

PAYROLL PROCESSING

CBIZ Payroll

Contact: Carrie Hobrough 612-436-4620 / chobrough@cbiz.com

Members receive 20% discount off standard payroll products and services (excluding 401k).

SAFETY COMPLIANCE

Complete, Health, Environmental & Safety Services

Contact: Carol Keyes 651-481-9787 / carkey@chess-safety.com

AASP-MN members receive a 20% discount on Safety Data Sheet Management (SDSLinks), Right to Know(RTK)/ Hazard Communication program customized for your facility and monthly safety reminders, and other safety, OSHA or environmental assistance.

LIVE-ONLINE & ON-DEMAND TECHNICAL TRAINING

AUTOMOTIVE SEMINARS

Contact: Tim Houghtaling 920-866-9813 / tim@automotiveseminars.com

Discounted pricing to AASP-MN members on all liveonline events, as well as on-demand training videos.

Automotive Seminars specializes in diagnostic training that provides automotive technicians with knowledge, testing techniques and data interpretation skills needed to diagnose today’s vehicles. The live-online events and ondemand training videos focus on automotive electronics and engine management systems and are written and created by some of the industry’s leading diagnostic technicians.

BUSINESS COACHING

180BIZ

540-833-2014 / info@180biz.com

Members receive a 25% discount on Rick White's Pocket Business Genius subscription, offering independent auto shop owners fast access to actionable business advice from a leading industry expert.

SHOP SOFTWARE

Condition Now

888-868-5440 / conditionnow.com/body-shop

A platform that allows shops to supplement the accident or damage information reported on Carfax and Autocheck vehicle history reports. Every AASP member receives a discounted inspection rate, allowing them to generate additional revenue from their retail and dealer customers.