March 2018 | $7.20

It’s a

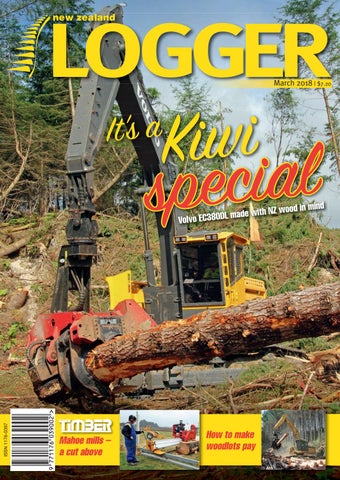

i w i K ial

c e p s

wood in Z N h it w e d a 0DL m

ISSN 1176-0397

Volvo EC38

Mahoe mills – a cut above

How to make woodlots pay

mind

March 2018 | $7.20

It’s a

i w i K ial

c e p s

wood in Z N h it w e d a 0DL m

ISSN 1176-0397

Volvo EC38

Mahoe mills – a cut above

How to make woodlots pay

mind