Exhibition & Conference

O shore Energy Exhibition & Conference is where the energy transition takes place. It is Europe’s leading event for the entire o shore energy industry and an opportunity to reach business leaders, highly qualified experts and professionals across global markets.

Participate with a stand and maximise your visibility by being part of this two day event filled with networking opportunities, matchmaking, collaborating with peers, doing business and broadening your horizon.

By sponsoring this event, your company is visible in pre-event and onsite communication materials and your branding will be noticed by thousands of visitors and exhibitors and 334,500 monthly online users.

Companies operating in any of the following sectors should participate:

Companies operating in any of the following sectors should participate:

Offshore NL is a magazine with the objective to promote the interests and export opportunities of the Dutch supply - and service companies in the upstream oil and gas industry. Moreover technological developments will be highlighted in order to contribute to a positive representation and positioning of the Netherlands as innovative and ingenious partner country.

Supported by

02 | Welcome by Andre Haspels, Ambassador

| Welcome by Sander Vergroesen, Managing Director IRO

Ensuring floating wind realizes its potential

Introduction way of working environmentally

Future of Walk to Work in Middle East

Advertising

Arthur Schavemaker, E-mail: arthur-ocean-energyresources@kenter.nl

Jeanet Draaijer, E-mail: jeanet-ocean-energyresources@kenter.nl Phone: +31 547 27 50 05

Editorial

Han Heilig - Managing Editor E: han@practica.nl

Production

Peter Ruiter - Practica Productions, IJmuiden

Contribution

Jeroen Tresfon (IRO) E: J.Tresfon@iro.nl ©All copyrights reserved by Offshore-NL

info@iro.nl

Welcome

What a pleasure to meet so many of you again in Abu Dhabi for our annual gathering at the ADIPEC. I am delighted to see the Netherlands well represented with over 40 companies present, a significant ‘Netherlands Pavilion’ and an incoming trade delegation focusing on hydrogen; the latter made possible by the IRO (The Association of Dutch Suppliers in the Offshore Energy Industry), RVO (Netherlands Enterprise Agency) and Dutch Embassies in the region.

The 2022 theme of ADIPEC ‘The Future of Energy: Sustainable, Affordable, Secure’ could not be more timely. ADIPEC is where the world’s energy ecosystem comes together, providing insights into the geopolitics of energy - without ignoring the consequences of the pandemic. International pledges and recent developments around energy have not gone unnoticed and the exhibition boasts a ‘Decarbonization Zone’ not too far from our own stand.

The energy transition is at the heart of the 2022 ADIPEC edition, unlocking real value in a decarbonized future, showcasing ground-breaking technologies and exploring actionable strategies and solutions to the challenges and opportunities created by complex global energy market dynamics. As always the Netherlands and Dutch companies have shown resilience and creativity in the face of change, as illustrated by some IRO companies present here today.

As you may know, the Netherlands is already Europe’s second-largest producer of hydrogen and aiming to develop a ‘national hydrogen backbone’, which could be ready by 2026.

With over 1,000 km of dedicated hydrogen pipeline, the country’s dense natural gas grid (136,000 km of high- quality pipeline) can be retrofitted to transport hydrogen at acceptable cost, connecting industrial clusters across the country: Chemelot in Limburg, the North Sea Port in Zeeland, the North Sea Canal, the Hydrogen Hub in Rotterdam, and the northern Netherlands, where the Hydrogen Valley cluster is being developed.

Progress is also underway in the UAE, which aims to become a hydrogen leader in the region: with the Emirate of Abu Dhabi developing new regulations and standards as well as establishing the Abu Dhabi Hydrogen Alliance. Nonetheless, as the UAE diversifies its energy mix, oil and gas exploration and production still remain high on the agenda during this transformation process. We are experiencing a.o. the decarbonization of offshore production.

2022 has proven to be a remarkable year so far: the Netherlands and the UAE are celebrating 50 years of bilateral relations, the Netherlands’ participation at Expo 2020 has further highlighted the opportunities for collaboration between our two countries in the energy field and it was announced COP28 will be hosted at Expo City Dubai in November 2023. The time is now and the Dutch are ready to cover the full spectrum of the energy transition!

For further questions about the UAE, GCC and beyond, feel free to reach out to our respective Economic Departments in Abu Dhabi and/or Dubai via email: abu-ea@minbuza.nl (for the Embassy in Abu Dhabi) and dba-ea@minbuza.nl (for the Consulate-General in Dubai). Our teams will be happy to assist, providing valuable insights, contacts and expertise.

Lody Embrechts, Ambassador of the Kingdom of The Netherlands to the UAE

IRO members play huge part in energy transition!

As Managing Director of IRO - The Association of Dutch Suppliers in the Offshore Energy Industry, I am proud to present you the latest edition of Offshore NL during ADIPEC!

ADIPEC Exhibition and Conference 2022 occupies a prominent place on the global stage of energy transition and is developing into the biggest tradeshow worldwide on energy sourcing. From 31 October to 3 November more than 150,000 energy professionals will gather in Abu Dhabi to gain and share knowledge in the field of making our energy management more sustainable. We are looking forward to welcome you at our Netherlands Pavilion and our Energy Transition Lounge. With 425m2 and members like Heerema, Boskalis, Soluforce and GustoMSC, I am proud to mention we have a large Netherlands Pavilion that is no less than 30% larger than last year.

The Decarbonisation Zone at ADIPEC 2022 is a new addition that reflects the growing need for decarbonisation strategies in the energy industry. The zone will be a forum for leaders in the energy ecosystem to discuss low-carbon technologies, and the essential role the oil and gas sector plays in accelerating the transition from fossil fuels to cleaner forms of energy. IRO members play a huge part in that.

To complement the ADIPEC programme we are organising a separate hydrogen mission in cooperation with the Dutch Embassies in the Gulf region and the

Netherlands Enterprise Agency (RVO). During this mission a visit and presentation on a project of a new hydrogen factory in the new port of Abu Dhabi, KIZAD will be part of the programme.

Energy is a need which will only grow the next coming decades. Which means we need all the resources to provide in this daily requirement. However, renewable energy is not the only energy supply which can provide in this growing demand. We still need fossil-based energy since renewables can only supply 50 percent of the total energy demand in 2050. At the moment fossil fuels, including oil, coal and natural gas, supply around 80% of the world’s energy. But it is for sure, we must find workable model for energy transition. One that is resilient enough to absorb external shocks, such as geopolitics and pandemics, yet pragmatic enough to reduce emissions associated with human activities. Achieving net-zero targets will require fundamental transformation of the energy industry. A central role in this process will be played by carbon capture, hydrogen, reducing methane emissions and other new technologies.

The Dutch offshore energy industry, as one of the top five in the world, is a key player in the use of smart techniques and solutions for the many issues concerning the offshore energy transition.

For instance, for hydrogen the Netherlands is in a good position

partly thanks to our knowledge of gas and electrolysis technology, the great wind energy potential in the North Sea and the energy-intensive industry that must focus strongly on sustainability. Our innovative– companies are commissioned by the major energy companies to build, transport, install, maintain and clean up platforms, transformer stations and wind turbines after use. Great opportunities and challenges lie in making processes more sustainable.

Whilst our IRO members will keep focusing on cost-efficiency, sustainability and innovation in conventional oil and gas developments on a global scale, the energy transition presents us with vast opportunities to maintain our position as a frontrunner in the global more and more renewable energy industry. The Dutch are ready since we are pioneers by heart!

I wish you all a pleasant reading of the latest edition of Offshore NL and lots of good experiences with the Dutch suppliers in this dynamic industry!

The Dutch look forward to doing business with you and hope to meet you at our Netherlands Pavilion and the Energy Transition Lounge in Hall 11 at ADIPEC 2022!

Sander Vergroesen, Managing Director

IRO - The Association of Dutch Suppliers in the Offshore Energy Industry www.iro.nl

Mammoet recognizes market needs

Floating

Ensuring floating wind realizes its potential

A complete floating wind farm turbine consists of a floating foundation, manufactured by specialist fabricators, and the turbine tower, nacelle and blades, manufactured by a wind industry OEM. While the manufacturing process remains similar for everything above water, the sheer size of each floating foundation will mean huge changes to its supply chain, logistics and launch.

Facilities that fabricate floating foundations will face demand to increase production rates as the sector grows. What’s more, given the broad similarity between floating founda tions and petrochemical modules, competition for facilities will be high as they will require the same facilities, equipment and personnel to build.

Space needed for the storage of these giant foundations will challenge even

the largest facilities, ultimately opening the market up to new entrants. Clearly, storing foundations that can measure 100m square on land will not be a viable long-term option, and will mean that manufac ture and logistics must go hand-inhand.

Then there is the task of managing the load-out of these huge structures, akin to the demands seen during

wind can play a major role in the world reaching carbon neutrality in the coming decades, but how will this emerging technology develop so it is deployable at commercial scale?Load-out substation in Dubai.

modularized projects for the petrochemical sector. The industry will need to look beyond Europe to locations such as Southeast Asia, China and the Middle East to make best use of the facilities available.

Using multiple fabricators in several locations will allow more of each project to be undertaken in parallel, and by specialist facilities - shortening the schedule of projects and therefore increasing cost-effectiveness. This, in turn, will increase the viability of projects and allow more of them to move forward.

When fabrication of foundation is complete and it’s time to get them in the water, there are further challenges. For one, this must be achieved for the most part without the use of dry docks, as the majority of these will be unsuitable for objects of this size. Ports of a suitable draft are also needed, typically around 12m or more.

Choosing the right partner to handle lifting and load-out operations will be crucial if developers are to best manage risk and increase the cost-effectiveness of projects without being tied to one particular region.

Luckily, the expertise that has been used in the past to load-out modules of over 40,000t can be re-deployed to match the needs of floating wind, as foundations grow ever-larger.

Launching 16,000t components

With weights of anything between 3,000t and 16,000t, the launch of floating foundations is far from simple – the key challenge being to find a safe, cost-efficient and scalable method for placing large units in the water.

To date, a range of different solutions have been used to perform launching and one common approach has been the use of semi-submersible vessels. But there are questions over whether enough vessels will be available to meet demand, and whether they will be cost-effective when hired over a long period of time, during which they will be stood idle for long periods. So, what are the solutions for projects where this is not a suitable - or available - option?

Mammoet has found that moving foundations directly into the water is the most effective method of launching, as opposed to the use of transition equipment such as a floating platforms.

A promising methodology is to use a hybrid approach, whereby the floater is lifted from both land and sea and lowered onto the water directly at the quayside.

As components are placed directly into the water right next to the quay, the process takes less time, is therefore less costly and requires less auxiliary equipment – generally needing only commonly available grades of barges.

Super crane capacity

With water depths at sea ruling out assembly solutions such as jack-up vessels, the most efficient way to integrate turbines onto floating foundations is to position the floater in the water directly alongside the quay, and piece it together using a large crane. But crane assembly presents its own challenges.

As already mentioned, the largest floating foundations can be 100 meters square. If the turbine lies close to the center of the foundation, the lifting radius required could be as much as 55m – that is, half of the foundation’s width plus the space between quay edge and crane.

At the same time, nacelle weights are expected to reach 1,000t in the near future, and hub heights a staggering 170m. This means that even the largest of crawler cranes are no longer sufficient, and that far fewer suitable cranes are suitable than the market may realize.

Given that a large capital expenditure investment to purchase a suitable crane is unlikely to be an appealing option for many, Mammoet is able to provide a large ring crane that lifts some floating foundation types directly into the water and also assemble wind turbines - all from a single position – turning the quayside into a highly efficient production line.

BRIDGES2000 introduces way of working environmentally

Every day repairs have to be done and platforms and bridges are built. BRIDGES2000 does that. In addition, the BRIDGES2000 team recently started promoting its special way of working. Hendrik van der Ham, who in addition to his position as Head of Operations is also the founder of the company, has established a platform called New Circular Economy Companies Platform for companies in the Maritime and Offshore sector that want to work according to the same principle. The platform provides ideas and a mode. The aim is to burden the environment as little as possible while still being functional. The Platform will be introduced at the BRIDGES2000 booth during Adipec.

In 1997 Van der Ham started in the bridges. From that moment on, he was already innovative. Awards were won from the Aluminum Centre for most innovative pedestrian bridge and also for the aesthetic and lightness of the various components, which could be assembled quickly. Approximately four men were able to assemble an entire bridge from the pallet to 15 m in one afternoon.

BRIDGES2000 now works with a team that understands its objectives and wants to promote them. “Of course, it’s about safety, speed of delivery and precise fitting,” says Van der Ham, “but also about being innovative and thinking about the environment. We use all kinds of leftovers, which are on our shelf in various sizes. When we see the hall of BRIDGES2000, there are the plates and tubes ready that can be used immediately, so that the transport is less burdened. In addition, reuse is emphasized.”

Aluminum Manufactured from aluminum, BRIDGES2000 has many bridges, stairs and gangways in stock to rent out and function in various situations. In addition, the team receives daily questions to make specials. For example, Van der Ham’s team has been able to put together a number of specials and, among other things, an Accommodation Ladder has been made that keeps its steps horizontally downwards, flat and upwards. This is excellent for shipyards where ships protrude below and above the quay for a period of time every day due to the tide and where there is no large deck space on the ship. This solution also reduces the load on the quay, because it only moves parallel to the quay.

Offshore Access Systems

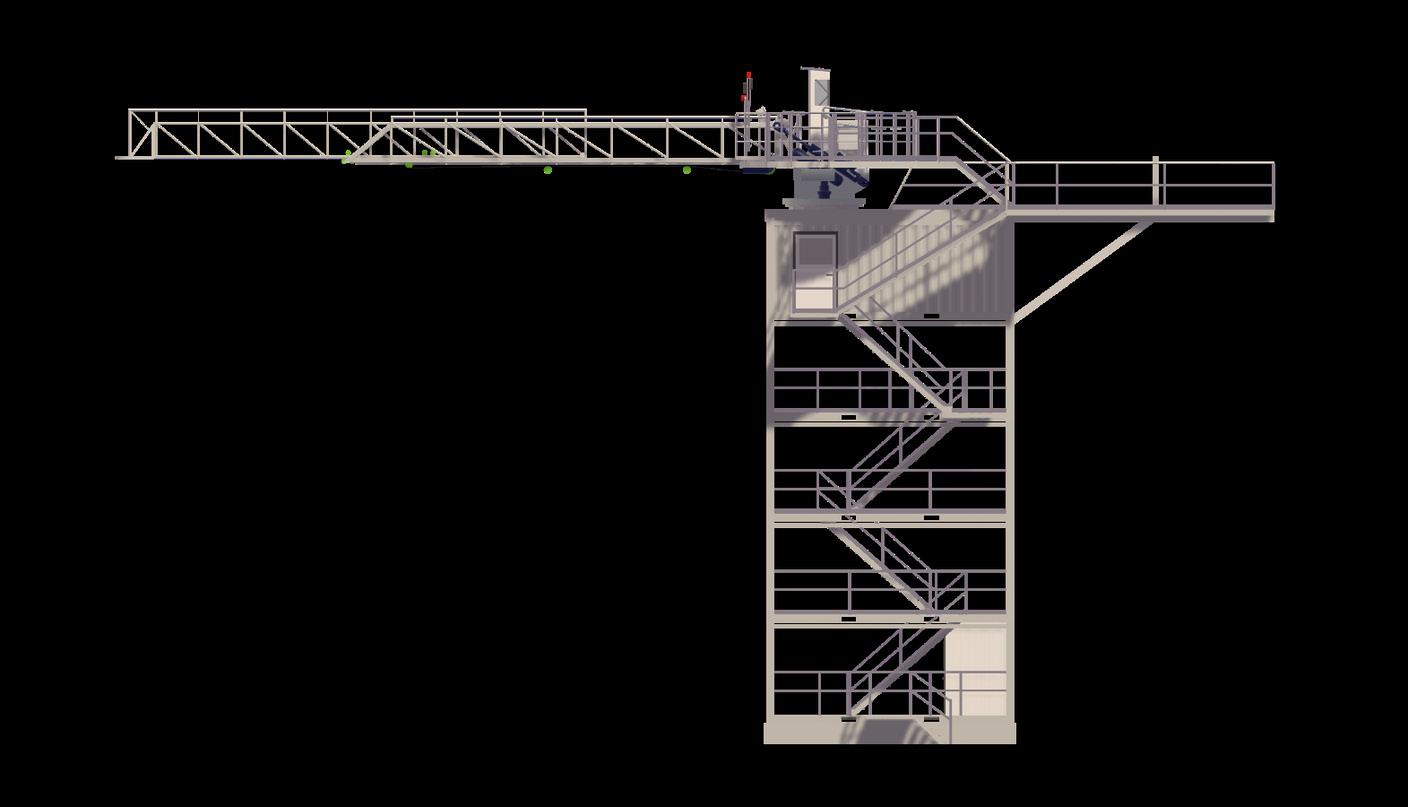

A completely different solution that BRIDGES2000 is working on is a solution for offshore platforms.

The CGS 2 is an Access System that works the other way around than other well-known Walk-2-Work systems. Instead of working from the ship, the system works from the platform at sea and has a moving, stabilizing part at the bottom, the landing gear is dynamic and compensates the Roll and Pitch. In this way, a New Circular Economy solution is thought of, because every ship can drop people off and pick them up from the offshore platforms with this system.

Innovation & Challenge

BRIDGES2000 invites people from companies that also want to work in a New Circular Economy way. Come to the stand at ADIPEC 2022, where you receive the ‘Ten Tips for New Circular Economy Companies’ and where you can participate in being selected as one companies that the BRIDGES2000 team wants to guide to also become a New Circular Economy Company.

The future of Walk to Work in the Middle East

The introduction of Walk to Work (W2W) has permanently changed the face of the global offshore energy sector. In a rapidly changing energy infrastructure, it has become crucial to maximise efficiencies, maintain the highest safety standards and reduce the environmental impact of offshore operations. Ampelmann designs and builds motion compensated gangways that extend weather windows, increase workability and provide safe access to offshore installations. As W2W offers significant advantages over traditional offshore access solutions, it has become a key area of innovation in the modern offshore service industry.

Ampelmann introduces newly designed F-type

Ampelmann introduces newly designed F-type

Globally, W2W has made its mark on the offshore energy sector and is becoming increasingly well-known in the Middle East. Cost-effective and efficient, motion compensated systems increase year-round productivity and increase the safety of offshore operations. Reduction of carbon emissions and improved energy efficiencies will be achieved through the electrification of these systems, clever use of digitised services and by designing new systems that suit regional needs and make W2W an appealing offshore access solution.

Flagship system

Since Ampelmann’s first operations in the Arabian Gulf over twelve years ago, the company has already transferred more than 1,200,000 people and has opened two offices in Qatar and Dubai. With eight projects running concurrently in Qatar, Oman, Azerbaijan, Abu Dhabi and Saudi Arabia, there clearly is a growing market for Ampelmann’s W2W solutions. Ampelmann’s flagship system, the A-type, already sees frequent use in the Middle East and has become a testament to the type of efficiencies that motion compensated systems can bring to the global offshore energy sector.

Electrification

The coming years will see the full electrification of the A-type fleet. By reusing the hydraulic pressure on the hexapod, 90 percent of the total energy consumption is fed back into the system. The result is an energy efficient gangway with a very low carbon footprint. The first electric A-types have already been commissioned, and a variation of this system, the S-type, currently sees use on the Aqua Helix, a prizewinning fast crew change vessel that supplies on demand offshore access in the North Sea. As the S-type is fully

integrated, it is lighter than the regular A-type, making it ideally suited to be fixed on smaller DP vessels that are prevalent in the Arabian Gulf.

F-type

Together with the electrification of its older systems, Ampelmann has introduced new gangway designs that address specific shortcomings in the regional access market. One example is the newly designed F-type, a cost-effective modular gangway that is height-adjustable, easy to mobilise and enables the continuous transfer of personnel in sea states up to 2.5m Hs. Like the electric A- and S-type, the system uses electric recuperation to store and reuse energy from the vessels motions. Its modular containerised design allows for greater operational flexibility as t can be transported much more cost effectively and adjusted in between projects. Designed specifically for a large variety of vessels, the system has a 21m gangway that is perfect for a variety of work scopes in maritime conditions like those in the Arabian Gulf and Asia Pacific.

Alongside the electrification of its systems and the introduction of specialised fully electric gangways,

Illustration of F-type.

the company has created robust product service alignments. All its customers can benefit from the advantages of 24/7 support through the Operation Control Center (OCC) and Ampelmann Insights - a data tracking tool that provides workability forecasts and enables the company to track carbon emissions during offshore operations. This allows Ampelmann, as well as its clients, to be extremely focused on the potential energy savings that can be made and leads to the identification of new ways to reduce environmental footprints further down the line.

Future

Through the introduction of electric regenerative technology, modularity, and strong product-service alignments, Ampelmann retains its focus on the future. In 2020 the company cut almost half of its carbon emissions. By measuring all emissions throughout the entire value chain and offsetting those that currently cannot be accounted for through the electrification of its systems and the improvement of onshore and offshore ecological footprints, Ampelmann became 100 percent carbon neutral in 2020.

Continuous innovation lies at the heart of Ampelmann and the company believes it is imperative to lay the foundation for the future. The last two decades have seen a tremendous growth of W2W in the Middle East as an important alternative mode of offshore access. By focusing on what is important to regional markets, Ampelmann has gained significant traction throughout the world and continues to have a marked impact on the safety and efficiency of offshore operations.

chapeau

From timber to aluminium helidecks of Bayards

Aluminium perfect solution for offshore upgrades in Middle East

Everyone knows helidecks are an engineering challenge to start with. So one can only imagine the immense challenge of replacing 179 decks. This was the case for the timber decks used on the ADNOC (Abu Dhabi National Oil Company) platforms in the Persian Gulf. Since the old helidecks were decayed and rusty – and therefore a safety hazard –they had to be replaced by new decks. On top of that, the platforms needed to be kept in operation while installing the new helidecks.

Aluminium turned out to be the perfect solution for this project’s challenges, as it is lightweight, maintenance-free and thus costeffective. Having to install one helideck per week and still meeting the highest quality and safety standards, the pressure was on. Fortunately, because of the fast assembly process, valuable time was saved. Also, the lightweight properties of aluminium compared to steel contributed to saving time and thus costs in the process. That is, no extra resources were necessary to strengthen the existing support structures. As a result, no heavy lifting equipment had to be employed, which reduced the costs significantly.

Clever assembly system

In just 20 weeks, the conceptual design of the helidecks was finalized, which was one of the challenges for the engineers on this project.

Because it concerned an offshore project, welding was not an option. To avoid welding, a clever new assembly system was designed which is completely bolted. This system allowed for the helidecks to be installed easy and fast with no need of special labour force. The aluminium, including the extruded profiles used in this system, comes from the Middle East. This ensures a significant amount of local content, but above all, cost and time effectiveness. By sharing both knowledge and experience, a constructive long-term partnership with ADNOC was realized.

Installation

Today, all helidecks have been installed for ADNOC. Installing a helideck takes approximately 8-10 days and – thanks to the innovative assembly system – it doesn’t involve any cranes. Instead, small, supervised teams of technicians carry out the

on-sight installation. The newly installed platforms are not only cost-effective in the short term because of the easy installation, but also in the long term. That is, the platforms will be free of maintenance for the next 40 years, since they are corrosion resistant and don’t need any painting or repainting. ADNOC expects these platforms to successfully produce oil for the next 30 years. And with the helidecks’ life expectancy of 40 years, that’s no problem: exactly the reason why aluminium is the perfect solution for offshore challenges.

Over the years ODS has seen that the custody transfer flow measurement world is transforming from a mechanical driven technology to a digital environment. Traditional mechanical components are being replaced by digital and SMART instruments. The quantity of information coming

from the field increased drastically while the overall system functionality remained the same. How can we translate all this new information into real metering functionality? The answer is MOMS (Metering Operation & Management System).

With MOMS you digitalize your metering systems, makes them smarter, more transparent and reliable. It converts all available data into real actions and makes the day to day life for the operator, maintenance engineer and management easier. It is an unique tool to minimize exposure from non-compliance to laws, standards and regulations. MOMS continuously verifies the real time performance, traceability and integrity of your metering systems.

You can use MOMS from a single metering stream system to multiple metering systems that are installed on a variety of metering locations.

For single locations we developed MOMSonsite. The onsite version can be used for single stream applications to multiple metering systems with a combination of metering principles and technologies.

To connect multiple MOMSonsite metering systems on different locations or multiple servers ODS

offers MOMSenterprise. This allows for a complete control and overview, in a centralized location such as a head-office, to all your MOMSonsite equipped metering systems worldwide.

ODS understands that every metering application is different. Laws and regulations vary from location to location. Each MOMS application will be designed custom to the applicable localand client requirements.

Netherlands Pavilion

Ampelmann Operations ** 11327

Anamet Europe ** 11236 Boskalis * 11320 Brooks Instrument ** 11230 Cosco Shipping Heavy Transport (Europe) ** 11250 DCN Diving * 11326

EMCE winches * 11310 Hatenboer-Water * 11325 Heerema Marine Contractors * 11315 KOKS Group ** 11234 Mammoet * 11316 Mokveld Valves 11210 ODS Metering Systems ** 11251 Paradigm Group * 11252 Rolloos ** 11237 Royal Van Beest ** 11231 SoluForce ** 11314 Thermo Electric Instrumentation & Tradinco Instruments * 11235 VTN Veiligheidstechniek Nederland * 11312

Ampelmann Operations

Rotterdamseweg 380 2629 HG Delft

The Netherlands

phone +31 (0)20 240 0121 mail sales@ampelmann.nl

www.ampelmann.nl

Ampelmann is an offshore access provider delivering innovative, safe and reliable Walk to Work systems and services to the offshore energy industries globally. With a track record of more than 7 million safe people transfers, over 18.6 million kg cargo transfers and 400 projects world wide, the company operates in Europe, Africa, Asia Pacific, the Americas and the Middle East.

www.anameteurope.com

For over 75 years, we have supplied specialist hoses, conduits, and systems for protecting electrical cables and transporting liquids and gases.

With a broad range of specially designed and engineered products and a professional sales and support team, we pride ourselves on being a reliable partner for our customers in many industries.

Anamet Europe

Galwin 5 1046AW Amsterdam

The Netherlands

phone +31 (0)20 586 3586 mail sales@anamet.nl

Our solutions are a part of critical systems and must therefore fulfil the highest quality requirements. Therefore, many of our products as well as our personnel and methods are specially certified by renowned independent test institutes, such as UL,

Stand Number 11327

Ampelmann maintains a fleet of 60 operational gangway systems used for transferring crews and cargo to offshore structures. It works with a full-service rental business model, provides clients with trained operators and with data insights into their offshore operations. Ampelmann’s services are tailored to the needs of different market segments, sea states, cargo and crew loads, and are used by key players in the global industry.

Stand Number 11236

CSA and Lloyd’s Register, to meet and comply with national and international requirements.

R&D, system testing and manufacturing takes place at our facilities in Amsterdam using state-of-the-art technology. This enables us to quickly realise a solution and deliver it on time. An added bonuswe can also draw on the expertise and facilities of our sister companies in the USA and Canada.

Bayards Helidecks

The Netherlands phone +31 (0)18 468 3000 mail sales@bayards.com

Stand Number 11215 www.bayardshelidecks.com

Bayards Helidecks, part of the Dutch Bayards Group, designs, engineers, manufactures and installs turn-key helidecks, including:

• Support structures

• Safety netting

• Access systems

• Firefighting systems & equipment

• Lighting systems

• Heat tracing

Our solutions in aluminium are tailored to the specifications of our clients. In addition, our structures are engineered and built to the highest quality standards and the latest international safety

regulations. Combined with the material’s natural advantages, it makes Bayards the perfect partner for advanced and sustainable solutions in aluminium. Reduction of maintenance and weight without any loss of strength is why aluminium is a valuable construction material in the Offshore Industry.

We comply with all international standards such as ISO and OHSAS and product regulations such as CAP437, NORSOK, NORMAM, AVV, ICAO and USCG to ensure premium quality.

To help meet future demand for energy Boskalis offers a wide range of specialist services combined into integrated solutions. With dedicated professionals and versatile fleet, Boskalis creates New Horizons for its clients, offering services for the entire offshore energy project life cycle.

Every project brings new challenges; it’s how you deal with them that makes the difference. With an impressive track record of multidisciplinary projects Boskalis knows how to manage interfaces, mitigate risks and simplify execution.

With safety as the core value, Boskalis offers a unique range of offshore services to the international energy sector - oil, gas and renewables. Realizing projects in remote locations with a heightened environmental focus, is one of Boskalis’ areas of expertise.

Whatever you are looking for - standard, complex or full life cycle services - Boskalis can provide an innovative and cost-effective solution to suit your needs.

BRIDGES2000

Rotterdam

The Netherlands

phone +31 (0)10 820 1770 mail info@bridges2000.com

BRIDGES2000 already 23 years a trustworthy name & company working in Maritime and Offshore sector. In a world 24/7 on the move Safety is highest important factor.

For safe access, fast help and fit for purpose solutions BRIDGES2000 is 24/7 available.

Next to gangways, accommodation ladders and special platforms BRIDGES2000 delivers a new system for access from platform offshore to ships. This Walk2Work system works the other way around. One of the examples the team of BRIDGES2000 proclames.

Stand Number 11230 BrooksInstrument.com

Brooks Instrument is a company of highly trained specialists with 75 years of global flow experience in over 80 countries. Serving EPC companies with projects in oil, gas, chemical and other industries, Brooks Instrument is their trusted source for high-performance flow meter technology and in-depth technical expertise. Our EPC partners come back to us project after project, year after year.

Our portfolio includes:

• Metal Tube Variable Area (VA) Flow Meters

• Glass Tube Variable Area (VA) Flow Meters

• Thermal Mass Flow Meters and Controllers

• Pressure-based Mass Flow Meters and Controllers

• Coriolis Mass Flow Meters and Controllers

• Pressure Controllers and Regulators

• Variety of flow accessories

Brooks Instrument

Einsteinstraat 57 3902 HN Veenendaal

The Netherlands phone +31 (0)31 854 9300 mail info@BrooksInstrument.com

Cosco Shipping Heavy Transport

Montevideo Offices, Otto Reuchlinweg 1142 3072 MD Rotterdam

The Netherlands phone +31 (0)10 240 4777 mail commercial@coscoht.com

Serving EPC companies with projects in oil, gas, chemical and other industries, Brooks Instrument is their trusted source for high-performance flow meter technology and in-depth technical expertise.

Stand Number 11250 www.coscoht.com

With more than 35 years experience and a fleet of 12 modern purpose-built vessels, COSCO SHIPPING Heavy Transport is widely recognized as a leader in the semi-submersible market.

We specialize in the handling of high value heavy cargoes for traditional oil & gas and renewable energy clients. We have a long track record of providing safe, reliable and fast transports.

DCN Diving, established in 1957 (as Vriens Diving), has over 60 years-experience in subsea operations. It is a family-owned company with its head office based in the Netherlands and supporting subsidiaries in the UK, Belgium, Germany, Malaysia and Singapore, Nigeria and UAE.

DCN Diving operates as a world-wide subsea service contractor and is an IMCA member for Surface supplied diving, Saturation diving and ROV operations. DCN Diving is specialized in:

• Hyperbaric welding and hyperbaric testing using specialized in-house experience and equipment including its Hyperbaric Test Facility

• Creating dry space underwater with the use of

habitats, cofferdams, bulkheads and more

• Subsea rehabilitation of hydropower dams

• Underwater concreting and other civil works

• Pipelines installation dive support

• Subsea support in the renewable energy sector

• Vessel Inspection and Maintenance

• Offshore subsea Inspection Repair and Maintenance (IRM)

DCN is certified according to ISO 9001:2015, ISO 14001:2015, ISO 45001, SCC**, SCL and FPAL and has various certificates for In-water Survey and has class certificates for its Surface Supplied and Saturation Diving systems.

BRIDGES2000 is a New Circular Economy Company and has started New Circular Economy Platformfor companies in the Maritime and Offshore sector that want to work according to the same principle. The platform provides ideas and a mode.Heerema Marine Contractors Nederland SE

Vondellaan 47 2332 AA Leiden

The Netherlands phone +31 (0)71 579 9000 mail info@hmc-heerema.com

EMCÉ Winches designs and manufactures electric-, hydraulic and air operated winches, capstans, hose reels, hoists & BOP systems for the marine, offshore & renewable markets.

In close cooperation with our global dealer network and EMCÉ branch offices in Bahrain & Belgium our mission is to excel in product safety, quality, durability and performance.

With our experienced team we tackle every lifting and pulling challenge up to 250 T and ‘tailor’ our modular designs very efficiently to customer specifications.

Fast, cost effective, ISO certified, to any standard and with a strong focus on total cost of ownership, fully summarized in our motto: Every winch a winner!

The Pioneers of Offshore Engineering

GustoMSC is recognized for providing advanced design & engineering consultancy for mobile offshore units and equipment. In close cooperation with our clients, we translate experience, science, and technical knowledge into realistic & innovative ideas. The performance of new and existing jack-ups, vessels and semi-submersibles is further optimized by our operational support and engineering consultancy. In this way, GustoMSC enables and supports safe and efficient operations at sea, contributing to a sustainable future.

ESG, a natural course for offshore pioneers Projects at sea in offshore oil & gas and offshore wind are our most important markets. GustoMSC has been addressing the essential changes in the offshore energy market since years. Technological challenges and pushing boundaries are part of GustoMSC’s DNA. We believe we can help our clients move forward as the global energy transition accelerates. Energy efficiency and sustainability are an essential consideration in all GustoMSC design and equipment solution processes. This is a natural course for us as offshore pioneers.

Stand Number 11325 www.hatenboer-water.com

We are experts in water treatment, water management, and freshwater production.

Hatenboer-Water has a long history of providing the Maritime & Offshore industry with solutions to generate, treat and maintain ‘Safe Water Onboard’ (SWOB). The global efforts focus on safe and reliable water quality, nowadays especially with solutions to reduce the use of plastic water bottles. Offering tools to calculate savings in costs, logistics, and showing instantly your ROI.

For 116 years, the privately-owned company has grown to an internationally renowned full-service

player in the water treatment market. At HatenboerWater they design, construct, and supply fresh water (RO) modules, comprising all relevant components needed for the water production and filtration. Resulting ultimately in the safe consumption of fresh water onboard. Crew can be trained (online) to guard the vulnerable quality of the water and to become aware of the necessity of proper water management.

Through its worldwide network of agents and own offices (Houston, Rotterdam, Dubai and Singapore), the company supports its installed base with local spares and consumables available from stock.

Stand Number 11215 www.heerema.com

Heerema Marine Contractors is a world leader in transporting, installing, and removing structures for the offshore energy industries. Clients have trusted Heerema for nearly sixty years to deliver solutions that make the impossible possible offshore.

Heerema’s headquarters are in Leiden, the Netherlands, and the company has permanent offices in Houston, London, Mexico, Singapore, and Qatar. From these locations, Heerema manages the entire supply chain of project execution, offering solutions that include front-end engineering, planning, logistics, project management, and the execution of projects worldwide.

The company has unique skills and capabilities with a world-class fleet of vessels and barges used to provide tailored solutions that fit client requirements.

Within Heerema’s assets is the world’s largest crane vessel Sleipnir, with a lifting capacity of 20,000 metric tons. In addition, the company owns barge H-851, a specially designed floatover barge that can install structures that weigh around 50,000 metric tons.

Heerema is your ultra-heavy lift contractor.

The Offshore Energy supply industry in the Netherlands belongs to the Top 5 of the world.

Established half a century ago, the association IRO is an independent non-profit organisation that supports and promotes the interests of its 400 member companies.

Acting as the gateway to Dutch suppliers in the energy industry, the IRO mission is ultimately aimed at maintaining and strengthening the position of the offshore energy supply industry by creating a level playing field for its members. A sharp focus on cost efficiency, innovation and sustainability amongst the IRO members are instrumental to achieve this goal.

The IRO members consist of a wide variety of both multinationals and SMEs. They represent the entire supply chain within the Offshore Energy Industry, with activities covering: Engineering & Consultancy, Construction & Fabrication, Plant & Equipment Supply, Contracting & Installation, Exploration & Production and Personnel & HSE.

The range of services that IRO provides to its members varies from maintaining government & NGO relations and facilitating networking opportunities within the IRO community, to participating in international trade missions as well as in exhibitions and providing Business Intelligence and training courses.

KOKS Robotics is market leader and manufacturer of innovative no-man-entry tank maintenance robots for ATEX zone 0.

We offer robots for safer and faster turnaround maintenance and cleaning of above-ground hazardous tanks by using innovative and state of the art robotic no-man-entry industrial tank maintenance systems. Specialized in tank cleaning robots, hazardous waste cleaning robots, nuclear robots, underwater robots and inspection robots.

Safety is number 1 and is aimed at the user, the robot and the environment.

KOKS Robotics is part of the KOKS Group, which is an international manufacturer and supplier of ADR (Ceoc) vacuum trucks and heavy industrial cleaning equipment. Since her foundation in 1989, the Dutch company KOKS Group has grown into a globally operating, dynamic company, consists of eight specialized subsidiaries in the USA, The Netherlands, Czech Republic, Saudi Arabia and Slovakia. As a progressive, innovative, solvent and reputable vacuum truck body builder, KOKS Group has gained an excellent reputation in the oil & gas sector, (petro)chemical sector and other industries.

Helping you to build efficiently. safely. on time.

We offer solutions for lifting, transporting, installing and decommissioning large and heavy structures in the oil and gas, onshore and offshore, mining, power and civil industries. Our long-standing operational and engineering expertise complemented by our state-of-the-art fleet, allow us to combine techniques to meet each specific project’s requirements. We help clients improve construction efficiency, optimizing the uptime of plants and installations.

Our services comprise:

• Engineered heavy lifting

• Engineered heavy transport

• Plant Turnaround / Shutdown Management

• Site-wide construction services

• Factory-to-Foundation / Port-to-Foundation logistics

• Relocation and decommissioning

footprint, all this at high availability and lower operational and life-cycle costs.

At Adipec we will display our sustainable valve solutions allowing companies to achieve their net-zero goals. Mokveld’s latest valve is a unique and environmentally sound innovation: a true ZERO emission valve with no leakage throughout the lifetime of the valve, very low electric power requirements and extremely accurate.

Also on display our low shear control valve for sustainable treatment of produced water and our low power actuated (≤ 60W at 24V) choke which is ideally suited for UPS, battery operation or solar powered systems.

ODS Metering Systems

Donk 6 2991 LE Barendrecht

The Netherlands

phone +31 (0)18 064 0889 mail ods.metering@kloeckner.com

Stand Number 11251 kloeckner.com

We are ods metering systems! Your partner in custody transfer maesurement solutions.

ODS Metering Systems, THE worldwide specialist in custody flow measurement solutions. As an independent fiscal measurement solutions provider, we offer an unique combination of expertise in mechanical engineering, instrumentation, electrical engineering and process automation. An unmatched combination of industry knowledge, project management skills, hands-on experience and customer-focused commitment, makes ODS Metering Systems a reliable choice for an integrated solution provider to manage high-performance custody transfer flow measurement and control applications effectively.

We offer our clients the best possible technical and economical concept-to-commissioning custody transfer metering and control solutions. With our independent project approach towards technologies and manu facturers, we are able to make the best choices for your project based on the regulatory framework, performance requirements, commercial conditions and client preferences. Our decades of expertise and track record in both oil and gas metering packages complete with our own designed meter prover skids, sampling systems, analyzer systems and metering control systems makes ODS Metering Systems your ideal partner for custody transfer measurement.

Navingo

Offshore Energy Exhibition & Conference 2022 brings together buyers and suppliers for two days in RAI Amsterdam. Think of buyers from the marine and offshore energy industry at this year’s events, including ship owners, commercial shipyards, offshore wind operators, energy companies and many more. Offshore Energy Exhibition & Conference 2022 is an ideal place to showcase sustainable solutions to a diverse audience. The mix of decision makers from different sectors that are present on Offshore Energy Exhibition & Conference 2022 will bring business opportunities for your company.

Offshore-Energy.biz connects communities to tell the story of the energy transition and sustainable solutions in the maritime and offshore world. Expect daily news from markets of interest, in-depth articles and videos, insights from industry leaders, an overview of the important players in the business landscape and job boards.

With 336.000 monthly users and 75.000 newsletter subscribers OE.biz reaches the entire offshore energy industry. Use our reach to get the attention your company deserves.

Paradigm Group Ambachtsweg 7 2964 LG Groot-Ammers

The Netherlands phone +31 (0)18 460 9419 mail info@paradigm.eu

Stand Number 11252 www.paradigm.eu

Paradigm Group was established in Groot-Ammers, The Netherlands, in 2009, to develop & commercialize new technologies & innovations for the upstream Oil & Gas Industry. With a broad width of market participation, Paradigm Group consists of four specialisms.

• Drilling Optimization

• Production Efficiency

• Well Intervention

• Fire Protection

PAT-Kruger Group

Lifting safety in heavy duty industries to a higher level.

Wherever heavy weights need to be moved by either lifting, pulling or skidding, you simply cannot rely on a pair of human hands and eyes to guarantee people’s safety and avoid damage to equipment. Since our inception over 45 years ago, we designed and installed countless robust systems with a long time span around the globe.

Solutions: Our solutions include crane safety and control, force and inclination measurement, crane anti-collision and wireless load measurement. ATEX certified CCTV systems, boom tip and 360° view

Each area of expertise boasts unique technologies supported by strong Intellectual Property positions. Even in this challenging business climate, an aggressive R&D effort continues and including joint development partnerships with major oil and gas operators.

Stand Number 11215

cameras. Data logging, real-time data access and remote data access.

Parts: Wired and wireless force sensors; loadpins, loadcells, line-riders, rope tension, wigablocs, wind speed sensors. Extensive stock of spares enabling us to carry out repairs on short notice.

Service: Our service engineers carry out maintenance on any possible equipment, regardless of brand or type. They operate worldwide, both onshore and offshore. Force sensors calibration and system board repairs are carried out in our own workshops.

Rolloos

Buitendijks 29 3356 LX Papendrecht

The Netherlands phone +31 (0)10 4500 500 mail info@rolloos.com

Stand Number 11237 www.rolloos.com

FMJ Rolloos is the supplier of explosion proof CCTV systems to the oil & gas industry, to the (petro) chemical industry and to the renewable energy market. From the harsh North Sea to the heat in the Middle East and from the Gulf of Mexico to the Far East.

Each Rolloos CCTV system is designed for remote and harsh environments. On offshore production platforms, FPSO’s, drilling rigs and wind farm substations, as well as onshore land drilling rigs, petrochemical facilities and tank farms.

With 60 years’ experience all over the world, FMJ Rolloos offers you reliable and state of the art solutions.

Royal Van Beest Group

P.O. Box 57 3360 AB Sliedrecht

The Netherlands phone +31 (0)18 441 3300 mail sales@vanbeest.nl

www.vanbeest.com

Green Pin® is the leading manufacturer of premium quality below-the-hook lifting and lashing fittings such as shackles, turnbuckles, hooks, and Green Pin Tycan® Chain.

Green Pin® is a brand of The Netherlands-based Royal Van Beest Group and is sold in more than 90 countries worldwide. Our co-exhibitor Irizar Forge is the leading expert in the metallurgy of heavy-duty crane components and their application in harsh environments.

Stand Number 11231

Stand Number 11215 www.sdcverifier.com

SDC Verifier is an engineering company on a mechanical and structural design that provides engineering consultancy services and tailor-made code-checking software.

Since 1998, we have built the trust of top global companies in the Offshore, Oil & Gas, and Maritime industries. The SDC Verifier software is a powerful standard checking tool that works within different FEA solutions, such as ANSYS, Femap, and Simcenter 3D. It helps to automatically verify your FEA results according to multiple industry standards as DIN, EN, Eurocode, FEM, AISC, Norsok, ISO, DNV, ABS, FKM Fatigue, and DVS code.

The holistic functionality of the SDC Verifier app has proven to boost engineering teams’ productivity and bring them to a new level of convenience. Contact SDC Verifier when needing consultancy on FEA, design review according to standards, or have specialized extra software needs related to FEA or industry standards.

SoluForce offers non-metallic and high pressure Flexible Composite Pipe (FCP or RTP) systems. As originator and technological leader, our systems are used for a variety of applications such as high pressure flowlines, water injection, gas transport, mining and hydrogen.

With over 3.500 km of SoluForce pipe systems installed around the world in on- and offshore applications, our customers have been benefitting from our reliable solutions, know-how and experience since the year 2000.

Stand Number 11314

The SoluForce system is completely flexible and certified according to multiple international standards.

They are maintenance free without scaling or corrosion and can be installed almost anywhere, quickly and easily. Moreover, with our durable and reliable fitting systems, our solutions are easily connected to existing infrastructure.

SoluForce Flexible Composite Pipes are revolutionising the way energy is transported.

Thermo Electric Coenecoop 71 2741 PH Waddinxveen

The Netherlands phone +31 (0)85 760 7321 mail info@te-instrumentation.com

www.te-instrumentation.com

Thermo Electric Instrumentation is market leader in engineering, manufacturing and servicing thermocouples, RTD`s (Pt100) and thermowells. Thermo Electric temperature sensors can be used for measuring and controlling every process with a temperature range from the absolute zero point up to 1500 °C and utilized in processes dealing with corrosive chemicals, vibrations, electrical interventions and high pressure.

The product range of Thermo Electric includes multi-level temperature sensors for cracker-, storage-, or catalyst-reactor applications, tube-skin temperature sensors for boiler or furnace applications, spiral type thermowell constructions for high velocity applications and high-temperature resistant constructions with for example a double ceramic thermowell assembly.

VTN Veiligheidstechniek

For over 40 years, VTN Veiligheidstechniek Nederland (VTN Breathing Air Systems) has been producing, supplying and maintaining high-quality personal protective equipment that increases the personal safety of people in hazardous work situations and environments. We can rightly call ourselves a leading supplier for, among others, fire brigades, law enforcement, defense, but also for large (chemical) industries, industrial cleaning companies as well as storage and transshipment companies that deal with hazardous substances. As such, we de not only supply an entire range of specialist personal protective equipment, but we also maintain and repair all products supplied by us upon

request. And we always do so according to one basic principle: Safety first.

Additionally, VTN Safety supplies a wide range of VTN-manufactured Breathing Air Systems. These products, which are produced at our facility in The Netherlands, all come with an official Lloyd’s Register/TÜV CE marking and meet the latest SIR guidelines.

On top of that, we press and certify a wide variety of customized breathing hoses in accordance with EN14593 and EN14594.

Stand Number 11215 www.trustlube.com

TrustLube high-end lubrication systems and lubricants

Your world never stands still. Just like your machinery. Perfect lubrication is essential to guarantee continuity and safety for your machines. TrustLube’s smart solutions assure applying exactly the right amount of lubricant, in the right place, at the right time. Day or night, companies in the maritime and offshore sector all rely on our lubrication systems, 24/7. Additionally, we supply sustainable lubricants and monitoring solutions for the optimal result.

Automatic lubrication systems

Lubrication demands precision. With trustlube, every lubrication point has its own lubrication unit, each injecting

precisely the right amount of lubricant into the lubrication point, using the right product. Individual lubrication units function completely independently of each other.

Heavy duty lubricant

TrustLube Xtreme lubricants offers high-quality lubricants for use under extreme conditions. All over the world, industrial users rely on our proven successful lubricants to increase machine uptime and maximize the lifetime of their equipment. There is a product for every application. TrustLube xtreme lubricants is a product of trustLube, an expert in the field of automatic lubrication systems and lubricants.

Stand Number 11215

Valvetight was founded in 2014 by Jeroen Pronk who had been a Plant Manager of several Underground Gas Storage installations in Germany and The Netherlands. In this role he faced many challenges caused by leaking isolation valves.

The leakage caused conflicting interests regarding execution of the required planned maintenance whilst the remaining installation stayed in operation, versus the required safety level for these maintenance activities. This is a common problem often faced by other companies in this field.

In his search for a practical solution, he invented the method of creating, maintaining and monitoring

a vacuum lock in the bleed section. A patent was obtained and Valvetight was born.

The technology has been perfected and approved by major international Oil & Gas and Petrochemical companies. We are particularly proud on the approval of both Shell and Saudi Aramco for use of the DBB-SAVER on ALL assets and their internal Technical Authority report to provide easy acceptance for Plant Managers worldwide.

This ground breaking technology is now also available to solve your problems with leaking valves!

VBR

VBR Turbine Partners is an independent competence centre for GE LM aeroderivative gas turbines and their control systems, auxiliary systems & enclosures: LM2500(+,G4,DLE), LM6000 (PA-PH) and TM2500(+). We support onshore and offshore LM users worldwide to improve their efficiency, reliability, availability & maintainability and to reduce their day-to-day operation & maintenance costs in a sustainable way.

Established expertise and capabilities:

• Fast & reliable global spare parts & tooling supply

• On-site inspection & repair

• Technical troubleshooting & problem solving

• Education & Training

Wagenborg Foxdrill is an all-round varied service provider to the oil, gas, and renewables industries. Our mission is to keep your assets running and to minimize your costs.

Rig Surveys: independent rig surveys on all assets including: Condition & Compliance Surveys, Factory Acceptance Tests, Rig Acceptance Surveys, and more.

Maintenance: WF services electrical, mechanical, hydraulic, electrical (EX) and High Pressure equipment. WF can also provide in-house developed Maintenance Management Software.

Inspections: WF provides API 4G derrick inspections. Dropped Object surveys are also offered to reduce hazards on your asset.

Repair: Repairs such as exchange/alignment of guide

• LTSA’s – long term maintenance service agreements

• On-site hot section exchanges (and HS repairs on condition)

• Speedtronic and Woodward control systems (repairs, upgrades, retrofits)

• Smart remote condition monitoring & maintenance support (DECIDE, RAPID, MetalSCAN)

• Fully automated efficiency optimization (AutoTune DLE)

• LM2500 SAC lease engine

• Power plant relocations

VBR customer promise: Support Beyond Expectation.

tracks, sheave replacement, AHC cylinder replacement, cleaning/touch ups, and modifications of vent lines can all be executed by WF. Complete derrick overhauls & refurbishments are also offered.

Conductor Installation: We provide turnkey conductor installation including: studies, supply, and installation for on- and offshore.

Derrick Assembly & Disassembly: Complete assembly of rigs and derricks. We also strip & disassemble derricks for decommissioning works.

Rig Moves: WF has moved hundreds of rigs all over the world. We increase safety and significantly reduce rig move times. Door-to-door rig moves overseas are possible.