September - October 2022

September - October 2022

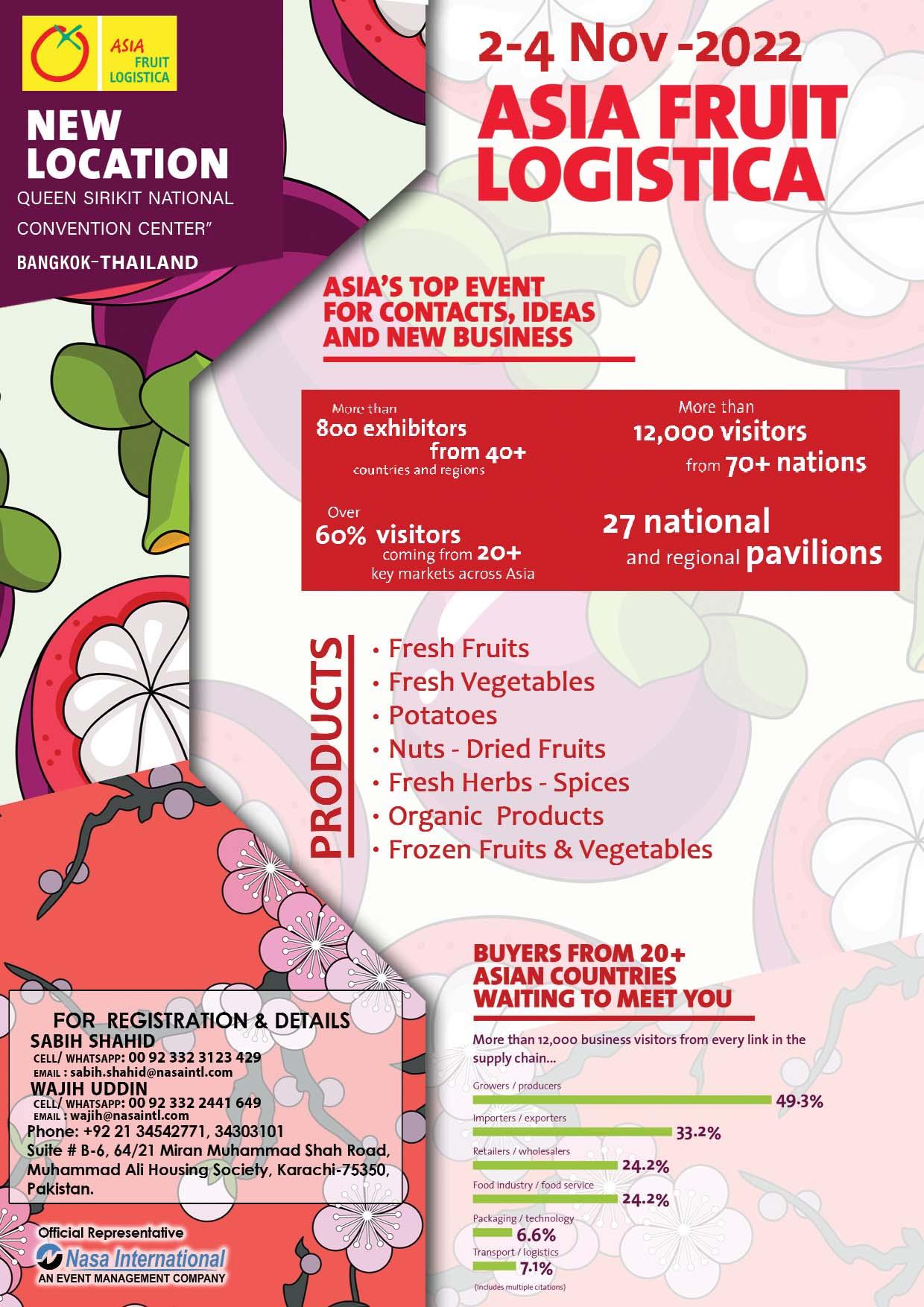

Date: 2 to 4 November 2022.

Venue: Queen Sirikit National Convention Center, Bangkok, Thailand.

Date: 8 to 10, February 2023.

Venue: Berlin, Germany.

Dates: 7 to 9 November 2022.

Venue: Riyadh International Convention & Exhibition Center, Riyadh, Saudi Arabia

Date: 8 to 10, November 2022.

Venue: Dubai World Trade Centre.

Date: 9 to 13, November 2022.

Venue: International Agricultural and Gardening Machinery Exhibition, Bologna, Italy.

Dates: 17 to 19 November 2022.

Venue: Shanghai World Expo Exhibition & Convention Centre, China.

Date: 14 to 17, February 2023.

Venue: Exhibition Centre Nuremberg, Germany.

Dates: 20 to 24 February 2023.

Venue: Dubai World Trade Centre, Dubai

Date: 7 to 9 September 2023.

Venue: Lahore Expo Centre.

Date: 7 to 11, October 2023.

Venue: Berlin, Germany.

Date: 20 to 29, January 2023.

Venue: Berlin, Germany.

Dates: 19 to 22, March 2024

Venue: Cologne, Germany.

Dear readers,

In our September-October 2022 edition, the editorial board of Pakistan Food Journal is focusing on the current exhibitions related to the food industry that are held worldwide in the coming months. Among them, Dubai World Trade Centre (DWTC) has announced a leading global trade fair, Gulfood Manufacturing, that will take place from 8-10 November 2022. Showcasing new global products, solutions and technologies across the food and beverage value chain. Gulfood Manufacturing 2022 will be the definitive destination leading the future of food production from new ingredients and advanced technologies to integrated supply chain solutions and breakthrough developments driving the industry forward.

In the event Asia Fruit Logistica, where exhibitors from some 40 different countries and regions are set to showcase their products and services at Asia’s premier fresh produce trade show. Leading machinery and technology players will exhibit a range of solutions at Asia’s premier fresh produce trade show. From optical sorting solutions to innovative tools to track products throughout the supply chain, tech is taking the fresh produce business to the next level.

The EIMA agricultural machinery exhibition to be held in Bologna from 9 to 13 November is the most important event of the year at the international level for agricultural companies, business operators and agro-mechanics technicians. It is also an important appointment for the world of gardening, landscaping, urban decoration and sports facilities. Indeed, the EIMA Green exhibition, held as part of the agricultural machinery show, offers a wide range of tecnologies for green maintenance.

Amina Baqai Editor in ChiefSmart farming technology to tackle UK farming’s invasive Black-grass problem

Pakistan, China join hands to achieve food security because factors of production in the agriculture sector of Pakistan and China can be complementary to each other. Both countries need to strengthen cooperation in agriculture and food security to achieve a win-win solution.

President Dr. Arif Alvi has said that Pakistan needs to adopt latest technology to enhance agricultural production to counter the effects of climate change.

Prime Minister Shehbaz Sharif has directed to all relevant ministries to prepare agricultural reforms plan on an emergency basis. Shehbaz Sharif said a comprehensive awareness campaign should be conducted to make the farmers aware of the modern methods of agriculture.

Pakistan’s agricultural exports are suffering from trade regulations in areas such as testing, certification and licensing because most countries have stringent regulations

in place to protect human health and the environment.

As the floods continue to wreak havoc, Pakistan's Finance Minister Miftah Ismail said the government can consider importing food from India as the monsoon rains have destroyed the standing crops.

The World Food Program said it is increasing emergency aid to reach 1.9 million people in Pakistan devastated by the worst floods to hit the country in more than a century.

Pakistan’s flood crisis could become a food crisis as the country continues to suffer from catastrophic flooding. Around onethird of the country remains underwater, and most of the 33 million people affected by the disaster have yet to receive assistance. But the crisis could still get worse.

Pakistan’s food imports, including wheat, palm oil, and soybean oil,

went up by 64.45% in July and August, data issued by the Pakistan Bureau of Statistics reported.

According to PBS statistics, Pakistan has imported food items worth Rs392.83 billion in the first two months of the fiscal year 2022-23.

Agricultural land inundated by flooding is set to have long-term humanitarian and economic impacts in Pakistan. Billions of dollars’ worth of rice, sugar and wheat have already been lost.

A humanitarian crisis has unfolded from the weeks of unrelenting flooding in the hard-hit country, which is in dire need of food, clean water, medicine and clean sanitary facilities.

Federal government in view of massive damage to agriculture following the current devastating floods has allowed immediate import of major agricultural commodities mainly onion and tomato.

Australia is having to face up to the realities of climate change. Volatile weather patterns always have been a familiar challenge. They’re coping as changes to technology and management have helped to limit the damage.

Fertilizer prices up in Bangladesh and the farmers expect hard time ahead. Sources in the agricultural ministry said there is adequate stock of all types of fertilizer in the country. The government has raised the price of urea fertiliser for the first time in 11 years, burdening the farmers with an increased production cost.

An international food crisis exacerbated by the Ukraine war has spurred Canada to boost an over $6 billion annual foreign aid budget to help the most hard-hit countries in Africa and the Middle East, Canada's aid minister said recently.

The agricultural ministers of the

German states have officially approved a proposal by federal minister Cem Özdemir to allow the cultivation of productive crops on certain fallow land in light of the war in Ukraine.

Germany's grain harvest in 2022 increased by almost 2 percent yearon-year to around 43 million tons, despite the ongoing drought, according to provisional figures published by the German Farmers' Association (DBV).

India has restricted exports of some varieties of rice, as the world's largest supplier tries to ensure domestic provisions amid global pressure on the food market.

Putrajaya will offer governmentbacked insurance plans to help compensate Malaysian farmers for losses after natural disasters, as part of measures to strengthen food security.

The NFU survey demonstrated the detrimental impact workforce shortages are having on the food and farming sector, resulting in significant crop losses at a time when the country is experiencing the worst cost-of-living crisis in generations.

The US Agriculture Secretary announced details of the U.S. Department of Agriculture’s (USDA) $300 million investment, including with American Rescue Plan funds, in a new Organic Transition Initiative that will help build new and better markets and streams of income for farmers and producers.

At the G7 Summit in June, President Biden and G7 leaders announced over $4.5 billion to address global food security, over half of which will come from the United States..

President Dr. Arif Alvi has said that Pakistan needs to adopt latest technology to enhance agricultural production to counter the effects of climate change.

He was addressing the Youth Forum of Kazakhstan, Turkiye and Pakistan on Bio Technology in Islamabad. He said we will have to work on food security keeping in view the climate change. He said Pakistan's production of food grains is half as compared to the production of other countries. He said it is inevitable to enhance agricultural production by using latest technology.

The President said the Muslim Ummah will have to change its mind-set by keeping in mind the changes taking place in the world. President Dr Arif Alvi stressed the need for ethical and moralitybased research and development in agriculture and egalitarian distribution of its benefits to provide food security to the entire world without discrimination between rich and poor countries.

He urged the Muslim world to take intellect-driven right decisions at right time for their people.

He argued that the Muslim world should be the first to adopt and generate new knowledge and bring innovation in every sector to cater needs of coming generations.

Factors of production in the agriculture sector of Pakistan and China can be complementary to each other. Both countries need to strengthen cooperation in agriculture and food security to achieve a win-win solution.

These remarks were made by Rabbia Nasir, Third Secretary of the Embassy of Pakistan in China, while attending the 2022 China Seed Congress and the Nanfan Agricultural Silicon Valley Forum recently. As good neighbours and allweather strategic cooperative partners, Pakistan and China have been working together to ensure food security with food being one of the major sources of trade between the two countries.

According to Chinese customs statistics, Pakistan exported $610 million of agricultural products to China in the first

half of 2022, up 30.85% year-on-year. Among them, rice exports amounted to $345 million.

Chinese investors are also investing more and more in Pakistan’s agriculture sector. Both countries are engaged in agricultural cooperation under the Belt and Road Initiative and the Global Development Initiative.

To further enhance agricultural cooperation and food security, “we should make the most of the complementary factors of production in agriculture of both countries,” Nasir affirmed. For instance, Pakistan could contribute a friendly policy of affordable factors of production, abundant agricultural products and investment in food processing, she cited and highlighted that China could share its experience with Pakistan in training, agricultural modernisation, cold chain technology, logistics, seed technology and agricultural demonstration areas.

Prime Minister Shehbaz Sharif has directed to all relevant ministries to prepare agricultural reforms plan on an emergency basis. He said this while chairing a high-level meeting on agricultural sector reforms held in Islamabad.

The Prime Minister said agricultural reforms will be implemented on an emergency basis. He said that the government will work on the construction of silos for storing wheat and agricultural commodities.

Pakistan’s agricultural exports are suffering from trade regulations in areas such as testing, certification and licensing because most countries have stringent regulations in place to protect human health and the environment.

To address these issues and expand market reach the Pakistan Single Window (PSW) conducted capacitybuilding sessions in Faisalabad and Gujranwala in collaboration with the All Pakistan Bedsheets & Upholstery Association of Pakistan (APBUMA) and the Seed Importers and Producers Association of Pakistan (SIPAP) as part of its Change Management component. The sessions were attended by a large number of importers and exporters transitioning to the Single Window system for crossborder trade

Shehbaz Sharif said a comprehensive awareness campaign should be conducted to make the farmers aware of the modern methods of agriculture. Matters related to procurement of future wheat, cotton and self-oil production, modern machinery at low cost to farmers, subsidy on urea and DAP, expected production and import, quality seeds, better use of water and provision of timely loans to farmers were discussed during the meeting.

The Prime Minister was briefed by sub-committees of wheat, cotton, edible oil, fertilizers, agricultural research, water use in agriculture, climate change and agricultural machinery in the meeting. Federal Ministers Tariq Bashir Cheema, Ahsan Iqbal, Marriyum Aurangzeb, Miftah Ismail, Special Assistants Ahad Cheema, Muhammad Jahanzeb Khan and high ranking officials attended the meeting.

Boosting trader participation in the capital market will improve the volume of transactions in Pakistan. One of the key challenges facing Pakistan at the moment is the volume of business. Trade regulations in areas such as testing, certification and licensing are challenging for 60 percent of Pakistan’s agricultural exporters. This is large because most countries have stringent regulations in place to protect human health and the environment.

As the floods continue to wreak havoc, Pakistan's Finance Minister Miftah Ismail said the government can consider importing food from India as the monsoon rains have destroyed the standing crops. The minister said Pakistan can consider importing vegetables and other

edible items. In August 2019, Pakistan snapped trade ties with New Delhi over the Kashmir issue.

Pakistan has been witnessing a massive surge in the prices of various vegetables and fruits due to devastating floods as the supply of vegetables from Balochistan, Sindh and south Punjab has badly been affected because of the disaster.

Responding to a question during a press conference in Islamabad, the minister said the government could "consider importing vegetables and other edible items from India". When he was told that ministers advocating trade with India had to go home in the past, the finance minister said he wasn't afraid of it.

The World Food Program said it is increasing emergency aid to reach 1.9 million people in Pakistan devastated by the worst floods to hit the country in more than a century.

WFP spokesman Thomson Phiri said emergency food aid already has been distributed to more than 400,000 people in the hardest hit Balochistan, Khyber Pakhtunkhwa, and Sindh provinces. He said the WFP is continuing to expand its operations across the country.

“We have reached 400,000 people, but of course, the floods have affected a record 33 million people and it is the deadliest in more than a decade,” he said.

The United Nations said torrential rains have inundated a third of the country, killing some 1,400 people, including hundreds of children. It said more than half a million homes have been destroyed, hundreds of bridges and roads demolished or washed away, cutting off vulnerable communities from humanitarian assistance.

Phiri said more than 630,000 people are in overcrowded relief camps where they are exposed to outbreaks of waterborne diseases. “In addition to food distribution, the World Food Program is providing specialized, nutritious food for 31,000 young children and 28,000 pregnant and nursing women to prevent malnutrition and boost their immunity,” he said.

Phiri said the WFP is looking beyond the emergency phase of its operation. He said Pakistan needs longer-term support to restore people’s livelihoods.

“Once the initial relief response is concluded, the World Food Program will immediately implement recovery programs to improve community infrastructure, create livelihood opportunities and boost resilience, combined with cashbased transfers, through early 2023,” he said.

Phiri said the WFP will be working closely with the government to help communities strengthen their ability to withstand climatic shocks. He said some of the projects include plans to create irrigation channels and dams in drought- and flood-prone areas. He noted both men and women will be given vocational training and income-generating activities to boost their livelihood prospects.

Pakistan continues to suffer from catastrophic flooding. Around one-third of the country remains underwater, and most of the 33 million people affected by the disaster have yet to receive assistance. But the crisis could still get worse. Recently the retaining wall of Pakistan’s largest lake gave way under rising water levels, imperiling communities downstream. More monsoon rains are expected in the coming weeks.

International aid is pouring into Pakistan, and a newly established humanitarian air corridor has facilitated the arrival of emergency relief. More than a dozen countries have pledged assistance. United Nations Secretary-General António Guterres—who has described the floods as a “monsoon on steroids”—will visit Pakistan on Friday to survey the damage. The immediate focus is on providing food, clean water, and shelter.

Pakistani officials and international donors are also working to address public health challenges.

However, another disaster with direct global implications looms: a major food crisis. With crops, livestock, and agricultural land damaged or destroyed, Pakistan will struggle to feed itself and the countries that depend on its food exports. This risks exacerbating the global food market crunch triggered by coronavirus pandemic supply chain shocks and Russia’s invasion of Ukraine.

According to preliminary estimates, 65 percent of Pakistan’s main food crops—including 70 percent of its rice— have been swept away during the floods, and 3 million livestock have died.

Pakistan’s planning minister says 45 percent of agricultural land is now destroyed. Such territory is precious in the best of times: Of Pakistan’s total land area, less than 40 percent is arable, and land erosion inflicts heavy damage on agricultural land.

Wheat is Pakistan’s top food crop, and the annual planting season begins soon. More than 90 percent of Pakistani households are wheat consumers. But with so much land destroyed or damaged, the wheat harvest could be jeopardized; some farmers fear their land won’t be usable within the next three months. Pakistan will likely have to import more food, which could raise costs

and worsen the country’s balance of payments crisis. Before the floods, food inflation was at 26 percent, and in recent days some costs have surged by as much as 500 percent.

These high costs will be felt heavily in cities, which are home to large poor and working-class populations. If history is any guide, it could lead to urban unrest. It will manifest differently in rural areas, which are home to around two-thirds of Pakistan’s population. Rural land ownership is wildly unequal, and most residents own little or no land, which compounds food insecurity. In the longer term, this could exacerbate a public health challenge: stunting in children attributed to poor nutrition.

A food crisis in Pakistan would have international implications. The country is the fourth-largest global rice exporter, with buyers from China to sub-Saharan Africa. Any dramatic drop in exports will only add to global food insecurity fueled by reduced wheat exports from Ukraine, although high global rice stocks could soften the blow. Pakistan also exports many non-food crops, especially cotton.

Pakistan’s food imports, including wheat, palm oil, and soybean oil, went up by 64.45% in July and August, data issued by the Pakistan Bureau of Statistics reported. According to PBS statistics, Pakistan has imported food items worth

Rs392.83 billion in the first two months of the fiscal year 2022-23. Last year, the country’s food import bill for the same months was Rs238.88, PBS stated.

The biggest spike was noticed in the wheat import which went up by a staggering 2435% in the first two months of the fiscal year. Pakistan has imported wheat worth Rs68.49 billion this year, while the wheat import bill for July and August 2021 was only Rs2.70 billion.

Moreover, the country also imported tea worth Rs30.23 billion in July-August 2022 which is 20.92 higher than JulyAugust 2021. Pakistan also imported pulses worth Rs35.95 in July-August 2022 which is 43.70 higher than last year.

Additionally, Pakistan imported palm oil worth Rs157.79 billion (68.67% higher than last year), and soybean oil worth Rs9.48 billion (255.36% higher than last year), the PBS data stated.

Agricultural land inundated by flooding is set to have long-term humanitarian and economic impacts in Pakistan. Billions of dollars’ worth of rice, sugar and wheat have already been lost.

Flooding in dozens of districts in Pakistan’s Balochistan, Sindh and Punjab provinces have destroyed wide swaths of agricultural land. The country could soon face food shortages if thousands of acres of cropland are not restored.

“We are concerned that if the farmlands aren’t drained right now, we won’t be able to plant crops for winter season, the most important of which is the wheat crop,” Nazia Bibi, a farmer in Pishin district of Balochistan, told media.

There is a fear that Pakistanis will be unable to find essential food staples in markets. To cope with the challenge, the government is importing tomatoes and onions from neighboring Afghanistan and Iran.

Pakistan’s National Disaster Management Agency (NDMA) is leading relief efforts in coordination with the UN and other international organizations. The United Nation’s World Food Programme (WFP) has so far provided over 464,000 people in Balochistan, Khyber Pakhtunkhwa (KP) and Sindh with relief food assistance. The WFP added that it aims to provide 1.9 million people facing food insecurity in flood-affected districts with food assistance, according to a September situation report.

“The intensity of the situation in villages is such that people are snatching ration packs from each other during distribution drives. It’s really heartbreaking to see that,” Abid Mir, a social activist and professor at a university in Sindh, told DW.

Muhammad Younas, an official at the Provincial Disaster Management Authority in Balochistan, told to media that foreign aid was being distributed to people through the NDMA. “The NDMA delivers aid to provincial disaster management authorities, who then pass it to the

district management and other administrative units.”

“International NGOs have their own local partners who they give their aid to. They have their own mechanism and ways of assessing the damages and victims’ needs. They, however, must get permission from the government to work in a particular area,” Younas added. Although the Pakistani government plans to provide cash payments to over 4.5 million flood-affected households through the Benazir Income Support Programme (BISP), Islamabad has been criticized for not doing enough to prepare for the monsoon season.

A humanitarian crisis has unfolded from the weeks of unrelenting flooding in the hard-hit country, which is in dire need of food, clean water, medicine and clean sanitary facilities.

A dire situation has emerged out of Pakistan after weeks of deadly flooding displaced more than 100,000 from their homes and devastated countless acres of crops, leaving those stranded in desperate need of food, water and medical care.

Flooding in Pakistan over the past

month has been brought on by record monsoon rains and melting glaciers in the country's northern mountains. According to Pakistan's National Disaster Management Agency, the floods have killed at least 1,314 people, including 458 children, and have impacted 33 million overall as of Sept. 5.

In July and August, Pakistan recorded 15.4 inches of rain - nearly 190% more than the 30-year average, The Guardian reported. And Pakistan's largest city, Karachi, more than tripled its monthly rainfall in 24 hours during monsoon downpours in late July, according to reports.

Structural damage throughout the country has been immense, with nearly two million homes and businesses destroyed, along with 7,000 kilometers of roads and numerous bridges washed away.

Federal government in view of massive damage to agriculture following the current devastating floods has allowed immediate import of major agricultural commodities mainly onion and tomato.

According to sources, during an urgent meeting held at the ministry of

commerce to review the availability of agro commodities, prices and import options, it was decided to import two largely consumed agricultural products to meet the anticipated shortages in Pakistan.

Soon after disruption in supply after the floods in Pakistan, the prices of vegetables and fruits have skyrocketed and further hikes in prices are being expected.

The meeting, chaired by federal secretary of commerce Saleh Farooqi, was attended by senior officials of the Ministry of National Food Security and Research, FBR and other stakeholders. Diplomatic representatives of Iran, Turkey and Afghanistan also participated in the meeting.

During the meeting the representatives of Pakistan Fruit and Vegetable Importers Exporters Merchants Association (PFVA) have proposed immediate abolition of duties and taxes on the import of onions and tomatoes for at least a period of three months. The importers see exemption of duties and taxes necessary to stabilize the local market.

While keeping in view the cost of import from other countries, the association, according to Waheed Ahmed of PFVA, had proposed the government to import the vegetable items from India. However, the government was reluctant to allow import from the neighboring country under the existing unfavorable bilateral relations.

According to importers, keeping the cost in view, import of the vegetables is only viable from India. An insider informed this scribe that the officials of the commerce ministry would take up the

case of import from India with higher authorities soon. The government may lift the ban on import from India to avoid the prevailing commodity crisis.

During the meeting it was informed that more than 80% of the onion crop in Sindh has been destroyed due to floods. On the other hand, tomato crops have also been severely damaged. Earlier the onion crop in Baluchistan was also badly destroyed by torrential rains and floods. However, according to traders, other vegetable items including potato are luckily available in good stock.

As per the initial negotiation between the two sides, Litong Food in collaboration with the Guard Group of Pakistan will sow high-yielding hybrid chilli crop over 5,000 acres of land during the coming season while another 3,000 acres will be sown on its own in Pakistan.

As per the plan, this area under the chilli crop will be increased to 200,000 acres of land in the future. Setting up of a processing plant after achieving 50,000 metric tons of hybrid chilli production and a breeding station to ensure the transfer of technology to chilli production is also part of the proposed collaboration.

Guard Agricultural Research & Services (Pvt) Ltd’s CEO Shahzad Ali Malik said the Chinese government had short-listed its two companies under its CPEC projects in agriculture and livestock. Litong has been selected for Agriculture while Royal Company has been selected for livestock projects.

He said his company was already experimenting with the sowing of highyielding hybrid chilli seed in Pakistan for the last six years and got very encouraging results. He claimed that the Chinese company keeping in view the track record of successful promotion of hybrid rice, chilli and tomatoes contacted them to work in collaboration with them.

It has also been planned to set up a 500 acres model farm in Southern Punjab which would start working by the end of October after the signing of a Memorandum of Understanding (MoU) between both companies.

Perhaps more than anywhere on earth, Australia is having to face up to the realities of climate change. Volatile weather patterns always have been a familiar challenge, but now the country’s grain and oilseeds producers are dealing with, on average, more difficult growing conditions and reduced incomes. They’re coping as changes to technology and management have helped to limit the damage. Even so, every part of the agrifood supply chain is expected to be affected.

In a report, “Climate Change Impacts and Adaptation on Australian Farms,” published this year, Neal Hughes and Peter Gooday of the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) explained that “in recent decades, Australia has seen a shift towards higher temperatures and lower winter rainfall, which has had significant effects on many farmers.”

They also noted that “there remains much uncertainty over the long-run effects of climate change on farm businesses. Australia’s climate has warmed on average by 1.4°C since 1910, with most of this occurring since 1950,” the authors said. “There has also been a decline in winter season (April to October) rainfall in southwestern Australia (20% since 1970) and southeastern Australia.”

Citing ABARES’ latest modeling, Hughes and Gooday said “changes in seasonal conditions over the period 2001 to 2020 (relative to 1950 to 2000) have reduced annual average farm profits by 23%, or around A$29,200 (US$20,100) per farm.”

“These impacts have been most pronounced in southwestern and southeastern Australia, with northern Australia and the coastal higher rainfall zones tending to be less affected,” Hughes and Gooday said. “Conditions during the post-2000 period have also contributed to increased risk in terms of more variable cash income and profits.”

From 2000 to 2020, the risk of very low farm returns (due to climate variability) essentially doubled (relative to the period 1950 to 2000), increasing from a one in 10 frequencies to more than one in five, the report said.

Looking forward to 2050, using a series of models, Hughes and Gooday forecast that cropping farms in western Australia are more heavily impacted than other regions under most climate scenarios, due largely to the more substantial projected declines in winter rainfall and the resulting effects on crop yield.

Sources in the agricultural ministry in Bangladesh said there is adequate stock of all types of fertilizer in the country. The government has raised the price of urea fertiliser for the first time in 11 years, burdening the farmers with an increased production cost. The new hike of Tk 6 per kilogramme took effect yesterday, and farmers now have to pay Tk 22 for per kg fertiliser. The last time the government increased the price of the fertiliser was in June 2011, when it was raised to Tk 20 from Tk 12 per kg. Two years later, the government reduced the price to Tk 16 per kg.

Experts said the recent hike will increase the production cost of paddy by up to Tk 600 to Tk 700 per acre, which will ultimately push up food prices amid already spiralling prices of essentials.

They said that though the price increase is not much, it will have a negative impact on farmers as it will reduce their profits and discourage them from

cultivating more rice. The government provides subsidy for fertilisers as part of its efforts to achieve food security.

M Asad uzzaman, former research director at Bangladesh Institute of Development Studies (BIDS), said the government might have taken the decision as per the prescription of the International Monetary Fund that always discourages subsidies.

“The decision has come when farmers are already apprehensive about reduced production due to less rainfall. Now the price increase of urea fertiliser will raise the production cost and ultimately increase the burden on the people,” he said.

Agro economist Jahangir Alam said the price of fertiliser has been showing a declining trend in the global market. “The

government should have waited for a few more months before increasing the price,” he said.

In February, the agriculture minister said the import cost of urea was Tk 96 per kg in fiscal 2021-22. According to an agriculture ministry release yesterday, that cost is now Tk 81. Jahangir further said, “The farmers may reduce the use of fertiliser to cut costs, which may bring down the total production of rice.” Farmers may also feel discouraged from cultivating rice due to higher production costs, in which case, Jahangir said, “The government would then have to import rice at higher prices.”

Following the rise in the price, dealers will have to pay Tk 20 instead of Tk 14 to buy each kg of urea, the agriculture ministry press statement said.

The price of the fertiliser is currently Tk 81 per kg in the global market. As a result, the government will have to pay a subsidy of Tk 59 per kg even after the price hike of Tk 6, the release added. Sources in the agricultural ministry said there is adequate stock of all types of fertiliser in the country. The demand for fertiliser in the Aman season (July-September) is usually around 6,19,000 tonnes and currently there are 7,27,000 tonnes in stock.

According to the agriculture ministry press release, fertiliser prices in the global market have seen three to fourfold increase, and accordingly the government had to raise subsidy almost fourfold.

An international food crisis exacerbated by the Ukraine war has spurred Canada to boost an over $6 billion annual foreign aid budget to help the most hardhit countries in Africa and the Middle East, Canada's aid minister said recently.

"The Ukraine crisis is creating shock waves when it comes to supply chain and especially food security and impacting the most vulnerable at the most difficult time," said Harjit Sajjan, Canadian Minister of International Development.

"We are making adjustments to reflect this ... People are going hungry

because the prices of food have gone up," Sajjan told Reuters in an interview in Jordan, the first leg of a regional tour that also takes him to Egypt and Lebanon.

He did not give the new aid figure but Ottowa-based Canadian International Development Platform said there was a 27% rise in foreign aid last year to around $6.6 billion.

The United Nations has said a global food crisis fuelled by conflict, climate shocks and the COVID-19 pandemic is growing because of the ripple effects of the war in Ukraine driving rising prices of food, fuel and fertilizer.

Over 50 million people in Eastern Africa will face acute food insecurity this year, according to a new study backed by the U.N. World Food Programme (WFP) and Food and Agriculture Organization (FAO).

Sajjan said Canada is boosting aid to the WFP, whose annual requirements have reached an all-time high of $22.2 billion, without taking away from other development programmes.

"We have increased our support for the Middle East region when it comes to food," he said citing as one example Lebanon, which has a significant reliance on Ukraine wheat and is facing bread shortages.

Canada was also looking at how to help improve resilience in African countries, noting in particular the continent's shortage of food storage.

The agricultural ministers of the German states have officially approved a proposal by federal minister Cem Özdemir to allow the cultivation of productive crops on certain fallow land in light of the war in Ukraine.

According to the decision taken on Tuesday (16 August), farmers may continue to grow cereals, sunflowers or certain legumes for one year on land that they would otherwise have been obliged to take out of production under the reformed EU Common Agricultural Policy (CAP), which will start being applied by EU member states from January 2023.

Contrary to Özdemir’s original position, Germany is thus partially implementing the derogation proposed by the EU Commission at the end of July, which allows member states to relax certain environmental requirements within the CAP in light of the impact of the Ukraine war on global grain markets.

This includes the so-called good agricultural and environmental conditions (GAEC) 8 standard, which as of 2023 requires farmers to leave a certain proportion of farmland – 4% in Germany –fallow in order to improve biodiversity.

Özdemir had initially been critical of the Commission’s proposed relaxation, which aims to increase domestic grain production in light of reduced supplies from Ukraine while accusing the EU executive of avoiding responsibility over the global food crisis.

However, many regional ministers, including the current chairman of the Conference of Agriculture Ministers, Saxony-Anhalt’s agriculture minister Sven Schulze of the Christian-democrats party (CDU), had called to fully implement the relaxation allowed by the EU executive.

At their most recent meeting at the end of July, the federal and state governments, therefore, failed to reach an agreement on the matter.

Germany's grain harvest in 2022 increased by almost 2 percent year-onyear to around 43 million tons, despite the ongoing drought, according to provisional figures published by the German Farmers' Association (DBV).

Due to the effects of climate change, crop volumes in 2022 remained "significantly below the average" of 45.6 million tons for the years 2014 to 2021, DBV said in its crop report.

Autumn crops such as corn, potatoes and sugar beet have "suffered massively" in regions affected by the drought, said DBV president Joachim Rukwied. Considerable yield losses are expected for this type of crop, he added.

Meanwhile, a spokesperson for the German Ministry of Food and Agriculture (BMEL) told Xinhua that the consequences of the climate crisis are showing up in the fields, vegetable plots, orchards

and vineyards. In order to secure supply, it is important to support farmers in "successively adapting to the changed climate conditions," the spokesperson said.

Fields in Germany have been hit by a combination of above-average temperatures and hours of sunshine, as well as little rainfall since May, the country's National Meteorological Service (DWD) said earlier this month. This has caused soils to "dry out severely."

"The prolonged drought in many regions of the country shows once again that farmers are feeling the effects of climate change very directly," Rukwied stressed. "Looking at yields in recent years, it is clear that there cannot be any room for further area-wide restrictions on food production."

The European Union (EU) plans to reduce the use of chemical pesticides by 50 percent by 2030. Furthermore, the

rules for handling such pesticides are to be tightened to ensure more sustainable food systems by 2030.

Food prices in Europe's biggest economy are outgrowing inflation, rising to 14.8 percent year-on-year in July, according to official figures. Meanwhile, flour and cereal products were 34 percent more expensive, with the Russia-Ukraine conflict affecting international supply.

India has restricted exports of some varieties of rice, as the world's largest supplier tries to ensure domestic provisions amid global pressure on the food market.

The government said it has prohibited exports of broken rice -- fragmented grains that are generally cheaper and more accessible to the poor. It has also imposed a 20% tax on export sales of some varieties, including husked brown rice and semi-milled or wholly milled white rice.

The move comes amid concerns over lower rice production during the ongoing crop season as uneven monsoon rains have left some areas parched. Outside India, the decision is likely to fuel worries over food inflation, already being exacerbated by Russia's invasion of Ukraine, a key wheat supplier.

Addressing reporters on Friday, Sudhanshu Pandey, India's food secretary,

said prices of rice have been trending higher in recent months. He said broken rice, which is also used in animal feed, had hit 22 rupees per kilogram -- up from 16 rupees in January. Total rice sowing this season is down by 3.8 million hectares compared with last year, he said.

While explaining the reasoning for the curbs, Pandey was also quick to downplay supply risks, saying the worst-case scenario was a "not very significant" production loss of 10 million to 12 million tonnes. "Sowing has just ended and if yield is good in some areas, this could get compensated also," he added.

According to Indian government data, the country is estimated to have produced a record 130.29 million tonnes of rice in the last crop year, from July 2021 to June 2022, beating the five-year average of 116.44 million tonnes. However, a U.S. Department of Agriculture report released last month warns that Indian rice production may decline 0.9% this year.

"This is the first decline in India's rice production since 2015/16," the USDA said. Overall, India is the world's secondlargest rice producer, after China, accounting for 40% of the global rice trade. It exports the grain to over 150 countries, helping to feed Asia and Africa, from Nepal and Vietnam to Benin and Djibouti.

In the financial year that ended in March, India's total agricultural exports grew 19.92% to touch $50.21 billion. "[The] highest ever exports have been achieved for staples like rice ($9.65 billion), wheat ($2.19 billion), sugar ($4.6 billion) and other cereals ($1.08 billion)," the government said in a statement on last year's exports.

Internationally, the FAO Food Price Index, a key barometer, has been easing in recent months but remained 7.9% higher on the year in August, according to the United Nations agency.

The NFU survey demonstrated the detrimental impact workforce shortages are having on the food and farming sector, resulting in significant crop losses at a time when the country is experiencing the worst cost-of-living crisis in generations.

As the survey represents around a third of the UK horticulture sector, the NFU estimates the overall value of food wasted accumulates to more than £60 million.

This devastating amount of wasted food comes at a time when millions of people across the UK are struggling to put food on the table.

As Tom Bradshaw, deputy president of the NFU, explained, “It’s nothing short of a travesty that quality, nutritious food is being wasted at a time when families across the country are already struggling to make ends meet because of soaring living costs.

“At the same time, the prolonged dry weather and record temperatures have created a really challenging growing environment for our fruit and veg. Every crop is valuable – to the farm business and to the people whose plates they fill. We simply can’t afford to leave food unpicked.”

Carina Millstone, executive director at Feedback added, “At a time when many farmers are going out of business and many families are struggling due to the devastating cost-of-living crisis, this is an absolutely unacceptable scandal.”

According to Vicki Hird, head of the sustainable farming campaign at Sustain, the impact of this colossal food waste is also detrimental to climate change efforts. She explained, “The waste that means is totally unacceptable in times of shortage and as climate change starts to bite here and for our overseas suppliers too.

“We need systemic changes ensuring more of the food pound reaches the farmers, workers and the land, more targeted support to create a more diverse farming industry to increase the size and diversity of domestic supplies in ways that protect nature and build resilience against climatic shocks.”

Agriculture Secretary Tom Vilsack announced details of the U.S. Department of Agriculture’s (USDA) $300 million investment, including with American Rescue Plan funds, in a new Organic Transition Initiative that will help build new and better markets and streams of income for farmers and producers. Organic production allows producers to hold a unique position in the marketplace and thus take home a greater share of the food dollar.

According to the USDA National Agricultural Statistics Service, the number of non-certified organic farms actively transitioning to organic production dropped by nearly 71 percent since 2008. Through the comprehensive support provided by this initiative USDA hopes to reverse this trend, opening opportunities for new and beginning farmers and expanding direct consumer access to organic foods through increased production.

The initiative will deliver wrap-around technical assistance, including farmer-tofarmer mentoring; provide direct support through conservation financial assistance and additional crop insurance assistance, and support market development projects in targeted markets.

“Farmers face challenging technical, cultural, and market shifts while transitioning to organic production, and even during the first years after successful organic certification,” said Vilsack. “Through this multi-phased, multiagency initiative, we are expanding USDA’s support of organic farmers to help them with every step of their transition as they work to become certified and secure markets for their products.”

USDA’s Agricultural Marketing Service (AMS), Risk Management Agency (RMA) and Natural Resources Conservation Service (NRCS) are the primary agencies supporting the Initiative, which will focus on three areas.

Secretary Blinken travels to South Africa, the Democratic Republic of the Congo, and Rwanda, where the United States has been deploying resources and working in partnership with African governments, institutions, businesses, scientists, and other leaders to prevent hunger and combat the global food security crisis while also addressing the increasing rates of malnutrition, which has hit the continent of Africa the hardest.

At the G7 Summit in June, President Biden and G7 leaders announced over $4.5 billion to address global food secu-

rity, over half of which will come from the United States. This $2.76 billion in U.S. government funding will help protect the world’s most vulnerable populations and mitigate the impacts of growing food insecurity and malnutrition, including from Russia’s war in Ukraine, by building production capacity and more resilient agriculture and food systems around the world, and responding to immediate emergency food needs. We have recognized the need for immediate action to prevent far-reaching consequences, and we are responding with support targeting Africa’s own plans for food security and food systems transformation.

Of this $2.76 billion, $760 million will be for sustainable near-term food assistance to help mitigate further increases in poverty, hunger, and malnutrition in vulnerable countries impacted by high prices of food, fertilizer, and fuel. Of this amount, we are working with Congress to allocate $336.5 million to bilateral programs for Sub-Saharan African countries, including Burkina Faso, the Democratic Republic of the Congo, Ethiopia, Ghana, Guinea, Kenya, Liberia, Madagascar, Malawi, Mali, Mozambique, Niger, Nigeria, Rwanda, Senegal, Sierra Leone, Somalia, South Sudan, Tanzania, Uganda, Zambia, and Zimbabwe and regional programs in southern Africa, west Africa, and the Sahel.

Also of this $2.76 billion, USAID is programming $2 billion in emergency food security assistance over the next three months. As of August 8, 2022, the U.S. has provided nearly $1 billion specifi-

cally for countries in Africa toward this $2 billion commitment, including Central African Republic, the Democratic Republic of the Congo, Ethiopia, Kenya, Mali, Mozambique, Nigeria, Somalia, South Sudan, and Uganda.

In addition to the President’s G7 commitment, the U.S. has announced the drawdown of the balance in the Bill Emerson Humanitarian Trust, an effort in coordination with the U.S. Department of Agriculture which will provide an additional $670 million in food assistance to respond to historic levels of acute food insecurity around the world. Funds announced in July and August 2022 will be used to procure U.S. food commodities to bolster existing emergency food operations in countries facing severe food insecurity. Resources will be delivered to: Ethiopia, Kenya, Somalia, South Sudan, and Sudan.

President Biden also announced that the United States is expanding sustainable African food production through the U.S. government’s signature global food security initiative, to eight additional African countries, including Democratic Republic of the Congo, Liberia, Madagascar, Malawi, Mozambique, Rwanda, Tanzania, and Zambia. This expansion brings the number of priority countries globally to 20 and delivers on President Biden’s commitment in September 2021 to work with Congress to provide $5 billion through Feed the Future to end global hunger, malnutrition and build sustainable, resilient, inclusive food systems abroad.

Black-grass weed significantly reduces wheat crop yields, costing farmers’ money and impacting the UK’s agricultural economy

Tech and digital farming companies will work with strategic partners to develop a solution

Technology will include sprayers, cameras, data analysis with AI, and a digital platform to map and monitor Black-grass growth across a threeyear period

A team of experts from Bosch, BASF Digital Farming, Chafer Machinery and Rothamsted Research will use precision farming technology and artificial intelligence to help reduce the persistent problem of Black-grass in UK farms. Black-grass (alopecurus myosuroides) is a weed that inhibits the growth of wheat crop, reducing its yield and therefore damaging the productivity of farms.

It is one of the biggest challenges facing farmers in the UK today and it is

threatening the sustainability of UK cereal production. It is estimated that the weed is responsible for annual wheat loses of up to 800,000 tons, with associated economic losses of approximately £400 million*.

Bosch is the lead partner in the research and development (R&D) project consortium, which comprises recognised experts from BASF Digital Farming, Chafer Machinery, and Rothamsted Research. Together they have been awarded a grant of £1,452,614 from DEFRA and Innovate UK, the UK’s innovation agency, under the Farming Innovation Programme – Small R&D Partnership Projects.

Each partner brings unique expertise: Bosch is one of the leading companies for sensor and software technologies and will steer the project in collaboration with digital agriculture specialists BASF Digital Farming and sprayer manufacturer Chafer

Machinery. Together they will be supported and guided by the input of renowned academic experts in Blackgrass from Rothamsted Research.

Using the Bosch Smart Spraying camera technology and software, Chafer will design innovative boom sprayers to detect, identify and map Black-grass at different growth stages within cereal crops across a farm. The smart sprayer technology will be tested on commercial farms selected from the Rothamsted Black-Grass Research Initiative (BGRI).

Agronomists from Rothamsted will label the images and will support Bosch in training algorithms to recognise Blackgrass in cereal crops. This information is then processed and analysed by BASF Digital Farming and delivered to its advanced xarvio Digital Farming Solutions crop optimisation platform. In the plat-

form, the information will be used to map infield populations to support the development of integrated weed management plans for targeted Black-grass control.

Overall, the persistent problem of Black-grass should reduce in severity and the ambition is, with enhanced mapping, to improve sustainable Blackgrass management programmes.

Additionally, beside a superior performance in Black-grass control, the project could result in reduced herbicide volumes sprayed in-field. This would minimise unintended direct consequences on other organisms and reduce the potential for leaching into other vulnerable ecosystems, such as waterways.

Bharath Jayakumar, Innovation

Lead at Bosch UK, said: “At Bosch we’re constantly looking for solutions to the challenges people face and it’s particularly exciting when we see a way to develop new technologies to solve a problem. We believe our sensor, software and AI technology can make a difference for UK farmers and will help them to target Black-grass better in their fields.”

Daniel Ebersold, Head of Digital Farming Project House (Smart Machinery), BASF Digital Farming, said: “We are committed to helping UK farmers optimise crop production. By working together on this important project our shared aim is to find an innovative solution using smart farming technologies, agronomic expertise and artificial intelli-

gence that will measurably reduce the impact of Black-grass infestation over time.”

Rob Starkey, Managing Director, Chafer Machinery, said: “Integrating innovative technology to maximise the efficiency and accuracy of herbicide application is a key part of Chafer’s strategy to help UK arable farms increase productivity and reduce unnecessary impact on the environment. The Smart Sprayer project is a unique opportunity, working with leading industry partners, to contribute to the development of cutting-edge technology which will help solve the UK Black-grass problem”.

David Comont, Rothamsted Research, said: “Black-grass has become the UK’s most pressing weed problem, resulting in considerable wheat yield losses annually and causing ever-increasing herbicide use as farmers attempt to control this species. Developing “smarter” systems which can automatically monitor and more precisely spray this weed has the potential to maximise control, whilst reducing both herbicide use and costs to farmers.”

The funding was awarded as part of Defra’s Farming Innovation Programme and the UKRI Transforming Food Production challenge.

English Biscuit Manufacturers (EBM), the leading FMCG Company in Pakistan, has collaborated with Al Maya Group to expand their international business to the UAE. This marks one of EBM’s largest expansions in the Middle East and promises to spread the joy of EBM’s brands in the region.

EBM has a prolific international footprint in over 30 countries and a notable presence in the global market including the United States, Canada, the UK, the Middle East, and Africa. The journey of EBM's product to international markets reflects the company's commitment to R&D and innovation.

For over 50 years, EBM has held the largest production capacity in Pakistan

and this new endeavour enables the company to remain a leader of the FMCG sector both on a local and global scale.**

"Over the past years we have provided our customers and consumers, at home and abroad, with innovative highquality products," said Chief Executive Officer and Managing Director of EBM Dr Zeelaf Munir. "Our increasing presence in the international market is a testament to our commitment of providing every consumer with healthy & affordable nutritious brands. By extending our supply chain to the UAE with the largest distribution network, we will be able to introduce our innovative product range to new consumers and provide overseas Pakistanis with a taste of their homeland."

Deepak Pagarani, CEO of Al Maya Group, said, "Al Maya has introduced the finest food brands of the world within the Gulf region. It has also assured a seamless supply of brands to retailers and international supermarket chains. We're happy to have English Biscuit Manufacturers on board as we believe that we have what it takes to maintain the essence of the leading FMCG company through our exceptional B2B experience and trusted distribution network at the international level."

EBM envisions to continue providing products that are rich in quality and nutrition, thus making an impact through its purpose of nourishing lives, hearts, and communities.

The Board of Directors of ICI Pakistan Limited has authorised a partial divestment of approximately 26.5% of the issued and paid-up share capital of its subsidiary NutriCo Morinaga (Private) Limited (NMPL) to Morinaga Milk Industry Co. Ltd, a Japanese dairy giant, at an aggregate sale price of US$45.08 million, which translates into approximately US$2.07 per share.

In a notice sent to the Pakistan Stock Exchange (PSX) on Wednesday, ICI Pakistan said that it would continue to hold approximately 24.5% of the issued and paid up share capital of NMPL, a subsidiary of ICI Pakistan, upon completion of the transaction.

“The approval is subject to, inter alia, obtaining the requisite approval of the shareholders of the Company pursuant to section 183(3) (b) of the Companies Act, 2017, and all necessary regulatory and other approvals required,” read the notice.

Last month, Japanese dairy giant Morinaga Milk Industry sent a conditional offer to ICI Pakistan to acquire an aggre-

gate of approximately 33.3% of the issued and paid-up share capital of NMPL from NMPL's existing shareholders including that of ICI Pakistan.

The acquisition was set at an aggregate price of US$56.6 million which translates to approximately US$2.07/per share, ICI Pakistan had said then.

NMPL is a joint venture between ICI Pakistan, Morinaga Milk and Unibrands (Private) Limited to locally manufacture and distribute nutritional formula products, and was recently merged with NutriCo Pakistan (Private) Limited, which was involved in the import and distribution of select products of Morinaga Milk.

Moreover, Moringa Milk Industry, in its filing to the Tokyo Stock Exchange last month, said that the company has been exporting infant and toddler milk to Pakistan since 1978 and sees the South Asian country as an attractive market, boasting the fifth-largest population in the world, with continuing population growth forecast.

“Moreover, the Morinaga Milk Industry brand has gained broad recognition in Pakistan over many years through the export business, giving the Company a high chance of achieving further rapid growth in the Pakistan market.

“By acquiring management control over NutriCo Morinaga the company considers that it will be able to capture growth opportunities, leading to the further development of the Morinaga Milk Industry brand infant and toddler milk business in Pakistan and contributing to the growth and health of the consumers of the Company products,” it said.

Back in 2020, NutriCo Morinaga (Private) Limited commenced commercial operations of growing-up formula products at its manufacturing facility in Sheikhupura, Punjab.

At a cost of Rs5.5 billion, the manufacturing facility was the first asset investment by a global Japanese dairy and food company in Pakistan.

The Dmitrovskie Group is Russia's oldest supplier of vegetable products for the domestic retail market. In recent years, the company has actively driven forward its vegetable processing business and expanded its range of prepacked sliced vegetables, salads and cooked vegetable products.

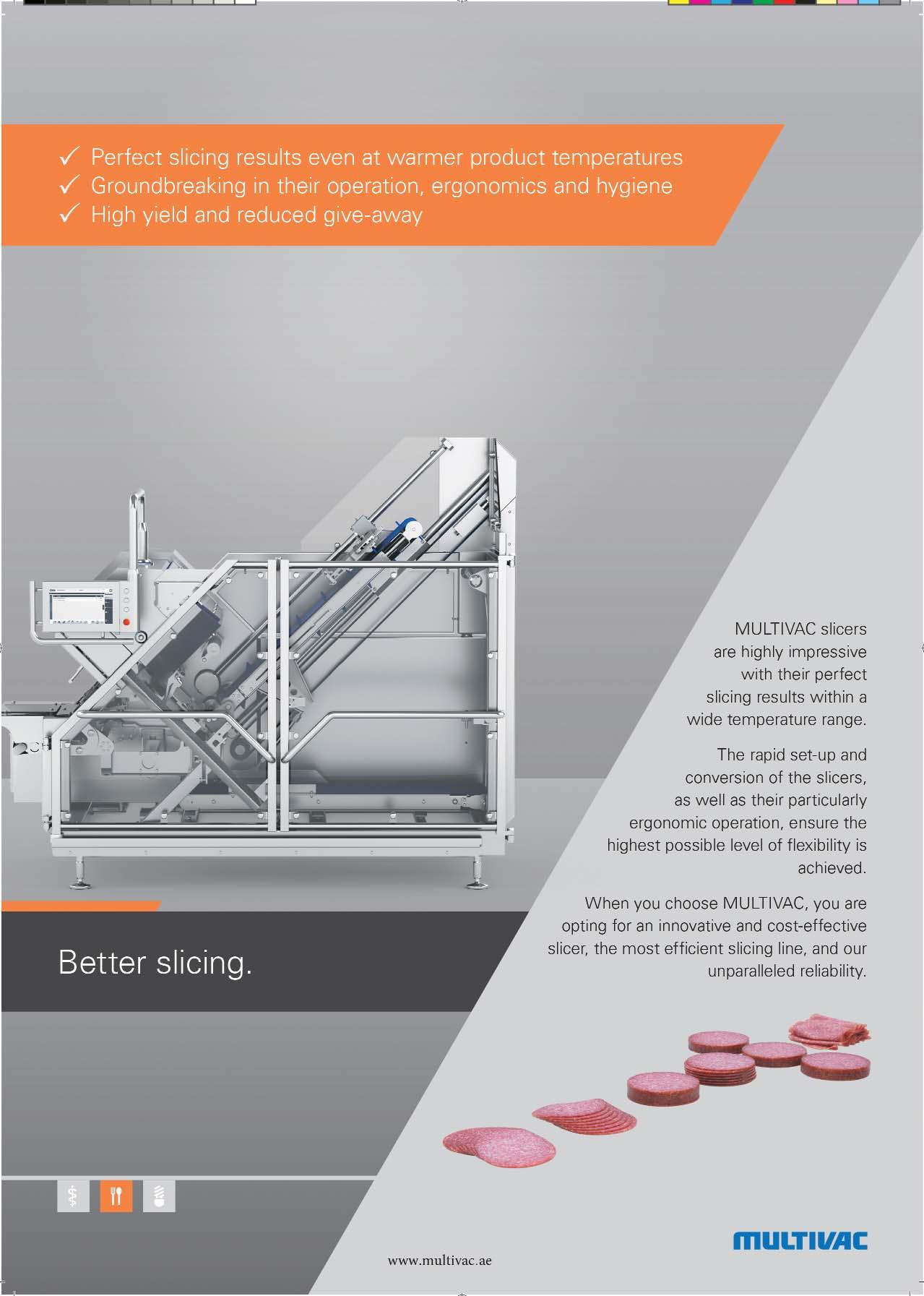

In order to increase the competitiveness of the rapidly growing, family-run company, the owners decided to focus on the automation of the production processes and concentrate in particular on the filling and packaging operations. MULTIVAC was selected as the strategic partner for the packaging technology.

Ivan Filippov, Development Director for the Dmitrovskie Group, reports in this interview on his experiences in the mutual collaboration with the experts from MULTIVAC.

Mr Filippov, your company's range of activities includes not only the cultivation

and supply of vegetables, but also the processing of these into vegetable products.

That is correct. We now feel rather misunderstood, when we are described as farmers. The Dmitrovskie Group has actually been involved in food processing for about a decade now. In 2009 we were the first company to launch washed vegetables from our own production onto the market. We are now the market leader in this sector.

About one and half years ago, initially as a trial operation, we started to produce cooked vegetable products, i.e. pas-

teurised and sterilised. It took a whole year for us to master the new production process for the vegetables, so their vitamins and micro-nutrients could be retained, while at the same time providing the shelf life for the product without the addition of preservatives.

Today we are able to offer potatoes with and without skin, as well as beetroot.

It takes only a few minutes to cook these products since they just have to be heated in the microwave. Thanks to our new production line, we can now offer high-quality products as healthy conven-

We

ience foods to consumers who have too little time or inclination for cooking.

Are the processed products packed on an industrial scale?

Yes. The expansion of our product range to include those with a greater degree of processing required a rethink on our part, involving a completely new approach to packaging.

By investing in new packaging technology, we also set ourselves the aim of automating the production process as completely as possible - right up to the filling of the finished product.

By completely automating the packaging process, we also wanted to ensure our products would meet the strict hygiene regulations. At the same time,our intention was also to increase the productivity and efficiency of our production by reducing the number of workplaces for less qualified staff.

Another benefit of introducing a new packaging solution was a longer shelf life for our products, which would further consolidate our customers' trust in our branded products.

Which packaging technology did you decide upon?

We currently use several thermoforming packaging machines from MULTIVAC.

Why did you decide on this company?

Two years ago we decided to automate our packaging line − and unfortunately we purchased our first thermoforming packaging machine from another supplier. To our great regret, however, we soon encountered difficul-

ties. There was a complete lack of support, which we urgently needed. We therefore ceased our involvement with this supplier immediately.

A year ago we were faced again with the urgent task of optimising our packaging line for pasteurised vegetables, and in particular to meet the demand for higher output. And so we contacted the specialists at MULTIVAC. They were very ready to help us with this project and, following an in-depth evaluation, developed a suitable solution for us.

How were the products packed previously?

Before the thermoforming packaging machines were introduced, we had to fill the vegetables by hand. We used chamber machines for the vacuum packing, as well as manual weigh feeders with pedal activation. But there was simply too much labour required to operate these effectively. By purchasing MULTIVAC technology, we have now finally got away from inefficient manual processes. After just one year we have been able to double the output of our packed products.

Which criteria applied when selecting the new partner, given the unhappy experiences with the first supplier?

Our Group includes the DmitrovAgroResource company, one of the oldest sales firms for agricultural technology in Russia, which has traditionally specialised in the sale of tractors and combine harvesters. We therefore know exactly, how one has to sell technology and equipment − we are not just selling our customers the individual machines,

we also see ourselves as real suppliers of solutions. In addition to the particular vehicle, we also offer servicing and technical support.

A trusting relationship with our business partners is very important to us. The result of our work depends precisely on how successful this is.

We therefore applied the same criteria to the supplier of the new packaging technology, as those that apply to ourselves.

This includes the manufacturing quality of the products, the level of technical support and the availability and delivery of spare parts. If the supplier can guarantee the required spare parts can be delivered to site on any day of the week, including weekends, this is for us an important factor when making the purchasing decision.

When choosing technical equipment, the evaluation of the supplier by other companies, who already have experience with this technology, also plays a significant role. If the opportunity allows, we will travel to these companies and ask them all the relevant questions regarding the equipment, particularly about the reliability of the technology and the technical support offered by the supplier.

Surprisingly the price as a selection criterion is not even worth a mention by them ...

That, which is good, can not be cheap. Quality has its price.

That means you were prepared to accept the price level of the market leader for packaging technology in Europe?

Essentially, it comes down to evaluating the price correctly. Here it is a question of considering not only the initial investment, but also much more the total costs of ownership, in other words the total cost of the investment over its entire lifespan. Ultimately it is also about the certainty, that the technology is futureproofed, and that there will be no problems with it over the next ten years. Given these preconditions, we were prepared to pay the appropriate price for the MULTIVAC packaging machines. And I am absolutely convinced, that every single rouble was well spent. We also conducted extensive research in the market for packaging machines, during which we spoke to a large number of our Russian and European partners, before we entered into the collaboration with MULTIVAC.

And after one year of cooperation there is presumably no reason to doubt the correctness of your decision?

I can say with complete conviction, that we have found the right partner for long-term collaboration. We are completely satisfied with MULTIVAC in every respect. This means not just price but also servicing and the assistance from MULTIVAC's local specialists.

Whenever the operating data from the machines is assessed, we always receive the technician's recommendations on how the operation of each machine can be optimised. With MULTIVAC, one never buys a "pig in a poke" as the expression goes. I always like to use the opportunity of getting information, for example, about a new model from MULTIVAC on the market. This means I am always kept up to date. Sometimes we can see or even test such models.

And last but not least, it is very important to us that we can order any spare part directly by phone. Spare parts are always delivered to us very quickly and can be fitted on the same day, at or latest, the following morning.

How would you assess the project management by the technical people at MULTIVAC?

I can perhaps best answer that with a typical example. We recently had a project for packing a new sliced vegetable product, and we originally intended to purchase an additional packaging machine. After the specialists at MULTIVAC had examined the User Requirement Specification, they suggested we should retrofit a new die set to the existing thermoforming packaging machine, rather than invest in an additional machine. It is perfectly clear that with such a simple solution we have not only saved money but also been able to use our production

area more effectively. I will leave you to judge whether another supplier would have been able to resist the temptation to sell us an additional machine. This is further proof of the value that MULTIVAC staff attach to the brand and the company, and how they see their relationship with the customer.

We have a motto here that the best partner is the one whom we never ask about the price. And who never asks us when we will pay. The MULTIVAC company has proven to us that it is such a partner. And today when I give my colleagues in the sector advice about packaging technology questions, I always recommend to all of them they opt for MULTIVAC as a supplier. Yes, it is more expensive in the initial investment, but ultimately it pays off, since over the long term many unnecessary problems can be avoided.

TOMRA Food and ICOEL S.r.l. have reached an agreement that positions ICOEL as a TOMRA Food integrated business partner for Europe and our partner in cherry solutions in LATAM. This new working relationship, announced today, will tap into the two businesses’ synergies to strengthen the sales, service and support provided to customers of the TOMRA Fresh Food business area and ICOEL.

TOMRA Food designs and manufactures sensor-based sorting machines and grading and peeling solutions. ICOEL designs and manufactures Fruit handling, processing and packaging equipment, for bin and crate emptying, treatment, manual packing, automatic boxes, bin-filling systems, and bin handling. Machinery from both TOMRA Food and ICOEL is often used by the same processing and packing plants, particularly in Europe.

Paul Slupecki, Head of Global Sales

TOMRA Fresh Food at TOMRA Food, said: “This is all about the customer. Both TOMRA Food and ICOEL have a culture of customer-centricity, and both recognize the opportunity to enhance customer support by working together. Now that ICOEL is a TOMRA integrated business partner, we follow the same processes and share information and resources. Customer sales and service for both companies’ equipment will now come from one source, making customers’ lives easier by providing a ‘one-stop-shop’. This alliance will also give TOMRA Food and ICOEL greater firepower when delivering big projects.”

Bruno Stravato, General Manager at ICOEL, commented: “ICOEL’s solutions integrate with TOMRA’s solutions, and this is significant because many more processing applications are becoming interconnected. Closer integration is something our customers want and

something that will enable us to enhance the quality of the solutions and services we provide. The joint focus of ICOEL and TOMRA will initially be on Europe, especially Italy, Greece, and Turkey, where ICOEL is strong. In the longer term, we expect to expand into other markets around the world.”

Customers using both TOMRA Food and ICOEL equipment will receive one full, integrated service for both brands, whether from a TOMRA engineer or an ICOEL engineer. To facilitate this new arrangement, TOMRA Food is expanding its team and some TOMRA functions are being integrated at ICOEL.

As part of TOMRA Food’s drive to work even more closely with customers, and to deliver solutions that are even more precisely specialized, the sales and service activities of the TOMRA Fresh Food business area are now categoryfocused.

World Food Day is celebrated across the globe on 16 October. This Year World Food Day theme is “Leaves No One Behind” In celebration of World Food Day, Pakistan Dairy Association in collaboration with the National Alliance for Safe Food are conducting a Seminar on Food Safety Matters: Leave No One Behind on 15th October, 2022 Lahore, Pakistan.

Collective action across 150 countries worldwide is what makes World Food Day one of the most celebrated UN days. Hundreds of events and outreach activities bring together governments, businesses, the media, the public, even youth. They promote worldwide awareness and action for those who suffer from hunger and for the need to ensure healthy diets for all, leaving no one behind. Pakistan is one of the fastest growing populations in the world. Fulfillment of nutritional requirements of such a huge population is a challenge in itself. In the 2021 Global Hunger Index, Pakistan ranked 92nd out of the 116 countries. Pakistan is a country with alarmingly high under-nutrition rates. World Food Day is an excellent opportunity to gather around and discuss challenges of food safety and security as well as find solutions to the challenges for a better, healthier future.

The National Alliance for Safe Food (NAFS) is a leading organization and Pakistan’s largest Food Professionals network striving for safe & nutritious food production and consumption for betterment of human society by training and

educating consumers and manufacturers. Annually, NAFS Pakistan celebrates the World Food Day campaign with the support of Development Organizations, Academic Institutes, Food Regulatory Authorities, Chambers of Commerce, Civil Society Organizations and Food Industries. It provides a platform to bring attention to the importance of Dairy industry, business opportunities, nutrition, food safety & human health and sustainable management of food resources.

Pakistan Dairy Association (PDA), is the representative body of forward looking dairy farmers and milk processors of the country. More than 90% of the packaged dairy products sold in Pakistan are produced by PDA members. In addition to delivering safe and healthy dairy products to the consumers, PDA members are the only private sector companies assisting the dairy farmers to improve quality and quantity of milk produced while providing them access to the market through a structured supply chain. Moreover, PDA provides a forum to dairy sector and allied agro fields, professionals as well as farmers, for the determination of knowledge and ideas in Research & Development, production, processing and marketing. It works to establish strong backward & forward linkages amongst the stakeholders in private as well as public sector and livestock farmers.

The aforementioned seminar was be attended by foreign missions of all countries in Lahore, Federal and Provincial

Secretaries, Regulatory Bodies, Food Industry Leaders, Food Regulatory Experts, Prominent Businessmen, Policy makers, INGO’s, Food Professionals and Food & Dairy Industry Service Providers. Furthermore, Seminar will host Guest speakers from various academia & research institutes to discuss the challenges, opportunities and innovations regarding food safety.

The Chief Guest of National Seminar was Sardar Husnain Bahadur Dreshak, Minster Food Punjab and other Guest of Honor, speakers and panelists includes Secretary Livestock Govt of Punjab

Muhammad Malik Bhulla, Dr. Talat Pasha VC University of Education, Farah Naz, Country Director GAIN, Hamed K Latif, CEO TTI Labs, Dr. Shahzad Ameen, CEO Pakistan Dairy Association, Dr. Hafiz

Rehan Nadeem President National Alliance for Safe Food, Mr. Yasin Akhtar Director PSQCA, Mr. Rao Imran Head of Rgulatory/Quality & Innovations Tetra Foods, Mr. Awais Bin Qasim MD

Tetrapack, Mr. Mian Mitha Manager Regulatory Affairs Nestle Pakistan, Dr. Shinawar Waseem Ali Chairman Food Science Department Punjab University and Mr. Awais Ali Vice President National Alliance for Safe Food. The National Seminar will be attended by Head of Food Department from Different Universities, Food Industry Professionals, Senior Food Scientists and Nutrition Experts along with the Civil Society and Media Activist.

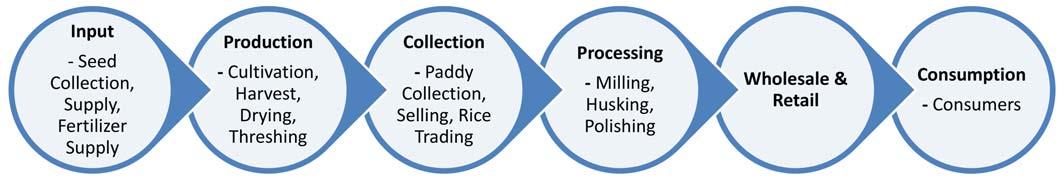

Rice occupies 2.5 million hectare that is 10.9% of the total cultivated area with production of 5.1 million tonnes of milled rice. In Pakistan’s agrarian economy rice plays multifarious roles. Firstly, it is a second staple food and contributes more than 2 million tonnes to our national food requirement.

Secondly, the rice industry is an important source of employment and income for rural people. Thirdly, it contributes to the country’s foreign exchange exchequer. For instance, during 19992000 about 2 million tonnes of rice worth 26 billion rupees was exported.

The barter trade on the Afghanistan border was in addition to this export. The significance of this commodity in our economy is evident from the above facts.

Therefore, it is imperative to focus on the efforts needed to further improve its competitiveness in the international market.

In Pakistan, rice is grown under diverse climatic and edaphic conditions. Basmati predominates in traditional rice.

In Swat (zone 1) at high altitude mountain valleys, temperate Japonica rice is grown. In the South of NWFP, Sindh, and Balochistan (zones 3 and 4) IRRI-type long-grain heat-tolerant tropical kinds of rice are grown.

Pakistan harvested a record rice crop of 8.9 million tonnes in the 2021-22 marketing year, up from 8.4 million tonnes the prior year, according to a Global Agricultural Information Network report from the Foreign Agricultural Service of the US Department of Agriculture (USDA).

“New higher-yielding hybrid rice varieties, improved agronomic practices, and increased planting area, as farmers shift out of cotton, are factors driving the increased production,” the USDA said. The agency noted that the Pakistan government’s policy of ensuring rice growers had adequate inputs also contributed to the record production.

Meanwhile, the country’s rice exports in 2020-21 (November-October) were

stagnant at 3.8 million tonnes, virtually unchanged from the previous year, the report said. Supply chain disruptions, shipping container shortages, and high transportation costs negatively impacted rice exports.

With this year’s record production adding more stocks, the total available supply is estimated to be 11 million tonnes, the USDA said. “Domestic rice consumption is 3.7 million tonnes, leaving an exportable supply of 7.3 million tonnes for 2021-22,” the USDA said. “This large

surplus will provide an opportunity to significantly increase exports, but Pakistani rice will continue to face stiff competition from India and Southeast Asia suppliers.”

Exports of Rice have shown remarkable performance during Q3 FY 2022. An increase in the export of Rice (1006) has been noticed. Pakistan's rice export share in Saudi Arabia and UAE is approximately one-fifth of total Rice export earnings.

The demand for Rice in these countries was mainly for Basmati Rice and very little or no demand for non-Basmati varieties. Pakistan’s main Rice export markets are China, Kenya, United Arab Emirates, Afghanistan, and Saudi Arabia. Pakistan’s non-basmati rice is largely exported to African countries, where it faces competition mainly from India in terms of crop availability and pricing. Basmati exports are still hovering a little over 1 MMT, just over 20 % of the total. In the past year, continuing devaluation of the Pakistani rupee against the dollar has helped Pakistani rice’s competitiveness in world markets. Farmers and SMEs in the sector are eligible to receive government-supported credit programs. In addition, the State Bank of Pakistan (SBP) provides loans to traders under an Export Financing Scheme (EFS). The only other major government involvement in the rice sector is R&D on rice varieties, extension services, and promoting Pakistan-branded basmati in overseas markets. With expectations for a growing exportable surplus, exports in 2022/2023 are projected at 5 MMT. Through the first three months of the 2021/22 local marketing year, the export pace was 13 % above the previous year, and the 2021/22 export forecast has increased to 4.5 million tons.