Autumn 2023

03 Comment

04 Asia: facilitating the transition

Dr Minh Khoi Le, Rystad Energy, discusses the current state of Asia’s hydrogen industry, and sheds light on how the region can implement a successful hydrogen strategy to achieve emissions reduction targets.

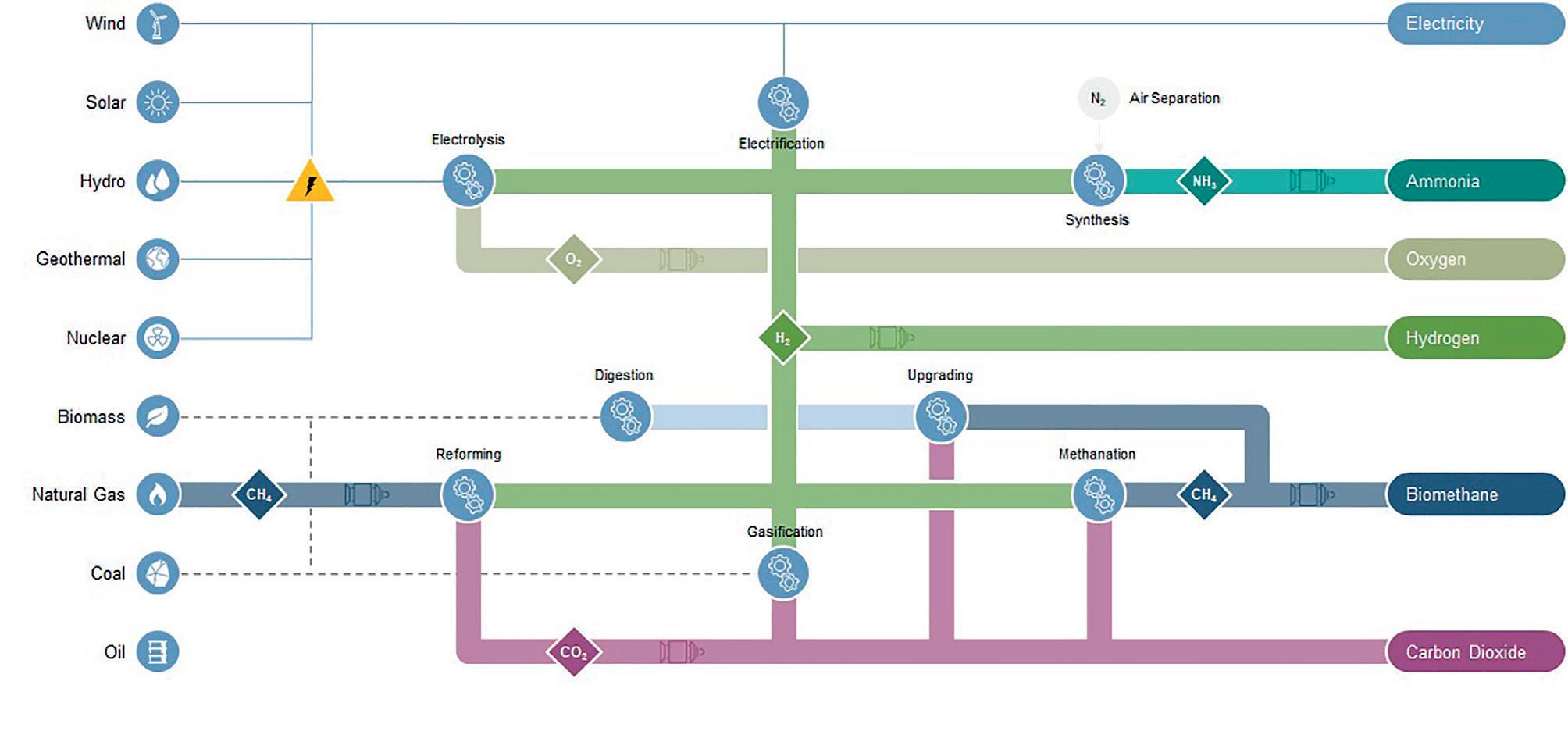

10 Hydrogen decarbonisation: options and considerations

As society heads toward a cleaner energy future, it is essential to build a secure and resilient hydrogen infrastructure. To do so will require taking advantage of the engineering that has been developed for hydrogen reforming processes, as well as the knowledge that exists for hydrogen use, storage and transport. Daniela Ribita, Burns & McDonnell, USA, explains.

18

Unlocking Namibia’s green hydrogen potential

Marco Raffinetti, Hyphen Hydrogen Energy, Namibia, explores how Namibia has the potential to transform Africa’s green hydrogen future.

22 Which route to go down?

Alex Brierley and Lucy Whitford, HYRO, UK, explore different ways to deliver green hydrogen to hard-to-electrify industries in the UK. 25

Keeping electrolysis cool

Evgenij Loginov and Alexander Gernhardt, Kelvion, Germany, analyse the heat exchange options that are available for electrolysis systems used in green hydrogen production.

29 Building a sustainable future for green hydrogen production

Peter Thomsen, Swagelok, Denmark, details how one Danish company is building a high-quality delivery system to make hydrogen the standard for renewable transportation fuels.

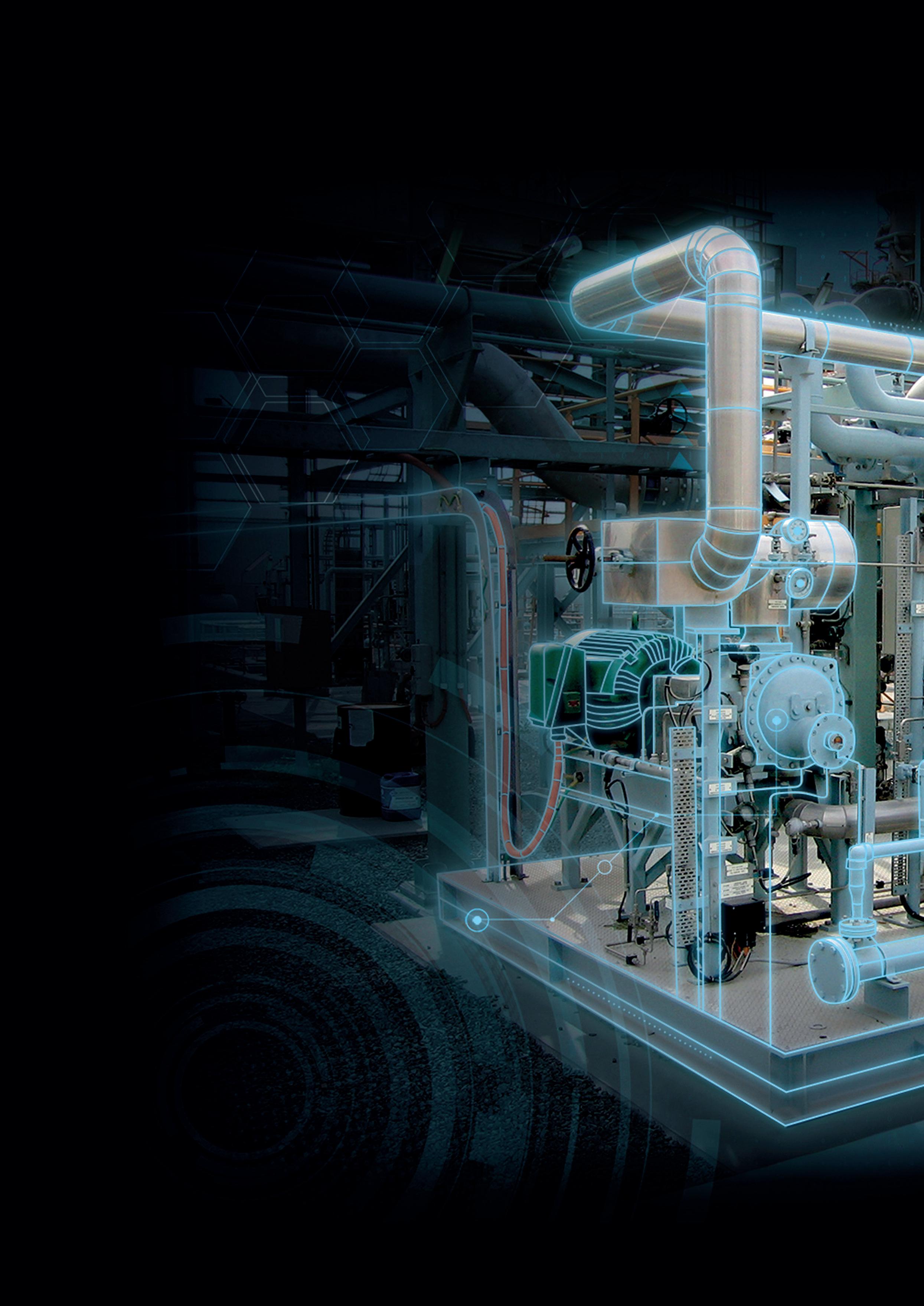

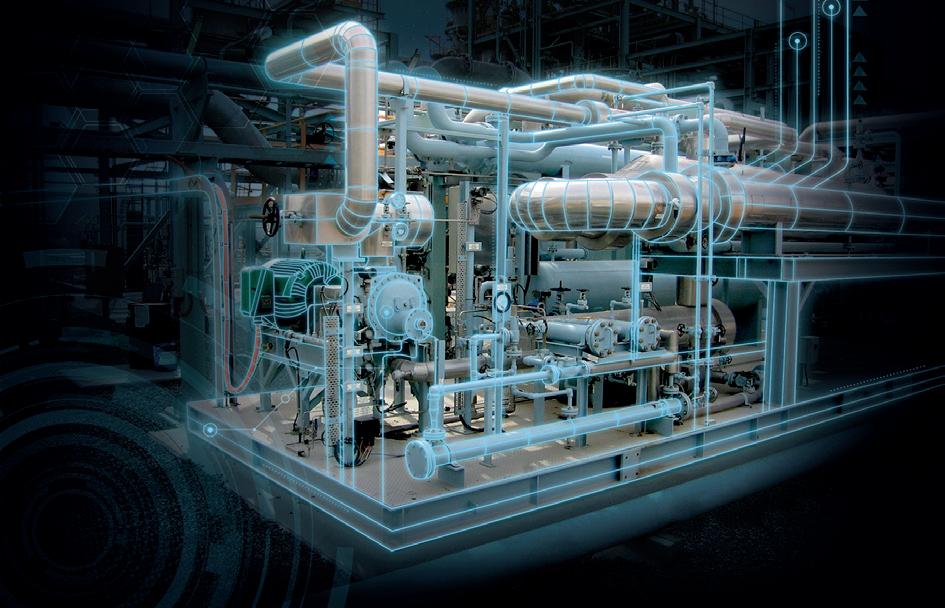

32 Compression to support decarbonisation

Marie-Laure Gelin, Howden, a Chart Industries Company, the Netherlands, explains why compression is such an important process within the hydrogen value chain.

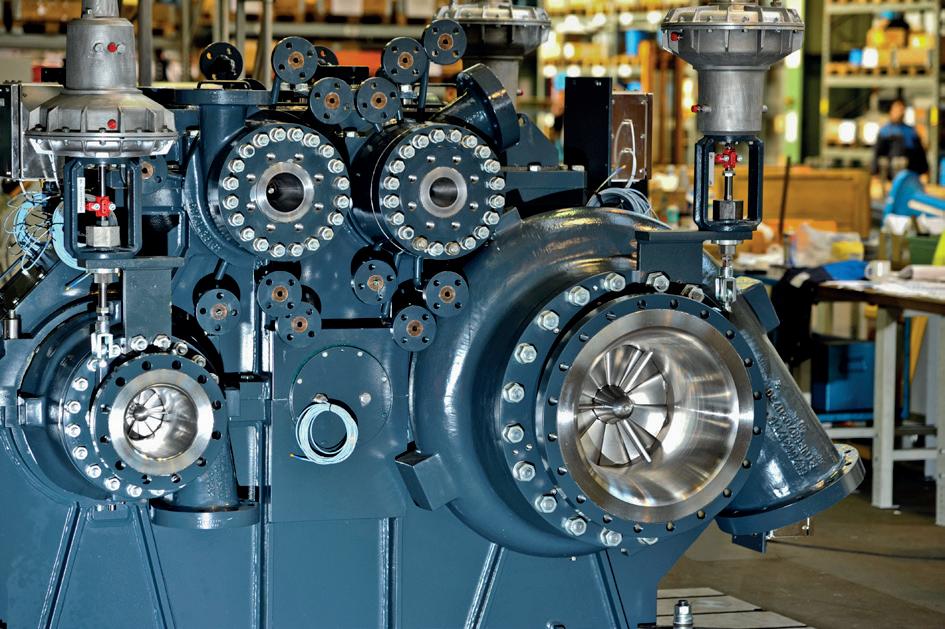

37 Finding the key

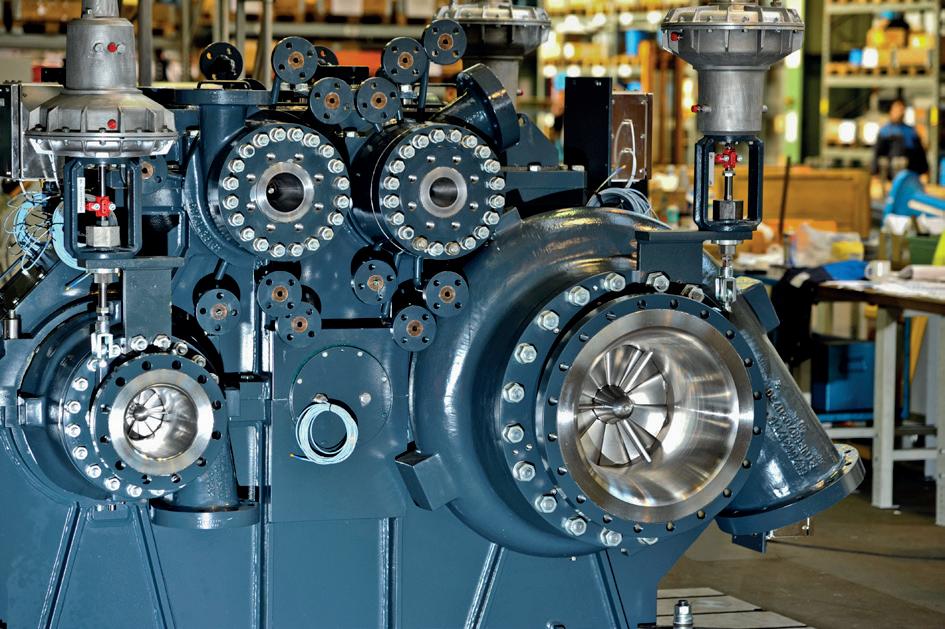

Todd Gibbs, Atlas Copco, USA, explains why centrifugal compressors will be key to developments in the hydrogen industry.

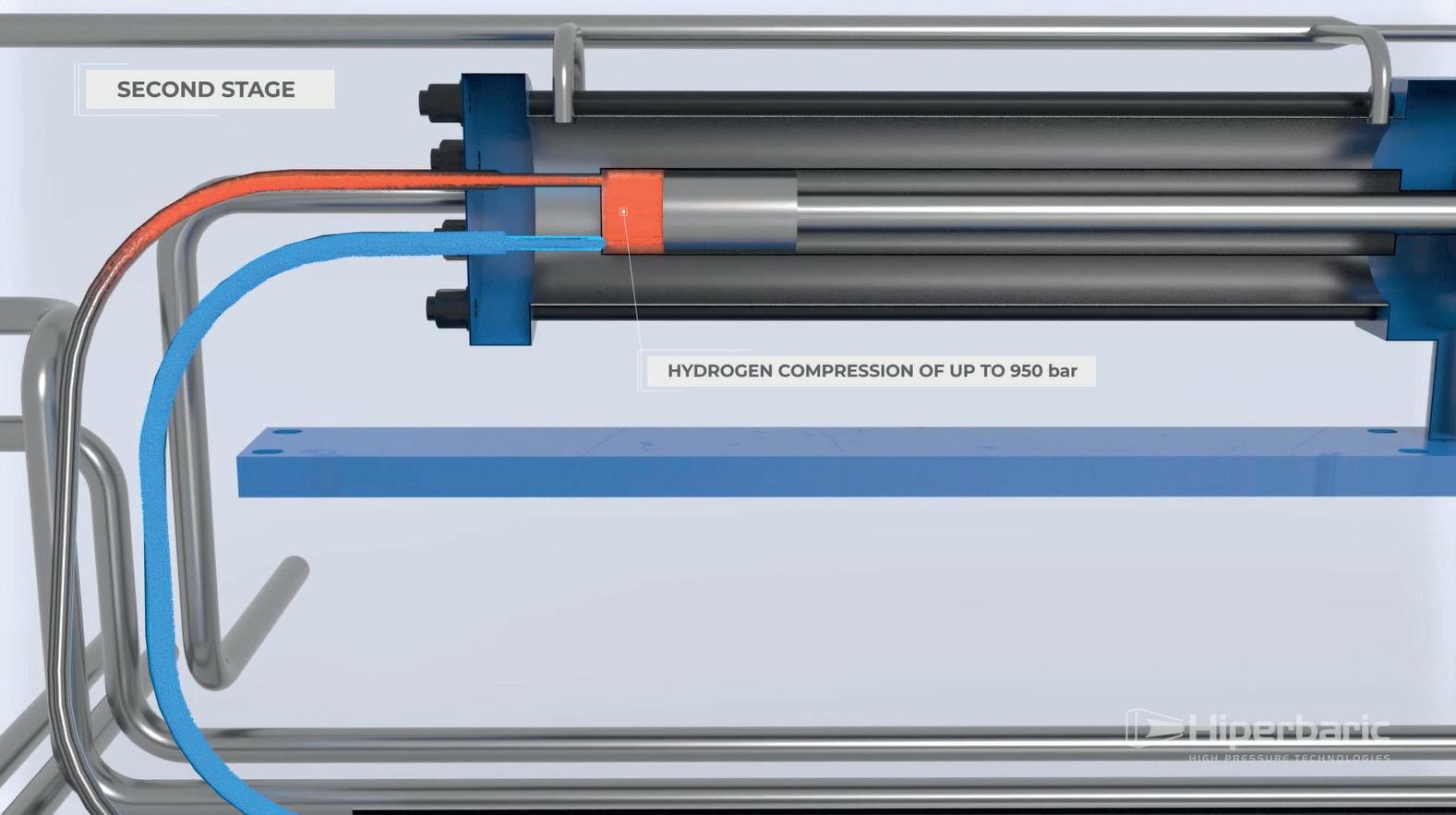

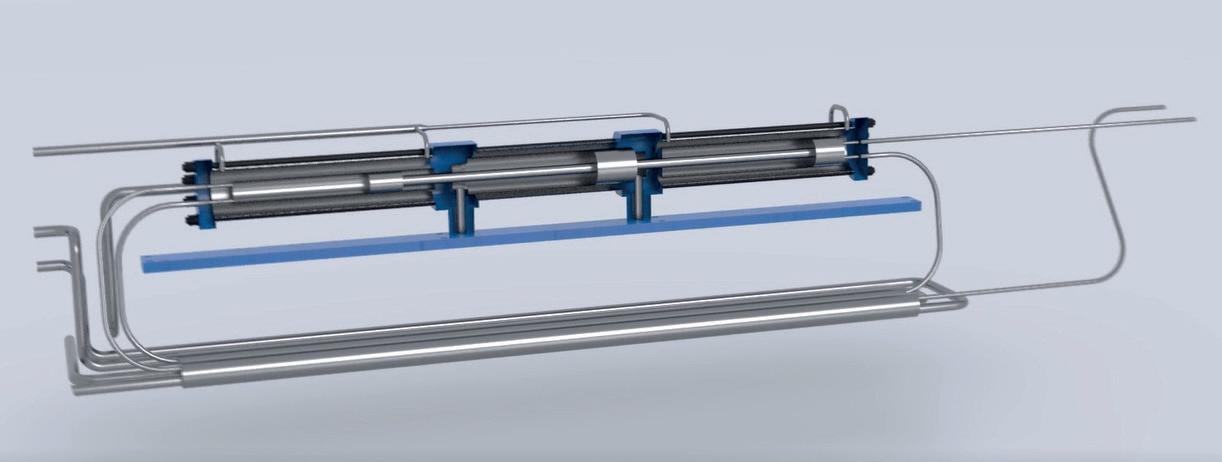

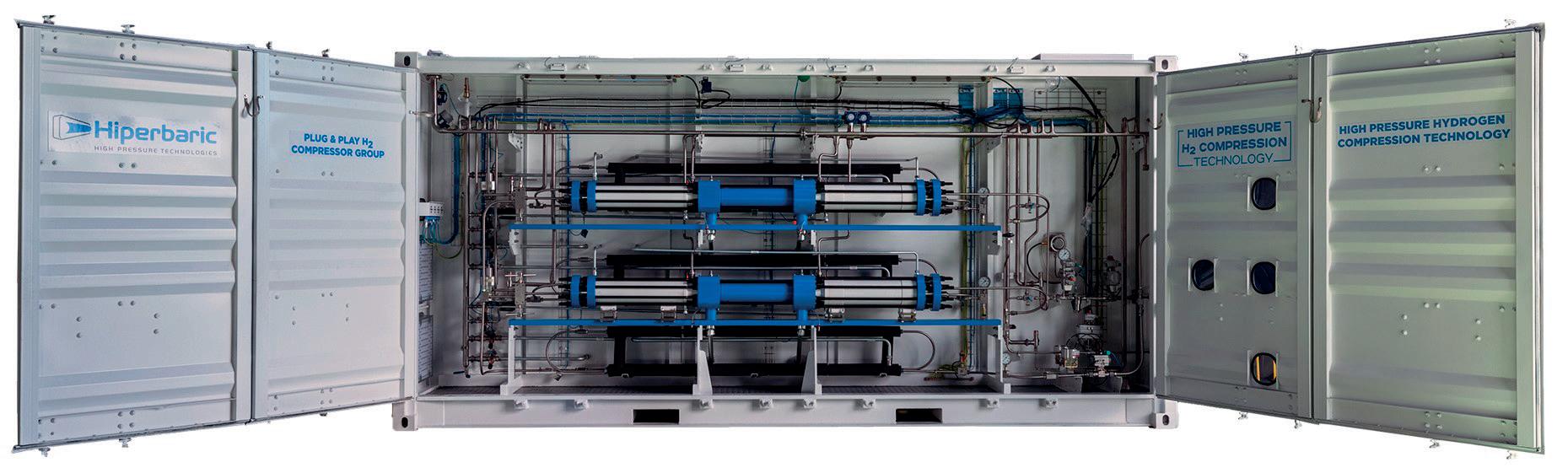

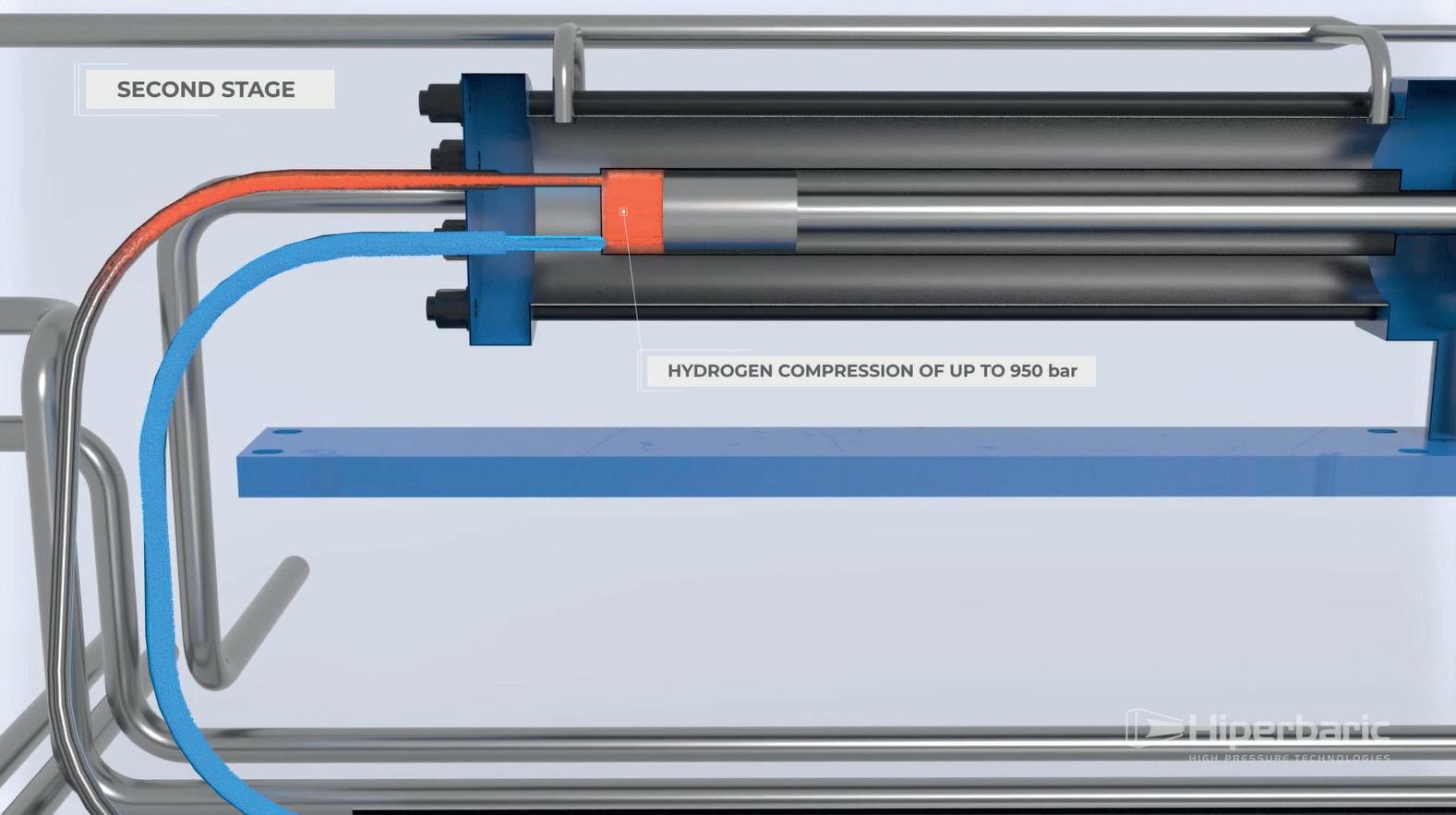

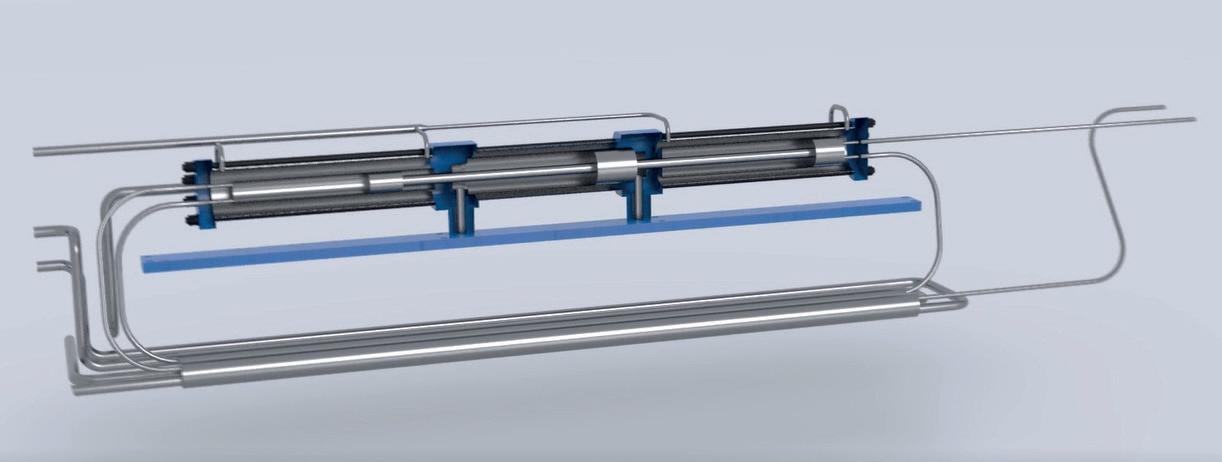

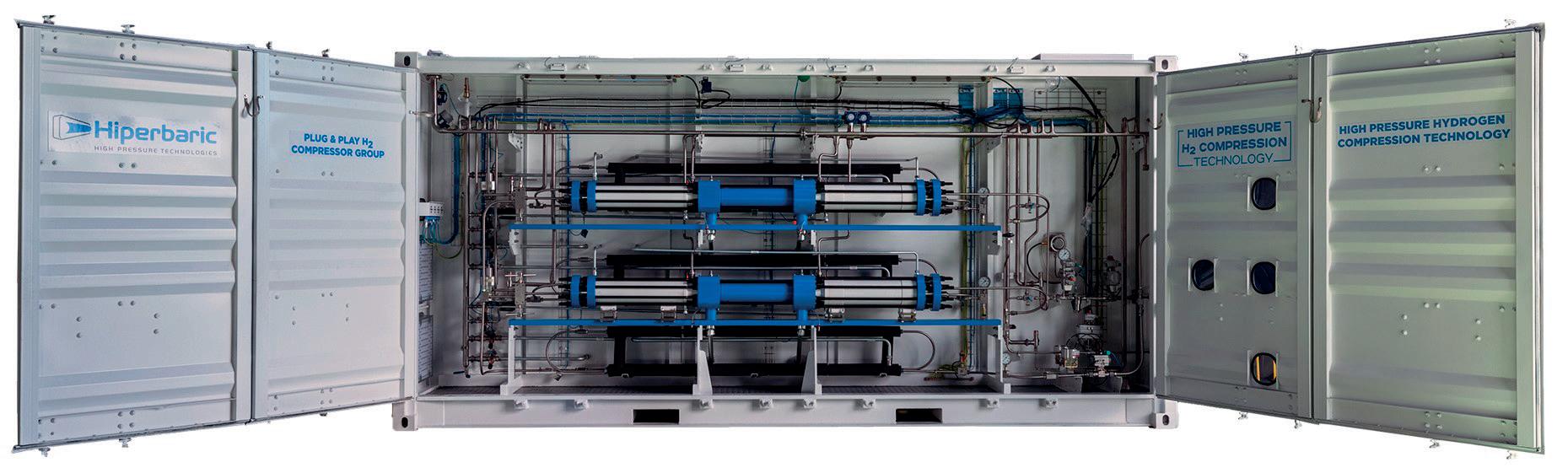

41 High-pressure hydrogen compression

Daniel Ballorca, Hiperbaric, Spain, explains why high-pressure compressed hydrogen is the most efficient way to store energy.

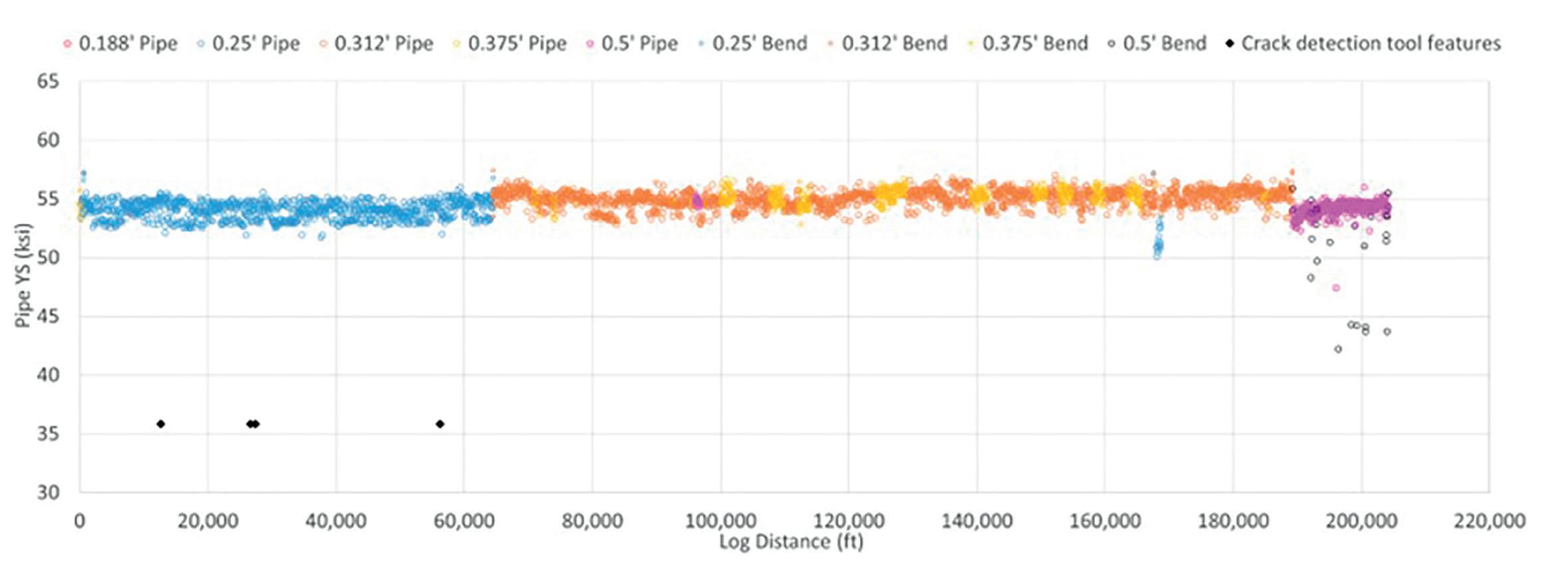

46 Integrity, testing and diagnostics

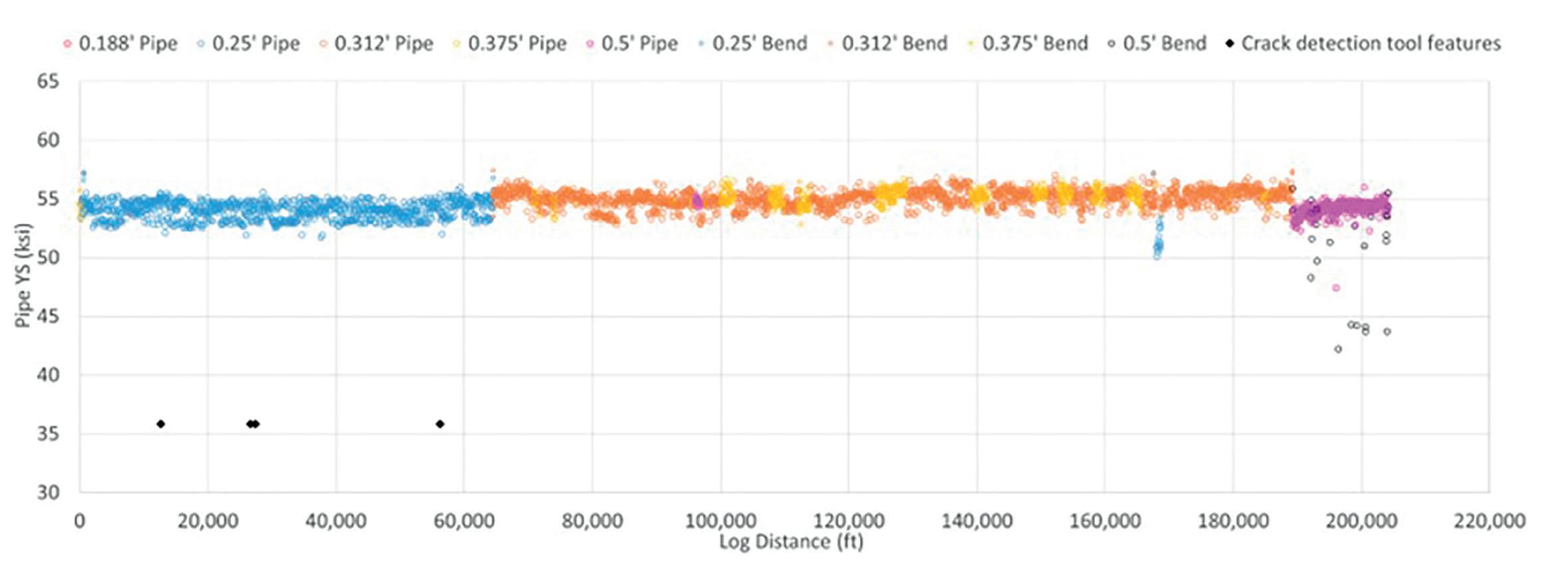

Neil Gallon, ROSEN UK, and Jens Voss, ROSEN Germany, discuss the importance of pipelines in the energy transition, and the management required to ensure their safe operation with hydrogen.

50 Fulfilling potential

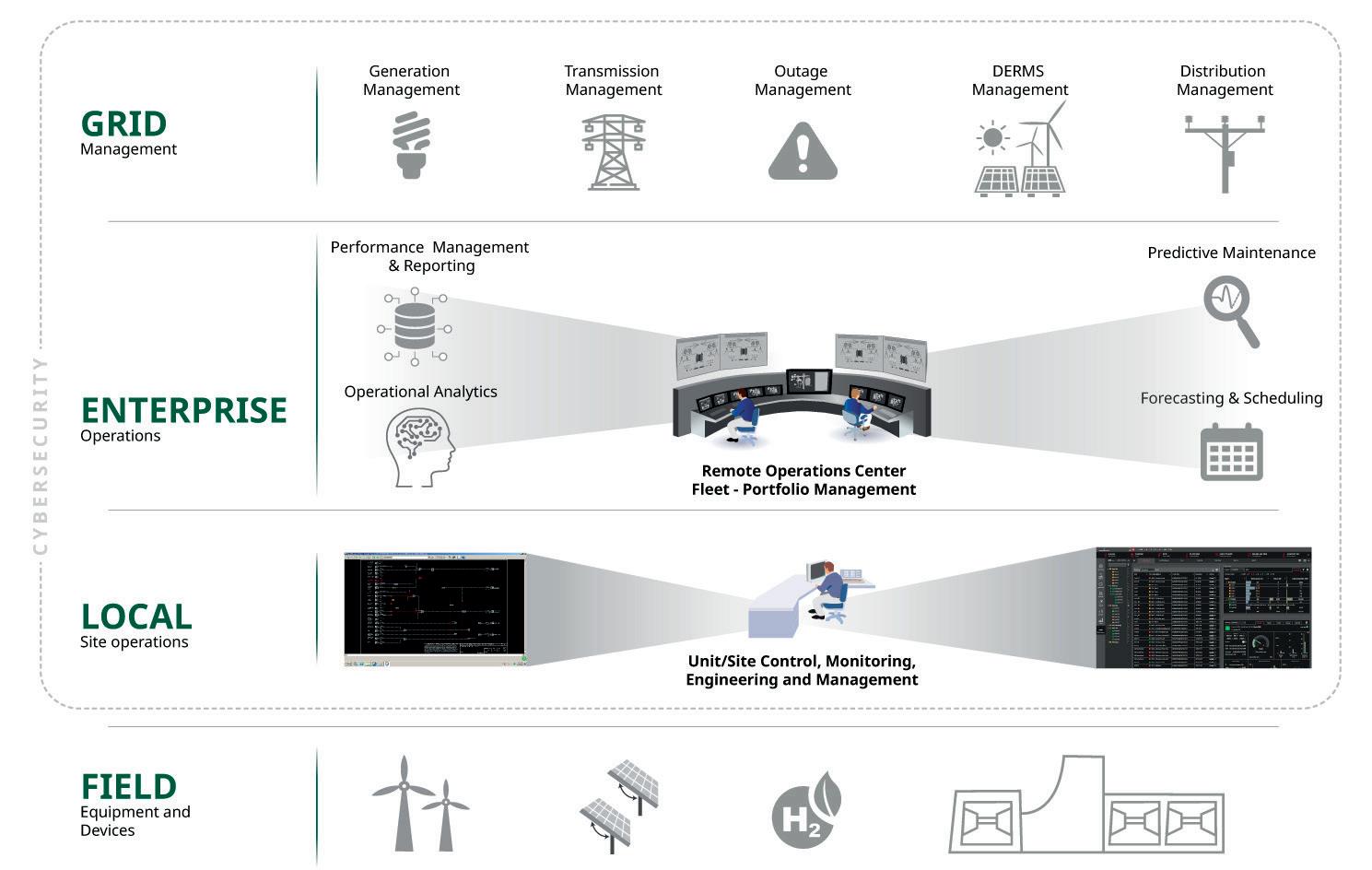

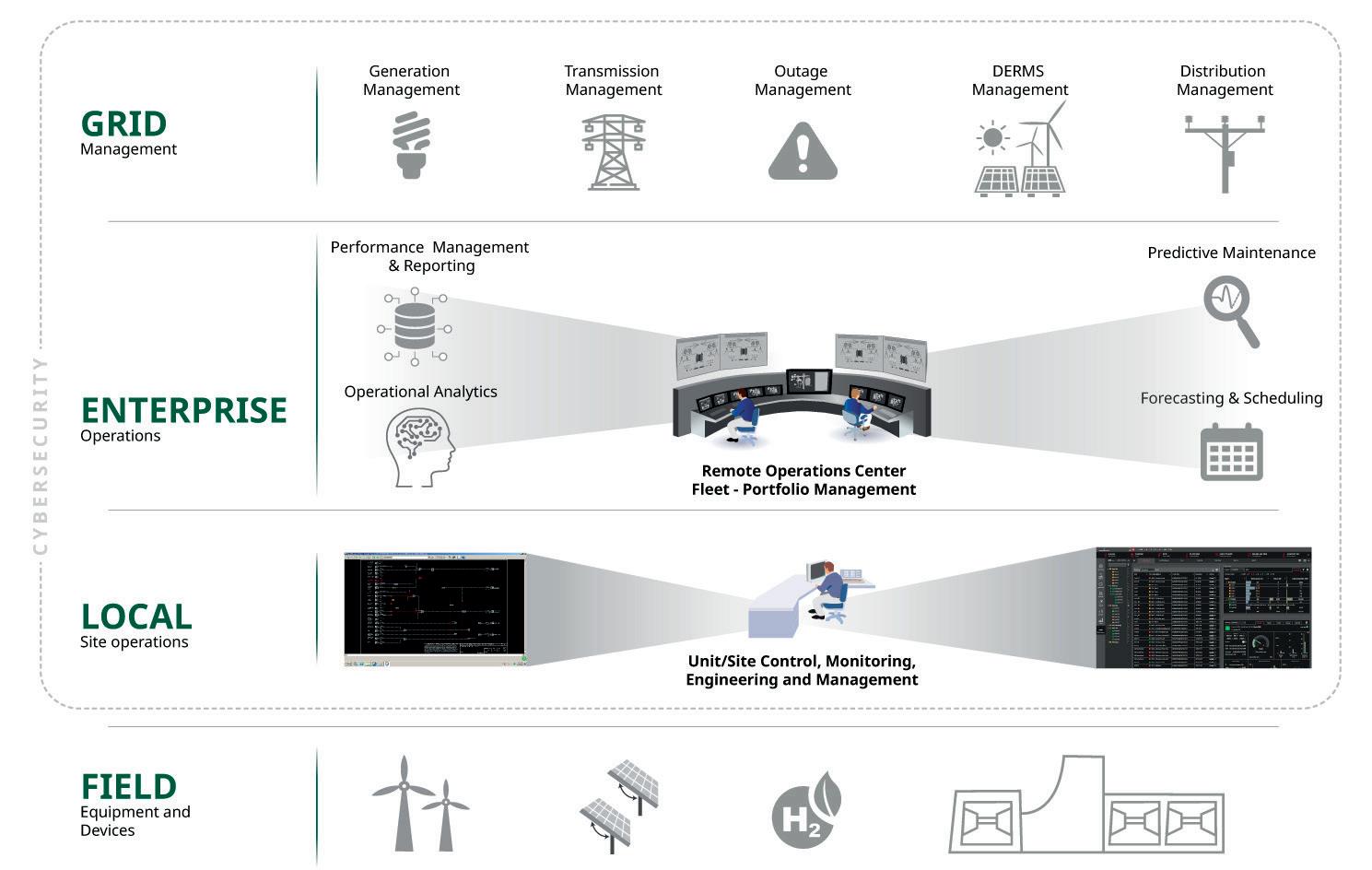

Dr. Sleman Saliba, ABB Energy Industries, Germany, explores how automation technologies can help green hydrogen to fulfil its potential as a driver of decarbonisation.

54 Greener on every side

Successfully navigating the bold adventure of a new green hydrogen value chain means starting with a strategic vision of a unified automation ecosystem. Lauren Wherry, Emerson, USA, discusses how this can be achieved.

60 Accelerating production

Alessandro Piscioneri, Comau, Italy, explores how automation can accelerate the production of emission-free energy for use in mobility applications.

63 Unlocking the economy

Richard Zhang, LIFTE H2, USA, explains why digitisation is key to developing the hydrogen industry.

Achieve net-zero with Mokveld’s Zero emission valve. This Environmentally Sound Technology (EST) reduces power consumption and achieves zero fugitive emissions over the full lifetime of the valve. The internal actuator removes the need for dynamic packing seals, eliminating the main leak path of more common valve designs. ‘Wear and tear’ resulting in increasing emissions to atmosphere are history. Visit mokveld.com/zeroemission for more information.

Copyright©

@HydrogenReview like join Global Hydrogen Review @Hydrogen_Review follow

part

publication

be reproduced, stored

a retrieval system, or transmitted in any form

any means, electronic, mechanical, recording or

prior

of the copyright

All views expressed in this journal

those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements.

Palladian Publications Ltd 2023. All rights reserved. No

of this

may

in

or by

otherwise, without the

permission

owner.

are

This month's front cover

Join the conversation

Autumn 2023

MORE BUSINESS LESS CARBON NATURAL GAS, FUTURE READY.

The case for blue hydrogen is clear.

Topsoe is ready to help you scale up and bring emissions down using natural gas resources.

Take the lowest energy route to ultra-low carbon intensity hydrogen with Topsoe’s industry-leading reforming technologies and integrated carbon capture.

Find out how: topsoe.com/bluehydrogen

Managing Editor James Little james.little@palladianpublications.com

Senior Editor Callum O'Reilly callum.oreilly@palladianpublications.com

Editorial Assistant Poppy Clements poppy.clements@palladianpublications.com

Sales Director Rod Hardy rod.hardy@palladianpublications.com

Sales Manager Chris Atkin chris.atkin@palladianpublications.com

Sales Executive Sophie Birss sophie.birss@palladianpublications.com

Production Manager Kyla Waller kyla.waller@palladianpublications.com

Events Manager Louise Cameron louise.cameron@palladianpublications.com

Digital Events Coordinator Merili Jurivete merili.jurivete@palladianpublications.com

Digital Content Assistant Kristian Ilasko kristian.ilasko@palladianpublications.com

Digital Administrator Leah Jones leah.jones@palladianpublications.com

Admin Manager Laura White laura.white@palladianpublications.com

As I write this comment, the BMW PGA Championship is underway –an annual men’s professional golf tournament on the European Tour. The ‘Festival of Golf’, as it has become known, usually grabs attention as it combines world-class golf with a sprinkle of glitz and glamour. As well as live music, the event includes a Celebrity Pro-Am, where numerous stars from other sports and show business play alongside some of the biggest names in golf. There is extra press attention on the event this year, with the entire European Ryder Cup team competing in the tournament, just weeks before the start of the 44th Ryder Cup.

Global Hydrogen Review has its own reasons for reporting on this year’s Championship: it is the first ever sporting event to have its television production powered entirely by green hydrogen.

European Tour Productions, the DP World Tour’s in-house production company, and its exclusive production and distribution partner, IMG, are working with UK-based clean energy company, GeoPura, to supply two hydrogen-powered generators (HPUs) that will be positioned on the fairway of the sixth hole at Wentworth Club in Surrey, UK. The HPUs work by utilising green hydrogen to generate emission-free electricity, which is being used to power the broadcast compound. GeoPura estimates that relying on HPUs will save a total of 16.4 t of CO2 compared to the 2022 tournament.

What’s more, the golf buggies at the tournament will also be recharged using electricity generated via hydrogen for the first time.

These innovative developments form part of the DP World Tour’s ‘Green Drive’ initiative, which has seen it become the first professional golf tour to commit to being fully net zero carbon by 2040. Richard Bunn, Managing Director of European Tour Productions, has confirmed that the plan is to roll out hydrogen power across multiple tournaments in 2024. He added: “We also want to share what we have learnt with our industry peers, as tackling the climate emergency must be a collective effort.”

And this point is key: knowledge sharing is essential to the future of this burgeoning sector. This issue of Global Hydrogen Review is packed full of interesting case studies and technical articles exploring the technology and solutions that will help green (and blue) hydrogen fulfil its massive potential as a driver of decarbonisation.

Editorial/advertisement offices: Palladian Publications

15 South Street, Farnham, Surrey

GU9 7QU, UK

Tel: +44 (0) 1252 718 999 www.globalhydrogenreview.com

And in the spirit of knowledge sharing, we’d like to invite all of you to join us for the third edition of our Global Hydrogen Conference, taking place on 2 November. This free-to-attend virtual event will include insightful presentations from industry experts including Wood Mackenzie, Baker Hughes, Siemens Industry Inc. and H2scan, covering a wide array of topics such as the long-term outlook for hydrogen, the use of control valves, and how digital transformation is revolutionising the hydrogen sector. You’ll also have the opportunity to pick the brains of our expert speakers during live Q&A sessions, and network with hundreds of industry professionals. Sign up for free by clicking/scanning the QR code.

Callum O'Reilly Senior Editor

Callum O'Reilly Senior Editor

4

Dr Minh Khoi Le, Rystad Energy, discusses the current state of Asia’s hydrogen industry, and sheds light on how the region can implement a successful hydrogen strategy to achieve emissions reduction targets.

Since 2015, a total of 30 Asian countries have published Nationally Determined Contributions (NDC), outlining the way in which they will progressively reduce greenhouse gas (GHG) emissions in accordance with the Paris Agreement in five-year periods. While more than 50% of Asian countries are now targeting net zero emissions and many of them by 2050, the reality is that the region still lags behind others when it comes to actual emission reduction commitments, with just 17 countries enshrining their NDC commitments into law. In turn, this has delayed the implementation of strategic roadmaps outlining the process for reaching emission reduction targets under the NDCs. In terms of economic prosperity, Asia is weaker than Europe and North America, with gross domestic product (GDP) per capita three times lower than in Europe, for example. Many parts of Asia are also still struggling to achieve the energy security needed to meet growing demand.

There is a limit to how much Asia can spend on supporting and incentivising new and often costly decarbonisation technologies. Clean hydrogen, which is widely accepted as a key pillar for the shift to low carbon energy, is one of these. However, whether it is blue hydrogen (fossil fuel-based hydrogen production using carbon capture and storage [CCS]) or green hydrogen (renewable energy from water electrolysis), clean hydrogen commands a premium compared to current fossil fuel-based alternatives. Asia is behind in the development of its hydrogen industry, with just four countries releasing official hydrogen strategies.

Prioritising hydrogen use

Hydrogen can be used as a decarbonisation tool in multiple sectors, from industry and power generation, to transportation and buildings. This flexibility has led to debate on where clean hydrogen use should be prioritised. Regardless, one of the imperative applications of clean hydrogen is to replace the 100 million t of fossil fuel-derived hydrogen that is currently being used in refining and chemical industries globally (mainly ammonia and methanol). Asia is the most exposed continent in this aspect, since it is the number one consumer of hydrogen at around 43 million t currently. Approximately 32% of this is being used in crude oil refineries, with the rest consumed in the form of ammonia and methanol to support fertilizer, chemical and plastics industries. With some of the largest industrial hubs in the world, countries such as India and China are consuming and producing significant amounts of ammonia and methanol. While it is possible that the demand for hydrogen in Asia’s refinery sector will reduce as transportation decarbonises through electrification, the chemical sector will need to adopt the use of cleaner hydrogen if it is to reach its climate goals. This need could propel hydrogen demand to 35 million t by 2050, compared to 29 million t presently. When it comes to producing plastics, China is the world leader and almost the only country using methanol-to-olefins to support demand at around 4 million t of hydrogen. Cleaning up the production of methanol by using clean hydrogen could provide a clear pathway for decarbonising the production of plastics. For now, Asia’s top-five hydrogen consuming countries are China, India, Indonesia, Japan and South Korea, with all but Indonesia having strategies in place to transition to using clean hydrogen.

Demand

Considering other emerging applications of hydrogen, Asia could be looking at hydrogen demand of 210 million t by 2050 if climate goals are to be met and global warming capped below 1.7˚C. The largest share of new demand will come from the steel producing sector, road transport and power generation, with a major contribution also met by demand from marine and aviation industries. China is the world’s largest steel producer, accounting for 54% of global production in 2022. India is also among the top three, producing some 6% of crude

5

steel globally. Through hydrogen, direct reduction of iron (DRI), emissions from steel production can be reduced or removed completely. Top producers such as Baowu and Tata all have indicated they will use hydrogen to decarbonise steel-making using DRI plants. One of the largest DRI plants, at 1 million tpy of DRI, is being built in Guangdong, China, by a subsidiary of Baowu Group.

When it comes to land transport applications for hydrogen, the options are passenger vehicles and heavy-duty transport segments. While electric vehicles (EVs) are emerging as the leading solution for passenger vehicles globally, fuel cell EVs (FCEV) are proving popular in Asia, especially in Japan and South Korea, with the latter dominating FCEV sales globally. South Korea is targeting 3 million FCEVs in use by 2040

compared to the 30 000 registered at present. Regarding heavy-duty transport, lengthy distances in China and India could spur the use of fuel cell trucks. Sinotruck and Weichai have recently reported combined orders for 1100 fuel cell trucks with many additional orders placed elsewhere for this class of vehicle.

Controversies and debates

The most controversial application for hydrogen planned in Asia is in power generation, with Japan announcing a target to use ammonia as a co-fired fuel in coal power plants. After successfully testing the use of ammonia as a fuel to reduce coal use, Japan now sees ammonia as a way to avoid mothballing coal-fired power plants, while also reducing emissions. JERA has issued a tender for 500 000 t of clean ammonia and has been busy establishing Memoranda of Understanding (MoU) globally with the likes of CF Industries and Yara. The plan has received a fair amount of international criticism, due to its costly nature and questionable emissions reduction potential, especially if there are no strict requirements for lifecycle emissions from ammonia, and therefore, hydrogen. Nevertheless, this has not stopped Japanese companies such as IHI and Mitsubishi from promoting the concept in Indonesia, Malaysia, Thailand and India. South Korea has similar plans for ammonia use, with China also testing the technology. With Asia’s power mix still heavily dependent on coal, clean ammonia could help many countries wean themselves off the fuel. Japan may also be looking to begin with ammonia as it works to become Asia’s leader in the global hydrogen economy.

6 Autumn 2023 GlobalHydrogenReview.com

Figure 1. Map showing NDC and hydrogen strategies in Asian countries (source: Rystad Energy climate policy solution).

Figure 2. Hydrogen consumption in Asia towards 1.7 ˚C scenario by sector and country (source: Rystad Energy HydrogenCube).

ACCELERATING BLUE HYDROGEN TOGETHER

The world’s energy systems are changing; and hydrogen is becoming a key part of the future energy mix. With that need for very large volumes of hydrogen on the horizon, Shell Catalysts & Technologies has developed a low cost, high capacity way to match those production needs via the Shell Blue Hydrogen Process. The processes bring together several proven technologies to deliver 500 te/day of hydrogen with >95% CO2 capture rate at the lowest levelized cost. It’s a hydrogen solution designed to help decarbonize hard to abate industries, lower the CO2 footprint of heavy transport, and reduce home heating emissions.

Learn more at http://catalysts.shell.com/bluehydrogen

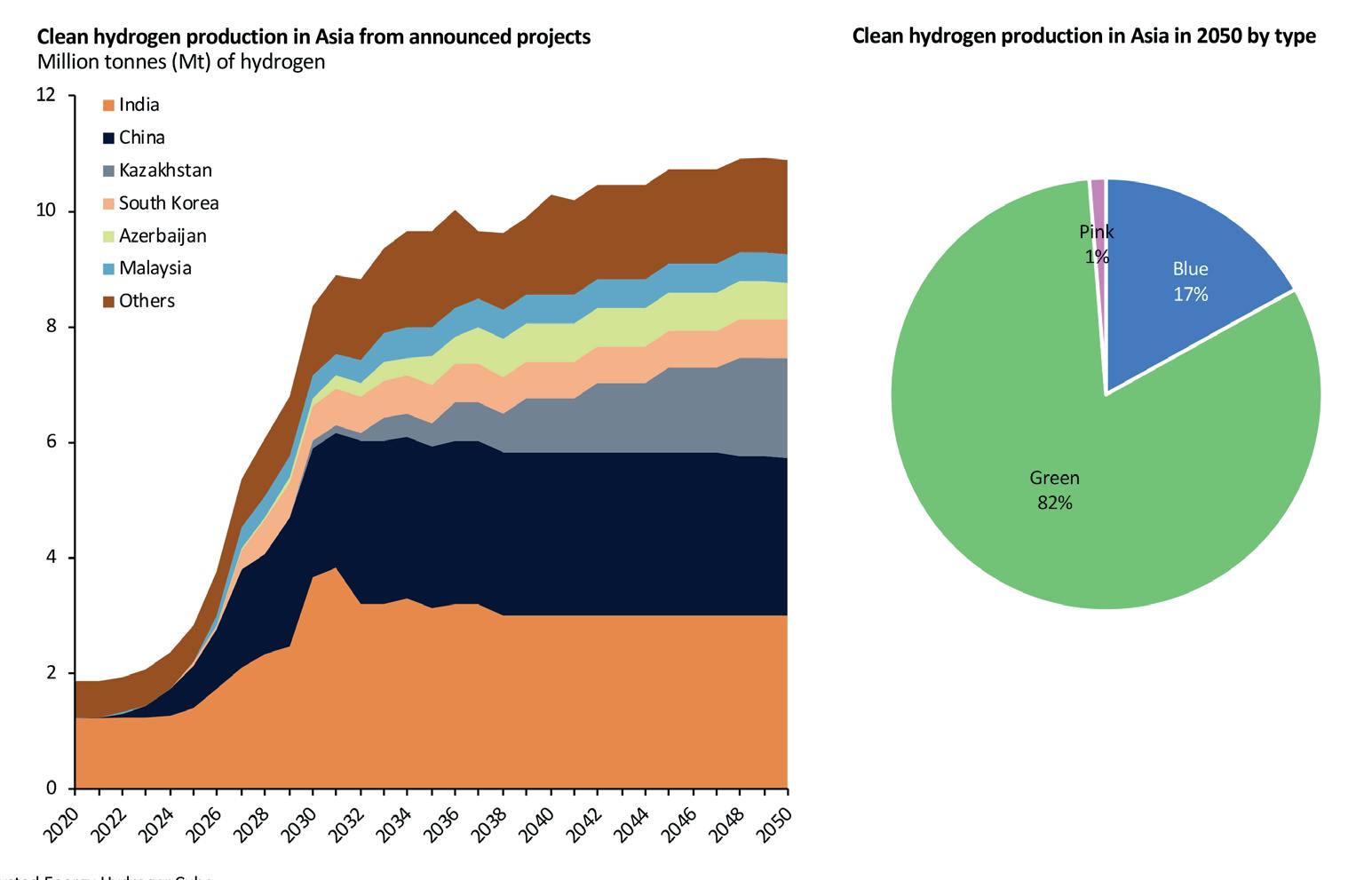

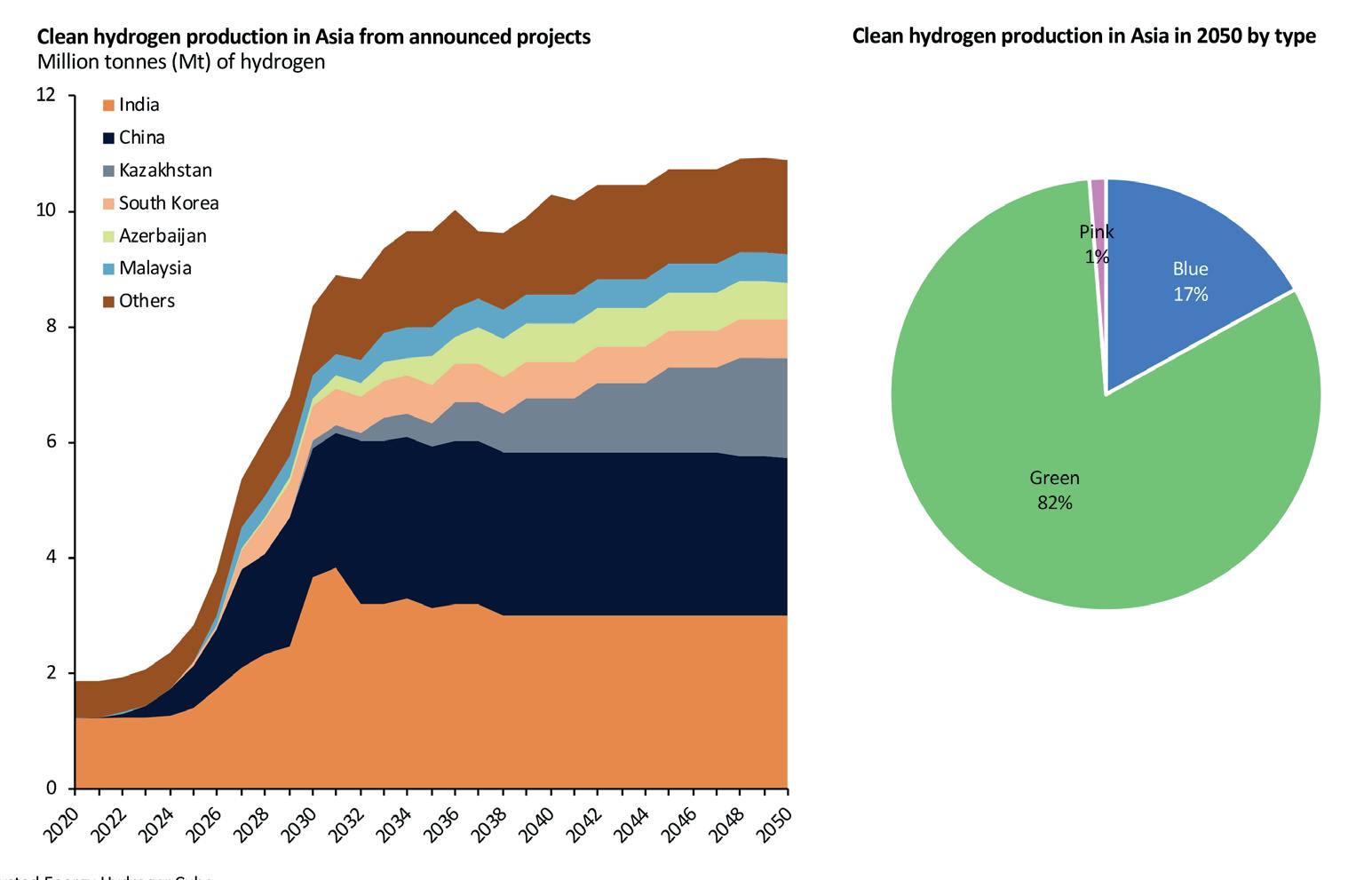

Despite the drawbacks, governmental and corporate commitments on using ammonia is one of the ways to incentivise the development of a hydrogen sector, especially on the supply side. Based on all projects globally that have been announced or have reached a certain level of maturity, Asia presently has just 11 million t of clean hydrogen projects in the pipeline by 2050. That is a far cry from the 210 million t required under Rystad Energy’s 1.7˚C scenario and a quarter of current grey hydrogen consumption in the region. India has the largest share of this supply pipeline and is neck-and-neck with China. India has had somewhat of a head start with the government committing to a target of producing 5 million t of green hydrogen by 2030. China, which is still suffering from fallout from the pandemic, has had a slower start. Rystad Energy expects that both of these countries will add considerably more capacity to their project pipelines, as demonstrated by the construction this year of the world’s largest electrolyser plant in China, the 250 MW Kuqa facility. Central Asia also features in the current project pipeline, thanks to efforts underway in Kazakhstan and Azerbaijan. With good renewables resources and good land availability, projects in these nations involve giga-sized electrolyser developments proposed by foreign entities such as Fortescue Futures Industries, ACWA Power, Masdar and Svevind, with the latter’s 26 GW hydrogen project in Kazakhstan the largest in Central Asia, and in Asia as a whole. Mirroring the global trend, green hydrogen dominates the outlook for clean hydrogen production in Asia, accounting for 81.8% of the project pipeline by 2050. The remainder comprises mostly blue hydrogen, though pink hydrogen from nuclear power also features, with Indonesia and South Korea leading in this respect. With South Korea considering building more nuclear power generation capacity, green hydrogen could be produced from this zero-carbon power source as well as conventional renewable energy.

Fulfilling potential

Considering the potential for renewable energy growth, China and India could likely meet much of their own hydrogen needs for decarbonisation. In other Asian countries, the situation is a little different. Japan and South Korea, which both have limited capability to build out renewables at the required pace, will look to be net importers of hydrogen, just as they are for other fossil fuels. Southeast Asian countries are likely to emerge as a mix of importers and exporters. Singapore will be a hydrogen importer due to its demand for power and bunkering for marine fuels, with Thailand and Indonesia also likely to become importers. In this respect, many Asian nations will need to look outwards for inexpensive green hydrogen sources, hence why MoUs are being signed with Australia and Africa (Namibia) to name a few.

Regardless, governments in Asia must reconcile their need for clean hydrogen with its expense at a time when energy security remains a pressing issue. Efforts and incentives to close the future hydrogen supply and demand gap are emerging. A green hydrogen tender by Solar Energy Corp. of India (SECI) has been issued, with the Singapore government calling for expressions of interest for hydrogen-powered generation and bunkering solutions. Japan proposed a contract-for-difference (CfD) incentive mechanism in its recently updated hydrogen strategies. Mirroring their supermajor counterparts, state-owned national oil companies such as Sinopec, Petronas, PTT and Pertamina, have also started to invest in hydrogen projects in the region.

One thing that Asia can bank on for hydrogen is its expertise in creating supply chains. The ability to scale up quickly and provide cost-competitive options compared to Western counterparts will continue to play a key role here, just as it has in the solar industry. China has been one of the largest producers of alkaline electrolysers for some time, with solar giants such as Longi and Sungrow now entering the global market. Multiple manufacturing plans have also been pushed in India, many of them backed by industrial giants such as Adani, Reliance or Larsen and Toubro, as the nation looks to compete with China from the concept stage, learning lessons from developing a solar supply chain. In China, major initial government incentives such as feed-in-tariffs have been used to create a successful domestic solar industry, an approach also likely to be used in developing a hydrogen industry.

8 Autumn 2023 GlobalHydrogenReview.com

Figure 3. Clean hydrogen production in Asia by country and type by 2050 (source: Rystad Energy HydrogenCube).

Invisible. Invaluable.

You can’t see hydrogen, a zero-carbon fuel that perfectly complements— and even accelerates–the integration of renewable energy sources for ammonia producers. But the impact of this essential element creates an invaluable path forward towards decarbonization, supporting expansion and energy transition for multiple energy consumers, including maritime, industrial, and power generation facilities.

Black & Veatch delivers on:

• Safe, reliable, and informed innovation across the hydrogen value chain

• Solutions across green hydrogen for power generation and storage, as well as the processing of blue hydrogen with carbon capture technology

• Diversity of experience and depth of knowledge, offering practical insight and access to the right resources at the right time

Let’s find ways to help you.

As society heads toward a cleaner energy future, it is essential to build a secure and resilient hydrogen infrastructure. To do so will require taking advantage of the engineering that has been developed for hydrogen reforming processes, as well as the knowledge that exists for hydrogen use, storage and transport.

Daniela Ribita, Burns & McDonnell, USA, explains.

10

Throughout the 20th century, hydrogen production has been used at sites for refining; fertilizer production; glass purification; ammonia and biofuels; fuel cells; and rocket fuel. Low-carbon hydrogen production will play an important role in the future energy market, due to its high energy density and clean burning fuel properties. Sustainable and low-carbon hydrogen production will likely satisfy versatile markets across the sectors of shipping, transport, heavy industries, chemicals, and sustainable aviation fuel (SAF), according to the US Department of Energy (DOE)’s National Clean Hydrogen Road Map, released in June 2023.¹ The challenges that come with large-scale hydrogen production, storage and distribution can be overcome to create a safe and resilient hydrogen market that plays an important role in advancing the future of energy.

There are four hydrogen synthesis pathways: reforming, electrolysis, gasification and pyrolysis. All methods are critical for reaching long-term hydrogen production goals, and offer opportunities for efficient and sustainable processes, such as biomass gasification and solar- wind- and nuclear-powered electrolysis. This article will focus on the opportunities and challenges that come along with using the most common hydrogen production method: reforming.

For existing reforming production sites, installing carbon capture, utilisation and storage (CCUS) is the leading market decarbonisation solution. The firms that are exploring greenfield hydrogen reforming sites have a considerable set of parameters to balance for a successful economic and environmental model, such as: hydrogen production plant design (including utilities, power and plot space), CCUS, hydrogen end users, delivery form (gaseous vs liquid), geographical location, and overall life cycle analysis (LCA).

The two main reforming methods are steam methane reforming (SMR) and autothermal reforming (ATR). Both use hydrocarbon gas and produce syngas that is rich in hydrogen and carbon monoxide (CO), with carbon dioxide (CO2) as a byproduct. The typical source of hydrocarbon gas is methane-rich natural gas and/or biogas. The reforming process converts at least 80% of methane to hydrogen.

The produced syngas is processed to purify hydrogen, typically via pressure swing adsorption (PSA), to levels that meet downstream sector needs – as high as 99.999%. Purified gaseous hydrogen user pathways

11

sometimes include manufacturing new products at hydrogen production sites. Certain hydrogen-based products, such as ammonia and methanol, can be used as liquid organic hydrogen carriers (LOHC) for transport via existing pipeline infrastructures. The use of LOHCs is being explored as a solution to overcome the challenges of large-scale hydrogen storage and transportation, such as leaks, steel embrittlement and initial CAPEX for new pipelines.

Pure hydrogen storage and transportation options for offsite use are contingent on gaseous hydrogen or liquid hydrogen. Once purified, the hydrogen can be kept in a gaseous form and compressed to high pressures of 750 – 1000 barg for specialised tube storage and transport, or liquefied to -420°F via two-stage cold box technology for specialised truck tanker transport. The gaseous hydrogen storage and transport for large-scale production is cost prohibitive because of the small volume of storage and transport hydrogen tubes. Liquid hydrogen provides more storage capacity and transport per unit of volume, although the large-scale liquefying methods are more energy-intensive and still developing.

Storage and transport costs along with greenhouse gas (GHG) cradle-to-grave impact are important parameters to consider when selecting the hydrogen production site. Proximity to end user opportunities should be thoroughly considered. For example, as hydrogen fuel stations grow beyond the market in California, US, companies may benefit from more location flexibility. The National Renewable Energy Laboratory has developed a projected hydrogen fuelling stations US map.²

In addition to pure hydrogen processing, transport and end user options, key economic and GHG opportunities exist within the hydrogen reforming process. To better understand reforming decarbonisation, the next section of this article will look at the chemistry of SMR and ATR.

SMR

In an SMR, natural gas is mixed with steam to produce hydrogen via two main reactions. First, the hydrocarbons are converted to syngas of mainly hydrogen and CO via the following endothermic SMR reaction:

CH4+ H2O ⇄ CO + 3H2 [ΔH˚ rxn = 206 kJ/mol] (1)

The secondary slightly exothermic reaction, water gas shift (WGS), promotes additional hydrogen production by combining the CO in syngas with more steam. CO2 is a byproduct of this reaction:

CO + H2O ⇄ H2 + CO2 [ΔH˚ rxn = -41 kJ/mol] (2)

Both equations’ equilibrium is favoured under excess steam, which is typically fed in a steam-to-carbon molar ratio of 2.5:1 – 3:1. Heat integration is a key economic process variable that can be controlled by minimising steam/condensate export requirements. Any unintegrated produced high-pressure saturated steam could be used within other facility units or exported offsite.

Overall, hydrogen production via SMR is highly endothermic and a large amount of heat is required to keep the reaction at a constant optimal temperature of about 800°C. The energy is supplied via natural gas and PSA tail gas to fire the reformer burners. While the flue gas from firing is released to the atmosphere, environmental regulations dictate allowable NO x levels due to its potency as a GHG (298 CO 2 e) and its role as a smog precursor. Low-NO x burners, coupled with ammonia or urea-based selective catalyst recovery (SCR), are systems used to mitigate NO x emissions.

ATR

The ATR converts natural gas into hydrogen-rich syngas via three reactions, two of which are the same as SMR. After the contaminants in the natural gas stream are removed similarly to SMR, the feed gas is mixed with oxygen and partially oxidised via an exothermic reaction:

CH4 + 1/2O2 ⇄ CO + 2H2 [ΔH˚ rxn = -36 kJ/mol] (3)

The partial oxidation reaction heat is used to drive the reformer reaction. Unlike the SMR, no natural gas/fuel gas is required in the ATR to support the endothermic reformer reaction because the heat generation reaction occurs in tandem with the reforming reaction. Fuel gas may be required in the fired heater upstream of the ATR for pre-reforming, but in smaller amounts compared to SMR reformer requirements. The oxygen source for the partial

12 Autumn 2023 GlobalHydrogenReview.com

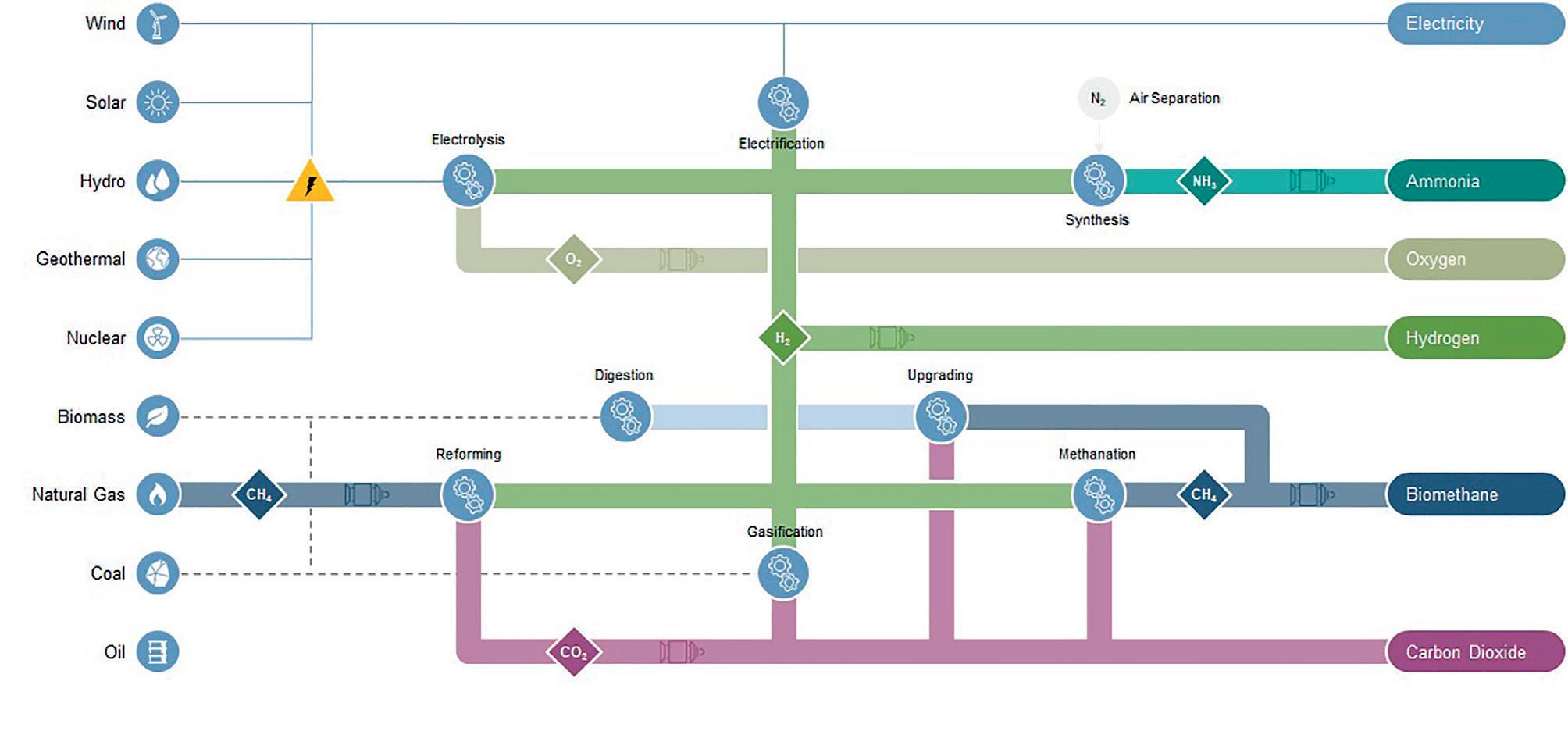

Figure 1. Reforming hydrogen production options and potential pathways for transportation.

Go Hydrogen.

Emerson’s precision, high-pressure Coriolis dispensing solutions reduce safety concerns without compromising capacity. Harness the power of alternative fuels to drive efficiency as you take your business to new distances.

Learn more at www.emerson.com/micromotionhighpressure

oxidation reaction can be an over-the-fence supply or from a dedicated air separation unit (ASU) onsite. Oxygen delivery could pose a significant economic and power impact on overall hydrogen production.

ATR efficiency and reaction equilibrium is highly dependent on the following two ratios: oxygen-to-carbon (typical = 0.6:1) and steam-to-carbon (typical = 0.5:1.5).

SMR and ATR comparison parameters

The economic and energy equilibrium between the SMR and ATR methods are intertwined and prone to discussion as companies attempt to balance out the benefits. The following section will discuss the main parameters of interest that can tip the scale. Typical comparison parameters are presented in Table 1.

There is general excitement about the ATR method due to the exothermic reaction heat that aids in the overall reforming process and mitigates CO 2 emissions related to atmospheric combustion. The ATR reaction requires less excess steam yet needs oxygen to run the exothermic reaction. Overall, the ATR method is expected to require approximately 10% less natural gas feed compared to SMR, thus assuming the potential of higher SMR operating costs.

On the other hand, the operation of an ASU incurs additional power and utility consumption and a potential waste of unused nitrogen byproduct. A theoretic economic break point is being explored in the industry where the ASU additional utility, power and economic incurrence no longer has a significant impact, when compared to the SMR technology. Ultimately, each facility will need to investigate options specific to the site, as particular production scale and site variables, including end user options, are typically in play to decide the production method for a specific project.

Carbon capture and its sequestration or use options are key considerations when looking at long-term sustainability goals as well as specific project goals for blue hydrogen. These considerations could also tip the scales when selecting the reforming technology, especially from a GHG perspective.

Blue hydrogen carbon capture

In blue hydrogen production, both the SMR and ATR are engineered to accommodate a carbon capture unit to meet net zero goals and reach carbon intensity (CI) scores that can reap the benefits of the carbon tax incentives provided under section 45Q of the 2022 Inflation Reduction Act (IRA). The typical carbon capture method in reforming is pre-combustion, downstream of the WGS reaction. Pre-combustion is expected to have a CO 2 recovery rate of 95% for ATR and about 60% for SMR.

Consideration to post-combustion methods could be given in an SMR plant where additional carbon can be captured off the reformer burner flue gas; however, this additional process will impact the economics/CI balance.

Pre-combustion carbon capture at a plant is expected to be performed via an adsorption or cryogenic unit. The carbon capture technology selection has another subset of parameters that can impact the plant’s economics. One such parameter is the use of either water or air cooling. The selection would result in either more utility water demands or higher initial capital costs, in the case of air coolers. The decision would be unique to site location (cold vs warmer climates, and proximity to existing utility infrastructure).

CO

sequestration or utilisation

2

CCUS is a complex subject that should be evaluated as part of the reforming-based hydrogen synthesis for technical, geological and regulatory considerations. The tax credit incentive under the IRA varies based on the carbon capture method and how the captured carbon is further processed: sequestration, or third party use. When selecting a new site, there could be benefits for locating within proximity of a facility that can use the CO 2 , such as a bottling or frozen food company, fertilizer plant, plastics synthesis site, CO 2 cement fixing, or methanol manufacturing facility.

If proximity to a CO 2 user is not an option, then the project owner needs to consider geologic or biologic sequestration. Biologic sequestration, such as offsetting, is a partial solution that many companies use to balance atmospheric CO 2 emissions. Underground geologic sequestration is the typical selected method that can handle large quantities of CO 2 and there are ongoing geological studies worldwide designed to analyse a multitude of potential deep sequestration locations.

Conclusion

It is an exciting time to be in the oil, gas and chemical industry as new and evolving technologies, processes and uses for hydrogen take shape on the way to a cleaner energy future. Entities interested in embarking on hydrogen and CCUS projects will face many challenges, but will find the process less frustrating and more efficient when working with knowledgeable partners who can help to successfully handle such multifaceted ventures.

1. https://www.hydrogen.energy.gov/pdfs/us-national-cleanhydrogen-strategy-roadmap.pdf

2. https://www.nrel.gov/gis/assets/images/map_hydrogen_fueling_ stations.jpg

14 Autumn 2023 GlobalHydrogenReview.com

References

Property SMR ATR Reaction type Endothermic Exothermic Steam to carbon molar ratio 2.5:1 – 3:1 0.5:1 – 1.5:1 Oxygen to carbon molar ratio N/A 0.6:1 – 1.0:1 Heat integration Capable Capable Natural gas feed Base 10% less ASU N/A Additional CAPEX (plot, equipment)/ OPEX (power, utilities) Carbon capture 60% without post-combustion capture 95%

Table 1. SMR/ATR comparison parameters

We understand how you need to reduce complexities at your plant.

CLEAN PROCESS + CLEAR PROGRESS

You strengthen your plant’s safety, productivity and availability with innovations and resources.

Endress+Hauser helps you to improve your processes:

• With the largest portfolio of safety instruments that comply with international regulations

• With applied technologies and people who have extensive industry application know-how

• With access to accurate and traceable information

Do you want to learn more?

www.endress.com/oil-gas

Protective Coating Solutions for the Emerging Hydrogen Economy

While the properties of hydrocarbons are well understood, and have a long history of industrial use, the hydrogen economy is still in its infancy. Reliable design and directoperational experience are still limited, so new standards and proven technologies that can address these unique hazards are required.

PPG’s global capabilities and respected protective coating range enable us to provide coating solutions for the clean energy segment. We offer a complete coating portfolio for corrosion protection, chemical resistance, and passive fire protections (PFP) for hydrocarbon and hydrogen (H2) facilities.

For H2 facilities utilizing steam methane reformer (SMR) process units, PPG coating solutions address H2 environments with a full product offering, including globally recognized brands such as PPG SIGMAZINC™, PPG SIGMAFAST™, PPG SIGMADUR™, PPG NOVAGUARD™, PPG HI-TEMP™ and PPG PITT-CHAR™. Please contact your PPG representative for guidance and product selection.

Since its introduction in 2019, the PPG PITT-CHAR NX coating has established itself as a leading passive fire protective (PFP) coating for many major LNG projects. Commonly referred to as the transition energy source, LNG is expected to remain as the primary low carbon hydrocarbon source and economically preferred option when combined with carbon capture systems.

As with hydrocarbon fuels, there is potential for jet fires to occur in H2 facilities, which will require the protection of critical structures and equipment using PFP coatings. H2 fires are expected to burn hotter and, due to the higher volumetric outflow, can burn much faster than most hydrocarbons currently in use.

To further strengthen PPG’s position as a coating solution leader, PPG identified the need to generate baseline performance in H2 fire environments using its PPG PITTCHAR NX PFP coating. The data will improve the industry’s understanding of H2 fire impact on PFP with the common goal of improving H2 fire safety standards, which will provide safety engineers with a reference point for future specifications.

A H2 fire hazard differs depending on the form in which it is being handled, with the most common forms being cryogenic liquid, cryo-compressed (CcH2), Hydrogen/ Natural Gas blends (typically up to 25% H2) and very highpressure storage in cylinders at pressures of 350 to 700 bar (5,000 to 10,000 psi) with the latter being preferred for a range of applications from fuel-cell vehicles to power for data centers.

The fires from leaks at very high pressure are of particular interest as they may be extremely erosive and little, or no, research had been carried out on their effects on PFP material.

PPG

Hydrogen (H2) is one of a few low carbon energy sources recognized as reaching established net-zero goals. Consequently, it continues to attract strong interest. Even if partially realized, the hydrogen economy equates to a greater number of hydrogen production and handling facilities.

PPG commissioned a third-party test facility to undertake hydrogen jet fire testing using their High-Pressure Hydrogen Release (HPHR) facility.

The hydrogen jet fire tests performed were intended to replicate the thermal and erosive effects from a leakage at very high pressure that could impinge on adjacent tanks or structures. Four tests were successfully completed with pressure and temperature data, video, photographs, and infra-red camera imagery to document and reinforce the resulting data.

Two tests were carried out on bare steel plates (similar to the material used in the ISO 22899-1 jet fire test standard). These tests showed that, although the hydrogen fires were relatively short in duration (depressurizing in approximately five minutes), the steel reached critical core temperatures of 400°C in less than one minute, less than half the time of the standard jet fire test, thereby risking failure of impinged tanks or structures before safe distances could be established or active fire protection solutions enabled.

Two further tests were conducted where the PPG PITTCHAR NX coating had been applied to the steel specimen. These tests demonstrated that the protective coating was quick to react to the heat of the hydrogen flame and was capable of resisting the highly erosive high-pressure jet, thus maintaining the steel temperature to below 100°C (212°F) for the full duration of the release.

PPG coating solutions are leading the industry when it comes to testing hydrogen PFP coating systems and focusing on the safety of the facility and its personnel. Contact your local PPG representative for further information.

For more information, visit www.ppgpmc.com or contact:

Asia Pacific

+86-21-6025-2688 ppgpmc.ap@ppg.com

Europe, Middle East and Africa

+32-3-3606-311 customers@ppg.com

Latin America

+57-1-8764242 ext. 201 ppgpmcandean-ca@ppg.com

North America (US & Canada)

+1-888-9PPGPMC PMCMarketing@ppg.com

The test results show that the PPG PITT-CHAR NX coating performs to the highest standard in a high-pressure hydrogen jet fire environment, effectively reducing the heat transfer to the substrate.

TEST DFT mm ∆ T°C Range °C Max Temp 1 Uncoated 976 988 2 6.6 mm 63 60 – 83 83 3 Uncoated 1031 1059

PPG PITT-CHAR NX coating resisting high erosive forces

The PPG logo, We protect and beautify the world, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners. © 2023 PPG Industries, all rights reserved.

18

To some, Namibia may not be the first country that springs to mind when thinking about the gateway to Southern Africa’s green hydrogen future. The 35th largest country in the world by landmass and the second least populated, Namibia holds large swathes of sparse, coastal desert – but it is these exact characteristics that make it the optimal location to become one of the world’s lowest cost green hydrogen producers.

The country is quickly realising its role as the key to unlocking an entire continent’s green hydrogen potential and achieving global decarbonisation goals. In partnership with the Government of Namibia (GRN), Hyphen Energy is planning to build Sub-Saharan Africa’s largest, and its only fully vertically integrated, green hydrogen project.

Blueprint for Namibia and beyond

Namibia has huge ambitions to scale up its green hydrogen production to 10 – 15 million tpy, making it one of the largest producers of green hydrogen globally. Hyphen’s project will help the country to achieve this.

A crucial element of this scale up is that all the high renewable resource land is owned by the GRN, allowing Namibia to plan for green hydrogen production volumes that are 50 times more than that produced by Hyphen, sufficient to sustain as many as 200 000 direct jobs annually.

To put this into perspective, the world needs to produce approximately 550 million – 660 million tpy of green hydrogen if global 2050 decarbonisation targets are to be met successfully. This equates to around 3000 Hyphen-sized projects just to meet the hydrogen energy mix for 2050 ambitions.

Namibia can provide the blueprint for sustainable, inclusive development of natural resources that the rest of Africa and indeed the world can follow.

Untapped potential

Green hydrogen only requires four ingredients: sun, wind, land, and water. This means that it can technically be produced anywhere in the world. However, when it comes to the first three of these key resources, Namibia has a competitive advantage.

Namibia is a vast country, with a population of only 2.5 million that predominately live in urban areas, meaning it has large tracks of uninhabited and undeveloped land with some of the highest onshore wind and solar resources in the world – in other words: huge, untapped potential.

Namibia’s ambitions are underpinned by a clear vision to position itself as a global player in the green hydrogen sector. The nation is leading the world in the development of government policy and supporting legislation to unlock the sector, enabling green hydrogen production to rapidly scale up.

World class project

Hyphen’s project will be located within the Tsau ||Khaeb National Park in the Namibian Desert.

Representing an investment of over US$10 billion, roughly equivalent to the country’s annual GDP, the project will consist of wind and solar renewable energy facilities that will power an electrolyser to produce hydrogen. This will then be converted into green ammonia for export.

The project will produce 2 million tpy of green ammonia for regional and global markets, from approximately 7 GW of renewable generation

19

Marco Raffinetti, Hyphen Hydrogen Energy, Namibia, explores how Namibia has the potential to transform Africa’s green hydrogen future.

capacity and approximately 3 GW of electrolyser capacity. This 7 GW of generation capacity is approximately nine times that of Namibia’s capacity and will cut 5 � 6 million tpy of global CO2 emissions. That is more than Namibia’s total emissions in 2021 (4.01 million t) and is approximately equivalent to the emissions created from powering one million houses for a year.

The Hyphen project will convert renewable energy to ammonia, which can then be carried and shipped long distances, to the global demand centres of Europe, South Korea, and Japan to help with the decarbonisation of their heavy industry.

Alongside decarbonising global industries, the excess electricity generated by wind and solar power will be provided to Namibia’s national grid, helping the country meet its own clean energy ambitions and act as a catalyst for energy independence while assisting in the decarbonisation of the wider Sub-Saharan African region.

A first of its kind agreement

Working closely with the GRN means that this project is structured in a way that is equitable, sustainable, environmentally responsible and socially just.

On 20 June 2023, the GRN announced that it was exercising the option afforded to it by Hyphen to take up a 24% shareholding in the company, making GRN, and the people of Namibia, a direct equity partner in the project. Nowhere else in the world has a project been structured in such an inclusive and sustainable manner. From an investor perspective, Namibia is one of the lowest risk countries in Africa, which enables a highly favourable investment environment, further underpinned by strong democratic principles, meaning that international project developers can plan for the long-term and attract financial partners.

Hyphen, in partnership with the GRN, has an enormous responsibility as Namibia’s first GW scale project, to establish the framework and architecture for the creation of an entire industry.

Impact on Namibia and beyond

At the heart of the project is Hyphen’s commitment to the socio-economic development of Namibia, through job creation and local procurement. This new industry at full scale could support around 200 000 direct jobs, with many more indirect roles being created in various sectors – from construction to retail.

Hyphen estimates that the project will create 15 000 new jobs during the construction phase and 3000 permanent jobs at full capacity. The target is for 90% of these jobs to be filled by Namibians. Hyphen is also targeting 30% local procurement of goods, services and materials during the construction and operational phases.

Hyphen launched its Socio-Economic Development Framework on 24 July 2023, setting out these targets that represent the company’s good faith estimates for employment and local procurement, which will be verified through baseline studies. These will provide GRN with the data needed to determine what levels of localised employment and procurement are actually feasible.

As well as job creation, the project will generate significant income to the Namibian fiscus through the payment of land rentals, royalties, and taxes. GRN has indicated that the increased revenues from the project are estimated at 20% of GRN’s annual fiscal collections. There are also all of the associated benefits that come with the project – improved infrastructure such as utilities, with electricity and potable water to the towns of Aus and Lüderitz, and educational opportunities through training and upskilling programmes.

What next?

GRN is driving the strategy for the creation of an entirely new industry in Namibia, with Hyphen being the lighthouse project from which it will be scaled. To realise these goals, the focus now shifts to the delivery of the project, with the GRN responsible for the development of the necessary legislative environment required to launch the industry. Meanwhile, Hyphen will focus on the final design and commercial contracting required to build, finance, and operate a project of this scale.

Creating a new industry of the scale envisioned by the GRN is never going to be an easy task. But working under the visionary leadership of the GRN, Hyphen is excited for what lies ahead and the company is ready to play its role as the foundation project on which Namibia’s green future will be built.

20 Autumn 2023 GlobalHydrogenReview.com

Figure 1. Projected images of Hyphen’s green hydrogen plant.

Figure 2. Pipelines will transport liquid green ammonia to ships.

Autumn 2023 21 GlobalHydrogenReview.com www.ChartIndustries.com/Hydrogen hydrogen@chartindustries.com Americas: +1 800 400 4683 Germany: +49 (0)2823 328 224 China: +86 519 8596 6000 Scan to download our brochure Chart’s liquid hydrogen fuel stations allow for quicker fueling of vehicles with more dense liquid hydrogen, using simpler equipment and requiring less infrastructure investment. Chart’s HLH2 vehicle fuel systems provide greater range and payload advantages using liquid hydrogen storage and an integrated heat exchanger for Fuel Cell Electric Trucks (FCETs). HLH2 vs. H35/H70 • Lighter Weight • Smaller Footprint • Easier to Install • Faster Fill Times • Customized Integration with Truck Manufacturer’s Fuel Cell Engine

Alex Brierley and Lucy Whitford, HYRO*, UK, explore different ways to deliver green hydrogen to hard-to-electrify industries in the UK.

Achieving net zero requires a significant reduction of emissions across all parts of the economy, including heavy industries. The simplest way for the UK to reach net zero is to electrify the services used on a day-to-day basis, and to couple this electrification with a rapid rollout of local sources of clean renewable energy in the country’s power system. However, many of the heavy industries that manufacture the products that people use every day rely on processes that cannot be easily electrified. These are called hard-to-electrify sectors.

For these hard-to-electrify parts of the economy, alternative ways to decarbonise need to be found. Hydrogen produced from

home-grown sources of clean energy, such as wind and solar, can be cost-competitive and reliable. This solution could also play a positive role in the UK’s national and global net zero goals.

As well as providing a clean route to decarbonisation for some industrial businesses, green hydrogen will also create new high-skilled clean jobs. This will help cement Britain’s position as a leader in the green economy and contribute to the country’s levelling-up agenda. The shift away from polluting fossil fuels will also result in greater investment in sustainable growth.

The UK government has recognised the importance of hydrogen for some industries, and already has a target to have produced 10 GW of hydrogen from low-carbon sources by 2030.

22

Green hydrogen production process

There are several ways to deliver green hydrogen to industrial businesses, including:

y Producing the hydrogen onsite or near to the customer and delivering to that customer via a short dedicated pipeline.

y Producing the hydrogen in a different location to the customer and then delivering it via road transport.

y Delivering the hydrogen via a water-based transport solution.

y Delivering the hydrogen by a pipeline.

On a practical level, the second option is difficult for large energy users who require green hydrogen in large volumes.

23

While the third option could become more relevant as international trade for hydrogen expands, it remains challenging to transport hydrogen in a gaseous form, so it will likely need to be moved by converting it into ammonia instead.

The fourth option could also work for trade in the future, but as plans and timelines for public pipelines are not clear, this cannot yet be relied upon.

For these reasons, Octopus Energy is focusing on producing green hydrogen on site and close to the customer. It is then supplied to the industrial businesses on that same site. In this scenario, there is already an offtaker, and the hydrogen does not need to be transported. Octopus Energy believes that this is the best approach to focus on in the short-term. When considering the urgency to reach net zero goals, one cannot afford to wait for other areas to progress first and should instead look for solutions that are currently available.

To make this work, green hydrogen plants – tried and tested electrolysers � use electricity generated from sources such as wind and solar energy to split water and create hydrogen. This process is called electrolysis. The hydrogen created is green because it has been produced using renewable electricity. This makes the most of local, clean sources of energy when the weather is sunny and windy.

The green hydrogen plants built onsite also incorporate a water treatment plant, transformers, and AC/DC rectifiers to supply the electrolyser with electricity. Storage tanks with compressors pressurise and store the green hydrogen onsite, and the green hydrogen is fed through a hydrogen pipeline into an industrial hydrogen-ready boiler.

Case study

For Kimberly-Clark, where electrification was not fully possible in its manufacturing facilities in the UK, green hydrogen will now provide an incredibly helpful route to decarbonise the company’s manufacturing processes and drive down emissions.

Kimberly-Clark, the parent company of household brands in the UK including Andrex®, Kleenex® and Huggies®, uses both electricity and gas (thermal energy). Making this electricity renewable is possible through the adoption of solar and wind power. In April 2023, through partnering with Octopus Energy, a new onshore wind farm was developed which now generates around 80% of Kimberly-Clark’s UK electrical power needs. Kimberly-Clark is also exploring the use of onsite solar solutions.

However, decarbonisation of thermal energy is complex, and Kimberly-Clark has been continuing to look at different technologies – including electricity, hydrogen, biomass, biomethane and syngas. Each of these technologies has benefits, as well as complexities.

The combination of decarbonisation technologies that the business opted for was also influenced by energy markets and regulatory frameworks. In the UK there is a favourable framework in place for green hydrogen. Kimberly-Clark has accelerated its adoption of green hydrogen because it requires minimal process modifications. The company will also have the ability to store green hydrogen short-term to accommodate the ups and downs of daily production at its sites.

HYRO, Octopus Energy Generation and RES’ joint venture (JV), already has projects underway with Kimberly-Clark. The company expects to reduce its natural gas consumption in the UK by 61% when these green hydrogen projects are operational at the end of 2025.

The two projects HYRO is working on with Kimberly-Clark will see green hydrogen produced and supplied to the company’s manufacturing facilities in Flint, North Wales, and Northfleet in Kent, England. The two electrolyser projects will have a combined capacity of 22.5 MW and will reduce the business’ CO2 emissions by thousands of tons per year.

The green hydrogen plants will be built on the land next to the factories and fed straight into the hydrogen boiler inside the factory. Kimberly-Clark’s decision to step away from gas will help to reduce emissions and also boost energy security. As a result, everyday products including tissues and toilet paper will be produced in a way that is far better for the environment.

These projects set the stage for decarbonisation and create a blueprint for more industrial businesses to follow.

The future is green

HYRO was set up with a purpose to help hard-to-electrify industrial businesses to decarbonise through the adoption of green hydrogen. Green hydrogen is forecast to play a key role in the energy transition and delivery of net zero targets. In addition to the UK’s ambitions, other countries in Europe have outlined strategies that set targets for approximately 60 GW of electrolyser capacity to be installed by 2030.

These targets provide a strong signal for the market, and regulatory programmes developing to support meeting these targets provide a huge tailwind for the sector. A significant effort will certainly be required to realise these ambitions.

When electrification is not possible for industrial players, it is clear that green hydrogen will provide an increasingly vital route forwards for companies aiming to reach net zero. This is only the beginning for this burgeoning sector.

Note

24 Autumn 2023 GlobalHydrogenReview.com

* HYRO is a green hydrogen joint venture (JV) between Octopus Energy Generation and RES.

Figure 1. Kimberly-Clark’s Northfleet factory, UK. Credit: Kimberly-Clark.

energy carrier and fuel. The areas of application in the hydrogen industry are diverse: from production to distribution, through to transport, storage and utilisation.

Unlike other forms of hydrogen production – such as grey hydrogen, which is created from natural gas – green hydrogen is made from renewable sources. It offers a zero-emission solution as an energy carrier and fuel for transportation, power generation, heat in process industries or buildings, and energy storage.

into its oxygen and hydrogen molecules through an electrochemical reaction, without emitting CO2. Currently, there are two mature electrolysis technologies: alkaline electrolysis (AEC), and proton exchange membrane electrolysis (PEMEC). In both systems, water is split at the cathode to form hydrogen, and oxygen forms at the anode. However, these systems currently have a 60 – 80% efficiency rate, which represents the level of electrical energy that will be transformed into hydrogen. The remaining 20 – 40%

25

Evgenij Loginov and Alexander Gernhardt, Kelvion, Germany, analyse the heat exchange options that are available for electrolysis systems used in green hydrogen production.

becomes heat that can either be recovered and reused in district heating, for example, or emitted by air coolers into the ambient air. This means that an electrolyser system with 10 MW capacity will transform approximately 2 – 4 MW of the electrical energy supplied to the process into heat.

Therefore, electrolysis used to generate green hydrogen from renewable sources requires thermal management in order to operate efficiently. There are a number of heat exchanger options for plant designers to choose from.

Stability and efficiency

It is crucial that all equipment interacting with the electrolysis process is carefully designed and selected for optimum stability and efficiency. This is particularly important for the cooling system, which requires heat exchangers for transferring the heat within the process, and dry coolers for releasing the heat to the ambient air.

Typically, the main heat exchangers required are the central coolers for the main working circuit, i.e., water coolers for PEMEC or KOH/lye coolers for alkaline electrolysis. Additionally, hydrogen coolers/condensers and oxygen coolers/condensers are needed to cool and pre-dry the gases before they enter the downstream purification process.

For electrolysis systems, Kelvion offers three different heat exchanger types – plate heat exchangers; shell and tube heat exchangers; and radiators and dry coolers – all of which are suitable for both AEC and PEMEC processes.

When choosing the type of heat exchanger, there are several things to consider: CAPEX and OPEX; required footprint; safety; thermal performance; pressure and temperature resistance; materials; media; and serviceability. It is also important to consider potential future capacity increases and load changes.

Plate heat exchangers

A plate heat exchanger transfers heat between two media separated by plates that are sealed by gaskets, brazed, or welded together. The plates are configured to form flow channels through which the hot and cold media flow

counter-currently, enabling the transfer of thermal energy from one to the other. This is made more efficient by corrugations in the plates that create turbulence in the media flow.

The gasketed, brazed and welded variants are similar in function, but may differ in configuration, structure and materials, depending on the application for which the heat exchanger is required.

Gasketed plate heat exchangers are compact and easy to maintain. Single gaskets and plates can be replaced, and more plates can be added to increase capacity. Although they are less resistant to pressure and temperature than other heat exchanger types, the limits are not disadvantageous for electrolyser systems for which they are ideally suited.

Kelvion models for this heat exchanger type have four notable features. Firstly, the OptiWave design of the corrugated plates, which allow the flow to be evenly distributed for maximum heat transfer and lower fouling rates. With the EcoLoc system, gaskets can be installed and maintained easily, while the PosLoc design enables plates to self-align and seal tightly every time the unit is closed, offering stress-free maintenance and operation over a long life cycle. Additionally, just one frame is needed, and this can be adapted with varying numbers of plates, allowing heat transfer capacity to be adjusted to meet changing needs. For applications with critical media and safety requirements that exceed the limits of conventional gaskets, plate cassettes with laser-welded flow channels are available.

Brazed plate heat exchangers have an individually-defined number of corrugated stainless steel plates bonded with copper, nickel or Vacinox in a vacuum brazing process. Thus, they are hermetically-sealed without gaskets.

This heat exchanger type is compact and fits easily into a containerised electrolyser, and is a highly cost-effective solution for oxygen coolers or hydrogen coolers. It also has a safety chamber feature that absorbs stress from thermal shock and pressure, preventing internal leaks and premature failure. This makes it a good option for PEMEC systems with short response times.

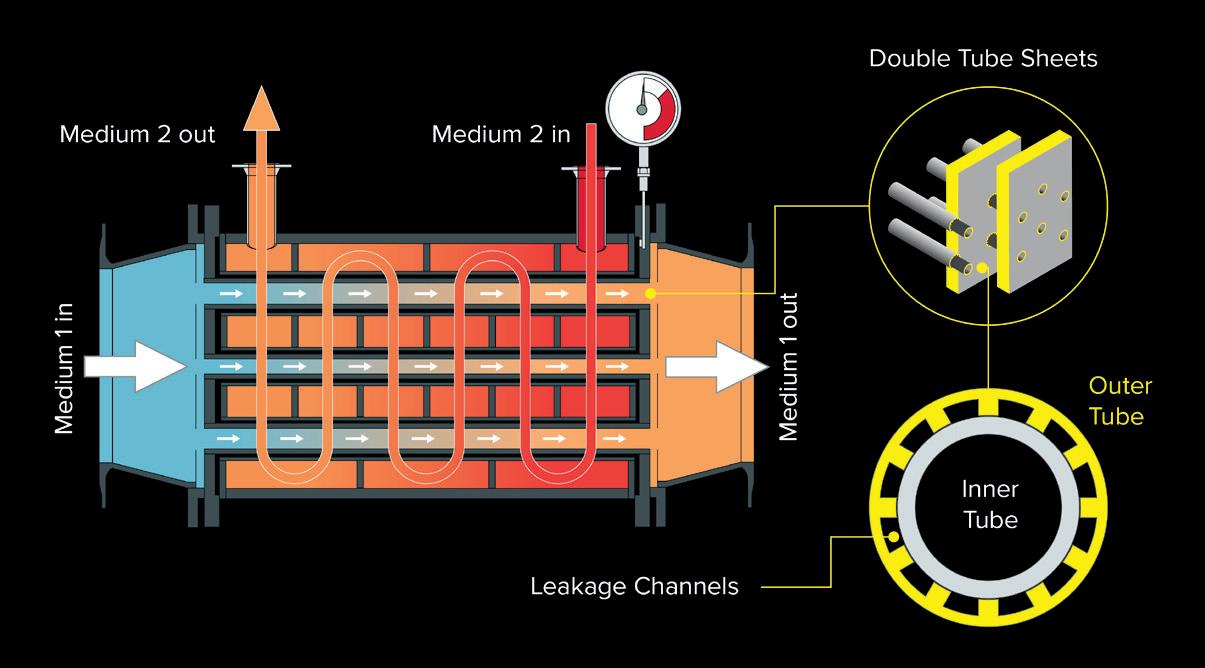

Shell and tube heat exchangers

As the name suggests, this type of heat exchanger comprises a tube bundle in a round shell. One medium flows within the tubes, and the second medium through the shell. Shell and tube heat exchangers are highly resistant to pressures and temperatures. They are widely used globally, as they can be easily customised to suit a broad range of industries, including hydrogen-related applications. However, this type is less efficient than a plate heat exchanger, which means that it requires more space.

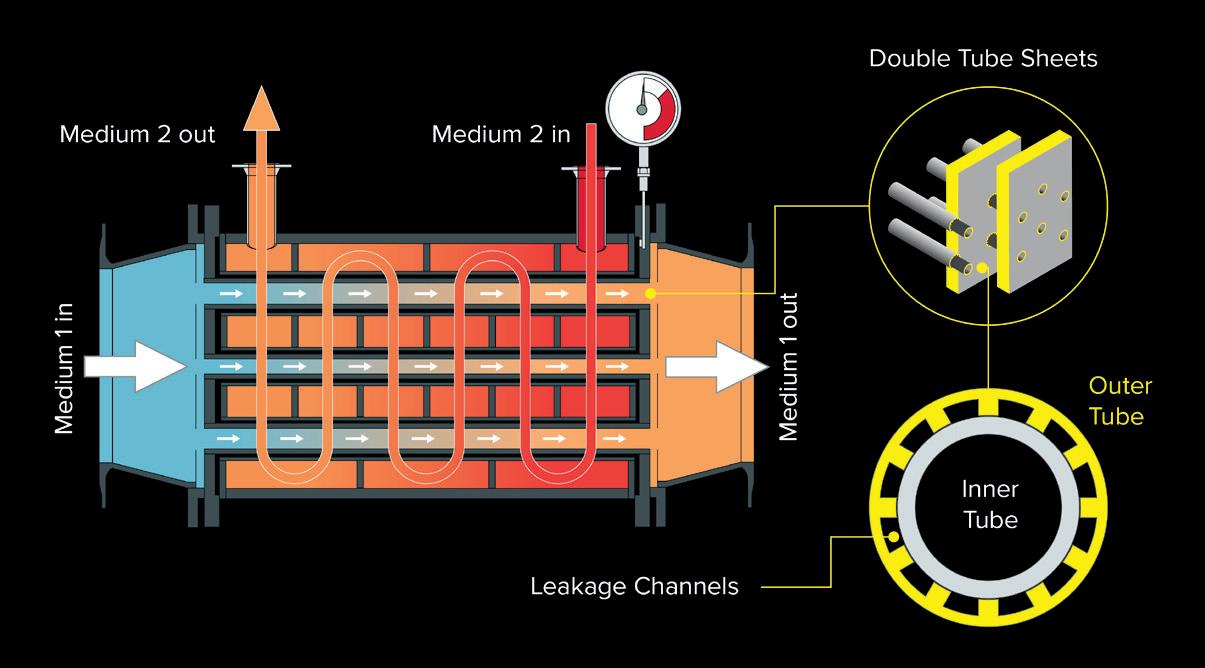

Besides the single tube format, Kelvion offers shell and tube double safety heat exchangers, which provide optimum system reliability and high plant availability – an important consideration when dealing with hydrogen.

The tubes in double tube safety models have two

consisting

an inner and outer

26 Autumn 2023 GlobalHydrogenReview.com

walls,

of

Figure 1. Every tube has two walls, consisting of an inner and outer tube, as well as two tube sheets at each end. The inner tube is form-fit into the outer tube. This generates a joint integrity. One of the tubes is equipped with a profiling, which therefore results in a leakage room between the tubes. In case of damage, leakages are detected and an alarm is triggered while media are kept separate.

tube, as well as two tube sheets at each end. Should a tube wall become damaged, the product would flow through channels between the tubes, into a leakage collection space, triggering the leak detection alarm. As the second tube wall remains undamaged, the media are kept separate. This enables the plant operator to continue running the unit until the next planned maintenance, avoiding costly unplanned downtimes and contamination of the process and equipment.

Dry coolers

In electrolysers, dry coolers are used to dissipate the process heat into the ambient air. They are available in a wide range of sizes to suit small, containerised electrolysers, as well as large-scale electrolyser plants. Additionally, they can be designed as a modularised or centralised re-cooling format.

Media flows through a finned tube bundle that is exposed to the ambient air. Fans force the flow of ambient air through the bundle to increase the cooling performance.

The coolers are available in a flat bed and V-Bank format. In a flat bed unit, one bundle is placed horizontally, whereas in the V-Bank two bundles are placed in a V angle. The advantage of this is that, for the same cooling capacity, only 62.7% of the footprint is required. Both units can have one or two rows of fans, and multiple units can be combined in a system. To further reduce the footprint of the cooler, or increase the heat exchange performance, adiabatic systems can be installed. This can lower the footprint by a further 30%, depending on the relative humidity.

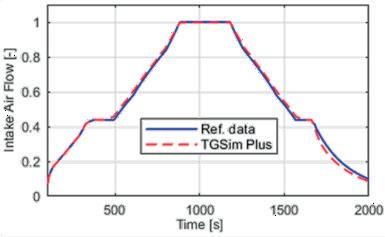

TGSim PlusTM

A REAL-TIME DYNAMIC SIMULATOR OF GAS TURBINES

DESIGN AND ANALYSIS OF GT MAIN SYSTEM AND AUXILIARIES

GT CONTROL SYSTEM VERIFICATION & VALIDATION BY HIL TESTING

SCENARIOS

Verify and validate the real GT Control System (GTCS)

Hardware-in-the-Loop (HIL) full system testing

Whole system performance analysis:

▪ Accurate performance envelope

▪ Start-up sequences

▪ Normal and emergency shutdowns

▪ Load rejection

▪ Investigation of fault events

TECHNICAL DETAILS

0-D modelling

GT component modules libraries

Real-time compatibility at millisecond scale

User friendly GUI & pre-/post-processing tools

Split stages or whole compressor maps management

Different applications require individual solutions

The optimal heat exchanger choice depends on different factors, such as media temperatures; pressures; available space; safety requirements; and thermal performance.

Plate heat exchangers offer the best thermal performance, which is why they are the most compact option and potentially the best choice for containerised solutions. Gasketed plate heat exchangers offer great serviceability as they can be dismounted for cleaning. Furthermore, their cooling capacity can be simply increased by adding extra plates later. If equipped with laser welded cassettes, gasketed plate heat exchangers fulfil higher safety requirements. Brazed plate heat exchangers are suitable for low to medium thermal duty, and are the most cost-effective option, but are not serviceable as the plate package cannot be dismounted due to the brazing process in manufacturing.

Shell and tube heat exchangers are not the most compact heat exchanger type, but are very resistant to pressure and load changes. They are also available in a wide variety and combination of materials and alloys, which means that they can cope with different media. In a fully welded construction, or even as a double tube safety, this heat exchanger is designed to ensure a leakage-free operation, and to trigger an alarm if the tubes become damaged, preventing media contamination. This offers an extra layer of safety, especially for operations involving the small hydrogen molecule, and can render intermediate heat transfer circuits obsolete.

Given the current lack of design standards in the emerging green hydrogen market, it is vital that plant designers and operators choose the heat exchanger type that is the best fit for their needs.

GT MAIN SYSTEM

GT CONTROL SYSTEM

GAS AUXILIARIES

LIQUID AUXILIARIES

START-UP & SHUTDOWN GVA 2

Modelling & Diagnostic software for process plants and machines Simulation services Consulting

www.sate-italy.com Venice - Italy

GT MODEL ARCHITECTURE

Single or bi-fuel combustion chambers GVA 1

Peter Thomsen, Swagelok, Denmark, details how one Danish company is building a high-quality delivery system to make hydrogen the standard for renewable transportation fuels.

As the world seeks innovative solutions to its growing climate change dilemma, the search for a cleaner energy source is front and centre. For many, hydrogen may offer significant promise as a fossil fuel replacement, given that it can be extracted easily from substances

such as water, and it burns without emitting carbon dioxide (CO 2 ). The challenge facing the industry is not the source itself, but building the infrastructure necessary to deliver it to an energy-intensive industry such as transportation.

As the infrastructure is being built, the highest-quality materials

29

Busting four hydrogen myths

Myth: hydrogen gas is hazardous to use or store

This myth is especially persistent, despite the fact that hydrogen is no more hazardous than other traditional fossil fuels. In fact, the dangers are more often significantly lower because of its non-toxic and low-volatility properties. In addition, a properly designed hydrogen fuel system will include safety procedures and protocols that make all aspects of refuelling hydrogen vehicles much safer and more reliable than other options. If it is properly handled, green hydrogen will offer an efficient and economical solution for an ever-changing transportation sector.

Myth: hydrogen vehicles are not a practical long-range solution

Unlike traditional electric vehicles (EVs), hydrogen-powered vehicles have far fewer range concerns because of hydrogen’s high energy density. It is more appropriate for use in heavy-duty vehicles than battery technology because its lighter weight maximises the truck’s payload capacity. In addition, operators can refuel hydrogen vehicles much more quickly than those using traditional battery technologies. Typically, hydrogen vehicles can be refuelled in minutes, whereas traditional electric batteries can take hours – downtime that can significantly hurt a transportation company’s bottom line. Finally, green hydrogen is more easily stored, which allows clean energy to be supplied consistently, no matter what the weather is like.

Myth: hydrogen is too expensive

Although green hydrogen is not yet less costly than traditional fossil fuels, the price, following the trends in other renewable fuels such as solar and wind, continues to plummet. Over the next decade, its price is expected to fall precipitously, and the belief held by most experts is that it will eventually cost the same as, or less than, conventional fuels. In addition, governments are increasingly insisting on cleaner fuel standards, which are expected to speed up green hydrogen’s development.

Myth: hydrogen is not environmentally-friendly or sustainable

The myth that green hydrogen cannot be produced in an environmentally-friendly or sustainable way is based on an outdated conception of how hydrogen fuel is produced. Whilst it is true that hydrogen has traditionally been extracted from fossil fuels, it has been demonstrated that hydrogen can be extracted in an environmentally-friendly way from other sources. Additionally, hydrogen fuel cells produce no emissions except water vapour, which will necessarily reduce greenhouse gas generation around the world.

should be used to prevent leaks and allow the system to last for years or even decades – and not all components meet these stringent standards. Producing and handling hydrogen fuel are not easy processes. They require components that can perform according to strict criteria throughout the entire system. Four of the most important criteria to consider include:

y Pressures: to achieve the desired density, hydrogen must be stored in on-vehicle tanks at 350 – 700 bar.

y Stress and vibration: systems must be able to withstand high speeds, bumpy roads, and inclement weather.

y Safety: refuelling stations must be safe for an average consumer to operate.

y Maintenance: systems must be simple for technicians to access and remake leak-tight joints as necessary.

Within a hydrogen fuel system, the valves are instrumental in the system’s operation and should meet the highest possible standards. Leaks must be prevented at connection points and shut-off points, and valves should be able to operate effectively while maintaining integrity under the unique conditions associated with hydrogen applications.

Addressing the barriers to adoption

Until recently, the hydrogen industry faced several barriers that have hindered its mainstream adoption:

y Extremely small hydrogen molecules are challenging to contain under pressure.

y Much of the hydrogen produced has been extracted from fossil fuels, which renders it less environmentally-friendly.

y At the current time, no infrastructure exists to compress hydrogen into a useable fuel.

Fortunately, these three factors are becoming less important as the industry evolves, and one company in Denmark is central to making these initial concerns obsolete.

High-performance hydrogen valves are essential

Everfuel is working hard to introduce hydrogen into multiple fuel applications across the world, in an effort to eliminate fossil fuels. Its goal is to create a green hydrogen infrastructure to replace fossil fuels in industrial environments, as well as to distribute and dispense hydrogen to the transportation sector.

To achieve these goals, the company has created the HySynergy project, which initially aims to build a 20 MW power-to-X (PtX) hydrogen production facility that is able to produce and store significant amounts of green hydrogen before it is transported to end users and neighbouring refineries. The goal is to have established a 1 GW hydrogen plant that uses renewable power as the source of green hydrogen by 2030.

Wind and solar will be used to provide power to the plant, and it is expected to produce no emissions. The aim is to prove that green hydrogen makes sense from an

30 Autumn 2023 GlobalHydrogenReview.com

environmental perspective, and that it can be a sustainable business in the long-term. Not only will the hydrogen be produced using renewable sources, but the plant will also have the capacity to store it for future use, depending on the grid mix during that given timeframe.

The process will also be regenerative in another way: the byproduct of using hydrogen in fuel cell vehicles is pure water. This creates a virtuous circle that allows the facility to sell its waste heat and oxygen, as well as produce additional hydrogen – all without the use of fossil fuels. In addition, compressed hydrogen carries more energy than traditional batteries and other storage technologies, which means maximising the fuel produced against the amount of fuel used in its creation.

How to contain and compress hydrogen

Part of the challenge of producing green hydrogen is its small molecules, which can escape through even the tiniest openings. This is why creating a leak-tight environment during containment and compression is so crucial. Using valve components made from high-quality stainless steel can help to prevent leaks. Not only can hydrogen leak through small crevices, but it can also weaken the materials of the valves used to contain it. This process, called hydrogen embrittlement, can lead to material failure if lower-quality stainless steel is used. For this reason, it is important to find a supplier that can provide components that use the highest-quality materials, including stainless steel with a higher nickel content; and hydrogen-specific ball and needle valves that can stand up to the corrosive nature of hydrogen. It is also useful to choose components that are easy to install and service. This will save installation time and improve operational performance, while requiring less maintenance in the long-term.

Working with a trusted supplier, Everfuel has already begun to significantly lower carbon emissions for its customers that are using hydrogen. By 2025, when the second phase of the project is completed, the facility will be able to displace up to 500 000 t of CO 2 emissions in the sectors of heavy industry and mobility, which equates to 11% of the CO 2 emissions from the Danish land-based transport sector.

Autumn 2023 31 GlobalHydrogenReview.com

Figure 1. Everfuel is in the process of building a green hydrogen plant to run on renewable energy, producing no emissions during the extraction process.

Figure 2. Once Everfuel’s facility is completed, it is expected to serve as a future example of what is possible in the production of green hydrogen.

Figure 3. Everfuel’s hydrogen electrolysers, which convert water and electricity into hydrogen and oxygen, feature high-quality components to transport the hydrogen, minimising the risk of hydrogen embrittlement for safer operations.

32

Amidst growth in the clean energy technology sector, and continuous energy efficiency improvements, global energy-related carbon dioxide (CO2) emissions grew by 0.9% in 2022, reaching more than 36.8 Gt, according to a report from the International Energy Agency (IEA).¹ The net zero imperative remains, and so should the will to integrate and leverage innovation to accelerate progress towards decarbonisation, sustainability and electrification.

Decarbonisation is a key component of the future energy map to enable a zero-carbon society to grow, while reducing greenhouse gas (GHG) emissions. This implies upgrading production sites to produce energy in a cleaner manner, while nurturing the development of a global and domestic hydrogen value chain. Hydrogen needs full recognition as a secondary energy source that acts as an energy carrier that is able to be stored and converted to serve a myriad of applications in industry, transport, power generation and building. Achieving a successful energy transition is possible with current technologies that leverage hydrogen and carbon capture value chains.

There have been efforts to deploy renewable energy-based projects, with the intention of including all emerging and developing economies in this new energy move. All countries that are willing to deploy renewable energy projects face similar financial, administrative and regulatory hurdles that need to be addressed by the different private, public and institutional stakeholders at international, national and regional levels.

33

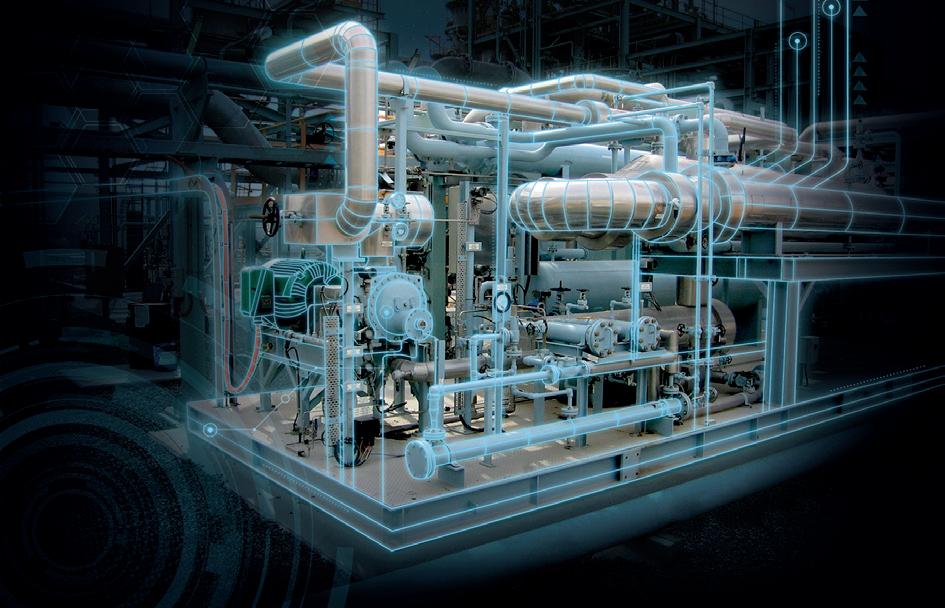

Marie-Laure Gelin, Howden, a Chart Industries Company, the Netherlands, explains why compression is such an important process within the hydrogen value chain.