The Benchmarking and Best Practices Conference

Outlook for 2025

NSF Funds Universities to Bolster Production

Protecting Processors from Digital Disruption

The Official Publication of the Association of Rubber Products Manufacturers

Outlook for 2025

NSF Funds Universities to Bolster Production

Protecting Processors from Digital Disruption

The Official Publication of the Association of Rubber Products Manufacturers

As we near the end of 2024, I want to take a moment to reflect on what has been an extraordinary year for ARPM. It’s been a year of growth, innovation and collaboration, all of which were vividly on display at the 2024 Benchmarking and Best Practices Conference. This event, one of the highlights of ARPM’s calendar, truly exceeded expectations, thanks to the remarkable engagement and enthusiasm of our members and sponsors.

The 2024 Benchmarking and Best Practices Conference brought together leaders and innovators for two and half days from across the industry in Indianapolis, Indiana, to share insights, strategies and solutions to the challenges we all face. The discussions were dynamic, the networking was vibrant and the ideas exchanged have already begun to influence how we think about the future of our industry. The feedback we’ve received has been overwhelmingly positive, and I’m particularly proud of how our members came together to make this event not just a success, but a transformative experience for all involved.

This year has been a milestone for the Association for Rubber Products Manufacturers (ARPM). We’ve seen recordbreaking participation in events and programs, a testament to the value members find in the resources and opportunities we provide. From training sessions and webinars to the rich content delivered through Inside Rubber and other platforms, it’s clear that the ARPM community is more engaged than ever. This level of involvement has helped us foster a stronger, more connected industry network and we’re excited about the momentum we’ve built.

One of the most significant achievements of this year has been the launch of new initiatives aimed at supporting our members as they navigate the complexities of today’s business environment. Whether it’s through enhanced training programs the ARPM Training Academy provides, the focus on workforce development or efforts to stay ahead of regulatory changes, ARPM has been at the forefront of helping its members adapt and thrive.

Another highlight of 2024 has been ARPM’s continued focus on benchmarking. By providing our members with the tools and data needed to compare their performance against industry standards, we’ve empowered them to drive improvements

Kaitlyn Triplett, ARPM

“TOGETHER, WE’VE ACCOMPLISHED A GREAT DEAL IN 2024, AND I’M CONFIDENT THAT 2025 WILL BRING EVEN GREATER ACHIEVEMENTS.”

in efficiency, quality and innovation. These benchmarking tools have become an essential part of how our members do business, and we’re committed to expanding and enhancing these resources in the year ahead.

As we look toward 2025, I can’t help but feel a sense of anticipation and excitement. The ARPM staff, board of directors and I are already hard at work planning new programs, events and initiatives that will build on the successes of this year. We’re committed to continuing our mission of providing you with the resources, support and community needed to succeed in an increasingly competitive marketplace.

In 2025, you can expect to see even more opportunities for learning, networking and growth. We’ll be honing in on benchmarking efforts, introducing new training programs and hosting events that will bring the community together in meaningful ways. We’re also looking forward to the continued evolution of Inside Rubber as a key resource for industry news, trends and insights.

I want to thank each of you for your continued support and engagement. It’s your participation that makes the association strong, and it’s your success that drives everything we do. Together, we’ve accomplished a great deal in 2024, and I’m confident that 2025 will bring even greater achievements.

Here’s to a prosperous and fulfilling new year! n

ARPM Training Academy: Addressing the Continuing Challenge of Workforce Development

By Joe Walker, ARPM Training Academy technical coordinator, Elastomer Technologies, LLC

By Tom Wojcinski, principal, and Michael J. Devereux II, CPA, CMP, partner, Wipfli

A look at rubber compound development in mixing rubber and additives such as fillers, processing aids and curing agents in fixed proportions to create a mixture based on specific physical and chemical properties.

By Chris Kuehl,

By Brett Stone, TC45/SC1

By Lindsey Munson, editor,

Do You Know the Markets You’re Working In?

By Dianna Brodine, vice president, editorial, Inside Rubber

ARPM Team

Executive Director Letha Keslar – lkeslar@arpminc.org

Managing Director Kaitlyn Triplett – ktriplett@arpminc.org

Project Manager Paige Heck – pheck@arpminc.org

Marketing Director Marcella Kates – mkates@arpminc.org

Analytics Director Tony Robinson – trobinson@arpminc.org

Director of Publications Susan Denzio – sdenzio@arpminc.org

Analytics Lead Andrew Carlsgaard – acarlsgaard@arpminc.org

Strategic Advisor Troy Nix – tnix@arpminc.org

ARPM Officers and Board of Directors

President

James Wideman, MBL (USA) Corporation

Vice President

Ryan Fleming, Freudenberg-Nok Sealing Technologies

Treasurer

Donovan Lonsway, BRP

Secretary

Joe Keglewitsch, Ice Miller LLP

Past President

Travis Turek, Bruckman Rubber Corporation

ARPM Board of Directors

Rich Balka, Home Rubber Company

Bill Bernardo, Ebco, Inc.

Kirk Bowman, The Timken Company

Russ Burgert, Maplan Rubber Machinery

Aaron Clark, Danfoss Power Solutions

Joe Colletti, Marsh Bellofram

Randy Dobbs, Sperry & Rice LLC

Carl Flieler, Zochem LLC

Doug Gilg, Continental ContiTech

Cedric Glasper, Mechancial Rubber Products Corp.

Diya Garware Ibanez, Fulflex, Inc.

Jeff Leach, Passaic Rubber Co.

Jon Meigan, Lake Erie Rubber & Manufacturing

Mike Rainey, HBD Industries Inc.

Mike Recchio, Zeon Chemicals L.P.

Brandon Robards, Ace Extrusion

Caitlin Steele, Gates

John Stone, The Rubber Group

By Lindsey Munson, editor, Inside Rubber

To be strongly positioned in 2025, rubber manufacturers should prepare strategically to embrace and navigate several key trends and factors, including advancements in technology and innovation, sustainable practices, automation, regulatory and geopolitical factors and shifting market dynamics. As global manufacturing becomes focused on the landscape for next year, companies need to prioritize short- and long-term strategic plans to meet opportunities and challenges head-on.

To better understand the rubber industry’s outlook for 2025, Inside Rubber conducted interviews with two leading rubber industry professionals and the Association for Rubber Products Manufacturers (ARPM), who shared the challenges presently being faced and what’s expected into the new year, how to mitigate those challenges, their thoughts on the economic and political impacts, and lastly, what investments companies should put at the top of the list.

As companies plan for 2025, what challenges are expected in the rubber industry?

JR Mohl is the North American sales director at MAPLAN, South Elgin, Illinois, a manufacturer of elastomer injection molding machines. Mohl said, “Global geopolitical tensions and ongoing transportation bottlenecks have stressed supply chains, making machine and component availability less predictable.” As an equipment manufacturer, MAPLAN has addressed these challenges proactively by optimizing its supply-chain partnerships and increasing local stock levels of critical parts to mitigate delays. Together with its customers, the company is ensuring it also stocks the appropriate level of parts based on the age of their customers’equipment.

“MAPLAN also has undertaken a large initiative to internally source a greater amount of the components of its equipment,” said Mohl. “One small example is a common wear item on injection molding equipment – insulation boards – now are being produced at the South Elgin, Illinois location. Previously, these were sourced from headquarters in Austria and required additional lead time and cost that now have been eliminated.”

Kaitlyn Triplett is managing director at the ARPM. She said, “As processors plan for 2025, ARPM anticipates several key challenges based on data from the 2024 ARPM Mid-Year Pulse Survey:

• Uncertainty around election results: With the upcoming elections, policy shifts and regulatory changes likely are on the horizon. This uncertainty could affect decisionmaking in areas like trade, labor laws and environmental regulations, causing processors to adopt a cautious approach to long-term investments.

• High interest rates: Persistently high interest rates are increasing the cost of borrowing, which directly impacts capital investments, expansions and even day-to-day operational expenses. This financial pressure may lead companies to delay or reconsider growth plans.

• Increased business costs: Inflationary pressures and rising costs – particularly in energy, raw materials and labor –are expected to continue being a major challenge. These increasing operational costs are forcing manufacturers to look for ways to improve efficiency and productivity to maintain margins.”

Jon Meighan is president of Lake Erie Rubber, Erie, Pennsylvania, a manufacturer of custom rubber parts specializing in injection, transfer and compression molding. Across the rubber industry, manufacturers are facing similar challenges,

and Lake Erie Rubber is facing labor-market highs and lows specifically in finding and keeping skilled workers. Meighan said, “Our biggest challenge is and continues to be hiring for technical positions. In rubber molding, it’s difficult to find talent in a small labor pool that has industry-specific training.”

How do the current economy and upcoming presidential election impact this area?

Mohl, MAPLAN: “The economy is poised for potential growth, with the Federal Reserve signaling continued interest rate reductions and with increased momentum toward onshoring in North America. These factors should foster more manufacturing activity domestically, benefiting sectors like rubber and silicone goods,” said Mohl. “However, household income disparities and the rising cost of essential goods have led to decreased discretionary spending, with many households compensating by taking on additional debt. This dynamic could influence consumer demand for certain rubber products, particularly in non-essential markets.”

As for the upcoming presidential election, Mohl said, “Uncertainty already is causing businesses to delay major capital investments. Many companies are taking a ‘wait and see’ approach, holding off on decisions about expansions, automation projects or new technology investments until they have clarity on future policies.”

“At MAPLAN, we’re aware of this cautious stance and encourage molders to focus on efficiency-enhancing investments that provide long-term benefits – such as our energy-efficient machinery, cold runner blocks and automation solutions. These investments can offer multiple decades of strengthened operations, regardless of the political outcome.”

Meighan, Lake Erie Rubber: Interest rates will play a large role in how Lake Erie Rubber is impacted – with foresight on economic improvements allowing for future growth and modernization. Meighan said, “With the potential for interest rates to go down in the next year, this could significantly improve our company’s ability to grow by adding additional equipment to the facility and improving other areas of the operation.”

Mohl, MAPLAN: “To effectively mitigate upcoming challenges, processors should focus on both operational improvements and strategic workforce investments. Automating production processes through solutions like MAPLAN’s MAP.autocell not only improves efficiency but also allows businesses to reduce reliance on low-skill labor, freeing up resources to pay higher wages to skilled workers. By eliminating or automating routine, low-value tasks, processors can reallocate funds to attract and retain top-tier talent for more complex roles – creating a competitive advantage as an employer.

In addition, processors should consider offering more competitive total compensation packages, which can include higher wages, benefits and development opportunities, as a strategy to differentiate themselves in a tight labor market. By investing in their workforce, companies can reduce turnover, improve operational stability and enhance productivity.

From an operational perspective, energy efficiency and predictive maintenance are critical. Systems like MAP. cooldrive and MAP.energywatcher help processors optimize their energy consumption and reduce operating costs, allowing for reinvestment in both technology and talent. Moreover, implementing lean manufacturing practices ensures that processors are minimizing waste and maximizing profitability, making them more resilient in an unpredictable market,” said Mohl.

Triplett, ARPM: “Processors can take proactive steps to mitigate the challenges anticipated for 2025, focusing on strategic planning, financial flexibility and operational efficiency,” said Triplett. Here’s how they can prepare:

y Stay Informed: ARPM membership offers access to economic intelligence from ITR Economics to help reduce risk and drive practical, profitable and informed business decisions. Economic overviews and insights are provided via quarterly reports, which provide a comprehensive overview of the economy and an in-depth look at key industry sectors.

y Operational Efficiency: Invest in technology and lean manufacturing practices to reduce waste and boost productivity. Automation can help offset labor shortages and control costs over time. Join ARPM’s Automation Wednesday Series to learn how others are implementing best practices into their facilities to kickstart automation.

y Supply Chain Management: Strengthen supplier relationships to negotiate better deals on raw materials or diversify the supply chain to minimize the impact of price hikes. Lock in long-term contracts where feasible to secure stable pricing. Take advantage of relationships with ARPM’s dedicated corporate sponsors and review the discount programs they offer to the membership.

y Training and Retention: With labor costs on the rise, investing in workforce training and retention programs can help maintain productivity while minimizing turnover. Promoting internal talent and fostering a strong company culture will be crucial for maintaining skilled employees. The ARPM Training Academy offers both in-person and virtual training options to meet an organization’s needs.

u

Triplett said, “By focusing on strategic foresight, cost control and financial flexibility, processors can better manage the uncertainties of 2025 while positioning themselves for longterm growth.”

Meighan, Lake Erie Rubber: “We are considering developing an internal apprentice program for direct hires through either the university or trade school. This will assist us in the immediate need to fill technical positions as well as create a future pool of skilled employees. We continue our efforts by investing in this challenge despite the economic uncertainty, especially with high interest rates. We hope to accelerate this process if interest rates decline and a more favorable environment occurs in the industry,” said Meighan.

What top three investments are recommended for those in the rubber industry looking to stay competitive in 2025?

Mohl, MAPLAN: “The most impactful investments rubber processors can make are in people, maintenance and customer relationships – all of which will strengthen their position in the long run,” said Mohl. Here are three key investments Mohl shared:

1. Invest in people, especially the top talent. The cost of recruiting, hiring and onboarding new employees is significantly higher than retaining and developing existing talent. More importantly, the loss of productivity while those roles are unfilled can be debilitating. Prioritizing training, upskilling and rewarding a company’s best employees not only boosts morale but also enhances overall operational efficiency.

2. Invest in maintenance and preventative maintenance (PM). Maintaining current assets and ensuring they run efficiently is crucial, particularly in an uncertain economy. Downtime from neglected equipment can lead to costly delays and lost revenue. By investing in regular maintenance and PM contracts, processors can maximize the lifespan of their equipment and prevent unexpected breakdowns. Well-maintained machinery ensures stable operations, which is a key advantage in volatile times.

3. Invest in customers. Strengthening relationships with existing customers can provide a significant competitive edge. In tough times, everyone is feeling the pressure –customers included. Offering enhanced support, close collaboration and mutually beneficial solutions to the strains both sides are facing can foster loyalty and ensure that customers have no reason to look elsewhere.

At MAPLAN, we are committed to providing excellent customer service. Building strong, loyal partnerships is essential in navigating economic challenges successfully.

Triplett, ARPM: As for ARPM, Triplett was asked what the association’s top three actions and priorities are for 2025 to support its members. She said, “As ARPM looks ahead to 2025, we are committed to delivering key initiatives that directly address the evolving needs of members.” ARPM’s top three priorities include:

1. Providing continued data through benchmark reports and ITR Economics partnership: ARPM will continue to equip members with crucial industry data through its comprehensive benchmark reports. These reports, along with insights from our partnership with ITR Economics, offer valuable market forecasts, economic trends and performance metrics that help businesses make informed decisions in an ever-changing economic landscape.

2. Expanding training opportunities both in-person and online: ARPM recognizes the importance of continuous education and skill development for our members. In 2025, we will continue offering in-person training programs while also enhancing our virtual portal to provide accessible, high-quality training resources. These programs will cater

to diverse learning needs, ensuring that all members –regardless of location – can participate in essential training and development initiatives.

3. Advancing digital transformation: ARPM will guide our members through the rapidly evolving landscape of digital tools and automation. In 2025, our focus will be on providing education and resources to help manufacturers integrate emerging technologies such as AI and automation. These tools will drive operational efficiency, reduce costs and streamline production processes, ensuring our members remain competitive in the global market.

“These priorities reflect ARPM’s commitment to delivering meaningful value and support to our members, helping them thrive in 2025 and beyond,” said Triplett.

In conclusion, the rubber industry likely will see growth and transformation. The companies that open their doors and embrace technological advancements and innovative approaches, while adapting to market conditions, will be optimally positioned to thrive through 2025. The industry’s ability to balance the evolving trends and factors will play a large role in shaping the future of rubber manufacturing. n

• Compound Development

• Failure Analysis

• Technical Training

• Prototyping

• Technical Consulting

• Physical & Mechanical Testing

• Dynamic Testing

• Custom Test Design

• Engineering Consulting

• Rubber and Plastics Mixing

• Rubber and Plastics Molding

CHEMICAL SERVICES

• Chemical & Analytic Testing

• Formula Reconstruction/Reverse Engineering

• Microscopy

• PPE Testing

• Pharmaceutical & Microbiological Services

Farrel Pomini, Ansonia, Connecticut, was established in 2011 to focus on the continuous mixing equipment sector of the HF MIXING GROUP member companies. The company recently celebrated its Chief Engineer Doug Mosher’s 60 years of service. Mosher joined Farrel Corporation out of college in 1964, with a Bachelor of Science in Mechanical Engineering from Clarkson College of Technology (Clarkson University). Hired into Farrel’s “Engineer-in-Training” program, Mosher then worked as an engineer in the Banbury® Mixer department, and then on the early Farrel Continuous Mixers. In addition, he worked on the first-generation Farrel Compact Processor (mixer and extruder together on a unitized frame). For more information, visit www.farrel-pomini.com.

The International Institute of Synthetic Rubber Producers (IISRP), Houston, Texas, an international not-for-profit trade association, has published the 2024 edition of Worldwide Rubber Statistics, the world’s leading source for authoritative data about synthetic rubber. This edition of the publication, which has been published annually for more than 30 years, has revisions to elastomer plant capacities as the synthetic rubber market continues to be dynamic.

The publication provides a comprehensive analysis of capacity by elastomer type, geographical distribution and corporate ownership. It also features a graphics section that emphasizes statistics in an easy-to-read format and a section on the capacities of synthetic rubber production facilities throughout the world, including a section on planned and announced expansions of synthetic rubber plants. For more information, visit iisrp.com.

Laur Silicone, Beaverton, Michigan, develops, manufactures and supplies custom silicone rubber compounds for a variety of applications. The company has added the COLMEC Conical Twin Screw Mixer (CTM™), increasing its production capacity. COLMEC, based in Italy, manufactures rubber mixing equipment and extrusion lines. With the addition of this machine, Laur Silicone increases production efficiency and speed while maintaining the highest quality standards. For more information, visit www.laursilicone.com.

Trelleborg Sealing Solutions, Fort Wayne, Indiana, a developer, manufacturer and supplier of precision seals, bearings and custom-molded polymer components, has named Heather Castleman as president of the Industrial Americas Business Unit of Trelleborg Sealing Solutions. Castleman has been a leader at Trelleborg for over two decades. Throughout her tenure, she has been responsible for developing and implementing new business capabilities, driving sales and customer experience and improving existing programs to achieve the business goals. She has contributed to the acquisition and integration of nearly 10 companies.

In addition, Trelleborg has named Jonas Karlsson as the Business Unit president for Industrial Europe, the Middle East and Africa (EMEA). The new role recognizes increased business activity in the region and oversees many of the sectors served by Trelleborg, including food and beverage, semiconductor, fluid power, energy, off-highway and automotive. Karlsson started his career with Trelleborg in 2005, as a segment manager and has experience in business development, marketing, planning, project management and general management up to the board level. For more information, visit www.trelleborg.com. n

By Lindsey Munson, editor, Inside Rubber

“Alright stop, collaborate and listen …,” boomed through the speakers and Vanilla Ice’s hit song became the entrance music for 650 manufacturing professionals to the Indianapolis Downtown Marriott’s main ballroom, kicking off the Benchmarking and Best Practices Conference. The conference was held October 2-4 and, over those three days, attendees took advantage of connecting with like-minded professionals, forged partnerships with leading solution providers and gained a competitive edge through roundtable discussions delivering practical strategies, real-world case studies and actionable insights.

ARPM and MAPP presented a theme for this year’s conference, “Ingenuity at Work,” reflecting their commitment to innovation, engagement and forwardthinking solutions.

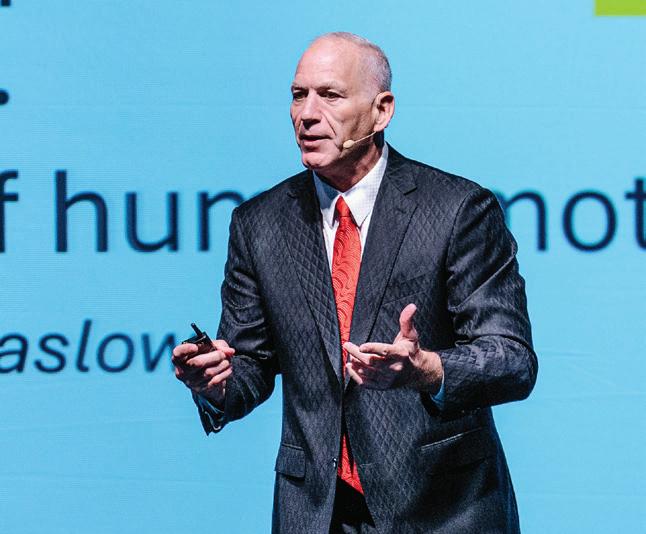

With “ingenuity” at the forefront, Troy Nix, master of ceremonies, appeared on the stage to set the tone and said, “Getting unstuck can be challenging.” He continued that being stuck is part of the journey and it happens to everyone, but changing a few daily habits can create a new path – leading to becoming “unstuck.” While there’s no right or wrong way to get “unstuck,” here are three habits that he encouraged:

1. Find the beauty (in being stuck, teammates, daily tasks, small victories, etc.).

2. Change how you speak to yourself. It’s a mindset. Be compassionate.

3. Just start moving. It’s progress, not perfection.

“You don’t have to have it all figured out to move forward,” said Nix. Attending the Benchmarking and Best Practices Conference, whether an industry veteran or young professional, is a step toward a better tomorrow and getting unstuck –creating change and putting “ingenuity” to work.

Troy Nix, master of ceremonies

“Blow

the dust off!”

Known as the master of ceremonies for the Benchmarking and Best Practices Conference, Nix walked on the stage with confidence but – unbeknownst to his audience – he was about to get uncomfortable and tell his story about “the power of belonging.” He said, “What is one thing you refuse to do because the thought of doing it makes you so uncomfortable?”

For the next 15 minutes, Nix told his story about shattering comfort zones, putting forth the effort and the “why” behind choosing to face his fears and take on the challenge. Where did it start? At the 2023 Benchmarking Conference, Nix encouraged attendees to get out of their comfort zones, and 10 days following the event, he seized the opportunity to get out of his safe space and began training in jiu-jitsu. Nix’s goal was simple – to shatter his comfort zone with the following objectives:

• Physical challenge – pain from the activity.

• Mental challenge – hard to learn under pressure.

• Grow and develop – changing the mindset; measure success in how many failed attempts; and keep showing up.

• Create relationships with driven purpose – hardest objective = fit in; everyone just wants to fit in.

Over the past 51 weeks of the jiu-jitsu program, Nix said he, “… put forth the effort to belong.” In that time, he had to persevere, meet challenges head-on, get extremely uncomfortable and forge through the above objectives. Nix began the program at ground zero as a white belt and noticed quickly that to “belong” he was going to have to put in everything he had physically and mentally to be a part of and build relationships with those in a different belt color. Nix shared, “I put forth the effort to belong. I learned their names. I had outgoing and positive energy. I acknowledged my classmates. I supported my team members. It’s as simple as saying ‘hi’.” As humans, being recognized is important to growth and being a part of a group gives value. All of those things build culture. Nix said, “Just say ‘hi!’ There’s power in belonging! Create a company culture that is team-focused. Build connections with employees and give recognition and appreciation when earned. ‘Blow the dust off!’”

As he sat on an airplane with his headphones secured to his ears, ready for the plane door to shut, an older Russian lady walked through the door (Stainton thought, “What are the chances she’ll sit in the empty seat next to me?”), shuffled down the aisle, pointed at the empty seat and sat down. For the next five hours, he retreated, listening to music – his escape – until the plane descended to the final destination. That’s when the lady tapped him and said, “Is home for you?” The conversation carried on and she mentioned that she was from Russia and had not been back since she was a music teacher. ‘Connecting the dots,’ Stainton shared he was listening to the song ‘Firebird Suite’ by Stravinsky, and the lady said, “Ah. Stravinsky. The Firebird. I was with him when he wrote it.” Then the plane pulled to the gate and Stainton never saw her again. Separated by five inches and a pair of headphones, he shared with attendees that this experience taught him that people are different, but in those differences are amazing ideas, conversation and experiences. He said, “Your next breakthrough could be one connection away.”

Is there a master key? It turns out there is. It’s called innovation. The first shift is a mindset. Stainton said, “It’s believing that you are creative. So much of our existence is about what we choose to think about ourselves. It’s believing that you deserve to be there and belong; it’s not a private club but an open playground.” He continued, sharing that the innovator/breakthrough thinker asks the question “How can this be better?” Innovation comes in small, medium and large wins. Innovation is not about a lightning bolt moment but “connecting the dots.” People need to start being dot collectors and dot connectors, because when dots are connected, and connections are made, ingenuity happens.

Stainton said, “What if the dots were different sizes, shapes and colors? What if they were the ideas, experiences, people and different beliefs in life? When the blinders are taken off, these dots open new possibilities and bring opportunities.” Everyone should ask, “What’s the yellow dot here?”

More information: www.talk.ac/billstainton (enter code: MAPP) u

Matt Booth

Delivering on what it takes to embrace a “basically incredible life,” Matt Booth engaged attendees by requesting each person to pair up and ask, “Tell me something good!” It wasn’t the typical question, “How are you?” It got attendees thinking and acting differently toward each other; in turn, shifting the energy and attitudes in the conference room. Following the exercise, Booth shared five basic principles to “Live an Incredible Life” that build a foundation balanced with common sense and simple, effective tools to inspire companies and their employees.

1. Attitude – It’s not always easy to have a positive attitude and it’s important to have strategies to pull employees in the right direction during tough times. Attitude is the start of everything, determining thoughts and then actions.

2. Communication – Within companies, it is extremely important to have the tools and techniques in place to communicate clearly and effectively.

3. Health and taking care of ourselves – Booth said, “There are no shortcuts.” Companies change direction for the better; people move in a positive direction because action is taken and something is done about it.

4. Have a plan/direction – It’s taking control of what can be controlled personally and professionally, including attitude, relationships, health, communication and so forth.

5. Have a source of power – To not only have the power to influence one’s mindset and attitude but to have the ability to influence another’s behavior, beliefs and actions.

“A small change in your attitude can make a big impact and create changes,” said Booth.

More information: www.mattbooth.com/basicallyincredible.

In its second year, the cuttingedge Automation Hall returned, bringing together the industry’s experts to display their cuttingedge technological advancements and automation achievements. Attendees explored the latest innovations and proven automation technologies that define excellence in top facilities across the US.

Michael Feuz, ITR Economics

A key member of ITR Economics’ team of expert economists and consultants, Michael Feuz contributes to the production of client reports, forecast reviews, economic research and regular client-facing communications. Taking a look at global markets and their impacts on US manufacturing, Feuz shared key insights into consumer spending, inflation, interest rates, the labor market and leading industry indicators. Lastly, he provided a high-level look at manufacturing’s outlook, including:

• Interest rates may ease lower later in 2024 and into 2025.

• The service sector is expected to hold up better than private manufacturing in 2024.

• Fiscal policy and high corporate cash levels and a buffer for the economy.

• Assess cash needs.

• Maximize competitive advantage.

• Think about expanding the asset classes invested in and plan to pivot hard in 2028-2032.

More information: www.itreconomics.com

As a founding partner of Inside Beltway and having worked in the nation’s capital for over 25 years, Omar Nashashibi provided conference attendees with insights and updates from Washington, D.C., including the latest from policymakers, trade talks with allies, efforts to increase taxes and regulations, and what steps lawmakers can take to address workforce and supply chain challenges. In addition, he spoke about the November election and what the coming year could mean for the manufacturing industry.

More information: www.insidebeltway.com. n

Jim Carroll

“Manufacturing is learning to work with the machines, and there will be future AI manufacturing careers,” said Carroll. He continued, asking attendees, “When it comes to a company’s ability to innovate, are you going to chase it or are you going to allow the future to happen?”

It’s time to stop avoiding innovation and get out in front of the progression in manufacturing. “Companies have to invest in experiential capital. Build an ‘Xbox room’ and explore the unknown with the next generation. Stop wasting time on frivolous things,” Carroll said. “Assess employee skill sets –become your future.” Carroll highlighted the following:

• “The future belongs to those who are fast.” In thinking about the rubber industry and a rapidly changing world, what does it look like in 10 years? Companies need to adapt, reinvent and keep up with the speed of change (i.e., reinventing a ketchup bottle from glass that had been shaken to get ketchup out to an upside-down plastic container that is squeezed).

AEC/Cumberland/Sterling

Americhem Eng Compounds

Aurora Material Solutions

Bamberger Amco Polymers

Barnes Group (Synventive)

Bear Industrial Group

Beaumont Technologies

Benesch

Chase Plastic Services

CognitionWorks

Colors For Plastics

Conair

CYFrame

DELMIAWorks

DeWalt

DME

DR Software Services

Federated Insurance

Ferris State University

Foster Corporation

Frigel

• “Velocity is the new normal.” It is important to ignore uncertainty. Carroll said, “Is your company waiting 1015 years for a recession that has yet to arrive – and it still is not here – when companies should be doing things that allow them to chase their future faster?” It’s a mindset. Companies that ignored uncertainty became winners because they focused on what needed to be done to align with future opportunities.

• “Why now – not when?” Companies that adjust expectations balance the risk and reward because every trend goes through a curve of peak inflation, slope of enlightenment and plateau of productivity.

• “Why now – and when? It is key to understanding the opportunity. AI is not one thing; it is many things. The different aspects of AI are at different places on the curve. In addition, Carroll said, “Companies have to anticipate the arrival of intelligent machines, creating the technology used through humanization and exact steps that can be transferred to the robot.”

• The future is coming at you faster than you think.” For companies, challenging the methodology is part of the process and can lead to efficiency gains (i.e., robots and cobots, digital twin technology, industrial IoT, preventive maintenance, quality control, etc.).

• “This is not Grandad’s farm anymore!” With the next generation of manufacturing within grasp, companies should absorb and implement generational changes.

“Above all – think big, start small and scale fast!” said Carroll.

More information: www.jimcarroll.com

Globeius

Grainger Inc.

Ice Miller LLP

iD Additives

INCOE

intouch monitoring limited

Krevera

LS Mtron

M. Holland Company

Mantle

MBS Advisors

MedAccred

Mgmt Recruiters of Tallahassee

Noble Plastics

PartnerShip

Paulson Training Programs

PCS Company

Penn State Behrend

Plante Moran

PolySource LLC

Progressive Components

Prophix Software

QSI Automation

RapidPurge

Rehmann

Resin Technology Inc.

RJG

Routsis Training

SIGMASOFT® Virtual Molding

Stout

US Compliance

Viega LLC

Vive LLC

WayPoint

Wipfli, LLP

Wittmann USA

X2F

Xact Metal

Yushin America

ZEISS

R U B B E R I N D U S T R Y P U B L I C A T I O N S

ARPM PROVIDES INDUSTRY TECHNICAL STANDARDS FOR THE FOLLOWING CATEGORIES:

CONVEYOR BELT

HOSE

POWER TRANSMISSION

PROTECTIVE LINING

RAW MATERIALS

SEALING

HANDBOOKS AND GUIDES

By Joe Walker, ARPM Training Academy technical coordinator, Elastomer Technologies, LLC

The ARPM Training Academy was created to address the demands of rubber product manufacturers in attracting and retaining employees. Workplace shortages have continued to be a significant challenge for all of manufacturing, and rubber product manufacturers are not exempt. Many employers are asking, “Why do workforce shortages exist?” and “How can this problem be addressed?”

First, to address why workforce shortages exist, the following information is key:

Aging population

• The proportion of the population 65 years of age approximates 18% compared to 12% in 2000.

• The baby boomers (those born between 1946 and 1964) have been retiring, and all will be 65 years old by 2030.

• The birth rate steadily has been declining and now is half of what it was in 1960.

• The number of people in the prime working age (21-34) is forecast to decline by 3% in the next five years.

Low labor force participation

• The current rate is 63%, down from 67% in 2000.

• That rate is projected to drop to 60% by 2032.

Productivity

• US productivity has been about 1.4% per year.

• According to TIME magazine’s January 2017 article, the US is the fifth most productive country.

• The top 10 are shown in Table 1.

Most Productive Countries, 2015

1

2

3

4

5

6

7

8

9

10

Table 1. Most Productive Countries, 2015

Low unemployment rates

• In May 2024, the nation’s unemployment rate was 3.7%.

• For comparison, historical unemployment rates are reported to be:

2010: 9.7%

2013: 7.4%

2015: 5.3%

2019: 3.7%

2020: 8.1%

In addition to the above, there is a strong demand for workers across all manufacturing sectors, and it is not confined to just the United States. To highlight this, a study by The Manufacturing Institute and Deloitte projects that there will be 2.1 million unfilled jobs by 2030. All this points to the requirement of employers to recognize the value of their workforce members. Employees are not commodities – and the necessity of investing in their workforce members is a real expression of each employee’s value, as well as showing appreciation for an employee’s contribution to the company’s success.

In order to deal successfully with the labor shortages, companies should be attracting, growing and retaining employees, and using a multi-prong approach of continuing education and training. As noted above, the aging workforce leads to the inability to pass on knowledge to new, entering members. Traditionally, new entrants were “shown” how to do their job. This is not training since, in most cases, the “cause-and-effect” connection is missing – so the value of doing the job correctly is missing. Additionally, lower birth rates point to a longer-term threat of decreased potential worker availability. To address these concerns, ARPM began the Training Academy – first, to educate the industry on key technologies; and then to expose the industry to alternatives to address the labor shortages; and finally, to increase overall productivity and competitiveness.

By providing the only industry-specific training in rubber product manufacturing, ARPM forms a holistic approach to hiring and retaining a high-quality workforce. ARPM believes that by doing this, its member companies will increase competitiveness, productivity and profitability, becoming more attractive employers while reducing employee turnover.

The ARPM Training Academy is, in actuality, a global campus. The essentials of shop-floor rubber manufacturing are addressed with its virtual series trainings, which can be accessed anywhere, at any time. This allows employers to immediately commence the training process with new entrants into the workforce.

In some cases, the successful completion is contingent upon completion within the probationary period or administered by a third party (e.g., employment service). The certificates that result from successful completion have elevated the industry’s employees to a specific skilled labor pool of sorts. ARPM is the only association that offers Best Practice and Technical Guidance documents that form a part of the Quality Management System for rubber product producers. Therefore, training on these important documents is needed.

Again, the ARPM Training Academy offers industry-leading training on these publications. Trainings are offered on sealing technology (static and dynamic), rubber compound production and the essentials of rubber materials science. The fundamental difference in the deliverables from the ARPM Training Academy is the understanding of the complex “cause-and-effect” relationships that exist in rubber product manufacturing. This output forms a large portion of the overall continuous quality improvement initiatives. Additionally, the Training Academy offers exposure to cutting-edge technologies such as AI, automation, data acquisition, traceability and lights-out manufacturing through its Advance Rubber Product Manufacturing Technologies series. The academy also is able to provide training cost reductions through the utilization of its resources, thereby reducing the need for internal, dedicated training.

By active participation in these offerings, rubber industry manufacturers gain a highly-skilled workforce. That provides a greater level of comfort to their customers, with a motivated workforce (one that is not only motivated by monetary

“IN ORDER TO DEAL SUCCESSFULLY WITH THE LABOR SHORTAGES, COMPANIES SHOULD BE ATTRACTING, GROWING AND RETAINING EMPLOYEES, AND USING A MULTIPRONG APPROACH OF CONTINUING EDUCATION AND TRAINING.”

compensation) through personal satisfaction and higher quality products. Participation also is an outward, tangible sign of valuing their workforce members through investing in them to improve skills and become more productive and satisfied. This, in return, reduces turnover and improves productivity, quality and profitability.

The ARPM Training Academy is committed to elevating and advancing the rubber product manufacturing industry’s image and importance to the marketplace. n

Joe Walker is the owner at Elastomer Technologies, LLC. With more than 45 years of experience in the rubber industry, Walker is the ARPM Training Academy technical coordinator and a scheduled trainer for over five associations and universities. Elastomer Technologies, LLC provides training in rubber science, technology, technical assessments, fit-for-function design reviews and risk management reviews.

Cancarb's Thermax® N990 medium thermal carbon black continues to be the industry's choice as a functional filler. That choice is made even easier knowing the waste heat from the production process is used as an energy source to produce power - 30 MW of net clean electricity from waste heat to the local municipality. Cancarb is committed to socially responsible business activities and will be a reliable supplier to the industries we serve for years to come.

The 2024 Benchmarking and Best Practices Conference was held October 2-4, 2024, in Indianapolis, Indiana. The ARPM team is grateful to the presenters, attendees, sponsors and vendors who helped make this event possible.

The Benchmarking and Best Practices Conference is the best conference in the manufacturing industry. ARPM hopes to see everyone next year, October 1-3, 2025!

The 2024 Annual Meeting of the members of ARPM will take place virtually on December 19 at 1:00 p.m. EDT. For more information about this year’s annual meeting and a schedule of events, visit www.arpminc.com/events/.

Do you have employees who are brand new to the rubber industry or who need a refresher on certain topics? The ARPM Online Training Academy is a perfect resource! There are several modules, including:

• Non-Molding Operations Quality in Rubber

• Manufacturing Job Set-up

• Production Flow

• Material Mixing

The Online Training Academy is a resource that is offered for free to all members. Interested in signing up? Email info@arpminc.org.

ARPM members get exclusive cost advantages with Grainger’s special discount pricing ranging from 15% to more than 25% on over one million items. Additionally, along with the costsaving program, Grainger ensures ARPM members receive 5% off on all other items not covered.

ARPM is excited to announce that these benefits now extend to members in Canada!

Don’t leave money on the table – make sure to be in the know on how Grainger’s program can help cut planned purchasing costs.

For more information, to answer questions or to access the full list of category discounts, contact Shelby Lasley at slasley@arpminc.org

After completing another great year of events, ARPM is excited to start scheduling plant tours, networking opportunities, functional area forums and more in 2025.

ARPM is looking for plant tour hosts for 2025. If interested in hosting or learning more, contact Kaitlyn Triplett at ktriplett@arpminc.org or 317.863.4072.

The ARPM In-Person Training Academy is looking forward to hosting three in-person trainings in 2025.

• March 3-5, Advanced Rubber Product Manufacturing

• May 6-8, Product Liability Training

• July 14-18, Seals Product Design and Manufacturing

The locations still are being determined. For more information, visit www.arpminc.com/events/.

Join other finance and accounting professionals at this virtual event taking place on November 13-14. This event will include presentations by experienced industry professionals, facilitated panels and peer-to-peer networking opportunities.

The agenda still is being finalized by the Finance Forum committee.

For more information and to register, visit www.arpminc.com/events/.

Launches December 2

ARPM’s leadership team strongly believes that information

is power and positioned itself as the information hub for the rubber processing industry.

The annual ARPM State of the Rubber Industry Survey was created to allow business leaders to stay in tune with the state of their industry, better understand current industry conditions, plan for the future and validate the status of their operations.

ARPM members that participate in the survey receive the final report, at no cost, and non-members that participate will receive the member discount.

The 2025 ARPM State of the Rubber Industry Survey will launch on December 2.

Please join ARPM in welcoming the following new members!

Alttran

Prince Rubber & Plastics

Hulpac

Specification Rubber

Copper State Rubber n

By Tom Wojcinski, principal, and Michael J. Devereux II, CPA, CMP, partner, Wipfli

While talking with a group of processors, one asked if there was anything a manufacturer could do to ensure its operations are not hacked. But, of course, there is no way that’s possible, especially in today’s connected manufacturing environment. Even if a processor disconnected everything from the internet, it still could be the victim of a technology hack if physical access is available to any bad actors or those working on their behalf.

Cloud-based ERPs, digital transformation and Industry 4.0 solutions are creating efficiencies, customer engagement and business intelligence that are improving operations and profitability, which cannot be duplicated on analog systems. Consequently, however, this increased digitization creates greater risk to processors’ data and operations; and the research has shown that no manufacturer is too small or too big to be safe from cyber-attacks. Leadership often assumes that no one will hack their company because the data isn’t valuable to others. The bad actors disagree, however. Data is valuable, and they would like to put the company in a position where it must pay a ransom to get its data back. And data isn’t just limited to financial information, it could include confidential customer information, bills of material, engineering drawings or mold designs, processing data, sampling results and more.

Wipfli recently conducted a survey of over 200 manufacturers. The survey found that almost half of the respondents experienced three or more network breaches in the past 12 months. That can be overwhelming to leadership, not to mention IT staff or the supporting organization.

A company’s data isn’t the only thing at risk. Cyberattacks can focus on physical assets, rather than digital assets. Cybercriminals can lock up or seize equipment operations. Not only can this result in a significant amount of unplanned downtime but can also pose a physical risk to employee safety.

For example, consider a processor that stores and recalls processing data for each job within an ERP or MES system. What happens if those digital services are disrupted or the underlying operational data is held hostage? Or a worse scenario, what if the technical specifications are changed, and the processor continues to make parts that don’t meet internal or external specifications? Similarly, vision and quality systems within the plant could be vulnerable and the target of

a potential attack. While some of this seems implausible or unlikely, cyber-attacks are becoming more sophisticated and aggressive, and exposure in these areas can cause very real risks to organizations.

Processors can protect their operations by building and implementing resilience strategies to cyber-attacks. In this instance, resilience does not mean “bullet proof.” Rather, it means that a company can resist an attack, to respond quickly and thoroughly when the attack occurs, and to efficiently recover any data or business operations that are compromised. That starts by identifying weaknesses in the digital perimeter and then building a multilayered strategy to protect and respond to the cyberattack.

For processors, there can be multiple physical and digital avenues into operations or data (including financial, operational, technical or front office information). Often, these paths are hidden or are seemingly insignificant. Outdated and unsupported hardware and software on the shop floor are two of the most overlooked sources of vulnerability. While this equipment may not be used like traditional PCs or laptops, it is still connected to the network. If it’s not maintained, it could be a security risk to the organization.

All too often, the IT department is not involved in all IT decisions. With the advancement of software-as-a-service model and cloud computing, it’s easier for employees to purchase new software, download applications or share files using the cloud, without the oversight of skilled IT or cyber professionals. Systems and software that are not vetted against company policies or maintained properly could pose additional, not-so-obvious risks. In addition, they extend the number of vectors a bad actor may use to gain access, often without a company’s knowledge, making it more difficult to protect data and operations.

A lack of real-time cyber monitoring is another common blind spot in processors. Without real-time monitoring, a company has no visibility into attempts to infiltrate its network. Stopping and safeguarding against attacks is harder if a company does not know that they’re happening. For instance, real-time monitoring can protect against the violation of impossible travel rules. In this scenario, a legitimate user logs into the network from his or her home office in Milwaukee, Wisconsin.

Let’s assume is the corporate controller of a processor, just outside of Milwaukee. Then, just three hours later, the corporate controller logs in from Dublin, Ireland. This is an impossible travel scenario and clearly a sign that the corporate controller’s credentials have been breached. However, it could go unnoticed for some period of time without proper, real-time monitoring in place.

The most effective means to resist an attack is to establish a multilayer security strategy. At its most basic level, the strategy should include:

• Password protocols: Require the use of strong passwords.

• Email protections: Technologies that limit spam and spearphishing attempts will reduce the risk of social engineering.

• Multi-factor authentication (MFA): MFA requires users to take additional steps to verify their identity anytime when logging in or accessing a system or company app. MFA should be implemented on all removed access points, as well as internal administrative accounts. This includes email, VPN and all cloud-based applications.

• End-point detection and response (EDR): EDR increases the ability to detect suspicious events by providing realtime visibility into potential attacks. EDR often is confused with antivirus software, which should also be used by all processors. Antivirus software looks for malicious programs running on the computer or network, while EDR searches for malicious activity in the memory of the computer.

• Regular vulnerability scans and penetration testing: If a company is not monitoring its environment, processors can not identify their vulnerabilities or ways to fix them. Monthly or quarterly penetration testing of the external systems and vulnerability scans of the internal systems are critical to identifying weaknesses before they can provide access to bad actors.

• Vulnerability management: Cyber criminals are regularly probing for security gaps. A company can make it more difficult for them by deploying security patches and software updates, removing unnecessary software and disabling unused system processes.

• Air-gapped backups & segmented networks: If an employee can browse directly to the company’s backup files from its primary network, they are not safe from ransomware or other cyber-attacks. Separated backup files on a stand-along network that requires separate credentials often mitigates this risk.

• Recovery testing: What happens if a company is attacked? Have steps been taken to restore the network, files or operations? Are the backups occurring as designed? A network failure or cyber-attack isn’t the best time to find out files haven’t been backed up or do not have the means of restoring them. Processors need to regularly test the backup process to confirm the protocol is working, as designed, and intended.

It’s critical that employees understand the importance of cybersecurity. Many hackers don’t hack systems, they hack people, as they’ve found it’s easier to trick someone into sharing their credentials than to break into a network. That is, if someone gives them the keys, why mess with the lock. It’s for that reason that employee engagement on cybersecurity is just as important as the focus on a company’s perimeter.

To start with, processors must put controls in place to govern how data and information are used, managed and stored. Sensitive data should be limited to those who absolutely require it to perform their job functions.

In addition to understanding where the data is stored and who has access to it, processors’ best practice is to implement a comprehensive training program. Hackers will use a variety of social engineering techniques to steal information, including email (phishing), SMS text messages (smishing) and phone calls/voicemail (vishing). Training employees to be skeptical is key. When employees understand what they need to do and why, company operations will be better protected against cyber criminals.

Finally, processors should engage in regular cyber assessments, whether that’s done internally by IT staff that keeps up with the cybersecurity trends or by an outside firm. These assessments provide visibility into potential avenues bad actors can access data. From there, processors can develop or modify safeguards and policies that can better protect them from cyber fraud. n

Tom Wojcinski is a principal in Wipfli’s cybersecurity and technology management practice. He leads a variety of engagements designed to help improve organizations’ cybersecurity posture, including cybersecurity risk assessment, control program development and implementation, incident response planning and simulation, vulnerability and penetration testing, security audit, control verification, and managed security services. Wojcinski is a frequent author and speaker on cybersecurity and information technology risk management topics.

Michael J. Devereux II, CPA, CMP, is a partner and director at Wipfli. Devereux’s primary focus is on tax incentives and succession planning for the manufacturing sector. He regularly speaks at manufacturing conferences around the country on tax issues facing the manufacturing sector.

More information: www.wipfli.com

Join the ARPM YP Network!

Members of ARPM’S YP Network:

Help organize events for ARPM’s YP Network

Participate in networking, leadership and development opportunities

Have the opportunity to sit on a committee

Gain access to industry mentors

Have a special pre-conference session at the annual Benchmarking and Best Practices Conference Network with other like-minded young professionals

Learn more or sign up for the YP network here!

A look at rubber compound development in mixing rubber and additives such as fillers, processing aids and curing agents in fixed proportions to create a mixture based on specific physical and chemical properties, intending to achieve these results cost-effectively.

330.577.4088

www.ace-laboratories.com

ACE Laboratories, Ravenna, Ohio, is an independent laboratory providing testing, expert technical consulting, research and development, ACE’s team of rubber experts can formulate compounds to a customer’s specific compound performance specification and processing parameters. ACE can formulate high-performance compounds that meet even the most stringent specifications. It also offers root cause analysis, reverse engineering and benchmarking services to support every step of the compound and product development process. ACE does comprehensive small batch mixing and rubber testing services for manufacturers seeking to optimize their rubber compounds or test multiple iterations of a compound recipe. Its labs are equipped with four types of industrial mixers, including tangential four-wing BR Banbury, tangential tilt body mixer, sigma blade mixer and ross mixer. ACE’s mixing and compounding experts have years of experience working with a wide range of base polymers.

330.650.2223

www.alttran.com

and get customers’ rubber products into production quickly. In addition, its lab testing includes heat agings, low-temperature brittleness, abrasion resistance, electrical conductivity and resistivity, fluid and swell testing, among others. Combine this with flexibility, potential for high capacity and the ability to mix both client-provided polymer formulas and custom rubber compounds in a wide variety of elastomers, ALTTRAN can get a customer’s rubber product efficiently done.

ALTTRAN, Hudson, Ohio, is a supplier of clean and consistent custom rubber mixing for color rubber and black rubber compounds in a variety of rubber processing applications. ALTTRAN Technical Services (ATS), a subsidiary, provides ASTM polymer testing, polymer formulation development, raw-material validations and productperformance evaluations. From rubber analysis to polymer testing to production, ALTTRAN can reduce development time

HEXPOL Compounding, Aachen, Germany, a global developer and manufacturer of quality, advanced polymer compounds, has a portfolio of high-performance compounding and advanced rubber compounding. Its High-Performance Compounding team supplies compounds that perform under the most arduous conditions, such as Silicone (VMQ), Fluoroelastomer (FKM) and similar materials such as FVMQ, AEM, ACM and HNBR. Highperformance compounds are materials with enhanced attributes, such as the ability to withstand extreme temperatures or being highly resistant to acids/alkaline. HEXPOL develops and produces high-performance compounds for various processing techniques, different compounding types and offers a large range of delivery and packaging forms. In addition, its Advanced Rubber Compounding team is knowledgeable in EPDM, NBR, SBR, NR and similar polymers. Developed to meet exacting specifications, this team delivers a wide range of rubber compounds suitable for a broad range of applications. n

By Chris Kuehl, managing director, Armada Corporate Intelligence

Given all the data, where does the economy stand? It is a bit of a broken record, but the old phrase for economists still is true: ‟It depends.” What economists know for certain is that some of the drivers of last year’s economy have faded and one has all but vanished. At the start of 2023, there were a lot of references to the supply chain collapse and how businesses were trying to adjust.

Today, inventory-to-sales ratios have returned to normal levels (although not in all sectors or completely). Some major supply chain bottlenecks have cleared (Panama Canal), but others are worsening (Red Sea and South China Sea). Manufacturing was booming as companies rushed to beef up their inventory, but now they are waiting to see that inventory diminish before they start seeing new orders again. Additionally, there are unanswered questions regarding the interest rate environment, labor situation, supply chain and, of course, the political environment.

There is a three-legged stool as far as the economy is concerned – still stable but not quite as resilient as the four-legged variety. The dominant factor is consumer spending, but over the past couple of years, it has been apparent that most of that spending originated in the upper-third of income earners (those making over $100,000). The bottom-third earners (under $50,000) essentially have retreated, and it’s estimated that 85% now are living paycheck to paycheck and buying only necessities. That leaves all eyes on the middle-third earners ($50,000-$100,000), who still are spending on recreation and entertainment while other non-essentials are being rejected.

The most important factor for middle-level consumers is job security. In the last few months, there has been a marked reduction in job offers across a variety of sectors.

Government spending has been an important leg but is rooted in infrastructure spending, and lately that has slowed – primarily due to election jitters. The bulk of the money allocated for infrastructure originally was aimed at energy issues and reacting to climate change. There was a lot of money set aside

for solar and wind, promoting EVs and conservation. These were never popular provisions within the GOP, and if there is a shift in congressional leadership, that money may be redirected to more traditional activities, such as roads, bridges and construction. There is very little of the government cash that was allocated during the pandemic left, and there doesn’t seem to be enthusiasm for more big spending sprees. On the other hand, there is little appetite for any spending cuts either.

The final motivator is non-residential construction, and there continues to be strong demand for anything related to logistics or high-tech. The demand for data-center activity has been estimated at over 200 terawatt-hours per year, which is a 160% increase in power demand. While there has been a marked reduction in demand for office buildings and retail outlets, at the top of the list has been anything related to logistics and supply chain.

The shift in the way that consumers shop has created a huge demand for warehousing, and that demand has been further amplified by the need for manufacturers and others to hold more inventory. The Just-In-Time (JIT) system is not what it once was as there have been too many inhibitions, and that has shifted emphasis toward holding more inventory.

Another fast-growing segment of non-residential activity has been medical, with a trend toward decentralization. Medical facilities are springing up in suburbs at a rapid rate. The fastest growth still is in manufacturing, as entities have adopted technology and robotics requiring alteration of their physical facility.

Total residential construction activity still is trending higher than expected, but there has been a shift in demand from the multifamily unit to more single-family. Overall, manufacturing demand is subject to growth drivers in a wide variety of industries. The industry remains complex because what is good for one sector may not reflect demand for another sector’s output.

What does this mean for manufacturing? Of the three legs that remain, it can be argued that manufacturing is tied to consumer demand, but in most cases, that connection is indirect. The majority of manufacturers are small- to medium-sized

suppliers to some larger entity that assembles all those disparate parts. They are distant from actual consumer wants and needs and depend on the companies they supply to figure that out. That leaves most without a lot of control over demand while also dealing with “customers” that constantly demand lower prices. It is a tough world!

Meanwhile – back at the Federal Reserve – at the same time the European Central Bank (ECB) has started to hedge its bets on rate cuts, there have been more signals of a Fed cut... and maybe as soon as September (as opposed to the end of the year). The points made by Fed officials include an observation that inflation pressures now are close to their target range, data shows the labor market softening a little and there is a general acknowledgment that those in the bottom third of income earners are struggling to make it from one month to the next.

It is important to remember that an interest rate adjustment (up or down) takes several months to start affecting the economy. Many other factors affect business expansion, and the triggers that encourage the reduction of rates are the ones that inhibit those expansion plans (slowing economy, higher rates of joblessness leading to reduced consumer activity, etc.).

The US wants to revitalize its industrial core, and it wants to find a way to be more competitive in a variety of modern technologies. This has necessitated a dramatic shift in overall trade policy and intent. The push for most of the past 50 years has been to emphasize the consumer so the US would have access to quality goods at a cheap price.

China set export records last month despite the fact its economy stuttered in the second quarter – falling to 4.7% growth. Currently, it manufactures 35% of all US apparel and accessories. Over the last few years, the Chinese have been exporting a great deal of high-tech and high-value goods to the US – everything from solar arrays and EVs to farm machinery, robots and electronics. The US now seeks to blunt this surge in export activity, and that is far easier said than done. The fact is that consumers always will be motivated to buy at the cheapest price. Sellers always will be motivated to find ways to serve that market.

With that, tariffs are taxes imposed on an export from another nation. The idea is simply to make that good more expensive than a local option. The consumer is the one who will pay that tax, and the assumption is the consumer will switch to buying an alternative product rather than pay the higher price. Unfortunately, for those trying to limit these imports, there are many ways around these tariffs. The simplest is to manufacture a product somewhere other than China. The strategy is simple – make most of the item in China, ship it to another nation that is not subject to tariffs and then send it to the US.

The bottom line is that tariffs and regulations fail far more often than they succeed. It means investing in what the US industry needs – manpower, infrastructure, innovation, research and development. It also means understanding priorities. Which is more important – accelerating the adoption of the EV in the US by allowing cheaper vehicles to be sold here or thwarting China in some limited way?

In conclusion, there is little threat of a recession but it seems a slowdown likely is possible (some would refer to this as a soft landing). Inflation still is a threat – primarily from wage growth in the service sector, but otherwise the rate of inflation is falling. The Fed will cut rates by the end of the year, but the question is whether that means September or December – and will this bring rates down below 5.0%? n

Chris Kuehl is managing director of Armada Corporate Intelligence. Armada executives function as trusted strategic advisers to business executives, merging fundamental roots in corporate intelligence gathering, economic forecasting and strategy development. Armada focuses on the market forces bearing down on organizations.

More information: www.armada-intel.com

By Brett Stone, TC45/SC1 TAG chair, ARPM technical coordinator

Modern existence depends on things humans can take for granted. Cars run on gas from any gas station, the plugs for electrical devices fit into any socket and smartphones connect to anything equipped with Bluetooth. These conveniences depend on technical standards, the silent and often-forgotten foundations of technological societies.

ARPM develops and manages a wide variety of standards for hoses, belts and seals. The process for creating and managing these standards may not be as a manufacturer might imagine.

Standards are developed by private or nongovernmental organizations that facilitate collaboration and cooperation among technical experts. In some industries, companies can make fortunes by defying established standards – think of innovative products from Apple or bold designs from leaders of the fashion industry. Standardization also creates losers, and it can be very costly to invest in the losing side of “standards wars” like Blu-ray vs. HD DVD, Ethernet vs. Token Ring network protocols and Apple Lightning port vs. USB-C. The iPhone now uses the USB-C standard port.

One example that may not be thought about is passports. Yes, these are controlled by a standard: ISO/IEC 7501-1:2008(en) Identification cards – machine readable travel documents –part one: Machine-readable passport.

In the world of standards, there are national standards and international standards.

National standards are developed and maintained by a country. Examples of the most predominate for rubber products and testing include:

• ARPM, American Society for Testing and Materials (ASTM) and Society of Automotive Engineers (SAE), United States

• British Standards Institution (BSI), United Kingdom

• Deutsches Institut für Normung’ (DIN), Germany

• Japanese International Standards (JIS), Japan

International standards are just that – international/global.

International Organization for Standardization (ISO) is the predominant standard organization in this category. In many cases, the ISO standard has replaced national standards or, if not replaced, the national standard is harmonized to the ISO. On the flip side, many ISO standards are/were derived from national standards, as that is where the expertise resides. Products made to a US national standard can be limited to US markets. In order to sell to global markets, products most likely need to be made to ISO standards. Not all aspects of a product are set in the standard. Some aspects are up to the manufacturer, but those aspects needed for interchangeability are defined in the standard.

Standards are developed by technical committees comprised of product experts from businesses (i.e., material suppliers, manufacturers, OEMs and downstream supply chains). Most committee representatives are employed by businesses and are supported to attend meetings by their employers. However, when at the committee meetings members are instructed to act in the best interest of the standard and not to push a single company’s agenda.

But … if a company doesn’t participate in the process, then it cannot complain about the standard or the impact of it on the company’s product line.

The general criteria for what can drive a product standard include:

• The product or technology must be widely produced by manufacturers.

• The product should be widely accepted in the marketplace.

• The product cannot have any Intellectual Property (IP) around it or the IP must be given up to the standard body.

ISO consists of over 25,111 standards, which include 349 Technical Committees – TC1 -> TC349 – and thousands of sub committees and working groups.

These standard committees cover a wide range of products and services, which can be found at https://www.iso.org/technicalcommittees.html.

ISO has a bureaucracy that rivals many governments. ISO imposes very tight controls on revisions, ballots, committee meeting notes and ballot comments. Ballots are a majority rule. When voting at various stages, each country gets one vote. The US gets one vote, as does Luxembourg.

American National Standards Institute (ANSI) is the national standards body for the US ISO. In the US, various standard bodies are used for secretaries in ANSI – ASTM, NFPA and ARPM, to name a few.

A US position of a ballot is accomplished through a Technical Advisory Group (TAG). All US TAGs have an administrator in ANSI. For ARPM’s TAG role, it is the administrator who runs the TAG process. The TAG process’s purpose is to develop a US position on an ISO ballot and submit the vote to ANSI for posting to ISO as a formal US vote. All ARPM TAGs run through a process that meets ANSI and ISO directives. The TAG is comprised of technical experts that are made up of producers, users, government and people with a general interest. The TAG administrator must submit a certification of process, procedures, roster and commitment to ANSI in order to maintain its administrator role. The TAG Chairman is responsible for running the TAG’s operation, creating TAG meeting agendas, minutes, member roster maintenance and keeping records of all process inputs and outputs, and ARPM

TAG procedures. The process must be reviewed and revised to make sure it meets ANSI directive written procedures. All of these may be reviewable by ANSI.

ARPM engages technical coordinators who are experts in hose, belt and seal products to manage the revisions of ARPM standards and participate in US and ISO product standard development activities for the applicable rubber products. These technical experts chair standard committees in national and ISO environments, chair ISO TAG committees, maintain ISO TAG process procedures and member rosters to compliance with ANSI directives, and answer questions on standards from the ARPM user community. There are three ARPM technical coordinators who manage hundreds of standards through the various committees for rubber products of hoses, belts and seals.

In the ARPM standards library, there are 11 hose standards, 23 belt standards and 22 seal standards, as well as associated hose and belt handbooks. n

Brett Stone, ARPM Technical Coordinator, has decades of knowledge and experience in the Rubber Industry. Currently serving as the TAG chair for TC45/SC1, Stone is instrumental in keeping ARPM Product Standards up to date and representing the association at a global level.

By Liz Stevens, writer, Inside Rubber

The US National Science Foundation has announced a first round of $26 million in federal funding to support universities for five years of domestic natural rubber production development and enhancement of workforce development for this new industry. Seven universities will focus on a trio of plant sources – mountain gum, a dandelion species and guayule – using engineering, biology and agriculture expertise to foster domestic natural rubber sources to alleviate dependence on Southeast Asia as the globe’s predominant source for natural rubber.

The Ohio State University will take the lead in the creation of the multi-institution Transformation of American Rubber through Domestic Innovation for Supply Security (TARDISS) Engineering Research Center, partnering with the California Institute of Technology, North Carolina State University, Texas Tech University, the University of California – Merced, Rensselaer Polytechnic Institute and Case Western Reserve University. The Goodyear Tire & Rubber Co., the Waters Corp. and the Rubber Division of the American Chemical Society are additional partners.

Per the Ohio State University, 1 “TARDISS, composed of academic partners and supported by industry stakeholders, will lead fundamental research supporting the creation of a ‘Silicon Valley of Domestic Natural Rubber Production,’” said Judit Puskas, professor of food, agricultural and biological

engineering (FABE) and a distinguished university professor at Ohio State. As principal investigator on the grant, Puskas will lead the center, along with its Director Ajay Shah, also a professor in FABE. Katrina Cornish, Ohio State professor emeritus and current director of the US Department of Agriculture’s Agricultural Research Service and Arid Land Agricultural Research Center, will serve as an external adviser to TARDISS.