Franchino Mold Stands Out in Workforce Strategies

Mold Manufacturing Outlook for 2025

Leadership Planning for Succession

Standards for Safe and Reliable Lifting

Franchino Mold Stands Out in Workforce Strategies

Mold Manufacturing Outlook for 2025

Leadership Planning for Succession

Standards for Safe and Reliable Lifting

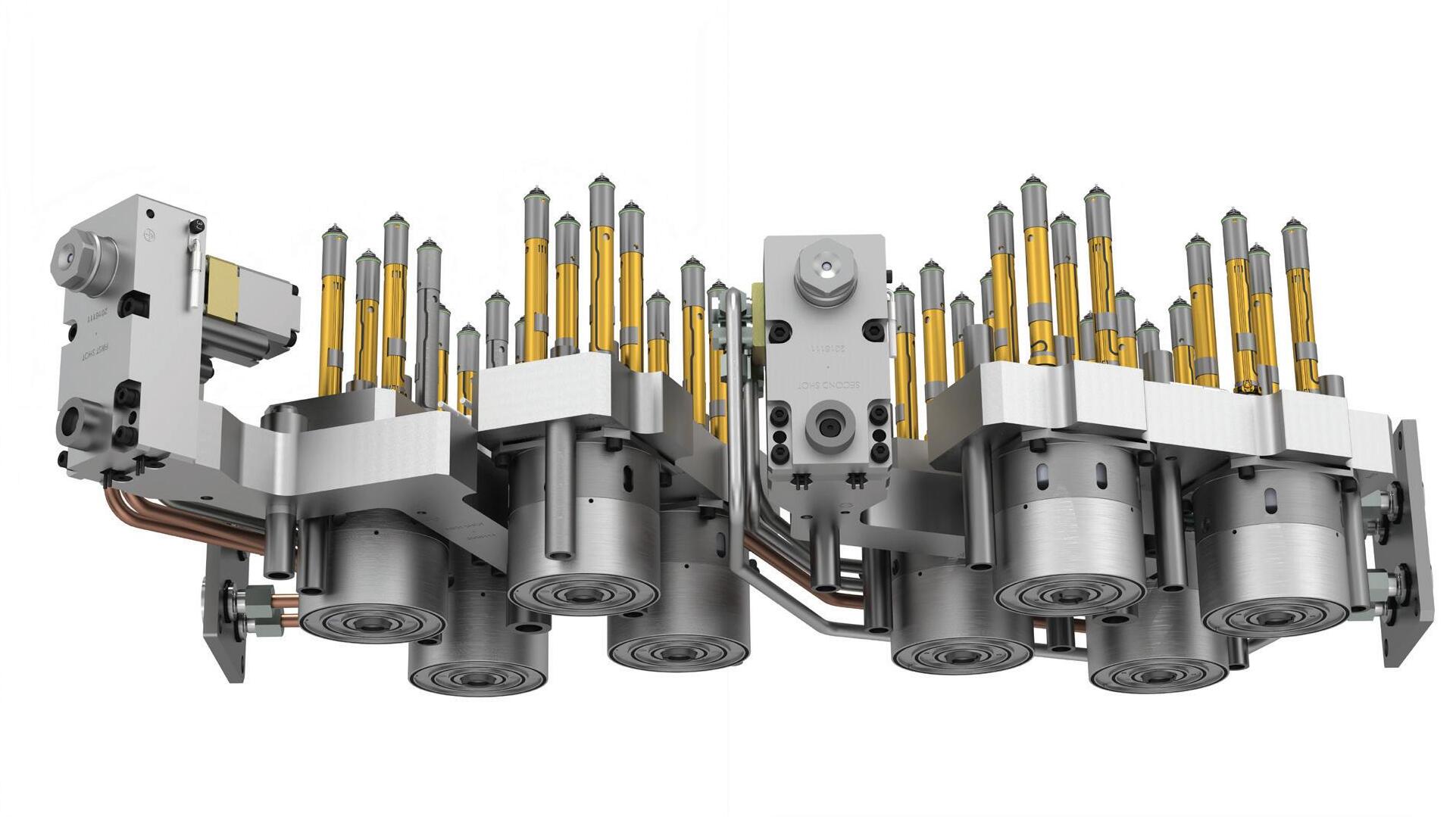

Mold Designers are always fighting for real estate within a mold, and demands for part quality are always increasing. Progressive understands these factors and continues to develop solutions:

• Top mount Taper Locks beginning with 1/2” diameter

• Flat Cavity Interlocks begin at 5/8” width, Rounds at 1/4”

• Bar Locks are now also available in a top machined series.

These exclusives are just the beginning to a better running mold.

Receive Pro’s new v16 Catalog and CADalog ® to further put our unmatched range of componentry to work for you.

Troy

Kym

Rachael

Olivia

TYLER VANREE AMBA President, LEGACY PRECISION MOLDS, INC.

Hello AMBA! I hope this message finds you and your business doing well. While 2024 has presented its fair share of challenges in manufacturing, there also have been some wonderful opportunities for connection and giving back that I hope you were able to participate in.

Personally, I had the pleasure of attending two AMBA charity golf events this summer. The West Michigan Golf Outing raised funds to support scholarships for young professionals, while the iWarriors Alliance Charity Golf Outing in Illinois raised funds to support wounded warriors. Additionally, United Tool and Mold hosted its annual golf outing at the end of October in support of iWarriors.

These events serve as powerful reminders of the positive impact AMBA membership can have on the industry. Whether it’s investing in the next-generation workforce or supporting those who have sacrificed for our freedom, it’s inspiring to see what can be achieved when we come together for a good cause. I applaud everyone who contributed to the success of these events.

I’d also like to highlight upcoming events this year: On December 10, AMBA will host a Business Outlook for 2025 webinar. This session will deliver valuable insights to help companies anticipate what the next 12 months may hold for the industry and how to best prepare for it. On December 4 and 12, there are two virtual roundtables to discuss best practices in employee engagement and retention strategies as well as CNC and operations. These are great opportunities to share challenges, ideas and best practices with peers in the industry. For more information and to register for these events, visit www.amba.org/events. Members also can access archived webinars in case a previous session was missed.

In other news, AMBA remains committed to advocating for you at the federal level by addressing key issues, such as government regulations, federal grant opportunities, tax policies and fair trade. Omar Nashashibi, a familiar face at AMBA conferences and webinars, continues to represent us effectively in these areas. Though Omar recently has transitioned to operating under a new business name called Inside Beltway, his partnership with AMBA and support remain the same.

In closing, I’d like to encourage you to find ways to express gratitude and appreciation to those closest to you, especially the co-workers you spend time with each week. Who in your life have you not thanked recently? When we take the time to show gratitude toward others, we benefit from it as well. As the old saying goes, “It’s always better to give than to receive.” I hope you finish the year strong and find time to enjoy the upcoming holiday season with family, friends and your team. It’s hard to believe 2024 is coming to a close, but I’m excited about what 2025 holds. I’m truly grateful to have a tribe of fellow mold builders and suppliers I can count on, walking alongside me every step of the way. You are the AMBA. We are the AMBA. Together, we are stronger.

Tom Barr, TK Mold & Engineering

OFFICERS

National President

Tyler VanRee, Legacy Precision Molds

Vice President

Andy Peterson, Industrial Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Fiedlander, Coplan & Aronoff LLP

Treasurer

Hillary Thomas, Westminster Tool

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume Engineered Diamond Products

Justin Gregg, Dramco Tool Co., Inc.

Mike Hetherington, Franchino Mold & Engineering

Kyle Klouda, MSI Mold Builders

Chad LaMance, United Tool and Mold

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

Scott Smith, Tessy Tooling

John Stocker, Swiss Steel USA, Inc.

By Liz Stevens, writer, The American Mold Builder

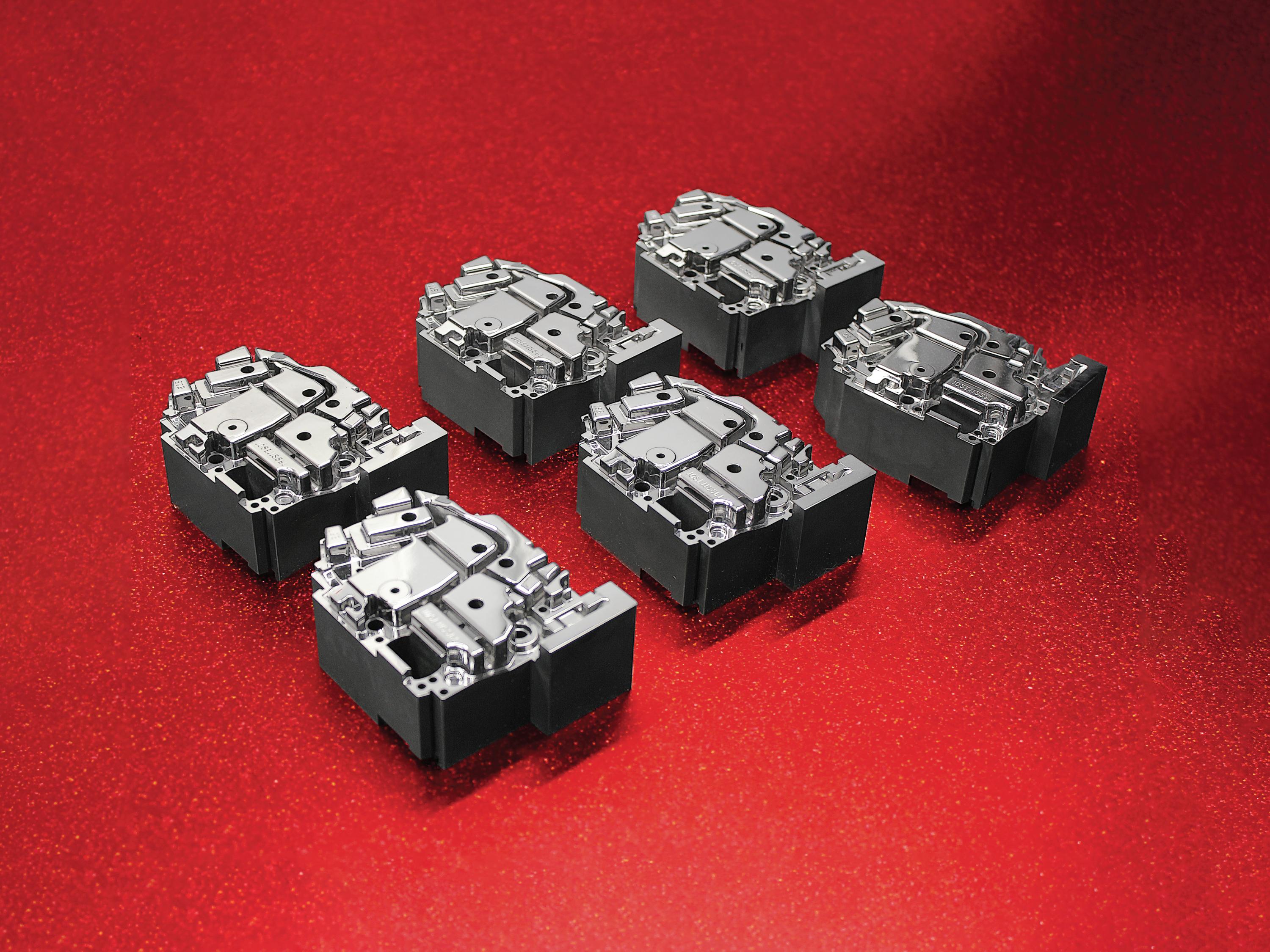

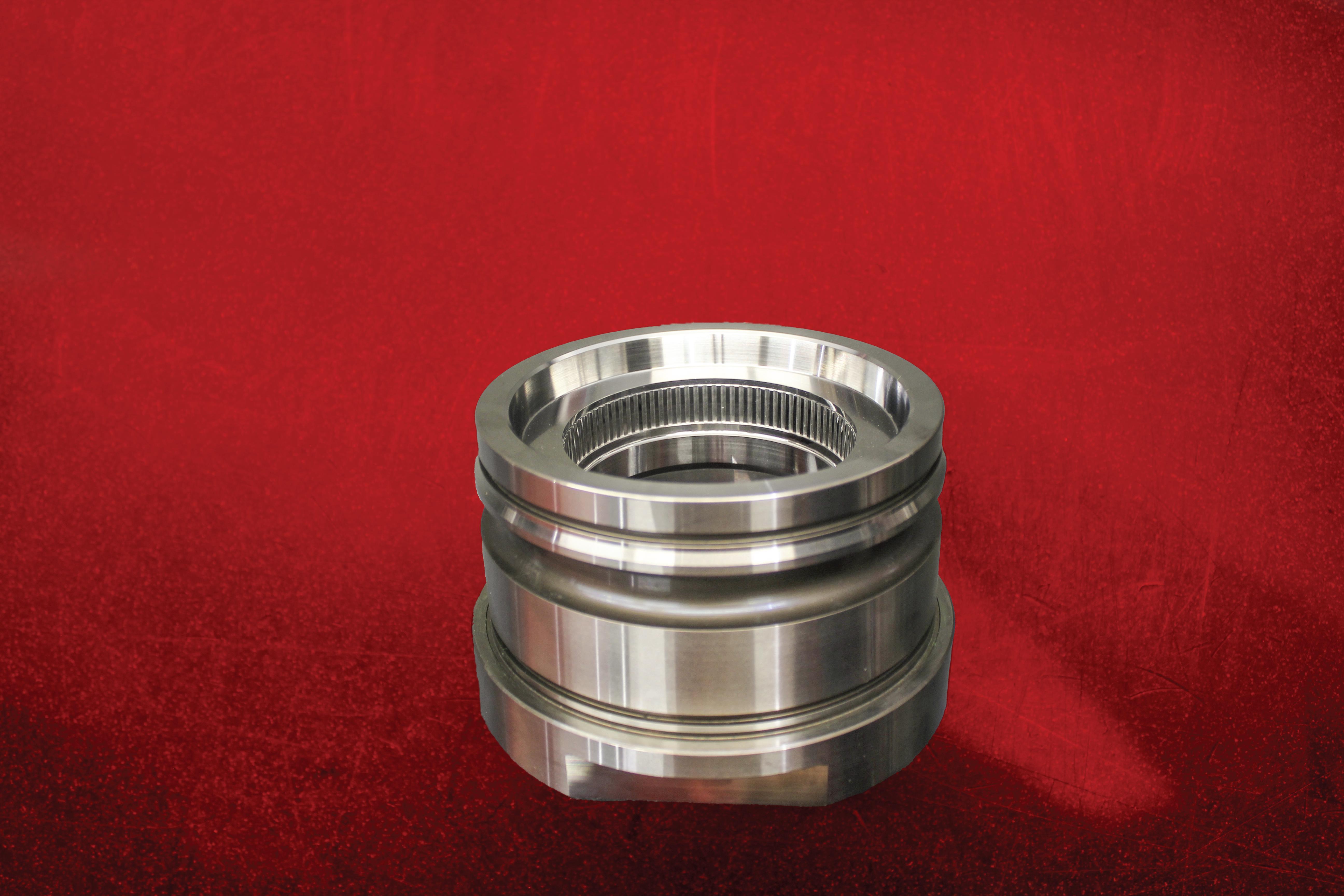

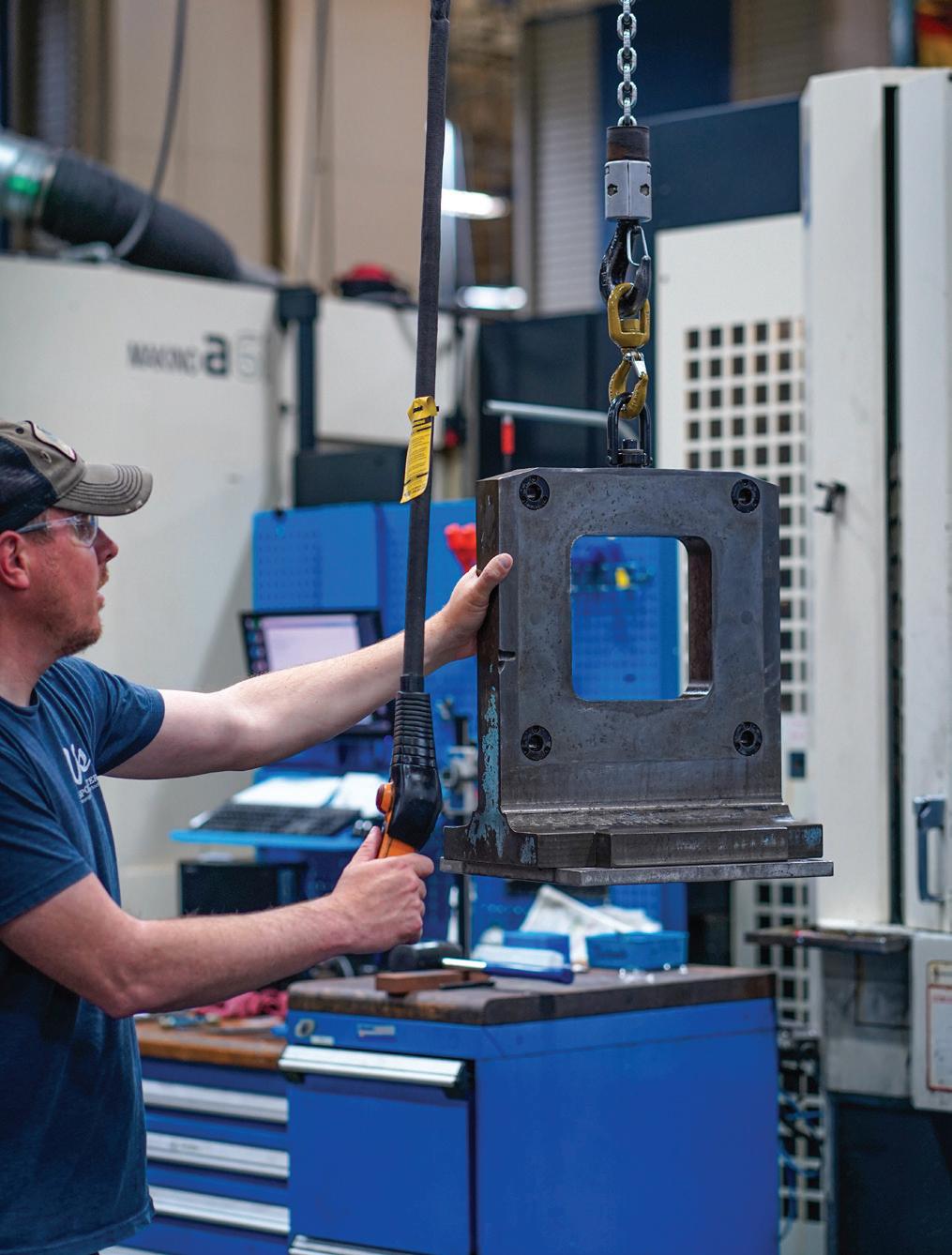

Franchino Mold & Engineering (FMEC), Lansing, Michigan, has served the mold and die industry since 1955. The company offers die cast dies, plastic injection molds, contract machining, die/mold repair and engineering services to the automotive, construction, consumer products and material handling industries. FMEC stands out, from its competition in two ways: It occupies a special niche in producing medium to large (including XXL) molds and dies, and it is a respected company operating on the cutting edge with its business philosophy and operation style, while embracing innovation and workforce development strategies. The company’s culture and its practices in employee recruitment, candidate selection, employee benefits and workforce retention stood out to The American Mold Builder, prompting a closer look. Brad Rusthoven, human resources manager, provided insight into FMEC’s best practices.

FMEC’s website, often a first impression for job seekers, reflects the company’s production standards, its perspective on technological innovation and its attitude toward its workforce. The website presents a company that works in meticulous medium- to super-sized production, employing dedicated associates who combine expert skills with stateof-the-art equipment in a modern, supportive environment. The website also is designed to make it easy for prospective employees to learn about jobs in manufacturing, see the job opportunities and apprenticeships available at FMEC, understand the company’s employee benefits and apply for a job through an online form.

FMEC clearly presents its culture on the website: “Our culture of continuous improvement, implementation of lean techniques and pushing ourselves to improve daily means that we stay on top of the latest technology, tools, techniques and quality systems.” During an employee interview, identifying job candidates who can embrace this culture and become valuable assets to the company is a two-step process. “The first step,” Rusthoven explained, “is finding the ‘right’ person. We do this by describing our core values for team members during an interview – hardworking, innovative, teamwork, integrity and trustworthy – and asking candidates to give examples of how they demonstrate each of these values. If the candidate demonstrates that he or she is the ‘right’ person, the next step is for us to find the ‘right seat’ for them from a role/ responsibility standpoint.”

The seats available in today’s manufacturing are a far cry from the picture of industry roles and working conditions that have persisted from their earlier days. Presenting today’s manufacturing environment, especially in a resurging industry with an already tight workforce pool, helps FMEC recruit talent. “We have been waving the flag for manufacturing since the recession nearly 15 years ago,” Rusthoven said. “The industry we are in is no longer a dark, dingy manufacturing setting. It is a clean, well-lit, safe working environment with the highest technology and the most advanced computerized equipment on the market.”

Being a company on the cutting edge with advanced technology, tools and techniques can be an attractive

environment for a job seeker. FMEC conveys this characterization as part of its culture. “This ties back to our ‘innovative’ core value,” said Rusthoven. “The company wants to be innovative and to implement technology that is advanced, flexible and automated; the majority of our equipment has been purchased in the past 10 years. From a technique standpoint, we want to define a process and follow it. However, we want our employees to be innovative as well. If they have a better way to do something, we want them to speak up so that we can evaluate new ideas and change the process, if warranted, for continuous improvement.”

FMEC’s position as a producer of super-sized dies and molds makes it stand out as a unique employer. “We let candidates know that our niche is designing and manufacturing medium to large plastic injection molds and die cast dies,” Rusthoven explained. “We show them this on the tour that we give during the interview. Some candidates are intrigued by the idea of working on big molds and dies, and others honestly are intimated by the size of the work. If they are mechanically inclined and have some foundational skills, we can train candidates who have a good attitude and work ethic and are punctual. In general, we will hire for character over skill; we can teach them what we do.”

FMEC collaborates with two local career centers to cultivate new workforce candidates with precision machining training. The partnerships began when Rusthoven contacted the career centers. “Our relationships with both local career centers (which have specific precision machining programs) began in 2011,” he explained. “I reached out to both instructors, and they invited me over to learn about their programs and gave me tours of their facilities.”

Rusthoven’s outreach led to a spot on each of the career centers’ advisory boards and FMEC’s participation in career center events, including in-class presentations, mock interviews, resume reviews, career days, student showcases and open houses. The relationships also led to the company hosting activities at its facility – tours, job shadows and work-based learning opportunities.

“The endgame,” said Rusthoven, “is to become the ‘employer of choice’ for the precision machining programs at the local career centers. We want the instructors, counselors and work-based learning coordinators to refer their top students to us after graduation.”

FMEC offers apprenticeships and an educational benefit to attract new workers and to help retain its valuable workforce. Two tracks are available – journeyman’s card or journeyman’s card plus an associate’s degree or certificate

– and it’s all on Franchino Mold & Engineering’s dime. The apprenticeship program is a comprehensive, accredited offering for CNC machinists, welding and mold building. The educational benefit allows employees to take jobrelated courses at the local community college.

The company’s apprenticeship program is well-established. “The first Franchino Mold employee completed an apprenticeship in 1969,” said Rusthoven, “and our apprenticeship program has been in its current hybrid form since 2011.” Of the company’s current workforce totaling 85 employees, 26 have gone through the apprenticeship program. Interest in apprenticeships seems to be on the rise – a welcome development for companies that need trained, skilled workers. “There has been an uptick in participation,” he said. “Enrollment in the machining programs at our local career centers are all wait-listed, and this is where we draw the majority of our apprentice candidates.”

It takes intentional policies and valuable benefits to retain a workforce. FMEC demonstrates its commitment to employees in a variety of ways, including the possibility of specializing in a role or gaining a broad understanding of the operation. “We have a lot of opportunities now available,” Rusthoven explained, “as our seasoned workers are retiring. New hires and current employees can specialize in a specific area or cross-train across multiple work centers.”

The company provides many other retention incentives. “We strive to offer a clean, safe and enjoyable working environment,” said Rusthoven. “We offer flex schedules, annual performance reviews, and competitive compensation and benefits.” FMEC’s benefits include health insurance, a dental allowance, reimbursement for prescription safety glasses, short-term disability coverage, paid time off/ vacations and holidays, a 401(k) program with matched funds, tuition reimbursement and a tool/equipment purchase program.

“We strive to be above average when it comes to our benefits package,” Rusthoven said. “The company’s tool/ equipment purchase program is another valuable benefit. It is like an interest-free loan for employees to purchase required tools for their job.”

In today’s tight job market and amid a resurgence in manufacturing, employers wishing to expand and protect their workforce would do well to consider the many ways that FMEC attracts, trains and retains its valuable employees.

More information: www.franchino.com

By Lindsey Munson, editor, The American Mold Builder

Mold manufacturing sets its sights on a positive outlook in 2025, from global market and economic growth to an increase in automation, operational efficiencies and sustainability practices. With that, manufacturers also are keenly aware, even in an optimistic state, to strategically plan and brace for challenges of supply-chain disruptions, labor shortages and skilled moldmaker demands, geopolitical concerns and more. The American Mold Builder worked with three professionals in the moldmaking industry and conducted a Q&A that gives context for what’s to come in 2025. These leaders share the challenges presently being faced and what’s expected in the new year, how to mitigate those challenges, their thoughts on the economic and political impacts, and lastly, what investments companies should have at the top of the list.

Jonathan Buss is president of Buss Precision Mold, Inc., Clackamas, Oregon, a manufacturer that designs and builds plastic injection molds. Buss said, “For Buss, there is significant uncertainty as we move into 2025 and, at this time, the election is setting the stage for where we go strategically.” He continued, sharing that planning is key, and posed these questions, “With the election and movement in Washington, will manufacturers see improvements and positive direction to alleviate some of the hardships over the past few years? Will the election outcomes sit in the status quo? Will the election further deteriorate the industry? Time will tell, and these are questions to think about when strategically mapping out 2025 and the next four years.”

“If the new administration and Congress are in full support of the manufacturing industry, pose tariffs on Chinese imports, close the de minimis loophole and reinstate R&D – and manufacturers strategically embrace it – there’s a fighting chance to see growth and ease on many of the factors that threaten this industry,” he continued. “In addition, tax credits and lower corporate taxes would greatly benefit manufacturers, but keep in mind that it will take time for the economy and manufacturing to ramp up.”

Scott Smith is the managing director for Tessy Tooling, a manufacturer that specializes in multi-cavity, tight tolerance medical injection molds. Tessy Tooling’s primary focus is on the medical market. Smith said, “We are fortunate that the primary market we serve is rapidly growing. However, manufacturing across every market is hoping and needing to get back on the ‘right side’ of the economy. But, even in a thriving market, such as medical, there always is reason to be cautiously optimistic. Currently, Tessy has no plans to make any major investments until it sees a change in manufacturing trends and the factors affecting them.”

Mike Stiles is the CEO of R&D/Leverage, an Adler Co., Lee’s Summit, Missouri. The company serves the food and beverage, home and personal care, and healthcare industries, offering mold manufacturing capabilities for PET tooling, IBM tooling, injection molds, as well as unit tool development, testing, validation and training. Challenges in 2025 will include several factors, Stiles said. “Labor, both skilled and entry-level, likely will continue to be a challenge,” he explained. “To retain talent, we have had to increase wages for incoming and skilled legacy employees. Because we are 90%-plus domestic supply chain, we haven’t been hit too hard with extended deliveries – just significantly higher prices. Those additional costs must be passed through, so it has caused an increase in our quoted prices, but we must be careful to stay competitive. Reshoring of previously imported products has increased our opportunities in at least some markets – medical being the most significant. We work diligently with our customers on their environmental/sustainability goals to determine how part weights can be reduced without compromising quality requirements.”

Buss, Buss Precision Mold, Inc.: Greatly! Buss has seen declining RFQs for new projects over the last few years due to an increase in interest rates, inflation and perceived lag from pandemic stagnation, as well as international and national supply-chain issues. Recent feedback on economic conditions from a few prototyping service bureaus is that

At Plastic Engineering & Technical Services, we are.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

tbusiness is very slow and layoffs are happening with a large percentage of employees. This means not many new projects are being designed and prototyped. Some customers lost design engineering personnel; in fact, they do not have the resources and are struggling to bring the same number of new programs to market that they did five to 10 years ago.

Smith, Tessy Tooling: As a company, we’re always strategically planning for what’s next but, in being fortunate within the medical market, we plan to stay the course. I do know many companies in this industry are hurting. With that, leaders are just cautiously optimistic, and they aren’t going to extend themselves in purchasing capital equipment and more until they see manufacturing trends turn around and stabilize.

Stiles, R&D/Leverage: There is little we can do regarding the current economy, other than deal with the hand that is dealt to us, being sure to remain competitive in the market to secure our share of available opportunities. I do believe election years can impact the timing of customer decisions regarding larger capital projects like the molds we design and build. However, projects that were viable pre-election typically are still viable after – regardless of election results.

Buss, Buss Precision Mold, Inc.: We are focusing on running lean, doing repair work, diversifying into precision machining as well as other toolmaking and moldmaking disciplines – to fill in for less injection moldmaking demand. In addition, our team will be doing deferred maintenance on equipment and shop layout/storage optimization.

Smith, Tessy Tooling: Control operations and cost – then you can’t get too far out over your skis. Right now, it is important to lock down and continue daily operations, focusing on fulfilling orders, finding efficiencies and building up your workforce. Strategically, companies know that one item on the wish list for 2025 may not happen because change doesn’t happen overnight but, over some time. Tessy moved into a new building with greater square footage. But even with that, we know not to go crazy with expenditures and new equipment, even if the economy is a little softer. Again, it’s in being ‘cautiously optimistic.’

Stiles, R&D/Leverage: Our job is to be certain that we deliver the best value to our customers when it comes to total project cost vs. output so that it makes sense to ‘choose us’ over the competition. Some markets are more easily influenced by economic swings, but with that, we work hard to make sure we have diverse markets where we are recognized as quality leaders. Consumer products and automotive might see huge swings. Personal healthcare and beauty are slightly less impacted. True medical and

Our job is to be certain that we deliver the best value to our customers when it comes to total project cost vs. output so that it makes sense to ‘choose us’ over the competition.

defense-related products are almost recession-proof. It is critical to have a balanced mix of work going through the shop to help balance those ups and downs..

Buss shared two investment options that Buss Precision will explore in 2025:

1. New technologies – “It is important to look for new opportunities to improve processes, but equally key to be wary of debt,” said Buss.

2. Refurbishing and upgrading specific equipment.

Smith, Tessy Tooling: Continually just to be better at what we do! It’s important to utilize the technology in the marketplace. Our goal is to be lights-out manufacturing and automate where we can within our operations. For 2025, we’ll look at new software, IT technology, machining technology, tooling technology and so forth – whatever can get us there quicker with excellent quality. Quality always is our main driver.

Over the past two years, R&D/Leverage, an Adler Co., has invested almost $20 million in buildings to consolidate operations and newest technology equipment.

Stiles, R&D/Leverage: This investment is to keep us at the leading edge of manufacturing capabilities. If automation is available on newly purchased equipment, we are optimizing those opportunities to maximize throughput with minimum expenditure on human resources. We are investing heavily in training our workforce to ensure the company can do more with less, by taking advantage of what the new technology can offer. New equipment, new software and automation allow us to analyze every process, no matter how ‘proven,’ to determine how it can be made better – with better being translated as higher accuracy, higher quality, equal or improved finishes, and higher output with total costs within projections that provide profitability.

In summary, if the industry works as one – there will be growth and strength in numbers, building a better tomorrow and year ahead.

More information: www.bussmold.com, www.tessytooling.com, www.adlertooling.com

By Shelly Otenbaker, president, WayPoint Marketing Communications

“An ounce of prevention is worth a pound of cure.” Many are aware of this phrase, but few follow it. In manufacturing, taking small, proactive steps to prevent a problem is far more effective and less costly than dealing with the consequences once the problem occurs –especially when managing a crisis.

A business crisis is a situation that negatively impacts customers, employees and/or a company’s reputation. They come in all shapes and sizes, including organizational (e.g., acquisitions, cybersecurity, reorganizations), natural disasters, accidents and work stoppages.

The best way to mitigate the risk and minimize the negative impact of a crisis is to be prepared. Many manufacturers have people in environmental, health and safety roles who have developed a plan for the facility to manage a crisis, but few have established a communication plan.

A crisis communication plan helps ensure clear and consistent messages are conveyed during times of uncertainty or emergency. A well-structured plan helps to manage information flow, minimizing misinformation and reducing panic. It outlines the roles and responsibilities of key personnel, ensuring everyone knows their tasks and can swiftly act. This preparation helps maintain trust and credibility with stakeholders, including employees, customers, investors and the public.

Developing a crisis communication plan does not have to be overly complicated. But it does need to be a living plan that adjusts as the business changes, and it must define processes and action steps. Here are a few steps companies can take when developing an effective crisis communication plan.

It is important to identify the employees that will support the plan because this will be the team responsible for managing and communicating during a crisis. When developing a team, think about the entire organization and the people who could be impacted by a crisis. It should include facility people – EHS, HR, plant leadership – as well as communications, legal and, potentially, the business owner.

If a company has multiple facilities, the team may need to expand to a head of the region or the corporate team. Having a pre-identified and trained team ensures all members know their roles and will help improve response time and effectiveness.

The response protocol is a step-by-step guide to guide the organization through a crisis and should contain several key tools.

First, the crisis team should brainstorm the type of crises the organization could face. This should be realistic but include scenarios that are not highly likely – before 2020, it is doubtful an organization had a pandemic in its crisis plan.

Additionally, the team should create crisis levels and the criteria that define each level. For example:

● Level 1 – controlled, minimal impact on employees or business, no injuries

● Level 2 – temporary, confined to facility, minor injury

● Level 3 – significant business impact, multiple or severe injury, community impact

● Level 4 – significant business impact (e.g., multiple facilities), death, regional impact

The levels should include general categories, align specifically to the business, cover all facets of the organization and increase in severity.

The next important tool is an incident report or some sort of mechanism to collect important data related to the crisis, such as what happened or is happening, who is involved and impacted, whether it’s an isolated/one-time incident or ongoing and any details related to the situation. Having access to correct information will be critical to an organization’s crisis response team’s ability to make informed decisions.

Next, an organization must define how to respond to different types of crises. An organization should ask: How will communication happen? Who initiates it and when does it start? What are the appropriate action steps based on the crisis levels and timing – immediate, first 12 hours, 24 hours and beyond? What communication tools will be used and what are the expected milestones?

During a crisis, every second counts so it is helpful to have materials or templates created and easily accessible to be utilized by the crisis team as needed.

● Key messages: Predefined messages about what the company does, what makes it unique and its values and priorities.

● Facility statistics: Information about all facilities – size, number of employees, products produced, etc.

● Scenario-specific messaging: Established messaging targeted at high-priority stakeholders (e.g., employees, customers) for specific scenarios that could occur within the facility.

● Contact lists: Create a list of names, emails and phone t

numbers for key stakeholders – employees (and emergency contacts), customers, emergency services and local media outlets.

● Spokespeople: Identify and train a small group of people who are tasked to communicate with employees, customers and media during a crisis.

● Communication tools: Identify and prepare tools that will be utilized to communicate during a crisis. Remember crisis teams may not always be able to utilize their facilities or traditional communication tools for all crises (e.g., loss of power, cell service).

Although there is no perfect outcome when it comes to a crisis, companies regularly should conduct drills and simulation exercises to test the effectiveness of their crisis communication plan. Creating different scenarios and running through them allows a team to practice roles and refine the plan based on lessons learned.

Finally, a crisis communication plan should be dynamic and responsive to changes in the organization and its environment. Regularly review and update the plan to reflect new employees, risks, stakeholders and communication technologies.

A crisis communication plan can significantly impact the overall outcome of a crisis. Anyone who has endured a crisis without a plan will share that it often can be chaotic and extremely stressful.

By having predetermined strategies and communication channels, organizations can address concerns, provide necessary updates and demonstrate control over the situation. This proactive approach not only protects the organization’s reputation but also reassures stakeholders the organization is competent and prepared to handle adverse situations.

Shelly Otenbaker is the president of WayPoint Marketing Communications, a leading business-to-business marketing communications agency focused on helping manufacturers attract and retain talent and acquire new business. The company specializes in building customized, strategic programs tailored to meet the unique needs of each client.

More information: www.waypointmc.com

Reprinted with permissions from Plastics Business (www.plasticsbusinessmag.com).

You’re INvited to our 138,000 ft2 state-of-the-art facility in Auburn Hills, Michigan, where we design, manufacture, assemble, test and service Hot Runner Systems for the North American Market.

In addition, INCOE, a USA family-owned business since 1958, offers engineering solutions, flow simulation, individualized training, 24/7 service and support that includes 300,000+ in-stock replacement components.

All to maximize your up-time and realize the most value from your INCOE Hot Runner System.

Welcome IN: Arrange your visit today - david.lange@incoe.com

May 7-9, 2025 | Grand Rapids, Michigan

The AMBA Conference 2025 – “Breakthrough Innovation” – is designed for US mold builders and industry suppliers looking to drive business growth, build executive connections and exchange insights with peers. Don’t miss this opportunity to explore industry best practices, tackle shared challenges and gain valuable insights into economic trends shaping future business opportunities.

For more information, visit www.ambaconference.com

Available for Purchase – AMBA 2024 Wage and Salary Report

AMBA’s annual Wage and Salary Report is the premier compensation study for the US mold building industry, providing an in-depth analysis of over 50 job classifications across diverse market sectors. This year’s report also includes benchmarks on cost-ofliving adjustments, vacation benefits, employee incentives, salary changes, hiring trends and more, offering mold manufacturers critical insights to remain competitive in today’s market.

For more information or to purchase this report, visit www.amba.org/publications

Join AMBA members on January 14, 2025, from noon to 1 p.m. (EST), for an exploration of current wage and salary trends presented by the AMBA benchmarking team.

Available for Purchase – 2024 AMBA Employee Engagement and Retention Strategies Playbook

valuable benchmarks to help companies foster a more engaging workplace. For more information or to purchase the playbook, visit www.amba.org/publications

Join AMBA members on December 4, 2024, from noon to 1 p.m. (EST), for a virtual peer networking session to dive deeper into these themes and exchange new ideas.

Business in 2025: Outlook and Insights

December 10, 2024 | noon-2 p.m. (EST)

AMBA will again host an end-of-year webinar, where industry experts and partners will share insights to help US mold manufacturers prepare for the coming year. This virtual session will cover key benchmarking data, industry challenges, supplier perspectives and legislative updates to support strategic planning in 2025.

December 12, 2024 | 11 a.m.-noon (EST)

This event brings together operations and plant managers, CNC operators and other professionals in related fields to exchange insights on best practices, emerging technologies and common challenges. Attendees can share questions on topics, including 3D printing growth, automation strategies, tooling advancements and more. It’s a collaborative space to discuss practical solutions and innovations impacting manufacturing.

These events are available to AMBA members at no cost and will preview concepts to be covered at AMBA Conference 2025. For more information and to register, visit www.amba.org/events

AMBA has released its newest playbook, Employee Engagement, Satisfaction and Retention Strategies. The report explores factors influencing job satisfaction, bonus structures, professional development and common causes of employee turnover. It also highlights how manufacturers can leverage company culture to enhance employee experiences and identify features that detract from the work environment.

This comprehensive look at engagement strategies provides

AMBA members wrapped up the year with the 2024 United Tool and Mold Golf Outing in support of the iWarriors organization. Similar events also were hosted earlier this year by M.R. Mold & Engineering and Alliance Specialties and Laser Sales. Altogether, these community-led efforts included 300-plus golfers, featured 110-plus sponsors and raised over $78,000 to iWarriors, which will help the organization assist severely injured members of all branches of the Armed Forces by providing them with personalized tablets to aid in their return, recovery and reintegration. For more information, visit www.iwarriors.org

WEST MI CHAPTER MERGER

AMBA is excited to announce the merger of its Southwest Michigan and West Michigan Chapters, now combining to form a 28-member chapter. Together, they’re stronger, more connected and better positioned to engage with the industry and communities, while delivering local-level association benefits.

The American Mold Builder (TAMB) magazine has launched a new website offering a fresh look and improved navigation, it’s now easier to explore articles, events, industry news and more. TAMB is the official magazine of the American Mold Builders Association, an organization dedicated to elevating the competitive advantage of US mold builders. For more information and to check out the new website, visit www.americanmoldbuilder.com.

Johnson Precision Mold & Engineering, Inc. 1001 Haines Blvd. Sturgis, Michigan 49091

Main POC: Randy Johnson, president Email: randy@johnsonmold.com Phone: 269.651.2553

Johnson Precision Mold & Engineering, Inc. was founded in 1990 to provide the highest quality custom injection molds at competitive prices with on-time delivery. Thirty-four years later, the company achieved this goal while investing in the best technology and equipment. Johnson Precision Mold & Engineering is determined to exceed its customers’ expectations.

Custom Etch, Inc. 1813 West State St. New Castle, Pennsylvania 16101 Main POC: Chad Hase, director Email: chad.hase@custometch.com Phone: 724.652.7117

Just a few clicks and you will find precisely what you need amongst 100,000 HASCO standard components. Your benefits:

Custom Etch, Inc. provides textures for the moldmaking and plastics industry that give the cosmetic appearance and/ or functional feel consumers want. The company services all market segments and can handle any texturing project without size limitations. Custom Etch, Inc. is America’s largest laser 5-axis job shop with more than 10 units to ensure clients receive expertise quickly and at the lowest cost. Custom Etch, Inc. – bringing today’s ideas to reality!

▪ Intelligent product search ▪ Fast mold configuration ▪ Direct interface to most CAD systems ▪ Simple cost calculation ▪ Live access to your quotations and orders ▪ Easy payment options

By Lindsey Munson, editor, The American Mold Builder

“If you can’t be replaced, you can’t be promoted,” are words that resonate with leaders.

This quote stands as a simple reminder and sound advice to those seeking a leadership role or being a “succession” – on-the-job training and sharing processes and procedures are critical components to reaching the next step on the ladder. When an employee makes a leader’s job easier and is disciplined in creating a cohesive environment of on-the-job training and sharing of job responsibilities throughout the team, these actions show that the employee is a continued asset to the leader and the company. In doing so, leadership and executives alike then can begin mapping a promotion or “succession” opportunity for that employee because they know there is a backfill of talent among the department team. Among the next generation of leaders, it is coaching them on mindset and critical thinking as well as sharing knowledge, teaching new skills, networking and training coworkers that opens the door to succession planning success for leaders and executives.

Effective leadership planning is essential to the longterm success of a company and recently, a presentation, “Preparing the Next Generation,” was given in March 2024 at a Human Resources Forum. It gathered industry leaders who share a common goal – to learn about succession planning and how to engage and build the next generation of leaders. It was presented by Dr. Daniel Walker, director of continual improvement at PolyFlex, part of Nefab Group in Farmington Hills, Michigan, a partner for molded manufacturing automation, product protection and material shipping solutions.

With over 35 years in the industry and currently mapping his succession plan, Walker has the education and experience both personally and professionally to create and execute an effective leadership plan that sets a company up for future success. From a BS in plastics engineering technology and

MS in management strategy and leadership to a Ph.D. in business management, as well as his tenure as a teacher, change agent and Six Sigma black belt, these tools have given Walker a platform to guide and support companies through the next stage of their leadership planning.

According to Walker, executives and leadership should map their succession plans to include four key stages: culture and communication, leadership and learning, mentoring and succession transition.

Walker shared, “Starting the succession planning process is important because developing a successor– or depending on the position and job responsibilities, two or more successors – takes time, focus, effort and commitment as a leader and across the entire company.” The end goal of a succession plan for a leader and the company should be that the business continues long after the predecessor hits retirement or transitions into another role professionally. He continued, “It’s finding the right fit in succession to continue building and advancing the success of the company well before the leader’s departure.”

In addition to Walker’s presentation, he highlighted the strategies and structure of succession planning from the book, “Succession Transition” by Bill Hermann and Gordon Krater of Plante Moran, Detroit, Michigan. “Since I am in the beginning phases of my succession planning process, I rely on the guidance from the authors of ‘Succession Transition.’ The authors lay out a systematic process for engaging with, training and mentoring future leaders,” he said.

A company’s most important asset is its employees. Walker said, “It starts with recruiting and retaining the ‘right’ employees. Recruiting employees in the beginning who are selected to be a part of the team is an important and key

step to ensure that, as a company, the culture is built from the ground up. This presents leaders with the time needed to develop, train and lead the next generation of employees, aligning the company’s internal structure to its values and mission. It also sets clear and concise communication from top to bottom of the organization.”

In succession planning, two factors play a vital role in the overall process and should be nourished and developed within the company – culture and communication. When a company invests in its people, a foundation is built on positivity, recognition and accountability, which naturally creates open, transparent and honest communication. By fostering a strong culture, a company empowers its leadership and employees – and ultimately, gives insight as to whether a successor lies within the employee base or if the search needs to happen externally. A leader should be equipped to identify a person early on in the succession planning on the basis that the potential successor can step into the role with his/her unique skills, mindset and talent – resulting in augmenting the company before, during and after the “succession” has occurred. Once a successor has been selected, cultural alignment and communication throughout the company are important as the environment serves as a place where the future leader can thrive and grow in professional experiences.

Communication sets the tone within the company; employees thrive when they can freely have a voice, are in the know and feel a part of the company’s day-to-day decisions. Before succession planning and throughout the process, a company and its leadership team should have strong internal and external communication so that when the time comes to make the announcement about a new leader stepping into the predecessor’s position, no one is caught off guard and the map of that position is clearly defined and charted. It exudes a sign of respect and value in the relationship between the leader and successor with clients, customers, partners and employees – speaking to the company’s culture and end goal of long-term sustainability.

In Walker’s succession plan experience, he said, “Company culture has been a significant focus for the last five to 10 years at PolyFlex. We find that if the culture aligns with our values, training succession candidates is much easier. Identifying potential leaders is a process of conversation and observation. If you pay close attention to building up culture, maintaining clear communication lines and nourishing high performers, potential successors naturally emerge.”

“We need to have the courage to explore ourselves as leaders – whether in a leadership role, new employee or future successor. Knowledge is power!” said Walker.

First and foremost, a leader should fine-tune and enhance his/her own “leadership skills” alongside noted hightier employees to build a pipeline of future leaders. Professionally investing in self-discovery, reflection and/or external coaching is a component in anticipation of starting the succession planning process, placing the right skills in the right place. By reading books, conducting personality tests, attending seminars and workshops (like the ARPM Human Resources Forum) and possibly hiring an outside coach, these active opportunities are ways to develop as a leader but also to assist in better understanding oneself. Walker said, “It’s leading by example and setting the tone of a learning culture within the company.”

In succession planning, there should be an element of continuous learning and training for leadership, future successors and employees by:

● creating a learning culture and environment;

● demonstrating learning;

● encouraging formal (i.e., trade school, college, etc.) and informal learning (i.e., seminars, workshops, etc.); and

● creating a safe space to fail.

Key to the progression of learning is the opportunities that open a door to understanding his/her leadership style through self-discovery, including personality profiles (i.e., DISC, Strengthsfinder from Gallup), a personal study and professional counseling outside the company. It’s in asking the question, “Who are you?,” seeking honest feedback through one-on-one conversations, 360° reviews and focusing on introspection – that delivers the result of leadership influence. Walker said, “By conducting a personal study and understanding my leadership behaviors, I adequately can align my view of myself with how others see me, because, as a leader, effective influence is a leader’s top asset.”

To take it one step further, professionals (whether in a leadership role or not) can incorporate a six-month executive coaching series to bring light to unique skills, mindsets and talents, which otherwise would have gone untapped. There is strength in understanding “who you are” as a professional and utilizing new skills or enhancing current skills to work toward the overall goal personally in the job role but also for the company as a whole.

Walker said, “The most valuable lessons learned in life are from failures – and the more significant the failure, the more that is learned. It is a leader’s responsibility to create a space where employees feel safe to fail without negative repercussions to learn from that failure. Through these learned lessons an employee or a future successor is given growth and development opportunities that can’t be found in a textbook or words but an actionable, taught lesson.”

tWhen there’s ownership of the “leadership transformation,” that’s when companies know a succession plan has the bones of a successful and seamless transition to the next generation of leaders. Walker said, “With the learnings from the personality profiles to the six-month coaching experience, I learned that surrounding myself with people who complement my strengths and compensate for my weaknesses transforms me as a stronger leader, giving me the tools to guide my future successor and overall creating a richer company culture.”

Polyflex reinforces the principles of leadership throughout its company and Walker has experienced this first-hand. He said, “As a leader, there is significant power in a company that backs the professional journey and lifelong pursuit of leadership development. For myself, my department and team, and the employees that fill various roles within PolyFlex, it is engrained to not give up on growth whether through formal education, books or learning from one another.” At PolyFlex, employees may join a formal leadership program (i.e., book club) that is based on a five-year trajectory, with many in the company sitting in various stages of learning – it’s in these types of employee investments that leaders rise and next-generation leaders are born.

In line with leadership exploration and learning, a succession plan timeline of all the events – professional exploration, identifying a future leader, mentoring and training, transitioning, etc. – should be set early in the process, because this is when a leader is contemplating and exploring his/her retirement or professional transition. Walker shared, “I am planning on a five- to seven-year process for my successor(s). The timeframe is not so much tied to a calendar but rather the ability of the new leader/ successor to learn and develop into the transitioning leadership role.”

No leader or company ever looked back on starting succession planning too early, so the sooner a future successor is identified for the transitioning position the more time is available for relationship building and mentorship. Professional exploration and learning as a leader are at the top of the list, but it is equally, if not more important to mentor and train the successor that will sit in the same seat one day. Especially, if a leader is in a position that may require more than one successor to fill the role’s responsibilities.

To identify future leaders/successors of the company, leadership should take the following into account and actively engage key stakeholders:

y Inventory skills and unique contributions of employees.

y Conduct and review team personality profiles.

y Look at department teams with a critical eye.

y Seek potential candidates for advancement by looking at behavior, attitude, ambition and skill sets.

Walker said, “It’s in getting to know high-potential leaders in the company that leaders begin to start seeing succession.” Once a leader identifies a successor, it’s time to continue building a high-quality relationship through time, attention, consistency and openness. With that comes “windshield time,” which provides both the leader and successor with opportunities to share good and bad experiences, ask questions, experience real-time learning, issue feedback, etc. – it’s an investment and commitment to the growth of the successor building a present and future foundation for the company.

As a mentor, it is the lasting impact of walking through self-exploration, real-case scenario training, answering questions with patience and listening that will guide, support and ease a future leader. In mentoring a successor, there are various methods a leader can use as tools to form a connection and build a bond but also set him/her up for success in the position, including shadowing, training and coaching. Walker shared, “Once a leader identifies his or her successor, the time has come to begin the mentorship of giving the knowledge and experience by allowing him/ her to shadow at business meetings, client visits and all the various activities that come with the role. A successor should take notes, observe the various daily situations and take in the decision-making process.”

He continued sharing, “Windshield time is a beautiful thing! As a leader, you should travel with your successor to get ‘windshield time’ where over two hours you do nothing other than share that time to talk, learn and listen. It’s time that allows the successor to ask questions, take notes to walk through scenarios, etc. Most importantly, this investment in time helps the successor not only understand what you do but also how it is done, and more importantly, the ‘why’ behind your actions as a leader.”

As a leader and future predecessor alongside the successor, the final piece to implement the succession plan is the transition of leadership. Throughout the succession planning process, a leader early on created and continued to monitor and adjust the transition of the successor based on assessment and progress throughout the timeframe. The transition goal, if a leader is truly committed to the “succession plan” and work behind the process of building a successor, should be a seamless hand-off between leaders

• MOLD FINISHING

• LASER WELDING

• LASER ENGRAVING

• HOT RUNNER REPAIR

• MOLD MAINTENANCE

• LASER MACHINE SALES

er mold finishing, laser welding, laser graving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom

Let Alliance make a di erence for you.

EVERY PART OF THIS MACHINE IS EASILY ADJUSTABLE TO ALLOW YOU THE VERSATILITY AND FLEXIBILITY YOU NEED TO MEET ALL OF YOUR DEMANDS

CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE.

May 7-9, 2025 |

Grand Rapids, MI

"Attending AMBA Conference 2024 was a transformative experience for me. It provided a vibrant platform for networking, elevated my understanding of current trends and best practices and pushed me to evolve professionally and personally. This event is a must-attend!"

AMBA Conference 2024 Attendee

and the company with a deliberate focus on cultural engagement and clear communication.

In creating and executing the transition, the successor and leader work closely together throughout the succession timeline by frequently meeting to assess and monitor progress, challenging each other to stretch as leaders and holding each other accountable. “It’s having constant communication and conversations on progress and expressing where you both are in the succession plan. In doing so, it holds the successor accountable for executing the plan alongside the leader and vice versa,” said Walker.

When the day comes and the transition of the leadership role is official, it is the day that the predecessor must step aside knowing he/she is leaving a department and company ready for change. The leader has led and guided the successor through diligent training experiences, mentored and coached with the company and employees at the forefront and finally, created a transition plan that brings positive results to all involved. Walker said, “The predecessor now can step aside physically, emotionally and mentally from the company.”

Walker continued, “At the end of the day, we’re all human!”

As a tenured leader, there are years of hard work, relationships built and passion for the company – it’s never easy to say, “goodbye,” but it is a critical and necessary step to “exit left.” In doing so, this is a positive step forward, showing employees that the new leader is indeed ready to take on the day-to-day operations and responsibilities of the role.

On the contrary, in post-transition, Walker mentioned that succession plan success doesn’t mention to just leave and never look back. Rather, the predecessor should remain available to help ease the new leader into the position. Walker said, “If there’s a special holiday celebration, company picnic, etc., show up! Be present at the special events.”

In closing, whether an executive or in a leadership position, now is the time to begin developing a succession plan or finetuning it to meet the expected outcome of the role. The succession planning process takes years and must be met with intention and strategic direction. The next generation of leaders is looming front and center, ready to be trained, coached and mentored to ultimately one day lead the company into future endeavors of smashing goals and successfully meeting or exceeding the bottom line.

“Discover Your CliftonStrengths – Strengthsfinder 2.0 from Gallup and Tom Rath” by Don Clifton

“Extreme Ownership: How U.S. Navy SEALs Lead and Win” by Jocko Willink and Leif Babin

“Inside” by Tasha Eurich

“Succession Transition –A Roadmap for Seamless Transitions in Leadership” by Bill Hermann and Gordon Krater

“The Speed of Trust” by Stephen M. R. Covey

“Unlocking Potential” by Michael K. Simpson

By Rachael Pfenninger, director of strategic execution, AMBA

Being a leader is more than supervising others and telling them what to do. In fact, leadership – at any level within a company – requires more internal reflection and active work than any other skill. But without training and guidance, the development of this necessary quality often is overlooked, impacting the performance of teams and companies alike.

To help address this challenge within US mold manufacturing, AMBA and its Emerging Leaders Network partnered with the Young Professionals Network in the Manufacturers Association for Plastics Processors (MAPP) and the Association for Rubber Products Manufacturers (ARPM) organizations to launch its final leadership development series of the year – A Leader’s Guide to Peer and Performance Management. This four-part virtual series (which ran from late October to mid-November) provided these up-and-coming professionals, department supervisors, management teams and executives with an opportunity to invest in their professional development, apply learned knowledge from week-to-week in their working environments and share experiences with manufacturing peers across a variety of functional areas.

ZingTrain Trainer and Keynote Speaker Elnian Gilbert, who has experience in customized training in visioning, employee training, open-book and change management and leadership, led the series via her expertise and experience. By the end of the training, attendees walked away with key takeaways related to ethical management and leadership philosophy and action, the “learn and teach” principle, an exploration of formal vs. informal feedback techniques, the “Next Time” feedback tool and key characteristics of effective performance reviews.

The first session in the series kicked off with a focus on the principles of servant leadership, decision-making and the stages of learning a skill. From vision and the provision of great service to concepts like “waterline decisionmaking” (a tool managers can utilize to make decisions about personal action and delegation) and “learn and

teach” methodology (a tool that explores unconscious and conscious learning and their role in employee training), Gilbert walked attendees through how theory can be applied in everyday situations, and developments and leadership engagements.

Although each of the above points will be useful tools, skills and resources that will aid each attendee’s professional growth (with additional tools explored in the final three sessions), an important aspect not to be overlooked is the element of community integrated into the series. By enabling their employees to forge peer connections through professional development opportunities like this series, employers are sending the message that their employees’ professional development is valuable and worthwhile, thereby encouraging the growth of a community that could positively impact their workforce for years to come.

“When we learned that, for a single rate, we could provide professional development to the majority of our supervisory staff, we didn’t hesitate to register for this series,” explained Maria Parina, human resources manager, Atalys. “The development of managerial skills, the ability to provide (and accept) peer feedback and take accountability as leaders within our organization are all skills that will help our staff with their day-to-day responsibilities. We’re looking forward to continuing with the series and working as a team to implement what we learn.”

While the series has ended, AMBA member companies that are interested in sharing and exploring employee engagement, growth and retention tactics are encouraged to register for AMBA’s final peer networking session on December 4, noon to 1 p.m. (EST), where members will share their strategies and best practices in employee growth, development and retention.

More information: www.amba.org

CGTech, Irvine, California, has announced a rebrand to Vericut, a supplier of manufacturing software. The initial brand transition began with the US website and selected global events, with plans to continue the worldwide rollout over the coming months. This phased approach allows the company to manage resources efficiently and sustainably, as existing materials branded with CGTech will be used until they naturally are phased out. For more information, visit www.vericut.com.

advanced manufacturing. It’s where groundbreaking ideas are sparked, key connections are made and significant progress happens – all in one convenient location. For more information and to register, visit www.mdmwest.com.

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance taps, thread mills, drills, end mills, clamping devices and other rotary tools, has named Mike Patterson as national sales manager for US and Canada. Patterson is responsible for leading the EMUGE-FRANKEN sales organization in the US and Canada to strengthen support for customers and distributor partners, as well as grow market share. For more information, visit www.emuge-franken-group.com/.

FRAI Elektromaschinenbau GmbH, Konrad, Austria, an automation company, has merged into WFL Millturn Technologies GmbH & Co. KG, Kinz, Austria, a global manufacturer that focuses exclusively on the production of multifunctional turning-boring-milling centers. WFL customers will gain access to a broader range of solutions and a more seamless integration of machines and automation. Strengthened by the merger, the WFL Automation Technologies division will continue to offer solutions for the automation of a wide range of machine tools and processes. For more information, visit www.wfl.at.

MultiCam, Dayton, Ohio, a machinery manufacturer that specializes in CNC cutting solutions, fabrication machines and more, has marked 35 years in the CNC routing market. MultiCam, a Kongsberg Precision Cutting Systems company, has delivered more than 15,500 of its machines, each built to last using American-made steel and components. The launch of its MultiCam Apex3R Evo, which signals a new era in high-performance routing capabilities, coincides with the anniversary. For more information, visit www.multicam.com

MD&M West, formerly known as MD&M, ATX, D&M, Plastec and WestPack, has opened registration for its threeday event filled with new product showcases, engaging educational sessions and opportunities to connect with the brightest minds in manufacturing. Celebrating its 40th anniversary, MD&M West is set to take place February 4-6, 2025, at the Anaheim Convention Center in Anaheim, California. The event brings together national and international buyers and suppliers focused on medical, critical and

norelem, Greenville, South Carolina, a global manufacturer and supplier of standard components for mechanical engineering and industrial applications, has opened a new facility in the US. This expansion represents a step in norelem’s international growth strategy and its commitment to better serving its customers in the US. The company has over 100,000 highquality standard components for machinery and automation. For more information, visit www.norelemusa.com

Okuma Corporation, OGUCHI-CHO, Japan, a global manufacturer of CNC machine tools and automation systems for the metalworking industry, has appointed Takeshi (Tad) Yamamoto as chairman for Okuma America Corporation, and Jim King as president, CEO and COO for Okuma America Corporation and as a senior officer for Okuma Corporation (Japan). In addition, Yamamoto serves as a member of the board of directors for Okuma Corporation (Japan), senior executive officer in charge of Global Sales, and chairman and CEO of Okuma Europe GmbH. Yamamoto started his career at Okuma Corporation (Japan) as a manufacturing engineer in 1982. King joined the Okuma organization in January 2010, as the senior vice president of sales. For more information, visit www.okuma.com.

By Sujit Sheth, monitoring business manager, Progressive Components

Molds are a molder’s most critical asset. When a mold is not running, – bad things happen – including parts are not being produced, labor is underutilized, revenue is not generated, supply chains are delayed and customer relations can be strained.

Despite these ramifications, many molders’ toolrooms are under-resourced, with secondhand benches as work surfaces; old, repurposed machinery; and a documentation system that might consist of handwritten notes within a three-ring binder, manual entries into a spreadsheet or an ERP work-order system not designed for maintaining production tooling.

Investing in a preventive maintenance (PM) program will help with more than reducing the negatives from unscheduled downtime. In addition, there are many other benefits that lead to success.

Regular preventive maintenance ensures consistent product quality. Any wear and tear on the mold can lead to defects in the final products, such as flash, surface imperfections, warping or dimensional inconsistencies.

Preventive maintenance is more cost-effective than corrective measures. Properly maintained molds are less likely to break down, reducing the need for costly repairs, refurbishment or replacements.

Mold breakdowns or failures can result in production downtime, which can be extremely costly. Routine maintenance helps identify and address potential issues before they cause significant disruptions in production.

Injection molds can be expensive to build and repair, so maximizing their lifespan is essential for a good return on

investment. Regular maintenance can extend the life of molds, allowing them to be used for their expected lifespan and beyond.

Well-maintained molds operate more efficiently, ensuring consistent cycle times. This reliability in production planning helps meet targets without unexpected delays or variations in output.

Maintaining molds at optimal conditions ensures higher utilization by reducing production defects, unexpected mold-related issues and unplanned downtime.

Molds in poor condition can pose safety risks to workers. Regular maintenance is a proactive measure that helps identify and rectify potential safety hazards, ensuring a secure work environment.

Inadequate mold maintenance can lead to defective parts, resulting in increased material scrap or sorting costs. This is both environmentally and economically unfavorable.

In some industries, there are strict quality and reporting standards that must be met. Regular mold maintenance can

help ensure compliance with these standards and prevent issues.

Ultimately, consistency in product quality from wellmaintained molds leads to higher customer satisfaction. These customers then are more likely to award new projects to their most consistent suppliers.

Implementing effective preventive maintenance programs offers numerous benefits as outlined. Considering all forms of potential investments – and implementing those that most apply to and benefit your specific tooling needs – is a path to increasing manufacturing competitiveness and longterm company profitability.

Sujit Sheth is the monitoring business manager for Progressive Components’ Mold Monitoring Division. As such, he works with other team members to develop and implement all products related to asset management and mold monitoring, including the exclusive CVe Monitor, components for ProFile that make remote, real-time

monitoring of tooling possible. The monitoring product line also includes System Cooling for real-time monitoring of flow and temperature through every circuit of the mold. With 20 years of experience in the operations and injection molding sectors of manufacturing, Sheth’s experience helps greatly with anticipating and understanding customer needs and the issues they face regarding mold program management.

Progressive Components, Wauconda, Illinois, is a global leader in componentry and mold monitoring solutions for the production tooling industry. Progressive’s off-the-shelf standards speed mold builds and reduce downtime, while ProFile asset tracking and mold management technologies provide exclusive maintenance and asset tracking advantages for molders and OEMs.

More information: www.procomps.com, Sujit.sheth@procomps.com

By Omar S. Nashashibi, founder, Inside Beltway

In 2023, Mexico surpassed China as the largest importer of goods into the US, increasing shipments by nearly 5%.

Also in 2023, China’s Foreign Direct Investment (FDI) in new facility construction and expansion in Mexico reached $5.6 billion, up from $267 million in 2018. In addition, during the first eight months of 2024, the shipment of goods from China to Mexico jumped 22% following a 33% increase over the same period last year.

The numbers detail an important narrative. During an October 2024 trip to Brazil, US Trade Representative (USTR) Katherine Tai said that the US has observed “potentially concerning developments in terms of Chinese company acquisitions in Mexico to build factories.” In private meetings and public hearings, the AMBA has raised similar concerns with the Office of the USTR, including AMBA Managing Director Kym Conis testifying before the federal agency in May 2024.

The increased correlation between imports from China to Mexico and the surge in shipments across the border also has caught the attention of lawmakers. Members of Congress in recent months introduced legislation supported by AMBA targeting investments by non-market economies, such as China, into other countries with the intent to evade the US tariffs. Targeting the investments before a product is

manufactured will help the US industry play offense, rather than waiting to respond until after injury to the industry occurs.

The US Congress is expected to move legislation to address trade enforcement, exports and investments with China in its lame duck session following the November election. Sources in Washington, D.C. indicate that lawmakers may include provisions in the annual National Defense Authorization Act language to begin addressing some of these concerns.

Transshipment and transnational subsidies are playing an increased role in the Chinese Government’s strategy to evade US tariffs. Many of the containers entering Mexico hold products manufactured in China, often for transshipment into the US but frequently for assembly –allowing a more finished good to bear the ‘made in Mexico’ label and travel across the border tariff-free. A product that is assembled in Mexico with parts from China typically is considered substantially transformed and, therefore, made in Mexico.

AMBA members and other manufacturers report that, in addition to products being shipped from Mexico, the companies backed by Chinese investors often use tooling,

tand even workers, from China in their Mexico facilities. This effectively places competition with the People’s Republic of China in the backyard of American industry.

US manufacturers can no longer rely on lead time as a competitive advantage when a Chinese competitor can ship across the southern border and send the profits back to China. In addition, industry in Mexico increasingly is raising concern over shipments from China negatively impacting its domestic industry. Alarm bells are ringing across the Mexican automotive market and downstream suppliers as Chinese-manufactured models accounted for 20% of passenger vehicles sold in Mexico during 2023.

The US Government, at the urging of industry groups such as AMBA, is placing pressure on Mexican officials to tighten enforcement on goods entering from China. Much of this will come to a head regardless of the next occupant of the Oval Office. In July 2026, the US, Mexico and Canada will come together for the mandatory six-year review of the updated NAFTA, known as the USMCA.

Following its entry into force in 2020, the USMCA mandates a six-year review, during which the parties may extend the agreement for an additional 16 years, announce an intent to depart the pact or continue to renew the USMCA annually until the sides reach an agreement on changes sought by negotiators. A Trump or Harris administration would demand changes by Mexico particularly on foreign ownership and content entering the US through the southern border.

During the campaign, both presidential candidates stated their intention to make changes to the USMCA and address the surge in imports from China through Mexico. A bipartisan group of Senators sent a letter in September 2024 to President Biden calling for administrative action to “address China’s rampant exploitation of Mexico as an intermediary for the transshipment of goods.”

The lawmakers are among an increasing number of policymakers in Washington, D.C. seeking to impose Section 301 tariffs on Chinese goods manufactured in Mexico. Products originating from any of the three USMCA nations are not subject to tariffs or duties under the agreement, requiring Mexico to agree to allow the US to impose the tariffs. Of course, the President simply could ignore their counterparts and take unilateral action and impose tariffs on imports produced in facilities owned by interests based in China.

In September 2024, the US Department of Commerce proposed a rule barring importation of hardware and software from China related to connected vehicles. This is

Members of Congress in recent months introduced legislation supported by AMBA targeting investments by nonmarket economies, such as China into other countries with the intent to evade the US tariffs.

a major action that effectively prevents vehicles and certain components from entering the US. Negotiators likely are to build off those efforts in talks with Mexico and Canada, seeking to create a unified front against imports from companies subsidized by the Chinese Government and related interests.

Many of us lobbying on manufacturing trade policy see transshipment, transnational subsidies and investments into Mexico supported by the Chinese government as the top issues facing manufacturers and policymakers alike. The 2026 USCMA negotiations present a clear time to update the agreement to require Canada and Mexico to take steps and restrict importation of select imports from China. The greater challenge is addressing investment by the People’s Republic of China into Mexican operations and shipping those goods into the US.

The new administration is sworn into office on January 20, 2025, and is not expected to wait until 2026 USMCA negotiations to address this emerging issue. AMBA will work with the new administration to prevent a surge in molds and tooling from Mexico manufactured in facilities connected to the Chinese Communist Party. The association, however, needs its members’ assistance now to provide stories and data about products from China transshipped through Mexico and subsidized goods entering from the southern border. Providing the incoming administration with real-world information will better prepare it to defend the industry.

Omar S. Nashashibi is the founder of Inside Beltway, a nonpartisan lobbying and strategic consulting firm in Washington, D.C., retained by the AMBA. He works with policymakers on trade, taxes, environmental and workplace regulations, supply chains, job training and identifying grants and funding to support manufacturing.

Progressive Components, Wauconda, Illinois, a developer and distributer of components for the production tooling industry, has introduced two new runner components, including a gate insert and runner turn-off (RTO), as standardized items for controlling a mold’s runner system. The gate insert offers a compact, off-theshelf solution to address the issue of abrasive materials opening gates. The RTO provides a method to block or redirect material flow within the runner, which is common with family mold tooling. Both components may be used together or independently, as required by the mold’s design. For more information, visit www.procomps.com.

ANCA CNC Machines, a global supplier of CNC grinding technology with US headquarters in Wixon, Michigan, has launched AIMS Connect, a job management and production control software designed to benefit tool manufacturing by optimizing processes, enhancing quality and reducing costs. As a smart solution to integrated manufacturing, AIMS Connect has the potential to boost productivity by 20% or more. Key features and benefits of AIMS Connect include centralized machine file management, ERP/MES connectivity, production control and optimization, legacy machine integration and worker guidance system. For more information, visit www.anca.com

HASCO, Fletcher, North Carolina, a supplier of standard components and accessories for the tool and moldmaking industry, has released Streamrunner® Shadowfree, which eliminates the flow shadows in valve gate systems and enables a faster color change in the hot runner. In addition, Shadowfree technology offers a solution for sensitive materials in terms of heat stability in combination with valve gate systems. The leak-proof system also is particularly suitable for multi-cavity systems. For more information, visit www.hasco.com

HEIDENHAIN, Schaumburg, Illinois, a developer and manufacturer of linear and angle encoders, rotary encoders, digital readouts and CNC controls, has launched the TNC7 control system that offers process reliability for 5-axis machining. The TNC7’s hardware versions, available with 24-, 19- and 16-inch monitors make it adaptable to various applications. The TNC7 basic is designed for 3- and 2-axis machines and provides features like MAS graphical 6D set-up support, DCM collision monitoring and OCM trochoidal milling. In addition, HEIDENHAIN highlighted its StateMonitor software. This software, part of the Digital Shop Floor including, energy monitoring and ERP interfacing features, allowing businesses to analyze detailed data and improve operational efficiency. For more information, visit www.heidenhain.us.

CAM-TOOL, Muncie, Indiana, a company specializing in die and mold manufacturing tools, has released CAM-TOOL Version 20. This version introduces features that streamline the machining process, enhance precision and reduce set-up time for CNC machinists and engineers. The Version 20 features include a 5-axis roughing capability, AI-driven data mining methodology, adaptive roughing mode to manage tool load, and settings for optimization, stock calculation and transforming machining workflows. The release of Version 20 not only improves its software capabilities but also sets a new standard for the integration of AI in the machining industry. For more information, visit www.camtool.com.

PCS Company, Fraser, Michigan, a supplier of mold bases, mold components and molding supplies, has added Kistler Cavity Pressure Sensor Heads and Coaxial Connecting Cables to its line of mold components. The two pressure-sensor heads from Kistler include the 9204 cavity pressuresensor head and the 9211B miniature cavity pressuresensor head. In addition, the PCS line includes the Kistler 1645C Coaxial Connection Cables. For more information, visit www.pcs-company.com.

$4,800 more than average member dues.

amba members saved an average of $6K in mro spend in 2023Get involved to start saving today.