AMBA Celebrates 50 Years

Tool Builders Focus on 2023 Priorities

Building Resiliency in a Mold Shop

Powering Growth: AMBA Conference in Michigan

AMBA Celebrates 50 Years

Tool Builders Focus on 2023 Priorities

Building Resiliency in a Mold Shop

Powering Growth: AMBA Conference in Michigan

For American mold builders and molders to succeed, everything must be done right. Progressive understands, and works to deliver quality in all that we do for you:

• Verified CAD models available in multiple native formats

• Best-in-class Customer Service and Order Fulfillment

• Dimensional precision for consistent mold assembly

• Performance between the platens for unmatched longevity

Contact Progressive at 1-800-269-6653 to discuss new standard mechanisms, greaseless components, and exclusive mold monitoring innovations.

For parts with shot sizes from a fraction of a gram to multiple kilograms, INCOE provides Hot Runner Technology solutions throughout the entire process — from engineering mold review and filling simulation to on-site technical support.

Our global commitment is to be your Melt Logistics® partner — producing value in your process — and ultimately delivering satisfaction where it counts.

AMERICAN MOLD BUILDERS ASSOCIATION 7321 Shadeland Station Way, #285 Indianapolis, IN 46256 P: 317.436.3102 • F: 317.913.2445

info@amba.org • www.amba.org

AMBA TEAM

Troy Nix, Executive Director

Kym Conis, Managing Director

Susan Denzio, Business Manager

Rachael Pfenninger, Director of Strategic Execution

Brittany Stratmann, Public Relations

Development Coodinator

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

PUBLISHED BY:

2150 SW Westport Dr., Suite #101

Topeka, KS 66614 P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members.

Dear Colleagues, I hope this finds you happy, healthy and with more business than you can handle. If that’s the case, I’d like you to put your feet on your desk and try to remember where you were 50 years ago… I was 13 years old, had just met my future bride and worked summers pumping gas at the local marina. Not a bad gig for $2 an hour. Boats, water, pretty girls, I had it made. Little did I know that two things were happening that year that would change our world: Hip Hop music began in New York City and the American Mold Builders Association (AMBA) was founded.

Now my hunch is the AMBA will long outlive Hip Hop (I’m more of a Jimmy Buffett fan), but both have greatly impacted our lives. While your feet are still up, try to remember the words to “Rappers Delight” and be thankful that dozens of trailblazers had the foresight to create the AMBA. Our industry is a force, a voice in Washington D.C. and a conduit to provide best-in-class assistance to our members because a group had the conviction that our industry needed an association. I’m thankful they did.

Some say the best part of our Association is our upcoming conference. They are right! If you’ve not been in a few years, this is your year! Our team is hard at work developing programming that is relevant to industry issues at hand. At last year’s conference, I challenged all the owners to bring their young guns and show them how dynamic this industry is. Tom Barr at TK Mold did and still reaps the benefits. This year is your turn. I’m bringing my young superstars, and I hope you will too! Let’s make this a record year, with more shops attending and each bringing their best and brightest. Join us!

A strong voice and presence are needed in Washington D.C., now more than ever. We’re facing renewed pressure on keeping in place tariffs on Chinese tools and have awful tax laws and new regulations in play that will affect each of us. Omar Nashashibi and his team at The Franklin Partnership are leading discussions that are important to our industry. Thanks to the nearly 60 member shops that helped mobilize comments regarding our need for consistent tariffs on Chinese tools. Washington heard us loud and clear. We will continue to push for laws and regulations that are favorable for our industry and our members.

I think we would all agree that developing our teams is our top priority. Your AMBA is leading the way with our Emerging Leaders Network. This specialized group for our next generation of leaders is designed to help them develop the skills necessary to succeed in supervisory and/or managerial roles.

I’m thankful to be working with a smart, experienced Board, a dedicated and focused AMBA staff and you, our member companies to ensure we have the strongest industry association possible. But we always can be better. If you have ideas on things that can help you and your business be more successful, please let us know.

I hope you remember the words to “Rappers Delight,” are thankful for our association pioneers and make your reservations for Grand Rapids with your young superstars. I look forward to seeing you then. Call anytime! All the best! DDD

OFFICERS

National President

Don Dumoulin, Precise Tooling Solutions

Immediate Past-President

Jim Sperber, Master Tool & Mold

Vice President Tyler VanRee, Legacy Precision Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Friedlander, Coplan & Aronoff LLP

Treasurer

Tom Barr, TK Mold & Engineering

BOARD OF DIRECTORS

David Bowers II, JMMS, Inc.

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume

Dan Glass, Strohwig Industries

Eric Karaman, Michiana Global Mold

Chad LaMance, United Tool & Mold

Andy Peterson, Industrial Molds Group

John Stocker, Swiss Steel USA

Hillary Thomas, Westminster Tool

The American Mold Builders Association (AMBA) is celebrating its golden anniversary during 2023. At 50 years old, the association has hit its stride, now leveraging a half century of history and experience, along with expertise of today’s landscape, challenges and tools. Alongside its community of mold builders, it looks towards a bright future of continued support, advocacy and resource provision.

Troy Nix recalled his first assessment of AMBA in 2011 when he became the association’s executive director. “My first impression was that the core of what AMBA provided was unique and valuable,” said Nix, “With a more concentrated effort of data and resource delivery, AMBA would be able to escalate its mission – to be the competitive advantage for US mold builders by creating better business leaders, better organizational contributors and greater bottom-line impact for its members.”

Kym Conis, AMBA managing director, has been with the association since the First Resource management team was engaged to run the organization. “The AMBA has weathered a lot of ebbs and tides, but the fact that it has made it through 50 years – which is quite a landmark achievement – validates the strength of the foundation upon which the association originally was built,” she said. “Some of AMBA’s foundational aspects are mutual respect, collective intellect and connectivity. Those have persisted through the decades and through the different phases and changes that the organization has experienced. With that foundation

remaining strong, members still can look to the association and identify the core aspects that make it what it is. That is one of the reasons why we have endured for 50 years.”

For Conis, marking this occasion is a good time to gauge what has worked and to gear up for the future. “Turning 50 gives the AMBA opportunities to not only measure where it has been,” she said, “but also to pause and examine what new opportunities exist that can help the industry get to where it needs to be in the next decade and beyond.” For example, the board of directors has just gone through a strategy initiative, looking three years out. “As we work with AMBA’s board of directors on AMBA’s strategic direction, we truly feel there is no better time to be embarking on the association’s next 50 years,” stated Conis.

AMBA has been helping its membership in a variety of ways over the years. Don Dumoulin, CEO/owner of Precise Tooling Solutions, Inc., Columbus, Indiana, has been an AMBA member for eight years and is the current board president. “The value of the membership to individual members is really three-pronged,” he said. “The first thing is that members are able to benchmark what the competition is doing – our friendly competitors, in most cases – and learn about the best practices in the industry.” Dumoulin pointed out that this might include hearing about business techniques for dealing with delinquent payments from customers, recruiting new workforce candidates, training new hires or learning about the latest technology.

“The second prong,” said Dumoulin, “is the simple fact that we have a partner in AMBA that is looking out for the industry. That is so very important in today’s age of government regulations and tough customers. We have a partner that works on the industry’s behalf every day.” Rounding out Dumoulin’s trio is the value of community. “The third thing that is most important about the membership is just the great people that we get to know,” he said. “We are all in this together, and usually everybody is very cooperative and helpful.”

To illustrate how AMBA is a partner that looks out for the industry, Dumoulin recounted the association’s legislative approach to maintaining US tariffs on molds from China. “Four years ago,” said Dumoulin, “we were faced with the disastrous effects of the lifting of government tariffs on Chinese tools. The tariffs were suspended by the Trump Administration based on some bad advice that had been received. AMBA, along with folks like Laurie Harbour (Harbour Results), myself and our lobbyist, Omar Nashashibi at The Franklin Partnership, took on the problem. Together, we motivated our members to write to and call their Congresspeople and their Senators, and we got the tariff removal overturned.” Today, there continues to be a 25% tariff on all tooling that comes from China, helping to level the playing field for US mold manufacturers.

Tom Barr, president/owner of TK Mold & Engineering, Inc., Romeo, Michigan, echoed some of Dumoulin’s thoughts. “One of the biggest values to being a member of AMBA,” Barr said, “is the sense of belonging. Being surrounded by peers in the same industry and AMBA partners allows us the opportunity to network and share best practices.” Barr also pointed to plant tours, as well as workshops. “My alltime favorite,” he said, “is our yearly conference. Motivational speakers and suppliers at the conference ‘pump up’

Formation of the American Mold Builders Association (AMBA) – Chicago

Fourteen Chapters were Created Between 1973-2010

First AMBA Chicago Chapter President Art Dashut, Deluxe Die Mold

AMBA Hires First Executive Director Jeanette Bradley

Launch of Journeyman Certification

First Issue of Membership Directory Is Published (Known Now as the AMBA Sourcebook)

Association Launches Website, www.amba.org

AMBA Executive Director Jeanette Bradley Retires

AMBA Names New Executive Director Melissa Millhuff

Launch of Chapter of the Year Award (Known Now as the Tooling Trailblazer of the Year Award)

AMBA Honors 8 Charter Members as Part of Its 40-Year Anniversary

Launch of the American Mold Manufacturing Advancement (AMMA) Grant

AMBA Hosts First Annual Convention in Lincolnshire, Illinois

First Issue of AMBA Quarterly Publication – News & Views (Known Now as The American Mold Builder)

Launch of Mold Builder of the Year Award

Launch of Partner Program AMBA Travels to Washington D.C. to Meet with Legislators

AMBA Names New Executive Director Troy Nix

First Plant Tour Workshop at Mold Craft, Inc.

AMBA Becomes Crucial Communications Hub for COVID Resources

AMBA Celebrates 50th Anniversary

Launch

Emerging Leaders

AMBA Launches Tariff Initiative with The Franklin Partnership

the value of skilled trades, remind us why we do what we do and share insight on how to do and be better.” Barr said that AMBA’s strategic initiatives – based on members’ needs –are another valuable perk. “One of the newest additions to AMBA,” said Barr, “is the Work Capacity Tool, which now is on the association’s website. This tool helps companies network with each other when they are experiencing slow or busy stages in their businesses, to find ways to share and balance their workloads.”

Barr pointed out that AMBA membership is valuable on several levels. “I am a third-generation moldmaker,” said Barr, “and I started my own company in 2003. AMBA has been a resource both professionally and personally.” At the professional level, Barr has gained new insight into technology and efficiencies through AMBA partnerships and by networking with other companies. “On a personal level,” he said, “I have made many new friendships and have been able to share both the rewards and struggles of this trade. For me, getting input, sharing my experiences and coming up with possible solutions is rewarding.”

Ray Coombs said that the sense of community he found at his first AMBA conference was immediately evident. Coombs, president/owner of Westminster Tool, Plainfield, Connecticut, has been an AMBA member since 2012 and is a former member of the board. “At that first conference,” Coombs said, “I just realized that I really was not alone. At that time, people in the industry were becoming more collaborative and willing to share. The most immediate value of membership was and is having direct access to our actual peers. They are not our competition – they are our peers –and together, we make up an industry which provides a great quality of life for many people. We have got to remember that. We all tend to get into our own bubbles and think that we are better off going alone, but that is so untrue.”

Coombs credits his membership in AMBA as a significant factor in the success of his company, which was amid a transition/reinvention when he joined the association.

“AMBA played a big role in making my company what it is today,” he said, “by enabling me to take a little bit of input from each of the many places that I was able to visit and the connections that I made. The ability to see and talk to other mold builders – to learn what is going on out there –helped give me the resolve that, oh, okay, maybe I’m not out to lunch with my business plans.”

Coombs frequently visits other mold builders and takes plant tours. “I have visited hundreds of plants,” he said, “but the connections with AMBA members are the ones that have endured.” Coombs cites his connection with Michael Bohning, former owner/president of Creative Blow Mold Tooling in Lee’s Summit, Missouri. “Bohning was an

accountant by trade,” said Coombs, “and he bought a mold shop. I visited him and what he taught me about metrics and the importance of tracking the right metrics; it literally changed my whole outlook on running my business – just because I met him.” In Coombs’ mind, AMBA is a facilitator. “The association is designed to bring us together and help us gain an advantage in our marketplace as a unit,” he said.

The connections that Coombs has made through AMBA also include suppliers. “The suppliers that participate with AMBA, in my opinion, are people that I want to do business with because they show me that they give as well as take,” said Coombs. “They are committed to the industry, and they are interested in more than just making a profit.” A case in point is Progressive Components, which sponsors AMBA’s “Mold Builder of the Year” and “Tooling Trailblazer of the Year.” Awardees choose an educational institution to receive their cash prize. “We have won a couple awards and Progressive Components gave $5,000 to the charities of our choice,” Coombs said. Spurred by that example, Coombs company now funds the Makerspace program in its locale.

Francine Petrucci, president of BA Die Mold of Aurora, Illinois, and past Chicago chapter president, agreed that suppliers affiliated with AMBA are a special breed. “There is a lot of support for mold manufacturing here in Chicagoland, and right in our own backyards,” she said. “The suppliers always are willing to help out at Chicago chapter events, including supporting us on supplier night when we fundraise for our education committee efforts.” Suppliers also speak on technical topics at chapter dinner meetings, giving members in-depth information on processes or services that mold builders use all the time.

Petrucci values the connections she has made with other AMBA members, especially in the Chicago chapter. “We get to know people well enough,” Petrucci said, “that if we are in a pinch or find ourselves in a situation – an OSHA visit or even just trouble getting paid – we have industry friends

For Conis, marking this occasion is a good time to gauge what has worked and to gear up for the future. “Turning 50 gives the AMBA opportunities to not only measure where it has been,” she said, “but also to pause and examine what new opportunities exist that can help the industry get to where it needs to be in the next decade and beyond."

to turn to for advice.” She also cites the value of having industry insiders with whom to compare notes on business, in general. “When we are going through times like now that are particularly slow, painfully slow, and then we hear that some of the other guys are slow, too, we are relieved to learn that this is happening to everyone, and we have to just ride it out.”

Troy Nix described how AMBA contributes to the strength of the mold building industry. “AMBA’s members strengthen the industry by contributing knowledge,” he said. “Through the distribution of benchmarking, best practices, connections and more via a network of nationwide mold builders, business owners, management teams and individuals are able to make better decisions about their businesses and become better industry leaders, which then continues to drive the advancement of the US mold manufacturing industry.”

The stronger AMBA is, the more it can benefit the moldmaking industry as a whole. “Advocacy for the industry is a recent effort that widely has been successful,” Coombs said. “AMBA has facilitated it, so we speak with a single voice. I’m involved with my local legislature and with

academia, and both are starving to help our industry, but when they hear from us as a fragmented group that is talking in moldmaking and manufacturing lingo, it is difficult for them to grasp our needs. When we come together as a group, it carries clout. In my opinion, that is the greatest value of AMBA – its advocacy for us as an industry.”

Barr knows that workforce education and recruiting are top priorities to address for the association and for AMBA members. “Most people understand that skilled trades will be in jeopardy if we do not continue to advocate, and to build up and train our current workforce,” he said. “This drove the strategic plan for AMBA five years ago, and led to the development of such initiatives as the Plant Tour and Workforce Development Playbooks and the AMBA Emerging Leaders Network (for 40-and-under upcoming leaders in the trade).”

Petrucci agreed that the need for education and recruitment is crucial for the welfare of the industry. “I don’t know how we are going to sustain this industry if we don’t somehow get people interested and trained,” she said. Petrucci got her passion for recruiting young people and newcomers to the industry from her father, who spoke about the industry at

In 2016, for the second year in a row, the Chicago Chapter was honored as AMBA Chapter of the Year at the annual conference in Michigan. local high schools and taught at the school AMBA had for apprentices. Like father, like daughter, Petrucci formed a chapter education committee ten years ago. “The original mission was simply to inform parents, students, teachers and counselors about the career path available in mold manufacturing,” she explained. “We have raised funds and given grants to local high schools, participated in career fairs, and even held symposiums for counselors and teachers to learn about careers in the mold manufacturing industry,” Petrucci said.

In his role as board president, Don Dumoulin has contributed to an ambitious vision for the organization’s next 50 years. “Our toughest challenge is to convince our customers that they need to build tools in the United States,” he said, “and that the global supply chain, while sometimes less expensive, is fraught with risks.”

Dumoulin said that what he thinks about regularly and what has become an AMBA strategy is for the association to do everything it can to influence the government, OEMs and plastics processors that tools made in America simply are a better investment than buying from outside the country. “If we can do that,” said Dumoulin, “the industry will become more robust over the next 50 years.”

While recent history has taught us that it is extremely difficult to predict how the global economy and US manufacturing will change, as AMBA managing director, Kym Conis has focused intentions for the association. “The vision for the next 50 years is to continue to provide members with critical resources that will help their businesses compete as a crucial part of the domestic supply chain.” Conis foresees AMBA evolving in ways that are innovative, exploratory and datadriven in an effort to support its strong network of mold builders now and into the future.

Francine Petrucci’s experiences reflect her involvement with the AMBA Chicago chapter, the first chapter that was formed and one of the association’s most active chapters. “My dad, Alan Petrucci, was one of the founding members of the American Mold Builders Association,” she explained. “He has been very involved over the years; he has served on the national board of directors and has been Chicago chapter president a couple of times.”

Kym Conis related the history of AMBA’s start and its chapters. “The Chicago chapter was instrumental,” she said. “As a matter of fact, AMBA started as the Chicago chapter and then became a national association.” The chapters were initially started to create a regional connectedness among the members, especially in areas where a large number of mold builders located in one area could draw on each other and, in essence, becomes partners and have a collective strength within the community. “Creating a chapter,” said Conis, “allowed mold builders to form a tightly knit geographic network to discuss challenges, share best practices and distribute work overloads.”

AMBA ultimately formed 12 chapters over a period of 15 years. “The chapters that continue to meet today have a commonality: They have a large number of shops geographically located together,” said Conis. “The chapters that didn’t have as many shops located in one area found it too difficult to gather for in-person events and quarterly meetings.” Now, the national AMBA has taken on the responsibility of connecting its members in all areas of the US. “We connect our members from the west coast to the east coast,” said Conis. “We do that through events – in person and virtually – and through sharing data and benchmarking. It is our goal and our responsibility.”

Coombs credits his membership in AMBA as a significant factor in the success of his company, which was amid a transition/reinvention when he joined the association. “AMBA played a big role in making my company what it is today,” he said.

May 10-12, 2023 – The Amway Grand Plaza Hotel – Grand Rapids, Michigan

AMBA Conference 2023, “Powering Growth,” promises to be a conference unlike any other –encouraging attendees to think outside of the box and challenge previous ways of doing business.

Set to take place May 10-12, 2023, Grand Rapids, Michigan, attendees will experience a shift in mindset as they explore never-before-considered strategies, technologies and best practices while embracing how they can best lead teams, drive team productivity and support company profitability.

Featured content will include an exclusive, three-hour pre-conference session for AMBA Emerging Leaders; inspiring and insightful keynote presentations; best practices in business strategies, profitability and leadership development and more.

Troy Nix is the executive director of the AMBA and serves as the master of ceremonies for AMBA Conference 2023. Known for his spirit, enthusiasm and belief in American manufacturing, Nix delivers an opening address that never fails to spark emotion in each attendee’s inner core. This year’s message will focus on the role that continual improvement plays in becoming a better leader, manager and organizational contributor. Join Nix, as he highlights the best practices for empowering personal and professional growth. Nix’s tag line, “America Is What America Makes” is an essential ideal that motivates those attending the conference to strive for excellence.

WEDNESDAY

1:00 p.m. Emerging Leaders Pre-Con Session – optional

4:00 p.m. Emerging Leaders Networking Reception

5:30 p.m. Welcome Reception

THURSDAY

7:00 a.m. "Business over Breakfast" Connections

8:00 a.m. Welcome Kick-Off

» Troy Nix, AMBA Executive Director

8:30 a.m. Opening Keynote: Leverage Your Mindset

» Ricky Kalmon, International Speaker, Motivator and Mindset Expert

10:00 a.m. Supplier Trade Fair / Networking Break

10:30 a.m. General Session: TBD

11:30 a.m. Networking Lunch Or

Lunch and Learn with Ricky Kalmon

1:00 p.m. Breakout Sessions: Operational Business Strategies (Topics TBD)

2:15 p.m.

General Session: Washington, D.C.’s Plans for Manufacturing in America

» Omar Nashashibi, The Franklin Partnership

Supplier Trade Fair / Networking Break

Closing Keynote: Resiliency in the Midst of Uncertainty: Building a Culture That Thrives

» Paul Krismer, Inspirational Speaker, Trainer and Certified Executive Coach

Celebration

FRIDAY

7:00 a.m. "Business over Breakfast" Connections 8:00 a.m. Peer-to-Peer Roundtable Discussions 9:15 a.m. Breakout Sessions: Data Application Within Business Operations

Supplier Trade Fair / Networking Break

General Session: Emerging Leaders Panel

Up

» Troy Nix, AMBA Executive Director

ambaconference.com

Ricky Kalmon, international speaker, motivator and mindset expert Mindset expert, motivational speaker and author of the book, LeverageYourMindset, Ricky Kalmon will show attendees how to change the way they think to reduce stress, leverage a growth mindset, overcome challenges, adapt to change, tap into unrealized potential and ignite purpose and prosperity. Kalmon works with Fortune 500 companies, sales teams, leaders, executives and sports teams, teaching them how to reinforce their thoughts and beliefs to enhance their results. “Leveraging Your Mindset” offers ways to turn best intentions into great accomplishments on a consistent basis. Tapping into the most powerful asset – the mindset – attendees can begin to grow beyond excellence, into a spectacular realization of their best selves.

Paul Krismer, inspirational speaker, trainer and certified executive coach Uncertainty is a powerful, emotional context that permeates all aspects of daily life. A global pandemic, economic threat and political strife are layered onto already hectic, demanding lives. How can people not only cope, but thrive personally and professionally? Paul Krismer brings the science of positive psychology to bear, exploring tools that can be utilized and skills that can be learned to insulate workers from burnout and emotional exhaustion, connect positive emotions with stress management and create a culture of inspiration amongst the workforce.

Omar Nashashibi, The Franklin Partnership

The AMBA has taken the lead in the nation’s capital the past four years, first lobbying to reinstate and now to retain the 25% tariffs on imported Chinese molds and dies. Because members of both political parties in the House, Senate and White House continue to promote manufacturing in America as the nation heads towards the 2024 presidential campaign, the status of these tariffs and other issues in manufacturing remain hot-button items. AMBA’s lobbyist in Washington, D.C., Omar S. Nashashibi with The Franklin Partnership, LLC, will provide insights into what the Biden administration is considering on the Section 301 tariff action on Chinese imports and how that will affect the mold manufacturing industry. Attendees also will hear the latest from Capitol Hill and which pending regulations could impact their operations.

PLATINUM EVENT SPONSORS

Matt Lesser, leadership coach and author, Uniquely Normal Leadership, at its core, is investing in people so that they then can become leaders themselves. During this workshop, attendees will investigate two principles of guidance in leadership that often are overlooked, yet critical to this mission: delegation and performance optimization. By understanding the why, who, when, how and what of delegation, attendees will be better equipped to optimize both team member performance and their own. Through small group discussion, practical application and engaging exercises, attendees will walk away with an understanding of the strategies, methodologies and principles that will help them impact and improve everyday management scenarios, such as performance reviews, effective communication, feedback and more.

A DEEP DIVE INTO DRIVING ORGANIZATIONAL PURPOSE AND IMPACT

Ricky Kalmon, international speaker, motivator and mindset expert

Ricky Kalmon will return to the AMBA stage for a deep dive into the strategies attendees can employ in mindset development throughout their organizations. Through a clear definition of purpose and ensuing empowerment of internal leadership, executives and managers alike will learn how to drive concrete, measurable results within their executive and management teams.

Discover historic charm and modern comforts at the Amway Grand Plaza Hotel, Curio Collection by Hilton. Nestled downtown by the Grand River, the hotel is perfectly situated for exploring the city’s many attractions, restaurants, craft breweries and more. The property offers nine on-site restaurants and bars, an indoor pool, a fitness center and an onsite spa. The special AMBA rate is $189/ night and includes complimentary highspeed internet access in guest rooms and commons areas, as well as self-parking or valet. To get the AMBA rate, reservations should be made on or before April 18. For reservations, call 616.774.2000 or visit www.ambaconference.com.

This session is back by popular demand! Growing peer-to-peer networks is a primary component of AMBA Conference 2023. Attendees will have the chance to interact with peer groups during this session on topics that are unique to their job functions in their specific groups. Driven by past attendee feedback, these focused sessions have highly been requested and are expected to be one of the biggest hits of this year’s conference. They are a perfect way for professionals to find new ideas, expand their professional networks and explore new methods of improvement. Areas covered include operations, owners/presidents/CEOs, sales and marketing and workforce development.

Cautious optimism reigned in this year’s American Mold Builders Association (AMBA) 2023 Business Forecast Report, where just over 90% of respondents indicated that business conditions were fair or better. However, other economic factors – such as inflation and continuing pressure from foreign competition – continue to challenge the industry, leading to an increased focus on process efficiencies, capital investment and reallocation of personnel.

Now in its 13th year, AMBA’s annual Business Forecast Report analyzes data collected from mold manufacturers all over the United States. This year’s report represented 83 US mold manufacturers across 17 states, over three-quarters of which were concentrated in the Midwest region. With the aggregated data supplied in this report, industry executives are able to better benchmark how their companies stack up to industry norms and better align their anticipated outlook for the year.

As the industry heads into 2023, the current state of business remains relatively stable. When considering year-over-year conditions (up, down or the same), approximately 40% or more of survey respondents indicated that employment and backlog were the same, followed by another 35% or more who indicated that they were up. In the case of shipments and backlog, these percentages were swapped; over 40% indicated that both were up, followed by over 30% who said they were the same.

When comparing Q4 2022 conditions with Q3, both shipments and employment improved, while quoting and backlog each fell. None varied more than 5%, with the dramatic exception of those who reported that backlog was up; last year, 39% of respondents indicated that backlog was up heading into Q4, while this year, that percentage fell to 25% (a fall of 14 percentage points).

In addition to surveying respondents on the

current state of their pipeline, AMBA surveyed companies on their current and anticipated capacity utilization. Overall, the industry showed considerable improvement in both its current and anticipated capacity utilization percentages. Current capacity utilization rose to 74% (a 3% increase over last year’s data), while anticipated capacity utilization rose to 78% (a 9% increase over 2022 data).

To better understand capacity and sales activity within the mold building industry, respondents again supplied data regarding jobs received as a percent of jobs quoted. Thirtyeight percent of respondents received between 26% or more (up to 75% plus) of all work quoted, while 32% of respondents received 10% or less; of that 32, a shocking seven received 2% or less of all jobs quoted. This data represented an average win rate of 31% for all jobs won.

Although workforce development continues to be the number one challenge for US mold builders, it continued to shrink this year in response to the growing threat of other varied challenges. For example, while familiar industry challenges such as maintaining profitability, cost pressure, new business development and operational efficiency remained on the list of concerns (Chart 1), a new red flag was raised when rising inflation was cited as the top contributor to weaker profits (cited eleswhere in this year's report).

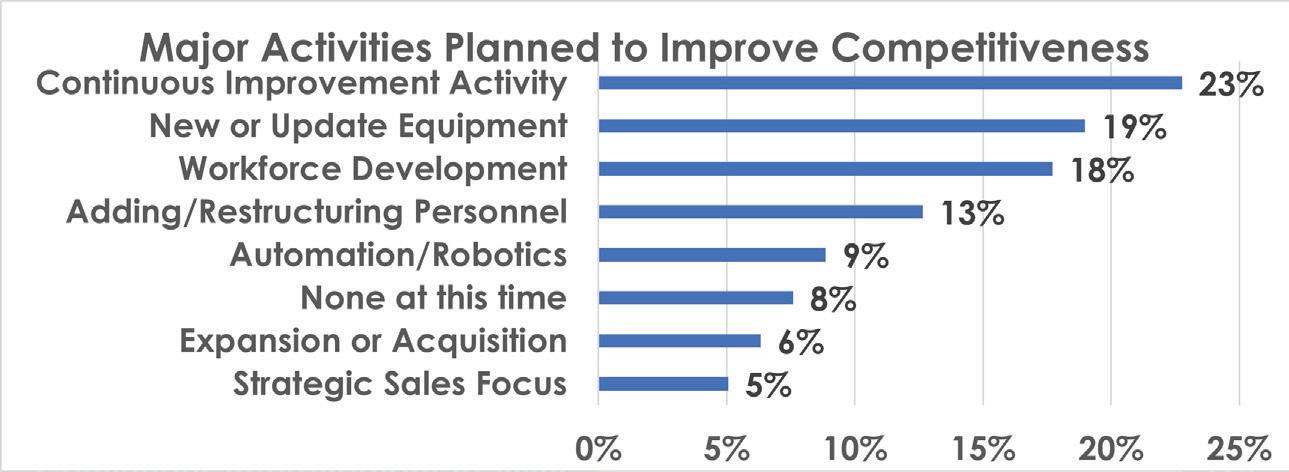

In an effort to mitigate increasing costs and improve competitiveness, mold manufacturers plan to further invest in process efficiencies, new equipment and personnel

development that will enhance operational efficiency, automation and personnel development – all prevailing areas of focus moving forward according to a majority of survey respondents (Chart 2). Additionally, over one-third of respondents agreed that additive manufacturing will enhance business operations and nearly two-thirds indicated that sector-specific revenue will increase in 2023, with the sporting goods category at the top of the list.

One bright light that shone at the end of the tunnel in this year’s report was the positive impact seen in employment. Although 92% of mold manufacturers reported having at least one open position to fill (and nearly 40% reported three or more open positions), the percentage of respondents who reported that employment was up vs. three months ago rose to its highest level since 2018; before that, the previous peak was 2013. This pairs with positive news reported from the 2022 AMBA Wage and Salary Report as well, where the group of employees aged 50 and under rose to its highest level since 2015.

For the first time, a new, interactive format for this report has been created and now is available to AMBA respondents at no cost, as well as to AMBA members at $299 and nonmembers at $499. The new layout utilizes existing data, video insights and “how-to” tips to help viewers draw conclusions and better utilize the data in day-to-day business.

To learn more about the 2023 Business Forecast Report, the state of the mold building industry and to access additional benchmarking information, visit www.amba.org.

OPEN MIND Technologies, Wessling, Germany, a leading CAD/CAM software solutions developer worldwide, has introduced its latest hyperMILL® 2023 CAD/CAM software suite. This suite offers users new and enhanced features for even more powerful and simplified NC programming in applications ranging from 2.5D machining to 5-axis milling. For easy programming of recurring shapes with a single click, hyperMILL® 2023 has a new General Transformation Pattern feature. Additionally, an enhanced milling surface extension is offered for “3D Z-Level Shape Finishing” and “3D Profile Finishing” strategies, ensuring high-quality and reliable surface extensions when required. For more information, visit www.openmind-tech.com.

HASCO, Fletcher, North Carolina, launched a new mold tag, A5910, that provides a Radio Frequency Identification tag (RFID) and enables the easy and reliable digitalization of original HASCO standard mold units in injection molding tools. The mold tag offers unambiguous identification with forgery-proof certification of origin and allows direct access to relevant product information to ensure the correct installation of the mold units. In addition, HASCO released a cooling range system in the US, offering a variety of elements that can be combined, including nipples, couplings, sleeves and hoses. This allows future-oriented solutions for all challenges in cooling technology. For more information, visit www.hasco.com.

A component supplier for the injection molding, die casting and moldmaking industries, Nonnenmann, Inc., Sterling Heights, Michigan, offers practical and economical solutions in its portfolio for the flexible and application-specific design of temperature control systems and hoses. The temperature control manifolds (Series 117), offer a cost-effective and flexible option for machine and mold tubing; available in different variants and dimensions. The standard stainless steel six-way manifold (FL9931), introduced in the summer of 2022, can be used for tempering in high-temperature ranges up to 392° F. Accessory components matched to all distributor variants also are available: shut-off valves, mini ball valves, coupling nipples, reducers, double nipples,

plugs, hose nozzles, quick-action couplings and others. For more information, visit www.nonnenmann-inc.com

Seco Tools, Troy, Michigan, is a global provider of metal cutting solutions and has introduced a new High Feed SP milling system. The system features a combination of dedicated cutting geometries and insert grades, as well as optimized lead angles, that combine to boost material removal rates, maximize chip evacuation and extend tool life. Designed for ease of use, the robust High Feed SP milling tools provide simple, foolproof insert indexing that prevents operator mistakes, unexpected machine downtime and scrapped parts. Plus, users quickly can access product information through the Seco data matrix code scanning. For more information, visit www.secotools.com/milling.

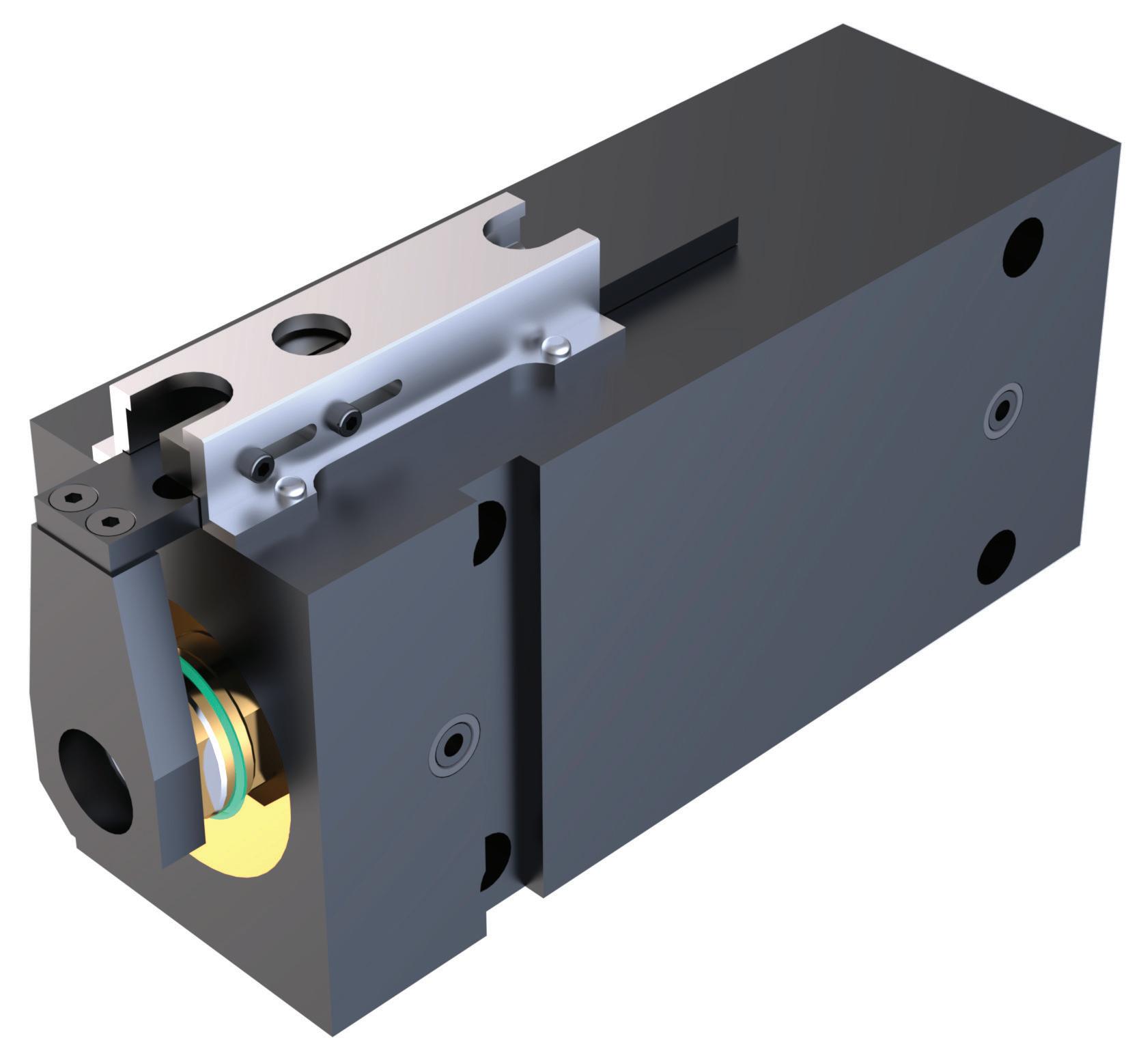

PCS Company, Fraser, Michigan, provider of solutions and innovative products for the plastic injection molding, moldmaking and die casting industries, has announced it is a distributor of tunnel gate inserts from i-mold Molding Innovations, Erbach, Germany. The tunnel gate inserts are developed and produced in-house at i-mold and are made of highly wear-resistant M2 tool steel. Known for their ability to produce cost savings throughout the molding process, they also allow for automatic degating of the plastic part from the runner and are used to hide the gate mark on the underside of the molded part. For more information, visit www.pcs-company.com.

Meusburger, Wolfurt, Austria, has created a new hot runner controller for injection molders. The profiTEMP IM is a compact, handy, powerful hot runner control unit with many advantages and easy handling. It enables precise temperature control with a short heating phase, features 12 control zones, a user-friendly touchscreen interface with 15 languages, real-time detection of plastics leakages, load guard in case of short circuit, five operating modes per zone and four heating variants, among many other advantages. For more information, visit www.meusburger.com

By Maggie Taylor, writer, The American Mold Builder

By Maggie Taylor, writer, The American Mold Builder

After several unpredictable years, the mold manufacturing industry is primarily reporting positive sentiments as the first quarter of 2023 gets underway.

“We’re on very good momentum right now,” said Tammy Barras, president of Westec Plastics Corporation in Livermore, California. “We’ve made a lot of improvements over the last five years, including seven new machines, and we’re super excited about the new technology we’re bringing in: A Mantle 3D printer for custom mold building.”

Mike McLean, general manager of Byrne Tool + Design in Rockford, Michigan, shares this positive outlook: “We’re confident that we’re going to experience more growth.”

David Bowers, CEO of JMMS Inc. in Easley, South Carolina, also is feeling hopeful. “We’re looking into a lot of big opportunities, especially the continued electrification of the automotive sector. In 2020, we started a project with one of the Japanese OEMs, and they informed us that, according to its upper management, this would be the final new combustion engine that they bring to market. We’re looking into how that’s going to play out with a lot of the things we do. It’s a bit of a challenge, but it’s also an opportunity for us to investigate where that’s going.”

Even with growth and new opportunities on the horizon, the industry is facing a few headwinds. Many industry leaders have named inflation as the primary challenge for their respective companies in 2023.

“This year, it’ll cost me $300,000 more to do business than it did three years ago,” said John Sullivan, owner of Sullivan Tool & Repair in Elgin, Illinois. “That’s because of wages, workman’s comp, soap, toilet paper, electric, gas –everything is going up. You also have to pay workers a lot more money than you did three years ago.”

“Everything is so expensive,” says Barras. “Even power has gone up astronomically. All the supplies have gone up. Passing it along fast enough to keep up with it really is challenging.”

Some price increases are more challenging to manage than others. “We’ve been passing a lot of those material price increases to our customers fairly easily because it’s not just us; it’s all over,” said Barras. “When prices go up or down by more than 5%, we requote raw materials. Our customers understand. We’re all just trying to make the same margins. It’s more challenging on machine rates and overhead. That’s harder to explain and document to the customers. It’s not something you can see coming; it just happens. You need to review your machine rates and make sure you’ve got that captured.”

Sullivan credits his efficient workforce for helping his business weather the challenges of inflation. “I’ve been able to adjust the business every year to be able to do it. Our young workers keep getting better and better. Their wages have gone up, but we’re making more money off them. They can operate two machines efficiently.”

McLean relies on key metrics and Byrne Tool’s decades of experience to ensure growth profitability. “We don’t want to erode margins just for the sake of a growing topline.” He keeps a close eye on man-hours to sales hours, on-time delivery and scrap-and-rework metrics. “We also look at the mix of the types of orders we get: new tools, repairs, engineering changes, that sort of thing. The tooling industry is known for boom-and-bust cycles and the challenge of staying consistent from month to month. But with 25 years in business, we have a solid history of knowing what type of work is profitable.”

McLean also emphasized the importance of ensuring that all employees can see the impact of their own work. “We give everybody access to technology. Everybody in our shop has access to our job tracking software and scheduling, ability to review the CAD and see what’s going on and how they can improve their part of it. We want to make sure we’re instilling a culture of continuous improvement. Transparency with those KPIs and sharing select financials also is something we’re working on. We want people to see exactly how their efforts are affecting the bottom line.”

The challenges of inflation are offset by long-awaited improvements in other areas of business. Barras spoke to a drastic – and hopeful – shift to the hiring market. “We actually have options when it comes to hiring for certain positions,” she said. “We’re currently hiring a tooling engineer, and I’ve interviewed six people already and am interviewing two more that are qualified. We also hired a quality technician, and we had lots of applicants who are all qualified. It sounds silly, but it’s nice to be able to find the person that’s right for the job instead of finding a person that could do the job. I’m getting to pick this time.”

Even with the job market recovering, mold manufacturers still are contending with the challenge of a maturing workforce. Attracting and retaining younger workers is a top priority for many companies.

Bowers speaks of the benefits of tapping into local career development resources and connecting with younger populations. “One of the things we’ve participated in is trying to drive awareness of manufacturing down into lower age groups. The AndersonOconee-Pickens (AOP) tri-county area has what’s known as the AOP Business & Industry Showcase, which specifically is catered to eighth graders in the region. The workforce development section of the government works with economic development councils from the three counties to pull off a two-day event, where we have manufacturers and employers from the tri-county area set up what essentially is a tradeshow booth to demonstrate what careers are available in their industry segment. It’s centered around career clusters, that the career and technical centers in all three counties are offering as certificate programs during high school.”

Bowers credits the region’s European influence for driving this focus on connecting with younger students. “We’re in the wide swath of BMW, Michelin and other European OEMs that have had a much different focus on education for many years: apprenticeship programs, asking kids to declare interests at a much younger age and providing school-towork opportunities.”

JMMS Inc. has fully embraced the benefits of the European approach. “We participate in a school-to-work program: High school kids go to school for half the day for general curriculum requirements and then come to the job site for technical skills and training. We’ve partnered with five different disciplines – machine technology, mechatronics, CAD design, aerospace and welding – and we’re constantly recruiting out of those programs.”

Sullivan has been investing significant time and money into recruiting younger workers for nearly a decade. “Back in 2014, I had all old guys working for me. Then I talked to my son, who was getting married. He was running a tire shop and making good money, despite never having touched a trade. I told him to come work for me.”

This led to Sullivan also hiring several of his son’s friends, with excellent results. “These guys are awesome and super bright. My son’s brother-in-law was a computer genius, so we were able to show him how to run a CNC right away. My son had a friend in welding who didn’t like welding, so we hired him. He’s been here six years, and he’s turned into one of the best toolmakers you can imagine. We got two other people the same way. We try to find kids that are borderline geniuses and have hardworking skills. Now, I’ve probably got one of the youngest shops out there.”

Sullivan is transparent about the sacrifice required. “I make no money off them for a year. But you have to be willing to sacrifice. I have friends who are owners, and I’ve tried to tell them to do this, and they say, ‘Oh, no, I can’t do that. I can’t afford it.’ A lot of these companies that are closing had so many workers retire that they didn’t have enough people to do the work anymore. But you have to find a way to have the finances to do it. It’s challenging. I’ve had to change up my thoughts and do different things a lot.”

Sullivan makes an effort to nurture employee loyalty and ensure that Sullivan Tool & Repair is a nice place to work.

He’s also strategic about protecting the business from the possibility of losing a worker. “Never make it so only one guy knows a given machine,” he advises. “People can walk and put you out. I have two people who know every machine no matter what, so if someone goes on vacation or walks out, nobody can put me out of business.”

Sullivan also is careful to protect his business from the challenges associated with ongoing supply chain delays. “We have everything in-house. If things break down now, you might be waiting three months to get it back up and running. We have a hole popper, but if it ever broke down, we’d be in trouble, so we bought another one. You have to keep upgrading equipment.”

Bowers takes a different approach to ensuring capacity. “One of the things that separate (JMMS Inc.) from many other mold manufacturers in the US is we primarily utilize what I refer to as the ‘supply chain concept of manufacturing.’ Many other US manufacturers set themselves up so that they’re capable of every machining discipline and requirement needed to manufacture molds. At JMMS Inc., we only manufacture inhouse when we are the best fit for a project and we do a lot of purchasing and subcontracting.”

JMMS Inc. has leveraged a proprietary resource for AMBA members to find reliable partners for outsourced work: the AMBA Work Capacity Tool, which was launched in August of 2022. “The Work Capacity Tool is not so much a marketplace as a networking platform, all based on open capacity among AMBA members,” said Bowers, who is on the AMBA Board of Directors. “There are two sides to it. You, as an AMBA member can enter your open capacity, categorized into different machining and process disciplines associated with mold manufacturing. Or, if you need to outsource work, you can go into the database and query for open capacity. The database will give a list of pre-qualified companies who have capacity in a requested discipline, and you can reach out to them directly to see if they have any interest in bidding on your project.”

Bowers has successfully used the tool to find and establish partnerships with other companies for outsourced work. But he understands that some companies may feel reticent about using it, especially in an industry that often prefers to keep things in-house. “I’ve been engaged in the process of outsourcing for nearly 25 years, but other companies have been focused on doing everything themselves. They’re concerned about the risks of this process of going to the outside. Throughout history, this phenomenon has been present in the mold manufacturing industry.”

His conversations with AMBA members about the tool often reveal recurring concerns. “They’re asking, ‘How can I trust them not to steal my customer? What if they don’t

make their delivery? What if they have some quality mistake that is detrimental to my customer?’ It’s very difficult to make someone feel comfortable about something they’re uncomfortable with.”

Bowers believes the entire industry, not just JMMS Inc., can benefit from a more collaborative approach. “It’s just as important for me to talk about the challenges of this industry as much as it is personal business. There are so many more industry-wide challenges and opportunities for us to seize as an industry. But the idea of collaboration and cooperation with other companies is only happening in pockets. That

continues to be a challenge in our organization, and that’s one thing the AMBA Board of Directors is trying to strategically address.”

Bowers has clear advice for mold manufacturers on protecting themselves in collaborative partnerships. “Be clear about the data and have very good written specs and documentation. Specify what the quality requirements are, along with the level of inspection and validation. That’s the best you can do to protect yourself and control your purchase.”

Barras’s advice during any season is to stay focused on a company’s north star – its employees. “I recently gave a presentation that included a slide on our ‘Why.’ We don’t do this because of the products. Obviously, we have to make money, but that’s not the reason we do it. The reason we do what we do is the people that work here. People can buy houses, send their kids to soccer camp, go on vacation and build their lives because of the work they’re doing at Westec. Our people are our most important asset. They make it happen.”

With over 160 years of steel Steel Group is not only a Their comprehensive range Die® grades allows you to cation. In addition, an extensive more alternatives from one www.swisssteel-international.us

With over 160 years of steel production experience backing their brands, Swiss Steel Group is not only a pioneer, but also a market leader in specialty steels. Their comprehensive range of Formadur®, Thermodur®, Cryodur®, and Mold Die® grades allows you to choose the ideally suited mold material for your cation. In addition, an extensive range of value added services provides you more alternatives from one source, Swiss Steel USA / Canada.

With over Steel Group Their comprehensive Die® grades cation. more alternatives

www.swisssteel-international.us

www.swisssteel-international.ca

With over 160 years of steel production experience Steel Group is not only a pioneer, but also a Their comprehensive range of Formadur®, Thermodur®, Die® grades allows you to choose the ideally cation. In addition, an extensive range of value more alternatives from one source, Swiss Steel

+1 800 323 1233

With over 160 years of steel production experience backing their brands, Swiss Steel Group is not only a pioneer, but also a market leader in specialty steels. Their comprehensive range of Formadur®, Thermodur®, Cryodur®, and Mold Die® grades allows you to choose the ideally suited mold material for your application. In addition, an extensive range of value added services provides you with more alternatives from one source, Swiss Steel USA.

www.swisssteel-group.com

+1 800 323 1233

www.swisssteel-international.ca

+1 800 323 1233

www.swisssteel-international.us

www.swisssteel-international.us

www.swisssteel-international.ca

With over 160 years of steel production experience backing their brands, Steel Group is not only a pioneer, but also a market leader in specialty steels. Their comprehensive range of Formadur®, Thermodur®, Cryodur®, and Die® grades allows you to choose the ideally suited mold material for your cation. In addition, an extensive range of value added services provides you more alternatives from one source, Swiss Steel USA / Canada.

+1 800

With over 160 years of steel production Steel Group is not only a pioneer, but Their comprehensive range of Formadur®, Die® grades allows you to choose the cation. In addition, an extensive range more alternatives from one source, Swiss www.swisssteelgroup.com

+1 800 323 1233

www.swisssteel-international.ca

+1 800 323 1233

Even with growth and new opportunities on the horizon, the industry is facing a few headwinds. Many industry leaders have named inflation as the primary challenge for their respective companies in 2023.

It’s been an interesting three years for the manufacturing industry. In 2020, the industry was hit by COVID-19. Together, everyone learned what to do. Despite starts and stops, ups and downs, the tooling industry persevered. Then, in 2021, it was a year of unprecedented high demand for energy and major durable goods, driving major supply chain challenges in every region.

Additionally, labor continued to be an issue, not just because people didn’t go back to work for a variety of reasons, but because demand was so huge. Then, labor rates went up incredibly high and businesses had to pay to attract and retain employees. From there, the industry had its biggest shortage of semiconductors ever seen and consumers changed their living and buying behavior, more than ever before.

When 2022 came, manufacturers thought it would be a great year for the tool and die industry, but it progressed to be almost more challenging than previous years, with much of the uncertainty a result of global unrest in Ukraine and between China and Taiwan. Then, there has been a major energy crisis (particularly in Europe), inflation, rising interest rates and a pending recession that has impacted nearly all businesses. Despite these challenges, manufacturers still see great opportunity on the horizon for the automotive tooling and other durable goods industries.

Looking forward, the future is bright for this industry. Harbour Results’ 2022 Automotive Tooling Forecast, released in November 2022, predicts automotive vendor

Ram, Ford and General Motors, which source most of their tools in North America, are planning to source tooling for all new full-sized pickup trucks and SUVs in 2025 and 2026. On average, a truck requires 20 to 40% more tools per vehicle, so these vehicles significantly increase tooling demand in this region.

tooling spend in North America to increase year-over-year at a rate of 13.4%, resulting in $8.3 billion in spending in 2025. This is a significant increase from the 2022 estimated spend of $5.7 billion. Additionally, the number of tools needed during the same duration will increase 14%.

It is important for mold shops to understand what is driving the growth – automaker profitability and the introduction of EV vehicles are two key factors. Despite a drop in North American vehicle demand from 15.8 million to 13.7 million units, most automakers are experiencing record levels of profit per vehicle sold. This is funding investment in technology and new vehicles, which will all require investment in new molds.

Additionally, from 2023 to 2029, the number of vehicle nameplates in the region will grow 18% from 210 to 249. And, battery electric vehicle (BEV) nameplates will grow from 20% of the mix in 2023 to 46% of the mix in 2029. The new nameplates and vehicle introductions generate more vehicle launches, which require more tools. It is important to note that the tooling spend per vehicle for BEVs is, on average, lower than internal combustion engine (ICE) vehicles by about 28%.

Finally, Ram, Ford and General Motors, which source most of their tools in North America, are planning to source tooling for all-new full-sized pickup trucks and SUVs in 2025 and 2026. On average, a truck requires 20% to 40% more tools per vehicle, so these vehicles significantly increase tooling demand in this region.

However, it is not all good news. Although automakers are seeing record profits, the automotive supplier community is being squeezed and forced to make difficult investment and resource decisions to remain viable. Additionally, the threat of a recession has had some automotive companies put some

future investments on hold. All of these factors, as well as new and used vehicle pricing and consumer demand, could impact the future of tooling spending.

In the next 18 months, the manufacturing industry will continue to face challenges and mold shops will need to be intentional with their future business plans and strategies. There are several factors that must be considered when planning for 2023 and beyond.

Know the market intel by studying launches and building sales forecasts based on core competencies. Also, know which OEM is launching and whether allnew, major or facelift so the plan can be based on the company’s customer base.

Understand customers’ needs and plan for them also while staying focused on the team and their growth.

Focus on lead time reduction by focusing on gaps and driving improvement.

Build flexibility to drive resiliency and hunker down financially – be smart, focus on cash and quality of earnings.

There are a lot of factors – globally and regionally – occurring simultaneously, making it even more critical to continuously monitor the health of the industry and customers to better understand how it all impacts a manufacturer’s bottom line.

As president and CEO of Harbour Results, Inc. (HRI), Laurie Harbour leads a team of analysts and manufacturing consultants to help small- to medium-sized manufacturers develop short- and long-term strategies, improve their operations, reduce risks and optimize business. As a trusted advisor to the North American manufacturing industry, HRI monitors, researches and analyzes the manufacturing value stream to identify strengths and weaknesses, gaps and risks, and business and operational opportunities in an effort to help the industry transform to be more successful in the global marketplace. For more information: www.harbourresults.com.

It’s free to sign up using your FedEx account number, and there are no quotas or commitments. Typically, your FedEx discounts will be available 7 to 10 business days after you join the FedEx Advantage program.

Members of the American Mold Builders Association (AMBA) sent a loud message to the Biden administration in January 2023 – keep the 25% tariffs on imported Chinese industrial molds and dies in place. More than 50 members of the AMBA filed formal comments with the Office of the US Trade Representative (USTR) calling on them to continue defending American mold builders by keeping the Section 301 tariff action in place.

The Biden administration is required by law to review the tariffs after four years, a process triggered in July 2022. At the time, AMBA successfully lobbied the USTR to keep the tariffs in place as it underwent the full review, despite significant pressure on President Biden to suspend the tariffs during USTR’s review. With the tariffs still in place today at a 25% rate, 67% of AMBA members reported that they have taken on new business previously sourced from China as a result of the Section 301 action covering industrial molds.

AMBA supported its members who filed by submitting its own comments to USTR on behalf of the industry. In its filing, the association told the Biden administration that

63% of members reported that lifting the tariffs would result in reducing their workforce or lead to a hiring freeze. Furthermore, 78% of members reported that they have lost work in the past 24 months due to unfairly low-priced foreign competition.

While hundreds of mold builders currently exist in the US, imports from lower price countries, such as China, continue to cause injury to the domestic industry. The 25% tariff on molds and dies imported from China has leveled the playing field for US manufacturers. Before the tariff, Chinese shops sold molds and dies for as much as 40% lower than a comparable product manufactured by a domestic shop. As a result of the tariff, Chinese mold shops reported between a 10% and 30% drop in revenue, helping level the playing field with the tariffs acting as a countermeasure against the subsidized Chinese molds and dies.

Even by the White House’s own admission, AMBA members play an essential role in the supply chain. Industrial molds appear in the 100-day review under White House Executive Order 14017, “Building Resilient Supply Chains,

Revitalizing American Manufacturing, and Fostering Broadbased Growth.” This is an important recognition by the federal government that industrial molds are a critical component of the supply chains, without which, manufacturers could not produce their plastic and other products in the US for national and economic security.

Mold capacity utilization rate in the US is currently around 72%, putting American companies in a strong position to meet current and future domestic demands. However, most of those seeking to lift the tariffs are simply chasing a lower price, and not as they often claim, unable to source in the US.

USTR received 1,497 comments from the public as part of this formal review process. Sources indicate it will take several months for government officials to sort through and analyze the input, which means a decision on whether to remove the tariffs on all or some of the Chinese imports is still further off – possibly into the summer of 2023. The Biden administration is under considerable pressure to make changes and not simply continue former President Trump’s tariff policy.

Former President Trump imposed the Section 301 tariff action starting in July 2018, to counteract Chinese IP theft and forced technology transfer. The Biden administration is conducting this review to determine the effectiveness “in obtaining the elimination of or in counteracting China’s acts, policies and practices related to technology transfer, intellectual property and innovation.”

AMBA responded to the question by saying that the tariffs serve as a mechanism to deter US manufacturers’ joint ventures in China, reducing the opportunities for IP theft and forced technology transfer. Manufacturers report that OEMs and suppliers are less interested in joint ventures in China as a direct result of the tariff action and, more importantly, that the tariffs also act as a deterrent from US businesses sourcing from China and incentivize the reshoring and onshoring of manufacturing to American mold manufacturers.

Few believe that USTR will lift all the tariffs, which cover more than 10,000 imports. It could, however, choose to remove tariffs on some imports while restarting an exclusion process, allowing importers to request an 18-month suspension of the 25% rate on a select list of goods. This is why AMBA mobilized its members last summer, and again this past winter – to make sure the White House hears the voice of the industry when it makes a decision on the tariffs later this year.

Aside from USTR’s review, China is taking center stage as a major focus of both political parties on Capitol Hill. In January, Republicans created a new US House of

Representatives Select Committee on China, chaired by Rep. Mike Gallagher (R-WI). Officially known as the Select Committee on Strategic Competition Between the United States and the Chinese Communist Party, both Democrats and Republicans will serve as they formulate strategies on a range of issues from economics and trade to defense and technology.

The committee likely is one of the few bipartisan actions that may be seen in the US House of Representatives in these early months of this new 118th Congress. Whether they can put forward legislation that can clear both the House and Senate remains a serious question. And what would that legislation look like? AMBA is well-positioned to work with the new committee and already has engaged with some of its members in the past on the importance of the Section 301 tariff action.

Few question that creating the committee only is going to further increase tensions between Beijing and Washington. The Biden administration is continuing to place export restrictions on American shipments to China and sources indicate they are in initial talks with the European Union on a semiconductor technology pact.

Taken together, all these actions point to the Biden administration making some type of decision on a pathway forward on the Chinese tariffs. AMBA built momentum across two administrations since 2019, first to reinstate the tariffs on Chinese molds and then lobbying for them to remain in place. The AMBA members who filed comments and the lobbying efforts of the association have positioned the industry well, in the effort to keep the tariffs in place. This summer could show the results of this rally in support.

Omar Nashashibi is a founding partner at The Franklin Partnership, LLC, a bipartisan government relations and lobbying firm retained by the American Mold Builders Association in Washington, D.C.

Mold capacity utilization rate in the US is currently around 72%, putting American companies in a strong position to meet current and future domestic demands.

2023 marks a major milestone for the AMBA – 50 years of service to the mold building industry! Celebrations began in early February, with a member reception at the Plastec West tradeshow in Anaheim, California, and will continue throughout the year. Join AMBA in commemorating its golden anniversary at the upcoming PTXPO (March 28-30 in Rosemont, Illinois) and AMBA Conference 2023: Powering Growth (May 10-12, Grand Rapids, Michigan). Check out the events page on AMBA’s website, www.amba.org/events, to keep up with where the association will be celebrating! To read more about AMBA’s 50th Anniversary, go to page 8.

Two key benchmarking initiatives that will help mold builders and suppliers alike prepare for 2023 are available for purchase. The 2022 AMBA Wage and Salary Report features high, low and average rates of pay across over 50 job functions commonly found in mold building, while the 2023 AMBA Business Forecast Report provides an in-depth analysis of past, current and anticipated business conditions.

To help executives utilize this critical data, AMBA members had their first opportunity in February 2023 to attend a virtual roundtable facilitated by Harbour Results, during which participants discussed the practical application of data from the AMBA 2023 Business Forecast Report. A recording of this session is available to AMBA members in the Archived Webinars section (underneath Events) on the AMBA website.

To access the Business Forecast Report, the recent Wage and Salary Report and other AMBA benchmarking initiatives, such as its 2022 Shop Rate Report, visit www.amba.org/ publications

FedEx® and UPS® have increased rates by an average of 6.9% in 2023 – an all-time high. Due to fees and other packagespecific charges, actual shipping costs likely will surpass the average increase. AMBA members can mitigate the impact of rising costs by enrolling in the FedEx Advantage®

program, which provides a 45% discount on FedEx Express® and a 25% discount for FedEx Ground®. Learn more about FedEx Advantage® and other cost-reduction programs through PartnerShip at www.amba.org/member-resources/ cost-reduction-programs

Sponsorship opportunities at AMBA Conference 2023: Powering Growth (May 10-12, Grand Rapids, Michigan) now are available to industry suppliers. Secure a place amongst top-tier suppliers and mold manufacturers at this year’s event at The Amway Grand Plaza, where attendees will be led to think outside of the box via thought-provoking breakout sessions, inspiring keynote presentations and numerous opportunities to connect with mold building peers. Mold builder registration is open, visit www.amba. org/events for details, registration and hotel. For additional event details, visit page 14.

Nominations for AMBA’s Mold Builder of the Year and Tooling Trailblazer of the Year Awards now are being accepted. AMBA members in good standings may nominate themselves. Nominees should be from member companies in good standing. Award recipients will be recognized at AMBA Conference 2023 in Grand Rapids, Michigan, May 10-12, at The Amway Grand Plaza, and will receive a prestigious award and a $5,000 scholarship grant from Progressive Components to be given to the educational institution, project or initiative of their choice. To submit a nomination, contact Susan Denzio at sdenzio@amba.org.

The AMBA Work Capacity Tool is an innovative resource available to AMBA members designed to help mold manufacturers share and fill capacity when needed. The userfriendly tool allows mold builders to log in open capacity over a 90-day period in over 50 areas of operation, including special machines and additional services. Members are encouraged to update capacity every 30 days, with automatic reminders sent to help keep the information current. With a

•MOLD FINISHING

•LASER WELDING

•LASER ENGRAVING

•HOT RUNNER REPAIR

•MOLD MAINTENANCE

•LASER MACHINE SALES

We offer mold finishing, laser welding, laser engraving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom. Let Alliance make a difference for you.

simple click of a button, the Work Capacity Tool connects members with shops that meet their needs providing direct links to email for quick communication and rapid results. For more information and to view a short video on how to best use this resource, visit www.AMBA.org/member-resources/ work-capacity-tool/.

Herman Mold + Tooling

501 S. 23rd St.

Fairfield, Iowa 52556

Rick Herman, vice president

Phone: 641.472.7300

Email: rherman@hhmold.com

Founded in 1987, Herman Mold + Tooling specializes in blow mold manufacturing. Services include new mold construction, mold design, mold repair and mold maintenance. The primary industries served are automotive, agriculture, construction, recreational vehicle, lawn and garden and consumer products. Corporate headquarters and the manufacturing facility are 99% solar powered.

Machining Technology

7700 68th Ave. North, Ste. 7

Brooklyn Park, Minnesota 55428

Laurent Deconinck, CEO

Phone: 651.324.7053

Email: ldeconinck@machining-technology.com

Machining Technology is an ISO-certified, fast-growing company committed to providing quality products and services. The company’s capabilities include designing and manufacturing plastic injection and die cast molds, as well as revising, repairing and maintaining existing molds. Machining Technology’s dedicated team continues to improve its systems and processes to exceed customer expectations.

Port Erie Plastics – Tool Room

909 Troupe Rd.

Harborcreek, Pennsylvania 16421

Jeff Horneman, support operations manager

Phone: 814.899.7602

Email: jeff@porterie.com

Port Erie Plastics tooling division specializes in designing, building and repairing production molds for both, the highpressure plastic injection molding and low-pressure structural foam industries. The company is well equipped to support a wide array of projects from small MUD inserts to large tonnage (30,000 lbs plus) multi-cavity family tools. Contract machining also is available.

Polydeck Screen Corporation

1790 Dewberry Rd.

Spartanburg, South Caroline 29307

Ryan Johnson, Sr., director of product and customer solutions

Phone: 864.579.4594

Email: ryan.johnson@polydeck.com

Polydeck is a manufacturing company that develops and produces an extensive range of injection molded screen media panels for the mining industry. The company’s mold shop focus is on the rapid development and production of unique solutions for its many customers.

AMBA is honored to have corporate partners that support the organization through products and services specific to the mold building industry in various ways. These partners share in AMBA member concerns and understand the challenges of the mold building industry. To learn more or apply for partnership, contact the AMBA office at info@amba.org Visit www.amba.org/partners to see a complete list of current AMBA partners.

By Lindsey Munson, editor, The American Mold Builder

By Lindsey Munson, editor, The American Mold Builder

Back by popular demand and on the heels of 2022’s inaugural event success, the Plastics Technology Expo (PTXPO) is gearing up for its second year, connecting processors to the plastics industry community with the goal of helping businesses succeed. A three-day event, PTXPO offers a full experience to attendees including an expansive exhibit hall, education, first looks at the newest plastics machinery and a variety of networking opportunities.

PTXPO is set to take place on March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois. The center will open on Tuesday and Wednesday from 9 a.m. to 4 p.m., and open on Thursday from 9 a.m. to 3 p.m.

The expo will be organized into major process pavilions, featuring over 200 exhibitors. This gives attendees the ability to easily plan their show experience and navigate the exhibitor floor. The pavilion categories include injection and blow molding, extrusion, thermoforming and compounding, auxiliary equipment, 3D printing, materials, recycling and moldmaking.

Mold builders, components providers, texture and engraving specialists, mold repair equipment suppliers, tool builders, hot runner providers, among many others will be at the moldmaking pavilion Examples of the newest machinery and applications that will be showcased are blow molding machines for packaging, extrusion-specific dies, conveying systems and more. Processors in the moldmaking pavilion

will be available to provide real-time solutions and valuable insight to attendees regarding their operations.

American Mold Builders Association (AMBA) will be exhibiting at the event, during which it will be promoting a reformatted, interactive version of its 2023 Business Forecast Report, as well as a copy of its recent 2022 Wage and Salary Report. The 2022 AMBA Wage and Salary Report features high, low and average rates of pay across over 50 job functions commonly found in mold building, while the 2023 AMBA Business Forecast Report provides an in-depth analysis of past, current and anticipated business conditions. The reports are available to purchase for AMBA members and nonmembers; and can be viewed by everyone at PTXPO.

The American Mold Builder also will be at the event, and all attendees will be able to pick up the latest issue of the magazine. Attendees are encouraged to stop by AMBA’s Booth #1724 and join the association in honoring its 50th anniversary, which will be celebrated during the show on March 29, 2:30-4:00 p.m. CST.

PTXPO tickets can be purchased online from March 1-27 for the price of $70.