New

Seat.........................................5

Pump: Technical Training Day Supplement ...........17

Missed

Pumps 101.............................20

Heat

Technical Training Day Understanding the differences between

New

Pump: Technical Training Day Supplement ...........17

Missed

Pumps 101.............................20

Heat

Technical Training Day Understanding the differences between

When you need to make a repair with a fitting you can trust, reach for SharkBite Max.

There are big changes coming to Canada in the refrigeration industry. In December 2023, the update concerning A2L refrigerants was finally released. This will mean that those in the industry that might not be familiar with flammable refrigerants will have to learn quickly as some of the older refrigerants that they are familiar with may soon be phased down or out.

This will become extremely important as Canada switches its supply of heat pump to products and refrigerants that will work better in cold climate while always having a lower GWP. The push for electrification is ramping up.

So many of the heat pumps that are being introduced to the market right now are focusing on electricity as its main energy source. But that isn’t to say that there aren’t plenty out there that also focus on natural gas or a mixture of fuel sources.

Hybrid systems will be the reality for at least the near and semi-near future as all the puzzle pieces needed come together.

I have had many conversations in the industry with people around the push towards hydrogen. Sadly, most of the people that I speak to about this technology are skeptical at the minimum and flat out resistant to it at most.

While I know that I might not understand all the nuances that come with it, and know

Facebook: @PlumbingandHVAC

LinkedIn: Plumbing + HVAC Magazine

that Canada is a geographical monster of a country, I am still epically confused as to why so many people are so skeptical. This past AHR Expo in Chicago, Illinois, there was even products that were dual fuel but with the potential for 100 per cent hydrogen.

I pose this question then to the tradespeople reading this column, what do you think of hydrogen? And for a second question, what are you most excited about for the future of HVAC/R?

Introducing

Plumbing & HVAC magazine is pleased to announce the appointment of Chris Luttrell as the new national sales manager. Chris has spent his entire career in sales and marketing, working for agencies like Publicis and BBDO. He later went to work in the trenchless market for Nu Flow as their marketing manager. We are thrilled to have Chris join the team. Chris can be reached at chris@plumbingandhvac.ca or 365-662-4112.

Twitter: @Plumbing_HVAC_

Instagram: plumbing_hvac_

YouTube: @plumbing-hvacmagazine

January/February 2024

Volume 34, Number 1

ISSN 1919-0395

Publisher

Mark Vreugdenhil

(289) 638-2133 ext.1

Cell: (416) 996-1031

mark@plumbingandhvac.ca

Editor

Leah Den Hartogh

(289) 638-2133 ext. 2

Cell: (289) 830-1217

leah@plumbingandhvac.ca

National Sales Manager

Chris Luttrell

(289) 797-2138

Cell: (365) 662-4112 chris@plumbingandhvac.ca

Assistant Editor

Francesco Lo Presti (289) 638-2133 ext. 3 francesco@plumbingandhvac.ca

Contributing Writers

Glenn Mellors, Greg Scrivener, Michael Ridler, Ron Coleman

Design and Production

Tim Norton/Janet Popadiuk production@plumbingandhvac.ca

All articles and photos by Plumbing & HVAC staff unless noted.

PLUMBING & HVAC Magazine is published seven times annually by Marked Business Media Inc. and is written for individuals who purchase/ specify/approve the selection of plumbing, piping, hot water heating, fire protection, warm air heating, air conditioning, ventilation, refrigeration, controls and related systems and products throughout Canada.

Marked Business Media Inc.

286 King Street W, Unit 203, Oshawa, ON L1J 2J9

Tel: (289) 638-2133

Postmaster: Send all address changes and circulation inquiries to: Plumbing & HVAC Magazine, 286 King Street W, Unit 203, Oshawa, Ontario, Canada L1J 2J9. Canadian Publications Mail Sales Product Agreement No. 43029513. Postage paid at Toronto, ON.

Annual Subscription Canada: $40.00 plus applicable taxes, single copy $5.00 plus applicable taxes. Annual Subscription United States: $60.00

U.S. Annual Subscription foreign: $90.00 U.S.

Copyright 2024. The contents of this magazine may not be reproduced in any manner without the prior written permission of the Publisher.

A member of:

• Canadian Institute of Plumbing & Heating

• Mechanical Contractors Association of Canada

• Ontario Plumbing Inspectors Association

• American Society of Heating Refrigerating & Air Conditioning Engineers

• Heating Refrigeration and Air Conditioning Institute of Canada

• Refrigeration Service Engineers Society of Canada

Following an increase in October, the total value of building permits decreased in November, down 3.9 per cent to $10.9 billion, reports Statistics Canada. Declines were seen across almost all sectors.

The total value of residential building permits declined 2.8 per cent overall to $7 billion in November. This comes despite eight

provinces seeing monthly gains in residential construction intentions.

British Columbia (down 10 per cent) and Quebec (down 17 per cent) more than offset the residential gains in the rest of the country in November.

However, gains in residential building values were seen in the Atlantic (up 30

per cent) and Prairie (up 9.8 per cent) provinces.

On the commercial side, the total value of building permits decreased 5.8 per cent from October to $3.9 billion in November. This marks the third consecutive decrease for the commercial sector.

Building permit values in the commercial component have decreased since the record high of $2.9 billion in March 2023.

Year over year, the $1.7 billion value of commercial permits issued in November 2023 was 16.2 per cent less than November 2022 levels.

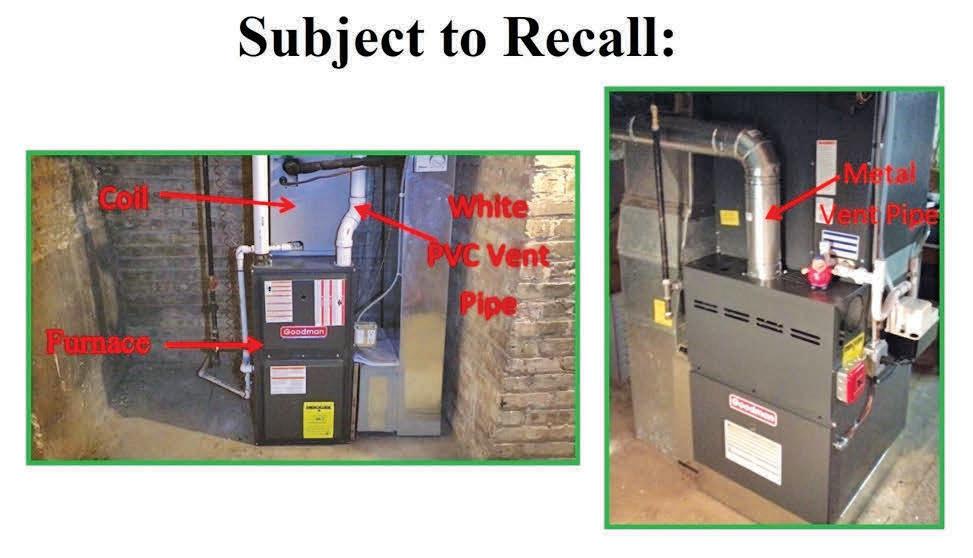

Daikin Comfort Technologies Mfg. expands its recall of evaporator coil drain pans to include additional units.

The moulded plastic drain pan at the bottom of the evaporator coil can overheat, melt, and deform, posing a fire hazard. As such, Daikin has recalled about 3,600 additional units, with only about 12 units sold in Canada. Previously, 298,300 evaporator coil drain pans, and 44,000 in Canada, were recalled in November 2021 and July 2022.

The recall was issued on Jan. 11, 2024.

Thousands of small business owners who took out a CEBA loan will soon have an increase in their debt.

Business owners looking to secure the forgivable portion must repay up to $40,000 or apply for a refinancing loan with the bank that issued their original CEBA loan by Jan. 18. If they miss this deadline, their CEBA debt will rise by 50 per cent to $60,000.

Despite 57,000 business owners asking for an extension, the deadline to repay the loan is set for Jan. 18, which the Canadian

Federation of Independent Business (CFIB) finds extremely disappointing.

“Ottawa failed to address the most critical issue on outstanding CEBA loans — the loss of the forgivable portion. I believe the government will regret the decision not to grant more time as small businesses fail and default on their entire loan. For many businesses, CEBA will be the straw that breaks the camel’s back,” said Dan Kelly, president of CFIB.

CFIB states that it garnered support

from all 13 Canadian premiers and three federal parties to advocate for an extension.

The association also adds that many bank staff do not understand the process around the refinancing extension to March 28. As a result, the CFIB is urging all businesses looking to use this provision to send an immediate written request for refinancing to their original CEBA bank and keep any documentation they’ve submitted.

Women looking to join the skilled trades have the opportunity to receive money back in their pockets through a government-funded program. The Ontario government is accepting applications for its Women’s Economic Security Program (WESP). Since its inception in 2018, the program has helped 237 women find jobs in the skilled trades.

“The Women’s Economic Security Program is empowering women with the skills they need to join the workforce and help build Ontario together,” said Charmaine Williams, associate minister of women’s social and economic opportunity.

WESP aims to expand and increase training opportunities for low-income women to equip them with the skills, knowledge, and experience to find a job or

Three industry associations are partnering to produce a joint tradeshow.

The British Columbia Electrical Association (BCEA), Alberta Electrical Alliance (AEA), and the Canadian Institute of Plumbing and Heating (CIPH) announced that they would combine their respective trade shows to produce the CIPHEX West and Electrical Learning Expo trade shows in Vancouver in 2025 and Calgary in 2027.

“CIPH is proud to partner with the British Columbia Electrical Association and the Alberta Electrical Alliance to put a spotlight on the electrical and building mechanics industry. We are excited to see our industry leaders, member companies, and their customers coming together to celebrate and

start a business and increase their financial security.

Training will be provided in the following four streams: skilled trades, entrepreneurship, information technology and general employment. Through the program, women can access support resources such as childcare, transportation and food. There are also specialized support resources for intimate partner violence.

WESP has helped more than 2,100 women secure employment, become entrepreneurs or pursue further training and/or education.

Currently, the provincial government has invested $5.5 million, including an additional $496,000 this year.

Rehau Group is honouring 75 years of business with a year-long celebration.

“Rehau is now celebrating its 75th anniversary,” said Dr. Thomas Troeger, CEO of Rehau Americas. “Together with our customers, suppliers and employees, Rehau is looking back and drawing inspiration from the pioneering spirit and visionary power of our founder. But above all, the Group is looking at how we can create even better experiences for our customers.”

Helmut Wagner founded the company in 1948 in the German town of the same name. The German-based company manufactures industrial polymer-based products, including mechanical and plumbing solutions such as PEXa hydronic piping systems for radiant heating and cooling.

Rehau has 190 locations worldwide and more than 20,000 employees. Its North American division is headquartered in Leesburg, Virginia.

grow the built environment in the West,” said Satinder Chera, CEO of CIPH.

The CIPHEX + Electrical Learning Expo West trade show will feature the latest and innovative products and services from the electrical, renewal energy, lighting, plumbing, hydronic, HVAC/R, and water quality industries that serve the residential,

commercial, and industrial sectors.

This new partnership brings them under one roof, highlighting the importance of the built environment and maximizing value for exhibitors and attendees, reports CIPH.

CIPHEX West was held in Calgary this past year and featured around 3,000 attendees and 156 exhibitors.

The NPF Advantage: The NPF heats water by burning the gas in a sealed combustion heat exchanger, completely isolated from the airstream. The heated water is then pumped through a hydronic heat exchanger that gently transfers the heat into the air. The fully enclosed Ultra-Low NOx premix burner provides extremely quiet operation, high efficiency of 97% AFUE, and allows for an industry-leading variable capacity that can modulate down to 15% for a next-level comfort experience.

Explore the new NPF at Navieninc.com.

NPF Horizontal

NPF Upflow

NPF Horizontal

NPF Upflow

The Residential Construction Council of Ontario (RESCON) is calling on political leaders from all levels of government to step up their efforts in tackling the housing supply and affordability crisis.

“Last year was a painful year for housing construction and, at the rate we are going, we’re not even close to fixing the crisis,” said Richard Lyall, RESCON president.

RESCON highlights how serious efforts should be made by all levels of government to reduce the burden of fees on new housing as

they are far too high. According to RESCON, taxes, fees, and levies account for 31 per cent of the cost of a new home. On a $1 million home, a buyer is paying $310,000 to the government.

RESCON also advocates for a modernized and digitized development approvals process to move developments along more quickly.

Additionally, RESCON is encouraging government leaders to provide financial assistance and tax breaks to incentivize companies to build more modular housing

The U.S. Department of Energy’s Residential Cold Climate Heat Pump (CCHP) Technology Challenge is heating up. Four heat pump manufacturers are joining the challenge — Bosch, Daikin, Midea, and Johnson Controls. They join the ranks of Lennox, Carrier, Trane, and Rheem.

The new successful heat pump prototypes will join in on the field testing stage of the challenge. The challenge has two segments, the 5 F and the -15 F challenge. The 5 F challenge is for CCHPs optimized for 5 F (-15 C) operation. While the -15 F challenge is for CCHP optimized for -15 F (-26 C) operation.

The next stage of the 5 F challenge involves installing and monitoring more than 23

prototypes in various cold-climate locations throughout the U.S. and Canada over the next year.

Eight companies, Bosch, Carrier, Daikin, Johnson Controls, Lennox, Midea, Rheem and Trane, will now participate in the field testing phase of the 5 F challenge.

Lennox developed the first prototype that achieved the challenge’s lab testing standards, delivering 100 percent heating at 5 F (-15C) at double the efficiency and 70 per cent to 80 per cent heating at -5 F (-20 C) and -10 F (-23 C).

Established in 2021, the challenge called on manufacturers of residential, centrally ducted, electric-only heat pumps to promote the adoption of efficient cold-climate heat pumps.

Carrier is selling its global commercial refrigeration business to its joint venture partner, Haier, for $775 million.

This marks the second business sold by Carrier following the sale of its Global Access Solutions business to Honeywell.

“Following our decision to exit the commercial refrigeration business and a robust competitive process, we identified Haier as the right fit to grow the business moving forward, building upon our successful 22-year refrigeration partnership with them,”

manufacturing plants in Canada and provide research and development funding so the industry can keep pace with new technology and building techniques.

“Ridiculous red tape, along with excessive fees, taxes, levies, development charges and bureaucracy, are choking the housing supply and pushing home ownership out of reach of many. Builders often must wait years to get approval for projects. This is a major pinch point that is unnecessary and slows construction of new homes,” said Lyall.

Until the housing supply is sorted out, RESCON maintains that adding more costs and further regulatory interventions should be stopped, and systemic issues should be ironed out to speed up construction.

Midea is one of the latest heat pump manufacturers to join the residential cold climate heat pump challenge.

said Carrier chairman and CEO David Gitlin.

Carrier previously declared its intent to divest these two divisions, along with its industrial fire, and residential and commercial fire segments. Carrier expects net proceeds from the transaction with Haier to exceed $500 million and intends to use the proceeds to reduce debt.

The next rebate programs have the opportunity to learn from the shortcomings of the Greener Homes Grant program.By Glenn Mellors

Build up a database of repeatable customers that have had maintenance or service work done by your company. This will help future proof your business.

The balance of 2022 and all of 2023, our industry was met with unprecedented challenges caused by political influence. I often refer to three pain points that an HVAC/R retail can be faced with that can significantly alter the way they do business — economic, environmental, and political influences.

If we look back on early 2023, our industry was turned on its head by the introduction of the Greener Homes Grant (GHG) program. At no time did the people that introduced the GHG program understand our industry, the supply chain, qualifying equipment, or even understand what qualifying means.

Let us go back to previous government programs that were introduced without warning. The air conditioning requirements for rebates was set to 15 SEER. At this point, manufacturers had prepared for the products of 13 and 14 SEER air conditioners. Distribution filled its network with inventory in that lower SEER tier. So, when the program launched there was an inadequate inventory of qualifying products. The

wholesale chain was flooded with these lower SEER air conditioning products that were now collecting dust because of consumer demand watching the higher SEER units. By the time the industry was able to catch up, the supply chain was flowing smoothly with higher SEER units. It was at this time that the program came to a halt and the industry itself reverted to a low SEER marketplace. The higher seer units were discounted to move products through the system and damaged the industry profitability for yet another year.

Fast forward to January 2023 and the introduction of the GHG program. Again, our industry found itself in turmoil due to a very limited supply of qualifying products.

From a consumer standpoint, there was a limited amount of information to make informed purchasing decisions. There were early adopters, there were naysayers and there were wait and see in a few years. Thankfully, the early adopters were prepared to wait for the equipment to come into availability.

Once again, the manufacturers were caught off guard. Add on the fact that there was a lack of necessary components to build the approved equipment and our industry was put on hold. Many overseas manufacturers saw the opportunity to fill the void that was left within the North American market.

As the year progressed, there was another group of early adopters that were driven solely by the rebated, and as such, increased the demand for products. North American manufacturers found themselves in a situation where the products they were producing didn’t qualify for the rebates, and therefore demand fell. This led to potential layoffs.

From a contractor standpoint, we were already battling labour shortages. This created a very treacherous position for companies. They didn’t want technicians standing around with no equipment available to complete the jobs. But then again, they also didn’t want to lay off workers as they would simply move on to a competitor at a moment’s notice. I can’t remember a time when we went into the heating season with almost zero inventory available.

To combat these product shortages, manufacturers and distributors turned to products from overseas. Many quadrupled their order to mainland China. Better late than never, but at least the equipment was on its way.

By mid-November, we were informed that

the GHG program would be ending, ironically around the same time that inventory was now showing up in the supply chain.

All through December, conflicting reports of timelines and dates for the consumer to take advantage of this program

Continued on page “15”

Are

The NEW UPSe

Model: UPSe 15-58F

P/N: 92603106

The FULLY DIGITAL ALPHA

Model: ALPHA 15-58F

P/N: 92603115

Continued from page “13”

hit the newspapers. With the deadline drawing near, there was an incredible drain on the energy home auditors. At the time of publication, the program put a hold on new registrations so that energy home auditors could catch up for the remaining funding under the GHG.

Once again, our industry found itself in flux. Many are concerned about what effect this will have on workflow, inventory management, and staffing requirements.

One man’s opinion

I suggest that your first and immediate reaction should be to do nothing but sit back and wait. Most, if not all of you, have enough work to carry you through till the March deadline.

The announcement doesn’t mean that the work will dry up for the next nine to 12 months. There are thousands and thousands of people that have registered for the program

carbon reduction in every country across the globe. This would only lead one to believe that the shotgun approach in the earlier programs require a more focused target.

As our homes become less dependent on fossil fuel to provide energy, there will be more demand put on our electric energy grid.

From a contractor standpoint, we were already battling labour shortages. This created a very treacherous position for companies. They didn’t want technicians standing around with no equipment available to complete the jobs.

and are waiting for the audits to start before taking action. This should mean that we will continue to have a high demand for our sales staff, office staff, and installers to fulfill the remainder of the program.

Moving forward into 2024, I suspect that the political influence on our industry hasn’t come to an end. Instead, the introduction of new programs will only ramp up.

There continues to be a commitment to

If we remind ourselves of the end goal, that is to produce net zero accommodation for future generations, it will only make sense that we need to transfer the demand on the grid to self-sufficient electrification of each individual home.

It would make sense then that the next generation of rebate programs will continue to look at ways of reducing energy consumption. Products focusing on solar, wind, and water for energy production may finally get their time to shine.

How do we recession proof our companies?

How do we prepare ourselves for any economic, environmental, or political challenges?

First, build a database of repeatable customers that are going to look to you first when it comes to their home comfort. How? By following the example of the big box players and building a large database of maintenance and service customers.

Next, start preparing to bring on qualified electrical technicians. They can assist you in the transfer of servicing fossil fuel equipment to servicing electric products and equipment.

Lastly, look to train yourself and your people on new products in the energy generating sector. As for today, focus on the work ahead, support the balance of the GHG program as it stands, and prepare yourself for a new programs in 2024. :

Glenn Mellors was born into a plumbing family and started in the industry in 1973. He entered the HVAC side of the business in the 80s, working in wholesale, and then joined Lennox in 1992. In 2008 he joined the ClimateCare Cooperative Corporation, an Ontario contractor group, where he is director of training and implementation. Glenn can be reached at gmellors@climatecare.com.

Intellihot, Chicago, Illinois, introduces its newly released family of Electro tankless heat pump water heaters. The electric heat pump water heater utilizes carbon dioxide as its refrigerant and is paired with a specially designed battery. It absorbs heat from the external air, then this energy is stored in the thermal battery; that way, when there is demand, cold water flows through a heat exchanger located inside the thermal battery and the water is heated to the required temperature. It features a COP of 4.9.

Intellihot www.intellihot.com

Caleffi, Milwaukee, Wisconsin, announces its new 290 series service valves kits specifically designed for tankless water heaters, combi boilers, and electric tanktype water heaters. The contractor-friendly valves connect directly to standard 3/4-inch MNPT nipples on tankless water heaters to allow for efficient isolating, flushing, and servicing of the heaters. Variations of the kit are available with the 520 series TankMixer. These codes add point-of-distribution temperature control featuring its AngleMix thermostatic mixing valve and cold-water tee with recirculation connection. Caleffi www.caleffi.com

Noritz, Fountain Valley, California, upgrades its EZ series of residential condensing tankless water heaters. The EZ series now offers a Uniform Energy Factor of 0.96, while maintaining a 25-year warrant on its redesigned stainless-steel heat exchangers. The primary heat exchanger is made of a tensile strength stainless steel material to resist heat shock and cracking under high temperatures. The secondary exchanger extracts latent heat from the combustion process, producing acidic condensate. A stead BTU mode eliminates concerns over high incoming water temperature. Both EZ models, the EZ98DV and the EZ111DV, have minimum BTU per hour outputs of 18,000. Its burner-control technology reduces the minimum input to under 5,000 BTU per hour whenever incoming water temperatures approach 90 F.

Noritz www.noritz.com

PVI, Fort Worth, Texas, expands its Conquest family of condensing, semi-instantaneous firetube water heaters with 1,100 MBH and 1,200 MBH units rated for indoor or outdoor applications. With new, larger-capacity water heaters, the Conquest family now support direct hot water demands from 199 MBH to 1,200 MBH. Ideal for retrofit and new commercial applications, its combustion gases are counter-flow to the direction of the potable water, enabling the coolest flue gases to contact the coldest water and raise low-fire efficiency. To reduce burner cycling during periods of low hot water demand, Conquest water heaters employ burner modulation with a variable speed blower. This allows low flow conditions to be met with continuous, low BTU input and without short cycling.

PVI www.pvi.com

Uponor, Mississauga, Ont., reintroduces its AquaPEX blue pipe for residential and commercial domestic-water applications. Designed to address skilled labour challenges, it now offers fullcolour differentiation for cold-water plumbing lines. The PEX-a pipe is available in 1/2-inch, 3/4-inch, and one-inch coils and straight lengths. It features a six-month UV resistance along with chlorine resistance rating of five.

Uponor www.uponor.com

GE Appliances, Toronto, Ont., introduces the expansion of its atmospheric offering with ultra low NOx and power vent gas water heaters. RealMAX products will be available in 30-, 40-, or 50-gallon models. The ultra low-NOx products provide quick recovery with optimized burner performance. It can be installed using standard water and gas connections to allow for easy retrofit installations. Its SmartShield safety system monitors the surrounding air and automatically shuts off the unit if abnormal temperatures are detected. The RealMAX water heaters carry an eight-, 10-, or 12-year tank and parts limited warranty based on the model.

GE Appliances www. geappliancesairandwater.com

With the next generation of heat pumps coming to Canada, education and training will be important to ensure proper installation practices.

n Low-GWP refrigerant

n Boilers vs. heat pumps

n Back-to-the-basics

n Commercial VRF systems

people still fighting the change coming down the pipeline, but they aren’t going to have much choice as governments shift codes and regulations. If not, there will sadly be plenty ofbusinessesthatwilllikelyhavetoclosetheir doors for good.

Beyond Boilers

Design differences: heat pumps vs. boilers

Anyone unfamiliar with heat pumps at this point might as well be living under a rock. Call them Patrick Star and maybe ask how their buddy SpongeBob is doing.

The ads for heat pumps are everywhere at this point. I remember the day that I was pushing my cart around Value Village and heard a Greener Homes Grant advertisement on the radio highlighting the benefits of heat pumps. I couldn’t help but laugh.

I can’t tell you how many conversations I’ve had around the fire pit amongst family members discussing heat pumps and whether or not they can work in Canada. I might not have been in this industry when the first wave of heat pumps was being installed but I am seeing firsthand how this next generation of heat pumps are doing in the Canadian climate. To say I am intrigued would be an understatement.

There are so many exciting innovations that are hitting the market; from low GWP refrigerant solutions for heat pumps (check out my carbon dioxide refrigeration article for heat pumps on page 38) to hybrid systems. There is a lot going on in this sector and training couldn’t be more important.

We tried to find a nice balance for the

attendees of our very first Technical Training Day. There was something for everyone in the industry, whether they are in the residential, commercial, industrial, or institutional sectors. We tried to have some extra little fun with a live boiler build going on throughout the day.

In the close to six years that I’ve been in the industry, it has been an amazing journey watching the way people are willing to adopt new technology. Of course, there are many

Iwanttosavethediscussionsurrounding the recent AHR Expo in Chicago, Illinois for the next issue of the book. But I will say this, the amount of heat pumps that are coming to the market is incredible. The even more fascinating part of the story is that it is growing at a surprisingly quick rate for this “historically slow to adopt new change” industry Hydronic heat pumps might have been the dominating piece of technology at this show More to come.

To view any of the presentations from the Heat Pump: Technical Training Day, please visit the Plumbing & HVAC YouTube page :

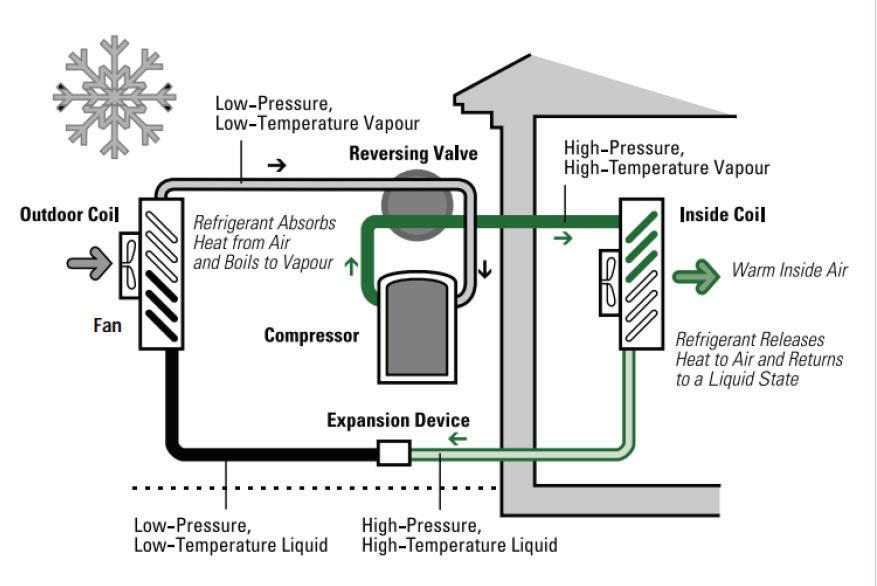

moves from higher temperature to lower temperature. If I have a ball in my hand, and I raise my hand up, and let the ball go, the ball will drop down. As heat will go from a higher to a lower temperature. However, as it is possible to apply energy to raise the ball against gravity, it is also possible to move heat against its natural direction of flow. That’s how every air conditioner works, it moves heat from a cooler temperature to a warmer temperature.

But is there that much heat outdoors in winter? Let’s just say there is enough to run heat pumps at 100 per cent efficiency at -22 C. So how does this magic work? To explain that let’s review the classic vapour compression cycle quickly.

The four components include an evaporator and a condenser. An evaporator is a heat exchanging coil that allows liquid

As fuel costs increased and governments applied policies to shift away from fossil fuels, people started to look for new ways to heat indoor spaces. One of the new technologies that is being promoted is heat pump.

refrigerant to evaporate by heating it up. A condenser is also a heat exchanging coil that allows the vapour refrigerant to condense by cooling it down. An evaporator uses the heat of the space that needs to be cooled to boil and evaporate the refrigerant. In other words, an evaporator absorbs heat from a space. The condenser contains compressed hot refrigerant which rejects heat to its

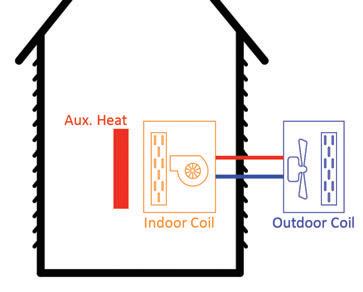

When the evaporator coil is indoors and the condenser coil is outdoors, the system works as an air conditioner because the indoor coil (the evaporator) is absorbing heat from indoors and the outdoor coil (the condenser) is rejecting heat to outdoors. A heat pump works in reverse.

surrounding and turns into liquid. The refrigerant picks up heat in the evaporator and rejects that heat in the condenser. How is the refrigerant moved around between the two coils? Mechanical air conditioning uses vapour compression cycles. In every cycle, the compressor brings in cold low-pressure refrigerant and compresses it into hot high-pressure refrigerant. Even though the refrigerant temperature increases two or three folds in the process, its heat content doesn’t increase much. Unlike a pressure cooker, a compressor can increase the temperature and pressure of a refrigerant without adding as much heat to it.

When the evaporator coil is indoors and the condenser coil is outdoors, the system works as an air conditioner because the indoor coil (the evaporator) is absorbing heat from indoors and the outdoor coil (the condenser) is rejecting heat to outdoors. But what happens if we switch the coil locations? Can an evaporator absorb heat from outdoors? Yes, it turns out they can do that fabulously.

Since heat will naturally flow from a higher temperature to a lower temperature, engineers designed coils that become colder than outdoor air. Hence, heat has no choice but to ‘pour’ from outdoor air to indoor

air. Once heat is captured in the bitter cold refrigerant in the outdoor coil, it is pumped by the compressor to indoors, increasing its temperature and pressure in the process. Remember compressors add very little heat to the refrigerant. Most of the heat that comes to the indoor coil, which is a condenser in this case, comes from outdoors. As the condenser has a hot high-pressure refrigerant, heat, again, has no choice but to ‘pour’ from the indoor coil to indoor air.

How can running a compressor be more affordable than burning natural gas or electric heating? It turns out that moving heat from one side of the wall to the other is not that expensive. For example, a 24,000 BTU/h airsource heat pump at -8 C outdoor air will consume 10,000 BTU/h and move 23,520 BTU/h of heat from outdoor to indoors. An electric heater, on the other hand, would be able to provide only 10,000 BTU/h for every 10,000 BTU/h it consumes because it must generate heat as opposed to moving it. Therefore, a heat pump can provide 2.35 times more heat than it consumes. This number can be slightly higher or lower than natural gas, depending on geographical location and fuel distributor.

Heat pumps have their own challenges. For example, every heat pump in operation is bound to form frost on the outside coil, which will require defrosting cycle. During defrosting cycle, a heat pump does not provide heat. For every heat pump application, there is a balance point temperature, below which, the heat pump cannot extract enough heat from outdoors to offset the heat loss. That is to say, a house might lose heat at a higher rate than the heat pump can provide heat. An auxiliary heat source is required below balance point. :

Sam Bilamjian is a gas technician and HVAC professor with over 15 years of experience designing and troubleshooting HVAC control systems. He co-founded TradesMasters, a group of skilled trades instructors with a passion for training and coaching.

•Unbeatable Customer Service: We prioritize relationships and are committed to providing unparalleled customer service.

mer service.

•Extensive Inventory Levels: Our inventory is strategically maintained to cater to your diverse business needs, ensuring you’re never left without essential products.

•On-Time Delivery: Your orders will consistently arrive on time, allowing you to maintain a seamless operation.

y Levels: tegically rse business needs, er left without sistently arrive on o maintain a ghturing mes

•Quality Products: Great selection of highquality products, featuring renowned brand names in the industry.

U.S. Boiler Company, Lancaster, Pennsylvania, introduces its new Ambient air-to-water hydronic heat pump for residential applications. The new heat pump has a five-ton capacity and provides space heating with outdoor temperatures as low as -13 F. Offering a COP of up to 3.96 and delivering supply temperatures of up to 140 F. The monobloc heat pump uses R-32 refrigerant and features DC inverter enhanced vapour injection technology. The Ambient heat pump is available with an optional dual-fuel controller. Other packaged accessories include a 40-gallon buffer tank with backup heating elements, a Taco 0013 circulator, circulator flange kit, flat plate heat exchanger, pressure relief valve, drain valve, and relays.

U.S. Boiler Company www.usboiler.net

Geothermal

WaterFurnace, Fort Wayne, Indiana, introduces its new 7 Series with OptiDry. An optional feature for the 7 Series geothermal heating and cooling system, it includes integrated reheat coil dehumidification technology. The geothermal heat pump requires no additional equipment, ductwork, electrical circuits, wiring, or dehumidstat. The patent-pending technology automatically switches between three modes — cooling-only, cooling with dehumidification, and dehumidification-only. It comes standard with a 10-year parts warranty and a five-year labour allowance for covered repairs.

WaterFurnace International www.waterfurnace.com

Air-to-water

IBC, Burnaby, BC, launches its new HPX air-to-water heat pump. Catering to residential and light commercial application, it is a self-contained, refrigerant-based monobloc unit that is easy to install and service without the need for refrigeration licenses. It is available in three-ton and five-ton options. IBC www.ibcboiler.com

Stone Mountain Technologies, Piney Flats, Tennessee, announces the availability of its Anesi branded heating products in North America for residential and commercial customers in February 2024. Anesi gas heat pumps are air-to-water heat pumps that can use natural gas, propane, or renewable gas as its fuel source. The Anesi gas heat pump, all refrigerants, its combustion process, and venting are all located outside. Only a warm water/food-grade glycol mixture enters the home through standard PEX or copper piping. It utilizes ammonia as the refrigerant.

Stone Mountain Technologies

www.stonemountaintechnologies.com

Gree Canada, Saint-Mathieu-de-Beloeil, Qué, introduces its new Ultra-Heat rooftop heat pump. The Ultra-Heat RTU adopts Gree’s patented two-stage, two-cylinder compressor, a key technology for low ambient temperature heating. It can maintain up to 80 per cent of heating capacity at outdoor temperatures of -30 C. Gree Canada www.greecommercial.com

Mark’s Supply, Kitchener, Ont, announces an exclusive new line of heat pumps at its locations. Quest Heat Pumps, manufactured by American Standard, can provide warmth at -30 C. During hotter months, it can produce air conditioning for the home. It features a variable-speed compressor. The Quest Heat Pump qualifies for Energy Star rebates and has a 10-year registered warranty. Its efficiency ratings for cooling is up to 20 SEER and heating at 10.5 HSPF. Available in two-, three-, four, and five-ton, it has a heating and cooling capacity of 24,000 to 54,000 BTU/h. It operates using R-410A refrigerant.

Mark’s Supply www.markssupply.ca

There is still plenty of hesitation amongst technicians when it comes to heat pumps. Education will play a key role in making sure the next generation of heat pumps are installed properly.By Michael Ridler

A common phrase that I like to often use is “heat pumps aren’t boilers.” This quote captures a critical point. Heat pumps can perform almost all tasks that a boiler can, but that doesn’t mean they are the same things. For instance, in my home, a five-ton air-towater heat pump handles heating, cooling, and soon, domestic hot water. It actually is not just serving the role of a boiler, but in my case, my old furnace that was taken out.

Understanding the differences in piping between boilers and hydronic heat pumps is essential, though it shouldn’t be a source of intimidation. The market is seeing innovative monobloc air-to-water heat pumps, placing plumbers and hydronic specialists in a prime position to excel with the right distribution and manufacturer partners. Heat pumps require different piping approaches compared to boilers, but mastering this is not overly complex.

To go back to the basics, when it comes to hydronic heat pumps, there are two types — air-to-water and water-to-water (geothermal). These can be installed in similar ways and viewing them under the collective term of “hydronic heat pumps” rather than “heat pump boilers” aids in setting up our industry for success. Heat pumps are not boilers, and

wereallyshouldnotcallitaheatpumpboiler or people will wrongly think we can apply traditional installation methods that may result in issues. To this end, the Canadian Institute of Plumbing and Heating (CIPH) is developing new air-to-water training modules, while the International Ground Source Heat Pump Association (IGSHPA) focuses on water-to-water, aiming for a universal training program for hydronic heat pumps.

Using heat pumps for domestic hot water is feasible, though they differ from boilers in rapid heating capabilities. A typical residential hydronic heat pump has about halftheoutputofastandardresidentialboiler. This difference necessitates a unique design approach. It’s akin to comparing a Toyota CorollatoaPorscheintermsofacceleration–both reach the same speed, but the time they take to get there differs. Think of heat pumps fordomestichotwaterliketheToyotaandthe boiler as the Porsche. Both will accomplish theendgoal,butonewilldoitveryefficiently

The market is introducing new domestic hot water technologies ideal for hydronic heat pump applications, potentially enabling

performance akin to tankless systems but powered easily by a hydronic heat pump with some potential limitations for large dump loads. I will be writing about and sharing photos and videos of testing in our live fire lab in the coming issues.

Buffer tanks can be vital in hydronic heat pump setups (and boilers for that matter) to ensure consistent system performance and prevent issues like high head pressure lockouts. Some hydronic heat pump systems require up to five-GPM per ton with a maximum Delta T of 5 F to 8 F. Buffer tanks play a key role in sustaining heat pump run times, maximising performance and decoupling loads, allowing for different Delta T’s on the primary/ secondary circuits. However, buffer tank necessity depends on system characteristics, such as modulation rates. Aligning heat generation with dispersion rates is vital to avoid idle periods and mitigate anti-short cycling issues.

Short cycling can drastically affect a heat pump’s coefficient of performance (COP) by reducing efficiency, causing uneven temperature control, and increasing energy usage. It also leads to more frequent start-ups,

which can cause excessive wear and tear on components. This additional wear and tear can shorten the lifespan of the heat pump. A buffer tank is not just about thermal storage, regardless of fuel source. It allows you to optimize operational cycles and consider system configurations.

The efficiency of hydronic heat pumps heavily depends on flow rates and temperatures. Although they generally offer better efficiency than boilers, designing with incorrect water temperatures can diminish this advantage, incurring higher operating costs.

In our live fire lab, we tested various hydronic heat pumps at different operating temperatures. For example, running the

These can be installed in similar ways and viewing them under the collective term of “hydronic heat pumps” rather than “heat pump boilers” aids in setting up our industry for success.

Enertech five-ton unit at a leaving load temperature of 113 F significantly improves the COP compared to running it at 131 F. This illustrates the importance of design in optimising system efficiency. With this in mind, it is important to recognize that emitter choice can also greatly impact performance.

Continued on page “27”

Low carbon, high performance, no compromise.

From light commercial applications to large multi-unit centralized plants, Climaveneta has a low carbon solution to help you realize your masterpiece, without compromise. So, whether you require a hydronic heating or cooling solution for a retrofit, a new construction project, or an industrial application, with Climaveneta you can bring your vision to life exactly as you imagine it.

• Climaveneta’s 50 years of experience meets Mitsubishi Electric’s nearly 100 years of innovation

• High-efficiency heat pumps that optimize heating perfor mance for the Canadian climate

• Reliable heating and cooling solutions to maximize occupant comfort and minimize operational costs

• Flexible and customizable options to suit your individual project needs

Learn more at:

Climaveneta.ca

Continued from page “25”

Designing around hydronic heat pumps requires an acknowledgment of their temperature output limitations. Most North American models currently use refrigerants like R-410 and are transitioning to R-454. This limits the temperature going out to the system at or below 140 F. There are new units arriving from Europe with R-32 and R-290 A2L refrigerants that can produce 150 F to 160 F water, but it is important to note that just because it can produce those temperatures doesn’t mean it should. After all, we are designing for efficiency and comfort.

Water’s limitations in storing latent energy led us to explore phase change thermal batteries, which operate at temperatures as low as 118

F.The technical mechanism of PCM batteries lies in its ability to absorb a significant amount of heat as it melts. This heat is stored as latent energy and can be retained without a significant rise in temperature. When the PCM solidifies, it releases this stored heat. This process of storing heat in the form of latent energy rather than sensible energy allows for more efficient energy storage within a smaller temperature range compared to traditional water-based systems.

This technology, still emerging in North America, has demonstrated the potential to reduce gas consumption by up to 50 per cent in gas boiler applications. Its application in hydronic heat pumps and the possibility of charging with ultra-low off-peak rates opens exciting opportunities for energy efficiency and sustainability in the hydronic industry.

There is a big concern in the industry over the

hesitation among skilled HVAC technicians to adopt these new technologies. It is critical to dispel these fears. For instance, monobloc air-to-water heat pumps are straightforward to install, requiring only water lines to be run from the exterior to the interior. Their operation is not drastically different from boilers, and with the right design partners and brand support, the transition can be seamless. :

Michael Ridler is the general manager at Eden Energy Equipment. He started out working for a Ont-based HVAC company and now focuses on providing field support and technical training to contractors, engineers, and builders on heat pumps, boilers, and all things hydronics. He can be reached at edenenergymike@gmail.com

1-888-290-6318

www.wolseleyinc.ca

1-800-661-5615

www.bartlegibson.com

BC, AB, NWT, & Swift Current, SK

1-604-270-7173

www.pacificcleanair.com BC

1-404-286-7467

www.klassmechanical.ca AB

1-905-238-1888

1-800-561-6192

www.pedcosupply.com

1-306-937-7741

1-306-242-1567

www.aquiferdist.com SK

Continental is recognized as an industry leader in Canada for our cold climate heat pump technology. Our new EQhub smart thermostat delivers efficiency and lower operating costs through fuel choice and time of use rates.*

Our hybrid systems are fully supported and eligible for federal and provincial rebate programs, benefiting homeowners. Count on our nationwide HVAC training and support for these innovative products to support the growth of your business. Visit us at CMPX to learn about our diverse range of products and connect with our dedicated team.

SCAN HERE TO VIEW PRODUCTS

continentalcomfort.com

1-519-364-7550

Hanover, ON

1-905-670-7966

Mississauga, ON

1-519-455-1010

www.diamondhvac.ca/ London, ON

1-905-728-6216

www.southernsupplies.ca

1-800-267-2135

*Time

Air-source heat pumps offer an attractive solution for Canadian homes as the country looks to decarbonize the built environment.

By Francesco Lo Presti

By Francesco Lo Presti

Air-source heat pumps rely on the refrigerant within the system to absorb heat from the air.

Information taken from William Russell’s, business manager of air conditioning at Panasonic, and John McLeod’s, territory sales manager at Nordics, “Heat Pump: Technical Training Day” presentation on Oct. 11. Watch here:

Canada has committed to reducing carbon emissions by 40 to 45 per cent by 2030. There is an infinite number of approaches that could be made to achieve this lofty goal. Let’s focus on the ways the building sector can help support reaching these goals.

It’s up to the manufacturers to develop the energy-efficient products, the distribution

network to stock the greener technology, and the technicians to stay up to date on what new products are coming to the market. Way easier said than done.

One such greener and energy-efficient product already introduced to the market, for several years now, is the air-source heat pump. A champion of rebates, it provides homeowners with an attractive option to both heat and cool their home.

In Canada, 18 per cent of all greenhouse gas (GHG) emissions comes directly from residential uses. Furthermore, 65 per cent of GHG emissions in residential applications come from space heating and cooling. This comes primarily from burning fossil fuels.

Currently, 75 per cent of Canada’s home supply of 15 million homes requires a carbonreducing primary heating or cooling system retrofit. Additionally, over 50 per cent of homes have an existing forced air furnace. This means that Canada must look at current solutions available in existing home and find ways to make this transition easier. This will be a significant opportunity for HVAC and heat pump installers to replace these existing systems.

This transition will be driven by grants and incentives (which the country has already seen via the Canada Greener Homes Grant and various other incentive programs).

Canada’s 2024 Federal Budget introduced new steps that will make increasing Canada’s housing supply easier. These steps will also include regulations limiting the primary heating and cooling system in homes to something less carbon-intensive, which will most likely be some hybrid electric systems.

Continued on page “33”

Triangle Tube is proud to introduce an industry leading loyalty program providing you with rewards for installing our best-in-class products. Join Connect and begin earning amazing rewards today!

Visit our website to learn more.

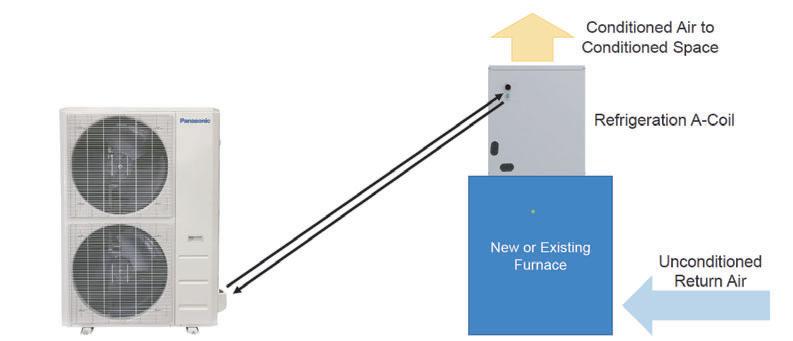

Continued from page “31”

Since there are still a lot of Canadian homes utilizing fossil fuel appliances, hybrid electric systems will be Canada’s biggest steppingstone in the transition to electrification. A hybrid electric system will involve three pieces: an outdoor heat pump unit, a refrigeration A-Coil, and a new or existing furnace. This system will be integrated with a smart thermostat, which can link to the outdoor unit’s ambient air temperature. What happens here is at a certain preset temperature, the heat pump will turn off and the furnace will supply the cold weather heating.

The benefit of this process is that a homeowner will be able to utilize both pieces of technology to their advantage. As many heat pump skeptics enjoy pointing out, there are efficiency losses to heat pumps in colder climates. But, by having that backup option, it remains a more cost-effective way of heating a home in the peak of winter. In the milder temperatures, between -5 C and up, this is where the heat pump will run and provide the heating for the home.

Additionally, when the refrigeration cycle is reversed during the summer, the heat

with a central heat pump. This system is comprised of an outdoor heat pump and indoor air handler unit and can fit on new or existing duct working, allowing for the replacing of a home’s air conditioning and furnace in both new build and retrofit applications.

The difference between this type of system and the hybrid electric system is that the latter system relies on the furnace’s blower to distribute air throughout the home. While the whole home electric system has a blower built into the indoor air handler, which can be found above the refrigeration A-coil.

The benefit of this system is that heat pumps can provide high efficiency cooling in the summer and high coefficient

of

performance (COP) heating in

the shoulder season. This

system can also reduce the strain on the electrical grid during peak draw periods.

pump will provide high efficiency cooling to the home. The benefit of this system is that heat pumps can provide high efficiency cooling in the summer and high coefficient of performance (COP) heating in the shoulder season. This system can also reduce the strain on the electrical grid during peak draw periods.

Another step forward into the transition to electrification will also include the introduction of a whole home electric system

This whole home electric system is designed to integrate with an ERV to meet fresh air requirements and optional auxiliary heaters can be built into the air handler to provide automatic additional heating in the winter.

This can affect air quality within the home. A lot of contractors are installing these systems with a typical blow through bypass humidifier and what they are finding

is the humidity levels are dropping and the air quality is not where it needs to be.

Pairing a cold climate ERV, a steam humidifier, and even a dehumidifier could help tackle some of these air quality concerns. Contractors are getting more comfortable with heat pumps and installing them. Now the next step is making sure we are cognizant of what the impact of the air quality in the home is. This means more training and education.

Heat pumps and furnaces tend to be compared to each other from an efficiency standpoint. With a furnace, there is the annual fuel utilization efficiency (AFUE). This is the percentage of fuel converted into heating. Basically, it’s a metric of how many kilowatts of natural gas is put in versus how many kilowatts of heating you get out.

With a heat pump, you are looking at the COP. Like the AFUE for furnaces, this metric refers to how many kilowatts of heat are produced versus how many kilowatts are needed to operate the heat pump compressor. The compressor used in the heat pump will be electric. Once the vapour goes into the compressor, it will become compressed, creating heat for inside. There isn’t anything burning in this cycle.

This process allows the compressor to transform one kilowatt of energy used into about three to four kilowatts of heat into the inside environment. A heat pump can have a COP between three to four at 8 C and a COP between 1.5 to 2.5 at -15 C. A furnace operates as a AFUE of roughly 80 to 95 per cent. :

system solutions will typically result in over engineered systems that may not realize its full benefit.By Chris DesRoches

The term heat pump is used a lot these days with many misnomers. Under the umbrella of heat pumps is a niche type that are quickly gaining momentum in both the commercial and residential sectors as a decarbonization tool for hydronic systems — air-to-water heat pumps. Unlike mini-split heat pumps or central air-source rooftop heat pumps, air-towater heat pumps extract heat from the outside air and heat water, which is then utilized as the distribution medium throughout the building to heat indoor spaces in the winter or even heat domestic hot water year-round.

It has been known for a long time that hydronics is a more comfortable and efficient way to transport energy and condition buildings compared to air-distribution systems, especially in spaces featuring high ceilings. As the marketplace rapidly transitions to net-zero, air-to-water heat pumps are often not considered as a viable solution for building electrification. This is oftentimes due to many other competing technologies that are widely available. They often get overlooked.

Geothermal heat pumps, or GSHP, (using water as a heat source via geothermal wells) have gained market adoption over the last

decade and can offer very high efficiencies and significant greenhouse gas (GHG) reduction, but they can be cost prohibitive to install. Further to this, GSHPs may not offer a scalable solution to tackle the magnitude of retrofit buildings that will be required to achieve net-zero in existing buildings by 2050.

Which brings us back to hydronic heat pumps. If we want to continue using hydronics in our HVAC designs, but electrify and decarbonize those systems, then an electric boiler, a ground-source or an air-to-water

If we want to continue using hydronics in our HVAC designs, but electrify and decarbonize those systems, then an electric boiler, a ground-source or an air-to-water heat pump are essentially the only options.

heat pump are essentially the only options. Advancements in technology and availability from more manufacturers in recent years for air-to-water heat pumps has brought this technology front and center in the hydronics world. Today’s equipment offers operation in lower ambient temperatures with modest outlet water temperatures in the medium to high temperature range, which can still be suitable for many applications.

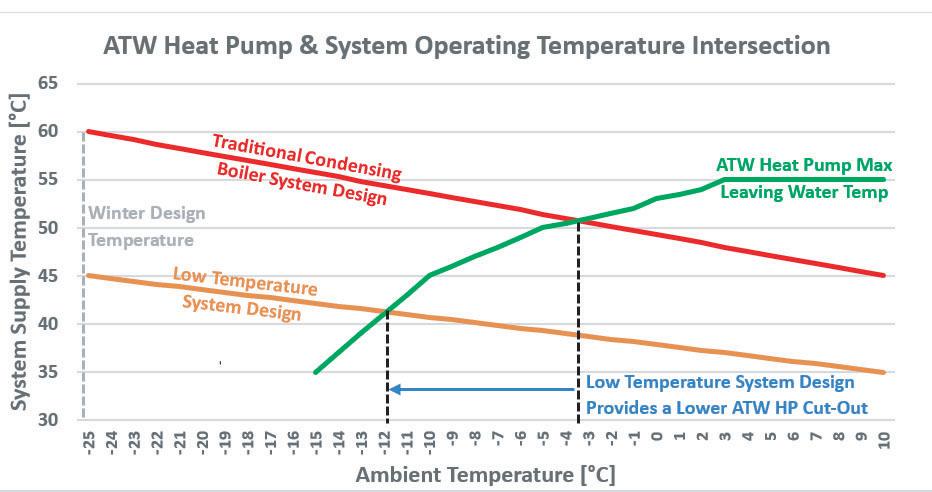

When considering an air-to-water heat

pump, there are three main considerations for the designer and installer. The first is selecting the operating temperature and being aware of the maximum supply temperature that is available according to the ambient temperature. Next, determine the capacity that the heat pump will be able to deliver, and lastly, figure out the efficiency the heat pump will operate at.

Conventional air-to-water heat pump equipment available in the market today can typically provide hot water temperatures of approximately 50 C at -5 C ambient temperature. New equipment coming to the market over the next several years employing newer refrigerants with lower GWP will offer better heating performance, with some manufacturers even starting to offer equipment that can produce 50 C hot water at -15 C or lower with efficiencies above two W/W (200 per cent) or more at very cold temperatures within this range, and operation down to as low as -20 C.

And this is where the challenge comes when comparing air-to-water heat pump systems to other heat pump types with air distribution. Some other heat pump types such as VRF systems or packaged rooftop heat pumps can operate with high heating capacities and deliver adequate air-temperatures with external air temperatures as low as -30 C, and come as a package. By heating air directly, the system is typically a bit easier to design. It is also worth noting however that some of these air-distribution heat pump systems will still utilize auxiliary heat sources like electric baseboards or duct heaters to handle the coldest days in winter.

Typically, with gas systems, we will put our supply temperature on an outdoor-reset curve where the supply temperature is decreased as it gets warmer outside. This strategy also works well with heat pumps.

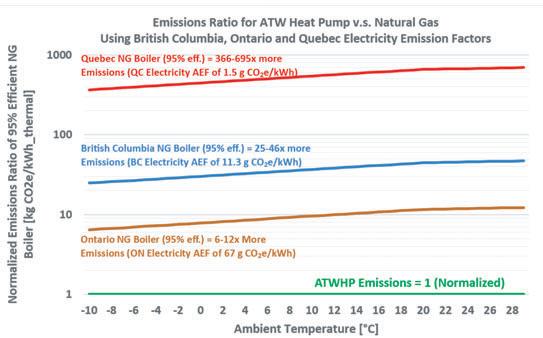

The emissions produced by a natural gas boiler (at 95 per cent efficiency) will remain higher compared to an airto-water heat pump, even when taking into account the heat pumps COP curve at full load, according to ambient temperature.

This is why we need to think more holistically about implementing heat pumps. The market is very binary when it comes to this; it’s all or nothing. Air-to-water heat pumps, as part of a hybrid system, can offer significant energy and greenhouse gas emission savings, even when only used during a portion of the heating season with natural gas supplementing the few hours where the heat pump is not able to provide adequate performance for space heating.

While air-to-water heat pumps may not be the silver bullet, if we consider a hybrid system with auxiliary fossil fuel boiler to handle the peak winter days where higher water temperatures and more capacity are needed, we can find a happy medium where a substantial period of the year the building can be heated by the heat pump leading to GHG emission reductions and operating cost savings.

Firstly, we need to utilize lower temperatures in hydronic systems. For example, with typical condensing boiler design where the heat emitters in the building are selected for 140 F (60 C), it is important to consider that this is the temperature and capacity needed on a peak winter day at the design temperature (for Toronto this is around -23 C). Usually with gas systems, we will put our supply temperature on an outdoor-reset curve where the supply

temperature is decreased as it gets warmer outside. This allows us to keep the buildings comfortable, and maintain higher efficiencies. This type of strategy works well with heat pumps since the heat pump is able to deliver decent supply temperatures down to about -10 C to -5 C (or -15 C with next generation equipment).

Depending on the electricity generation type by region, air-to-water heat pumps can have significant GHG emission savings for providing the same amount of energy to the

building compared to natural gas boilers. The changeover point from switching between an air-to-water heat pump to auxiliary boiler could be determined by a couple of factors. It could be determined by the temperature that the heat pump can supply. If the hydronic system cannot operate according to the design with a supply temperature below 45 C, then switch over to the boiler at the ambient temperature of the heat pump that corresponds to this. Alternatively, depending on the ratio of costs

Continued on page “37”

It may be more economical to operate the heat pump when the COP is above 2.5, when it falls below, this is when you could switch over to the back-up heating option.

The Central-Moov NEEP and AHRI listed add-on heat pump system consists of a Moovair M20 condenser and matched Moovair A-coil meets the NRCan ccASHP requirements.

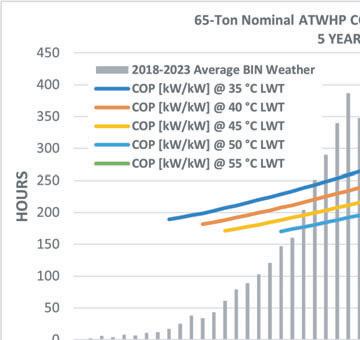

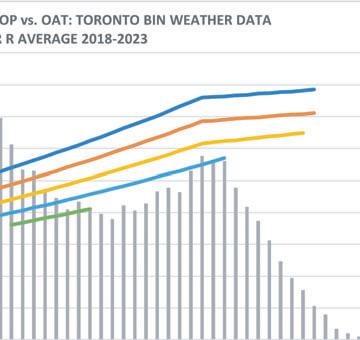

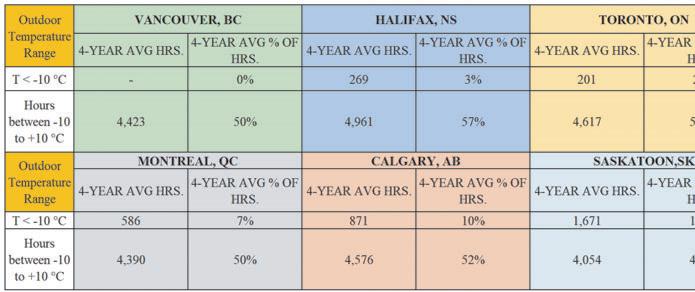

Weather BIN hours over the last four years for various Canadian climates and the number of hours spent, on average, below -10 C, between -10 C and 10 C, and above 10 C (where not much heating was required in buildings).

Continued from page “35”

between natural gas or electricity, it may be more economical to operate the heat pump only when the COP is above 2.5, in which case you could switch over to the auxiliary heat source according to the COP curve for the heat pump.

Consider the weather data

In today’s HVAC marketplace, we tend to seek a one-size-fits-all solution. The result? We tend to have over engineered systems but may not realize the full benefit. When we consider the weather data for various climates, we can design heat pump systems to

cover 90 per cent or more of the winter hours, and supplement with fossil fuels for only the peak days. The result is a much more flexible system, with balanced operating costs and built-in resiliency.

The chart below shows weather BIN hours over the last four years for various Canadian climates and shows the numbers of hours spent on average below -10 C, between -10C to 10 C, and above 10 C where not much heating is required in buildings. Above this point we tend to move into cooling season. :

Chris DesRoches is a mechanical engineer with extensive experience in the HVAC manufacturing industry in all aspects but specializes in air-to-water heat pump solutions for the commercial and residential sectors.

Carbon dioxide heat pumps will typically work way better when operating with lower water temperatures.By Leah Den Hartogh

Information taken from Trevor Matthews’, founder of Refrigeration Mentor, “Heat Pump: Technical Training Day” presentation on Oct. 11. Watch here:

Carbon dioxide is getting a revitalization due to the growing interest in heat pump technology. For anyone questioning why carbon dioxide might be a viable solution for a system’s refrigeration or heating needs can look at its extremely low amount of global warming potential. Carbon dioxide has an ozone depletion potential (ODP) of zero.

As more and more scientists began to understand the risks of using refrigerants with higher levels of ODP, governments started to phase out or phase down some of these refrigerants. This included CFCs such as R-12 and R-502. After CFCs came HFCs. These refrigerants are now being phased down or out because of its higher GWP. This is due to the Kigali Amendment to the Montreal Protocol. Countries across the world have signed onto this amendment which states that they will reduce the amount of HFCs they’re using and producing.

This means that every year or so there is a percentage drop in production. By Jan. 1, 2025, you can’t even use R-410A in chiller

applications. This puts a lot of pressure on the contractors, as well as the homeowners or businesses that have that type of refrigerant in their system. The prices for these refrigerants will only increase as the production is forced to slow down due to regulations.

These various rules and regulations put upon the different refrigerants, even in heat pump refrigeration applications, are going to continuously change. (For more information on the latest change to the Canadian refrigeration mechanical code, check out Greg Scrivener’s article on page 42).

Since carbon dioxide has a GWP of one, whereas R-410A has a GWP of 2,088, according to Natural Refrigerants Ltd, this means that for every one pound of R-410A released, you can release 2,088 pounds of carbon dioxide. This is just a hypothetical example as you never want to release any type of refrigerant into the atmosphere, not even carbon dioxide.

Speaking of, in terms of refrigeration specifications, carbon dioxide is considered

an A1 refrigerant and is non-flammable or identified as having no flame propagation.

A2Ls are considered a mildly flammable refrigerant. An example of an A2L refrigerant is R-32, which is one of the refrigerants that makes up the blend R-410A. And then you have A3s which are R-290 or propane and are considered flammable refrigerants. Each type of refrigerant will have its own set of

above the temperature and pressure of the refrigerant, you are above the critical point. So for R-744, it is considered super critical. That means that it is not a vapour, it’s not a liquid, it’s a fluid now! When you are above the critical point, there’s no pressure/ temperature relationship.

That’s a big difference for carbon dioxide and this is where heat pumps come into play.

Even though there are many areas within Canada that will get to be extremely cold. There is still heat there that can be used and transferred indoors.

rules and regulations that tradespeople must follow.

One of the cool things relating back to carbon dioxide is that it has a really high transfer of heat and has a very high coefficient of performance. This gives it a lot of advantages when designing systems. If you’re working on these types of systems or design them, you’ll see that the pipes will be a lot smaller than the systems you typically work on because you can move more heat.

When it comes to heat pumps, this is why carbon dioxide is an attractive choice. Its helpful to think about them as moving heat from outdoors to indoors. One of the benefits of using carbon dioxide in one of these types of systems is it an inexpensive refrigerant to put in a system.

Some of the important terms that anyone wanting to learn about carbon dioxide as a refrigerant is its number —R-744. In addition, its pertinent to understand its critical point.

Every refrigerant has a critical point, but carbon dioxide has a very low critical point. But what does that mean? When you get

This is where you are gaining a ton of heat for the system.

This means that there are design considerations that need to be made when working with R-744. For instance, when the ambient temperature is above 31 C or 87.8 F and the pressure is above 1,055 PSI, that means you’re above the critical points.

Another thing worth noting is its transcritical cycle. This means the system is running above the critical point and the heat pump will be producing a lot of heat. This heat will warm up the air or water, depending on the type of heat pump system installed.

The third term that you should be familiar with is something called the triple point. The triple point is where you have liquid, vapour, and solid. For example, you’re trying to charge a system that was just evacuated down below 300 microns. That means that you can’t just add liquid at that point. Anyone working with refrigerants, if you’re charging R-410A or any refrigerant that is similar, you are wanting to charge the system with liquid. But now, when getting into R-744, you will need a charge with vapour first. This

means that you’ll have to get above that triple point.

The good news is that a lot of heat pumps that you will work on will already have high standstill pressures. What that means is that it can handle the pressures, and won’t blow any relief valves or anything. Remember that you don’t ever want to trap carbon dioxide because the temperature can rise really rapidly. These safety features are important to know.

A benefit with carbon dioxide heat pumps is that they work way better with lower water temperatures. If you have really cold water going into the heat pump, you will have really hot water getting out. A difference with carbon dioxide is that you can get it up to almost 90 C. This isn’t exactly needed in most residential houses. But there are applications where this is needed.

When it comes to hydronic heat pumps, designers will need to understand the flow, how much it is slowing, and how fast it is flowing. Another thing that a designer is going to have to look out for is turbulence in the buffer tanks.

When it comes to charging R-744 systems, you need to make sure the system has been charged properly. You need the proper tools. You can’t just use regular gauges, you need hoses that can handle the pressure because inside a carbon dioxide cylinder at room temperature, you’re over 800 PSI. If it’s a hot day out, you could have 1,000 PSI in that tank. The gauges used in R-410A would have the hoses that are rated for 800 PSI.

Carbon dioxide provides an extremely attractive refrigerant for heat pumps, but there are applications where R-744 isn’t the right choice. If they are not designed properly, there will be lots of potential problems that could arise. This is where communication with your customer is crucial. Ask yourself, is this the right design for the system? :

Johnson Controls, Milwaukee, Wisconsin, announces the release of its Metasys 13 system, which creates scalable upgrade paths for customers with legacy system components. The Metasys interface is now available on the Metasys SNx series network engineers and is accessible through any client device type (phone, tablet, or PC). Additional features include enhancements to the local controller display, CG controllers with display, and SNC network engine display models, including live trending. The Metasys UI alarm notification bar helps the logged-on user identify, troubleshoot, and resolve issues quickly.

Johnson Controls www.johnsoncontrols.com

Navac, Lyndhurst, New Jersey, N2A4B manifold gauge is compatible with both R-32 and R-454B refrigerants and can measure the pressure of various gases and liquids, allowing technicians to reduce leaks and system failures. Featuring an aluminum body and ball valves, the gauge can diagnose and determine the status of four refrigerants in total. The N2A4B manifold gauge is designed to be impact-resistant and includes a moulded protective shell and rubber covering for shock absorption. It also features an integrated folding hook design for easy transport. Navac www.navacglobal.com

Posifa Technologies, San Jose, California, announces the release of its new sensor solution for detecting A2L refrigerant leaks in residential and commercial air conditioning systems, heat pumps, and refrigeration equipment. The new PGS6000 sensors detect A2L refrigerant concentration in the air by measuring the change in thermal conductivity of the gas mixture inside the cabinet. It features a patented heat transfer cavity that achieves highly sensitive and repeatable thermal conductivity measurement by eliminating possible occurrences of natural convection inside the cavity. The detectors are designed with a relative humidity sensor and a barometric pressure sensor. The PGS6000 detects R-32 and R-454B refrigerants and supports RS485 MODBUS RTU output.

Posifa Technologies www.posifatech.com

General Pipe Cleaners, McKees Rocks, Pennsylvania, launches its JM-1450 Jet-Set water jet, which uses high pressure water to clear drain lines clogged with grease, sand, sludge, and ice. The overall height of the JM-1450 is 34-inches. Remove the detachable hose reel and the height drops to just 14-1/2 inches. It is powered by a 1-1/2 hp sealed motor with GFCI that drives a 1,500 PSI, 1.7 gpm triplex pump. Ondemand Vibra-pulse technology helps propel hoses down long runs and around tight bends. Safety features include a thermal relief valve to protect the pump from heat damage, as well as a backflow check valve and inlet filter. An optional spray wand is also available. General Pipe Cleaners www.drainbrain.com

The HVAC industry is making a momentous transition to alternative refrigerants to meet Global Warming Potential Requirements. Manufacturers will need to meet the latest safety requirements to UL 60335-2-40 for certification.

Contact our experts today to learn more.

+1 800 WORLDLAB (967 5352)

icenter@intertek.com

Intertek.com/HVACR

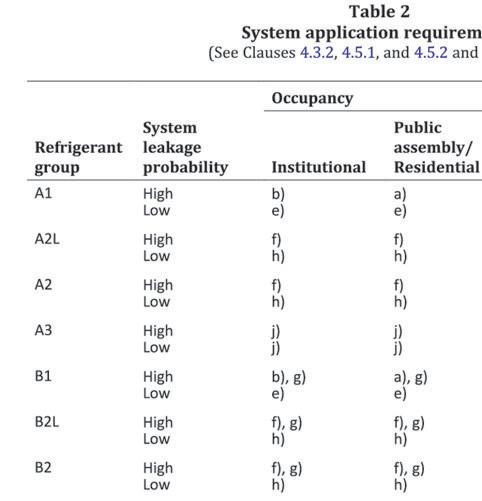

The release of CSA B52-2023 is just the beginning. Canada is likely to see rapid refrigeration code changes in the coming years.By Greg Scrivener

There have been annual updates to Canadian codes and regulations as the industry looks to transition to lower GWP refrigerants.

For the last several years, we’ve hadannualupdatesinthiscolumn as codes and regulations have been changing to accommodate the transition to lower GWP refrigerants, and specifically A2Ls for certain types of air conditioning and refrigeration systems in Canada. The most recent development is the release of CSA B52-2023: Mechanical Refrigeration Code at the end of 2023. The new version of the code has very substantial changes that will probably take some time for the industry to digest. The bulk of the changes are specifically related to A2L refrigerants and are, for the most part, well aligned with changes in the ASHRAE Standard 15-2022. There is not enough time to highlight every single change here, but this article will focus on a few of them and discuss the ongoing work that will likely make its way in CSA B52 in the near future.

CSA B52 Table 1 has (almost) disappeared. Table 1 was used in the 2018 edition and, prior

The next chapter for refrigeration will include A2L refrigerants. It will be important to understand the new changes to codes and regulations as it can be difficult to understand how to implement them.

to, listed the refrigerant concentration limits (RCL) for most of the refrigerants in common use. The data for the table has always been taken from ASHRAE 34 Designation and Safety Classification of Refrigerants and as the number of refrigerants in use has grown and changed rapidly, CSA B52 now simply refers to ASHRAE 34. Table 1 was moved to an informative appendix. One thing to note here is that Table 1 had some conservative altitude corrections to its values and ASHRAE 34 doesn’t. Instead, it requires the designer to make any necessary altitude corrections, so if you live in a high elevation location, you may have a bit of extra work to do applying ASHRAE 34 instead of just using the Table.

Users of CSA B52 know all too well the challenge of interpreting the application requirements defined in Table 2. The table references notes a) through j) and then individual note references for each one, creating an impressive web of requirements.

The result was accurate and served its purpose well, but with the introduction of A2Ls, it would have likely become unmanageable. In CSA B52-2023, we now see a flow chart replacing the table. At first glance, I would expect that this will be easier for users to follow but the requirements remain complex.

Historically, ASHRAE 15 and ASHRAE 34 have used the acronym RCL to discuss the

maximum allowable quantities of refrigerant in a space. Until the 2018 edition, CSA B52 didn’t specifically mention RCL, but used the same exact concept and parameters to restrict the refrigerant quantity.

To remind everyone, the RCL is a value determined by ASHRAE 34 that, in very simple terms, takes into account the toxicity and flammability hazards of a refrigerant and identifies the maximum safe averaged concentration in a volume of air based more or less on the worst case.

For the flammability component, the RCL is calculated as 25 per cent of the lower flammability limit (LFL) of the refrigerant; A1 refrigerants have their RCL determined

information together.

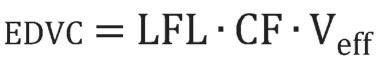

Simply, EDVC is the mass of refrigeration that can release into the space you are considering (the volume of the dispersal space is called Veff). In most systems using A1 refrigerants today, the EDVC is simply:

Which matches exactly how RCL, and refrigerant concentration was treated previously in the standard. However, a lot of research was completed to show that with specific safety measures implemented in the equipment, when we use an A2L, this

To remind everyone, the RCL is a value determined by ASHRAE 34 that, in very simple terms, takes into account the toxicity and flammability hazards of a refrigerant and identifies the maximum safe averaged concentration in a volume of air based more or less on the worst case.