Refrigeration Technical Training Day Supplement

Canada is entering a transition period within the refrigeration industry as the country looks towards lower global warming potential options

INSIDE

n Refrigeration transition update

n A2L compliance in Canada

n VRF case study

It’s like a force field against

Thanks to ProCoreTM high corrosion-resistant technology, you can have maximum confidence in our copper tubing

Tired of replacing leaky coils? ProCoreTM copper tubing provides the solution. Even in the most severe environments, tubing with ProCoreTM technology maintains refrigeration system integrity with no reduction in capacity. Install with confidence, and bring longer-lasting comfort to your customers.

• Dramatically inhibits pitting & corrosion

• Maximizes reliability of the heat transfer system

• Enabled a drastic reduction in replacement coils over the last 5 years Stronger and more resilient than standard & oxygen-free copper

Time’s are changing

It’s kind of fun to look back at the years that I have been working at Plumbing & HVAC magazine. I started when I was freshly 22 years old, green-eyed, bushy-tailed and ready to learn about all things plumbing, refrigeration, and HVAC-related. Fast forward now, six years later (yes, I am still young, but I can confidently say that I am a little less scared of this industry), and I can honestly say that I could never have predicted wheretheindustrycurrentlysits.

Back then, I wouldn’t have even been able to tell you what the acronym HVAC stood for let alone what types of products were on the market and what was popular. While I will neverbeanexpertinthisfieldmyself(that’swhy I interview and talk to the experts), I have picked up a thing or two alongtheway.

When I was the assistant editor of the magazine, back when I was that green-eyed, bushy-tailed and fresh out of university youngling, I was terrified to write anything about refrigeration. Luckily, we have one of the best refrigeration experts in Canada writing for our magazine every issue (you should check out his article on Refrigeration Piping Design on page 32), so I didn’t have to touchthatsectorofthisindustry

Fast forward a few years, and I was leading the editorial department of this magazine, that I decided that I was going to challenge myself a bit and learn a thing or two about the refrigeration

sector. I wrote my very first article on natural refrigerants and synthetics. I sat down with some pretty intelligent people who explained the history of refrigeration, what global warming potential meant, and the important global agreements (I’m talking Montreal Protocol and Kigali Amendment) that have been made.

Refrigeration had changed from being

something that I wasn’t so scared to utter anymore (think of something closely related to Voldemort) to something that is absolutely fascinating. The complexities of this industry haven’t been lost on me but understanding the basics has become one of the most useful skills I have picked up in my role.

I am so glad that years ago I took that challenge to learn something about the refrigeration sector as it has been invaluable. The change that is occurring nowadays is on a constant rise. Whether it is relating to specific refrigerants being phased out or down, the readopting of old practices, or the introduction of new products (I’m talking about A2Ls refrigerants), it is ever changing.

The popularization of heat pumps also makes this conversation ever so more important. I don’t see it slowing down either.

Canada’s refrigerant transition is coming at full speed

By Sandy MacLeod

View the full presentation on “Climate Change and the Refrigerant Transition” here:

ClimateChangeisonthemindsofCanadians.We seeiteverydayinthenewsandtheHVAC/Rsector hasnotescapedtheimpact.Astheheatingandcoolingofbuildingsaccountforjustunder20percentof thecarbonemissionsinCanada,wewillbeimpacted bycarbonreductionplansbeingannouncedorcontemplatedfederally,provinciallyandmunicipally.

The Heating, Refrigeration, and Air Conditioning Institute of Canada (HRAI) has conducted work with all levels of government to lower carbon dioxide (CO2) levels in buildings. Currently, the most active file is the refrigerant transition. We are committed to helping ensure a smooth conversion to lower global warming potential (GWP) refrigerants in the com-ing months.

The shift towards using low-GWP products is a global trend and means moving from refrigerants that are classified by ASHRAE as A1 (non-toxic, non-flammable) to lower GWP alternatives that primarily fall into the A2L category (non-toxic, but slightly flammable). This is an important distinction as it means shifting an entire industry towards mate-rials that are not currentlyrecognizedbyCanadianregulations.

Over the past year, HRAI has been working with Environment and Climate Change Canada (ECCC) and provincial regulators to ensure that regula-tions, codes and standards are updated and aligned as much as possible with regulations in the United

HFC Phasedown & the

Refrigerant

The CSA B52 committee released the latest version at the end of 2023, with each province anticipated to adopt the building codes by October 2024

States to ensure we can handle, transport, service, and install products charged with the new refrigerants.

The pace of change in Canada is primarily being driven by recent announcements in the United States. In December, the Environment Protection Agency (EPA) ruled that no products can be manufactured in the U.S. containing high GWP refrigerants after Jan. 1, 2025. Most of the air conditioners, heat pumps, and refrigerant equipment currently sold in Canada come from U.S. based OEMs.

Gathering comments

Canada is meeting our HFC phase-down requirements. However, ECCC is investigating changes to the ozone-depleting substances and halocarbon alternatives regulations in Canada in response to the

Transition

� Ozone-depleting Substances and Halocarbon Alternatives Regulations (ODSHAR) implement Canada’s phasedown of HFCs

� Ensures that Canada meets its international obligations under the Montreal Protocol, including the Kigali Amendment

recent changes in the United States.

HRAI has asked for member input. While organizations may choose to respond directly to the request for submission, HRAI is urging members to send any thoughts in writing to them as well. Gathering your comments, empowers us to respond on behalf of the industry. Please specify what you would like to see changed or added and why. Statements such as “aligning with the EPA guidelines” are too vague. This initiative seeks to gather insights on the current state of HFC alternatives' usage and adoption in Canada. Specifying which sections/charts/attachments, from the EPA you would like to see duplicated will allow us to build stronger arguments for a greater alignment between Canada and the U.S.

In addition, HRAI reports progress across the provinces in adopting CSA B52 Chapter 13. The CSA B52 committee released the latest version at the end of 2023, allowing us to begin meeting with provincial authorities to encourage early adoption of B52 to ensure the installation of lower GWP products can proceed in each province. See Plumbing & HVAC magazine’s article, “Updates to CSA B52 present clear direction on working with A2Ls,” for more details regarding CSA B52.

Generally, the provinces have agreed to an early adoption. Most provinces are expected to adopt the building codes by October 2024. The next 90 days will set the stage for the balance of the year.

Several OEMs have started converting their manufacturing sites to products with lower GWP refrigerants with an expectation that the Canadian marketplace will be served by these products by the end of the year. There are currently no limits to shipping air conditioners or heat pumps charged with legacy A1 refrigerants but they are practically being phased out by the OEMs to comply with regulations in the United States. This file will remain very active over the coming months. This move to more flammable refrigerants will require technicians to be retrained.

Canada’s refrigerant phase-downs and phase-outs are due to the signing of the Montreal Protocol and the Kigali Amendment.

Sandy MacLeod, is the president and CEO at the Heating, Refrigeration, and Air Conditioning Institute of Canada (HRAI). He joined the association in 2018 and has been working with various levels of government on the refrigeration transition in Canada. He can be reached at smacleod@hrai.ca.

A2L COMPLIANCE

AND WHAT IT MEANS FOR CANADA

The

reality is that R-454B and R-32 will be valuable alternatives as Canada looks to introduce refrigerants with lower GWP.

By Francesco Lo Presti

Information taken from Tim McRae’s, account technical manager of thermal and specialized solutions at Chemours Canada, presentation on “A Deep Dive into Refrigerant Innovations, A2L Compliance and What it Means for Canada,” on June 26. Watch here:

Changes are coming to the refrigeration industry, specifically concerning the adoption of lower global warming potential (GWP) refrigerants. Canada and the U.S. have accelerated the adoption of A2L refrigerants, and new standards and regulations are being released to further help the adoption.

In a non-logical way and defying physics, whatever happens in the U.S. will trickle North toward Canada about refrigeration regulations. Before we get into specific regulations, it’s important to distinguish between Canadian and American regulations. In Canada, we refer to them as the Canadian Ozone Depleting Substances Regulations (ODSHAR). In the U.S., it is called the American Innovation Manufacturing Act (AIM Act).

Canada has already started on this path towards low GWP refrigerants, thanks to the Montreal Protocol, which introduced the phaseouts of CFC and HCFCs like R-22, and the Kigali Amendment, which saw the phasedown of HFCs such as R-410A. This started in 2016, and the U.S. had similar regulations, but due to various reasons, they were abandoned until 2023.

During that period, new innovations and refrigerants came along and were approved, which meant the U.S. regulations leapfrogged Canada’s.

Canadian regulations

ODSHAR contains two parts — the phasedown of HCFCs and the specific prohibitions for new equipment. Environment and Climate Change Canada (ECCC) has begun reviewing the process of these regulations in an attempt to prevent the same fate as the U.S. regulations mentioned above.

The Kigali Amendment introduced regulations concerning the cap and reduction of HCFCs. This is determined by multiplying the GWP refrigerant by how many kilograms are imported. From there, a cap is determined, followed by a reduction.

Canada is already at the 60 per cent reduction, thanks largely to the

automotive industry moving to the R-1234YF refrigerant (GWP of four) and foams moving to lower GWP solutions (less than 150 GWP). The heating and cooling sector has also transitioned to lower GWP non-flammable A1 refrigerants like R-448 and R-449.

Canada has been relatively successful in the HFC consumption phasedown, as seen in Graph 1.

Looking ahead, Canada will be well above the cap in 2029. As time moves on, there needs to be an introduction of even lower GWP solutions, particularly with new equipment.

Graph 1 The green line demonstrates the cap, and the blue lines demonstrate how much has been consumed versus the quota.

Graph 2 This graph shows that Canada cannot use GWPs greater than 2,200 for new equipment in centralized refrigeration.

Southern counterpart

It is worth noting that the new equipment regulations in the U.S. have values similar to those of Canada. As stated in their regulations, the U.S. can no longer manufacture equipment with a GWP greater than 700 in the air conditioning sector. America already has equipment coming down the pipeline to meet these demands — rooftop units, ducted split units, and mini-split units will come to market in 2028, 2026, and 2026, respectively.

However, since there are sell-throughs allowed for existing equipment, manufacturers have begun converting to low GWP refrigerants to replace existing refrigerants, primarily R-410A. This includes manufacturers in Canada, the U.S., and around the world. The U.S. has GWP limits on systems such as commercial condensing units both over and under 200 pounds and chillers. For over 200, it is a GWP of 150, for under 200 it is 300, and for chillers its 700.

Understanding A2Ls

Turning our heads towards A2Ls, the first thing of importance is to understand that this refrigerant class is only to be used in new equipment, not retrofits. Currently, you cannot retrofit a R-410A system to a R-32, R-454A or R-454B class.

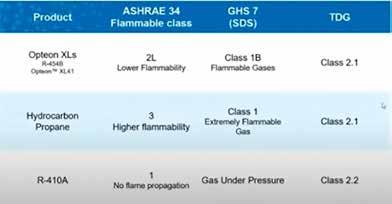

The next thing to remember is that the various governing bodies will classify A2Ls differently, which you can see in Graph 3.

Graph 3 Governing bodies within the industry have chosen to classify A2Ls differently.

“The first thing of importance is to understand that this refrigerant class is only to be used in new equipment, not retrofits. You cannot retrofit a R-410A system to a R-32 or R-454A and R-454B class.”

Cylinders will also be classified differently. For example, an A2L cylinder will have a red top, and small A2L cylinders will have left-handed threads. When it comes to ASHRAE Standard 34, it is important to remember the difference between the flammability classifications between A2L and A3 propane. The difference is between the lower flammable limit of how much concentration would form a combustible mixture and the energy or heat of combustion. A test called ASTM E68 is used to determine flammability.

With the U.S. and Canada having specific GWP limits for upcoming products and there will need to be new solutions, as shown in Figure A.

Firstly, in that chart, Opteon is the brand name Chemours adopted for lower GWP refrigerants.

From that chart, it is clear that going forward, in the transition to lower GWPs in new equipment, R-454A, R-454B, and R-454C will be common solutions in the air conditioning and refrigeration sectors.

It is worth noting that condensing unit manufacturers are considering A2L because of the refrigeration capacities and the design similarities to R-404A systems.

For less than 700 GWP, R-454B will be the primary replacement for R-410A in air conditioning equipment because it has properties similar to R-410A.

For less than 150 GWP, R-454C will be an option. This transition is common because R-454C has a similar capacity to R-22.

Within the industry, 12 original equipment manufacturers (OEMs), including Carrier, York, and Trane, publicly announced the transition to R-454B, while five, including Fujitsu and Daikin, announced the transition to R-32. Only time will tell which one will become the more common choice, but the reality is that both R-454B and R-32 will be valuable alternatives.

Figure A Each sector will have different refrigeration transition options.

Our HVAC products have been designed on a foundation of excellence, with a selection of advanced Gas Furnaces, Central Air Conditioners, Central Heat Pumps, Air Handlers, and Thermostats. Each one of our HVAC products incorporates the latest cutting-edge and energy-efficient technologies to help your customers enjoy each day in total comfort while optimizing their energy use.

Like everything Continental designs and builds, each unit is exceptionally easy to use and install, and designed to last a lifetime.

n Refrigeration Technical Training Day Supplement

Motorized valve control

Danfoss, Oakville, Ont, expands its digital portfolio for industrial refrigeration by introducing the new ICAD B for motorized valve control and connectivity. The ICAD B enables professionals to see industrial refrigeration in a new light with real-time monitoring. The new actuator eases workflows, while the wireless interface offers remote control and adjustment, eliminating the need to climb the valve. The ICAD B is available in a series of four variants: RS485 with display, ethernet with display, RS485 without display, and ethernet without display.

Danfoss u www.danfoss.com

Hot gas drain pan

SGS Refrigeration, Mississauga, Ont, introduces its improved hot gas drain pan designed for industrial evaporators. The hot gas drain pan brings a fresh take on defrost and is assembled using laser welding technology. This creates a hermetic seal and provides improved heat transfer efficiency and other benefits, including enhanced durability and better corrosion resistance. The new SGS hot gas drain pan is suitable for applications requiring pressure ratings of up to 120 bar, encompassing all environmentally friendly, sustainable and natural refrigerants such as NH3 and CO2 SGS u www.spxcooling.com/sgs-refrigeration

Valve core removal tools

High profile evaporators

KeepRite Refrigeration, Brantford, Ont, announces the arrival of its newly engineered high-profile evaporators. The KHP utilizes optimized tube spacing and advanced microchannel technology to maximize heat transfer efficiency. The new evaporator has single-fan and multi-fan configurations, improved energy saving defrost control, a honeycomb fan guard and a new fan blade design. The KHP is suited for warehouse/industrial cooler and freezer applications. AWEF-approved models are available. Keeprite u www.k-rp.com

Oil-free centrifugal compressor

Copeland, St. Louis, Missouri, releases its new oil-free centrifugal compressor to market, delivering high-lift performance, reliability, and efficiency enhancements in demanding chiller applications. The compressor features aero-lift bearing technology, enabling the compressor shaft to self-levitate and operate independently, without friction or reliance on electromagnetics, complex controls, or proximity sensors. The new oil-free centrifugal compressor platform is being developed for the 50- to 200-ton capacity range and is optimized for use with the next generation of lower-GWP A2L and A1 refrigerants such as R-1234ze, R-515B and R-513A. Copeland u www.copeland.com

Fieldpiece Instruments, Orange, California, debuts its new line of HVAC/R valve core removal tools (VCRTs). Designed to improve system charging, recovery and evacuation tasks, the VCRTs remove the valve core from service valves in air conditioning, heat pump, and refrigeration systems to replace defective cores and provide an unobstructed flow of refrigerant for faster servicing. The VCRTs lineup features an integrated sight glass, an interior gasket, and a comfort spinner. All VCRT models are equipped with a 1/4-inch service port fitting that can be swapped in the field with an optional 5/16-inch service port fitting for mini-split systems.

Fieldpiece Instruments u www.fieldpiece.com

Digital manifold gauge

Navac, Lyndhurst, New Jersey, announces the availability of its newest digital manifold gauge, the NX1 Nexus. The new digital manifold gauge combines advanced smart device technology with Bluetooth and wireless connectivity to enhance the diagnostics process for HVAC professionals. The NX1 Nexus features four operation modes: manifold, leak test, evacuation, and decay test. The gauge is A2L ready and compatible with 72 types of refrigerants.

Navac u www.navacglobal.com

PIPE DESIGN IN REFRIGERATION

One of the most important elements in understanding refrigeration is to know how much refrigerant needs to be moved within the system.

By Leah Den Hartogh

Information taken from Greg Scrivener’s, lead refrigeration engineer at Laporte Consultants, presentation on “Refrigeration Pipe Sizing and Design,” on June 26. Watch here:

"It would take much more than just one hour to be able to properly go over everything related to refrigerant piping design, sizing, material, and a little bit of insulation," said Greg Scrivener, lead refrigeration engineer at Laporte Consultants. The topic itself is quite broad.

One of the important elements to understand in a refrigerant system is to know how much refrigerant actually needs to be moved. This is where the following equation comes into play:

There are a lot of complexities behind this calculation, along with assumptions and variables that will tell you, for example, what your refrigerant enthalpy out of your evaporator is. This is all very dependent on the system’s parameters. These are all properties of the refrigerant and the refrigerant cycle. Then, it is about how much mass will be moved through the refrigerant compressor and piping system. This will tell how much net refrigerating effect the system will have. The net refrigerating effect is the BTUs per hour of the refrigeration system.

This is the fundamental equation to use when calculating the net refrigerating effect. The reason to go through these equations is because there are certain variables that are going to affect the pipe sizing. For example, when you take mass flow, you break it down into its constituent parts. We end up with the density of the refrigerant multiplied by the area of the pipe, multiplied by the velocity of the refrigerant. The area and the velocity are parameters that are related to each other and related to the size of the piping, but the density is not. The density is related to the properties of the refrigerant — what temperature it is, what pressure it is, etc.

Setting up the picture

For the sake of the discussion, there will be a sample unit used and will be referenced again and again. The sample unit is a condensing unit sitting outside, air-cooled, and with a condensing temperature of 105 F, with 10 F of sub-

"This is why piping sizing is different for every refrigerant and why some refrigerants can’t just change from one to another.”

cooling in the condenser. What that means is the refrigerant is condensing, turning back from a vapour to a liquid at 105 F and then getting a little bit colder than that, coming out of the condenser at 95 F. We have an evaporator that’s inside a building that is evaporating at 20 F with a superheat of about 5 F. It’s coming out of the evaporating coil at 25 F, and then it’s warming up a little bit more going through the suction line, going back to the compressor, and it’s warming up to about 40 F before it goes into the compressor.

So, the first thing, going back to the previous mass flow equations, was the enthalpy-out and the enthalpy-in. This is where the energy is being absorbed.

In terms of types of refrigerants that are commonplace in the industry, R-448A is still very common, alongside R-507, which is currently being phased out. Other refrigerants that were highlighted include R-134A, a lowerdensity refrigerant, and R-32, one of the new A2L flammable refrigerants, alongside R-454B and R-410A, which are used for air conditioning. Isobutane is very common in refrigerators and small-region coolers.

Table 2: A lot of refrigerant densities are similar, with a few differences among them.

With these refrigerants, what is being shown is the net refrigerating effect per pound. This is why the hout minus the hin for this specific cycle that is being looked at. You can notice a few things. The first is that a lot of the refrigerants are similar in that 40 to 70 range. There’s a couple that are a little bit higher, and then there’s ammonia, which is extraordinarily high compared to the rest of the refrigerants. That’s a unique feature of ammonia, that it doesn’t have to move very much mass around to create refrigeration compared to some of the other refrigerants.

From this listing, R-507A is the refrigerant that’d have to move the most around in order to get the same amount of refrigeration.

Refrigerant density

The next part of the comparison is the density. Taking a look at Table 2, a lot of the densities of refrigerants are fairly similar, with some differences among

them. This is, of course, except ammonia, which is very, very low and that means that you have to move quite a bit of volume to get refrigeration. It’s very interesting to note that even though you have to move less mass, you still have to move more volume. This results in ammonia, in the end, being similar as far as BTUs out of cubic feet.

The reason why this matters is due to the fact that how many cubic feet that is being moved is representative of the compressor displacement. The larger this volume is, the physically larger the compressor displacement is going to need to be to get that much refrigeration.

In this case, R-32 ends up requiring fewer square cubic feet, so more BTUs per cubic feet. These are refrigerant properties, which in turn, affect how much mass and then eventually, the pipe size requirements. This is why piping sizing is different for every refrigerant and why some refrigerants can’t just change from one to another. In addition, this is why sometimes it doesn’t work to change from R-22 to R-134A.

Understanding pressure drop

There are a lot of factors that go into influencing the amount of pressure drop that happens in piping. The Darcy-Weisbach equation, shown below, shows which factors influence press drop and it has this friction factor in it, which is solved by the Colebrook equation, also shown below.

Within the Colebrook equation, you’ll see the pipe diameter, and the Reynolds number, which is affected by pipe diameter. Within the DarcyWeisbach equation, you’ll see the length of the pipe, the velocity of the refrigerant and the diameter of the pipe again. These are the variables that affect how much pressure drop that is happening in the pipe.

When it comes to the relationship between pressure and temperature, it’s important to recognize that temperatures and pressures are different. If you have R134A at 24 F with a 21 PSI, and I drop down to 22 F, I’ve gone down one PSI. These conditions would be one PSI saturated suction pressure change for 2 F of saturated section temperature change.

The reason this matters is because of energy efficiency. There is a rule of thumb that for every 1 F drop in saturated suction temperature, you decrease the energy efficiency by two per cent. This is an approximate drop in efficiency as each refrigerant has a slightly different drop.

ROOFTOP VRF SYSTEM RETROFIT

Cementing its goal of reaching net zero by 2031, Mitsubishi Electric retrofitted its head office with a brand new VRF system.

By Francesco Lo Presti

Information taken from Gary Chang’s, lead engineer of the HVAC Division at Mitsubishi Electric, presentation on “Case Study of Mitsubishi Electric's Head Office Retrofit” on June 26. Watch here:

Canada has cemented its position on electrification following its initial signing of the Montreal Protocol and then agreeing with the Kigali Amendment. Consequently, Canada has set targets to reach net zero by 2050.

This means that the residential, commercial, industrial, and institutional sectors will need to transition to energy-efficient technologies and solutions. This transition has started with the implementation of technologies, such as heat pumps. The next step for Canada is the transition to lower GWP refrigerants for certain types of air conditioning and refrigeration systems in Canada. For more information on the transition towards A2L refrigerants, visit Tim McRae’s article on page 26.

Since then, companies have accepted the challenge of adopting new refrigerants, embarking on new product lines and embracing them in their facilities. One such example is the retrofit of Mitsubishi Electric’s head office, which saw a variable refrigerant flow (VRF) heat recovery system replace its rooftop unit.

Net zero sustainable vision

Mitsubishi Electric has committed to following its company-wide net zero transition. The manufacturer has a sustainability vision for 2050, which consists of its subsidiaries being net zero by 2031. To achieve this goal, the company followed the greenhouse gas protocol, which provides organizations with a full picture of its environmental impact.

Scope one focuses on emissions created directly by the company. Scope two focuses on emissions indirectly created through purchased energy. Scope three focuses on the entire value chain.

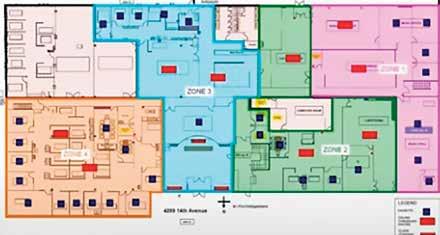

Figure 1: The structural layout of the head office presented issues when determining the best solution during the retrofit project.

Currently, Mitsubishi Electric is on scopes one and two. This was a driving force behind retrofitting its head office, which was constructed in 1991 in Markham, Ont, and consists of two floors and occupies 20,000 sq. ft.

The equipment for the building has been the same since the building’s construction. The equipment includes a 90-ton R-22 rooftop air handling unit with a VAV box for cooling, and baseboard and duct heaters for heating the first floor.

As stated in the testing and balancing report conducted in September 2019, the outside air damper is fixed at 10 per cent open and is mixed with return air, conditioned, and ducted to fan-powered boxes throughout the main floor. The central rooftop unit serves the whole first floor of the office, resulting in the fan-powered boxes having electric reheat coils to serve the perimeter spaces with heat while cooling the interior spaces.

The system had a partial retrofit done in the past, which saw the addition of a geo-

exchange water source VRF system that was paired with a small ERV and ducted to the cassette fan coils in each of the spaces for conditioning and distribution.

There are also three dedicated cooling-only split systems to serve the computer server room in the central-western part of the office.

The rooftop unit was a Trane unit with two compressors, each with two stages. However, the heating coil inside the unit was never used, so the system relied on an electric duct heater and baseboard heater. Over the years, the rooftop unit had various issues, including compressor replacements and leaks.

Challenges

No retrofit project is ever straightforward. There were some challenges that needed to be solved. The first was that the existing VAV, ductwork, and baseboard heaters had to stay. The second was ensuring there was comfort throughout the entire first floor with various needs for large offices, meeting rooms, small offices, open spaces, and common areas. Lastly, the office’s innovation center would utilize the existing geothermal loop.

With this in mind, there were three potential solutions: replace both the cooling coil and R-22 compressors inside the existing RTU with a condenser and LEV kit, replace the entire RTU with a new packaged system with ERV and heat pump, or install a VRF system. The option that was chosen was installing a VRF with an ERV, with the VRF utilizing R-410A.

Compared to the previous system with electric heaters, the COP of the system was one, while the new VRF system has a COP of up to four.

Getting the job done

This retrofit project started in July 2022 and finished later that year. The full equipment list for this project included nine outdoor units, nine branch controller boxes, 44 indoor units (ducted and cassette), eight lossnay ERVs, two cooling-only P series, eight humidifiers, and a web-based central control system.

The benefits of choosing a VRF with an ERV system included reducing the cooling capacity from 90-tons to 60-tons, the ERV was now providing zone-to-zone ventilation while the VRF was providing zone-to-zone temperature control. With the office setup, the VRF system would be placed closer to the zone it serves. This decision reduced the amount of refrigerant, piping, and ductwork needed.

This setup also helped change the configuration of the data center. Before, the office’s entire server was dedicated to the 90-ton unit. Now, the 60-ton unit requires just two racks. Additionally, with the new setup, the office can do precision cooling for just the

2: The rooftop at Mitsubishi Electric's head office now features new condensers.

3: The annual electricity usage at the head office saw a large decrease after installing the VRF system.

racks inside the room, reducing heat loss.

Energy analyses were conducted to determine which equipment would be used, alongside heat loss and gain calculations. Since the project required new condensers on the roof, a structural analysis was required to ensure all components of the system could safely be installed.

In 2023, the building was saving close to 50 per cent of electricity by switching to the VRF system. Additionally, the office saw its electricity usage reduced to 543,298 kWh, compared to 1,141,902 kWh in 2021, which resulted in savings of $53,000 in electricity usage.

Figure

Figure

+ FlashShield+ minimizes risk in comparison to any yellow CSST with the elimination of bonding and incidental contact with metallic building systems.

+ No bond wire or clamps are necessary, resulting in fewer call backs and/or red tags from inspections. Installs are quicker and material costs reduced.

+ Faster installs in closed-off joist spaces. No issues with minor contact with sprinkler pipe, ductwork.

+ Black jacket of FlashShield+ is aesthetically pleasing, especially in residential installations. FLASHSHIELD+ HAS BEEN THE CHOICE IN THE USA OVER YELLOW CSST FOR MORE THAN 10 YEARS. JOIN THE CHANGE AND SWITCH TODAY!